Automatic material feeding and taking robot

An automatic feeding and robot technology, applied in metal processing equipment, feeding devices, stripping devices, etc., can solve the problems of low efficiency, prone to industrial accidents, and increase labor intensity of workers, so as to avoid industrial accidents, ensure safe operation, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

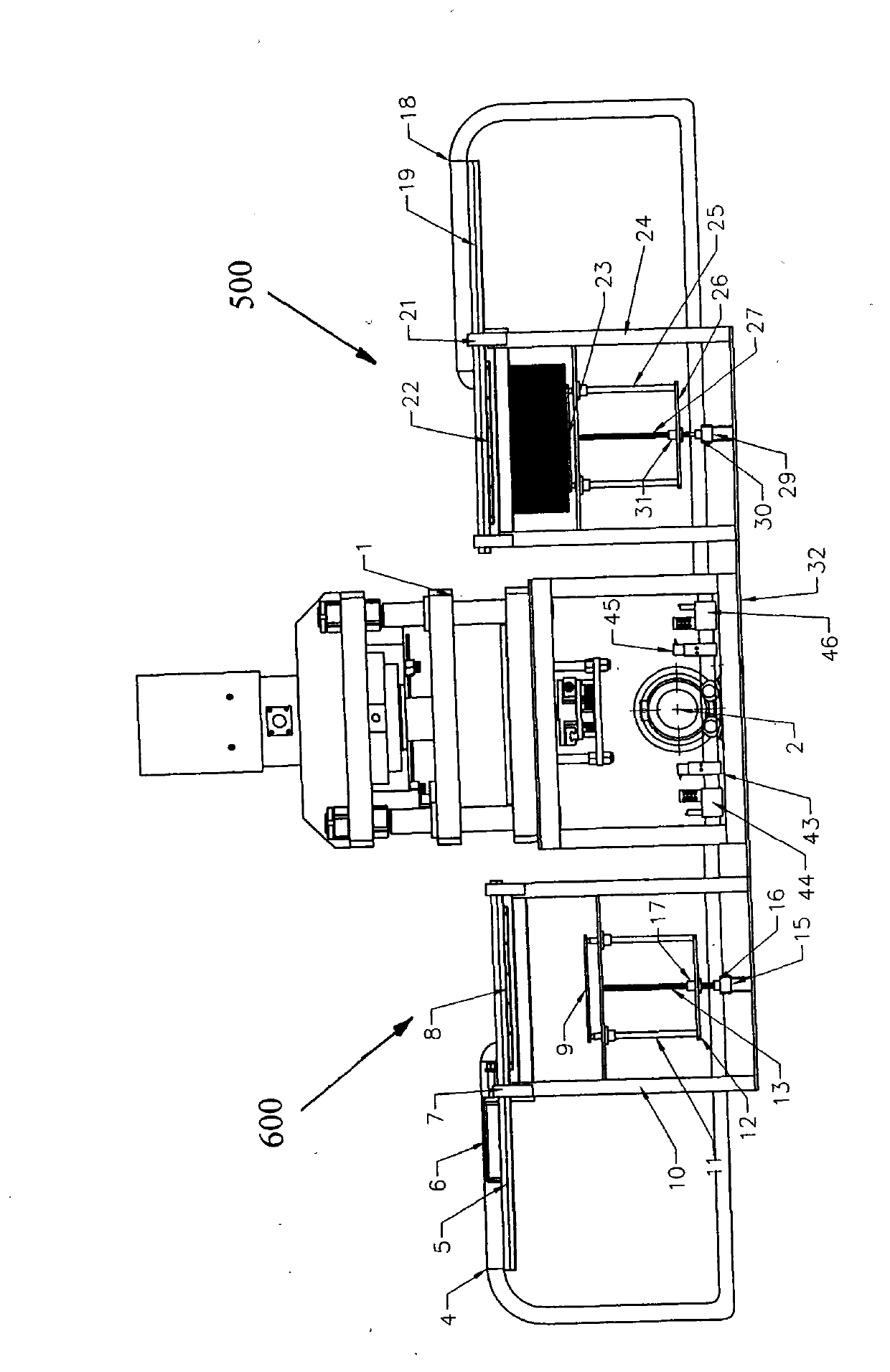

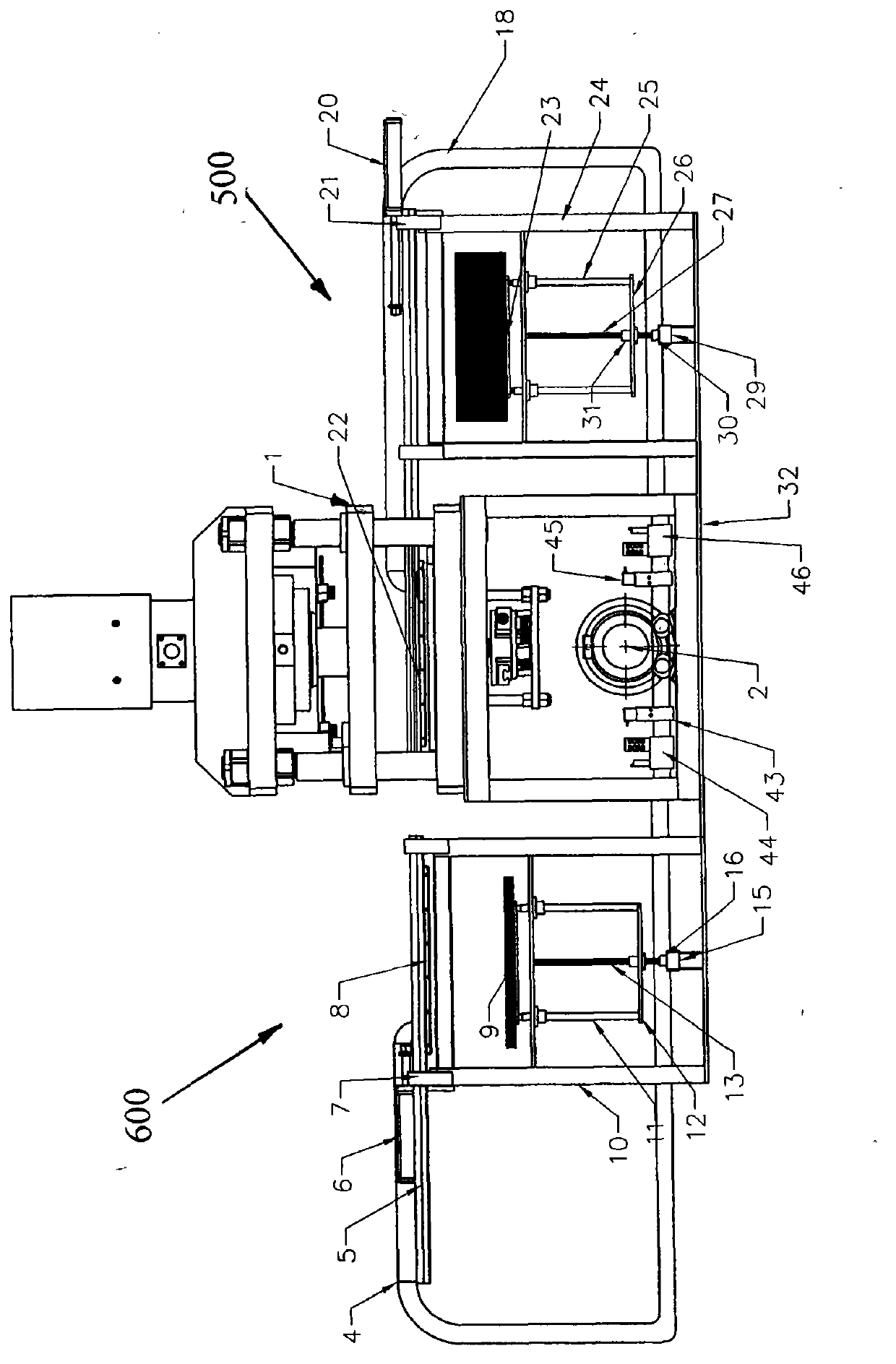

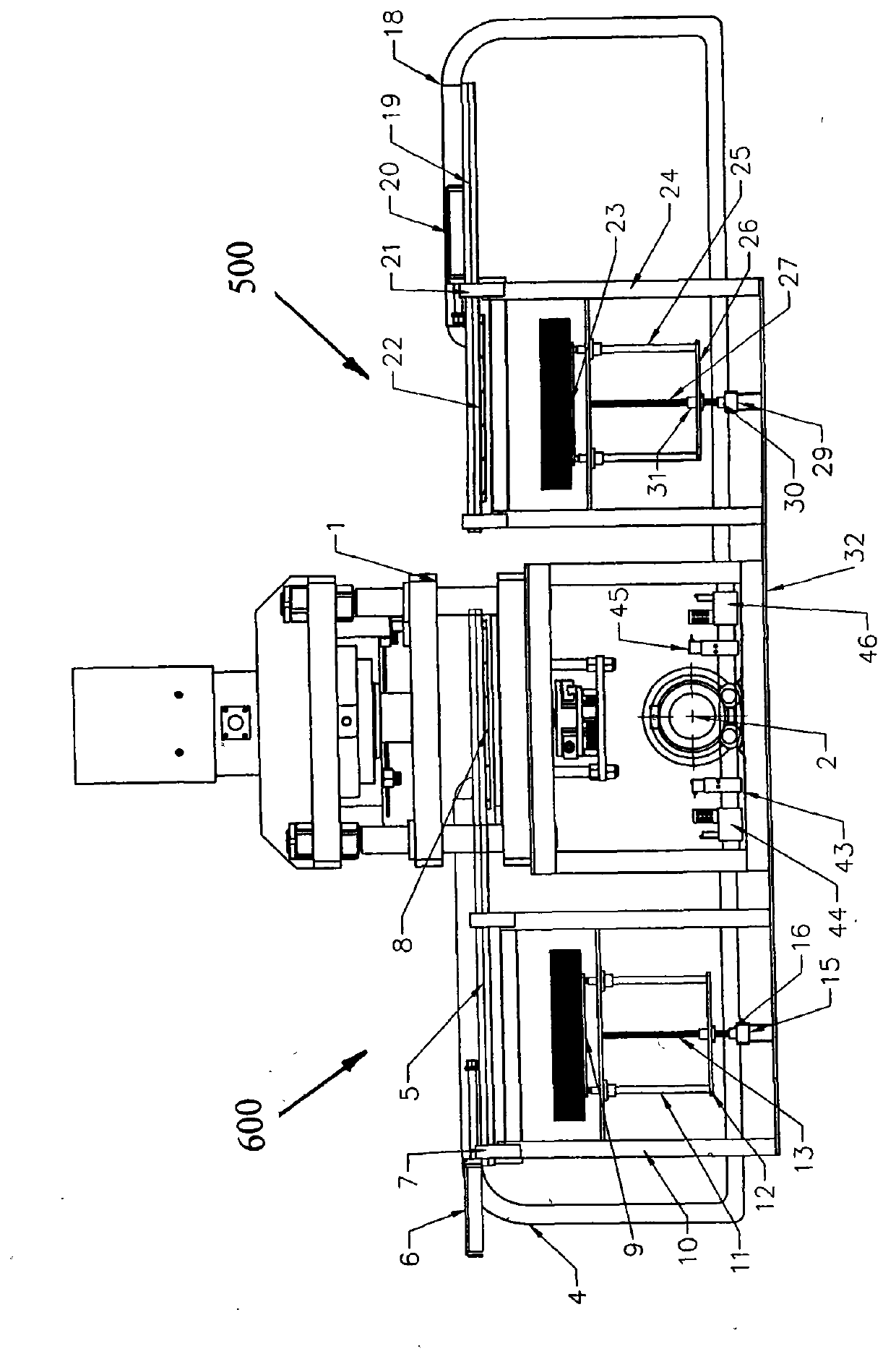

[0022] like Figure 1-Figure 6 As shown, the automatic feeding and retrieving robot of the present invention includes: an underframe 32 and a feeding device 500 and a retrieving device 600 fixed on the underframe 32 .

[0023] On the chassis 32, a vacuum pump 2 is arranged between the feeding device 500 and the taking-out device 600, and the feeding vacuum suction pipe 18 and the taking-out vacuum suction pipe 4 are connected to the vacuum pump 2 respectively. A punching machine, such as a hydraulic slicer 1 is fixed on the top of the vacuum pump 2 .

[0024] In the present invention, as Figure 7 and Figure 8 As shown, the feeding device 500 includes: a feeding frame 24, a feeding elevating mechanism 100, a feeding pushing mechanism 200, a feeding vacuum adsorption mechanism 300, two feeding guide rail mounting frames 21, two feeding guide rails 19, a feeding mounting plate 38, and the like.

[0025] like Figure 8 , The feeding lifting mechanism 100 includes: feeding li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com