Fiber reinforced plastic cylinder with interior spiral reinforcing bar and method for manufacturing the same

A fiber-reinforced plastic and internal spiral technology, applied in the direction of the barrel, can solve the problems of complex molding process, long processing cycle, and micro-cracks in the barrel, and achieve the effect of simple process, high production efficiency, and anti-leakage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

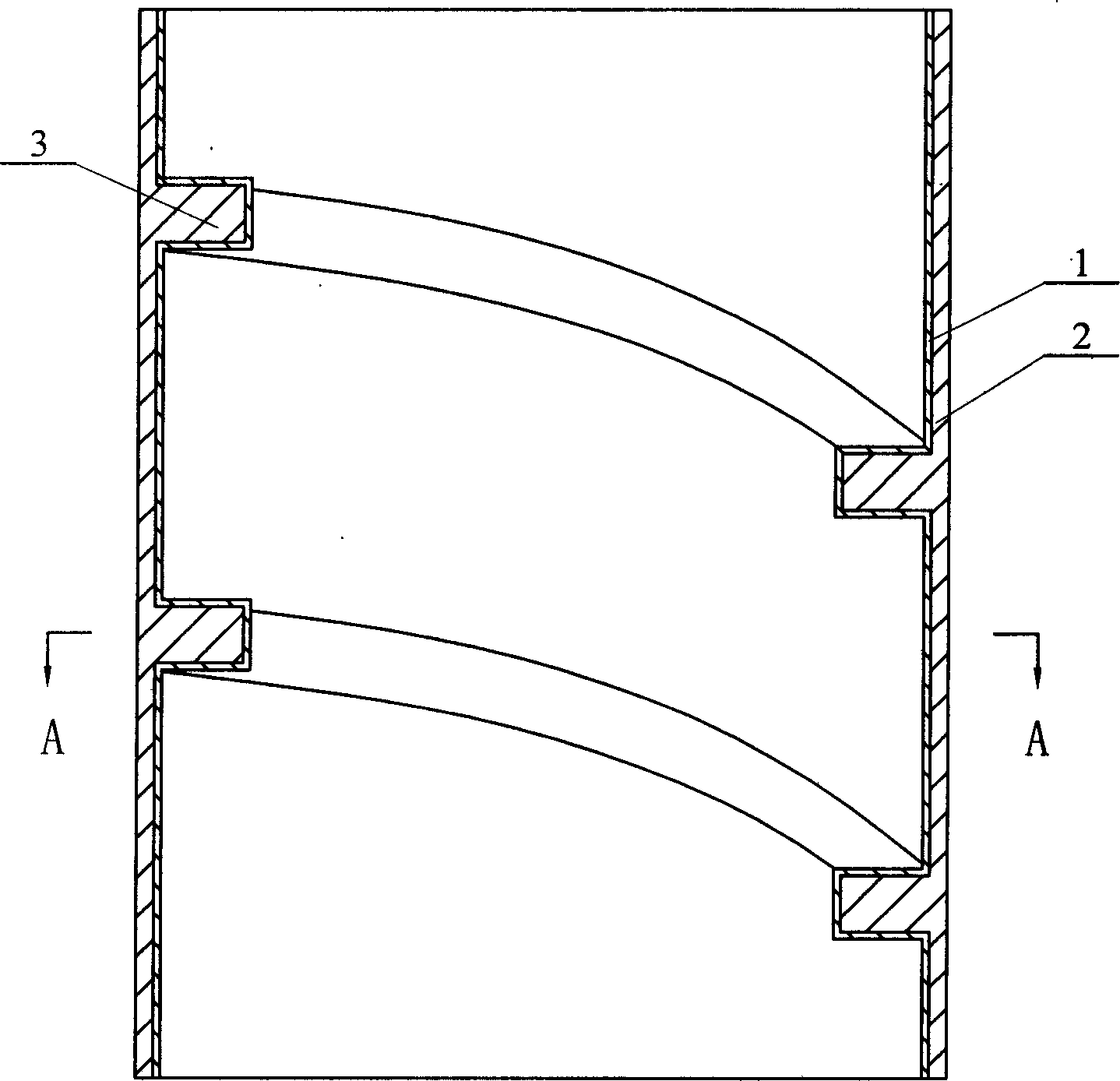

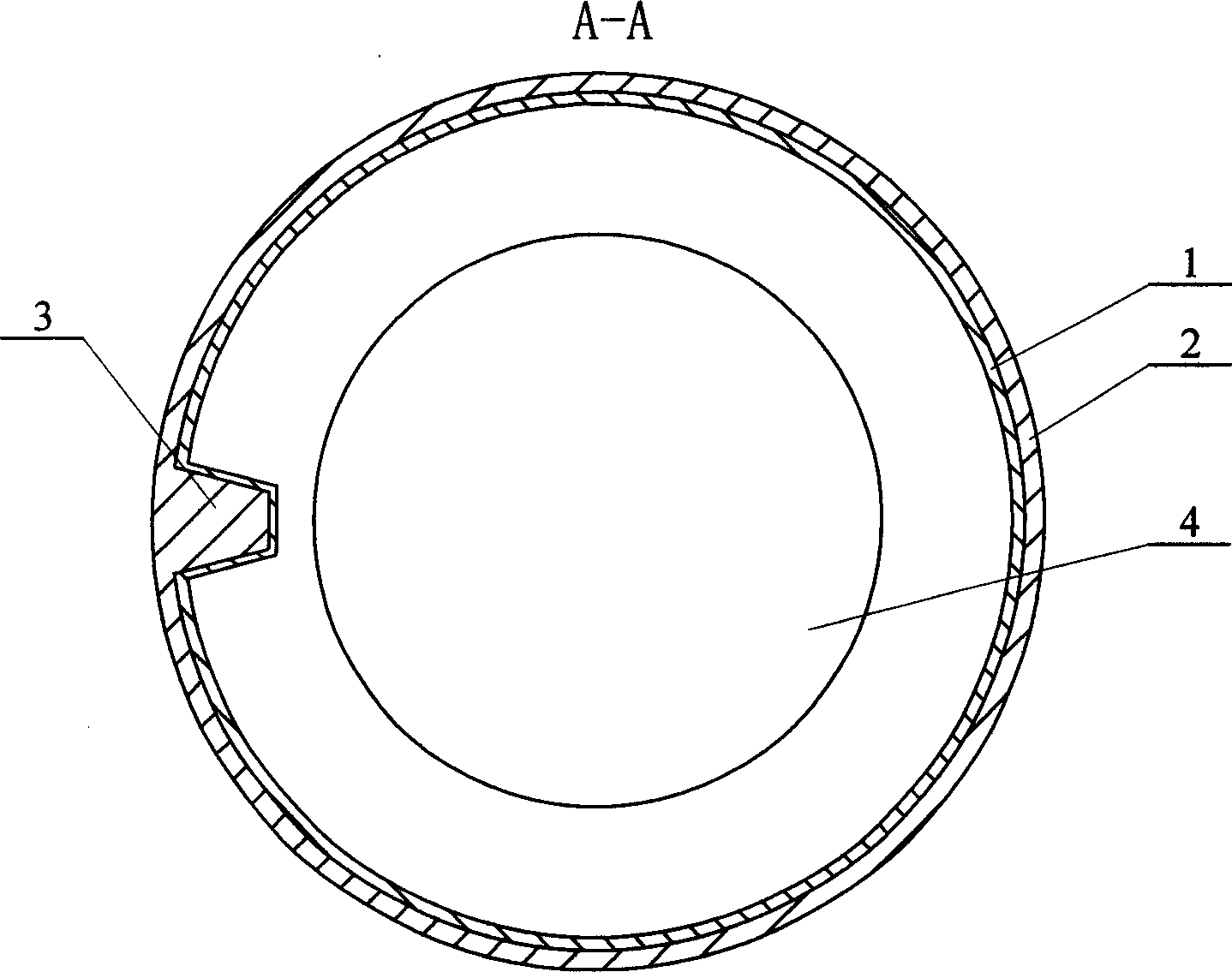

[0016] Specific implementation mode one: combine figure 1 The present embodiment will be described. In this embodiment, it is made by superimposing the inner lining layer 1 of the cylinder, the outer layer 2 of the cylinder and the inner spiral reinforcing rib 3. At least one spiral groove is arranged on the inner lining layer 1 of the cylinder. In the groove, the inner helical rib 3 is at least one-third of the length of the cylinder, and the outer layer 2 of the cylinder is fixed on the outer surface of the inner lining layer 1 of the cylinder and the inner helical rib 3 .

specific Embodiment approach 2

[0017] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the inner diameter of the cylinder is 10 mm to 400 mm, the multiple of the ratio of the length of the cylinder to the outer diameter is 5 to 300, and the pitch of the internal spiral rib 3 is greater than 2 times The internal diameter of the cylinder; the internal spiral ribs 3 are multiple and run through the length direction of the cylinder body.

specific Embodiment approach 3

[0018] Specific embodiment three: the cylinder inner liner 1 of this embodiment is made of a fiber volume content of 40% to 65%, and the balance is made of resin; ~65%, the balance is made of resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com