Wall and sub-floor water drain panel assembly for basement water-control

a sub-floor and water-control system technology, applied in foundation engineering, protective foundations, constructions, etc., can solve problems such as clogging resistance, drainage capacity in both lateral and longitudinal directions, and narrowing or closing water-escape channels between panels and walls and/or the surface of footings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

(s)

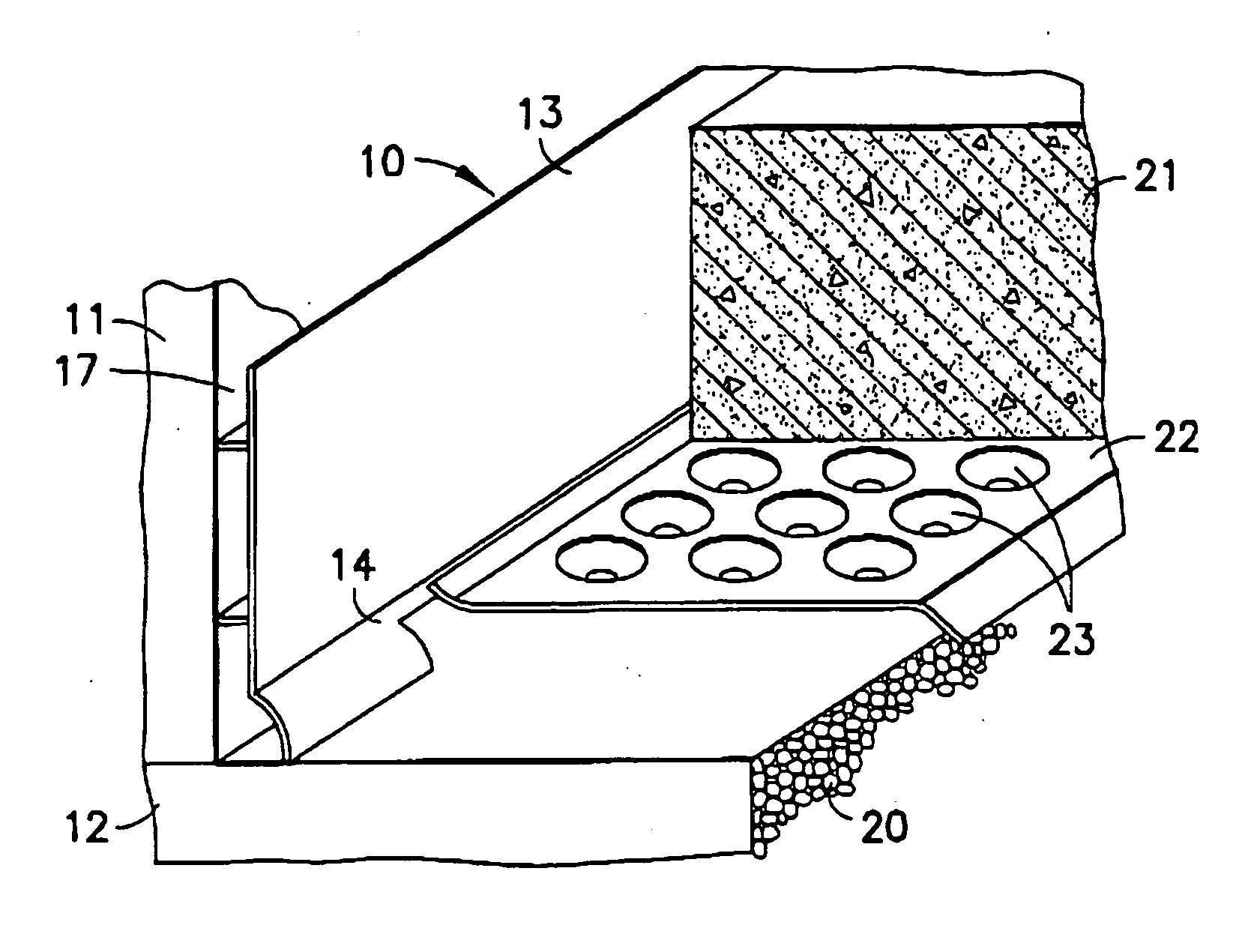

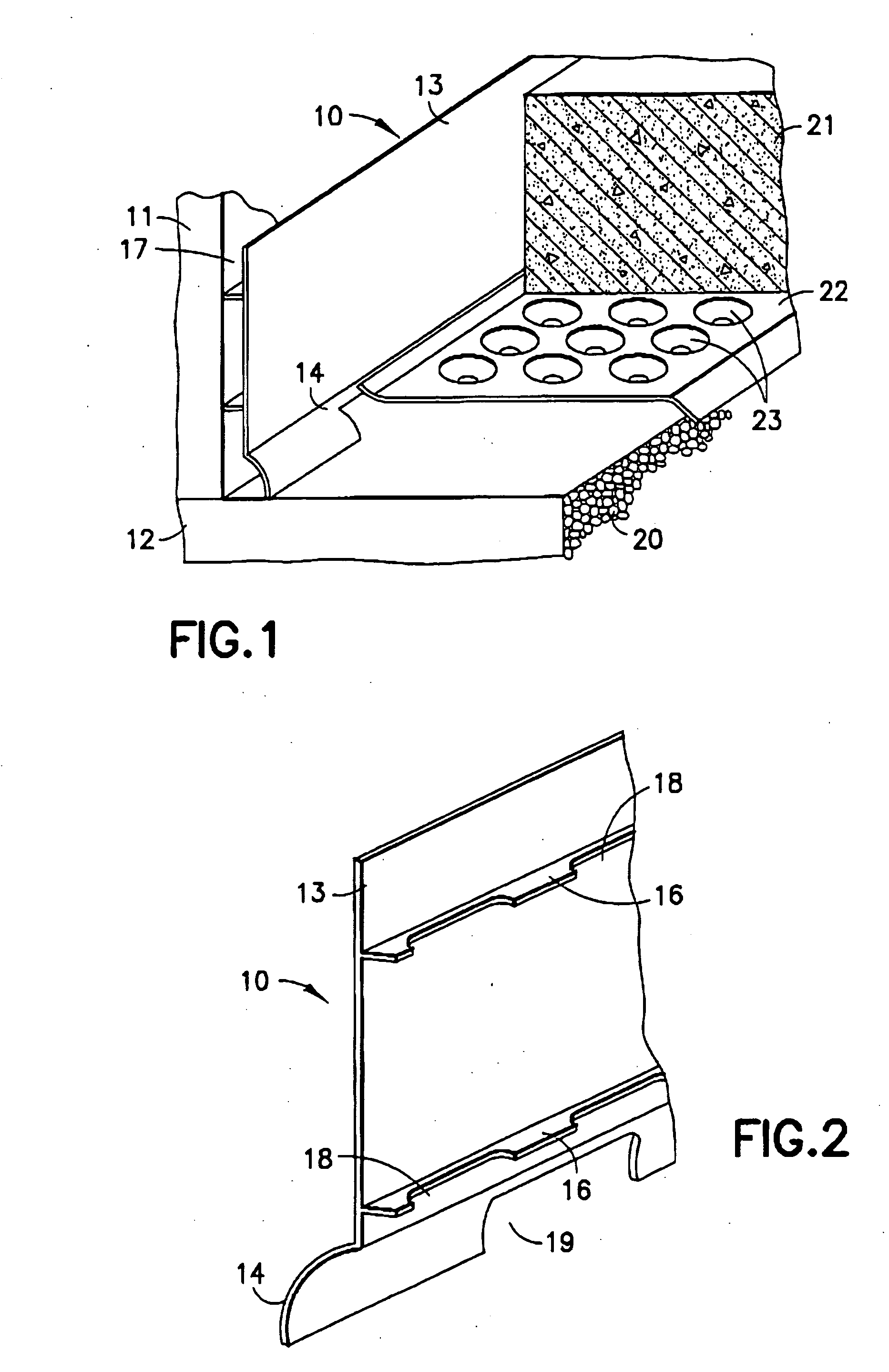

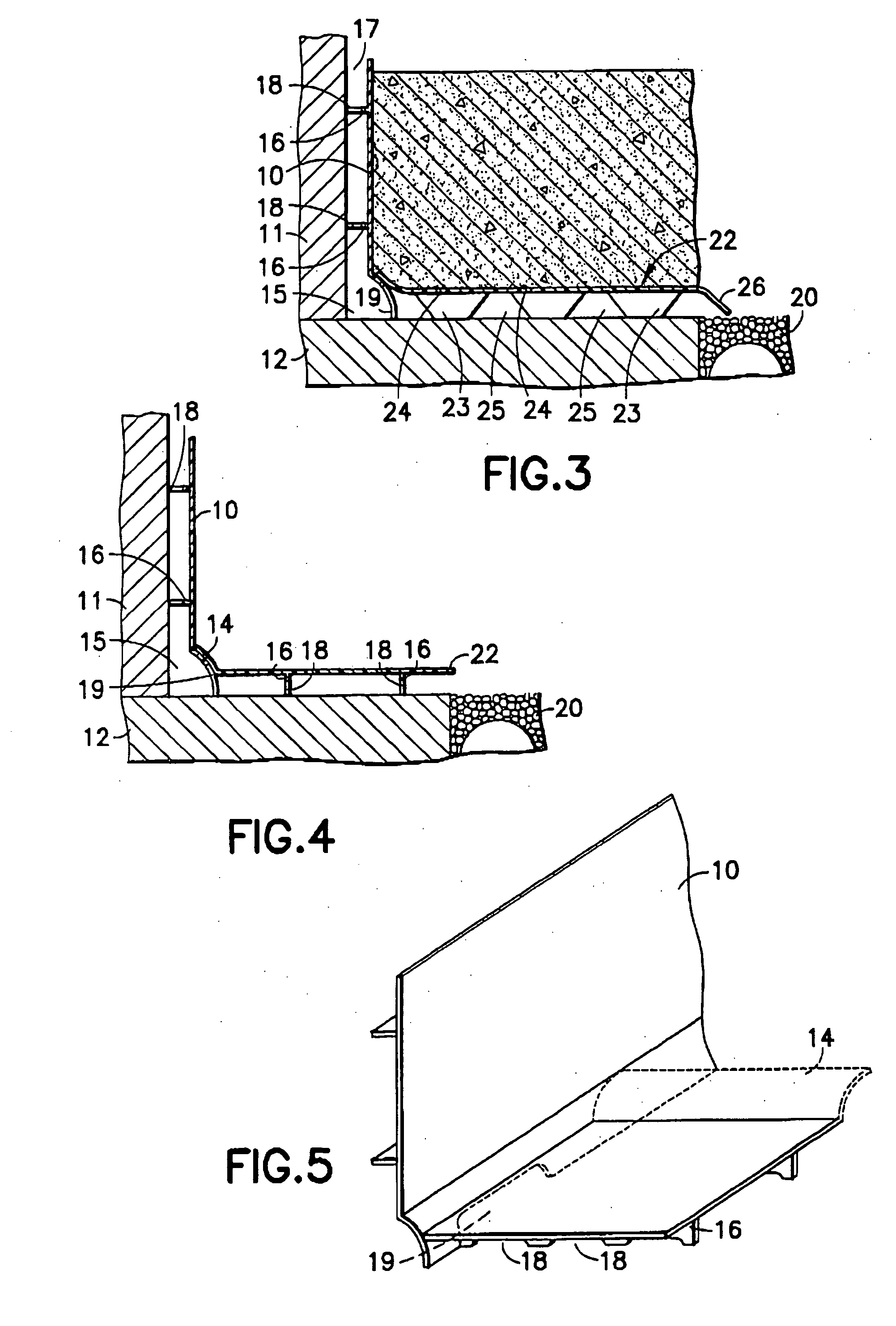

[0017] Referring to FIGS. 1 and 2 of the drawings, the present wall and sub-floor water drain panel 10 is a strong, flexible, semi-rigid panel molded from a suitable plastic composition, such as a polystyrene, polyethylene, polyvinyl chloride, nylon or acrylonitrile-butadiene-styrene polymer (ABS) in a flat shape so as to lay flat against a basement wall 11 and stand on the supporting concrete footing 12 at the wall / footing interface as illustrated by FIGS. 1 and 3. The panel 10 has an upper, vertical wall-engaging section 13 and a lower skirt section 14 which curves or projects outwardly from vertical to form a horizontal water drainage conduit portion 15 adjacent the wall footing interface, which enables water which enters from the interface to be confined and to flow along the length of the footing 12. The drain panel 10 is also provided with or molded with spaced stand-off ribs 16 or spacer ribs which support the panel in spaced position against the surface of the basement wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com