Effluent and drain temperature measurement and calculation method of heater with drain cooler on steam turbine

A hydrophobic cooling and hydrophobic temperature technology, applied in the direction of temperature measurement of moving fluids, can solve the problems of complex installation position, large thermal inertia, and high measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

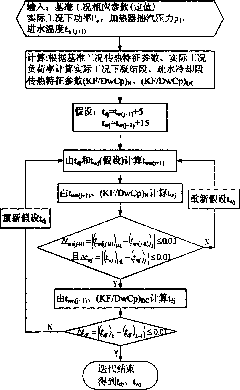

[0073] A method for measuring and calculating the outlet water and drain temperature of a heater with a drain cooler in a steam turbine, characterized in that,

[0074] Step 1: Calculate the intermediate transition point temperature t between the pure condensation section and the hydrophobic cooling section of the heater under the reference condition wn(j+1) o :

[0075] Select the rated load design condition of the unit or the performance assessment test condition as the reference condition, and the parameters with the letter "o" added to the symbol indicate that they are parameters under the reference condition. Parameter: shell side pressure p nj o , shell side extraction enthalpy h nj o , Hydrophobic temperature t dj o , outlet water temperature t wj o , Inlet water temperature t w(j+1) o and unit power P e o , and calculate the shell side pressure p according to the IAPWS-IF97 industrial water and steam thermodynamic properties model nj o The corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com