Patents

Literature

52results about How to "Improve work tempo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

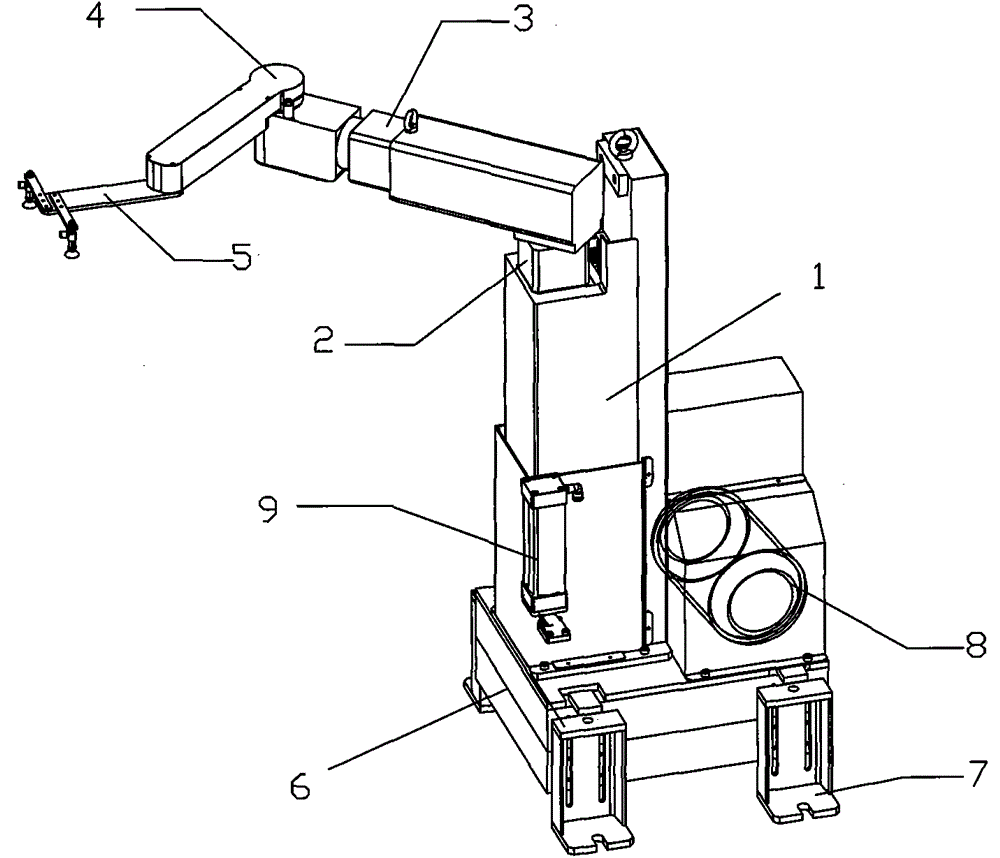

Multi-shaft horizontal joint intelligent robot

ActiveCN103978478AImprove operational efficiencyImprove work tempoProgramme-controlled manipulatorWorking environmentElectric machinery

The invention discloses a multi-shaft horizontal joint intelligent robot. The multi-shaft horizontal joint intelligent robot comprises an intelligent control mechanical hand, wherein the intelligent control mechanical hand is formed by a control device, an executing mechanism, a driving device and a base; the executing device comprises one shaft which is used for controlling vertical motion and three shafts which are used for controlling horizontal motion; a vertical moving function of a workpiece is realized in a way that the workpiece is driven to move on a sliding rail under the transmission of a screw rod by a first shaft; a speed reducing ratio is increased through a planetary gear reducer under the driving of a second shaft absolute value servo motor, and thus a horizontal 180-degree arm oscillating motion is realized as the mechanical hand is driven by a second shaft; a horizontal 360-degree arm oscillating motion is realized by a third shaft under the driving of a third shaft absolute value servo motor through the planetary speed reducer; a vertical 180-degree mechanical arm overturning motion is realized by a fourth shaft under the driving of a fourth shaft absolute value servo motor through a harmonic speed reducer. The multi-shaft horizontal joint intelligent robot disclosed by the invention has the advantages that the operation is simple and safe, horizontal and vertical moving ranges are larger, the locating is accurate, and the grabbing weight is large; a complicated carrying motion can be realized by simulating a person under a severe working environment.

Owner:HUIZHOU SUNNEMER AUTOMATION EQUIP CO LTD

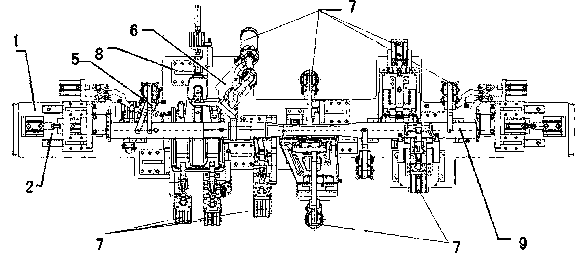

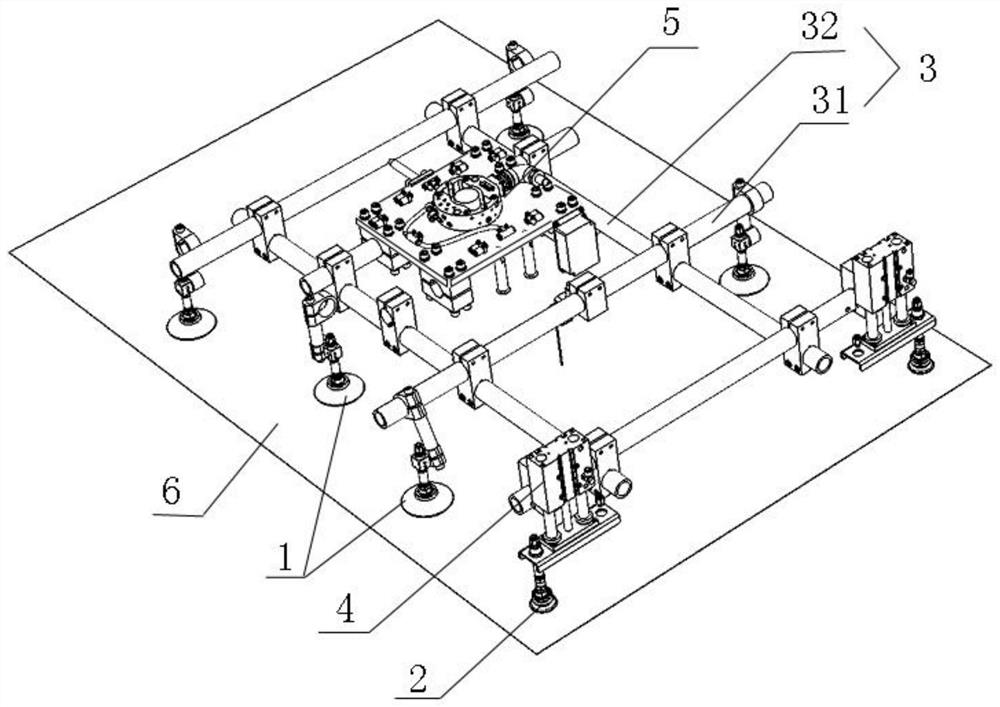

Instrument desk support welding tool

InactiveCN103624441AImprove work efficiencyImprove accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention provides an instrument desk support welding tool. The instrument desk support welding tool comprises a tool support. The two ends of the tool support are respectively provided with a locating substrate. A plurality of clamping tools are arranged between the two locating substrates. Each clamping tool comprises a clamping base. Each clamping base is provided with a clamping arm which is connected with an air cylinder. A fixed substrate is arranged on each locating substrate. The upper side, the lower side and the right side of each fixed substrate are respectively provided with an adjusting mechanism, and the adjusting mechanisms are in a screw adjusting mode. According to the instrument desk support welding tool, a clamping tongs clamping device is replaced by the mode of clamping driven by the air cylinders, so that working efficiency is improved, and the working rhythm is increased; when the size needs to be adjusted, only screws need to be adjusted, mobility is achieved, accuracy is high, and adjustment is convenient to conduct. The instrument desk support welding tool is simple in structure, convenient to manufacture, accurate in machining and capable of improving working efficiency.

Owner:江苏科博汽车部件有限公司

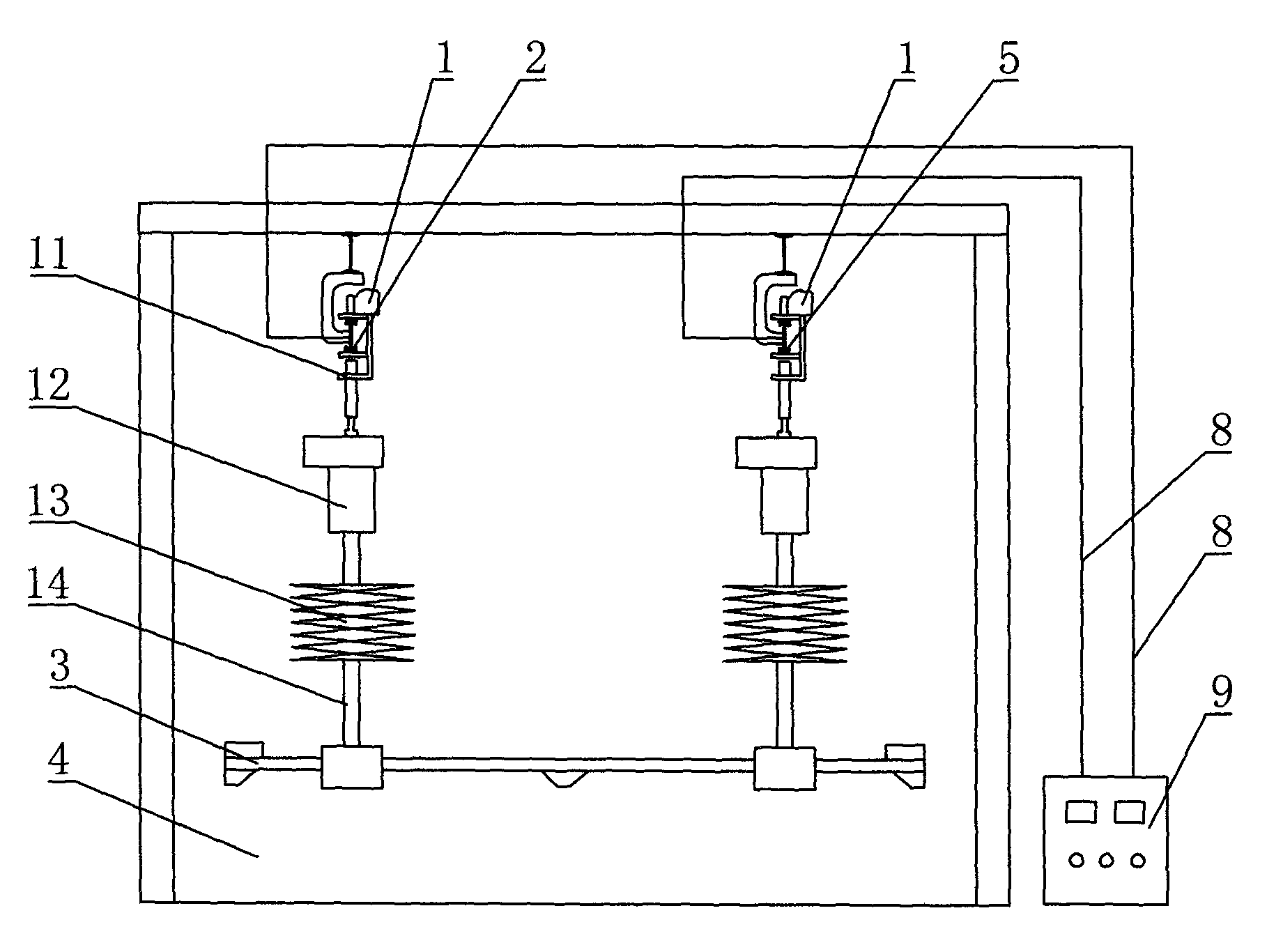

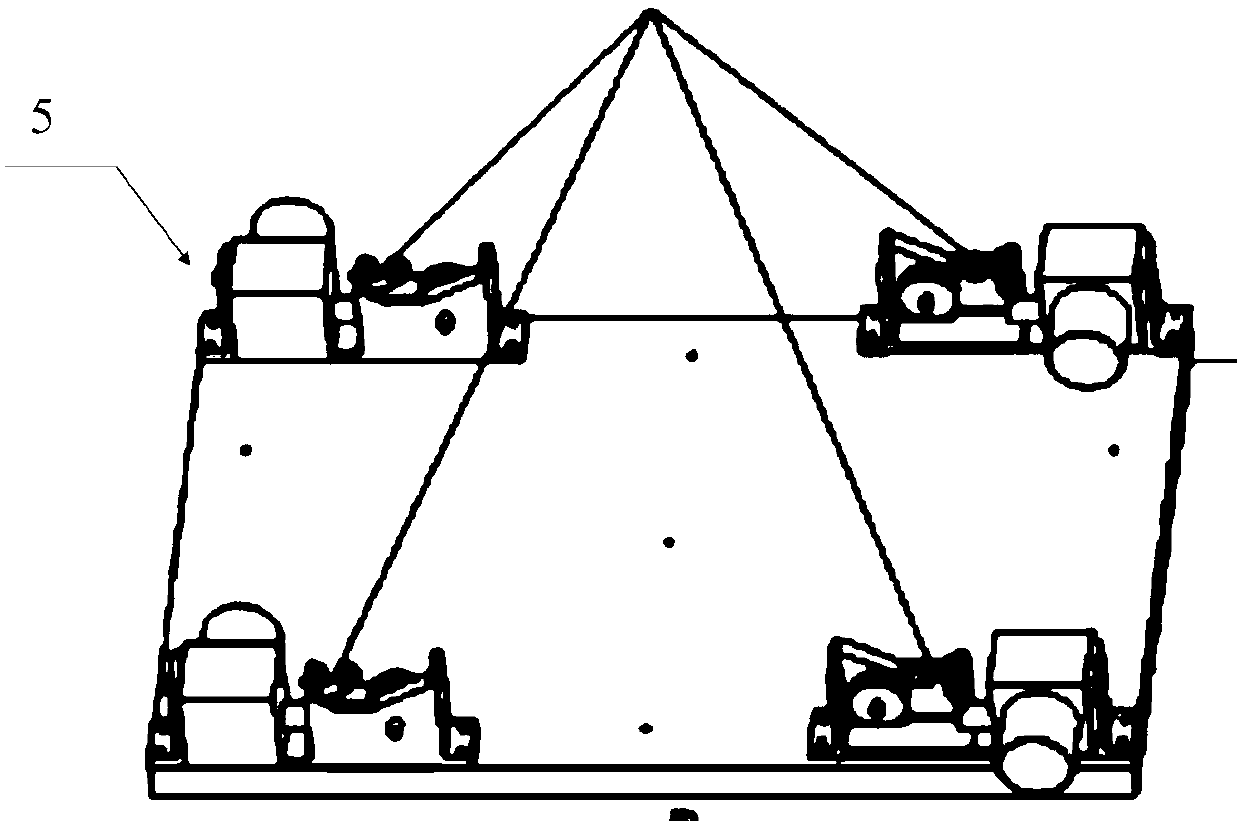

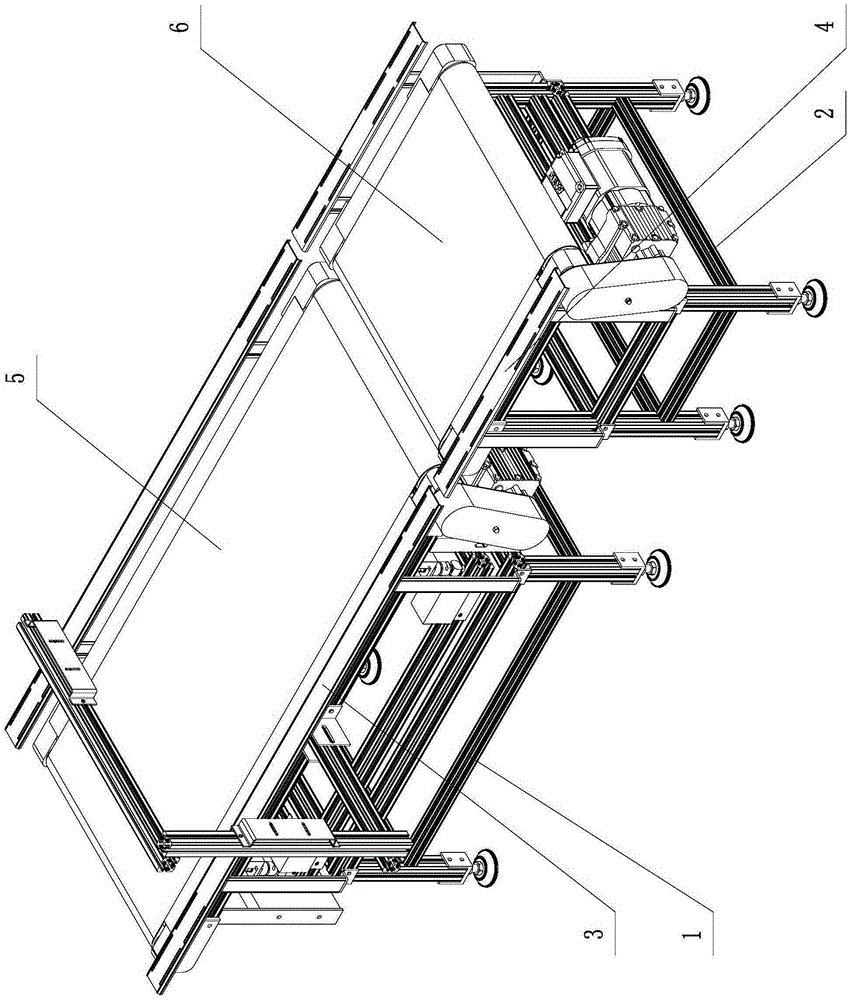

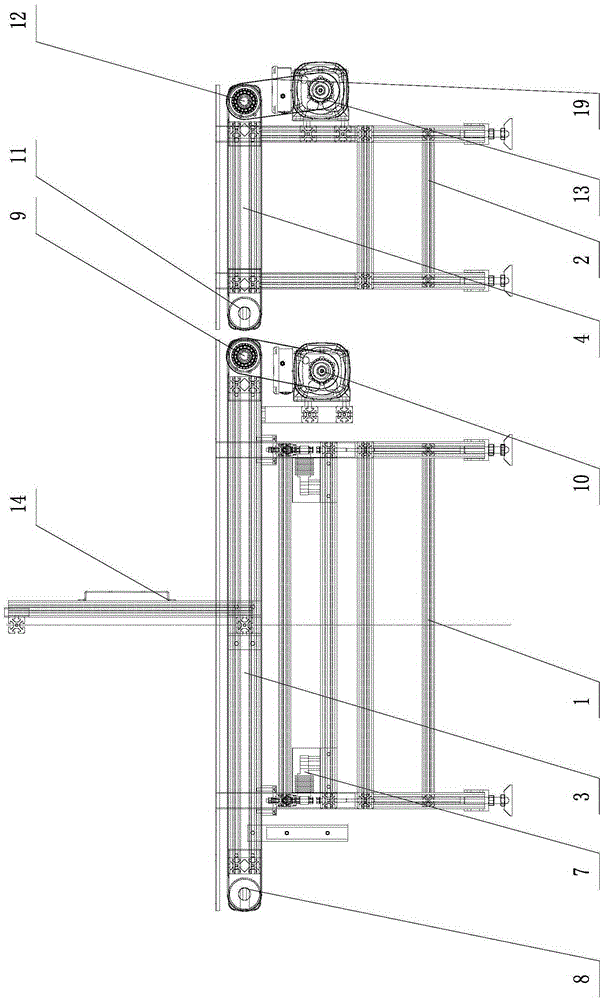

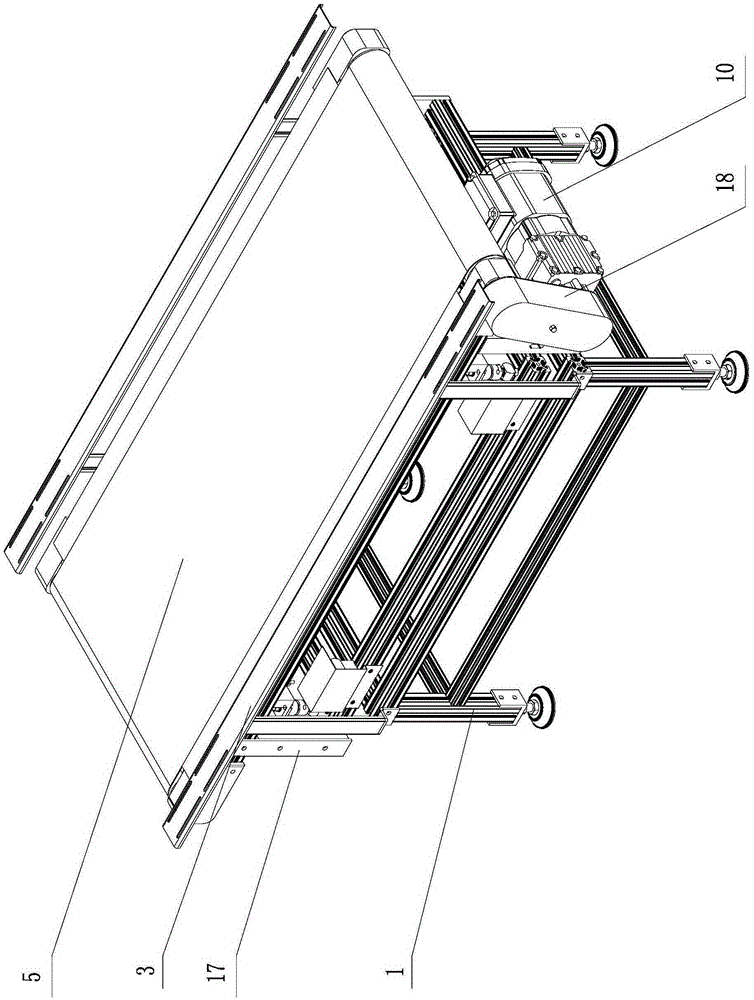

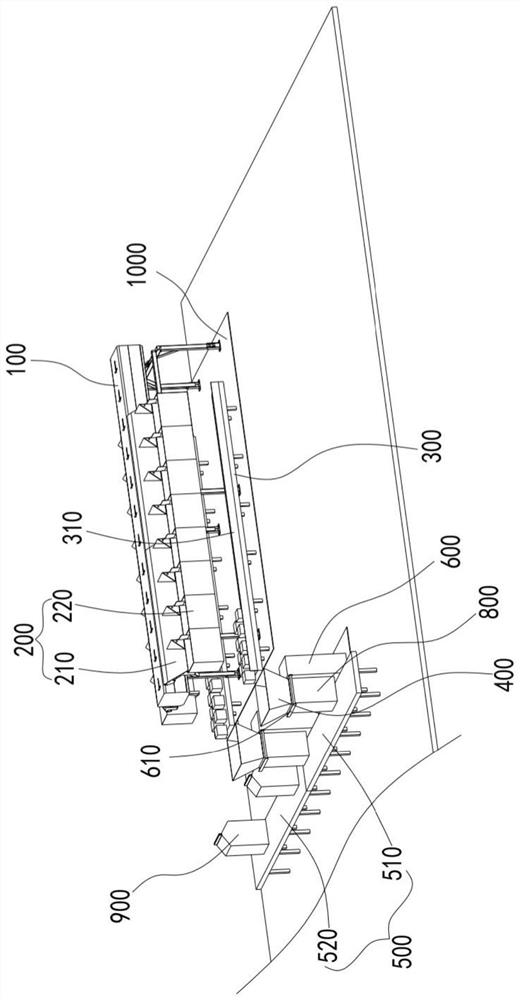

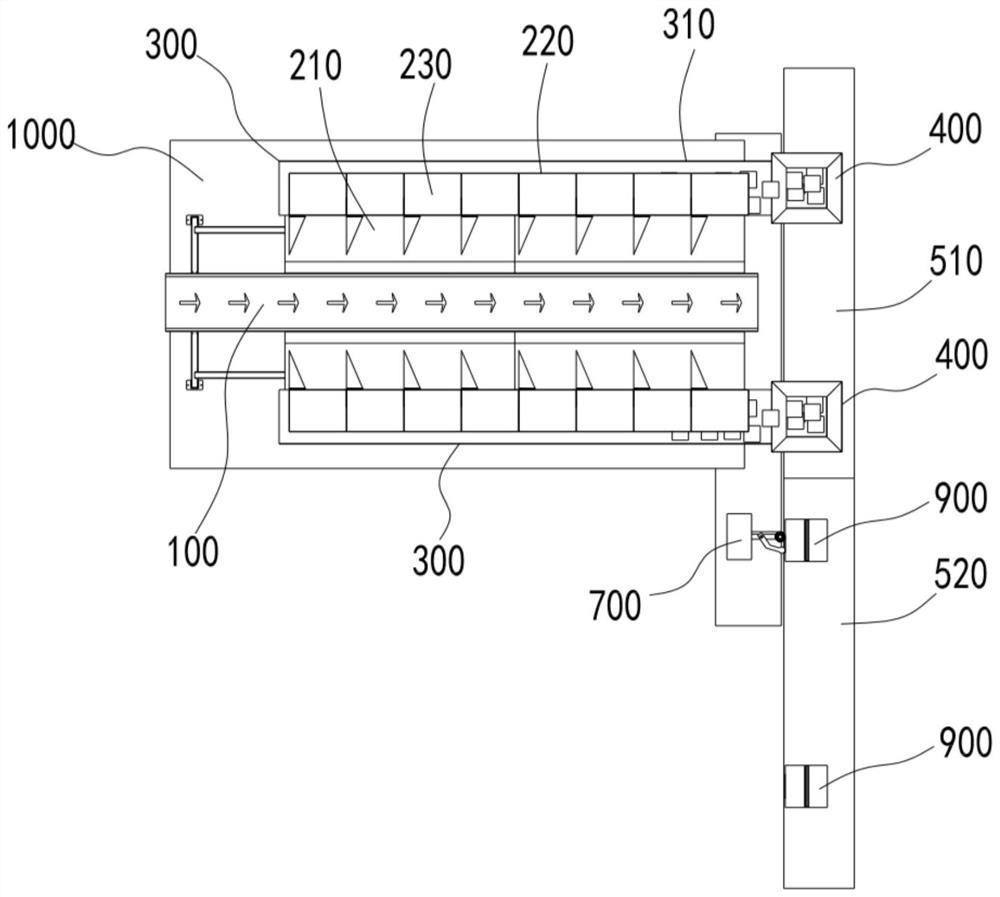

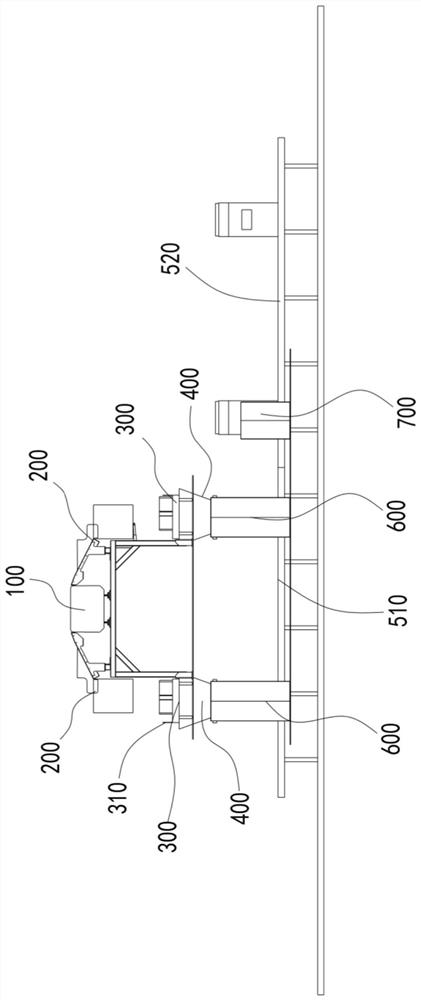

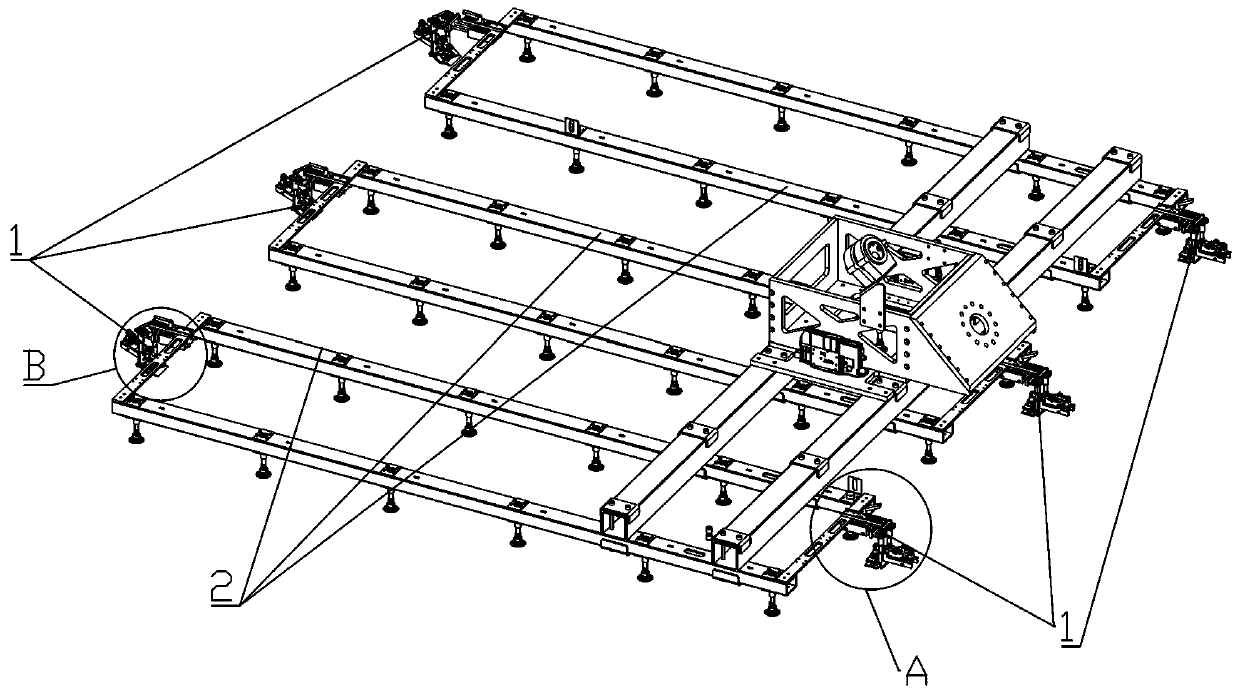

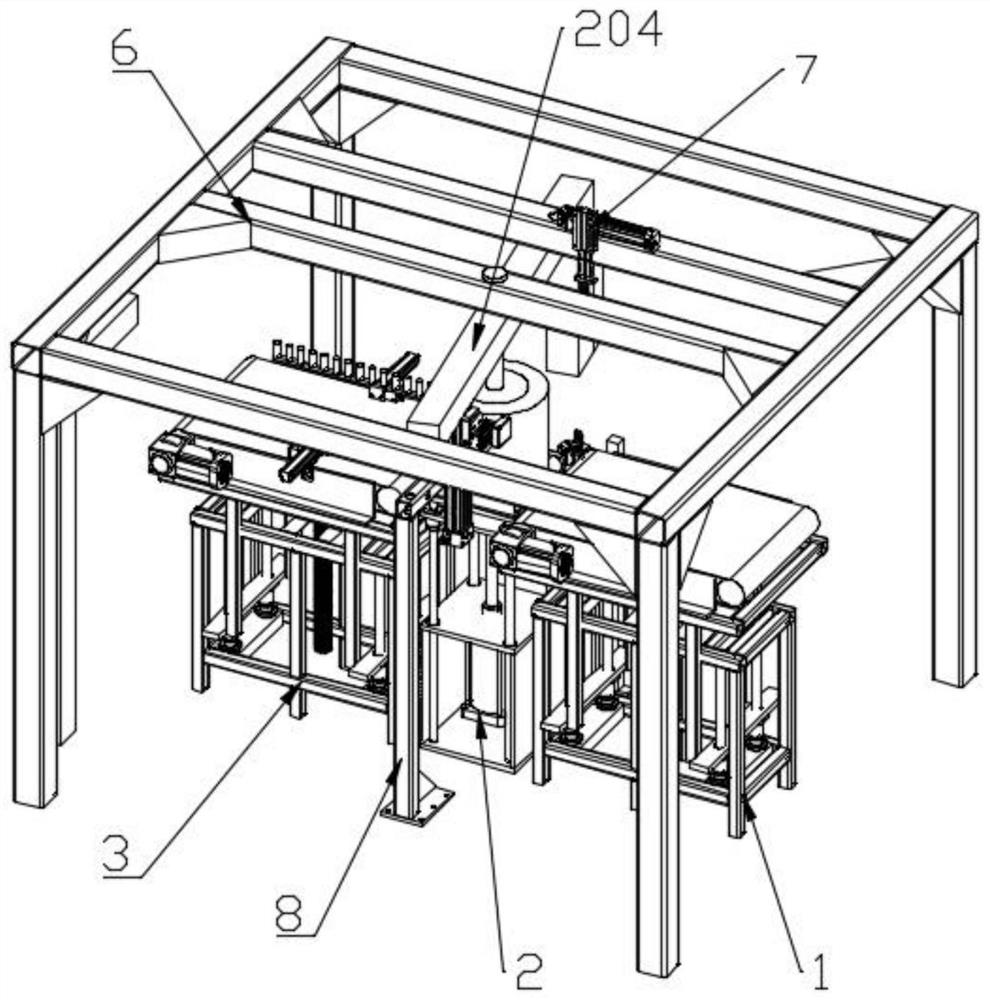

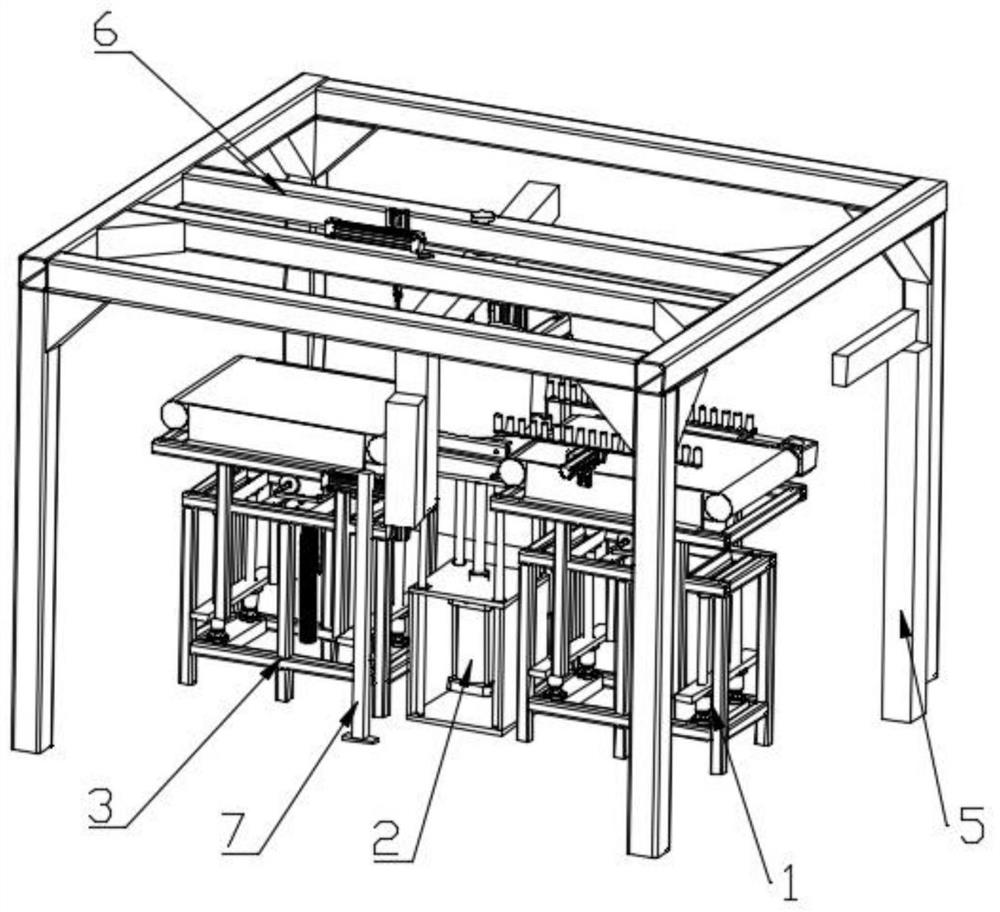

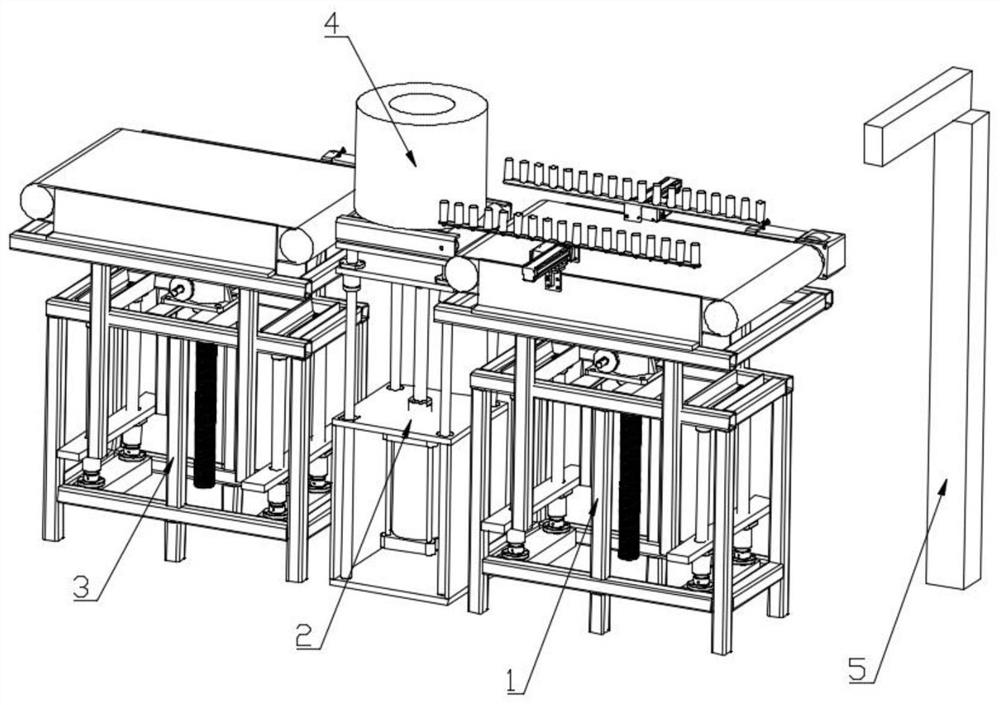

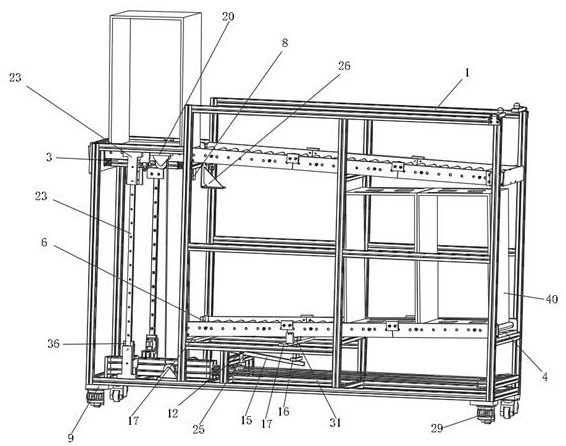

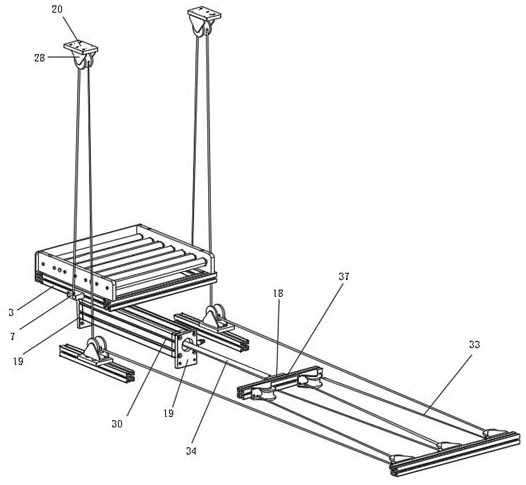

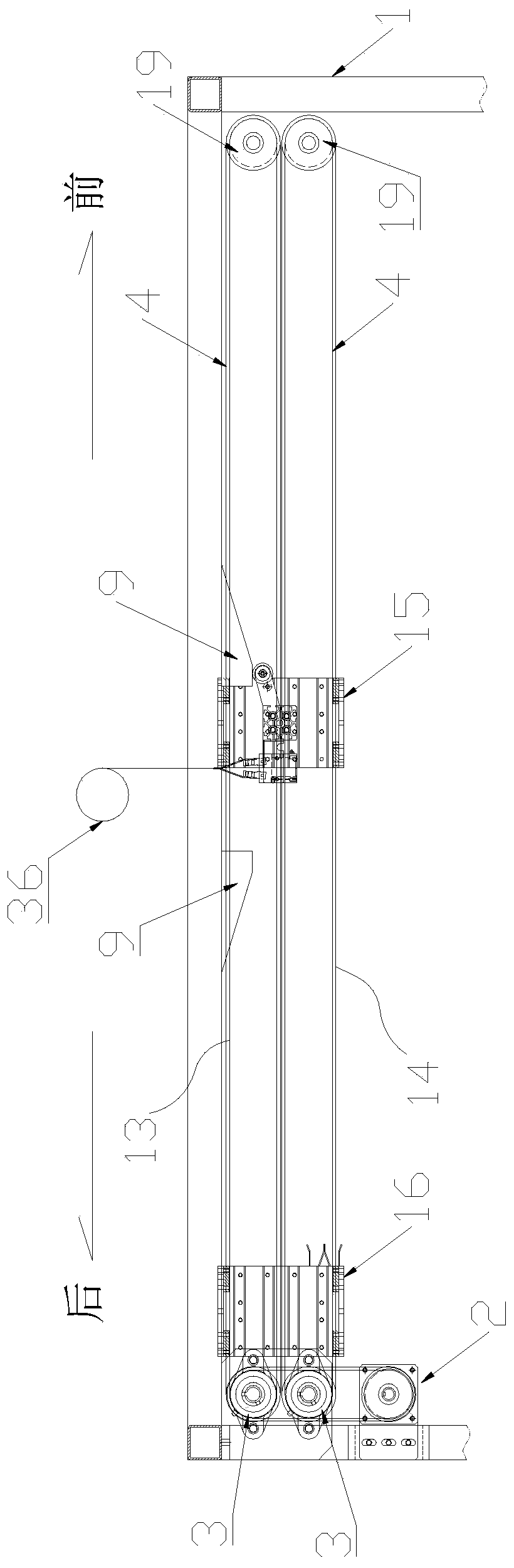

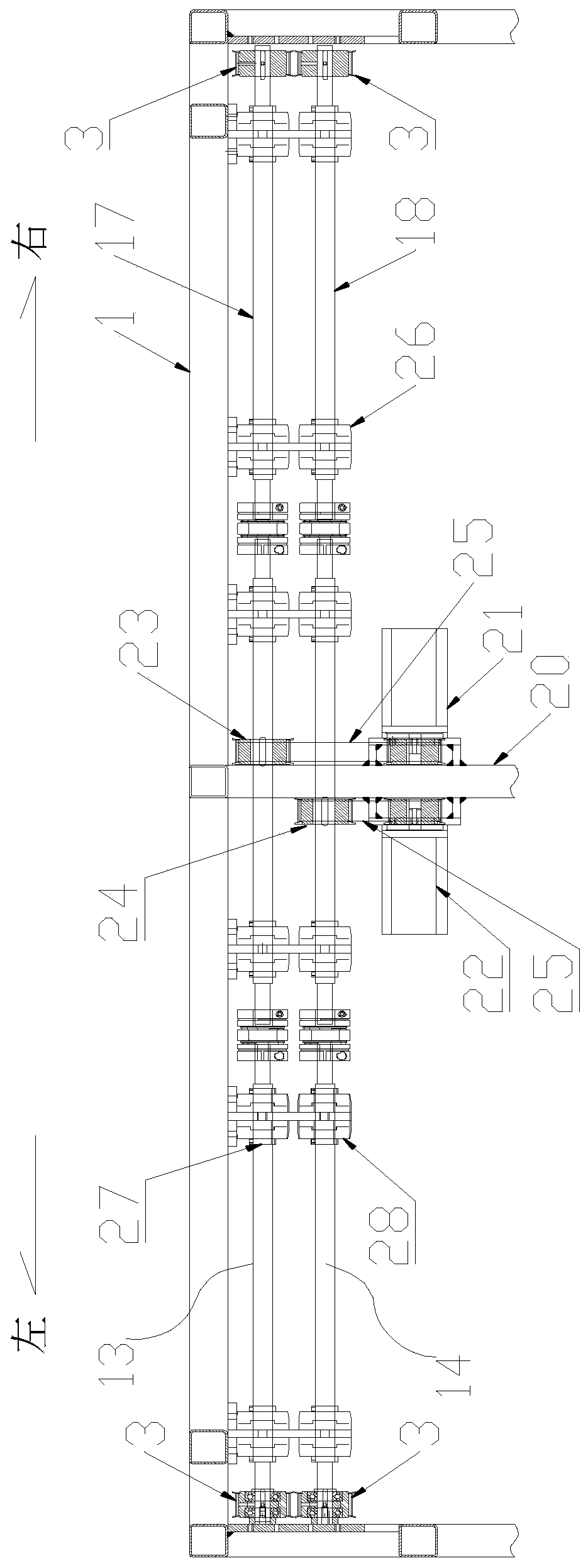

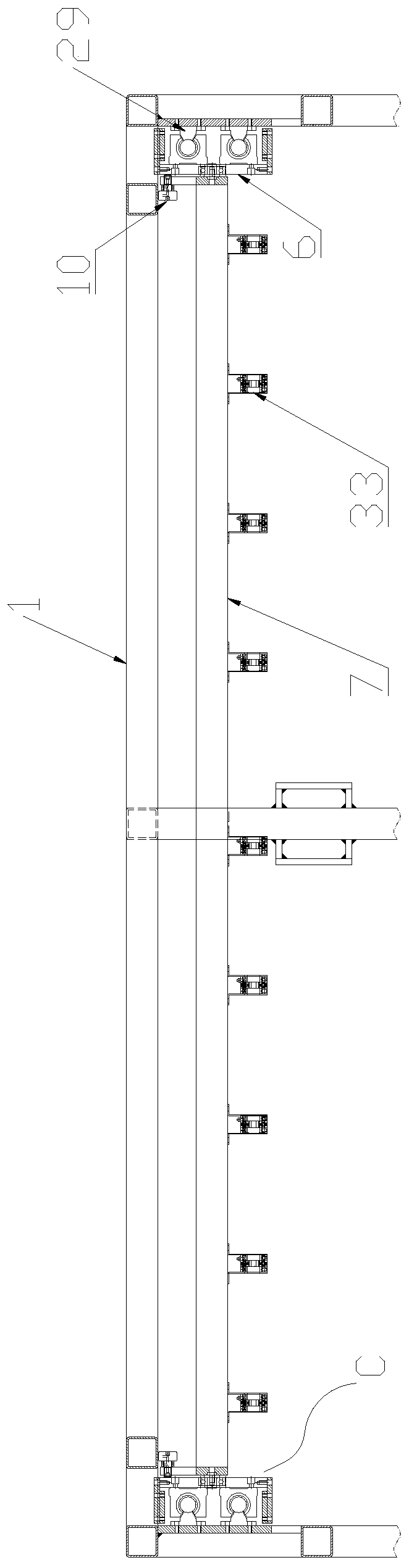

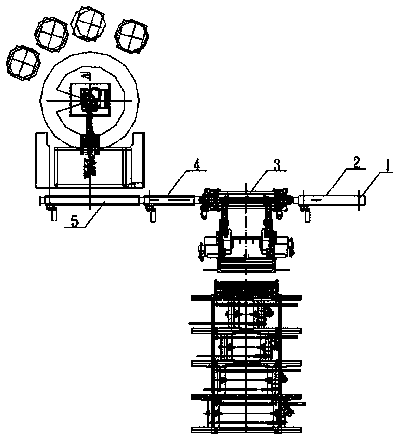

Synchronous transporting device of double trolley

InactiveCN103130102AReduced strength requirementsLight weightTrolley cranesProgrammable logic controllerElectrophoresis

The invention discloses a synchronous transporting device of a double trolley. The transporting device comprises two self-propelled trolleys transporter (1), a left rail (2), a right rail (5) and an electronic control cabinet (9). The two self-propelled trolleys transporting device(1)are hung respectively on the left rail (2) and the right rail (5). Each self-propelled trolley transporting device comprises a trolley (11), a chain hoist (12), a shear mode balance mechanism (13) and a lifting appliance (14). The trolley (11), the chain hoist (12), shear mode balance mechanism (13) and the lifting appliance (14) are connected successively. The electronic control cabinet (9) is provided with a programmable logic controller (PLC) which is connected with the two self-propelled trolleys transporting (1) to form an electric control loop through a wire (8). The transporting device has the advantages of being small in weight, small in inertia, high in locating precision, little in auxiliary time, safe and reliable, low in cost, convenient to maintain and long in service life, being capable of adapting to quick-beat transportation and being applied to pretreatment electrophoresis transporting device of a large-scale workpiece.

Owner:HUANGSHI HUATIAN AUTOMATION EQUIP

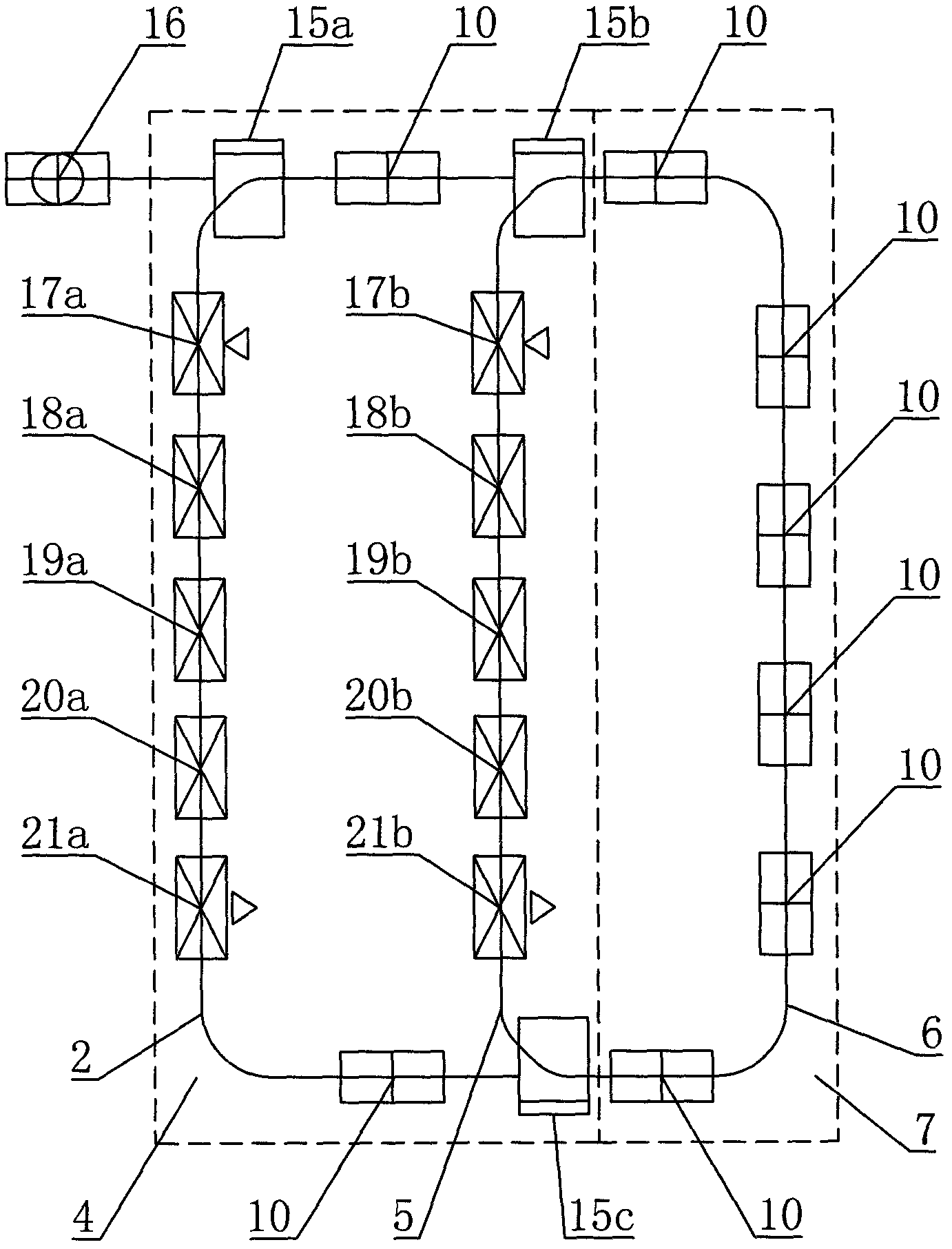

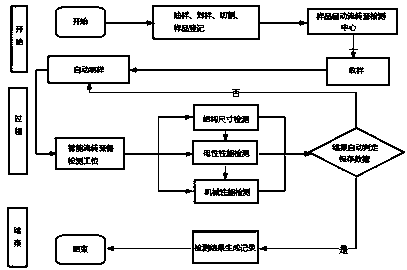

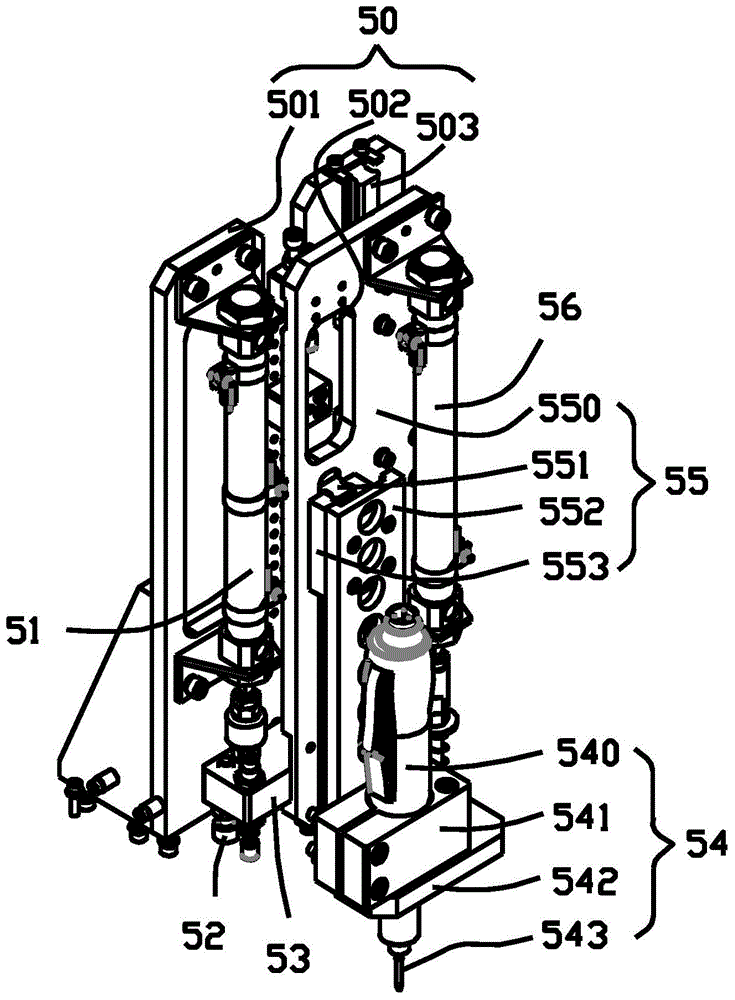

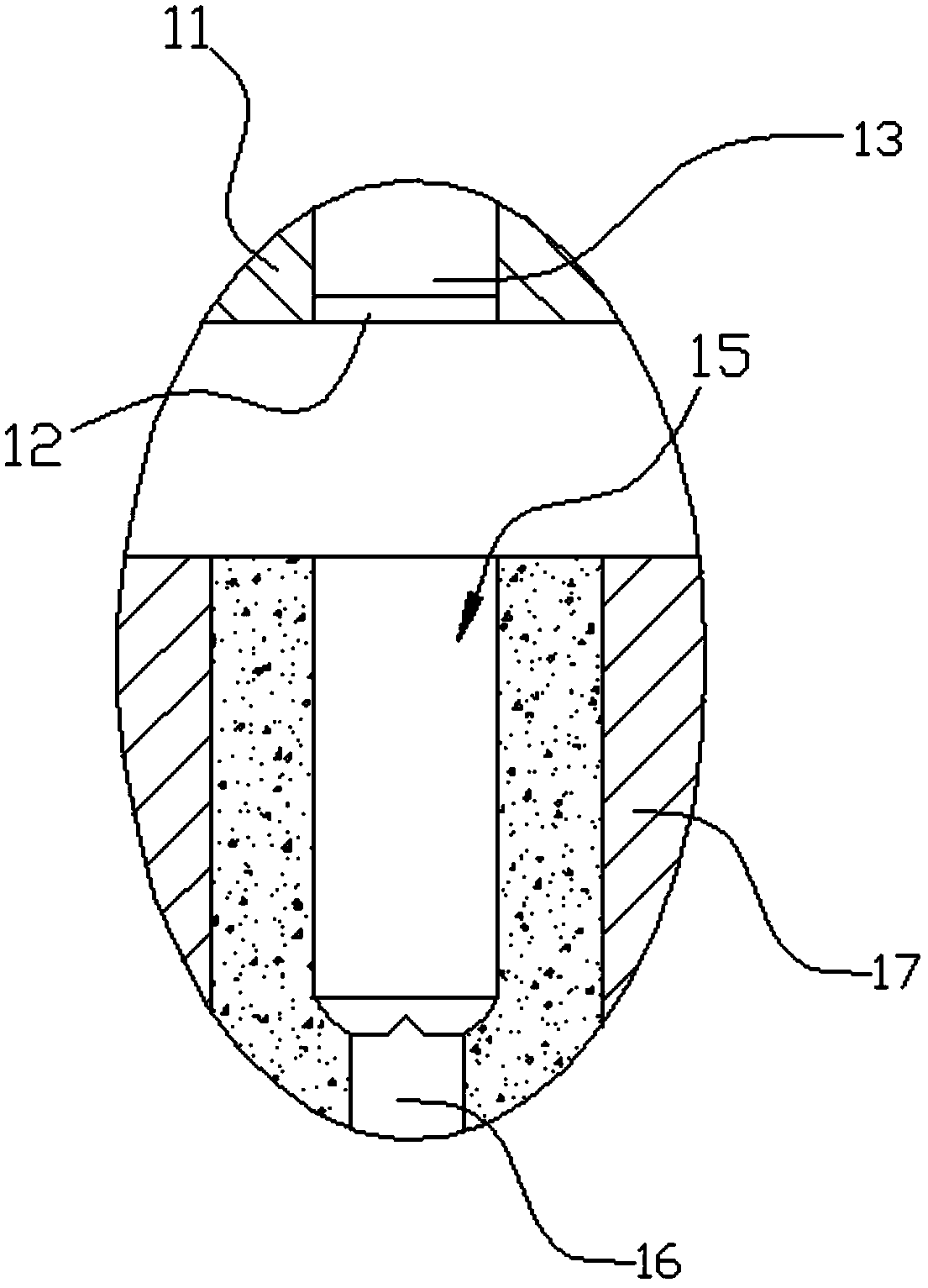

Cable automatic sample preparation detection system and method

ActiveCN110274906AReduce labor intensityReduce the uncertain factors in the process of measuring and marking linesPreparing sample for investigationMaterial analysis by optical meansElectrical conductorDevice form

The invention relates to a cable automatic sample preparation detection system. A wire and cable sampling support frame is included. The sampling support frame assists to identify cable head positioning. An automatic grabbing operating mechanism grabs and sends cable head winding. A fixing device and a cutting device used for cutting a cable are connected. The fixing device includes a cross frame, a blocking fan, an anti-collision baffle plate, a slide rail and a mechanical claw. The cutting device consists of the cutting device, a cutting platform and a cutting waste residue and waste material collection hopper. A measuring device forms a visual sense to identify an insulating color and records a number of single wires of a conductor. A measuring module is composed of a charge-coupled component visual measuring mechanism. The measuring device receives an output signal of a linear array charge-coupled component. A sorting processor sends materials to be sorted to a sorting operation area via a transmission band. A sorting system in the automatic grabbing operating mechanism carries out image capture on a source object through a collection image port so as to realize cable sample preparation, and a distribution one-stop mode. Labor intensity of detection personnel is mitigated, uncertain factors in a measurement and lineation link are reduced, and a detection ability and accuracy are increased.

Owner:JIANGSU ANFANG ELECTRIC POWER TECH

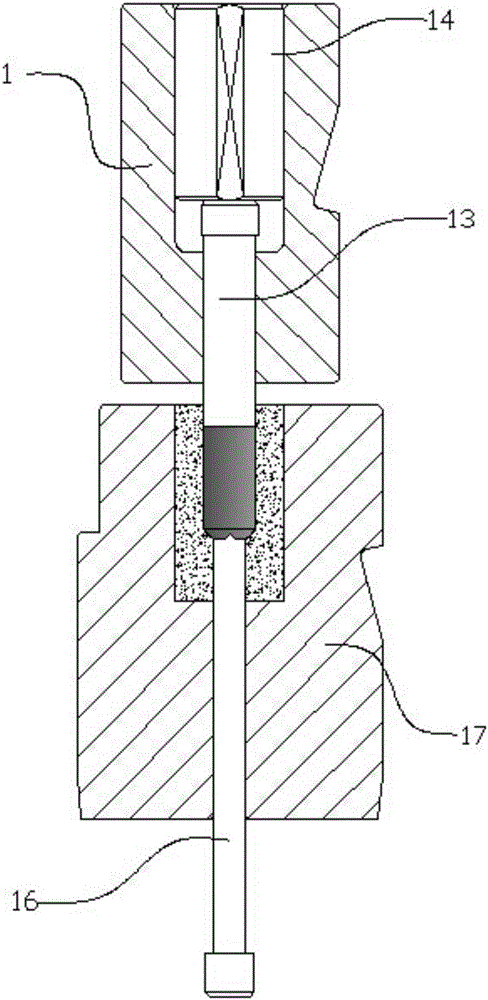

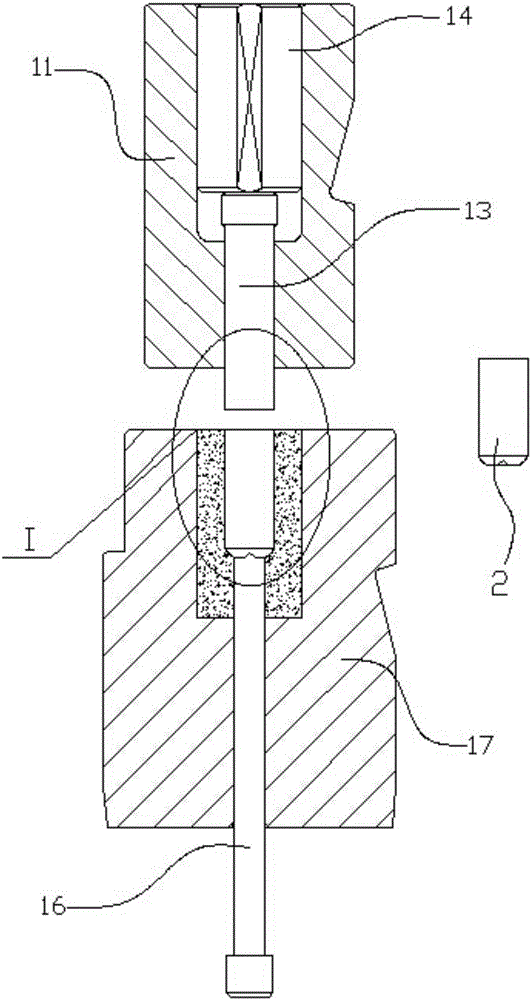

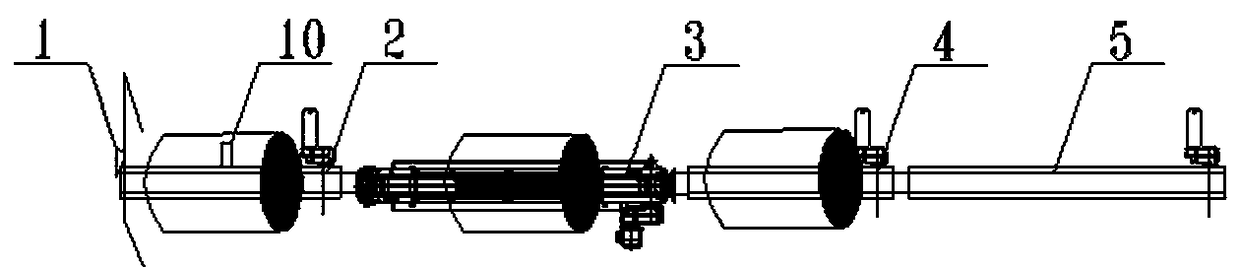

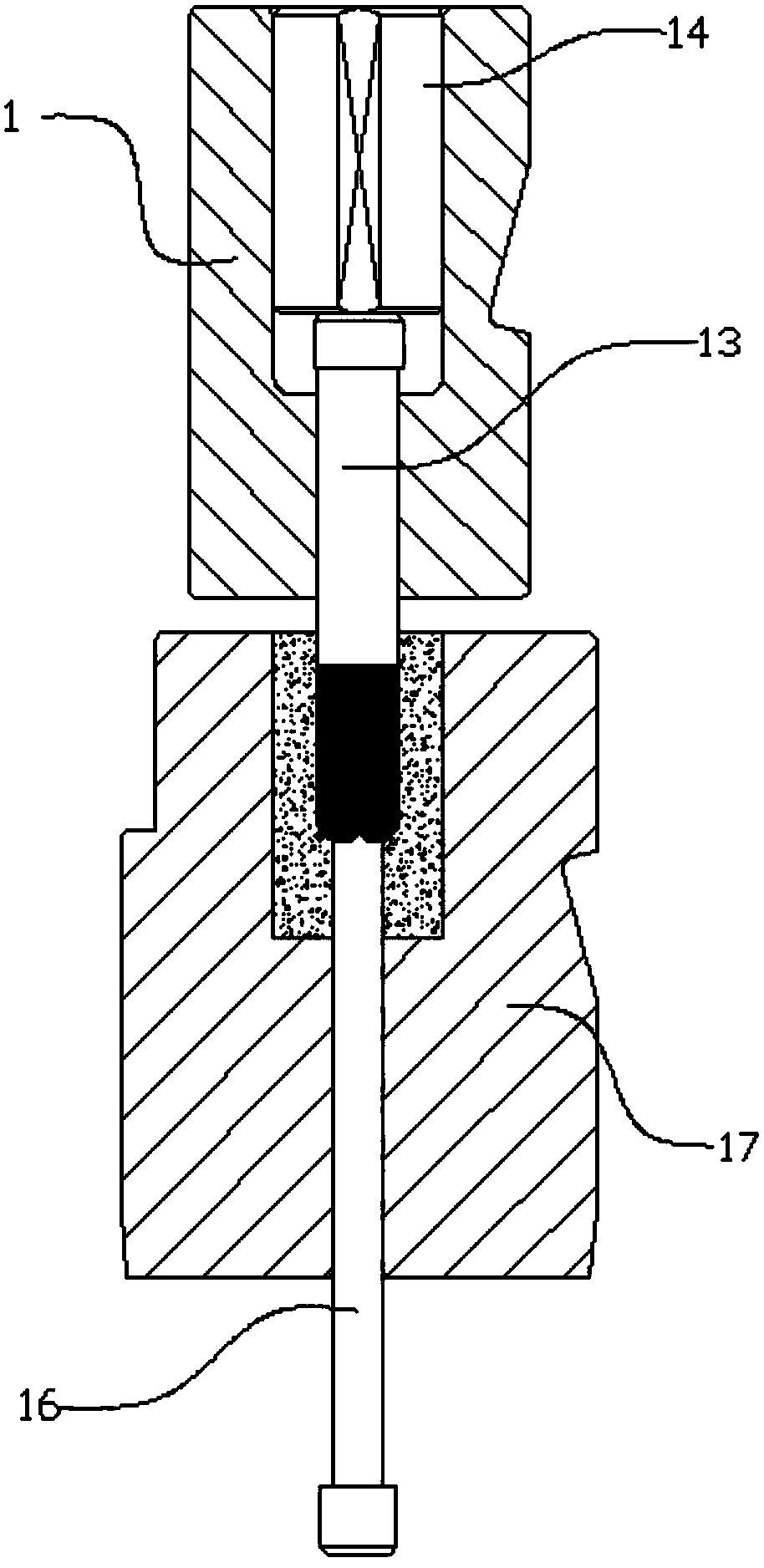

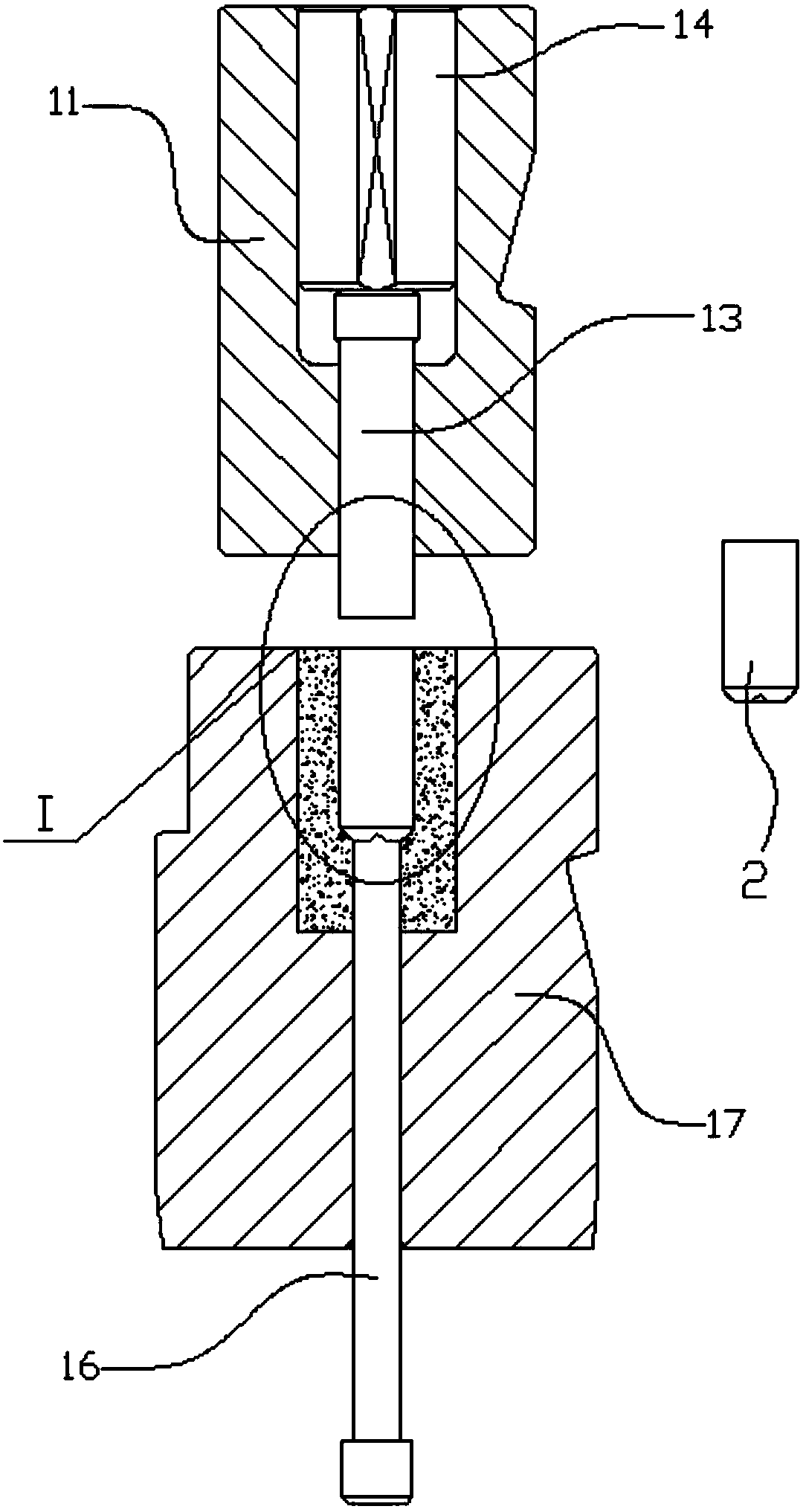

Plastic forming method of semi-hollow shaft pin

ActiveCN105750475AGuaranteed stabilityAvoid the phenomenon of mold collisionForging/hammering/pressing machinesEngine componentsPunchingMachining

The invention discloses a plastic forming method of a semi-hollow shaft pin. The plastic forming method comprises the following steps: step 1, extruding a part blank through a first punching die (1) to obtain needed sizes of a tail filleted corner, a bottom surface tapered hole and a rod part; step 2, extruding a part (2) in the step 1 through a second punching die (3), so as to obtain a needed size of a head pre-formed hole, carry out hole shrinkage and chamfering, and upset the rod part and a head to the needed sizes; step 3, extruding the part (2) in the step 2 through a third punching die (4) to obtain the needed size of the depth of a head hollow hole, and upset the head and the rod part to the needed sizes; and step 4, extruding the part (2) in the step 3 through a fourth punching die (5) to obtain a final size of the depth of the head hollow hole, and upset the head and the rod part to final sizes, so as to meet the shape and size requirements of a final product. The plastic forming method of the semi-hollow shaft pin, disclosed by the invention, is a part cold upsetting machining method which has the advantages of effective hole punching, stability of forming a product, simple procedures, convenience in machining, high material utilization rate and long service life of the die.

Owner:丽水市知源科技有限公司

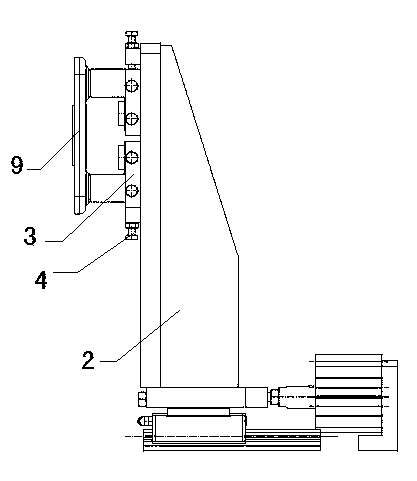

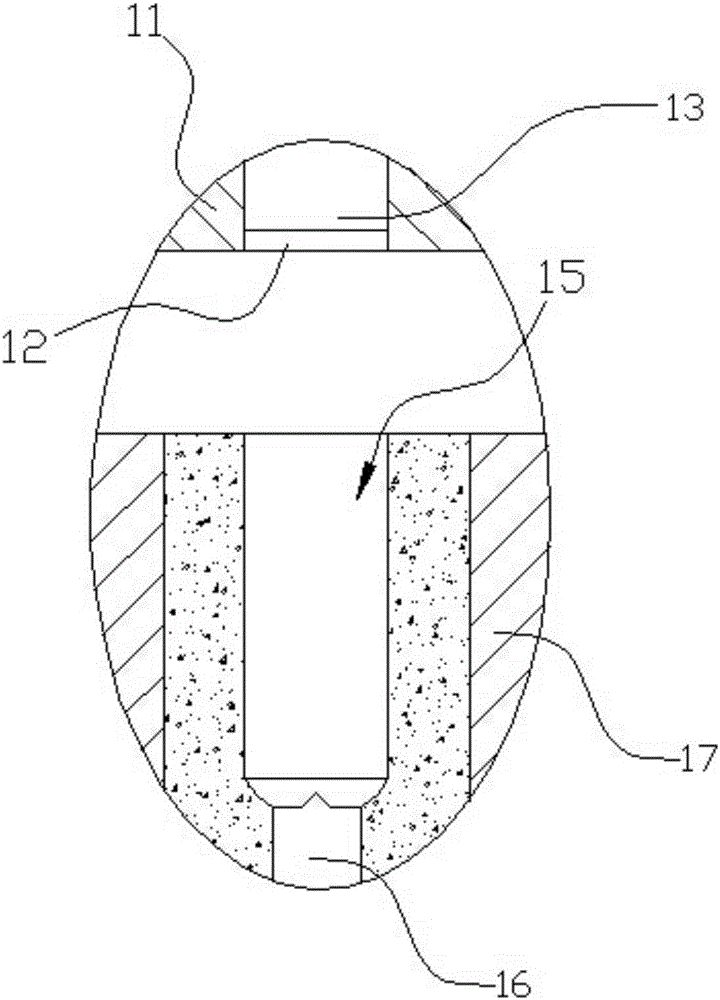

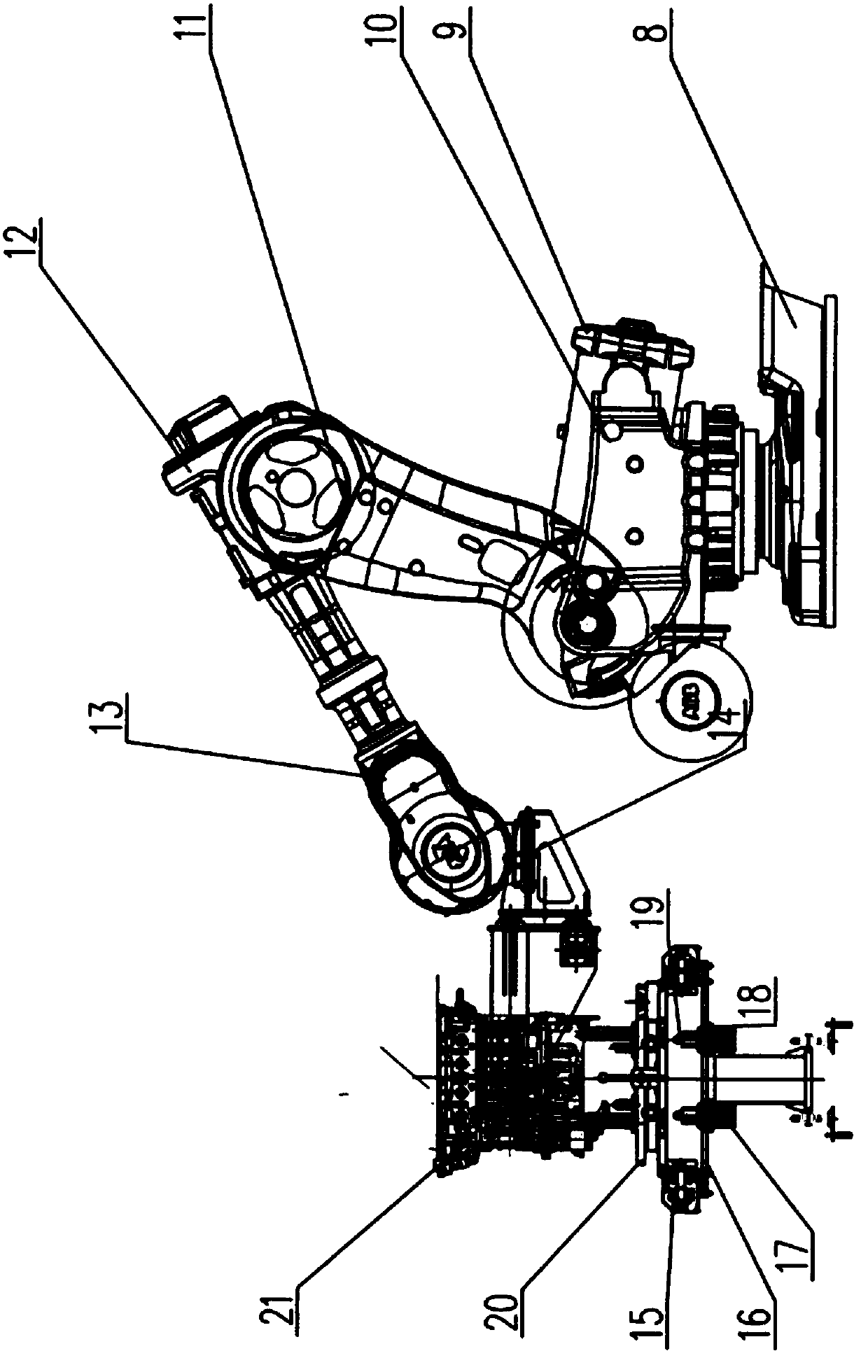

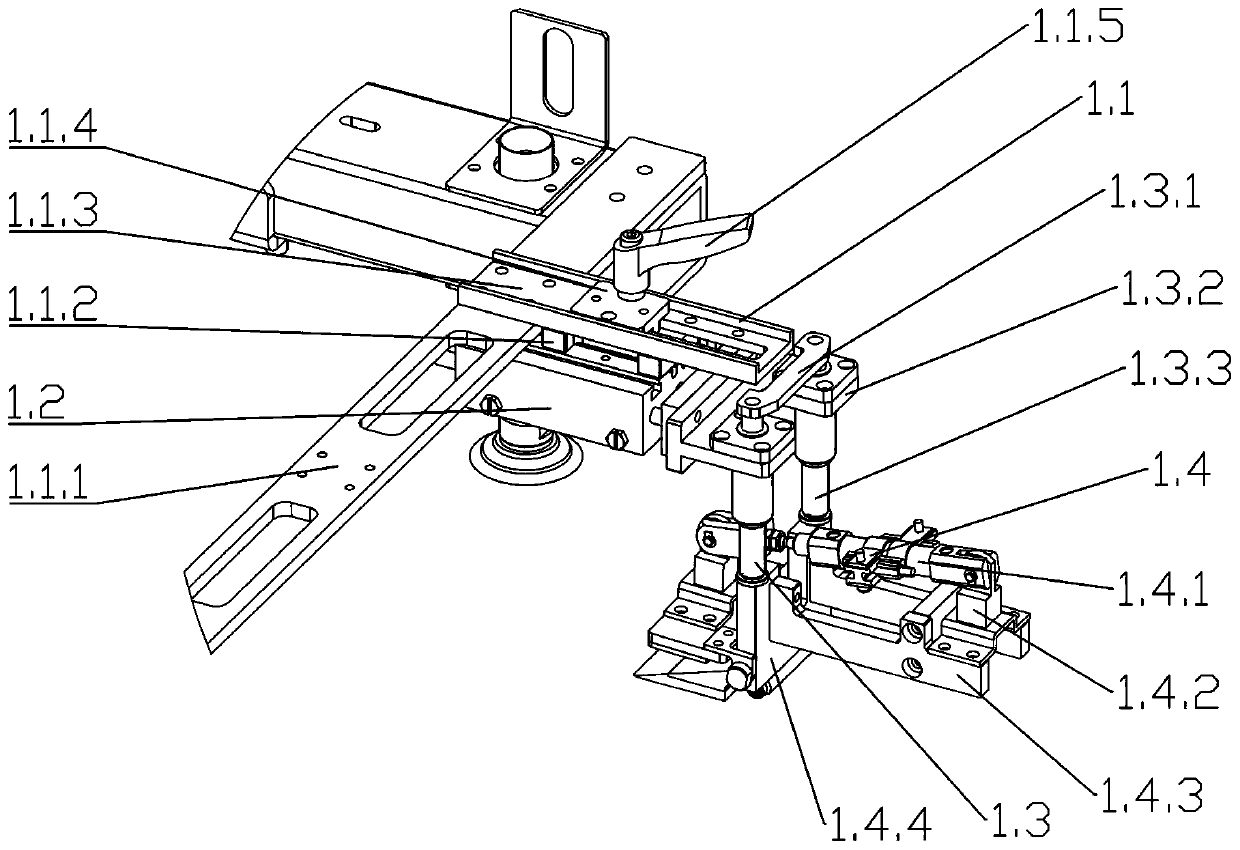

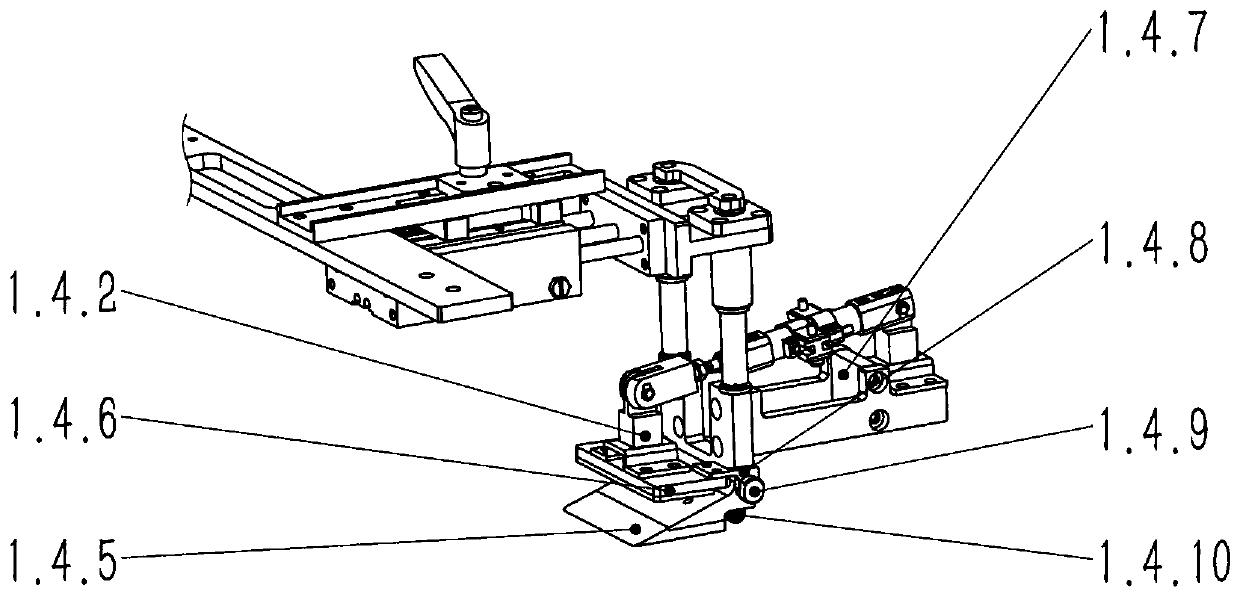

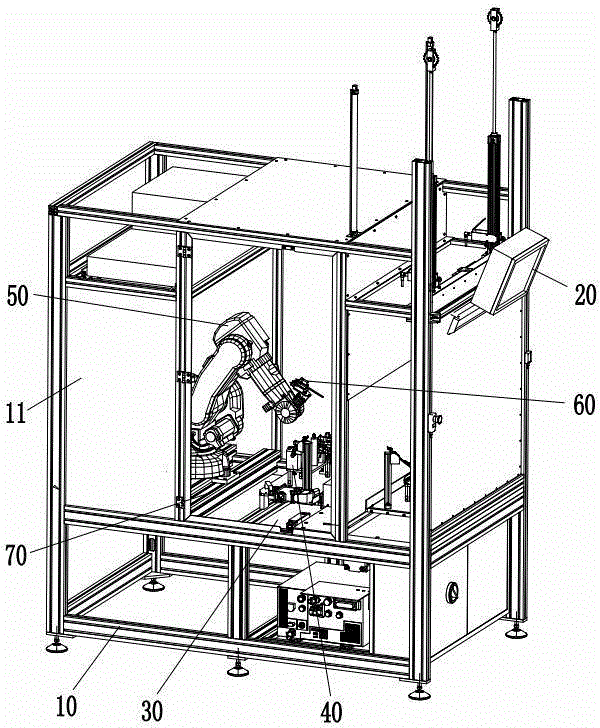

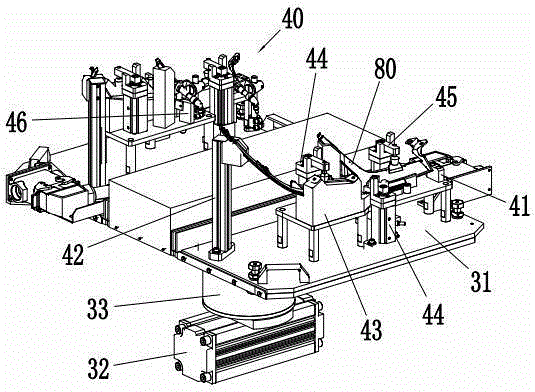

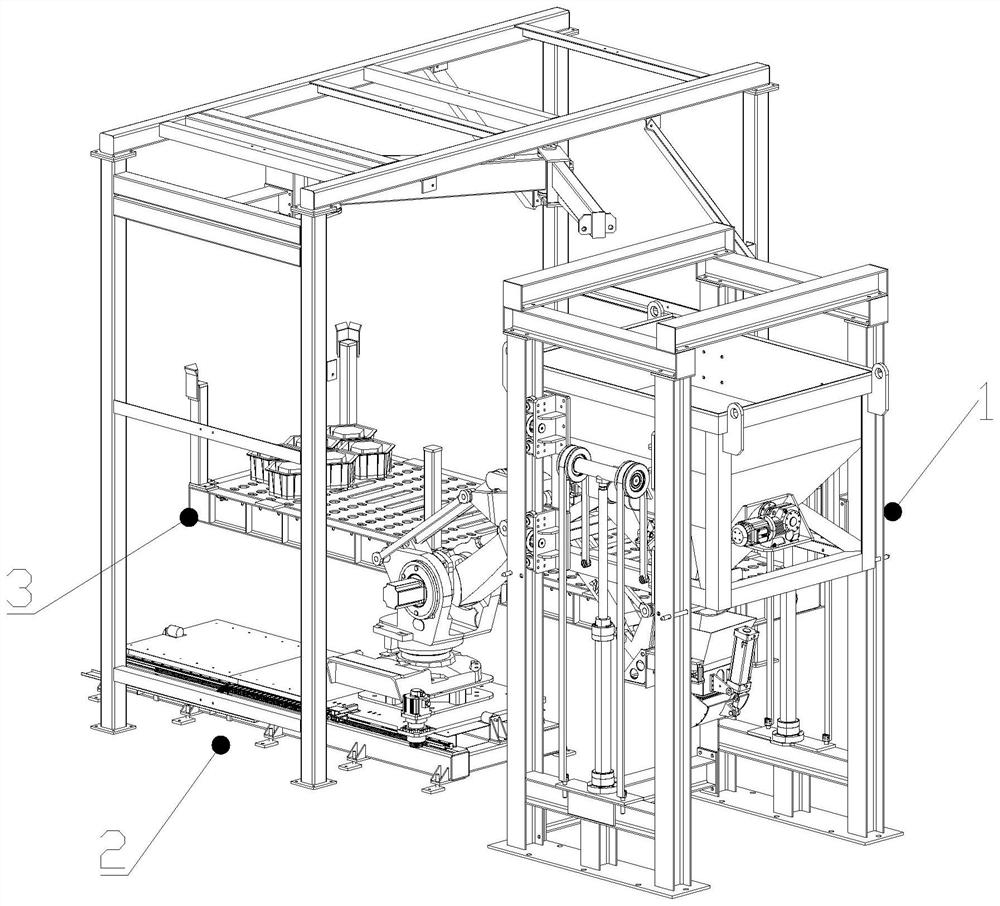

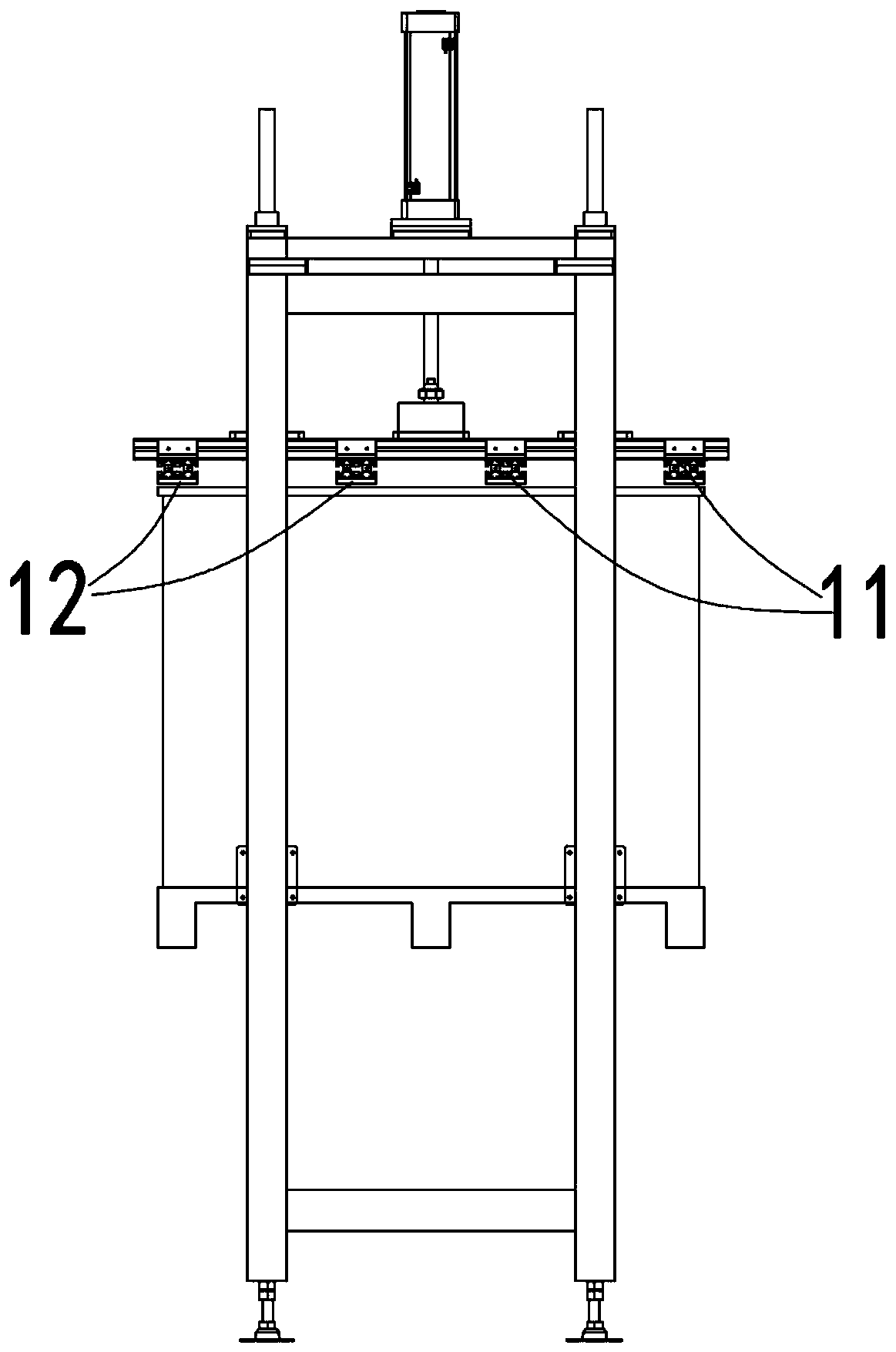

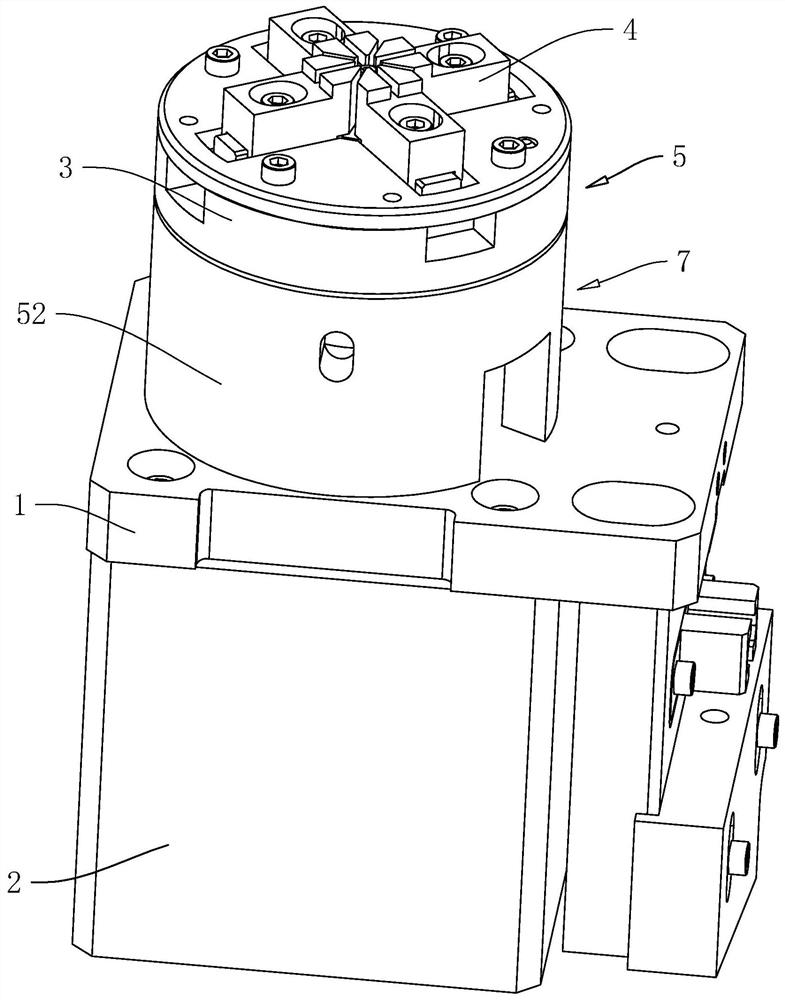

Automatic transplanting, turnover and tightening machine for robot

InactiveCN108015527ASimple structureReduce in quantityMetal working apparatusAutomatic controlEngineering

The invention provides an automatic transplanting, turnover and tightening machine for a robot. The automatic transplanting, turnover and tightening machine comprises a workbench, a workpiece positioning device, a stand column, a first linear guide rail, a second air cylinder, a shaft mounting base, a tightening shaft, a robot base, a buffer oil cylinder, a robot rotary arm, a first robot arm, a second robot arm, a third robot arm, robot claws, a conveying roller way, a first air cylinder mounting plate, a first air cylinder, a shaft sleeve, a dowel pin, a tray, a workpiece, a clamp mounting base, a right arm, a left arm, a third air cylinder, a locking nut, an air cylinder base, a second linear guide rail, a right positioning plate, a left positioning plate, a left dowel pin, a right dowel pin, a servo motor, a first lead screw base, a motor base, a shaft coupler, a first bearing, a rolling ball lead screw, a second lead screw base, a second bearing, a lead screw bracket, a second aircylinder mounting plate and a third linear guide rail. The automatic transplanting, turnover and tightening machine is simple in structure, and automatically controls the whole transplanting, turnover and tightening process through the robot and a mechanical device, so that working efficiency is improved.

Owner:CHANGSHA ZHANSHUO XUANXING INFORMATION TECH CO LTD

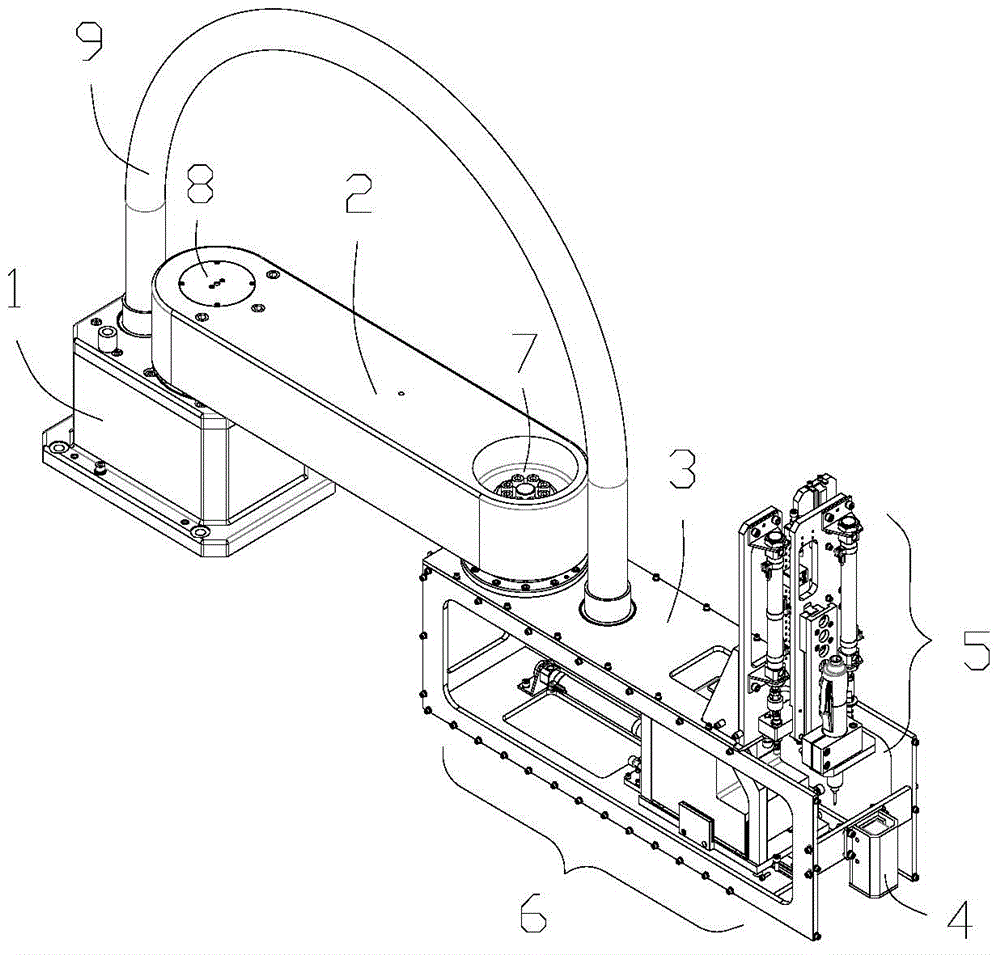

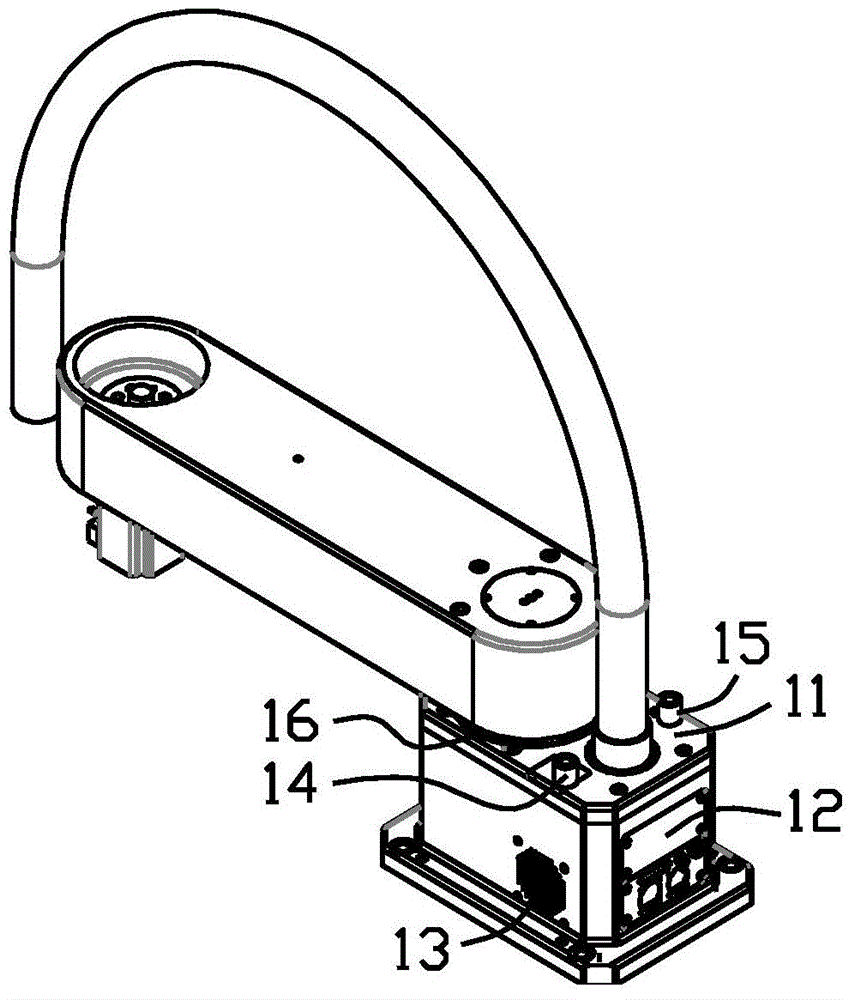

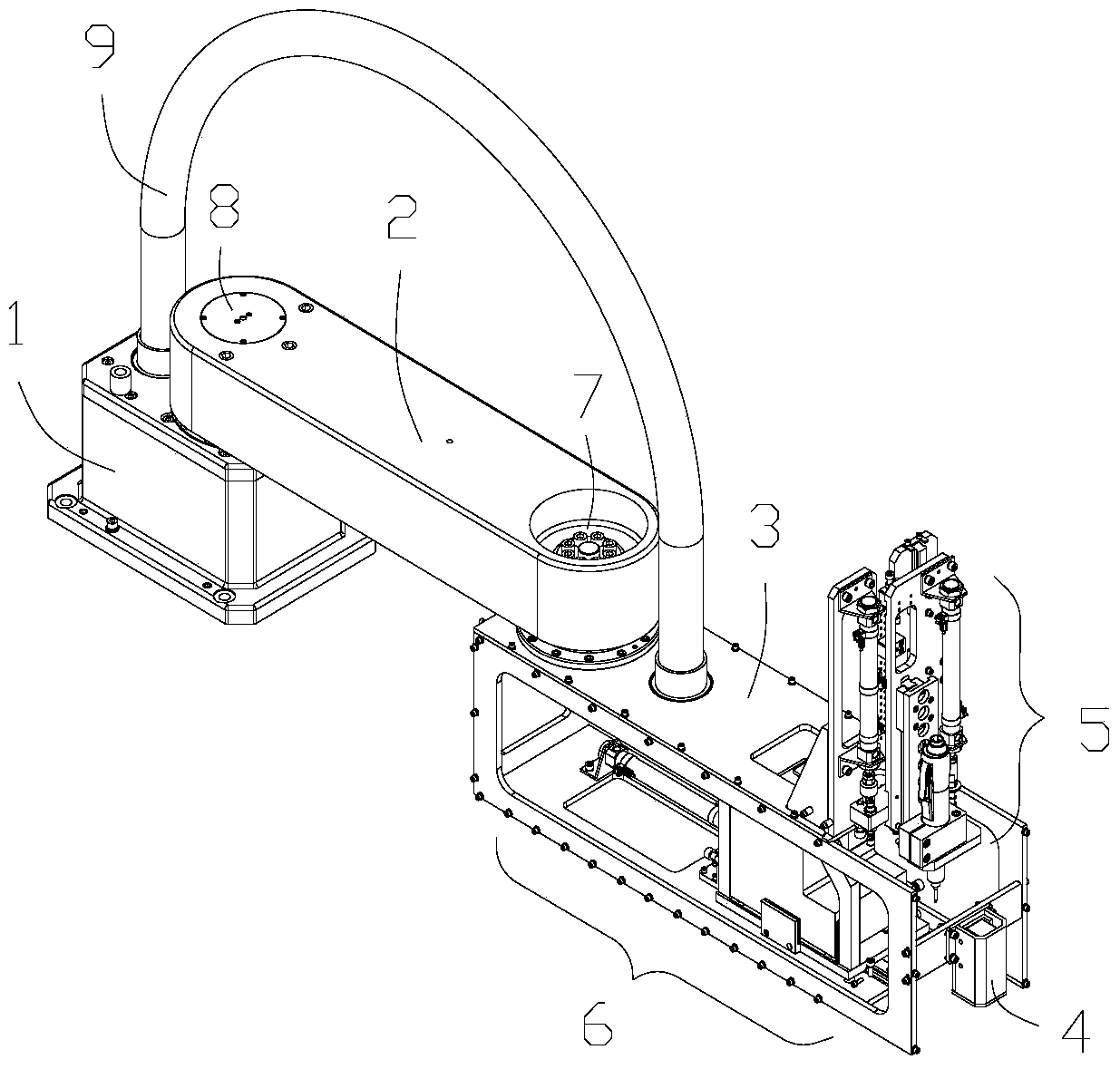

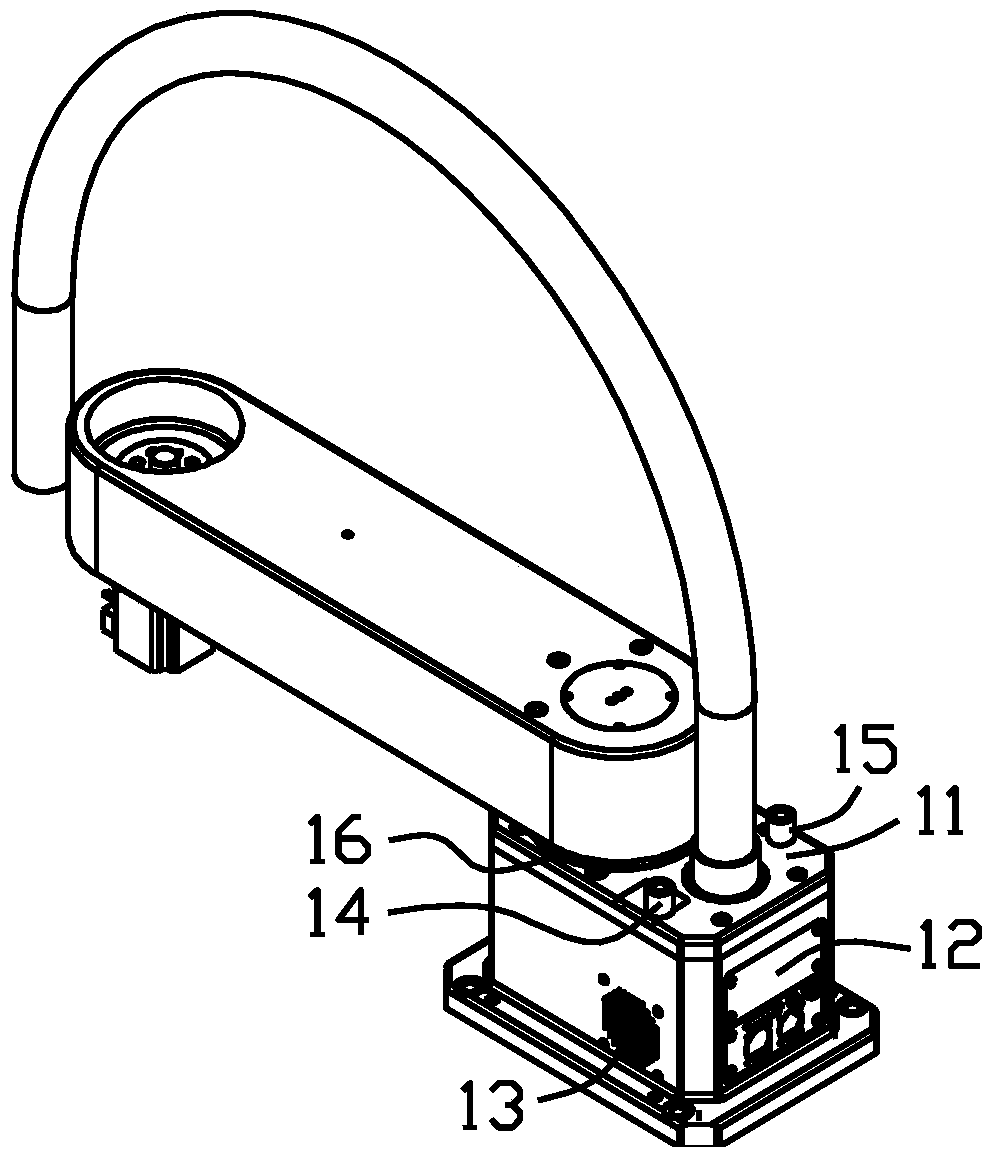

Automatic screw turning device

ActiveCN106584084AReasonable connectionReduce cumbersomeMetal working apparatusWork cycleMechanical equipment

The invention belongs to the field of automatic mechanical equipment, and particularly relates to an automatic screw turning device. The automatic screw turning device comprises a base, a big arm and a small arm. One end of the big arm is mounted at the upper end of the base, and the other end of the big arm is connected with the small arm. The base and the big arm are flexibly connected through a second motor, and the big arm and the small arm are flexibly connected through a first motor. A wiring hose is arranged between the base and the small arm. A screw supply mechanism is arranged at the lower end of the small arm, a screw turning mechanism is arranged at the upper end of the small arm, and a visual camera is arranged at the front end of the screw turning mechanism. Mechanical locating is utilized in the mechanisms, locating is accurate, and complexity brought by electric control is reduced; and the screw turning mechanism only ascends and descends vertically, the screw supply mechanism only advances horizontally, a servo air cylinder structure is adopted, implement is easy, cost is low, in addition, the distance between the screw turning mechanism and the screw supply mechanism is short, space position switching is flexible, and the work cycle can be improved easily.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION +1

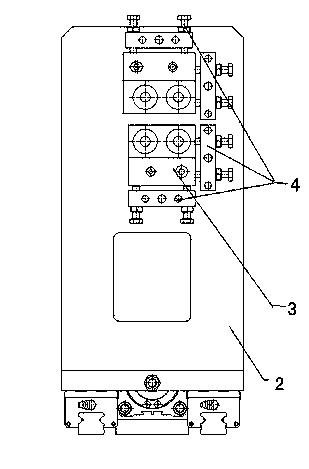

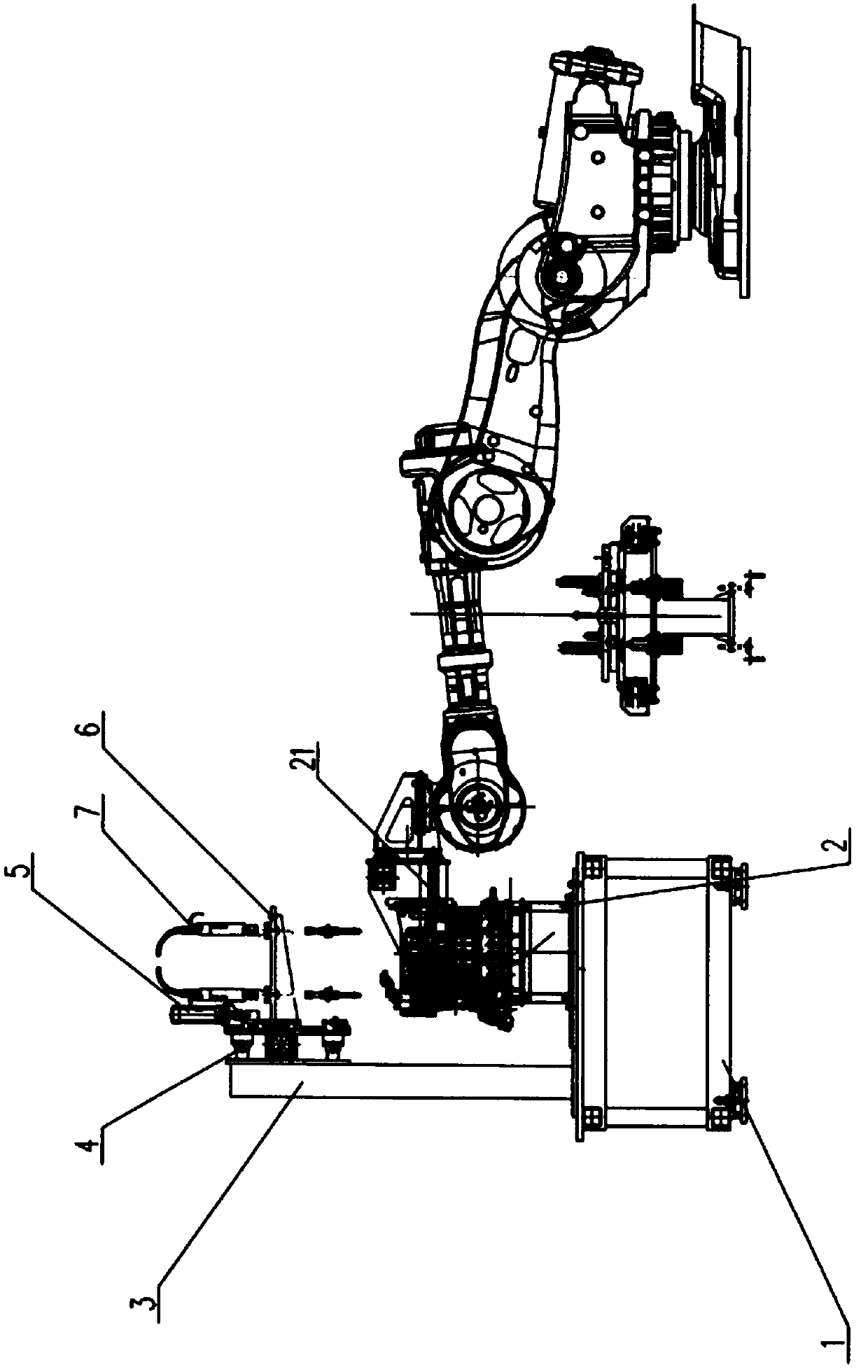

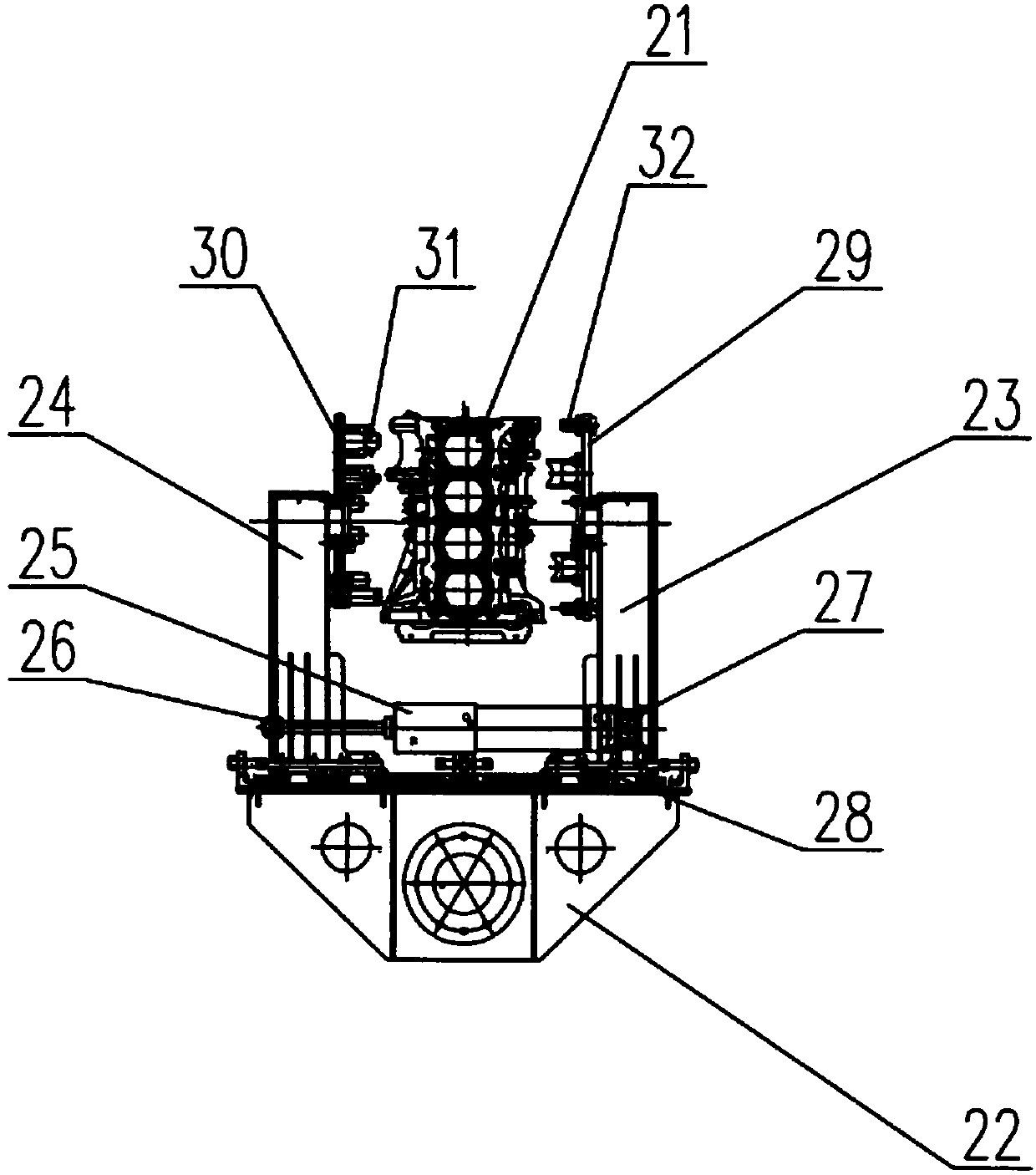

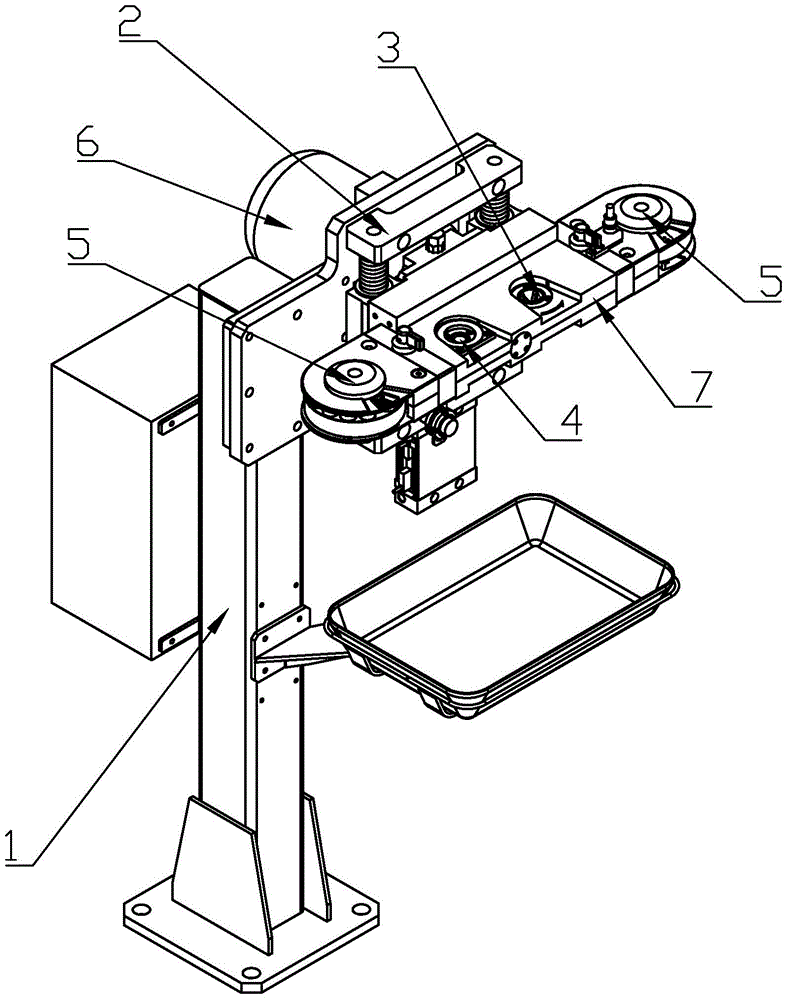

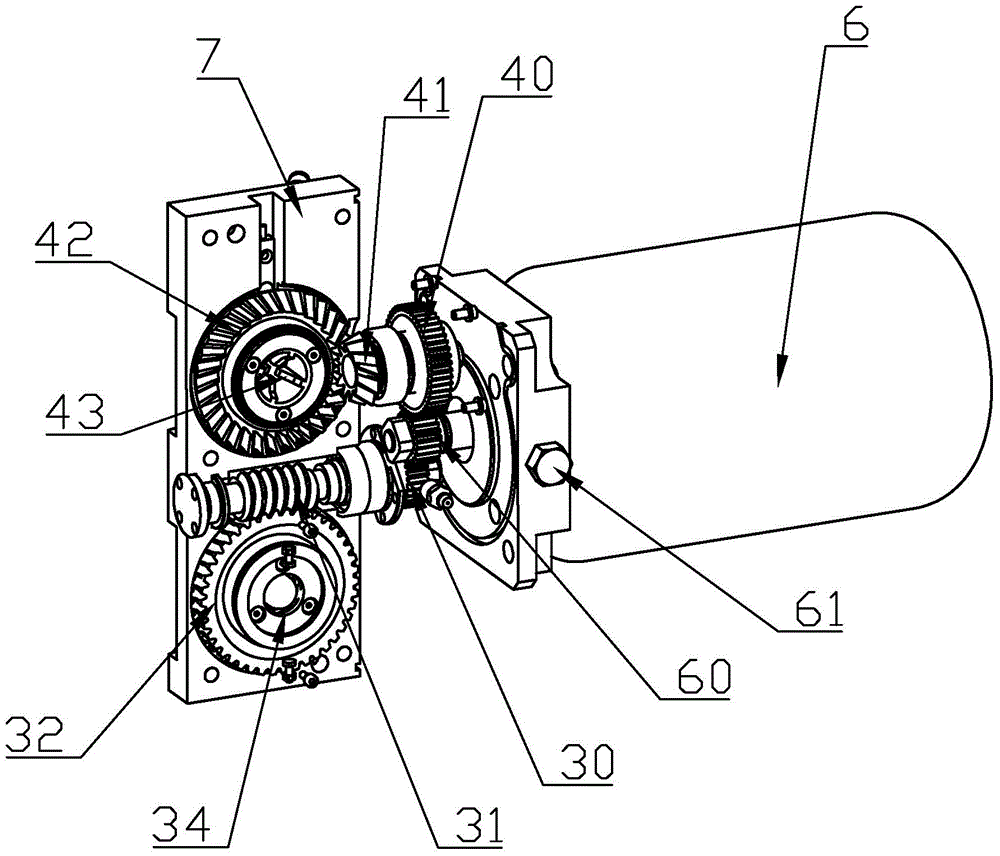

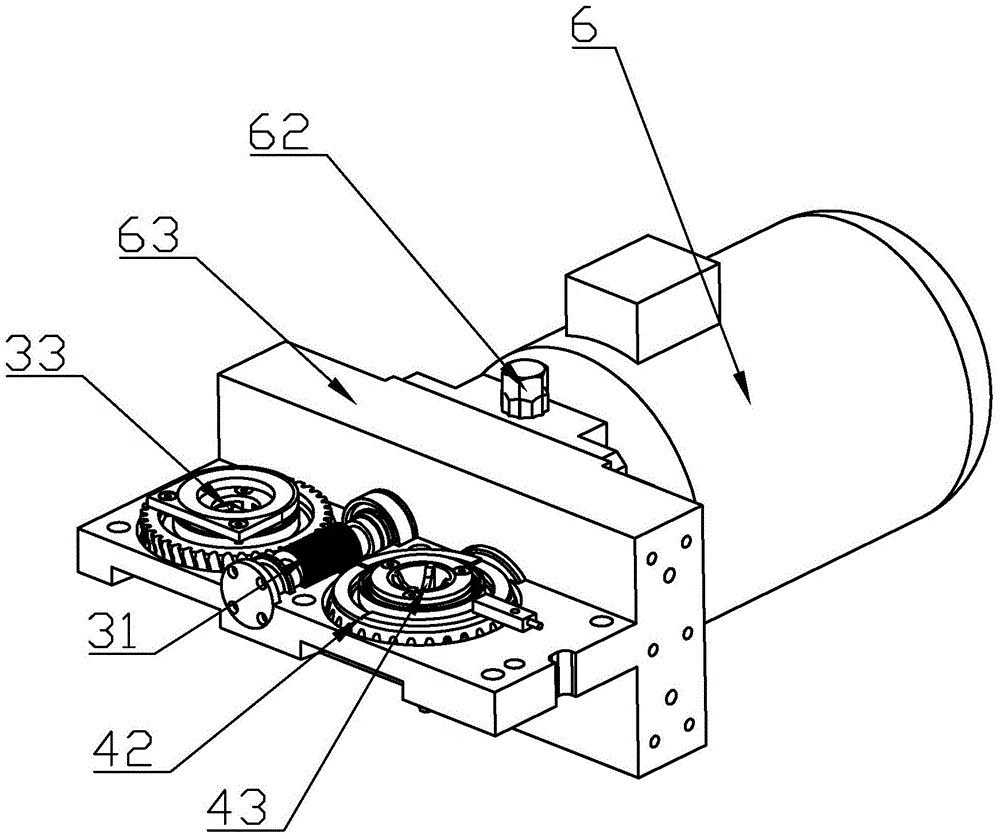

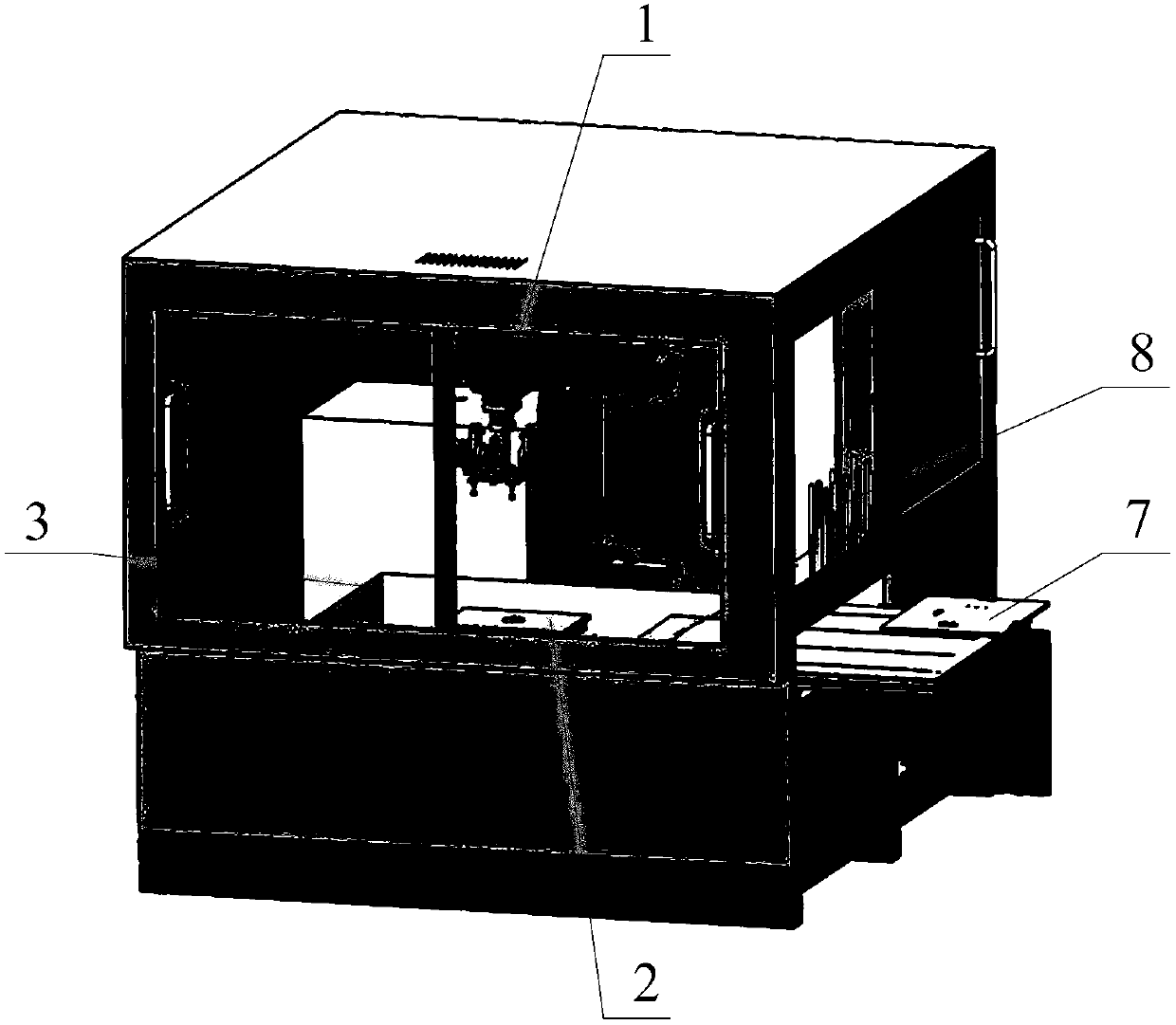

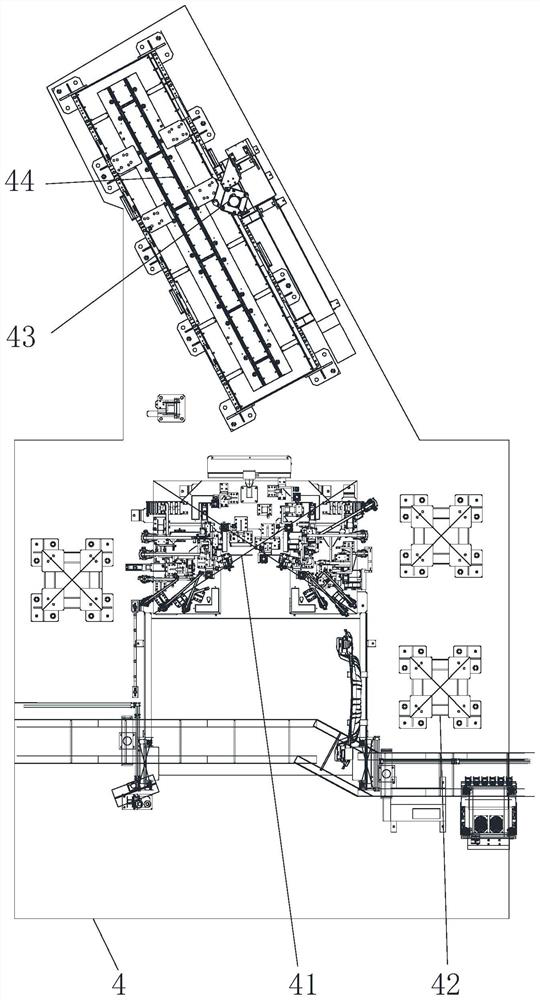

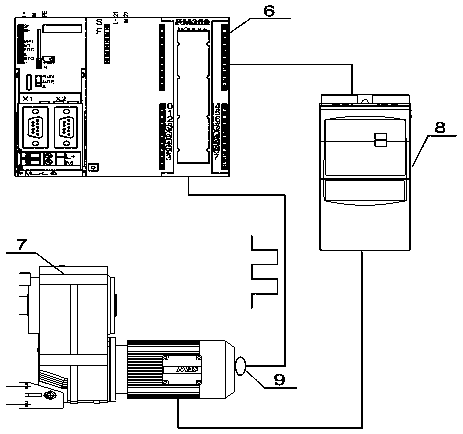

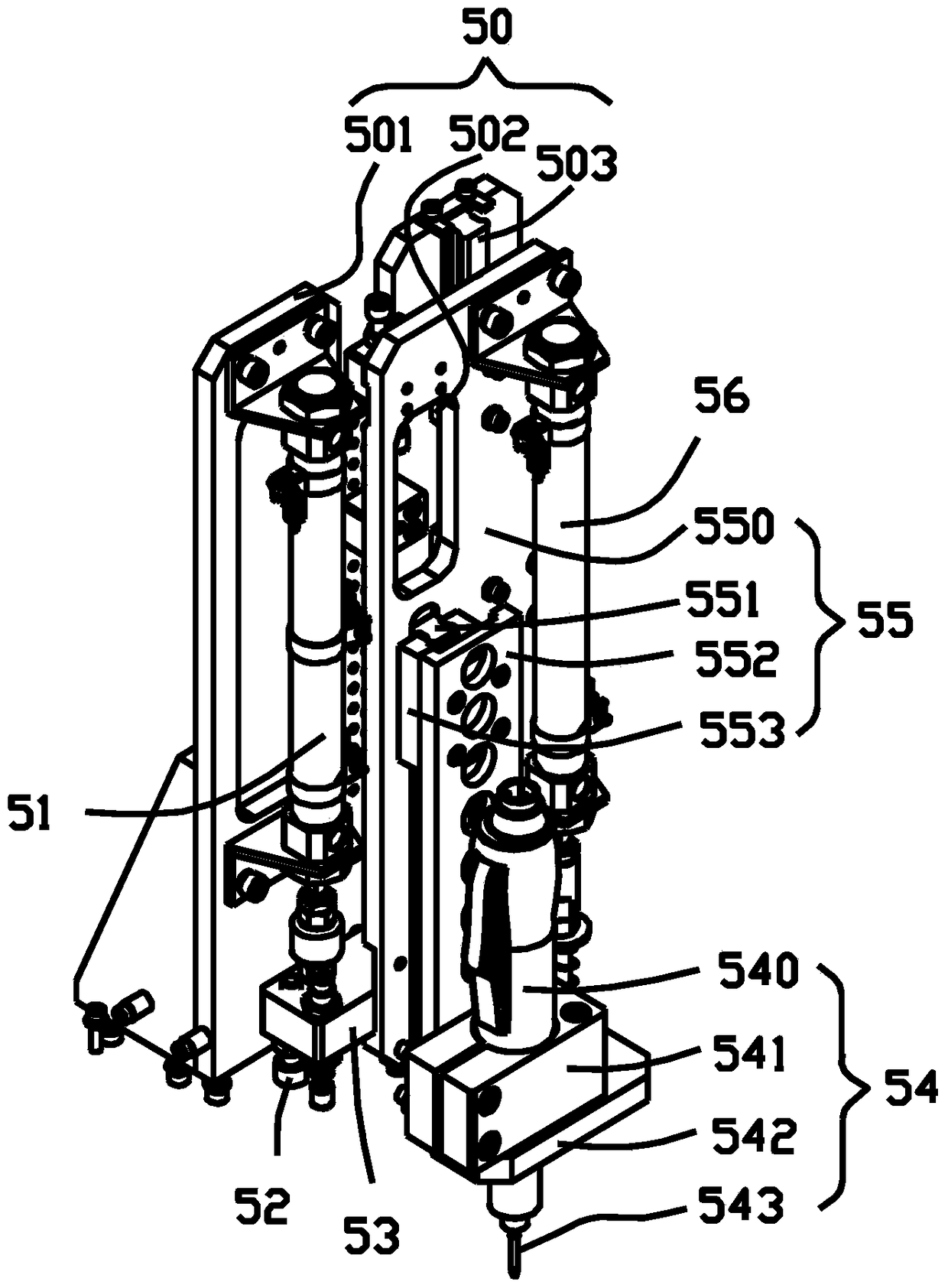

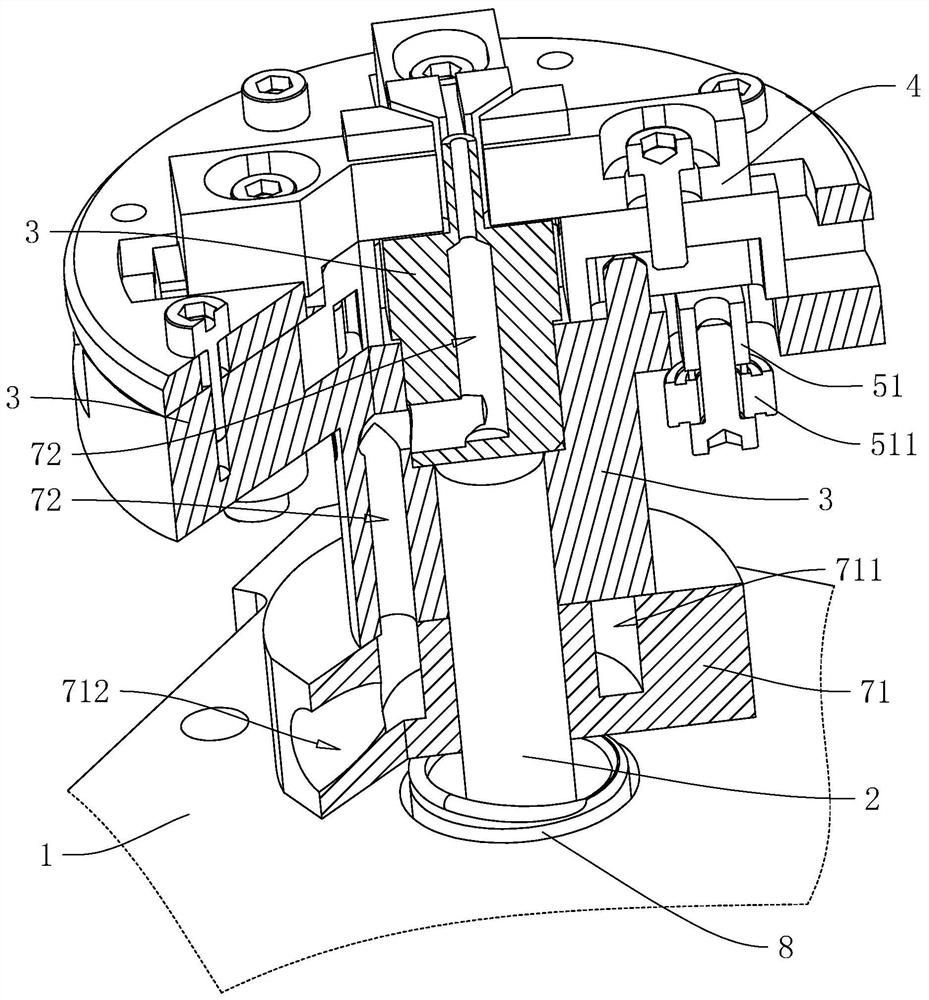

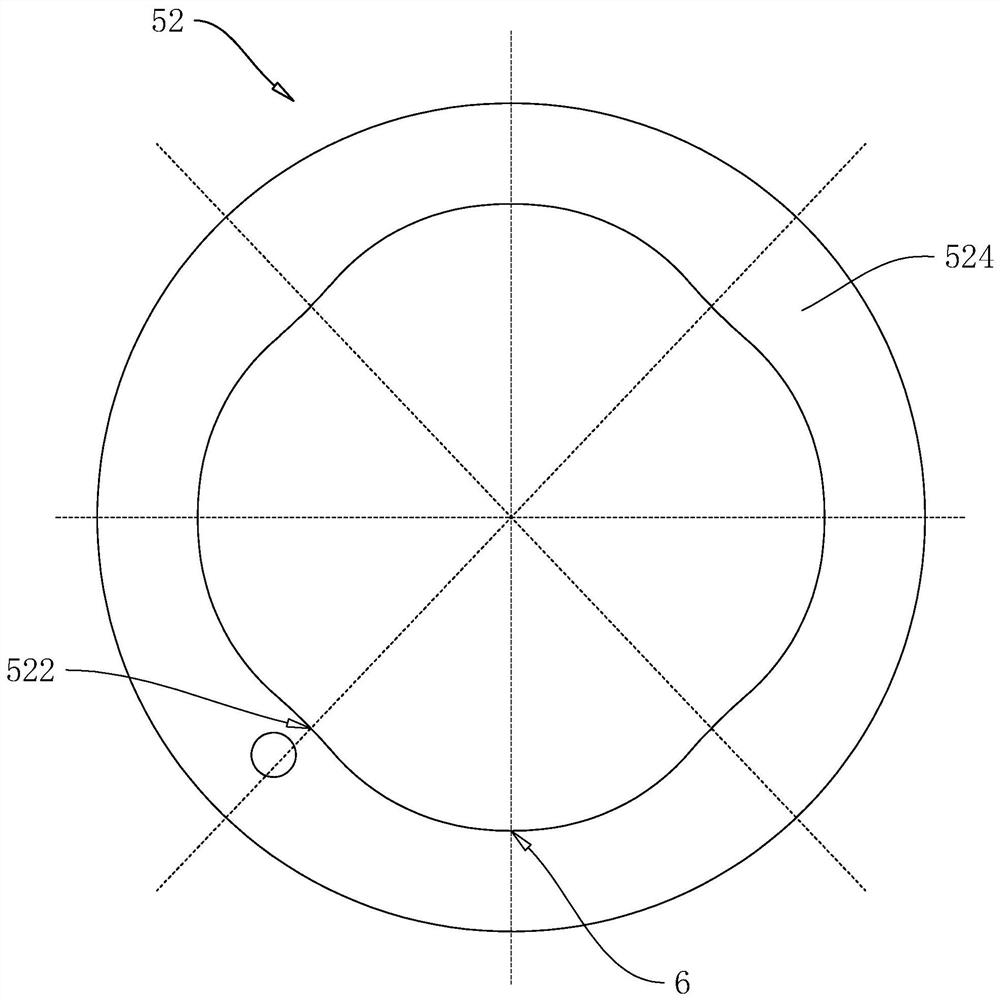

Electrode Grinding and Cap Changing Machine

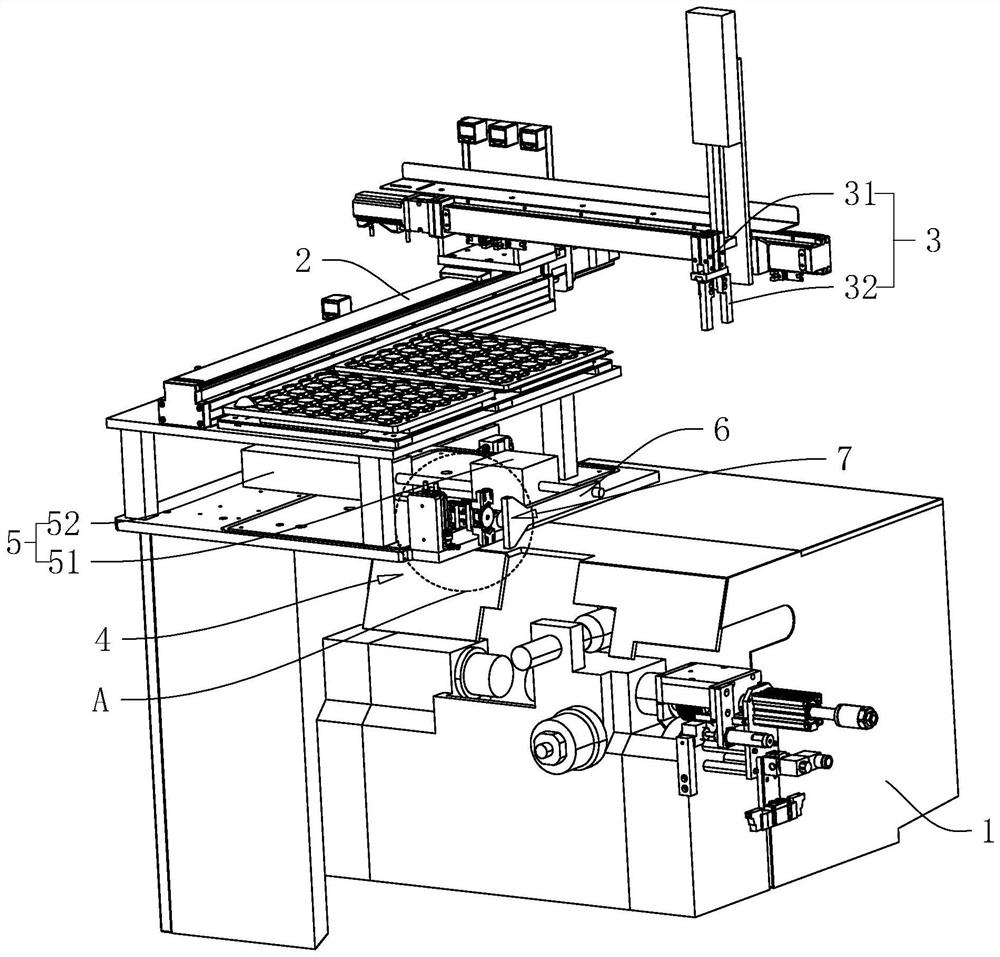

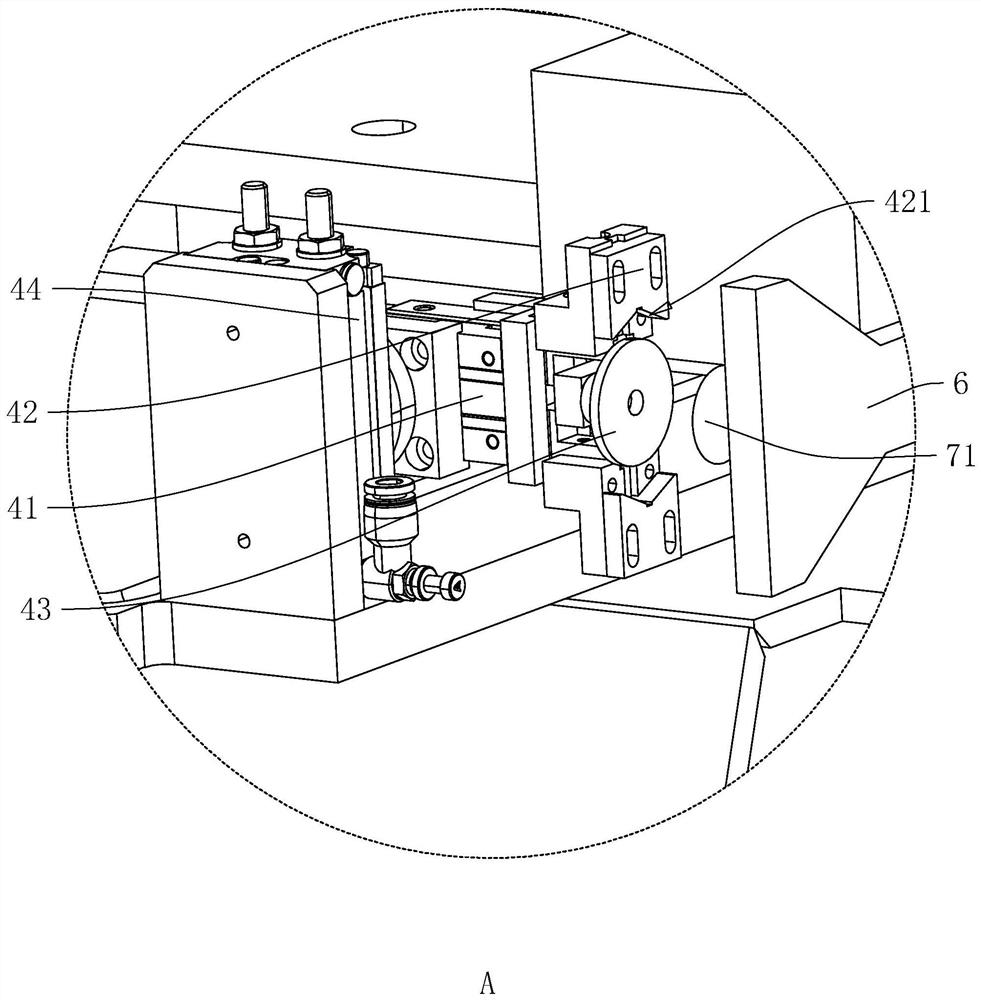

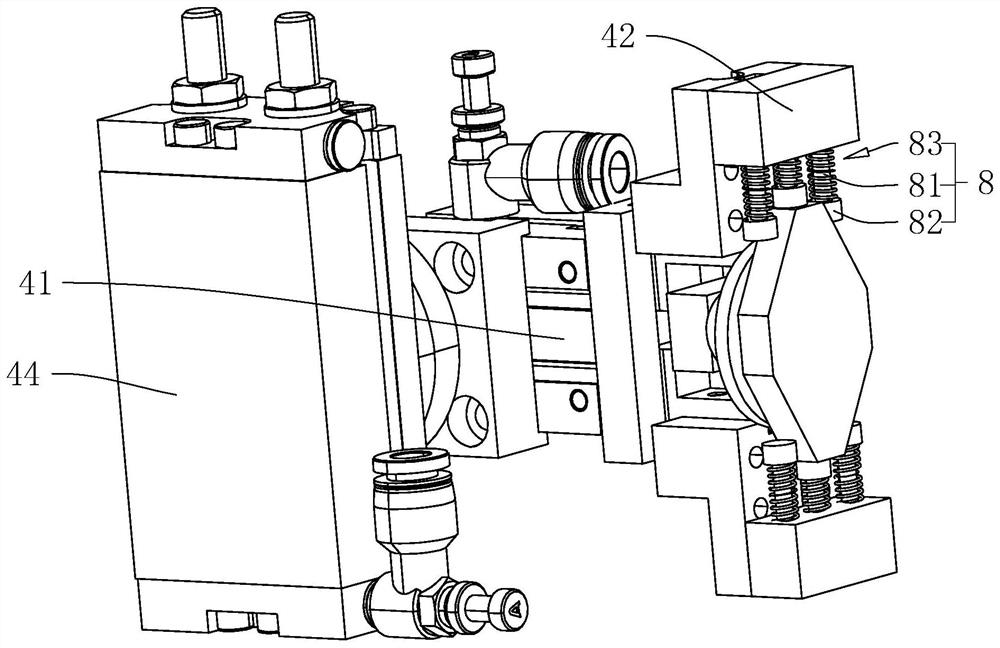

ActiveCN104002218BGuaranteed uniformityImprove work tempoGrinding machinesMetal working apparatusControl systemElectric machinery

The invention discloses an electrode cap coping-replacing all-in-one machine which comprises a machine frame, a driving motor and a balance floating unit. The driving motor and the balance floating unit are arranged on the machine frame. The output end of the driving motor penetrates through the balance floating unit and then is connected with a workbench. A cap detaching unit and a cap repairing unit are arranged on the two sides of a workbench. Electric cap storing units are arranged at the outermost ends of the two sides of the workbench. Electrode cap coping and replacing are completed in one device, and the two functions are achieved through the driving motor. The technical problem of manual line stopping cap replacing in a car production line is solved, and meanwhile the problem that if cap coping and cap replacing are separated, the occupied space of two machines is too large is solved. Electric cap coping and replacing are completed in a full-automatic mode, the takt of the car welding production line is obviously improved, the capacity of the production line is improved, and the electrode cap coping-replacing all-in-one machine is suitable for the car welding production line high in automation degree.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

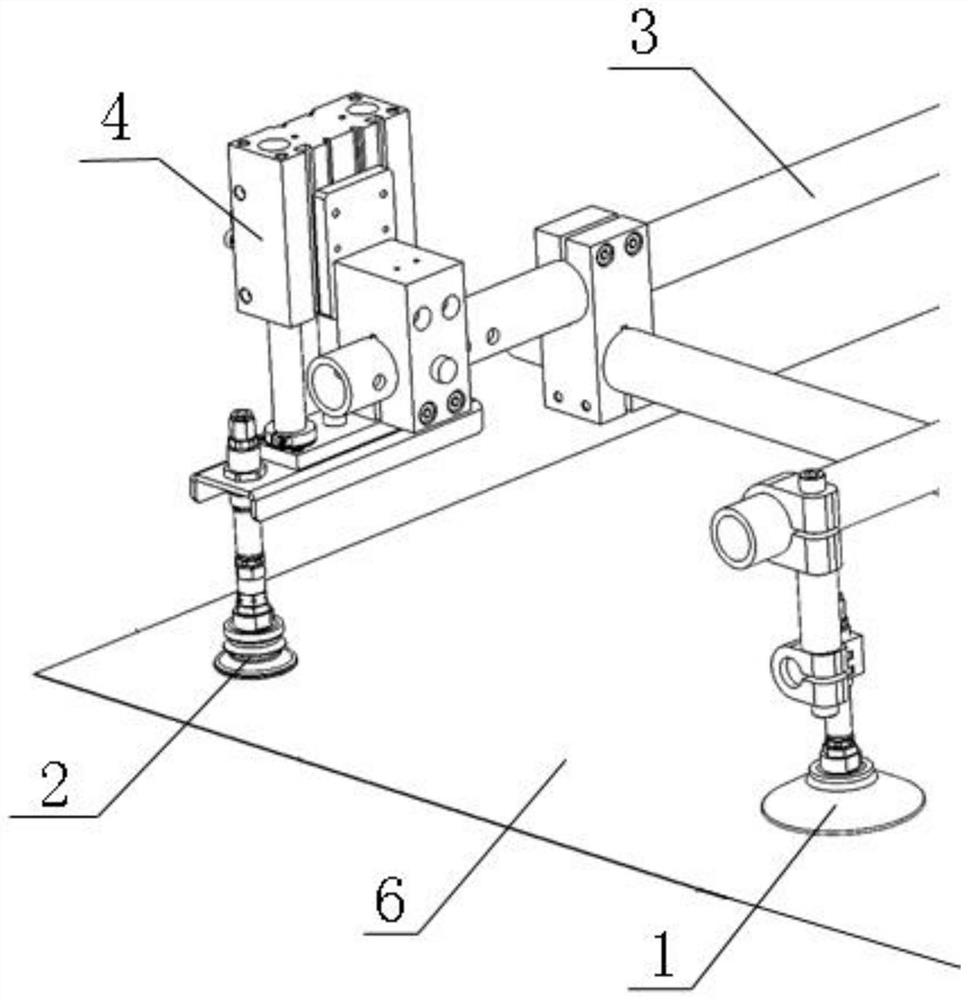

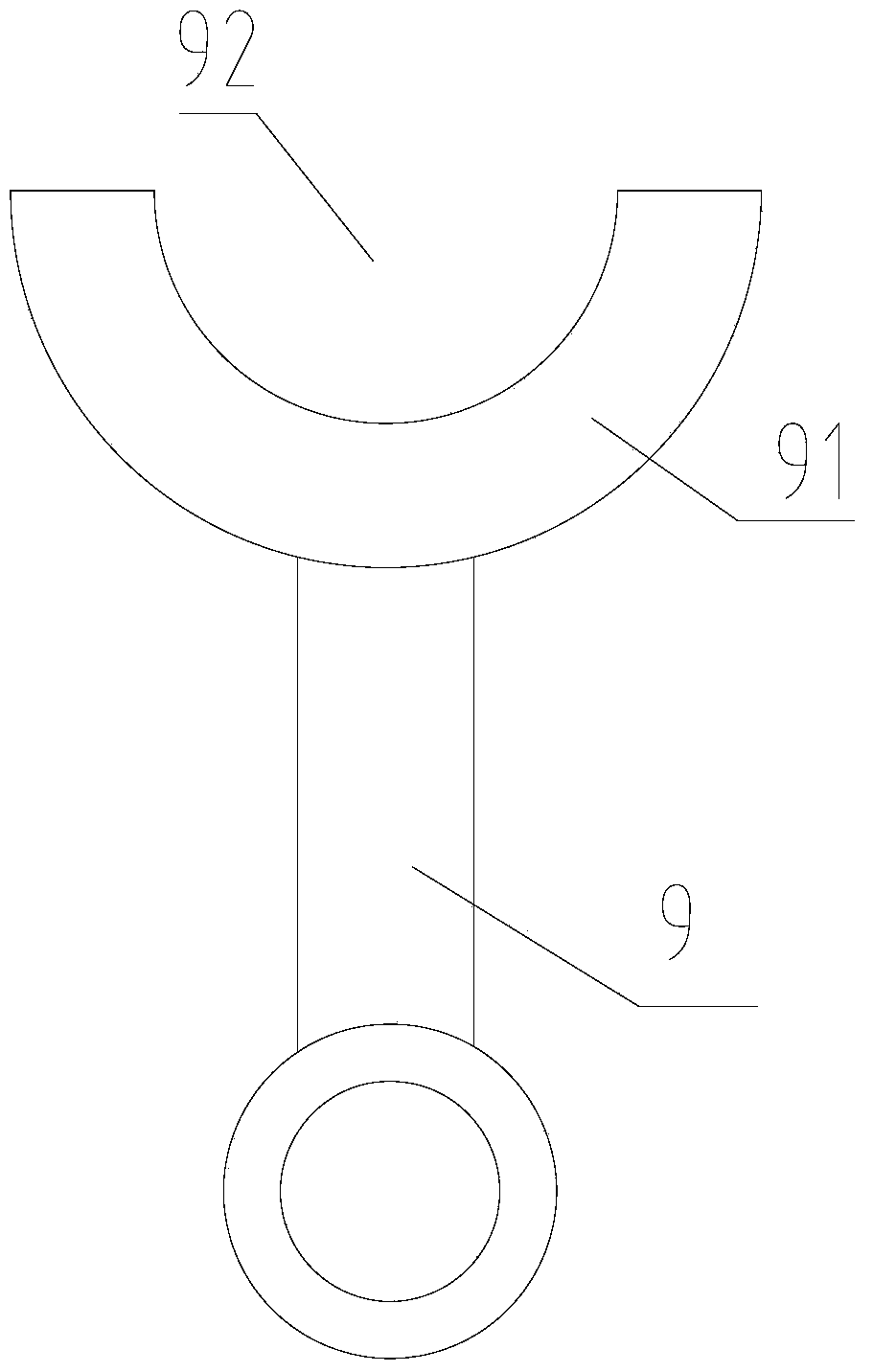

Non-magnetic sheet separation robot clamp and separation method

PendingCN112478841AReduce manufacturing costImprove work tempoArticle separationControl engineeringProcess engineering

The invention discloses a non-magnetic sheet separation robot clamp and a separation method, and belongs to the technical field of automatic equipment. The clamp comprises a movable pipe frame, a plurality of first suckers and a plurality of second suckers. The movable pipe frame can reciprocate in the thickness direction of a sheet. The first suckers are fixedly arranged on the movable pipe frame, and adsorption areas of the first suckers face the sheet. The second suckers are movably arranged on the movable pipe frame and can reciprocate relative to the movable pipe frame in the thickness direction of the sheet, and adsorption areas of the second suckers face the edge of the sheet. According to the non-magnetic sheet separation robot clamp and the separation method, the production and manufacturing cost is low, the separation cost between sheets can be effectively reduced, then the working rhythm of a robot is improved, and the automatic production level of the robot is improved.

Owner:SHANGHAI FANUC ROBOTICS

Grinding work station and method for generating machining tracks thereof

ActiveCN108161660AMeet special processing needsImprove machining accuracyGrinding feed controlAutomatic grinding controlEngineeringWorkstation

The invention provides a grinding work station and a method for generating machining tracks thereof. The grinding work station comprises a jig, a water tank, four measuring equipment and a guider, wherein the four measuring equipment are arranged at four corners of the water tank respectively, the tail parts of first wire drawing sensors are connected with the tail parts of second wire drawing sensors through rotating shafts, hooks of the first wire drawing sensors are connected to a first point of the guider, and hooks of the second wire drawing sensors are connected to a second point of theguider. According to the grinding work station and the method for generating the machining tracks of the grinding work station, four sets of measuring equipment are arranged, and two wire drawing sensors are arranged in each set of measuring equipment, one hook is selected from each measuring equipment to form a set and is hung at the first point of the guider, the other hook in each measuring equipment is hung at the second point of the guider, and when the guider moves, the two points are used for generating two sets of machining tracks and vectors required by grinding on the tracks, and after the generated tracks are machined, a robot grinding execution program is formed.

Owner:CHONQING HUASHU ROBOT CO LTD

High-speed weighing scale

InactiveCN105241530AImprove work tempoImprove work efficiencyWeighing apparatus for continuous material flowEngineeringLoad cell

The invention relates to a high-speed weighing scale, which is characterized by comprising a first support and a second support arranged independently, wherein a first belt conveyor is arranged on the first support; a second belt conveyor is arranged on the second support; two ends of the first belt conveyor are provided with a first cylinder and a second cylinder; a first conveyor belt is arranged around the first cylinder and the second cylinder; four corners of the first support are respectively provided with sensor mounting blocks; sensor connection blocks in one-to-one correspondence with the sensor mounting blocks are arranged at four corners of the first belt conveyor; a weighing sensor is arranged between each sensor mounting block and the corresponding sensor connection block; and a weighing block is arranged at the bottom part of the first belt conveyor. When a former product leaves, the next product can be ensured to be weighed, the work rhythm is increased, the work efficiency is improved, measurement errors during the weighing process are reduced, and the measurement accuracy is improved.

Owner:WUXI KING CONTROL INSTR

Automatic cross-belt bagging system and bagging method thereof

PendingCN112373743ASimple structureReduce operating energy consumptionWrapper twisting/gatheringSolid materialStructural engineeringProcess engineering

The invention discloses an automatic cross-belt bagging system and a bagging method thereof. The automatic cross-belt bagging system comprises a cross-belt sorting loop line, wherein at least one sideof the cross-belt sorting loop line is provided with a sorting grid opening; a discharging opening of the sorting grid opening is provided with an automatic opening and closing door; a first conveyoris arranged below the discharging opening of the sorting grid opening; a discharging hopper is arranged at one end of the first conveyor; and a packaging bag carrying table is arranged below a discharging opening of the discharging hopper. According to the scheme, by arranging the sorting grid openings with the automatic opening and closing doors, certain goods can be conveyed to a first conveying line in batches so as to be bagged in batches after being stored, and sealing is conducted through an automatic sealing machine after batch bagging, so that a plurality of small objects can be effectively packaged into a large object; and meanwhile, the sizes of the packaged large objects are equal, so that transportation is facilitated, stacking is also facilitated, the utilization rate of a carriage space during loading is increased, the stacking frequency is reduced, and the efficiency is improved.

Owner:SUZHOU GP LOGISTICS SYST

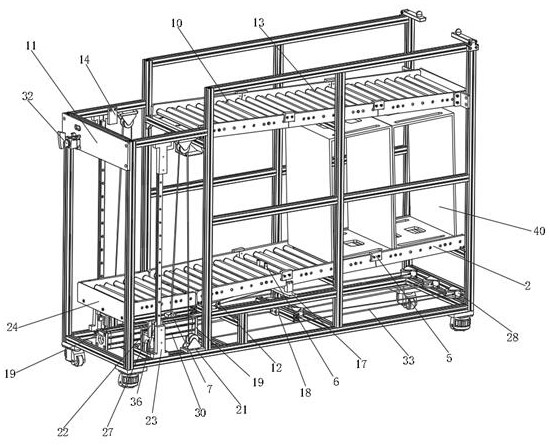

Carrying device

PendingCN111115270AReduce manual layingProcedures to reduce manual laying of dunnageCharge manipulationConveyor partsMechanical engineeringIndustrial engineering

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

Efficient film-wrapping device for glass fiber yarn rolls

ActiveCN112520108AEfficient wrapping workImprove work tempoWrapping material feeding apparatusConveyor wrappingGlass fiberYarn

The invention provides an efficient film-wrapping device for glass fiber yarn rolls. The efficient film-wrapping device comprises a fixed rack, a charging conveying mechanism, a film wrapping mechanism and a discharging conveying mechanism, wherein the charging conveying mechanism, the film wrapping mechanism and the discharging conveying mechanism are mounted under the fixed frame; the film wrapping mechanism is arranged between the charging conveying mechanism and the discharging conveying mechanism; lifting platforms are separately arranged on the charging conveying mechanism, the film wrapping mechanism and the discharging conveying mechanism so as to realize the phenomenon that simultaneous descending of the charging conveying mechanism and the discharging conveying mechanism can be achieved when the film wrapping mechanism is lifted and film wrapping is performed; and the transportation of the charging conveying mechanism needs the film-wrapped glass fiber yarn rolls, and the discharging conveying mechanism transports the glass fiber yarn rolls which are already subjected to film wrapping completely to the outside of the device, so that the time overlapping of charging, discharging and film wrapping operations can be realized, the working beats are effectively quickened, and the whole film wrapping effect is more efficient.

Owner:BEIJING TTSF TECH

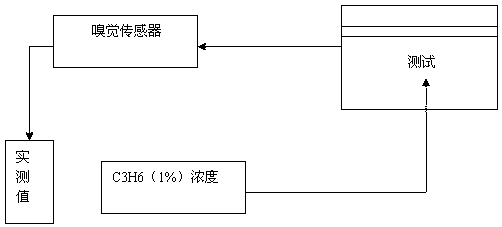

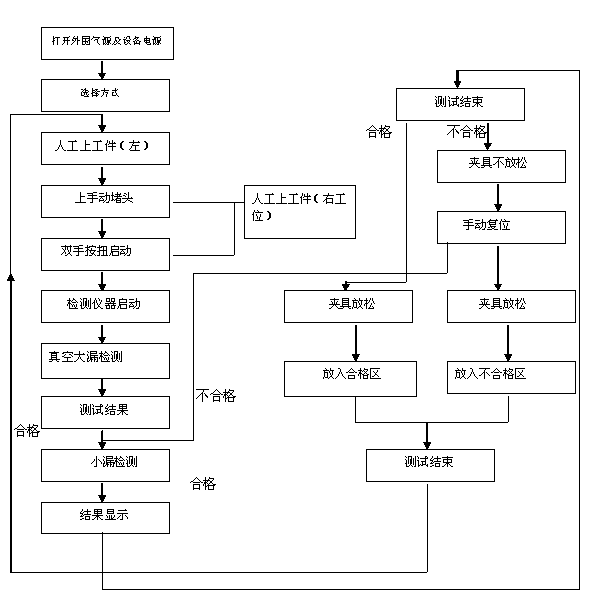

Method for measuring leakage of propylene

InactiveCN103048089AEasy to observeShorten the timeFluid-tightness measurement using fluid/vacuumMeasuring instrumentData acquisition

The invention provides a method for taking propylene for a commercial automatically-mounted fuel distributing pipe as a driving source, and conducting online airtight leakage amount detection by manufacturers. According to the method, the measurement is conducted through a smell sense sensor and an ATEQT520 measuring instrument by adopting the propylene as a driving source. The measuring instrument is used for determining the leakage upper limit and judging whether the qualification is achieved, the smell sense sensor is used for detecting a detected part in a sealing cover in real time. In the whole process, the leakage amount is displayed on a panel of a data collector in a manner of a two-dimensional curve so as to facilitate observation of an operator and conduct judgment on the maximum leakage amount. The testing pressure is 500KPa and adjustable; and the leakage amount standard is 0.00138Ncc / s. The equipment adopts a universal design, clamps can be changed randomly so as to detect different parts, and the test beat is 60-65 seconds per piece. The method has the advantages of being low in energy consumption, high in precision, small in noise, small in volume and pollution-free. Therefore, whether the leakage amount of the fuel pipe is qualified in working can be accurately judged, and the accuracy rate can achieve 100%.

Owner:SHANGHAI LIANNAN AUTOMOTIVE ACCESSORIES

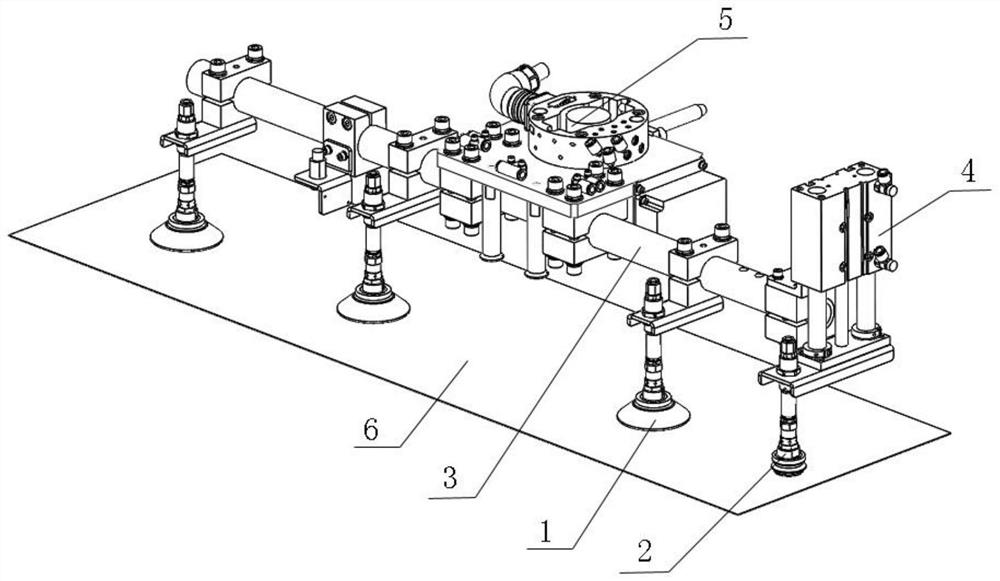

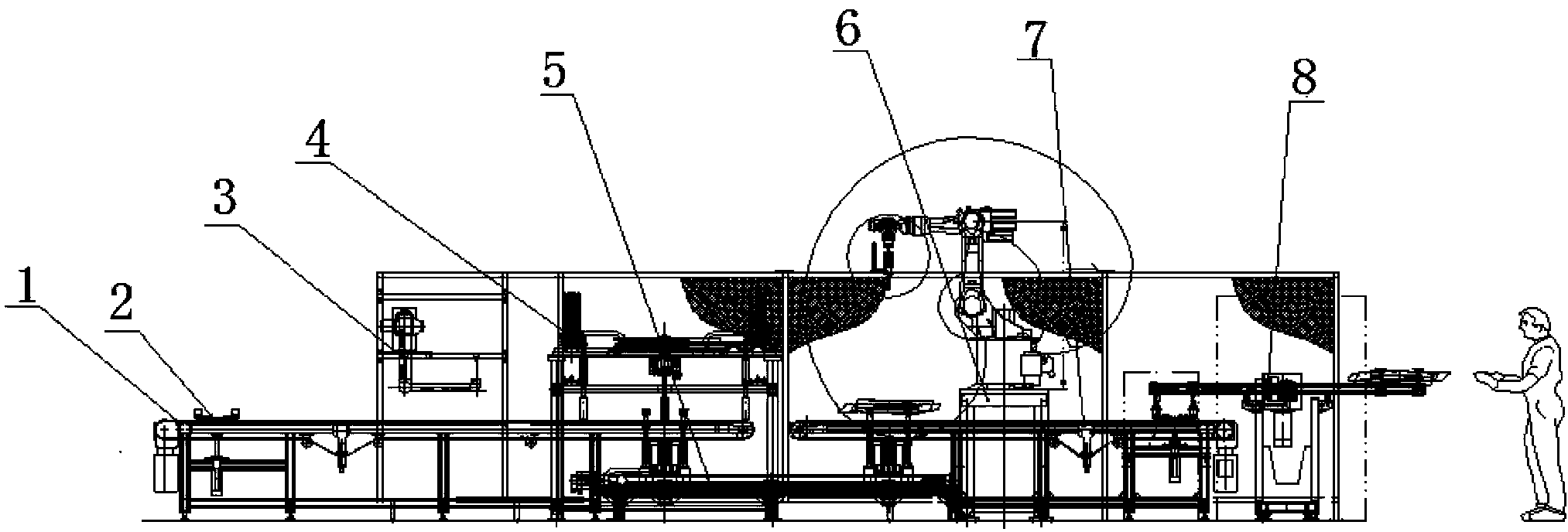

Fully enclosed robot laser automatic welding machine for assembling automobile lamps

ActiveCN104942438AImprove work tempoImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser

The invention relates to a fully enclosed robot laser automatic welding machine for assembling automobile lamps. The fully enclosed robot laser automatic welding machine for assembling the automobile lamps comprises an enclosed body and a PLC safety control device arranged on the body, the body is provided with a closed door, a rotary workbench device is arranged in the body and comprises a rotatable workbench, a welding fixture is arranged on the workbench, a six-axis robot is installed on the side, located beside the workbench, in the body, a laser generator is installed at the welding working end of the six-axis robot, and the PLC safety control device is connected with the rotatable workbench device, the six-axis robot and the laser generator. A workpiece to be welded is clamped through the welding fixture, the movement of the six-axis robot is controlled through the PLC safety control device, the production tact is increased, and the production efficiency is improved simultaneously. The fully enclosed robot laser automatic welding machine for assembling the automobile lamps is suitable for welding machining of automobile lamp parts, good in flexibility, suitable for welding of complex curved surfaces, good in stability of welding quality and higher in product uniformity.

Owner:WUXI ZHONGZHUO TECH

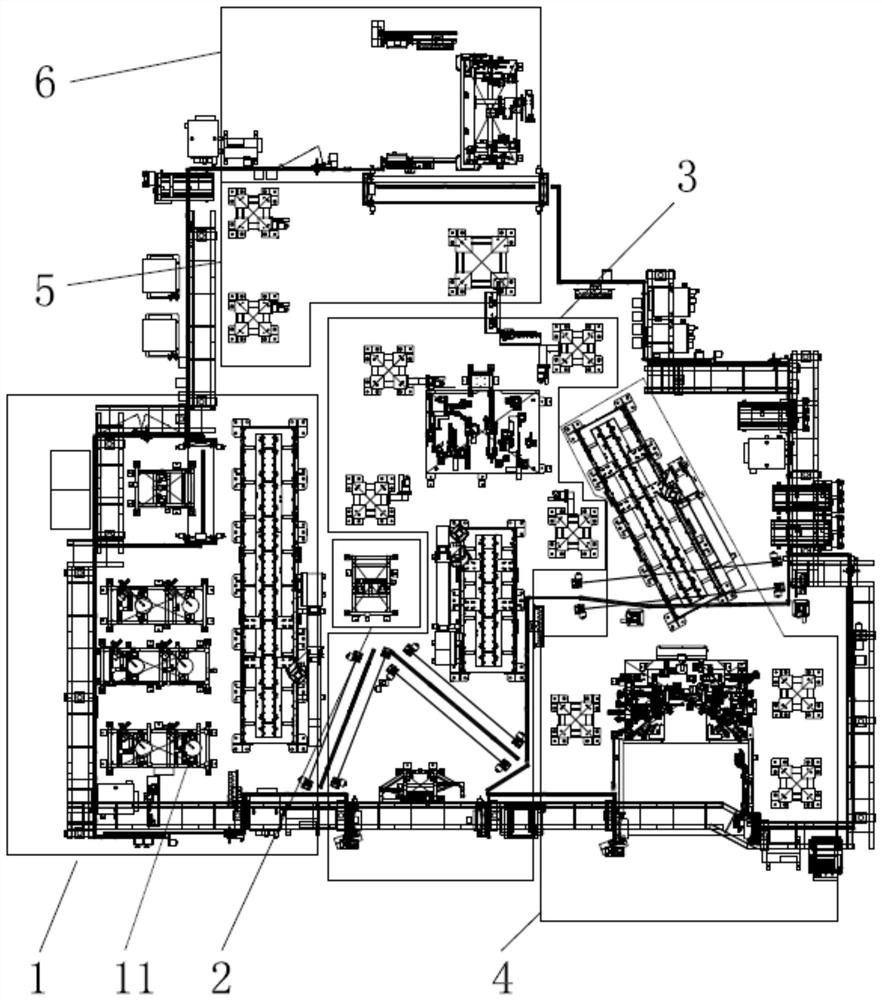

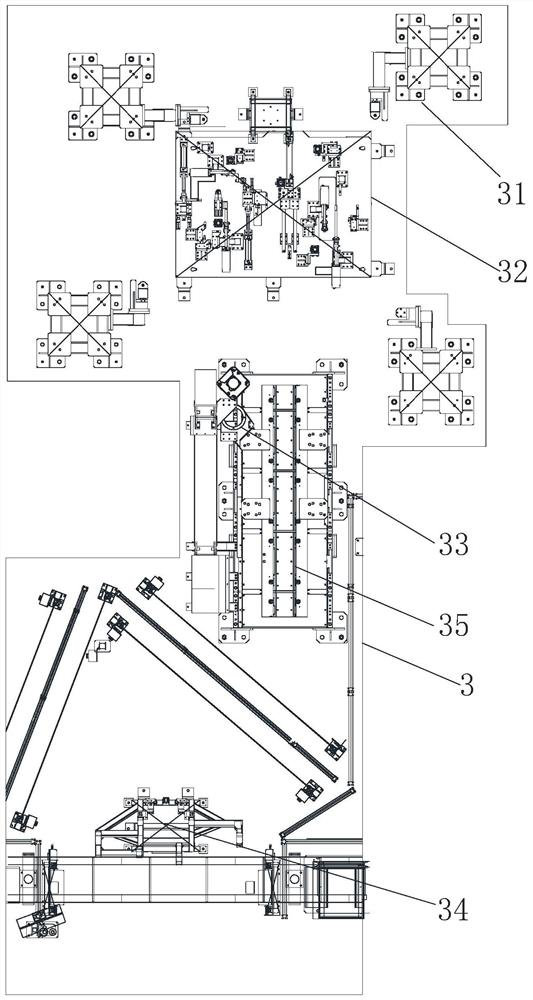

Automatic vehicle body part manufacturing system

PendingCN111975273AAvoid occupyingIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesManufacturing systemsIndustrial engineering

The invention provides an automatic vehicle body part manufacturing system comprising a workpiece holder placing area, a workpiece holder transfer placing table, a first welding station and a second welding station which are sequentially arranged. The second welding station provides second workpieces to the first welding station; a plurality of workpiece holders are arranged in the workpiece holder placing area, the workpiece holders are used for placing first workpieces, and the workpiece holder placing area provides the first workpieces to the first welding station through the workpiece holders; the first welding station is used for welding and fixing the first workpieces and the second workpieces to form a vehicle body part, and after the vehicle body part is removed from the workpieceholders, the workpiece holders are sent to the workpiece holder transfer placing table; and the workpiece holder placing area is also used for recycling the workpiece holders from the workpiece holdertransfer placing table. The automatic vehicle body part manufacturing system has the advantages of being reasonable in structure and capable of improving production efficiency.

Owner:GUANGZHOU FENGQIAO AUTOMATION TECH CO LTD

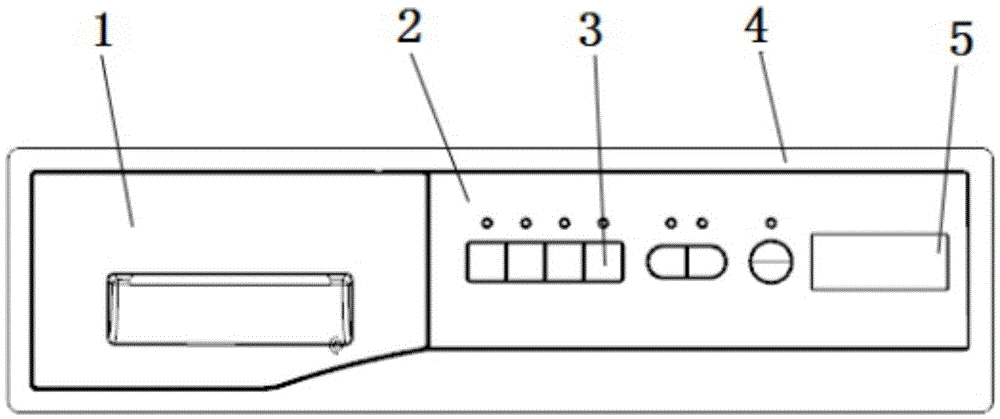

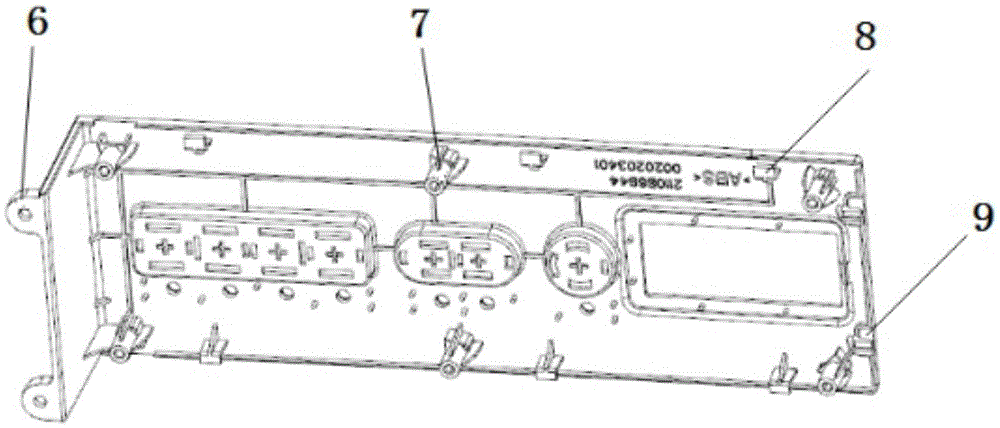

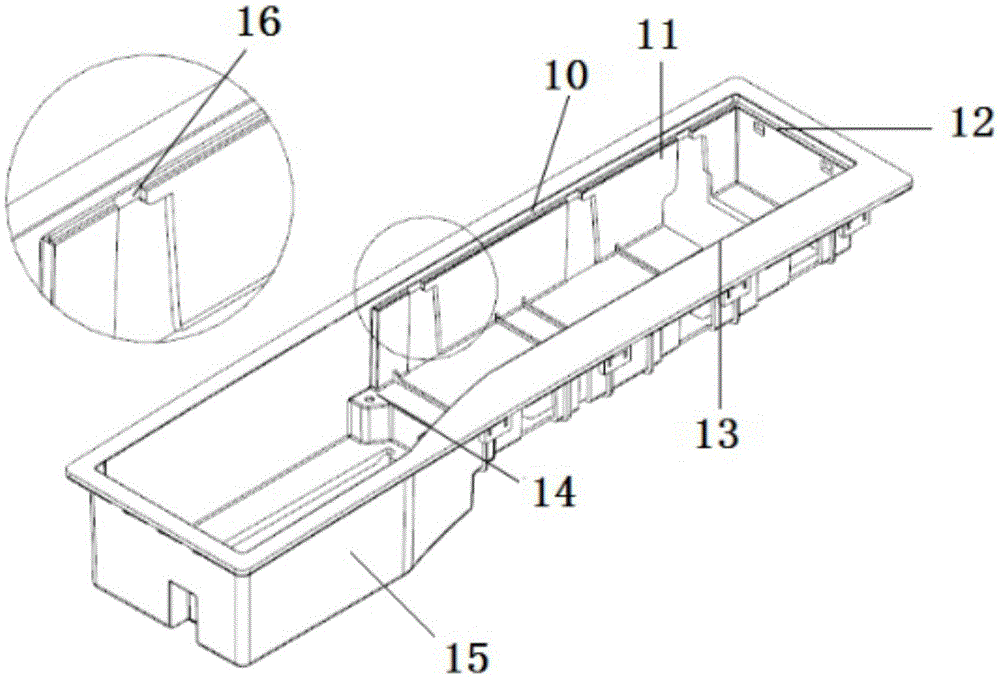

Easy-to-disassemble control panel structure and household appliance

PendingCN105525491ASolve installation difficultiesEasy to installOther washing machinesTextiles and paperProduction lineComputer engineering

The invention discloses an easy-to-disassemble control panel structure. The easy-to-disassemble control panel structure comprises a control panel seat, wherein the control panel seat is in a groove shape; the upper surface of the control panel seat is connected with a sliding cover through a set slide way; a closed space is formed by fixedly matching the control panel seat with the sliding cover; a computer board is arranged in the closed space. The invention also discloses a household appliance. The household appliance comprises a host computer, wherein the host computer is provided with the easy-to-disassemble control panel structure. The easy-to-disassemble control panel structure and the household appliance, disclosed by the invention, have the beneficial effects that by improving a control panel structure, the problem of difficulty in installation of the computer board can be solved, so that the computer board can be more easily installed by a production line worker, and the working rhythm is promoted; meanwhile, the problem of difficulty in maintenance and disassembly can also be solved, and the computer board can be replaced from the outer part of a washing machine by maintenance personnel without disassembling a control panel.

Owner:HEFEI HAIER WASHING MACHINE

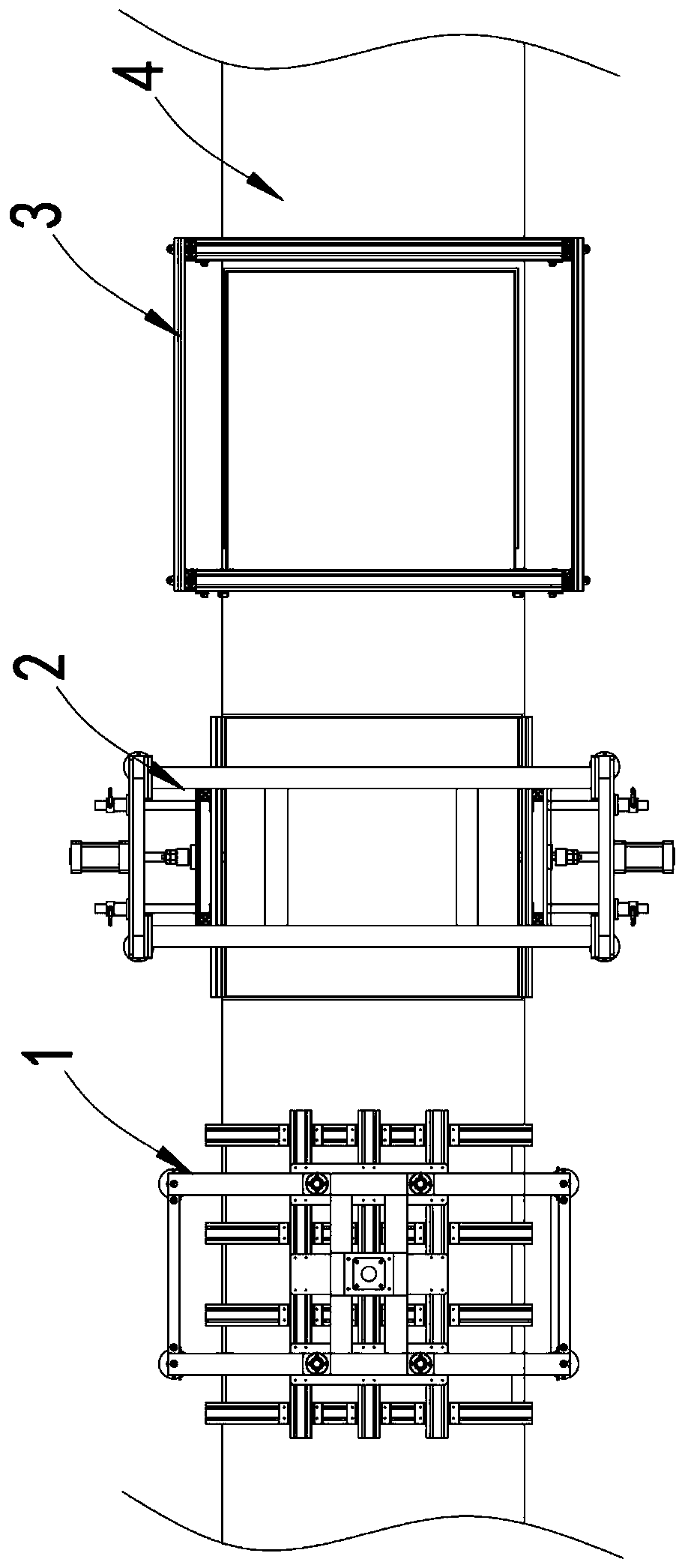

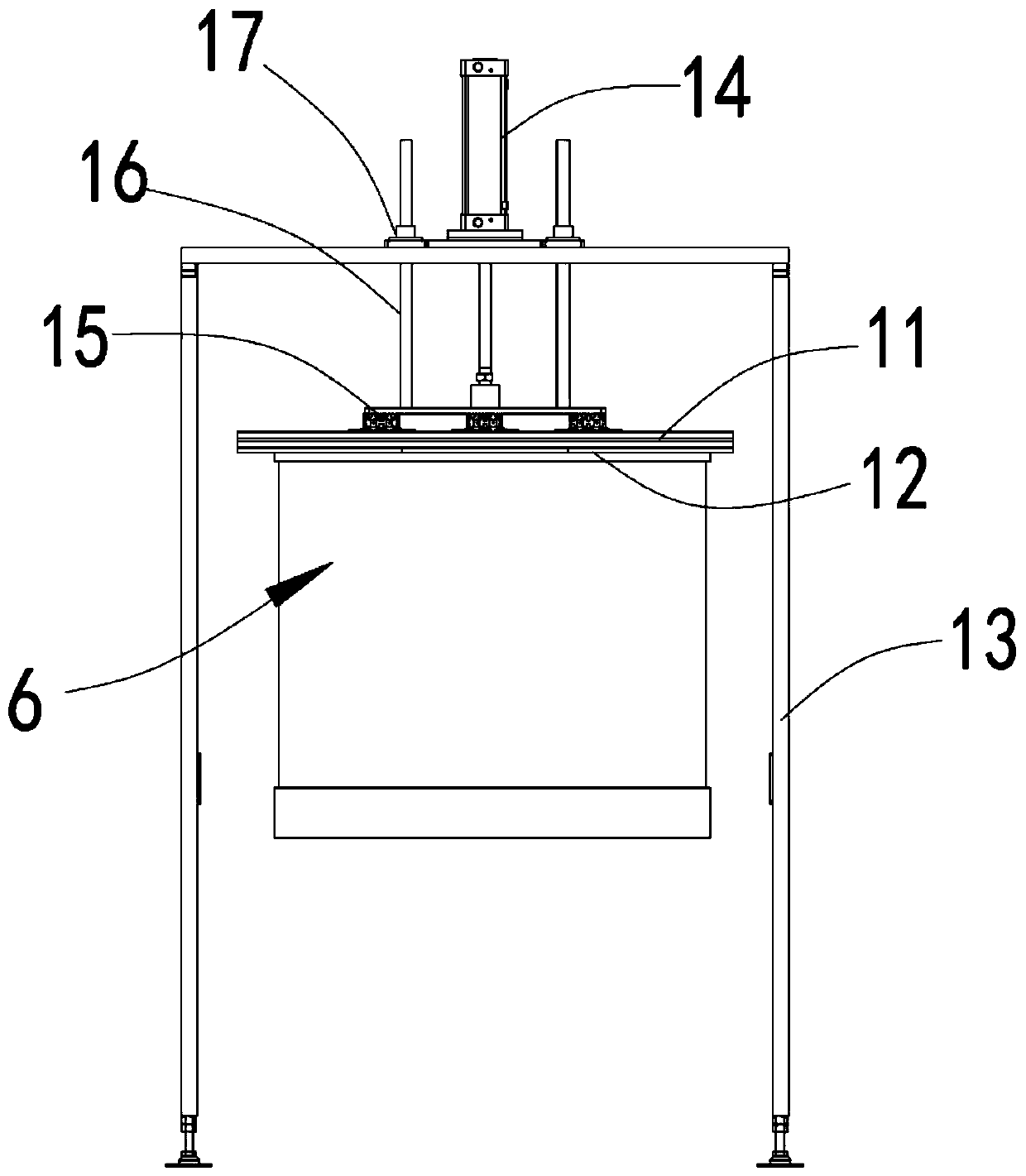

Lifting device and application method thereof

The invention provides a lifting device. The lifting device comprises a frame. The interior of the frame is divided into three layers. Three transverse fixed pulleys are arranged on the short side ofone side of the bottommost layer of the frame, and two cylinder fixing plates are arranged on two cross beams on the side, opposite to the short side, of the frame and used for fixing a cylinder. Oneend of a cylinder piston rod is connected with the interior of the cylinder, and the other end of the cylinder piston rod is connected with a cylinder connecting block. The cylinder connecting block is fixed to a movable pulley set. Two lower pulley fixing plates are arranged in the positions, on the two sides of the long surface of the cylinder, of the frame, and fixed pulleys are arranged on thelower pulley fixing plates. Two upper pulley fixing plates are arranged in the positions, opposite to the lower pulley fixing plates, of the upper portion of the frame, and fixed pulleys are arrangedon the two pulley fixing plates. Two height stop blocks are arranged on the left side of the two upper pulley fixing plates. Two guide rail fixing seats are arranged on the left side of the two height stop blocks. Two guide rail fixing seats are arranged in the positions, opposite to the two guide rail fixing seats at the upper end, of the lower portion of the frame. Two guide rails are arrangedin the four guide rail fixing seats. Each guide rail is provided with a sliding block. The inner side of each sliding block is provided with a sliding block fixing seat.

Owner:吉林省亿兆科技有限公司

Movable grabbing mechanism for towel cloth

PendingCN111573392ANew layoutCompact structureArticle deliveryWebs handlingDrive wheelElectric machinery

The invention provides a movable grabbing mechanism for towel cloth. The movable grabbing mechanism comprises a rack, a driving assembly and a grabbing assembly; the driving assembly is used for moving the grabbing assembly, a synchronous belt of the driving assembly is tensioned on a synchronous wheel and a driven wheel in the front-back direction of the rack, and a driving motor can drive the synchronous belt to operate; and the grabbing assembly is used for grabbing and horizontally pulling the towel cloth and comprises a connecting plate, a cross beam, a clamping jaw, a follow-up boss anda follower, the connecting plate is fixed to the synchronous belt, the cross beam is rotationally connected with the connecting plate in the left-right direction of the rack, the follower and the clamping jaw are fixed to the upper side and the lower side of the cross beam, the follow-up boss is fixed to the rack in the front-back direction of the rack and comprises a wedge-shaped reversing wall,and the follow-up device can be pressed by the reversing wall to rotate the cross beam when passing through the reversing wall so as to change the direction of the clamping jaw. According to the movable grabbing mechanism, the clamping jaw can be overturned without an external driving device, the towel cloth can be reliably grabbed and horizontally moved, the overall layout is compact, the actionis stable, and the synchronism is good.

Owner:常熟寿胜自动化机械有限公司

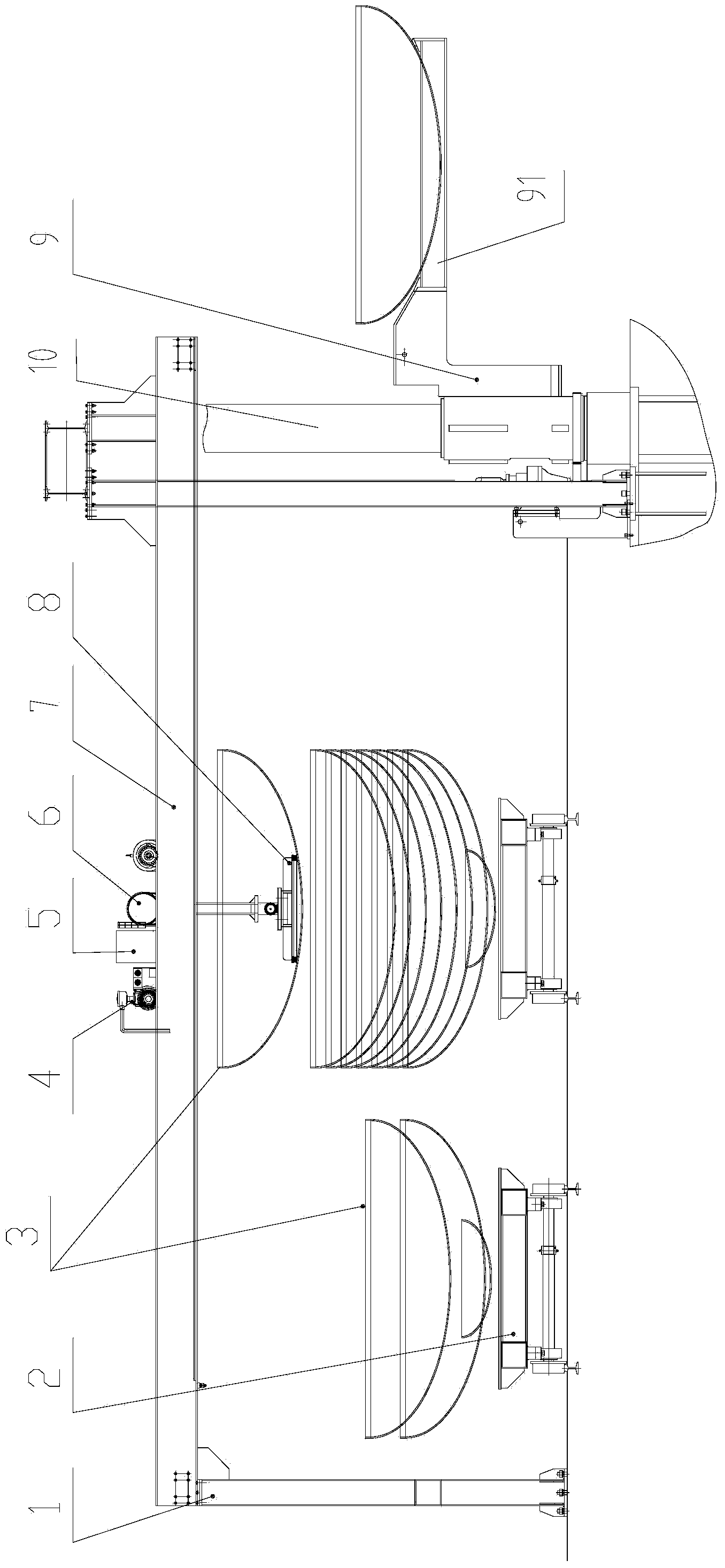

Discharging device of cold-pressing sealing-head hydraulic machine

InactiveCN103752753AImprove work efficiencyWon't shakeForging/hammering/pressing machinesEngineeringMechanical engineering

The invention discloses a discharging device of a cold-pressing sealing-head hydraulic machine. The discharging device comprises a rack and a conveying crossbeam arranged on the rack, a material taking workstation and a stacking workstation are sequentially arranged below the conveying crossbeam along the length direction of the same, the stacking workstation comprises a conveying trolley, a sliding seat is slidably mounted on the conveying crossbeam, a vacuum sucker capable of moving up and down is mounted on the sliding seat and driven by a lifting device arranged on the conveying crossbeam to move up and down, the material taking workstation comprises a material taking rotating arm, a supporting plate matched with the bottom of each forming sealing head is arranged at the front end of the material taking rotating arm, and the material taking rotating arm can rotate around a vertically-arranged rotating shaft and is driven by a speed reducing motor to rotate. The material taking rotating arm rotates by a certain angle after sequentially taking out the forming sealing heads, and the forming sealing heads are sucked and sequentially stacked onto the conveying trolley by the vacuum sucker. The discharging device has the advantages that time and labor are saved, working efficiency is high, and damage to the surface of each sealing head is avoided.

Owner:HEFEI METALFORMING MACHINE TOOL

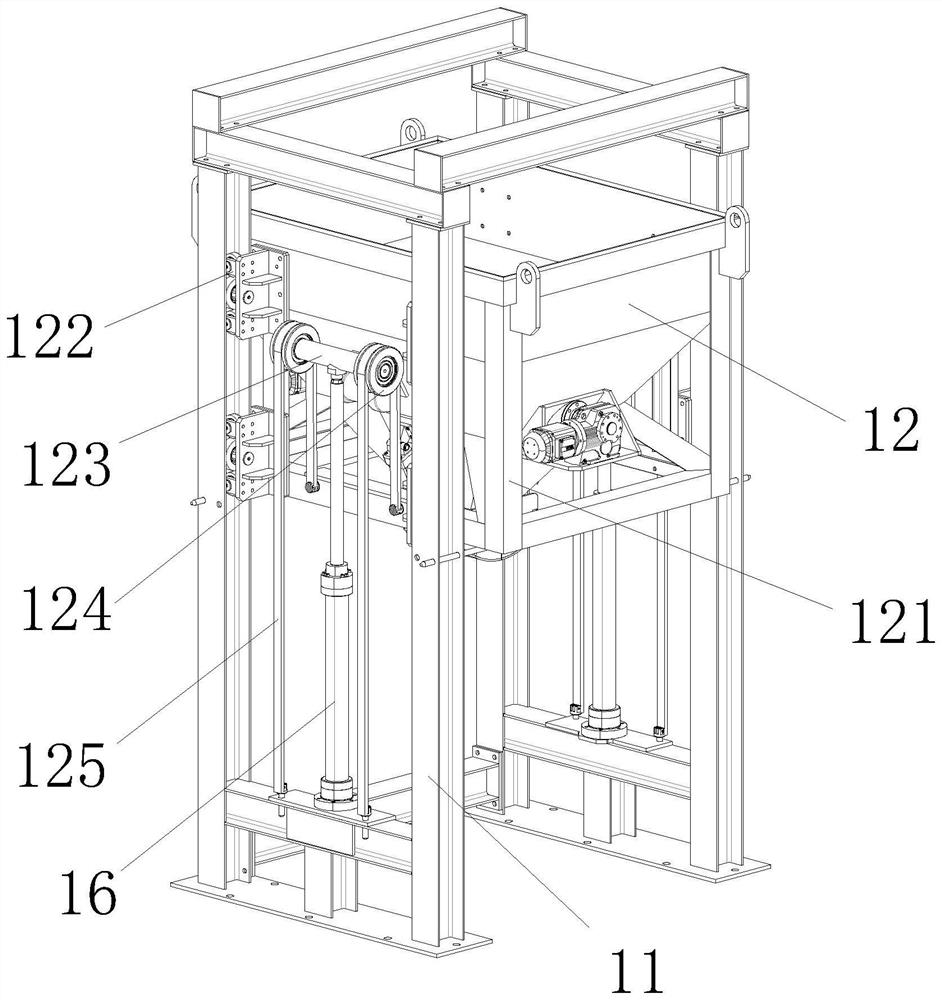

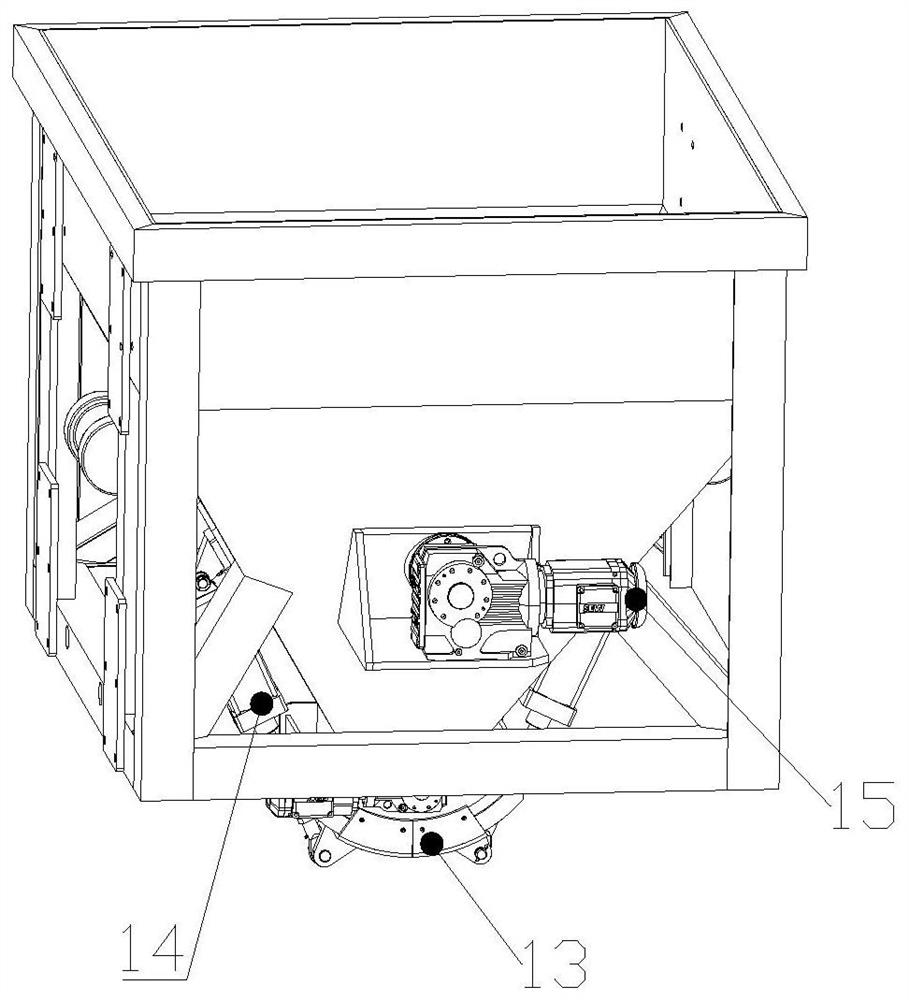

Material distributing device for concrete prefabricated parts

InactiveCN113001736AShort pause intervalEasy to take outFeeding arrangmentsStructural engineeringIndustrial engineering

The invention discloses a material distributing device for concrete prefabricated parts. The material distributing device comprises a material storage table and a material distributing mechanism. The material storage table comprises a frame, and a liftable material storage hopper is arranged on the frame; the material distributing mechanism comprises a support, a balance crane is mounted on the support, a mounting support is hung at the tail end of the balance crane, a material distributing hopper is arranged on the mounting support and elastically connected with the mounting support, and a material distributing baffle is arranged at a lower opening of the material distributing hopper; and a manipulator is arranged below the support, the mounting support is connected with the tail end of the manipulator, the material distributing hopper is driven by the manipulator to translate, and the balance crane moves along with the material distributing hopper in the translating process of the material distributing hopper. According to the material distributing device, the manipulator is adopted for feeding and material distributing, so that the labor amount can be reduced, the labor intensity of workers can be reduced, the concrete conveying process is omitted, and the production efficiency can be improved; and in addition, the manipulator is used for moving the material distributing hopper, material distributing is flexible, compared with a fixed material distributing hopper, material distributing of the different prefabricated parts can be achieved, and the material distributing device has higher universality.

Owner:北京好运达智创科技有限公司

Box step-by-step shaping and shape measuring machine

PendingCN111392147ALower requirementExquisite designUsing optical meansPackagingControl systemEngineering

The invention discloses a box step-by-step shaping and shape measuring machine. The box step-by-step shaping and shape measuring machine comprises a downward pressing shaping device, a side face shaping device, a shape measuring machine and a conveying line which are sequentially arranged, wherein the downward pressing shaping device is provided with a downward pressing plate for applying downwardpressure to a box body with a fixed position; the side face shaping device is provided with a side pressing plate for applying pressure to at least two opposite side faces of the box body with the fixed position; the shape measuring machine is provided with a group of photoelectric sensors with fixed positions, and an induction area which is composed of a plurality of induction lines and is consistent with a target box body in size is formed; and the conveying line extends to pass through the downward pressing shaping device, the side face shaping device and the shape measuring machine. According to the scheme, a plurality of stations can be used for processing a plurality of box bodies at the same time, so that the working cycle of the whole equipment is greatly increased, and the efficiency is improved; and in addition, the photoelectric sensors are adopted for carrying out shape detection, image acquisition and processing are not needed, only whether the sensors are triggered by the box bodies or not needs to be judged, the detection efficiency is high, the accuracy is good, the requirements for equipment and a control system are low, and the equipment cost can be better reduced.

Owner:SUZHOU HONBEST CLEAN TECH CO LTD

A Method for Accurately Aligning Multiple Chain Conveyors Simultaneously

ActiveCN105947574BHigh precisionImprove work tempoControl devices for conveyorsPackagingFrequency changerPulse number

A method for accurate centering of multiple chain conveyors moving simultaneously. The scanner is installed above the entrance chain conveyor in front of the synchronous moving chain conveyor, and reads the paper roll data by scanning the barcode information of the paper roll and transmits it to the chain conveyor. The machine provides the paper roll data information of the paper roll; calculates the number of pulses converted from the paper roll to the encoder value through the paper roll barcode width information. The encoder is installed at the tail of the motor of the chain conveyor, and the operation of the motor drives the encoder to run, which can directly read the number of pulses rotated by the encoder. The frequency converter is installed in the electric control cabinet, and is used for adjusting the speed value of the chain plate, and synchronous adjustment of acceleration and deceleration. The system PLC receives the number of feedback pulses in real time, and controls the operation and speed of the drive motor through the frequency converter to achieve precise alignment.

Owner:中轻长泰(长沙)智能科技股份有限公司

Glue-spraying apparatus for automobile windshield glass and glue-spraying method thereof

The invention discloses a glue-spraying apparatus for automobile windshield glass and a glue-spraying method thereof. The apparatus comprises a robot glue-spraying machine and a tilting machine, a base coating glue-spraying platform, a heat air-drying device and a centering positioning device, wherein the base coating glue-spraying platform is disposed at a first station; the heat air-drying device is disposed at a second station; the centering positioning device is disposed at a third station; the robot glue-spraying machine is disposed at a fourth station; and the tilting machine is disposes at a fifth station. The apparatus also comprises a first transfer line for transferring the bottom-coated windshield glass of the first station to the second station and the third station; a transplanting machine for transferring the centering-positioned glass of the third station to the fourth station; a second transfer line for transferring the glue-sprayed windshield glass from the fourth station to the fifth station; and the base coating glue-spraying platform, the heat air-drying machine, the centering positioning device, the robot glue-spraying machine, the tilting machine, the first transfer line, the transplanting machine and the second transfer line are connected with a controller. The glue-spraying method comprises five steps. The apparatus and the glue-spraying method can improve cycle time and reliability of equipment significantly.

Owner:CHERY AUTOMOBILE CO LTD

An automatic screw-tightening device

ActiveCN106584084BReasonable connectionReduce cumbersomeMetal working apparatusWork cycleEngineering

The invention belongs to the field of automatic mechanical equipment, and particularly relates to an automatic screw turning device. The automatic screw turning device comprises a base, a big arm and a small arm. One end of the big arm is mounted at the upper end of the base, and the other end of the big arm is connected with the small arm. The base and the big arm are flexibly connected through a second motor, and the big arm and the small arm are flexibly connected through a first motor. A wiring hose is arranged between the base and the small arm. A screw supply mechanism is arranged at the lower end of the small arm, a screw turning mechanism is arranged at the upper end of the small arm, and a visual camera is arranged at the front end of the screw turning mechanism. Mechanical locating is utilized in the mechanisms, locating is accurate, and complexity brought by electric control is reduced; and the screw turning mechanism only ascends and descends vertically, the screw supply mechanism only advances horizontally, a servo air cylinder structure is adopted, implement is easy, cost is low, in addition, the distance between the screw turning mechanism and the screw supply mechanism is short, space position switching is flexible, and the work cycle can be improved easily.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION +1

Edging full-automatic feeding and discharging machine

PendingCN113458907AIncrease profitImprove work tempoEdge grinding machinesGrinding feedersEngineeringTemporary storage

The invention relates to an edging full-automatic feeding and discharging machine which comprises a machine frame, an XYZ three-axis sliding table arranged on the machine frame, a first material taking piece connected with the XYZ three-axis sliding table, a workpiece temporary storage piece, a driving assembly, a swing rod and a second material taking piece. The first material taking piece can slide relative to the machine frame, and the first material taking piece can take a workpiece to the XYZ three-axis sliding table; the workpiece temporary storage piece is arranged on the machine frame, and the workpiece temporary storage piece can fix the workpiece on the machine frame; the driving assembly is arranged on the machine frame, is connected with the swing rod and can enable the swing rod to rotate; and the second material taking part is arranged on the swing rod and can take the workpiece to the swing rod, the workpiece temporary storage piece is located on the movement path of the second material taking piece, and the first material taking piece can move to the movement path of the second material taking piece. The edging full-automatic feeding and discharging machine has the effect that the feeding and discharging work cycle can be improved.

Owner:SHENZHEN JIANJIA ELECTRONICS CO LTD

A semi-hollow pin plastic forming method

ActiveCN105750475BGuaranteed stabilityAvoid the phenomenon of mold collisionForging/hammering/pressing machinesEngine componentsPunchingEngineering

The invention discloses a plastic forming method of a semi-hollow shaft pin. The plastic forming method comprises the following steps: step 1, extruding a part blank through a first punching die (1) to obtain needed sizes of a tail filleted corner, a bottom surface tapered hole and a rod part; step 2, extruding a part (2) in the step 1 through a second punching die (3), so as to obtain a needed size of a head pre-formed hole, carry out hole shrinkage and chamfering, and upset the rod part and a head to the needed sizes; step 3, extruding the part (2) in the step 2 through a third punching die (4) to obtain the needed size of the depth of a head hollow hole, and upset the head and the rod part to the needed sizes; and step 4, extruding the part (2) in the step 3 through a fourth punching die (5) to obtain a final size of the depth of the head hollow hole, and upset the head and the rod part to final sizes, so as to meet the shape and size requirements of a final product. The plastic forming method of the semi-hollow shaft pin, disclosed by the invention, is a part cold upsetting machining method which has the advantages of effective hole punching, stability of forming a product, simple procedures, convenience in machining, high material utilization rate and long service life of the die.

Owner:丽水市知源科技有限公司

A cable automatic sample preparation detection system and method thereof

ActiveCN110274906BRealize the removal processRealize automatic identificationPreparing sample for investigationMaterial analysis by optical meansElectrical conductorWaste collection

The invention relates to an automatic cable sample preparation and detection system, a wire and cable sampling support frame, the sampling support frame assists in identifying the positioning of the cable head, an automatic grab operation mechanism grabs and delivers the cable head for winding; it is connected with a fixing device for cutting cables and a cutting The fixing device includes horizontal frame, baffle fan, anti-collision baffle, slide rail and mechanical claw. The cutting device consists of cutting equipment, cutting platform, cutting waste slag and waste collection hopper, and measuring device, which constitute visual recognition of insulation color and recording of conductor single wire roots The measurement module is composed of the charge-coupled element visual measurement mechanism. The measuring device receives the output signal of the linear array charge-coupled element, the sorting processor, the materials to be sorted are sent to the sorting operation area through the conveyor belt, and the automatic grabbing operation mechanism The internal sorting system uses the image acquisition port to capture the image of the source object, realizing the one-stop mode of cable sample preparation and distribution, reducing the labor intensity of the inspection personnel, reducing the uncertain factors in the measurement and marking process, and improving the detection ability and accuracy.

Owner:JIANGSU ANFANG ELECTRIC POWER TECH

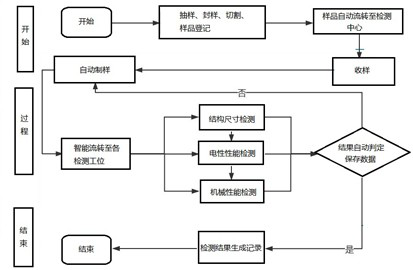

Posture changing device and posture changing method for component

ActiveCN113697442ASmooth entryReduce mistakesMetal working apparatusConveyor partsElectric machineryEngineering

The invention relates to a posture changing device for a component. The posture changing device comprises a rack, a driving motor and a rotating disc, the driving motor is arranged on the rack, and an output shaft of the driving motor is fixedly connected with the rotating disc; the rotating disc is slidably connected with a plurality of pushing blocks, the number of the pushing blocks is at least three, and the pushing blocks can abut against the multiple side surfaces of a workpiece at the same time; and a driving assembly connected with the pushing blocks is arranged on the rack and used for driving the pushing blocks to slide when the rotating disc rotates. The device has the effect that the posture of the workpiece can be corrected.

Owner:SHENZHEN HI TEST SEMICON EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com