Automatic feeding bending machine

An automatic feeding and bending machine technology, applied in the field of bending machine devices, can solve the problems of single bending steel bar, affecting work efficiency, and high work intensity, so as to reduce work intensity and work hazards, avoid work accidents, and increase work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

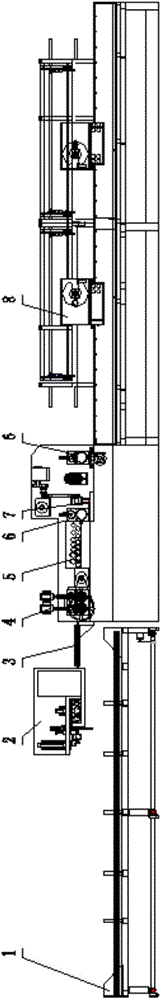

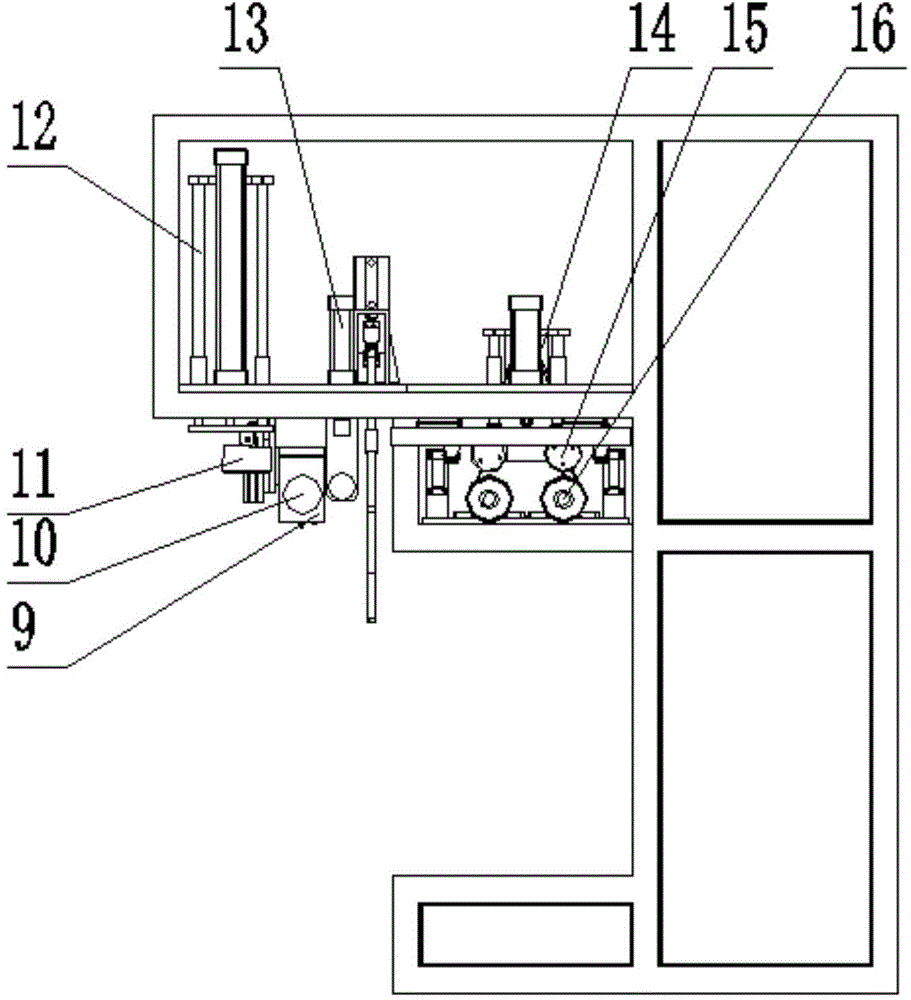

[0029] Such as Figure 1-10 As shown, an automatic feeding bending machine includes a body, and the body includes a feeding car 1, a feeding mechanism 2, a horizontal straightening mechanism 3 and a vertical straightening mechanism 5, a traction mechanism 4, a shearing mechanism 7, and a hoop bending mechanism 6. Propelling mechanism, aggregate mechanism, steel bar bending mechanism 8;

[0030] The feeding car 1 is respectively provided with a straight steel bar silo 43 and a coiled steel bar silo 44, the lower part of the feeding car 1 is provided with a wheel 45, the lower part of the wheel 45 is connected with a slide rail 50, and one end of the slide rail 50 is provided with a feeding car Electromagnetic suction head, the other end of slide rail 50 is provided with feeding mechanism 2, and wheel 45 moves between the electromagnetic suction head of feeding car and feeding mechanism 2, and the center of wheel 45 has transmission shaft 46 to pass through, and transmission sha...

Embodiment 2

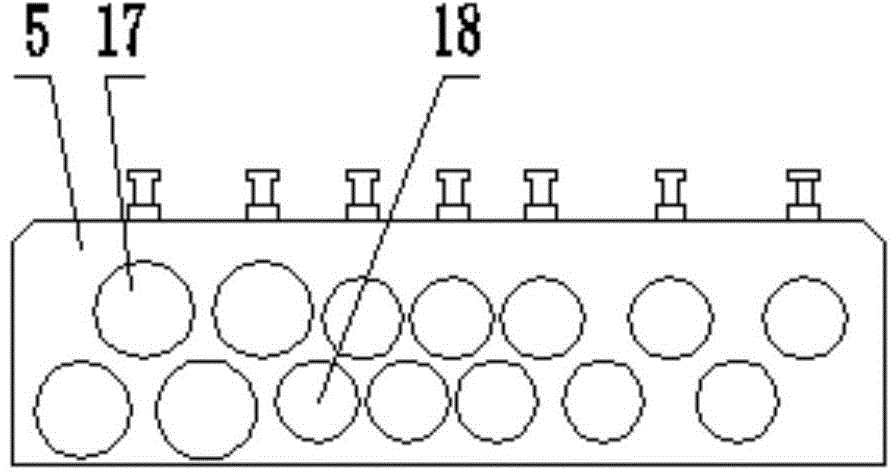

[0037] Such as Figure 1-10 Shown, a kind of automatic feeding bending machine comprises a body, and the body includes a feeding car 1, a feeding mechanism 2, a horizontal straightening mechanism 3 and a vertical straightening mechanism 5, and the vertical straightening mechanism 5 is divided into upper straightening wheels 17 and Bottom straightening wheel 18, top straightening wheel 17 are fixedly connected, bottom straightening wheel 18 is adjustable, traction mechanism 4, shearing mechanism 7, hoop bending mechanism 6, propulsion mechanism, collecting mechanism, steel bar bending mechanism 8.

[0038] The feeding car 1 is respectively provided with a straight steel bar silo 43 and a coiled steel bar silo 44, the lower part of the feeding car 1 is provided with a wheel 45, the lower part of the wheel 45 is connected with a slide rail 50, and one end of the slide rail 50 is provided with a feeding car Electromagnetic suction head, the other end of slide rail 50 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com