Patents

Literature

253results about "Electrode maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

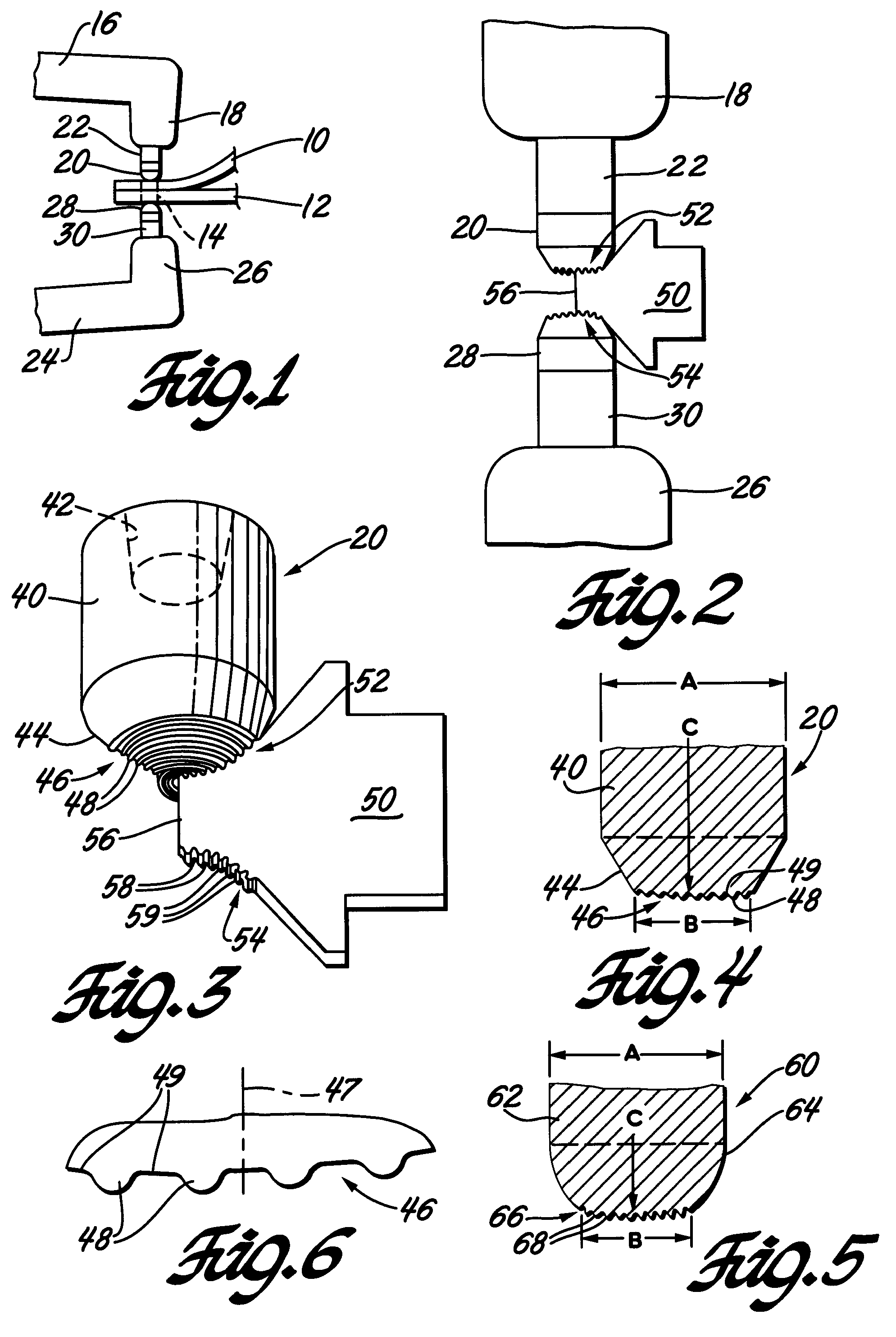

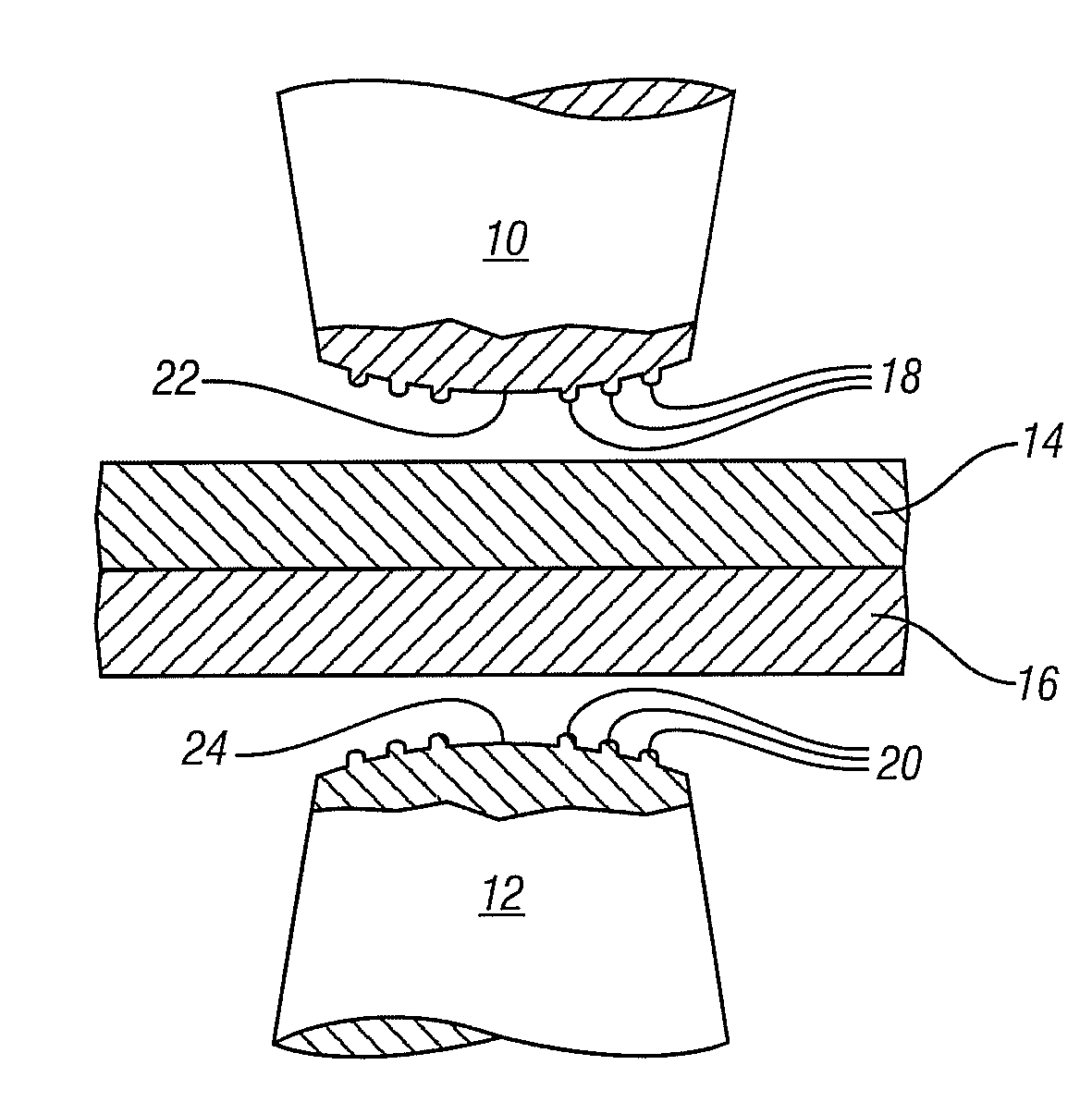

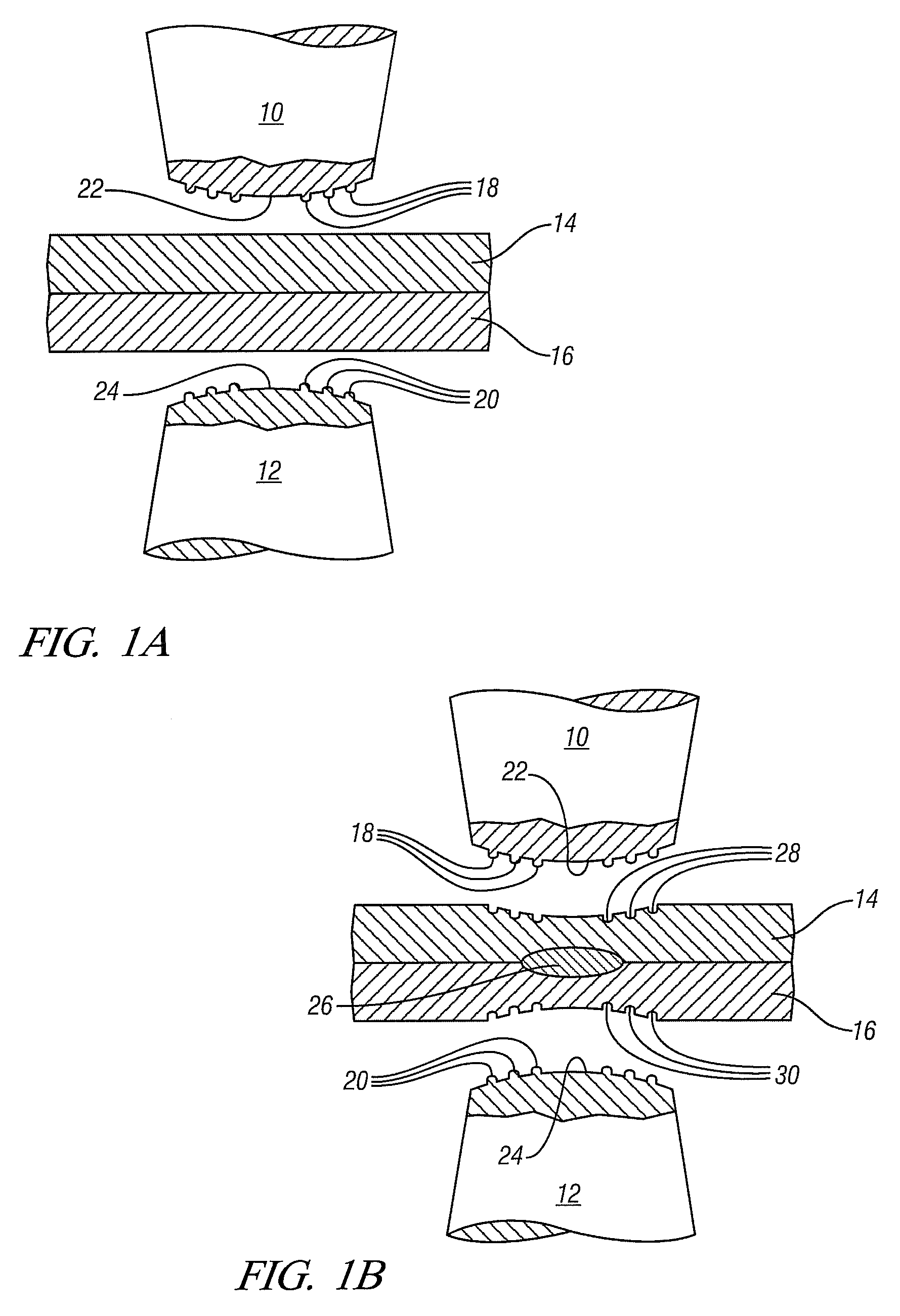

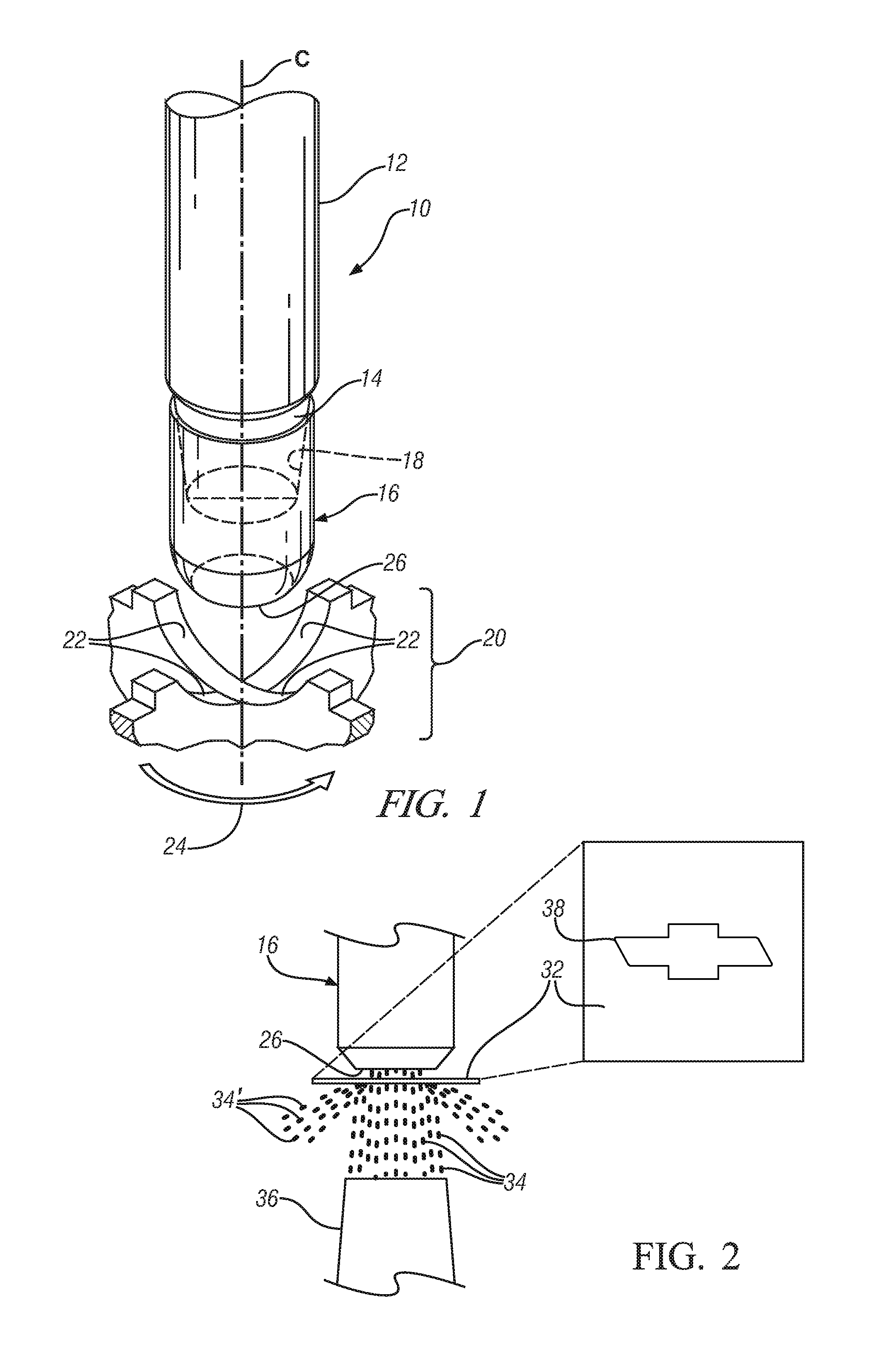

Welding electrode with contoured face

ActiveUS20080078749A1Well formedEasy alignmentTurning machine accessoriesOhmic-resistance electrodesElectrical resistance and conductanceEngineering

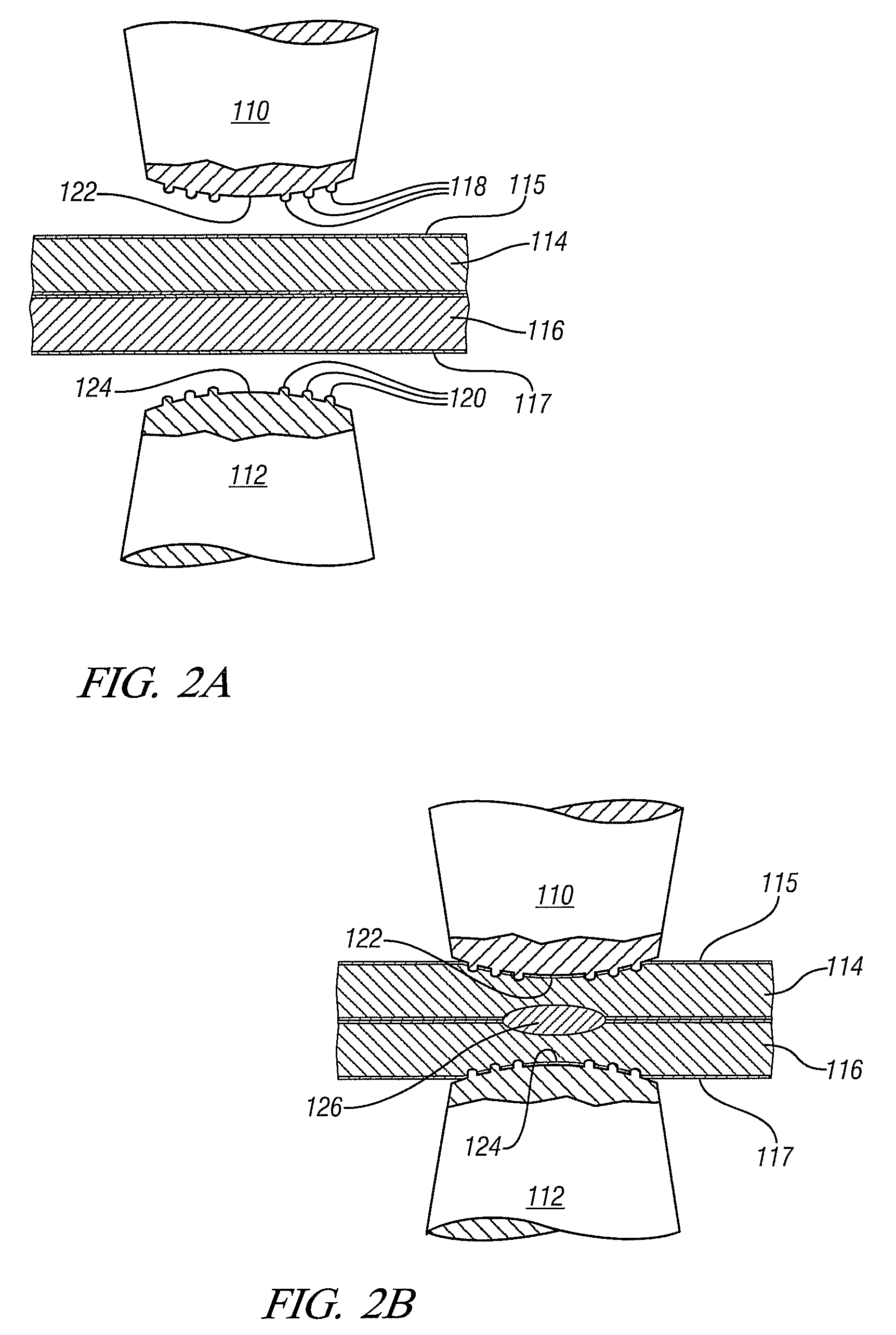

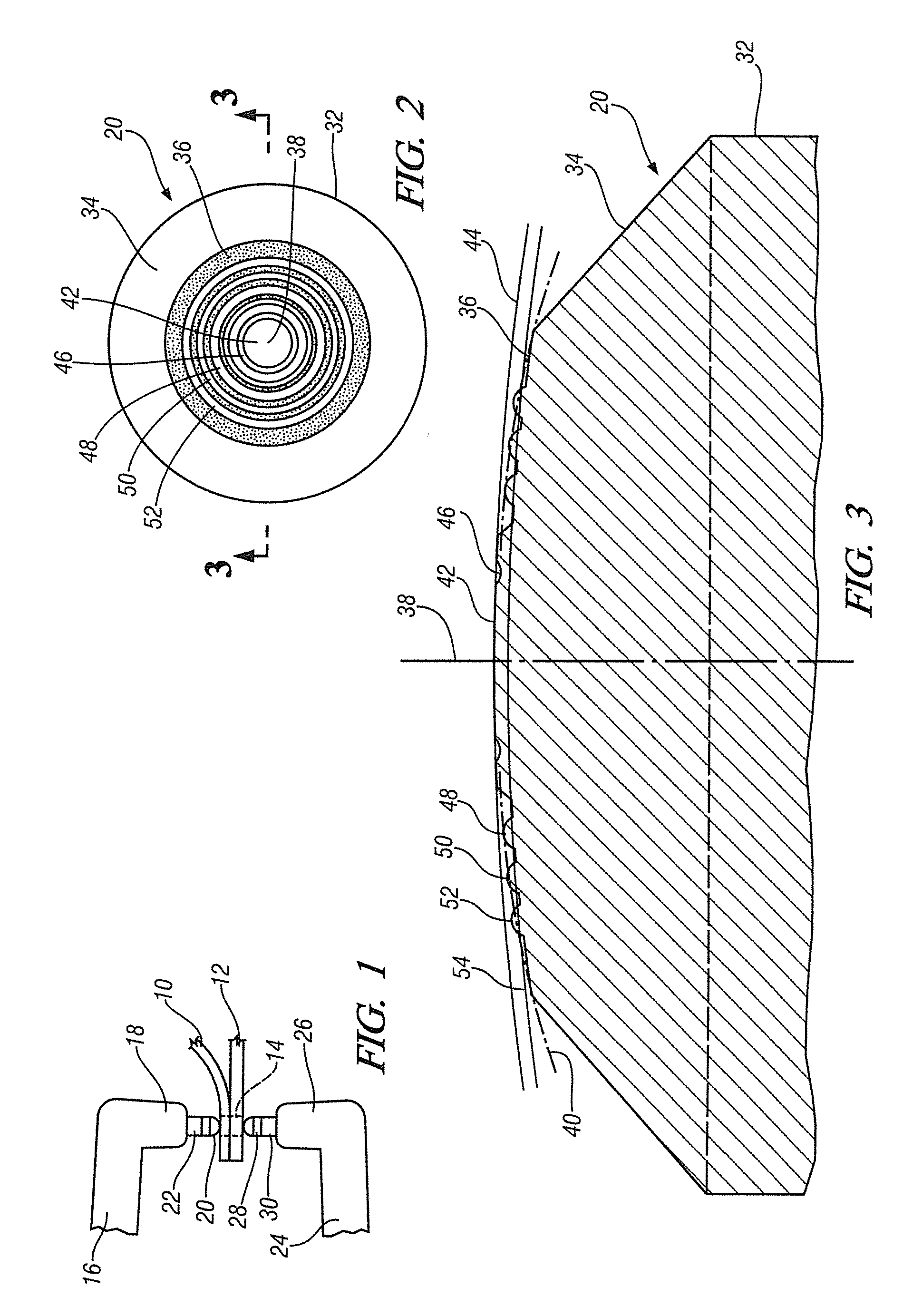

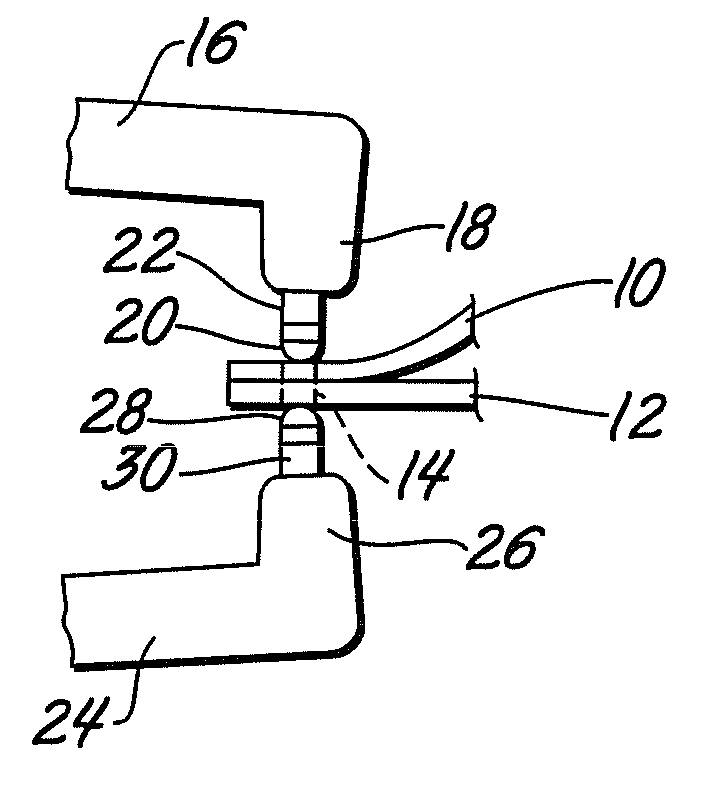

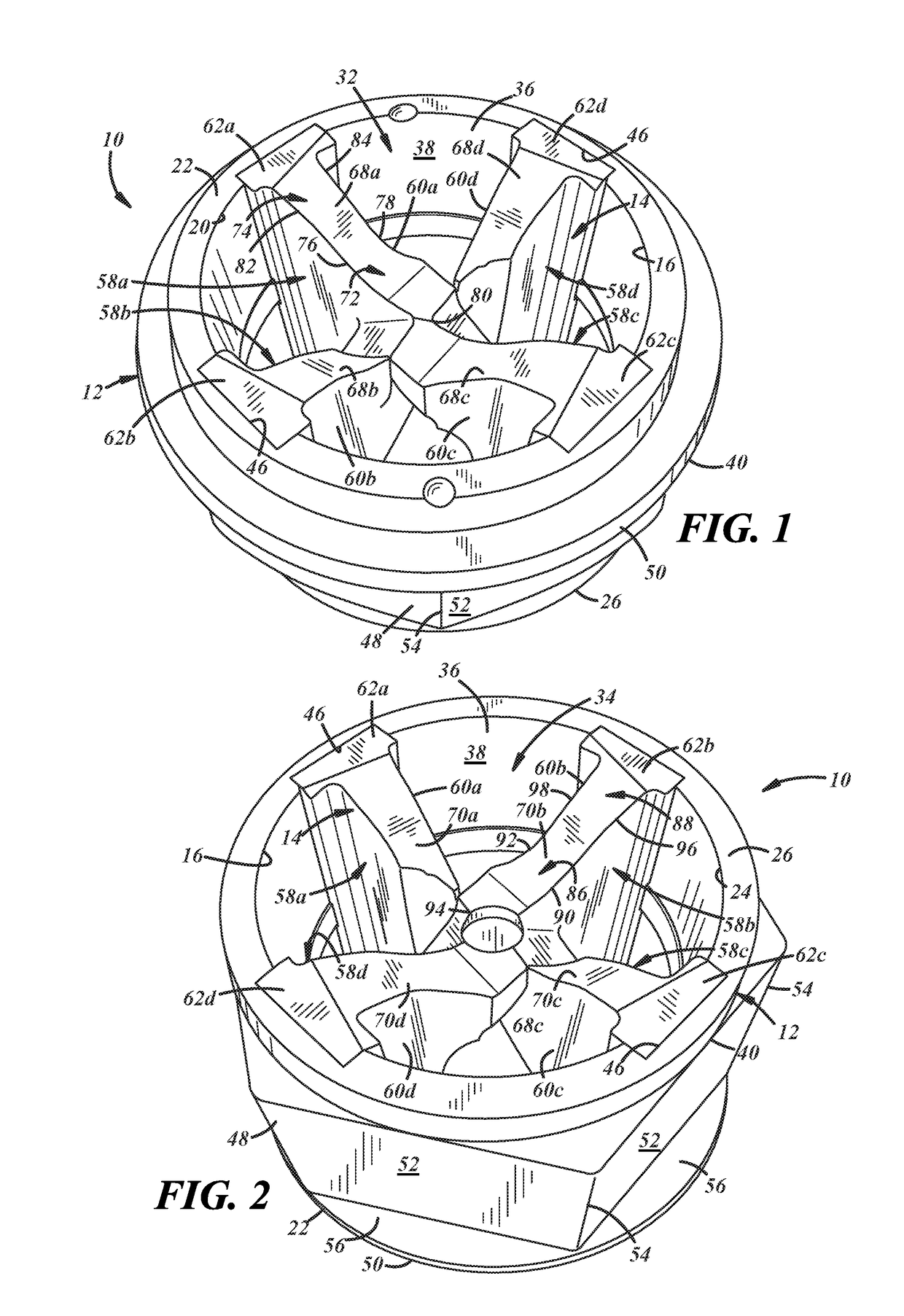

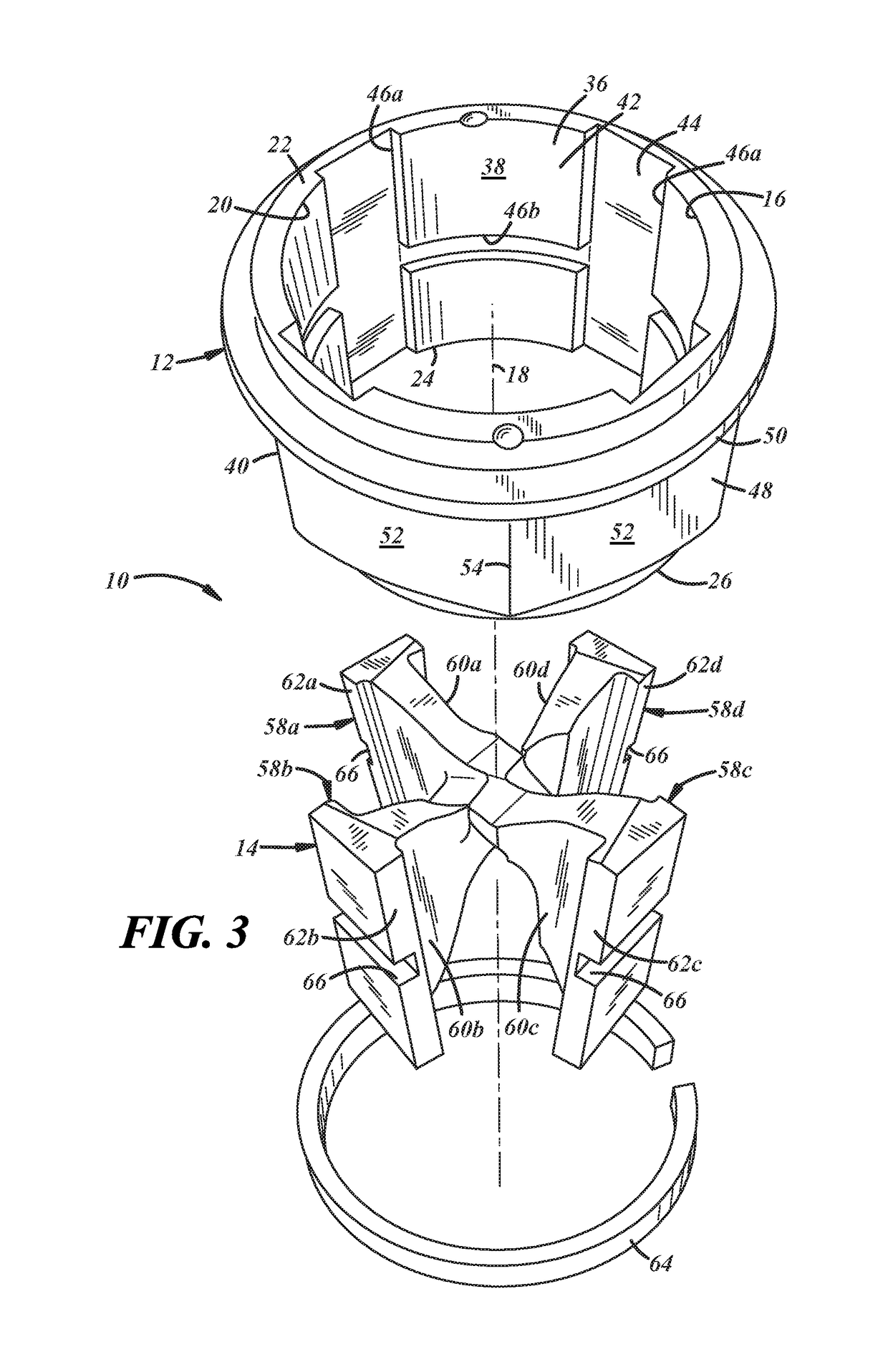

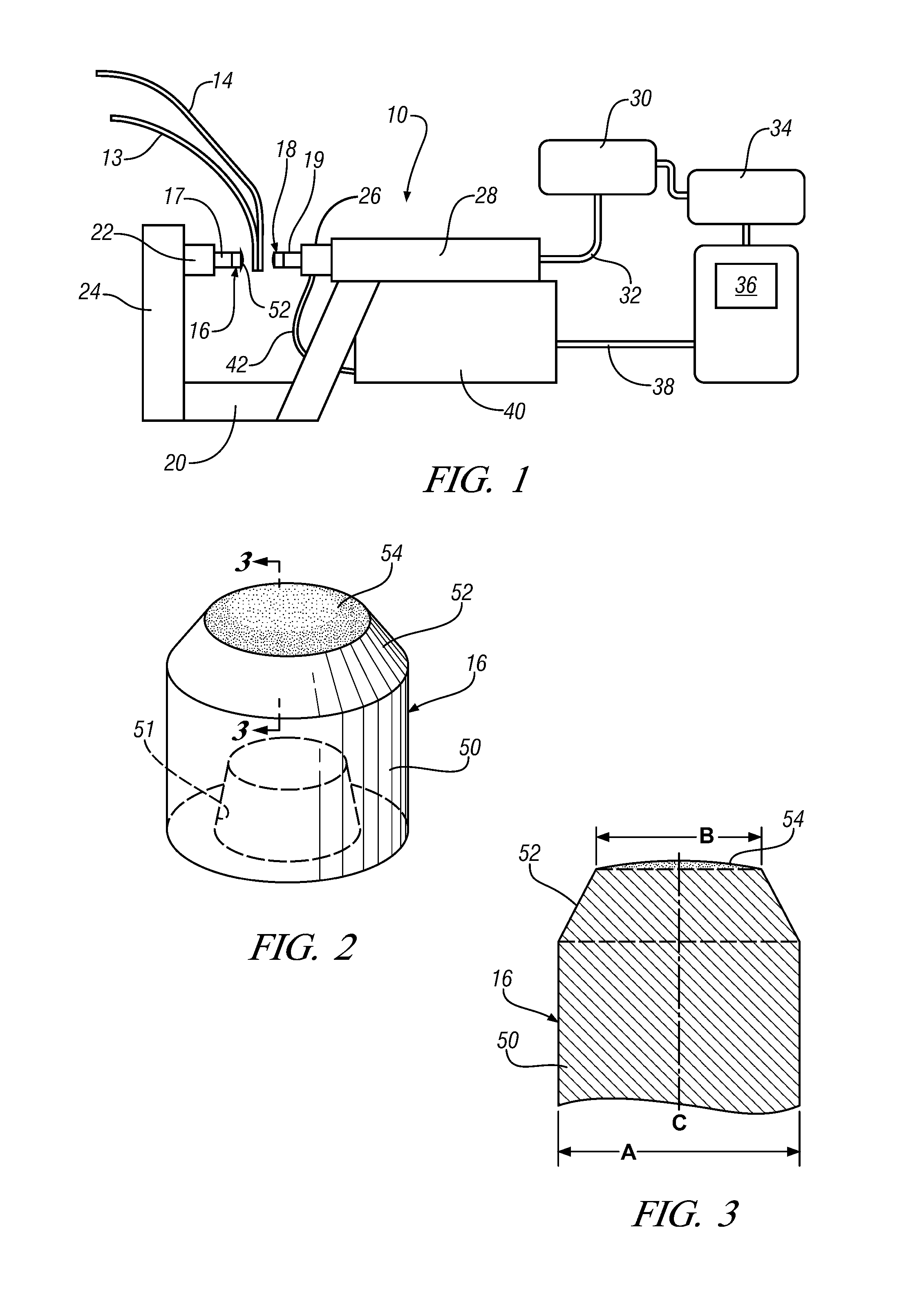

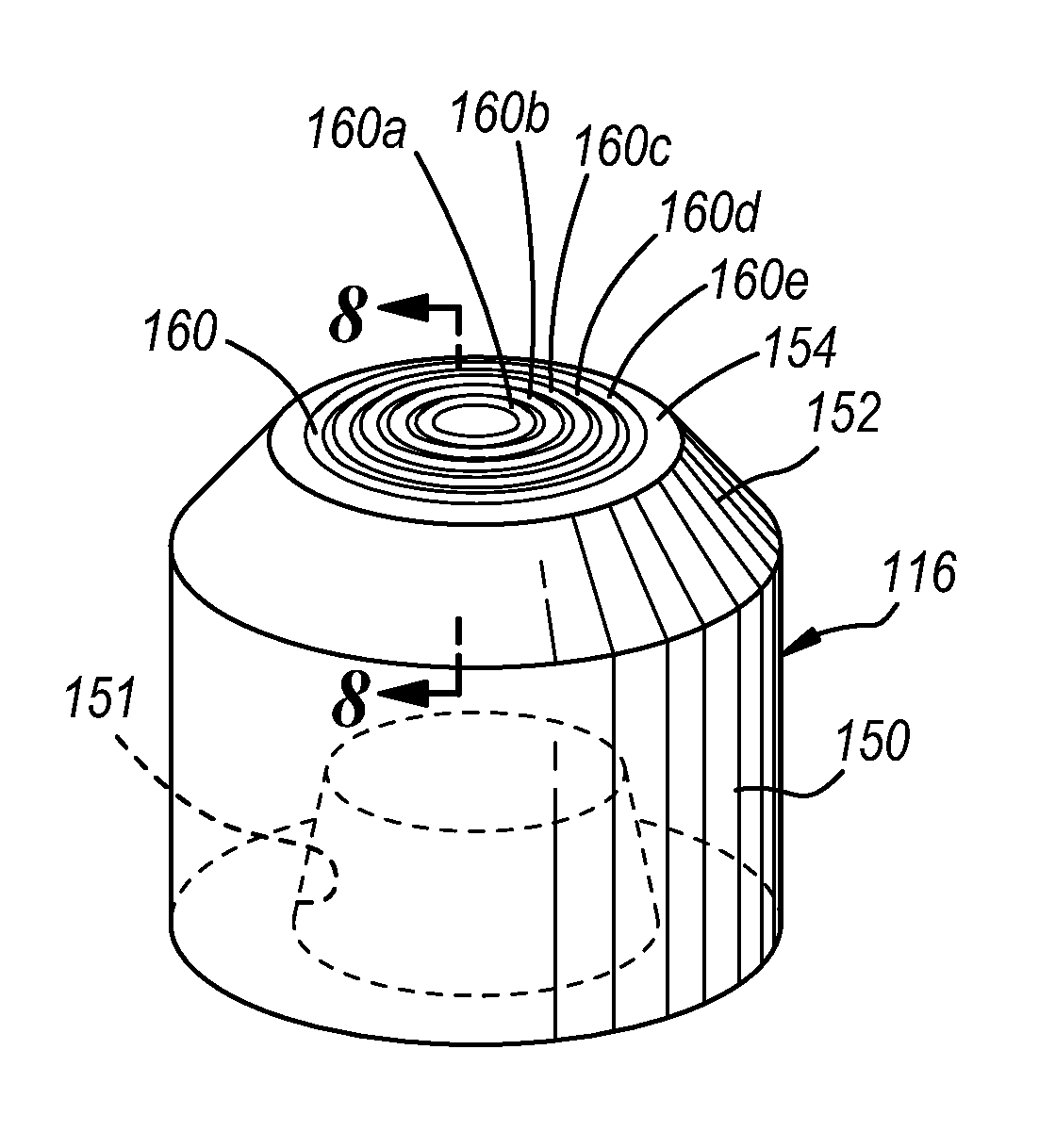

Welding electrodes with a welding face for contact with a metal surface for electrical resistance welding are provided with concentric contoured rings formed into the face. The rings may, for example, be ridges upstanding in the face or grooves depressed into the face. The contoured rings may be radially spaced with relatively flat (depending on the curvature of the face) intervening rings. When the electrode is pressed into contact with the surface of the workpiece for delivery of a welding current, the features of the concentric rings penetrate surface oxides or other conductivity barriers. When ongoing welding operations have eroded the contoured rings they may be rapidly reformed in the weld face in a surface re-dressing operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

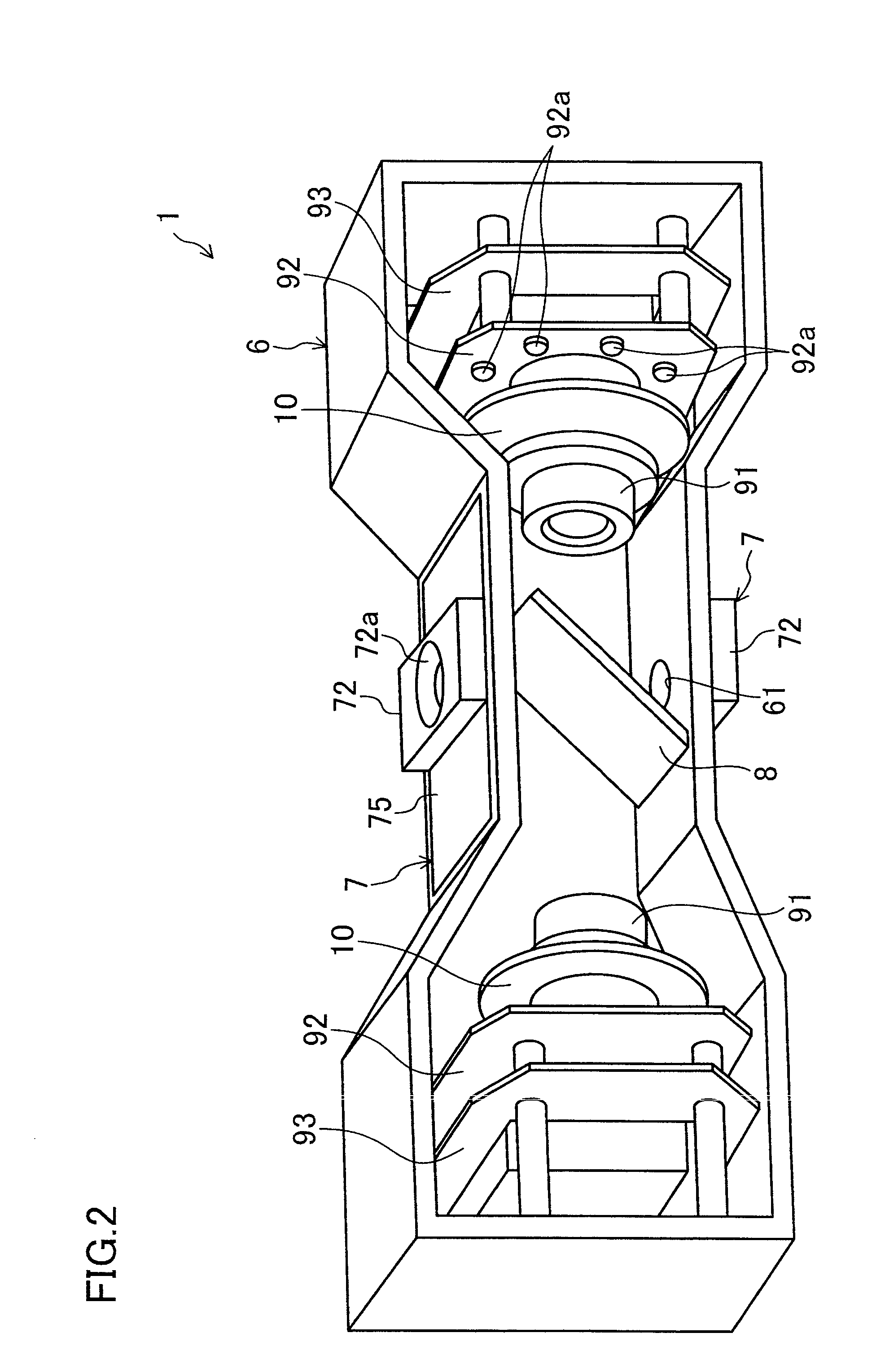

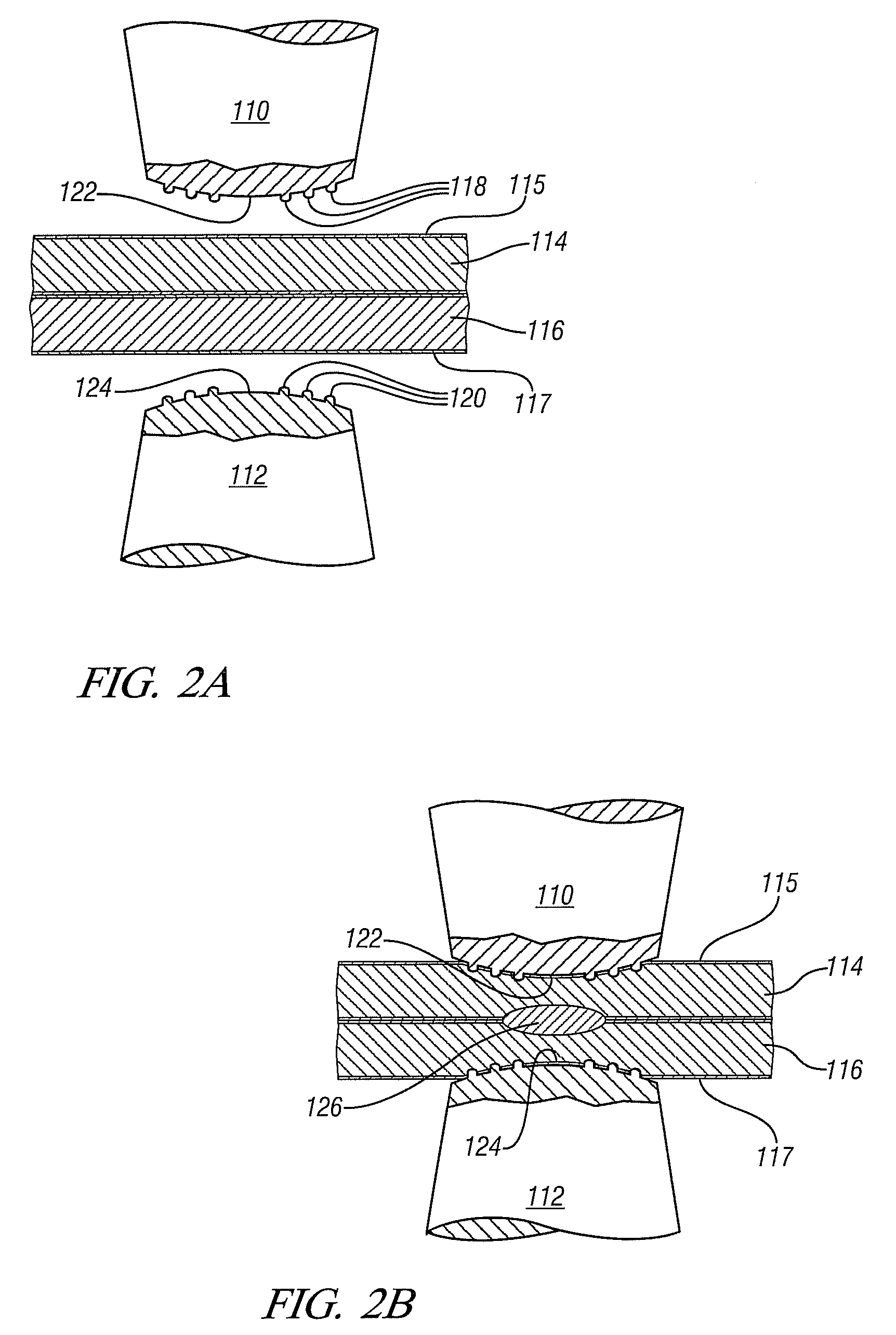

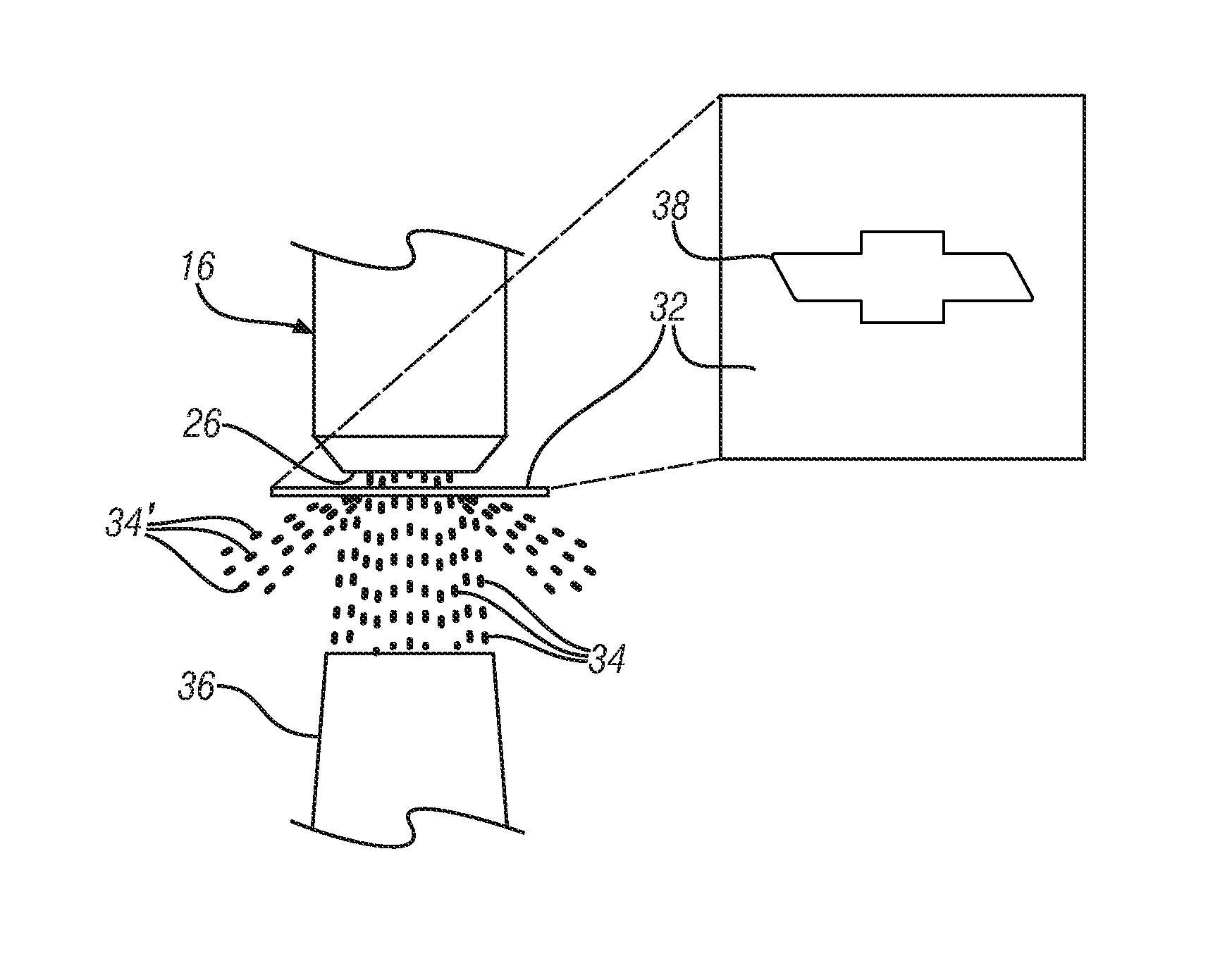

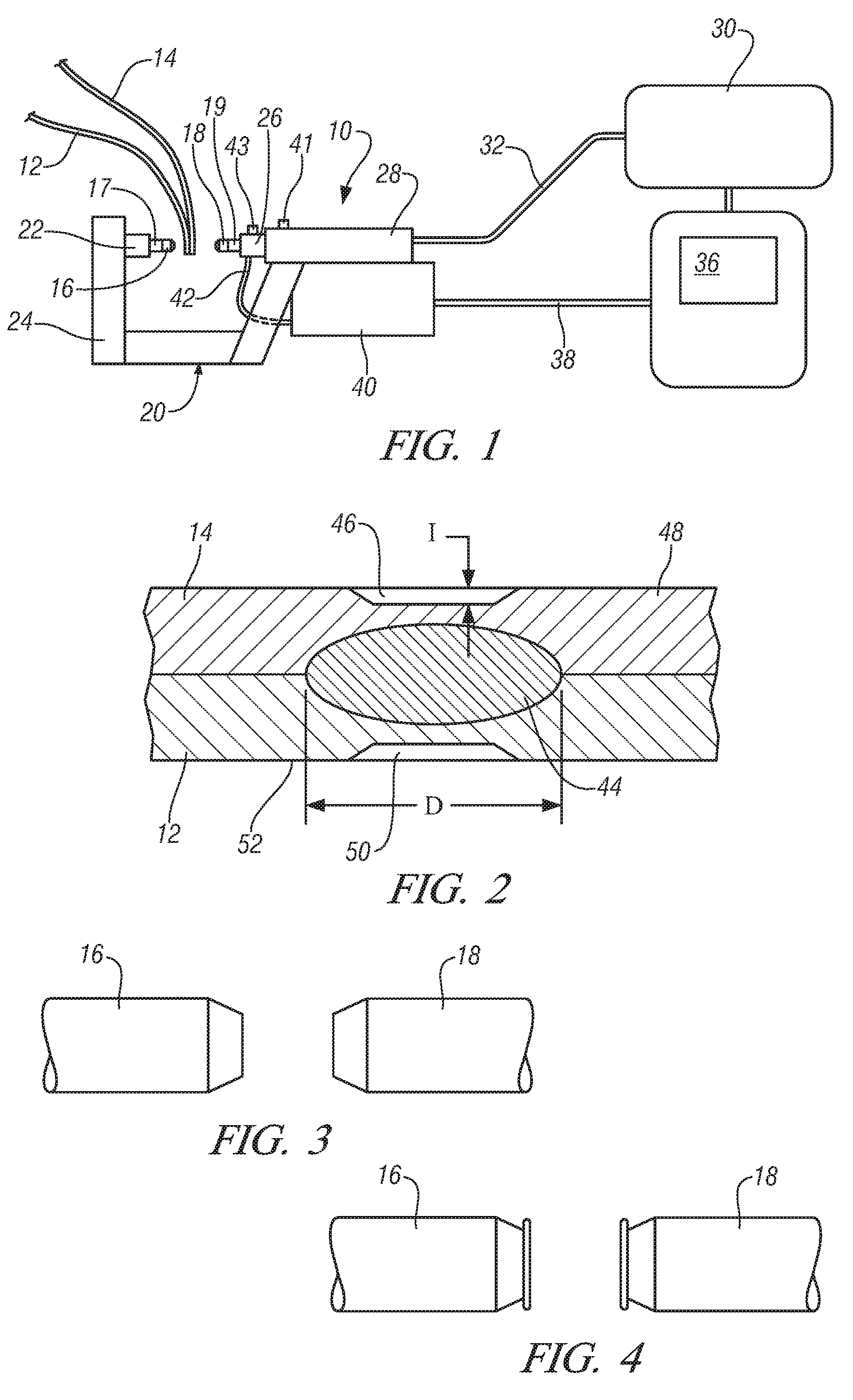

Weld electrode for attractive weld appearance

ActiveUS8222560B2High thermal and electrical resistivityHigh melting pointOhmic-resistance electrodesPressure electrodesSpot weldingVisible surface

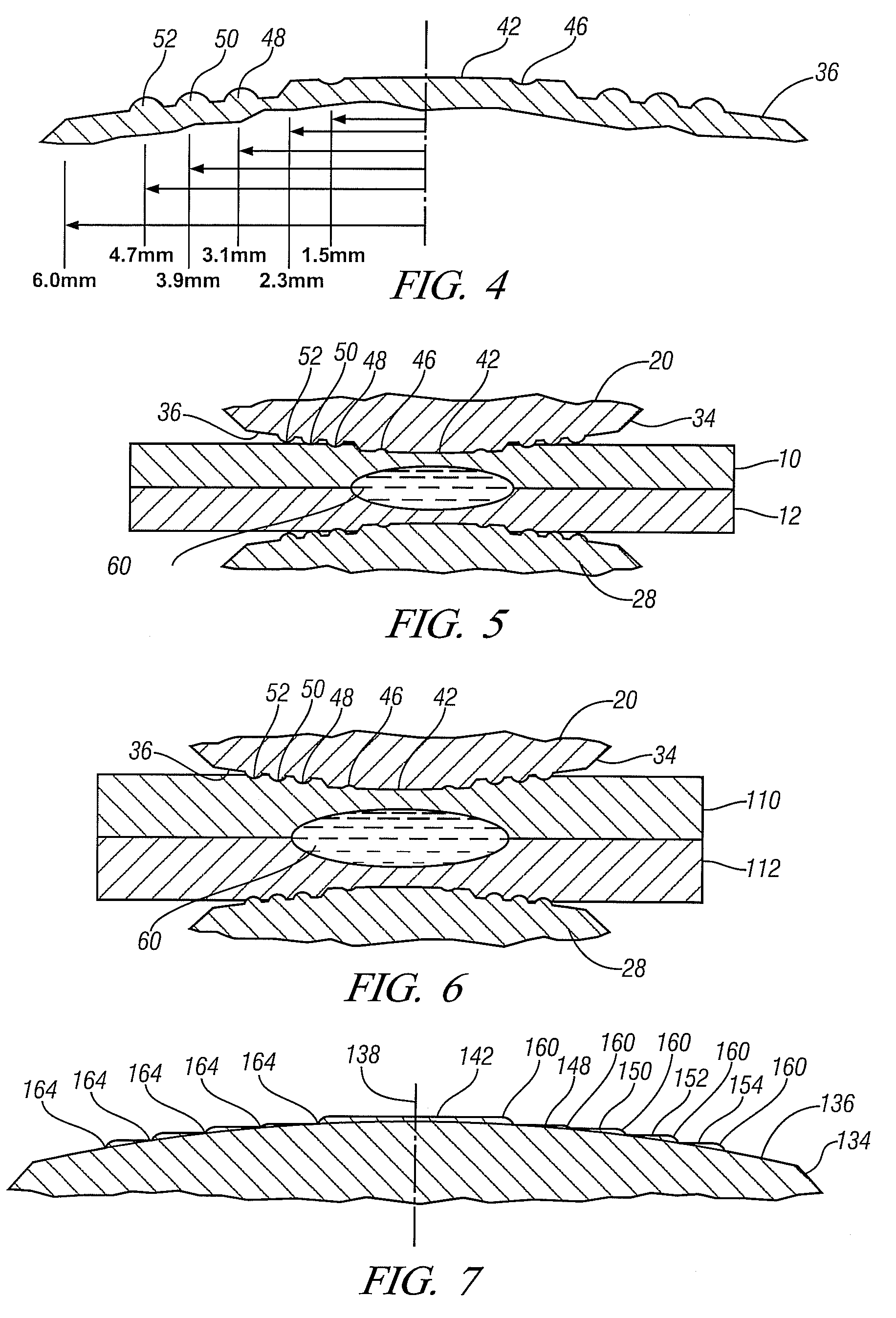

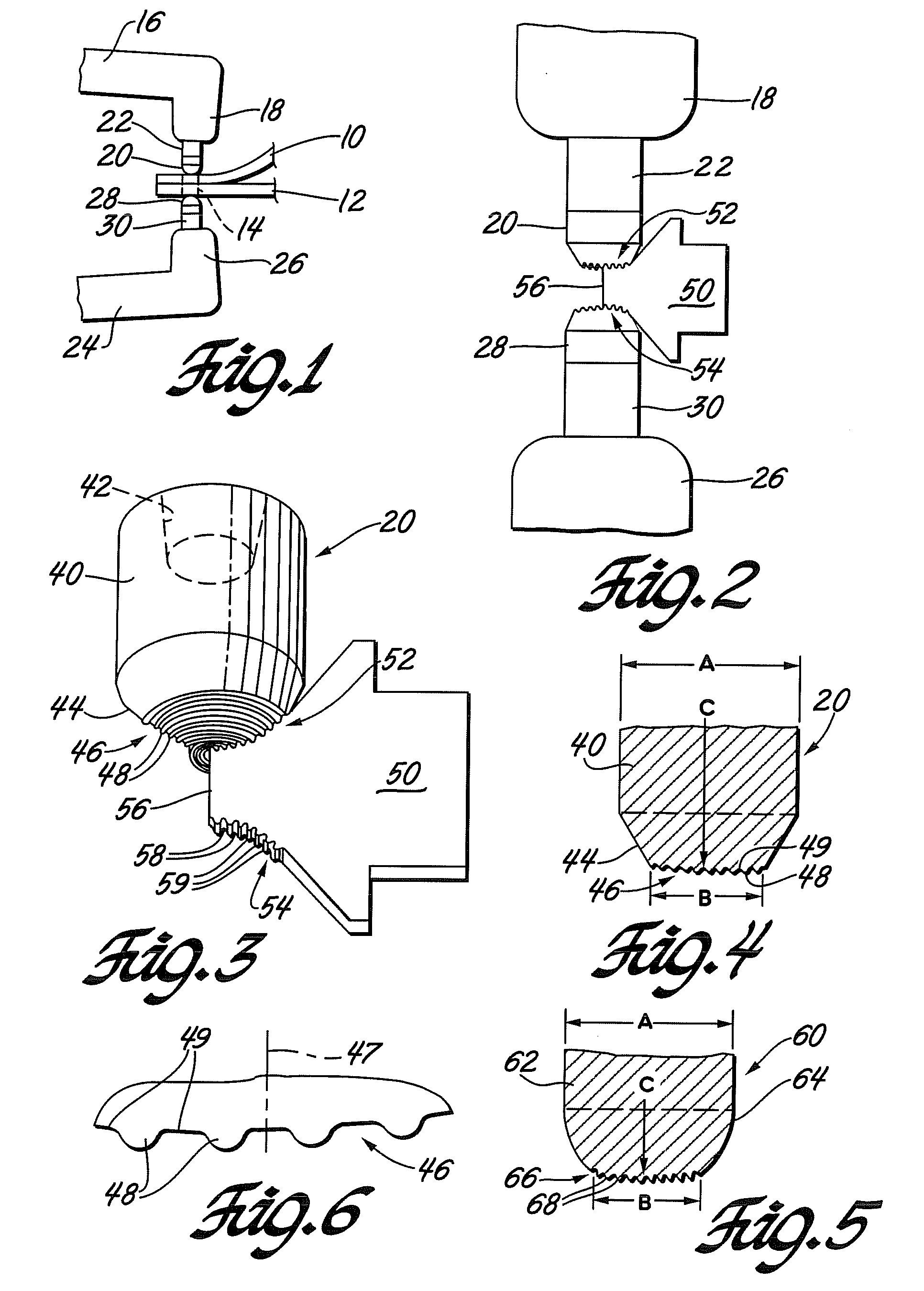

Weld faces of electrodes for resistance spot welding are formed with a suitable area of protrusions and / or intrusions. The size, shape, and elevation or depths of the protrusions or intrusions are determined for the formation of suitable spot welds in and between metal workpieces such as aluminum or steel panels for vehicle bodies. The protrusions or intrusions are also conceived and used to form an image on at least a visible surface of the welded article to produce an attractive appearance on the surface of the welded sheet.

Owner:GM GLOBAL TECH OPERATIONS LLC

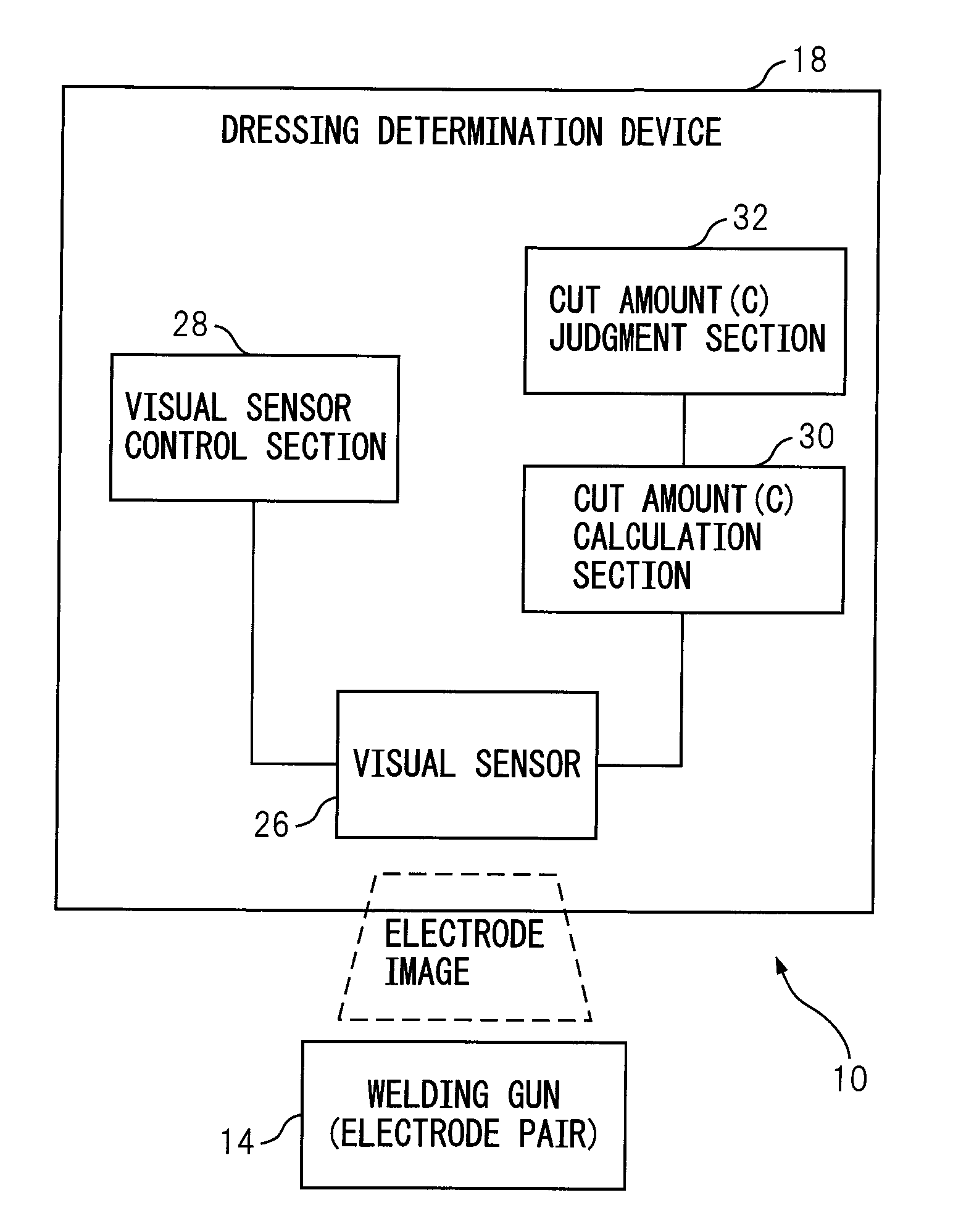

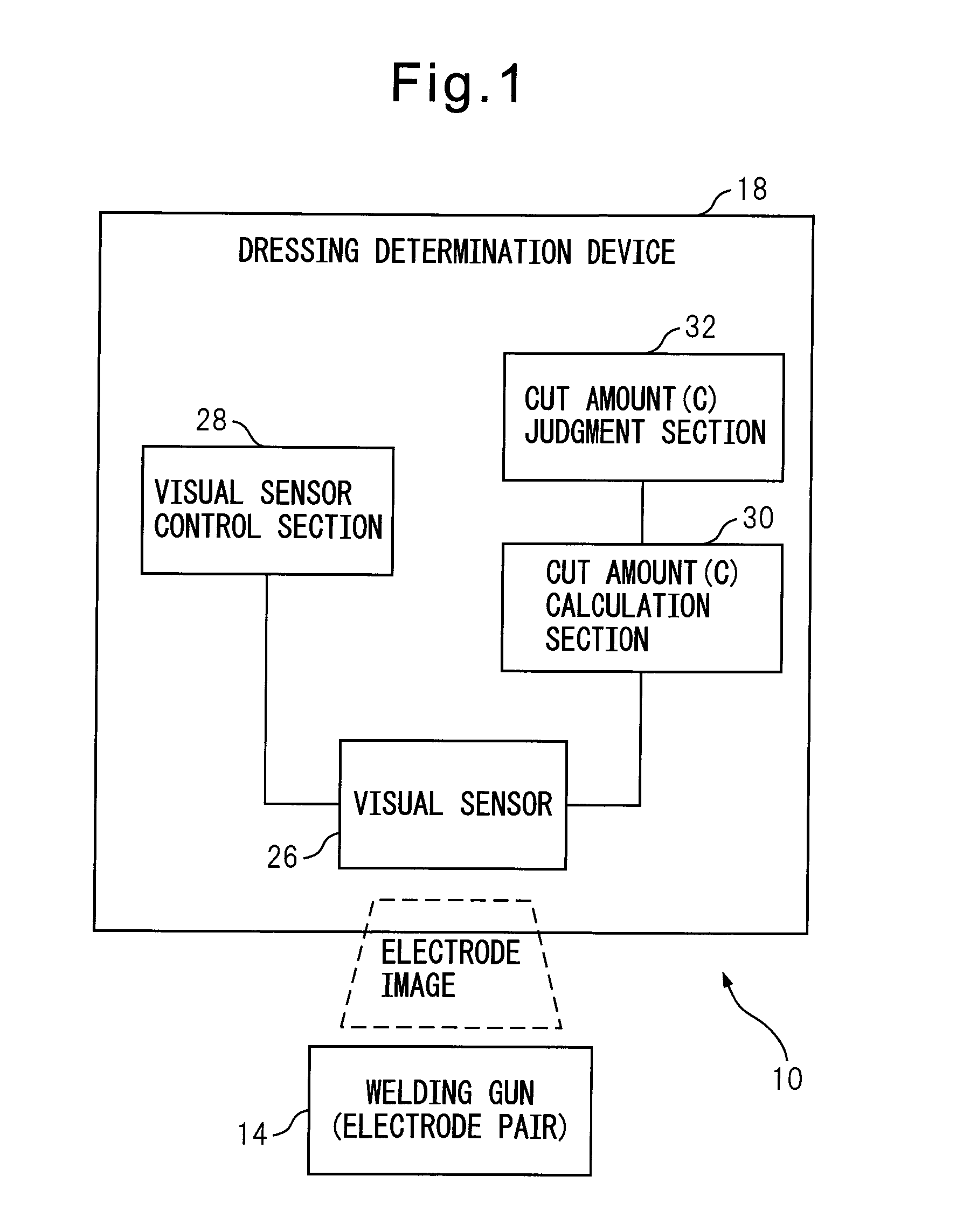

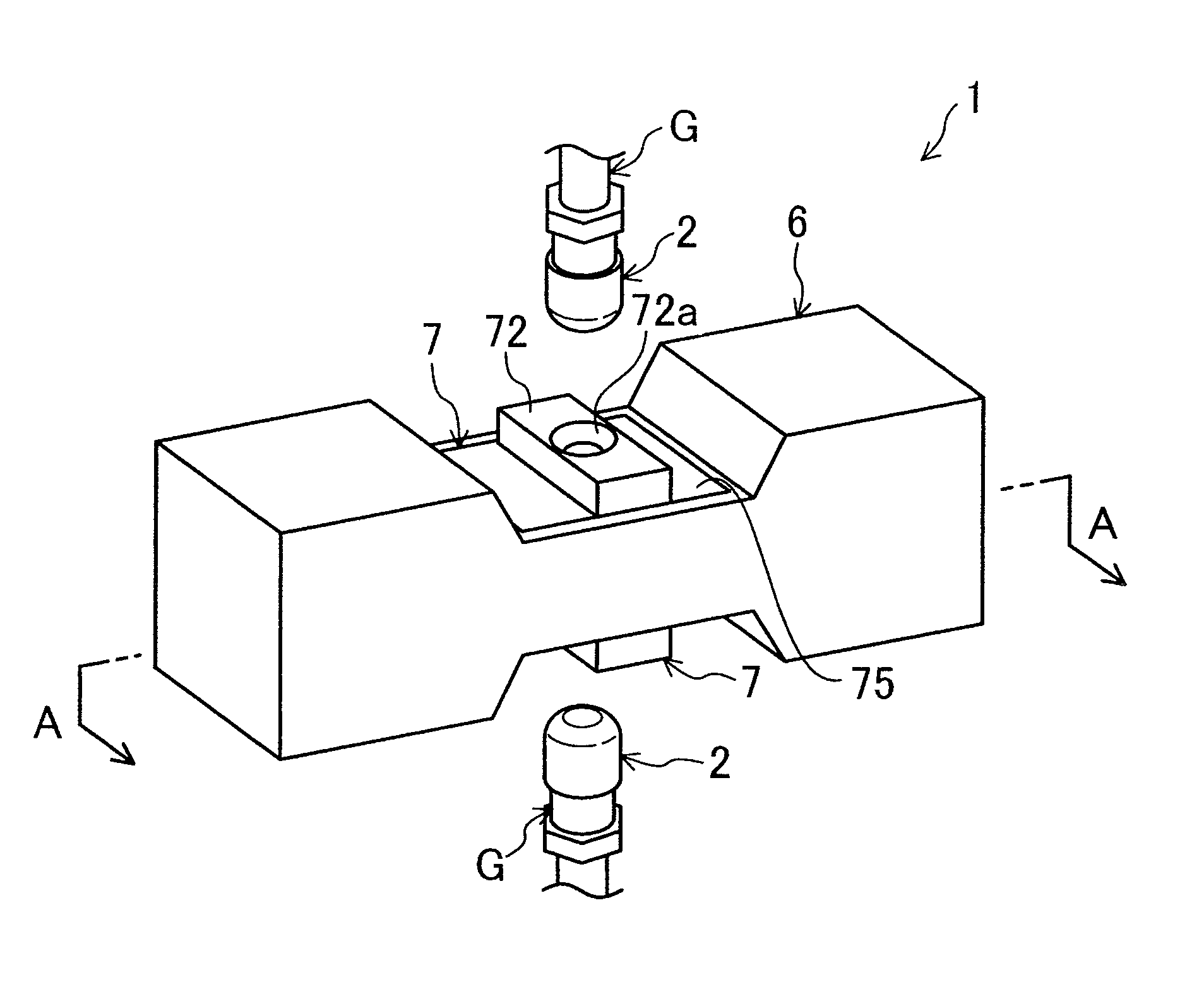

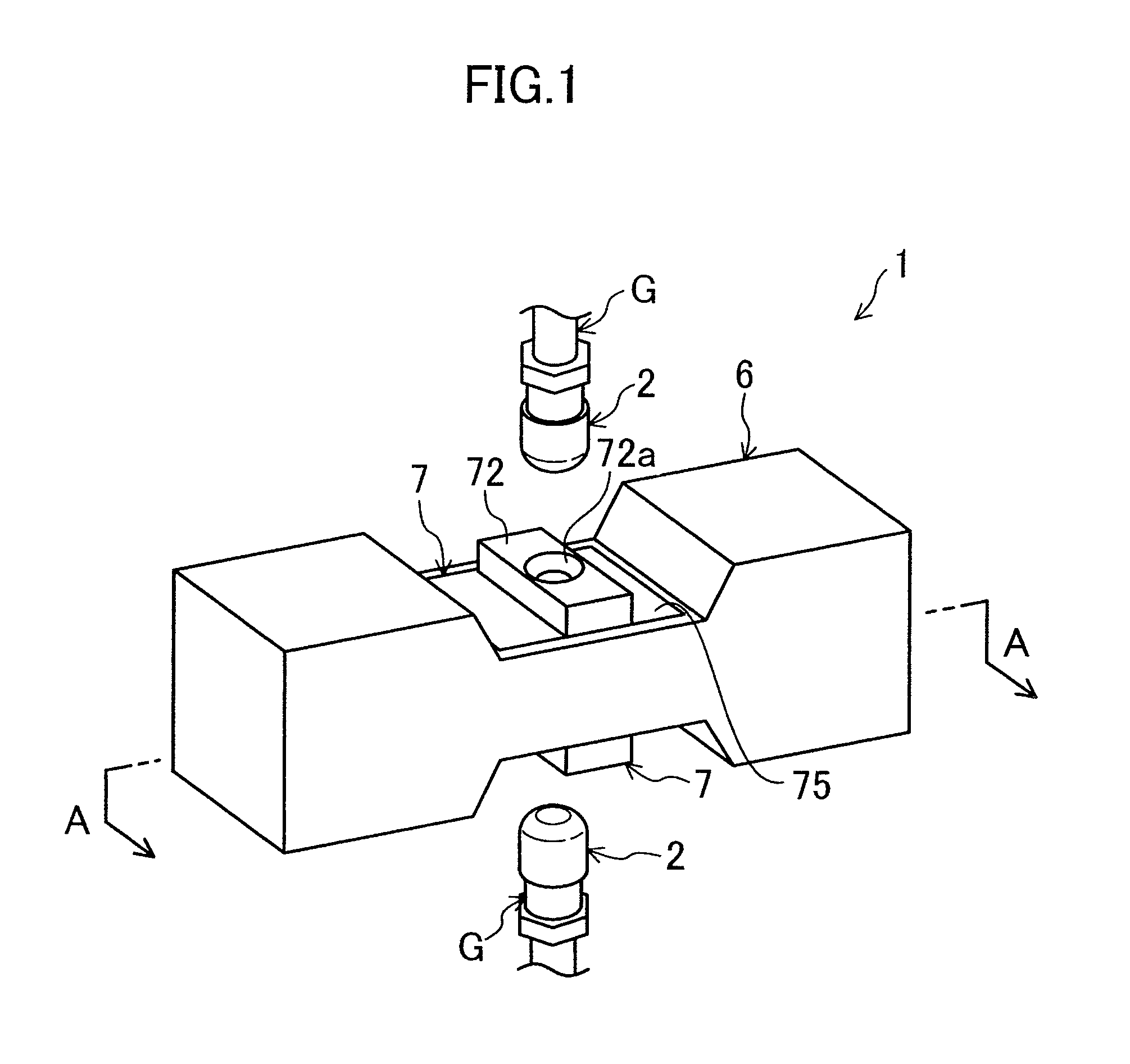

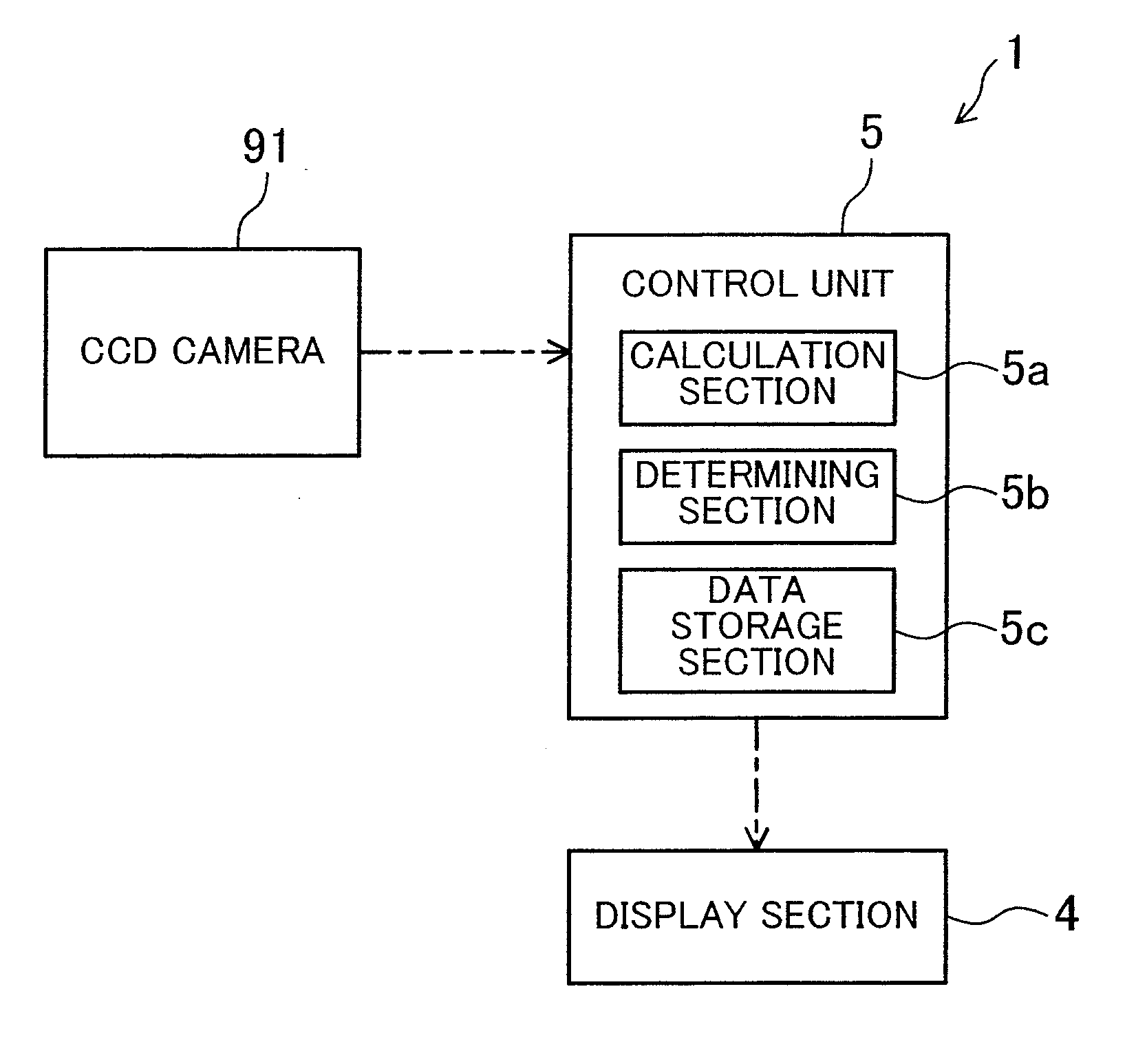

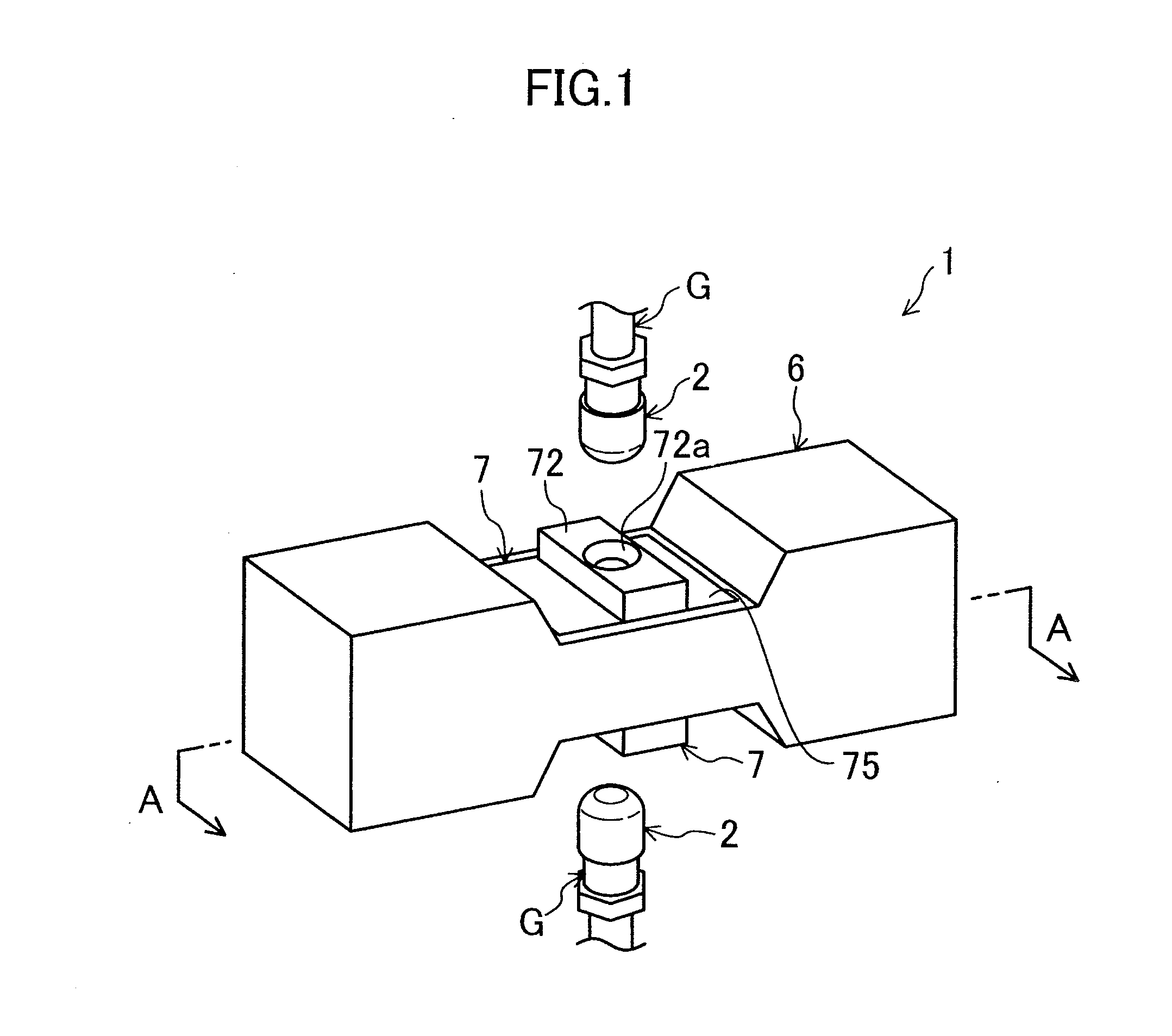

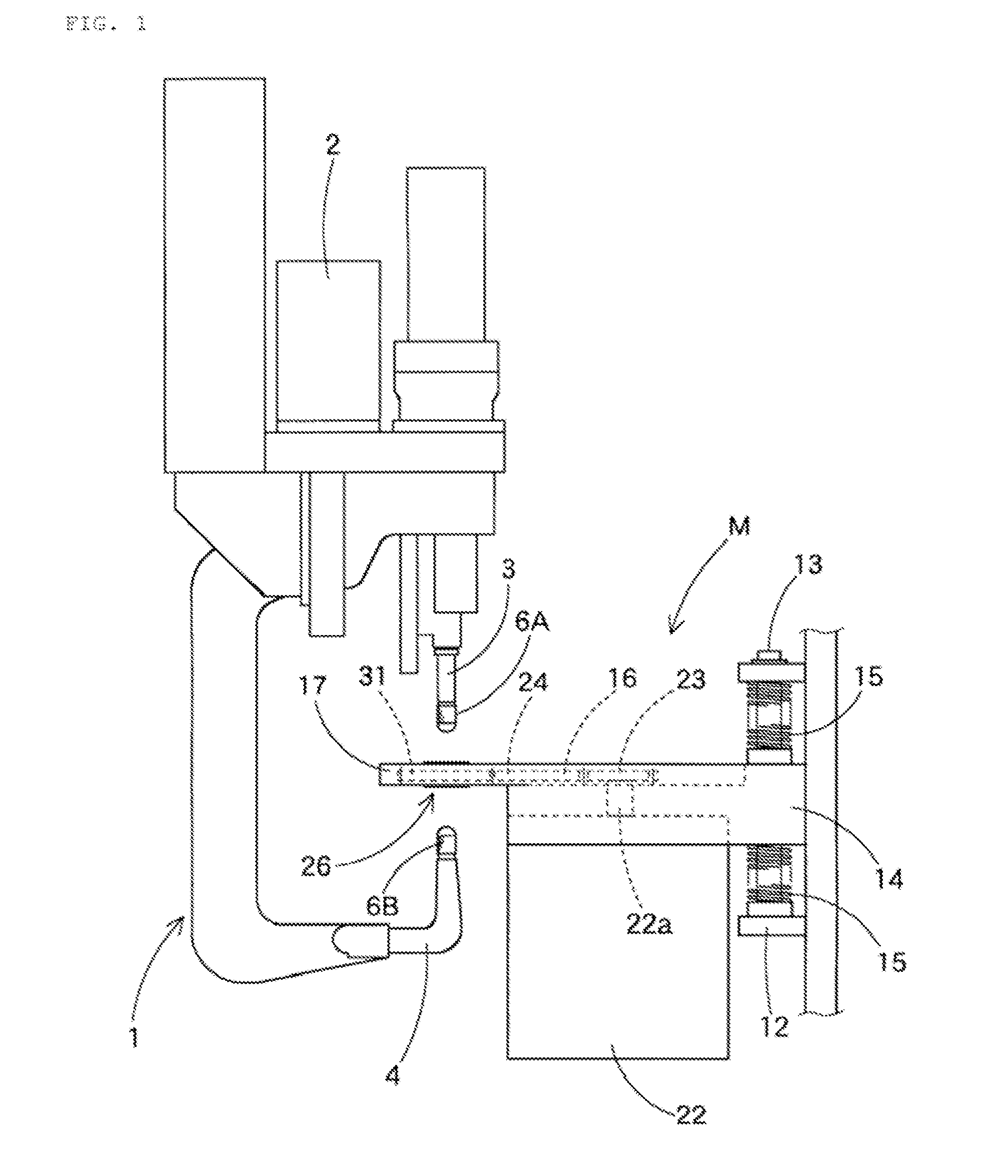

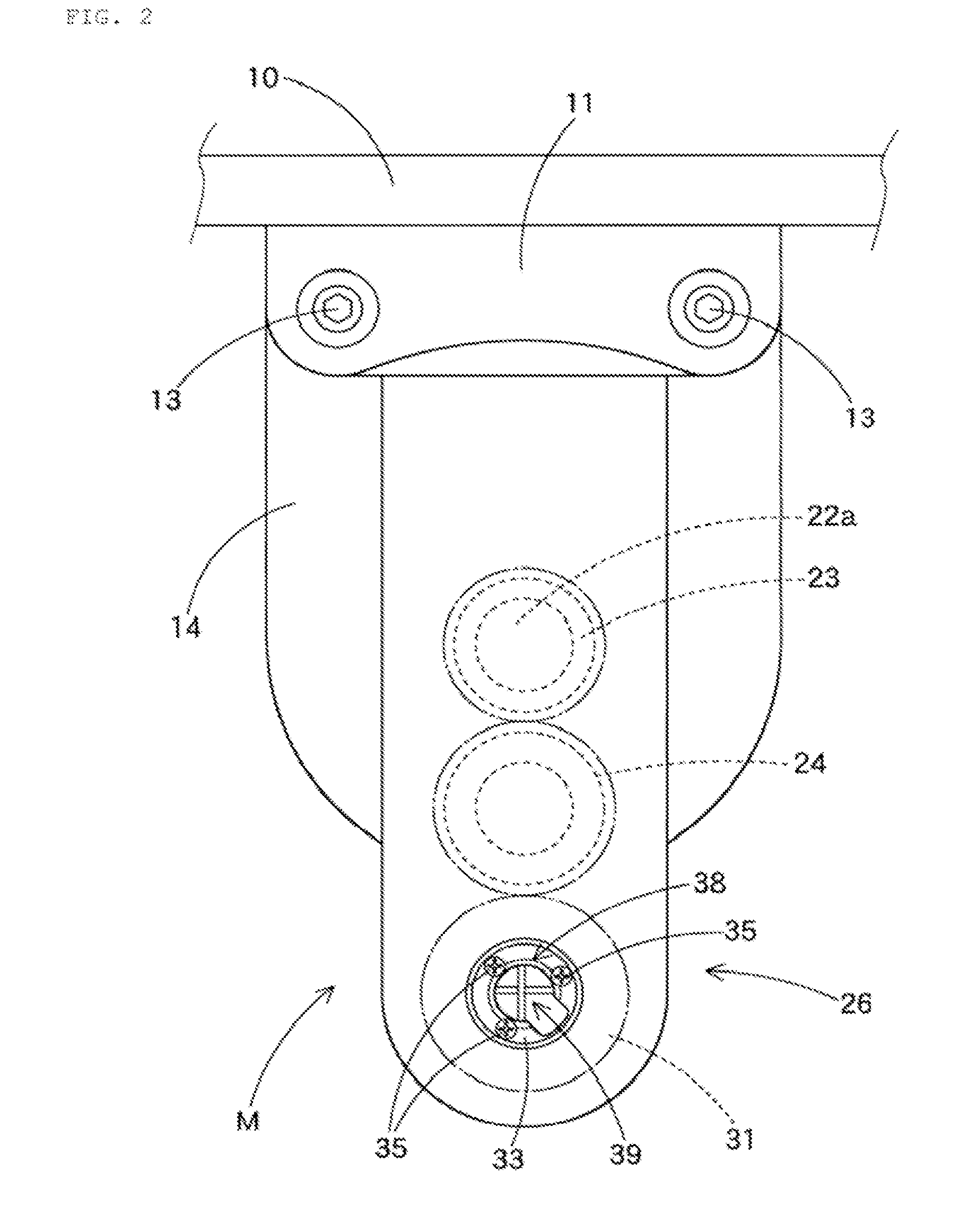

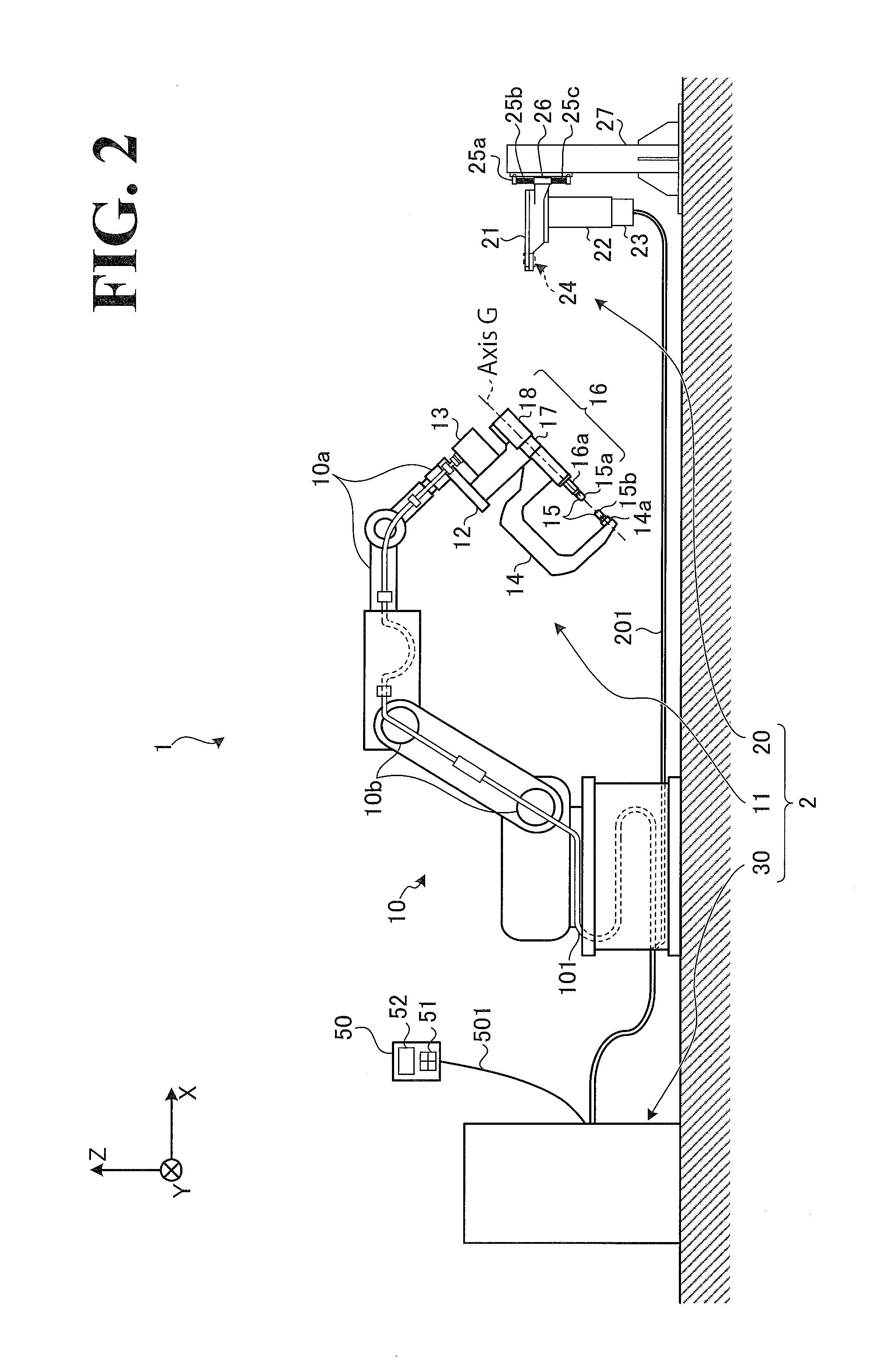

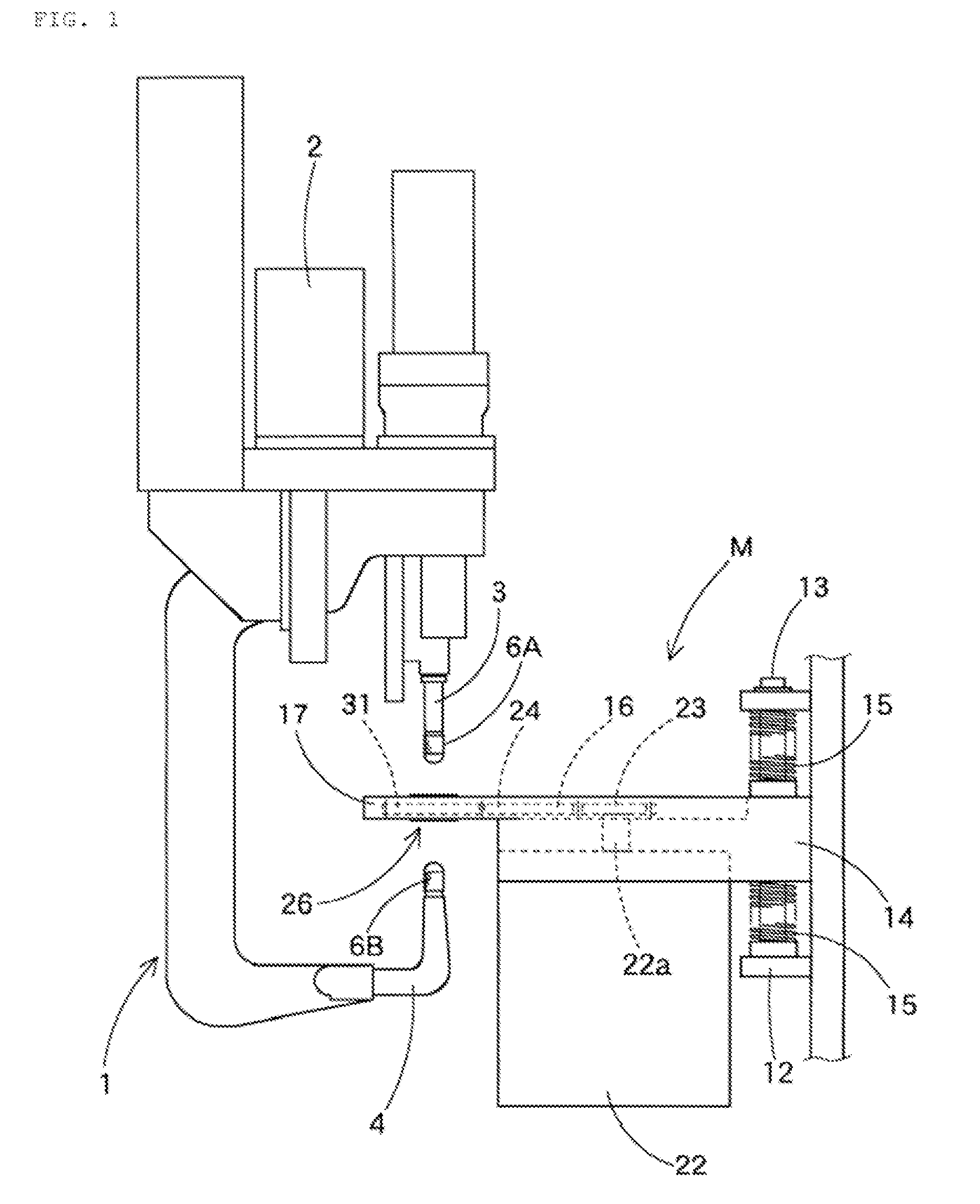

Spot welding system and dressing determination method

ActiveUS20110240605A1Easy to operateAccurate judgmentElectrode supporting devicesElectrode maintenanceImaging processingEngineering

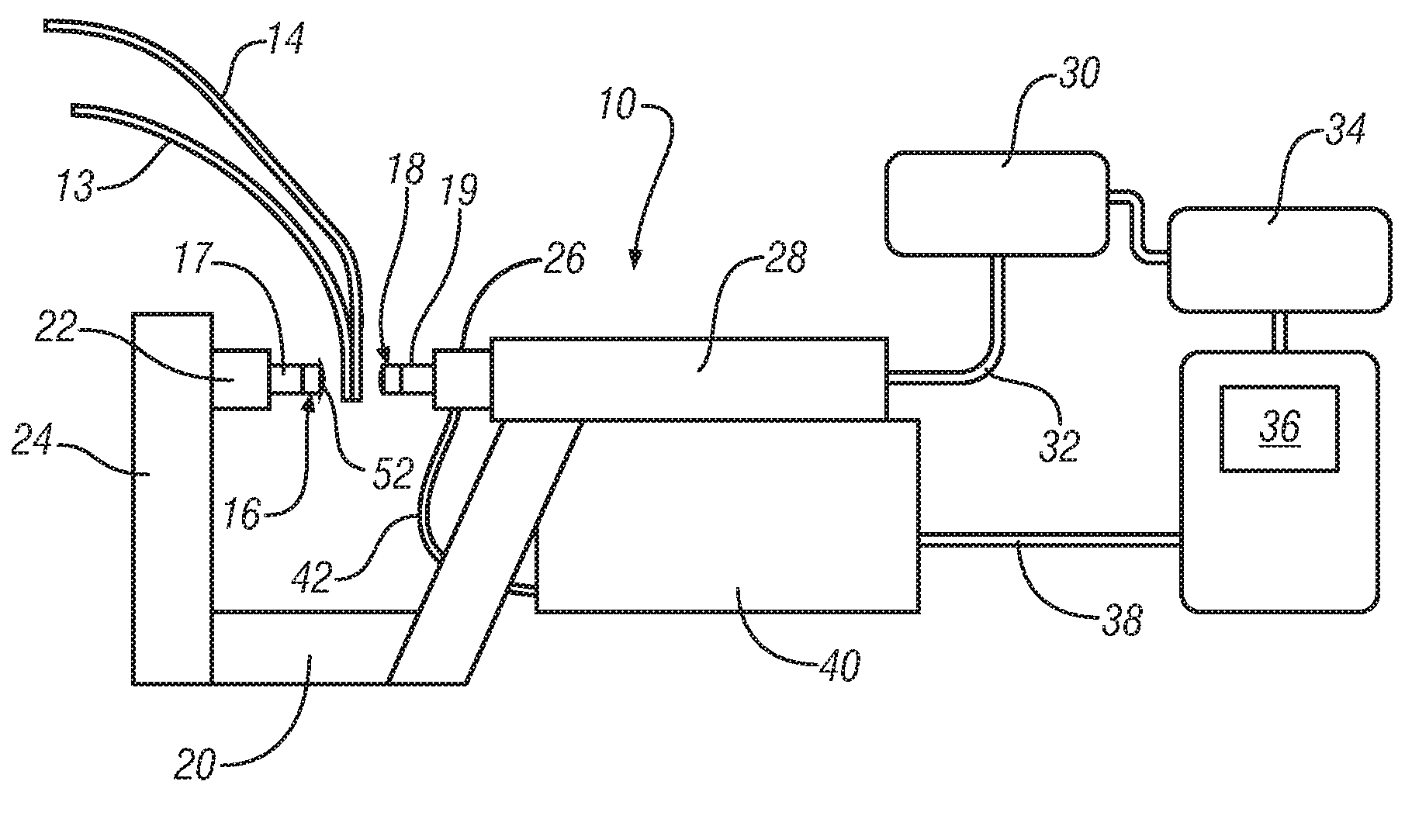

A spot welding system including a welding gun with an openable / closable electrode pair; and a dressing determination device determining a quality of a shaping process applied to an electrode of the electrode pair. The dressing determination device includes a visual sensor obtaining an image of the electrode, identifying a base and a tip of the electrode on the image and measuring a distance between the base and the tip on the image, by image processing; a visual sensor control section allowing the visual sensor to measure the distance immediately before and after the shaping process is performed; a cut amount calculation section calculating a difference between the distances measured by the visual sensor immediately before and after the shaping process is performed, as a cut amount of the electrode; and a cut amount judgment section judging whether the calculated cut amount is within a predetermined acceptable range.

Owner:FANUC LTD

Electrode inspection apparatus for spot welding

ActiveUS8953033B2Ensure correct executionReduce the ratioColor television detailsClosed circuit television systemsProduction lineEngineering

Owner:KEYLEX CORP

Electrode for spot welding

ActiveUS8525066B2Readily re-shapedOhmic-resistance electrodesWelding/cutting media/materialsSheet steelSpot welding

Owner:GM GLOBAL TECH OPERATIONS LLC

Welding electrode with contoured face

Owner:GM GLOBAL TECH OPERATIONS LLC

Weld electrode for attractive weld appearance

ActiveUS20090127232A1High thermal and electrical resistivityHigh melting pointOhmic-resistance electrodesPressure electrodesSheet steelSpot welding

Weld faces of electrodes for resistance spot welding are formed with a suitable area of protrusions and / or intrusions. The size, shape, and elevation or depths of the protrusions or intrusions are determined for the formation of suitable spot welds in and between metal workpieces such as aluminum or steel panels for vehicle bodies. The protrusions or intrusions are also conceived and used to form an image on at least a visible surface of the welded article to produce an attractive appearance on the surface of the welded sheet.

Owner:GM GLOBAL TECH OPERATIONS LLC

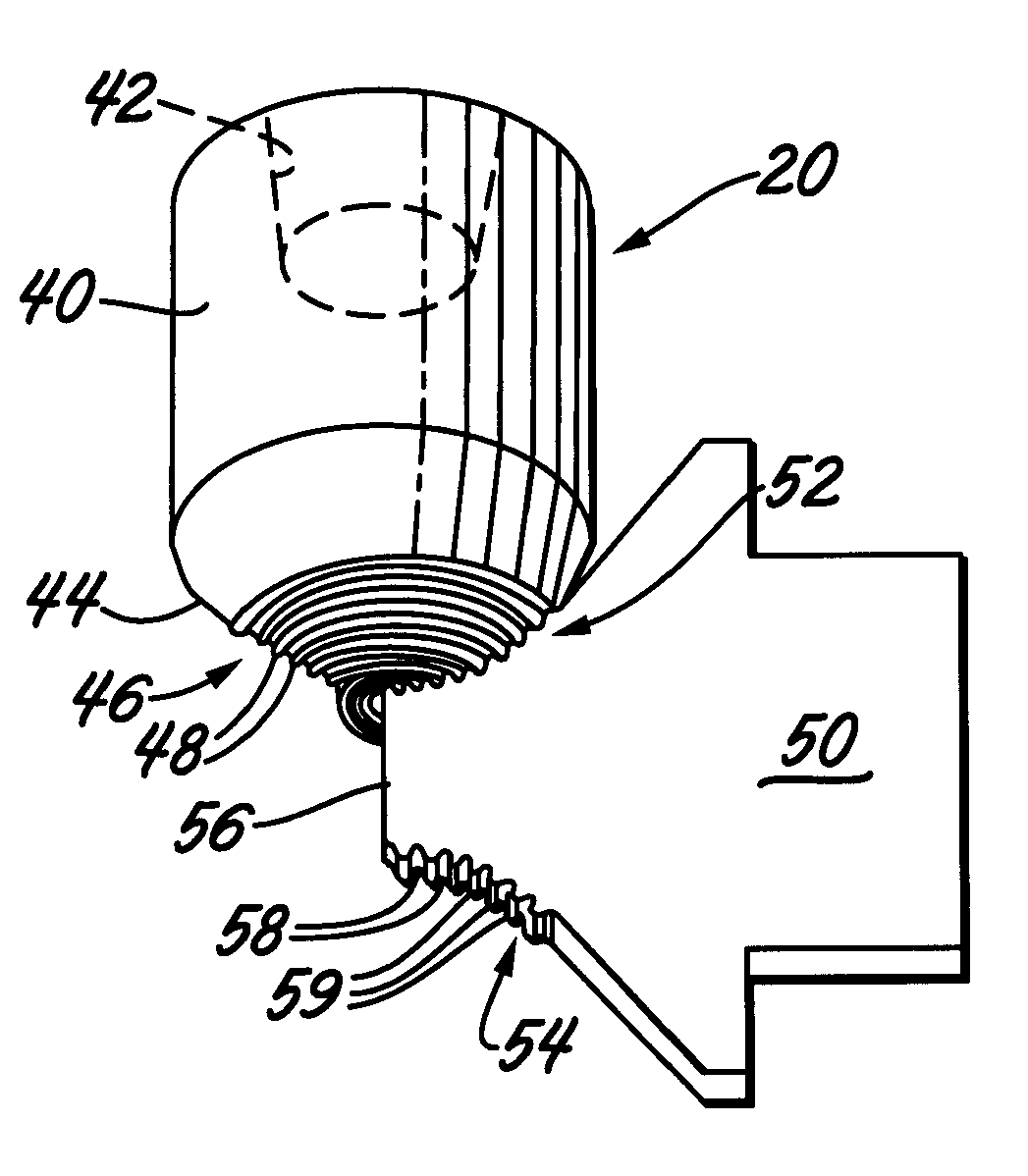

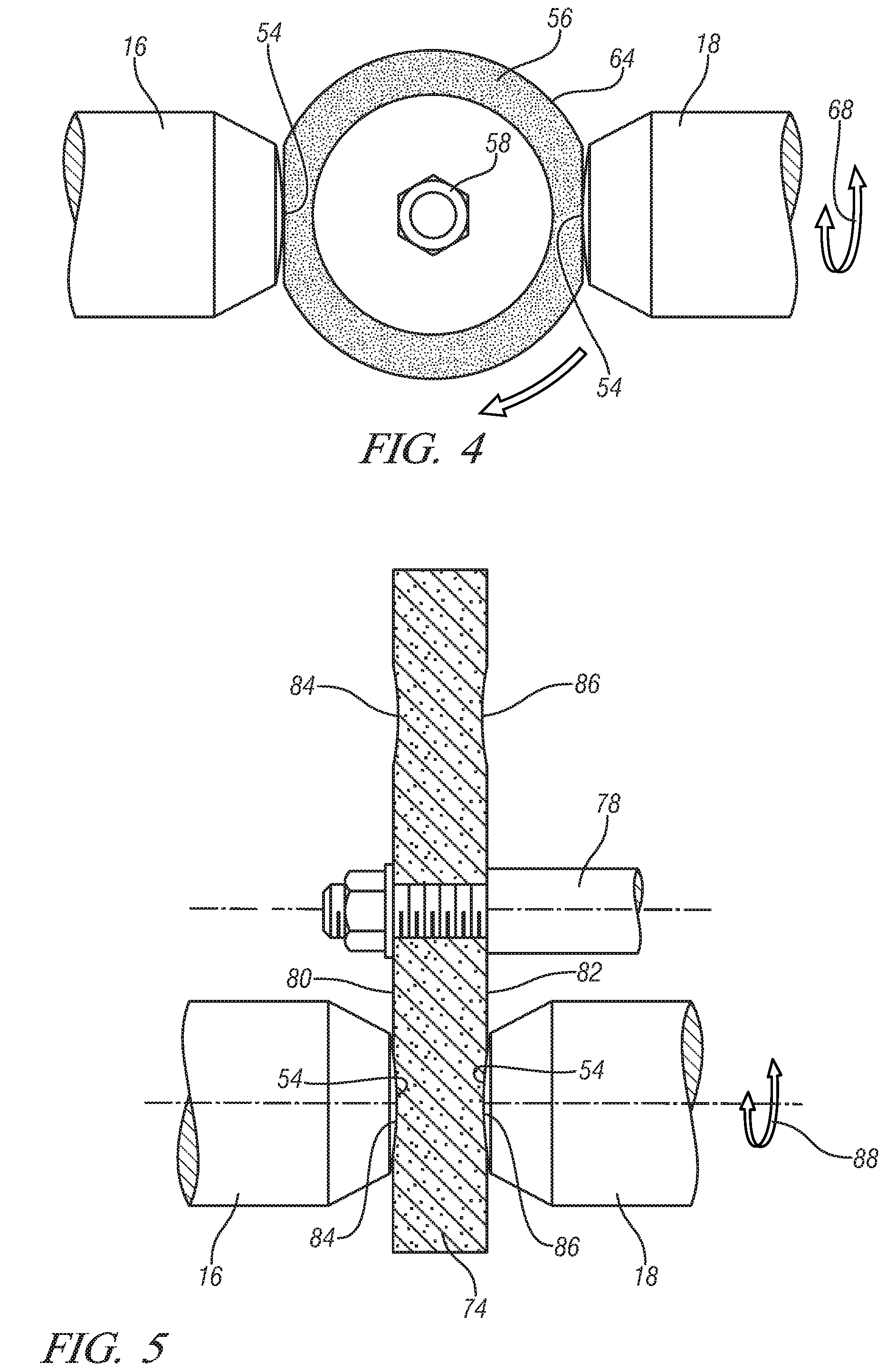

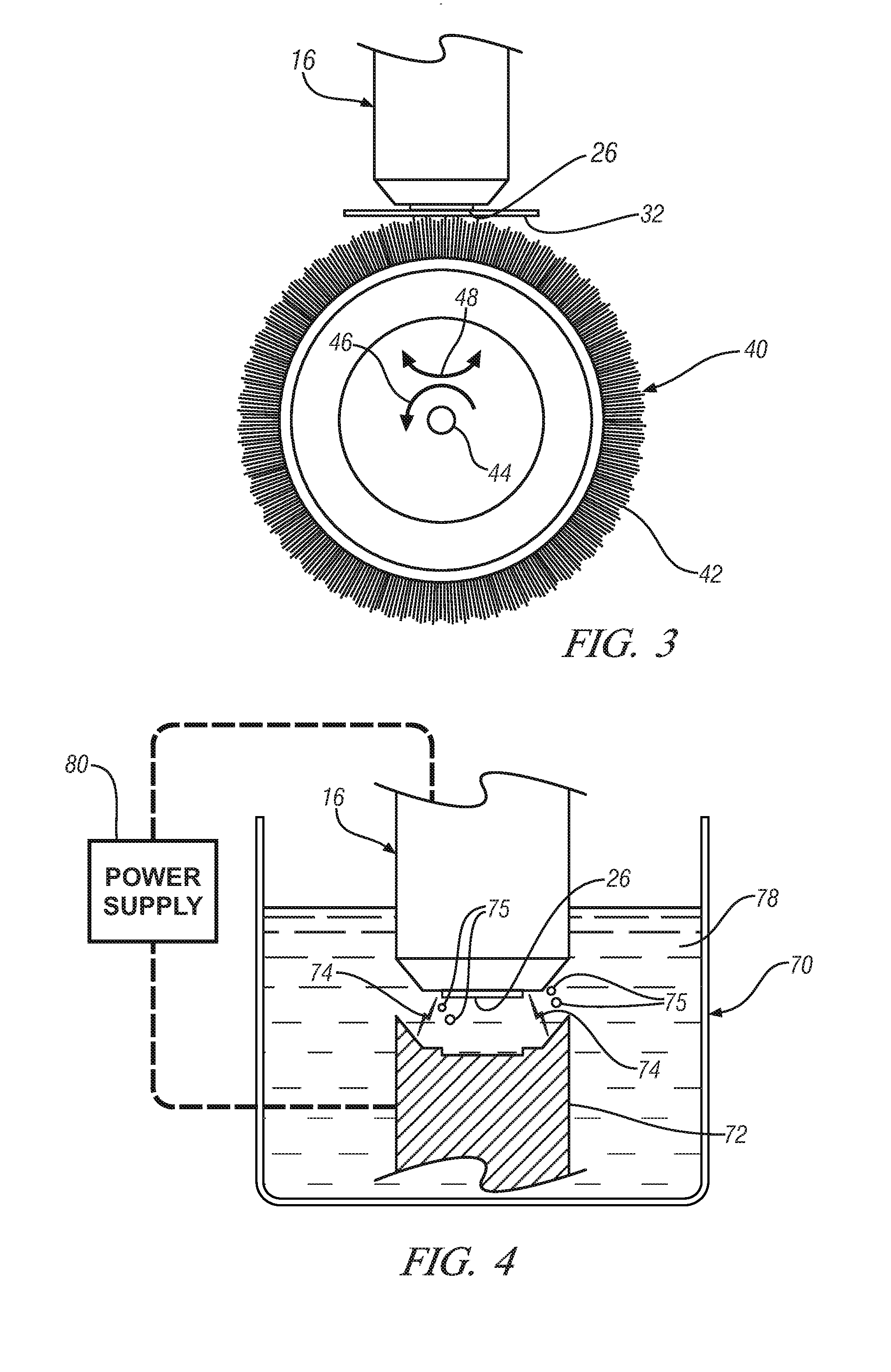

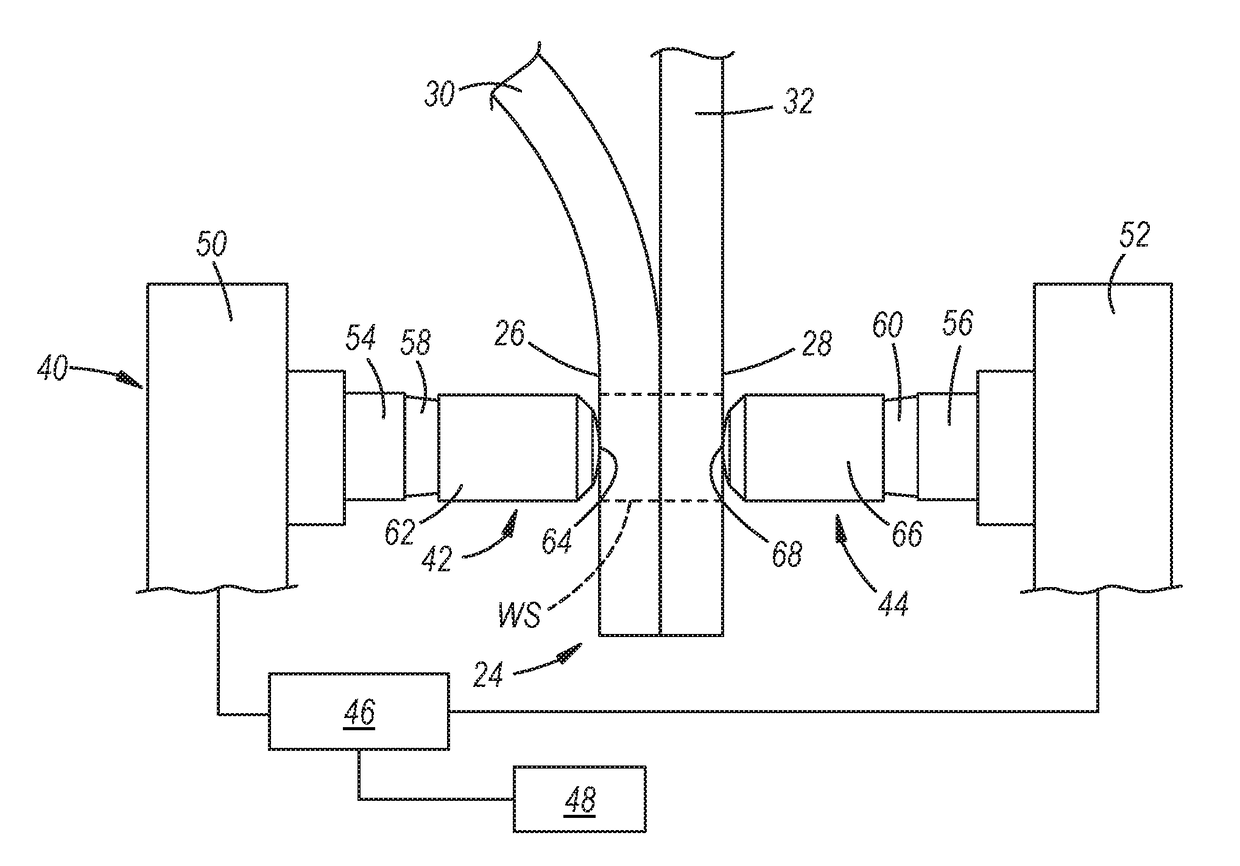

Forming and re-forming welding electrodes with contoured faces

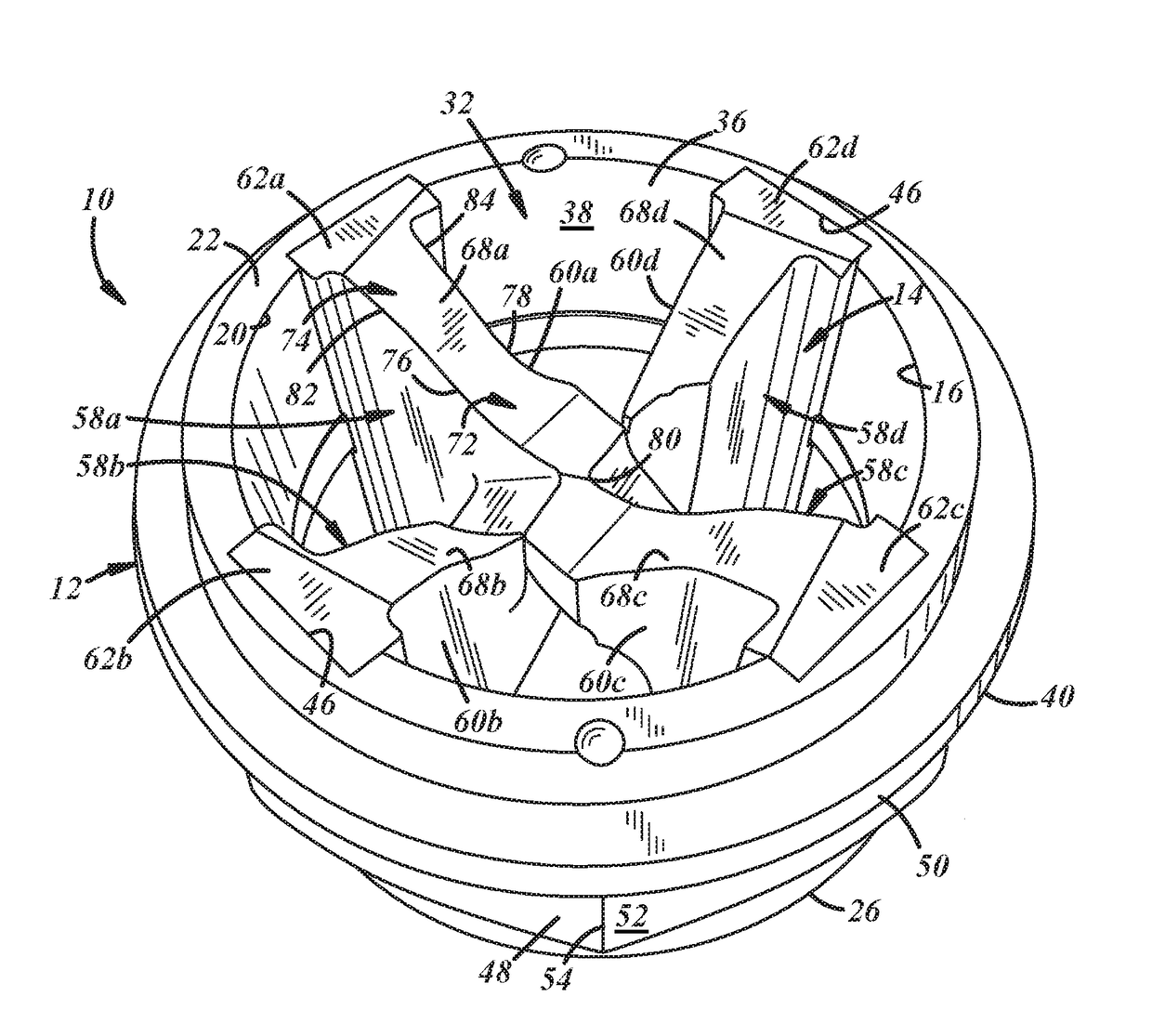

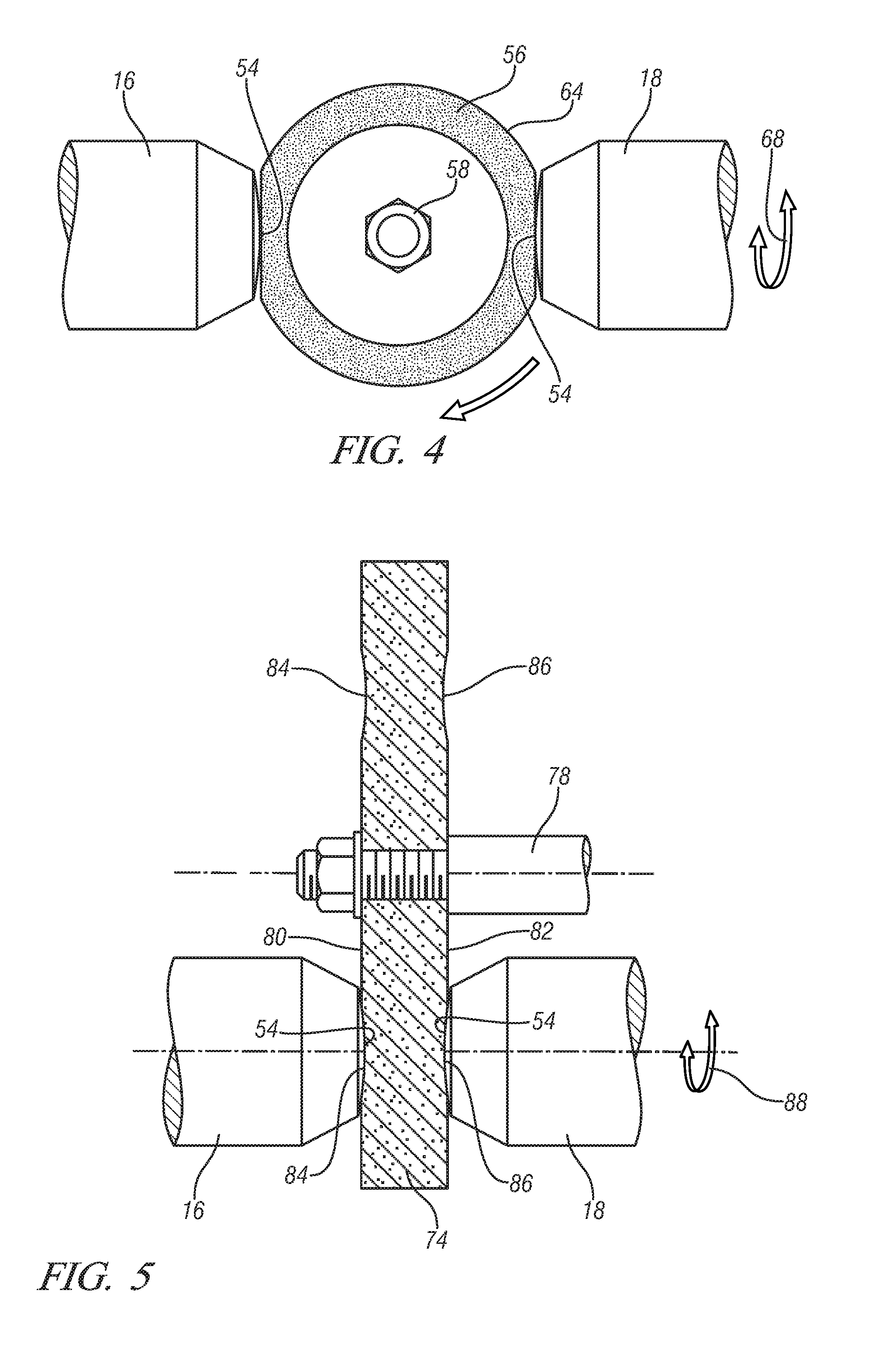

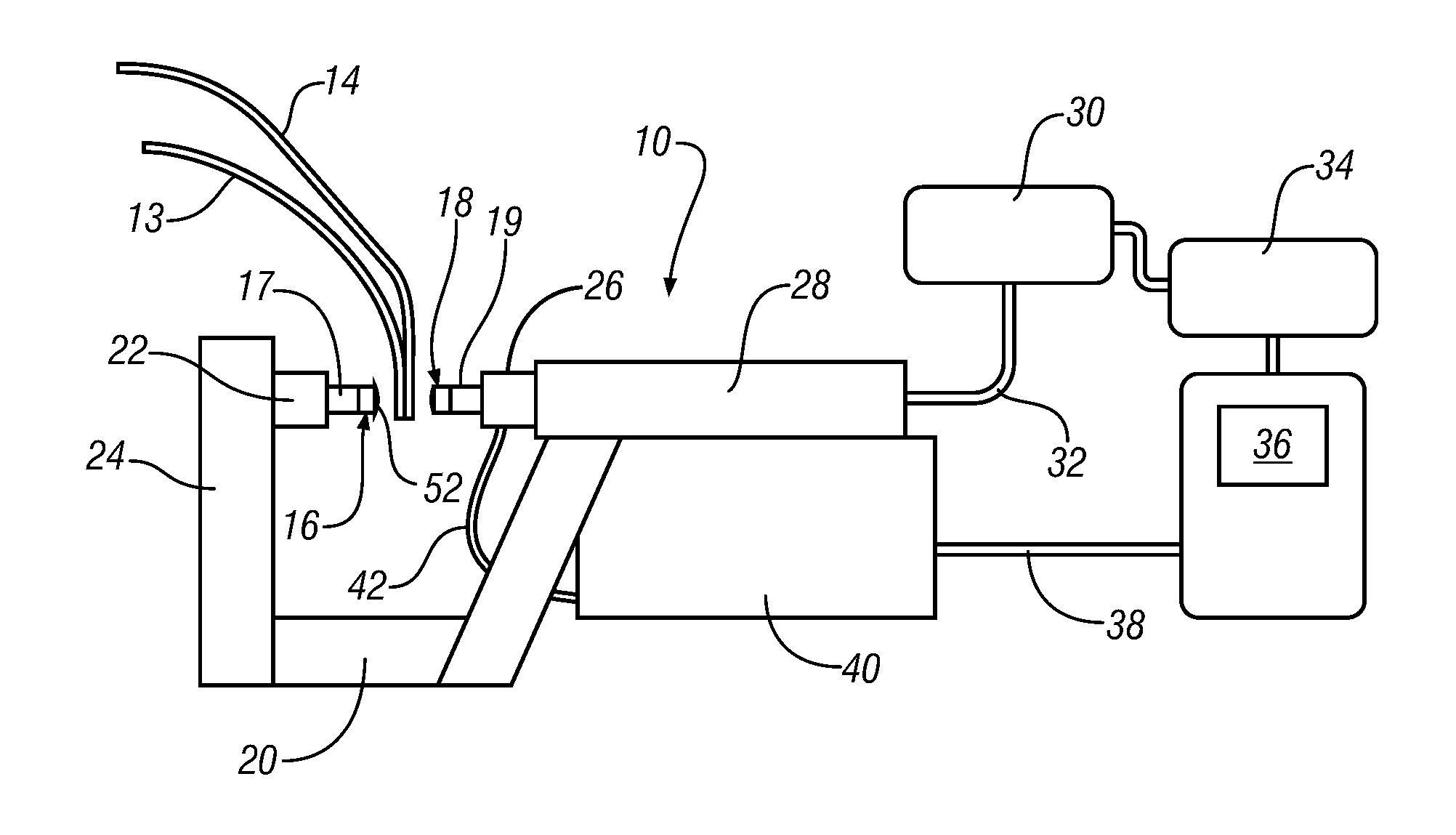

ActiveUS20100258536A1Easily fowled on new electrodesEasy alignmentTurning machine accessoriesPressure electrodesSurface geometryMechanical engineering

A method is disclosed for using welding electrodes with a spherically-domed welding face having concentric contoured features formed into the face for better contact with workpiece surfaces. The concentric contoured features may be initially formed by rotating a cutting tool with a contoured cutting edge, the cutting edge being in engagement with the electrode face. A similar practice may be followed to re-create the weld face surface geometry if it becomes eroded or malformed during welding use. A suitable tool may have a blade-like geometry, with a mounting portion for supporting and positioning the tool in a rotating holder and a cutting edge. The cutting edge may have a contour complementary to that of the weld face and extend at least from the center of the weld face to at least the radial extent of the concentric contoured features.

Owner:GM GLOBAL TECH OPERATIONS LLC

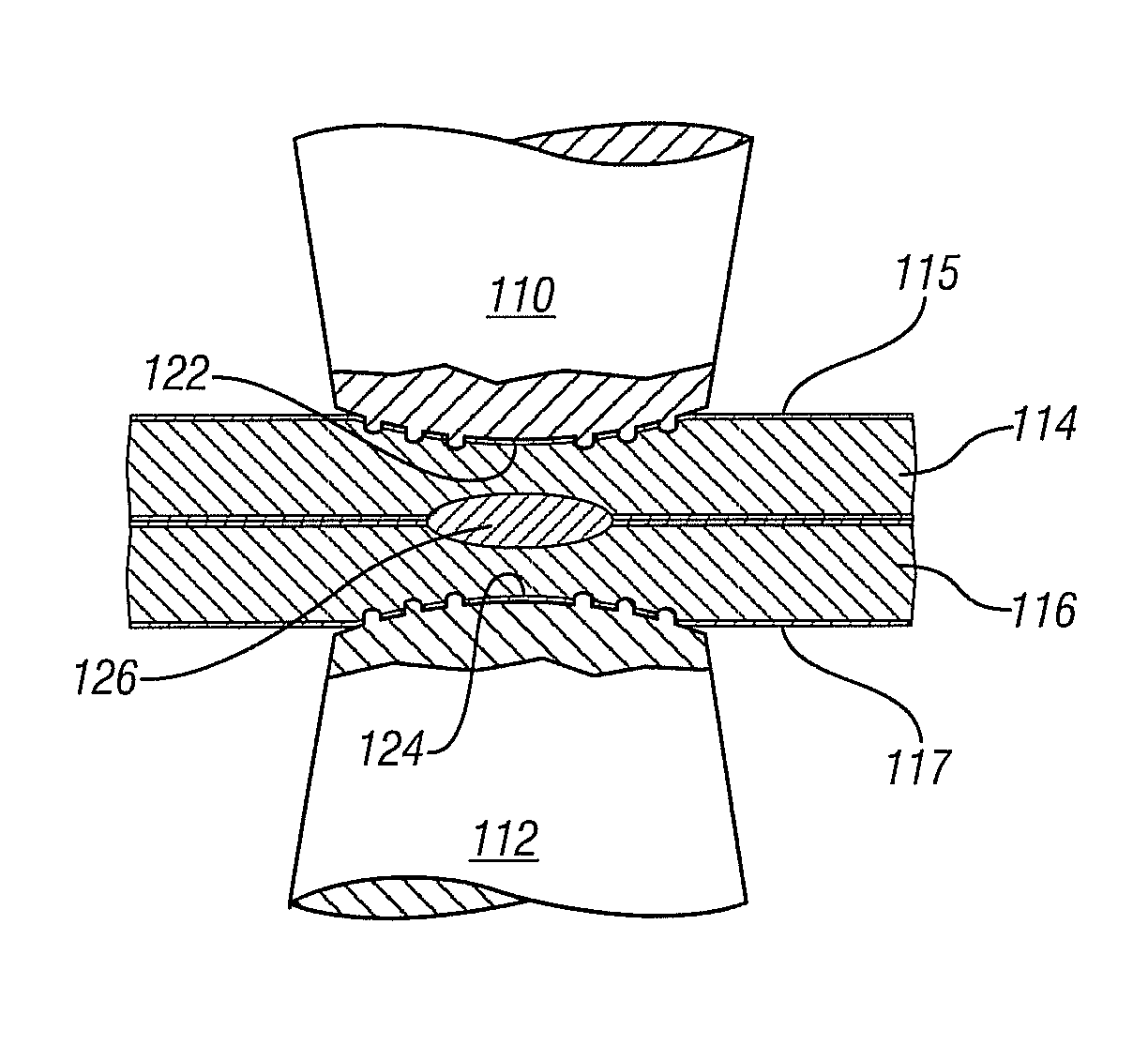

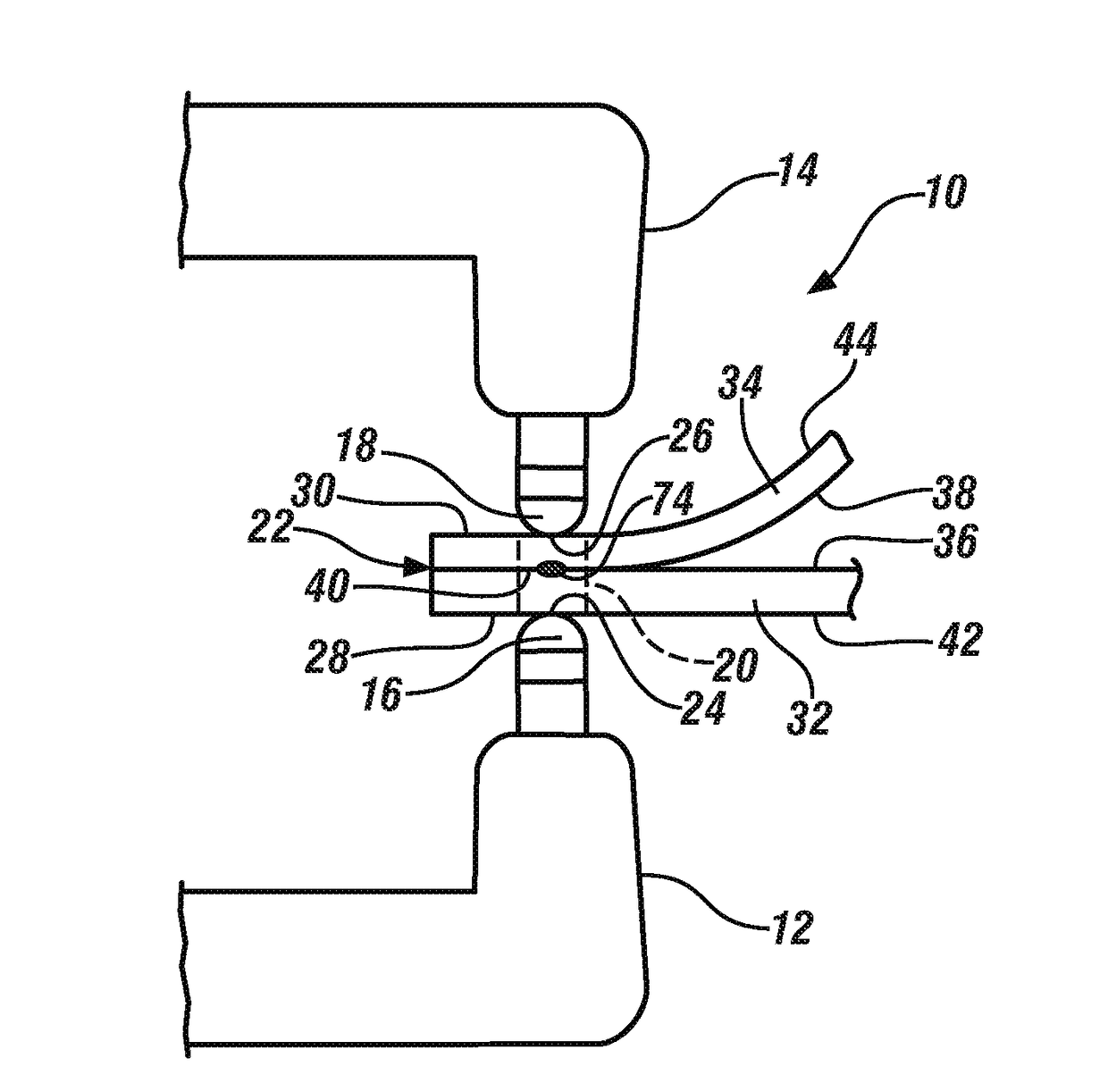

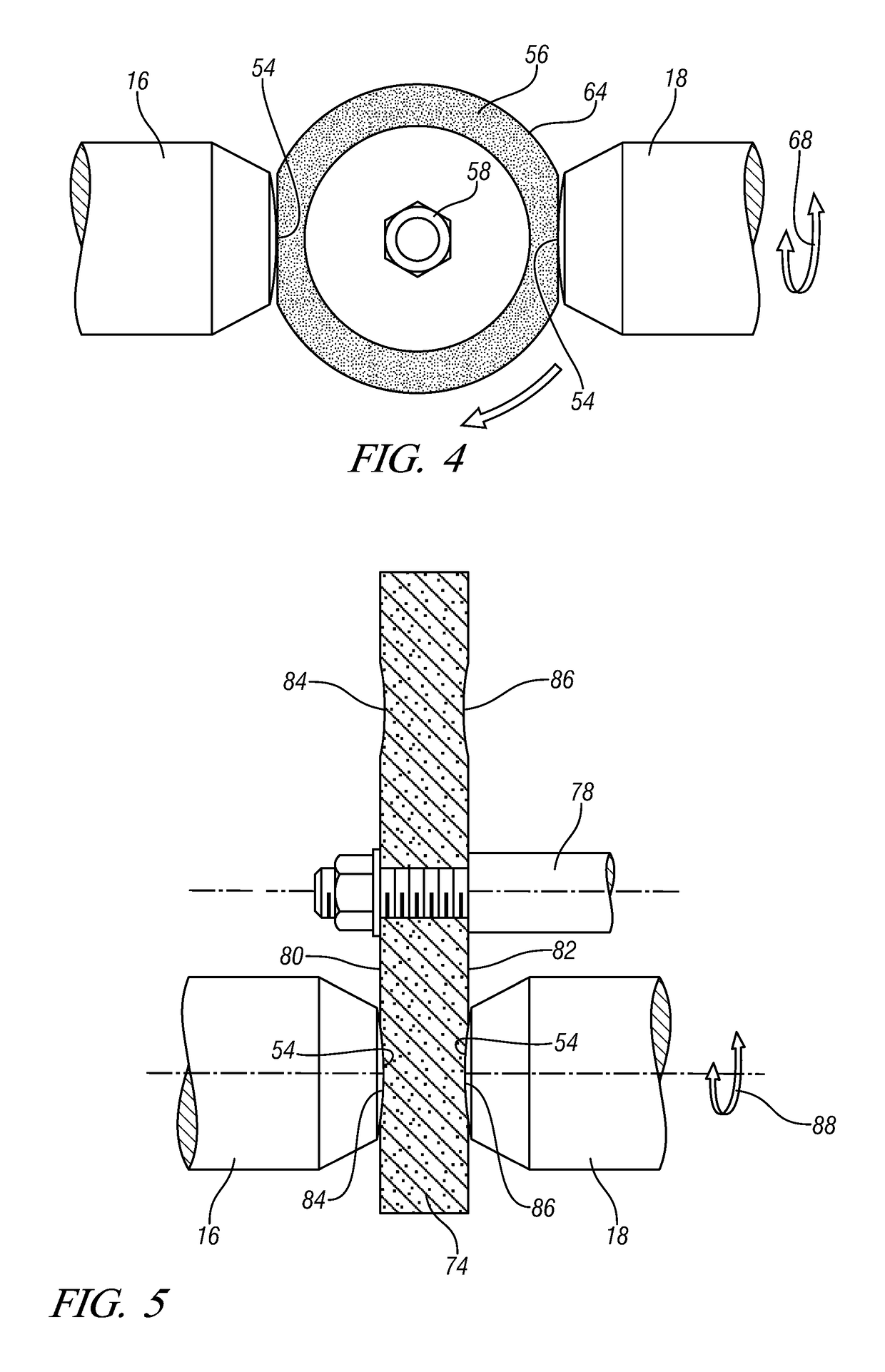

Resistance spot welding steel and aluminum workpieces using electrode weld face cover

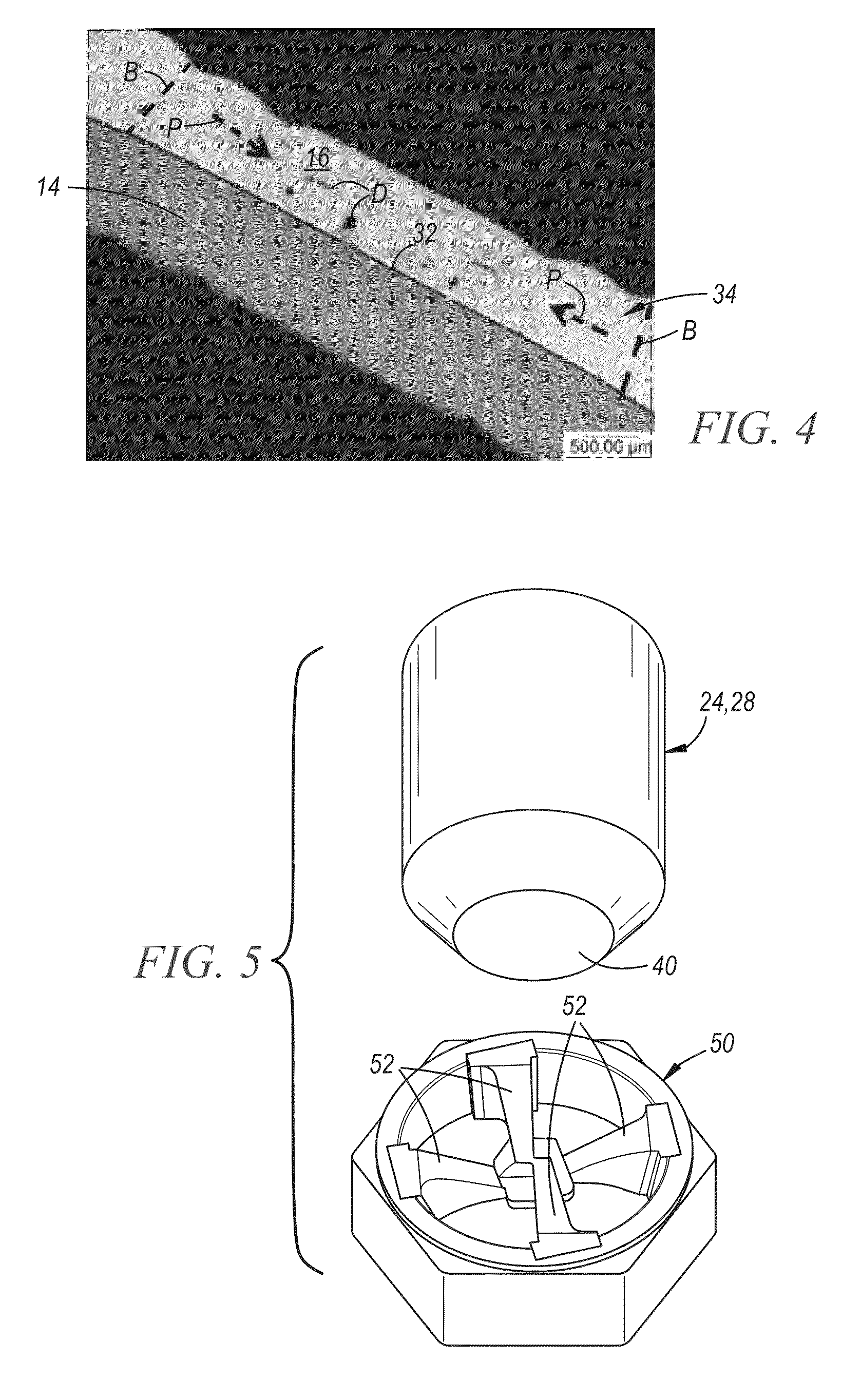

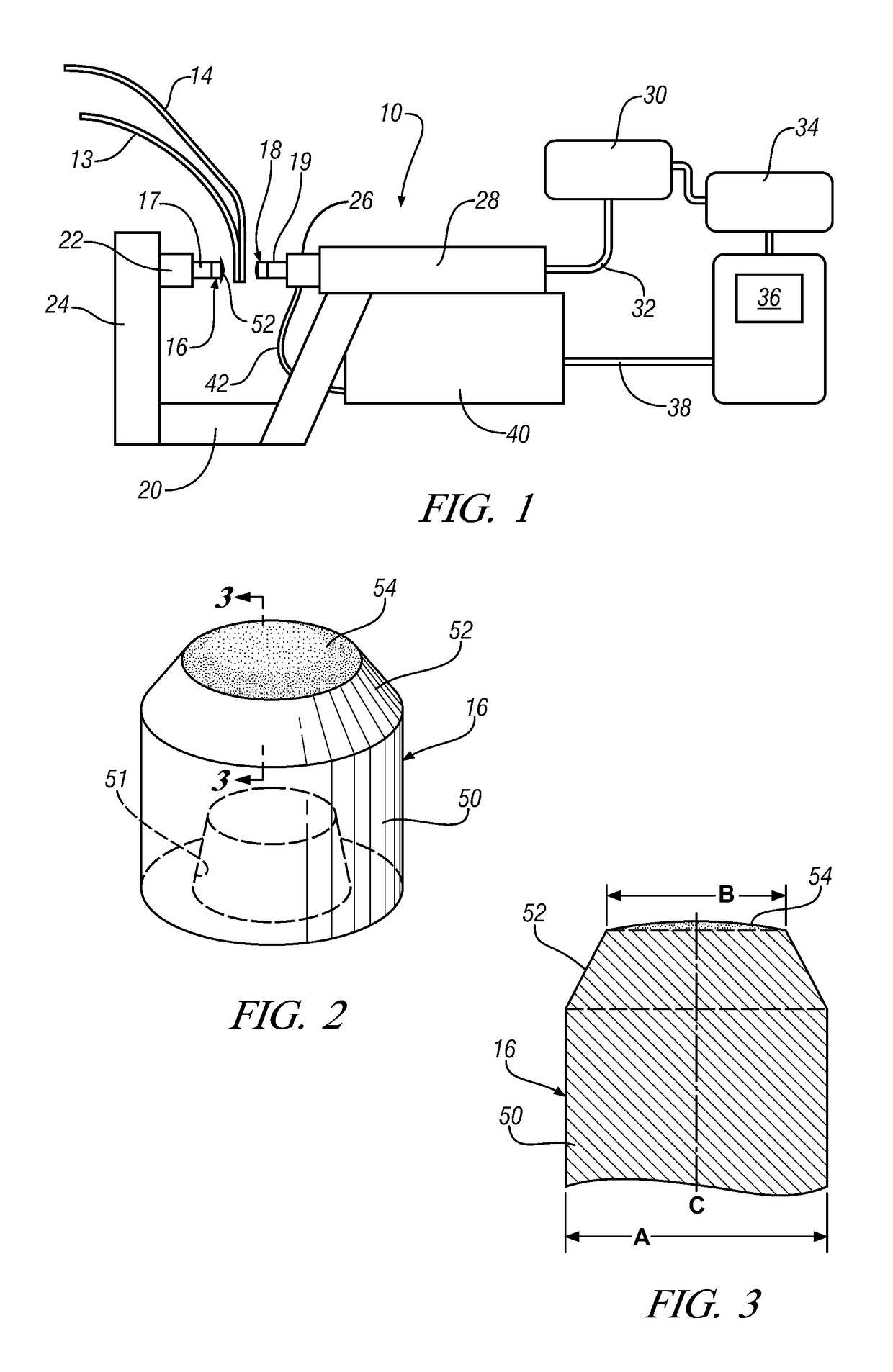

ActiveUS20150053654A1Reduce heatReduce the overall heightOhmic-resistance electrodesElectrode supporting devicesMetallic materialsSpot welding

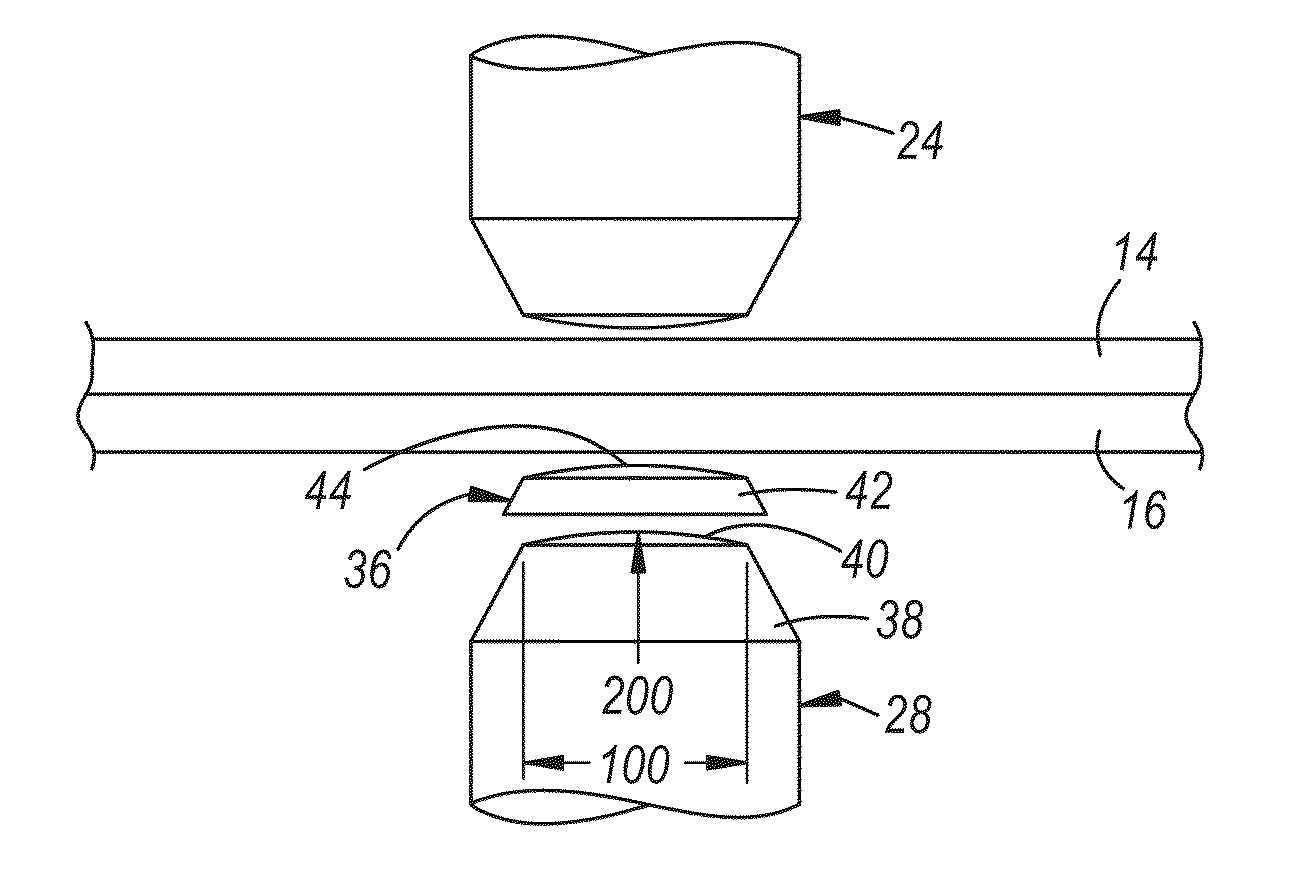

A method of resistance spot welding a steel workpiece and an aluminum or aluminum alloy (“aluminum”) workpiece together includes several steps. One step involves providing a workpiece stack-up with a steel workpiece and an aluminum workpiece. Another step involves attaching a cover over a weld face of a welding electrode. The cover is made of a metal material with an electrical resistivity that is greater than an electrical resistivity of a material of the welding electrode. Yet another step involves performing multiple individual resistance spot welds to the workpiece stack-up. The cover abuts the aluminum workpiece while the individual resistance spot welds are performed. And another step involves removing the cover from the welding electrode after the individual spot welds are performed.

Owner:GM GLOBAL TECH OPERATIONS LLC

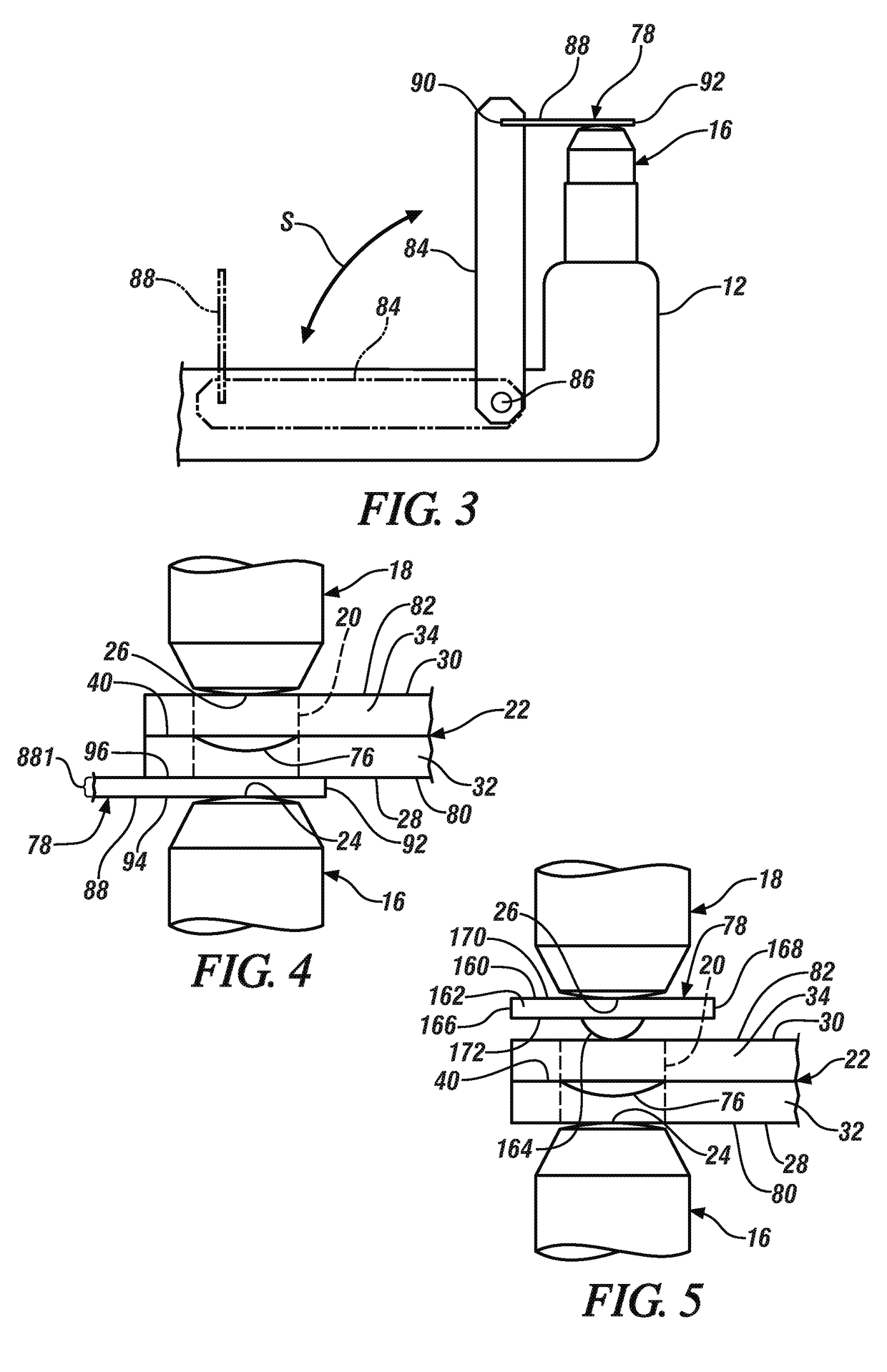

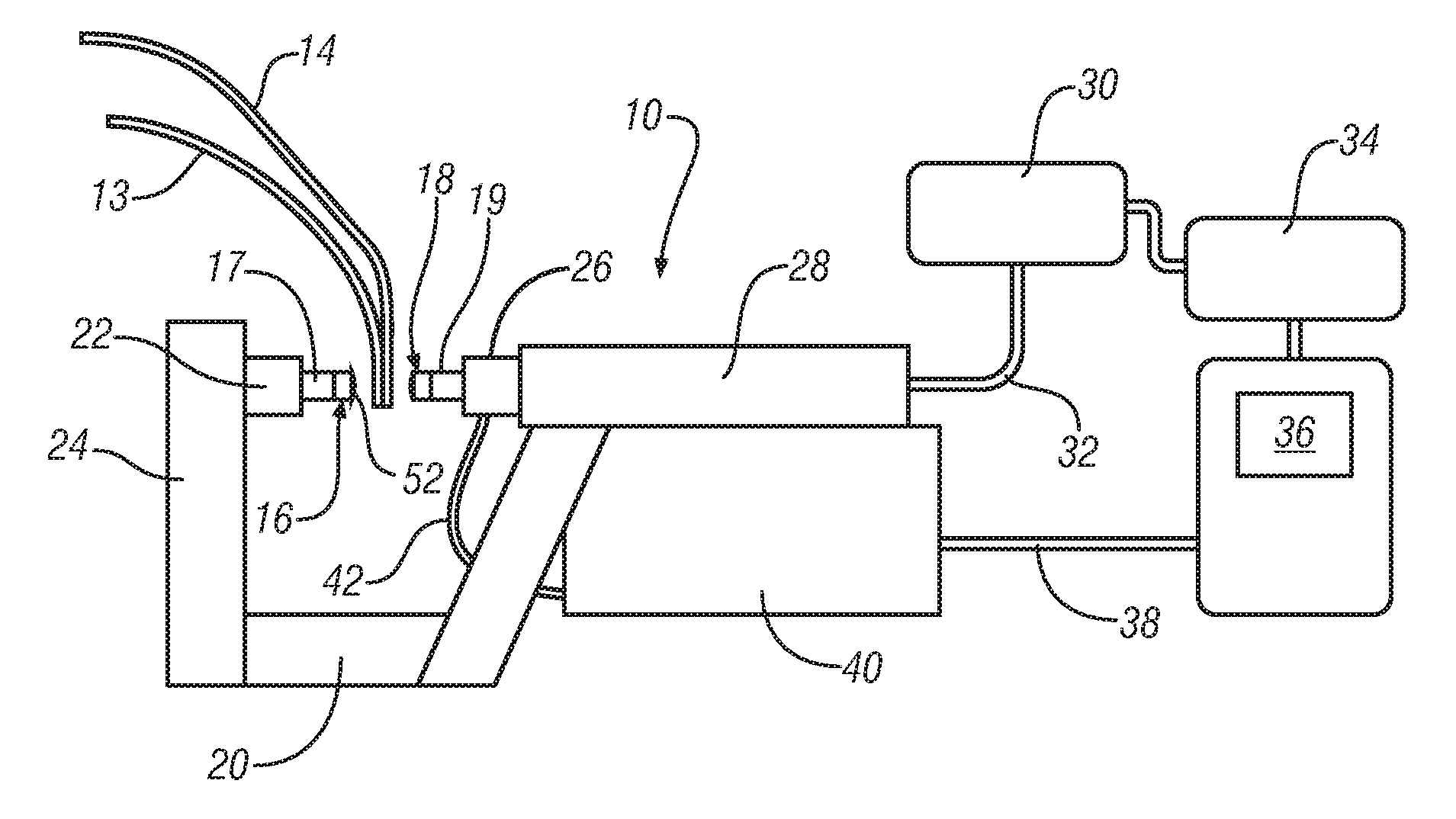

Welding electrode cutting tool and method of using the same

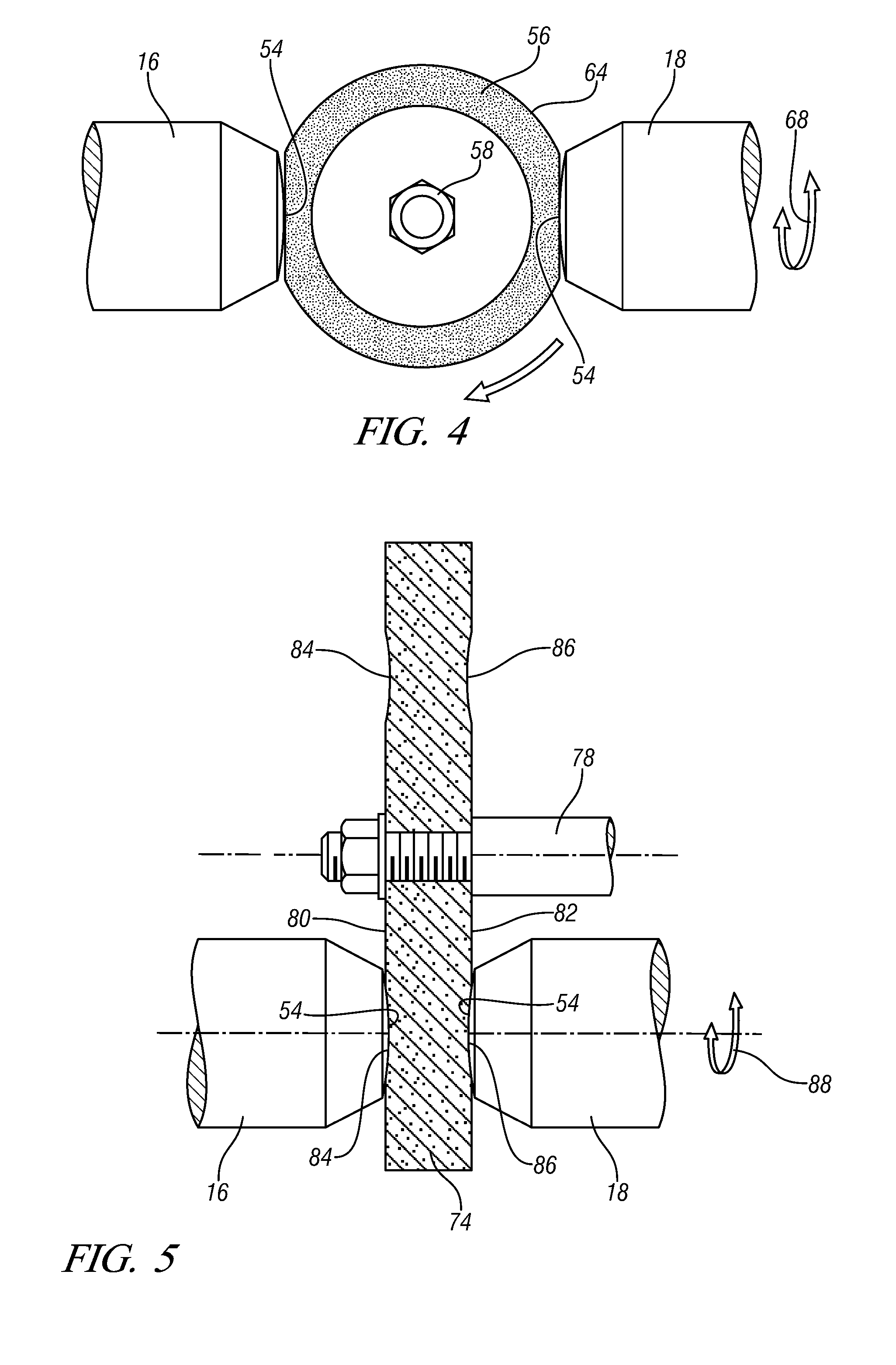

ActiveUS20170225263A1Turning machinesElectrode maintenanceElectrical resistance and conductanceEngineering

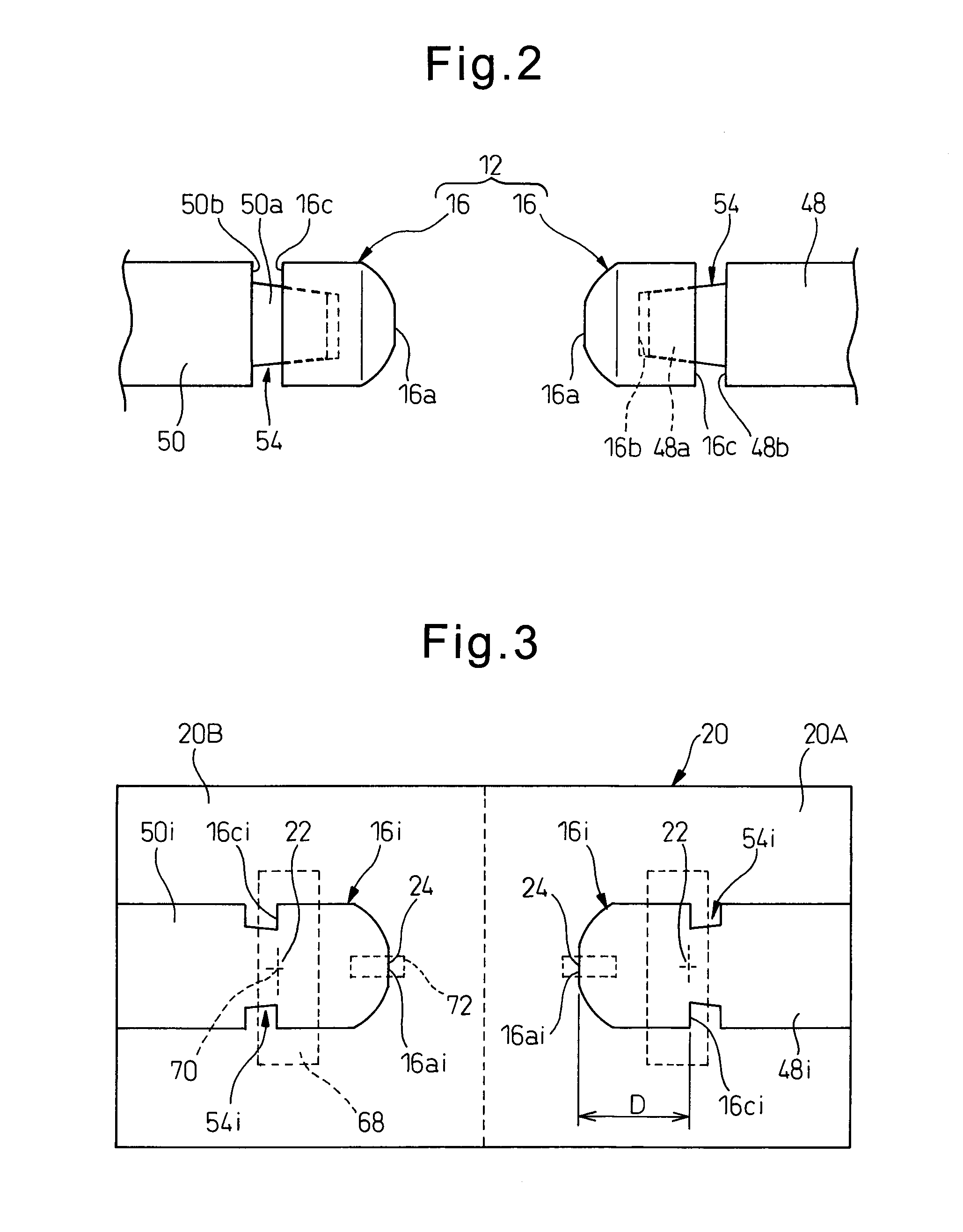

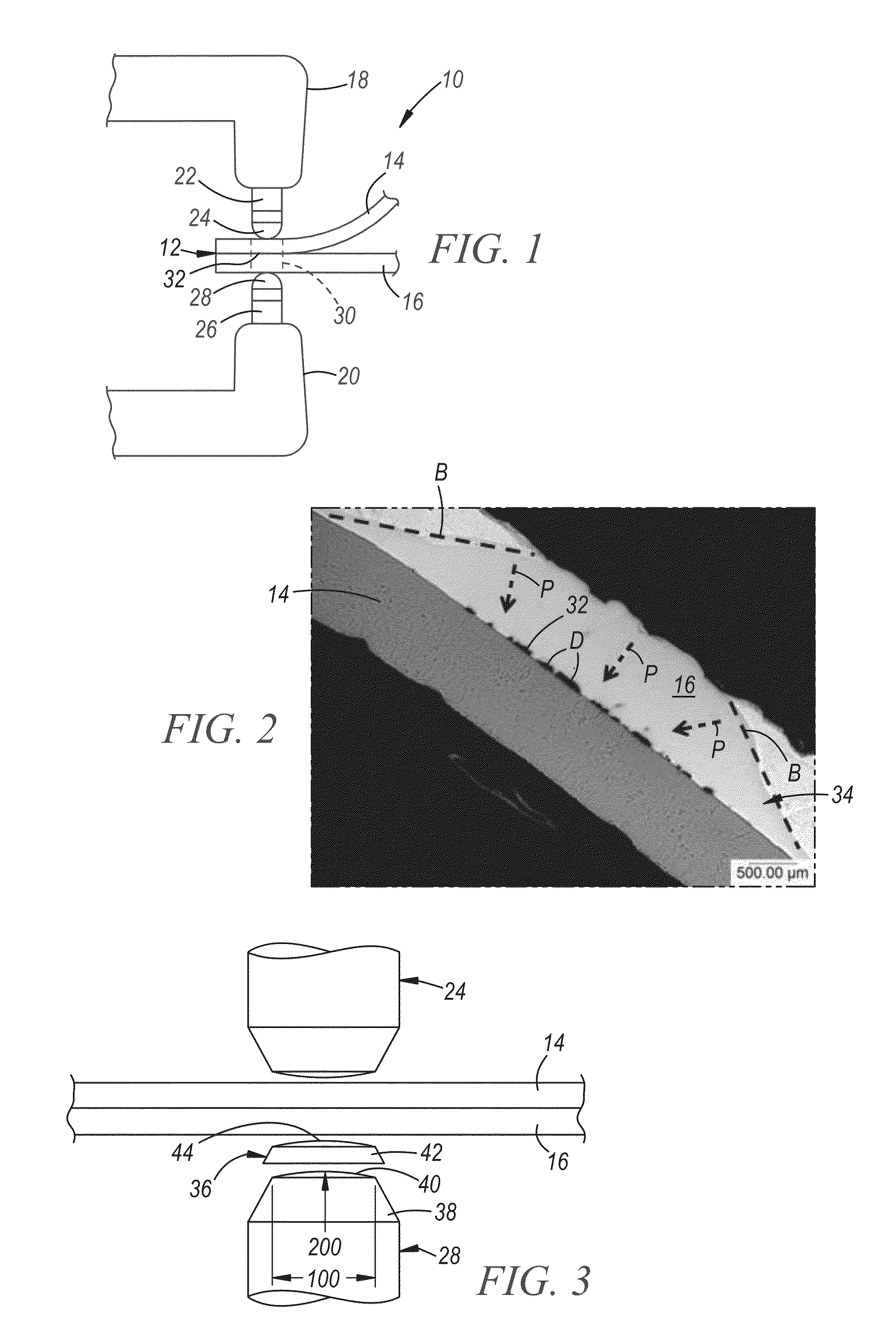

A cutting tool that can simultaneously cut and restore asymmetric weld face geometries of two welding electrodes that are subject to different degradation mechanisms is disclosed along with a method of using such a cutting tool during resistance spot welding of workpiece stack-ups that include dissimilar metal workpieces. The cutting tool includes a first cutting socket and a second cutting socket. The first cutting socket is defined by one or more first shearing surfaces and the second cutting is defined by one or more second shearing surfaces. The first shearing surface(s) and the second shearing surface(s) are profiled to cut and restore a first weld face geometry and a second weld face geometry, respectively, that are different from each other upon receipt of electrode weld faces within the cutting sockets and rotation of the cutting tool.

Owner:GM GLOBAL TECH OPERATIONS LLC

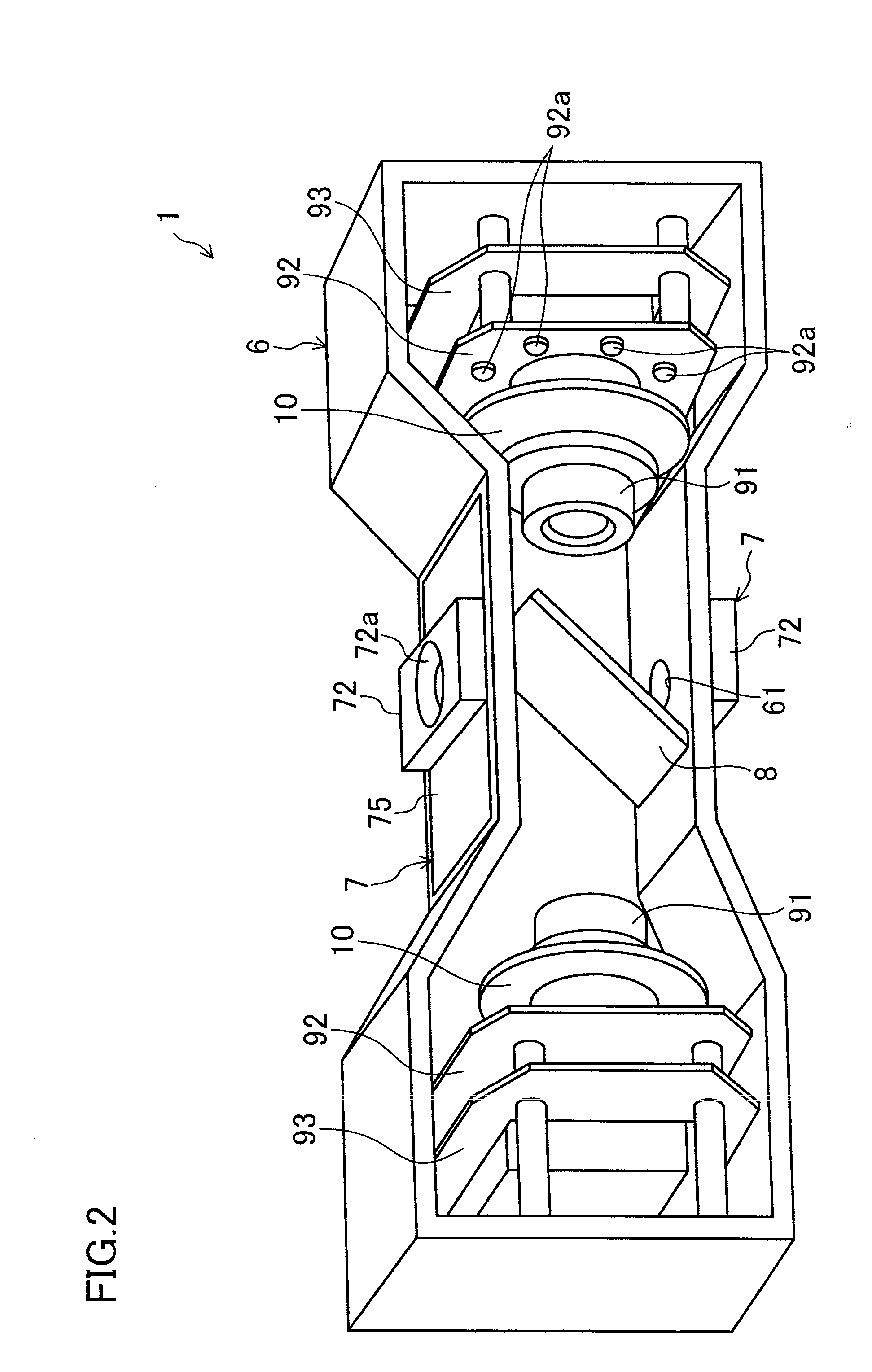

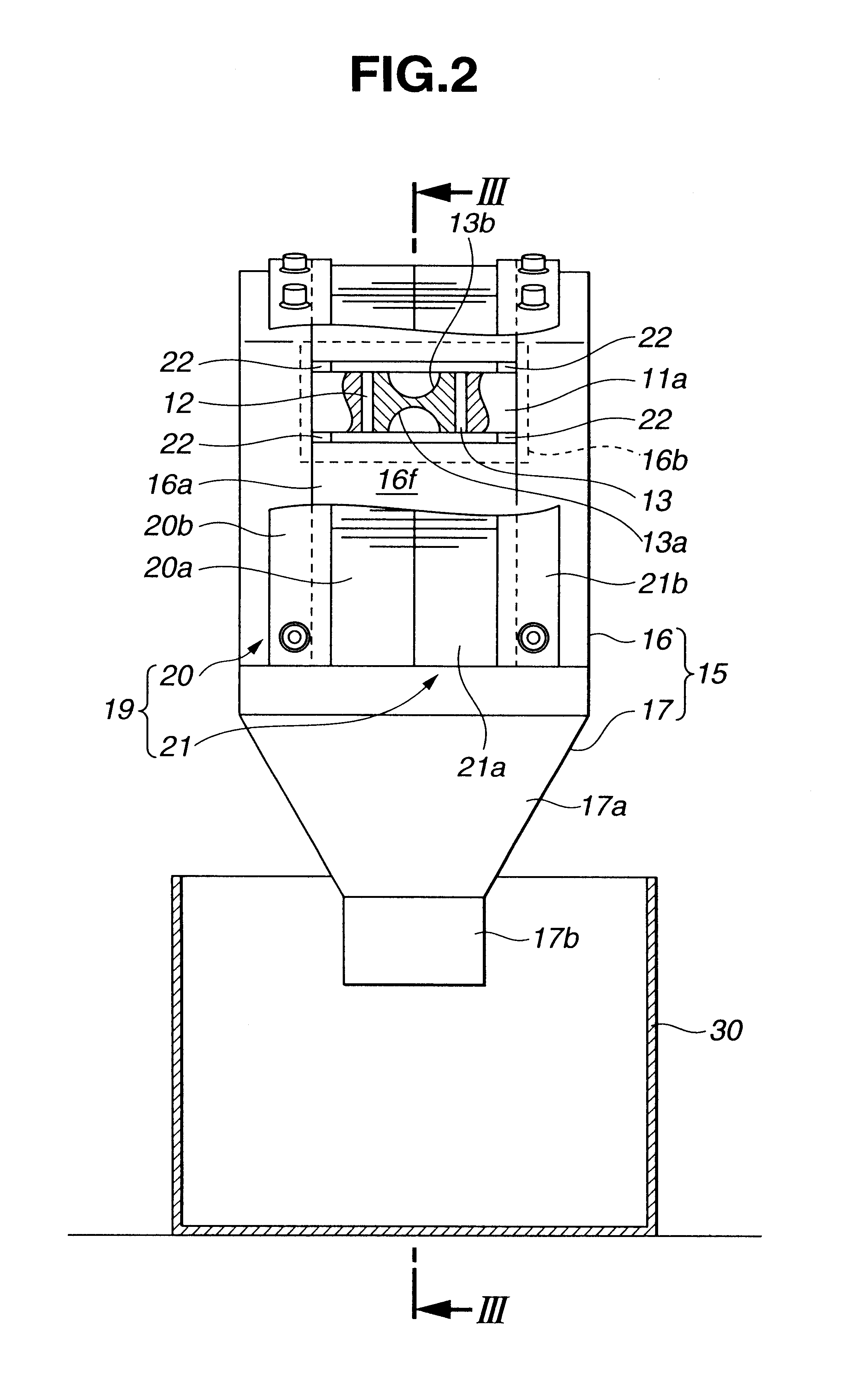

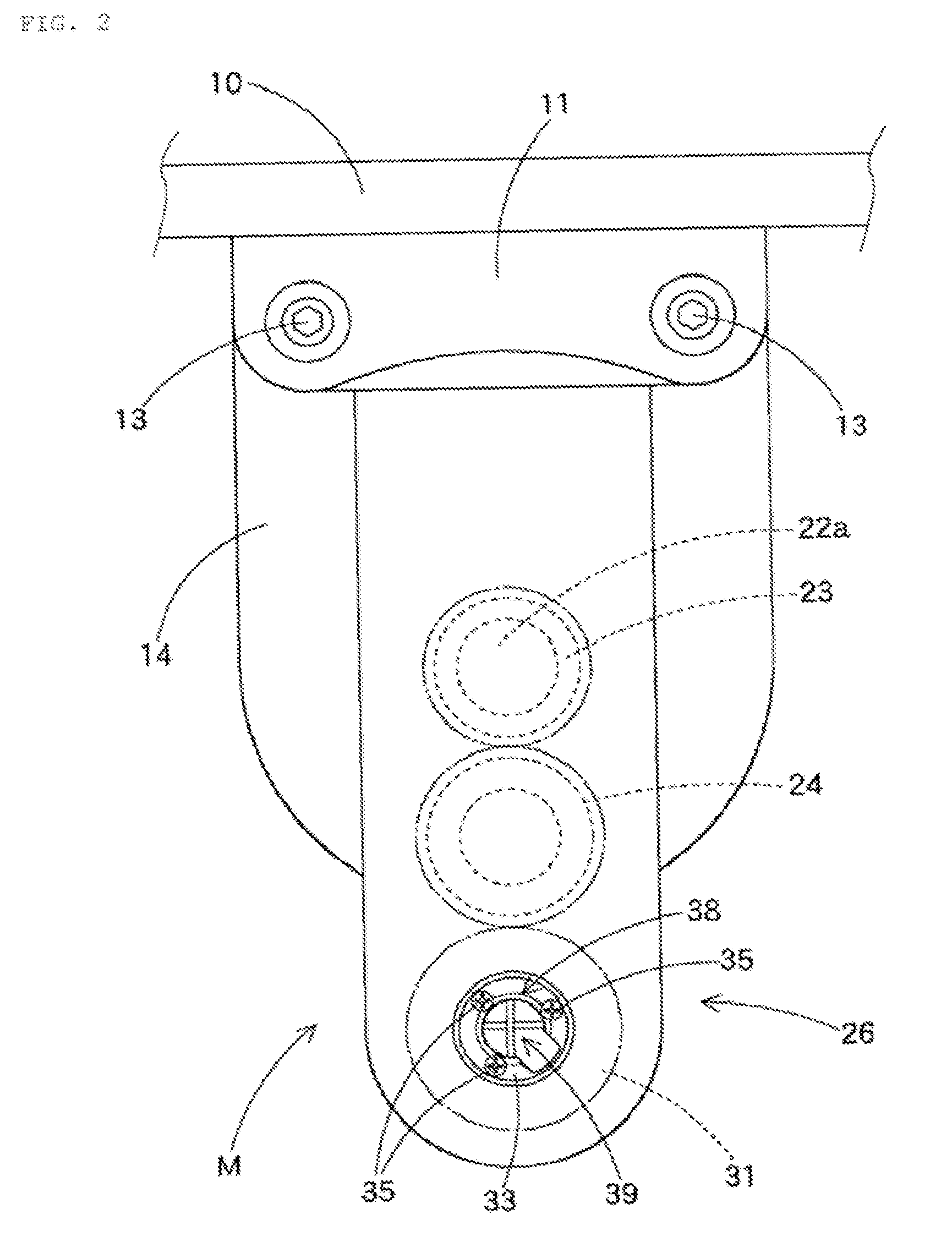

Electrode inspection apparatus for spot welding

ActiveUS20120200695A1Ensure correct executionReducing availability ratioColor television detailsClosed circuit television systemsProduction lineEngineering

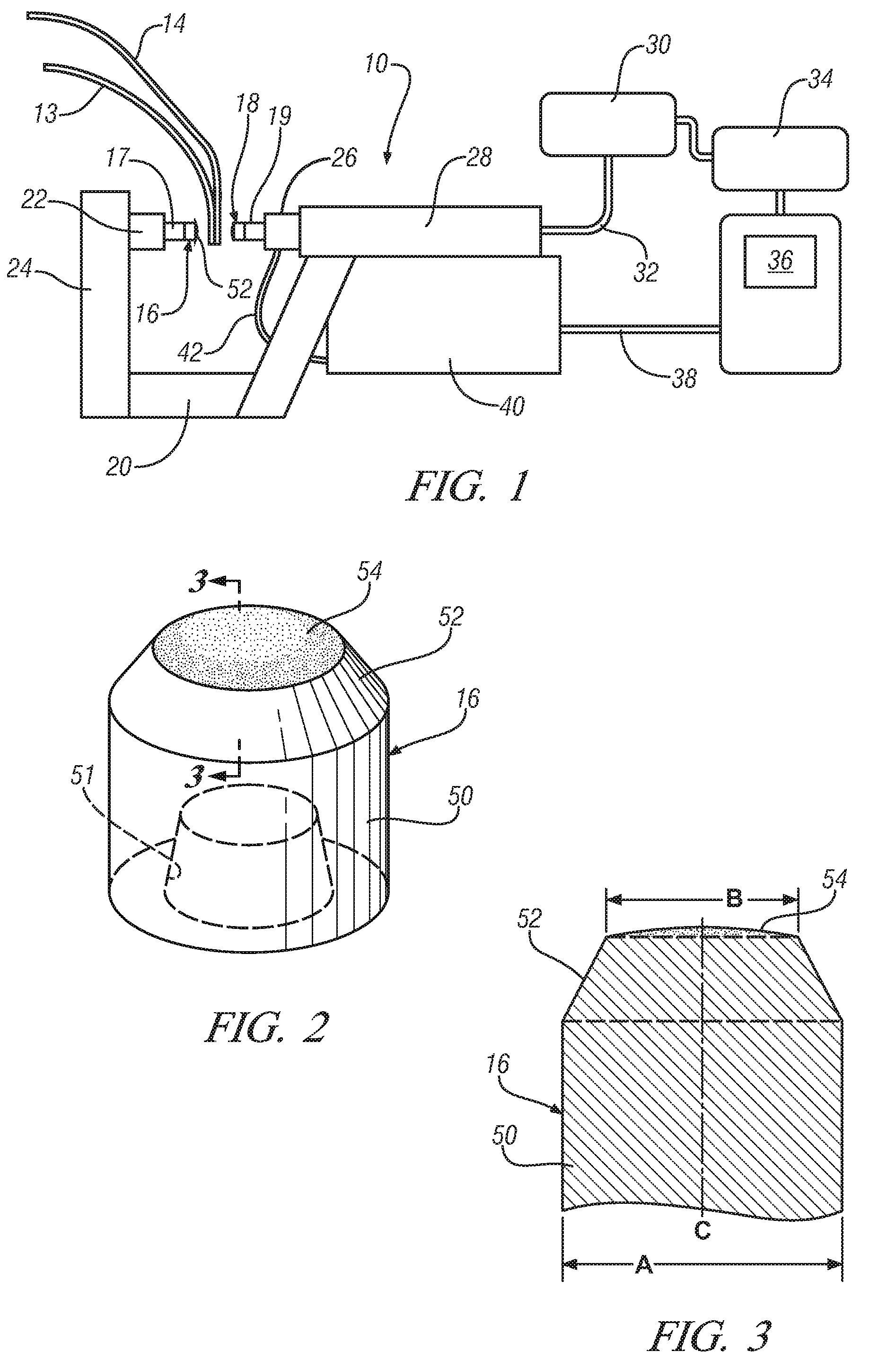

An electrode inspection apparatus for spot welding is provided for precisely measuring diameters of a tip of an electrode without reducing availability ratio in a production line, and is particularly useful when inspecting a weld gun having electrodes with a narrow distance therebetween.A CCD camera 91 for imaging the tip of the electrode held to the weld gun is disposed in an inspection apparatus body 6. The inspection apparatus body 6 includes a measuring reference unit 7 in which a fixing hole 72a for fixing the tip of the electrode is formed, and a mirror 8 obliquely arranged with respect to the electrode so as to be distant from the fixing hole 72a at a position opposite to the electrode with respect to the measuring reference unit 7. The CCD camera 91 is disposed in a side of the mirror 8 with a distance therebetween for imaging the tip of the electrode from a direct front thereof reflected on the mirror 8 by reflection.

Owner:KEYLEX CORP

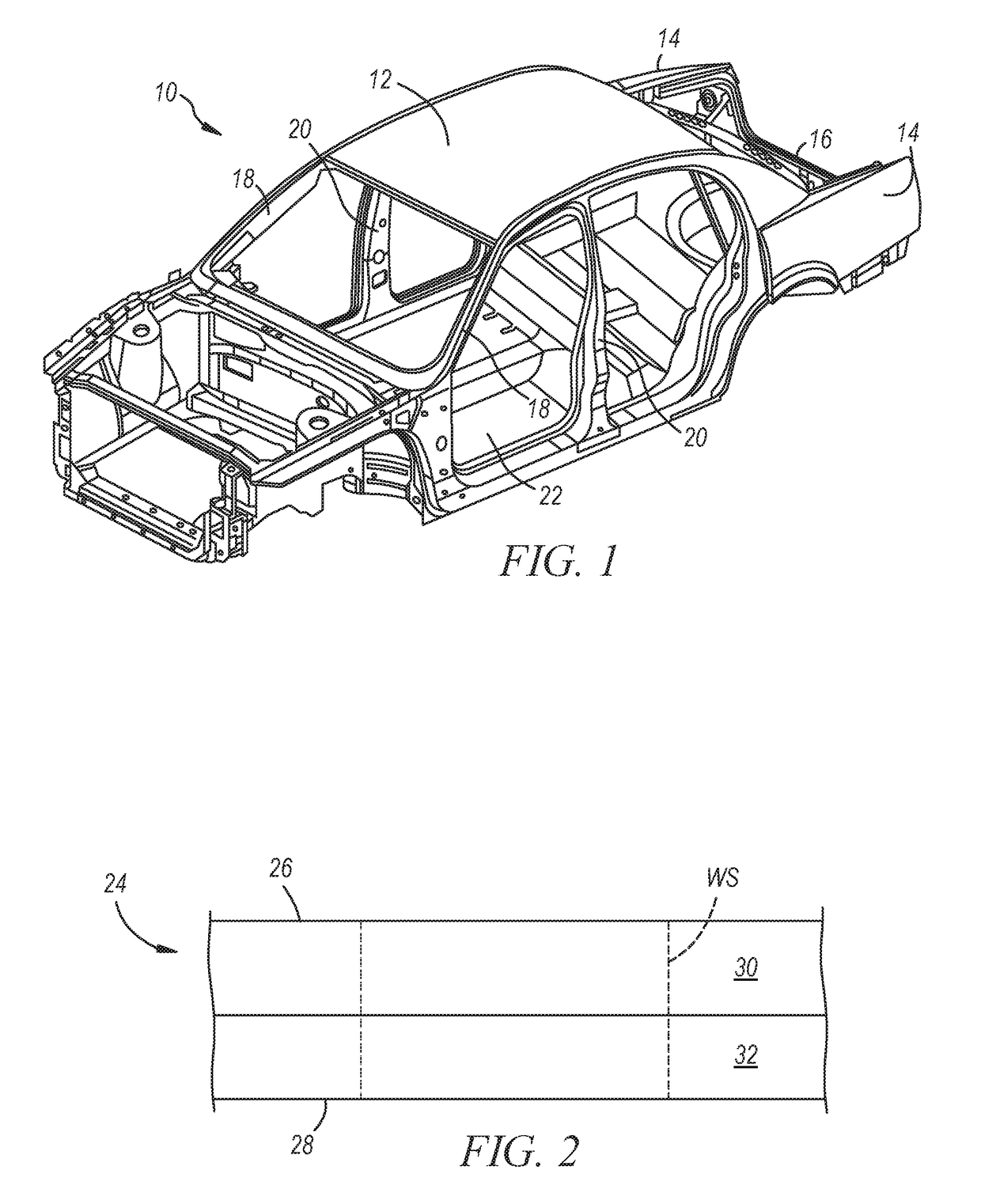

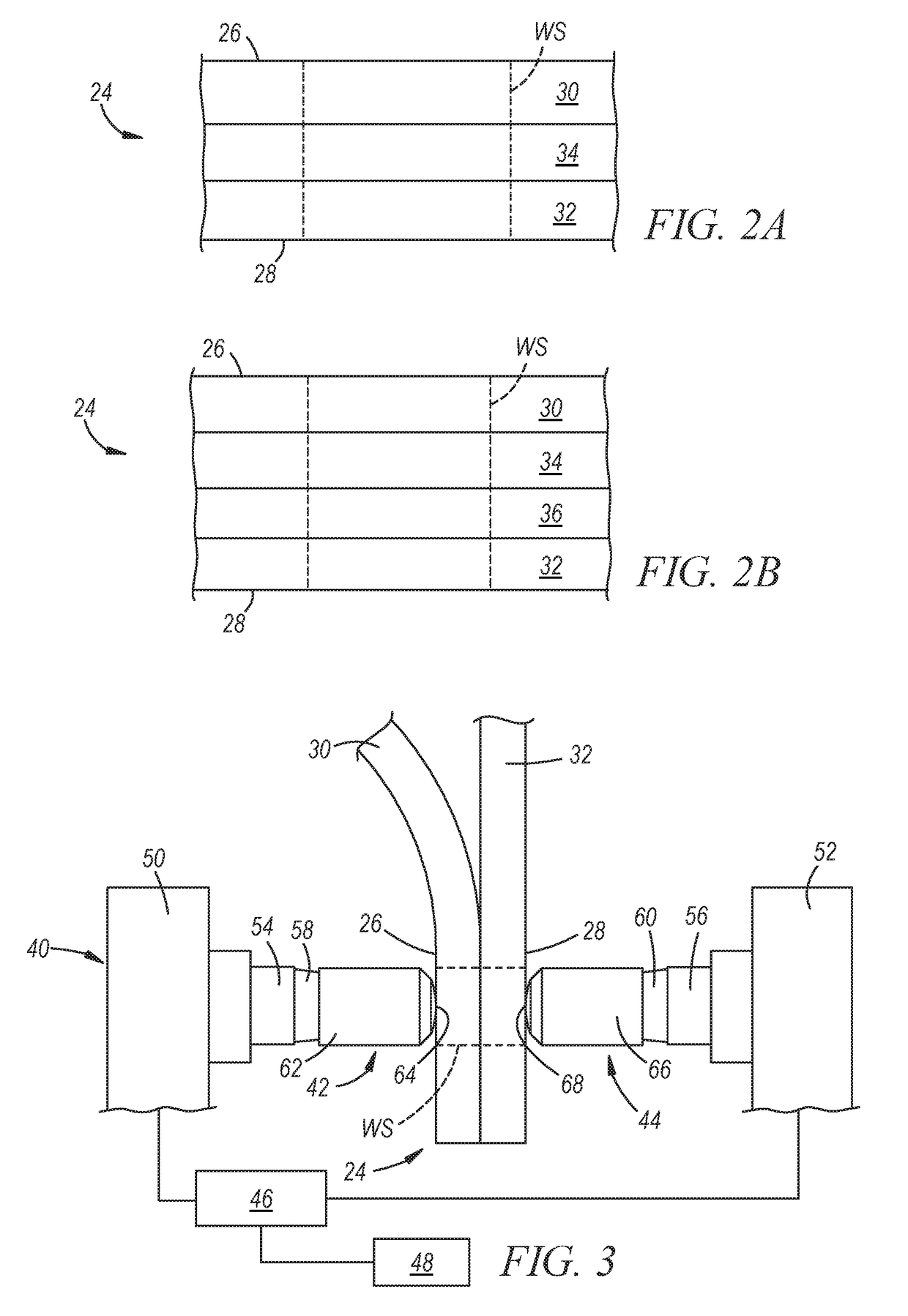

Resistance spot welding of aluminum-to-aluminum, aluminum-to-steel, and steel-to- steel in a specified sequence and using a cover

A series of many electrical resistance spot welds is to be formed in members of an assembled, but un-joined, body that presents workpiece stack-ups of various combinations of metal workpieces including all aluminum workpieces, all steel workpieces, and a combination of aluminum and steel workpieces. A pair of spot welding electrodes, each with a specified weld face that includes oxide-disrupting features, is used to form the required numbers of aluminum-to-aluminum spot welds, aluminum-to-steel spot welds, and steel-to-steel spot welds. A predetermined sequence of forming the various spot welds may be specified for extending the number of spot welds that can be made before the weld faces must be restored. And, during at least one of the aluminum-to-steel spot welds, a cover is inserted between the weld face of one of the welding electrodes and a side of a workpiece stack-up that includes the adjacent aluminum and steel workpieces.

Owner:GM GLOBAL TECH OPERATIONS LLC

Welding Electrode With Contoured Face

ActiveUS20110266260A1Improve high temperature strengthLow efficiencyWelding with roller electrodesWelding/cutting media/materialsMaterials scienceElectrode

A method for welding a plurality of aluminum to aluminum welds and a plurality of steel to steel welds using the same welder includes providing a resistance spot welder with a pair of weld electrodes having an electrode face radius of curvature in the range between 20 mm and 40 mm. The series of aluminum to aluminum welds is first made, and then, after completing the aluminum to aluminum welds, the series of steel to steel welds are made. After completing the steel to steel welds the weld electrodes are cleaned by an abrasive to remove any buildup or contamination of aluminum on the electrodes. In the event the electrodes have mushroomed, then dressing of the electrodes is provided and then the abrasive cleaning is performed to restore the surface texture.

Owner:GM GLOBAL TECH OPERATIONS LLC

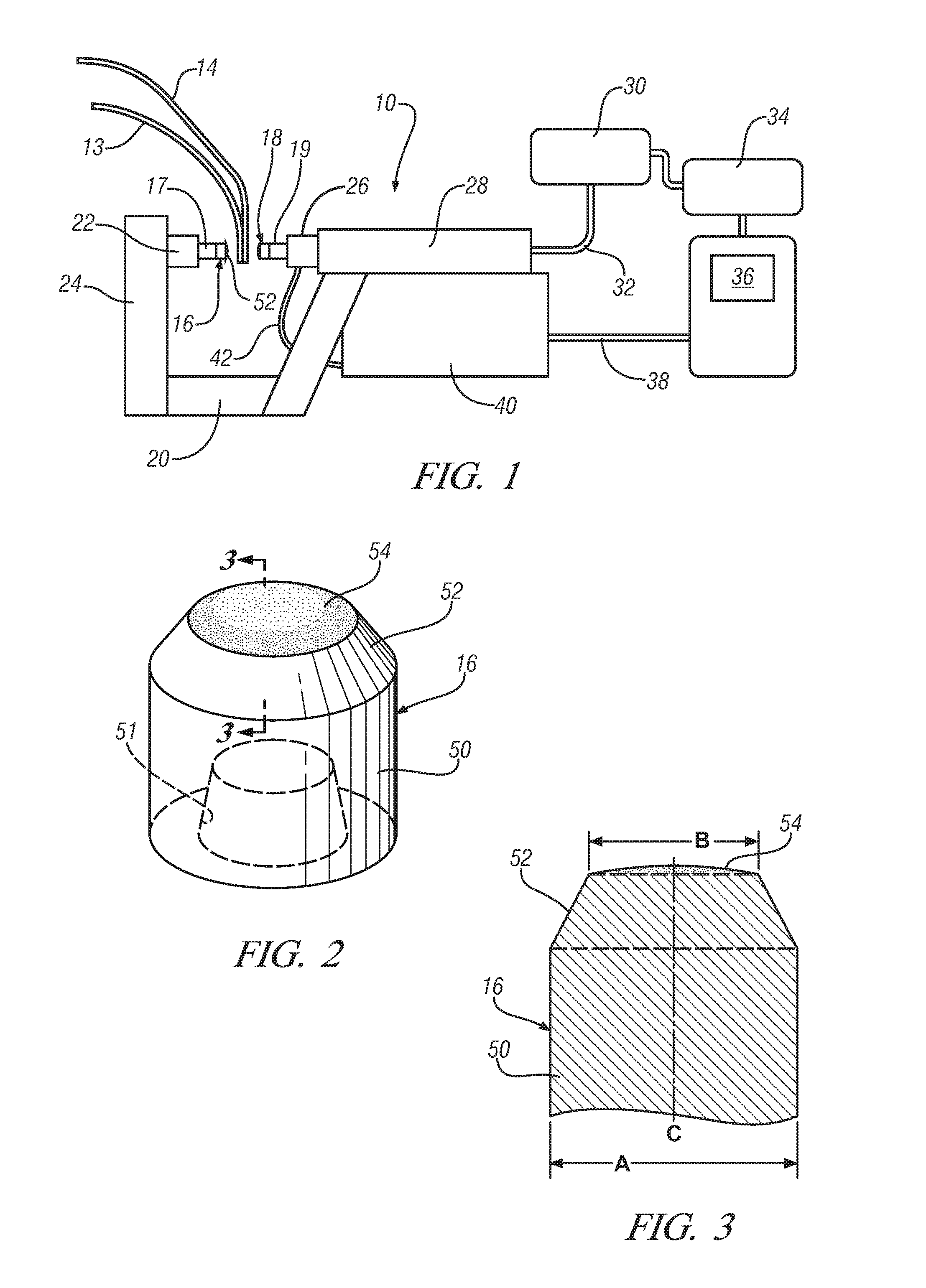

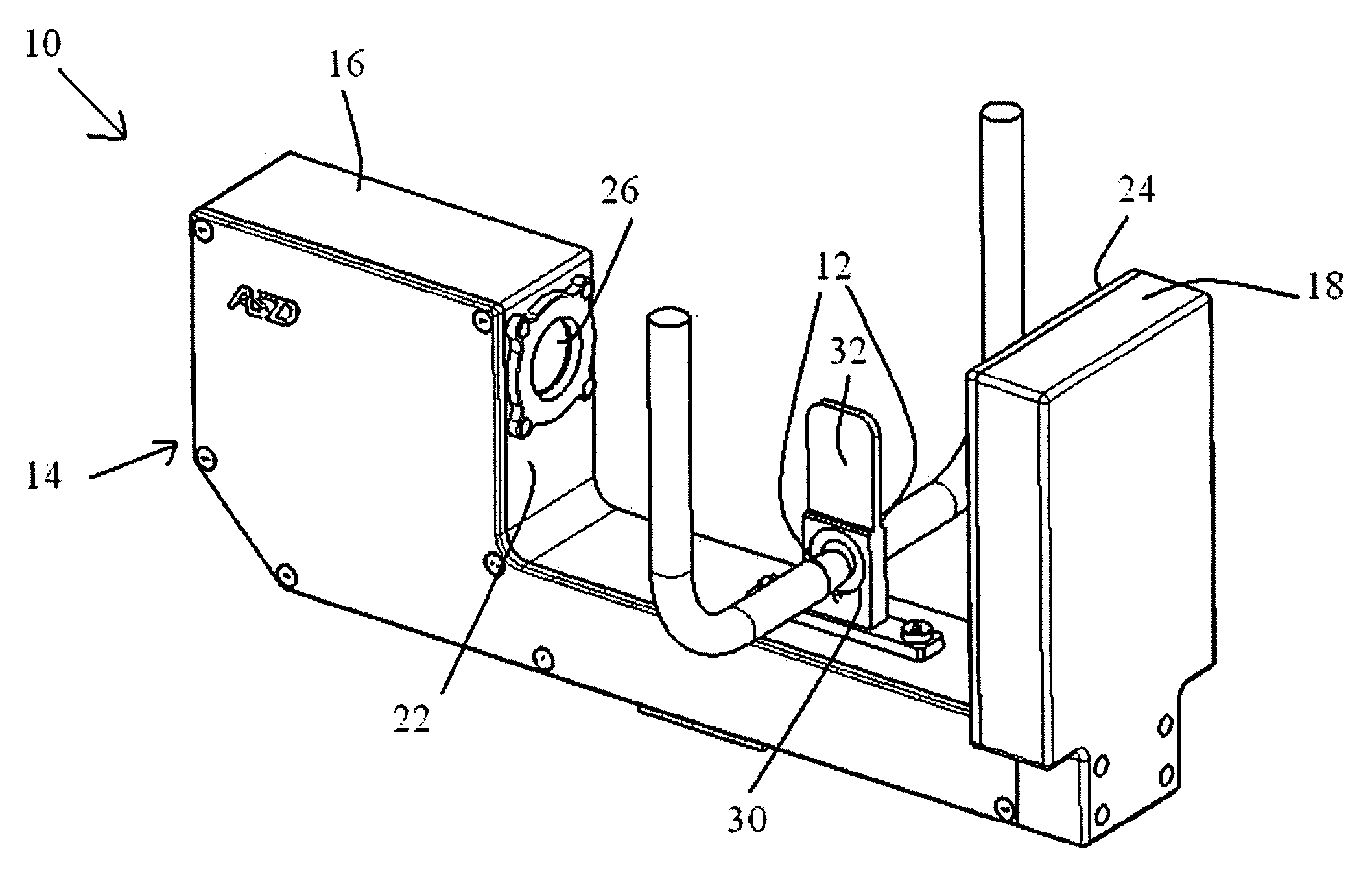

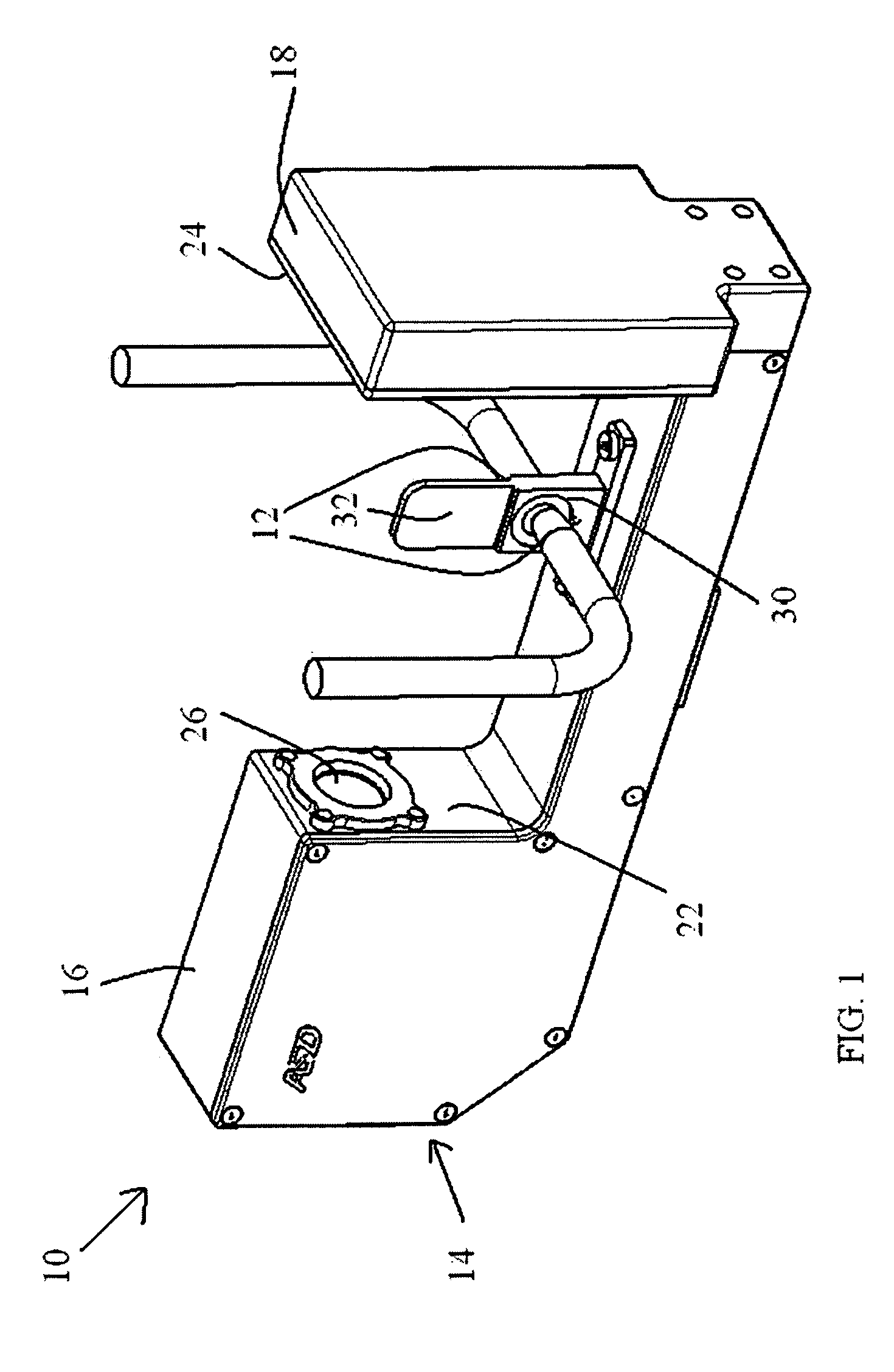

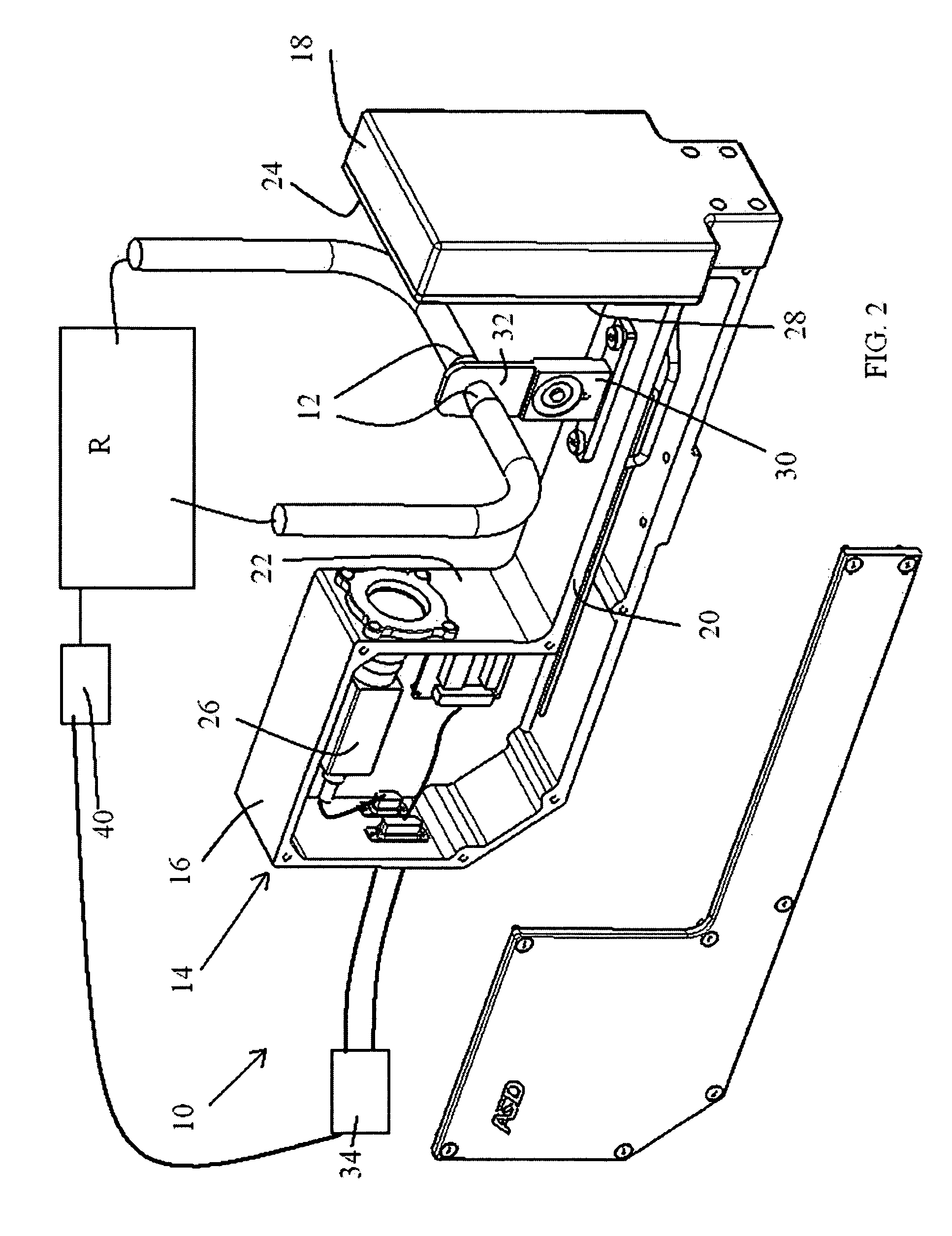

Method and Device for Measuring Resistance Spot Welding Electrode Tips While Connected to a Robotic Welder

InactiveUS20090289040A1Improve resistance spot weldingImprove the immunityArc welding apparatusWelding monitoring devicesElectrical resistance and conductanceEngineering

A method and device for measuring a resistance spot welding electrode tip includes a welding electrode tip monitoring device for monitoring a welding electrode tip, the welding electrode tip monitoring device communicatively connected to a robotic welder equipped with electrode welding tips in a manner to be automatically employed as part of a robotic step with the robotic welder and is equipped with a mechanism for generating characteristic data of the welding electrode tips without having to remove the welding tips from the robotic welder.

Owner:AUTOMATION SYST & DESIGN

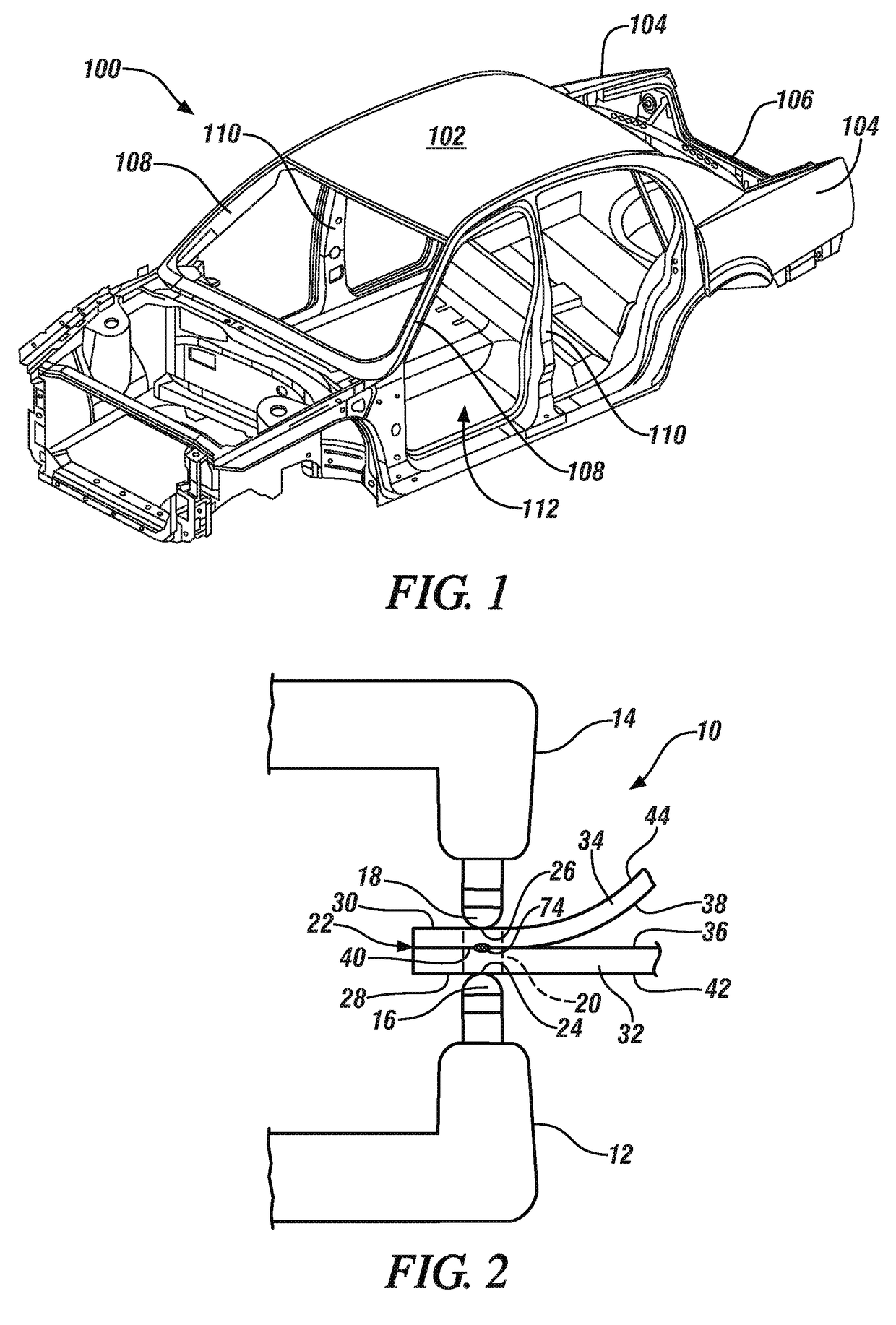

Modular vehicle assembly system and method

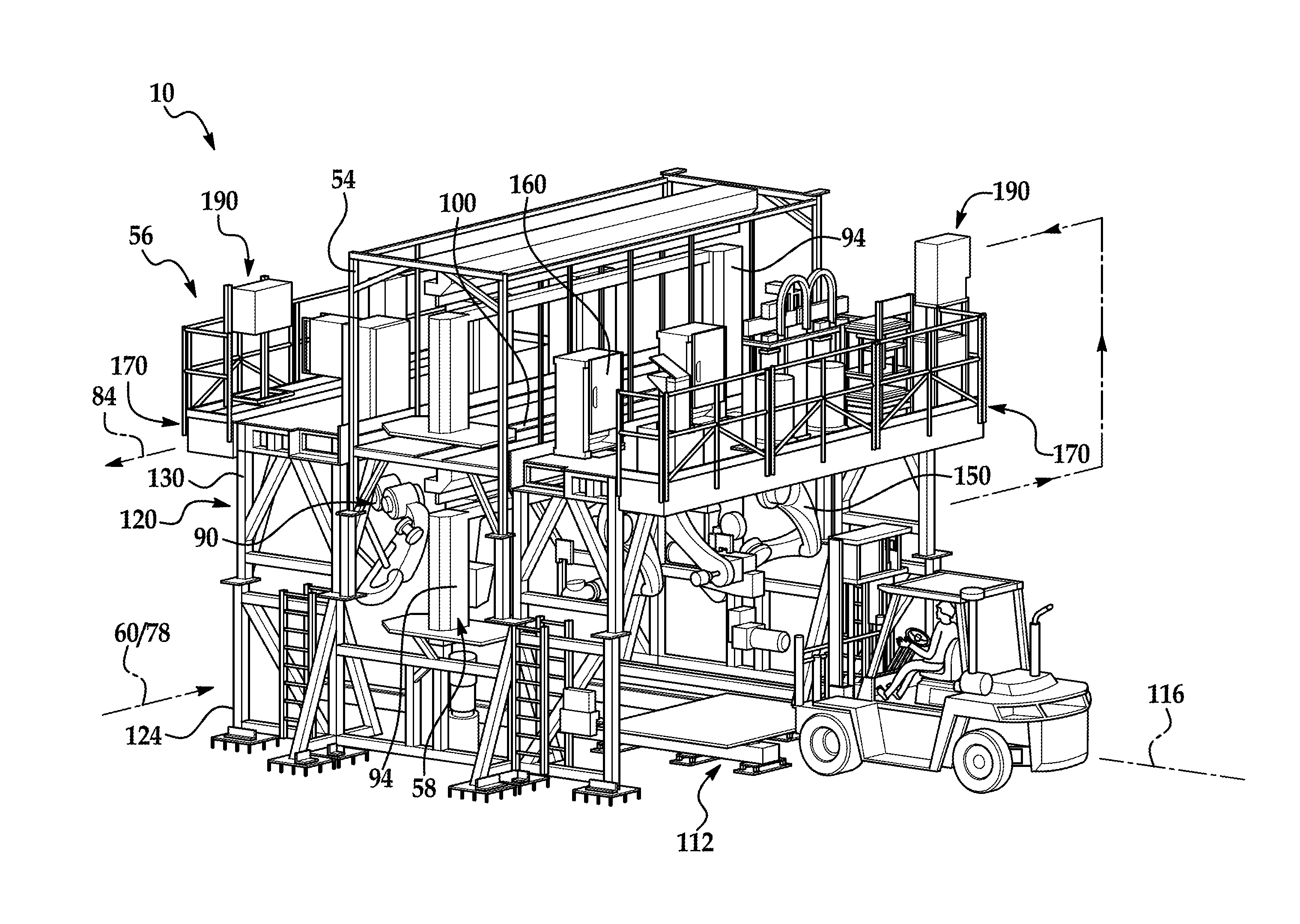

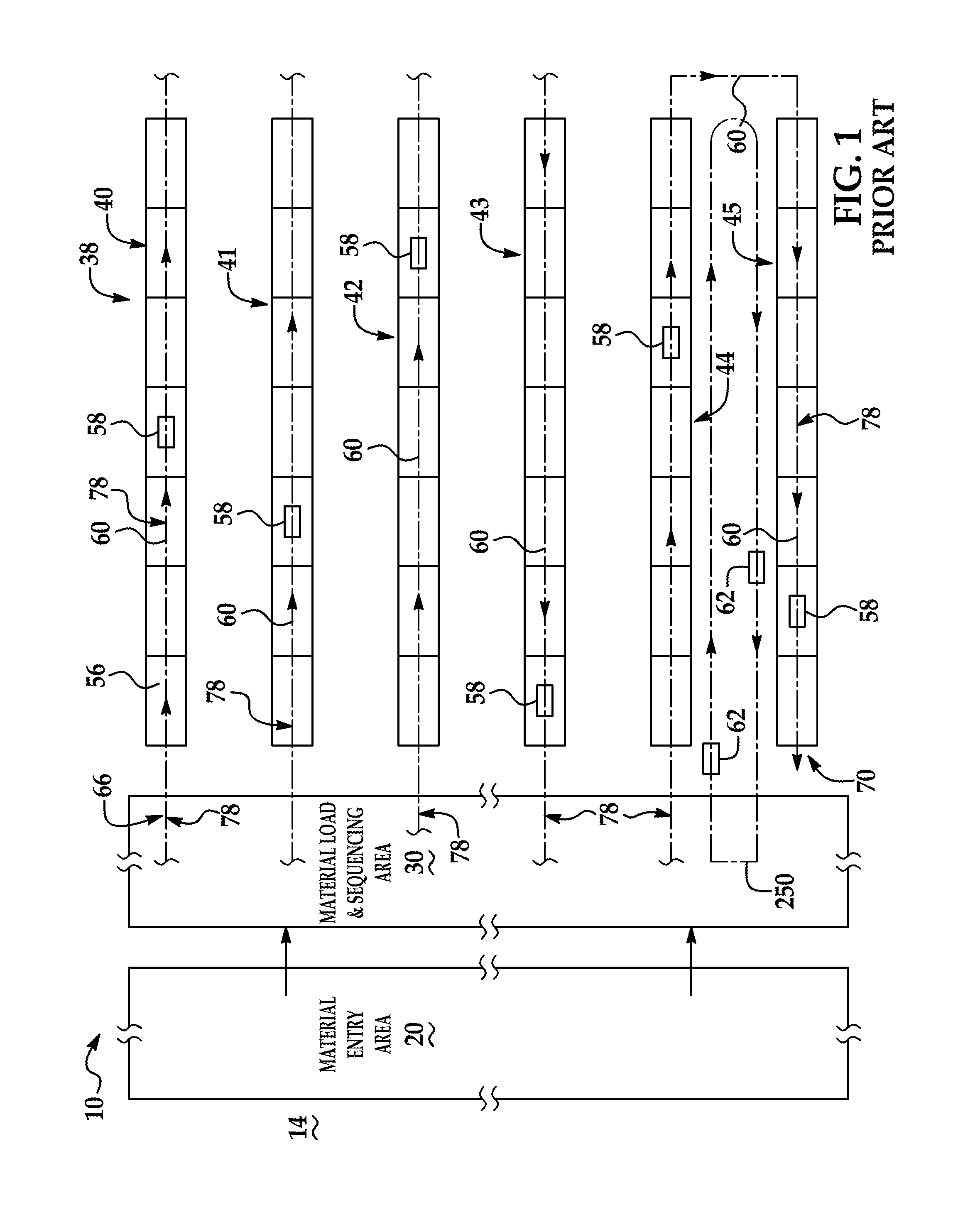

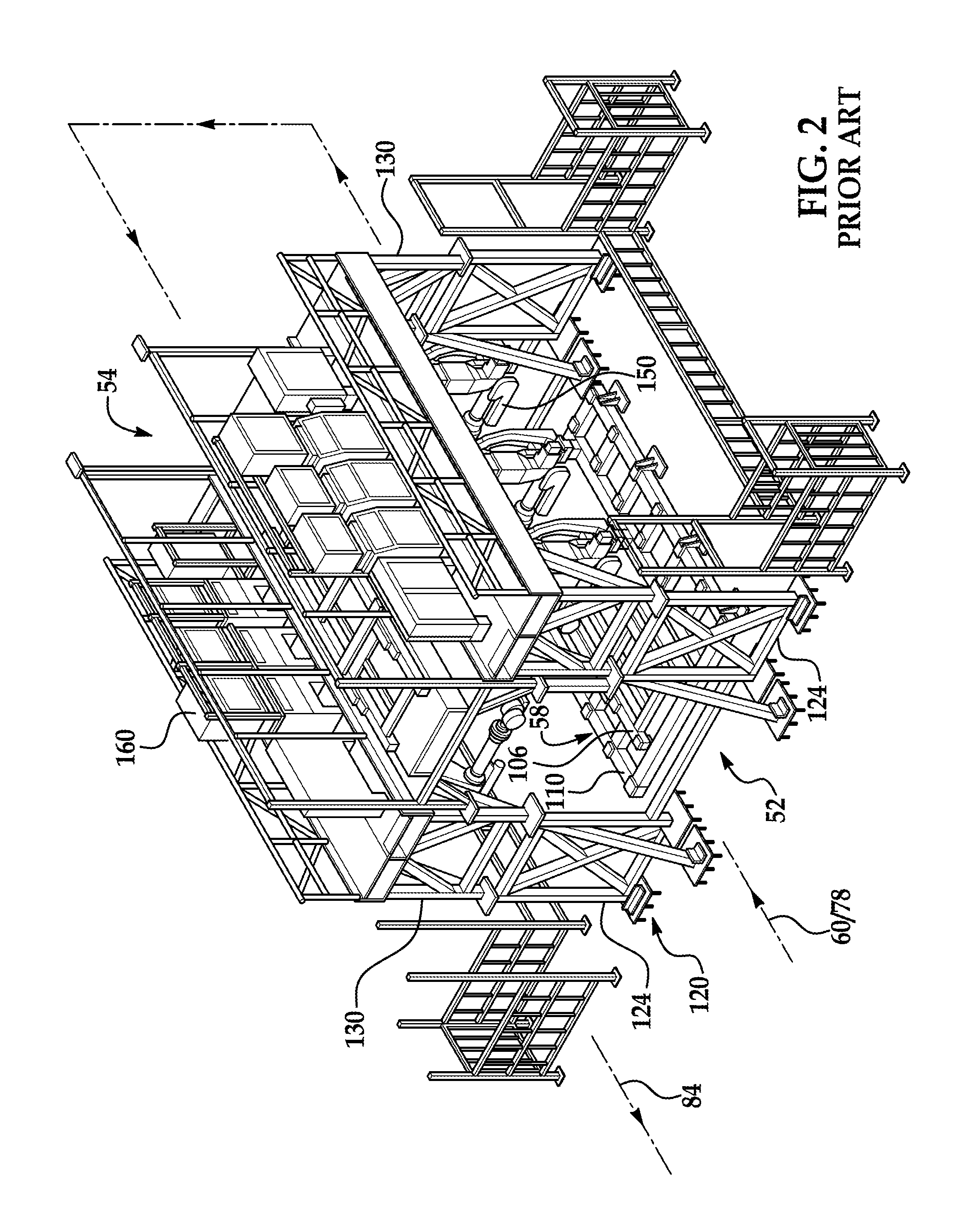

ActiveUS20160167724A1Simple logisticalEfficient connectionWelding/cutting auxillary devicesAssembly machinesValidation testWorking environment

A modular vehicle assembly system and methods for increased flexibility and adaptability of a high volume assembly facility which builds several vehicle models. In one example, the invention includes modular assembly equipment (AE) support pallets which are shipped to vendors for installation of selected AE equipment devices that are specific to a predetermined assembly operation and then validation tested prior to shipment. The modular AE pallets and AE devices are quickly installed and easily removable for maintenance or replacement. In other examples, modular AE support platforms and safety fencing are used to support ground level assembly operation and safer working environment.

Owner:COMAU LLC

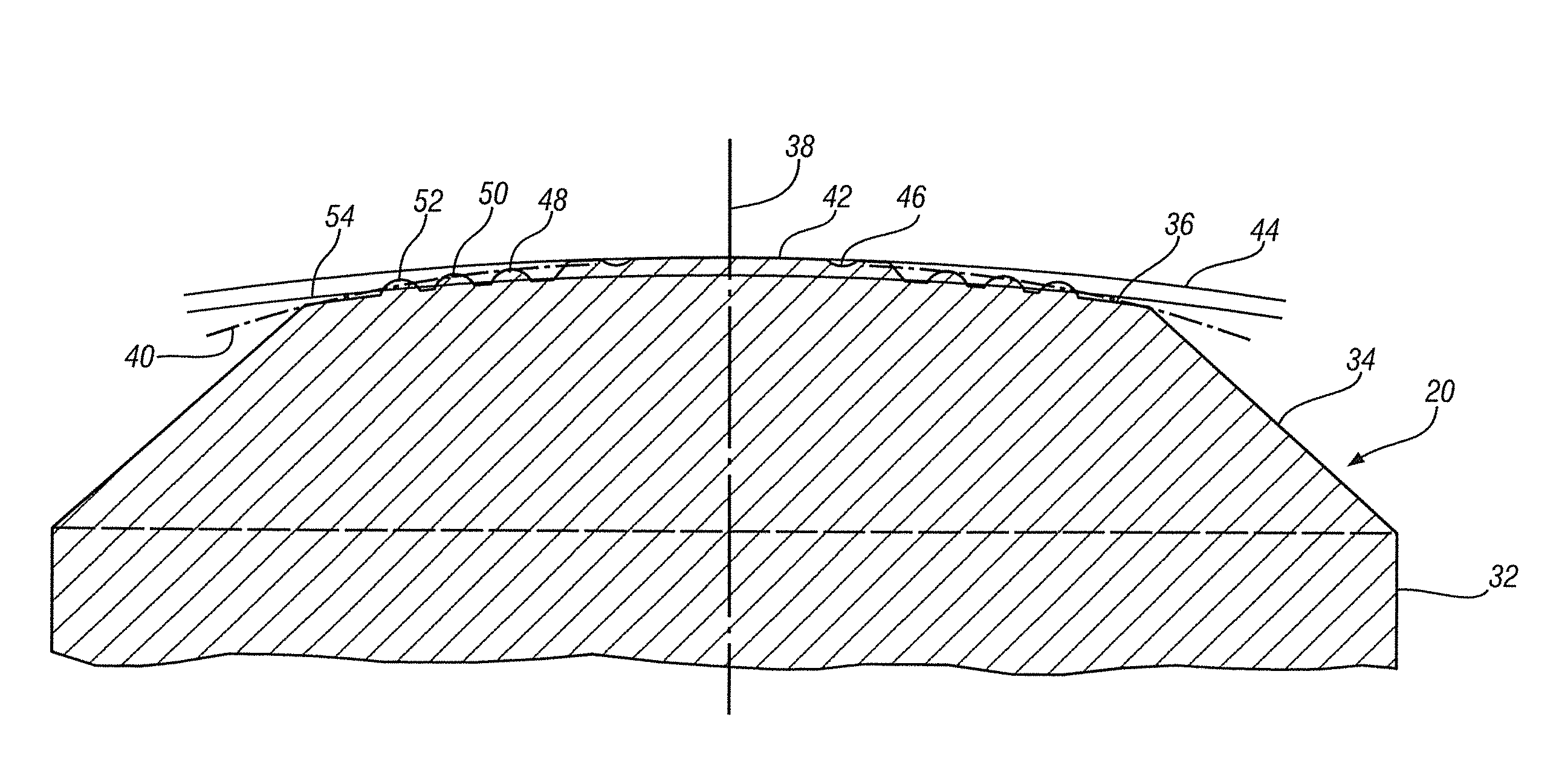

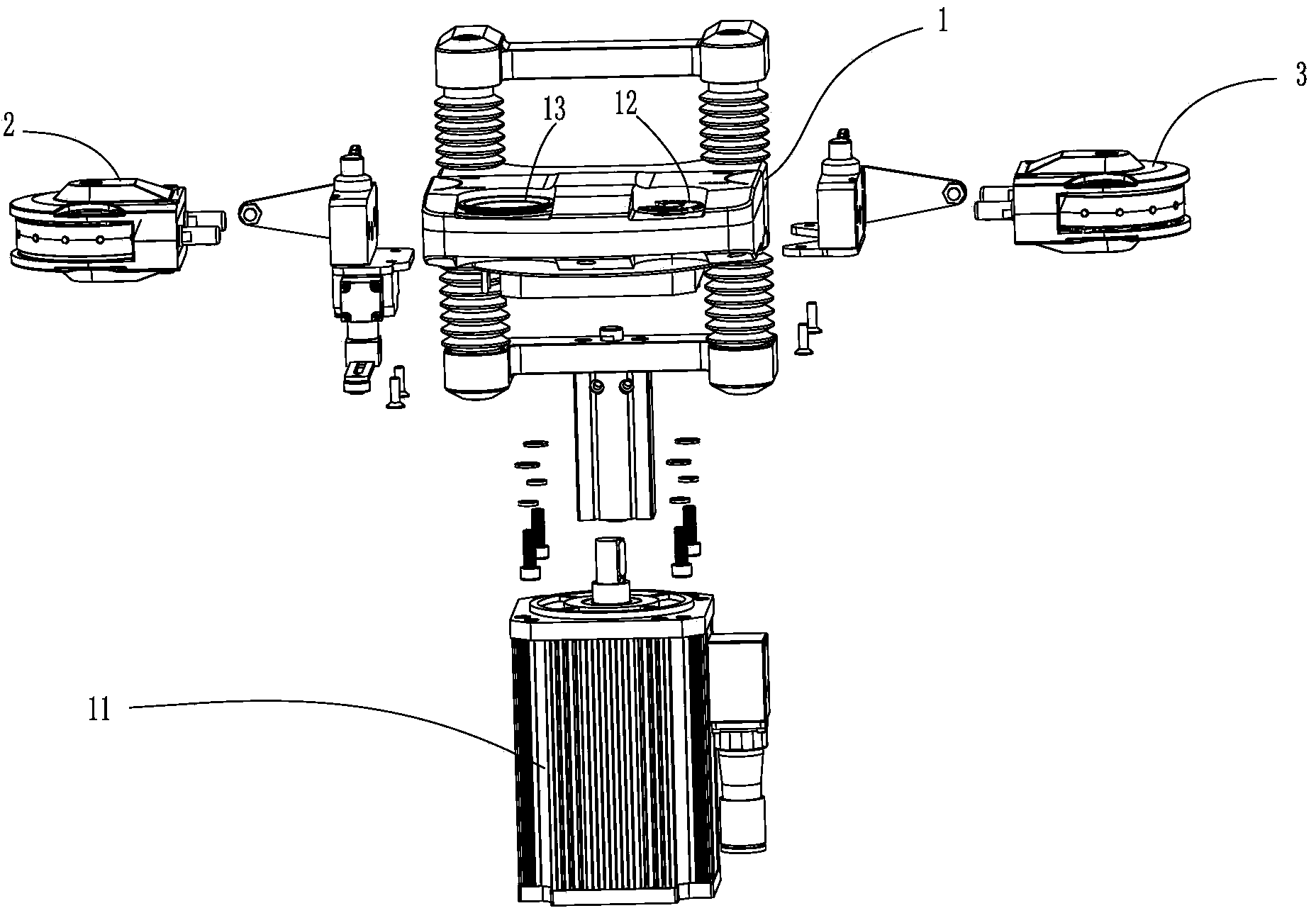

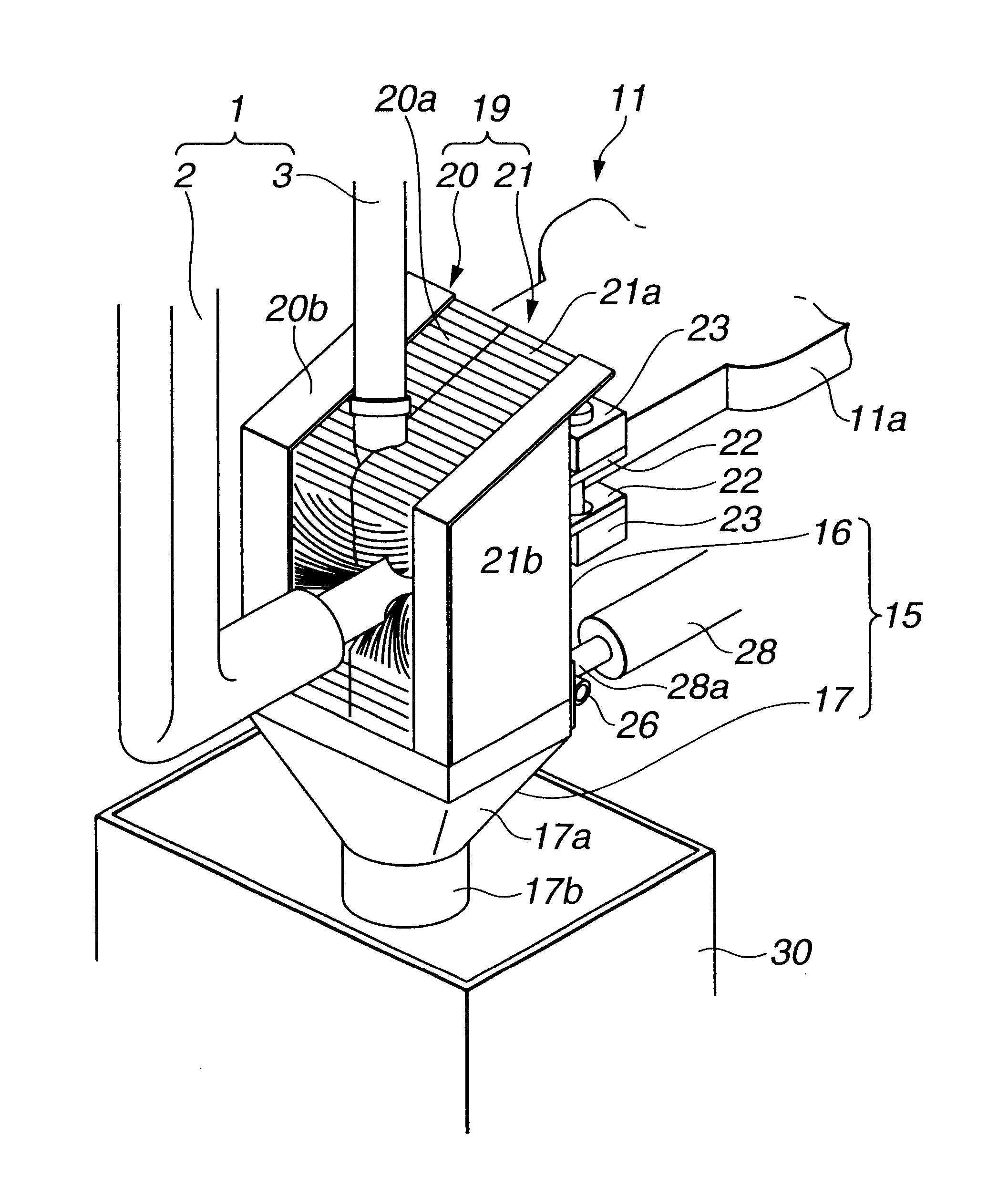

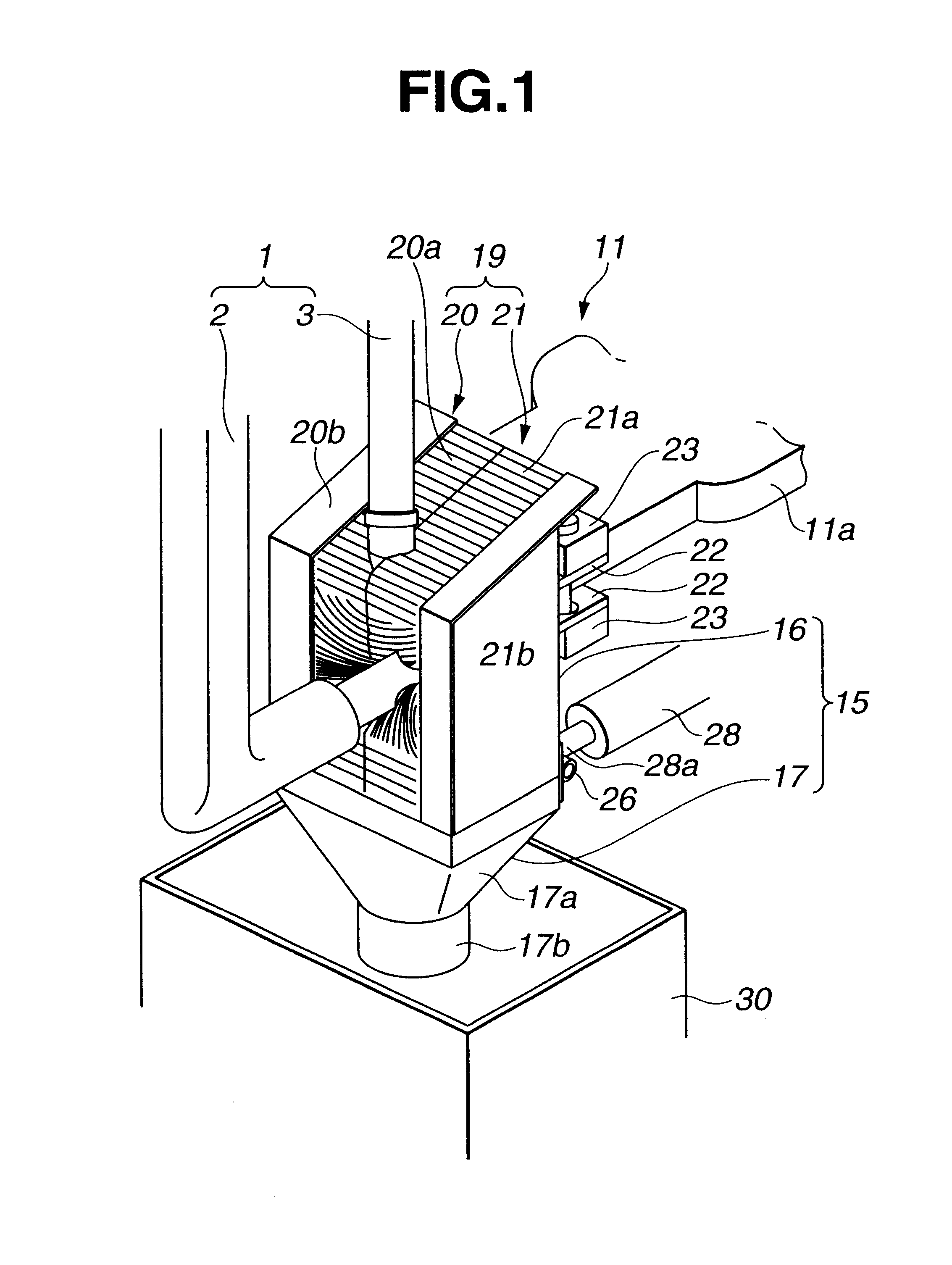

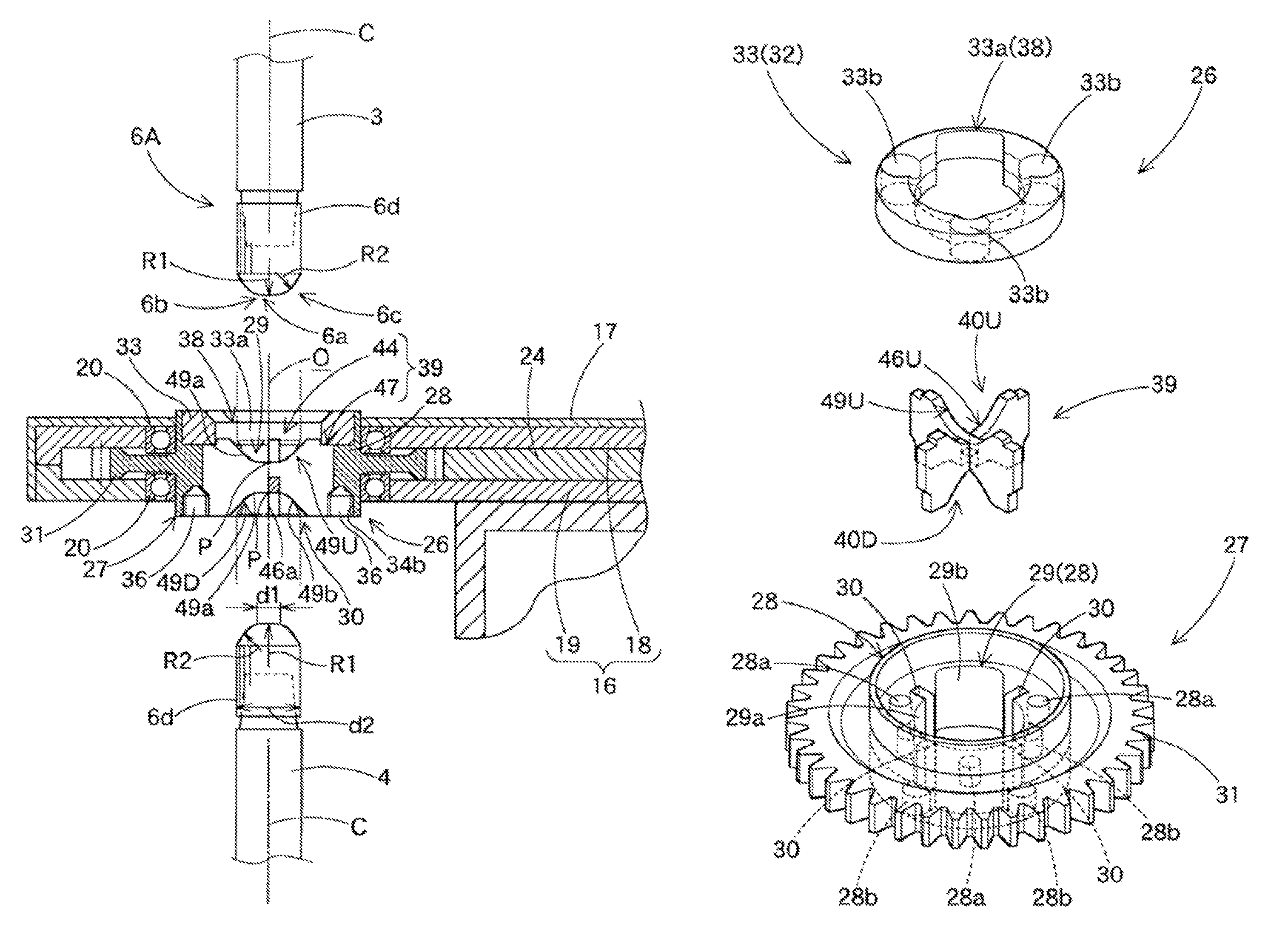

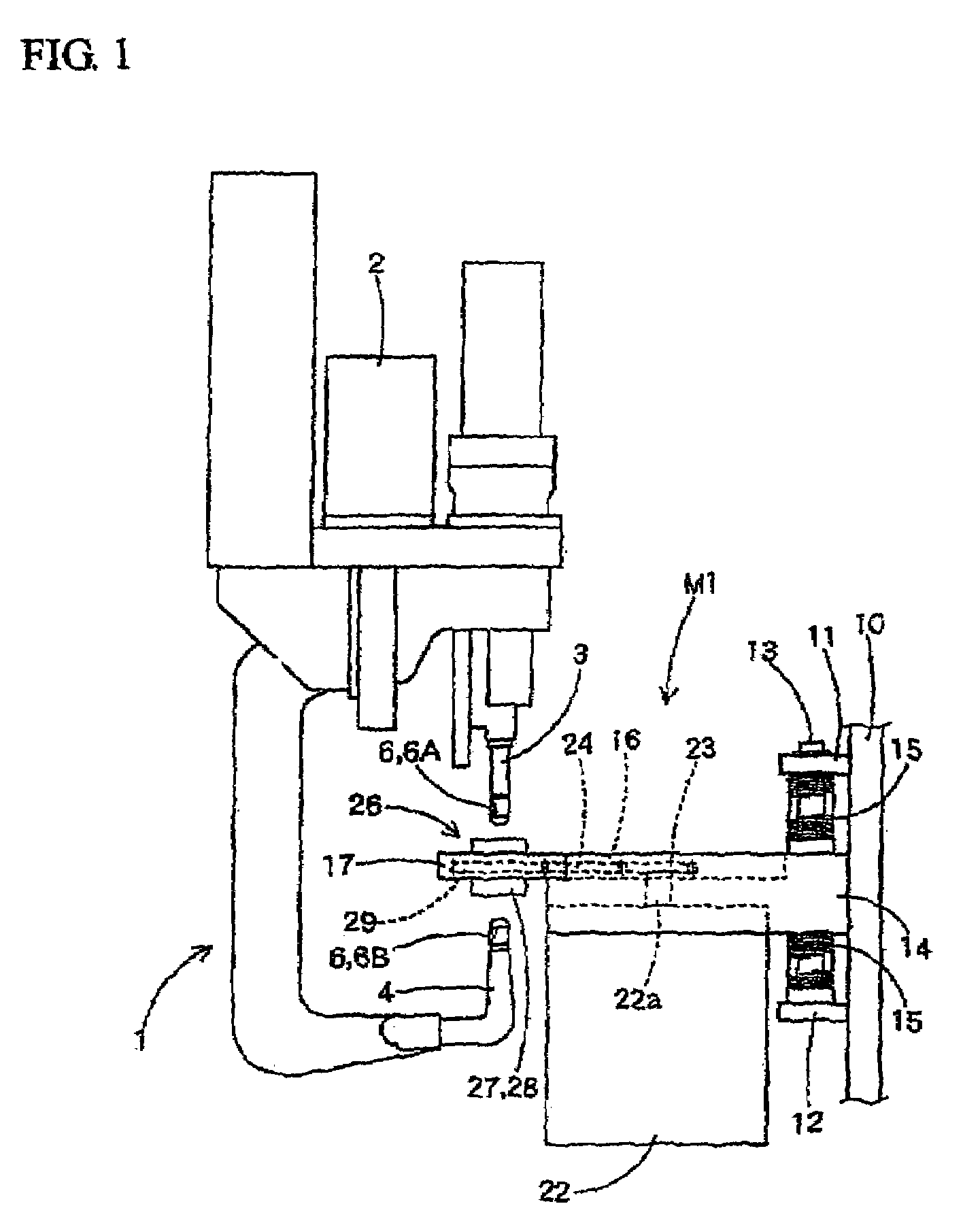

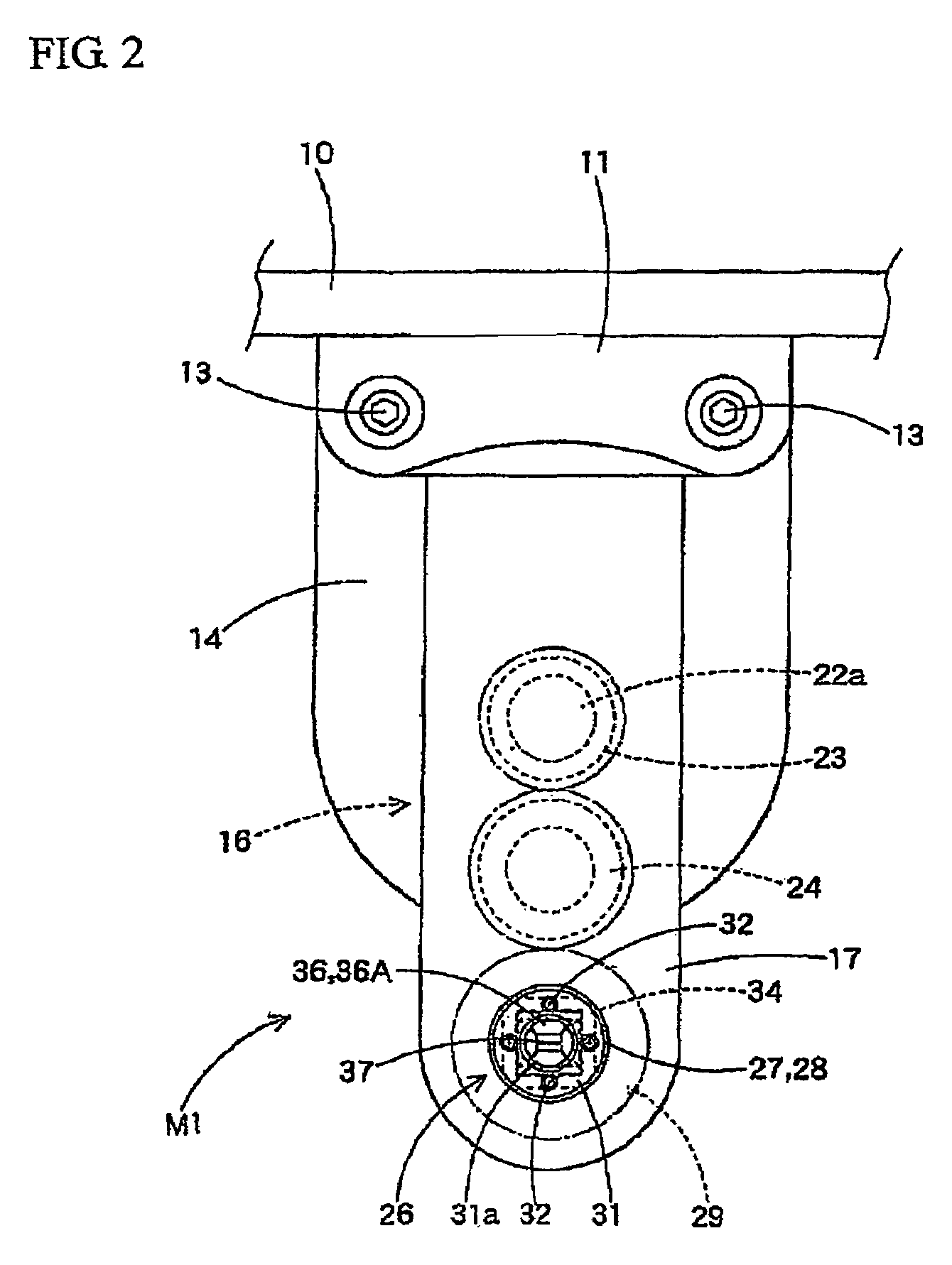

Tip dresser

InactiveUS20080075551A1Reduce the amount of cuttingEasy to shapeEdge grinding machinesOhmic-resistance electrodesSpot weldingElectrical and Electronics engineering

A tip dresser is disclosed, by which a cutter body can be easily formed and by which an end of an electrode tip can be quickly and neatly grinded. A tip dresser, which is configured to grind a pair of electrode tips used for spot welding in a manner of approaching ends of a pair of the electrode tips to each other, includes a cutter including a holder configured to foe rotationally driven with a rotation center axis matched to an axial center of each of the mutually approached electrode tips, a cutter body retained by the holder to cut vicinities of the ends of electrode tips in case the holder is rotated.

Owner:KYOKUTOH

Application of surface relief to spot welding electrodes

ActiveUS20110094999A1Avoid deformationPrevent removalArc welding apparatusPressure electrodesElectrical resistance and conductanceEngineering

The workpiece-contacting surface of the spot welding electrode may be suitably modified to incorporate a desired shape or form, generally comprising a depressed region outlining a recognizable shape, to form aesthetically-pleasing or functional features in the surface of a workpiece during resistance spot welding. Methods for creating the desired form in the spot welding electrode including abrasion, upsetting, and electrical discharge machining are disclosed. Preferably the electrode face is shaped and subsequently redressed during welding operations at the welding station.

Owner:GM GLOBAL TECH OPERATIONS LLC

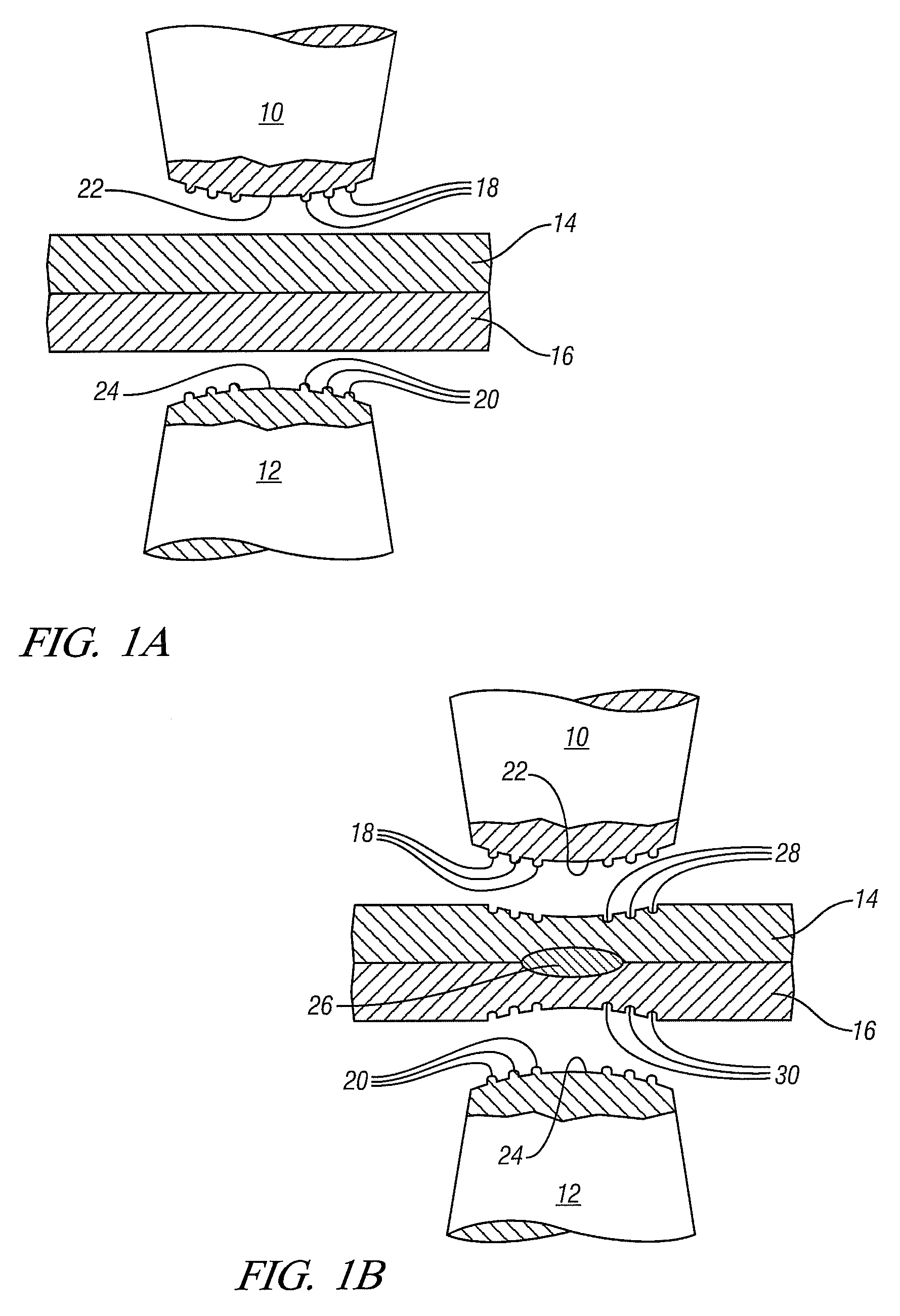

Alternately direct resistance spot welding of al-to-al, al-to-steel, and steel-t0-steel with welding electrode having oxide-disrupting structural features

ActiveUS20170304928A1Resistance electrode holdersWelding electric supplyElectrical resistance and conductanceEngineering

A method of resistance spot welding workpiece stack-ups of different combinations of metal workpieces with a single weld gun using the same set of welding electrodes is disclosed. In this method, a set of opposed welding electrodes that include an original shape and oxide-disrupting structural features are used to resistance spot weld at least two of the following types of workpiece stack-ups in a particular sequence: (1) a workpiece stack-up of two or more aluminum workpieces; (2) a workpiece stack-up that includes an aluminum workpiece and an adjacent steel workpiece; and (3) a workpiece stack-up of two or more steel workpieces. The spot welding sequence calls for completing all of the aluminum-to-aluminum spot welds and / or all of the steel-to-steel spot welds last.

Owner:GM GLOBAL TECH OPERATIONS LLC

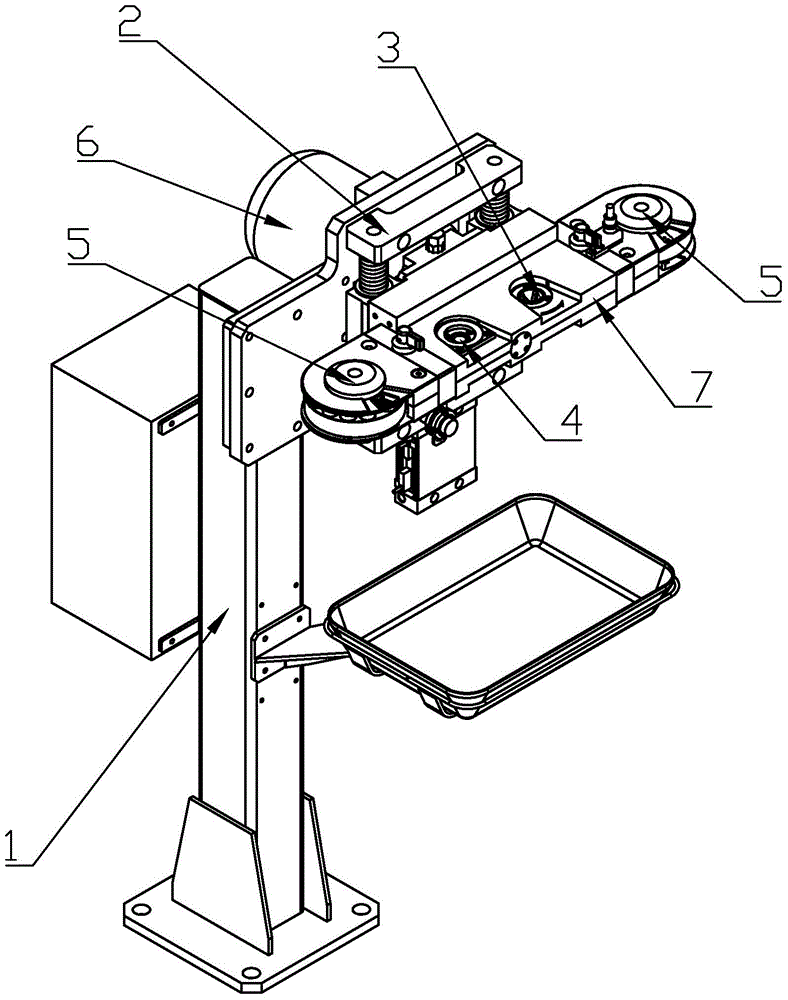

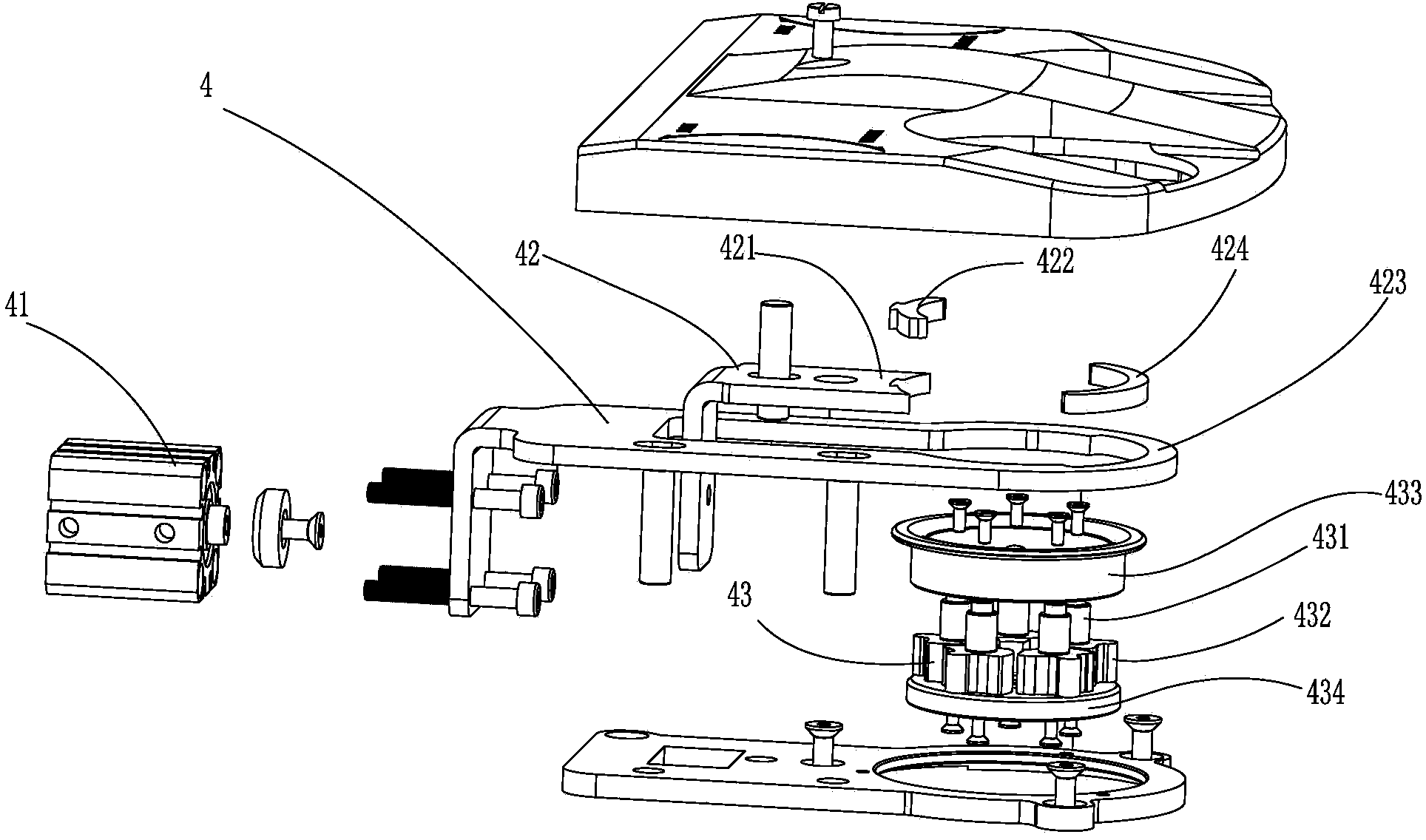

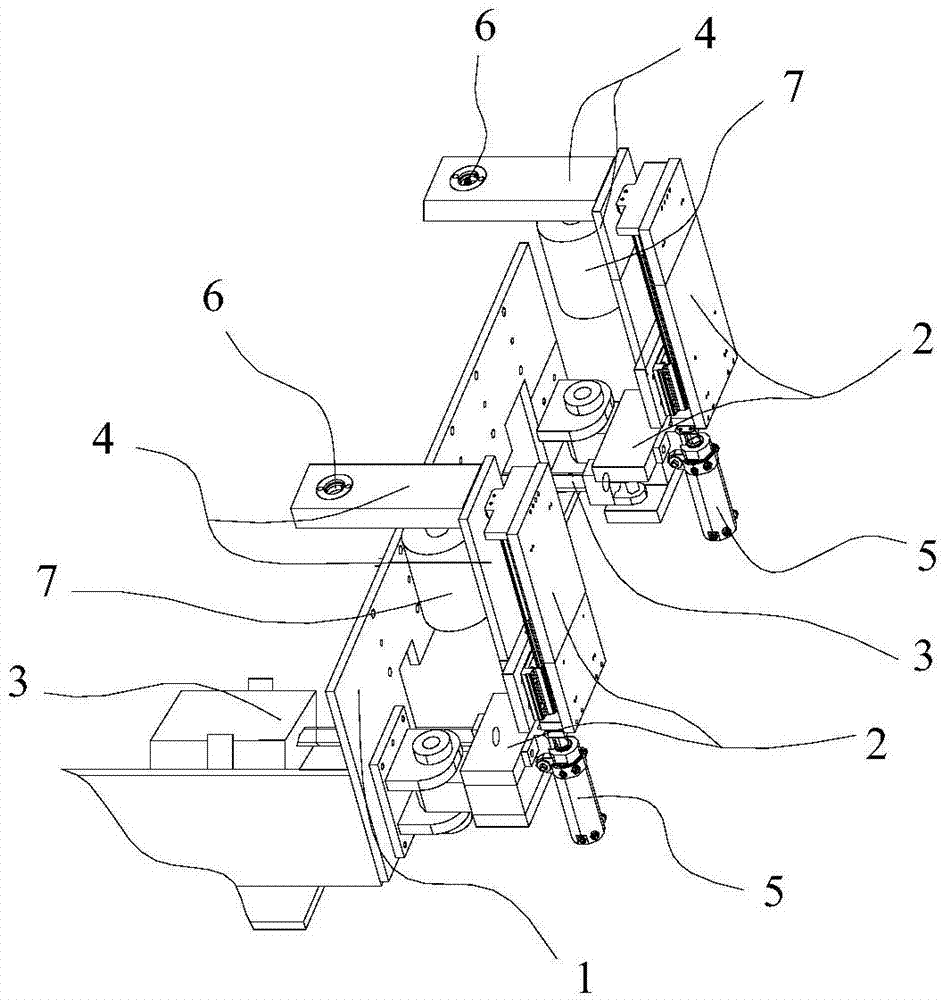

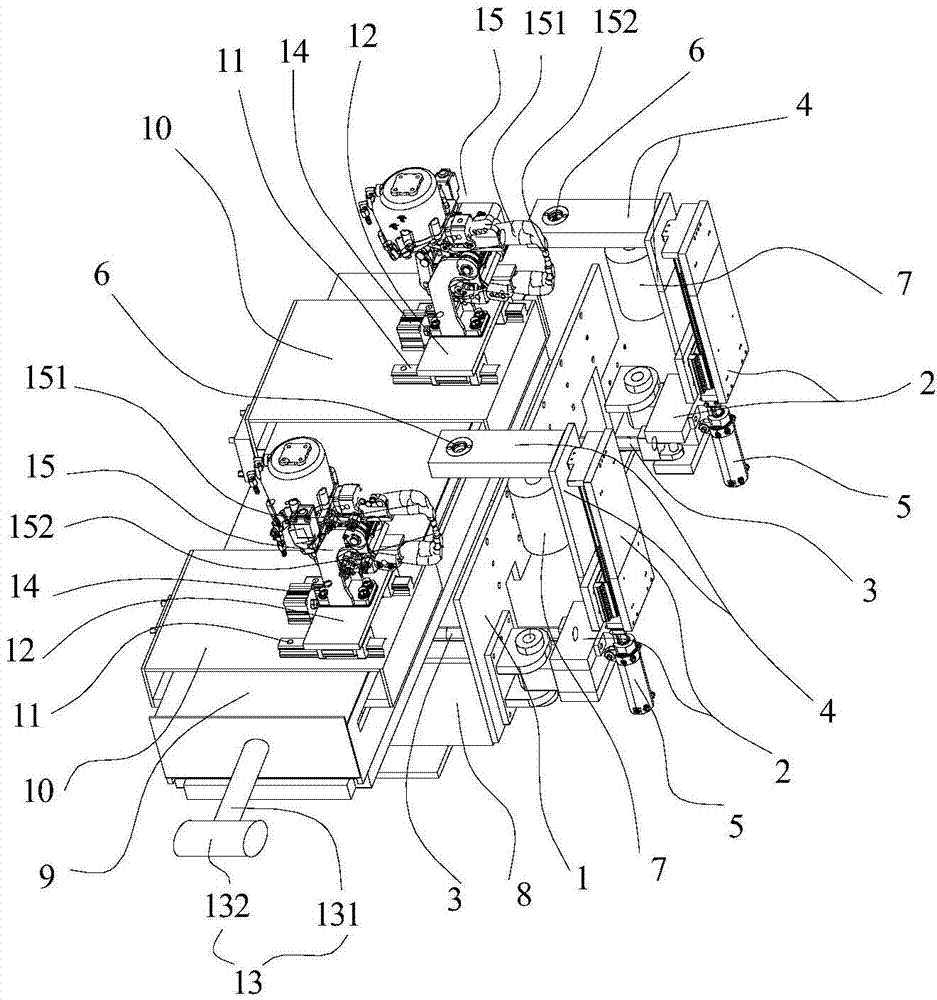

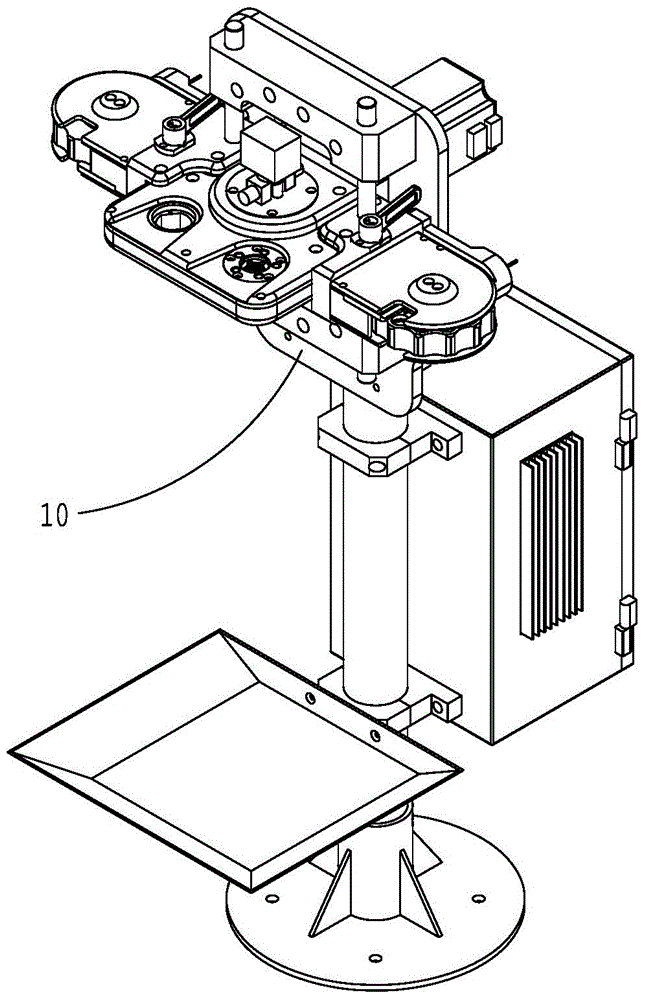

Electrode cap coping-replacing all-in-one machine

ActiveCN104002218AGuaranteed uniformityImprove work tempoGrinding machinesMetal working apparatusProduction lineControl system

The invention discloses an electrode cap coping-replacing all-in-one machine which comprises a machine frame, a driving motor and a balance floating unit. The driving motor and the balance floating unit are arranged on the machine frame. The output end of the driving motor penetrates through the balance floating unit and then is connected with a workbench. A cap detaching unit and a cap repairing unit are arranged on the two sides of a workbench. Electric cap storing units are arranged at the outermost ends of the two sides of the workbench. Electrode cap coping and replacing are completed in one device, and the two functions are achieved through the driving motor. The technical problem of manual line stopping cap replacing in a car production line is solved, and meanwhile the problem that if cap coping and cap replacing are separated, the occupied space of two machines is too large is solved. Electric cap coping and replacing are completed in a full-automatic mode, the takt of the car welding production line is obviously improved, the capacity of the production line is improved, and the electrode cap coping-replacing all-in-one machine is suitable for the car welding production line high in automation degree.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

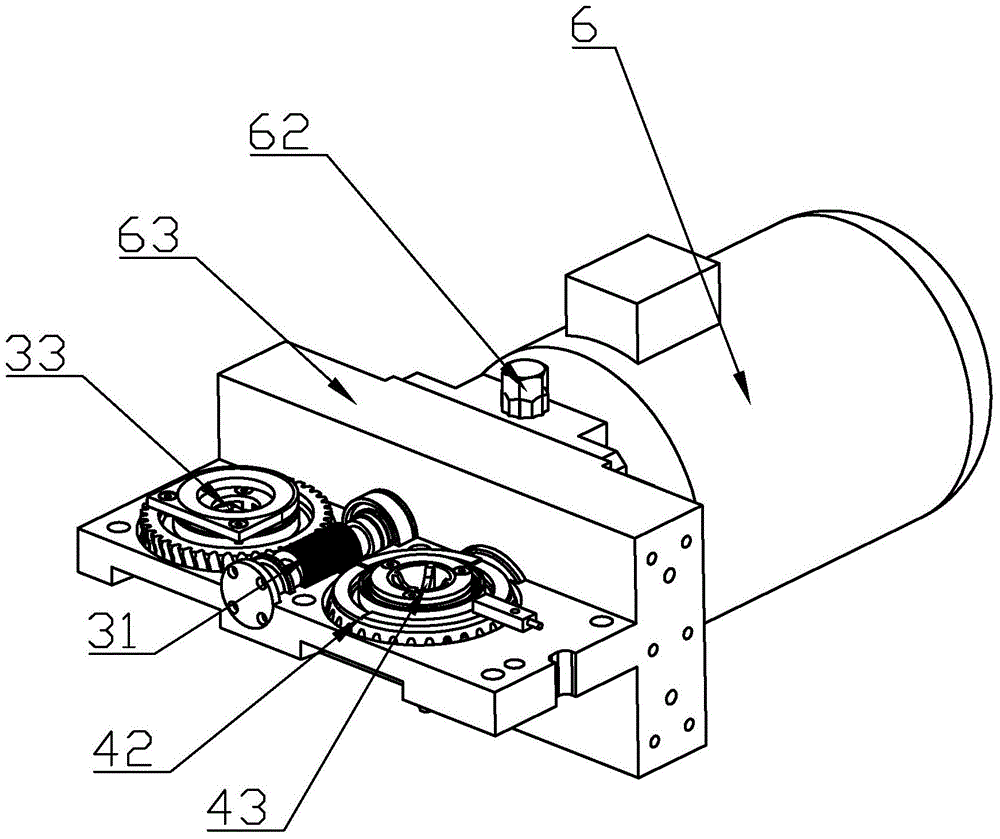

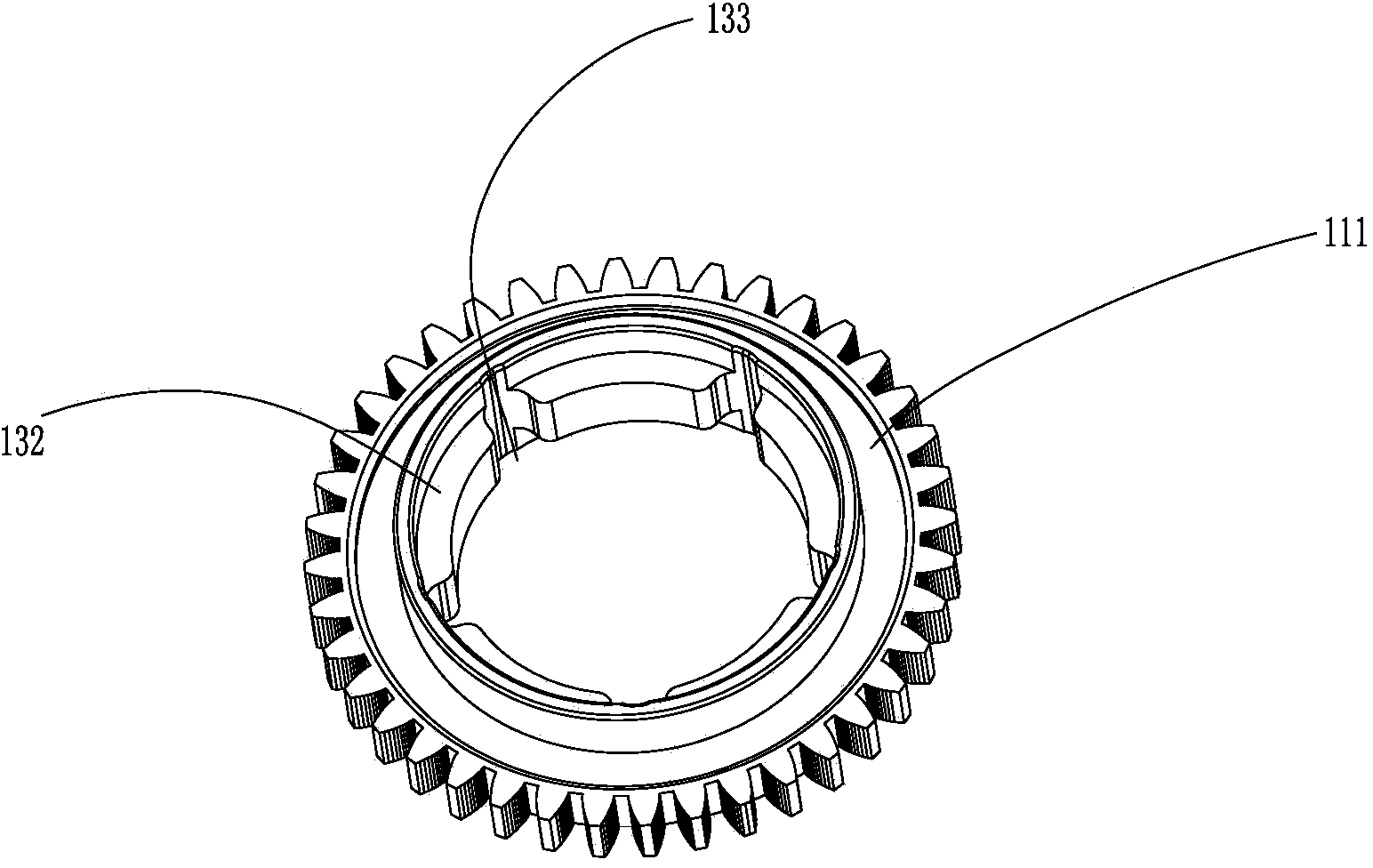

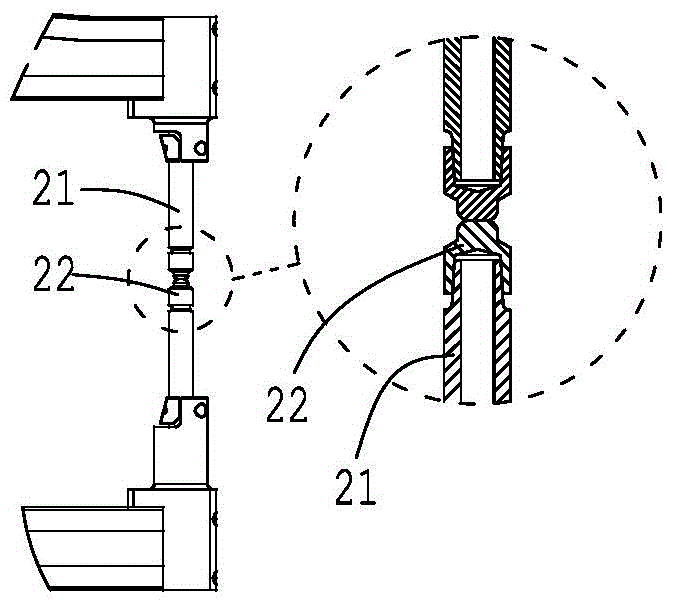

Coping and replacing device of electrode cap

ActiveCN104259642ASimple structureLow costGrinding machinesElectrode maintenanceEngineeringElectrode

The invention provides a coping and replacing device of an electrode cap. The device comprises a dismounting device; the dismounting device comprises a dismounting hole for containing the electrode cap, and a clamping mechanism for clamping a motor cap; the dismounting hole is positioned in the center of a dismounting gear; the clamping mechanism comprises a linear driving device, a damping mechanism and a clamping claw mechanism, wherein the damping mechanism is driven through the linear driving device; the clamping claw mechanism comprises a rotating shaft, clamping claws, an upper cover and a lower cover; a rotating shaft is fixed between the upper cover and the lower cover; the clamping claws, which are as much as limiting strips, sleeve the rotating shaft; each clamping claw comprises a center near end which is closer to the center of a circle of the dismounting gear, and a center far end which is far from the center of the circle of the dismounting gear; the center near ends of the clamping claws are positioned in clearances of the limiting strips, and while the center far ends of the clamping claws are in clearance fit with the clearances of the limiting strips; when braking, the damping mechanism is contacted and rubbed with the upper cover to enable the upper cover to be decelerated opposite to the dismounting gear, and as a result, the center near ends of the clamping claws extend into the dismounting hole and tightly clamp the electrode cap.

Owner:GUANGZHOU KYOKUTOH CHINA

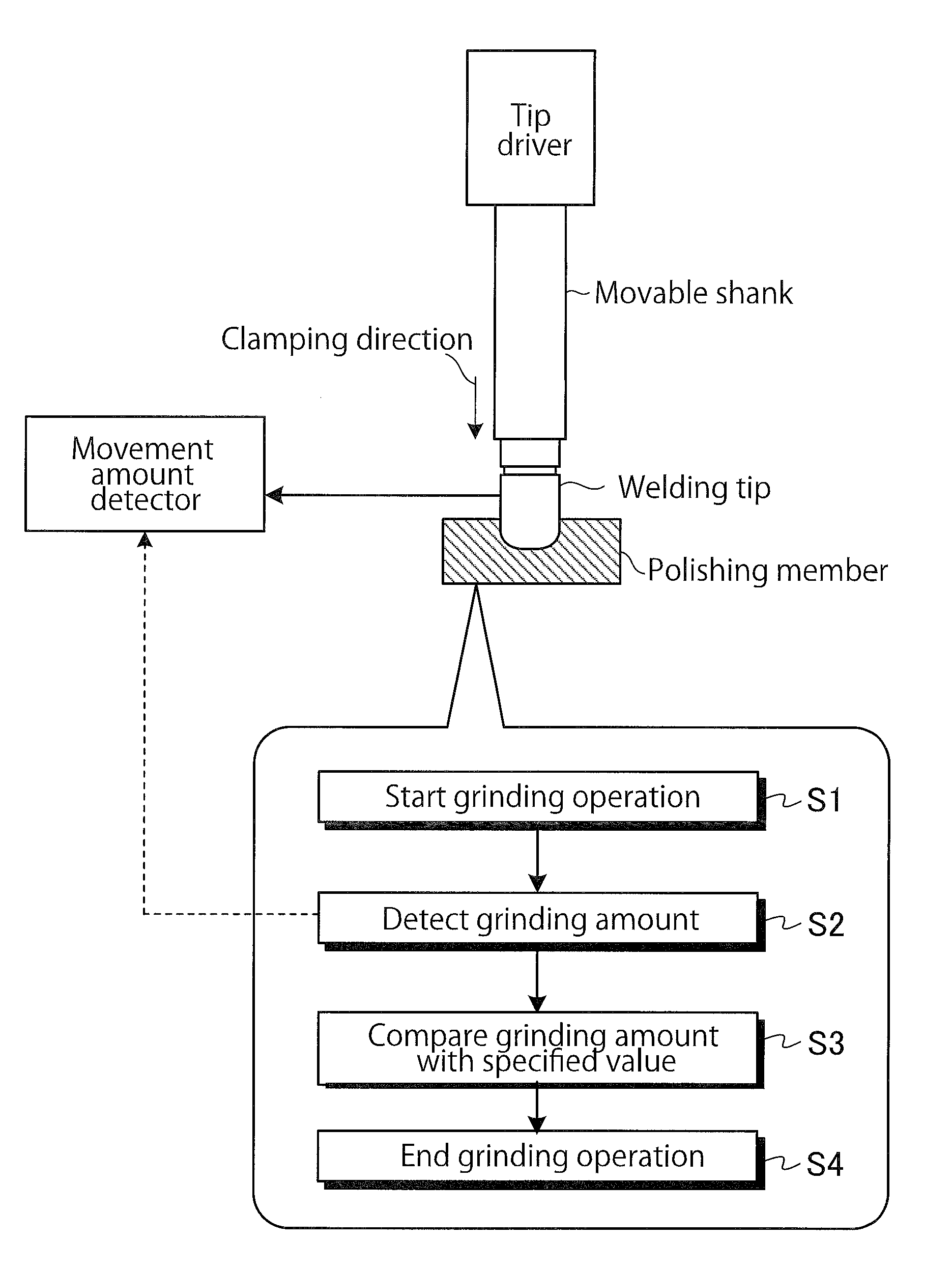

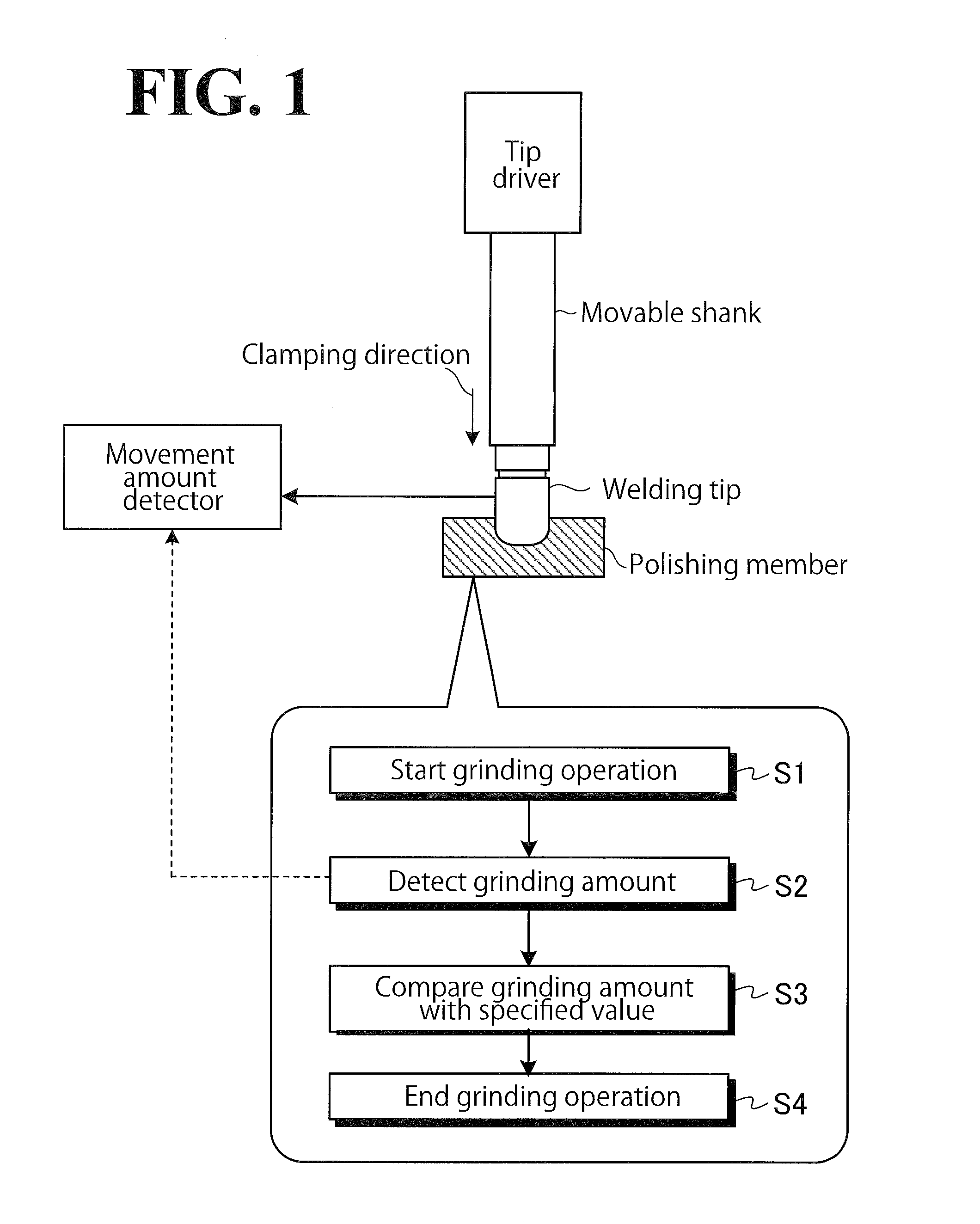

Grinding system and spot welding system

InactiveUS20150034607A1Improve operating rateElectrode supporting devicesGrinding feed controlSpot weldingSoldering gun

A grinding system includes a welding gun movable relative to a workpiece. A pair of clamp devices move relatively toward each other to clamp a workpiece. A welding tip is disposed on one of the pair of clamp devices. A detector detects a relative movement amount of the welding tip with respect to the other clamp device. A dresser grinds the welding tip. While the dresser is grinding the welding tip, a determinator determines whether to make the dresser end grinding the welding tip based on the movement amount detected by the detector. When the determinator determines to make the dresser end grinding the welding tip, an instructor instructs the dresser to end grinding the welding tip.

Owner:YASKAWA DENKI KK

Chip collecting apparatus for tip dresser

InactiveUS6863597B2Easy to checkReduce processing stepsEdge grinding machinesRevolution surface grinding machinesEngineeringSwarf

In a chip collecting apparatus for a tip dresser of the present invention, a chip pickup case mounted on a dresser main body is divided into an upper case and a lower case, and the lower end of an arm admission port formed in the upper case is opened downward. During teaching operation, the lower case is rotated to open the lower end of the upper case, through which the insertion of a first gun arm into a lower chamber can be visually checked, and thus an electrode tip provided at the end thereof and a dressing body for dressing the end of the electrode tip are guided such that the central axes thereof conform to each other.

Owner:SUBARU CORP

Resistance spot welding of aluminum to aluminum and steel to steel

ActiveUS20130015164A1Improve high temperature strengthLow efficiencyElectrode supporting devicesWelding/cutting media/materialsElectrical resistance and conductanceSpot welding

A method for welding a plurality of aluminum to aluminum welds and a plurality of steel to steel welds using the same welder includes providing a resistance spot welder with a pair of weld electrodes having an electrode face radius of curvature in the range between 20 mm and 40 mm. The series of aluminum to aluminum welds is first made, and then, after completing the aluminum to aluminum welds, the series of steel to steel welds are made. After completing the steel to steel welds the weld electrodes are cleaned by an abrasive to remove any buildup or contamination of aluminum on the electrodes. In the event the electrodes have mushroomed, then dressing of the electrodes is provided and then the abrasive cleaning is performed to restore the surface texture.

Owner:GM GLOBAL TECH OPERATIONS LLC

Electrode cap grinding device and automatic welding system

InactiveCN103537847ARealize automatic adjustmentIncrease productivityResistance electrode holdersOther manufacturing equipments/toolsElectrical and Electronics engineeringWelding

The invention relates to the technical field of automatic welding, and discloses an electrode cap grinding device and an automatic welding system which are invented in order to solve the problem that an existing electrode cap grinding technique is low in production efficiency and has potential safety hazards. The electrode cap grinding device comprises a turnover system and a grinding system, the turnover system comprises a bracket, connectors hinged to the bracket and first driving devices, and the first driving devices can drive the connectors to rotate between a first position and a second position relatively to the frame. The grinding system comprises tool rest plates, second driving devices, grinding tools and first motors, the tool rest plates are slidably connected with the connectors correspondingly, the second driving devices can drive the tool rest plates to slide linearly relatively to the corresponding connectors, the grinding tools are fixed on the corresponding tool rest plates, and the first motors can drive the grinding tools to rotate. The electrode cap grinding device is used for grinding electrode caps.

Owner:GREAT WALL MOTOR CO LTD

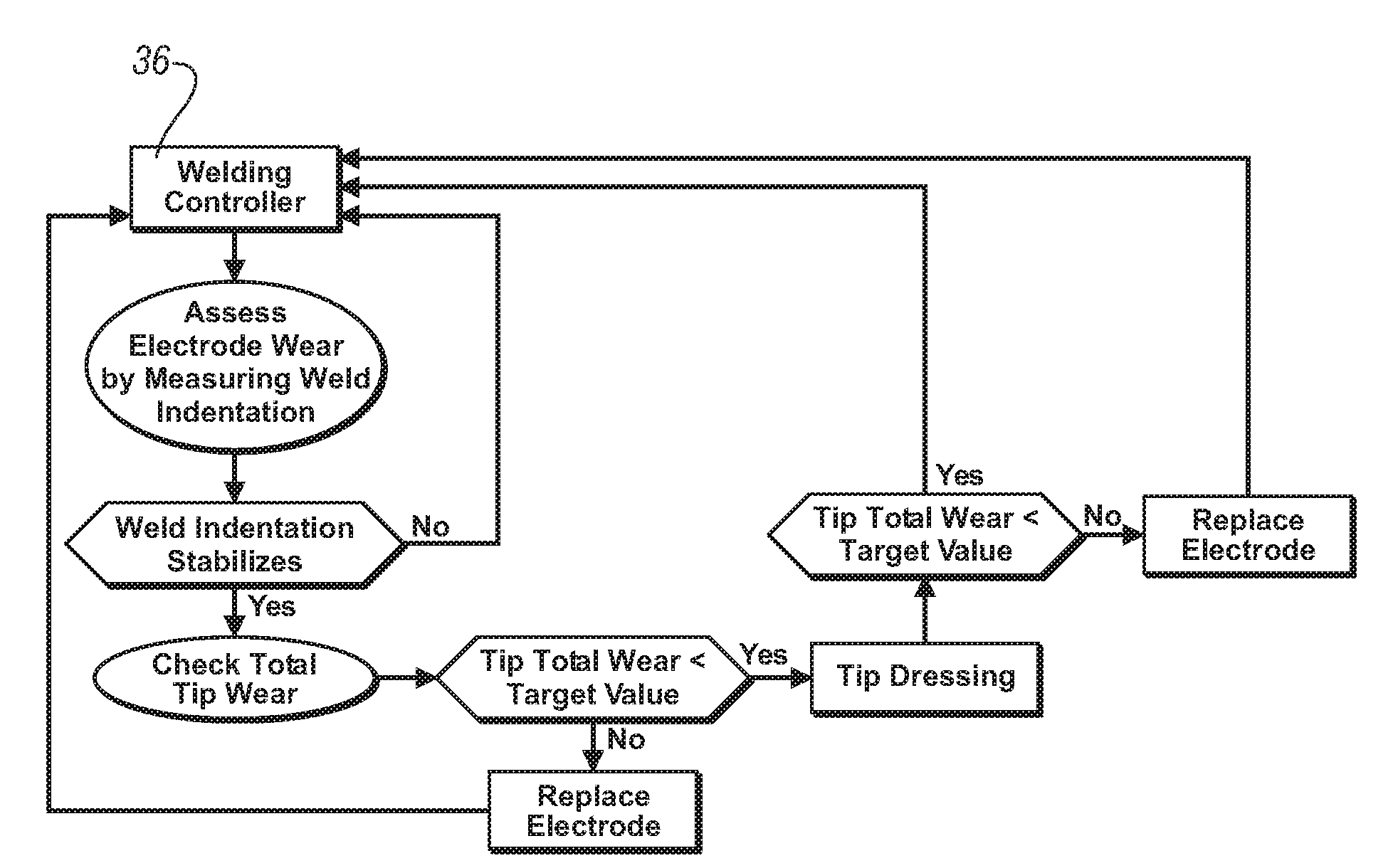

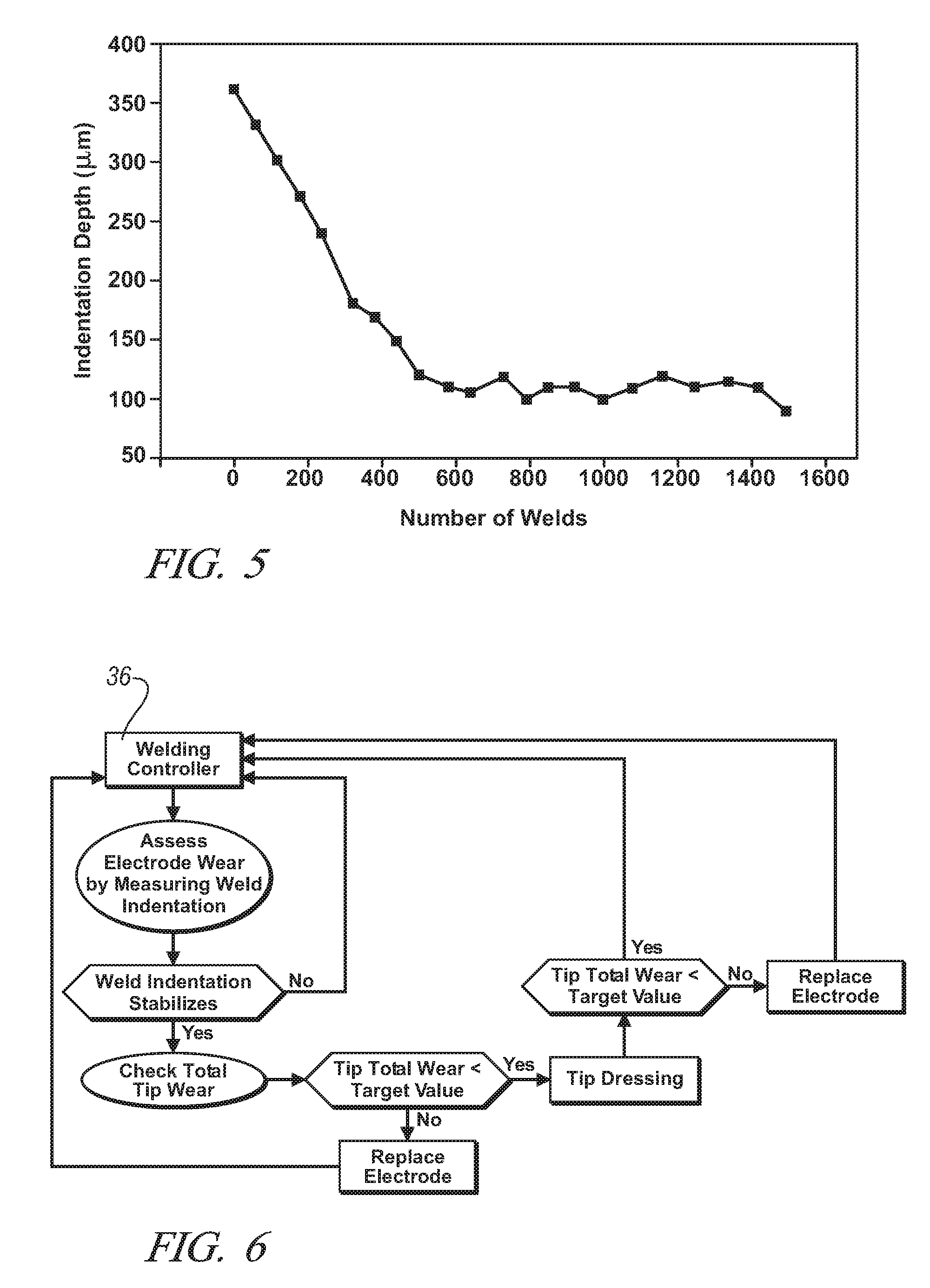

Decision method for dressing of welding electrodes

A method is provided for determining that the electrodes of an electric resistance welder are in need of replacement and dressing includes monitoring the rate at which the depth of the weld indentation caused by the electrode changes during the progressive wearing of the electrodes during the making of successive welds. The electrodes are then dressed when it is determined that the rate of change of the depth of the weld indentation formed by the electrodes has substantially leveled off to a stable depth of indentation.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

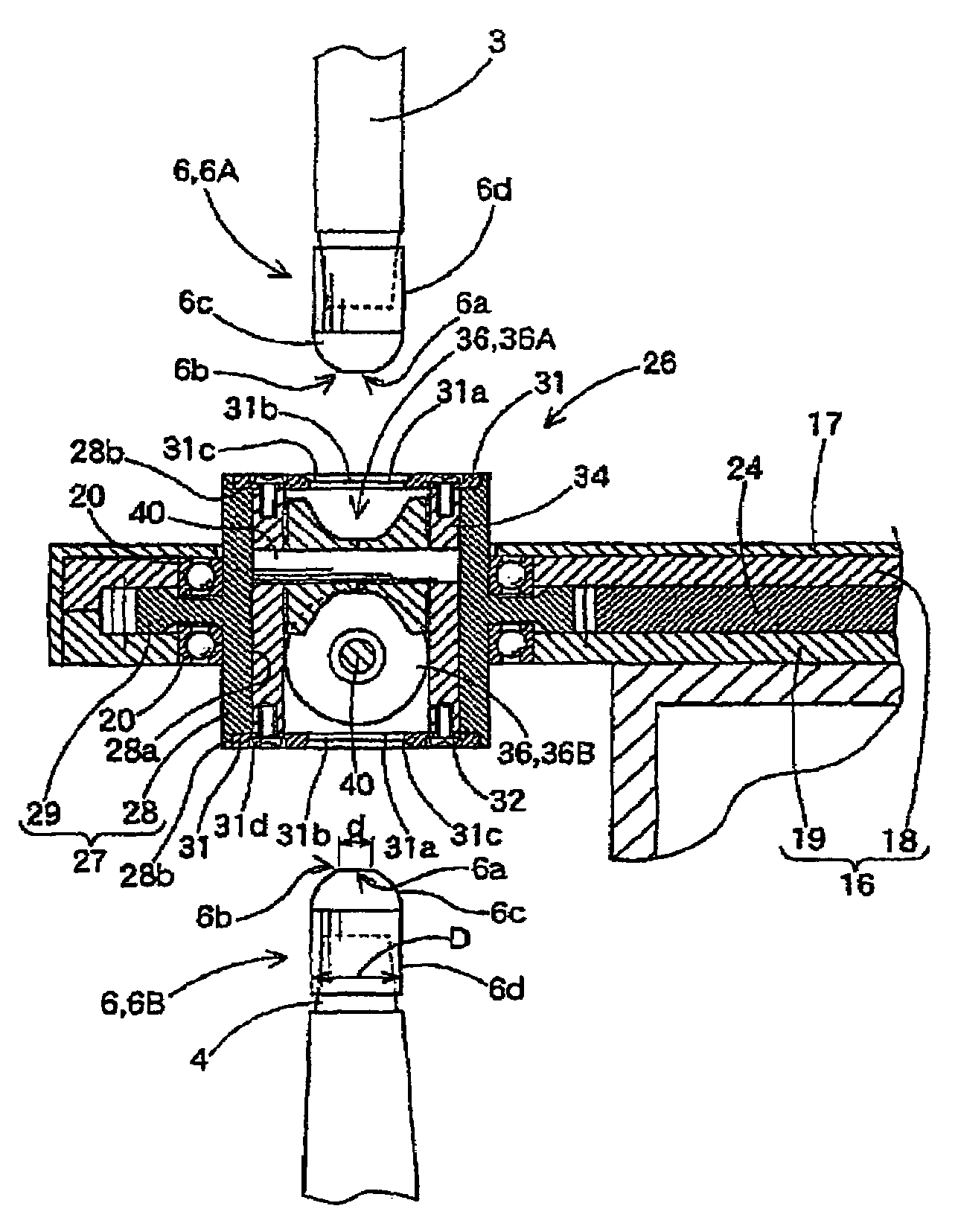

Tip dresser

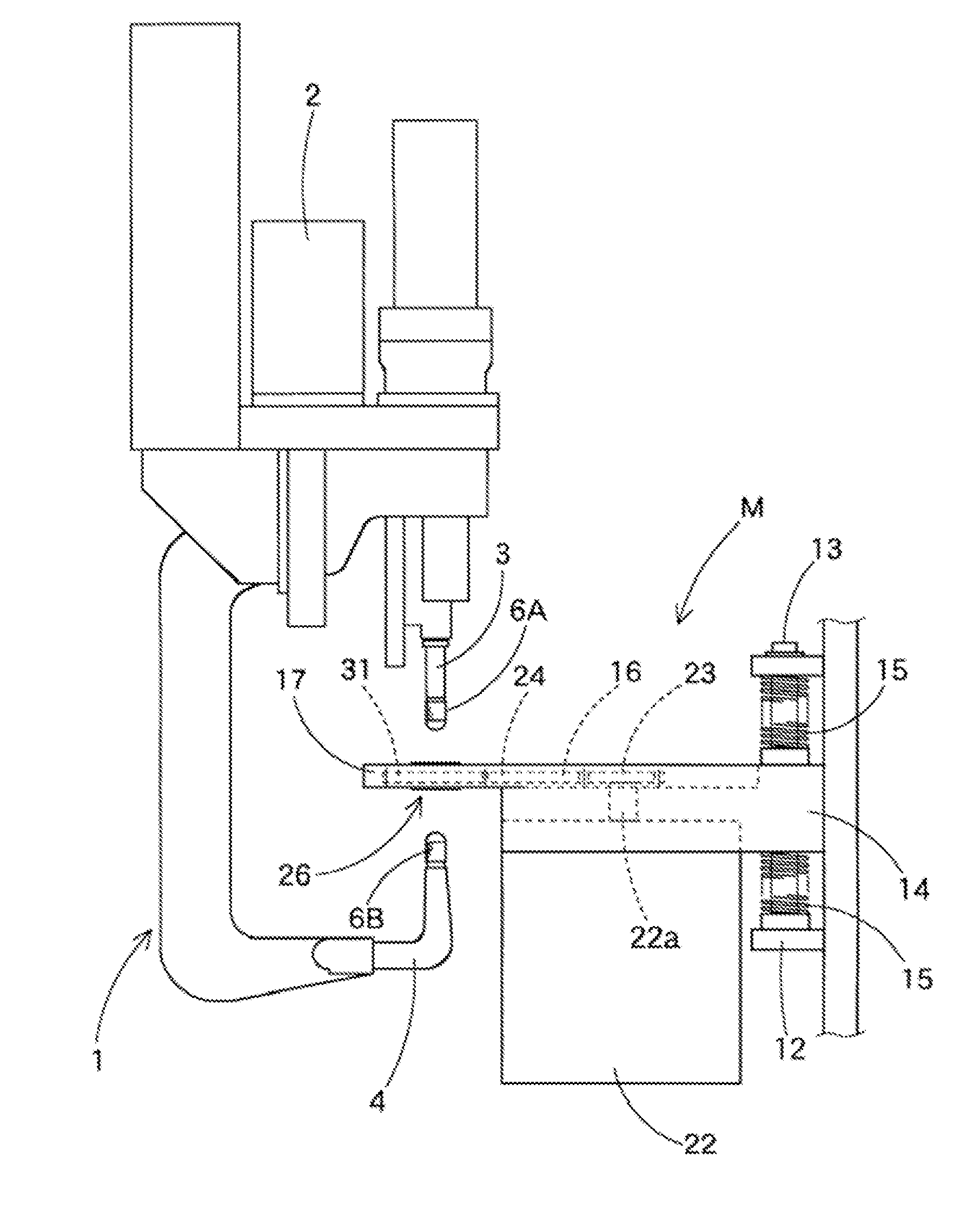

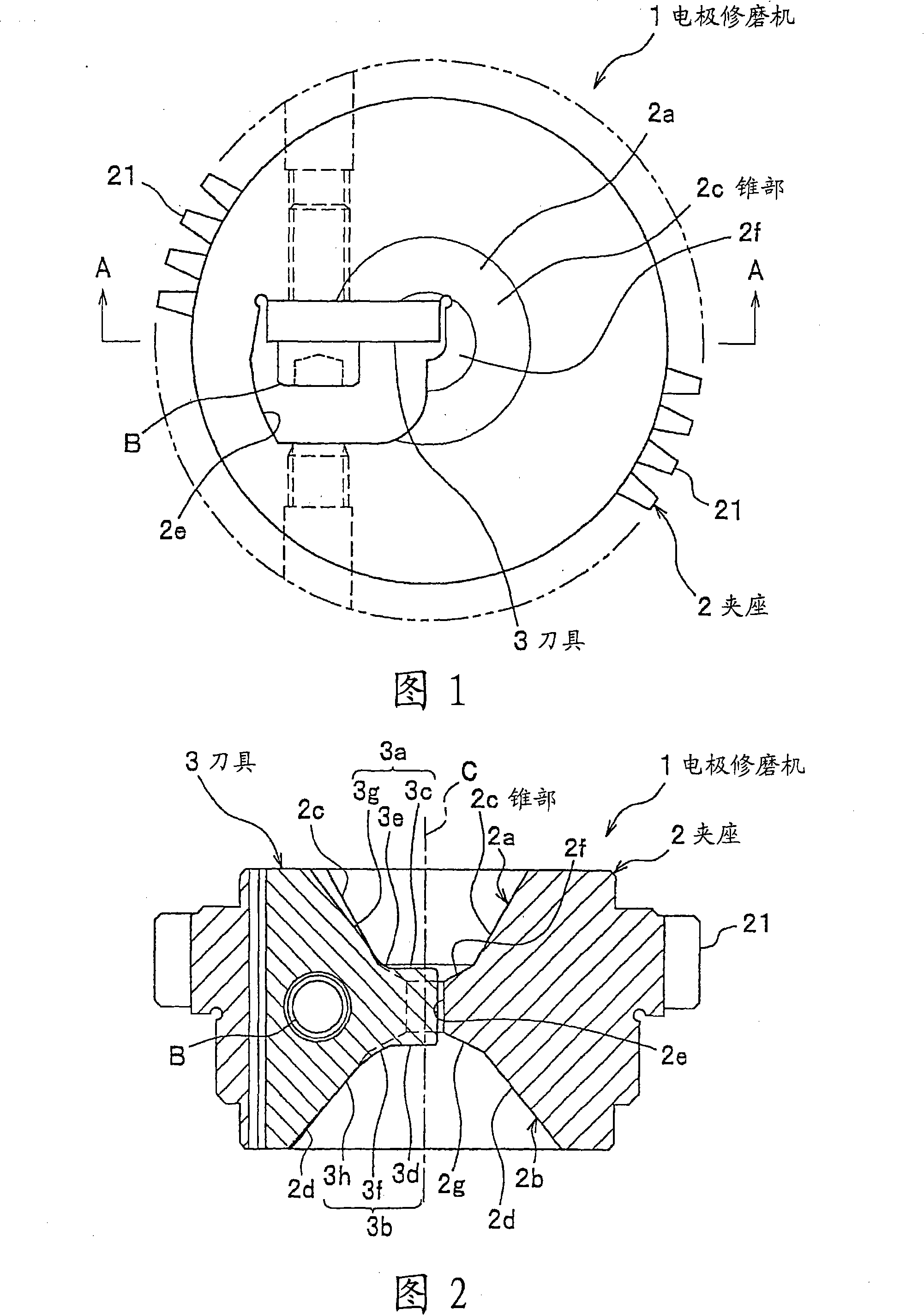

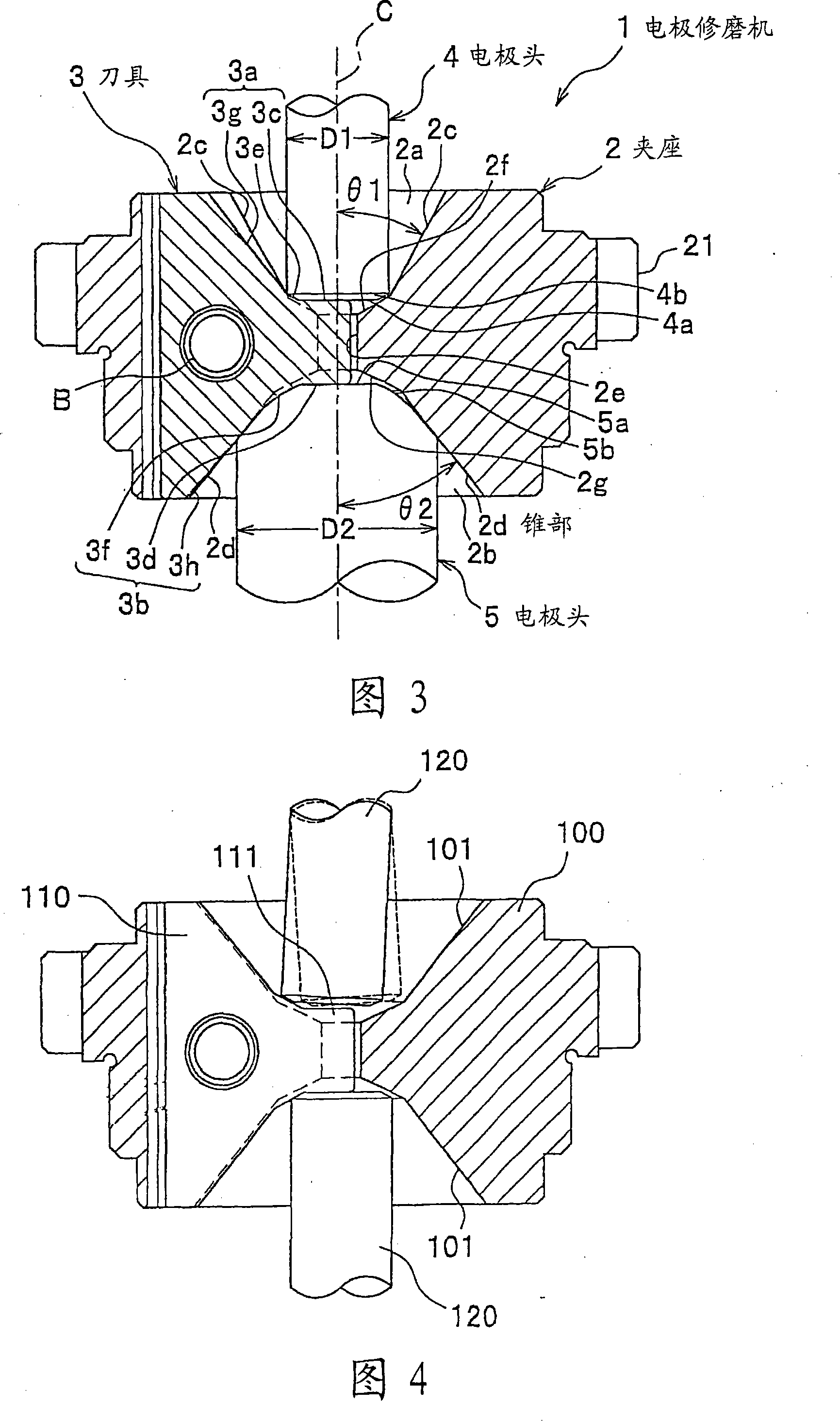

InactiveCN101232966ARadial Runout SuppressionPrevent radial runoutShaping cuttersElectrode maintenanceEngineeringElectrode

The invention provides an electrode grinding machine (1), which reshapes electrode heads (4, 5). The electrode grinder (1) includes: a clamp seat (2) that rotates around a rotation axis, and two surfaces of the clamp seat (2) have concave tapered portions (2) centered on the rotation axis. 2c, 2d); and the cutter (3), which is fixed on the holder (2) and only in the part closer to the inside than the outer diameter (D1, D2) of the electrode head (4, 5), The cutter protrudes from the tapered portion (2c, 2d) toward the electrode tip (4, 5) side.

Owner:HONDA MOTOR CO LTD

Resistance spot welding of aluminum to aluminum and steel to steel

A method for welding a plurality of aluminum to aluminum welds and a plurality of steel to steel welds using the same welder includes providing a resistance spot welder with a pair of weld electrodes having an electrode face radius of curvature in the range between 20 mm and 40 mm. The series of aluminum to aluminum welds is first made, and then, after completing the aluminum to aluminum welds, the series of steel to steel welds are made. After completing the steel to steel welds the weld electrodes are cleaned by an abrasive to remove any buildup or contamination of aluminum on the electrodes. In the event the electrodes have mushroomed, then dressing of the electrodes is provided and then the abrasive cleaning is performed to restore the surface texture.

Owner:GM GLOBAL TECH OPERATIONS LLC

Tip dresser

InactiveUS7458139B2Well formedEasy to manufactureCode conversionMilling machinesSpot weldingElectrical and Electronics engineering

Owner:KYOKUTOH

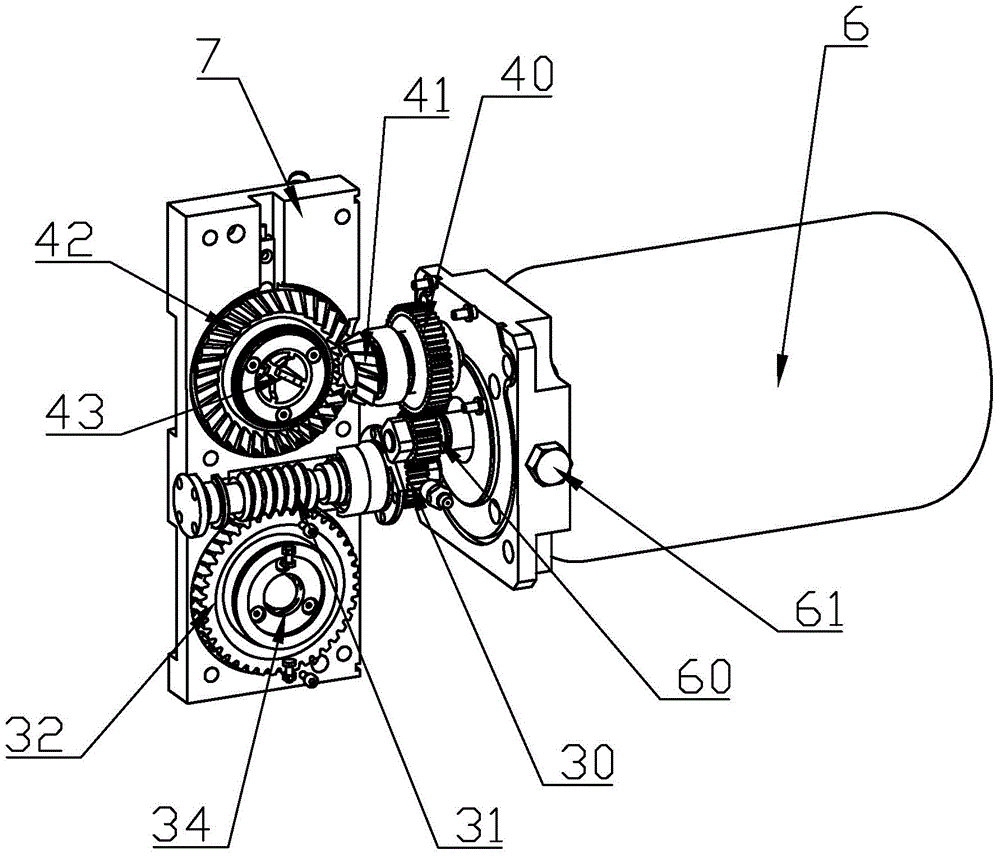

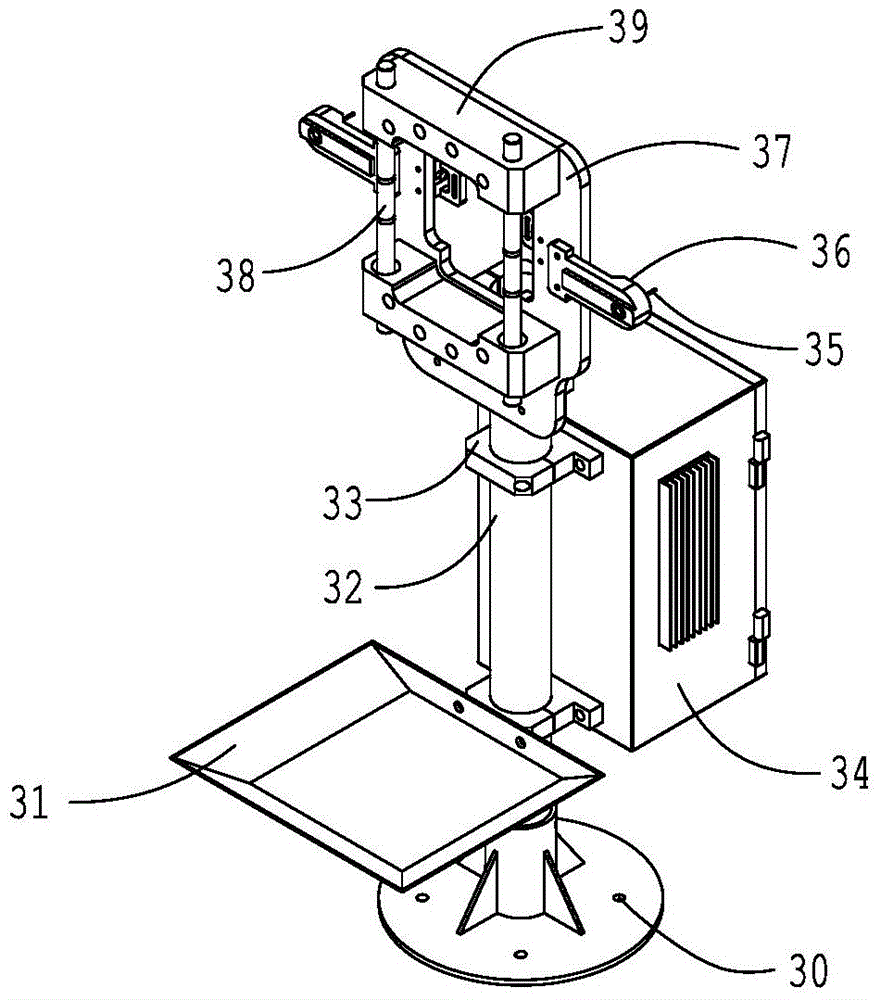

Mould-repair replacing equipment for electrode caps of welding machine

The invention belongs to the technical field of welding equipment, in particular to mould-repair replacing equipment for electrode caps of a welding machine. The mould-repair replacing equipment comprises an electrode cap mould repair device and a supporting part for mounting and supporting the electrode cap mould repair device, wherein the electrode cap mould repair device comprises a transmission body as well as a motor, a driven gear and a mould repair gear mounted on the transmission body; the motor drives the driven gear to rotate; the driven gear drives the mould repair gear to rotate; a mould repair plate is mounted in the mould repair gear; a blade is arranged on the mould repair plate; and the mould repair plate rotates along with the mould repair gear, so that the blade carries out cutting and mould-repair on the electrode caps. The mould-repair replacing equipment is used for carrying out mould repairing on the electrode caps on a pair of electrodes of an automatic welding machine; the completely scrapped electrode cap can be automatically dismounted, and a brand-new electrode cap can be automatically replaced; the electrode caps of the two electrodes can be mounted, dismounted or subjected to mould-repair simultaneously; and the end surfaces of the electrodes subjected to mould-repair are concentric and fitted, so that the mould-repair speed is high.

Owner:SHENZHEN HONGBAI TECH IND

Electrode tip dresser

InactiveUS7257872B2Avoid uneven wearReduced space required for installationEdge grinding machinesOhmic-resistance electrodesEngineeringElectrical and Electronics engineering

An electrode tip dresser is disclosed which can dress a pair of electrode tips to a usable state while achieving a desired accuracy of a tip surface of each electrode tip including an angular portion at a peripheral edge of the tip surface, without separating each electrode tip from a welding gun. The electrode tip dresser includes a holder which is rotatable about a common axis of electrode tips, a pair of support shafts which are held by the holder, are arranged in parallel in an approach direction of the electrode tips, and extend in a direction orthogonal to the approach direction, and a pair of dressing rollers which are rotatably supported by the support shafts, respectively, to dress the electrode tips to a usable state. Each dressing roller includes a groove which has a cross-section conforming to the outline of the tip section of the associated electrode tip when the cross-section is taken in a direction orthogonal to the associated support shaft, and the outline is taken after the dressing of the electrode tip. Each dressing roller includes two axially-divided roller bodies. The dividing plane of the divided roller bodies is arranged at the center of the tip surface of the associated electrode tip in a direction orthogonal to the axis of the associated electrode tip.

Owner:KYOKUTOH KOREA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com