Hydraulic machine with safety shields

A technology for safety baffles and hydraulic presses, applied in the field of hydraulic presses, can solve problems such as easily injuring operators, large impact loads, material cracking and splashing, etc., so as to avoid industrial accidents and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

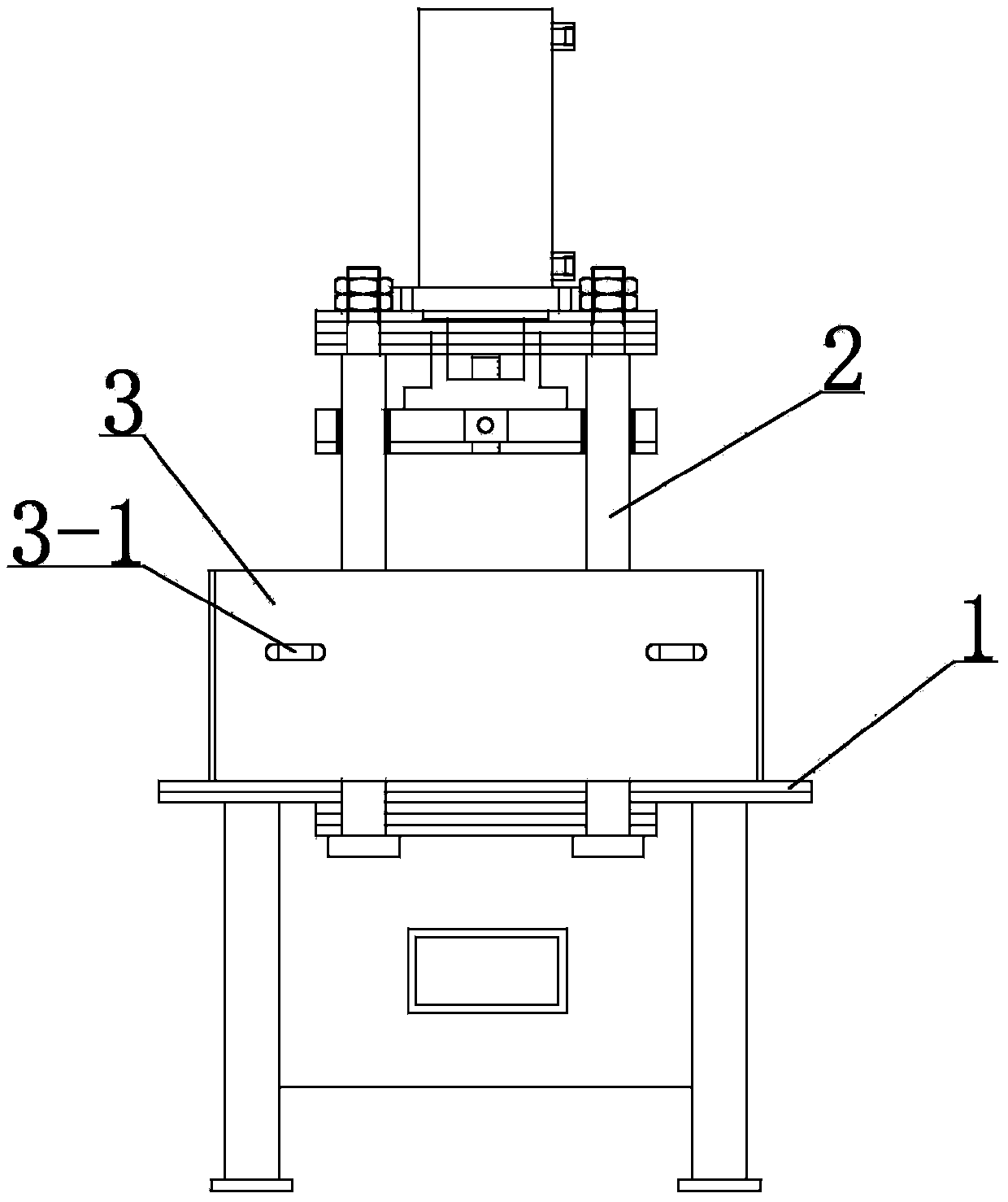

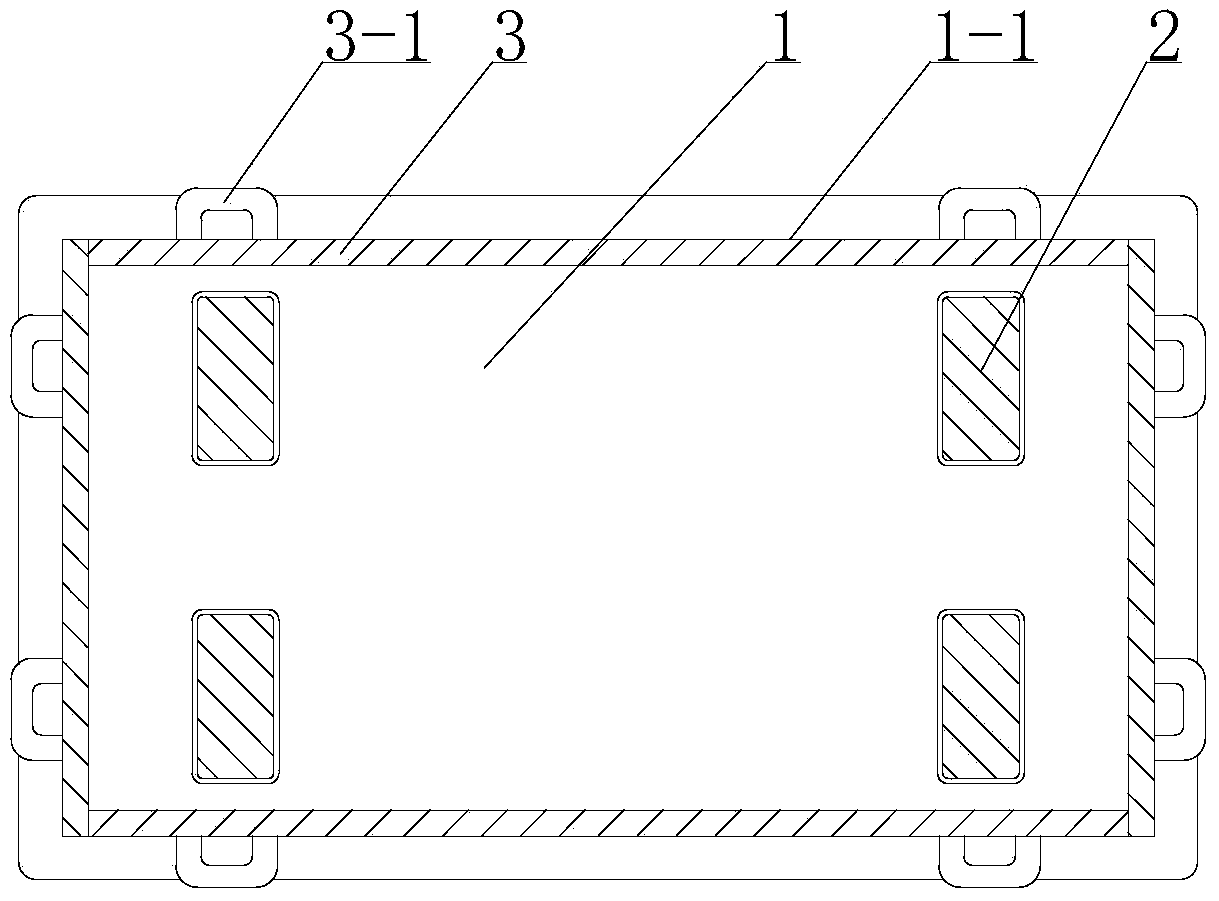

[0010] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0011] Such as figure 1 and figure 2 The shown hydraulic machine with a safety baffle includes a base plate 1 on which four guide columns 2 are arranged, on the base plate 1 and along the four A groove 1-1 is provided on the outer side of the root guide column 2, and a baffle plate 3 is inserted and installed in the groove 1-1, and a ring handle 3-1 is provided at both ends of the baffle plate 3 .

[0012] Inspired by the above-mentioned ideal embodiment according to the present invention, through the above-mentioned description content, relevant workers can make various changes and modifications within the scope of not departing from the technical idea of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com