Improved test board device for automatic transmission box analog simulation test

A technology of automatic transmission and simulation testing, which is applied in the direction of machine gear/transmission mechanism testing, etc. It can solve the problems of not having transient testing function, not being able to meet mass production, and manual operation with high labor intensity, so as to meet the requirements of mass production. , avoid industrial accidents, improve the effect of test quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

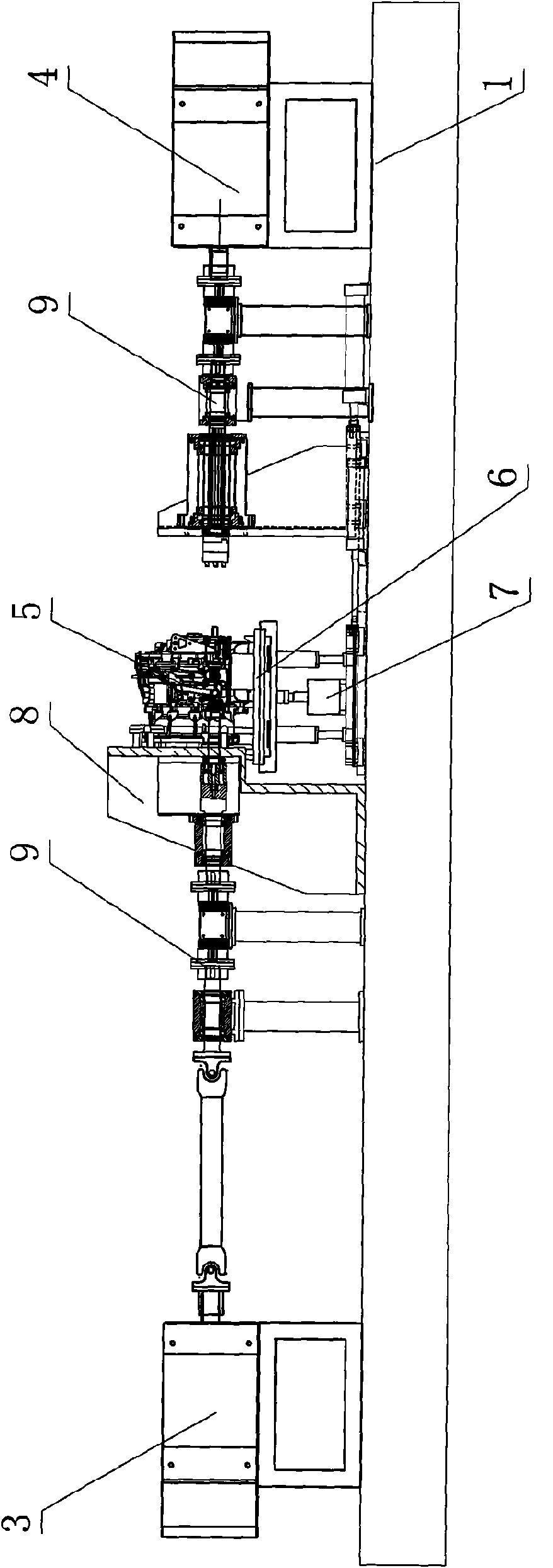

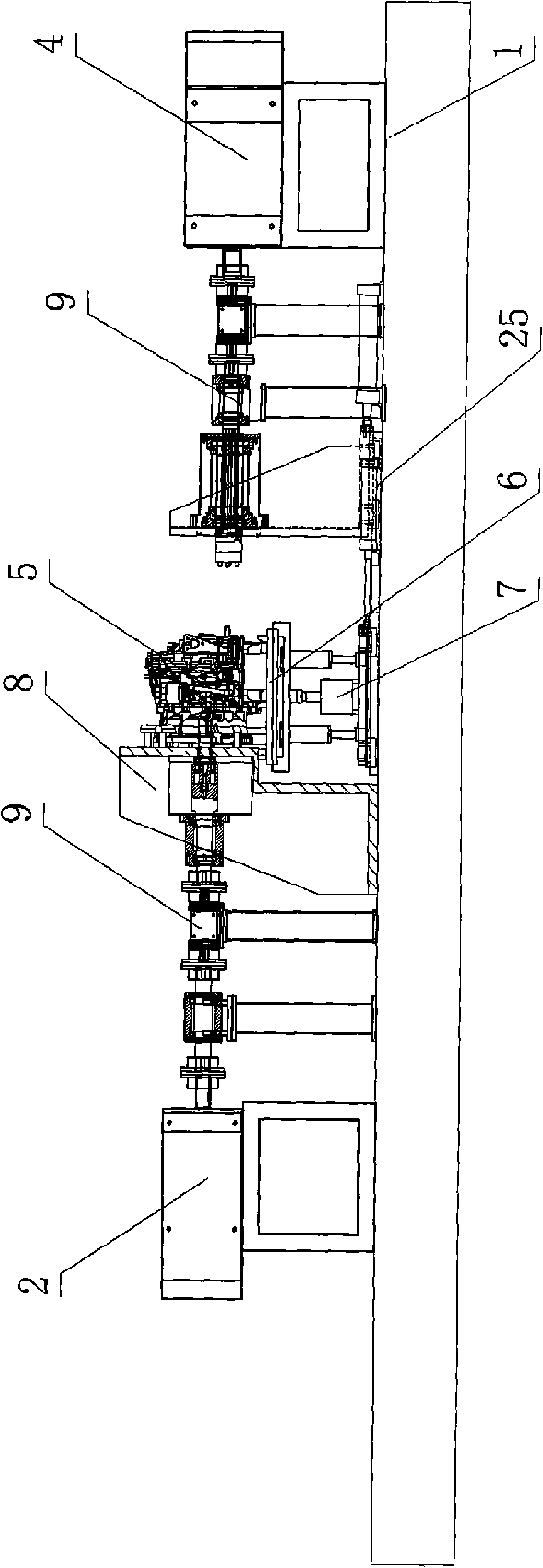

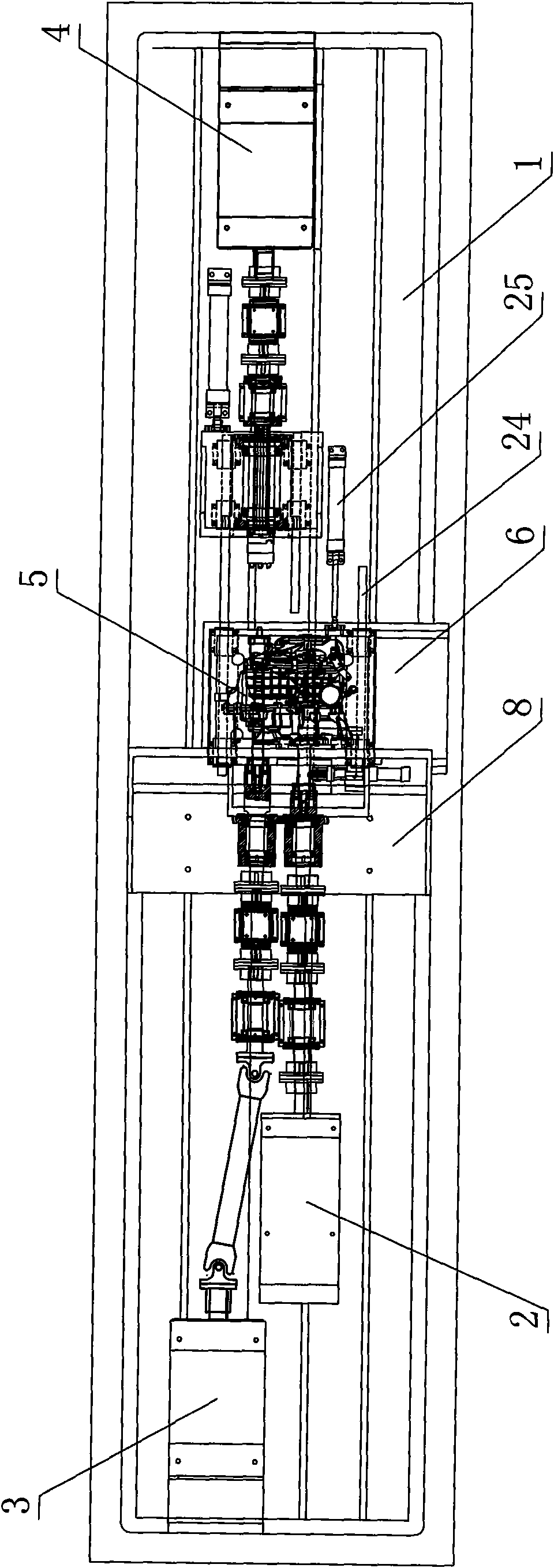

[0013] See figure 1 , figure 2 , image 3 , Figure 4 , the present invention includes a worktable 1, an input motor 2, two output motors 3, 4, an automatic transmission 5 is supported on a workbench 6, a jacking translation device is installed on the lower part of the workbench 6, and a fixed wall is installed on one side of the workbench 6 Board 8, an input motor 2 and an output motor 3 are installed on one side of the fixed wall board 8, and another output motor 4 is installed on the other side of the workbench 6, and the input motor 2 and two output motors 3 and 4 pass through the quick docking device 9 Connect the automatic transmission 5.

[0014] The quick docking device 9 specifically includes a shaft coupling 11, a bearing seat 12, a bearing 13, a torque meter 14, and a quick docking disc. The quick docking disc includes an inner disc 15 and an outer disc 16. The output shaft 18 of the motor 17 is connected to the connecting shaft through the coupling 11. 19. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com