Full-automatic intelligent paper model feeding and discharging system based on remote control

A remote control, fully automatic technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of hidden safety hazards and low degree of automation, and achieve the effect of liberating manpower, improving unity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

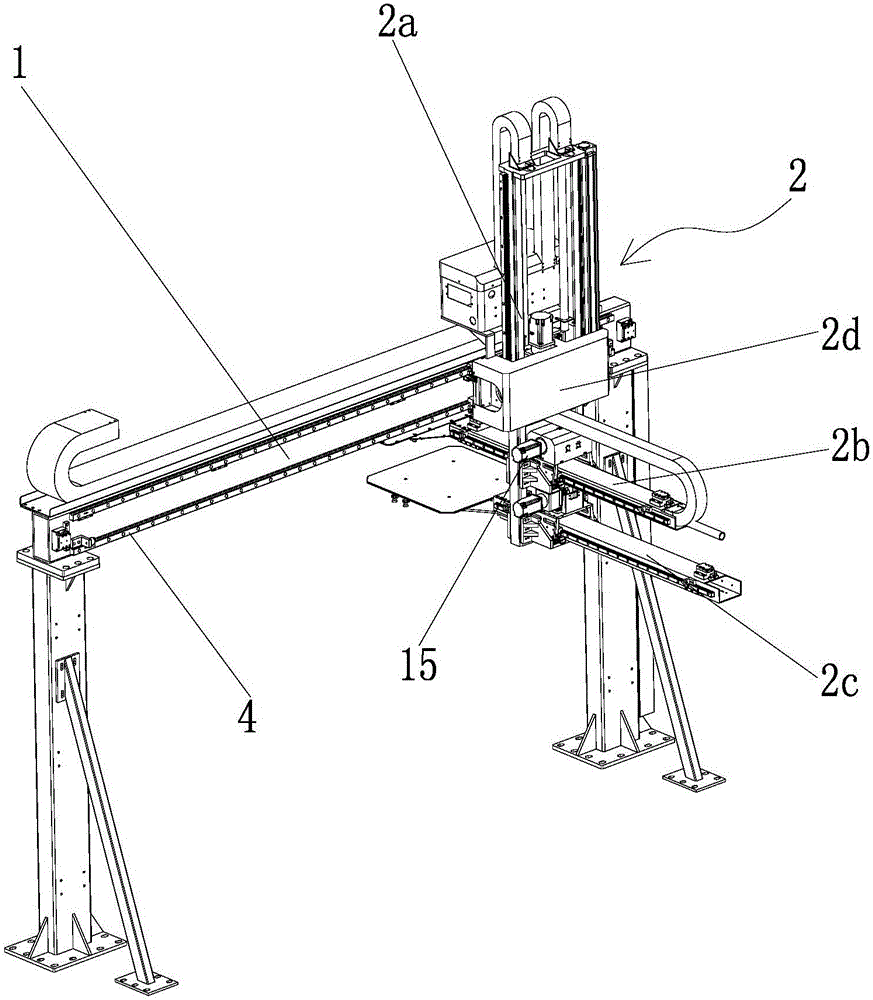

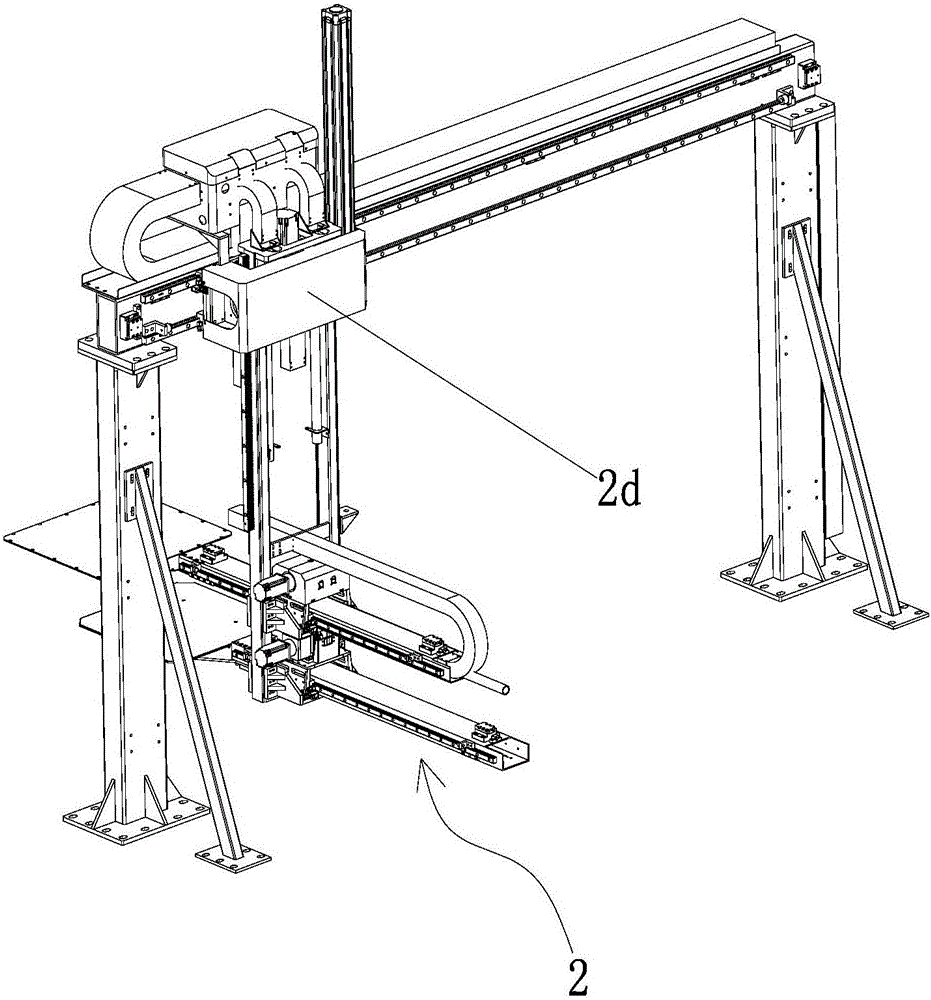

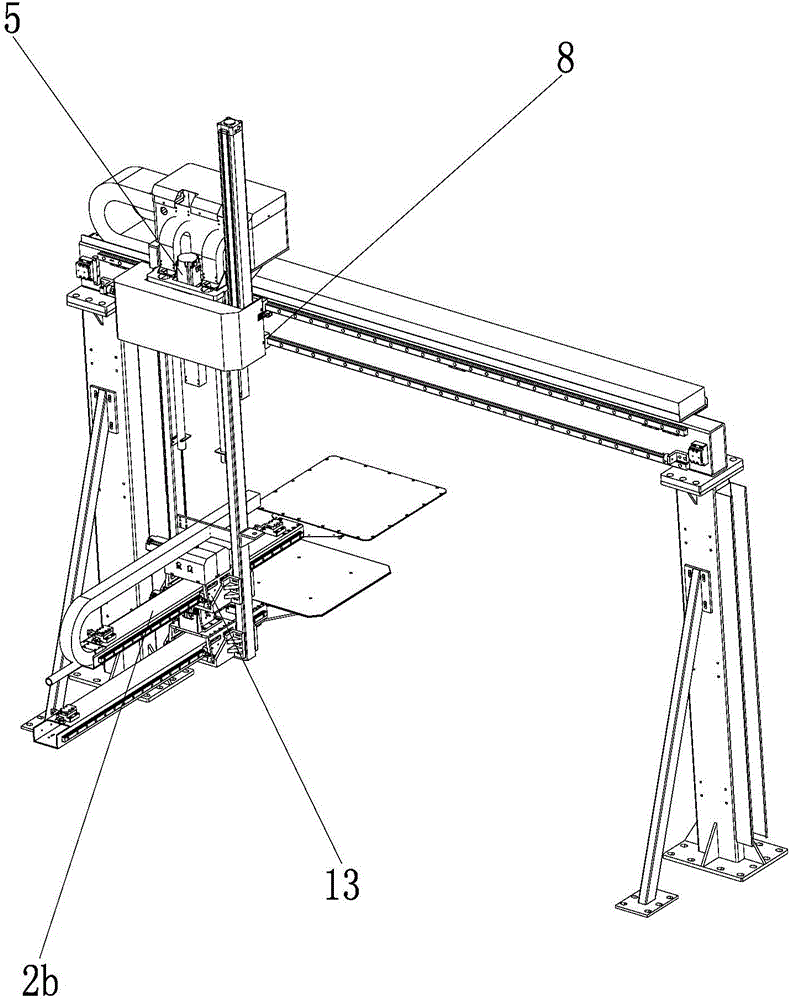

[0024] Please see attached Figures 1 to 8 , a fully automatic intelligent loading and unloading system for paper molds based on remote control, including a support 1, a movable manipulator assembly 2 arranged on the support 1, and the manipulator assembly 2 includes a first movable up and down mounted on the support 1 The mechanical arm 2a, the second mechanical arm 2b installed on the lower end of the first mechanical arm 2a and vertically movable back and forth with the first mechanical arm 2a, and the adsorption assembly 3 installed on the lower end of the second mechanical arm 2b, the The suction assembly 3 includes a first vacuum suction device 3a for sucking the paper mold, and the first vacuum suction device 3a is used to take out the preliminarily formed wet paper mold from the paper mold setting machine and place it in a high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com