Intelligent trundle automatic assembling machine

An assembly machine, automatic technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of monotonous process, easy to be affected by emotions, boring, etc., and achieve the effect of improving production efficiency and simplifying manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

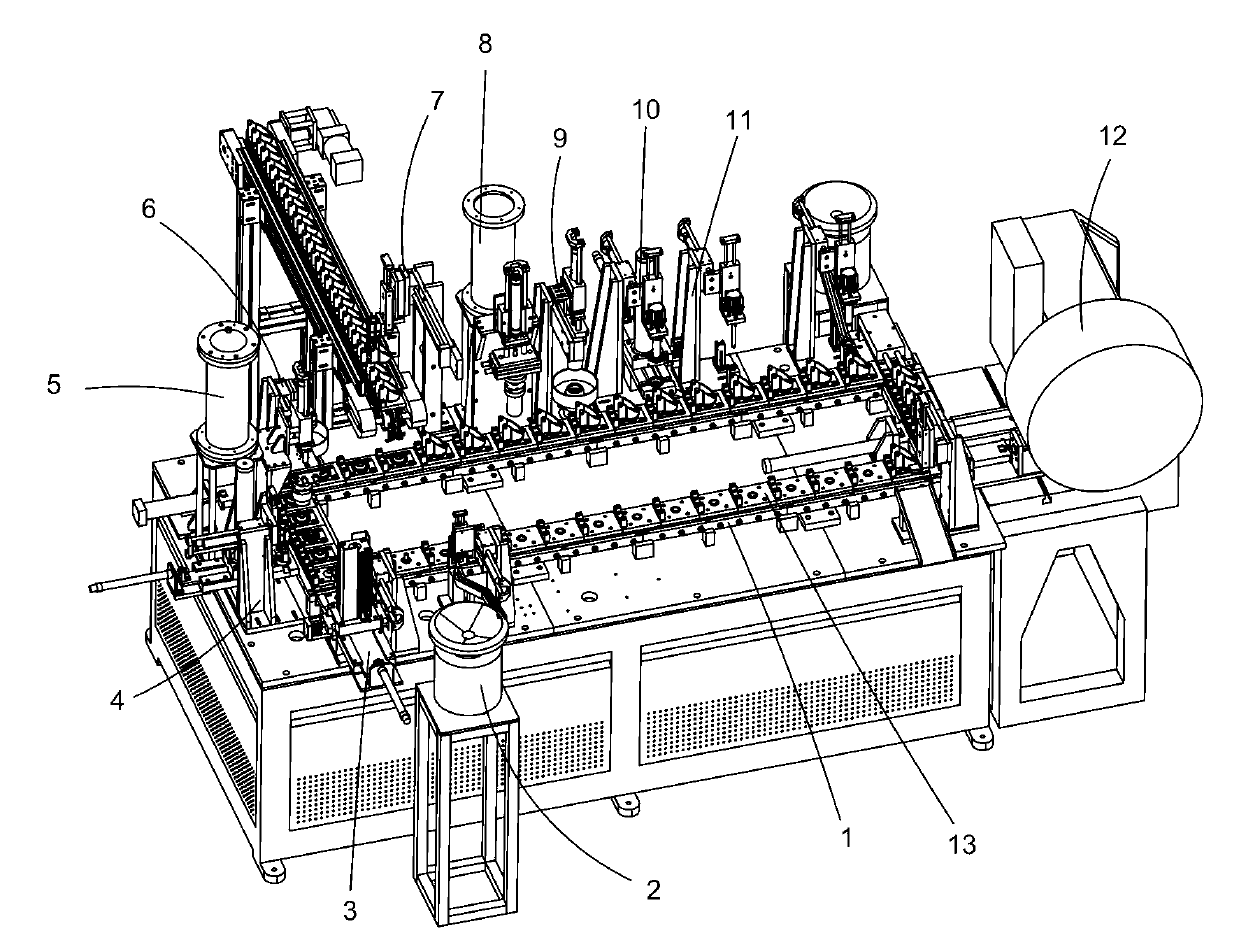

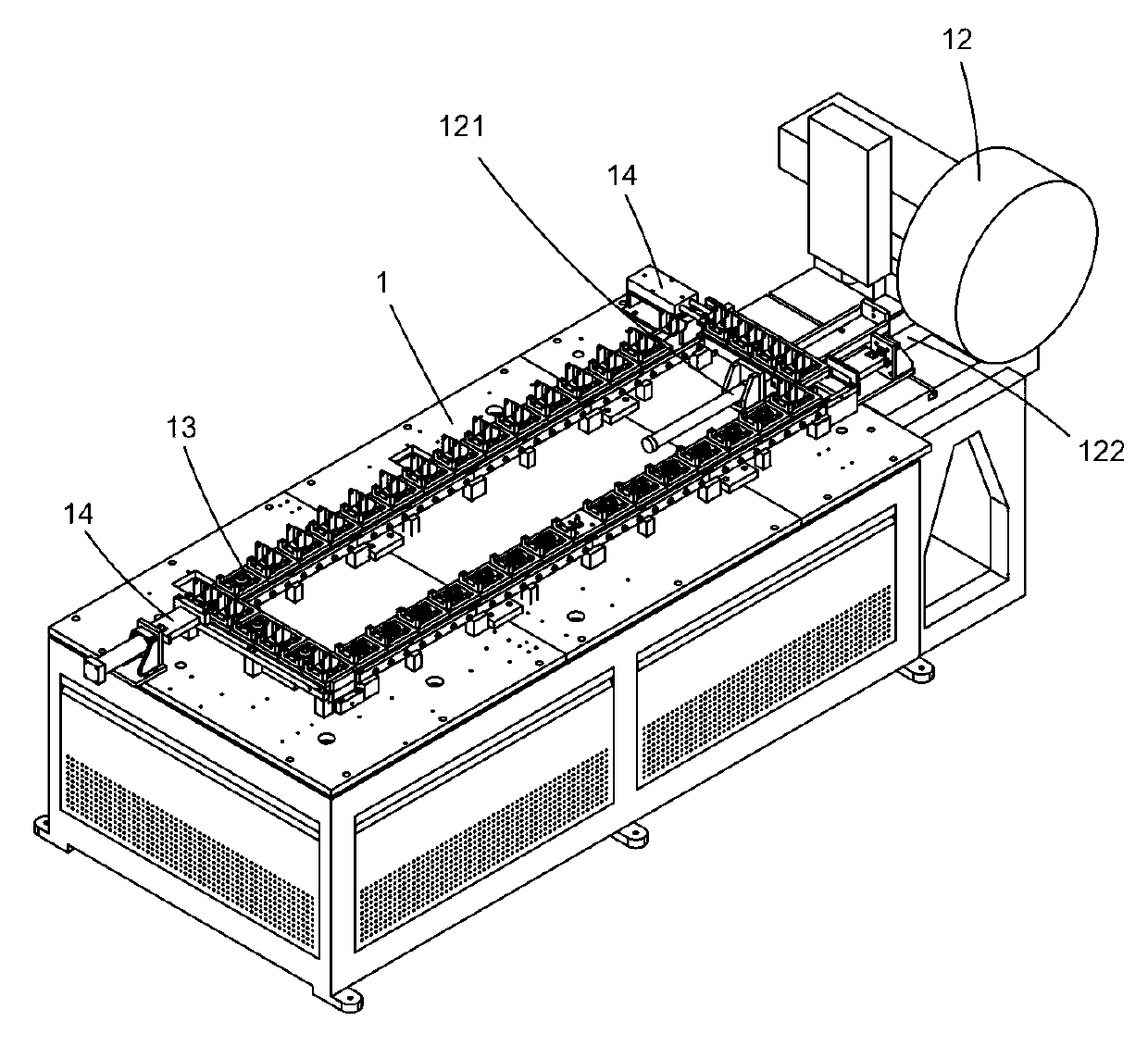

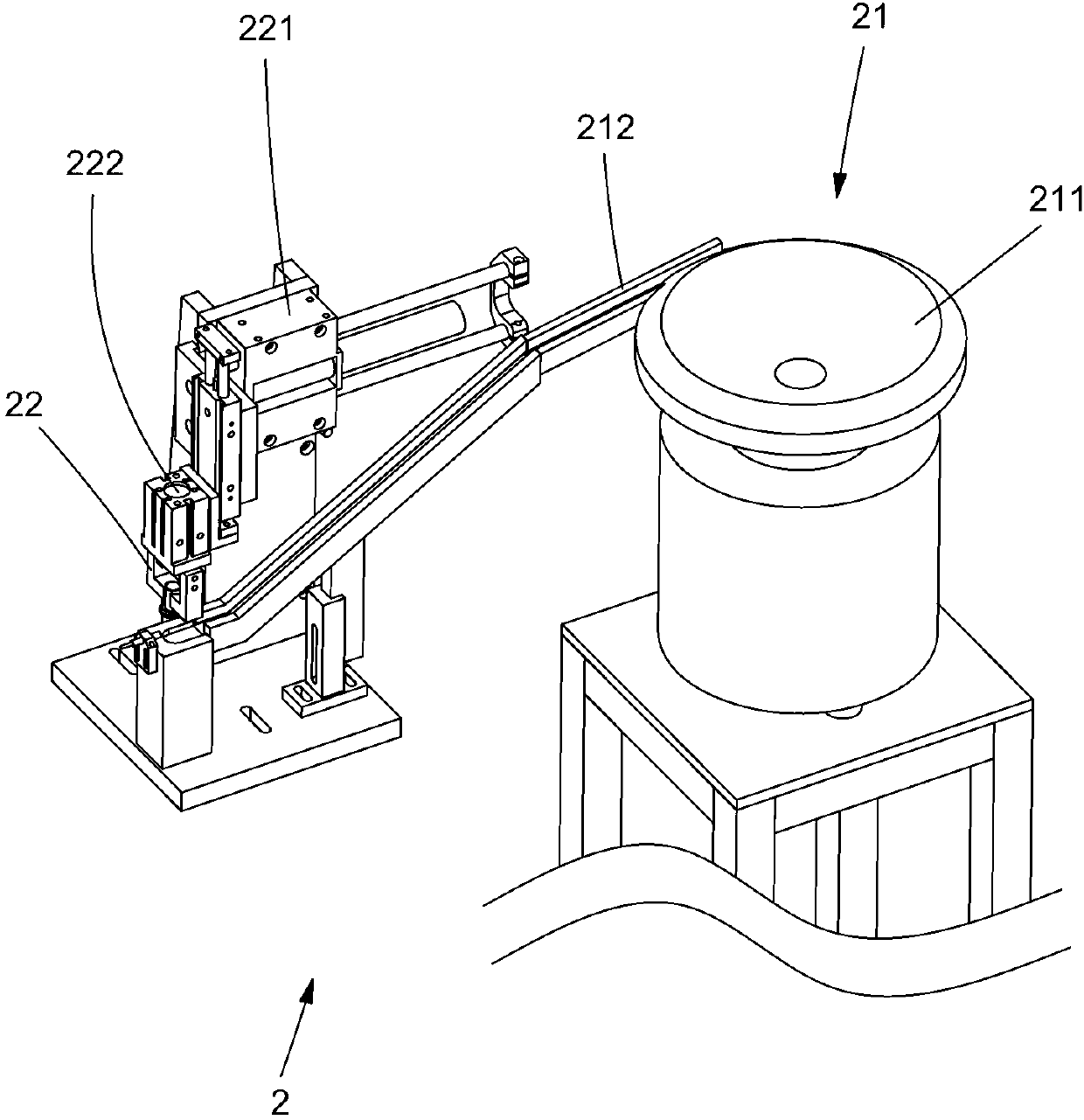

[0060] Below in conjunction with accompanying drawing, the present invention will be further described, as figure 1 As shown, it includes: a rotary table 1, a rivet clamping device 2, a large bottom plate device 3, a large steel ball tray device 4, a first oiling device 5, a large steel ball string device 6, a bracket device 7, a second oiling device 8, Small steel ball string device 9, wavelet disc device 10, spacer device 11, punch device 12, wherein, as figure 2 As shown, the turntable 1 is provided with a plurality of slidable workbenches 13, the turntable 1 is a rectangular structure, and a side position of the turntable 1 is provided to push the workbench 13 to slide circularly. The thruster 14, such as image 3 As shown, the rivet clamping device 2 includes a rivet clamp arm 22 for clamping rivets from a nail feeder 21 to the workbench 13. The nail feeder 21 includes a vibrating plate 211 and a nail feeding track 212. The rivet clamp The arm 22 is connected with a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com