Posture changing device and posture changing method for component

A technology for components and workpieces, which is applied in the field of position-changing devices for components, can solve problems such as errors that are prone to occur, and achieve the effects of improving work rhythm, smooth connection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

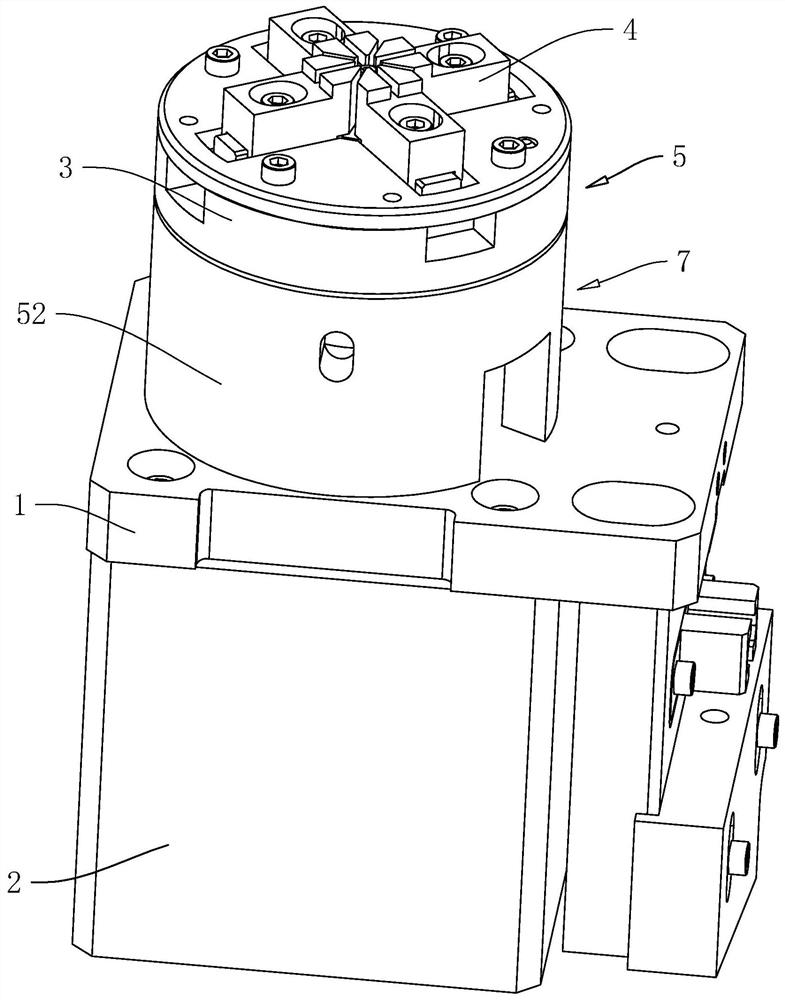

[0047] Embodiment 1, with reference to figure 1 The attitude changing device for components includes a frame 1, a drive motor 2, a turntable 3 and an adsorption piece 7. Specifically, the drive motor 2 is fixed on the frame 1 by bolts, and the output shaft of the drive motor 2 is vertically facing above; the turntable 3 is coaxially fixedly sleeved on the output shaft of the drive motor 2, and the upper surface of the turntable 3 is used to place workpieces, so when the workpiece comes out of the previous process, the workpiece can be placed on the center of the upper surface of the turntable 3 position, then the turntable 3 is rotated by a predetermined angle by driving the motor 2 to change the workpiece to the posture required for the next process, and then the workpiece can be removed from the turntable 3 and sent to the next process.

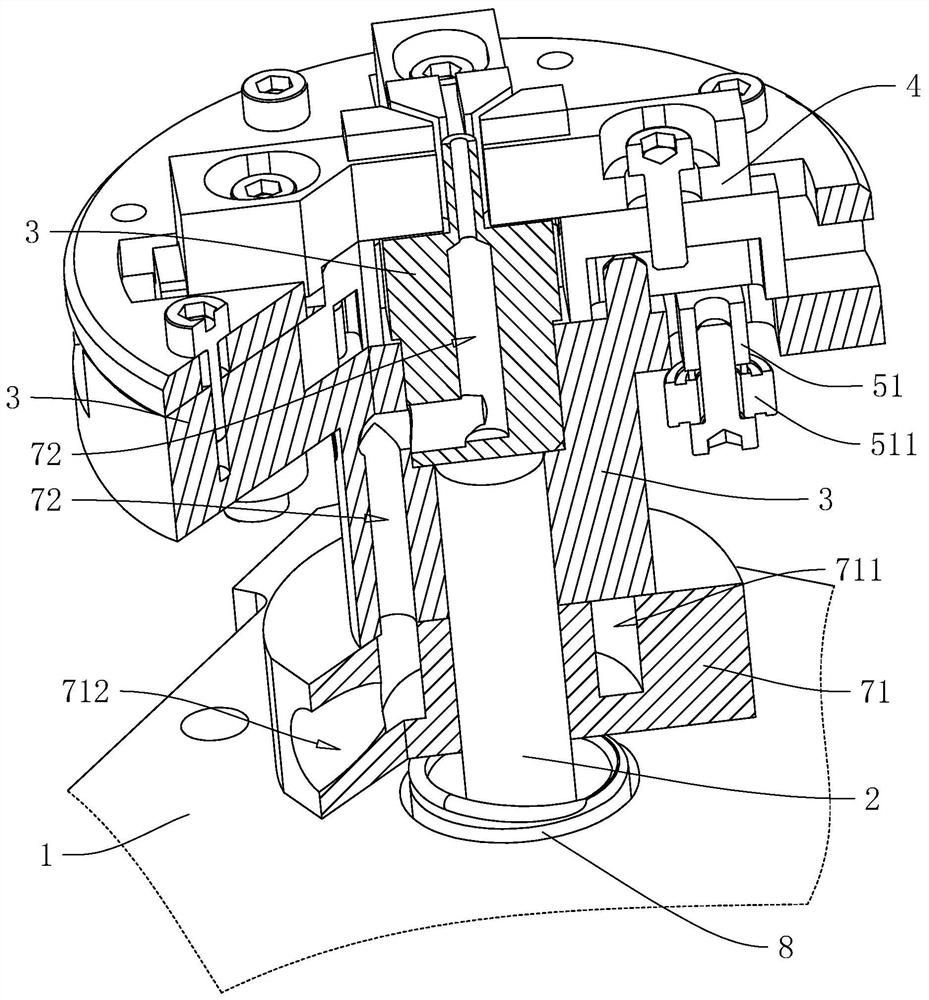

[0048] refer to figure 1 and figure 2 , the adsorption piece 7 includes a fixed block 71 and a flow channel 72 opened on the turntable ...

Embodiment 2

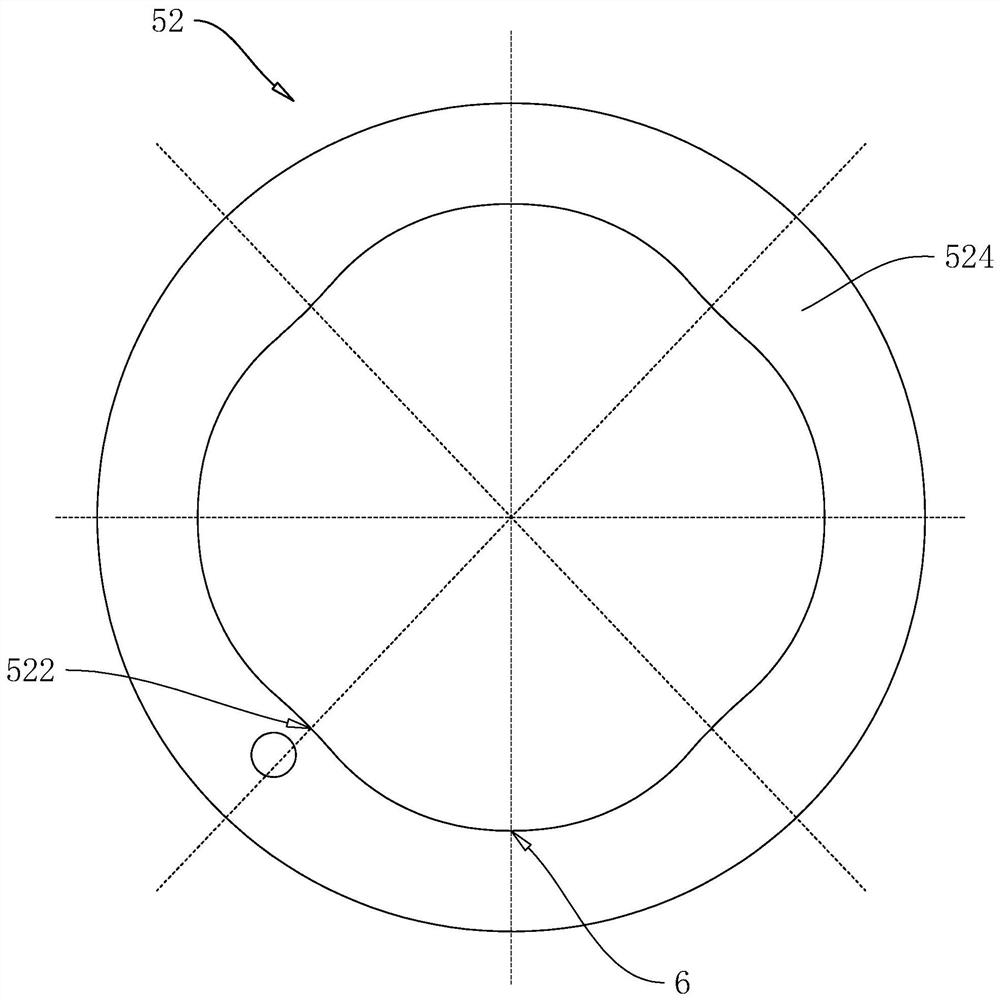

[0067] Embodiment 2, with reference to figure 2 and Figure 4, the difference from Embodiment 1 is that there are four push blocks 4, and the angle between the four push blocks 4 is 90°, if the angle of rotation of the turntable 3 is less than 90° but is a multiple of 90° For example, if the rotation angle of the turntable 3 is 45°, in this embodiment, the guide plate 52 includes four main guides 524 and four compensating guides 525, four main guides 524 and four compensating guides 525 makes the guide plate 52 a closed circular tube, wherein the guide plate 52 is evenly distributed along the circumferential direction with a plurality of far rest positions 6 and a plurality of correction positions 522, and the angle between adjacent far rest positions 6 is 45°, The included angle between adjacent calibration positions 522 is 45°, so that the tracks where the four abutting blocks 51 abut against the guide plate 52 also overlap on the same horizontal plane.

[0068] refer to ...

Embodiment 3

[0070] Embodiment 3, with reference to figure 2 and Figure 5 , the difference from Embodiment 1 is that when the angle between adjacent push blocks 4 is inconsistent with the angle of rotation of the turntable 3 and is not a multiple of each other, if the angle of rotation of the turntable 3 is still a multiple of 360° , the guide plate 52 can still be in the shape of a closed tube, which will be demonstrated with an example next.

[0071] refer to figure 2 and Figure 5 , if the workpiece is in the shape of a triangular prism, there are three push blocks 4, the angle between adjacent push blocks 4 is 120°, and the angle at which the turntable 3 rotates is 90°, and for the convenience of description, when the turntable 3 does not move, The projections of the positions where the three abutting blocks 51 abut against the guide plate 52 on the horizontal plane are set to A, B and C, so as to reflect the relative positional relationship between the three abutting blocks 51, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com