Triggering type probe calibration method of coordinate measuring machine

A technology of coordinate measuring machine and calibration method, which is applied in the direction of point coordinate measurement and electromagnetic measuring device, can solve the problems of unfavorable measurement results, non-negligible influence, difference between distance and nominal distance, etc., so as to improve calibration accuracy and ensure measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

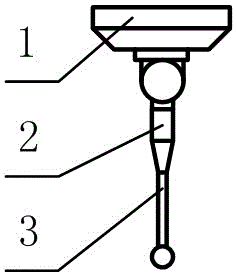

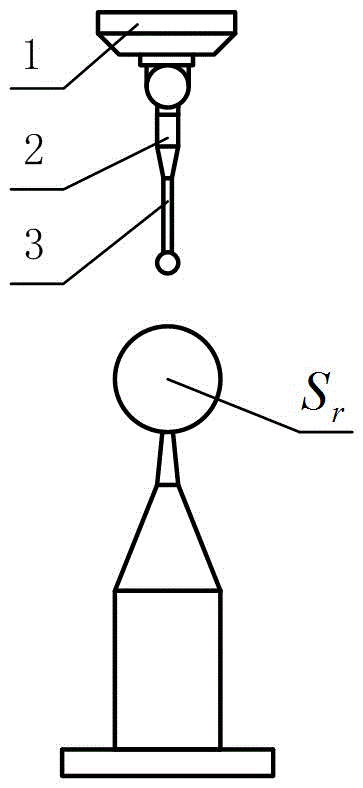

[0032] The present invention is described in further detail now in conjunction with accompanying drawing. All the accompanying drawings are simplified schematic diagrams, which only illustrate the basic method of the present invention in a schematic manner, so they only show the schematic diagrams of the touch probe, standard ball and measured spherical surface related to the present invention. A coordinate measuring machine trigger probe calibration method, including the coordinate measuring machine used probe and standard ball S r , the measuring head is mainly composed of a rotatable measuring seat 1, a measuring head sensor 2 and a measuring rod 3; it is characterized in that it is carried out according to the following steps:

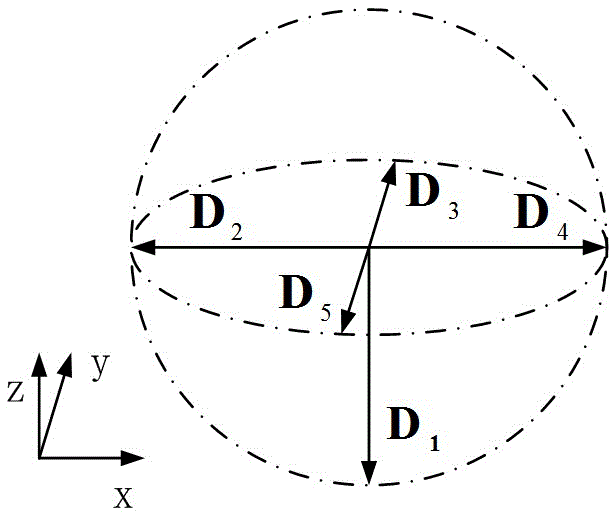

[0033] 1.1. Place standard ball S r Fixed, rotate the probe to four or more different directions D1 、D 2 ,...,D n (n≥4), under the condition of no probe compensation, that is, no compensation for the radius of the small ball at the end of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com