Synchronous transporting device of double trolley

A technology of conveying device and double trolley, which is applied in transportation and packaging, trolley cranes, cranes, etc., can solve the difficulty of seamless connection of program-controlled driving tracks, high requirements on steel structure and track strength of workshops, and inability to adapt to fast-paced transportation tasks. and other problems, to achieve the effect of shortening the conveying time, small inertia, and reducing the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

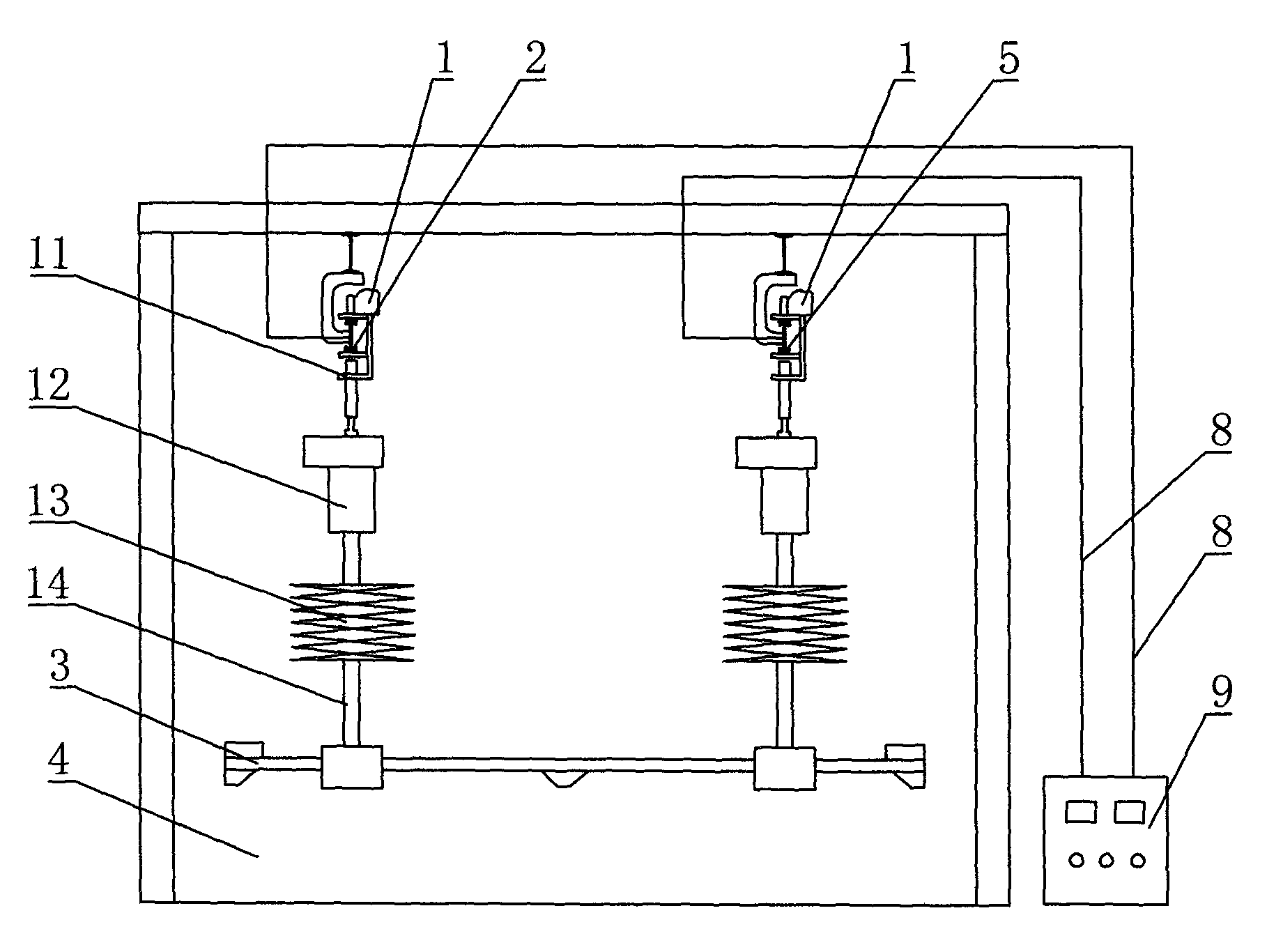

[0012] see figure 1 , the present invention comprises two self-propelled trolley conveying devices 1, left track 2, right track 5 and electric control cabinet 9, and described two self-propelled trolley conveying devices 1 are suspended and run on left track 2 and right track 5 respectively; Each self-propelled trolley conveying device 1 comprises trolley 11, chain hoist 12, scissors type balance mechanism 13 and spreader 14, and according to trolley 11, chain hoist 12, scissors type balance mechanism 13 and spreader 14 are connected in sequence; PLC is housed in the electric control cabinet 9, and is connected with two self-propelled trolley conveying devices 1 by wire 8 to form an electrical control circuit. The left rail 2 and the right rail 5 are hard aluminum alloy rails with the same cross-sectional shape and size.

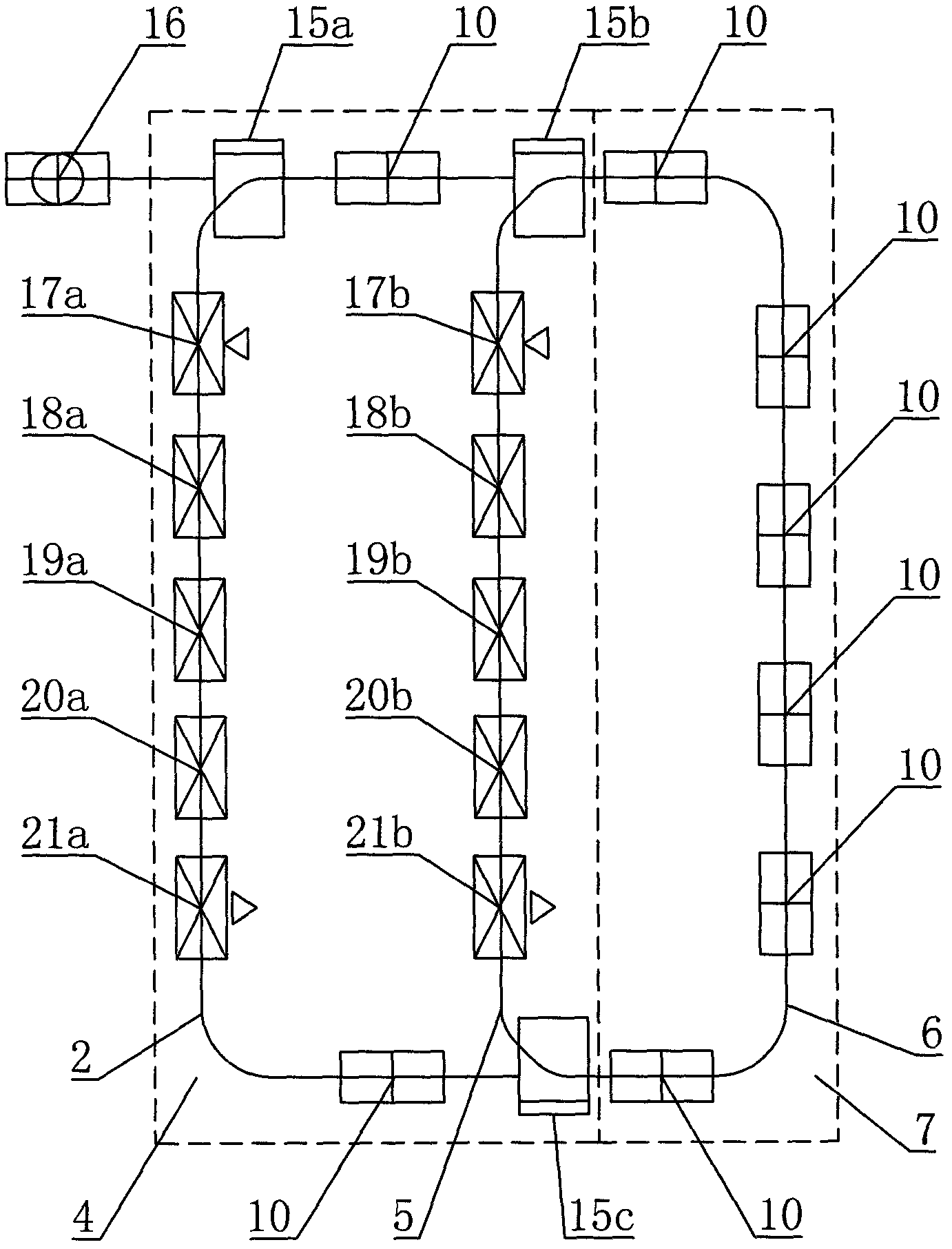

[0013] figure 2 Shown in is an explanatory diagram of the workflow of the embodiment of the present invention. During work, a self-propelled trolley con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com