Charging mechanism of automatic magnetic shoe deburring device

A deburring and automatic technology, applied in the direction of grinding feed movement, grinding machine parts, metal processing equipment, etc., can solve the problems of time-consuming and labor-intensive manual loading, burrs on the end of magnetic tiles, work-related accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

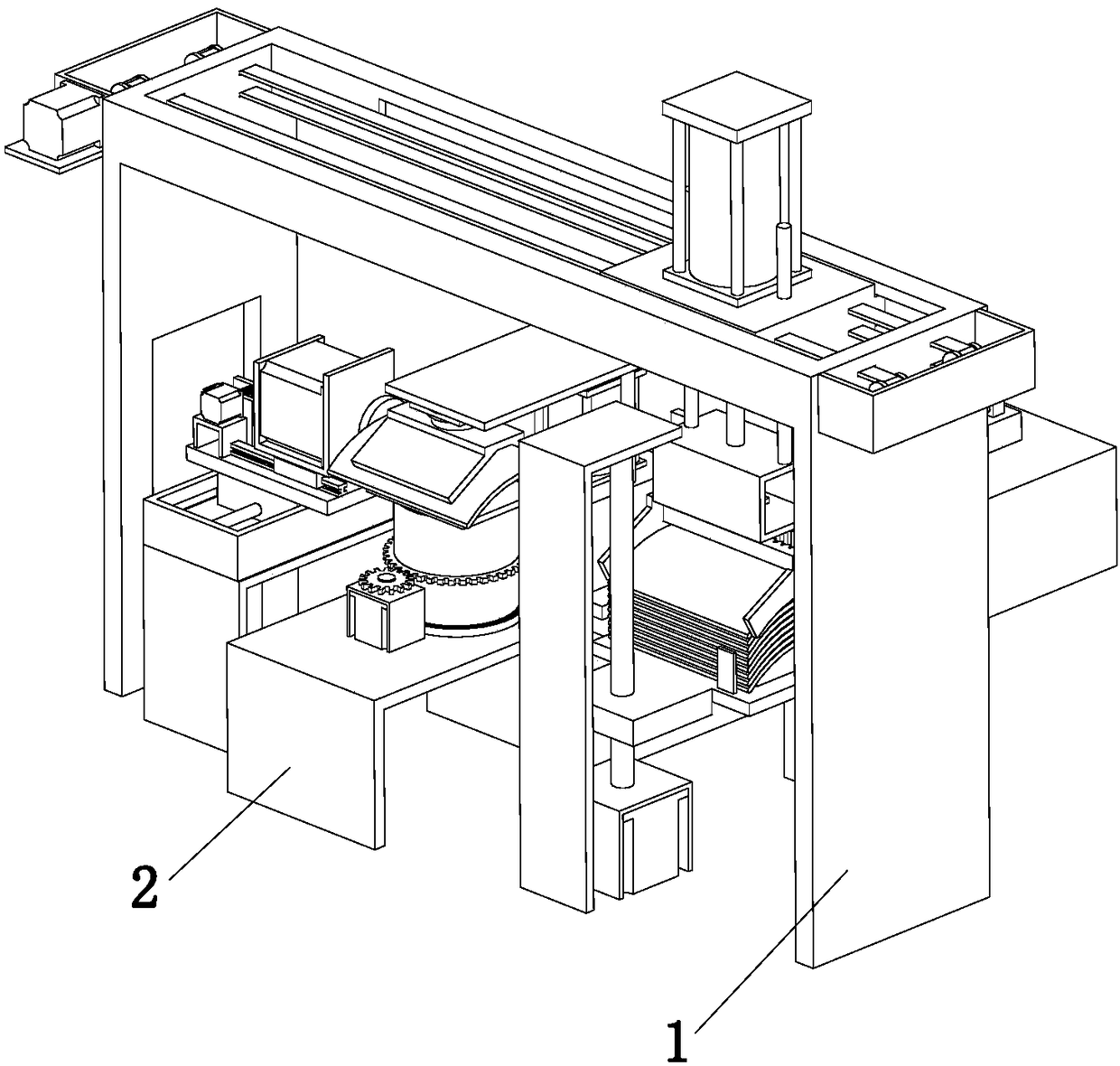

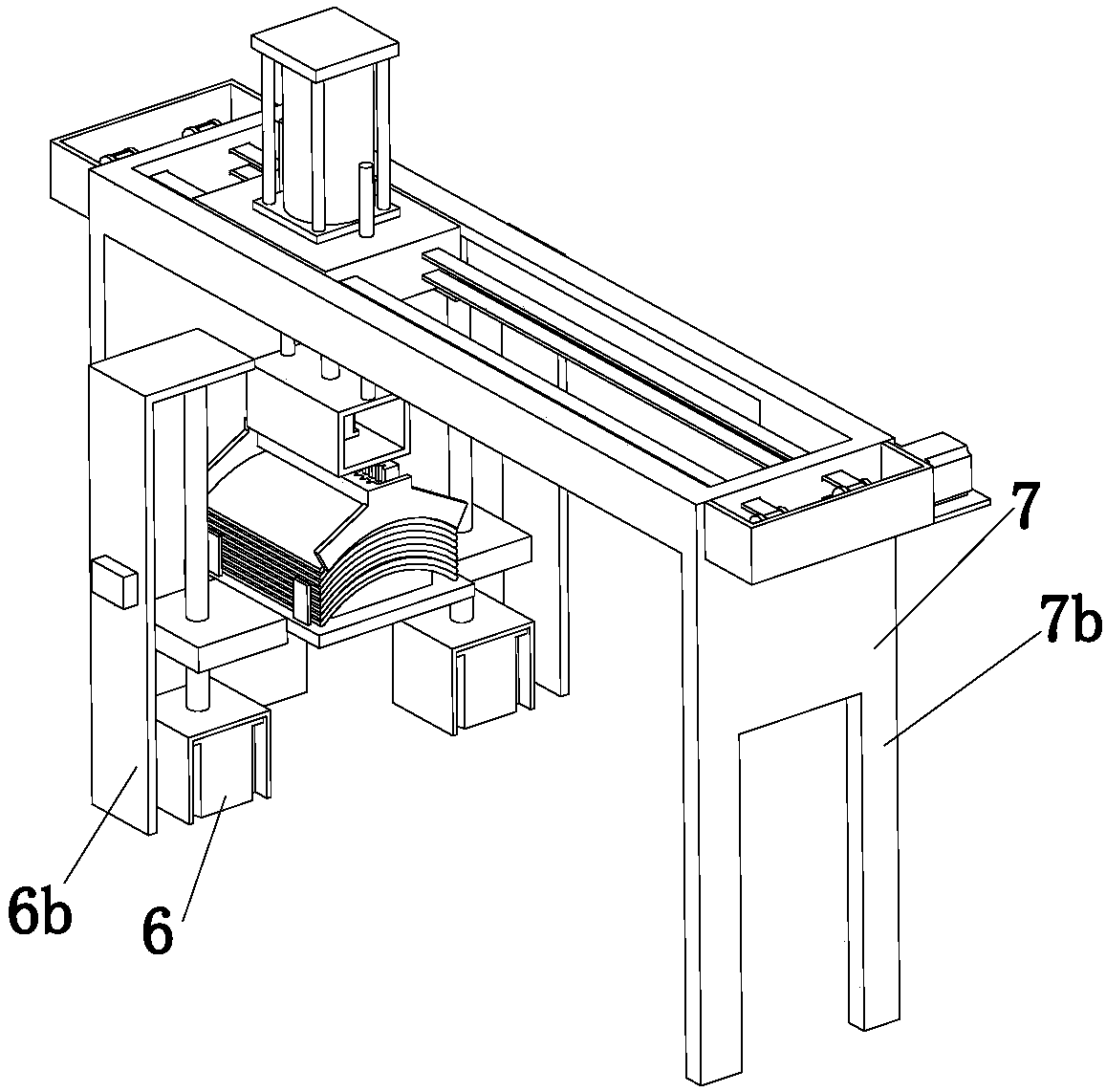

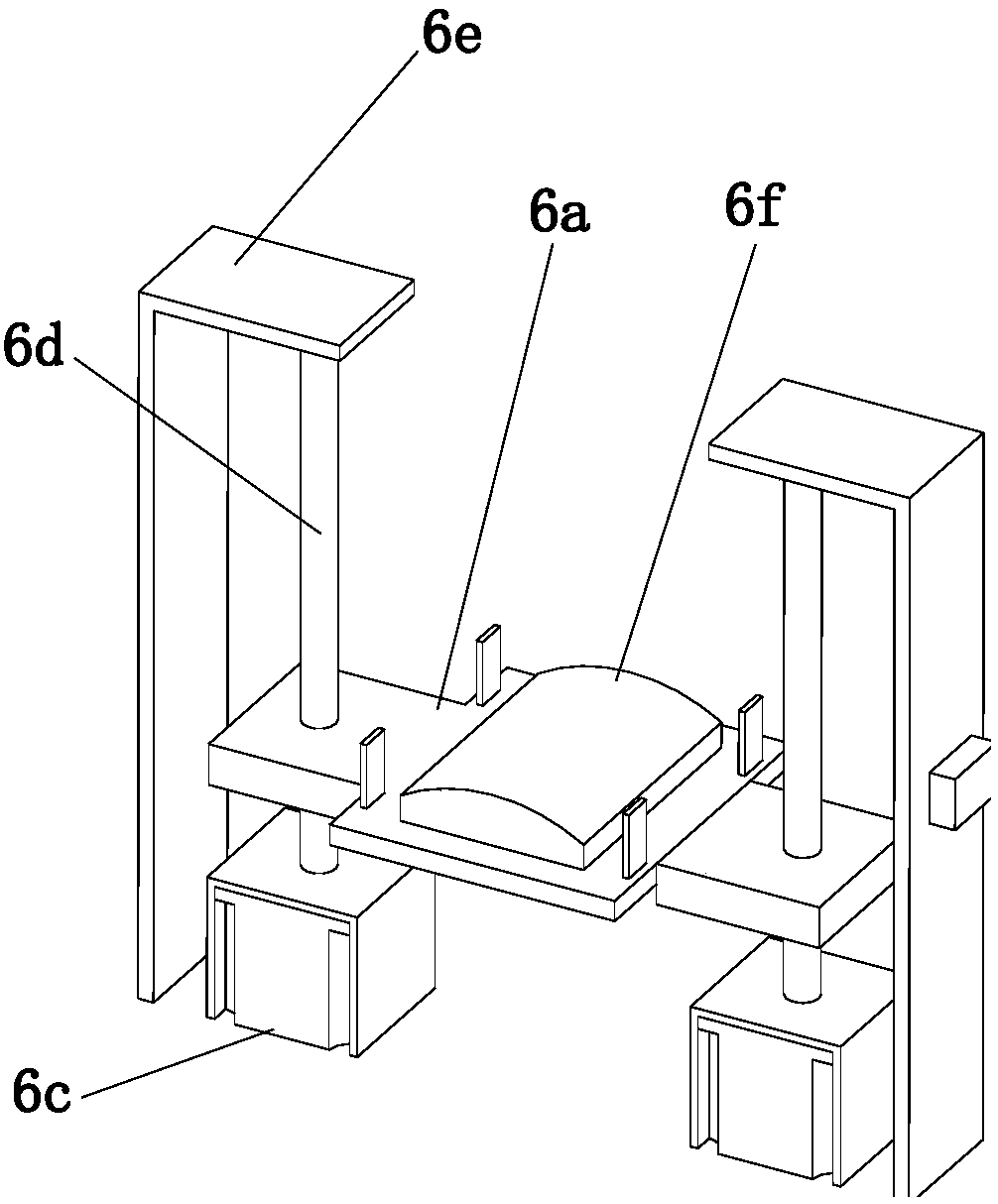

[0029] refer to Figure 1 to Figure 12 The shown automatic deburring device for magnetic tiles includes a feeding mechanism 1 for loading workpieces and a deburring mechanism 2 for deburring workpieces. The feeding mechanism 1 is located in the deburring mechanism 2 On the side, the deburring mechanism 2 includes a deburring assembly 3, a rotating assembly 4 for driving the workpiece to rotate, and a limit assembly 5 for limiting the workpiece. The rotating assembly 4 is located between the deburring assembly 3 and Between the feeding mechanism 1, the limit assembly 5 is located at the side of the rotating assembly 4, and the deburring assembly 3 includes a fixed frame 3a, a drive motor 3a1 and a material moving plate 3a2 above the fixed frame 3a, the material moving plate A U-shaped support plate 3a3 for installin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com