Patents

Literature

264results about How to "Avoid work accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

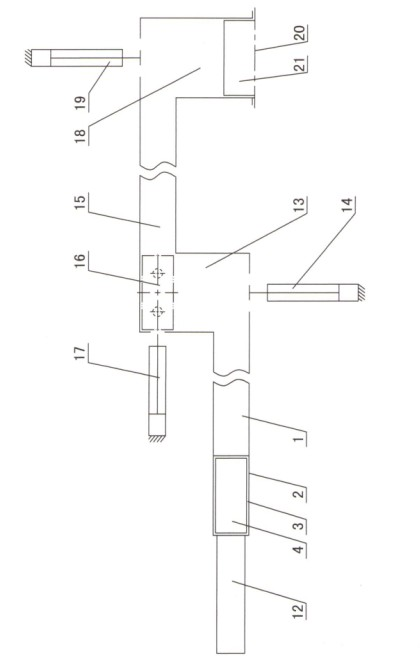

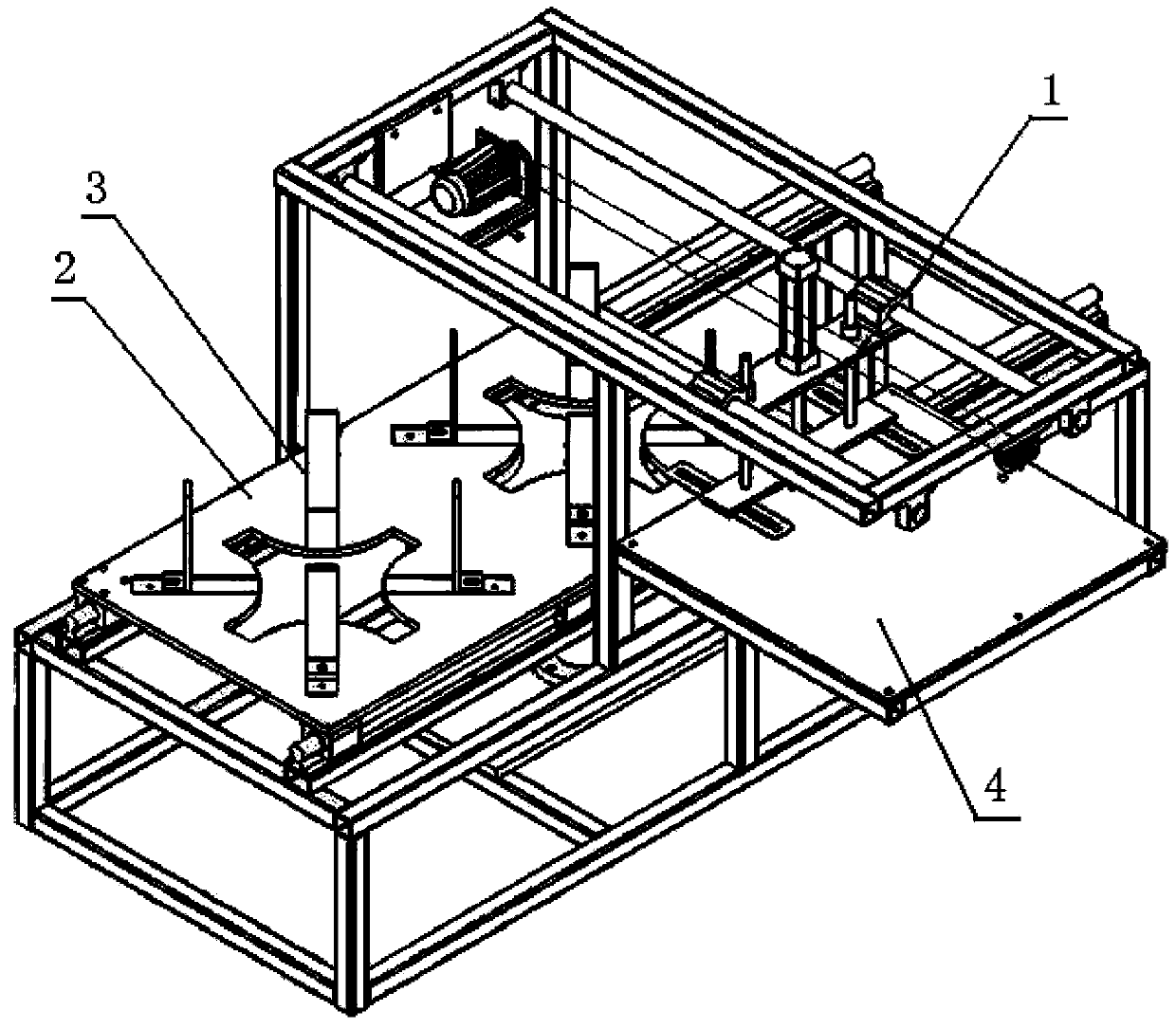

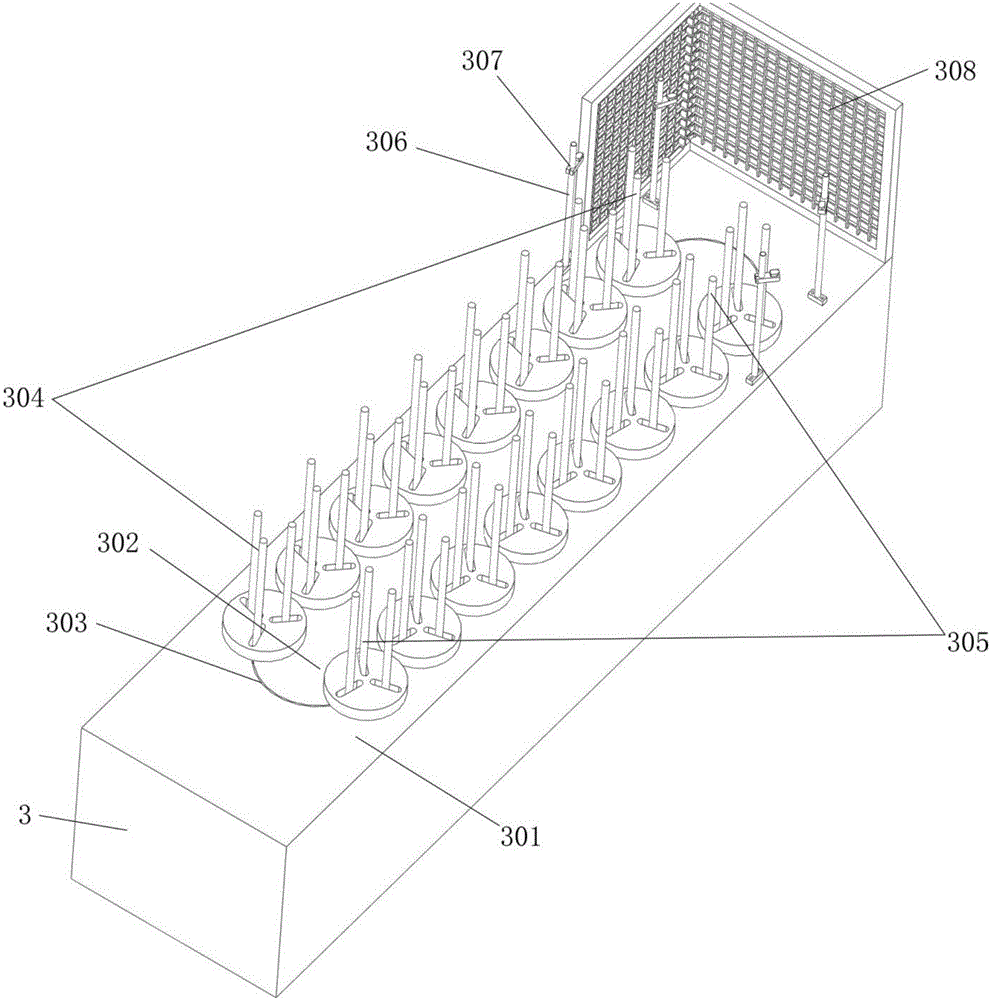

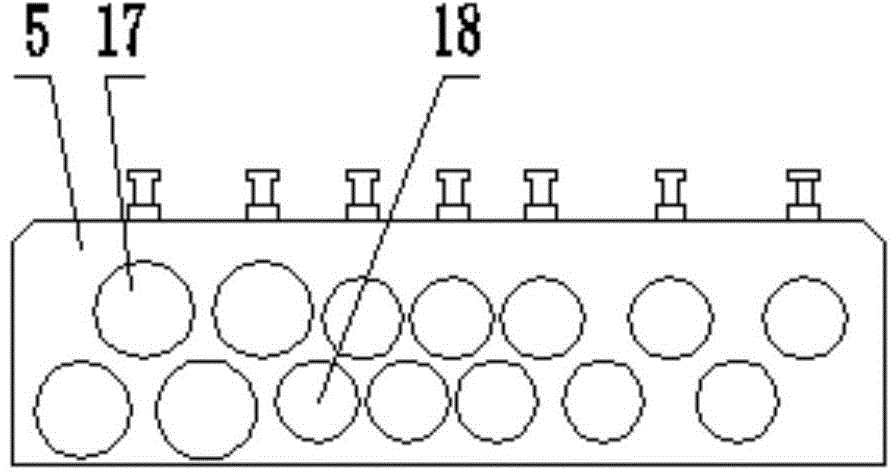

Full-automatic feeding device of punching machine

ActiveCN103394606AImprove intelligenceHigh degree of automationMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention belongs to the technical field of punching machines, and relates to a full-automatic feeding device of a punching machine. The full-automatic feeding device comprises a loading table and a feeding mechanism, wherein the loading table and the feeding mechanism are controlled by a controller to act. The loading table is specifically and structurally characterized in that a rotary table is fixed on a rotating shaft which is driven by a power unit and arranged on a rack; more than two positioning groove sets are evenly distributed in the same circles in the rotary table, wherein the radii of the circles are the same, and the circles are drawn around the same center; each positioning groove set is formed by two arc grooves which are arranged in a spaced mode; a positioning rod is arranged in each arc groove; a positioning rod positioning device is arranged on the lower side of the rotary table; a material position is formed between the two positioning rods of each arc groove set; a hole or groove used for an ejector bar to penetrate through is formed in each material position; the ejector bar driven by the power unit to act is arranged on the lower side of the hole or groove. The full-automatic feeding device of the punching machine has the advantages that materials are convenient to pile, take and feed, the degree of automation is high, and the full-automatic feeding device is applicable to the punching machine.

Owner:林爱福

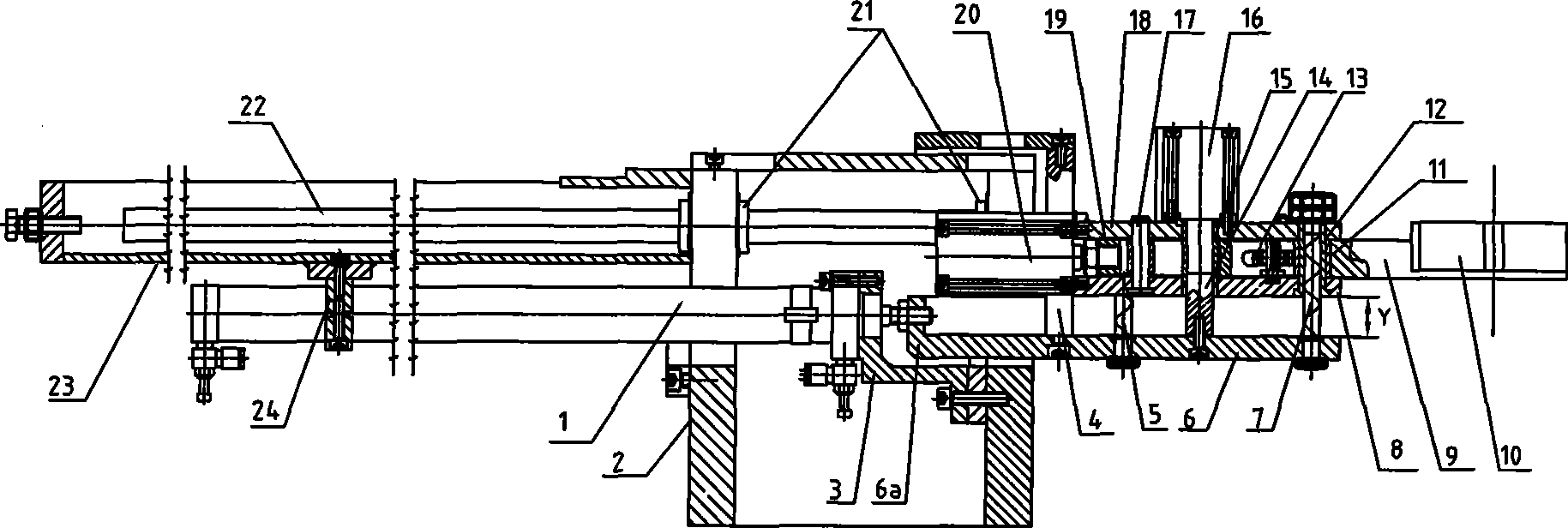

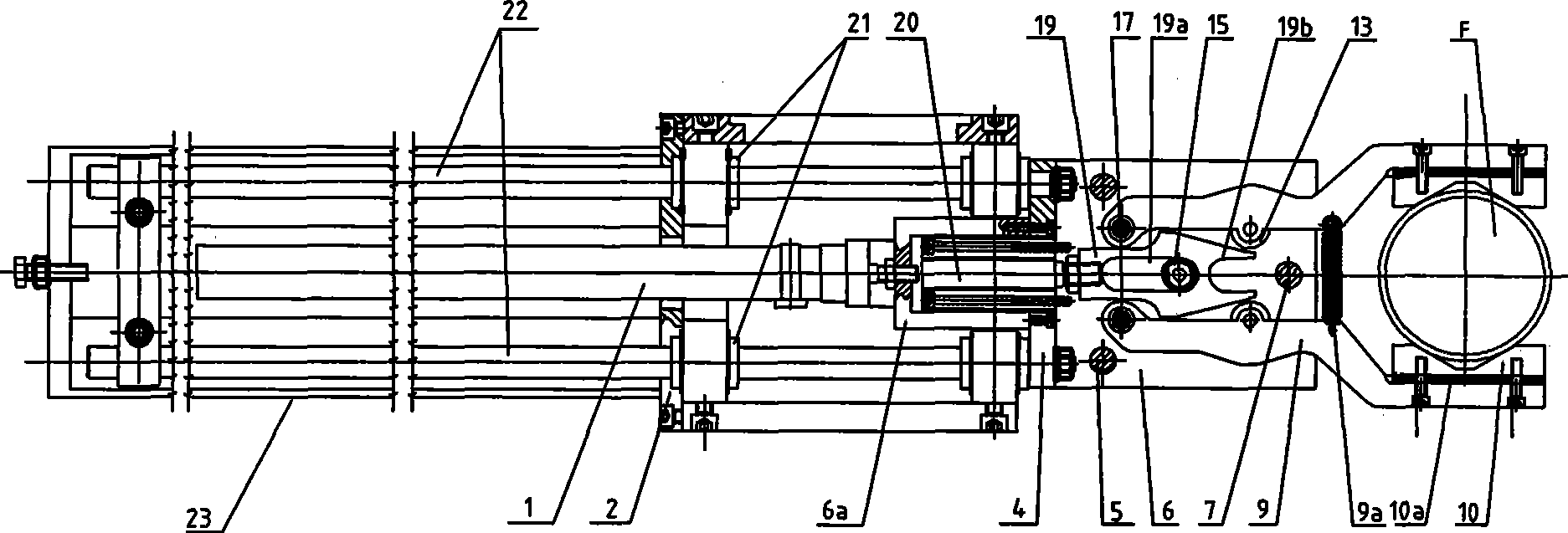

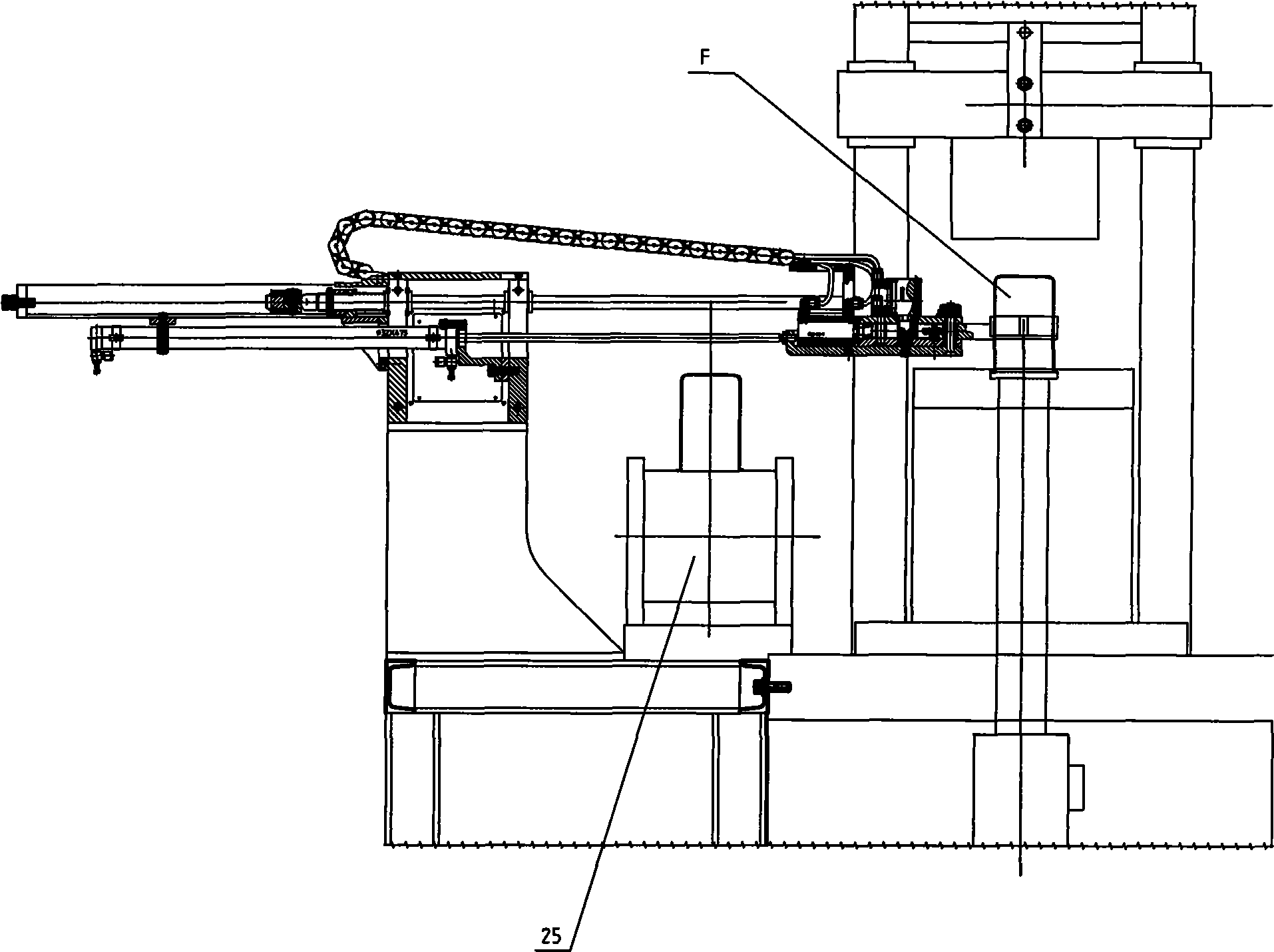

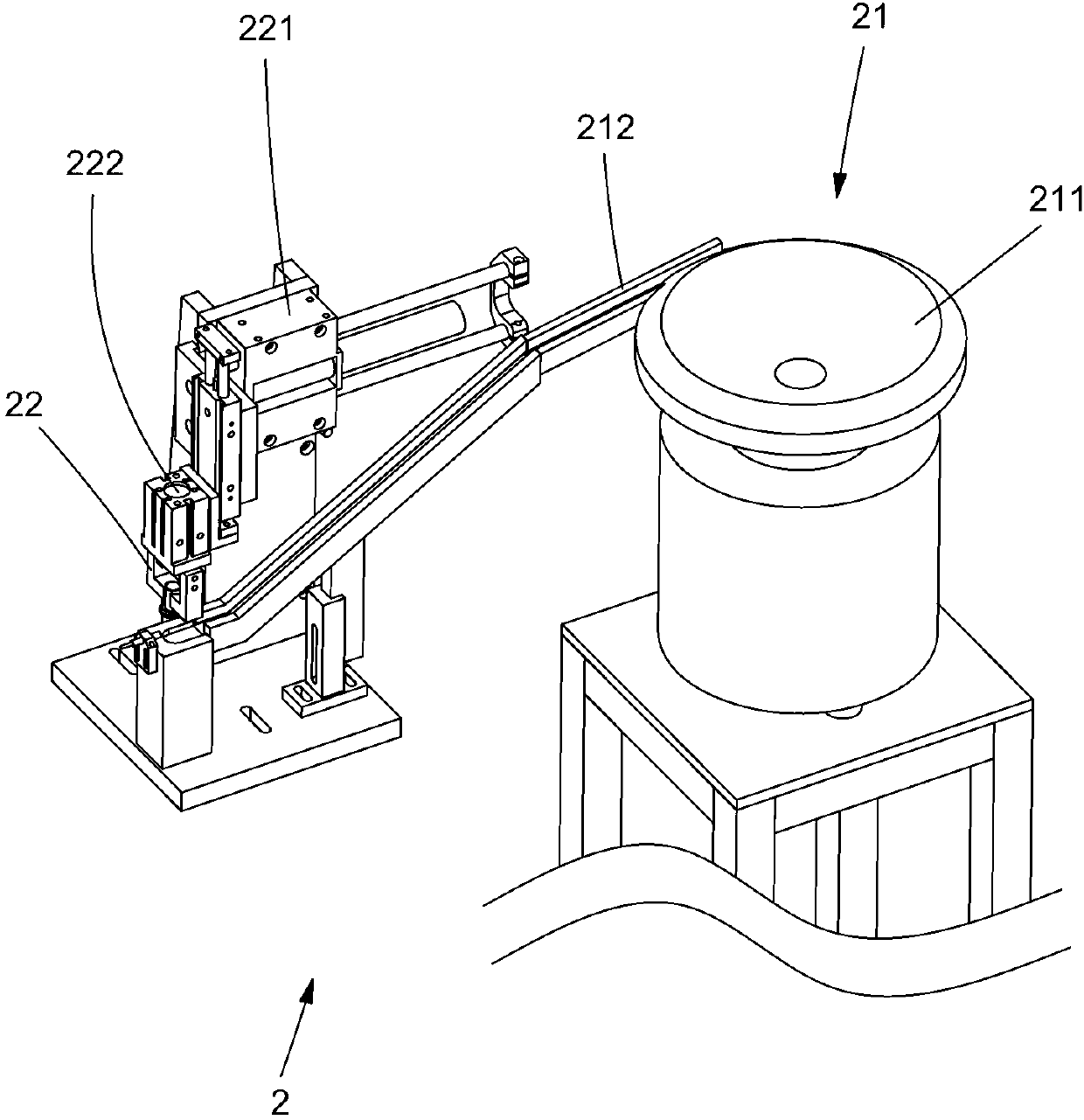

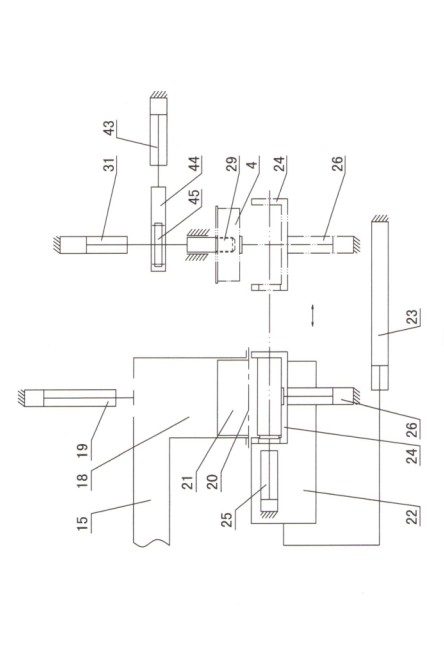

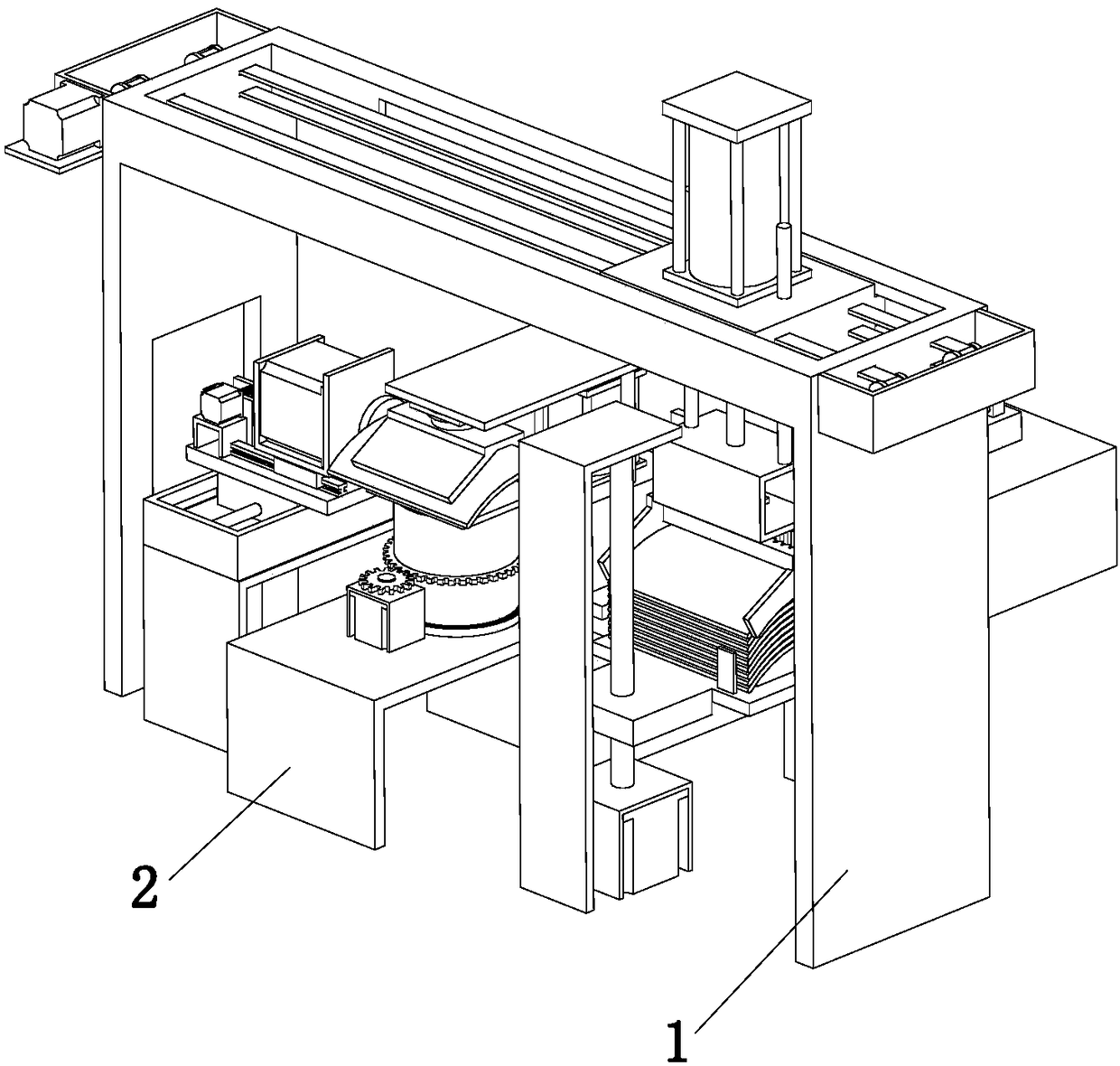

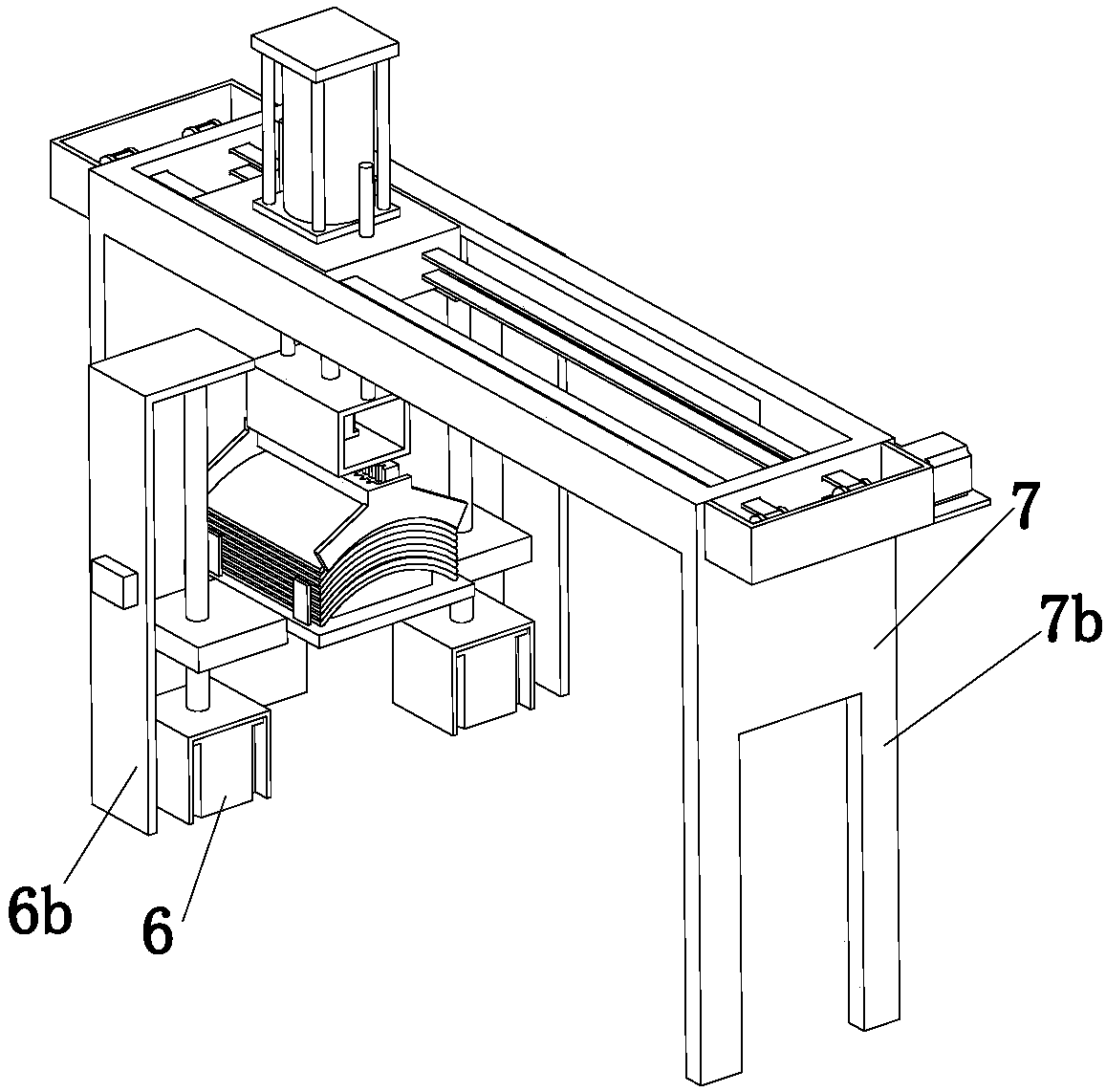

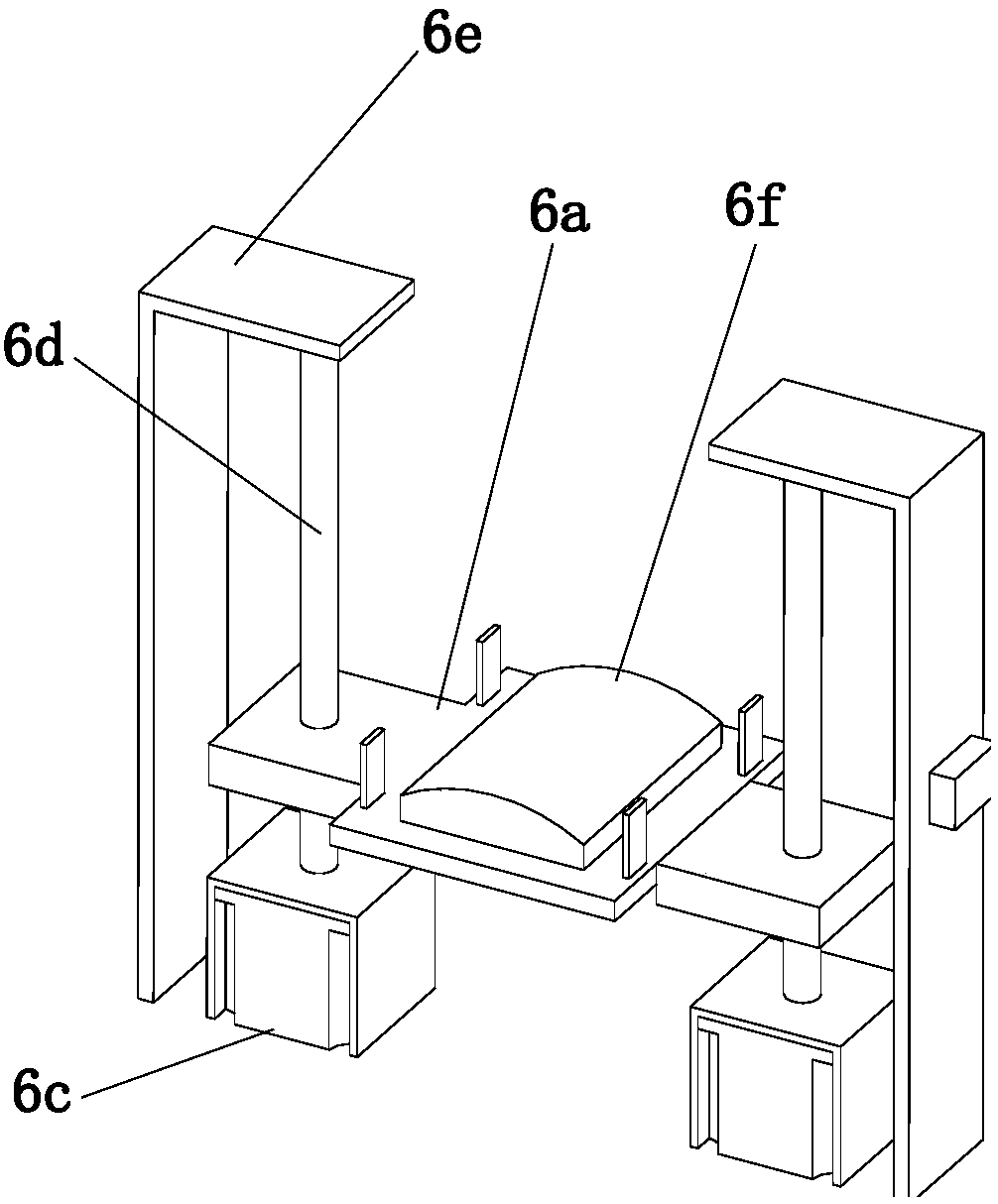

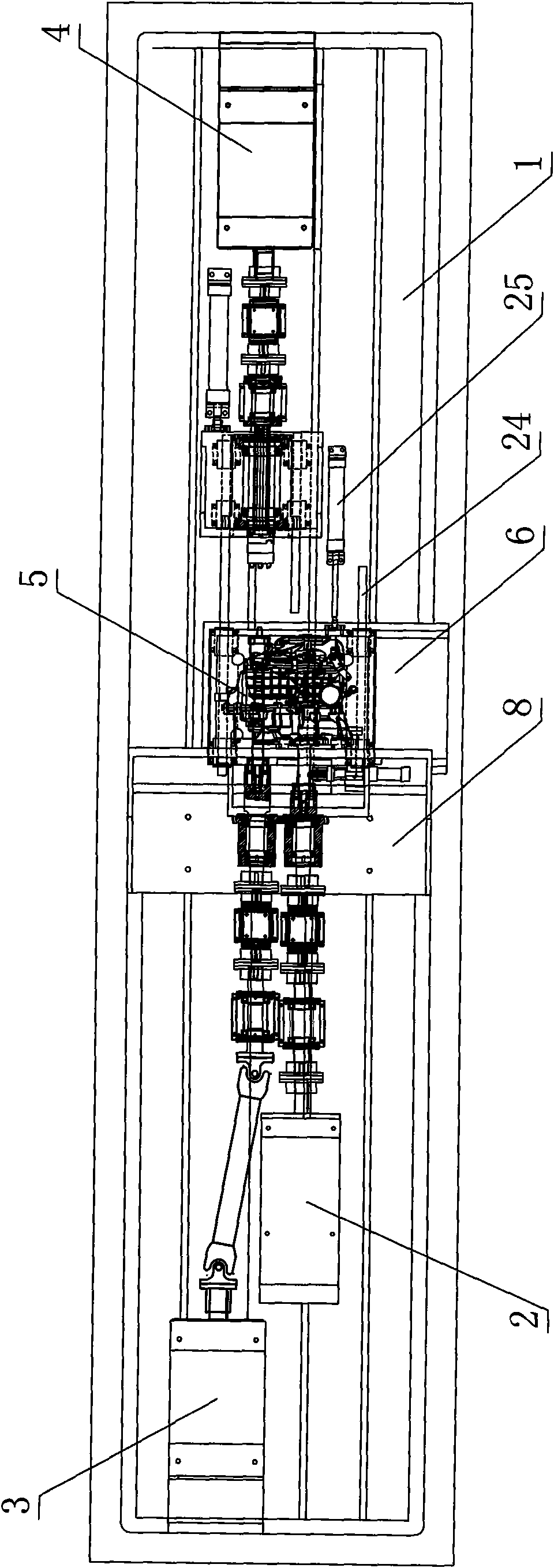

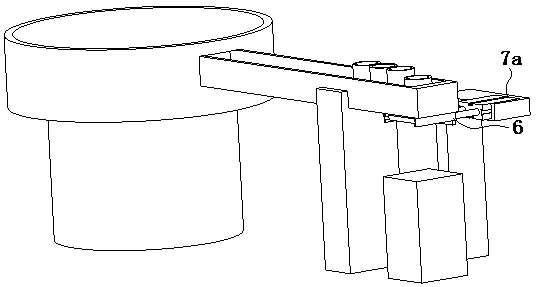

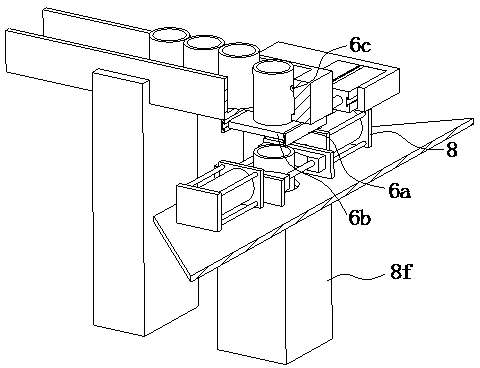

Automatic material-fetching machine for clarifier case formed by stretching

InactiveCN101497087ARealize automated productionIncrease productivityEngineeringMechanical engineering

The invention relates to an automatic stretching material taking machine for a filter shell, wherein a stander (2) is provide with a pair of guide rods (22) which are matched with a linear bearing (21); a piston rod of an arm cylinder (1) is connected with hand rest base plates (6a,6) which are connected with an upright plate (4); upper parts of the hand rest base plates are connected with the guide rods (22); the hand rest base plates are provided with a grabbing piece cylinder (20), a wedge block (19), a pair of clamping arms (9) and a tension spring (9a); and the inclined plane of the wedge block is matched with a bearing (13) of the clamping arms (9) to allow the clamping arms (9) and claws thereof to stretch and clamp. When a mechanical arm extends in place, the claws of the clamping arms stretch and clamp a workpiece F to lift the workpiece upward by 25mm, and retract the piston rod, and after the workpiece is in place, the claws stretch and put down the workpiece F. The automatic stretching material taking machine for the filter shell has the advantages of realizing automatic production of the filter shell, improving the production efficiency and preventing accidents at work.

Owner:BENGBU HAOYE FILTER

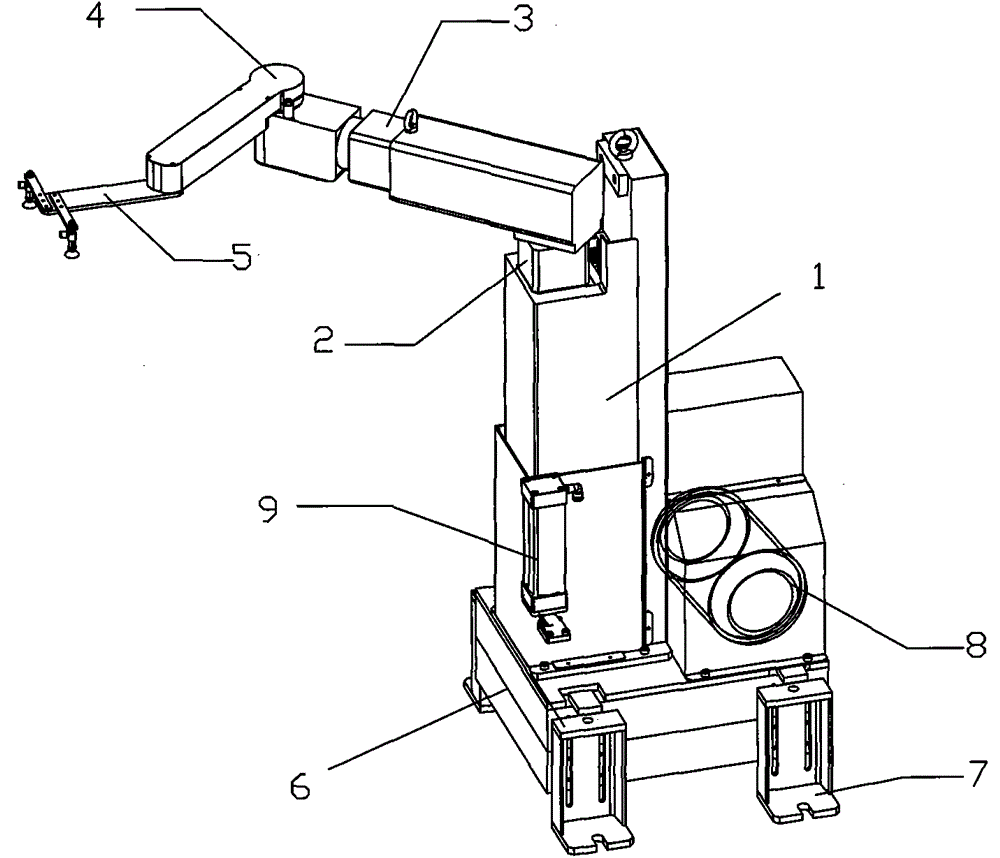

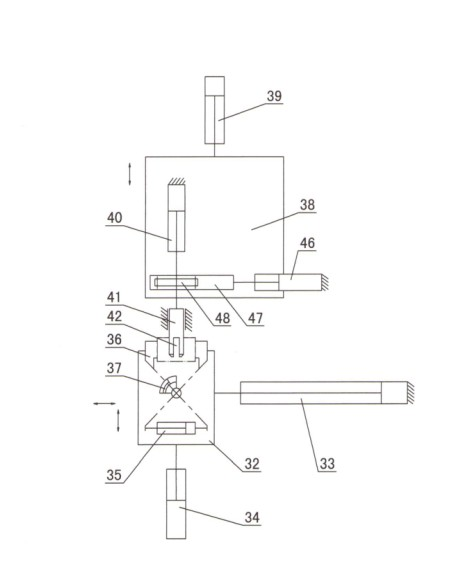

Multi-shaft horizontal joint intelligent robot

ActiveCN103978478AImprove operational efficiencyImprove work tempoProgramme-controlled manipulatorWorking environmentElectric machinery

The invention discloses a multi-shaft horizontal joint intelligent robot. The multi-shaft horizontal joint intelligent robot comprises an intelligent control mechanical hand, wherein the intelligent control mechanical hand is formed by a control device, an executing mechanism, a driving device and a base; the executing device comprises one shaft which is used for controlling vertical motion and three shafts which are used for controlling horizontal motion; a vertical moving function of a workpiece is realized in a way that the workpiece is driven to move on a sliding rail under the transmission of a screw rod by a first shaft; a speed reducing ratio is increased through a planetary gear reducer under the driving of a second shaft absolute value servo motor, and thus a horizontal 180-degree arm oscillating motion is realized as the mechanical hand is driven by a second shaft; a horizontal 360-degree arm oscillating motion is realized by a third shaft under the driving of a third shaft absolute value servo motor through the planetary speed reducer; a vertical 180-degree mechanical arm overturning motion is realized by a fourth shaft under the driving of a fourth shaft absolute value servo motor through a harmonic speed reducer. The multi-shaft horizontal joint intelligent robot disclosed by the invention has the advantages that the operation is simple and safe, horizontal and vertical moving ranges are larger, the locating is accurate, and the grabbing weight is large; a complicated carrying motion can be realized by simulating a person under a severe working environment.

Owner:HUIZHOU SUNNEMER AUTOMATION EQUIP CO LTD

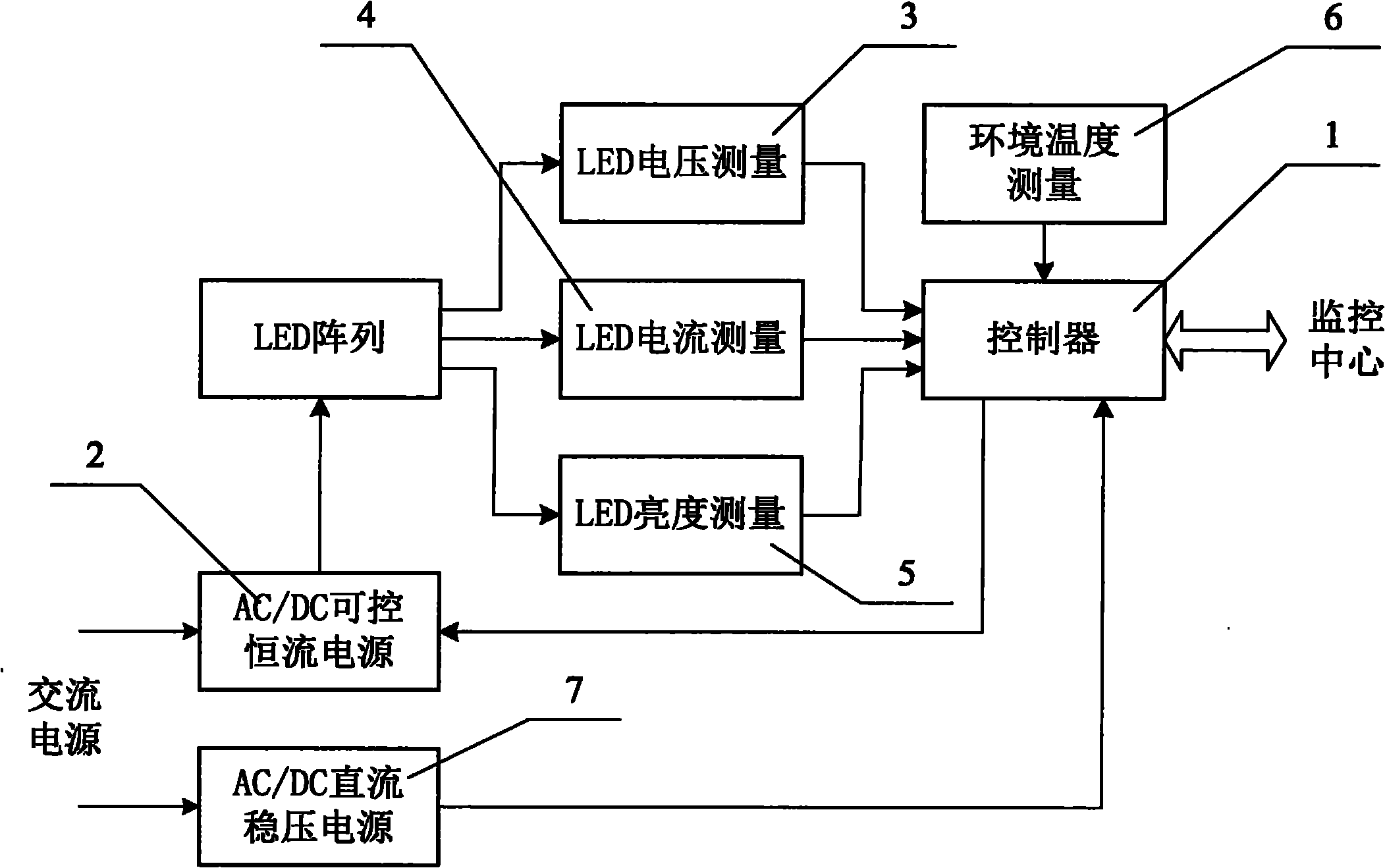

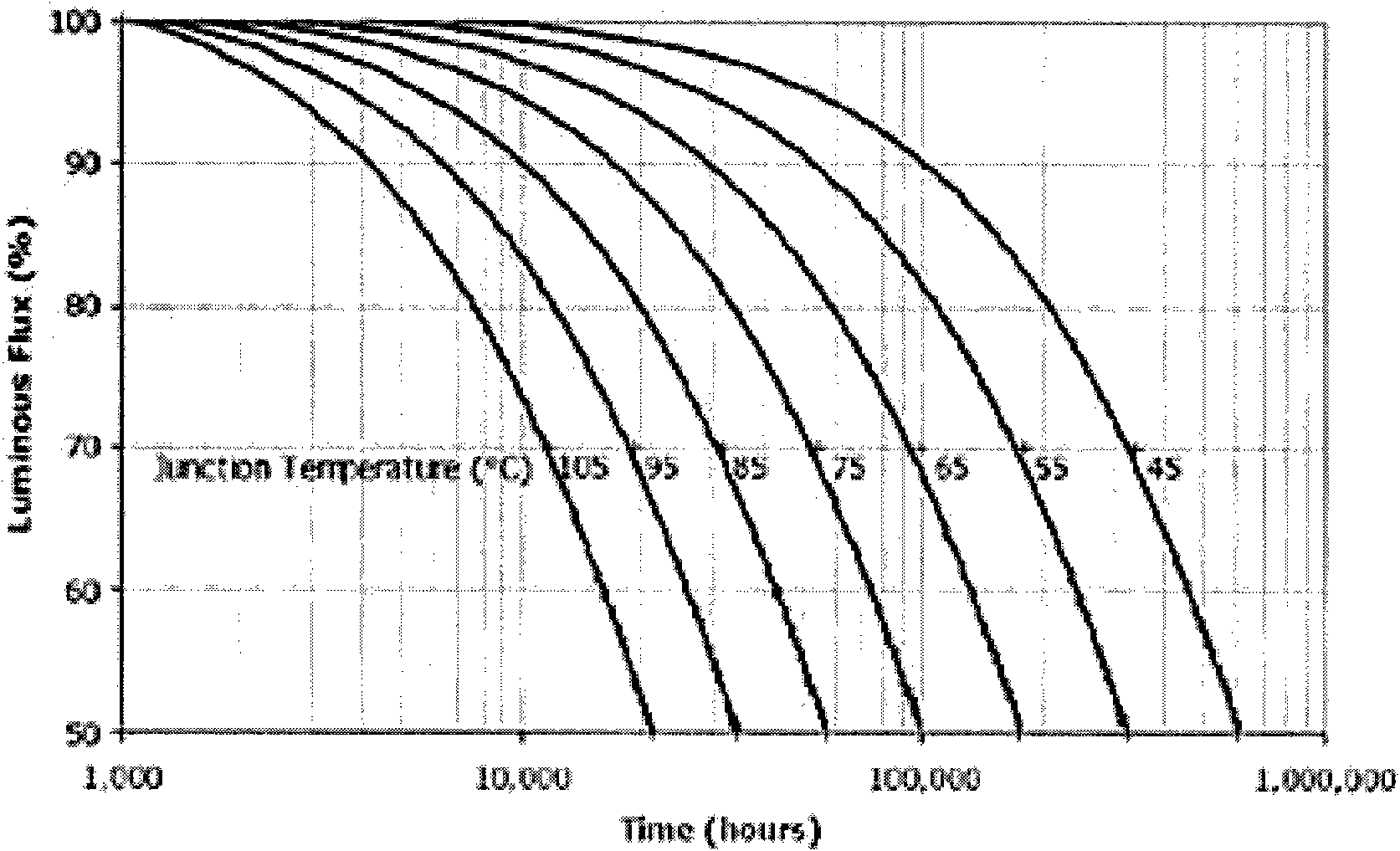

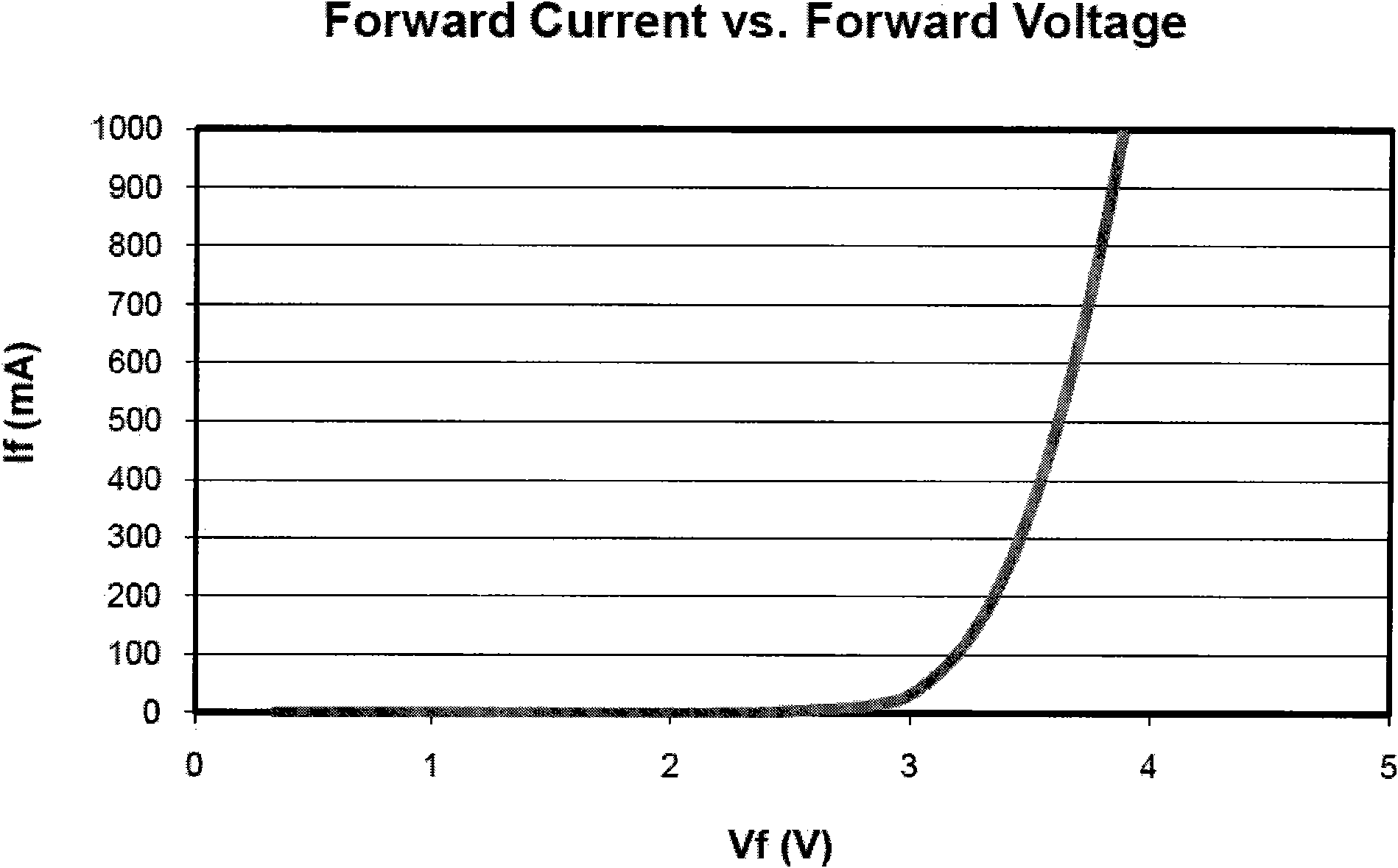

LED lamp control method and device without light decay

InactiveCN101841962AExtended service lifeCost-effectiveElectric light circuit arrangementCommunication interfaceTemperature measurement

The invention relates to an LED lamp control method and a device without light decay, the device comprises an AC / DC controllable constant current power supply, LED voltage measurement, LED current measurement, LED brightness measurement, environment temperature measurement and an AC / DC direct current voltage stabilizing power supply; the method comprises the following steps that after converting alternating current into direct current, the AC / DC controllable constant current power supply outputs constant direct current to an LED array according to the instruction of the controller: LED voltage measurement, LED current measurement and LED brightness measurement transmit the working conditions of the LED array to the controller in real time, and the controller sends the instruction of outputting current values to the AC / DC controllable constant current power supply according to preset control strategies and the measured environment temperature; simultaneously, once the working conditions of the LED array are found abnormal, the controller sends alarm information to a monitoring center in real time in a wired or wireless way through a communication interface; and the monitoring center can also send the working instructions to the controller in the wired or wireless way.

Owner:上海合亚经贸有限公司 +1

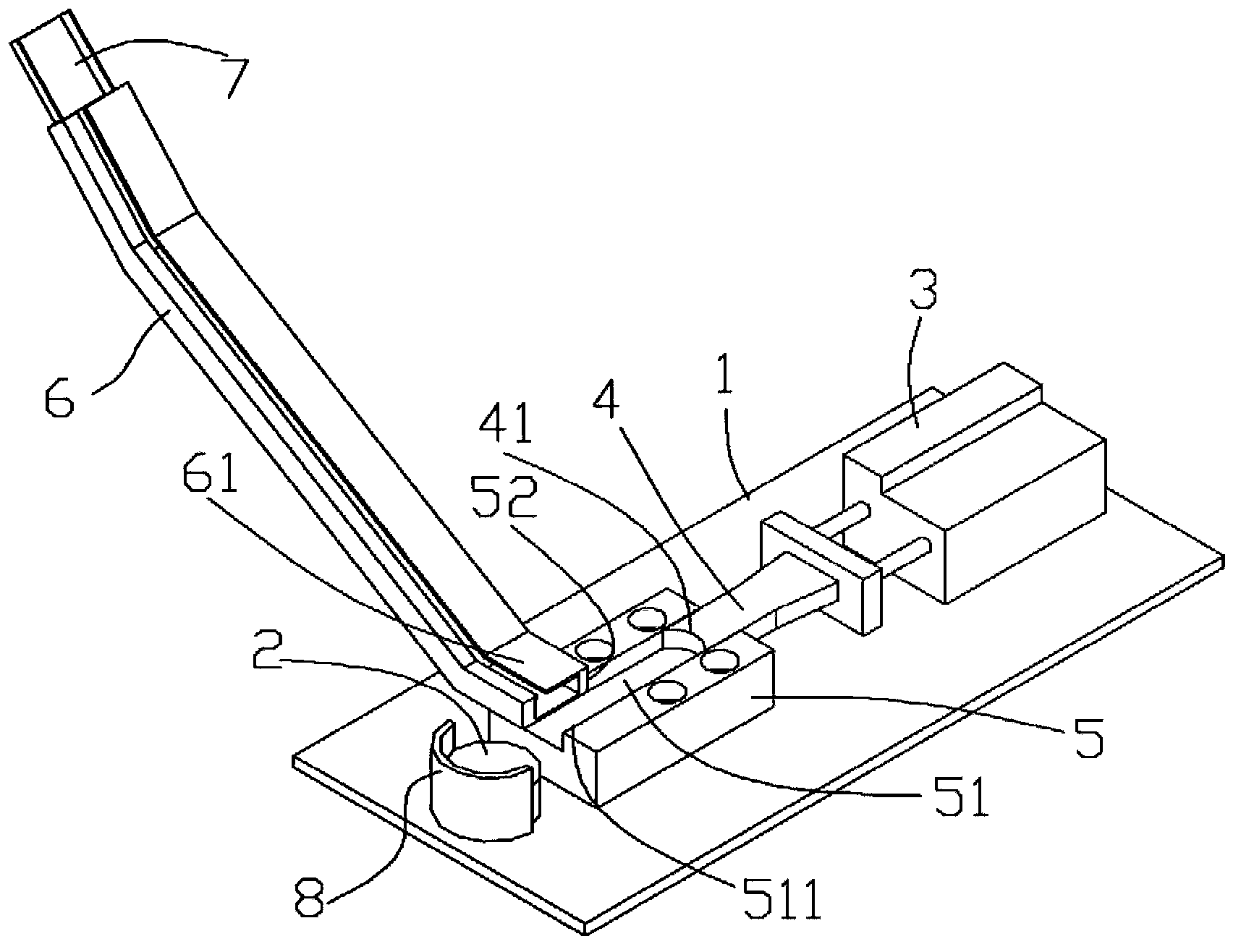

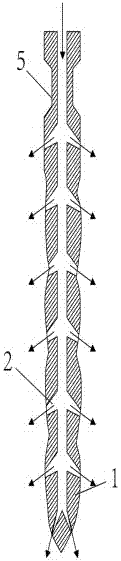

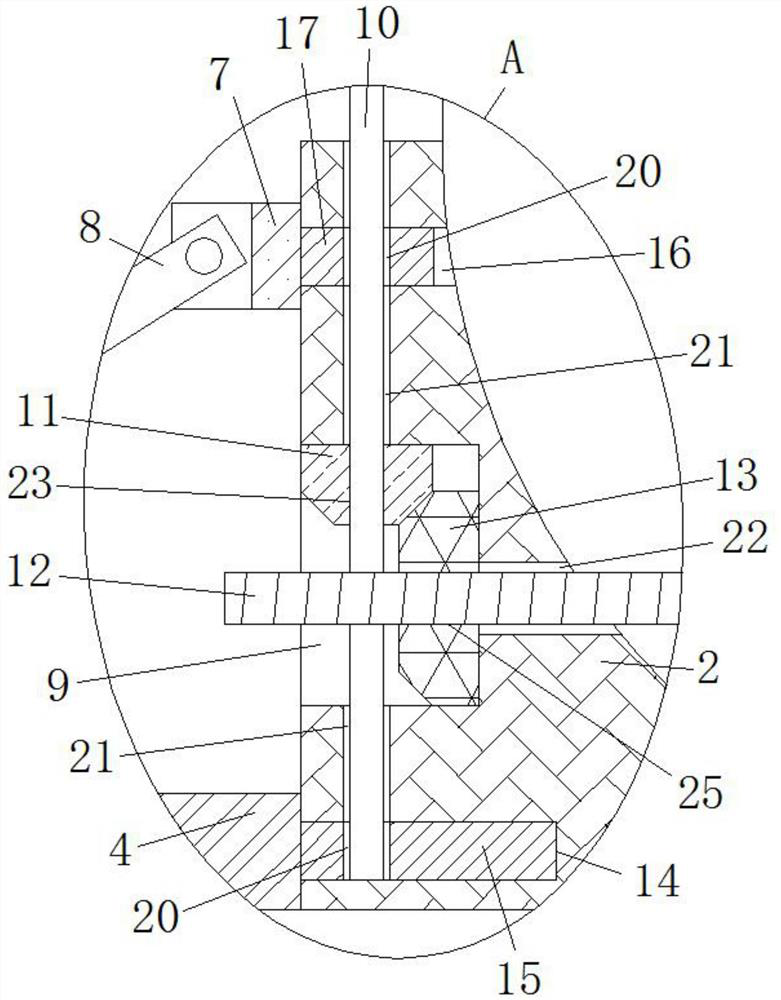

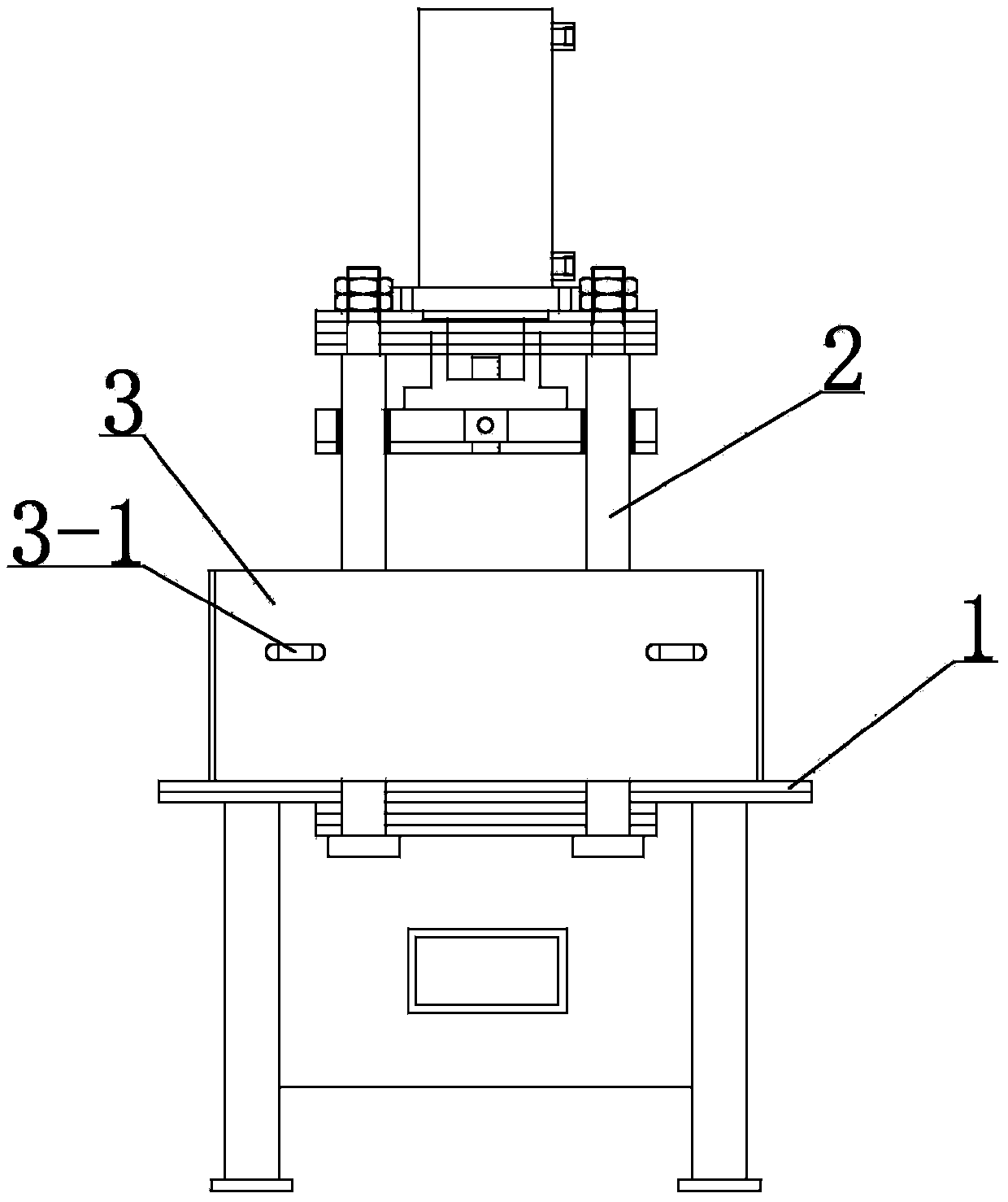

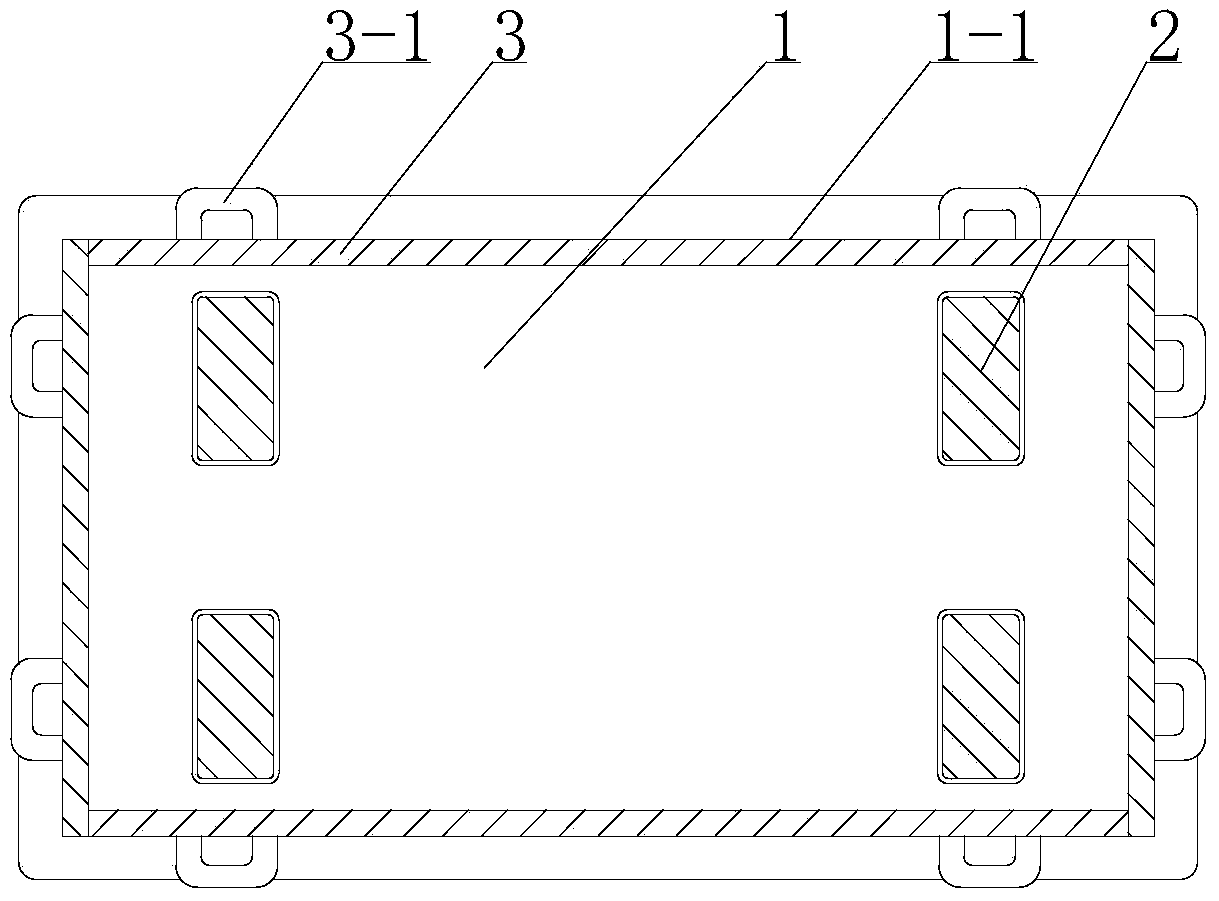

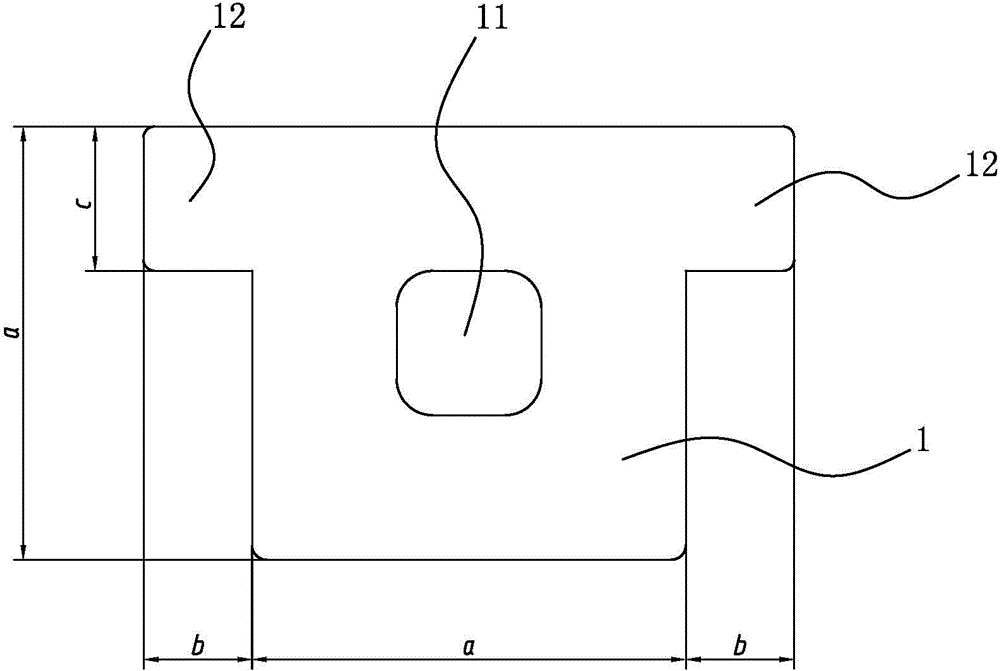

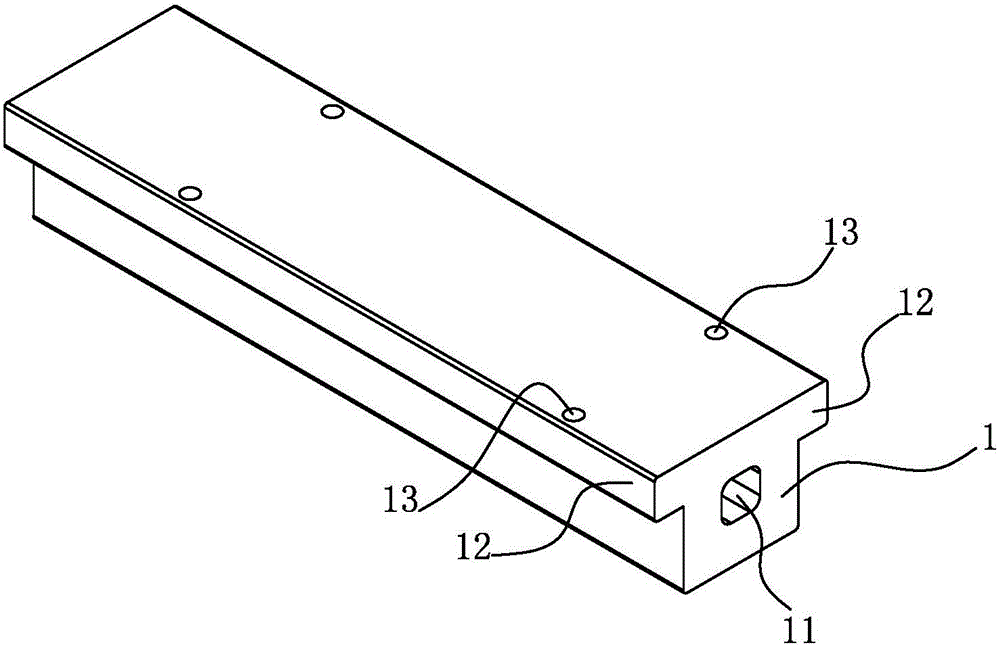

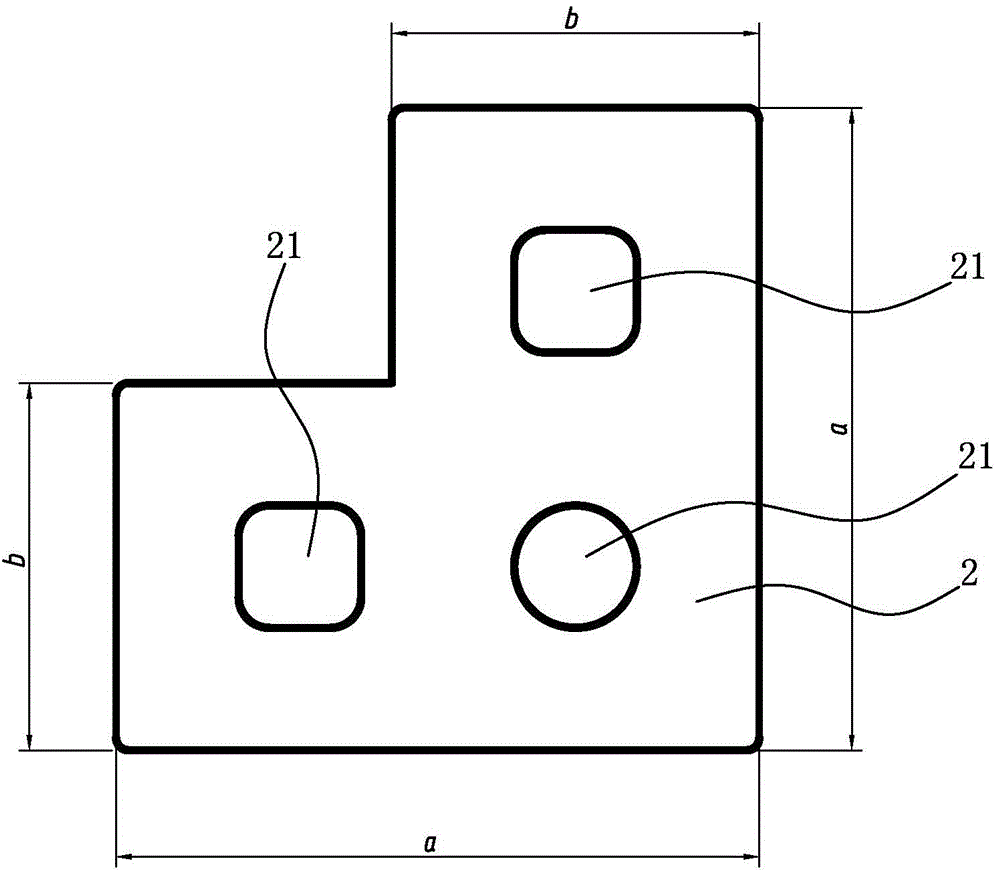

Stamping feeding device for circular workpieces

InactiveCN103406468AImprove processing efficiencyImprove stamping yieldShaping toolsMetal-working feeding devicesIndustrial AccidentPiston rod

A stamping feeding device for circular workpieces comprises a punch workbench (1); a stamping lower die (2) is fixed on the punch workbench (1); a workpiece pushing cylinder (3) is fixed on the punch workbench (1); an ejection plate (4) is fixed on a piston rod of the workpiece pushing cylinder (3); a through groove (51) and a notch (52) are formed in a square block (5); a discharge hole of a material channel (6) is connected with the through groove (51) in a communicating mode; the ejection plate (4) is inserted into the through groove (51) in a sleeve mode; a semicircular blocking piece (8) is fixed on the stamping lower die (2); a semicircular vice jaw (41) is formed at the front end of the ejection plate (4); the upper surface of the stamping lower die (2) and the bottom surface of the through groove (51) are in the same plane. The stamping feeding device for the circular workpieces has the advantages of improving the machining efficiency, avoiding industrial accidents and improving the rate of stamping finished products.

Owner:吴江市钱氏纺织有限公司

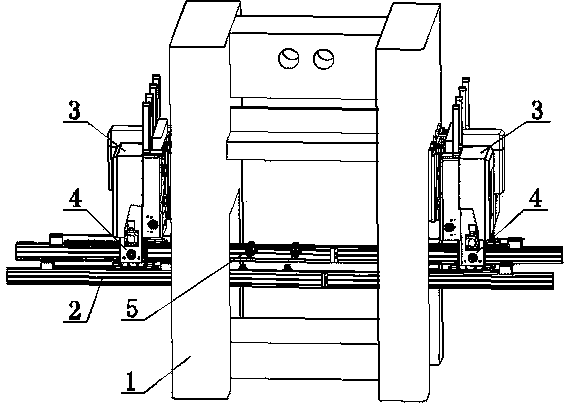

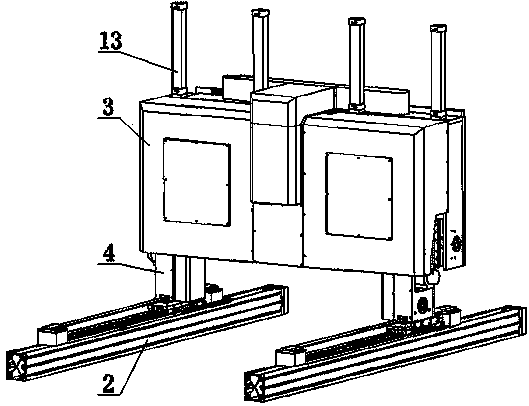

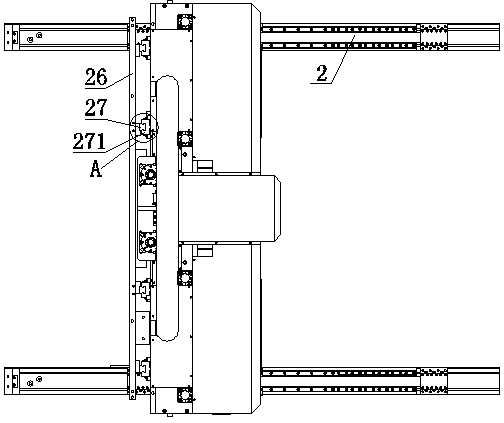

Three-dimensional mechanical arm conveyer for stamping equipment

InactiveCN103357777ASmall footprintUniform and reliable forceProgramme-controlled manipulatorMetal-working feeding devicesEngineeringManipulator

The invention relates to the technical field of stamping automation, in particular to a three-dimensional mechanical arm conveyer for stamping equipment. The three-dimensional mechanical arm conveyer for the stamping equipment comprises two fixture arms and a transmission body, and the transmission body comprises a rack which is provided with two supporting arms, a lifting transmission mechanism and a clamp opening transmission mechanism. The lifting transmission mechanism can drive the supporting arms to move up and down, the clamp opening mechanism can drive the supporting arms to move inwards and outwards, the two supporting arms are connected with the two fixture arms in a sliding mode, fixtures which can clamp stamping parts are mounted on the fixture arms, the supporting arms are provided with left-right transversely moving transmission mechanisms which can drive the fixture arms to move from left to right, the two supporting arms are symmetrically arranged on the front side of the rack, and the two fixture arms are symmetrically arranged on the back side of the rack. By means of the three-dimensional mechanical arm conveyer for the stamping equipment, lifting and transmission strength can be uniform, the occupied space of the transversely moving conveying part is reduced, and the three-dimensional mechanical arm conveyer can cooperate with large stamping equipment in use.

Owner:DONGGUAN JINGTIAN AUTOMATION EQUIP

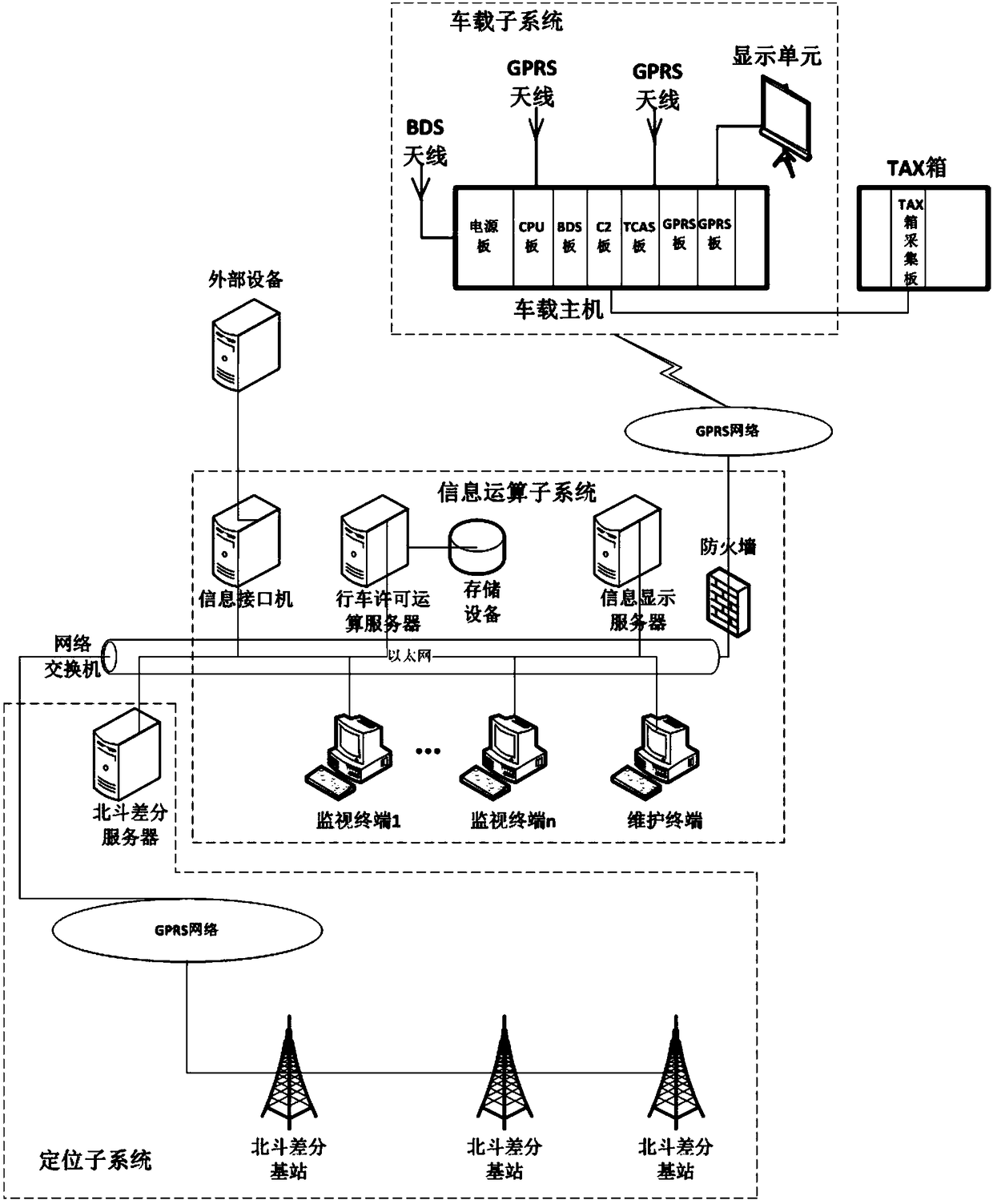

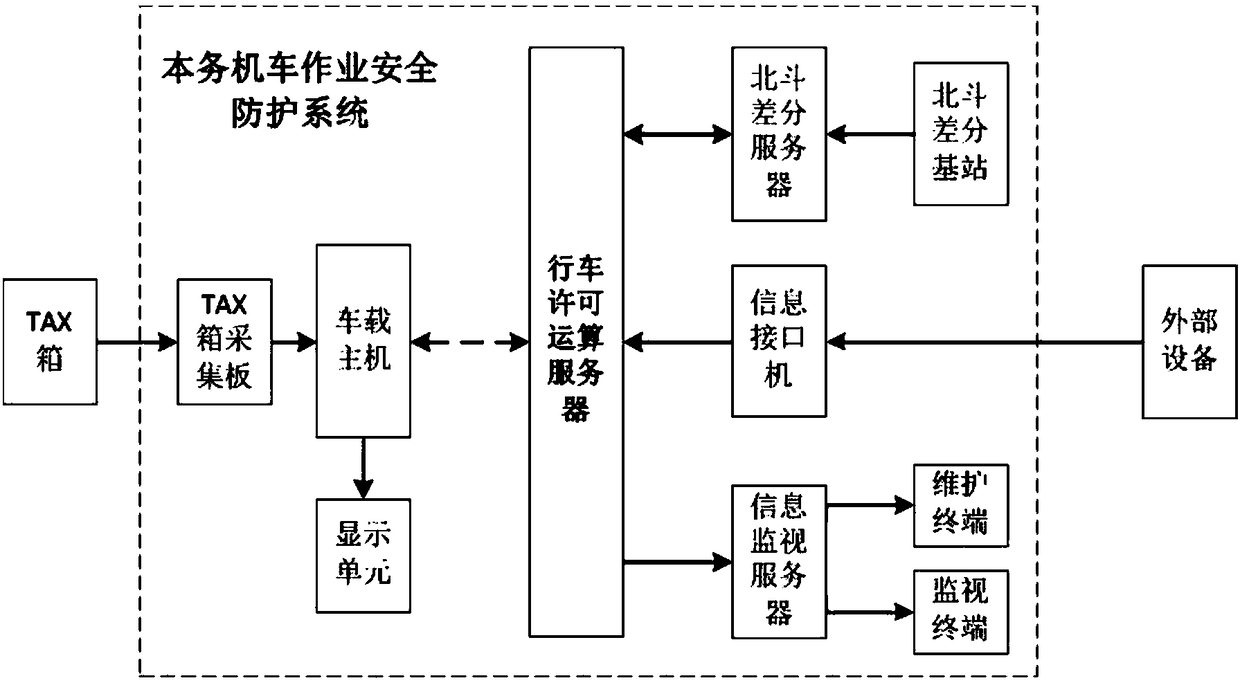

Leading locomotive operation safety protection system and method

PendingCN108622137AAvoid work accidentsRealize remote monitoringRailway traffic control systemsSignalling indicators on vehicleLongitudeEngineering

The invention provides a leading locomotive operation safety protection system and method. In the leading locomotive operation process, the position of a leading locomotive is located and tracked in real time, traveling permission information is output according to the accurate position, the station signal state and longitude and latitude station graph data in the locomotive operation process, andthen the traveling permission information is sent to a train-mounted device through a GPRS network to conduct graded early warning and display. In the device operation process, the system can classify, store and manage acquired locomotive position information, speed information, station signal state information and operation information of each subsystem, and a ground monitoring terminal can conduct real-time monitoring display and historical inquiry. The system and method have the beneficial effects that graded early warning or alarm reminding can be conducted in the locomotive operation process, meanwhile, the whole process can be monitored and recorded, an operation accident of the leading locomotive is effectively prevented from happening, and device use and maintenance conducted by auser are facilitated.

Owner:HENAN LANXIN TECH

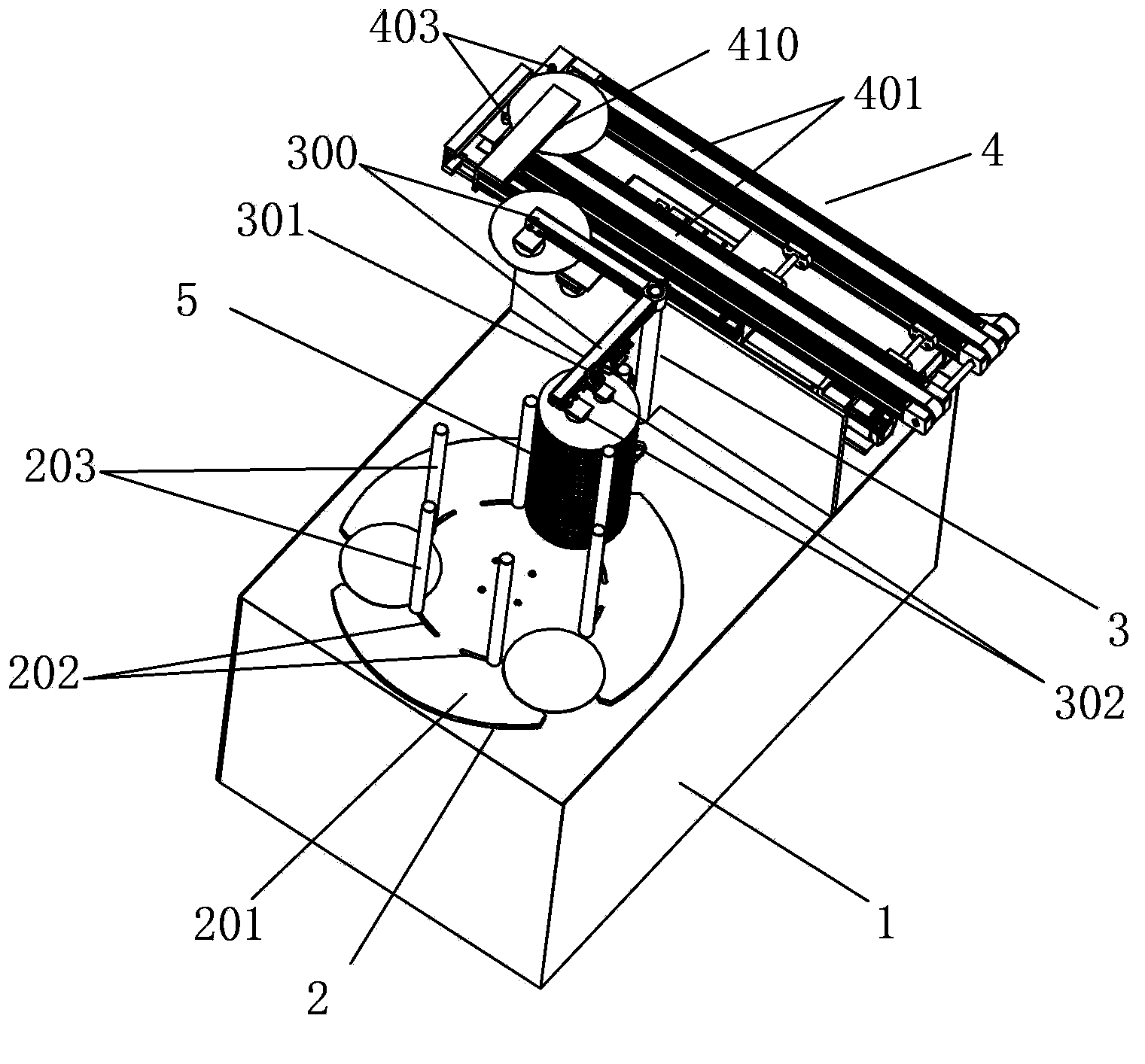

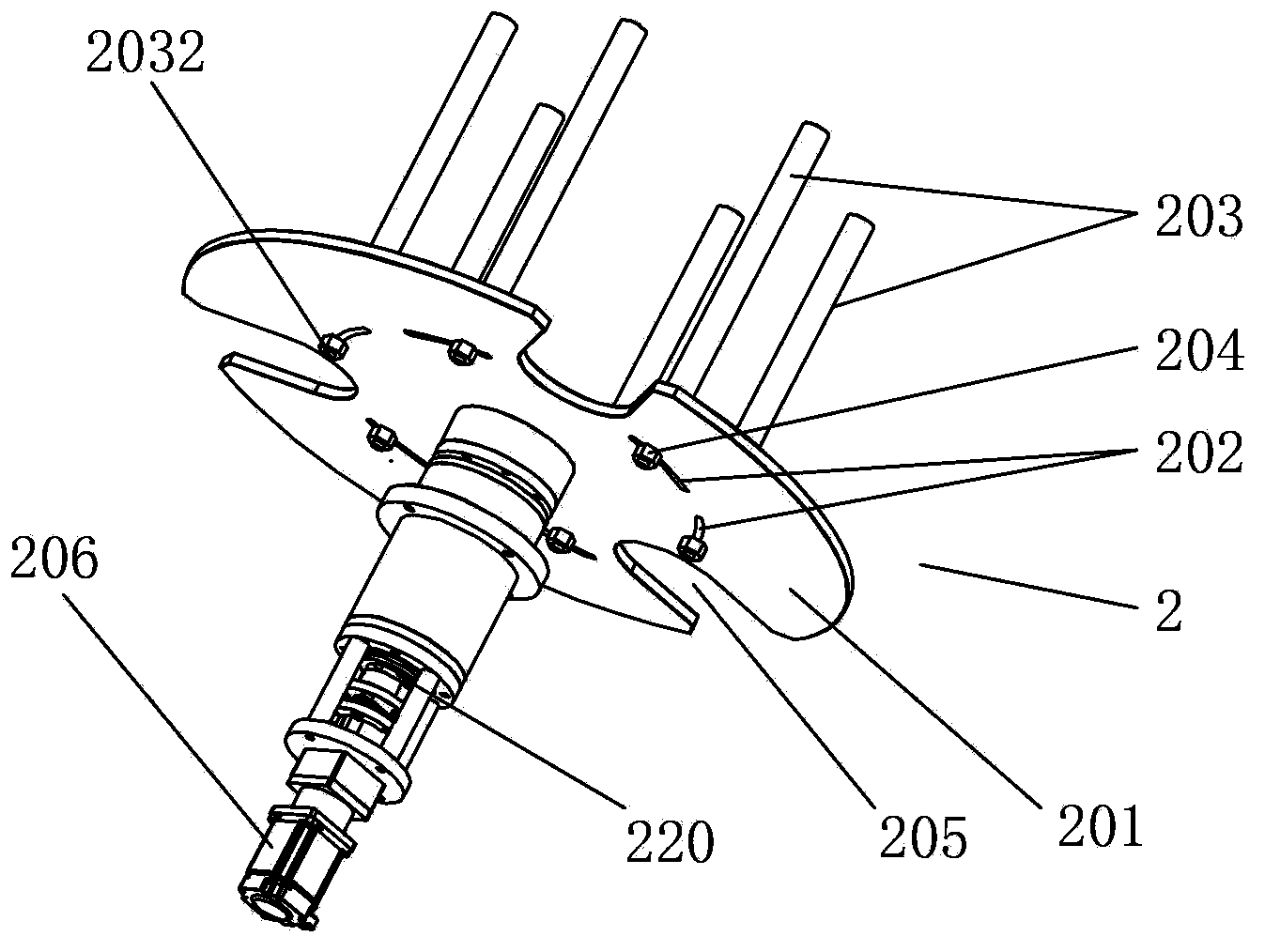

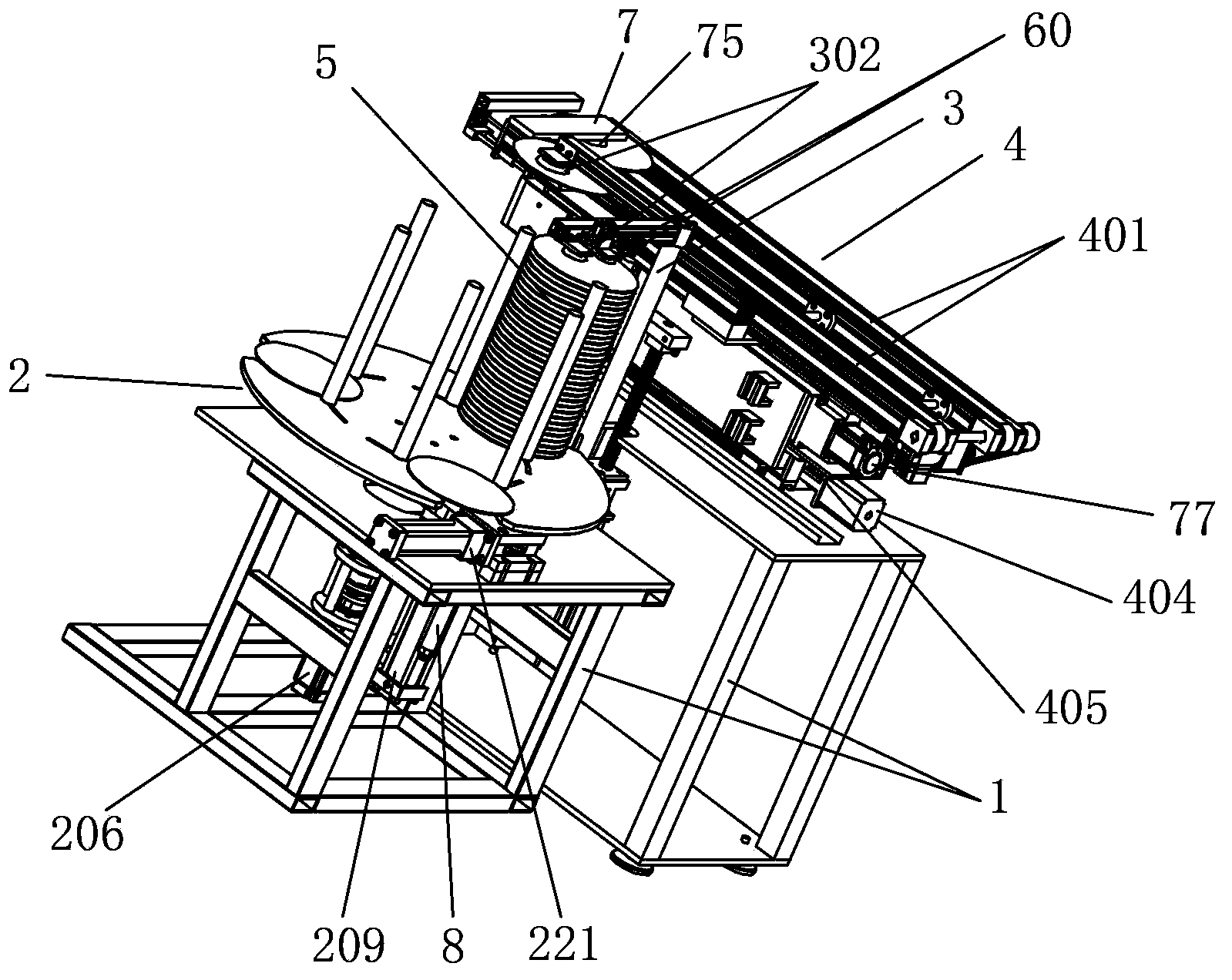

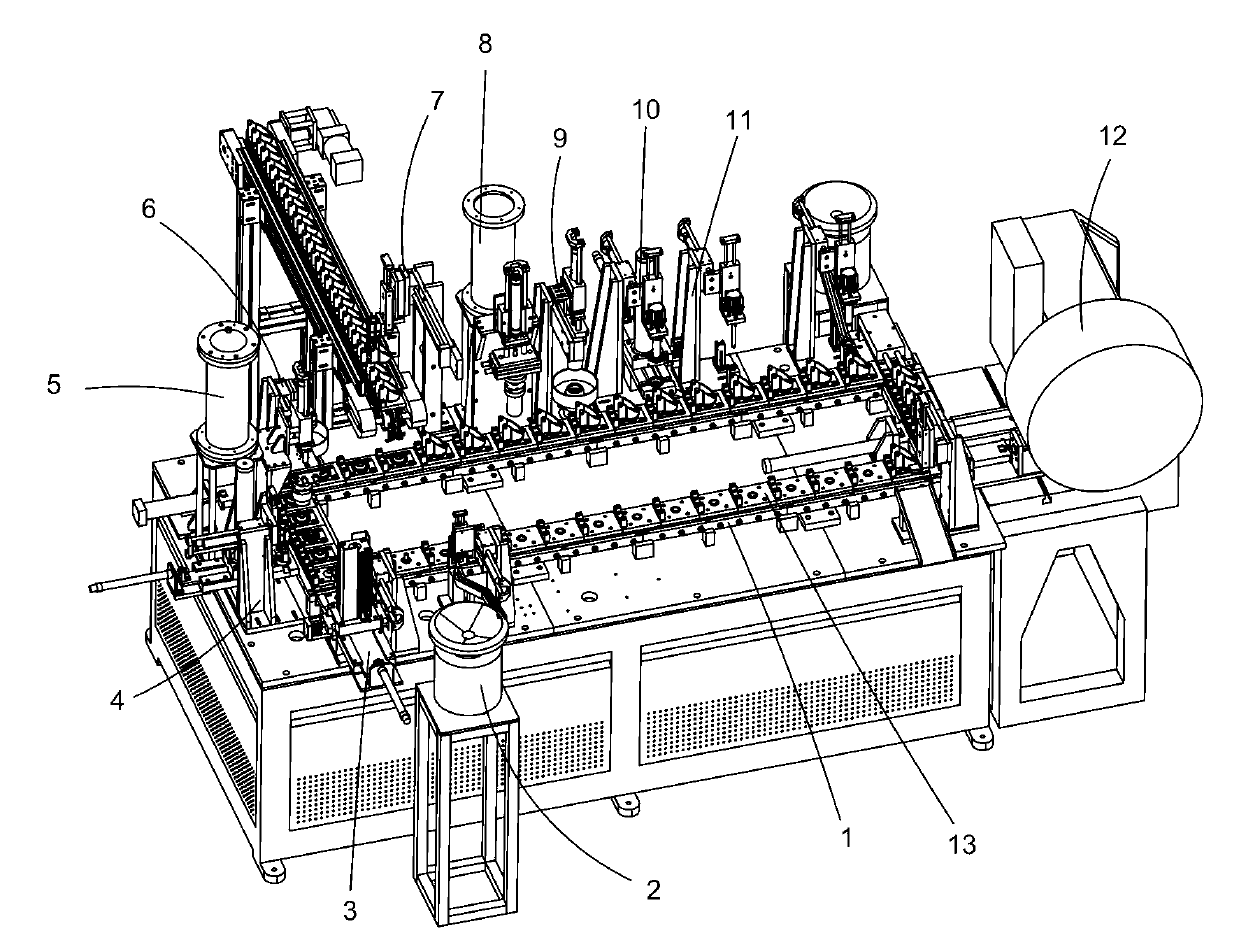

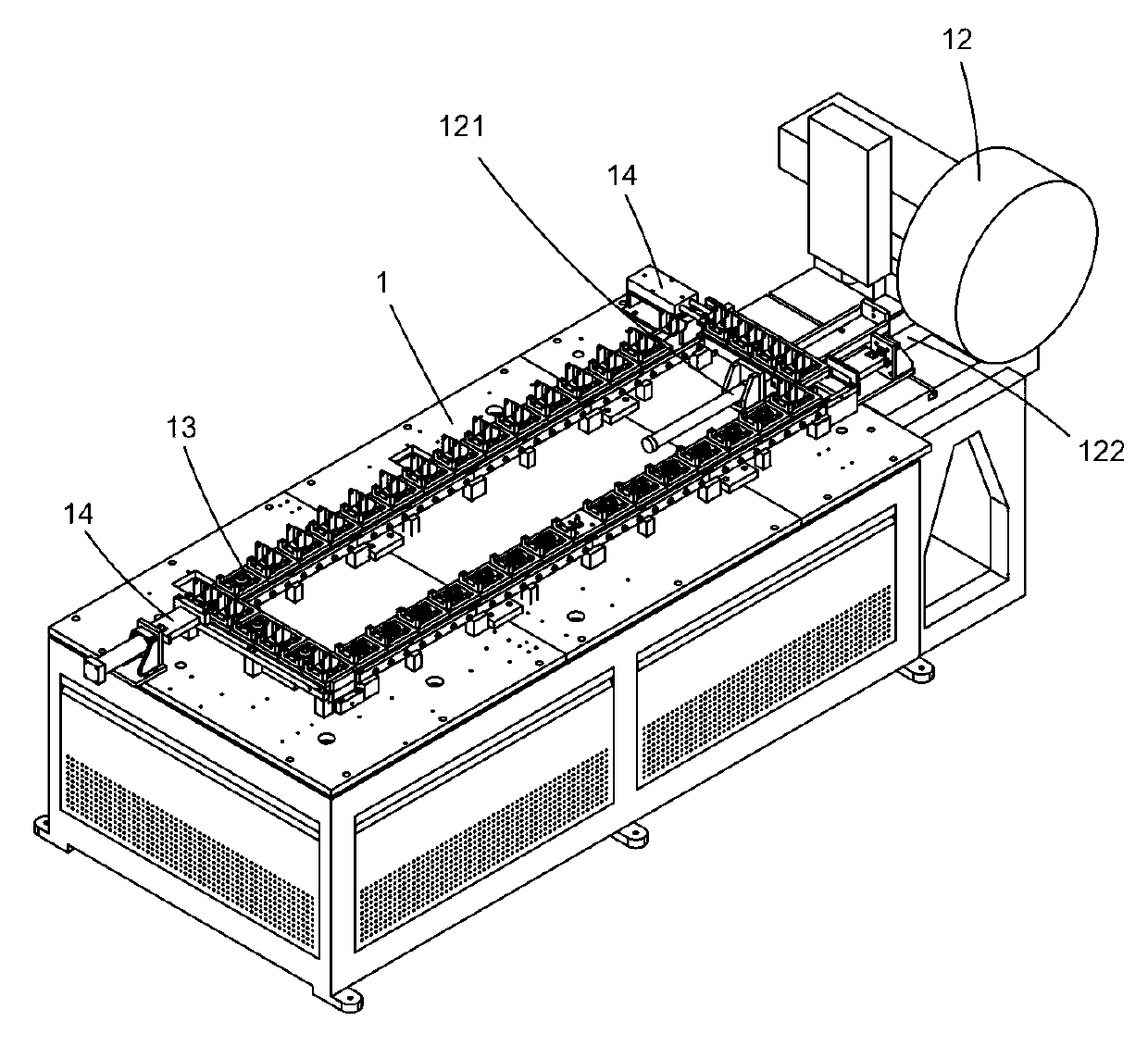

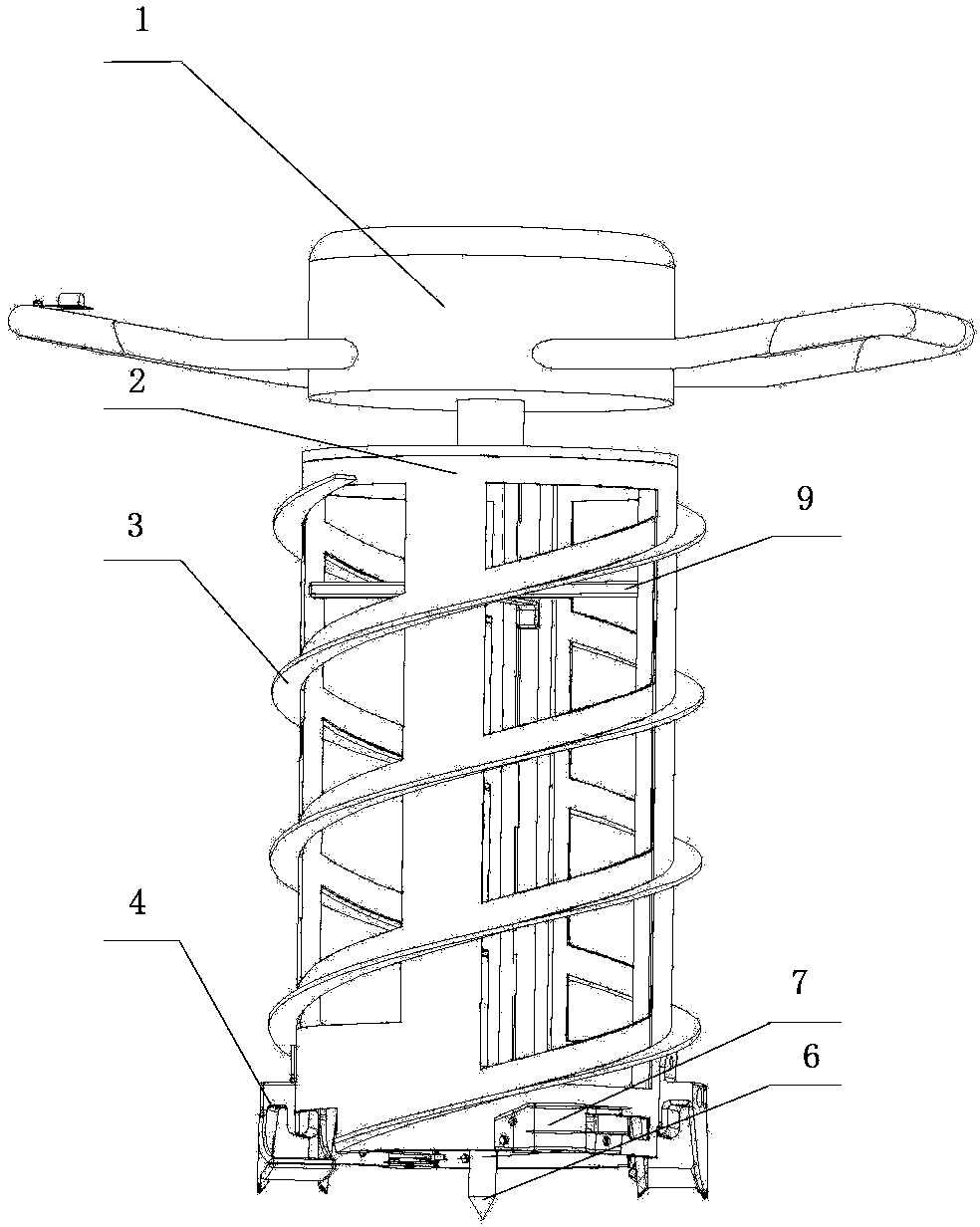

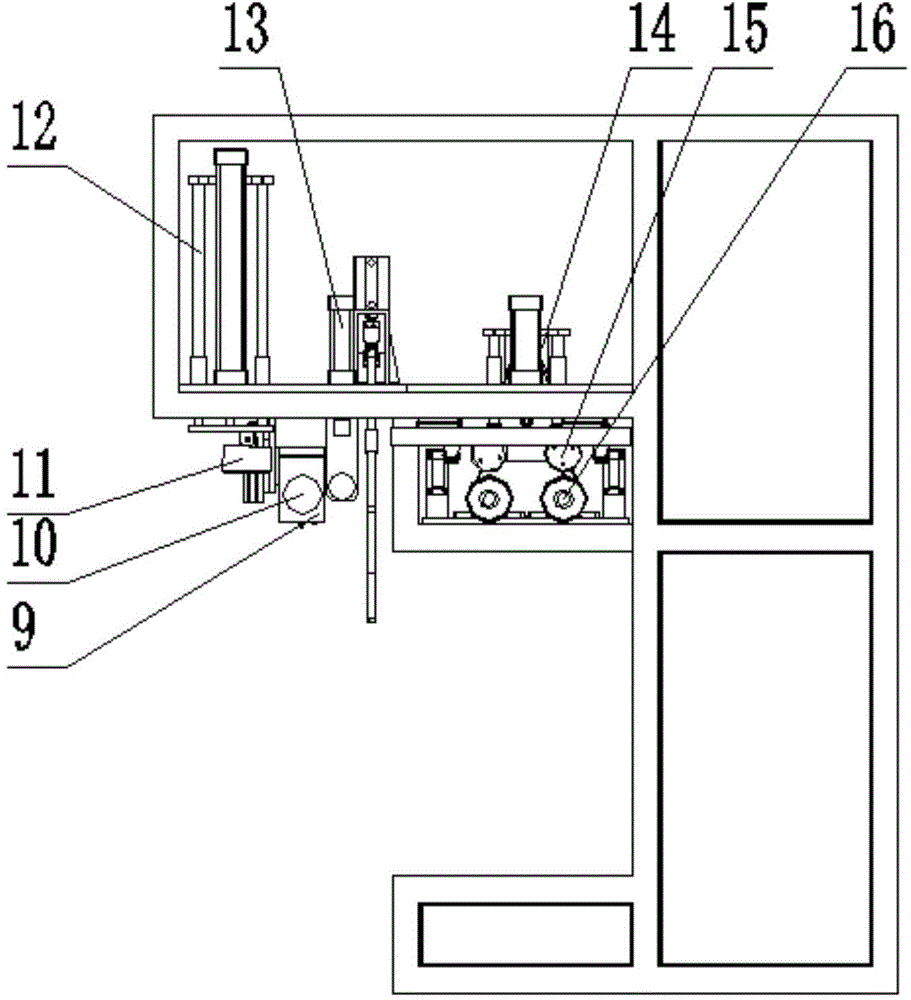

Intelligent trundle automatic assembling machine

InactiveCN103128546AIncrease productivityStreamlined manual operationsAssembly machinesElectricityIndustrial Accident

The invention provides an intelligent trundle automatic assembling machine. The intelligent trundle automatic assembling machine comprises a revolving platform, a rivet holding device, a big base plate device, a big steel ball tray device, a first oiling device, a big steel ball bunch device, a bracket system, a second oiling device, a small steel ball bunch device, a small wave plate device, a spacer device and a punch press device, wherein all the devices can be respectively installed on the revolving platform independently, also can be respectively electrically connected one by one, and are driven and controlled by a master control circuit, and simultaneously all the devices can be selectively installed on the revolving platform. Due to a purpose of achieving intelligent trundle production, the intelligent trundle automatic assembling machine can simplify hand operations on the premise of improving production efficiency, and avoids unnecessary industrial accidents.

Owner:佛山奔宇脚轮股份有限公司

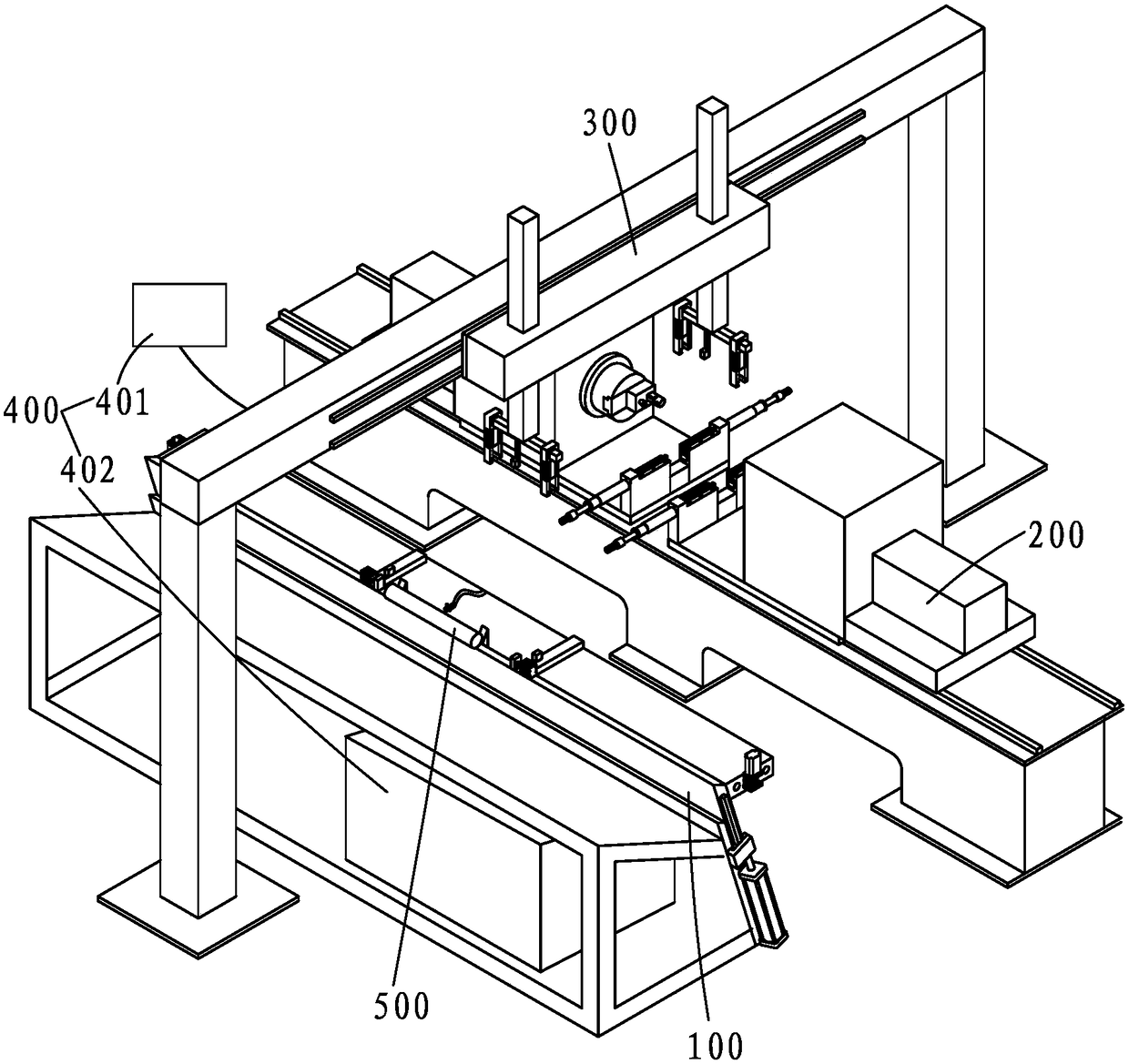

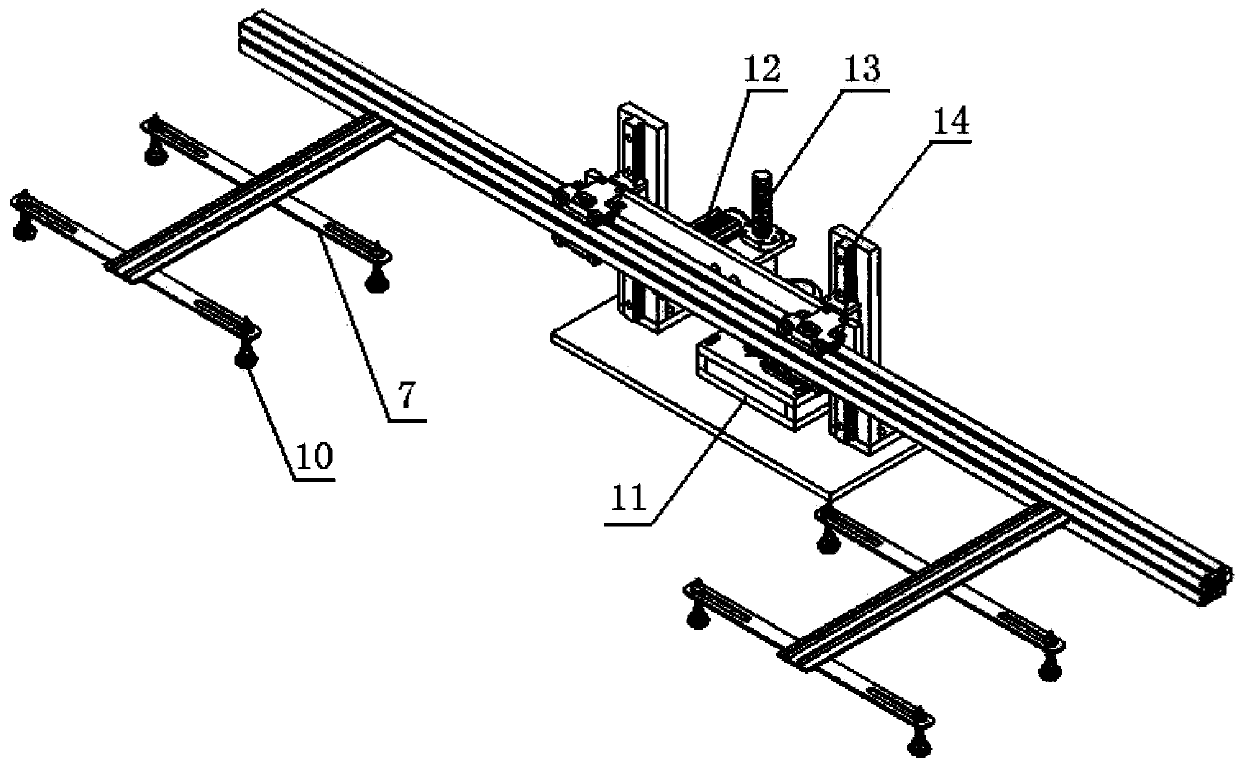

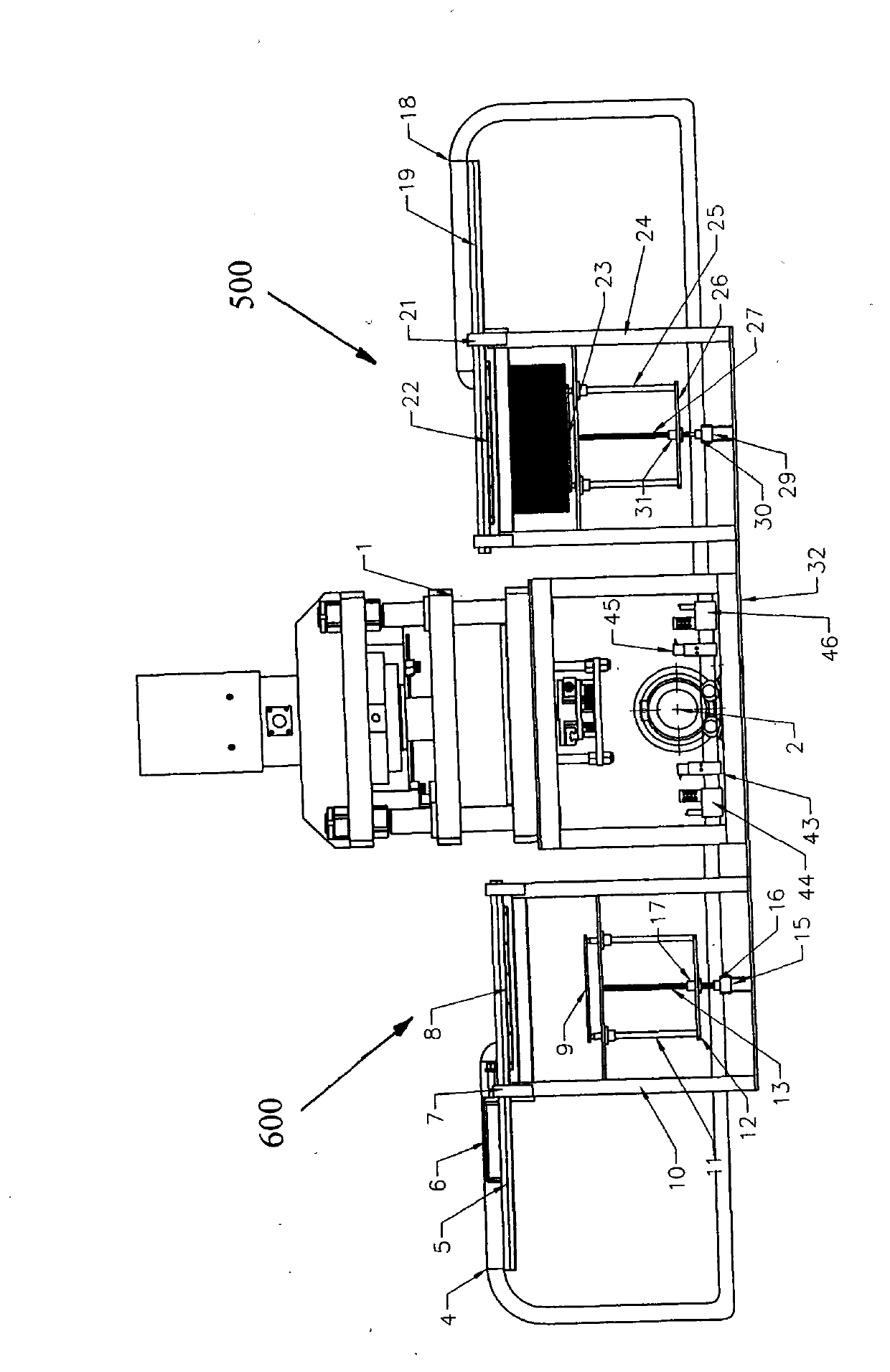

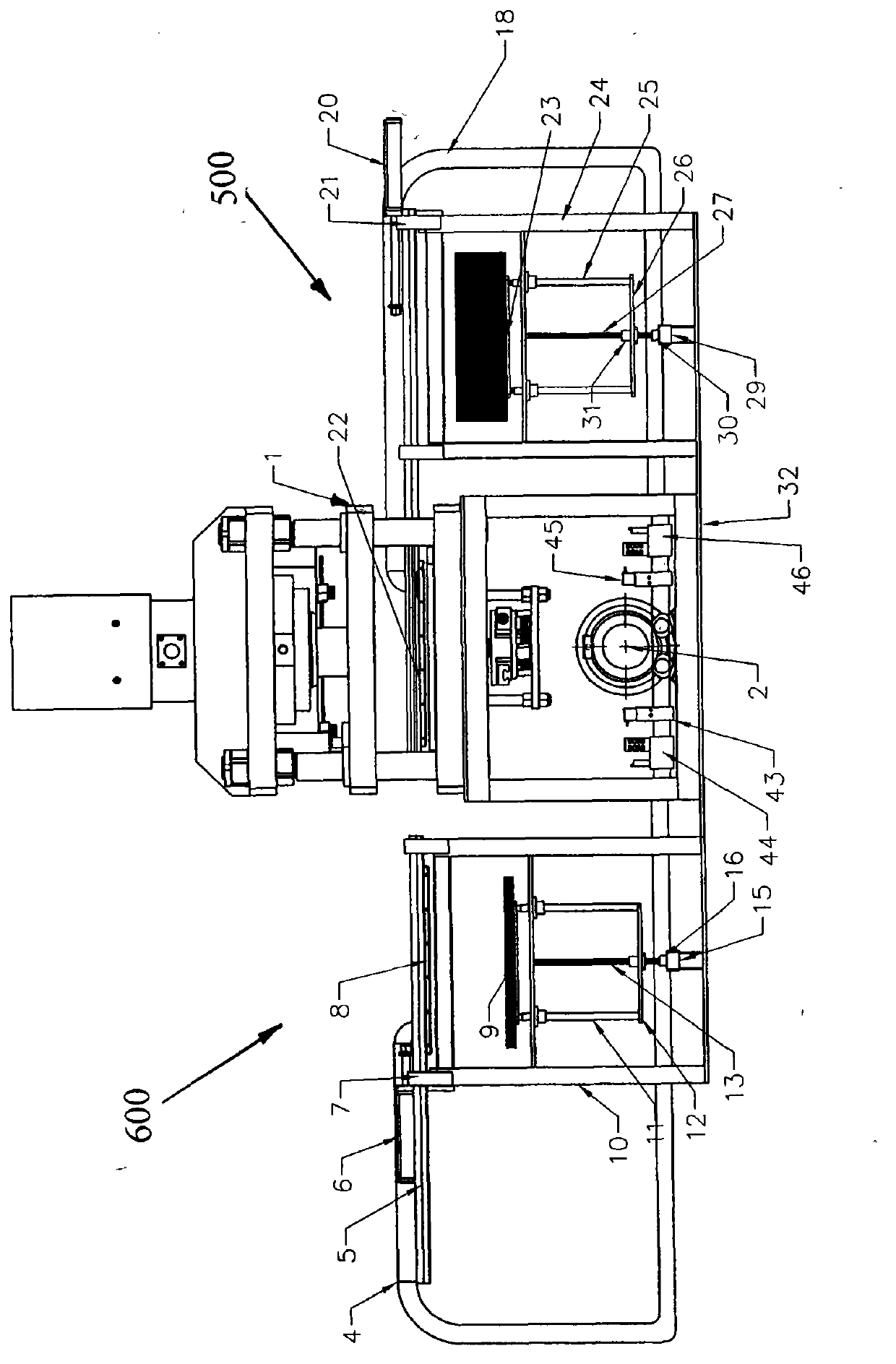

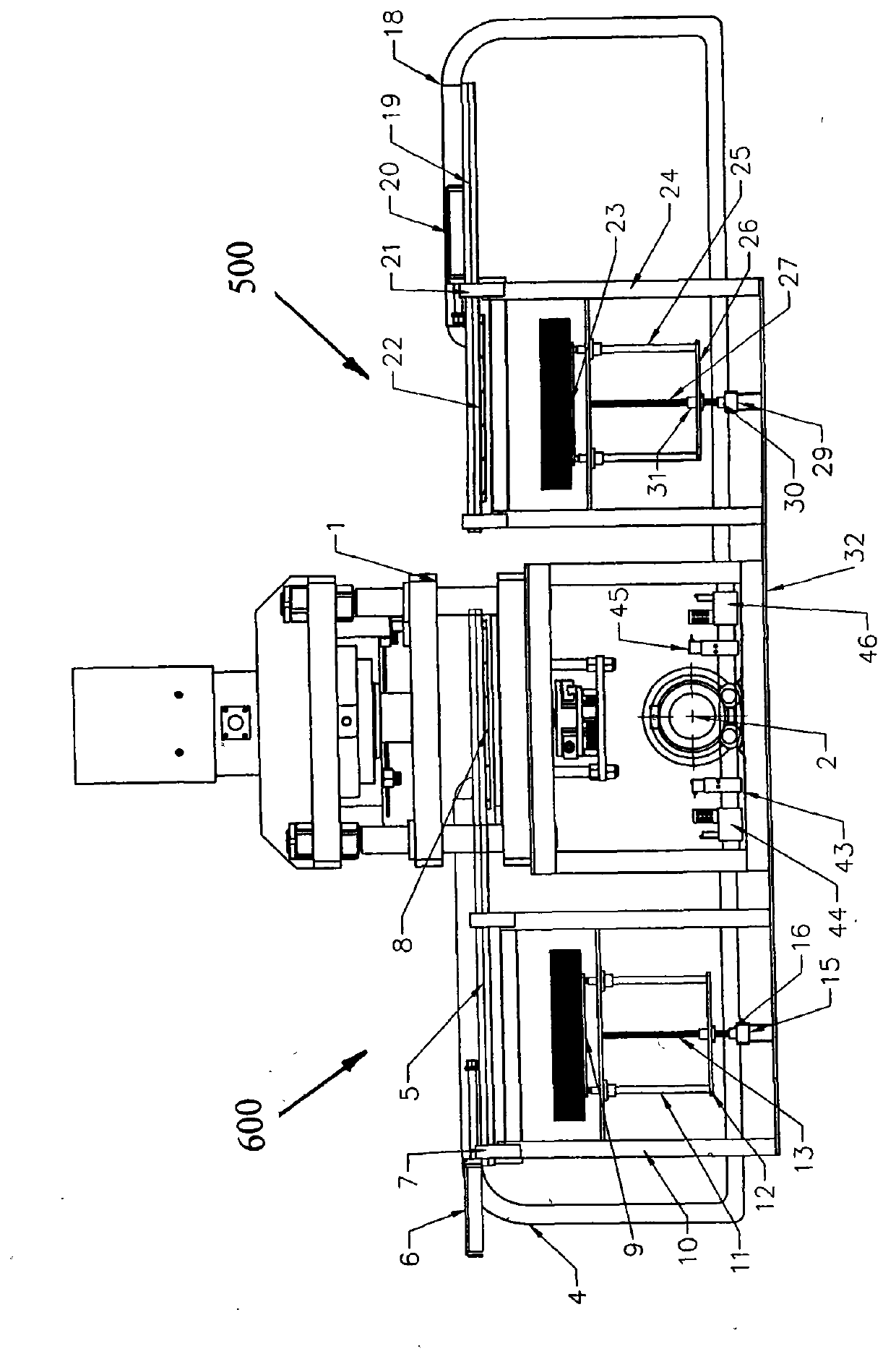

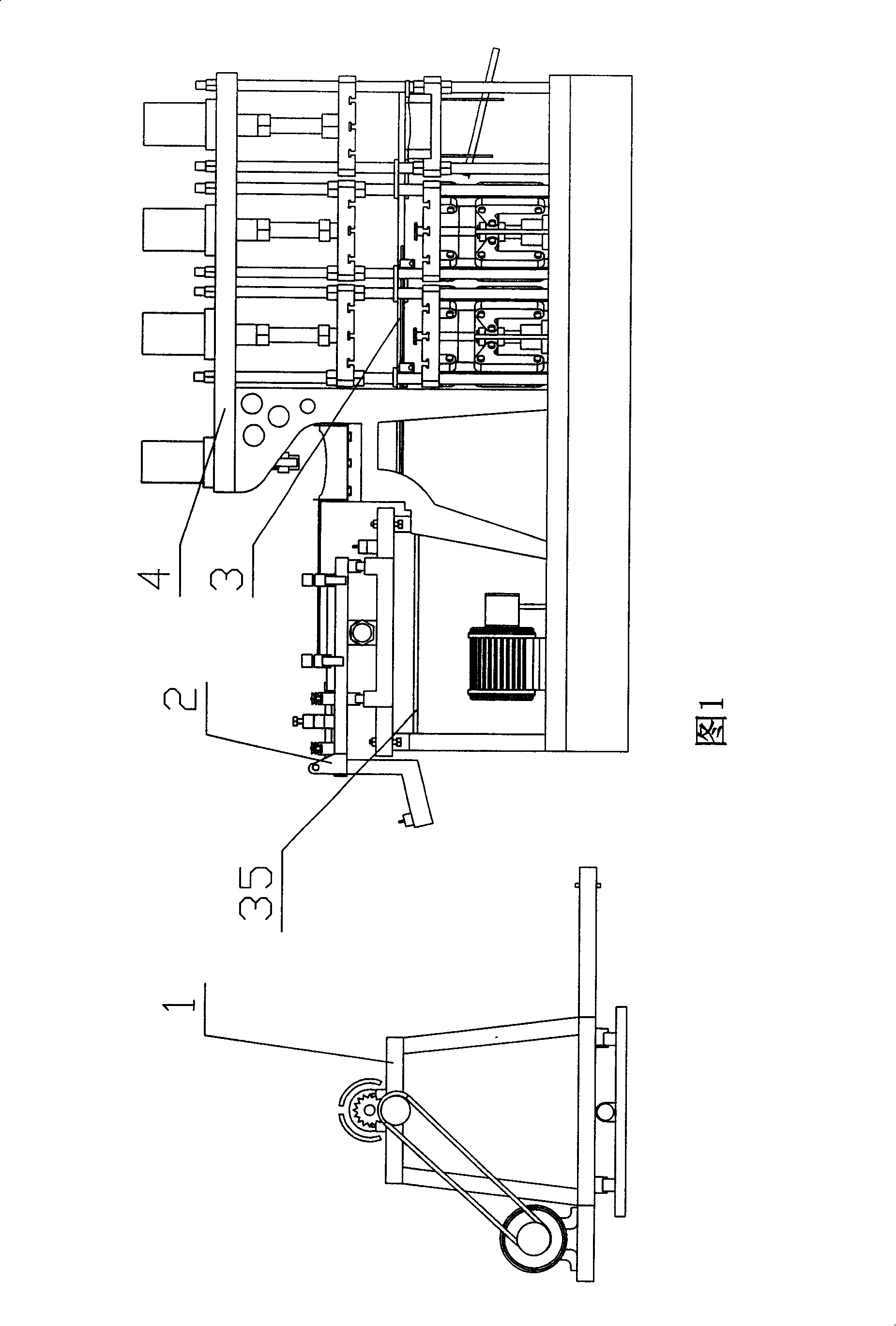

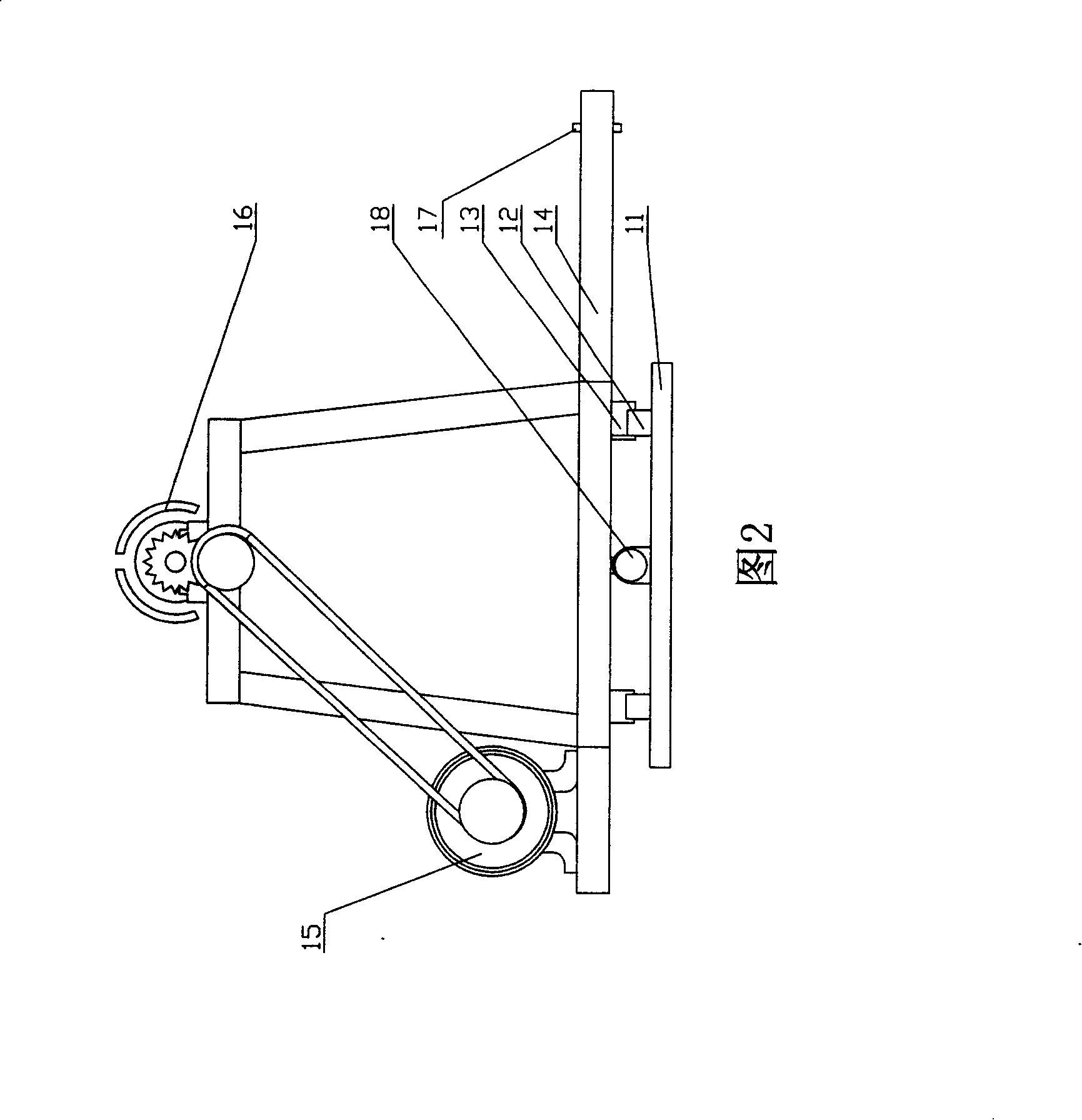

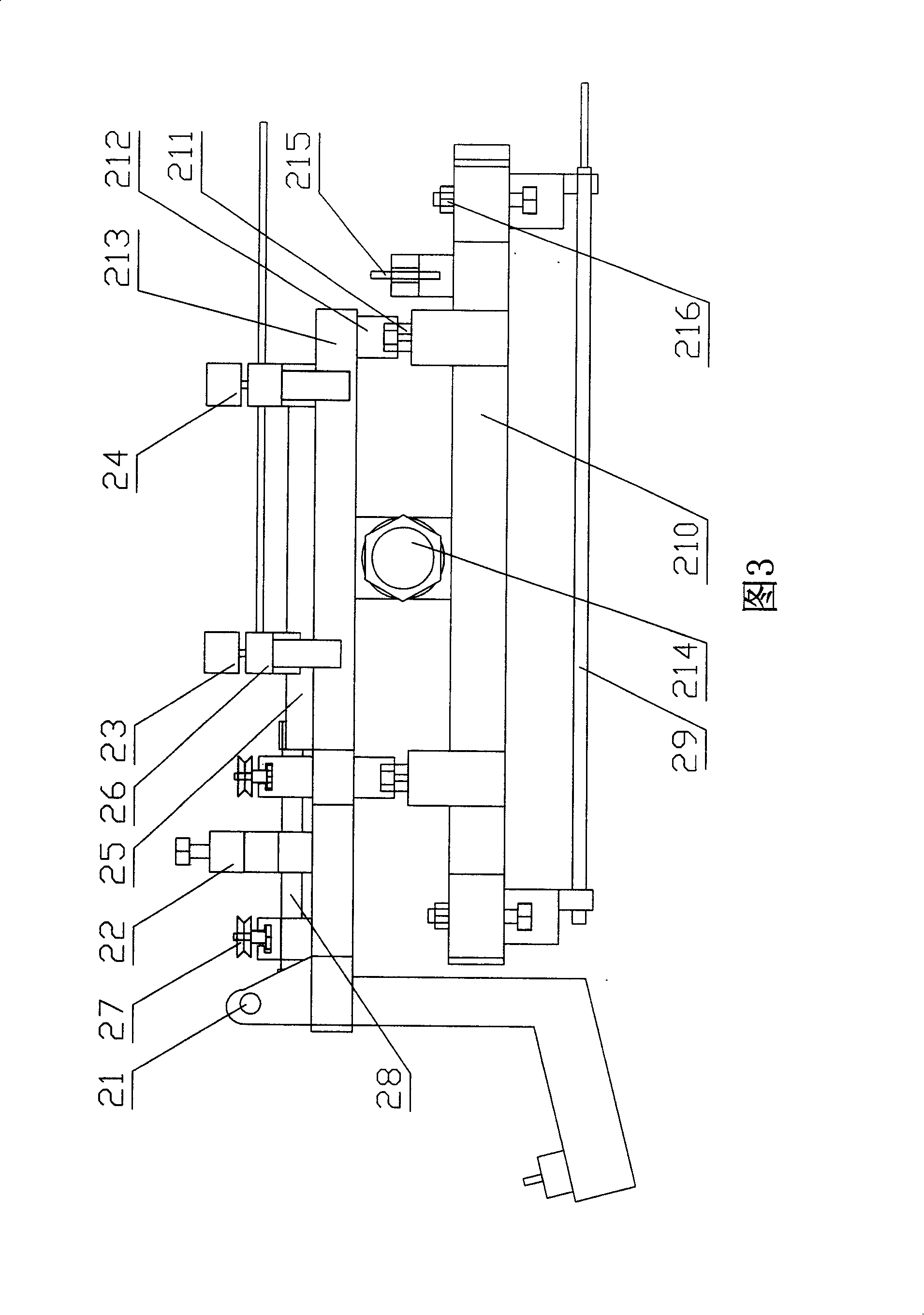

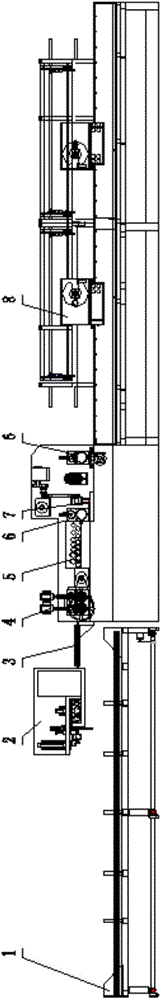

Machine tool integrating snap spring groove cutting, end face turning, chamfering and central hole punching of roller carrier shaft

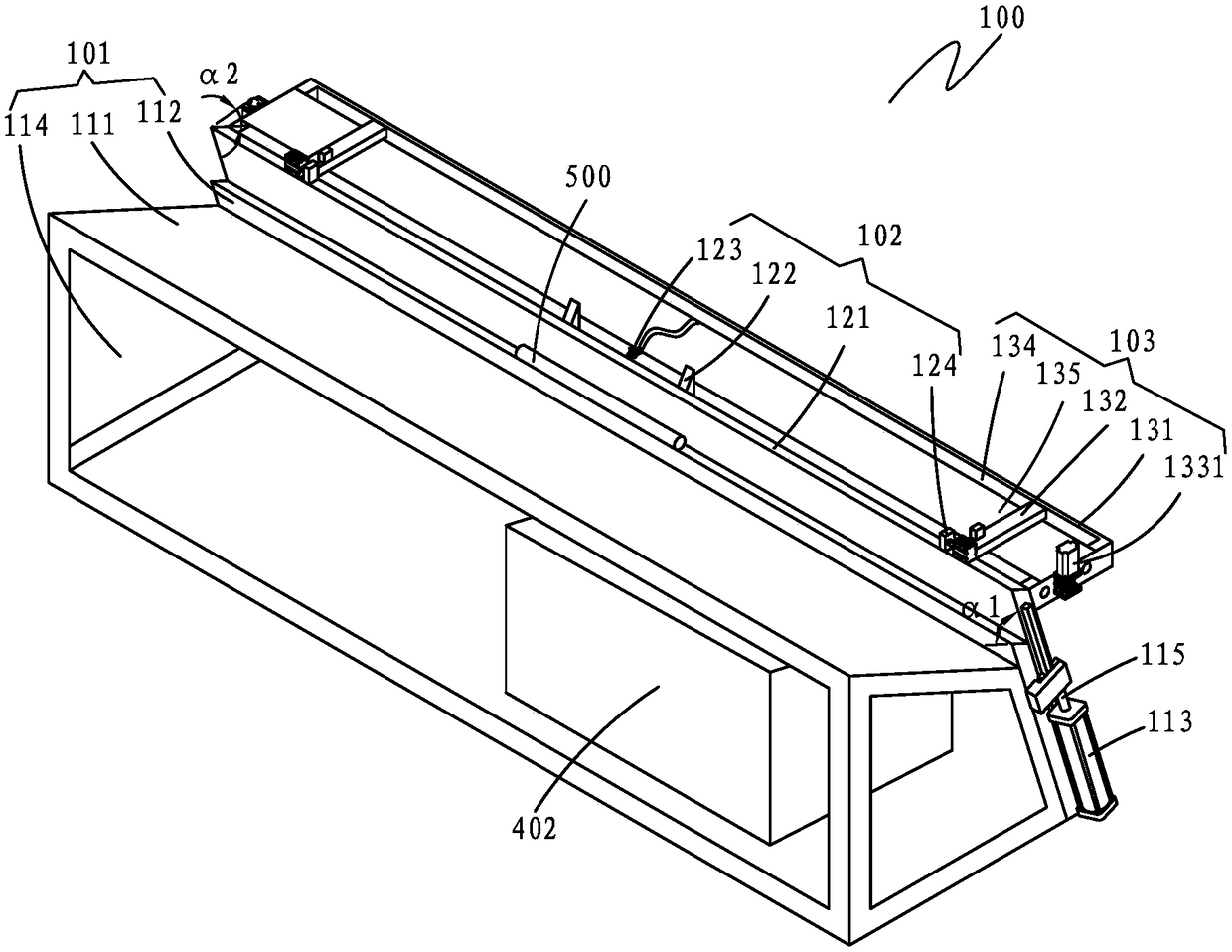

ActiveCN108381185AThe feeding stroke can be controlledImprove stabilityFeeding apparatusOther manufacturing equipments/toolsBall screwEngineering

The invention provides a machine tool integrating snap spring groove cutting, end face turning, chamfering and central hole punching of a roller carrier shaft. The machine tool comprises an automaticfeeding mechanism, a roller carrier shaft machining mechanism, an automatic material grabbing mechanism and a control mechanism. The roller carrier shaft machining mechanism comprises a machining platform, a workpiece placement platform, main linear guide rails, a roller carrier shaft machining device, a main ball screw and a main servo motor. The main linear guide rails are arranged at the end ofthe machining platform oppositely. The workpiece placement platform is arranged between the main linear guide rails. The roller carrier shaft machining device is installed on the main linear guide rails. The two sides of the main ball screw are fixed to the main servo motor and the machining platform respectively. The middle of the main ball screw is fixed to the roller carrier shaft machining device. The operation end of the roller carrier shaft machining device is flush with an arrangement port of the workpiece placement platform according to the height. The arrangement port and a placementport are arranged oppositely. Two mechanical arms of the automatic material grabbing mechanism are arranged above the arrangement port and the placement port respectively. The control mechanism is connected with the automatic feeding mechanism, the main servo motor, the roller carrier shaft machining device and the automatic material grabbing mechanism. With the machine tool integrating snap spring groove cutting, end face turning, chamfering and central hole punching of the roller carrier shaft, the machining efficiency is improved.

Owner:FUZHOU SANXUN MACHINERY

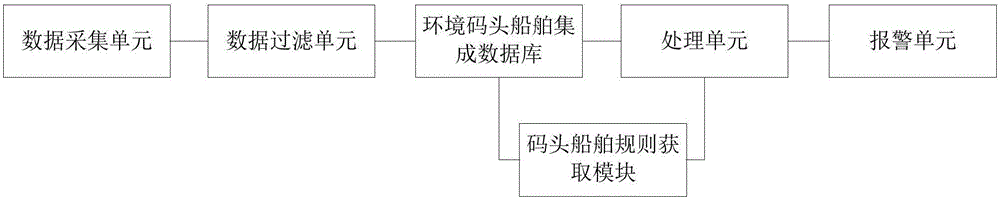

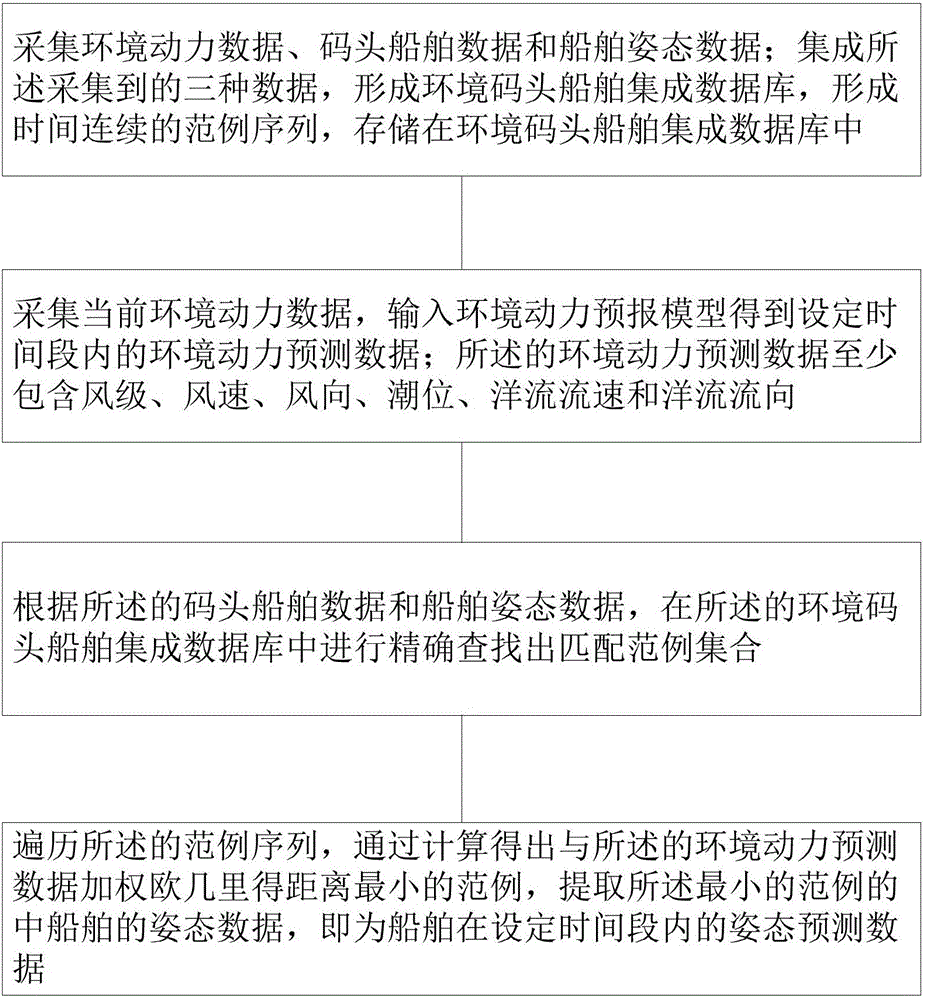

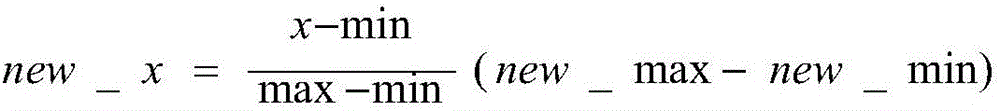

Method and system for predicting posture of ship moored at open type wharf

InactiveCN105836066ARealize reasonable schedulingEfficient use ofVessel stability improvementMovement controllersSmall sampleSample sequence

The invention discloses a method and system for predicting the posture of a ship moored at an open type wharf. The method comprises the following steps of collecting environment dynamic data, wharf ship data and ship gesture data; integrating the three data collected, to form a sample sequence in continuous time, and storing into an environment wharf ship integrated database; collecting current environment dynamic data, and inputting into an environment dynamic prediction model to obtain environment dynamic prediction data at a set time period; the environment dynamic prediction data at least including the wind scale, wind speed, wind direction, tide level, ocean current velocity and ocean current direction; traversing the sample sequence, performing calculation to obtain the sample at the smallest weighted Euclidean distance with the environment dynamic prediction data, extracting the posture data of the ship in the smallest sample, and taking the posture data as the posture prediction data of the ship at set time; and the ship posture data at least including data of six degrees of freedom, such as transversing, rolling, surging, pitching, rotating and lifting.

Owner:DALIAN JIAOTONG UNIVERSITY

Automatic stamping and conveying mechanism of duplex-glue black box threading hole

ActiveCN102179836AReduce labor intensityReduce manufacturing costMetal working apparatusEngineeringAutomatic testing

The invention relates to an automatic stamping and conveying mechanism of a duplex-glue black box threading hole, comprising a stamped bottom surface conveying device, a stamped long plate conveying device and a stamped short plate conveying device, wherein the stamped bottom surface conveying device is used for conveying a duplex-glue black box into a stamped bottom hole die; the duplex-glue black box passes through a stamped bottom hole of the stamped bottom hole die and is then conveyed into a stamped long plate die through the stamped long plate conveying device; after two sides of the duplex-glue black box are stamped, the duplex-glue black box is conveyed into a stamped short plate die by using the stamped long plate conveying device; and after short plates at two ends are stamped, the duplex-glue black box is pushed to a collection box through a stamped short plate jacking cylinder. According to the automatic stamping and conveying mechanism, the duplex-glue black box threading hole is automatically stamped by adopting the conveying mechanisms to realize automatic machining, and therefore, the production efficiency and the machining precision are improved, the labor intensity is lightened, and the production cost is reduced.

Owner:YONGGAO CO LTD

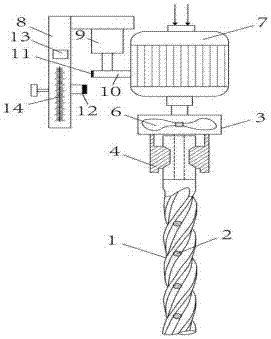

Bamboo root and tree root excavator

The invention relates to excavating machinery, in particular to an excavator used for excavating residual roots of felled plants such as bamboo roots and tree roots, and discloses a bamboo root and tree root excavator. The bamboo root and tree root excavator comprises a power device and a power control device integrated on the power device. An output shaft of the power device is fixedly connected with a cylindrical tool rest. A spiral mud guide piece is arranged on the outer wall of the cylindrical tool rest in a surrounding manner. A main tool matched with the spiral mud guide piece is fixedly arranged at the bottom of the cylindrical tool rest. Dovetail grooves are formed in the inner wall of the cylindrical tool rest. A positioning assembly is arranged in the dovetail grooves. A positioning pin is arranged at the bottom of the positioning assembly. Auxiliary tools are arranged on lateral sides of the main tool at the bottom of the cylindrical tool rest, and are movably connected with the cylindrical tool rest. Pull rod steel wires are arranged on the auxiliary tools and fixed on an auxiliary tool starting device. The auxiliary tool starting device is clamped in the dovetail grooves and positioned above the positioning assembly. The bamboo root and tree root excavator is safe, practical and effective, and applicable to different power conditions and ground conditions.

Owner:杭州吉美伟斯实业有限公司

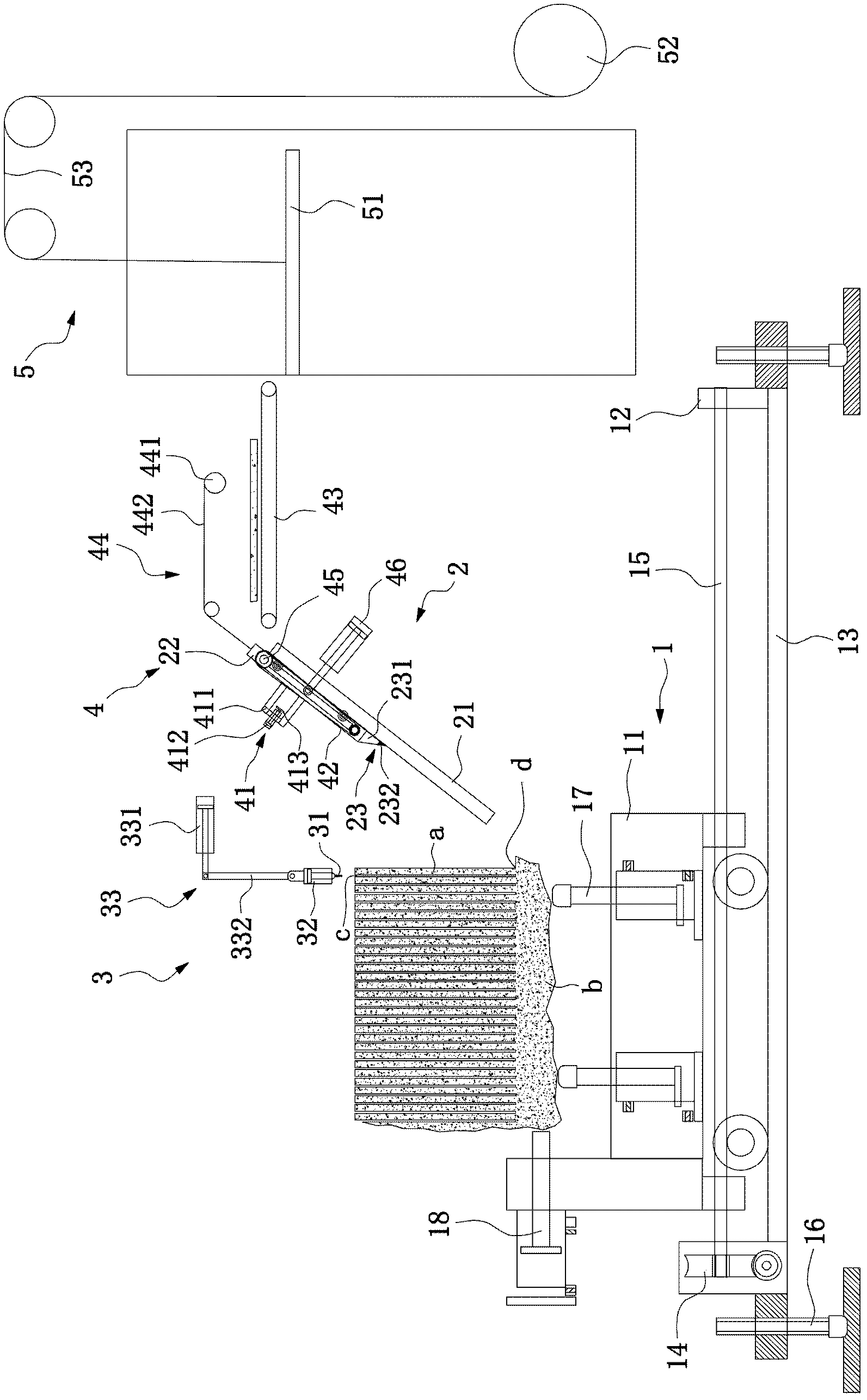

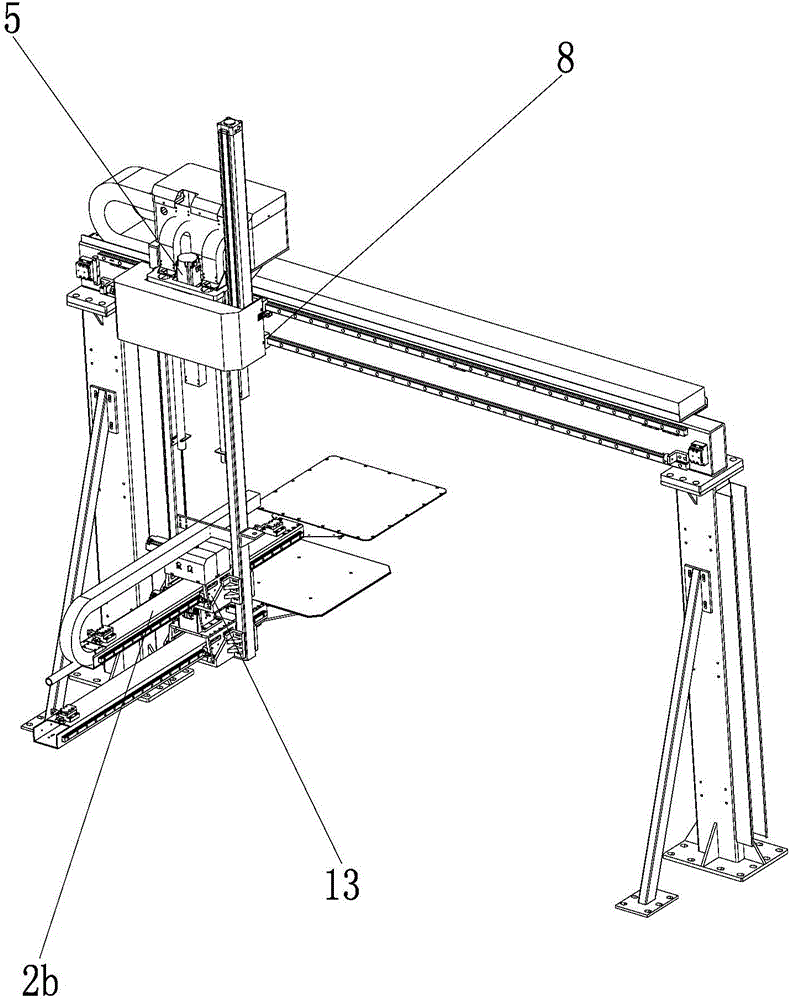

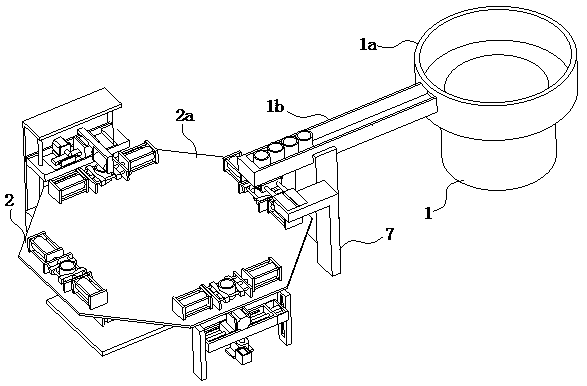

Automatic absorbing feeding device

InactiveCN103769491AReduce labor intensityAvoid work accidentsMetal-working feeding devicesPositioning devicesHydraulic cylinderPunch press

The invention provides an automatic absorbing feeding device. The feeding device comprises a feeding mechanism, a material taking mechanism, a control cabinet and a hydraulic station; wherein the feeding mechanism comprises a lateral feeding device, a material supporting platform, material supporting bins and a positioning platform; the lateral feeding device, the material supporting bins and the positioning platform are fixedly connected with the material taking platform respectively; a hydraulic cylinder is arranged at the lower part of one material supporting bin; the hydraulic cylinder is connected with the motor output end of the hydraulic station; the hydraulic station is connected with the output end of the control cabinet. The feeding device has the benefits as follows: by the arrangement of mechanical arms used for grabbing and putting down the materials, feeding and taking of stator and rotor plates can be accomplished accurately; manual participation is not needed in the whole process, so that labor intensity of workers is greatly reduced, and industrial accidents are avoided; since the feeding position is more accurate, the machining precision of the stator and rotor plates can be increased, the service life of a punching mould is prolonged, and the investment cost is reduced at the same time.

Owner:SHIJIAZHUANG LIANCHUANGZHONG NEW TECH

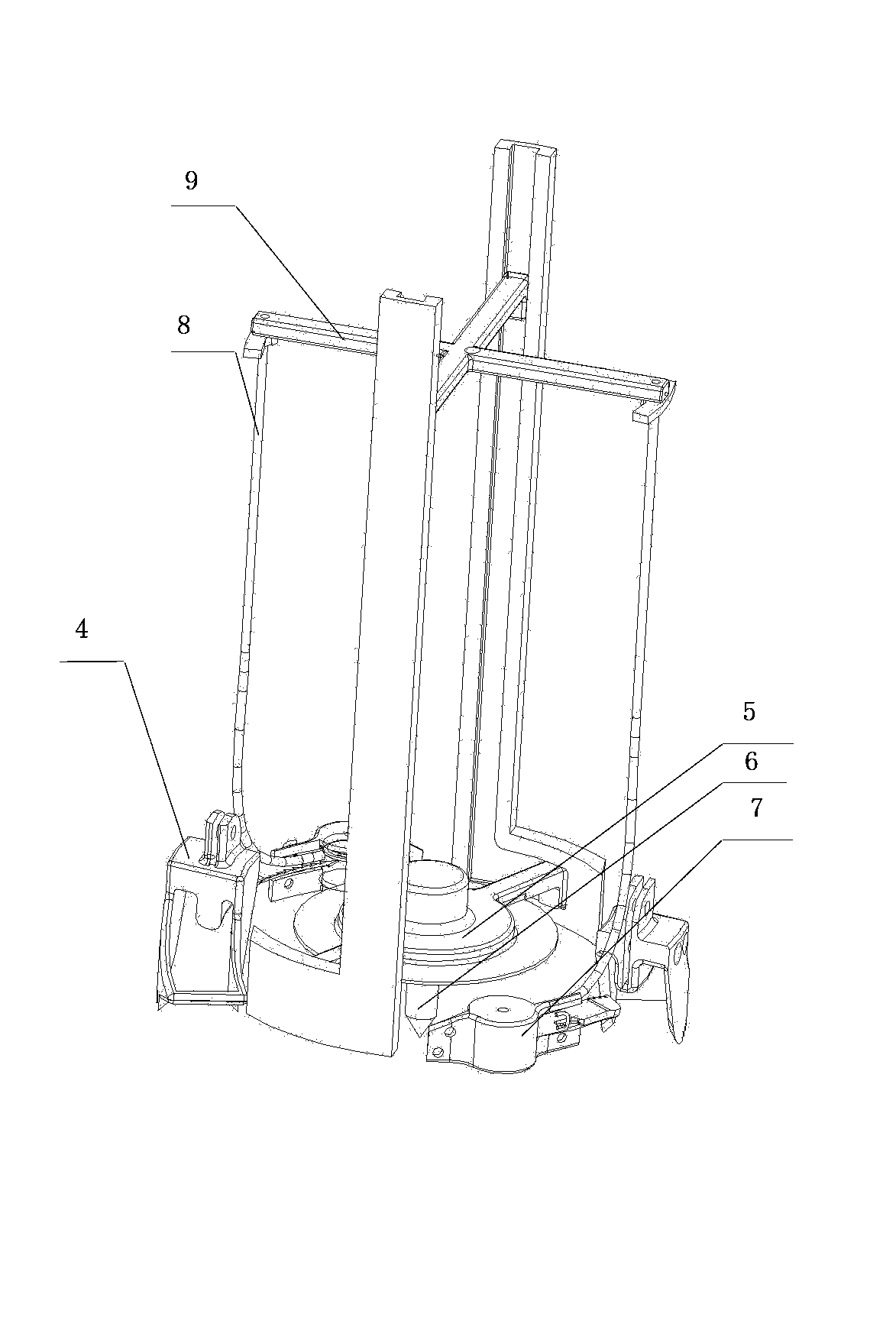

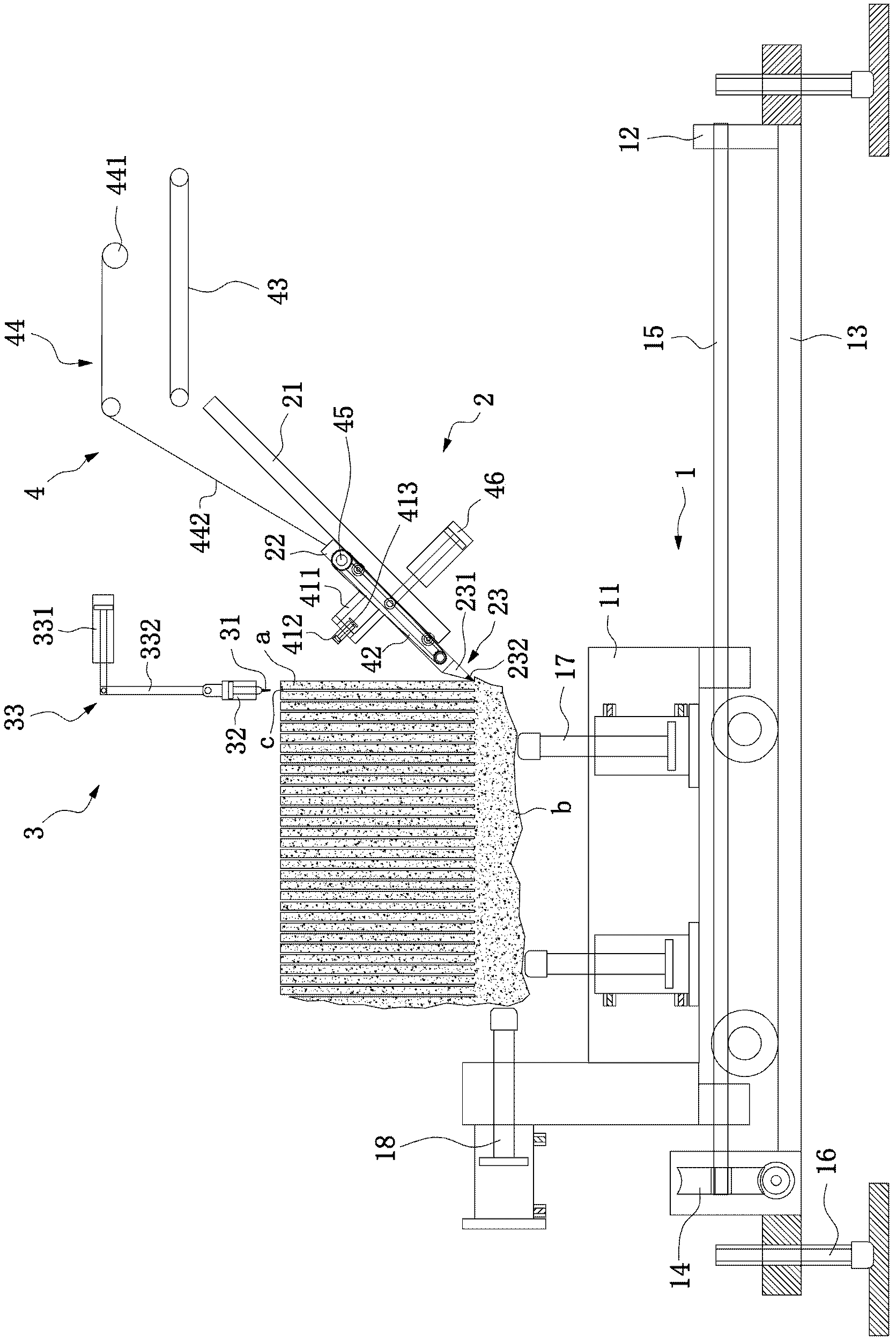

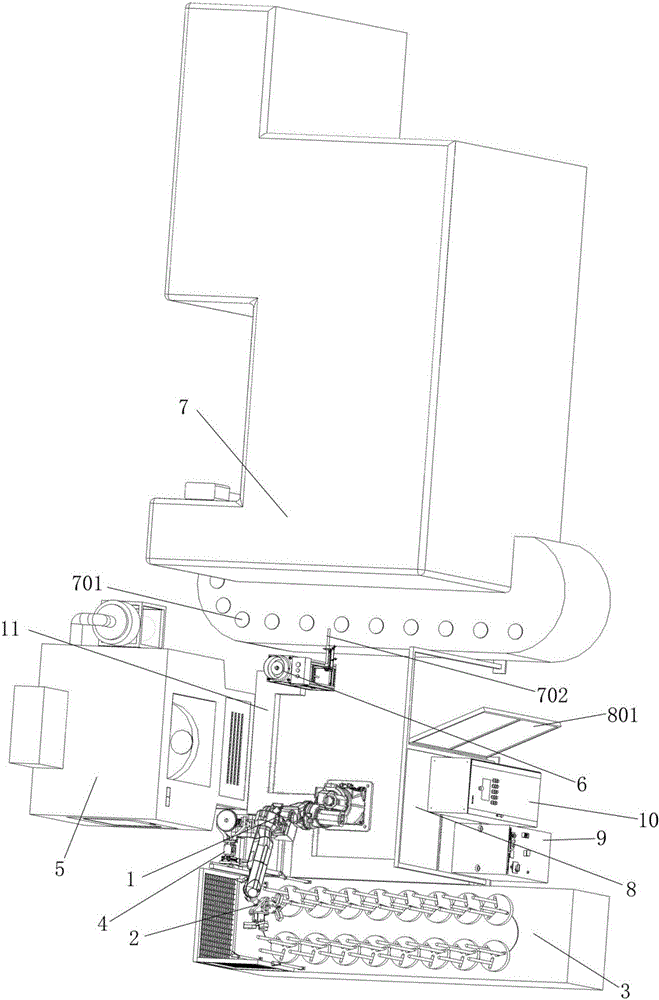

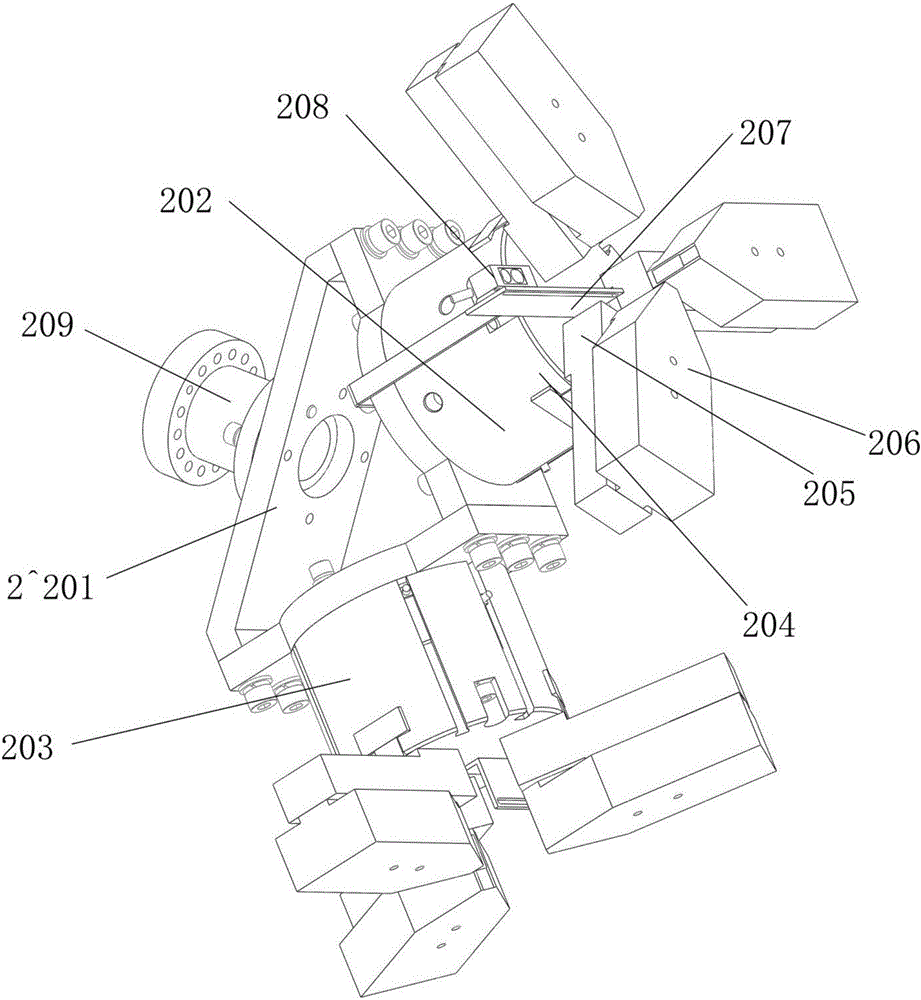

Automatic material feeding and taking robot

ActiveCN103962470AReduce labor intensityAvoid work accidentsMetal-working feeding devicesStripping-off devicesProduction rateOil pressure

The invention provides an automatic material feeding and taking robot. The automatic material feeding and taking robot comprises a chassis, a material feeding device, a material taking device and a vacuum pump, wherein the material feeding device and the material taking device are fixed on the chassis; the vacuum pump is arranged on the chassis and positioned between the material feeding device and the material taking device; the material feeding device comprises a material feeding rack, a material feeding pushing mechanism, a material feeding vacuum adsorption mechanism and a material feeding lifting mechanism; the material taking device comprises a material taking rack, a material taking pushing mechanism, a material taking vacuum adsorption mechanism and a material taking lifting mechanism; the material feeding device is used for sucking a to-be-processed sheet and placing the to-be-processed sheet at a processing position of an oil pressure slicing machine; the material taking device is used for sucking the processed sheet away from the oil pressure slicing machine. According to the automatic material feeding and taking robot, the labor intensity of workers is reduced, an industrial accident is avoided, and the production rate and the product yield are greatly improved.

Owner:DONGGUAN CITY HONGQI MACHINE CO LTD

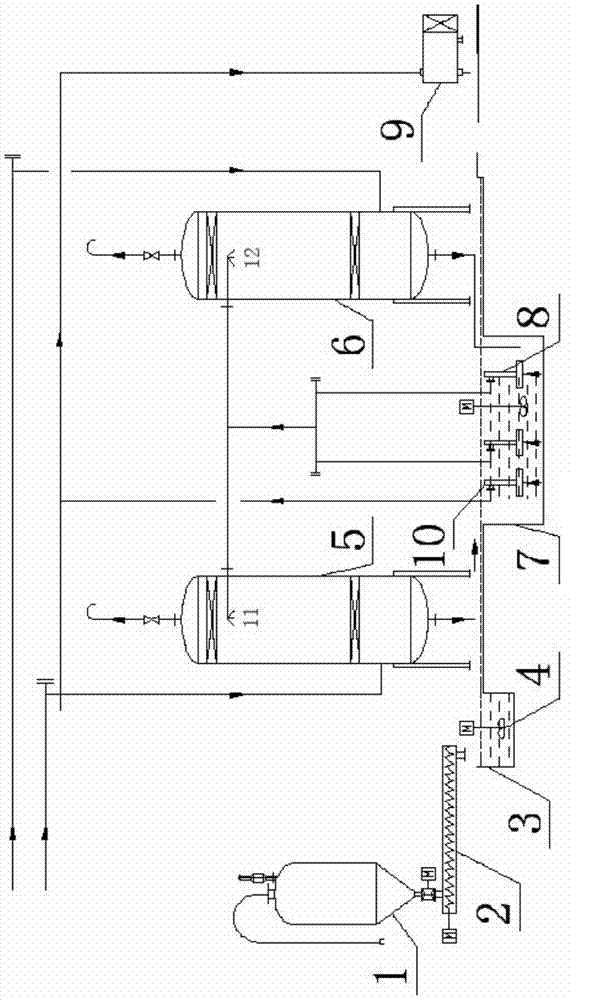

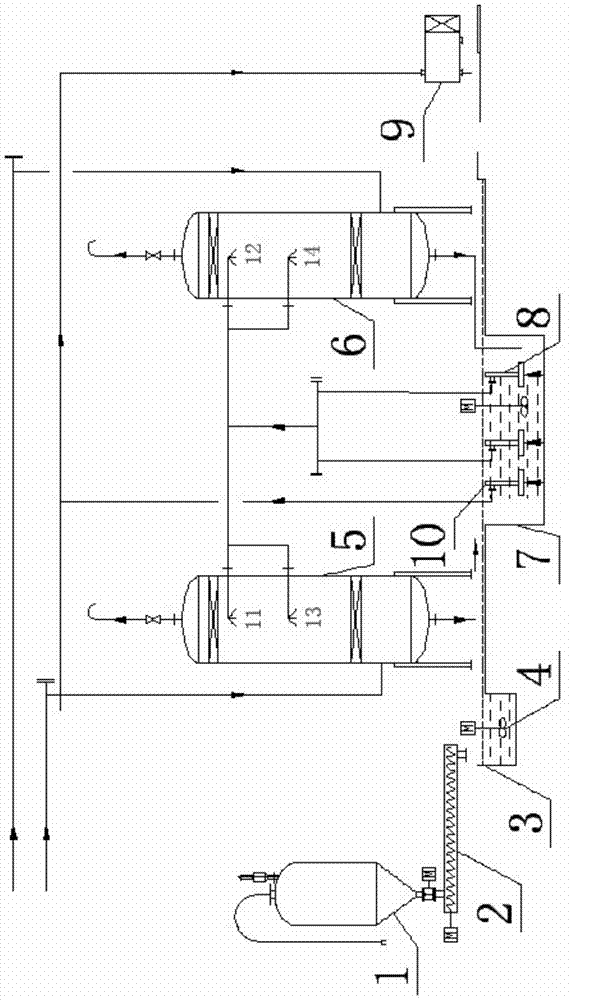

Fluorine-containing exhaust gas treatment device and method

InactiveCN104740985AStable concentrationRealize automatic continuous preparationDispersed particle separationTreatment effectFiltration

The invention discloses a fluorine-containing exhaust gas treatment device and method. The method comprises A, continuously preparing alkaline liquor from quicklime or calcium oxide by conveying quicklime in a quicklime storage tank into an alkaline liquor tank by a quicklime continuous feeding device and carrying out continuous adjustable preparation of alkaline liquor, B, carrying out exhaust gas absorption by distributing the prepared alkaline liquor down by an alkaline liquor distribution device above the interior of an exhaust gas absorption tower so that the alkaline liquor countercurrent contacts with fluorine-containing exhaust gas fed from the bottom of the exhaust gas absorption tower, discharging the gas without HF from the top of the exhaust gas absorption tower after contacting, and returning the waste liquid flowing out of a discharge outlet at the bottom of the exhaust gas absorption tower to the alkaline liquor tank, and C, treating the waste liquid by feeding precipitates on the bottom of the alkaline liquor tank into a precipitate treatment device such as a filtration device and carrying out treatment. The fluorine-containing exhaust gas treatment device and method have the advantages of environmental friendliness, safety and good exhaust-gas treatment effects.

Owner:XINDI ENERGY ENG TECH

Stone board unloader

InactiveCN102530503AWork comfortablyGuaranteed to workLoading/unloadingMechanical conveyorsWork related accidentOn board

The invention discloses a stone board unloader, which comprises a stone transport vehicle, an impact device, a stone board separation device and a stone board conveying device, wherein the stone transport vehicle can move step by step; the impact device is used for impacting a junction part of a stone board and a stone body; the stone board separation device is used for leading the stone board after the junction part is injured to separate from the stone body; and the stone board conveying device is used for conveying the stone board. The conveying device is positioned on a turnover track after the stone board is separated from the stone body and is pried by the separation device. The unloader of the invention has the beneficial effects that after automatic equipment is utilized, the stone board unloading works including stone board knocking, stone board prying, stone board conveying, stone board stacking and the like are all mechanically performed. The stone board unloading works can be finished as long as a worker operates the equipment, so that the work is very conformable and efficient, and the working environment can be greatly improved; and moreover, the worker does not need to be in direct contact with the stone board so as to avoid the occurrence of work-related accidents.

Owner:佛山市新海舟科技有限公司

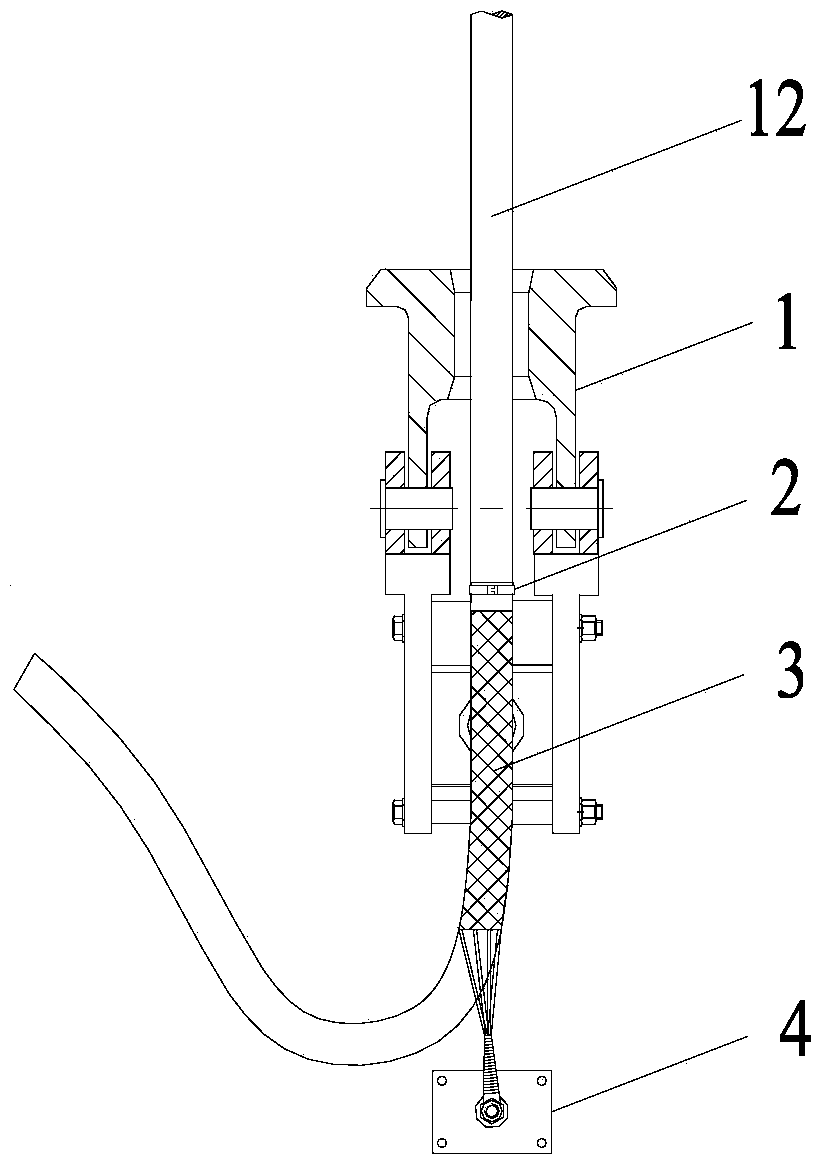

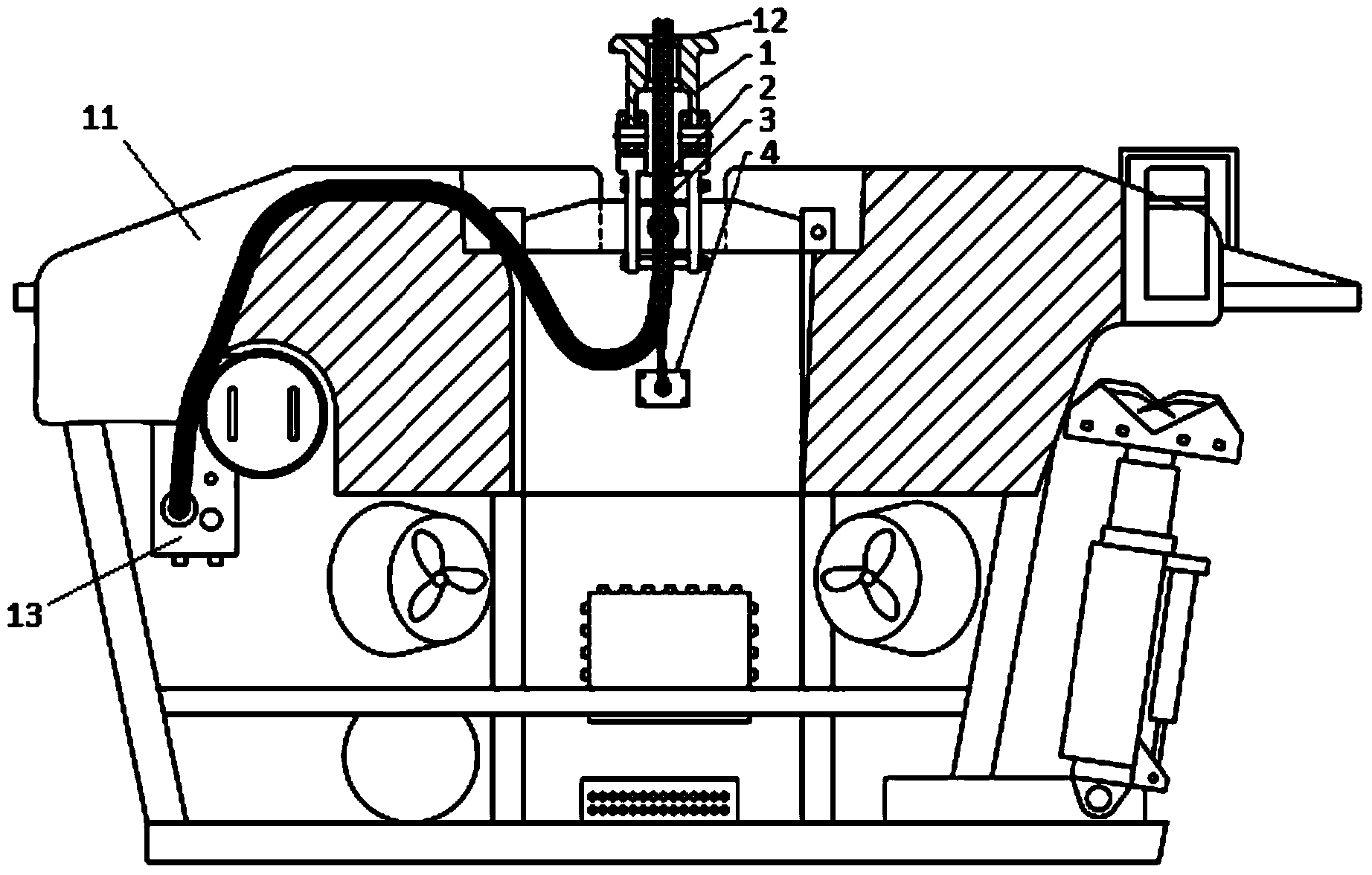

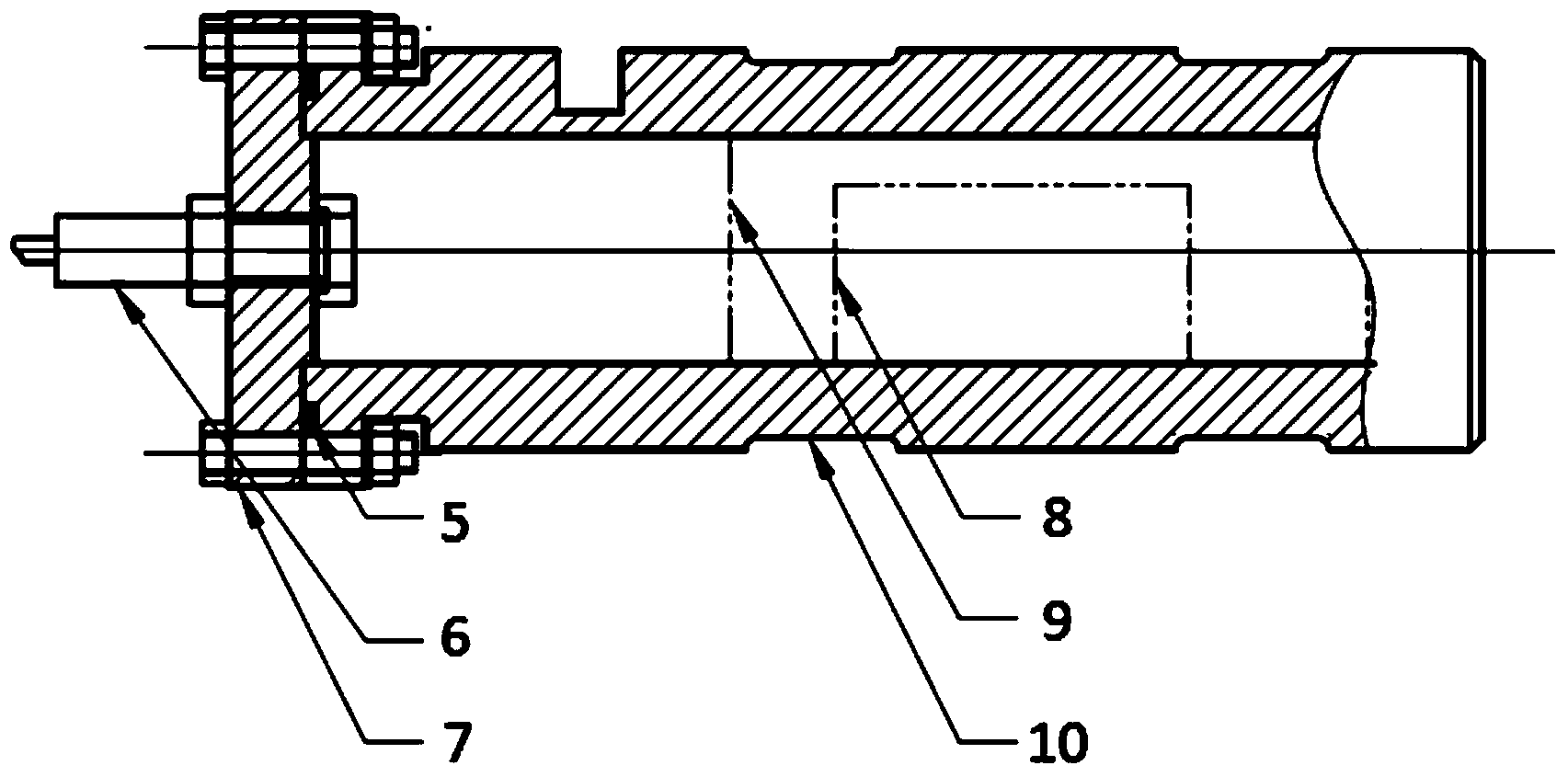

Device and method for monitoring tension of underwater umbilical cable

ActiveCN104296915ASimple structureEasy to assembleTension measurementCommunication interfaceEngineering

The invention relates to a device and method for monitoring the tension of an underwater umbilical cable in an ocean device. The device comprises a connecting device, a clamp, a steel cable hanging net and a tension monitoring sensor, wherein the connecting device, the upper end and the lower end of the steel cable hanging net, and the tension monitoring sensor are located on the same plumb line, the connecting device, the clamp and the steel cable hanging net are used for being connected with and fixing the umbilical cable, the tension monitoring sensor is arranged below the connecting device and connected to an instrument bin of a submersible device through a signal line and a watertight connector, a computer in the instrument bin is communicated with a water surface computer through an RS-422 communication interface, and voltage signals of the tension of the umbilical cable are transmitted to the computer in the instrument bin by the tension monitoring sensor and then are transmitted to the water surface computer through the umbilical cable. By means of the method and device, the tension of the underwater umbilical cable can be monitored and is prevented from exceeding a threshold value, necessary information can be provided for the operation of operation personnel in time so that the fatigue cracks of the umbilical cable and the operation accidents of the submersible device can be avoided, and the operation safety of a body of the submersible device can be ensured.

Owner:SHANGHAI JIAO TONG UNIV

High-safety-performance mechanical part machining drilling machine

InactiveCN107538050AHigh precisionEasy to useAutomatic control devicesDrilling/boring measurement devicesStopped workMechanical components

The invention discloses a high-safety-performance mechanical part machining drilling machine. The drilling machine comprises a drill bit and a rotary motor. An air blower is embedded in a clamp base.An opening of the tail end of a rotor of the rotary motor communicates with an air inlet of the air blower. A whole support is in an inverted-L shape. A hydraulic extending device is mounted on the inner side of a top end transverse rod of the support. A transversely-arranged fixing rod is connected with the bottom end of the hydraulic extending device. An NFC label is arranged at the end, close to the support, of the fixing rod. An NFC reading device is movably connected with the inner side of a vertical rod part of the support through a guide rail structure. According to the high-safety-performance mechanical part machining drilling machine, air outlets matched with the air blower are additionally formed in the surface of the drill bit, chips generated by the drilling machine can be discharged during operation, operation can be stopped in time after the drilling machine descends to a preset drill hole depth through an additionally arranged NFC displacement monitoring device, and theprecision of the drilling machine is improved.

Owner:常州弗列德立鼎自动化技术有限公司

Charging mechanism of automatic magnetic shoe deburring device

InactiveCN108356697AIncrease productivityAvoid affecting the loading operationGrinding feedersIndustrial AccidentMachining

The invention relates to the technical field of machining, in particular to a charging mechanism of an automatic magnetic shoe deburring device. The charging mechanism comprises a material lifting assembly, a charging assembly and a material taking assembly. The material taking assembly and the charging assembly are located above the material lifting assembly. The charging assembly comprises a sliding block of a cuboid structure, and a bearing assembly used for supporting the sliding block. The bearing assembly comprises a mounting frame and two supporting plates which are located at the bottom of the mounting frame and used for supporting the bottom of the mounting frame. The sliding block is located in the mounting frame and is in sliding fit with the mounting frame. The material takingassembly comprises a lifting assembly located at the top of the sliding block, and a clamping assembly located below the sliding block. Workpieces can be automatically moved to a machining waiting area, the production efficiency of enterprises is improved, the labor intensity of workers is relieved, in addition, the workpieces can be clamped through the material taking assembly, and industrial accidents caused by manual charging by the workers are avoided.

Owner:ANHUI NORMAL UNIV

Efficient environment-friendly and energy-saving gear overturning mechanism

ActiveCN106112137AReduce occupancyAvoid work accidentsMetal working apparatusGear-cutting machinesIndustrial AccidentEngineering

Owner:TATUNG GEAR KUNSHAN

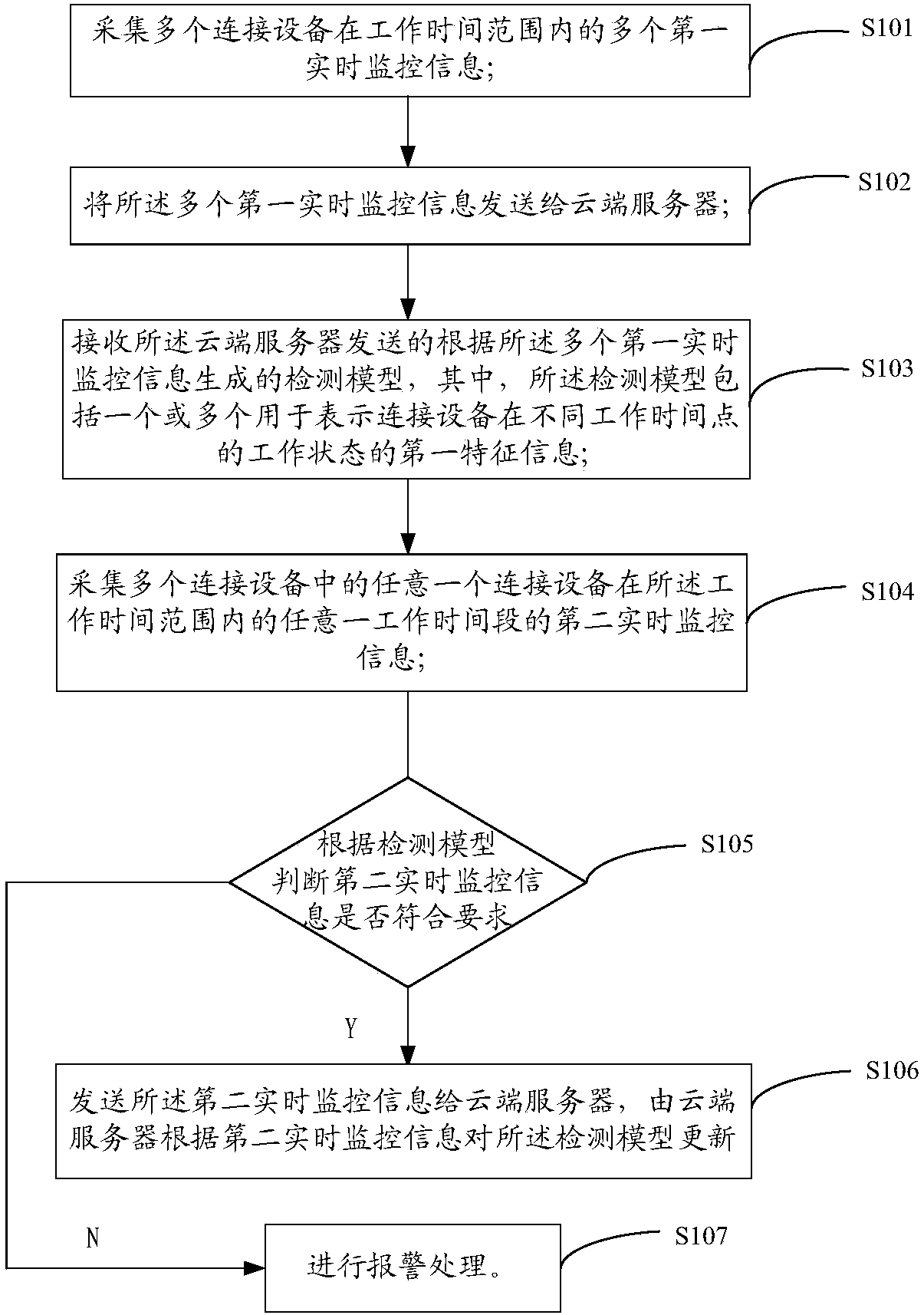

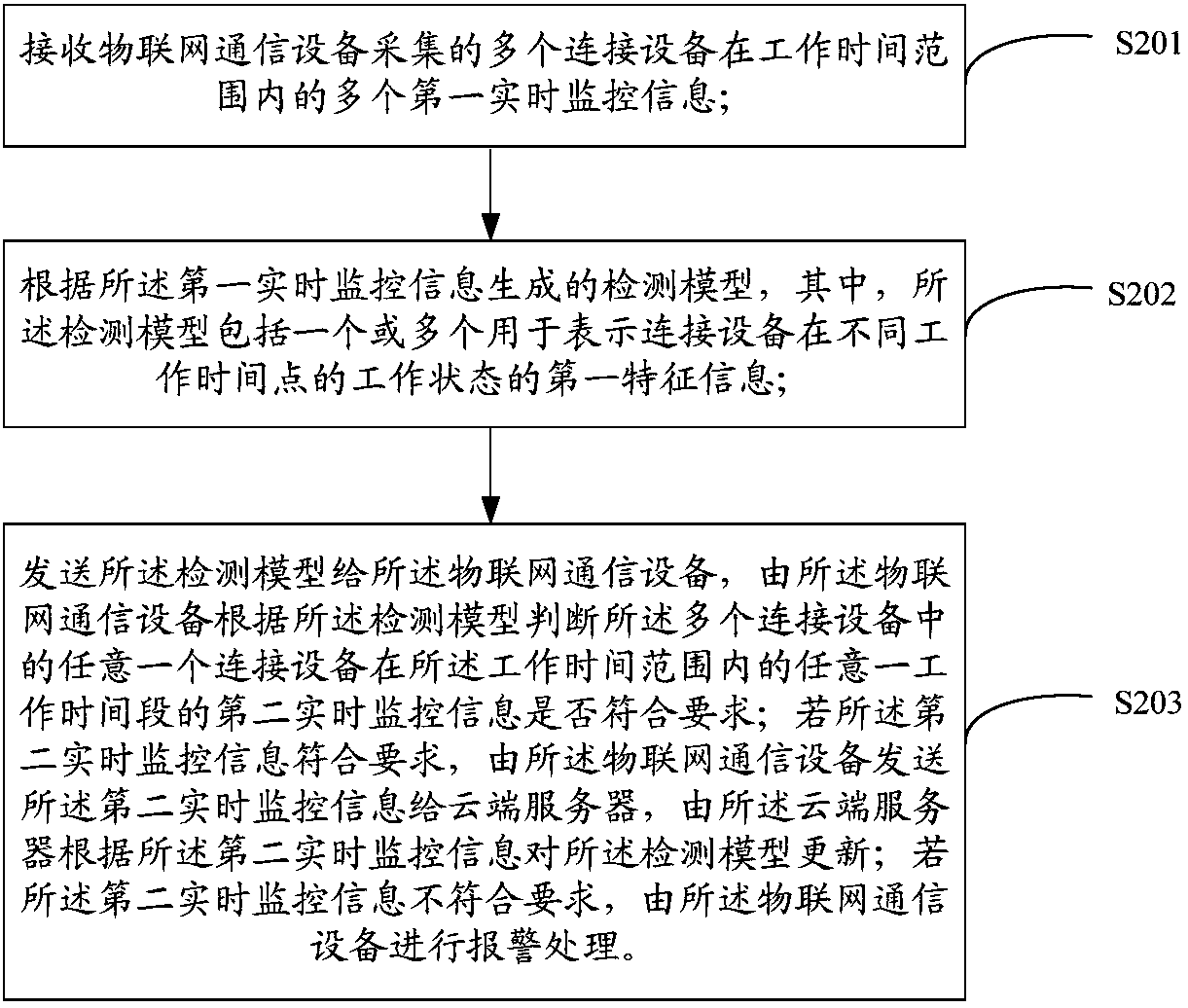

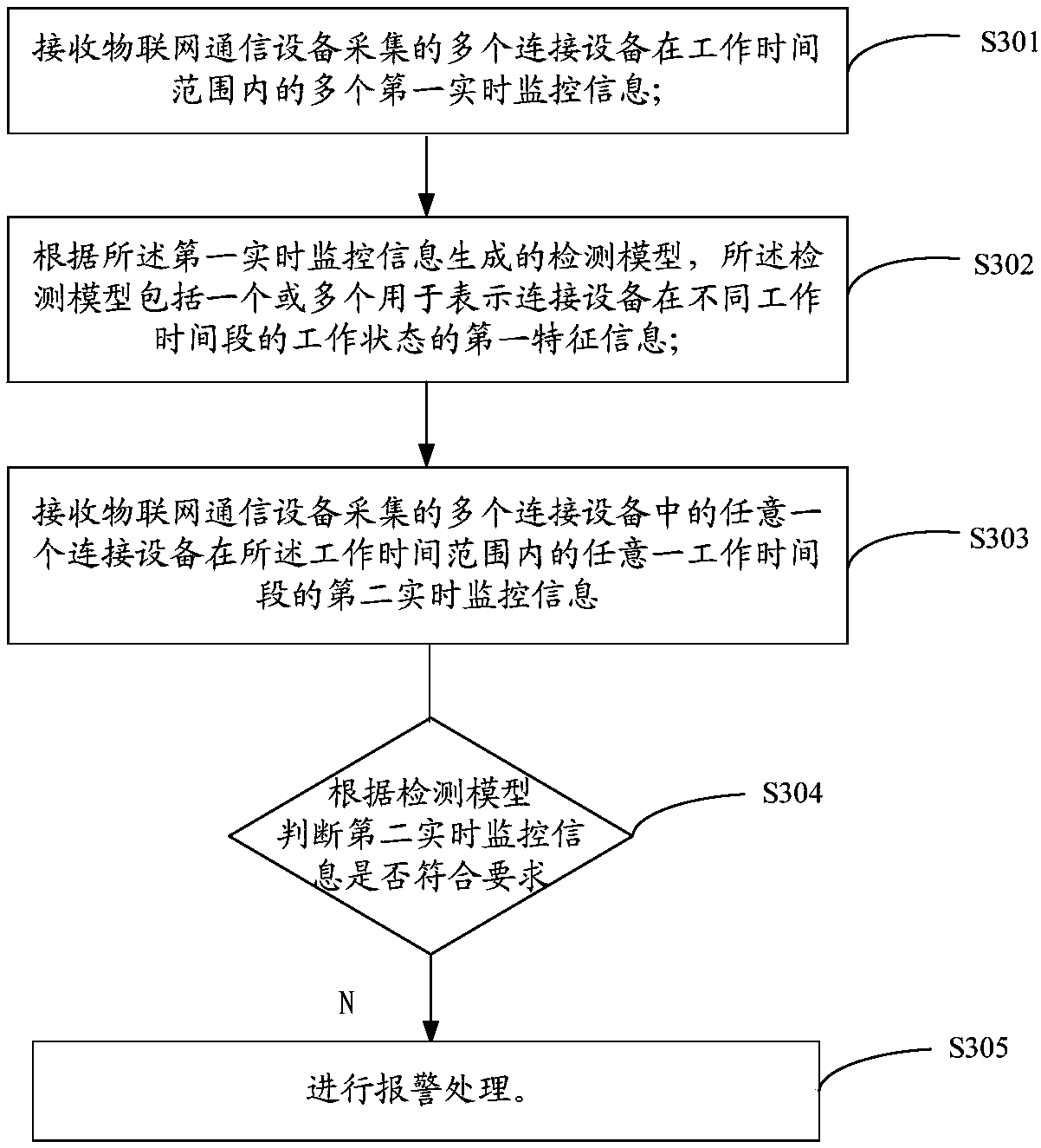

Method and device for monitoring connection equipment in real time

InactiveCN107707601AImprove the quality of workAvoid work accidentsData switching networksQuality of workReal-time computing

The invention relates to a method and a device for monitoring connection equipment in real time. The method comprises the following steps: acquiring a plurality of pieces of first real-time monitoringinformation of a plurality of pieces of connection equipment within a working time range; transmitting the plurality of first real-time monitoring information to a cloud server; receiving a detectionmodel which is transmitted by the cloud server and generated according to the plurality of pieces of first real-time monitoring information; judging whether second real-time monitoring information conforms to a requirement or not according to the detection model; if the second real-time monitoring information conforms to the requirement, transmitting the second real-time monitoring information tothe cloud server, and updating the detection model by the cloud server according to the second real-time monitoring information; and sounding an alarm if the second real-time monitoring information does not conform to the requirement. Through adoption of the method and the device in the embodiment of the invention, the state of the connection equipment can be detected effectively by monitoring the monitoring information of the connection equipment in real time; the working quality of the connection equipment is enhanced; and working accidents are avoided.

Owner:语祯物联科技(上海)有限公司

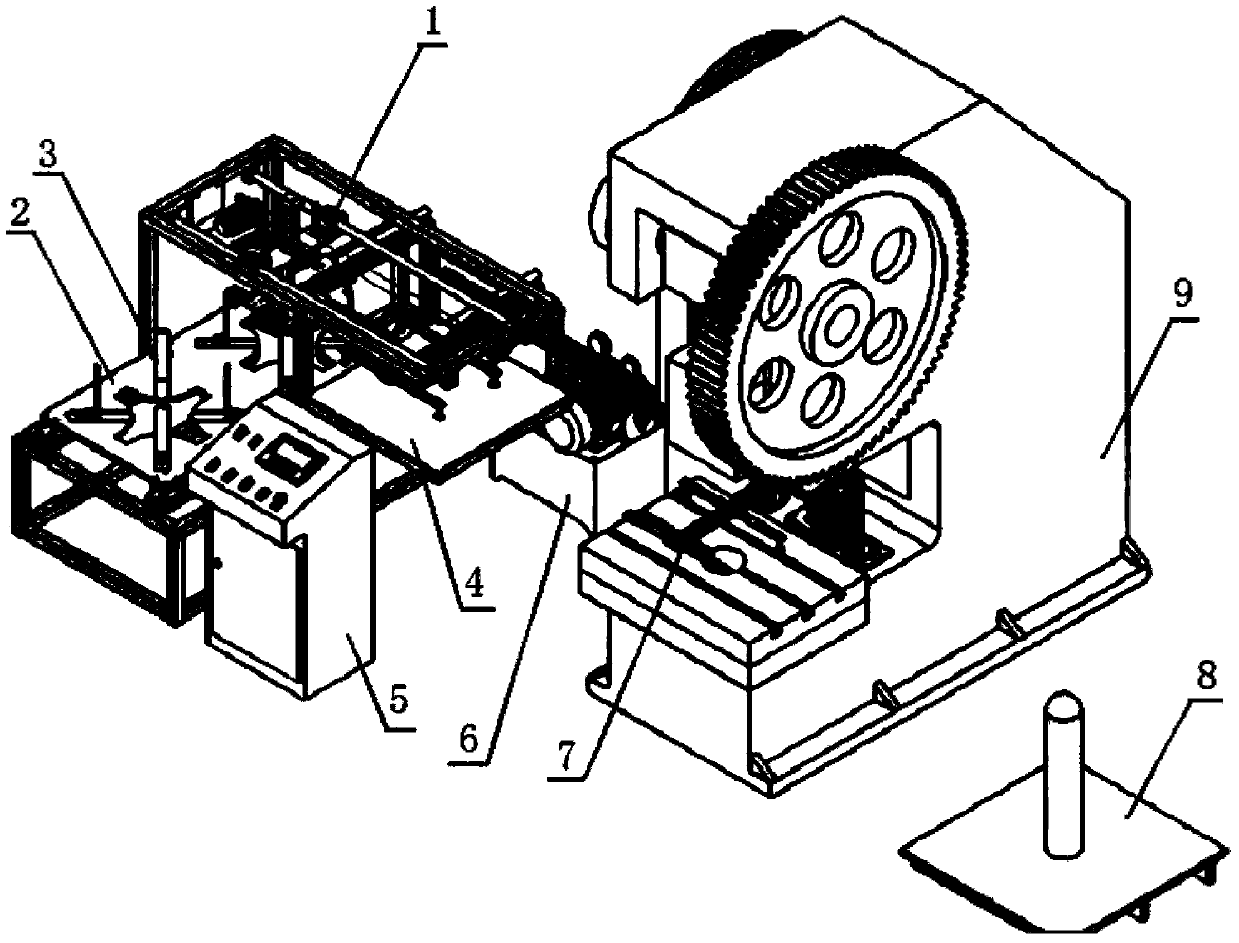

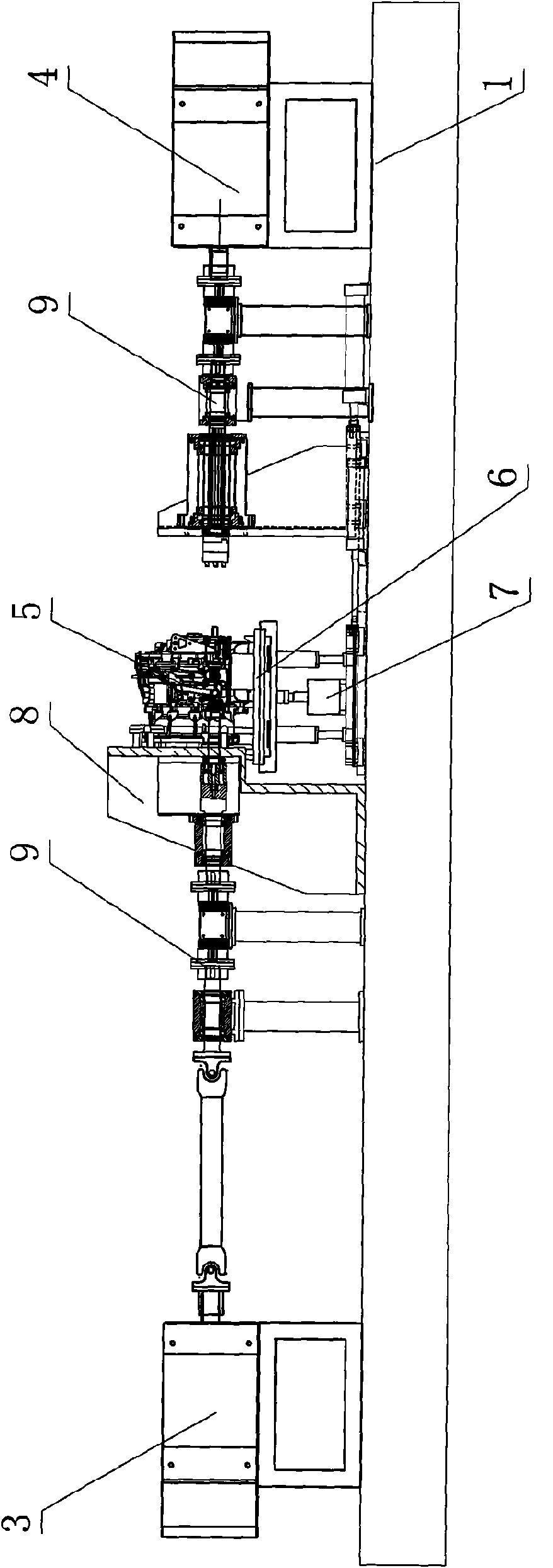

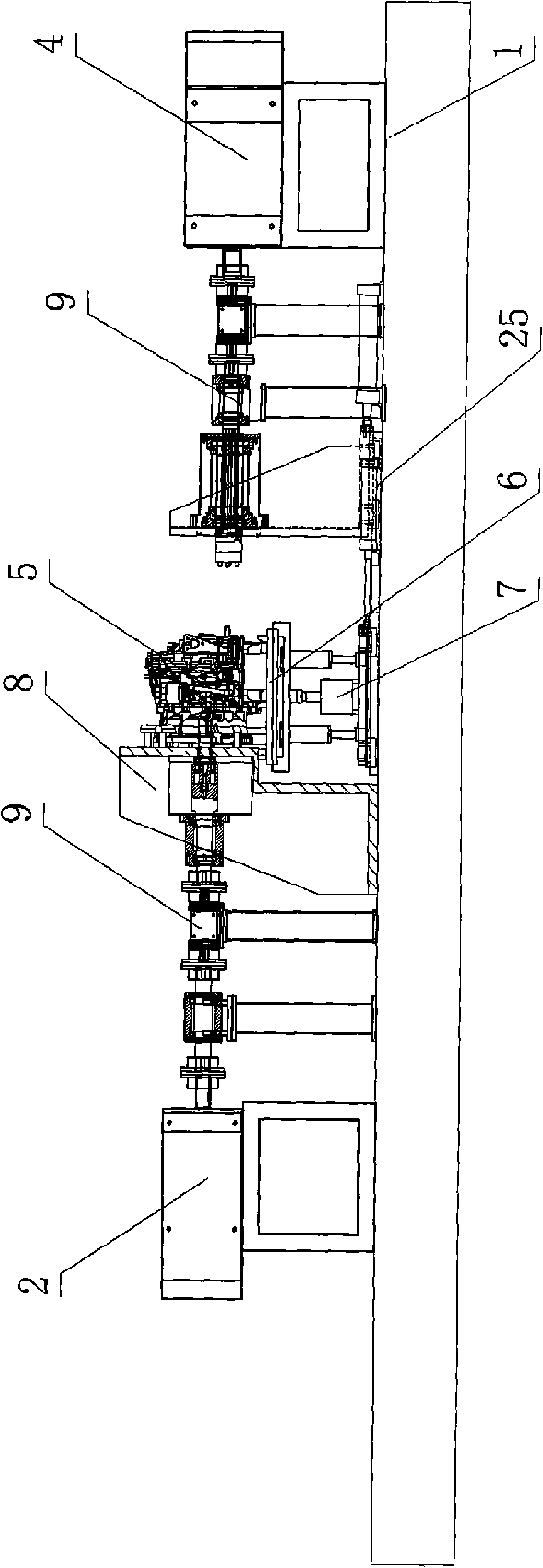

Improved test board device for automatic transmission box analog simulation test

ActiveCN101620026AAccurately reflectImplement automated testingMachine gearing/transmission testingComputer control systemIndustrial Accident

The invention relates to an improved test board device for automatic transmission box analog simulation test; the automatic test has low labor intensity, avoids industrial accidents, has high production efficiency, can meet requirements of mass production, can accurately reflect performance parameters and improve testing quality; the improved test board device comprises a working table surface, an input motor and two output motors; the improved test board device is characterized in that: the improved test board device is connected with a computer control system, the automatic transmission boxis supported to a working table, a top-lifting translation device is arranged at the lower part of the working table, one side of the working table is provided with a fixed wall board, one side of the fixed wall board is provided with an input motor and an output motor, and the other side of the working table is provided with the other output motor, and the input motor, and the two output motors are connected with the automatic transmission box by a quick butt-jointing device.

Owner:WUXI DAJINYI TECH CO LTD

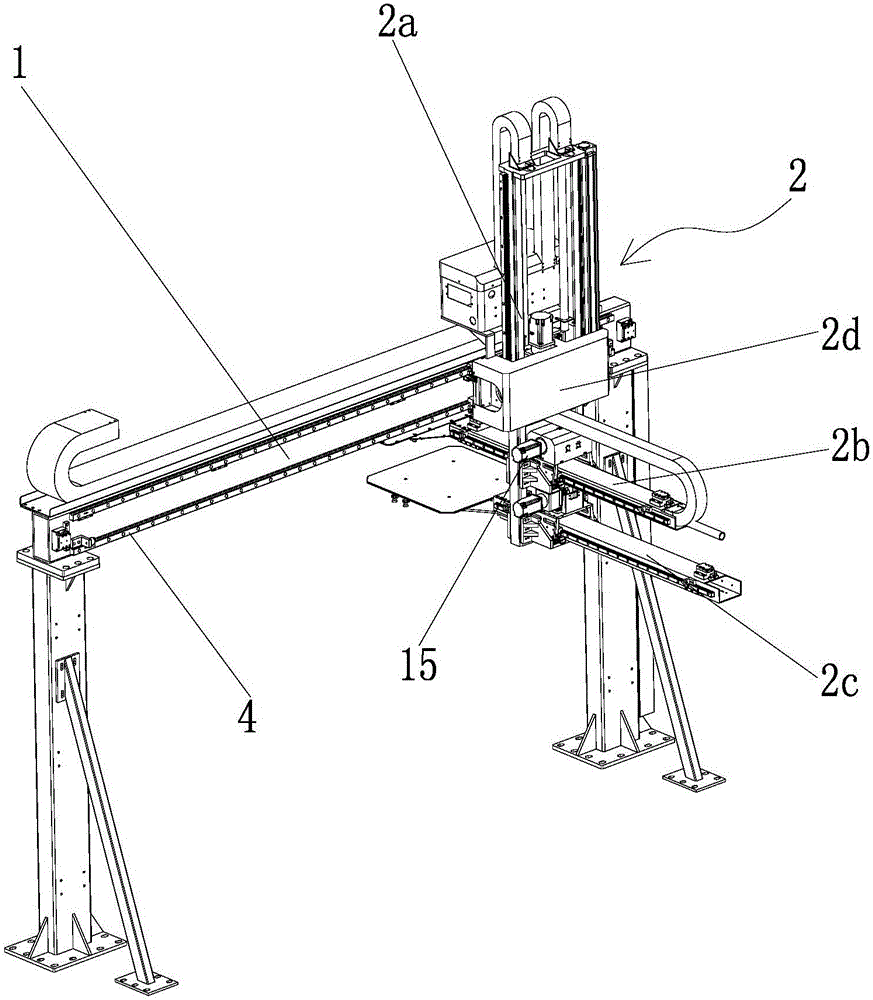

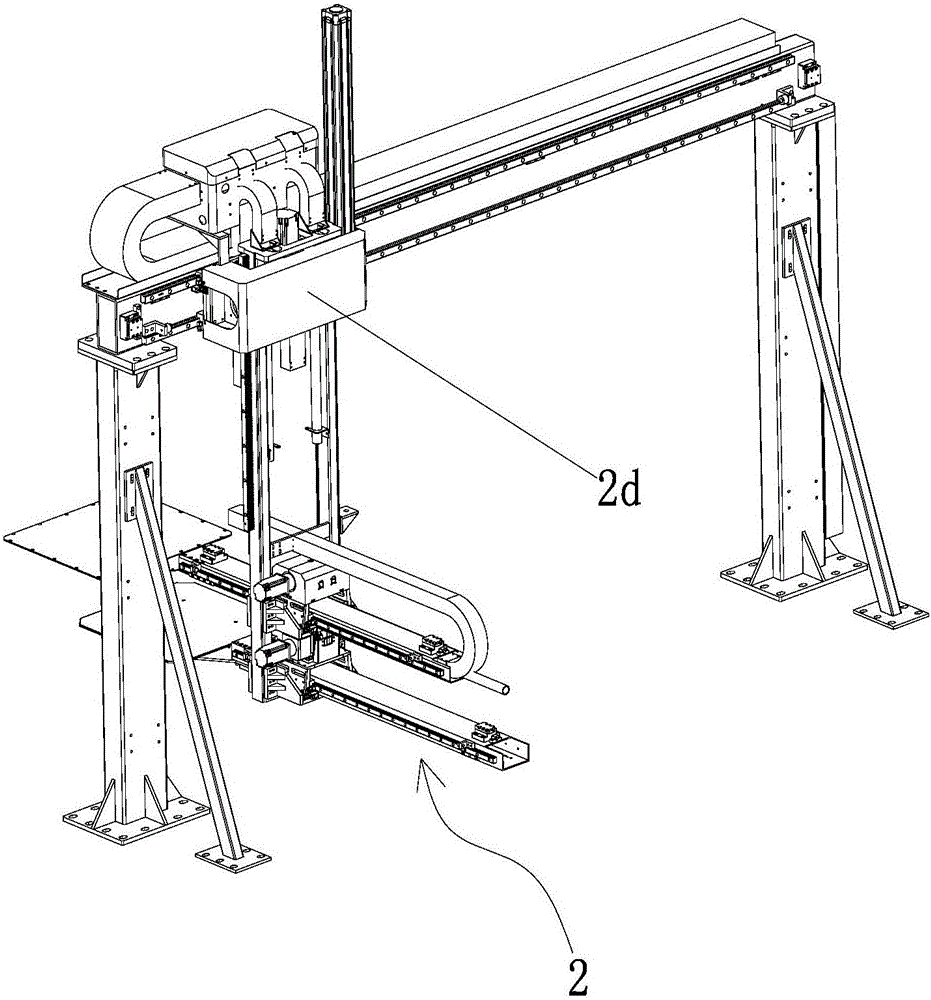

Full-automatic intelligent paper model feeding and discharging system based on remote control

ActiveCN105800309ALow costHigh degree of automationConveyor partsRemote controlPulp and paper industry

The embodiment of the invention provides a full-automatic intelligent paper model feeding and discharging system based on remote control. The full-automatic intelligent paper model feeding and discharging system based on remote control comprises a support and a mechanical arm assembly movably arranged on the support. The mechanical arm assembly comprises a first mechanical arm, a second mechanical arm and an adsorption assembly, wherein the first mechanical arm is mounted on the support and can move up and down; the second mechanical arm is mounted at the lower end of the first mechanical arm and is perpendicular to the first mechanical arm and capable of moving front and back; the adsorption assembly is mounted at the lower end of the second mechanical arm and comprises a first vacuum adsorption device used for sucking paper models; and the first vacuum adsorption device is used for taking out the preliminarily formed wet paper models from a paper model setting machine and placing the preliminarily formed wet paper models on high-temperature drying equipment for drying. The mechanical arm assembly can automatically suck and take out the paper models and place the paper models at the designated location, and is high in automation degree; and the paper models do not need to be taken out manually after being preliminarily formed, so that accidental occupational injuries are avoided.

Owner:GUANGDONG CLAW ROBOT CO LTD +1

Automatic steel wire products forming equipment

InactiveCN101199976AEquipment is safe and reliableIncrease productivityMetal-working feeding devicesPositioning devicesEngineeringIndustrial Accident

The invention discloses a full automatic forming equipment for metal product, comprising a material placing device, a feeding device, a conveying device and a forming device; the material placing device is arranged on the front end of the feeding device; the conveying device and the forming device are arranged on the back end of the feeding device; the front end of the conveying device corresponds with the back end of the feeding device. The invention place the material automatically by the material placing device, and then feeds material by the feeding device; the automatic feeding device has a multi-direction feeding function, the conveying device matches with the forming device; the forming is carried out after automatic conveying; and after the forming is finished, the next conveying goes on, making the falling plate, stretching, trimming cut or crimping to be automatically completed. The invention does not need manpower to operate punch press and drawing mill, thus the industrial accidents are avoided and the equipment is safe and reliable. The working process is full automated and the production efficiency is high. The main transmission is improved from the original mechanical transmission to the hydraulic transmission which has low noise.

Owner:三门力佳利不锈钢有限公司

Automatic feeding bending machine

Disclosed is an automatic feeding bending machine. The automatic feeding bending machine is technically characterized in that the automatic feeding bending machine comprises a machine body; the machine body comprises a conveying trolley, a feeding mechanism, a horizontal straightening mechanism, a perpendicular straightening mechanism, a hauling mechanism, a shearing mechanism, a steel hoop bending mechanism, a push mechanism, a material collecting mechanism and a reinforcing steel bar bending mechanism; a retractable material positioning rod is disposed on the feeding mechanism and connected with a spiral conveying shaft; one end of the spiral conveying shaft is connected with an electromagnetic suction head; a suction head air cylinder is arranged on the upper portion of the electromagnetic suction head; a compaction air cylinder is mounted on the upper portion of the hauling mechanism; a jacking air cylinder is disposed on the lower portion of the shearing mechanism; a push air cylinder is disposed at one end of the steel hoop bending mechanism; the other end of the push air cylinder is connected with a guide rack which is connected with a center shaft; the reinforcing steel bar bending mechanism comprises a traveling rack which is provided with a bending machine head. By means of the technical scheme, automatic feeding can be achieved, the working efficiency is improved, industrial accidents are avoided, coil-rod reinforcing steel bars and straight-rod reinforcing steel bars can be machined, and single-head bending and double-head bending can be achieved at the same time.

Owner:TIANJIN YINFENG MACHINERY SYST ENG CO LTD

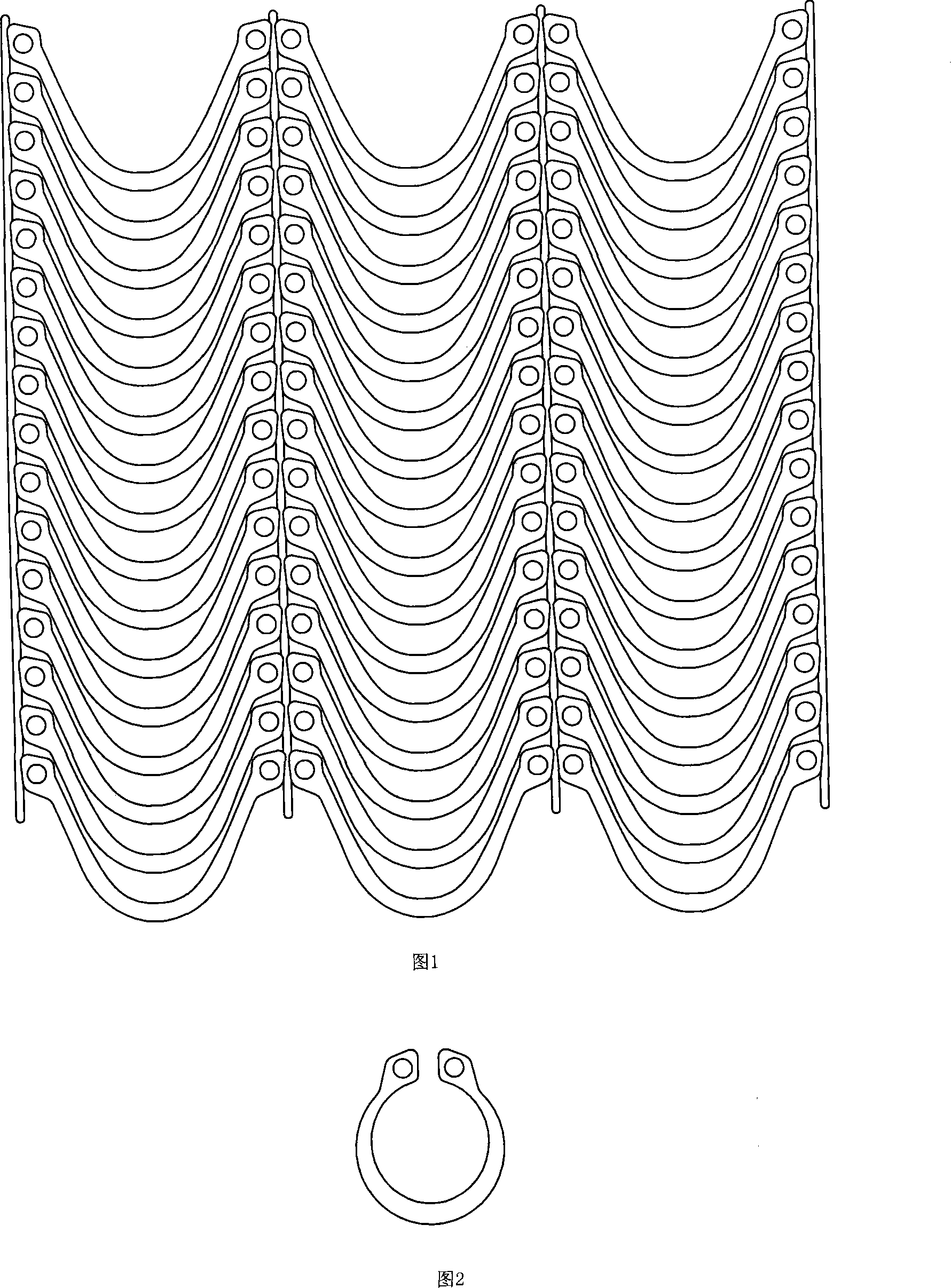

Preparing technique of back-up ring

InactiveCN101176899AIncrease profitFast punching speedMetal-working apparatusPunch pressMaterial consumption

The invention discloses a manufacturing process of a retaining ring, which is characterized in that a mold is first installed on a punching machine, and after the strip is taken and placed on the punching machine, the strip is punched into a shape with a certain curvature by using the mold of the punching machine. The arc-shaped strip, and finally the arc-shaped strip with a certain curvature is curled into a circle with an opening by punching equipment, which becomes a kind of retaining ring. Adopting this technology to make the retaining ring has high speed and high safety, especially reduces material consumption by more than 30%, and will be widely used in the standard part manufacturing industry.

Owner:陈福星

Short pipe end surface automatic polishing device

InactiveCN107717666AAvoid work accidentsImprove work efficiencyEdge grinding machinesGrinding carriagesEngineeringManufacturing enterprises

The invention relates to the technical field of polishing devices, in particular to an automatic polishing device for the end face of a short tube, which includes a feeding mechanism, a rotary mechanism, an upper end surface polishing mechanism and a lower end surface polishing mechanism. The rotary mechanism includes a stepping turntable and a drive assembly. The stepping turntable has an octagonal structure, and there are several clamping components on the top of the stepping turntable. The feeding mechanism includes a vibrating plate. One end of the stepping turntable is provided with a first through hole, the bottom of the feeding pipeline is provided with a support assembly, the upper end surface polishing mechanism includes a lifting assembly and a polishing assembly, and the lower end surface polishing mechanism includes a screw lifter and a screw slide table. The invention does not need manual feeding and clamping operations, thereby avoiding industrial accidents for workers, and can automatically polish the end faces of workpieces through the upper end surface polishing mechanism and the lower end surface polishing mechanism, thereby improving the work efficiency of the production enterprise.

Owner:饶琼珊

Portable new energy automobile bumper device

A portable new energy automobile bumper device is disclosed in the invention, and comprises a wheel, a front baffle and a rear baffle, the front baffle and the rear baffle are located on the two sides of the wheel correspondingly, bottom plates are detachably connected to the bottoms of the sides, away from each other, of the front baffle and the rear baffle correspondingly, rectangular holes are formed in the tops of the bottom plates, and horizontally-arranged first screws are rotatably connected into the rectangular holes; a sliding plate sleeves the outer side of the first screw in a threaded mode, rotating bases are detachably connected to the tops of the sides, away from each other, of the front baffle and the rear baffle, the rotating bases located on the same side of the wheels and the sliding plate are rotationally connected with the same traction rod, and first inserting grooves are formed in the bottoms of the sides, away from each other, of the front baffle and the rear baffle; and the sides, close to each other, of the two bottom plates are fixedly connected with one ends of first inserting rods. The device is reasonable in design, the distance between the front baffle and the rear baffle can be conveniently adjusted, the new energy automobile wheel can be stably clamped on the outer side of the wheel, advancing resistance of the new energy automobile wheel is effectively increased, industrial accidents caused by automobile self-starting are avoided, and the construction safety of workers is enhanced.

Owner:王正国

Hydraulic machine with safety shields

InactiveCN103737956AImprove securityAvoid harmEngineering safety devicesPressesIndustrial AccidentMechanical engineering

The invention relates to a hydraulic machine with safety shields. The hydraulic machine comprises a base plate, four guide columns are arranged on the base plate, grooves are formed in the base plate along the outsides of the four guide columns, the safety shields are inserted in the grooves, and circular handles are arranged at the two ends of each safety shield. According to the hydraulic machine, the safety shields with the handles are inserted in the base plate of the hydraulic machine, so that a material with loads applied is limited within the range of the guide columns during cracking splashing, operators are prevented from being injured, the safety of the hydraulic machine is improved apparently, and serious industrial accidents caused by material crashing splashing are prevented.

Owner:GUANGXI NANNING BAILANSI SCI & TECH DEV

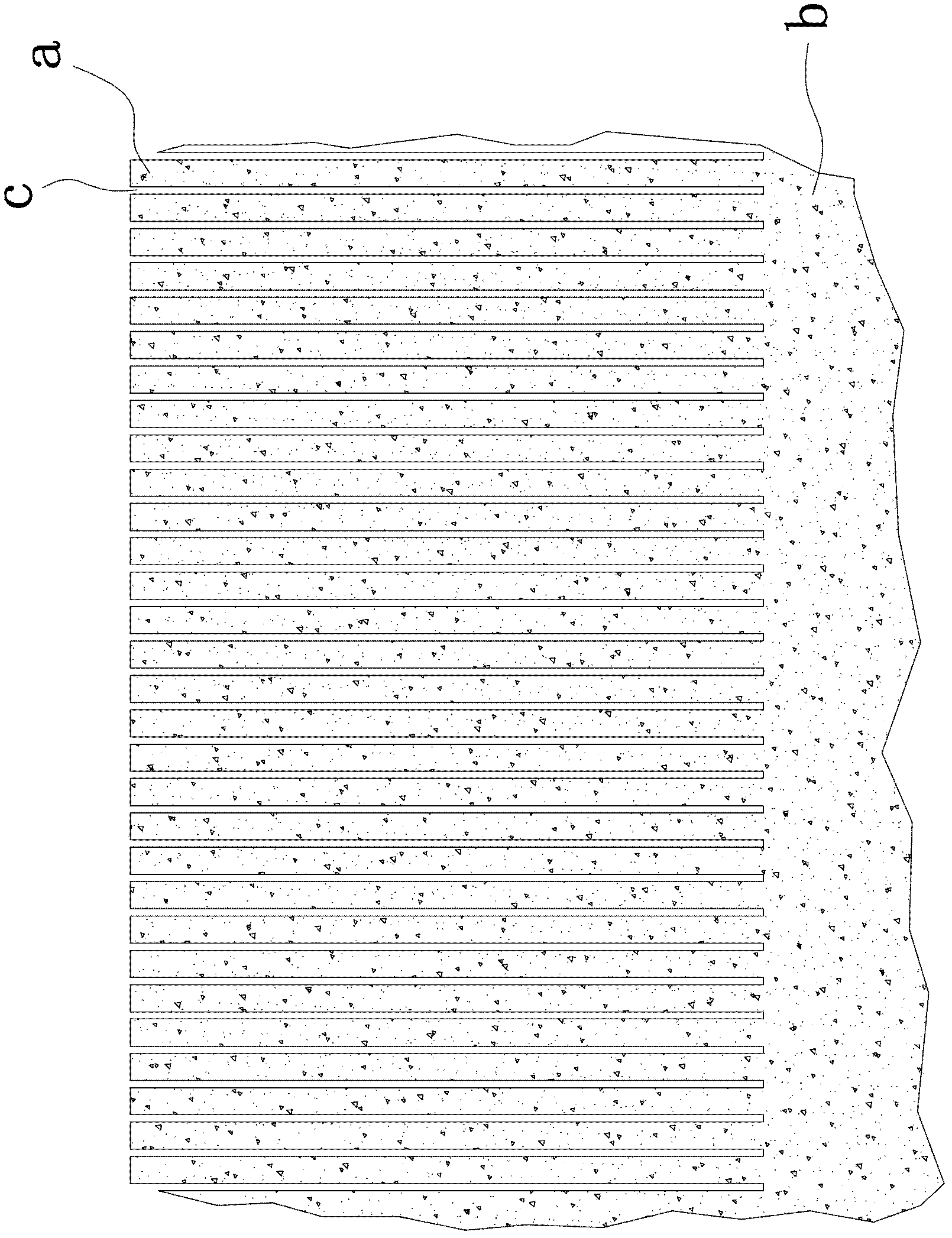

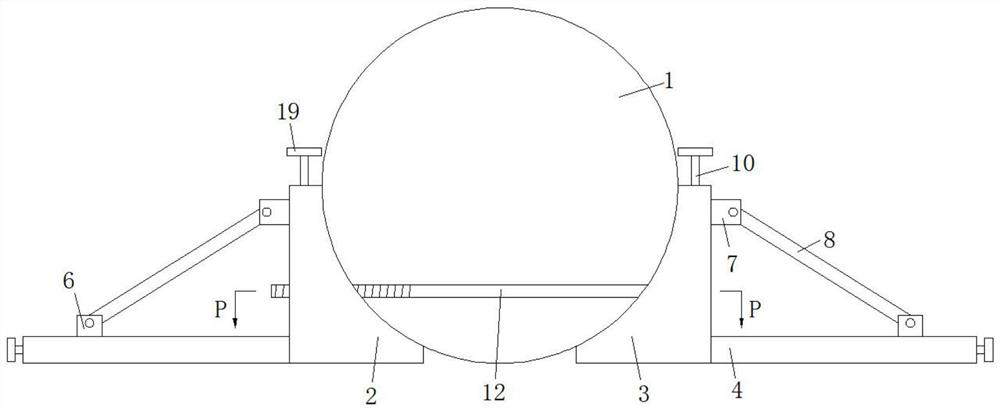

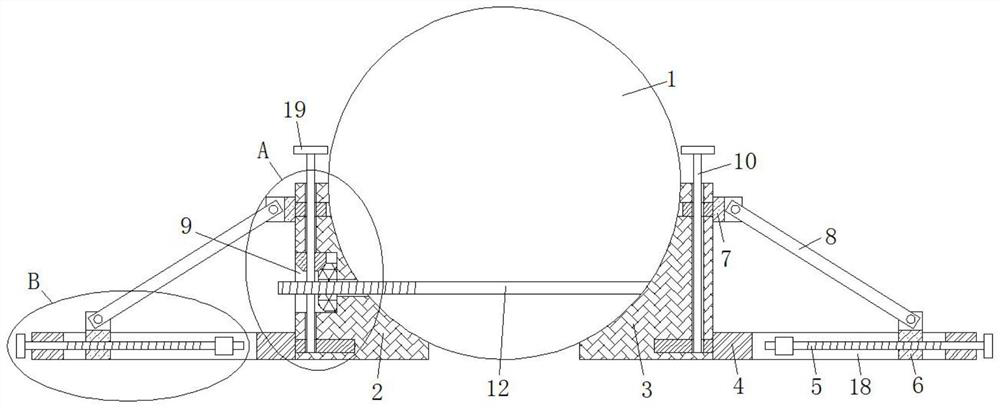

Building formwork system

InactiveCN104563485ALight weightHigh calorific valueForms/shuttering/falseworksForming/stuttering elementsArchitectural engineeringUtilization rate

The invention discloses a building formwork system. The building formwork system comprises a template and a support frame for supporting the template, and is characterized by further comprising a hollow plastic plane support profile with a T-shaped cross section, and a hollow plastic corner support profile with an L-shaped cross section, wherein cooling lightening holes are formed in the plane support profile and the corner support profile; the upper part of the plane support profile extends to two sides to form wing plates; multiple construction through holes are formed in the wing plates; the plane support profile is fixed on the surface of the template through the construction through holes, or is connected with the template with the adjacent plane; and the corner support profile is disposed at the corner of the adjacent template for support. The building formwork system uses the plane support profile and the corner support profile for replacing wood bars, so that the cost is low; the utilization rate is high; the wood resource is saved; and the construction efficiency is high.

Owner:浙江信得宝建筑新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com