Patents

Literature

427 results about "Spacer device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

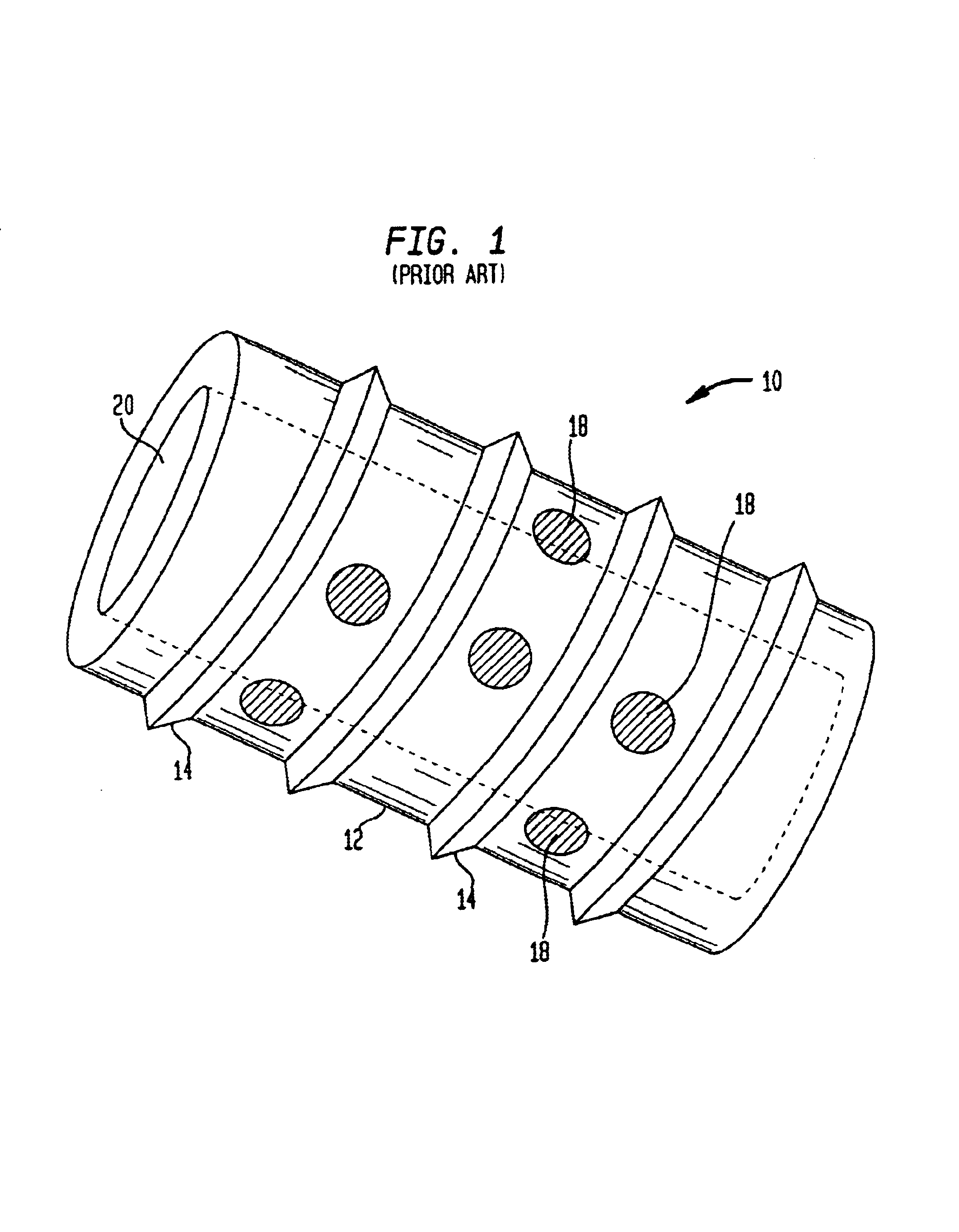

Expandable intervertebral spacer method and apparatus

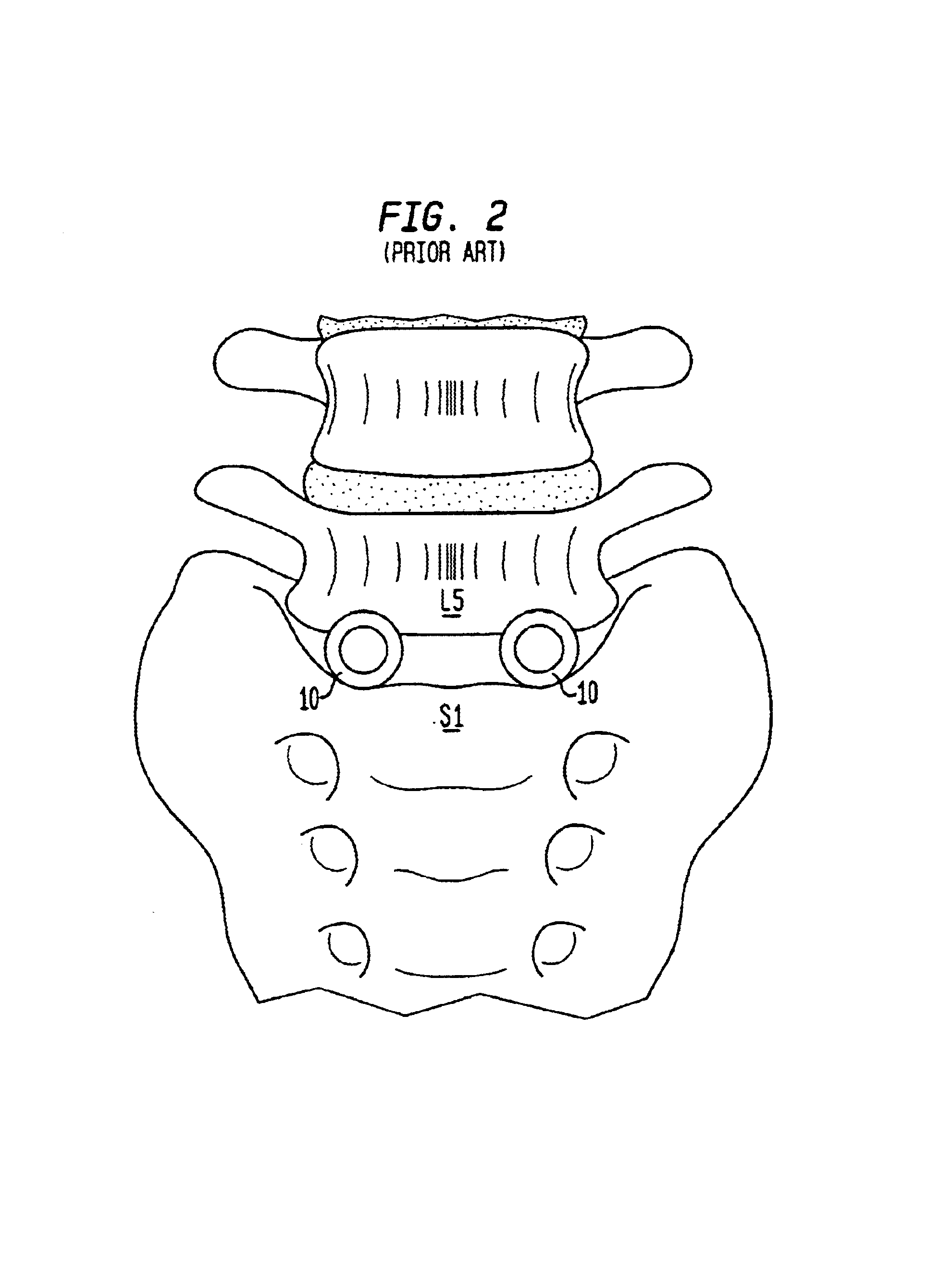

InactiveUS20060129244A1Restore disc heightBone implantSurgeryBiological activationIntervertebral disk

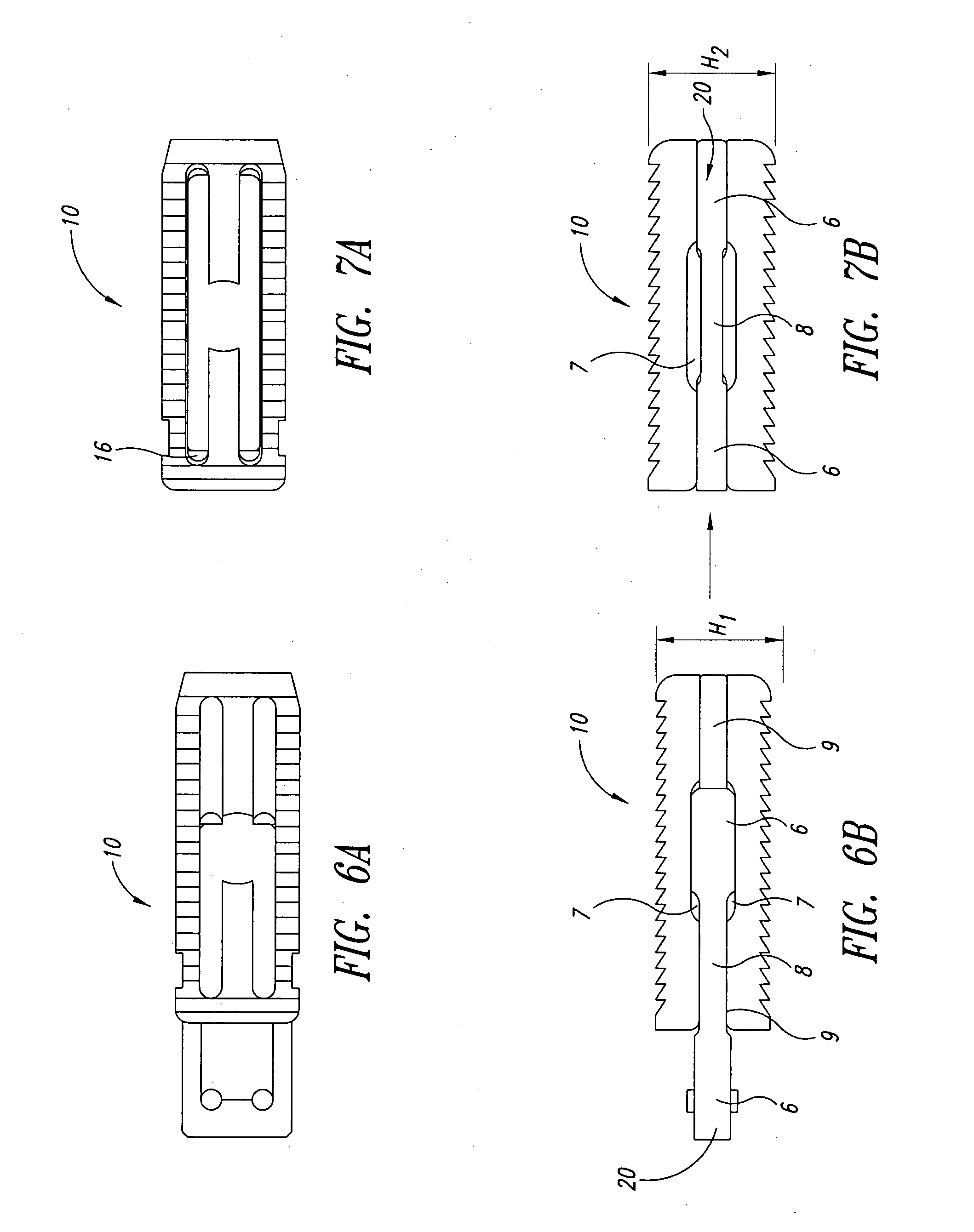

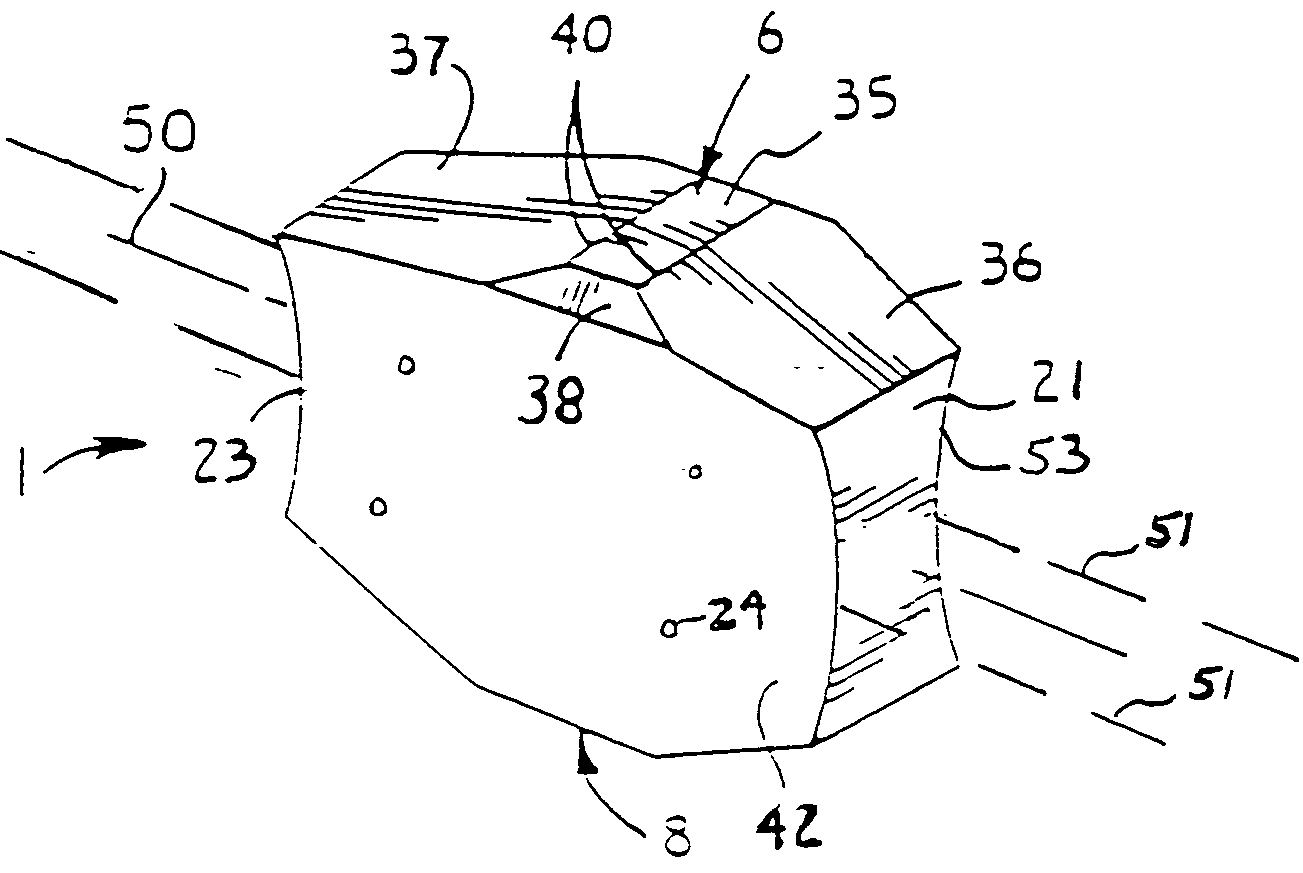

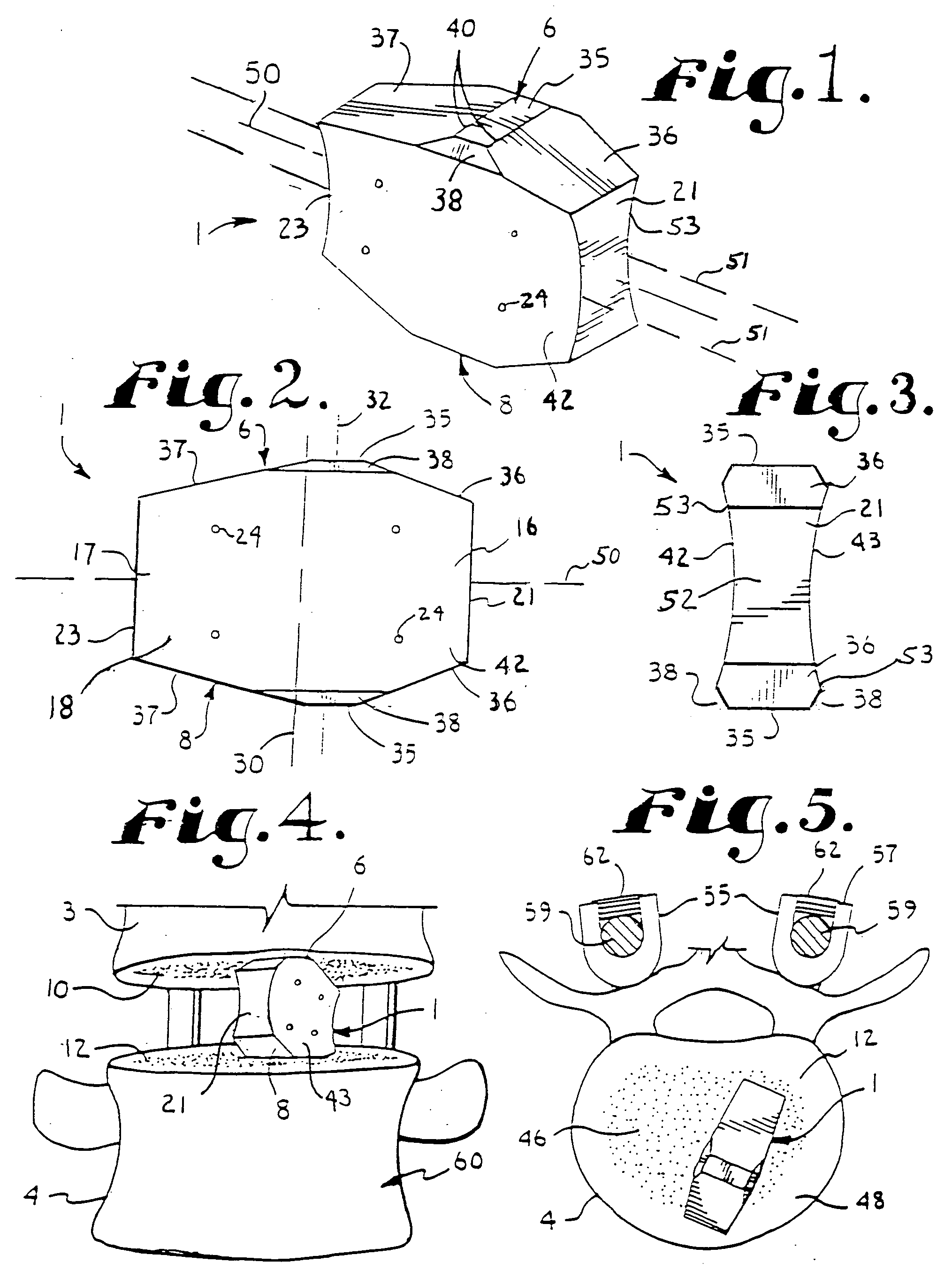

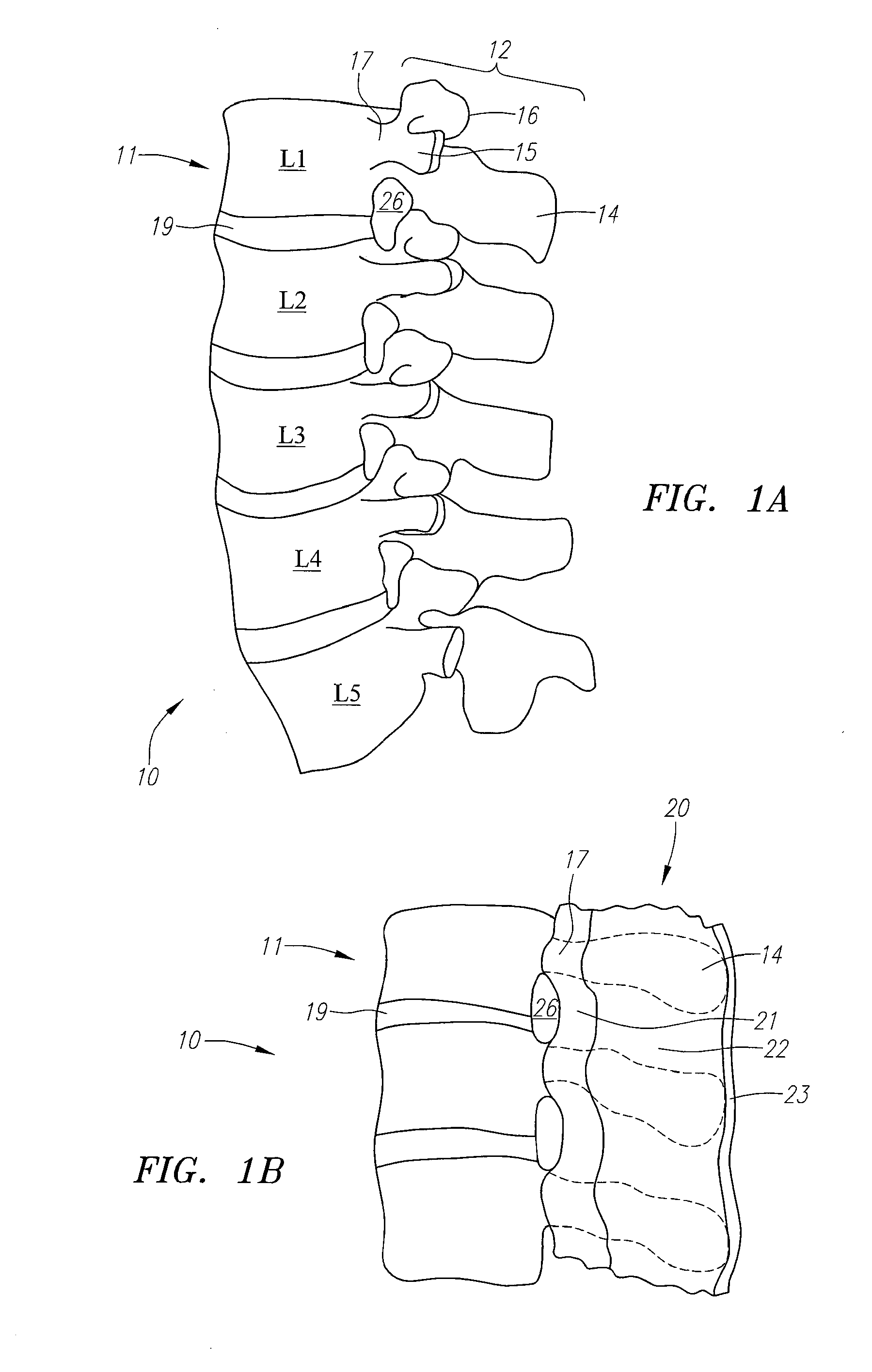

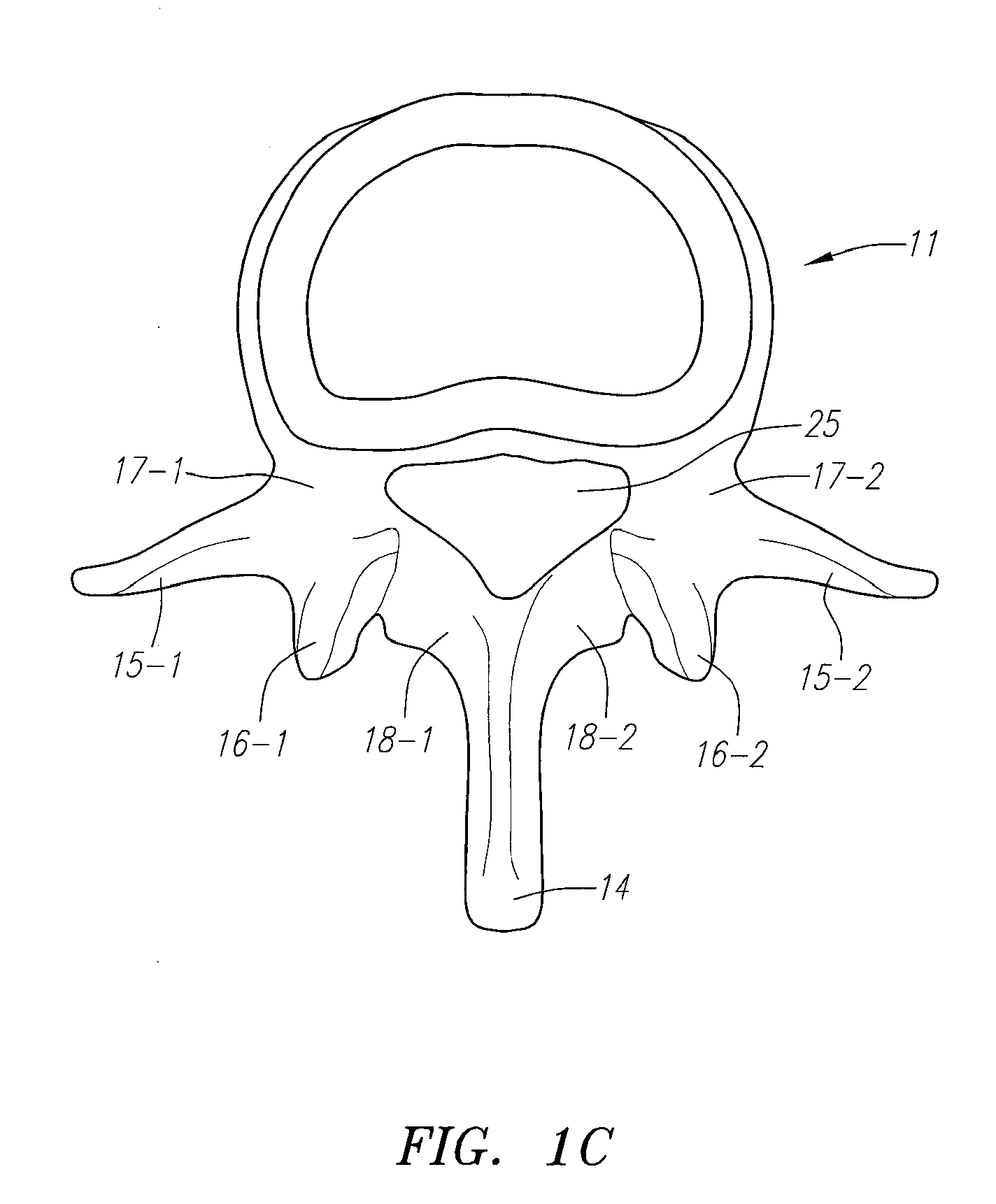

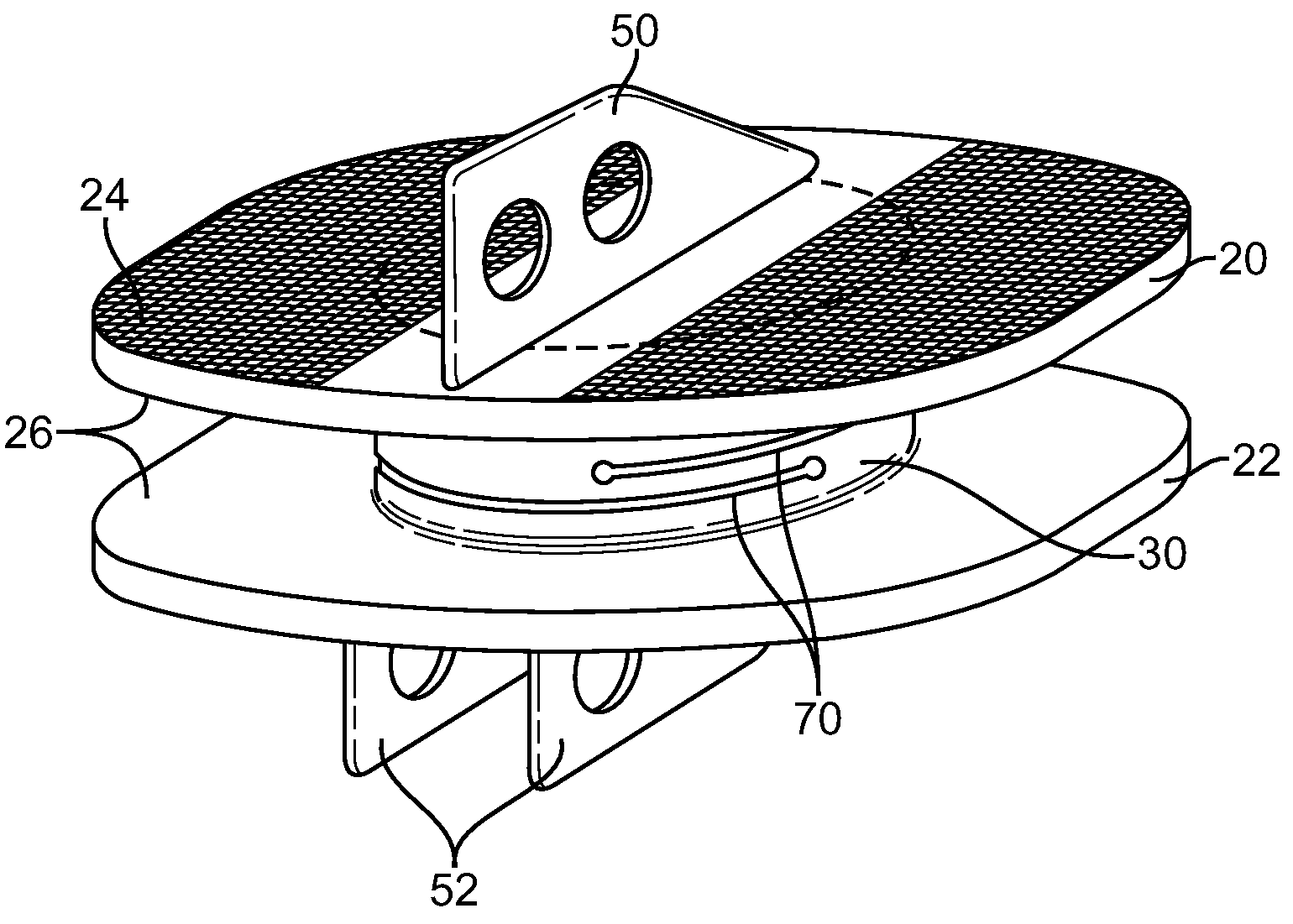

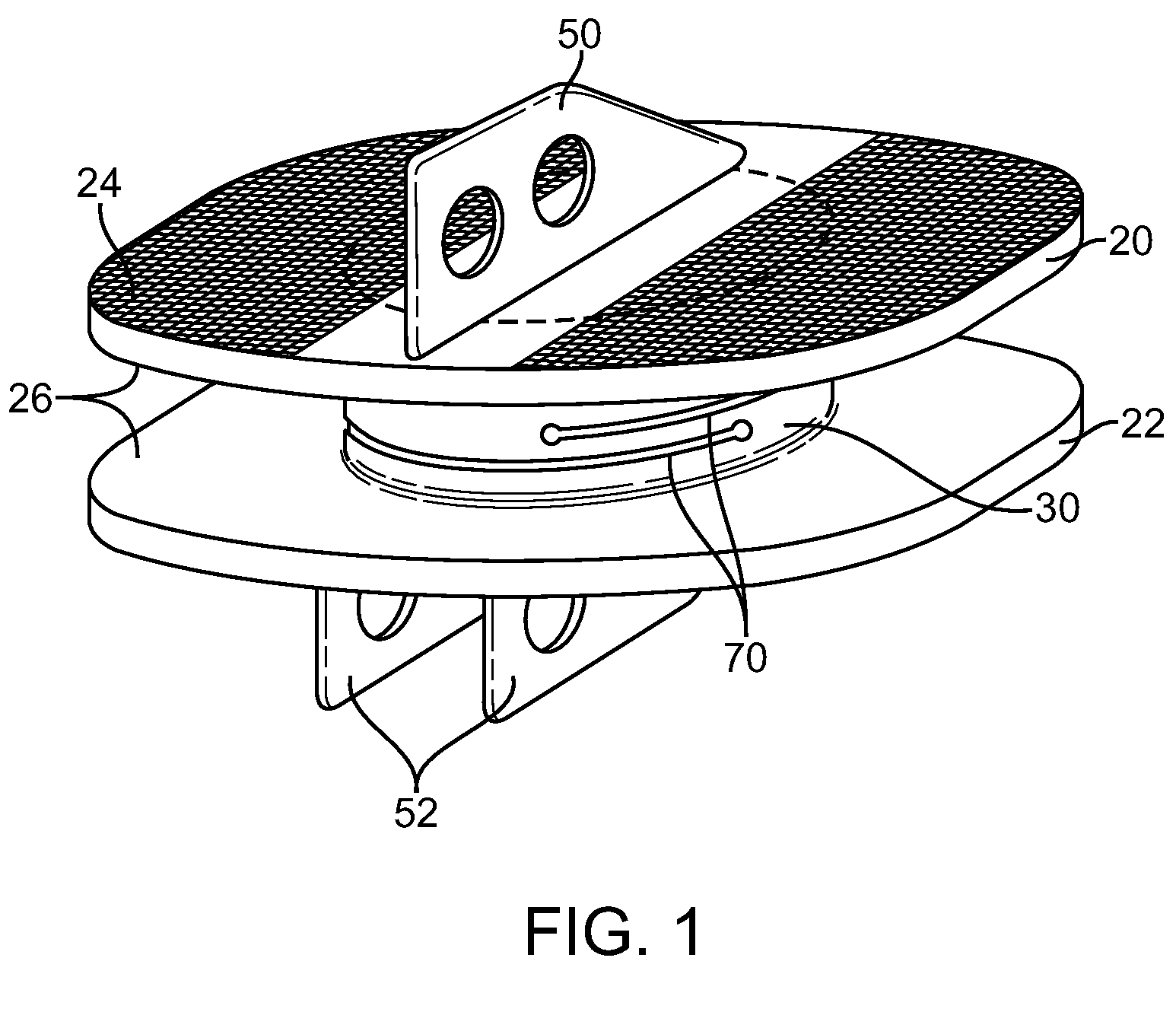

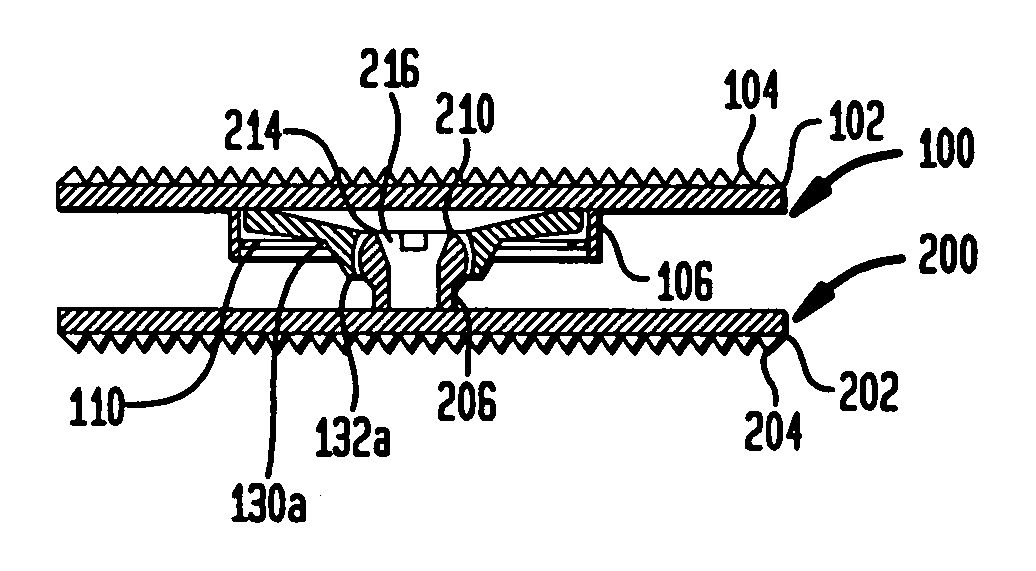

An expandable interbody spacer (IBS) device designed to restore the disc height between vertebral bodies. The expandable interbody spacer device has an integral, moveable expansion member or spreader, provided between two plates. The plates are connected by one or more connecting members that retain the plates in a position proximate to one another while allowing the plates to move from a first unexpanded position to a second expanded position upon activation of the expansion member. According to aspects of the invention, the interbody spacer device can be implanted in an unexpanded or collapsed configuration, and then expanded to full height by engaging the expansion member. In other embodiments, the interbody spacer device may take various forms, for example, it may be cashew, rectangular or annular.

Owner:ALPINESPINE

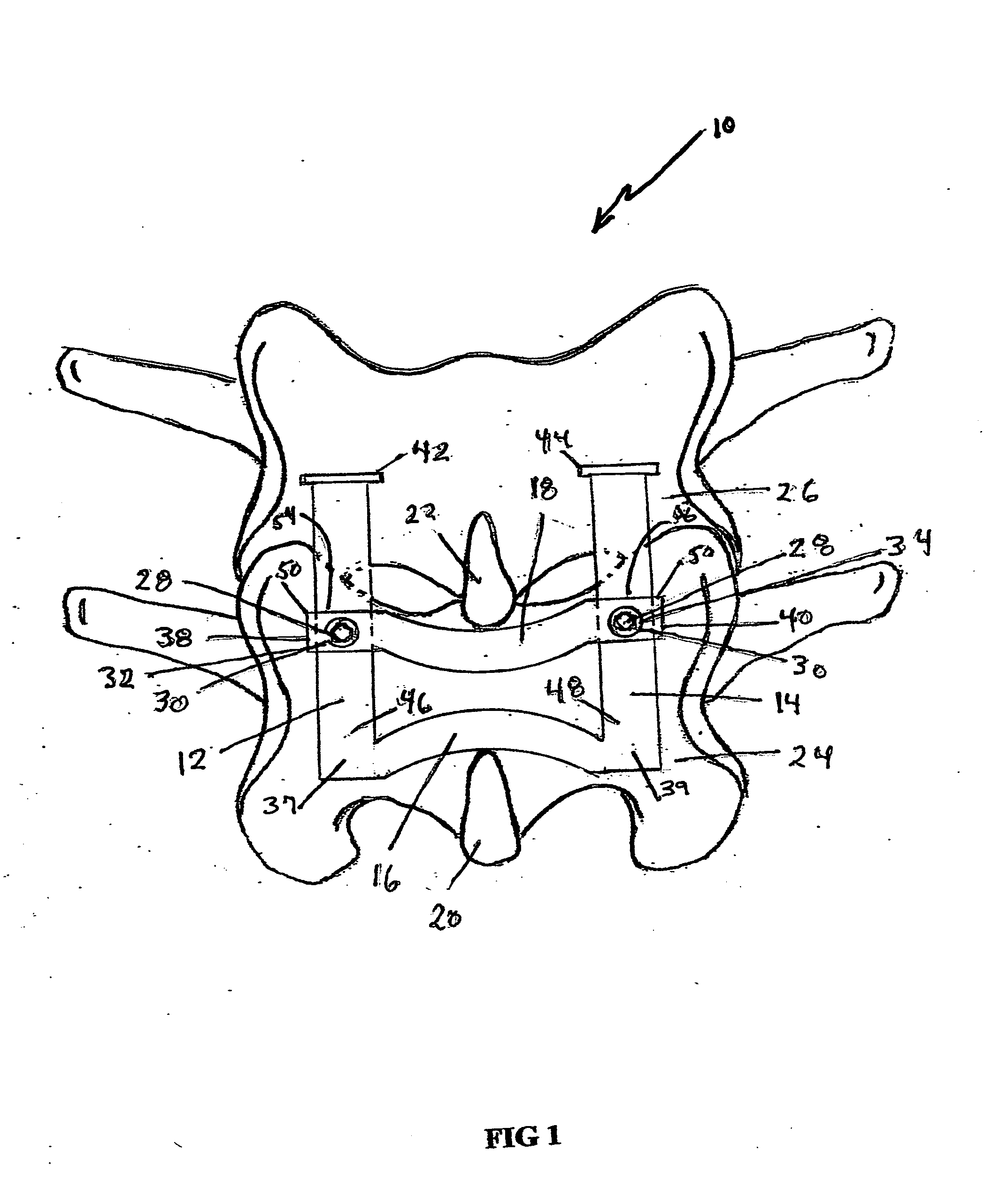

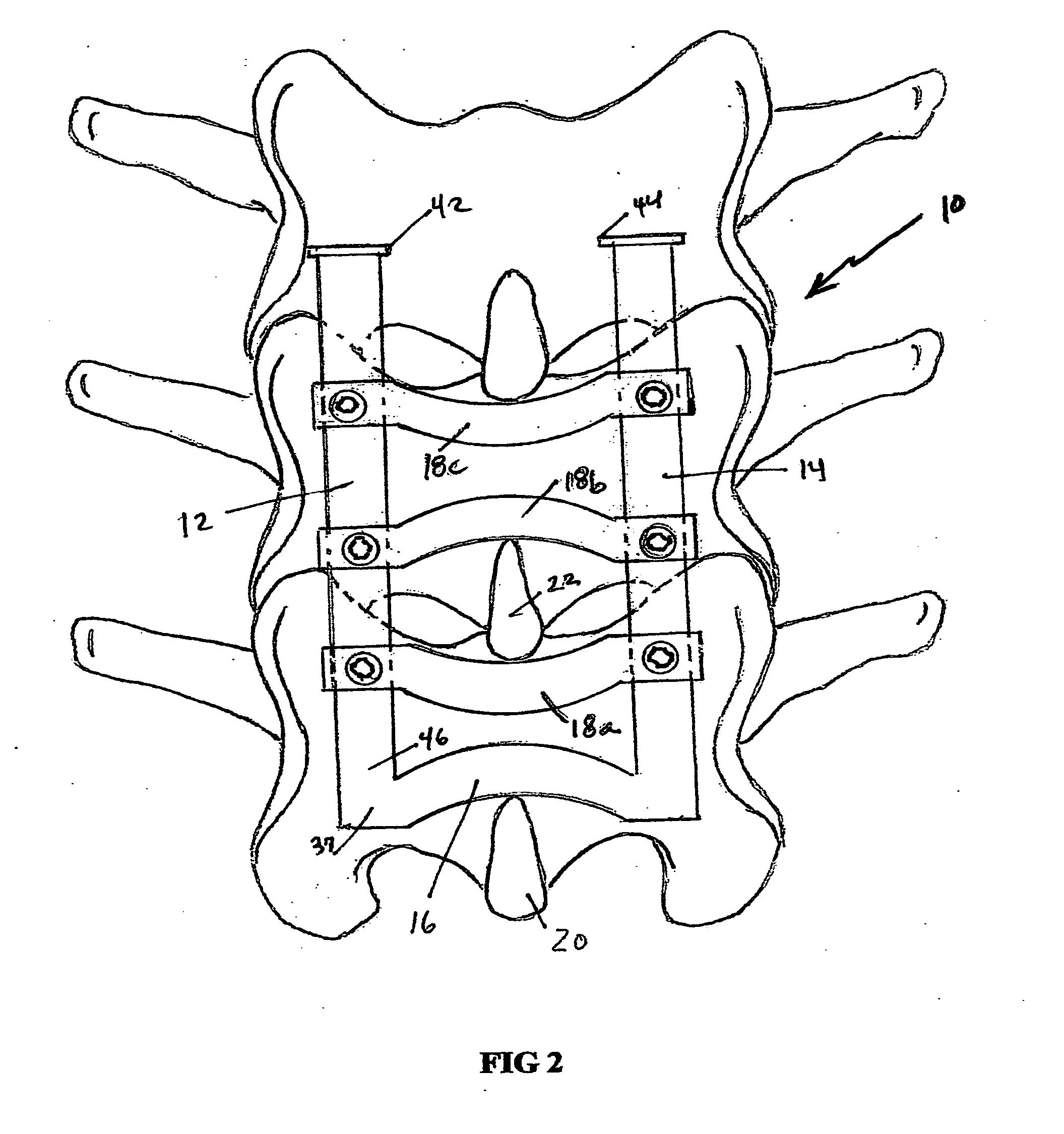

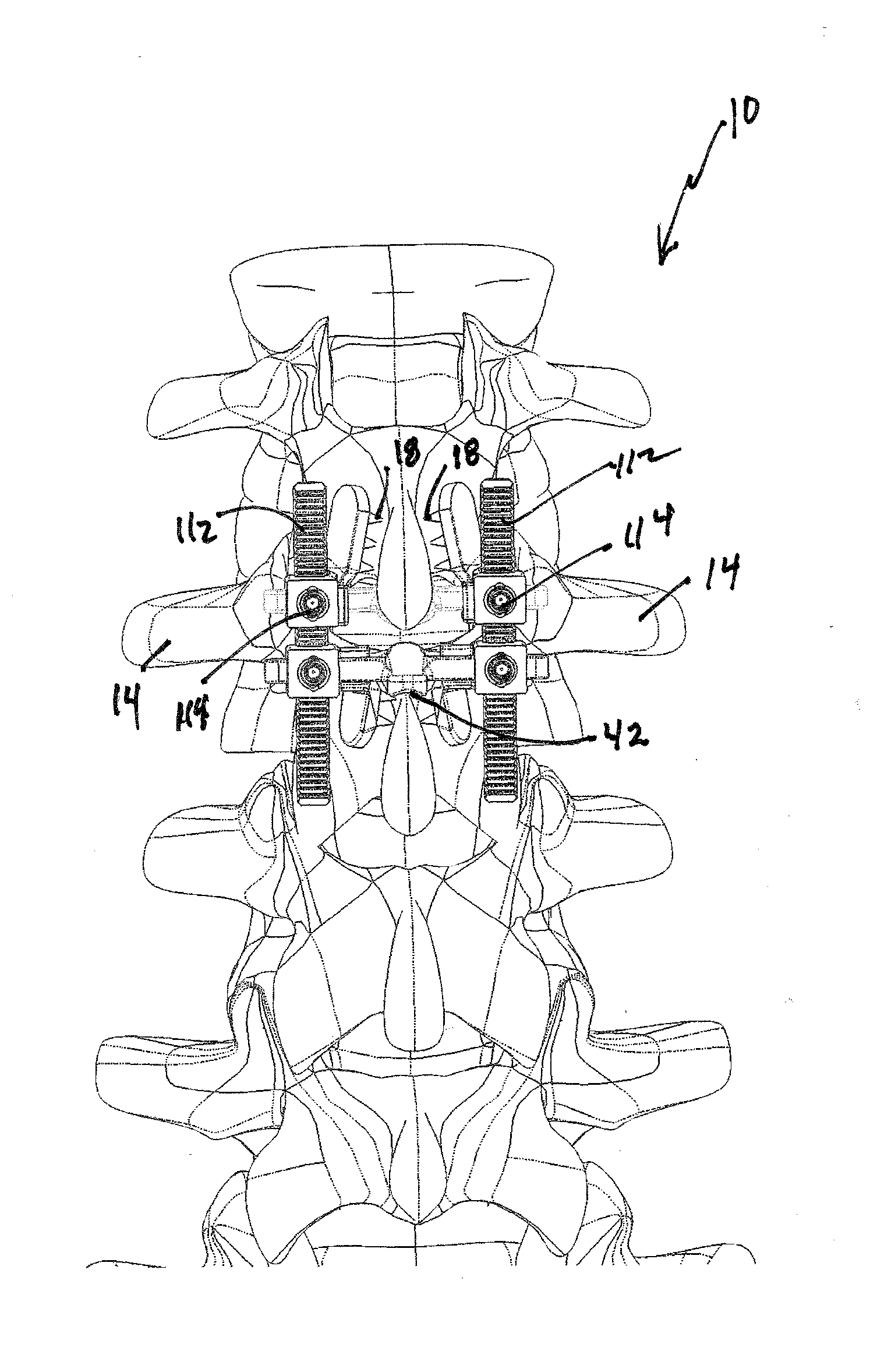

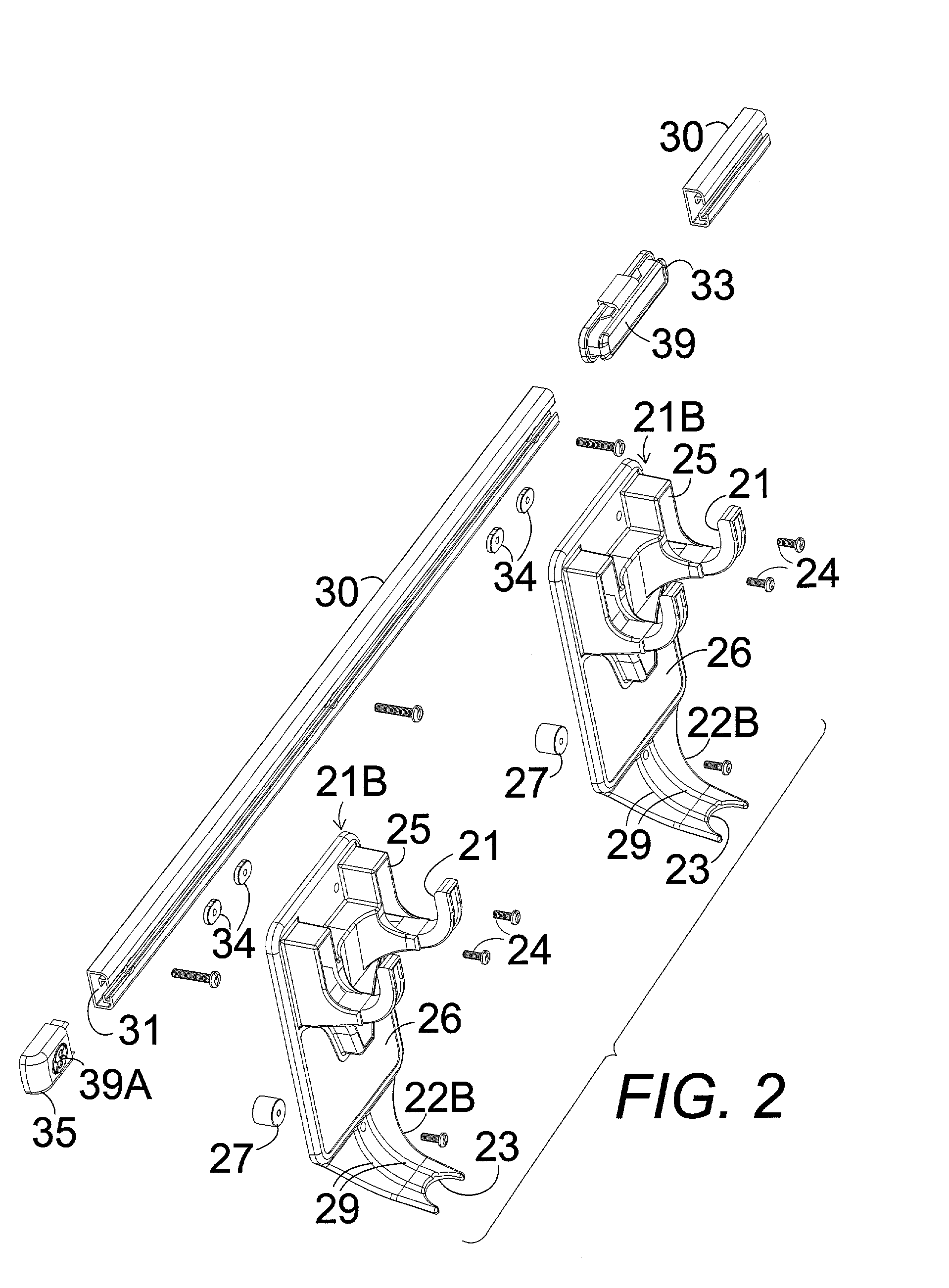

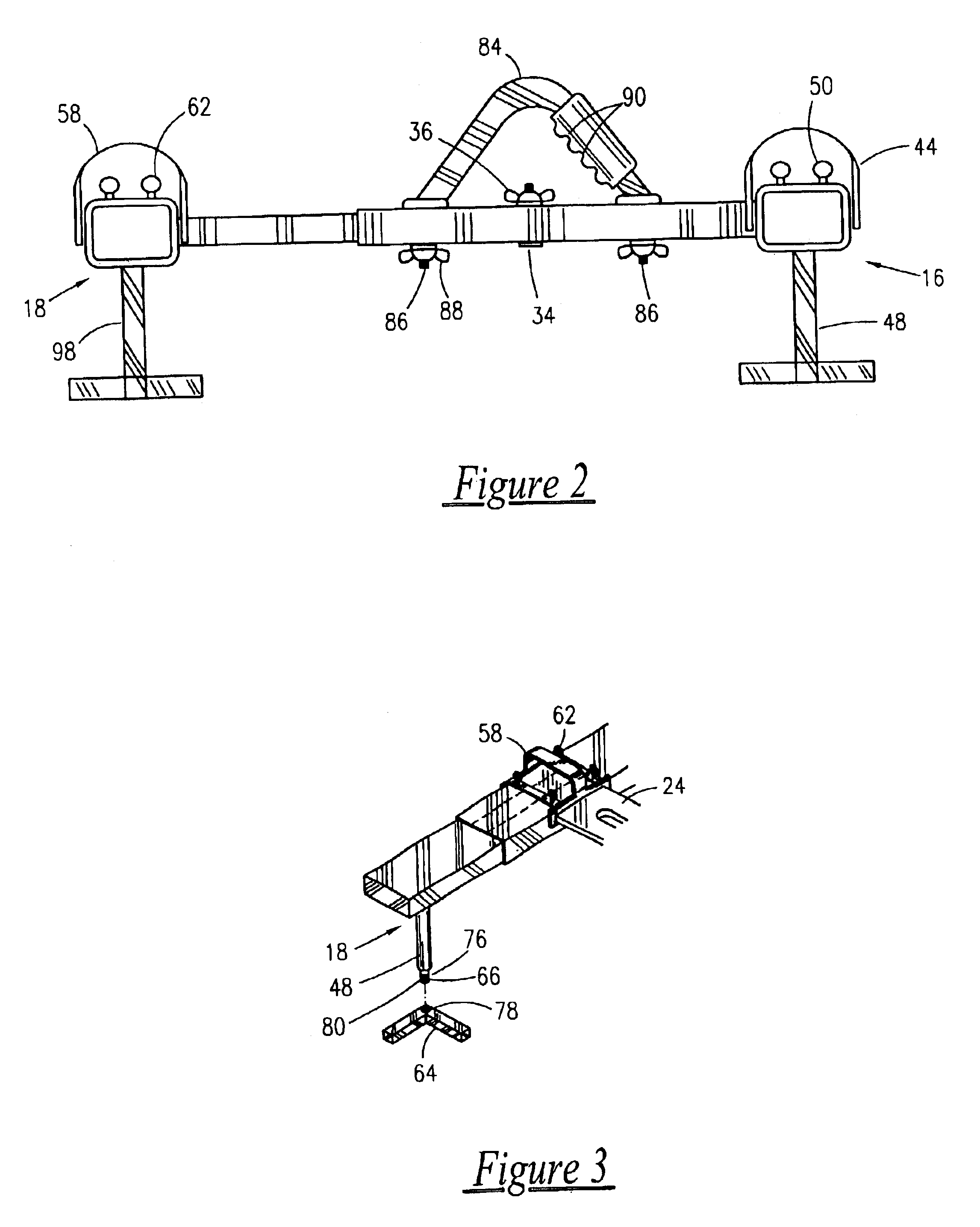

Adjustable spinous process spacer device and method of treating spinal stenosis

ActiveUS20070162000A1Precise positioningRelieve pressureInternal osteosythesisJoint implantsSpinal stenosisSpacer device

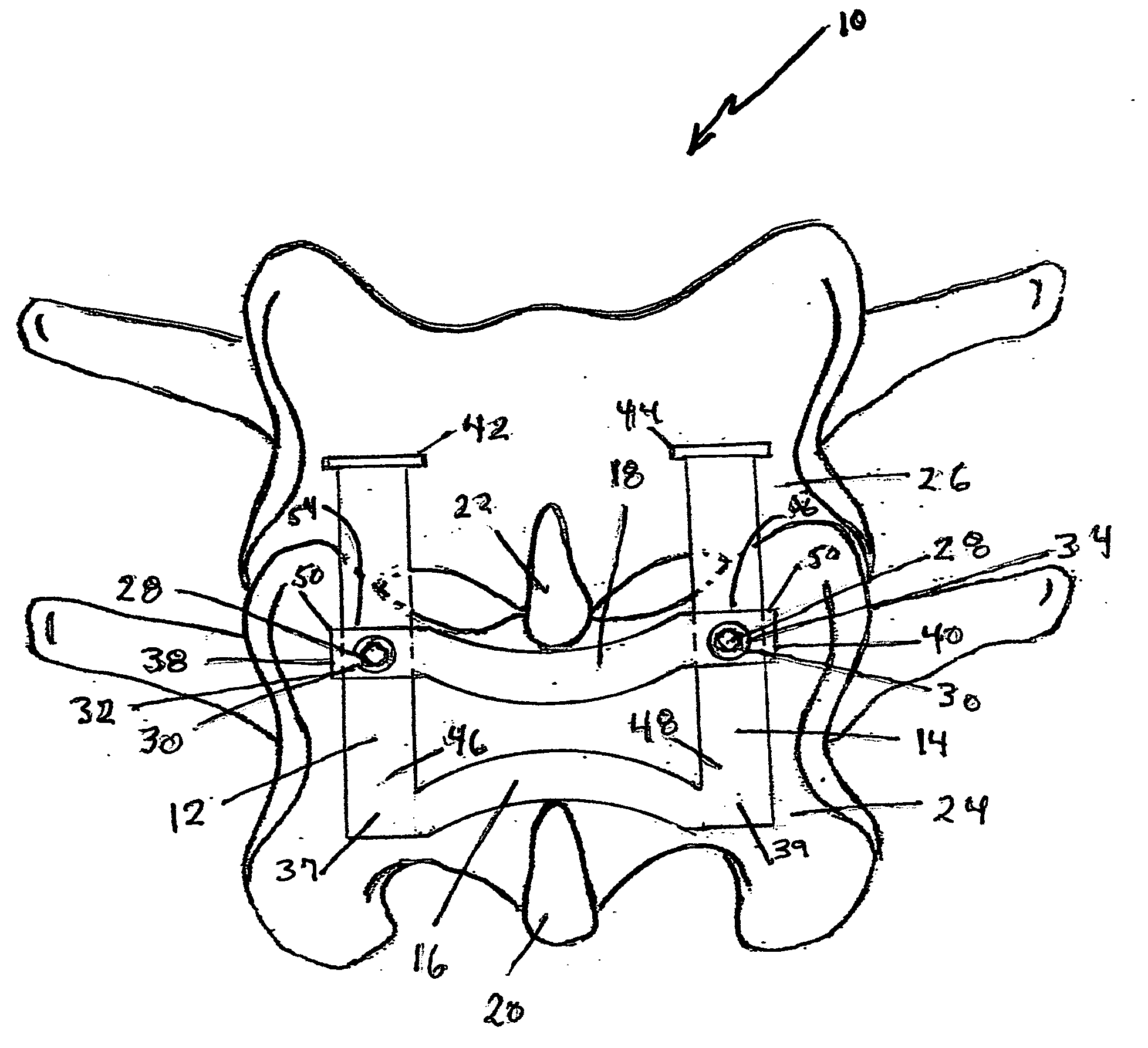

Provided is an adjustable spacing device configured to be placed between the spinous processes of at least two adjacent vertebrae and a method of using the device to treat spinal stenosis by restricting extension and allowing normal flexion of adjacent vertebrae relative to one another.

Owner:BRYSON MEDICAL TECH

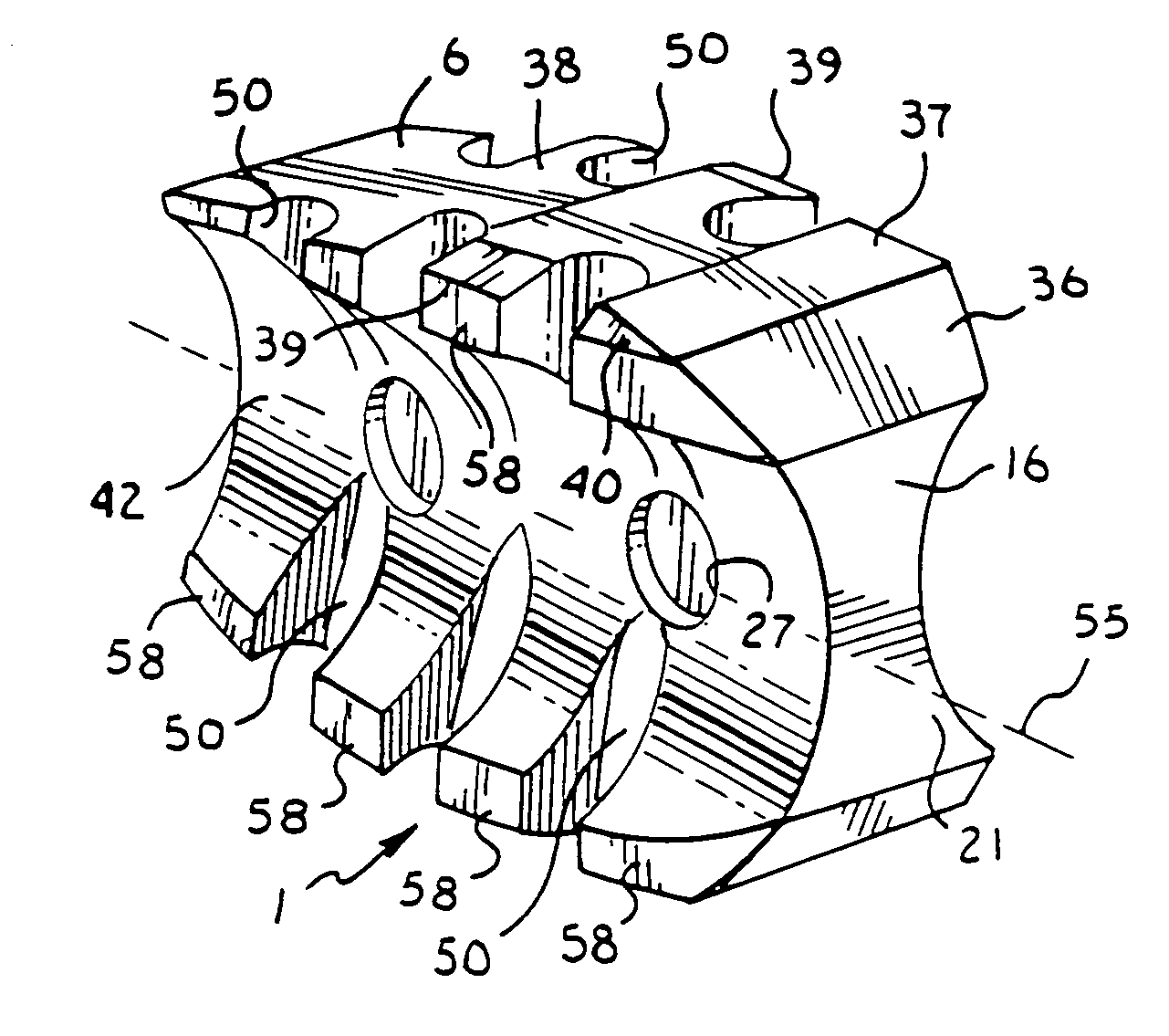

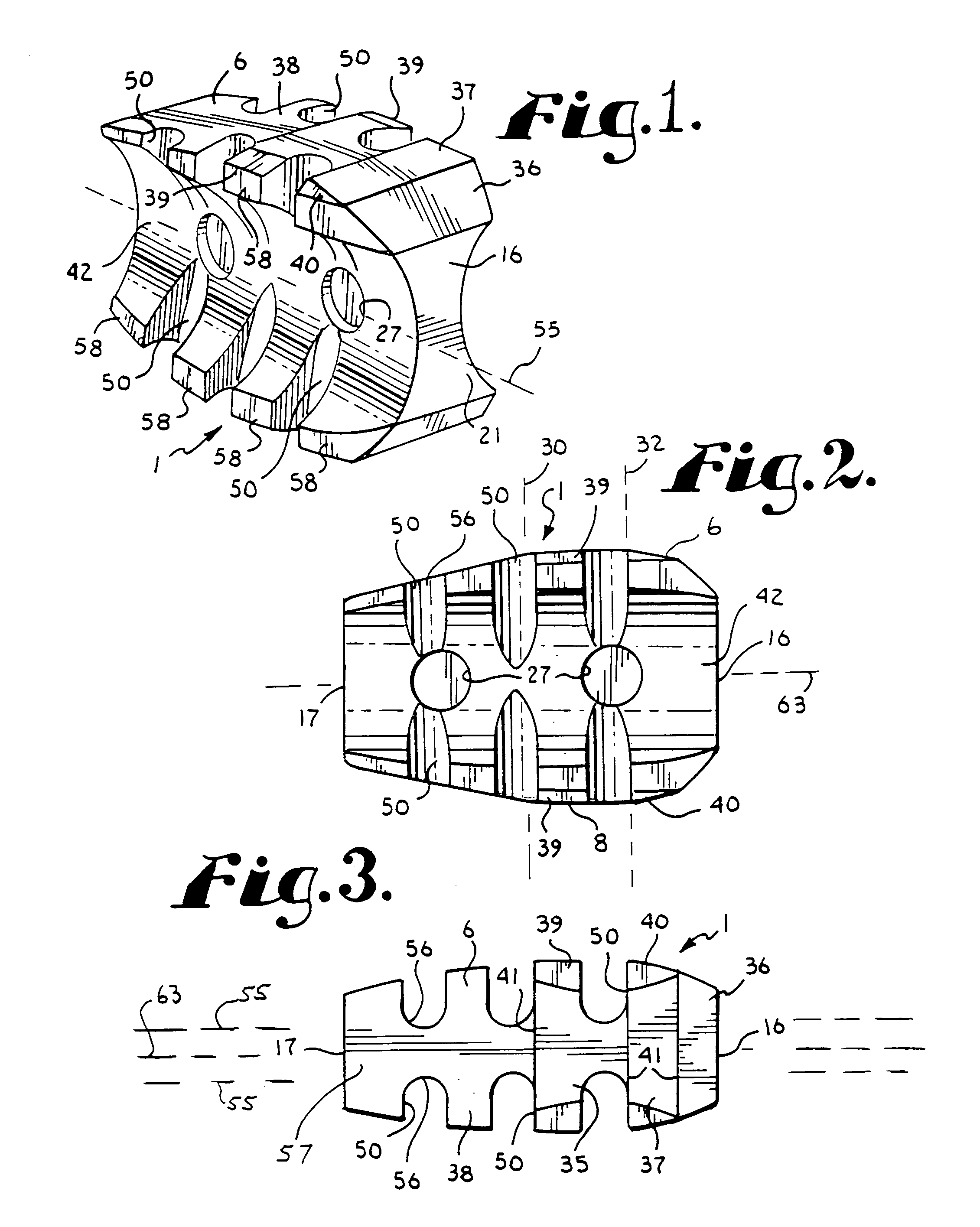

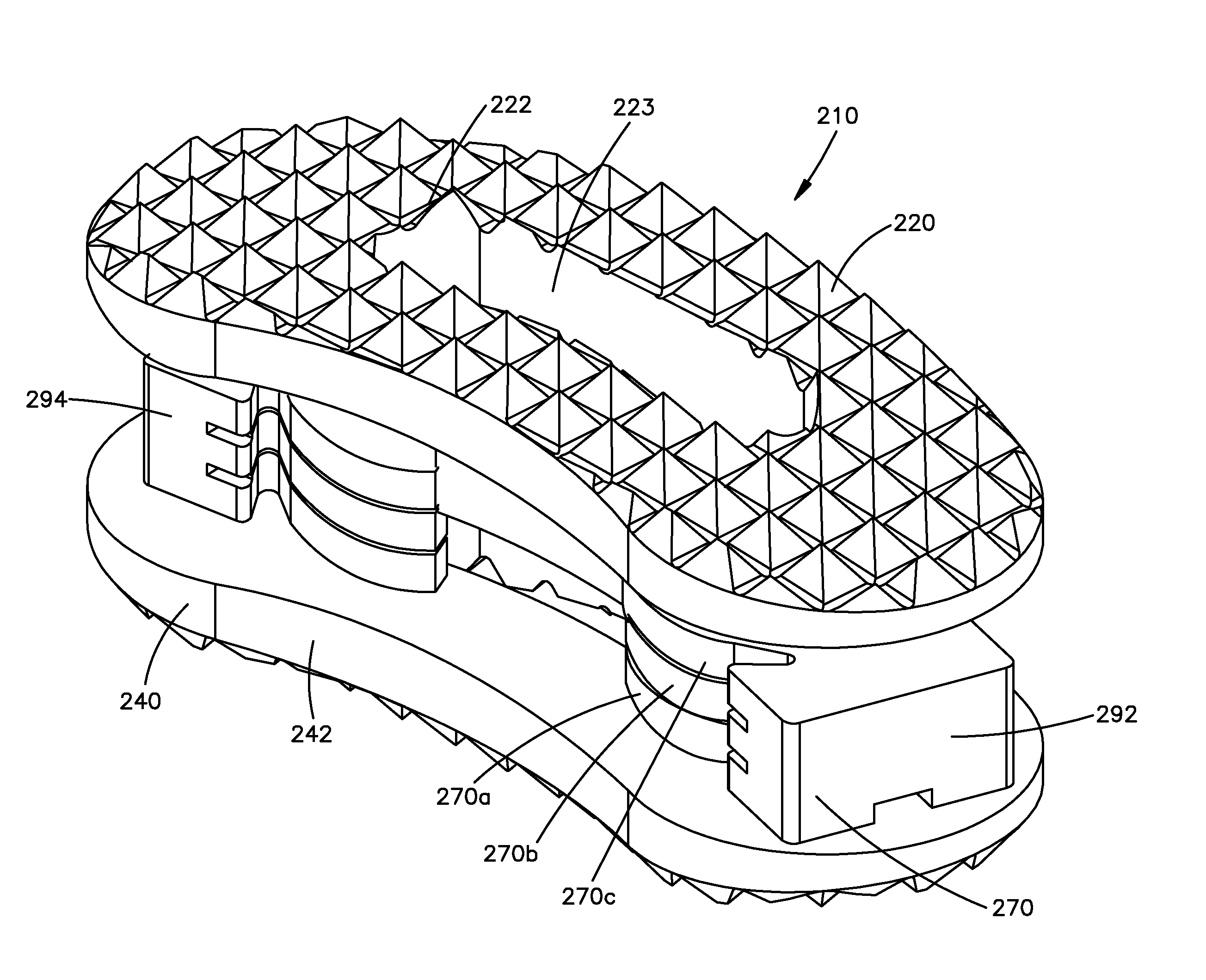

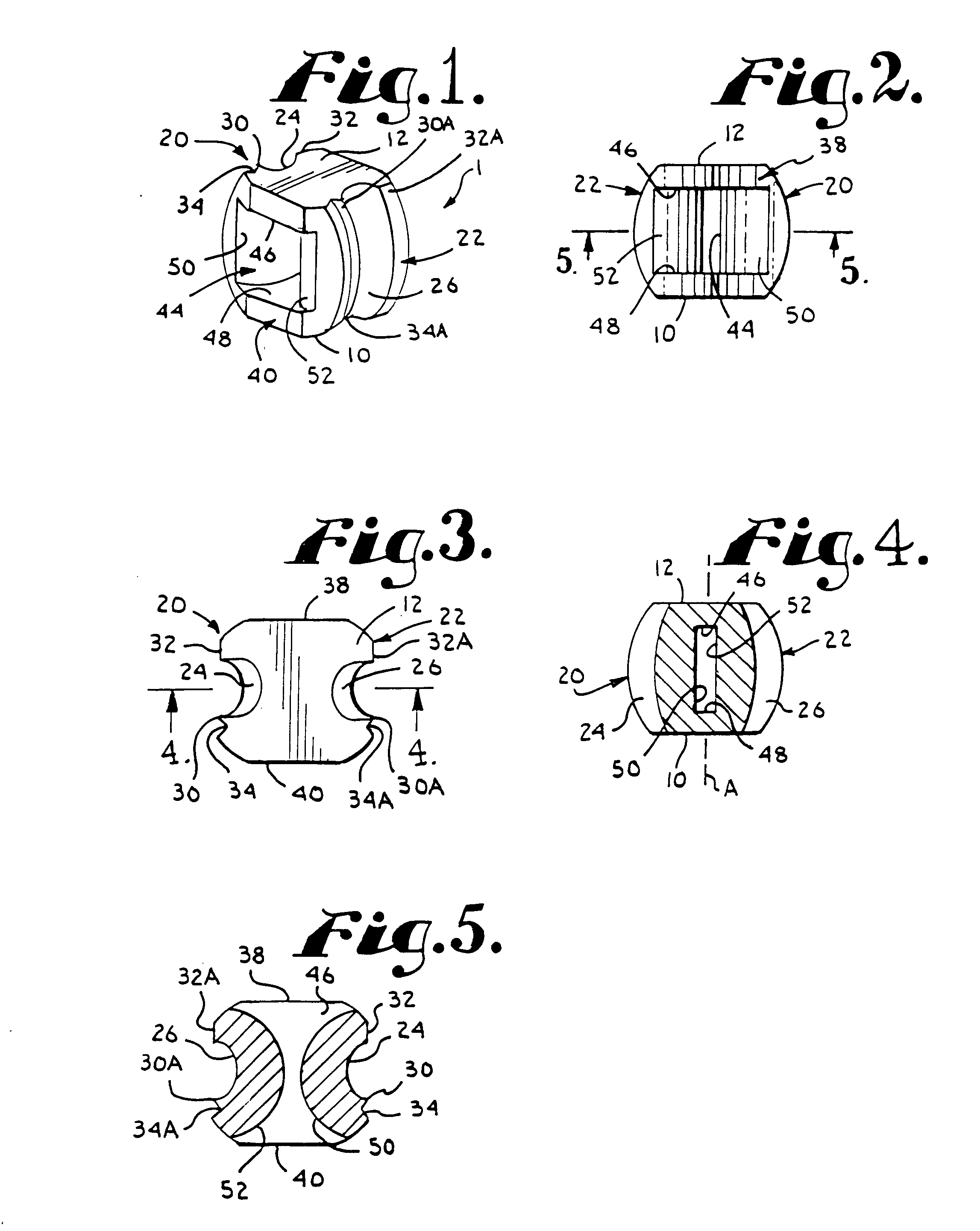

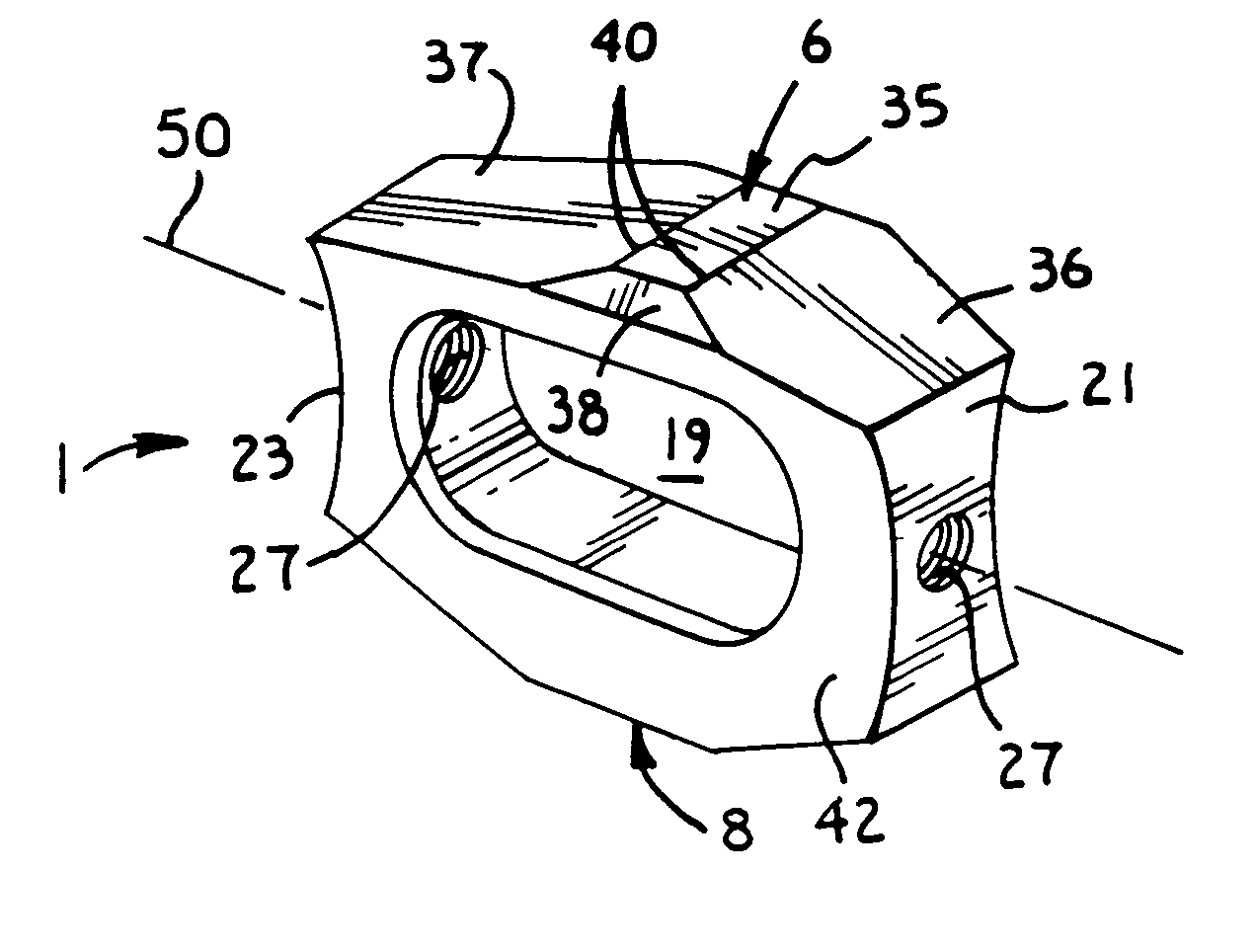

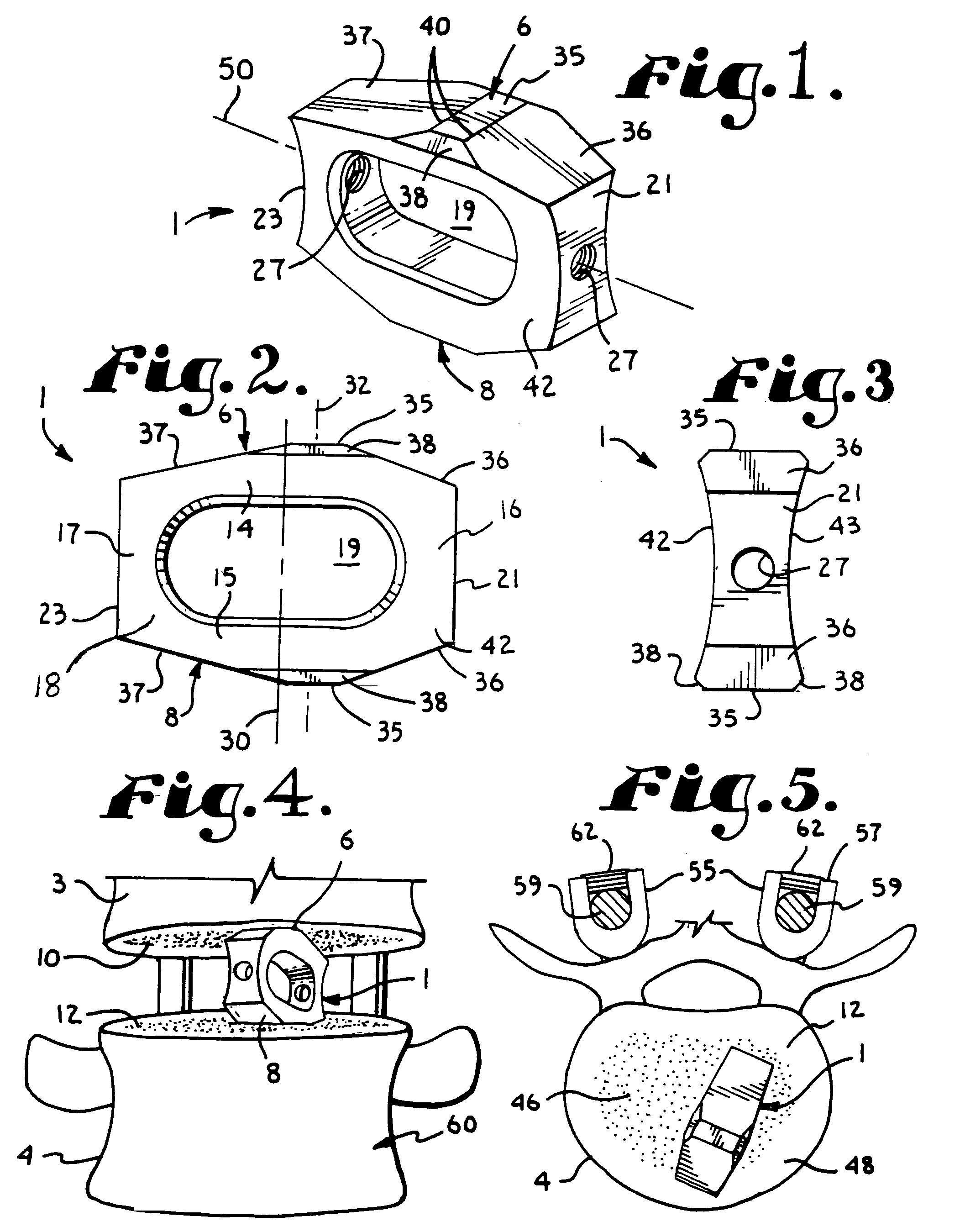

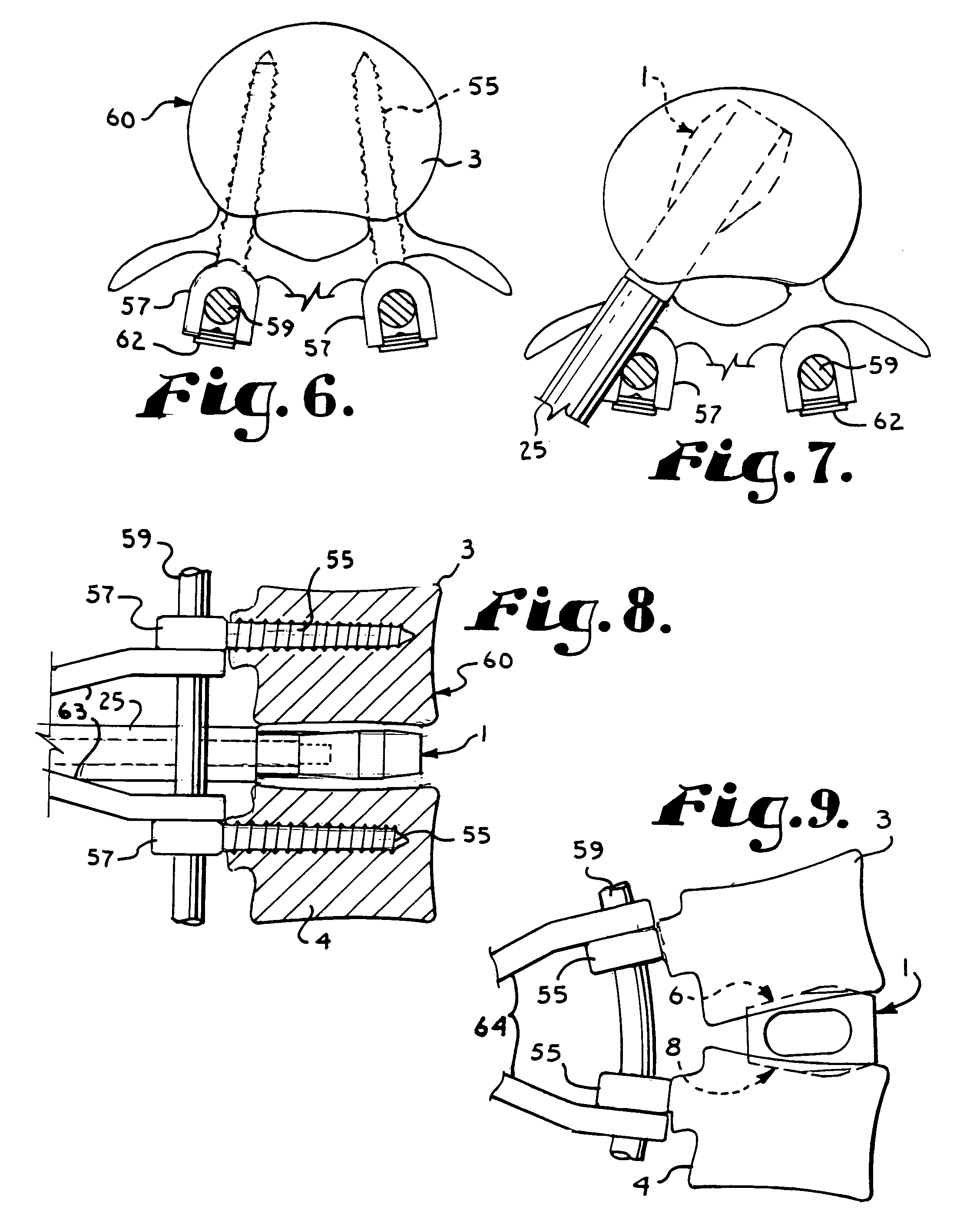

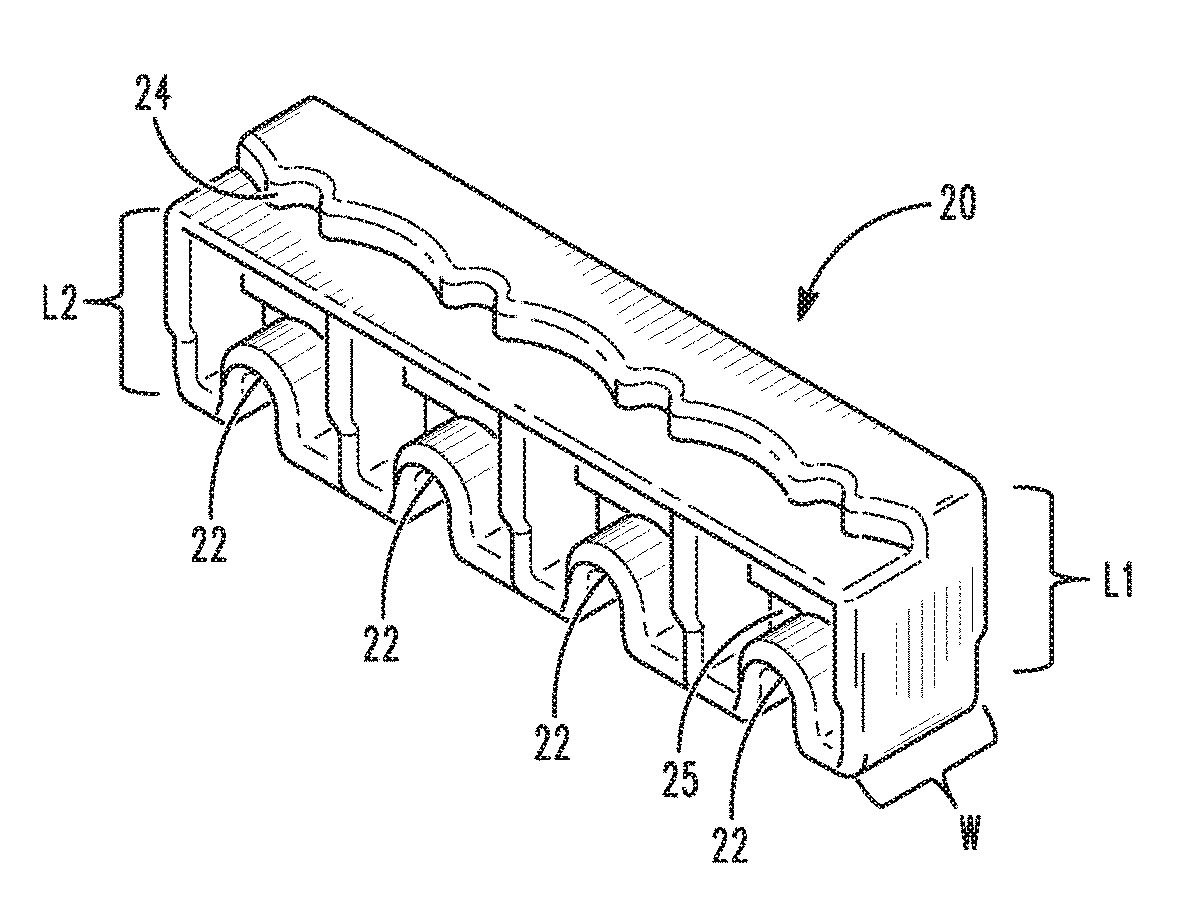

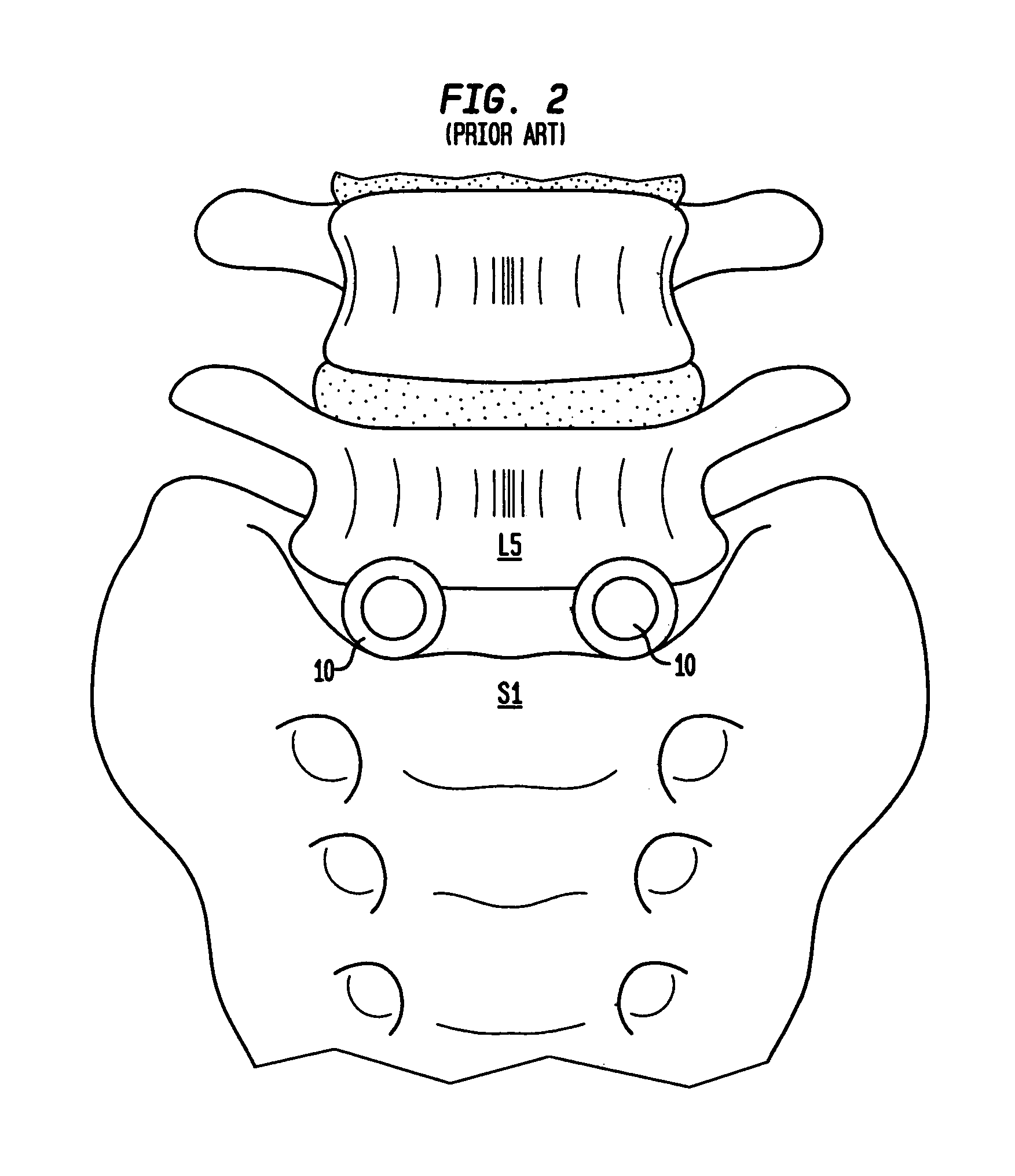

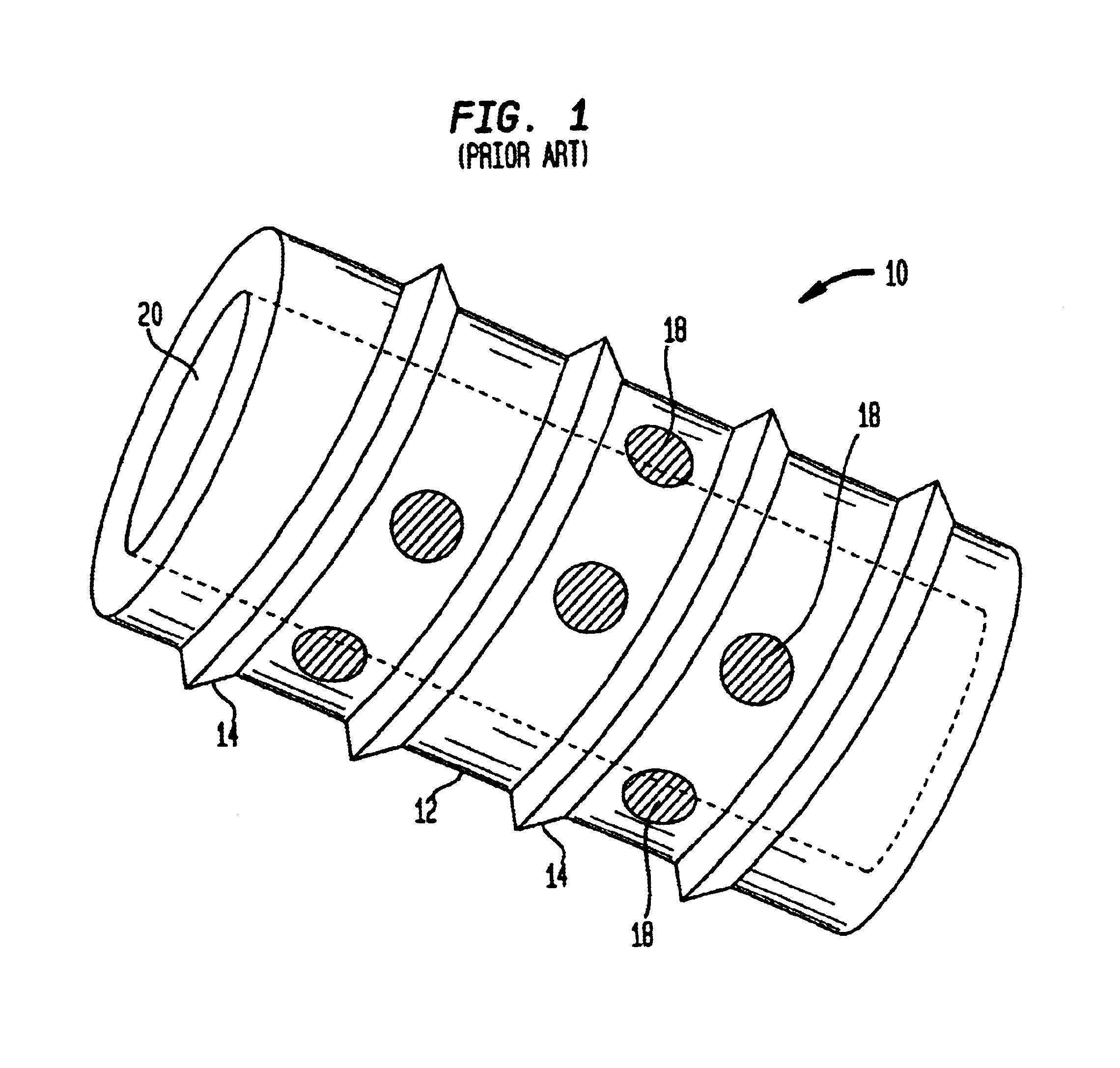

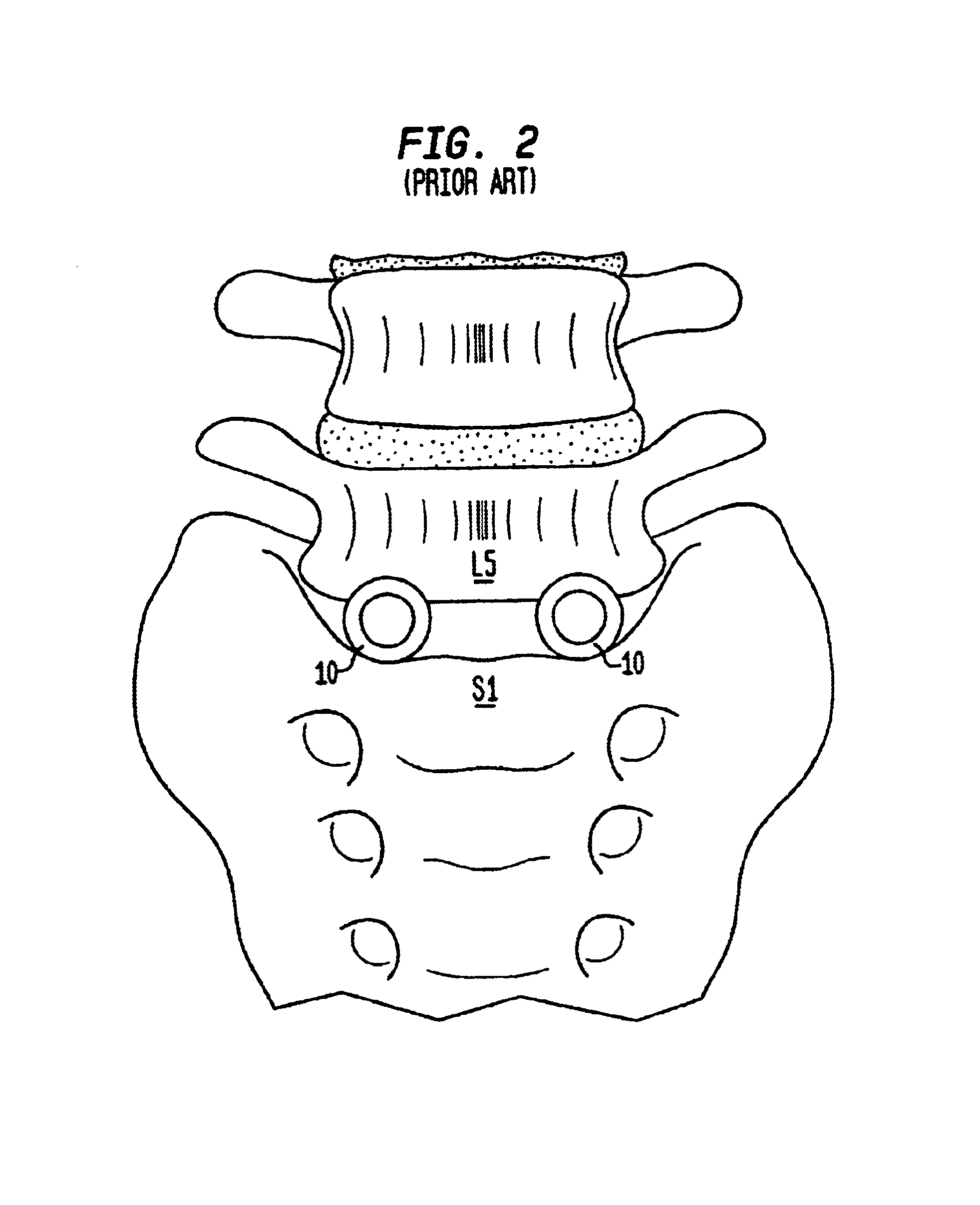

Spinal fusion interbody spacer

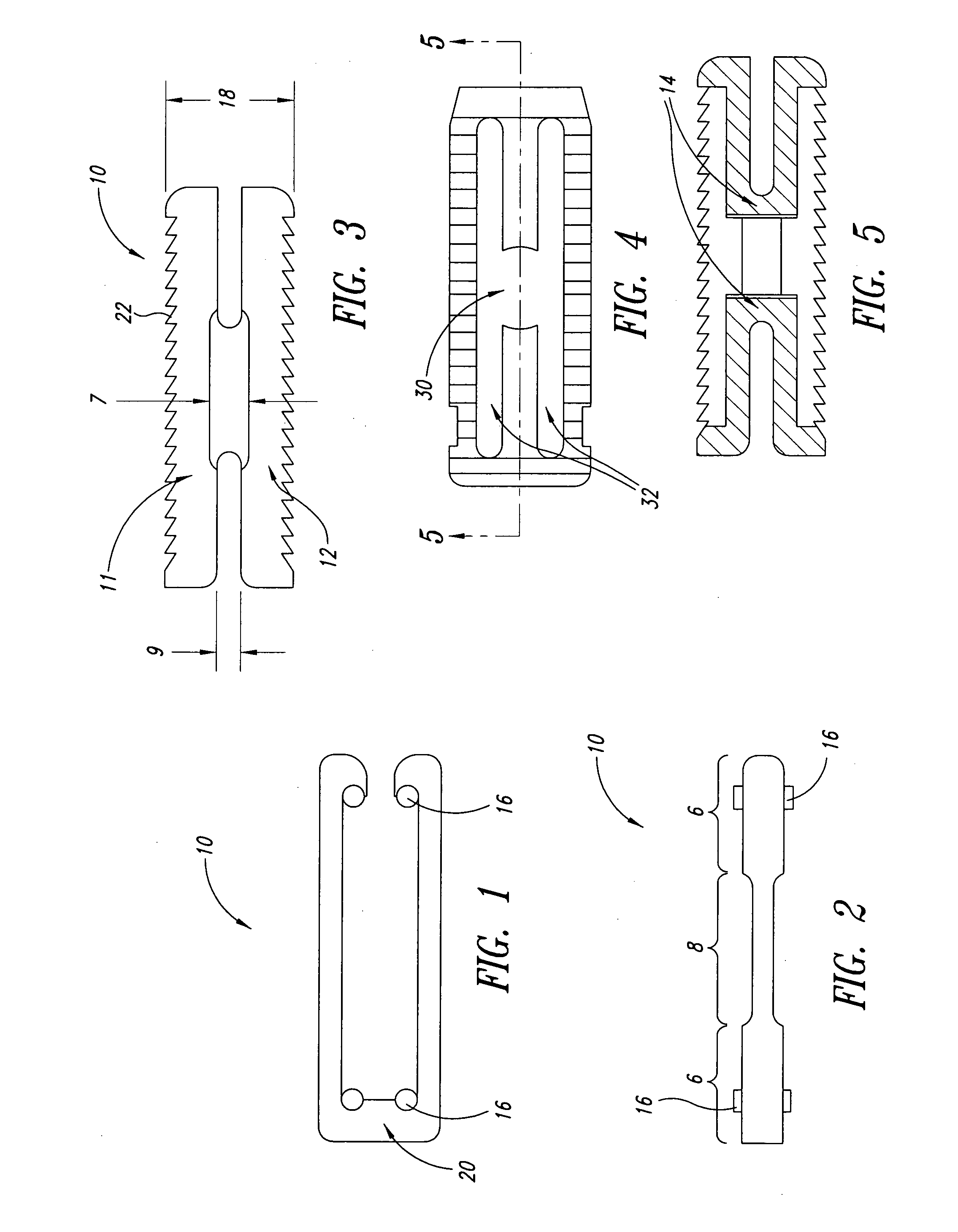

ActiveUS6942698B1Minimizing volumeMinimizing weightInternal osteosythesisJoint implantsSpacer deviceBiomedical engineering

A convex spinal fusion interbody space device includes spaced apart superior and inferior abutment surfaces which are effectively medially convex. The peak of such convexity is displaced anteriorly of a central plane through the device. The spacer device has front to rear lateral concave surfaces and top to bottom lateral side channels that intersect with said convex surfaces. The spacer device has a height which is greater than the width of the device. The spacer device is implanted between a pair of adjacent vertebrae by insertion in a tipped-over orientation and then reoriented to an upright orientation for engagement by facing surfaces of the vertebrae. Fusion promoting bone material is packed between the vertebrae and about the spacer device subsequent to implantation.

Owner:WARSAW ORTHOPEDIC INC

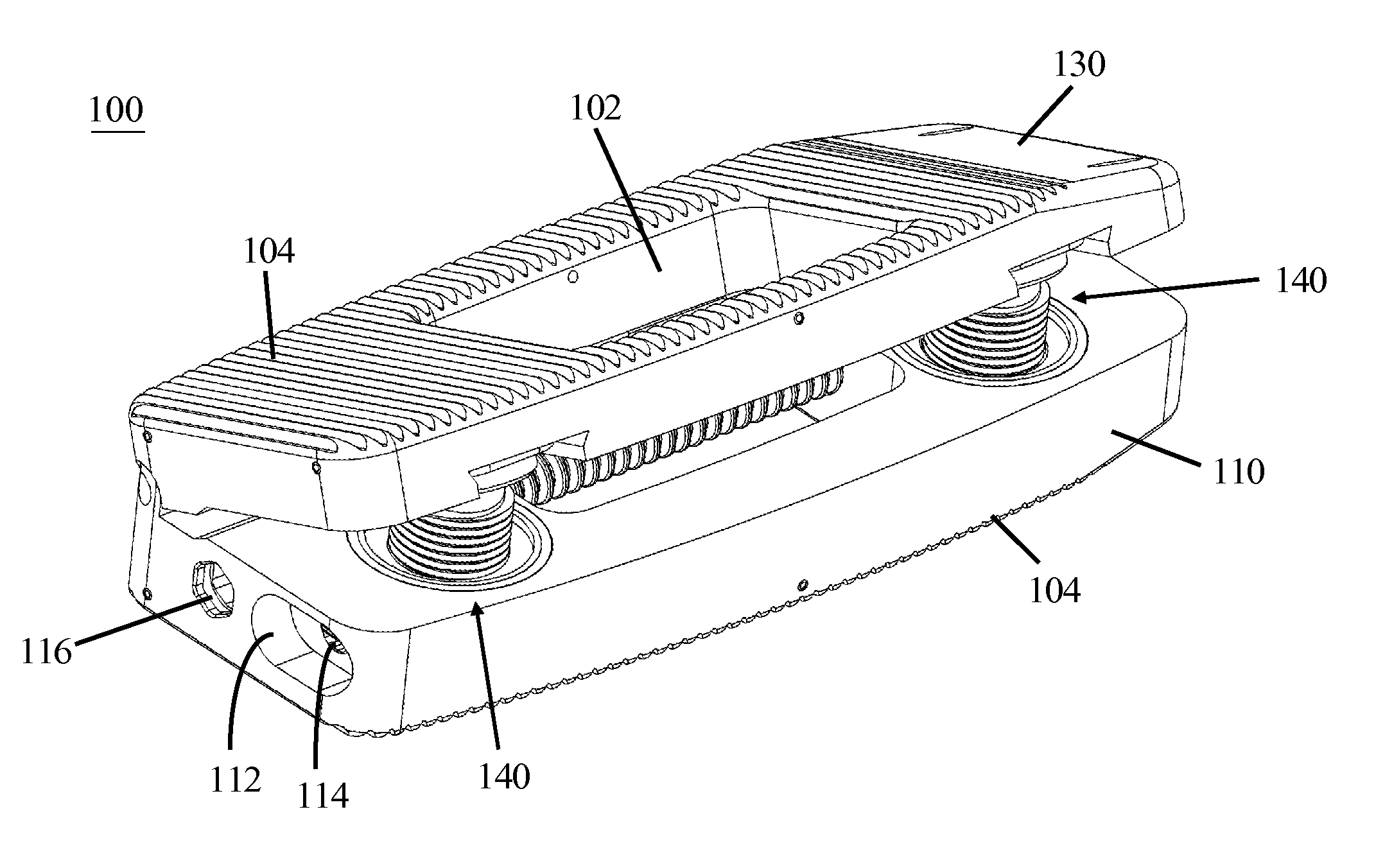

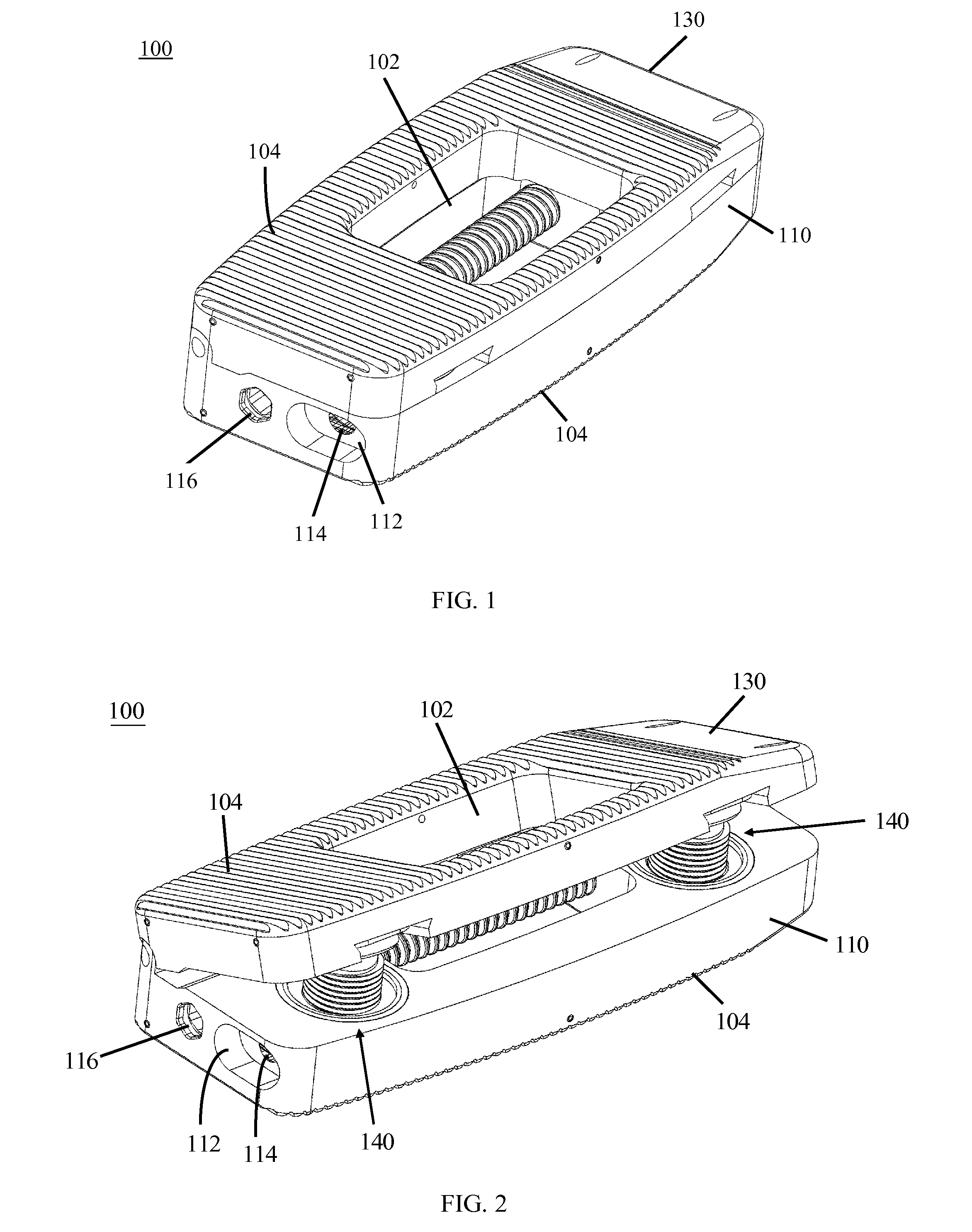

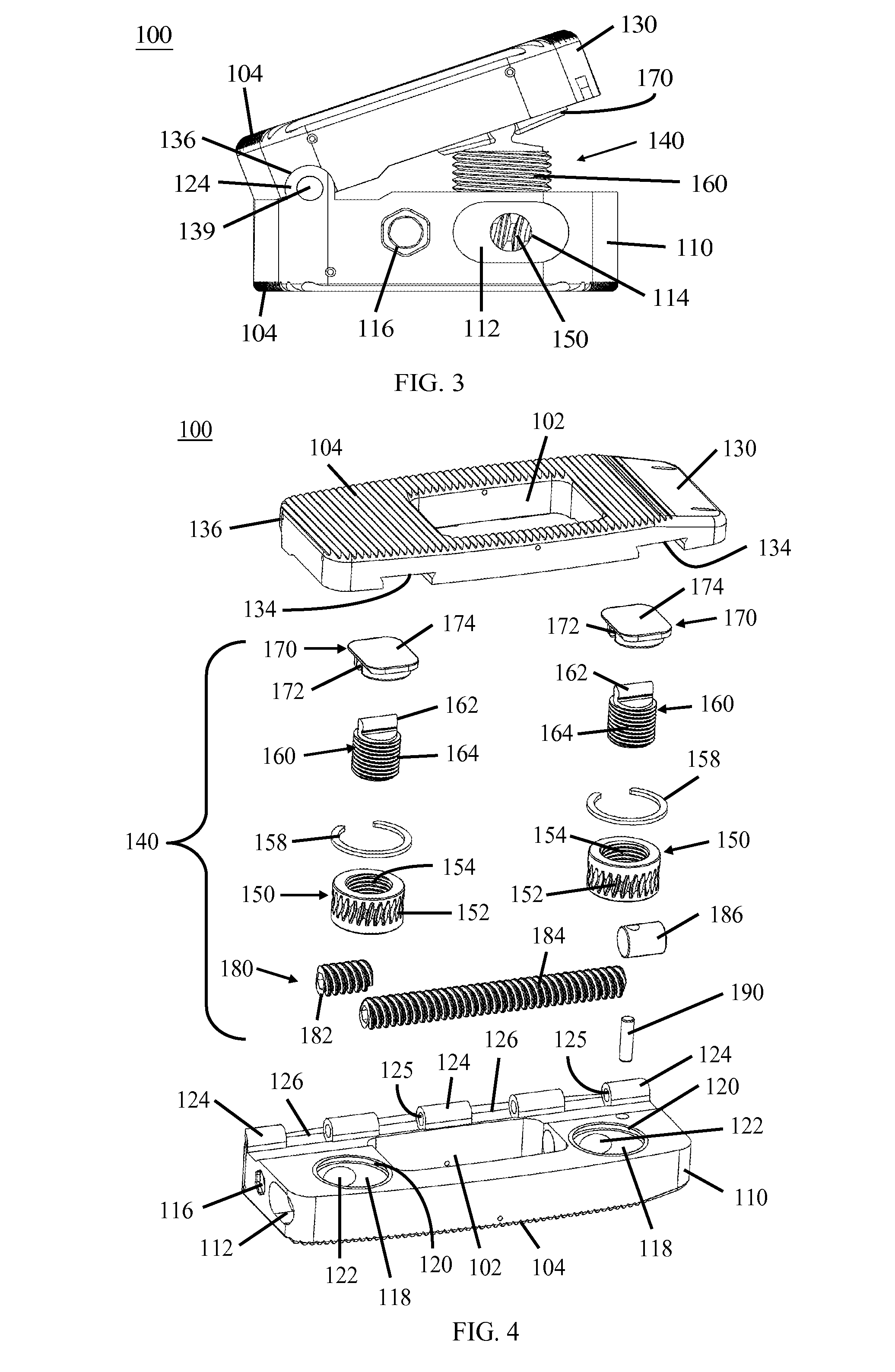

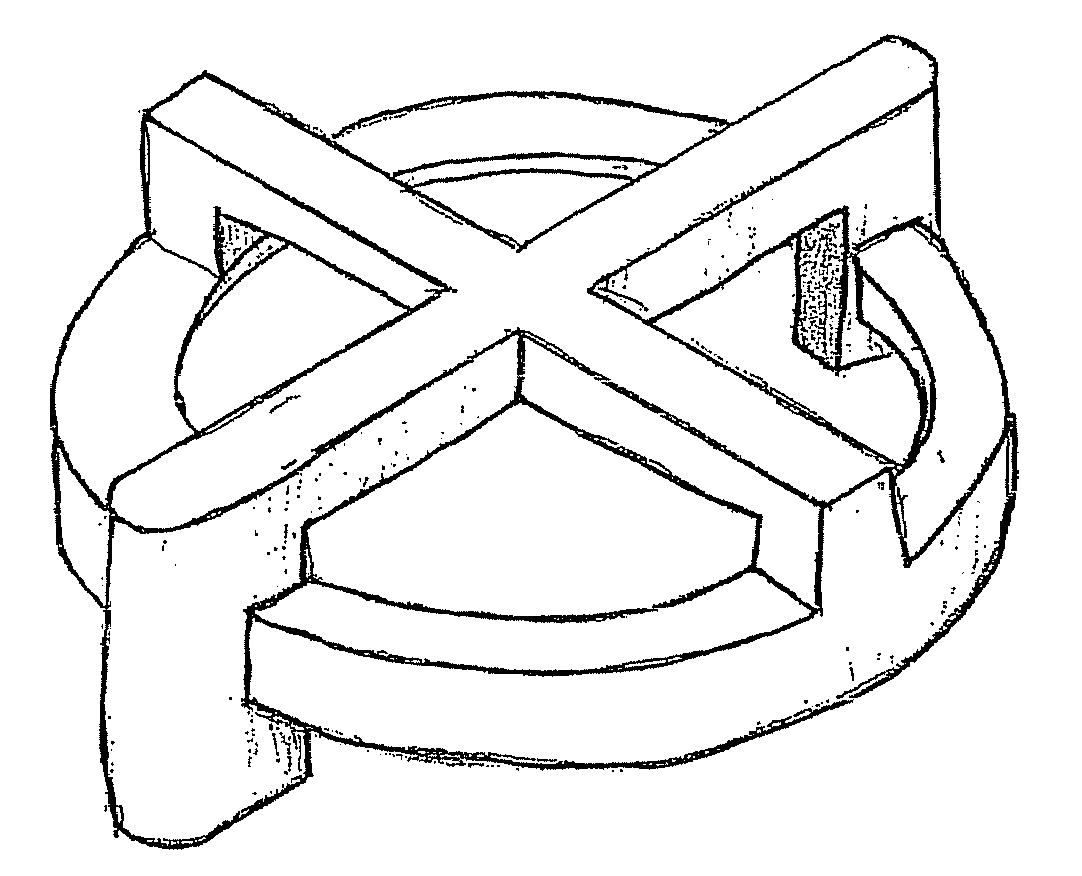

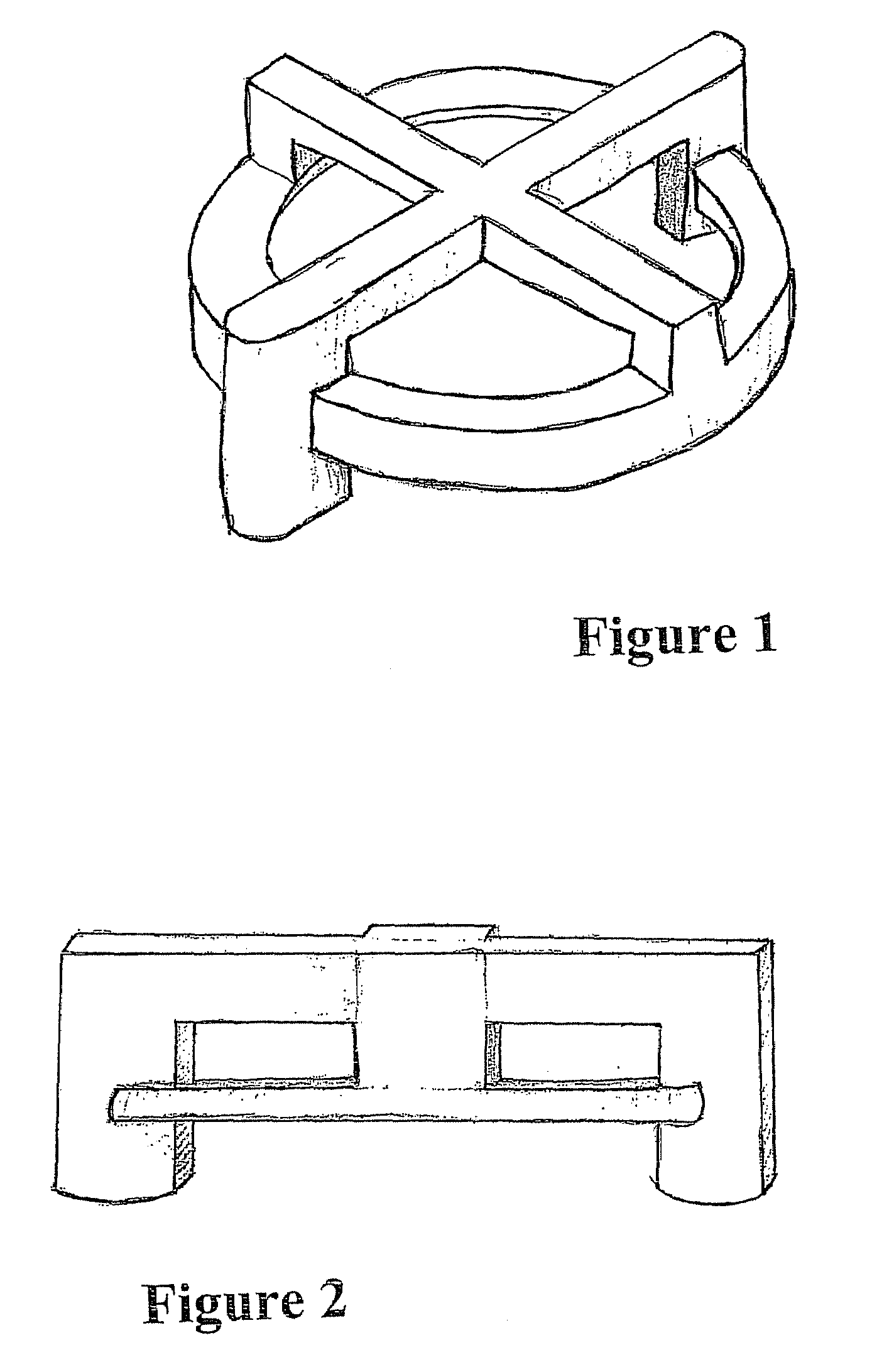

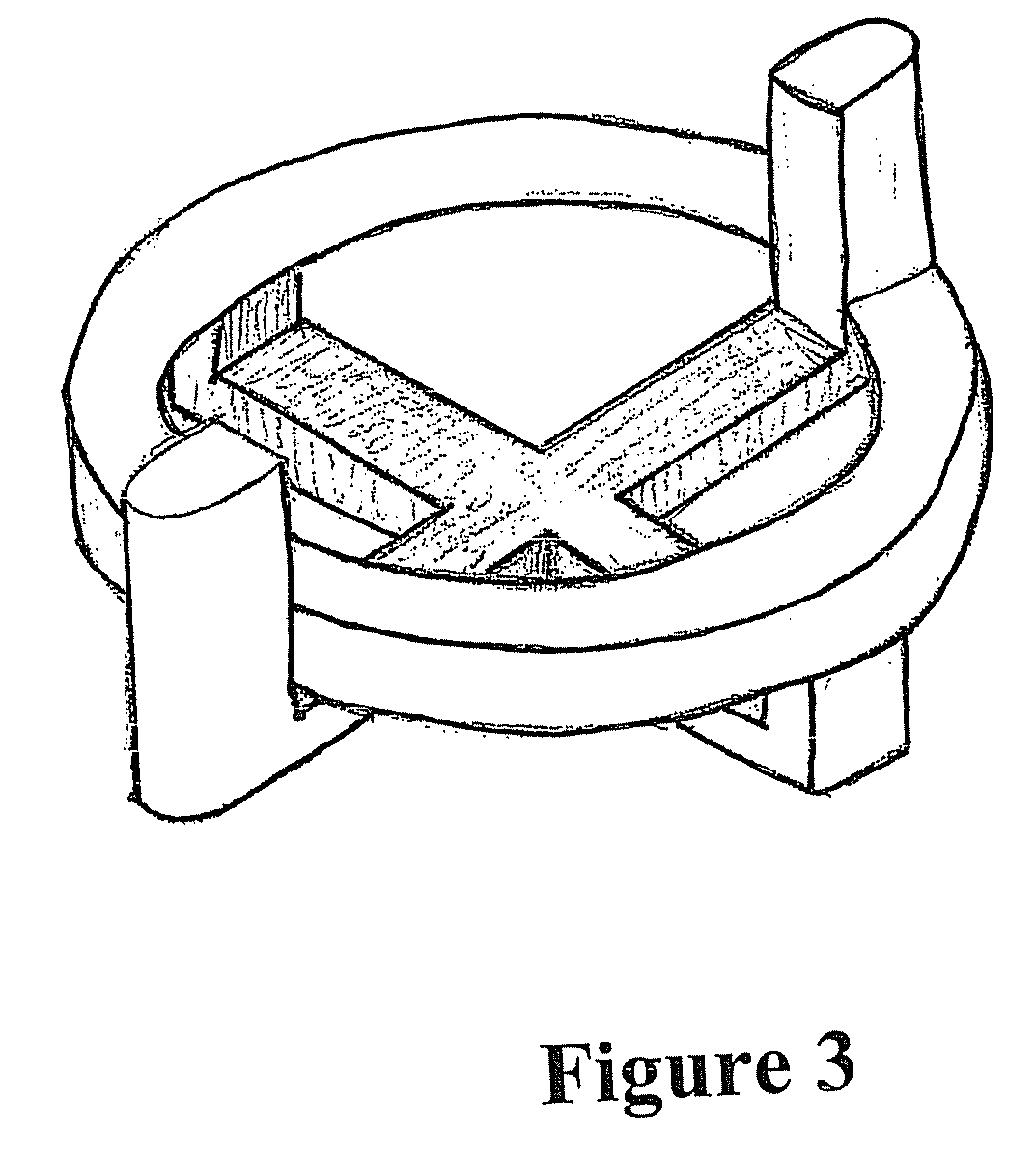

Expandable interbody spacer device

ActiveUS20110015747A1Big spaceInterfere with movementSpinal implantsSpacer deviceBiomedical engineering

Owner:DEPUY SYNTHES PROD INC

Vertebral interbody spacer

A spinal fusion interbody spacer device has a solid central core positioned between laterally opening opposed concave side surfaces. The device includes spaced apart superior and inferior abutment surfaces which are convexly arced. The spacer device is implanted between a pair of adjacent vertebrae by insertion in a tipped-over orientation and then reoriented to an upright orientation for engagement of the abutment surfaces by facing surfaces of the vertebrae.

Owner:WARSAW ORTHOPEDIC INC

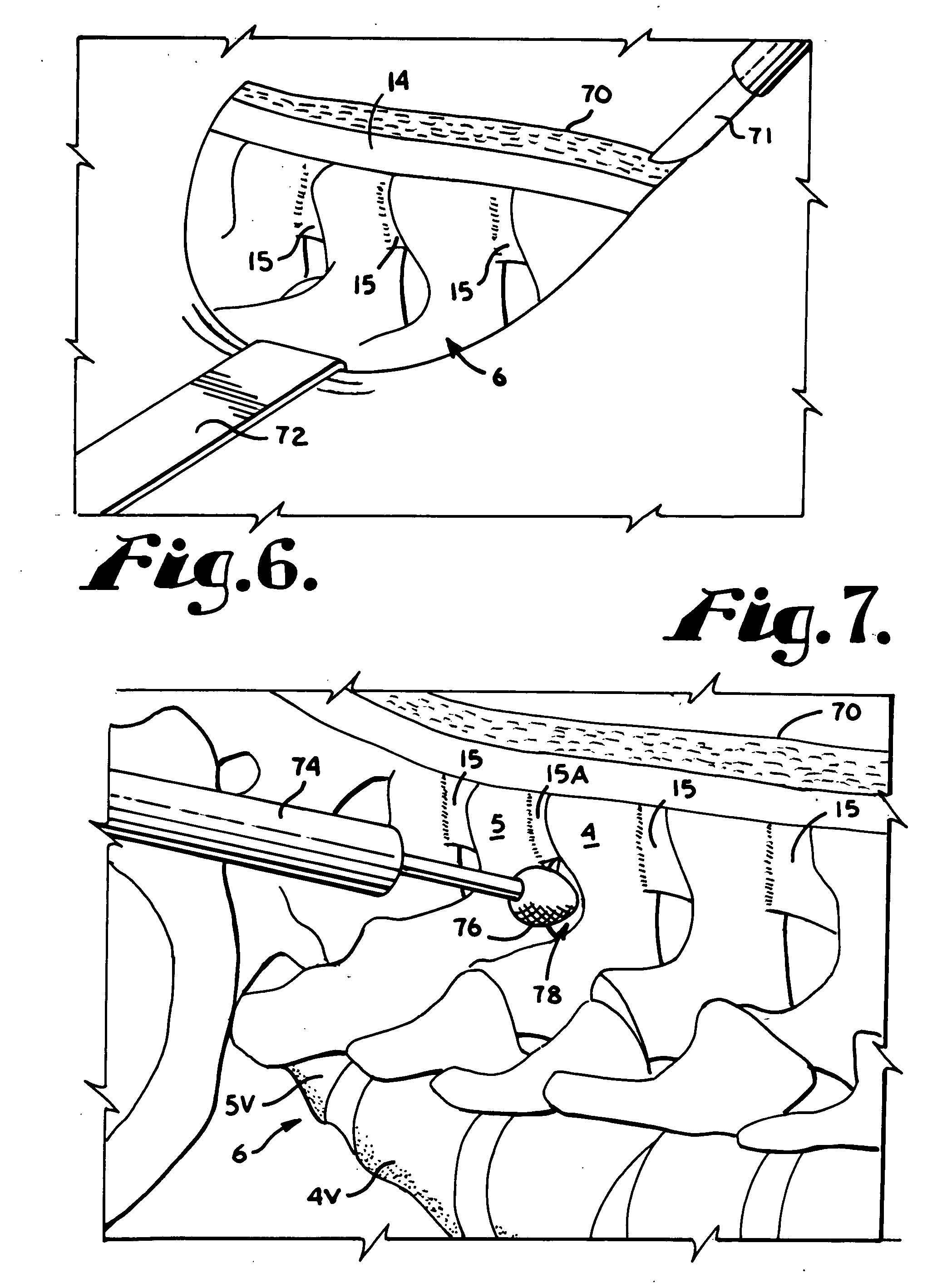

Interspinous process spacer

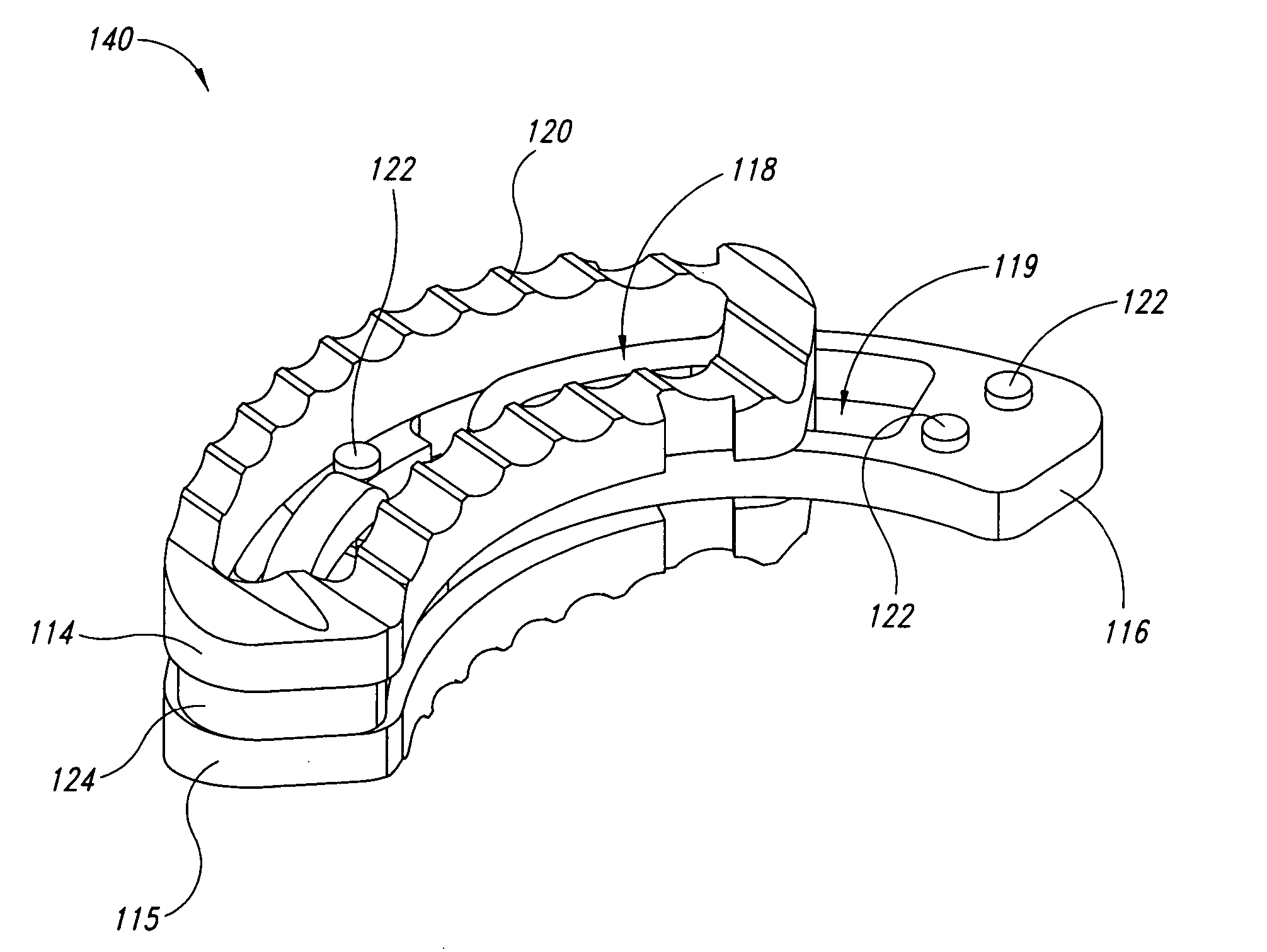

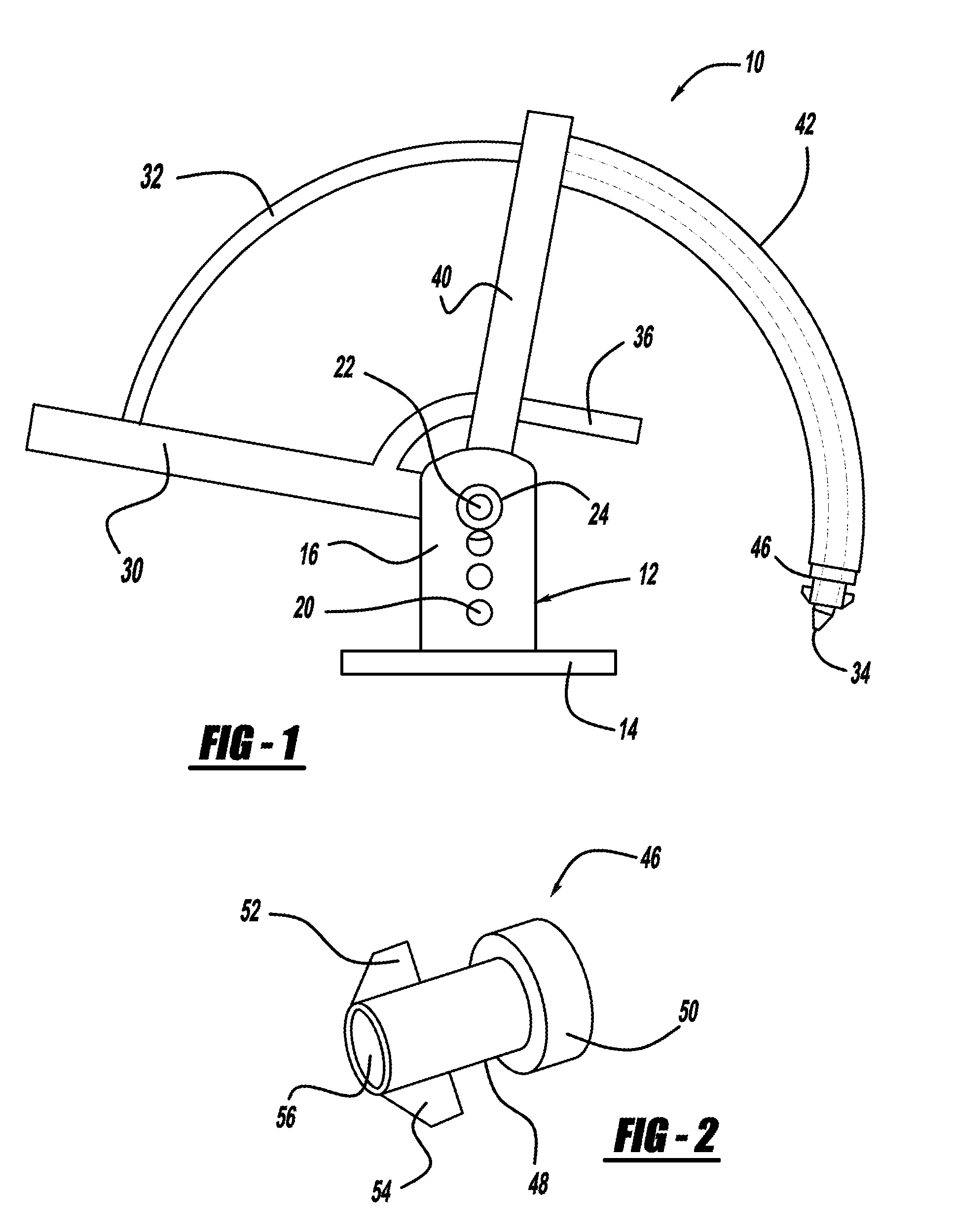

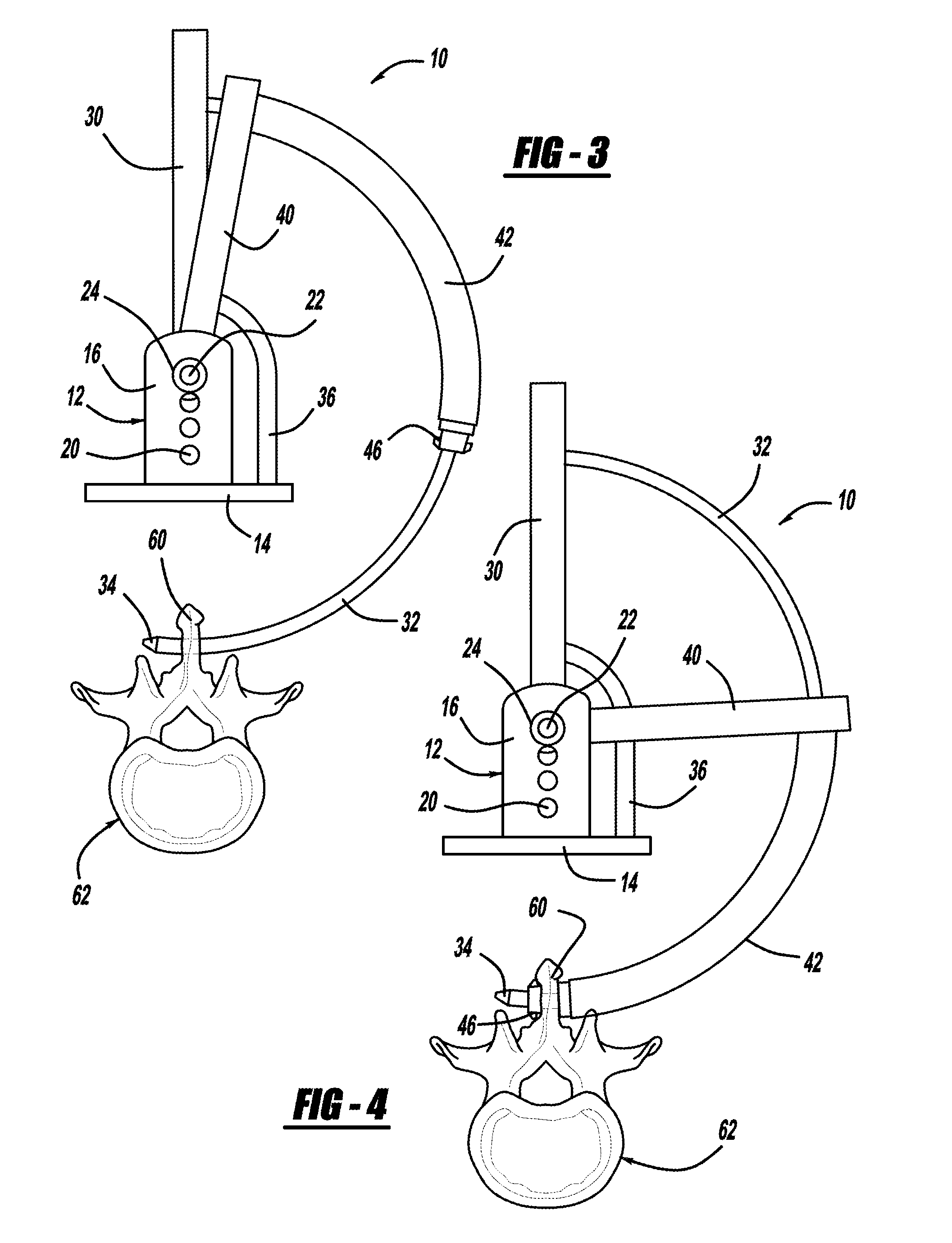

InactiveUS20080082172A1Easy constructionLow production costInternal osteosythesisSpinal implantsAbutmentEngineering

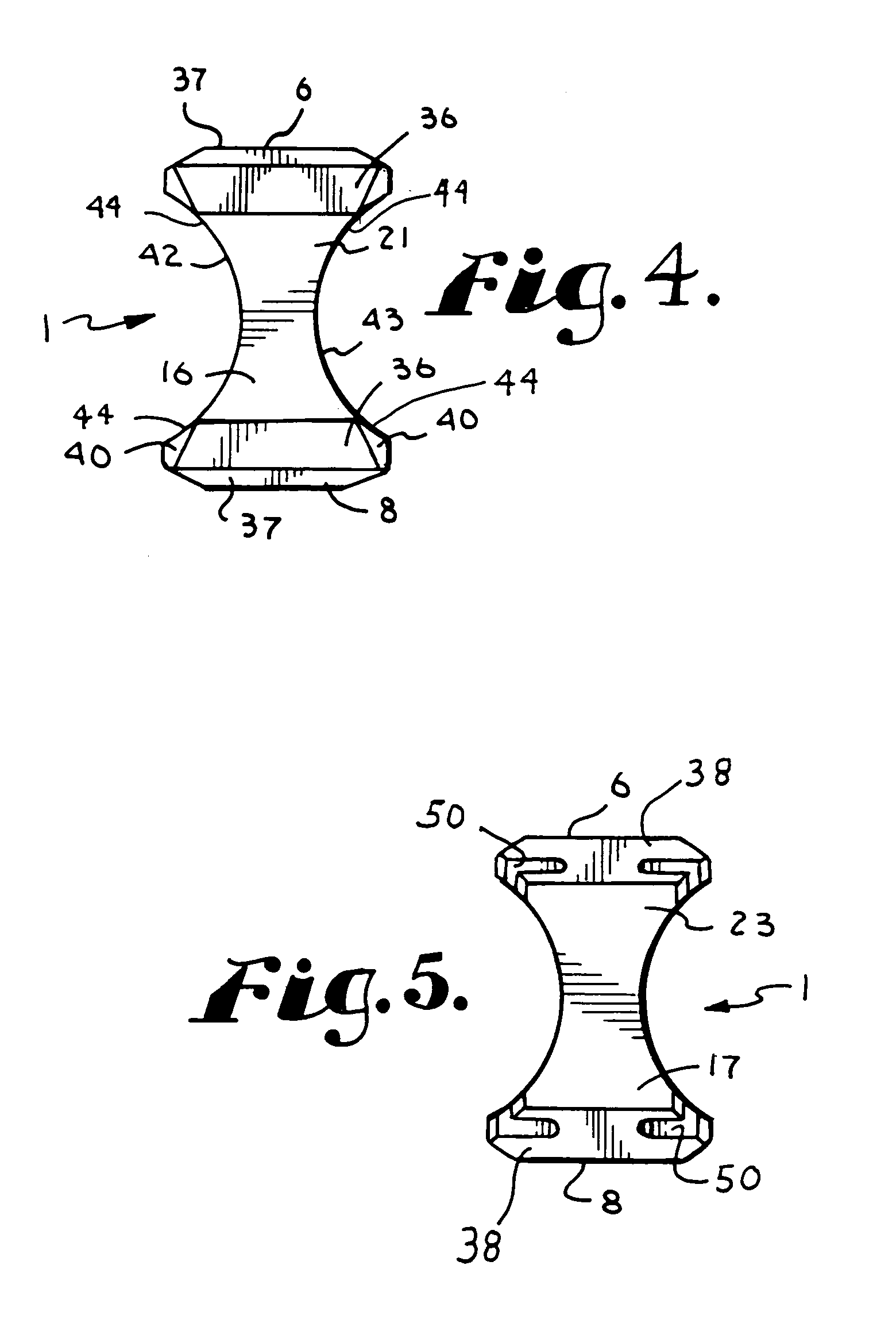

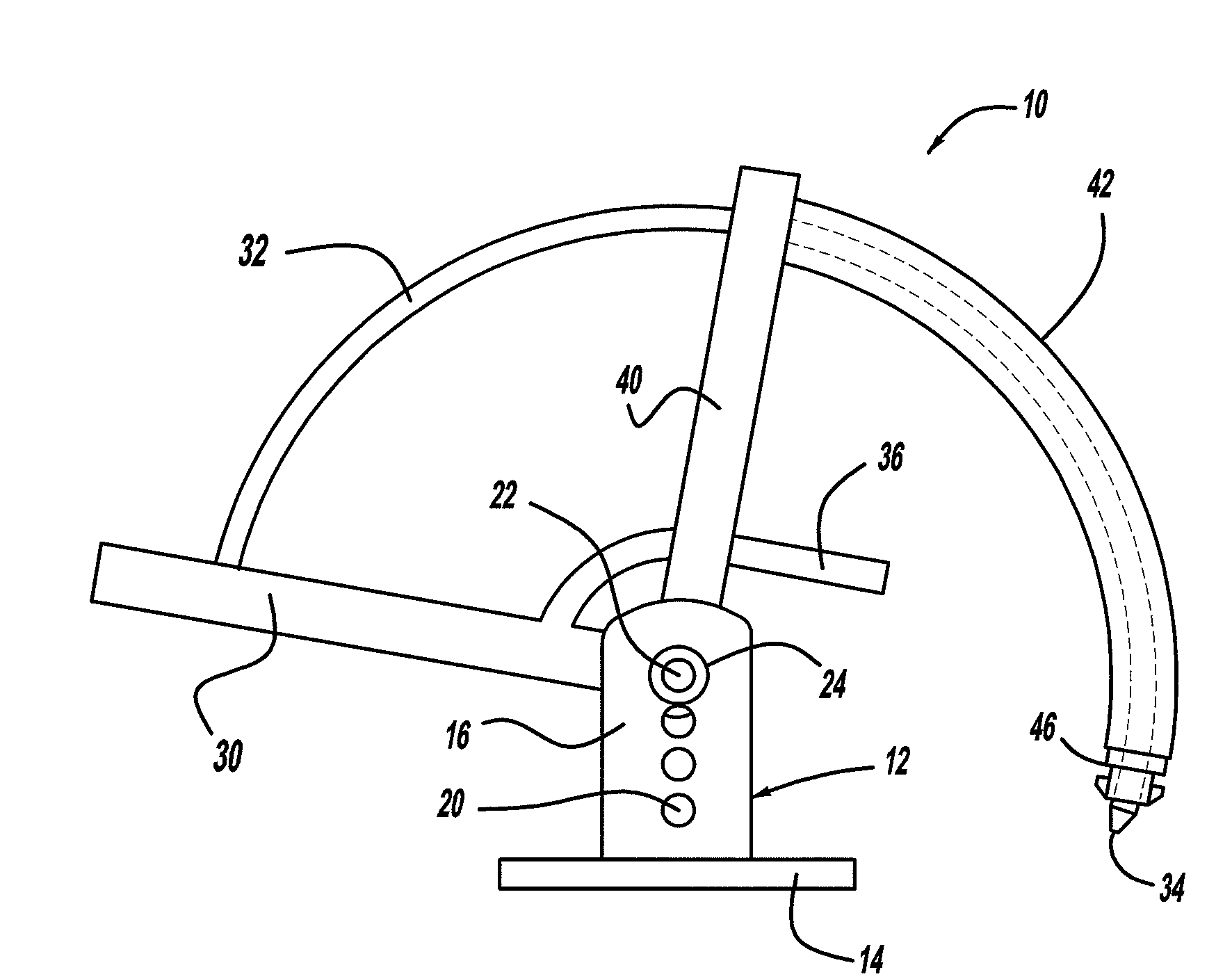

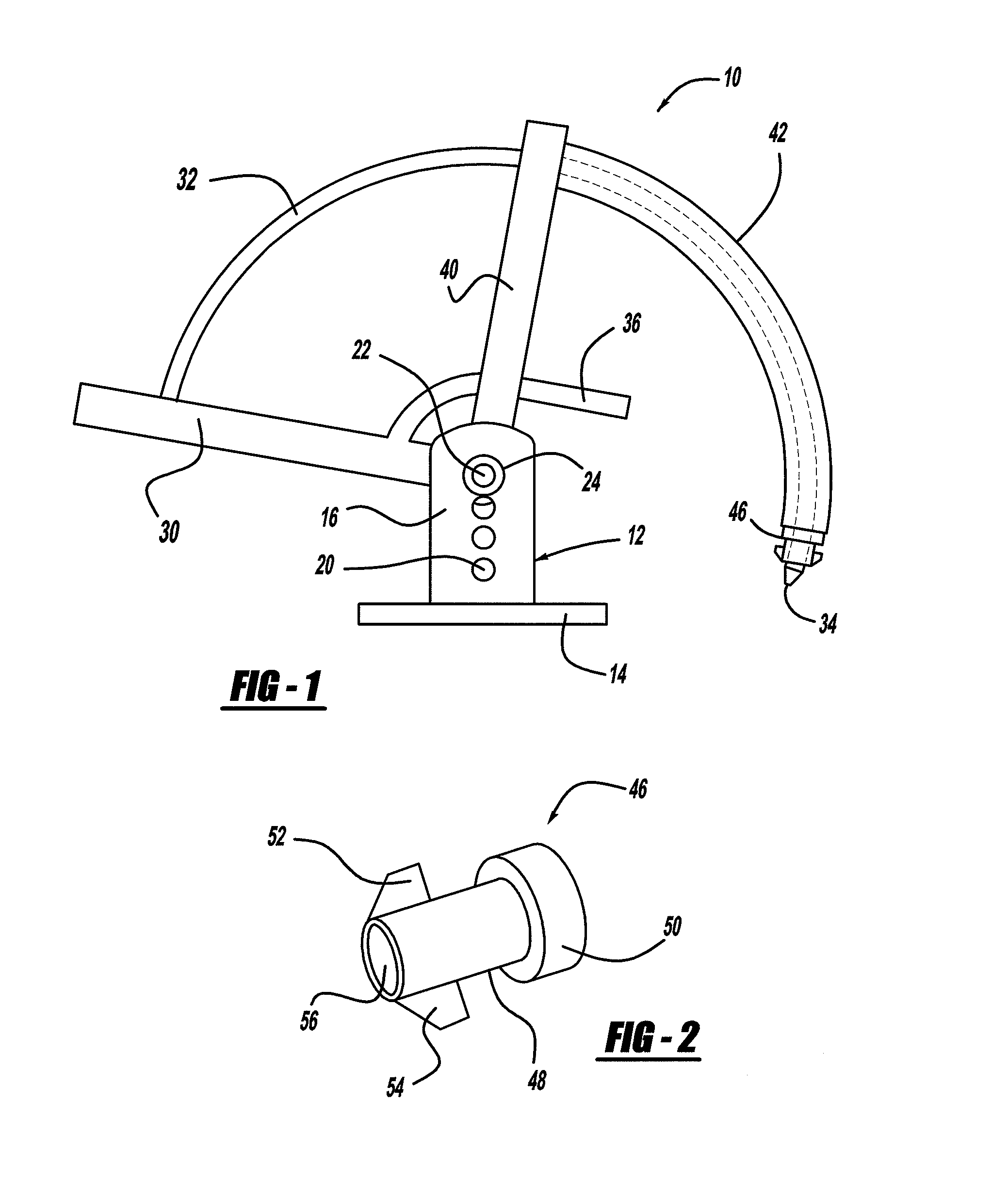

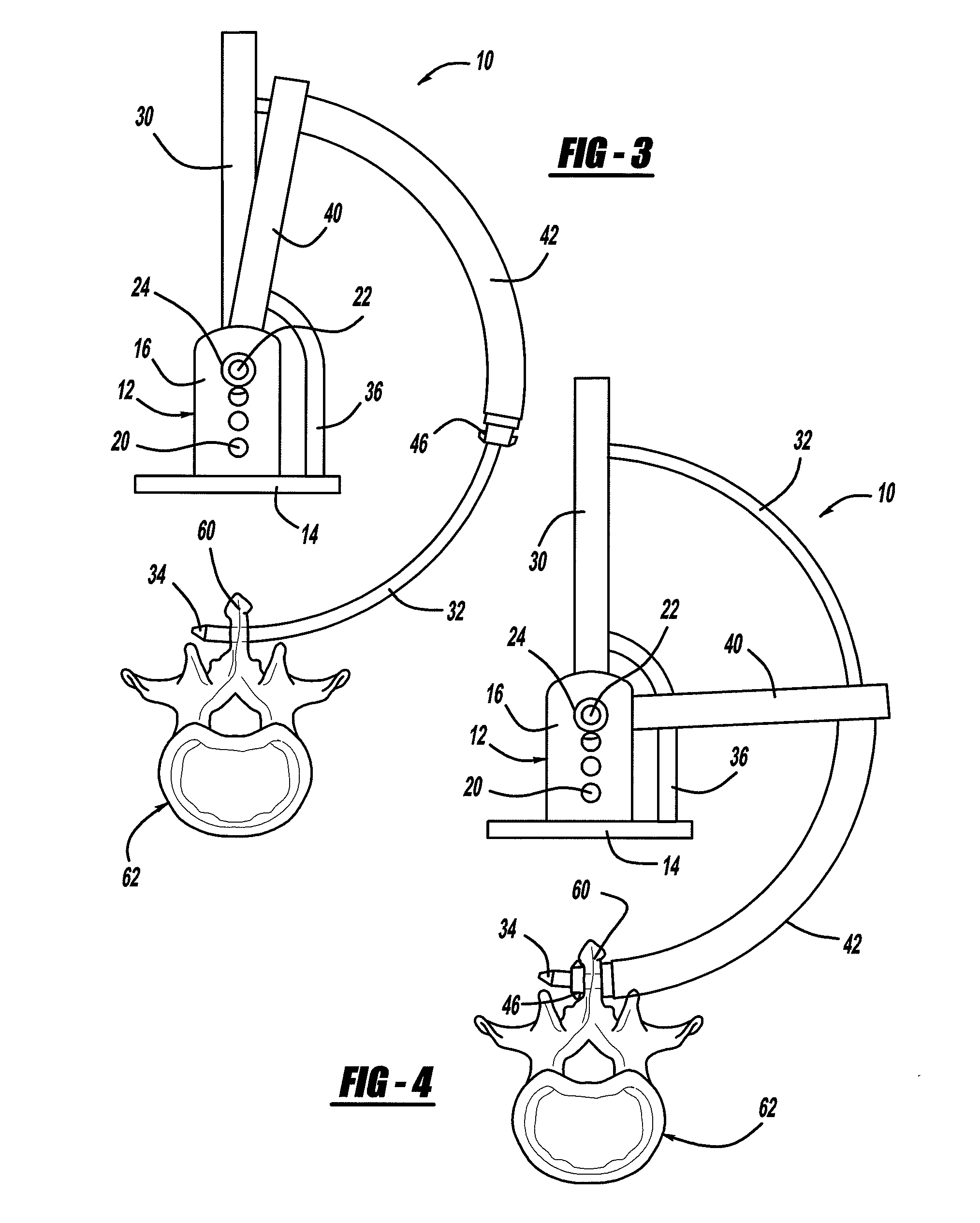

An interbody or intervertebral spacer device for placement in an interspinous space between a pair of adjacent interspinous processes includes arcuate opposed abutment surfaces sized and shaped for engaging adjacent spinal processes. A curved through channel is disposed between the opposed abutment surfaces. A pair of bands is receivable in the curved through channel. A method of implanting such an interspinous spacer includes the steps of making an incision lateral to the spine; laterally inserting the spacer between a pair of interspinous processes without detachment of the supraspinous ligament; and laterally securing the spacer to the pair of interspinous processes with a pair of bands.

Owner:JACKSON

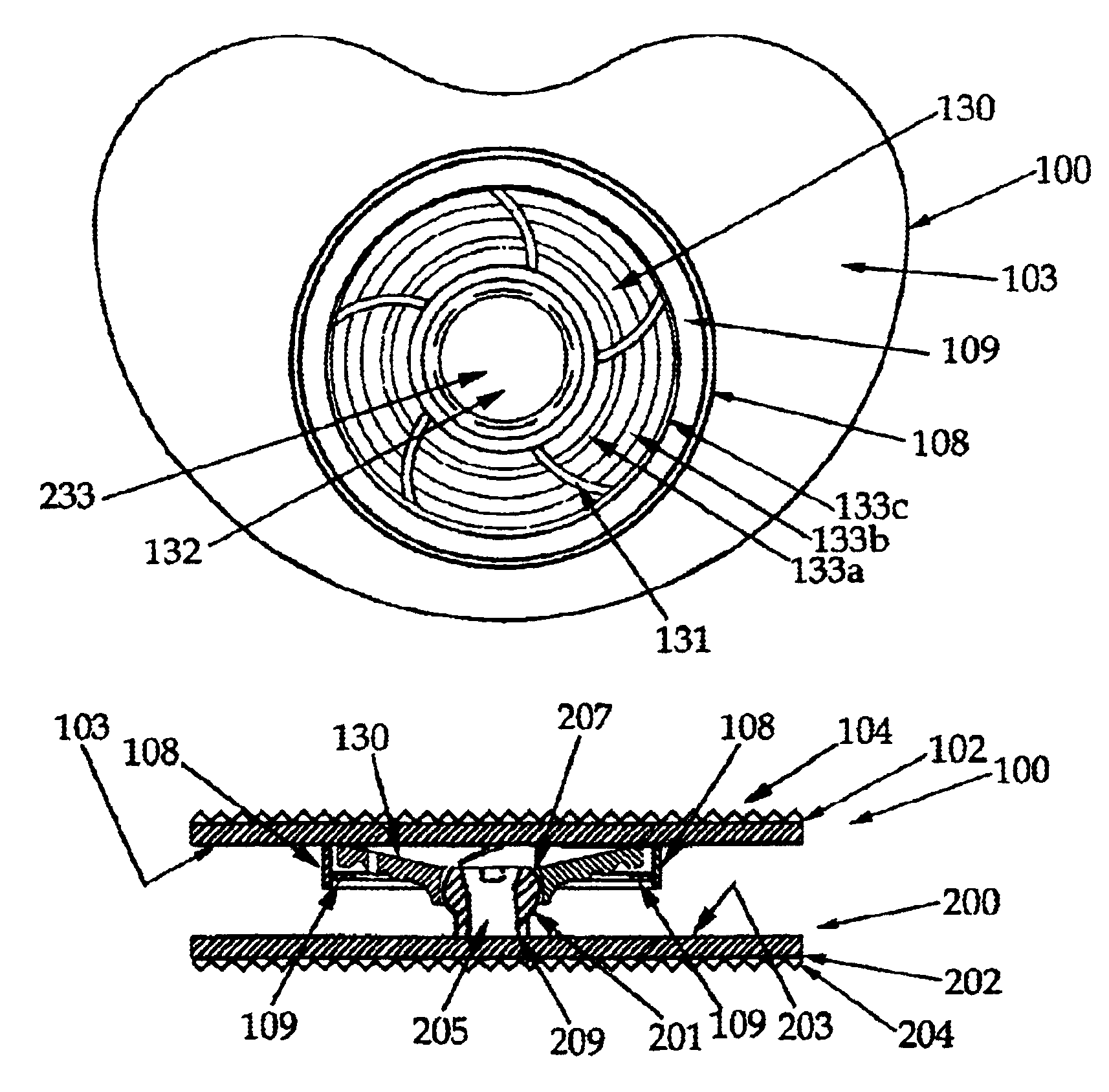

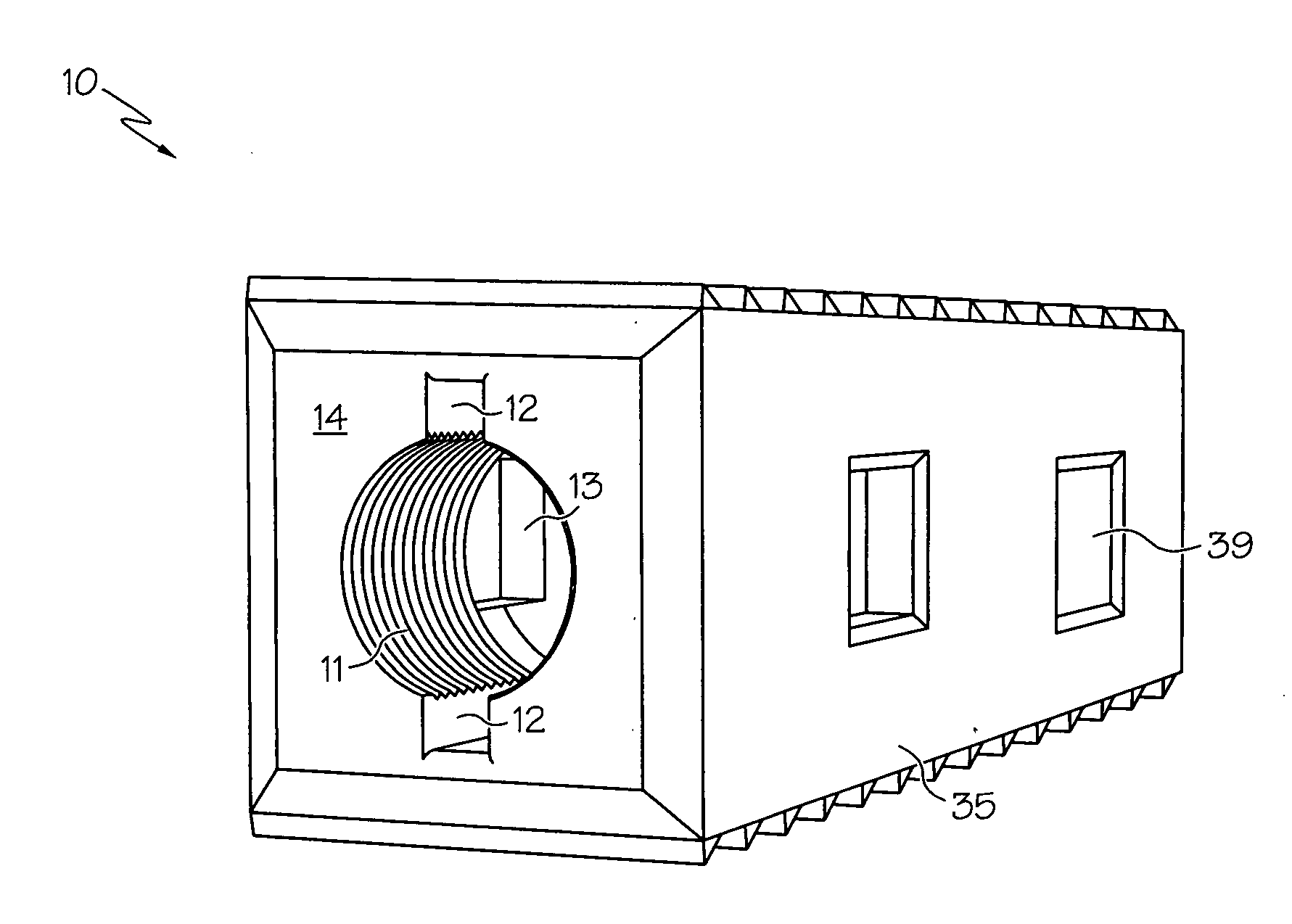

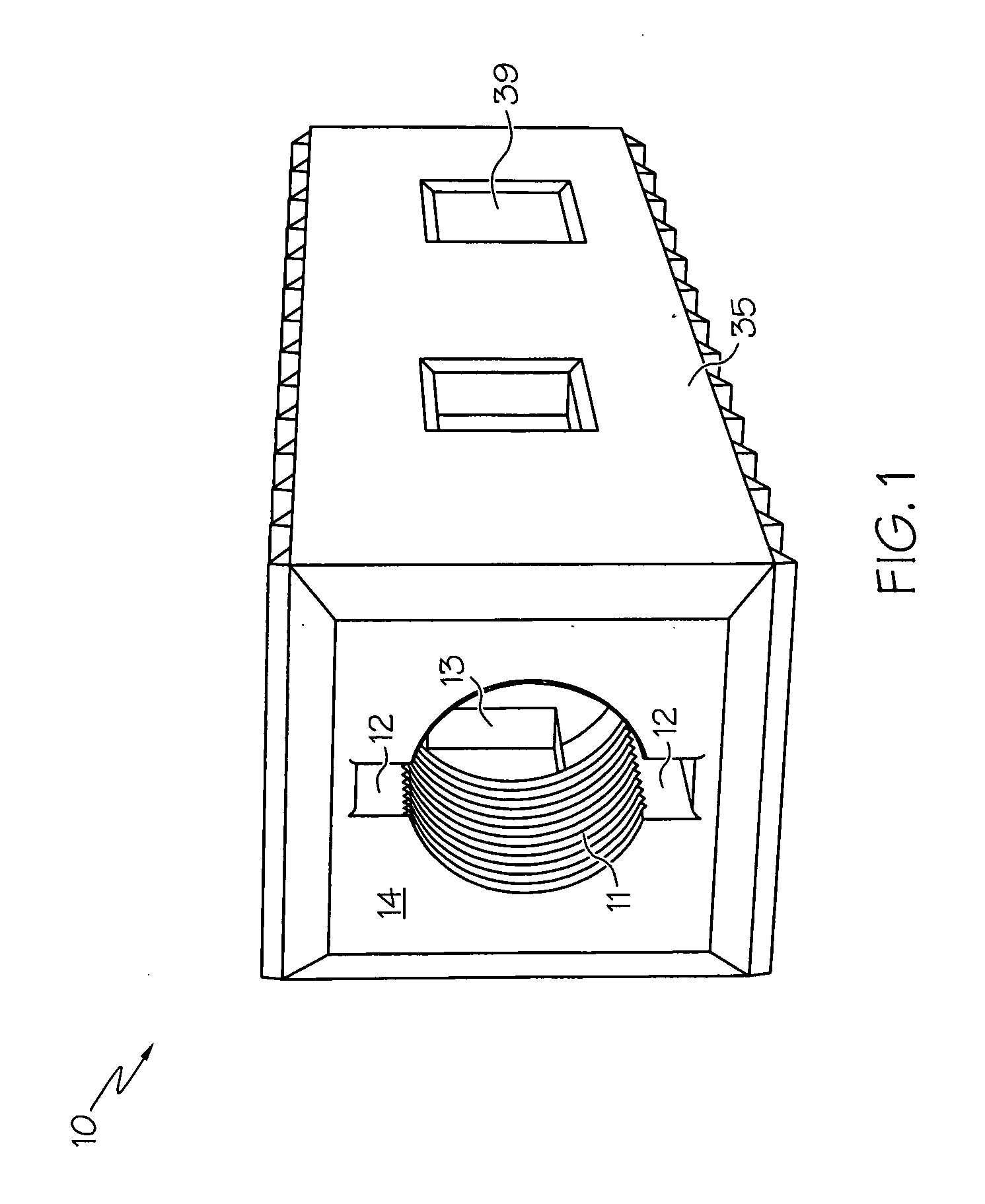

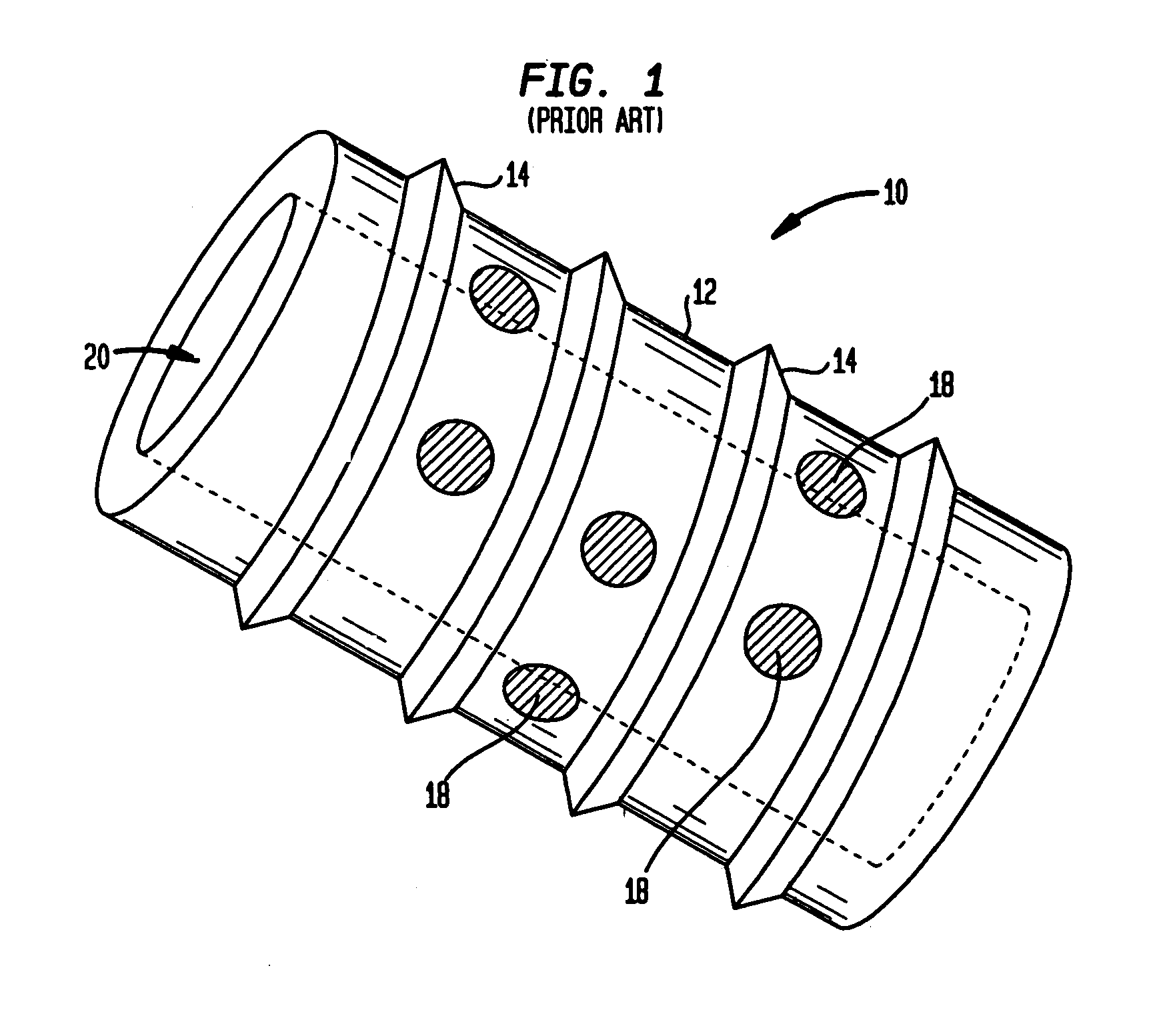

Intervertebral spacer device utilizing a spirally slotted belleville washer having radially spaced concentric grooves

InactiveUS6863688B2Reduce capacityAvoid skewJoint implantsSpinal implantsEngineeringBelleville washer

An intervertebral spacer device having a pair of opposing plates for seating against opposing vertebral bone surfaces, separated by at least one spring mechanism. The preferred spring mechanism is at least one spirally slotted belleville washer having radially spaced concentric grooves. In a preferred embodiment there is a single such belleville washer which is modified to mount onto a ball-shaped head. The lower plate of this embodiment includes a post extending upwardly from the inner surface of the plate, the post including a ball-shaped head. The modified belleville washer can be rotatably mounted to the head such that the wider portion of the washer seats against the upper plate.

Owner:HOWMEDICA OSTEONICS CORP

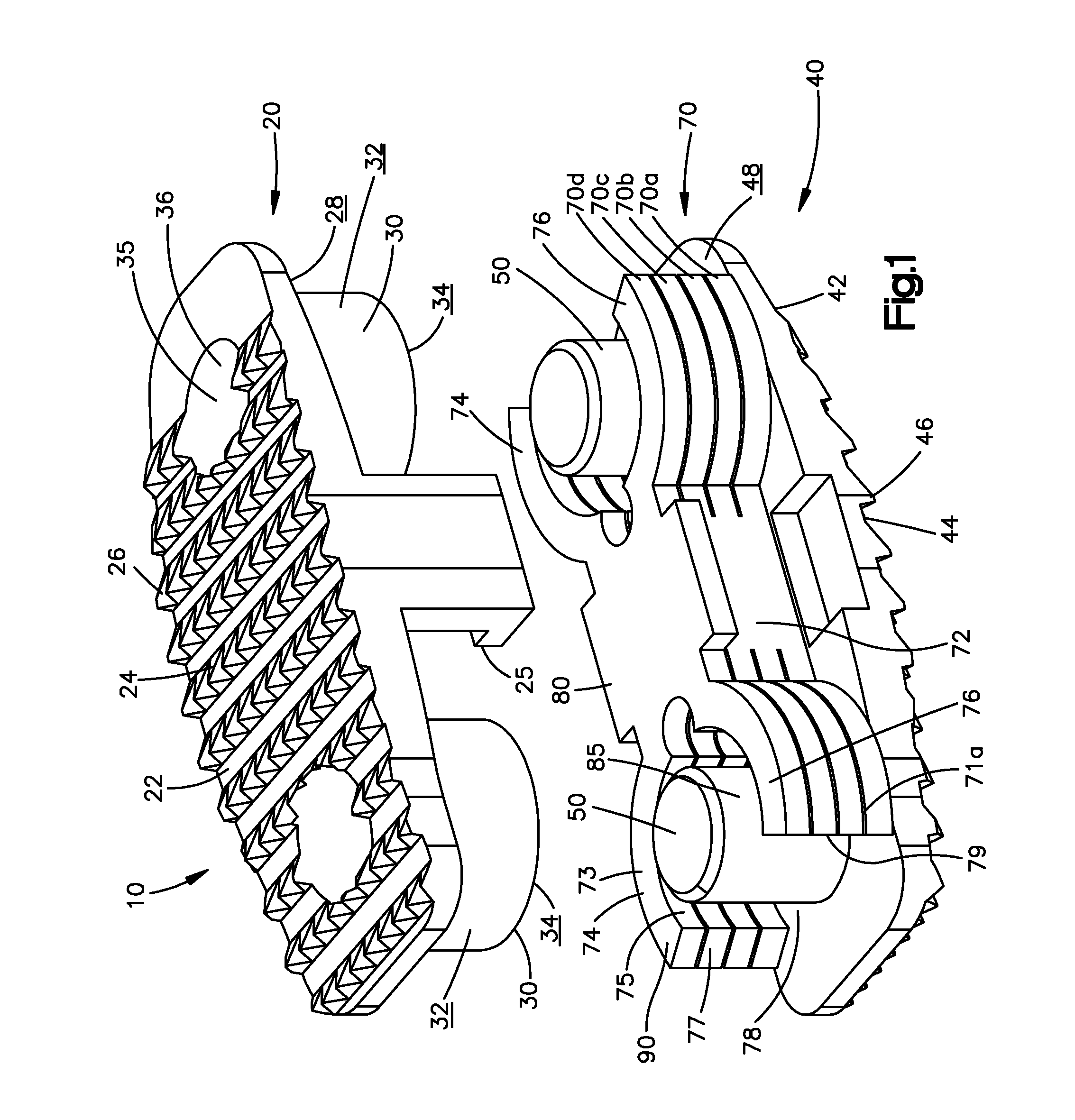

Adjustable interbody fusion devices

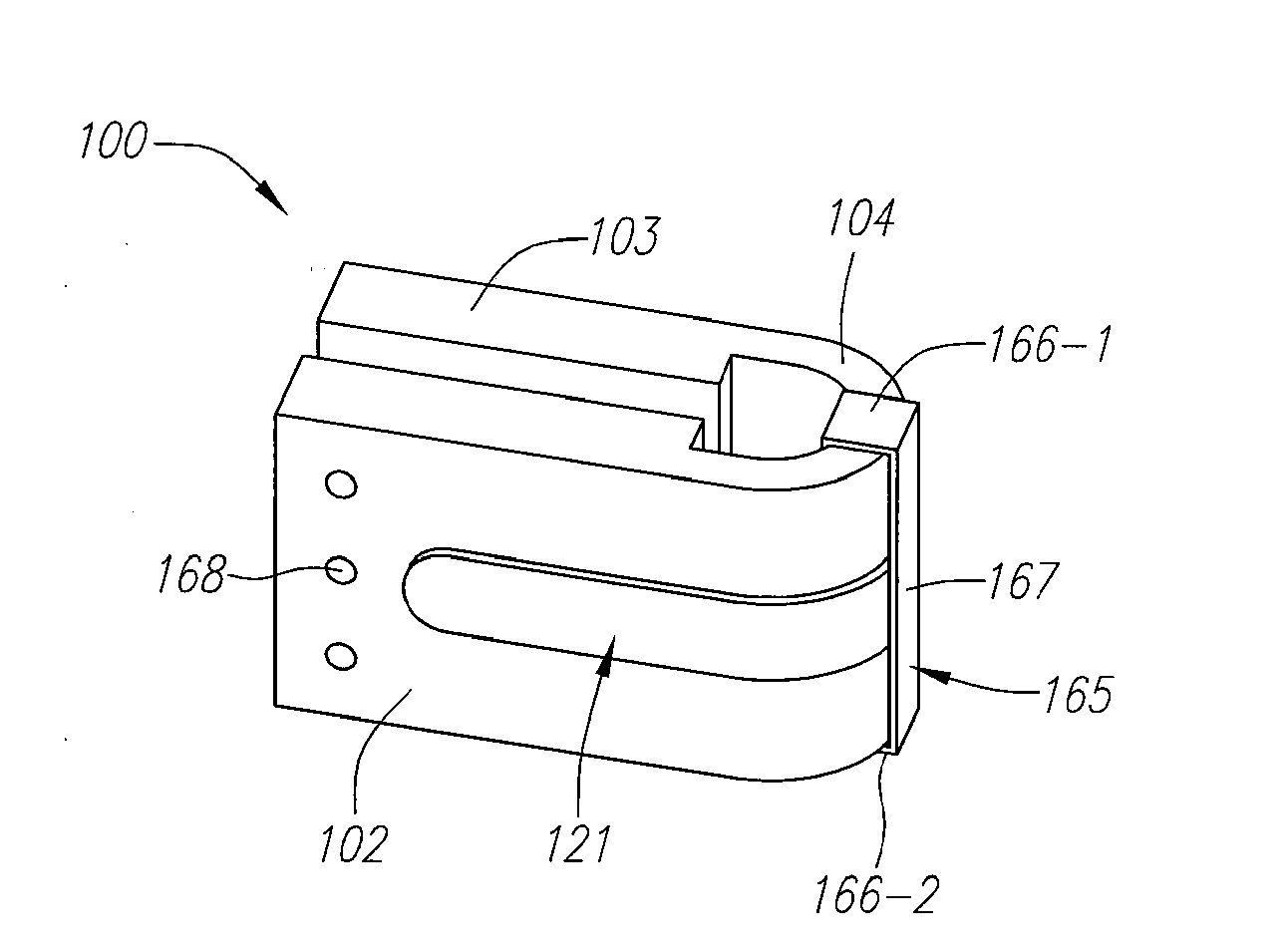

Interbody fusion devices, insertion tools, methods for assembling an interbody fusion device, and methods for inserting a medical device between two vertebral bodies are disclosed. The interbody fusion device includes a base member, a top member, and at least one movement mechanism. The base member includes at least one of a pivot cylinder and a hinge channel. The top member includes at least one of a pivot cylinder and a hinge channel. The at least one pivot cylinder of the base member engages the at least one hinge channel of the top member and the at least one pivot cylinder of the top member engages the at least one hinge channel of the base member. The at least one movement mechanism engages the top member and the base member. Also disclosed are a vertebral spacer device and an interbody spacer system including an insertion tool and an interbody fusion device.

Owner:BIOSPINE

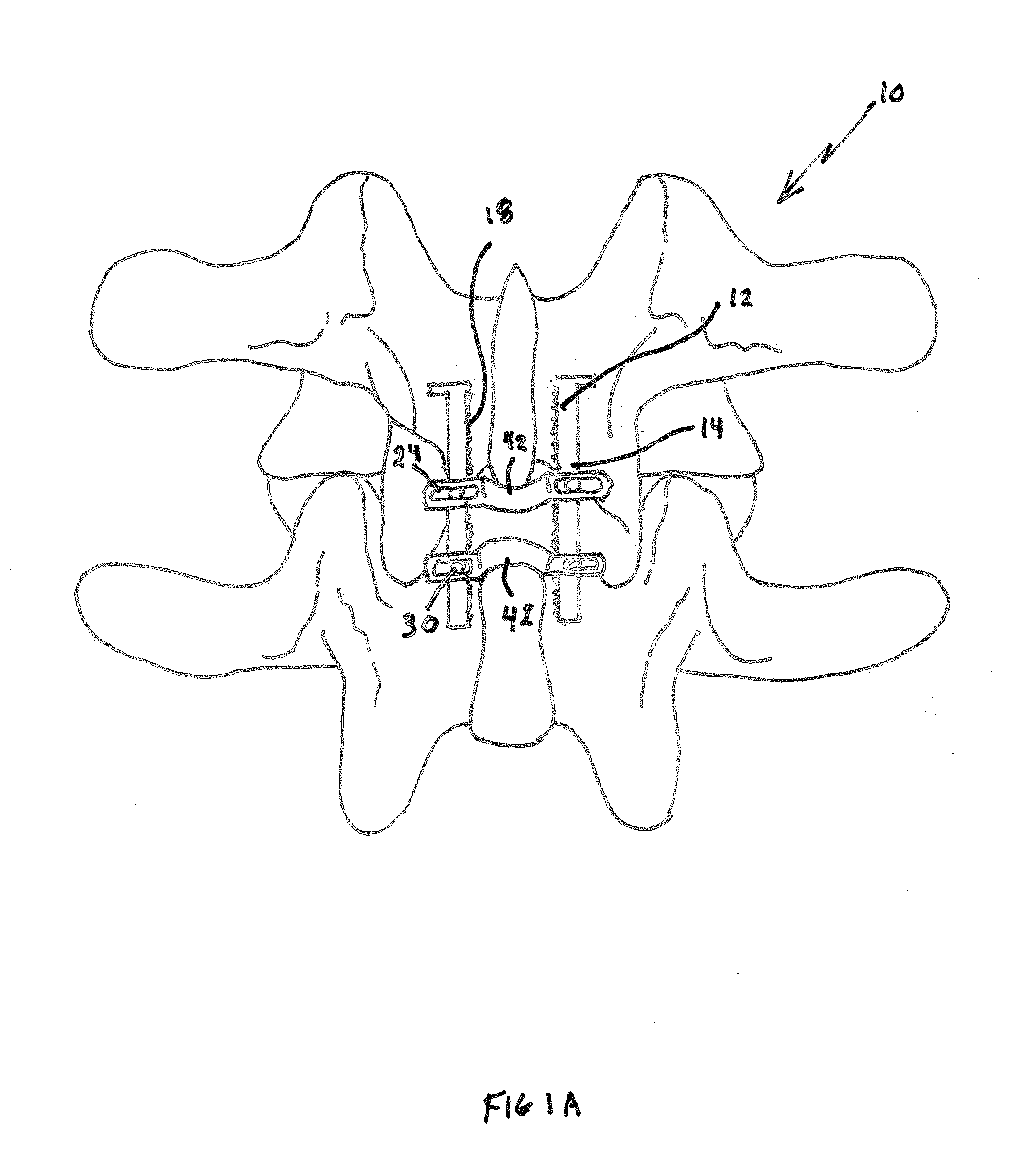

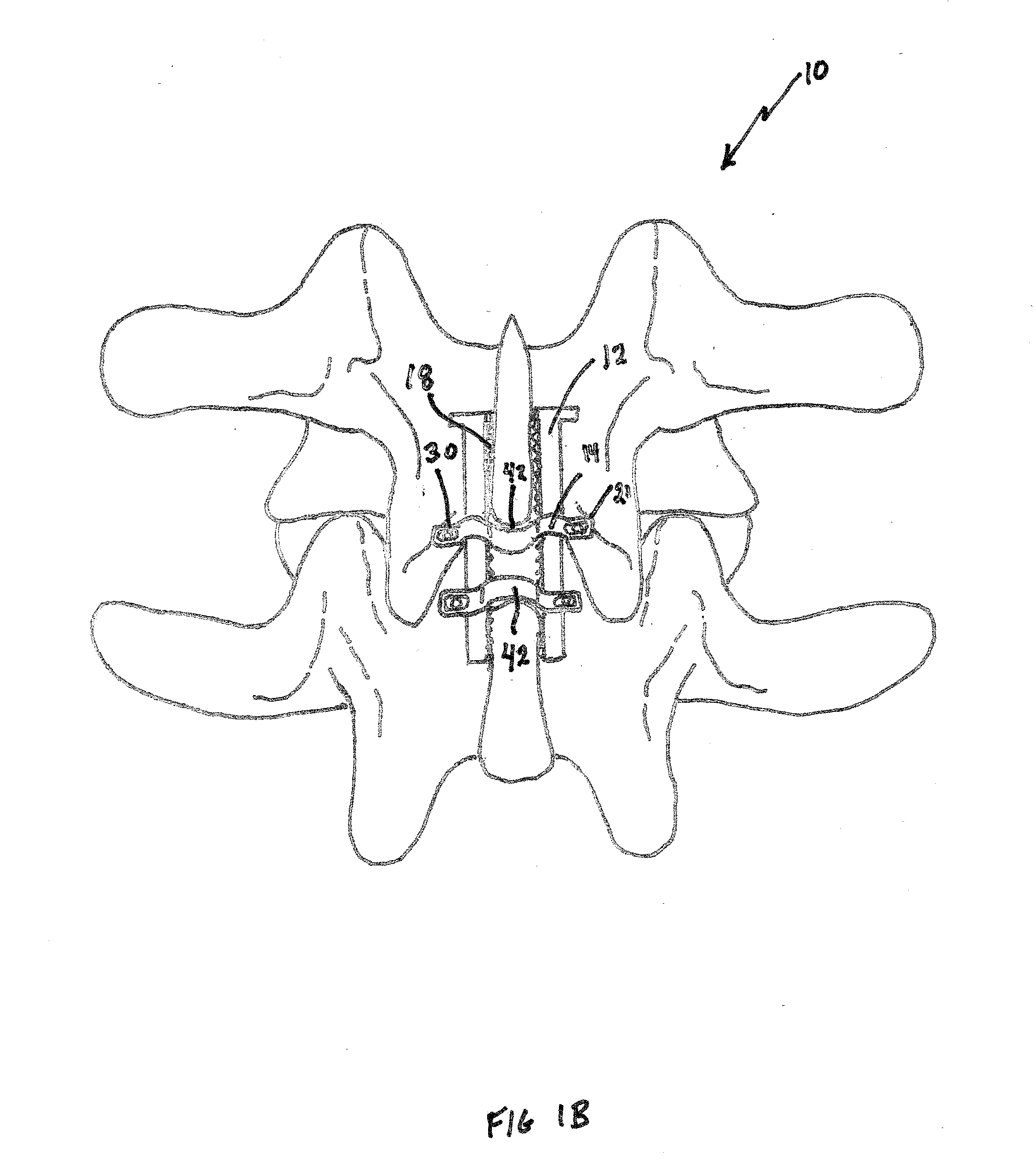

Interspinous Process Spacer Device

A spacer device that is to be inserted between the spinous process of adjacent vertebrae. In one embodiment, the spacer device is percutaneously inserted between the spinous process of adjacent vertebrae using minimally invasive surgical procedures. The spacer device includes a body portion having a channel extending therethrough, a plate member attached at one end of the body portion that is larger cross-wise than the body portion, and at least one retaining member attached proximate to an opposite end of the body portion from the plate member. The spacer device is inserted between the spinous process with the retaining member stored within the body portion. A deploying device is inserted into the channel to deploy the retaining member to lock the spacer device in place.

Owner:MI4SPINE

Spacer Devices and Systems for the Treatment of Spinal Stenosis and Methods for Using the Same

Spacer devices for treating spinal stenosis are provided herein. In some example embodiments, these devices are configured for attachment on the interspinous ligaments with minimal injury thereto. Also provided are systems for the delivery of the spacer devices, tools for measuring and assessing the interspinous space and methods for using the same.

Owner:PROMED

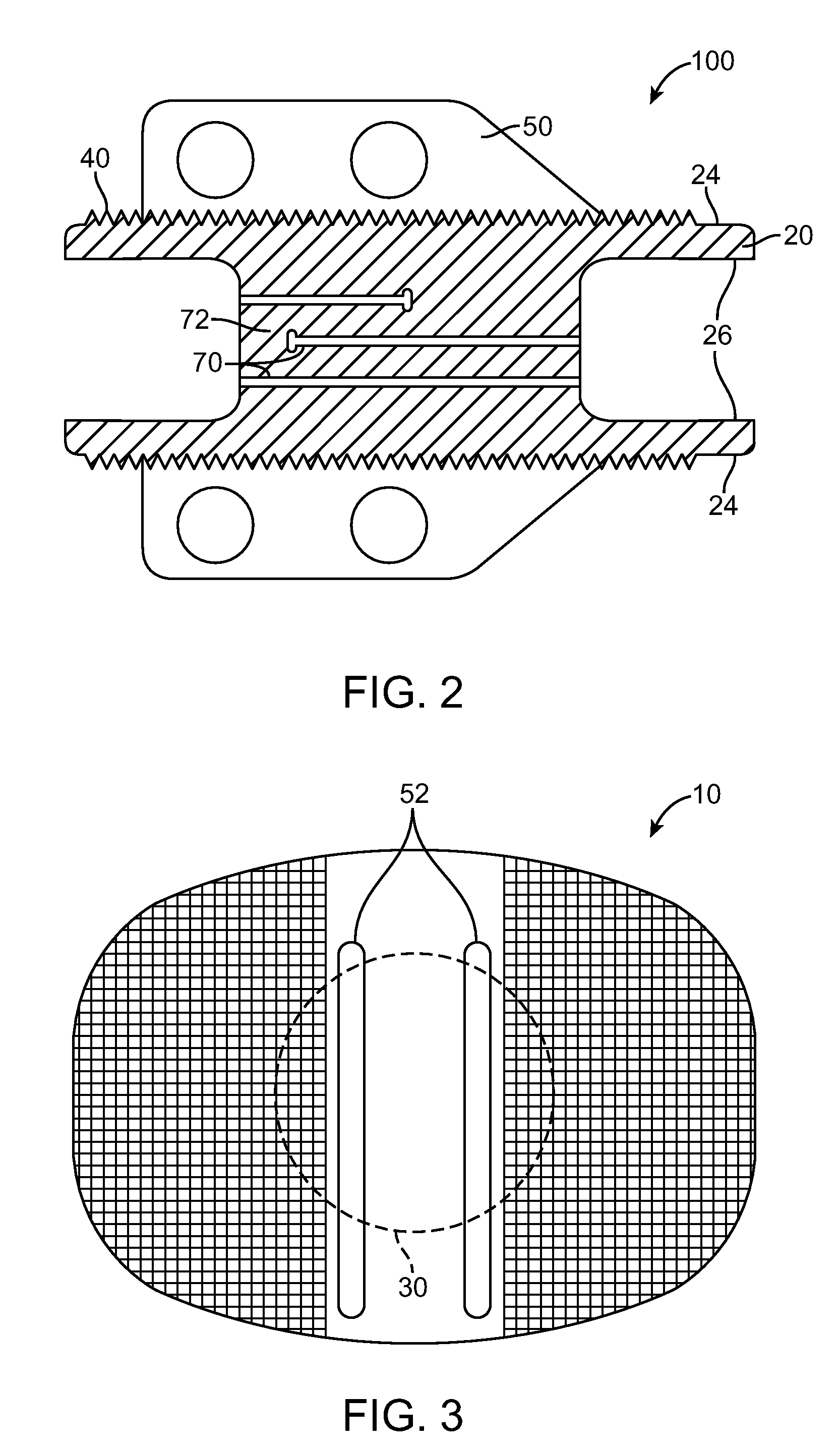

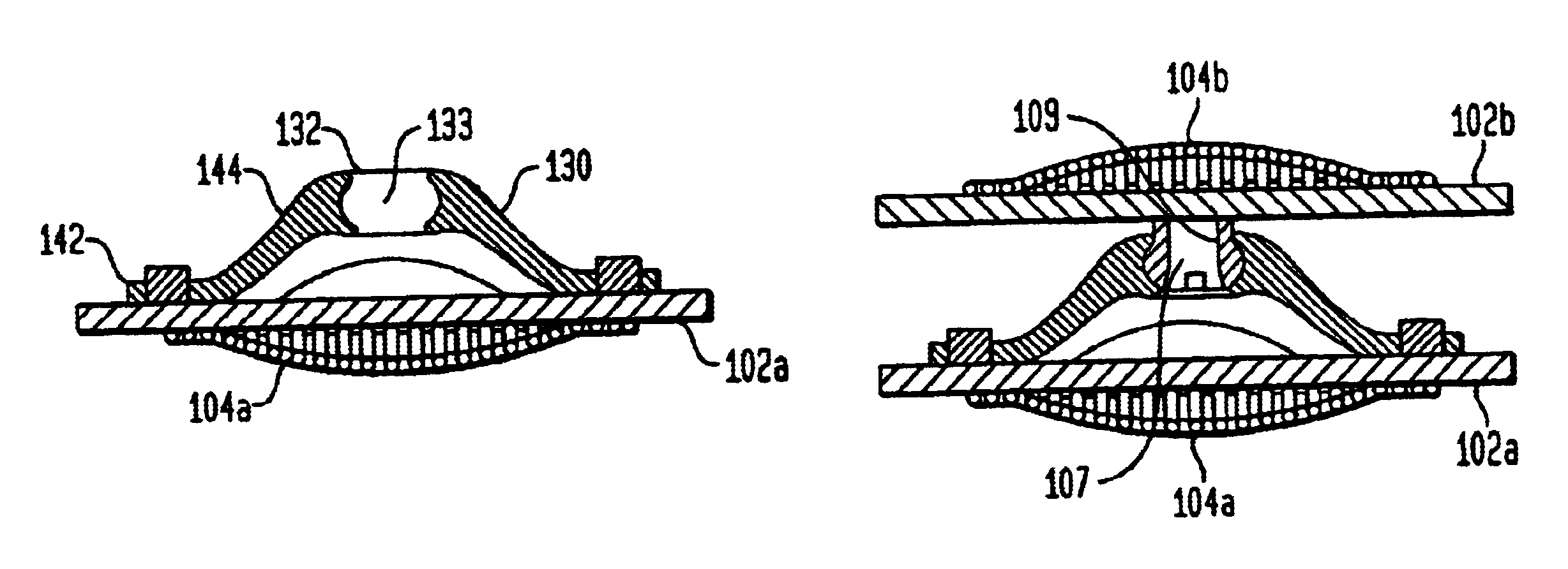

Dynamic Spacer Device and Method for Spanning a Space Formed upon Removal of an Intervertebral Disc

A compliant intervertebral spacer according to the present invention replaces a damage intervertebral disc and functions to maintain disc height and prevent subsidence with a large surface area while substantially reducing patient recovery time. The compliant intervertebral spacer for spanning a space formed by upon removal of an intervertebral disc includes two end plates sized and shaped to fit within an intervertebral space and a compliant connector interconnecting the inner surfaces of the two end plates in a manner which limits motion between the plates to less than a total of 5 degrees of motion in any direction. The intervertebral spacer is configured to permanently maintain the disc space between the two adjacent discs without the use of bridging bone.

Owner:SIMPLIFY MEDICAL PTY LTD

Convex spinal fusion interbody spacer

A convex spinal fusion interbody space device includes spaced apart superior and inferior abutment surfaces which are effectively medially convex. The peak of such convexity is displaced anteriorly of a central plane through the device. The spacer device has a height which is greater than the width of the device. The spacer device is implanted between a pair of adjacent vertebrae by insertion in a tipped-over orientation and then reoriented to an upright orientation for engagement by facing surfaces of the vertebrae. Fusion promoting bone material is packed between the vertebrae and about and within the spacer device subsequent to implantation.

Owner:WARSAW ORTHOPEDIC INC

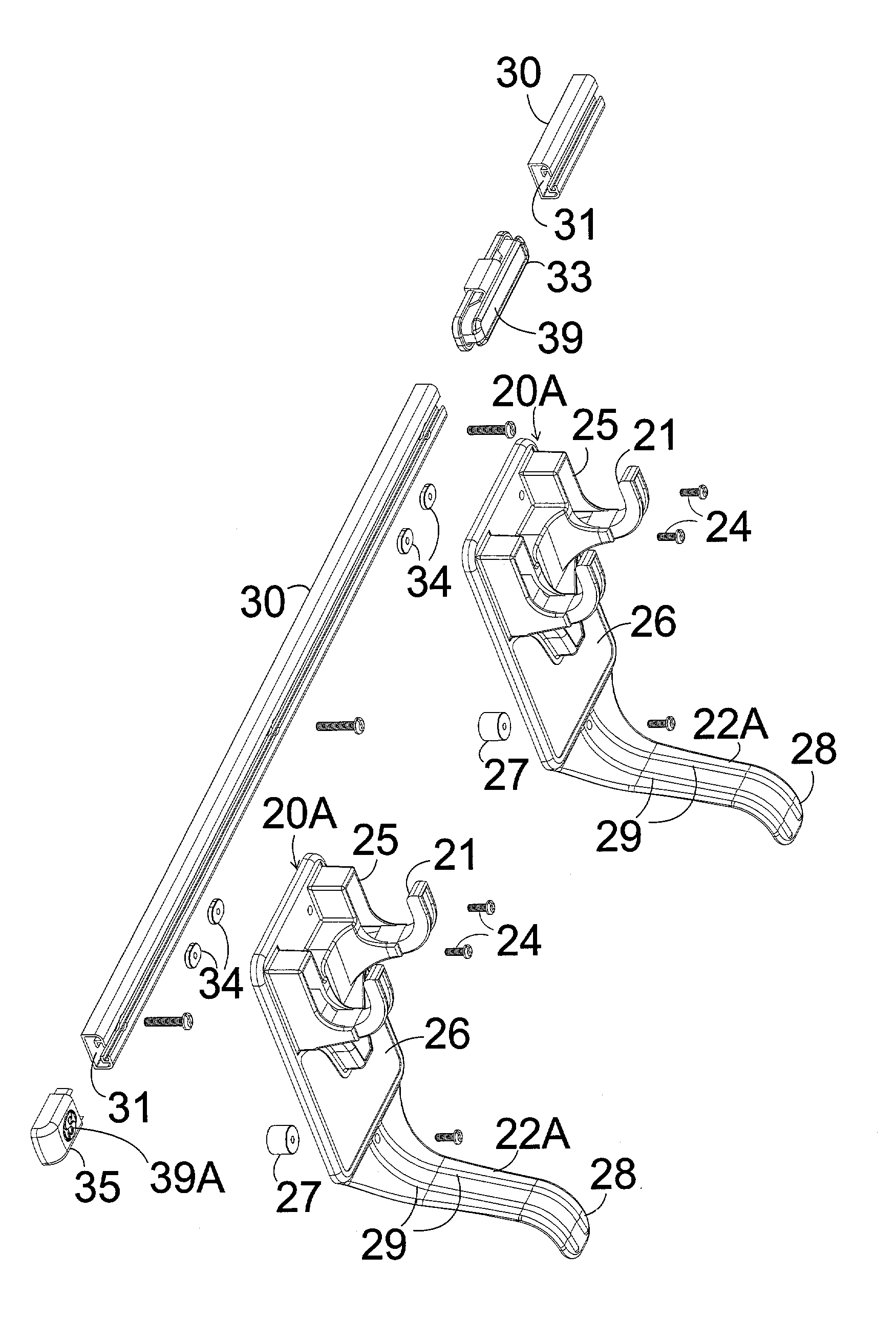

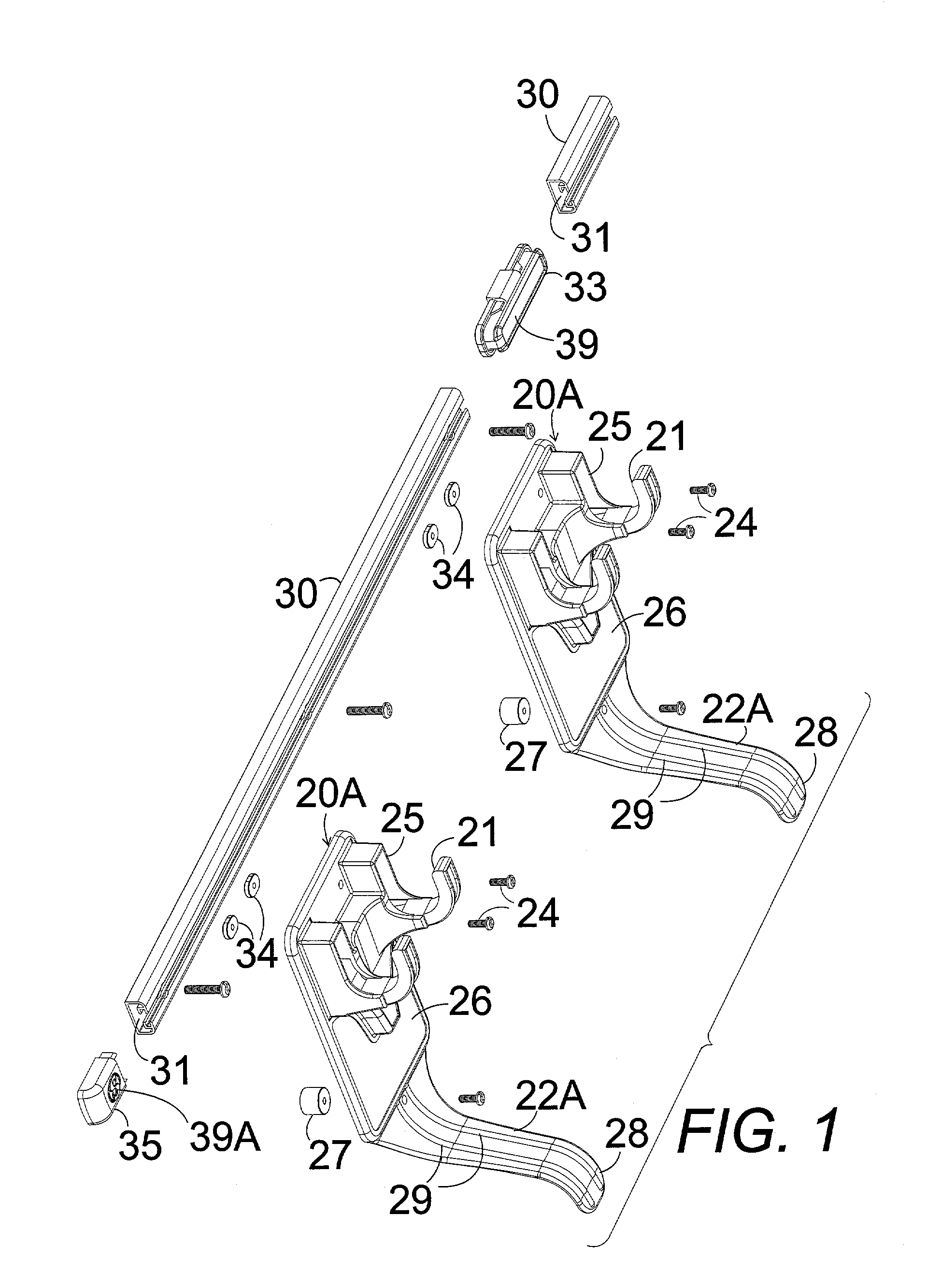

Adjustable spinous process spacer device and method of treating spinal disorders

InactiveUS20130296939A1Precise positioningRelieve pressureInternal osteosythesisJoint implantsSpacer deviceBiomedical engineering

Provided is a bi-dimensionally adjustable spacing device configured to be placed between the spinous processes of at least two adjacent vertebrae and also adjusted laterally to securely contact the lateral surfaces of the spinous process. A method of using the device to treat spinal disorders is also provided.

Owner:PERKINS RICHARD

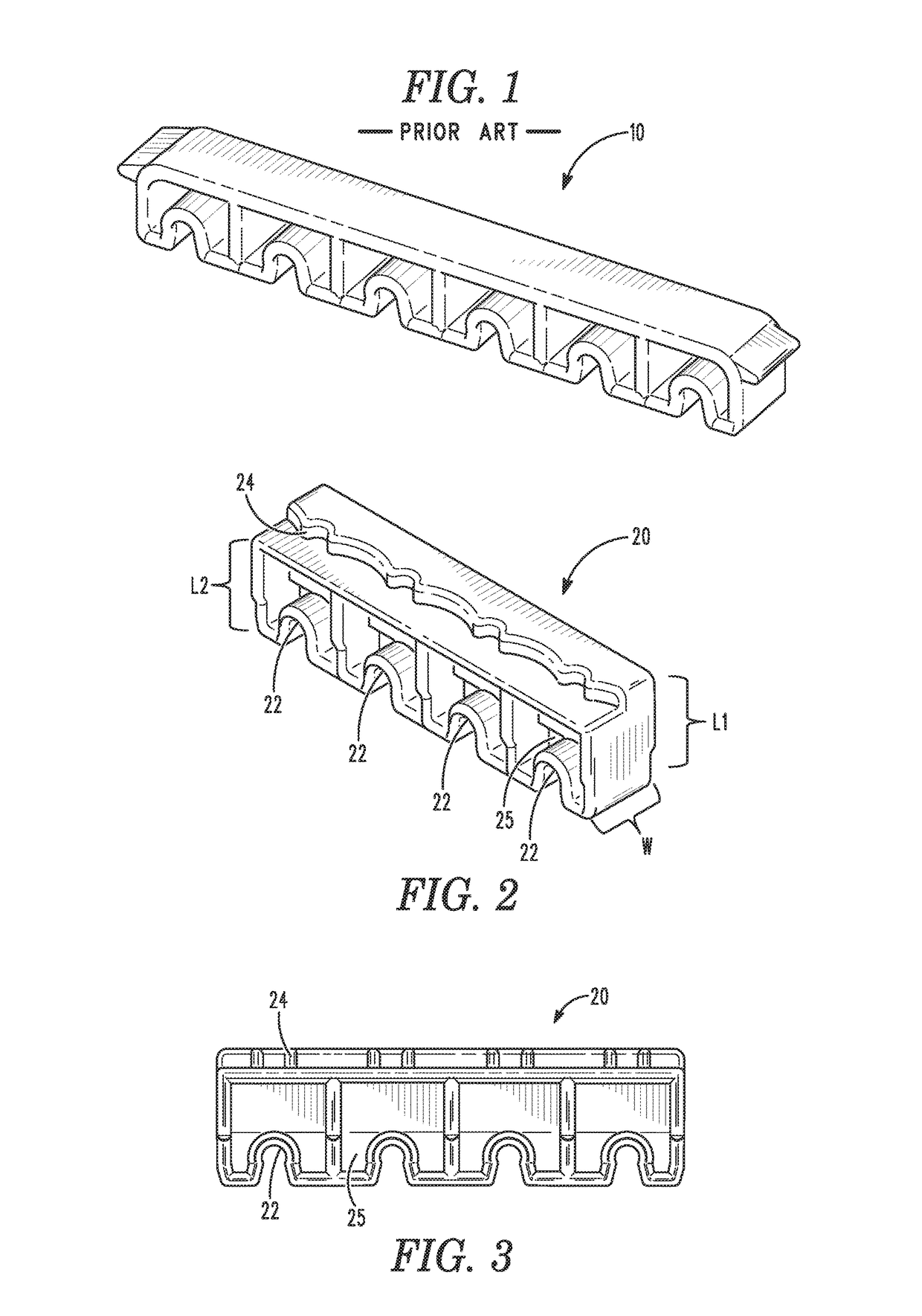

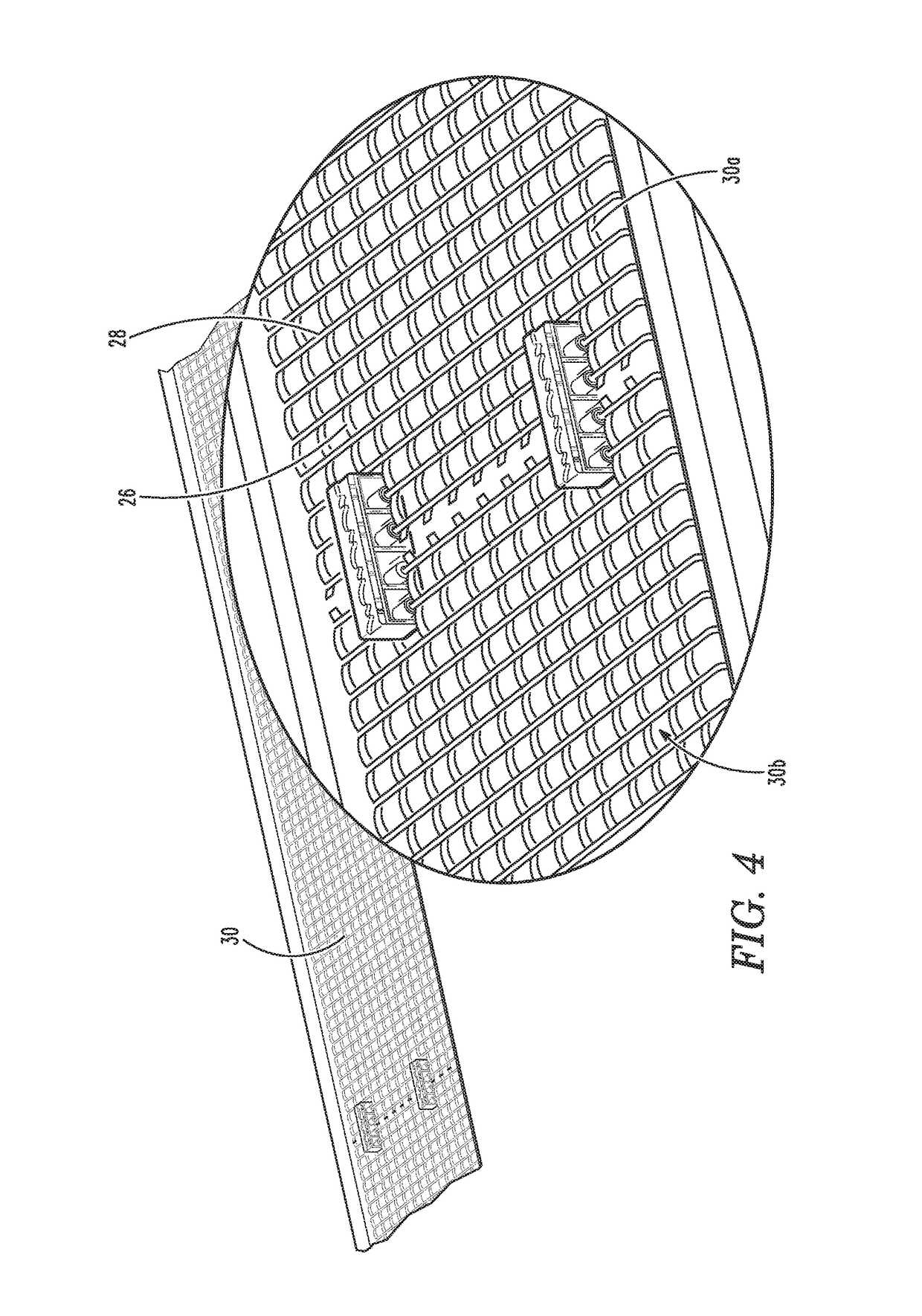

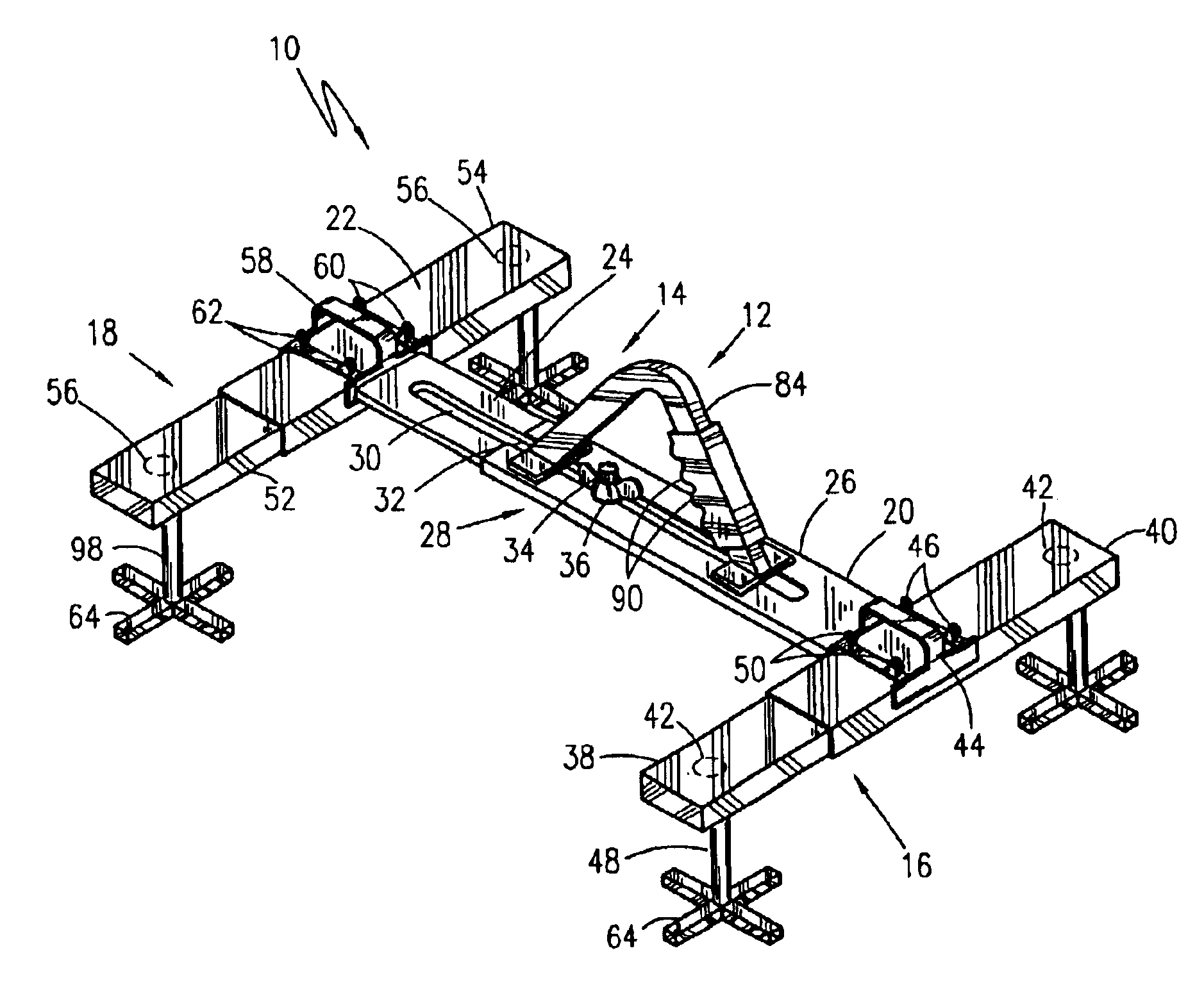

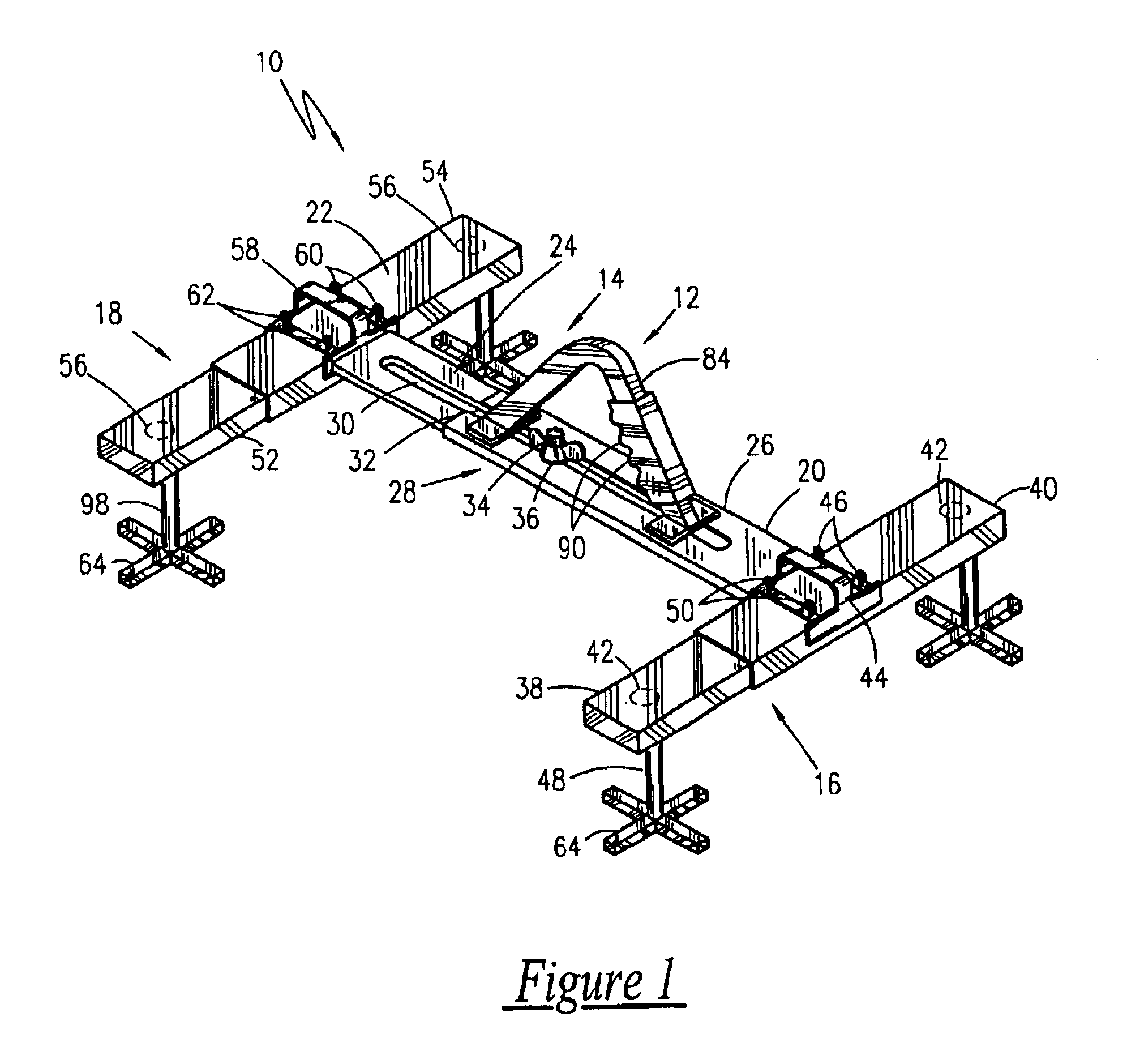

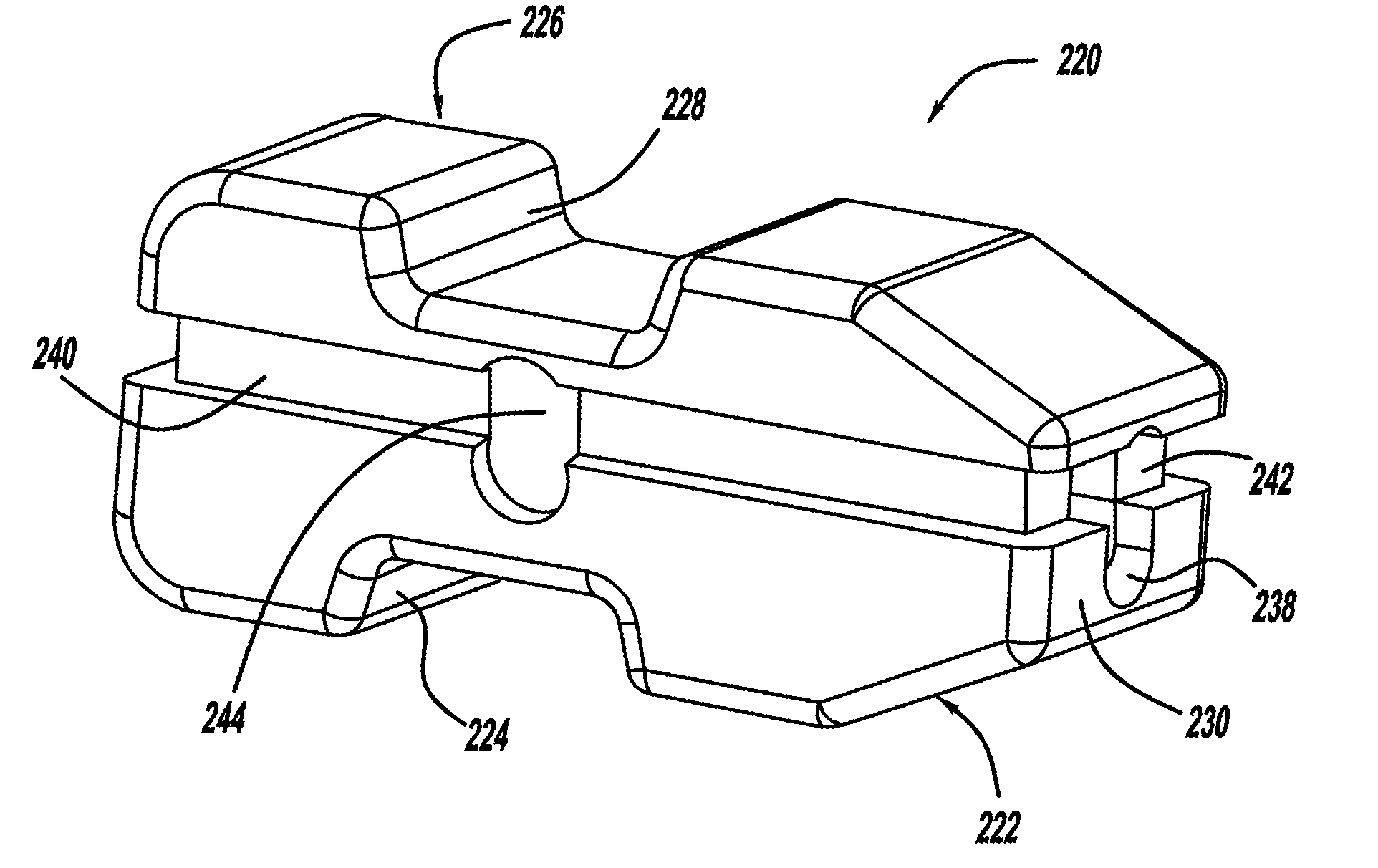

Grating connector and spacer apparatus, system, and methods of using the same

ActiveUS9731730B2Length of may varyAccurate spacingAngles/taper measurementsWagons/vansGratingEngineering

The present invention relates to an apparatus, system, and method of using the same for connecting and spacing grating and the like. Specifically, the present invention relates to connecting and spacing wire gratings, for example wire gratings used as vehicle tire support material or for mounting wheel chocks thereon in the transportation of automobiles. Even more specifically, the present invention may be used to connect a plurality of wire gratings together and to space in a first direction the plurality of gratings apart from each other at multiple selectable distances in one configuration. In a second configuration, the present invention may be used to space in a second direction the plurality of gratings from other objects, such as a wall or guard rail. The second configuration may be used in multiple orientations in order to provide multiple different spacing distances.

Owner:HOLLAND CO

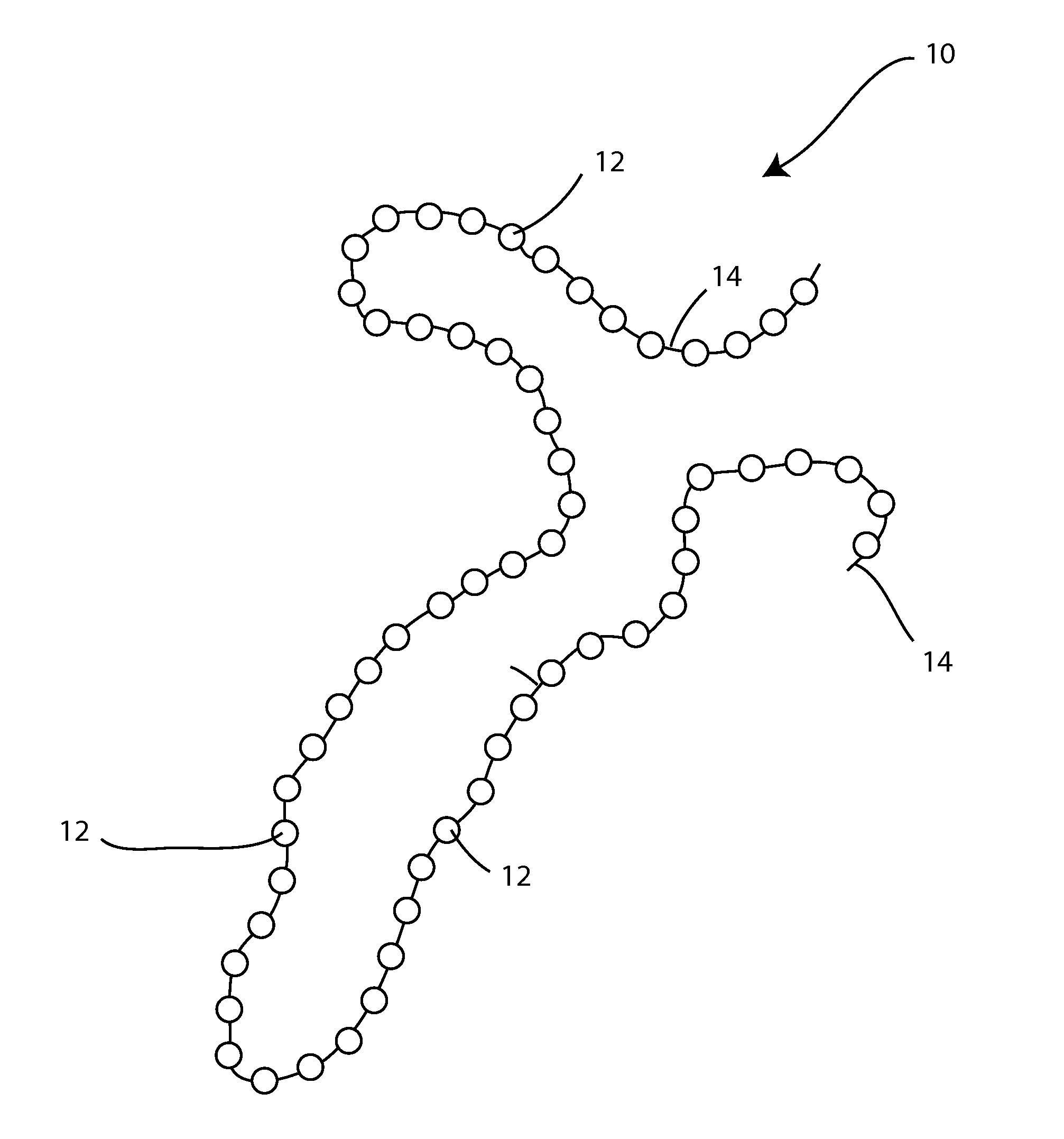

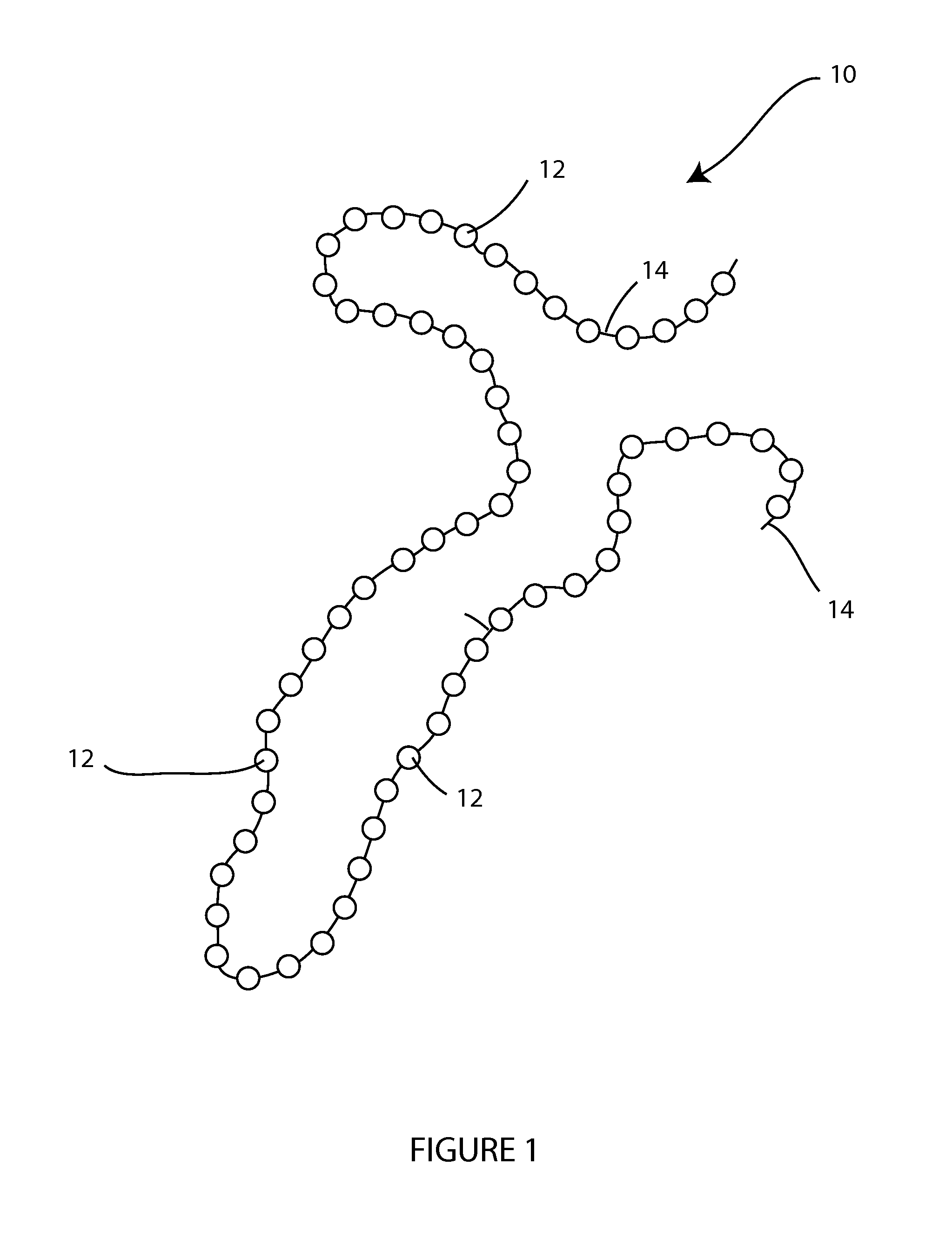

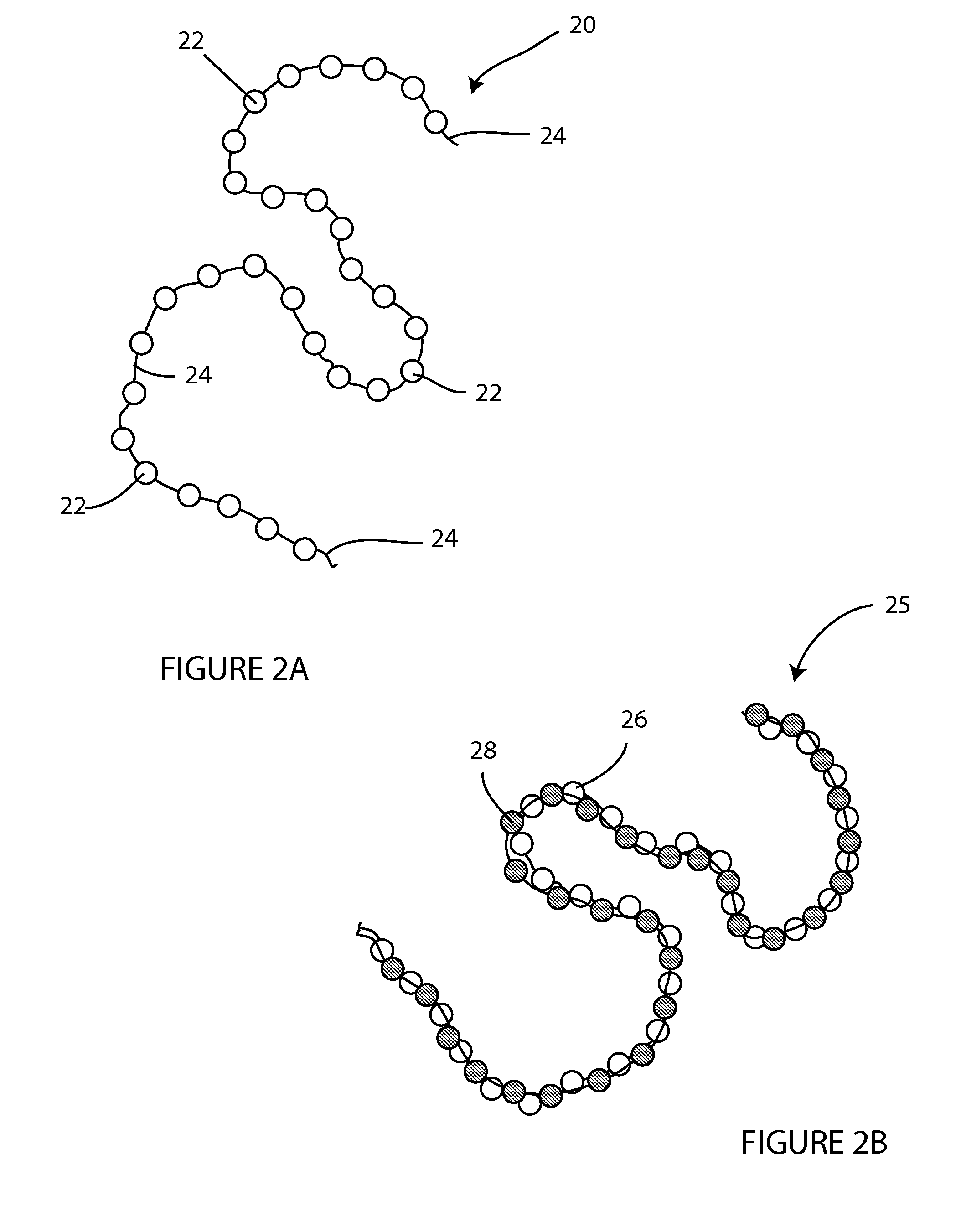

Beaded Wound Spacer Device

InactiveUS20080188819A1Good adhesionImproved handling of deviceSuture equipmentsAntibacterial agentsMedical unitElution

A wound spacer device comprising multiple beads connected by non-absorbable suture material is disclosed. The device can be applied, for example, by a first responder to an injured individual, or can be applied by a trauma treatment facility, such as a Level 2 medical unit. In typical embodiments the device allows for site-specific controlled elution of an antimicrobial agent, such as Tobramycin, including defined elution over a period of time, such as 48 or 72 hours.

Owner:SURMODICS INC

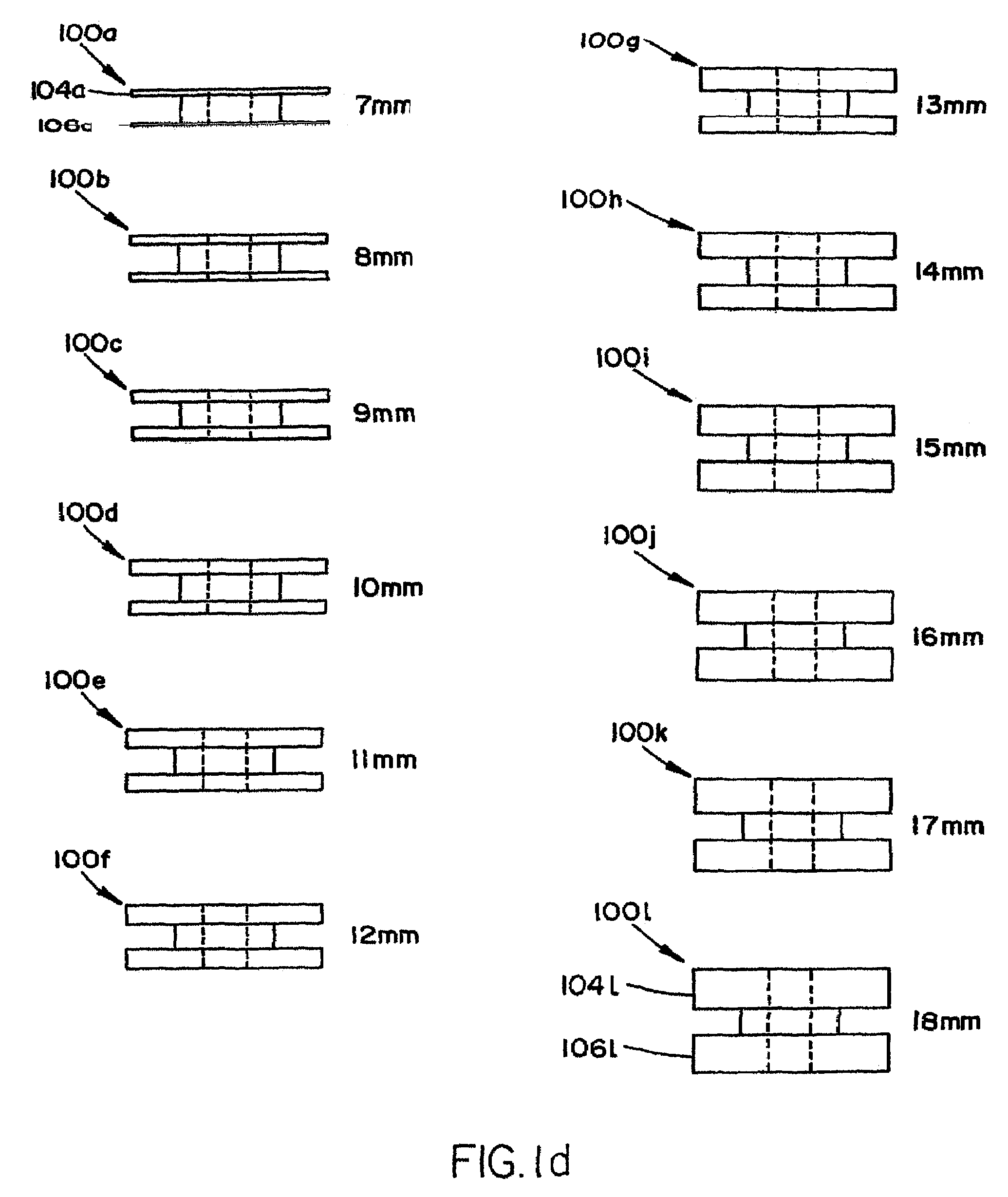

Trial intervertebral distraction spacers

InactiveUS7217292B2Restoring appropriate anatomical statusEasy to integrateJoint implantsSpinal implantsDistractionPhysical therapy

An orthopedic spacer device comprising a spacer body having an external surface that includes at least two relative angle designation marks such that a rotational angle of the spacer body relative to a known reference is determinable.

Owner:HOWMEDICA OSTEONICS CORP

Wall hanger and spacer for skateboards and scooters

A small flat wall mountable panel having a flat visual display surface has two spaced apart upwardly arched hooks mounted on backstop spacers and aligned horizontally to receive a skateboard wheel mount or a scooter handle bar therein. An outwardly arched spacer arm below the hooks contacts the board or scooter to maintain the skateboard or scooter away from the wall. A rail with a sliding track can receive and mount a number of the hanger / spacer devices horizontally aligned on a wall. End caps and interconnectors between rails have flat surfaces for visual displays.

Owner:DETTORRE ROSS D +2

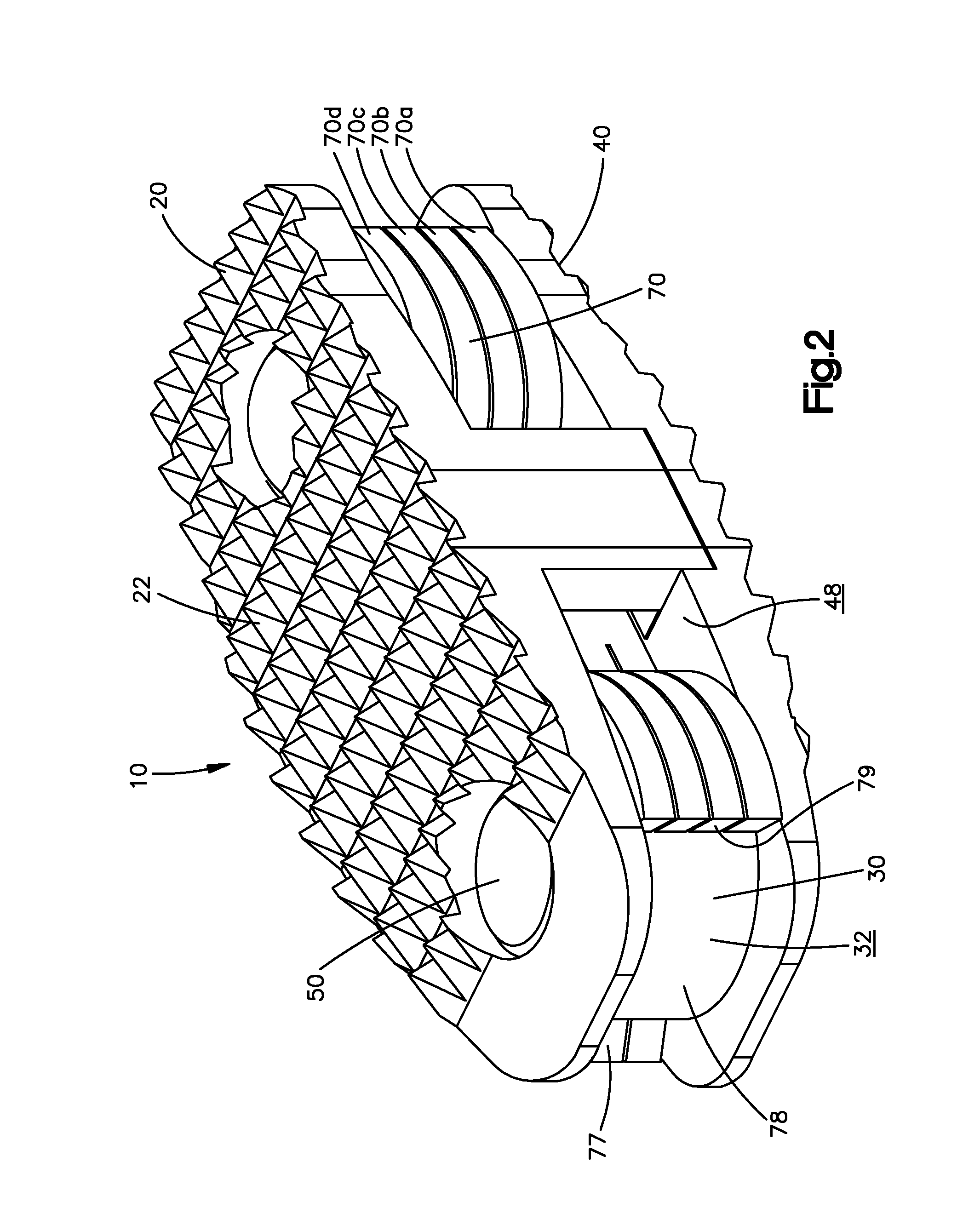

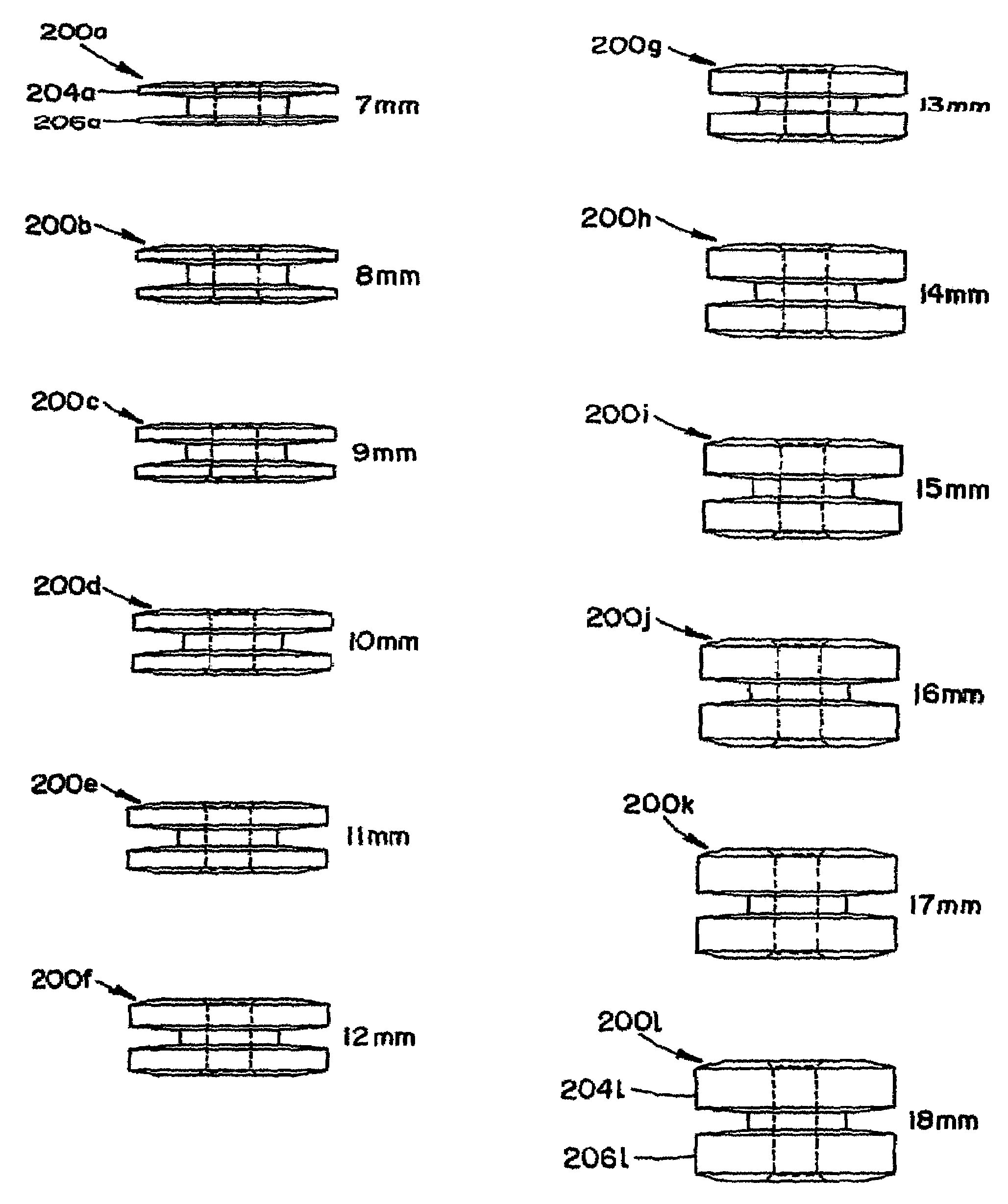

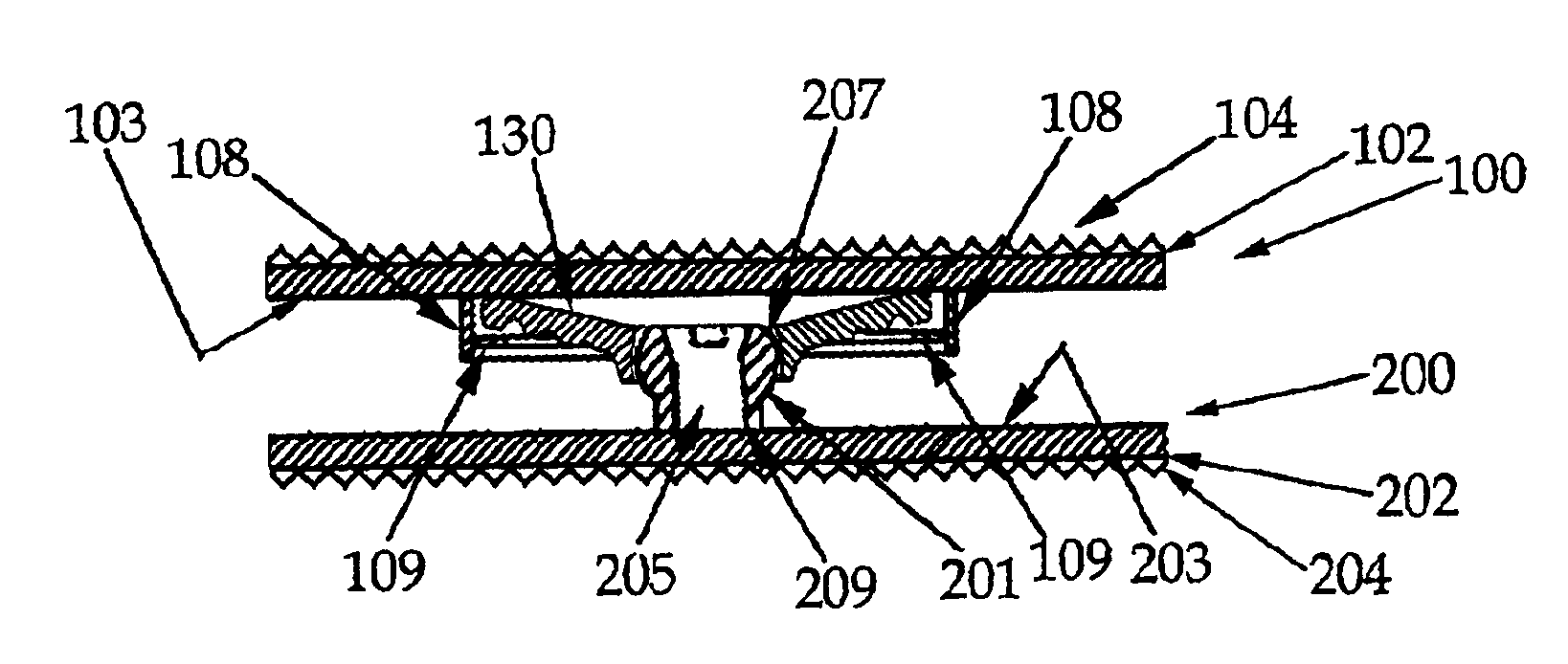

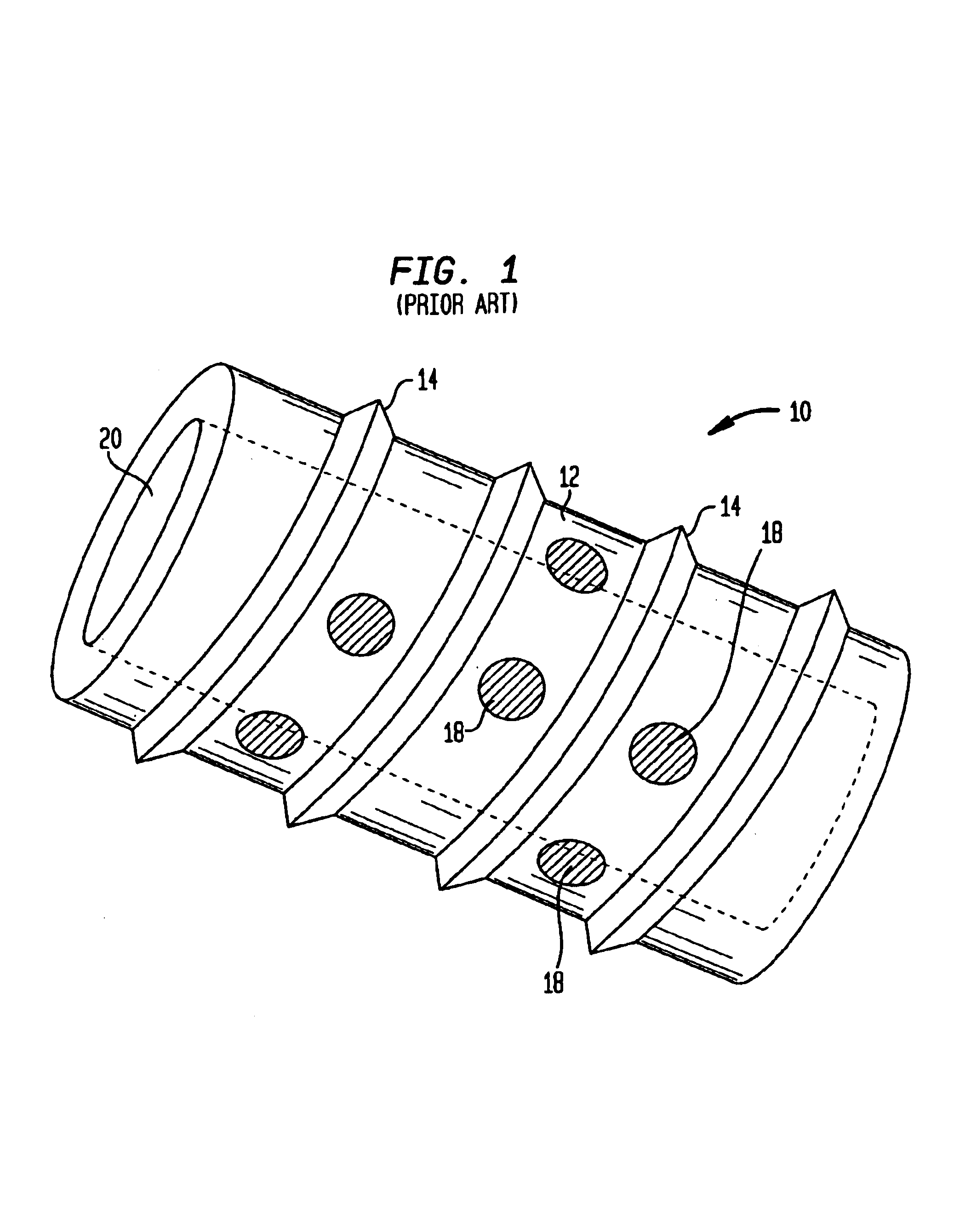

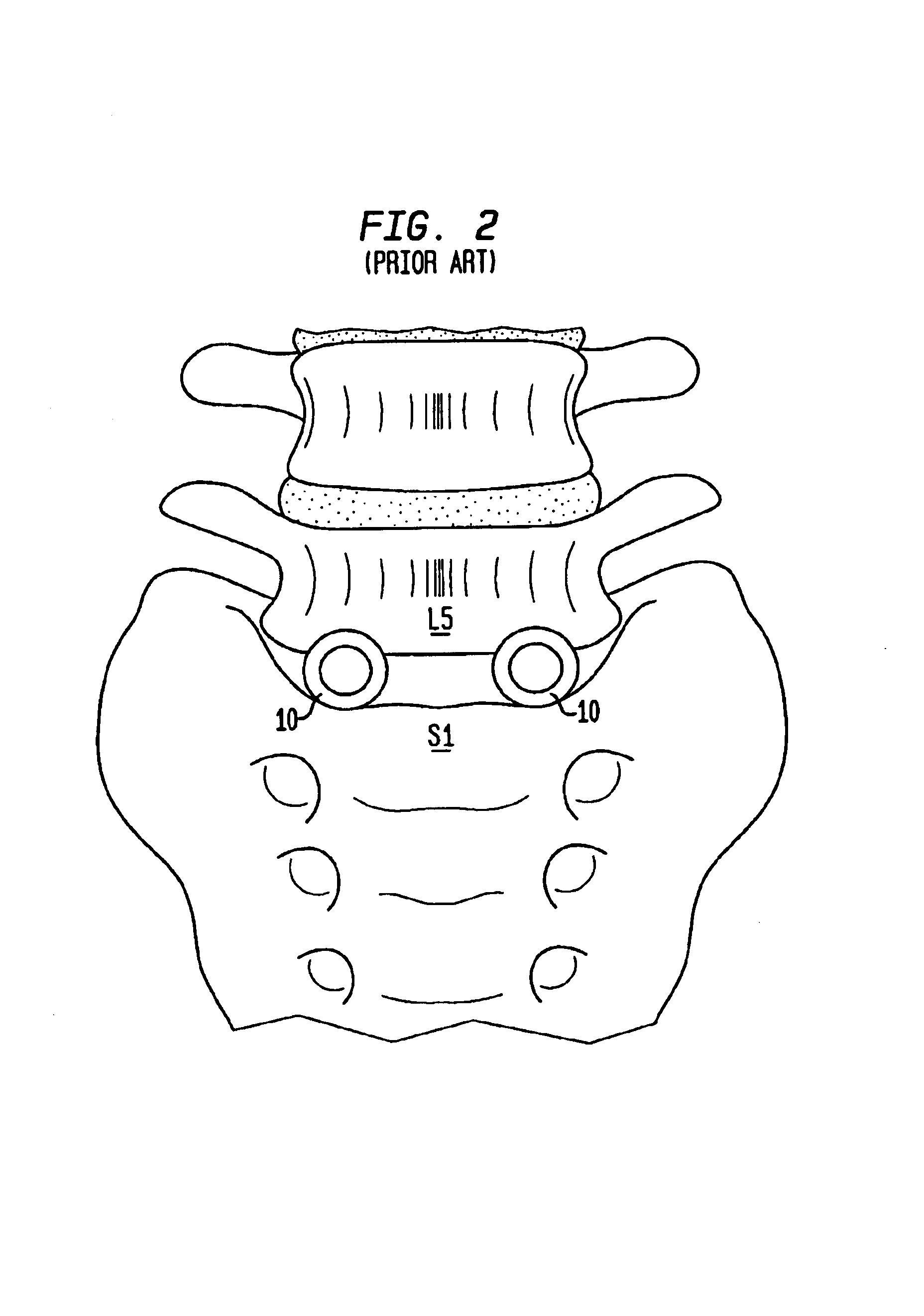

Intervertebral spacer device utilizing a belleville washer having radially spaced concentric grooves

InactiveUS6887274B2Reduce capacityAmple spring-like performanceJoint implantsSpinal implantsEngineeringBelleville washer

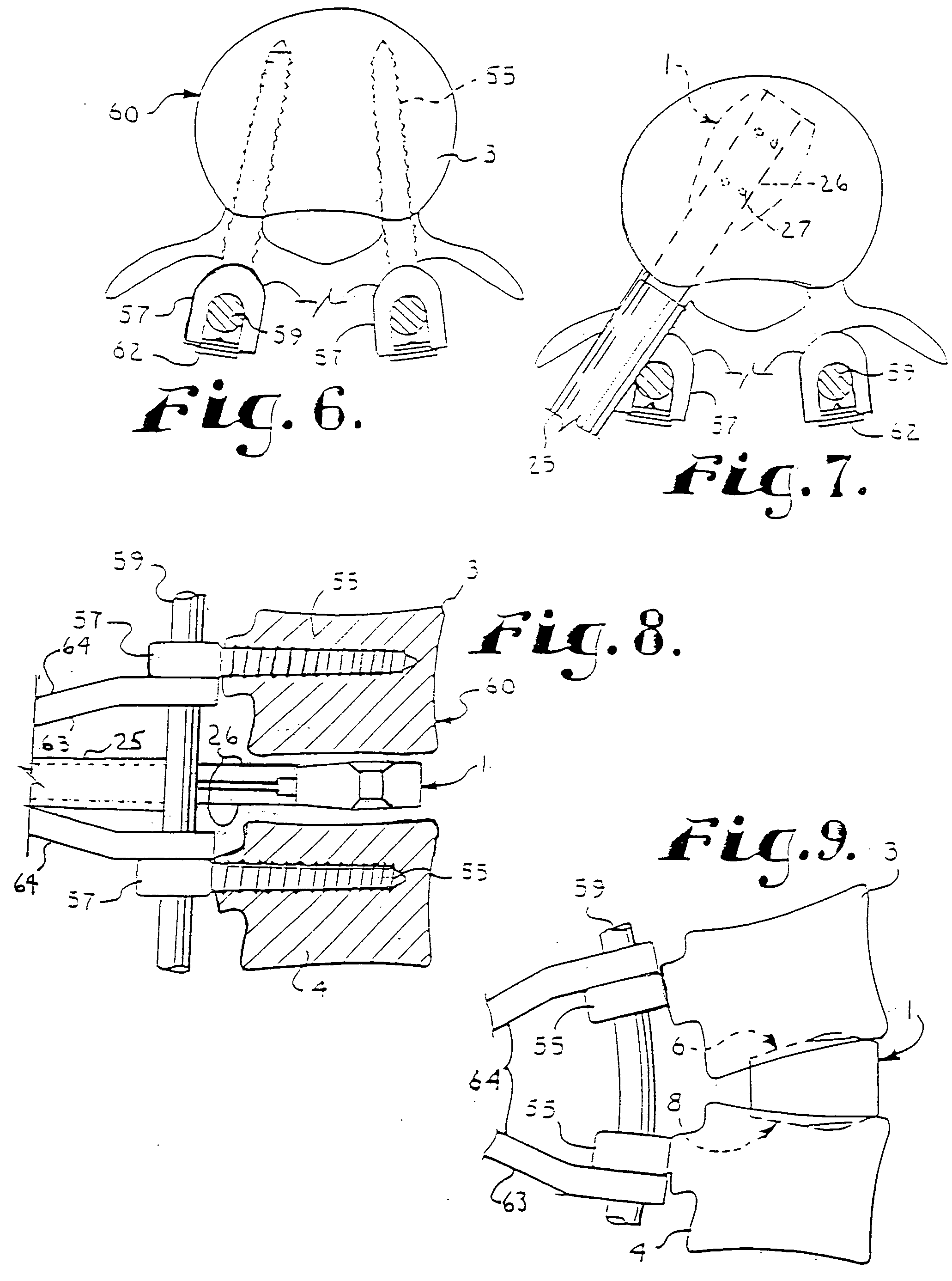

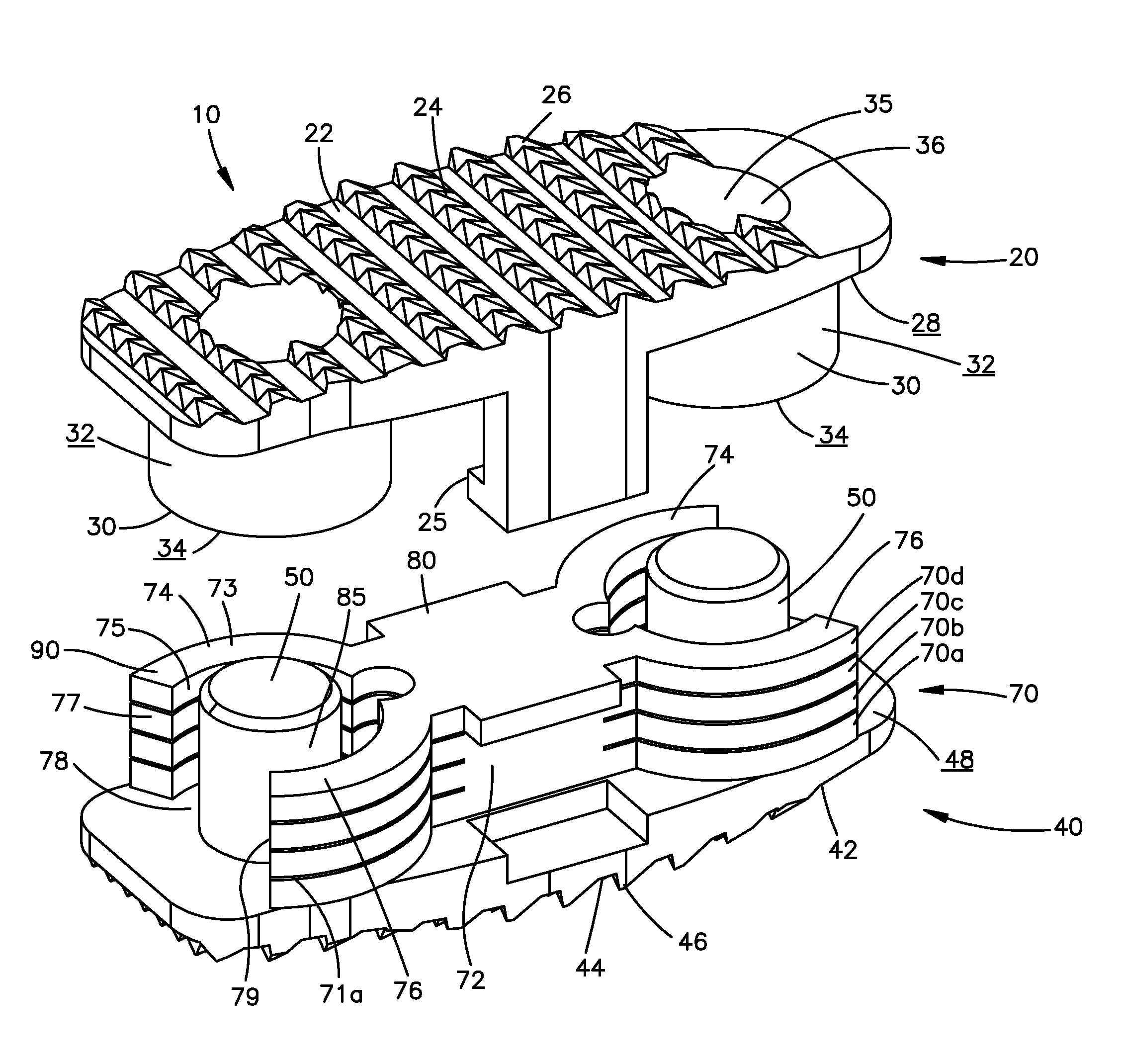

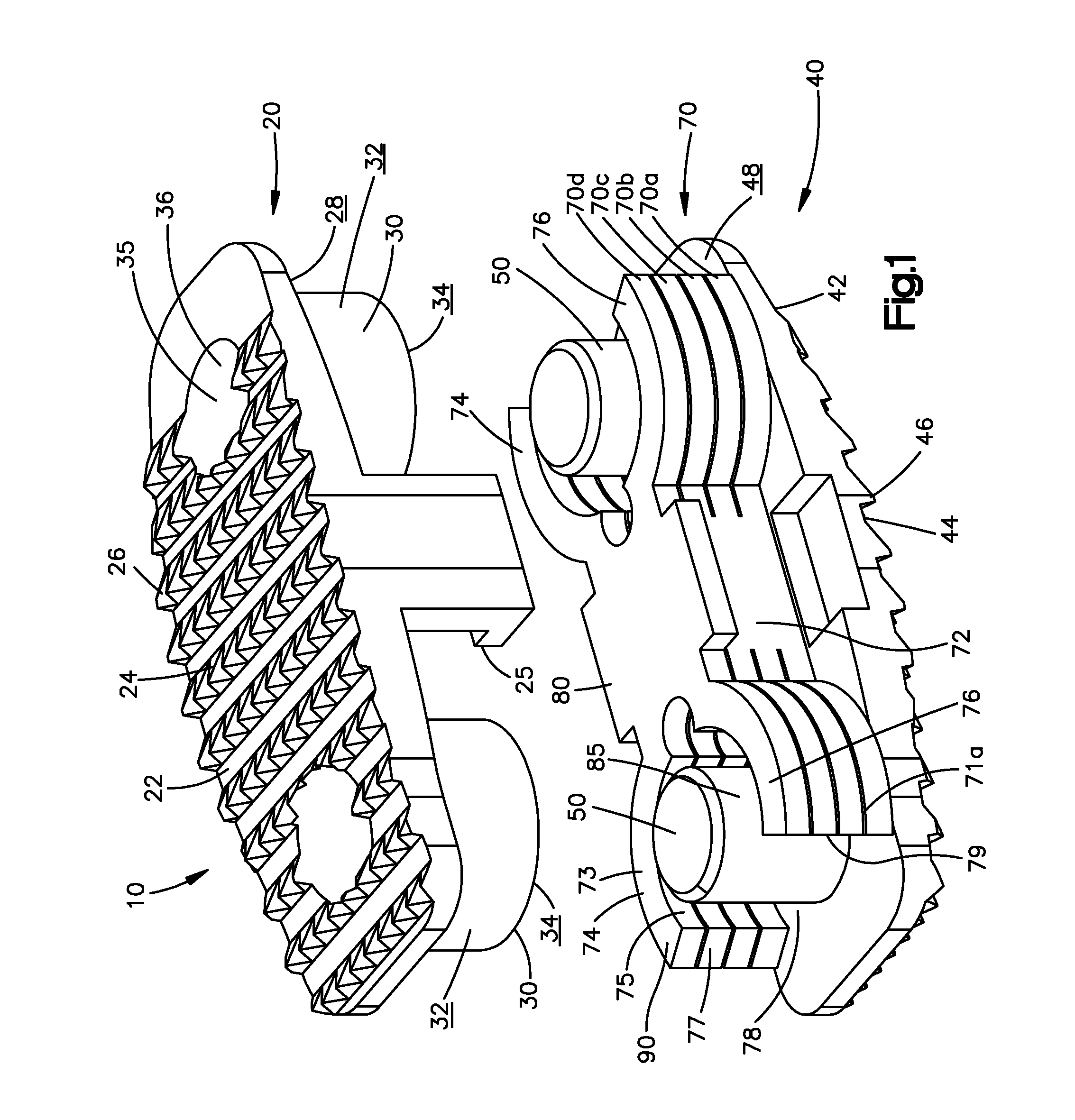

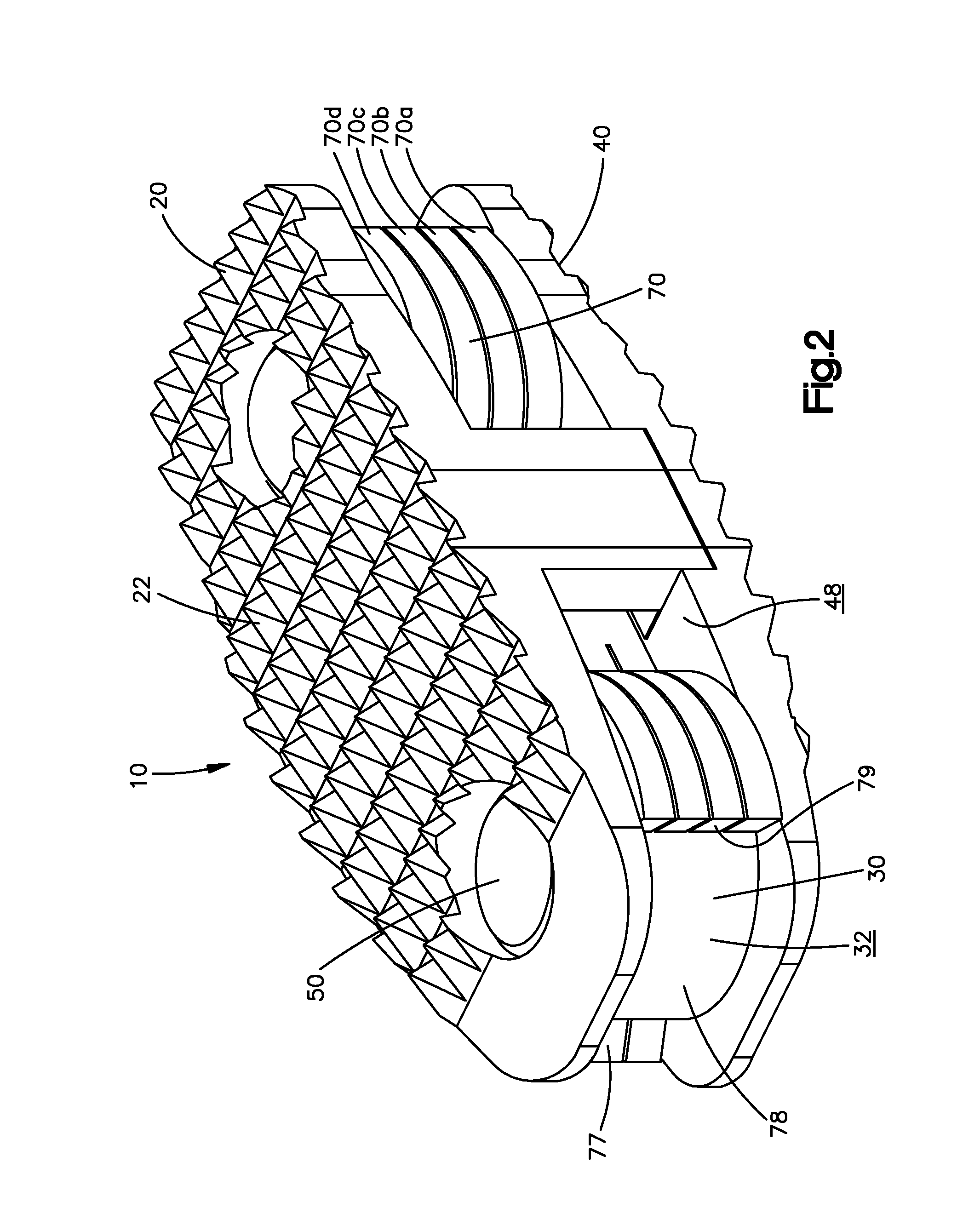

An intervertebral spacer device having a pair of opposing plates for seating against opposing vertebral bone surfaces, separated by at least one spring mechanism. The preferred spring mechanism is at least one belleville washer having radially spaced concentric grooves. In a preferred embodiment there is a single such belleville washer which is modified to mount onto a ball-shaped head. The lower plate of this embodiment includes a post extending upwardly from the inner surface of the plate, the post including a ball-shaped head. The modified belleville washer can be rotatably mounted to the head such that the wider portion of the washer seats against the upper plate.

Owner:HOWMEDICA OSTEONICS CORP

Spinal interbody spacer device

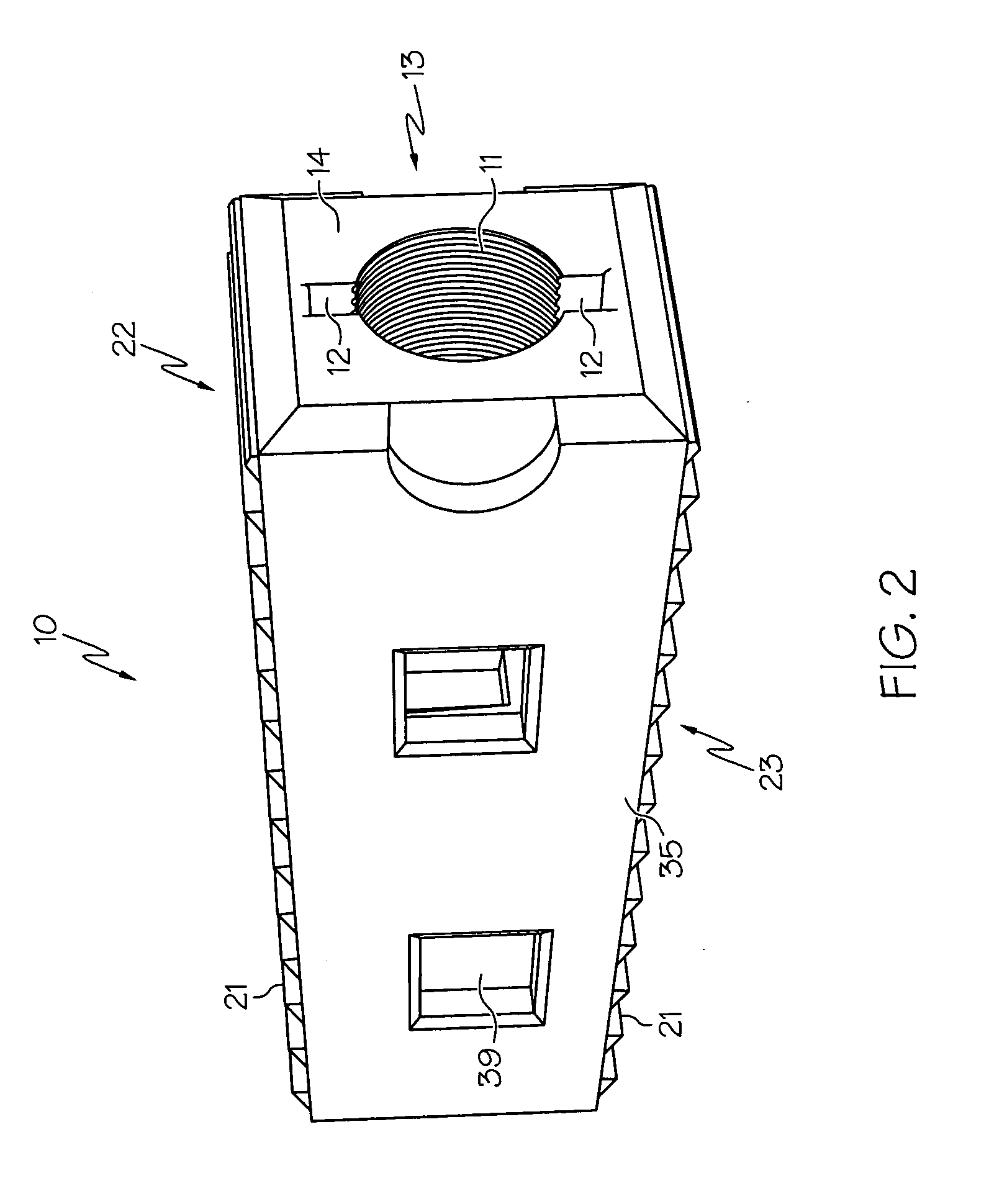

There is described an instrument set for use in spinal surgery that includes as elements a spinal body spacer, a placement tool, and an extraction tool. The spacer may be constructed with a body having a first wall and a second wall connected by a top face, a bottom face, and a lateral support. Further, the spinal body spacer has a threaded opening and keyways connected to the threaded opening positioned in a face. The spinal body spacer may also include a superior surface and an inferior surface with a plurality of antimigration furrows positioned on each of the superior surface and the inferior surface. The spacer may have an outer face positioned around the opening and the placement tool may also have a contact face such that the contact face comes into contact with the outer face when the placement tool is fully connected with the spacer. The placement tool has a threaded tip for connecting with the threaded opening of the spacer. The extraction tool has a tip configured to pass through the opening of the spacer, and the tool has tabs positioned on the tip such that the tabs pass through the keyways of the spacer. The extraction tool is configured such that it passes through the aperture, rotates, and then can be used to exert a pulling force on the spacer. The tip of the extraction tool may be a substantially blunt tip, a substantially pointed tip, or even a tip with a hollow area. The spacer may have at least one block disposed on an interior surface such that the block contacts the tabs of the extraction tool thereby restricting rotation of the extraction tool relative to the spacer. The spacer may have a backing plate, and the backing plate may itself include projections disposed in the matrix of the spacer.

Owner:THE CENT FOR ORTHOPEDIC RES & EDUCATION

Expandable interbody spacer device

Owner:DEPUY SYNTHES PROD INC

Slim spacer device and manufacturing method

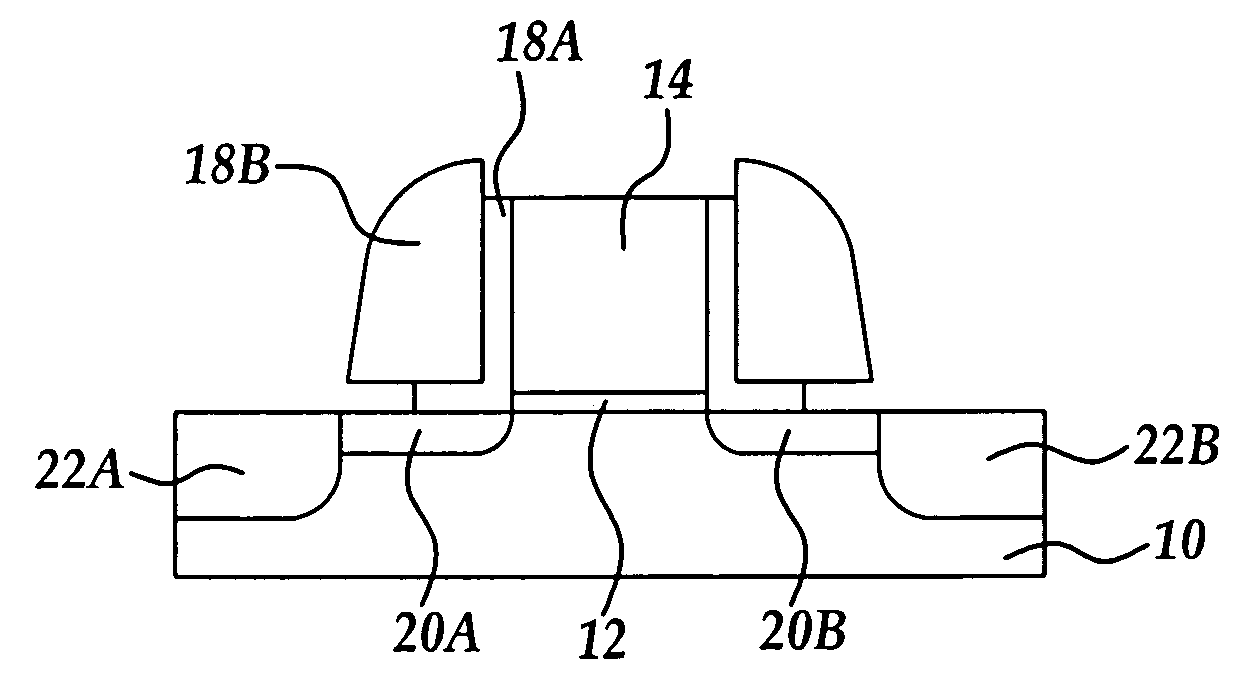

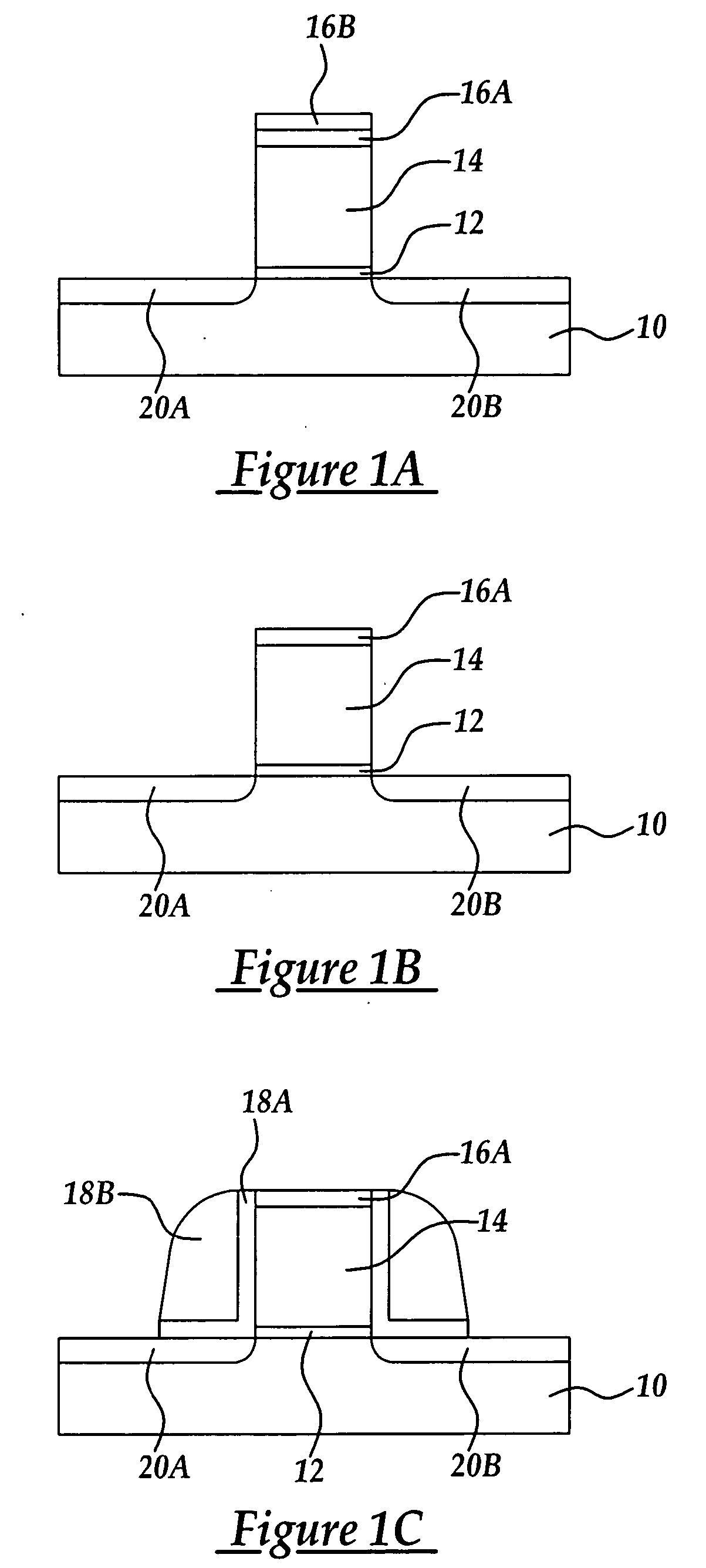

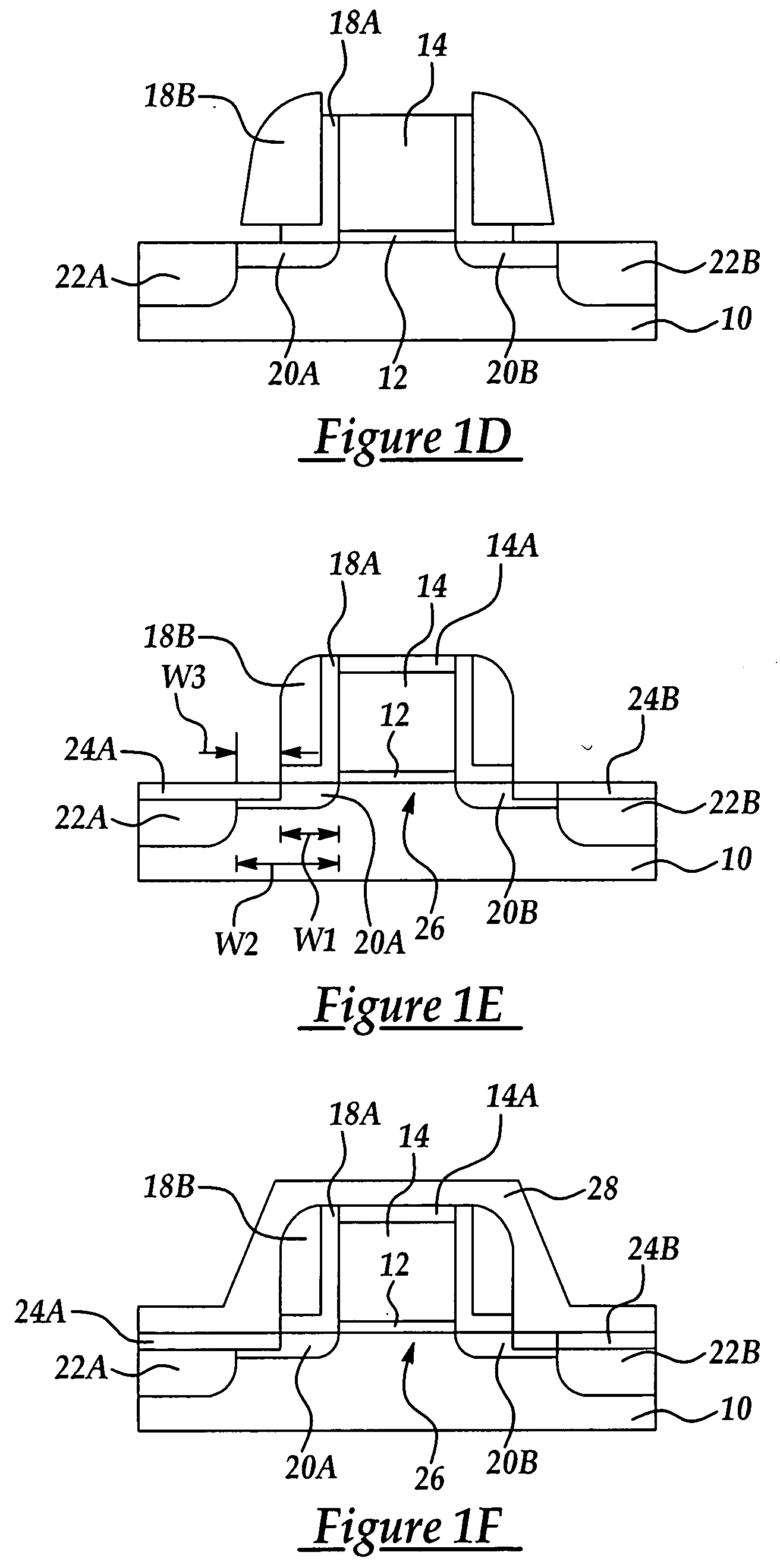

ActiveUS20050224867A1Reduce resistanceIncrease charge mobilityTransistorSemiconductor/solid-state device detailsCMOSSpacer device

A CMOS structure including a Slim spacer and method for forming the same to reduce an S / D electrical resistance and improve charge mobility in a channel region, the method including providing a semiconductor substrate including a polysilicon gate structure including at least one overlying hardmask layer; forming spacers selected from the group consisting of oxide / nitride and oxide / nitride oxide layers adjacent the polysilicon gate structure; removing the at least one overlying hardmask layer to expose the polysilicon gate structure; carrying out an ion implant process; carrying out at least one of a wet and dry etching process to reduce the width of the spacers; and, forming at least one dielectric layer over the polysilicon gate structure and spacers in one of tensile and compressive stress.

Owner:TAIWAN SEMICON MFG CO LTD

Intervertebral spacer device having a radially thinning belleville spring

InactiveUS7048763B2Reduce capacityAvoid skewJoint implantsSpinal implantsVertebral boneSpacer device

An intervertebral spacer device having a pair of opposing plates for seating against opposing vertebral bone surfaces, separated by a subassembly including a ball captured in a curvate volume, at least a portion of the curvate volume being formed in a convex element that is maintained against a first plate by a retaining wall and a retaining ring.

Owner:HOWMEDICA OSTEONICS CORP

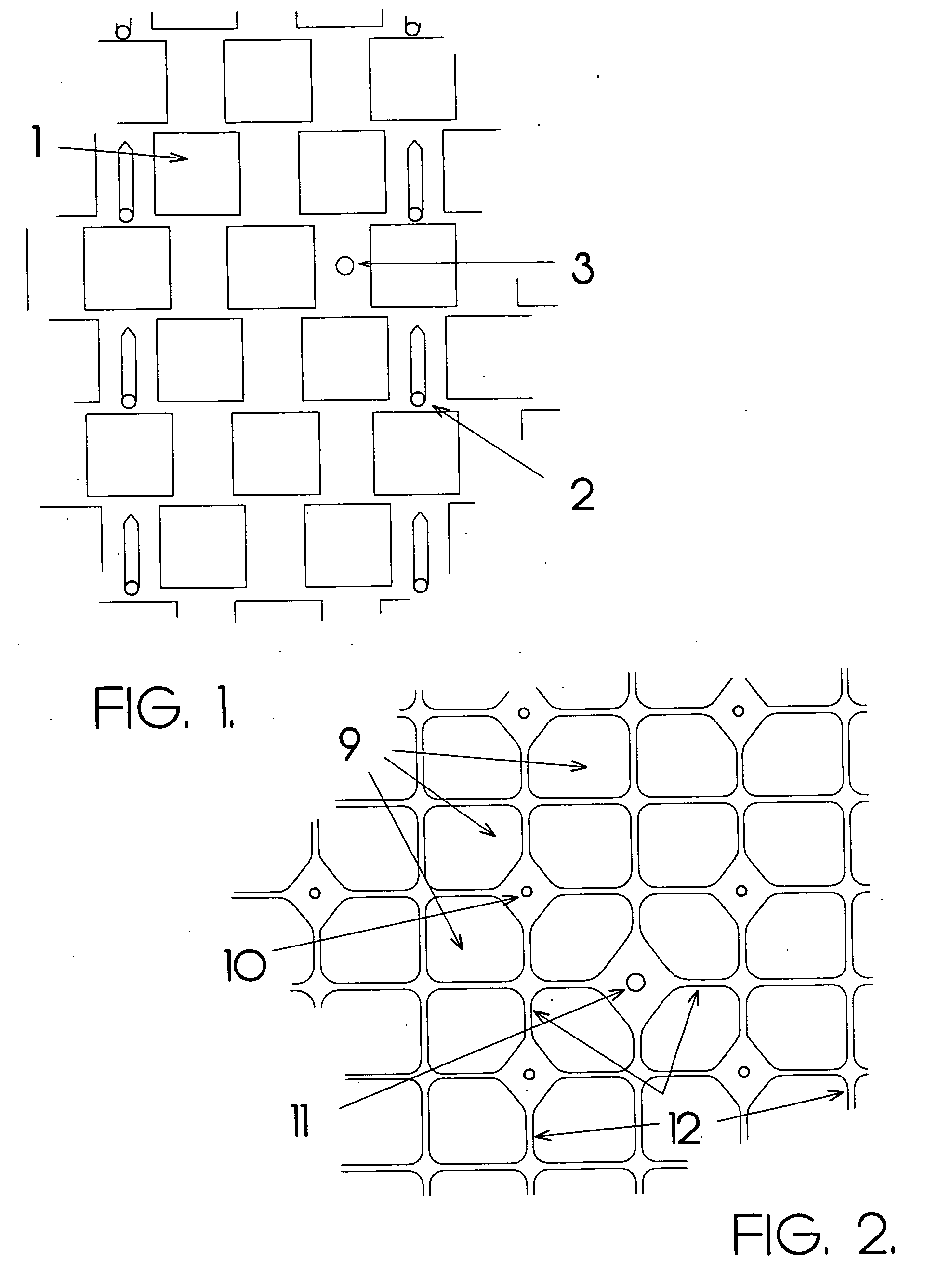

Adjustable tile spacing apparatus

InactiveUS6796049B1Uniform widthUsing mechanical meansBuilding constructionsEngineeringSpacer device

An adjustable tile spacing apparatus permits the setting tiles in a consistent pattern with perfect spacing relative to one another so as to obtain grout joints of uniform width. The adjustable tile spacing apparatus includes a central member and two perpendicular members at opposing ends of the central member, with each member adjustable in both width and length dimensions, via the use of telescoping members and fasteners. A spacer is affixed to each corner of the apparatus. The spacer can have an X-shape, a T-shape, an L-shape, or a linear shape. The spacers may be ¼ inch, 3 / 8 inch, and 1 / 8 inch in width to construct various sized grout line widths. A rubber handle with finger grips is provided for user comfort. The adjustable tile spacing apparatus is simply moved along as each tile is set and provides perfect spacing for the next tile to be set.

Owner:CLAXTON CURTIS

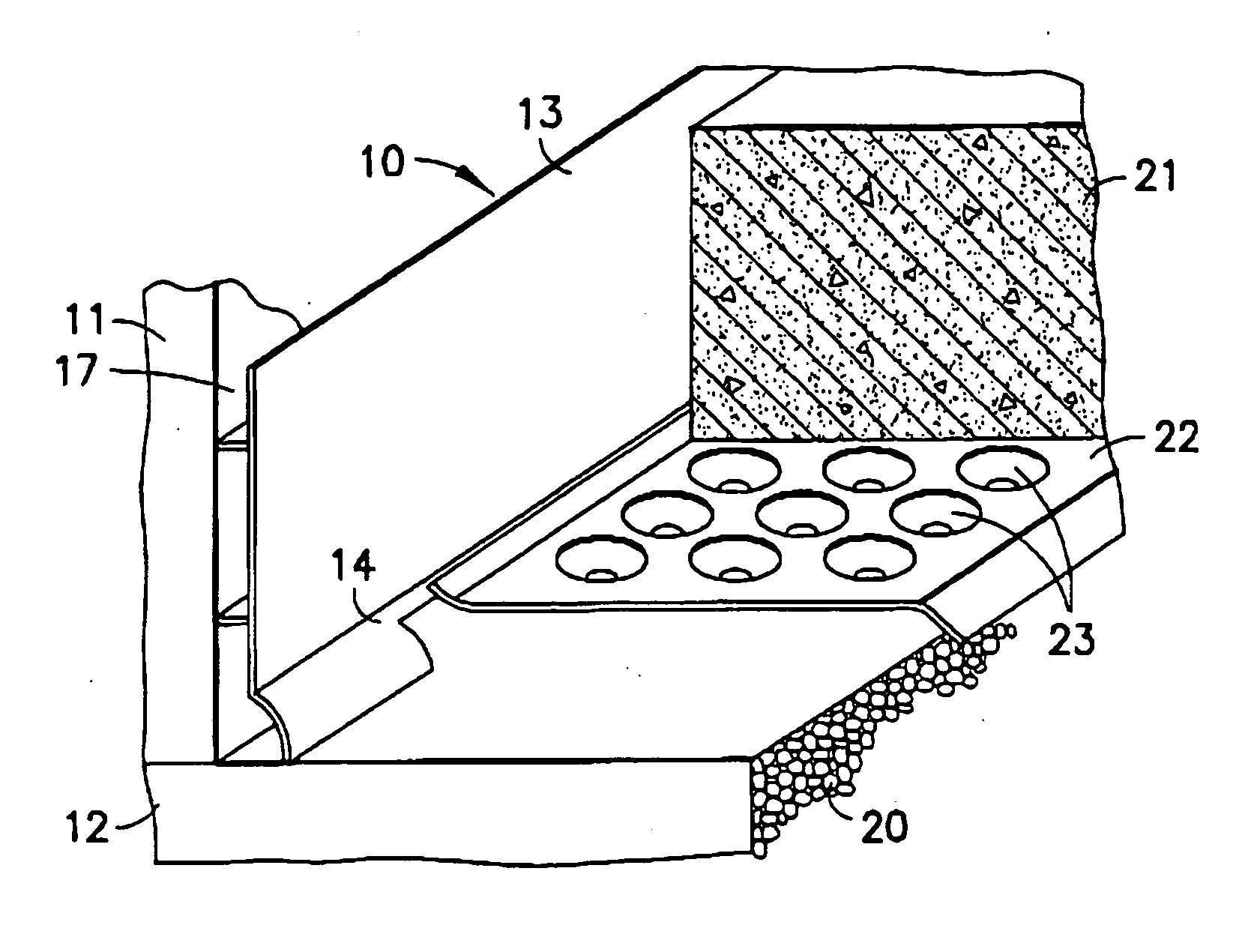

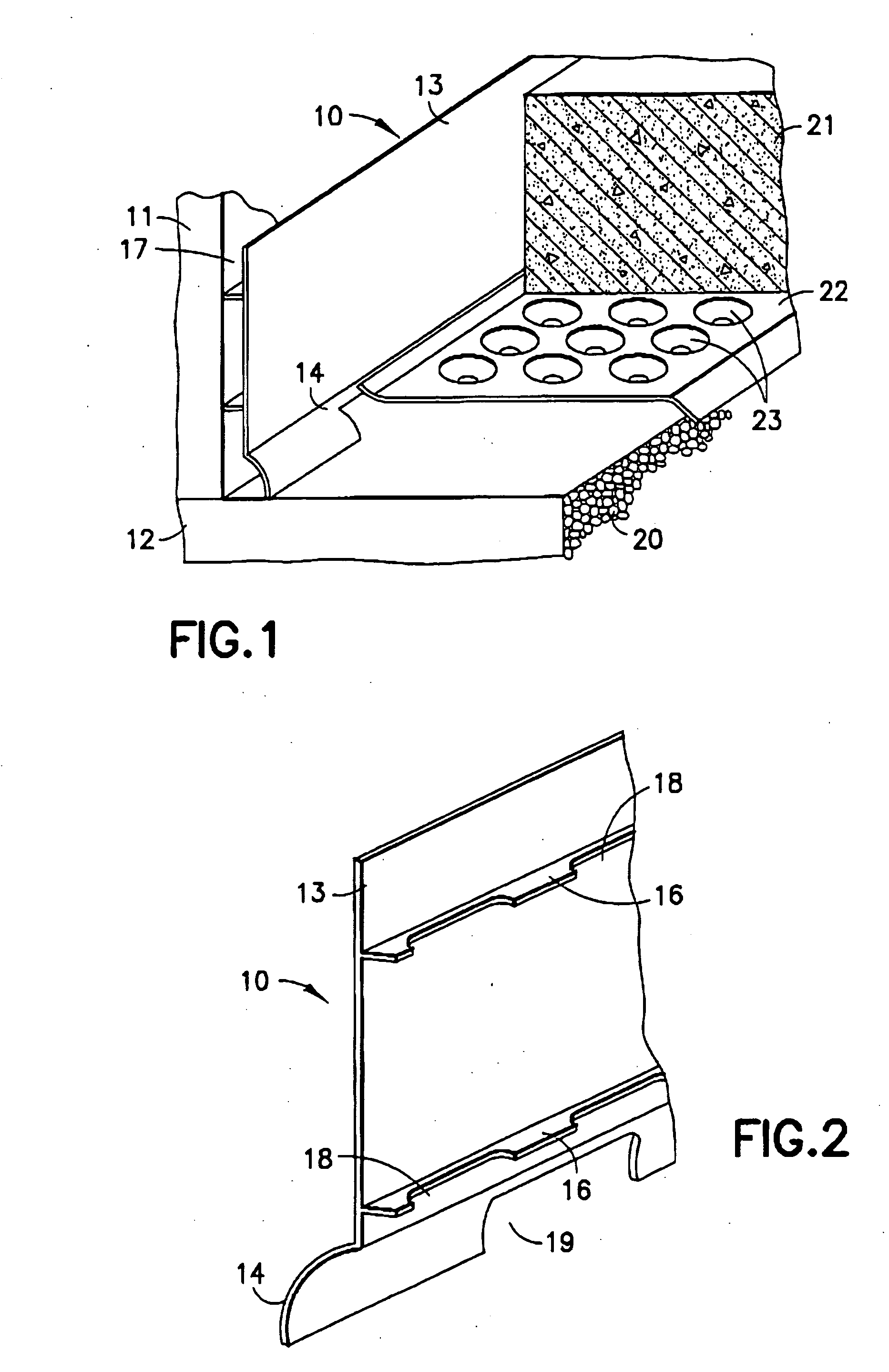

Wall and sub-floor water drain panel assembly for basement water-control

InactiveUS20050198916A1Smooth inner surfaceProtective foundationBuilding constructionsBasementWater leak

A drain panel assembly for the control of water leaking through a basement wall and / or entering a basement through the interface of a basement wall and a supporting footing. The assembly comprises a plastic drain panel having an upper panel section which extends vertically up from a lower skirt section. The upper panel section is positioned adjacent the basement wall and is closely-spaced therefrom by spacer means which are integral with the rear surface of the upper panel section to admit water running down the basement wall into the lower skirt section. The lower skirt section extends outwardly from the upper panel section and downwardly into contact with the supporting footing section to form a longitudinal water conduit which extends along the length of the footing and is open to the wall / footing interface to receive water therefrom. The water conduit enclosed by the skirt section is provided with a plurality of spaced openings along the footing for draining water therefrom outwardly over the footing into a drain tile.

Owner:JANESKY LAWRENCE M

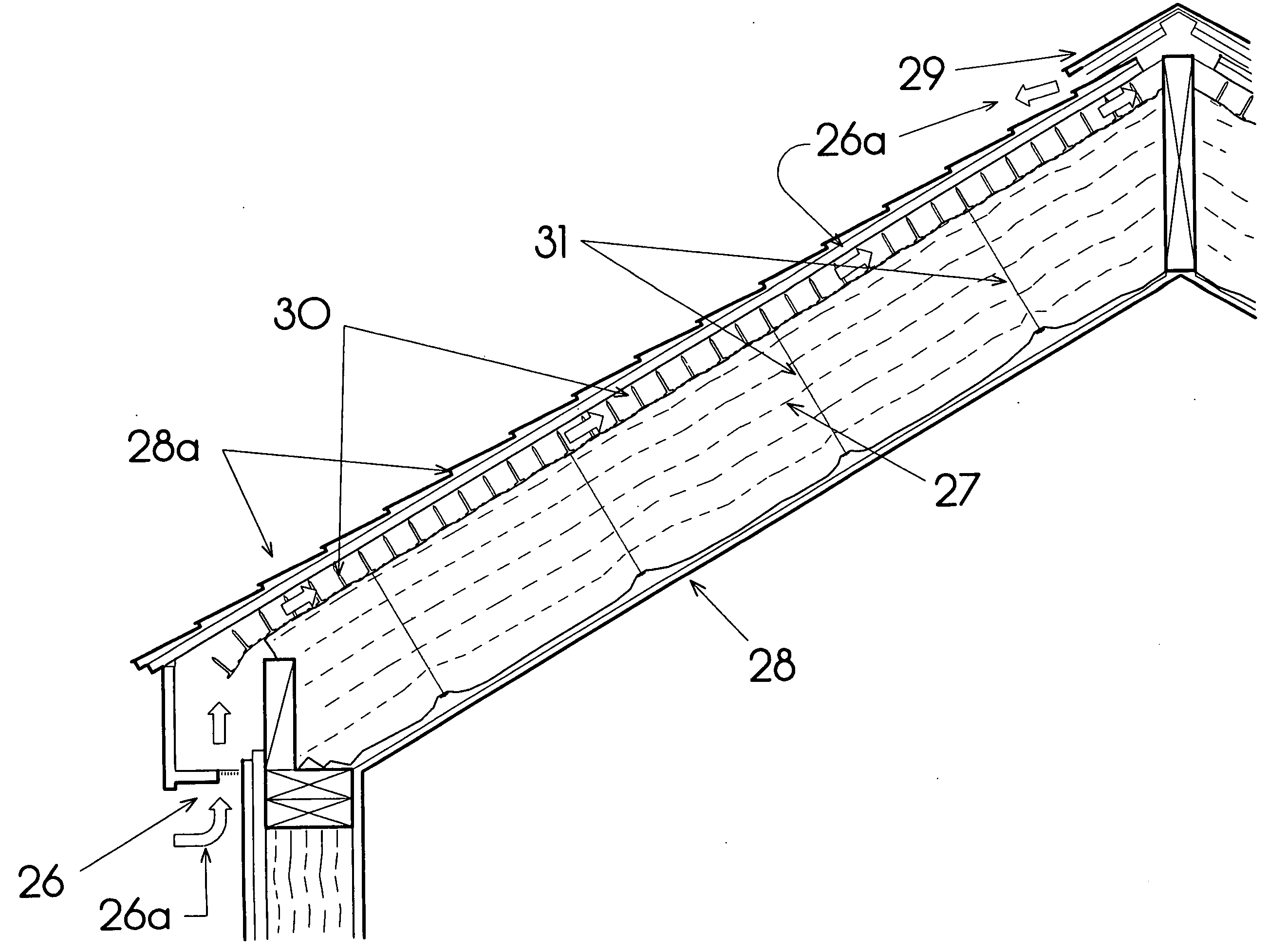

Low-obscuring tile installation spacer

InactiveUS7536802B1Prevent easy deformation and shiftingEasy to useUsing mechanical meansBuilding constructionsEngineeringSpacer device

The disclosure relates to tile-spacing devices for spacing tiles apart from one another during their installation, so as to create a space between the tiles, such as a space into which a grout, mortar, sealant, or other material can be inserted. Like previous tile-spacing devices, the devices described herein include one or more spacers disposed on a base. However, unlike previous devices, the devices described herein have a window that extends through the base, through which engagement of at least one of the tiles with the edge of a spacer can be visually observed.

Owner:TAVY ENTERPRISES

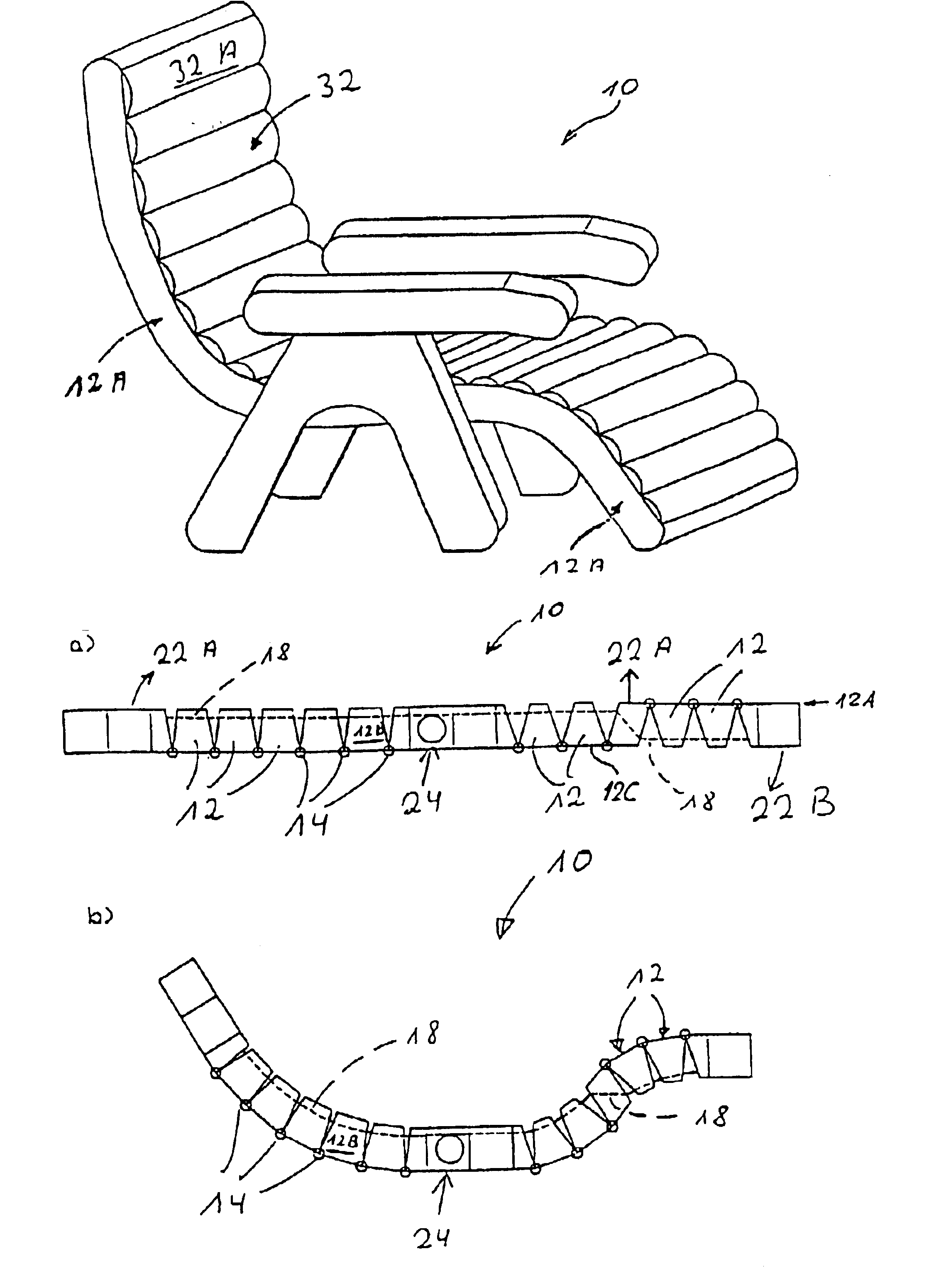

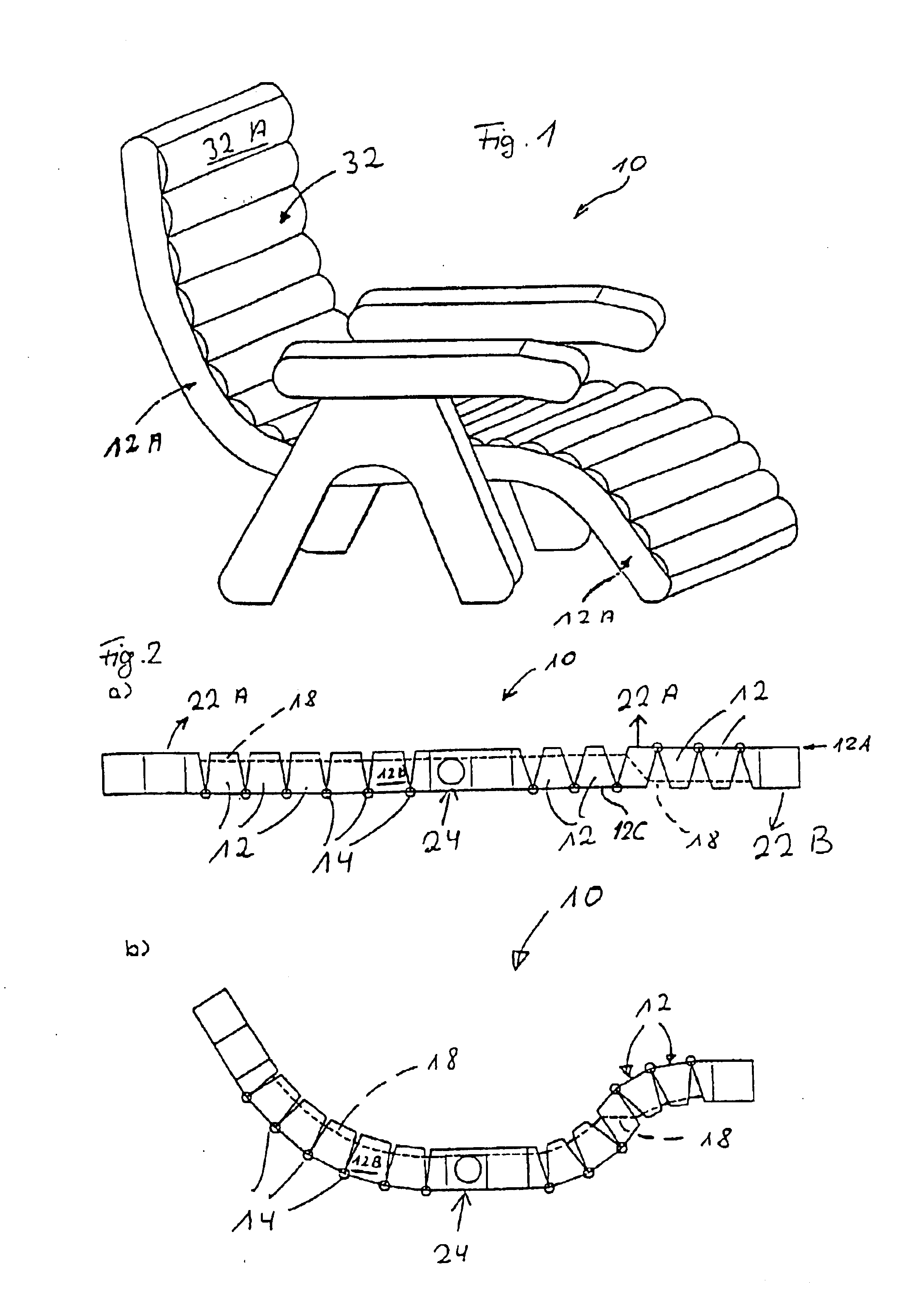

Adjusting device for beds, mattresses, seats and the like adjustable slatted bed-frames and adjustables seat or couch cushions

InactiveUS6877816B1Avoid great kinkingReduce the overall heightStuffed mattressesSpring mattressesEngineeringSpacer device

An adjustment device for beds, mattresses, seats and the like, which adjustment device includes several support elements extending across an adjustment direction and together spanning a support plane and at least one drive device for pivoting of support elements relative to each other for the purpose of a slope or trend change of the support plane. The support elements are provided with at least one mounting element extending across the support plane. Each mounting element is provided with a pivot joint in its first end region. Spacer devices are provided to maintain the spacing of adjacent mounting elements relative to each other in the region of the pivot joint. Spacing adjusters to change the spacing of adjacent mounting elements are provided on the region of the second ends of the mounting element opposite the pivot joints.

Owner:WESTMONT TECHN

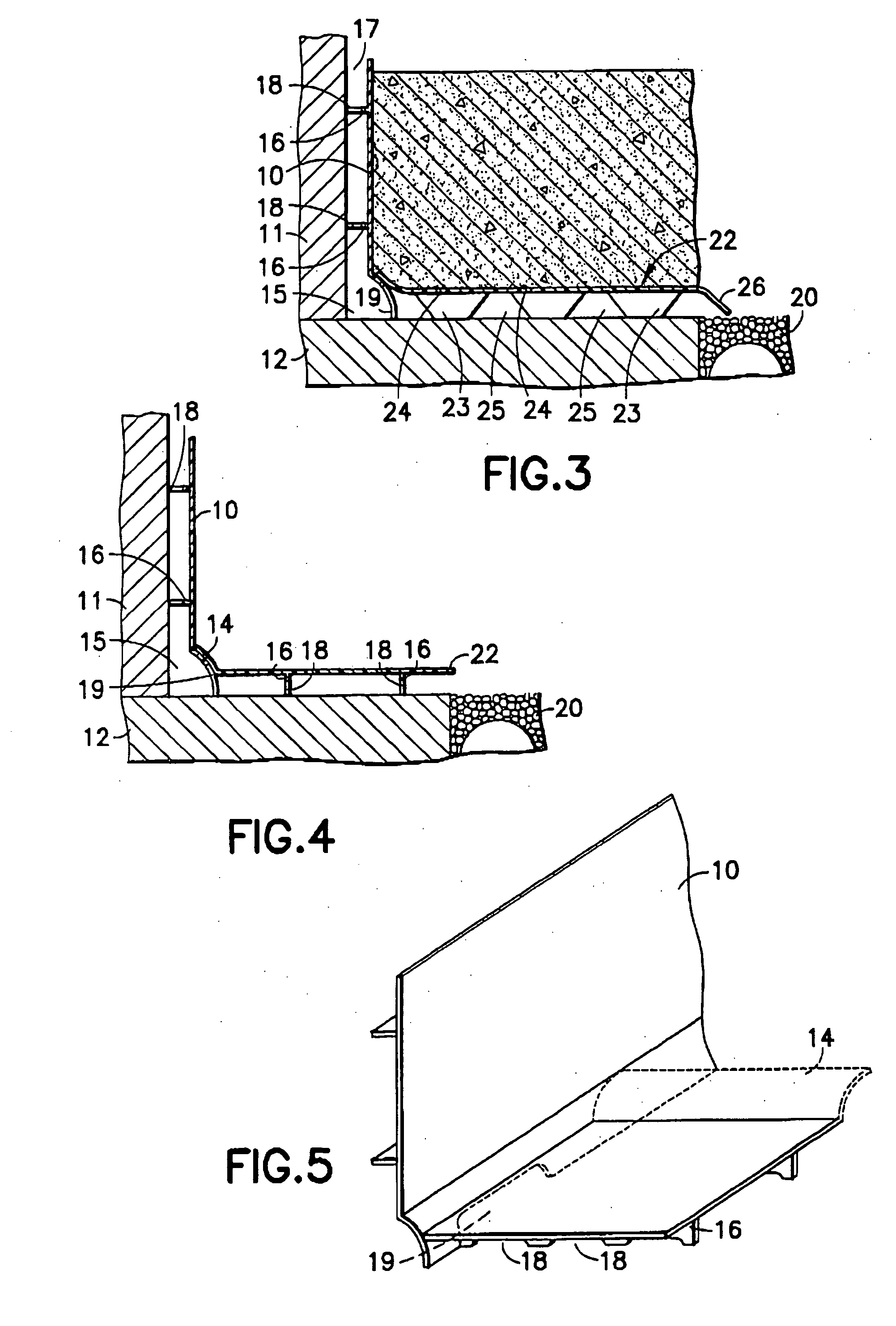

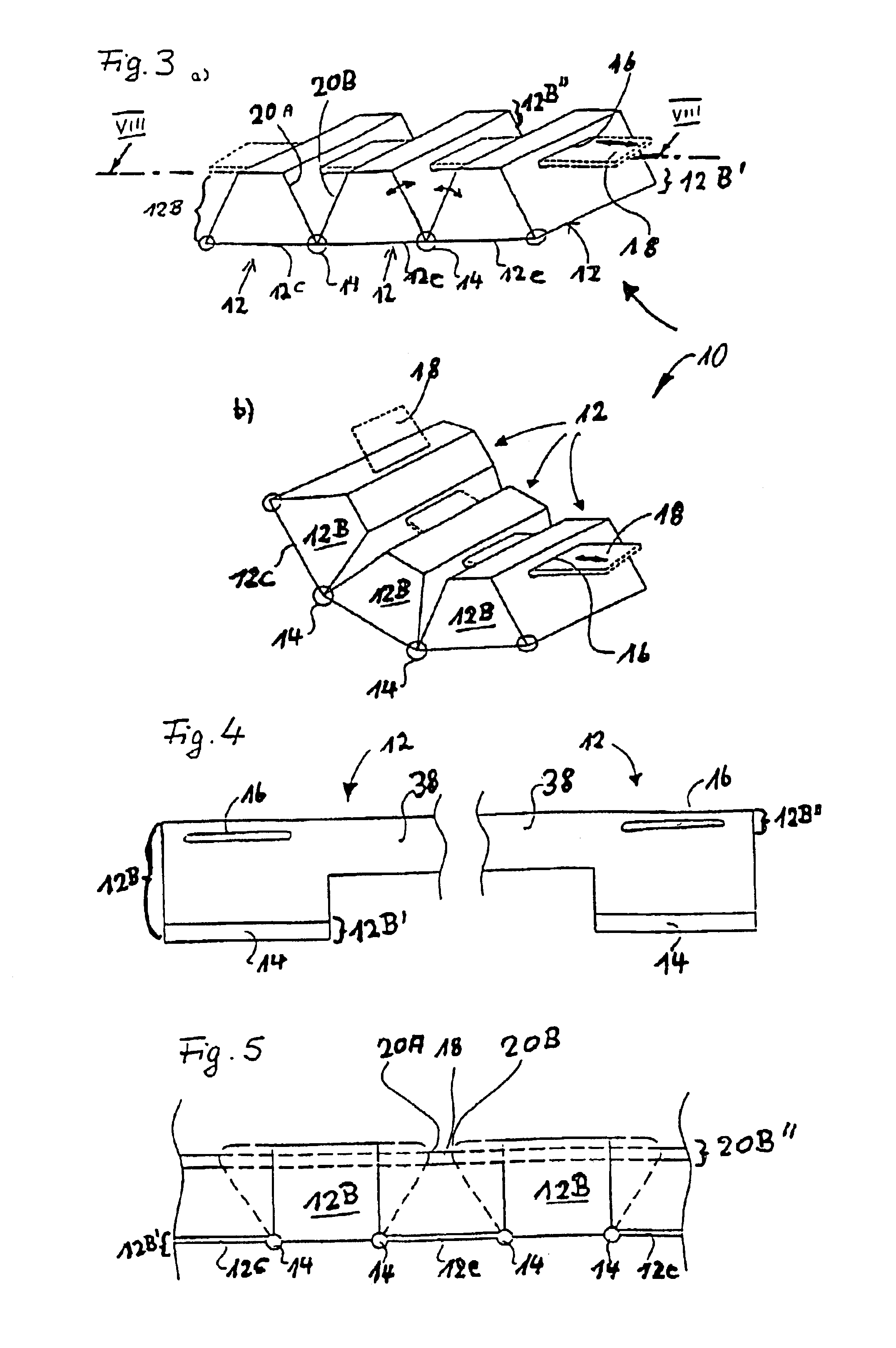

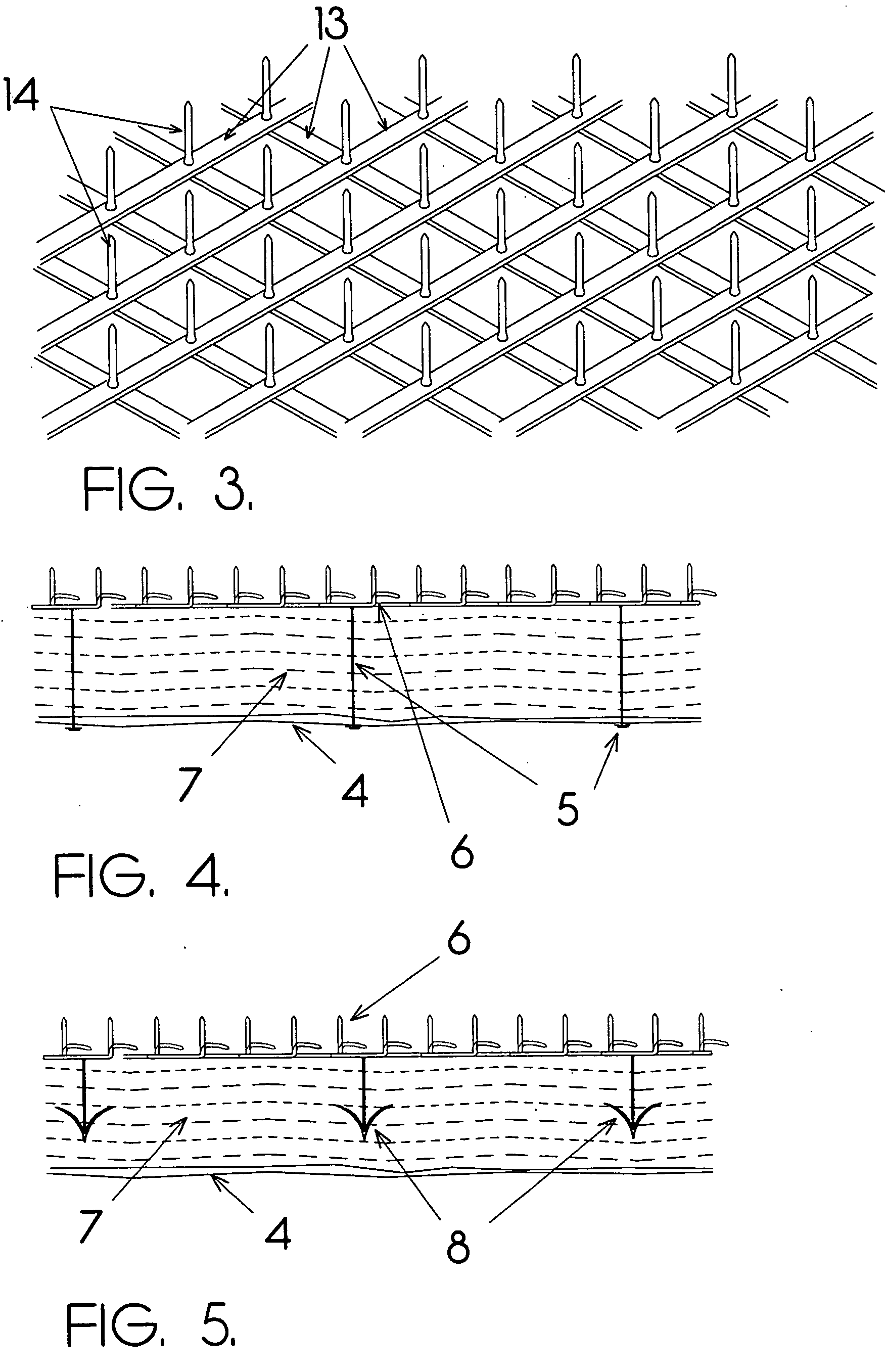

Device and method to provide air circulation space proximate to insulation material

A spacer device is provided including (1) a body having a plurality of openings defining an openwork, to allow the passage of air therethrough when placed in contact with insulation material, and (2) a plurality of spacer struts fixedly attached to the body. The struts are configured to maintain a predetermined distance between a first side of the insulation material and a building surface. The body and struts act together to define and maintain a space between the first side of the insulation material and the building surface, for example, for ventilation. The building surface can be the bottom face of a roof, an attic floor, wall sheathing or a soundproofed demising wall, for example. The spacer device can be capable of being transported and stored together with, or as a separate item from, the insulation material, and can also be stored in nested layers. The device can also be stored in rolled form. The openwork of the device can additionally or alternatively include a sheet of entangled net filaments.

Owner:HETTRICH HANSL

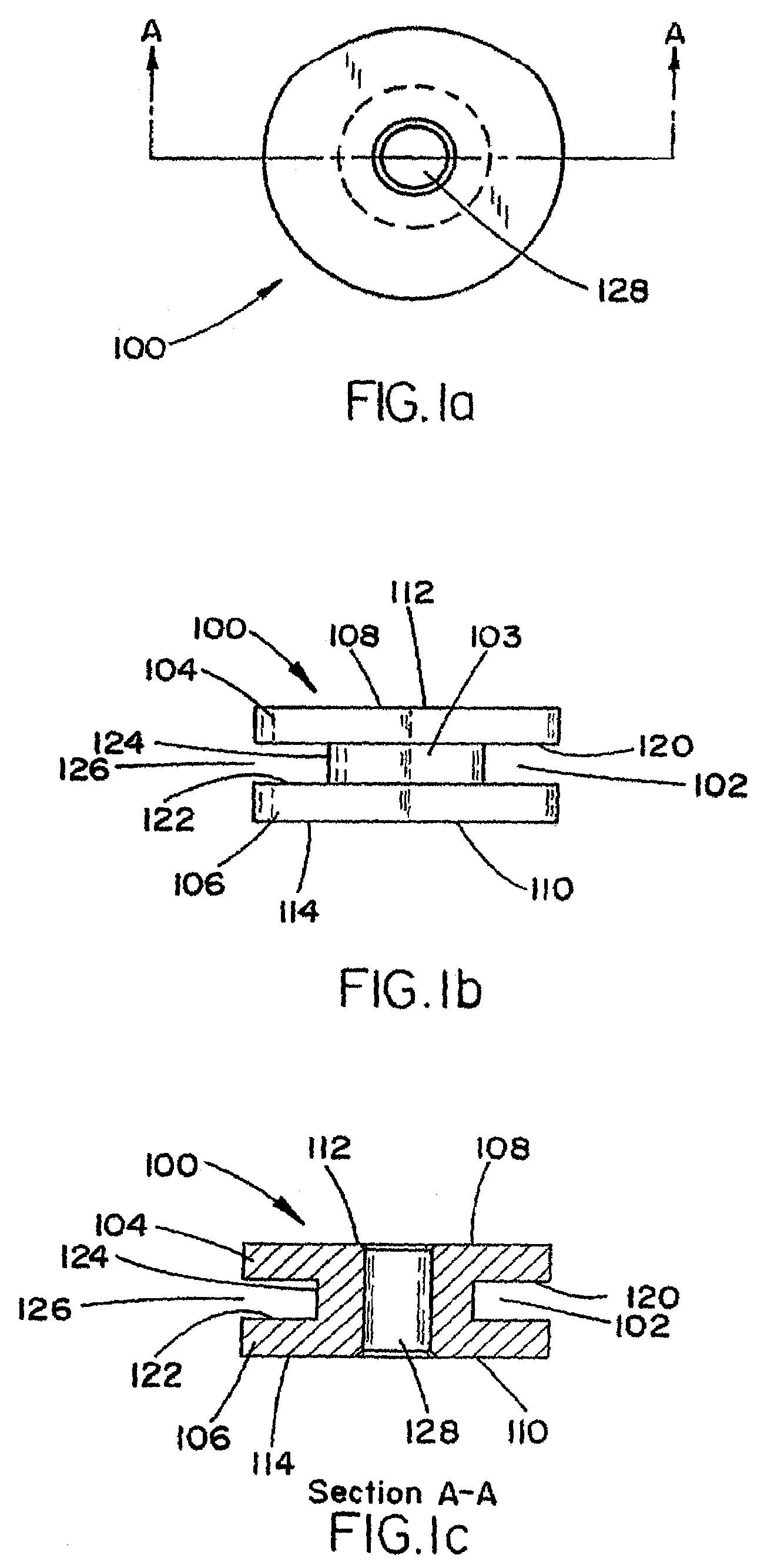

Intervertebral spacer device having a domed arch shaped spring

An intervertebral spacer device having a pair of opposing plates for seating against opposing vertebral bone surfaces, separated by a spring mechanism. The preferred spring mechanism is a domed arched strip spring which is coupled to the upper plate by set screws. The spring includes a socket formed in the peak thereof and mounts onto a ball-shaped head extending outwardly from the lower plate. The spring and post members are thereby flexibly coupled such that the upper and lower plates may rotate relative to one another.

Owner:HOWMEDICA OSTEONICS CORP

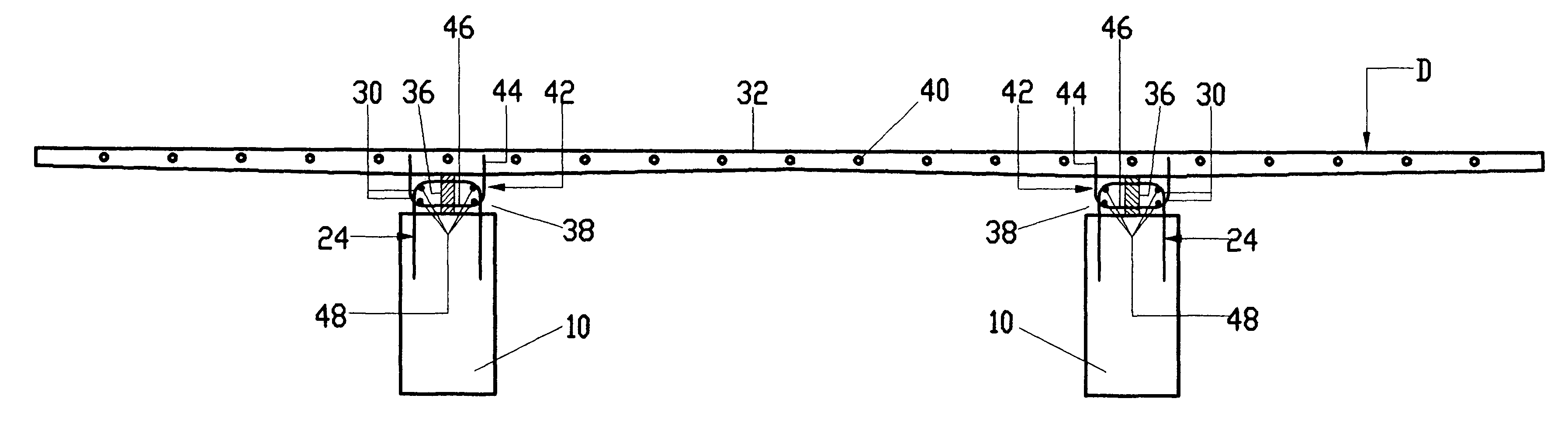

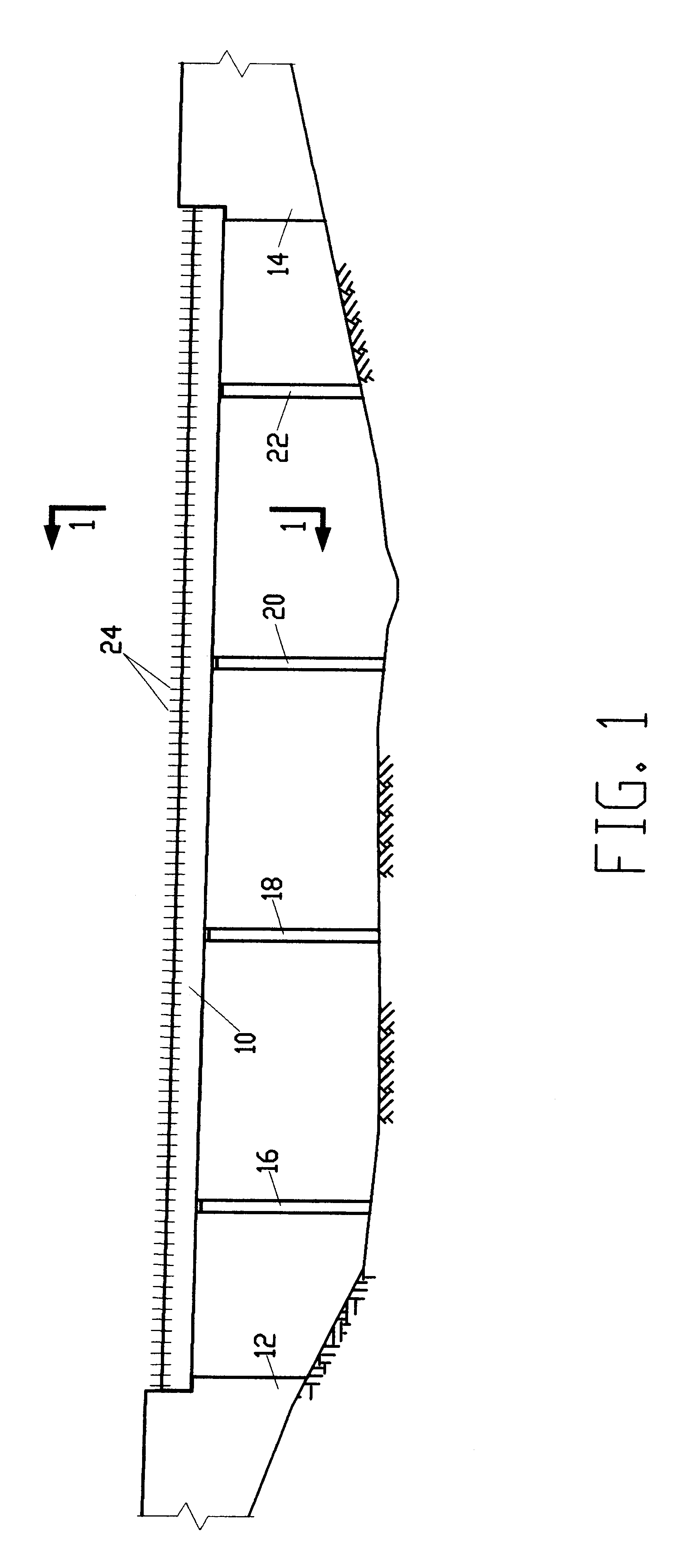

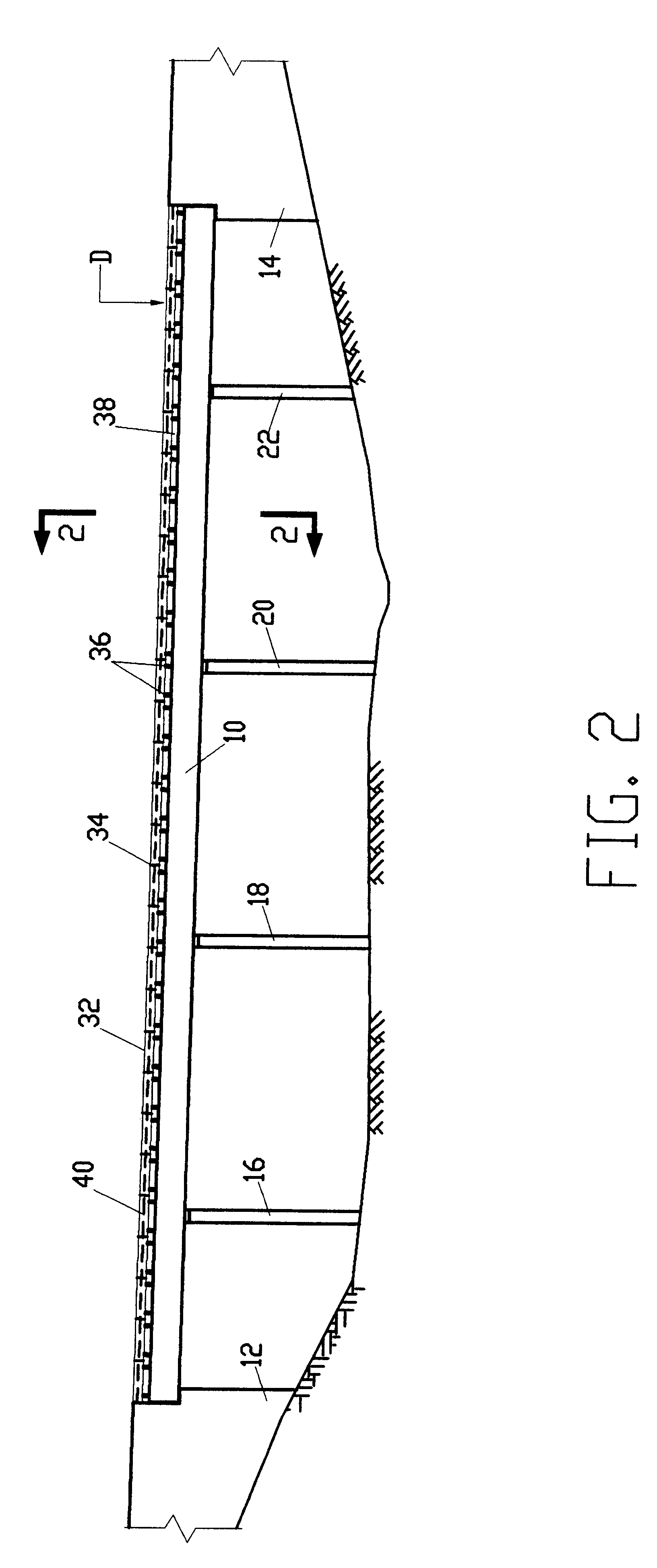

Composite bridge superstructure with precast deck elements

InactiveUS6470524B1Good ride qualitySaving maintenance costBridge structural detailsBridge erection/assemblyPre stressCrack free

A method for constructing a composite bridge superstructure of simple precast elements. According to the method, the bridge superstucture is comprised of one or more prestressed beams aligned substantially parallel to the bridge longitudinal axis. On top of the prestressed beams, there is placed a plurality of full width, precast deck slabs forming the bridge deck, with the precast deck slabs being transversely disposed side by side, with adjacent slabs attached by joints to complete the bridge deck structure. The deck slabs are spaced from the beams by spacing devices, such that a gap is left between the beams and the deck slabs and the bridge deck structure is prestressed separately from the beams. Subsequent to the prestressing of the deck structure and the beams, the bridge deck structure is connected to the beams by a concrete layer cast in situ in the gap between the bottom face of the precast deck slabs and the top face of the prestressed beams. The concrete is preferably of the low shrinkage type but normal shrinkage concrete may also be employed. The connection is further reinforced by a plurality of shear stirrups. The method is characterized by separate prestressing of the deck structure and the beams and by natural compression of the connecting concrete layer resulting in significant savings of construction time and costs. The construction sequence according to the method enables the deck structure as well as the cast in place concrete layer connecting the deck structure to the beams to undergo a natural compressing process due to time dependent creep and shrinkage contraction of the beams relative to the connecting layer and the deck structure, thereby eliminating the need to apply additional prestressing. In addition, the substantially separate longitudinal prestressing of the deck structure and the beams is highly effective, achieving considerable saving of prestressing steel. The natural compressing of the deck structure and the cast-in-place concrete layer result in crack-free condition and better riding quality of the deck, thereby eliminating the well known drawbacks of additional prestressing, and saving maintenance costs.

Owner:MAIRANTZ BENJAMIN

Interspinous process spacer device including a rotatable retaining member

A spacer device that is to be inserted between the spinous process of adjacent vertebrae. In one embodiment, the spacer device is percutaneously inserted between the spinous process of adjacent vertebrae using minimally invasive surgical procedures. The spacer device includes a body portion having a channel extending therethrough, a plate member attached at one end of the body portion that is larger cross-wise than the body portion, and at least one retaining member attached proximate to an opposite end of the body portion from the plate member. The spacer device is inserted between the spinous process with the retaining member stored within the body portion. A deploying device is inserted into the channel to deploy the retaining member to lock the spacer device in place.

Owner:MI4SPINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com