Patents

Literature

41results about How to "Reduced process flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

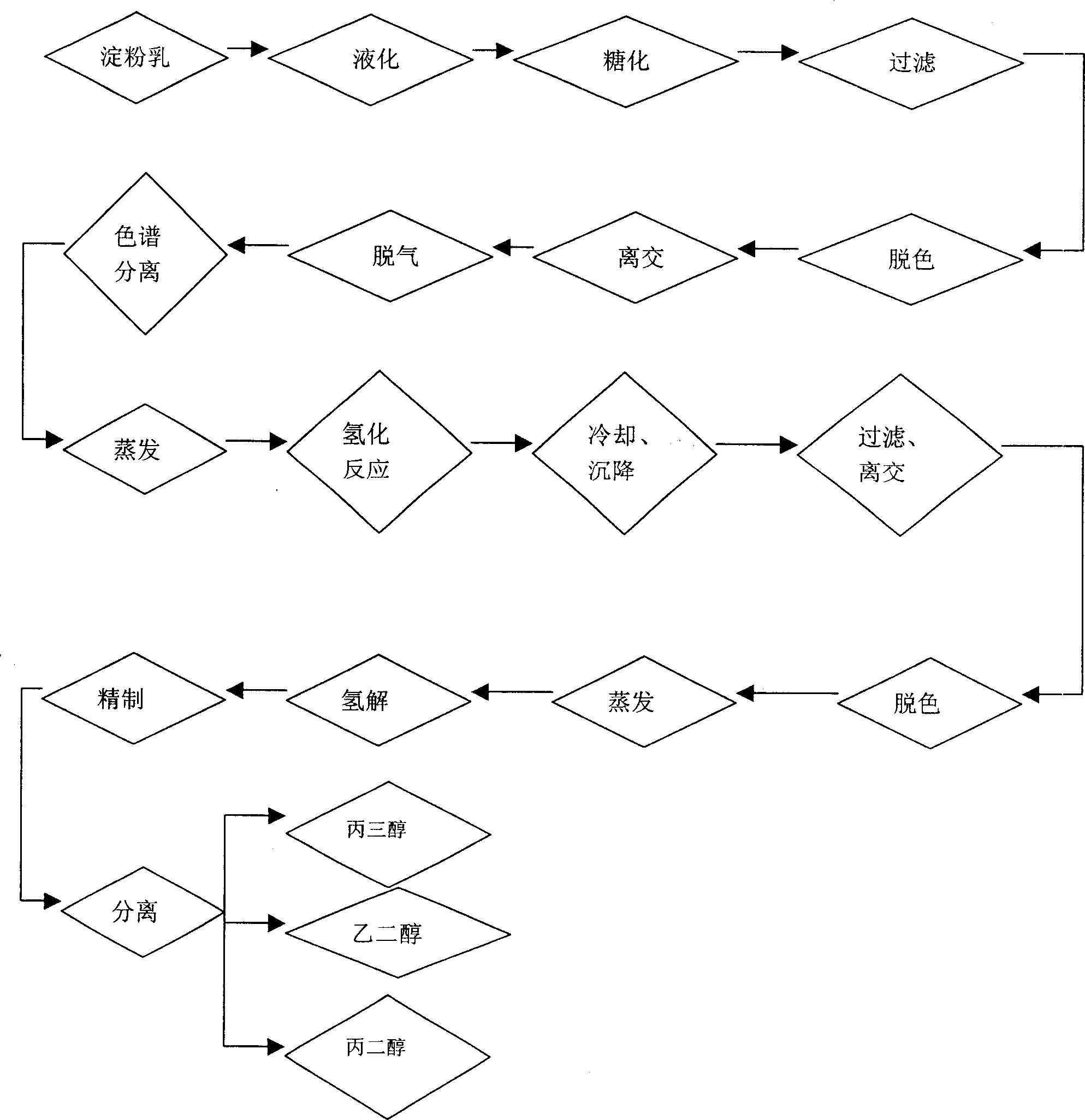

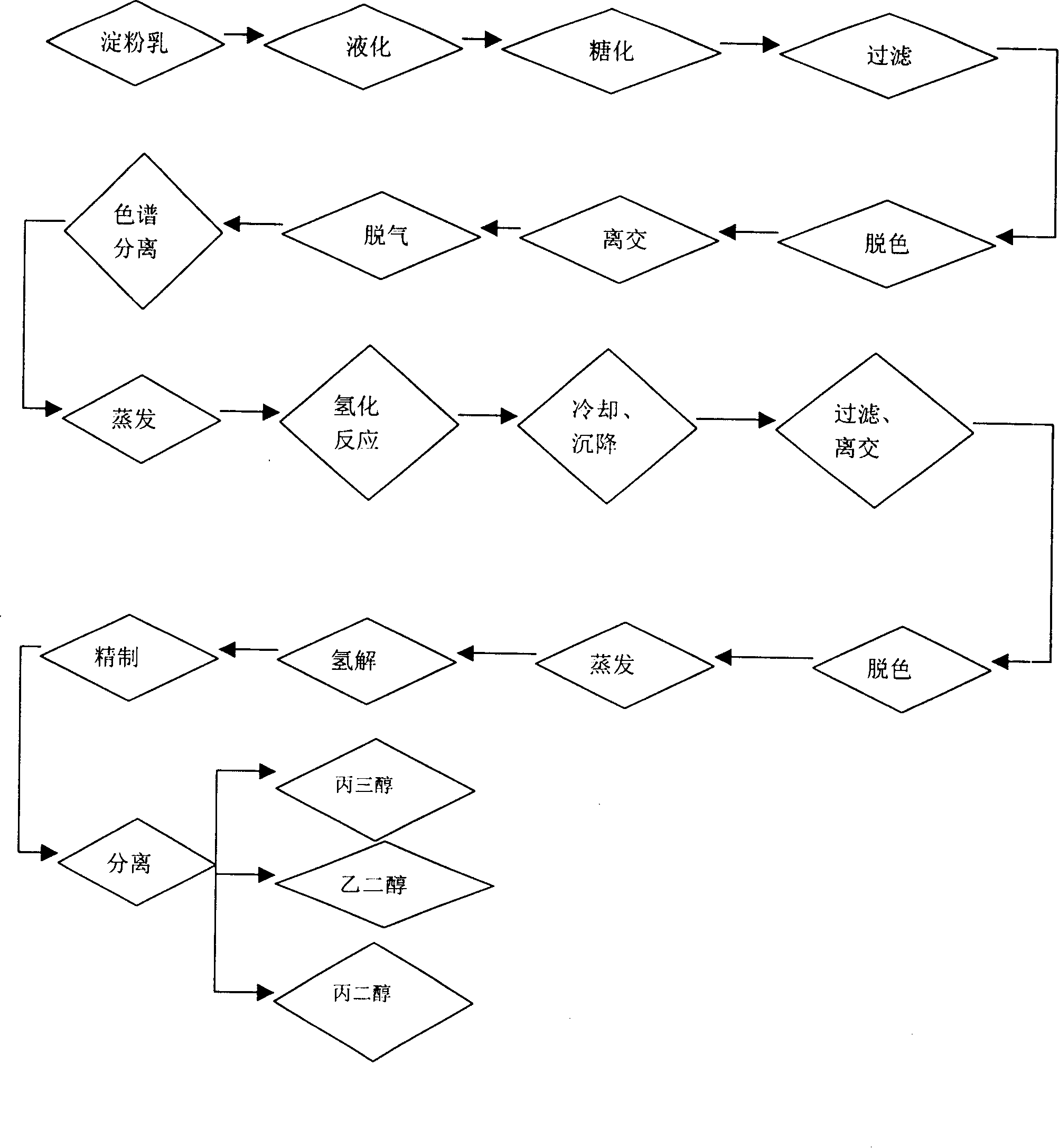

Novel technique for preparing ethylene glycol

InactiveCN1919814AReduce utilizationIncrease productivityOrganic compound preparationHydroxy compound preparationSimulated moving bedSlurry

The invention discloses a new technology to manufacture ethandiol, which is characterized by the following: liquefying starch emulsion; saccharifying; filtering; decolouring; separating through simulated mobile chromatogramic separating system; obtaining DX 99-99.7% glucose slurry; evaporating DX value glucose slurry to 50% as dried material; adopting ruthenium or nickel as catalyst; proceeding hydrogenation reaction to obtain the sorbitol solution; hydrogenolyzing for certain time under one catalyst of Ru, Ni / Ru and Co / Re to produce compound with ethandiol, glycerin and propanediol; cooling multi-alcohol; sedimenting; filtering; separating; decolouring; separating ethandiol, glycerin and propanediol.

Owner:SHANDONG XIWANG SUGAR

Preparation method of high-strength corrosion-resistant copper pipe for heat exchanger

The invention discloses a preparation method of a high-strength corrosion-resistant copper pipe for a heat exchanger. The high-strength corrosion-resistant copper pipe comprises a copper matrix and alloy metals. The alloy metals comprise, by weight, 0.5-0.6% of magnesium, 0.08-0.09% of silver, 0.2-0.4% of tin. 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.05-0.06% of nickel, 0.005-0.008% of titanium and 0.02-0.04% of mischmetal. The mischmetal comprises yttrium, berkelium and lanthanum according to a mass ratio of 1: (0.15-0.2): (0.4-0.5). The preparation method utilizes upward continuous casting, rolling and drawing processes to replace casting, sawing, heating, extrusion and pickling processes of the traditional preparation method so that processes are greatly simplified, continuous production is realized, a period is short, and efficiency is high. A copper pipe prepared by the preparation method has oxygen content satisfying the oxygen-free copper level standard, has fine grains, and has mechanical strength, high temperature resistance, corrosion resistance and wear resistance obviously superior to the same performances of the existing copper pipe.

Owner:山东兴鲁有色金属集团有限公司

Technological method for upwardly continuously casting, rolling, drawing and producing copper alloy tubes

The invention provides a technological method for upwardly and continuously casting, rolling, drawing and producing copper alloy tubes. The technological method comprises the following steps: melting copper alloy raw materials according to a content proportion; further homogenizing the contents of an undercurrent passing by a standing chamber; keeping the temperature of the undercurrent by a maintaining furnace; cooling the undercurrent by a crystallizer to enter a tractor; upwardly drawing and continuously casting copper alloy tube blanks; then rolling the copper alloy tube blanks by a rolling mill; and drawing finished products of copper alloy tubes by a drawing mill. The technological method simplifies a traditional technological process in a new once-forming technology and has little investment, small occupation of land, low energy consumption, high efficiency, high rolling yield, little pollution and low cost, thereby being an advanced technological method with a certain market competitiveness.

Owner:高玉树

Preparation method of high-strength and corrosion-resistant composite heat exchanger tube

The invention discloses a preparation method of a high-strength and corrosion-resistant composite heat exchanger tube. The composite heat exchanger tube consists of a copper base, alloy metal and filling particles, wherein the alloy metal comprises the following components in percentage by weight: 0.5-0.6% of magnesium, 0.08-0.09% of silver, 0.2-0.4% of tin, 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.05-0.06% of nickel, 0.005-0.008% of titanium and 0.02-0.04% of mixed rare earth; the mixed rare earth consists of yttrium, berkelium and lanthanum at a mass ratio of 1: (0.15-0.2): (0.4-0.5); and the filling particles comprise the following components in percentage by weight: 0.010-0.012% of tetrapod-like zinc oxide whiskers, 0.008-0.009% of silicon carbide, 0.005-0.006% of aramid fiber, 0.004-0.005% of glass fiber and 0.002-0.003% of nano titanium oxide. The oxygen content of the prepared composite heat exchanger tube is in an oxygen-free copper level; the crystal grain is tiny; and the mechanical strength, the high-temperature resistance, the corrosion resistance and the wear resistance are improved greatly compared with the existing copper tube.

Owner:QUANZHOU SHENGXIN MACHINERY

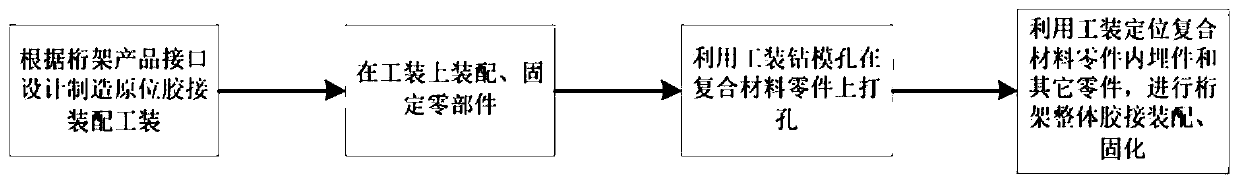

In-situ cementing assembling method for satellite composite material truss

ActiveCN111098507AReduce repairImprove assembly accuracyMetal working apparatusStructural engineeringMachining

The invention provides an in-situ cementing assembling method for a satellite composite material truss. The in-situ cementing assembling method for the satellite composite material truss comprises thefollowing steps that 1, an in-situ cementing assembling tool is designed and manufactured according to the truss structure and ports; 2, truss parts are assembled and fixed on the in-situ cementing assembling tool; 3, the truss parts are punched through a drill jig hole of the in-situ cementing assembling tool; and 4, the truss assembling parts and embedded parts in the truss parts are positionedthrough a positioning hole of the in-situ cementing assembling tool, and truss assembling positioning, cementing and solidifying are conducted. According to the in-situ cementing assembling method for the satellite composite material truss, the purpose that all installing hole of the truss are punched, positioned, cemented and solidified on the same standard can be achieved, repairing of the composite material parts can be effectively reduced, and the assembling precision is improved; and machining standard errors brought by composite material appearance deviation are effectively avoided, andthe machining problems brought due to the fact that the composite material parts cannot set the precise machining standards are avoided.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

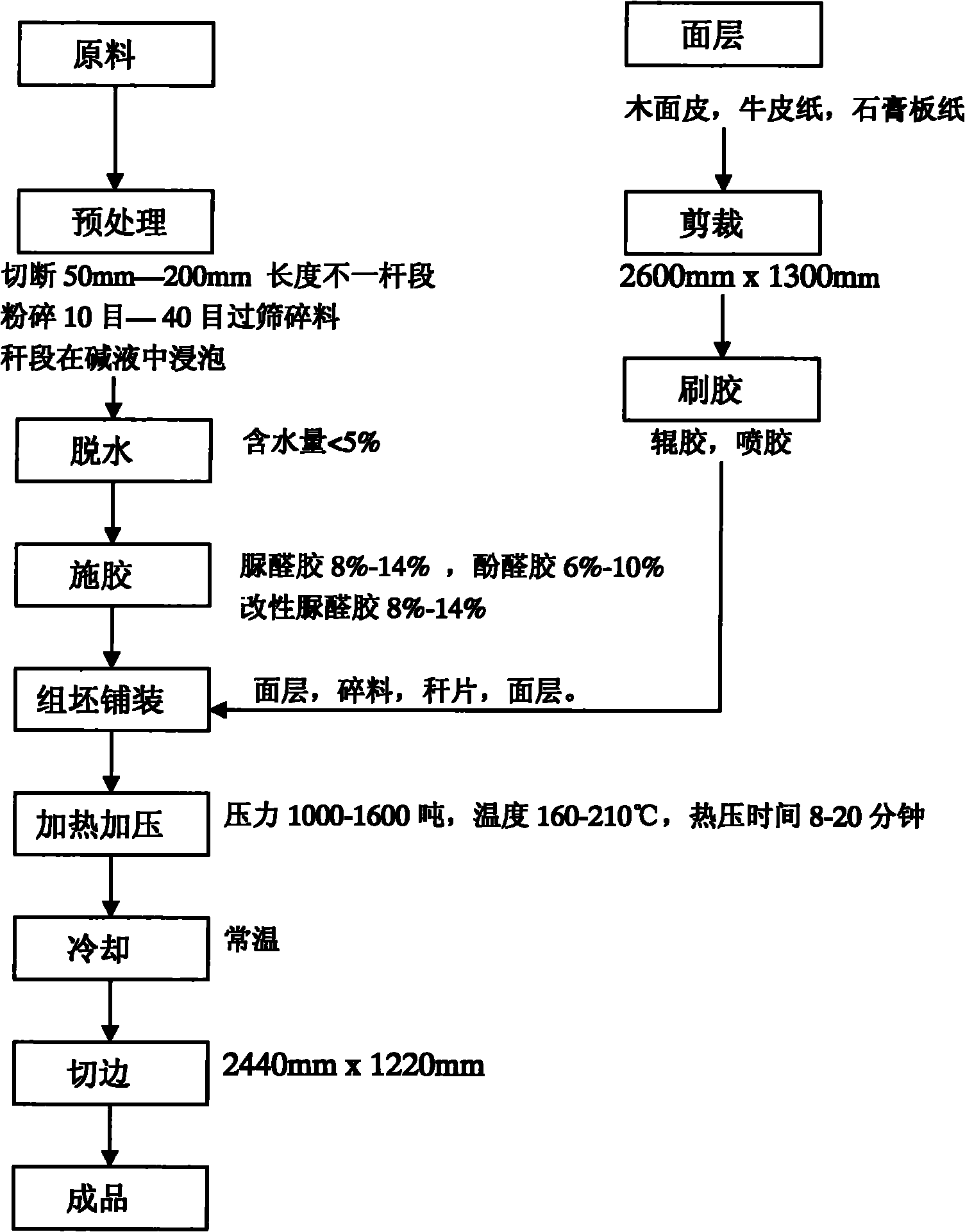

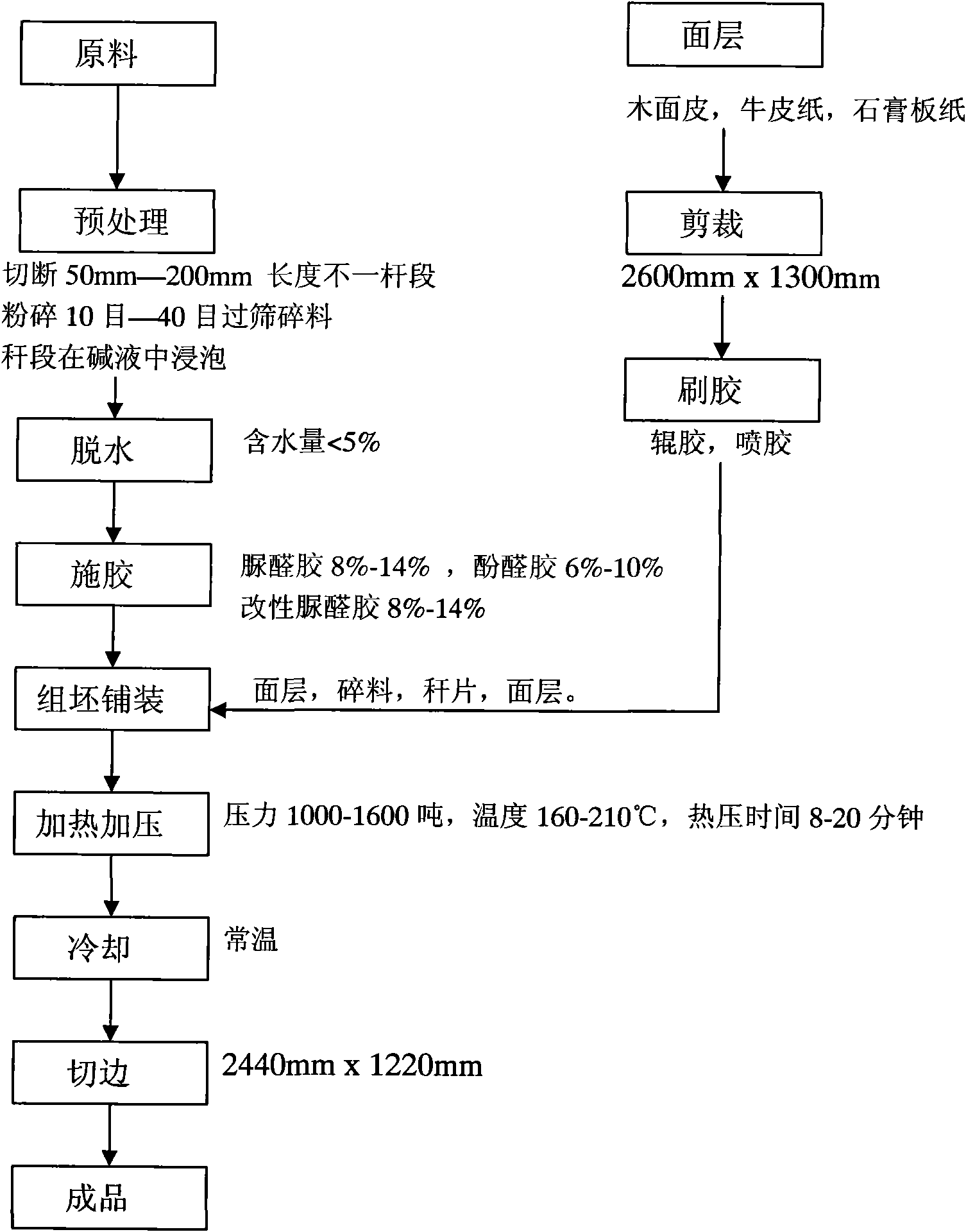

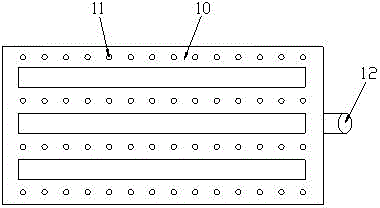

Process for pretreating raw materials of sunflower stalk composite boards and pressing assemblies

InactiveCN101941227AHigh strengthReduced process flowReed/straw treatmentAldehyde/ketone condensation polymer adhesivesPre treatmentPeanut hull

The invention provides a process for pretreating raw materials of sunflower stalk composite boards and pressing assemblies, which relates to the manufacturing industry of artificial boards of non-wood crop stalk hulls. In the process for pretreating raw materials and pressing assemblies, sunflower stalk is used as a main material of boards, and saw dust, rice hulls, peanut hulls, bean stalk, hemp stalk and cotton stalk are used for replacing wood to manufacture artificial boards. In the invention, the sunflower stalk is longitudinally broken and cut into stalk sections of which the lengths are 50-200mm to be used as main materials of the boards, thereby improving the strength of the boards; and the saw dust, the rice hulls, the peanut hulls, the bean stalk, the hemp stalk, the cotton stalk and part of broken materials of the sunflower stalk are used as auxiliary materials of the boards, thereby saving the wood. The concrete steps are described in the specification in detail.

Owner:刘金忠

Method for extracting aluminum oxide from sodium-free desiliconized fly ash

InactiveCN101759212AReduce the amount of materialReduced process flowAluminium oxides/hydroxidesSlagLow sodium

The invention relates to a method for extracting aluminum oxide from sodium-free desiliconized fly ash, which comprises the following steps of: taking dried sodium-free desiliconized fly ash, carrying out saturation calcium matching with limestone powder and / or slaking slag powder, sintering at 1330-1390 DEG C, controlling to cool the sintered material to obtain the self-pulverizing material, putting into a Na2CO3 solution to quickly dissolve out aluminum oxide, separating a solid from a liquid, extracting aluminum oxide according to the conventional method, and washing residues to obtain the low-sodium calcium-silicon slag. In the method, sodium-free desiliconized fly ash from which silicon dioxide is extracted and sodium oxide is removed is adopted as the raw material; the limestone sintering process can be used for extracting aluminum oxide, and low-sodium calcium-silicon slag can be obtained after extracting aluminum oxide; and both the aluminum oxide and the low-sodium calcium-silicon slag can be used as the raw materials of cement, thereby thoroughly eliminating secondary pollution.

Owner:SHUOZHOU RUNZE INVESTMENT DEV

Manufacturing method of water-proof and oil-proof coloured polyester staple fibers

ActiveCN102071479AWaterproof and oilproofWith waterproof and oilproof functionNew-spun product collectionFilament manufacturePolyesterPolymer science

The invention discloses a manufacturing method of water-proof and oil-proof coloured polyester staple fibers, aiming at solving the problems of nonwoven fabric deformation and coloured polyester staple fiber discoloration of the traditional coloured nonwoven fabric in the process of obtaining water-proof and oil-proof properties through padding finishing. In the invention, water-proof agents and oil-proof agents are attached to the surfaces of the coloured polyester staple fibers step by step and layer by layer so as to enable to the surfaces of the coloured polyester staple fibers to achieve the water-proof and oil-proof properties; a nonwoven fabric per se, produced by using the coloured polyester staple fibers, has water-proof and oil-proof functions, without being subjected to padding finishing to obtain the water-proof and oil-proof functions, and has the characteristics of difficulty in deformation and difficulty in discoloration of the coloured polyester staple fibers when dried; and in addition, the process flow is simplified, the energy consumption is lowered and the production cost is reduced.

Owner:浙江安顺化纤有限公司

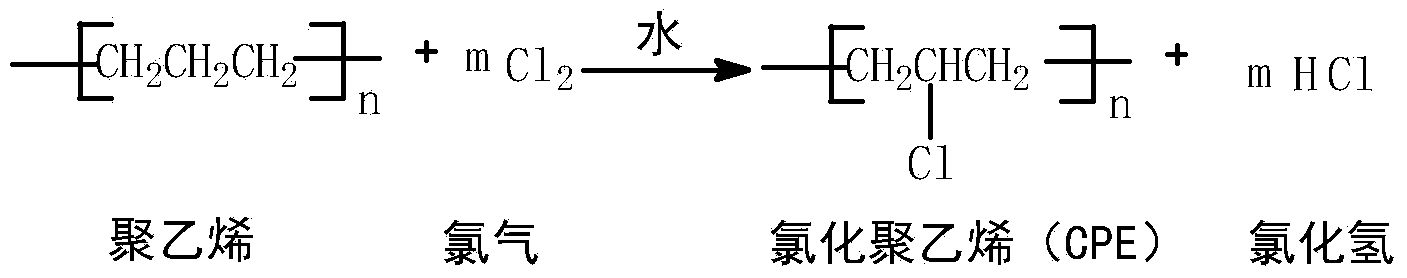

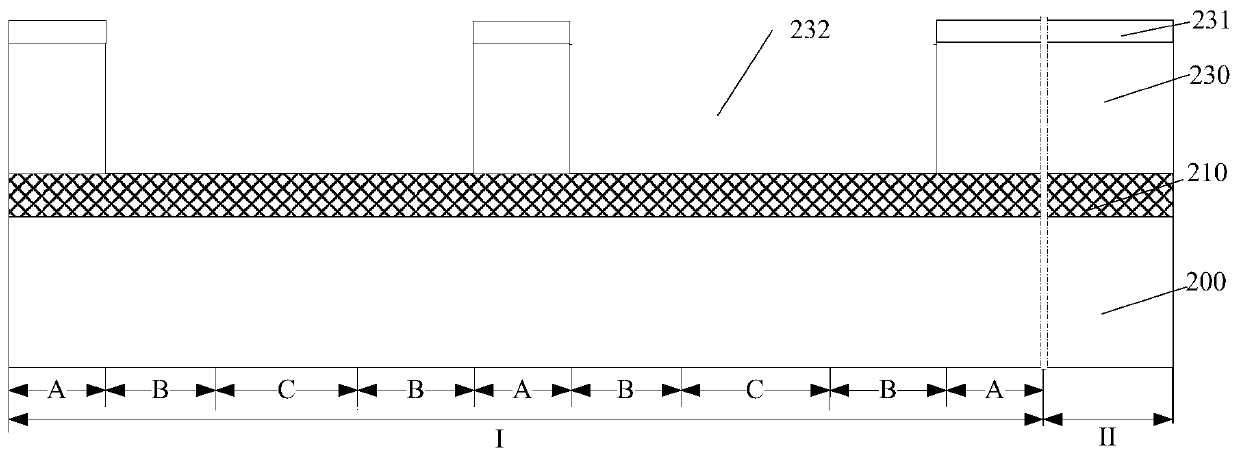

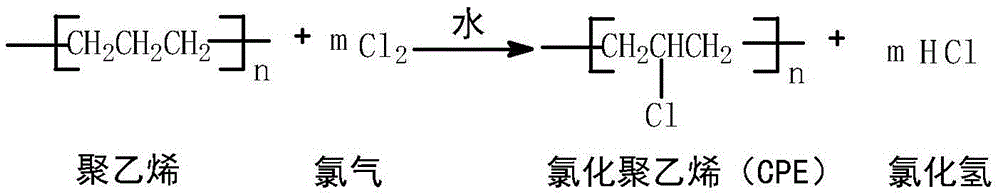

One-step production method of chlorinated polyethylene

ActiveCN104327202AComply with HG/T2704-2010 (chlorinated polyethylene) requirementsReduced process flowPolymer scienceAcid water

The invention discloses a one-step production method of chlorinated polyethylene. The method comprises the following steps: adding 10-20 parts by mass of high-density polyethylene to 80-90 parts by mass of water to generate a chlorination in the presence of an emulgator, a dispersing agent, an initiator and chlorine gas, adding 5-7 parts by mass of calcium oxide in batches in the chlorination process, thus generating chlorinated polyethylene resin and an aqueous solution of calcium chloride, wherein the addition speed of calcium oxide has to ensure that the pH value of the reaction system is controlled to be between 7.0 and 8.5; centrifuging and drying the obtained chlorinated polyethylene resin to obtain a finished chlorinated polyethylene product; and concentrating and drying the aqueous solution of calcium chloride to obtain a byproduct calcium chloride. The one-step production method of chlorinated polyethylene has the advantages that the process flow is simplified, the space occupied by devices and investment in devices are reduced, and the production cost is lowered; in the preparation process of chlorinated polyethylene, waste acid water is made a full use and prepared into a byproduct, and therefore the clean production level is high and relatively high economic benefit can be created.

Owner:ANHUI RES INST OF CHEM IND

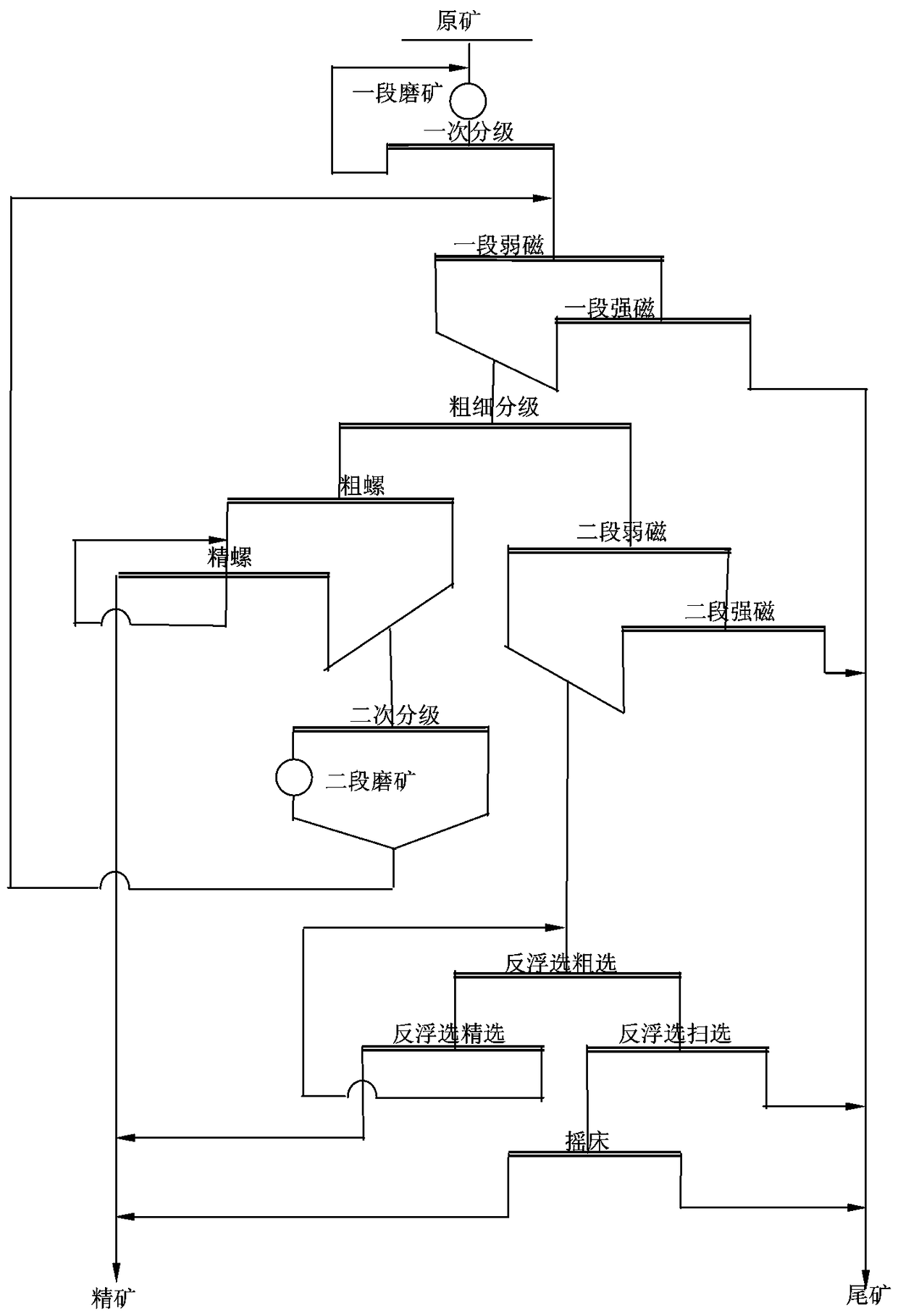

Separation technology for hematite containing iron carbonate

InactiveCN109201322AEnhanced strong magnetic coarse-grained tail throwingEnhanced tail throwGrain treatmentsWet separationSeparation technologyEngineering

The invention relates to a separation technology for hematite containing iron carbonate. The separation technology comprises the step that iron ores with the hematite distribution rate being higher than 40% are fed into first-stage closed circuit grinding operation. The separation technology is characterized by further comprises the steps of first-stage weak-magnetic and strong-magnetic operation,thickness grading operation, gravity separation operation, secondary-grading grinding operation, second-stage weak-magnetic and strong-magnetic operation and reverse flotation operation, wherein primary-grading overflow products and middling regrinding products are treated through first-stage weak-magnetic and strong-magnetic operation, first-stage weak-magnetic and strong-magnetic mixed concentrates are treated through thickness grading operation, coarse grain products subjected to thickness grading operation are treated through gravity separation operation, gravity separation operation tailings are treated through secondary-grading grinding operation, fine grain products subjected to thickness grading operation are treated through second-stage weak-magnetic and strong-magnetic operation, second-stage weak-magnetic and strong-magnetic mixed concentrates are treated through reverse flotation operation, and reverse flotation operation middlings are treated through table separation operation. The separation technology has the advantages that first-stage strong magnetic tailing discarding after rough grinding is enhanced, the middling circulation volume is decreased, the technological process is simplified, and the production cost is saved.

Owner:ANSTEEL GRP MINING CO LTD

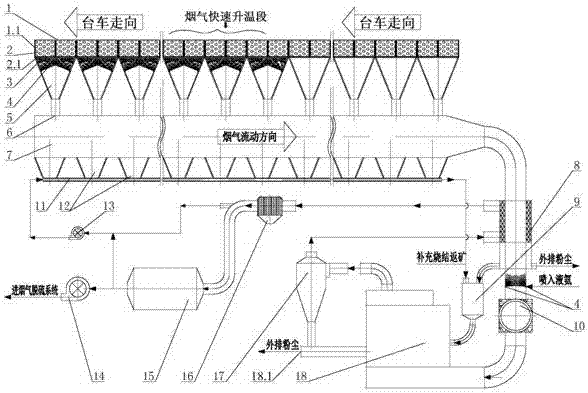

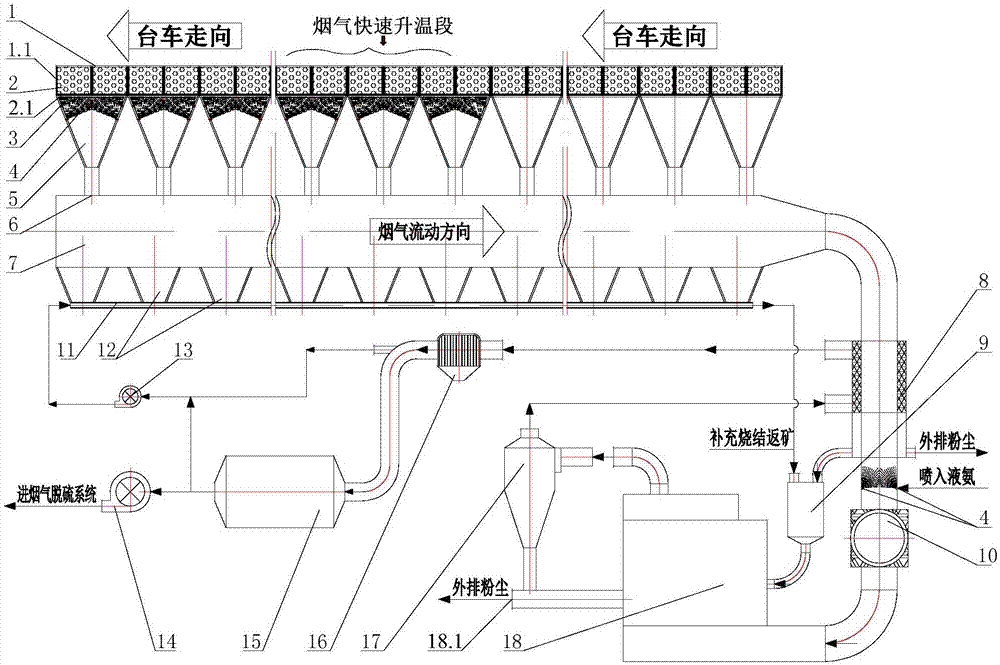

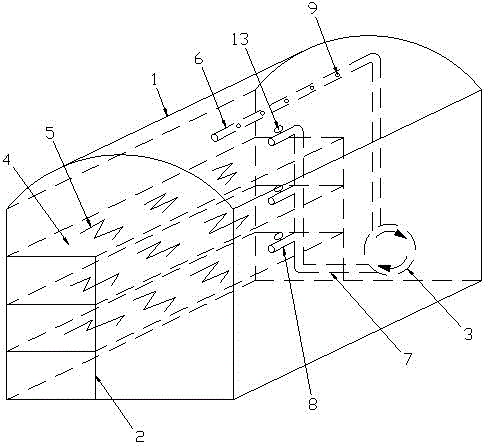

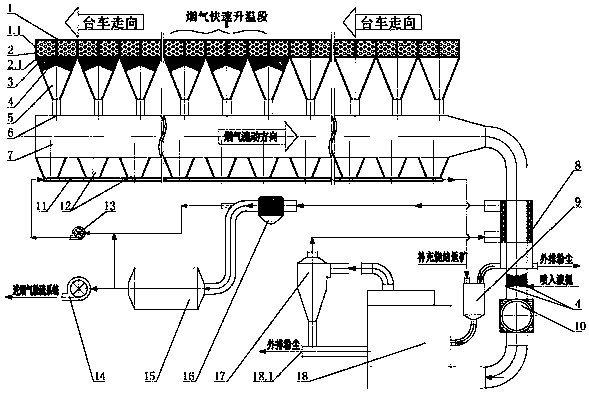

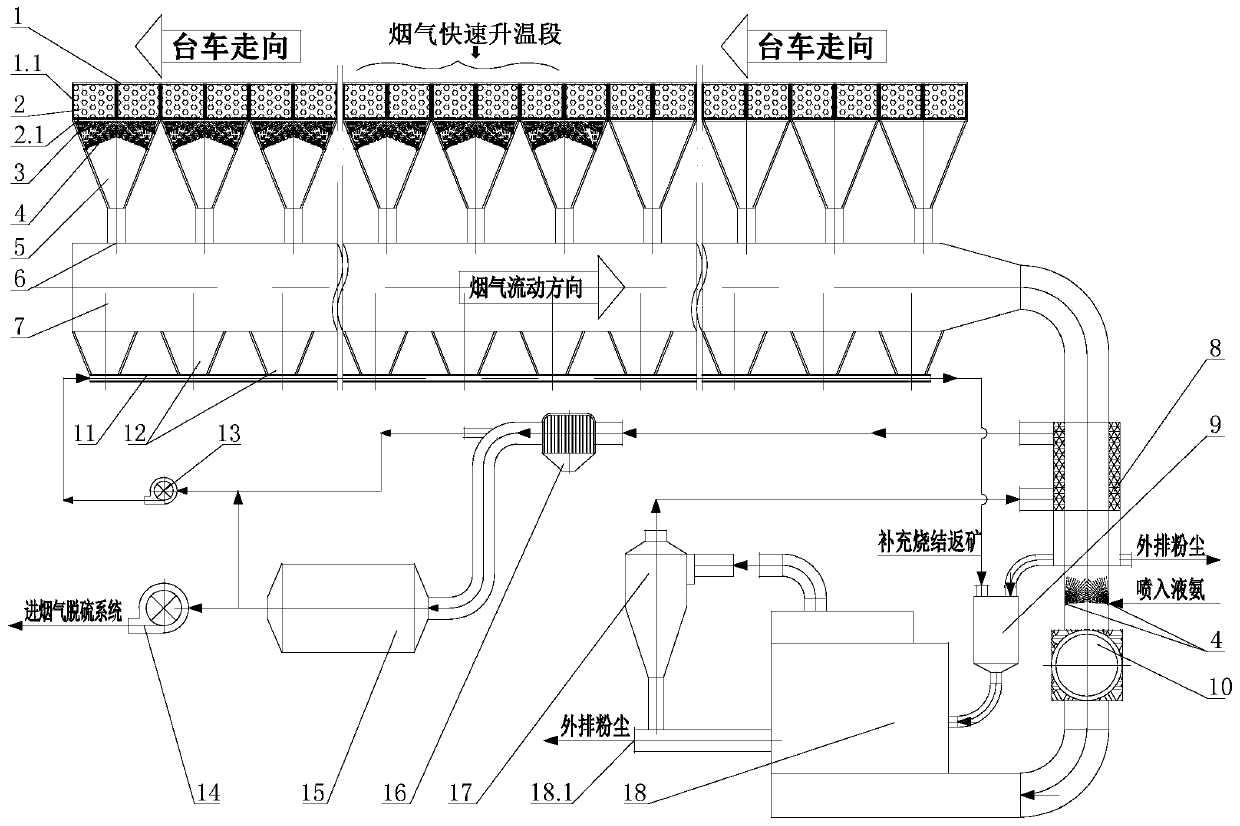

Sintering smoke self-catalyzing denitrifying system by coupling and utilizing residual heat of sintering smoke

ActiveCN107198962AReduce the cost of denitrificationGuaranteed denitrification efficiencyGas treatmentDispersed particle separationFluidized bedFlue gas

The invention relates to a sintering smoke self-catalyzing denitrifying system by coupling and utilizing residual heat of sintering smoke, which solves the problems of large investment, high running cost and lower denitrifying efficiency in the existing denitrifying system. The sintering smoke self-catalyzing denitrifying system adopts the technical scheme that the sintering smoke self-catalyzing denitrifying system comprises a sintering machine, wherein air bellows are arranged under a trolley of the sintering machine; an exit of the bottom part of each air bellow is communicated with a main flue; the sintering machine is sequentially provided with an ignition section, a machine head section, a flue gas quick heating section and a machine tail section along the moving direction of the trolley; the main flue is sequentially connected with a denitrifying reactor of a fluidized bed through a denitrifying flue gas heat exchanger shell or tube, and a flue gas heater; liquid ammonia spray nozzles are respectively arranged in the air bellows under the machine tail section to the flue gas quick heating section area, and in the flue gas exit pipeline of the flue gas heater. The sintering smoke self-catalyzing denitrifying system has the advantages that the system is simple, the additional purchase of the catalyst is avoided, the effective denitrifying and sintering process is realized, the recycling rate of residual heat is high, the energy-saving and consumption-reducing effects are realized, the land occupation area is small, and the equipment investment and running cost are low.

Owner:武汉钢铁有限公司 +2

Manufacturing method of water-proof and oil-proof coloured polyester staple fibers

ActiveCN102071479BWaterproof and oilproofWith waterproof and oilproof functionNew-spun product collectionFilament manufacturePolyesterPolymer science

The invention discloses a manufacturing method of water-proof and oil-proof coloured polyester staple fibers, aiming at solving the problems of nonwoven fabric deformation and coloured polyester staple fiber discoloration of the traditional coloured nonwoven fabric in the process of obtaining water-proof and oil-proof properties through padding finishing. In the invention, water-proof agents and oil-proof agents are attached to the surfaces of the coloured polyester staple fibers step by step and layer by layer so as to enable to the surfaces of the coloured polyester staple fibers to achievethe water-proof and oil-proof properties; a nonwoven fabric per se, produced by using the coloured polyester staple fibers, has water-proof and oil-proof functions, without being subjected to paddingfinishing to obtain the water-proof and oil-proof functions, and has the characteristics of difficulty in deformation and difficulty in discoloration of the coloured polyester staple fibers when dried; and in addition, the process flow is simplified, the energy consumption is lowered and the production cost is reduced.

Owner:浙江安顺化纤有限公司

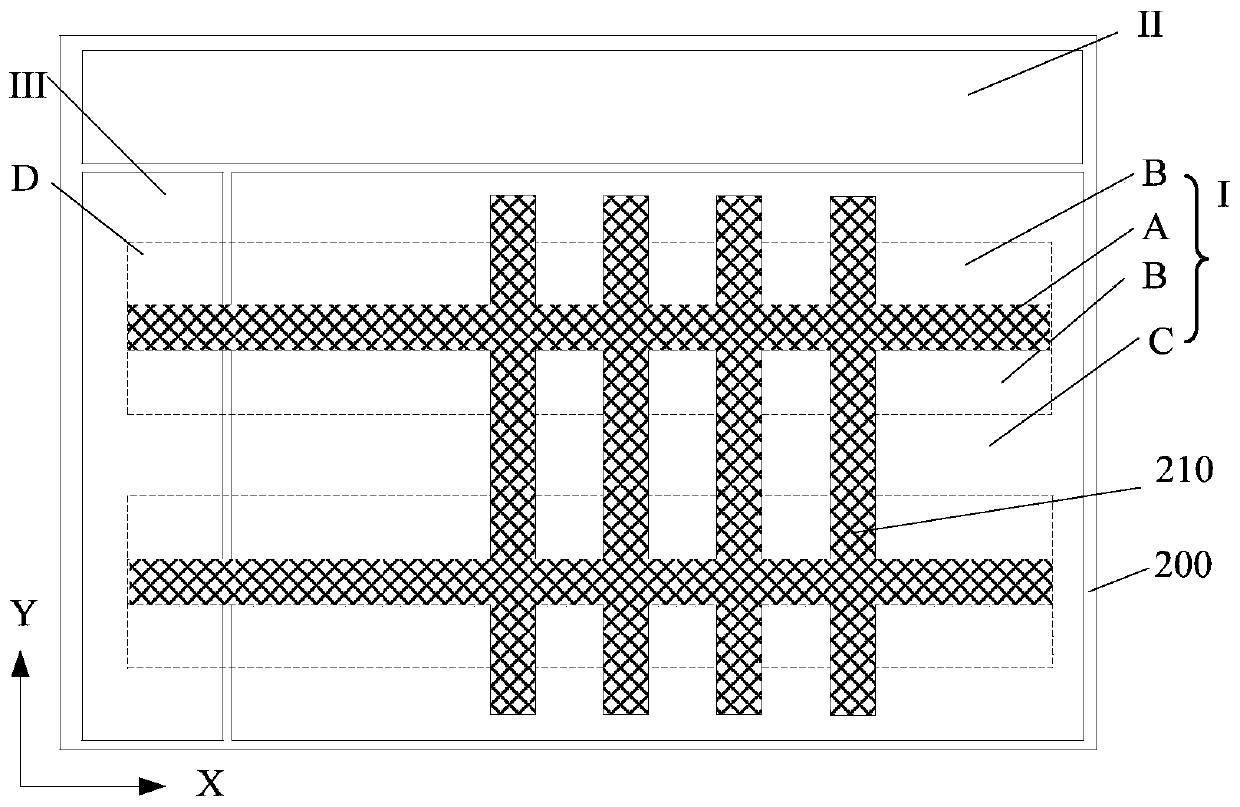

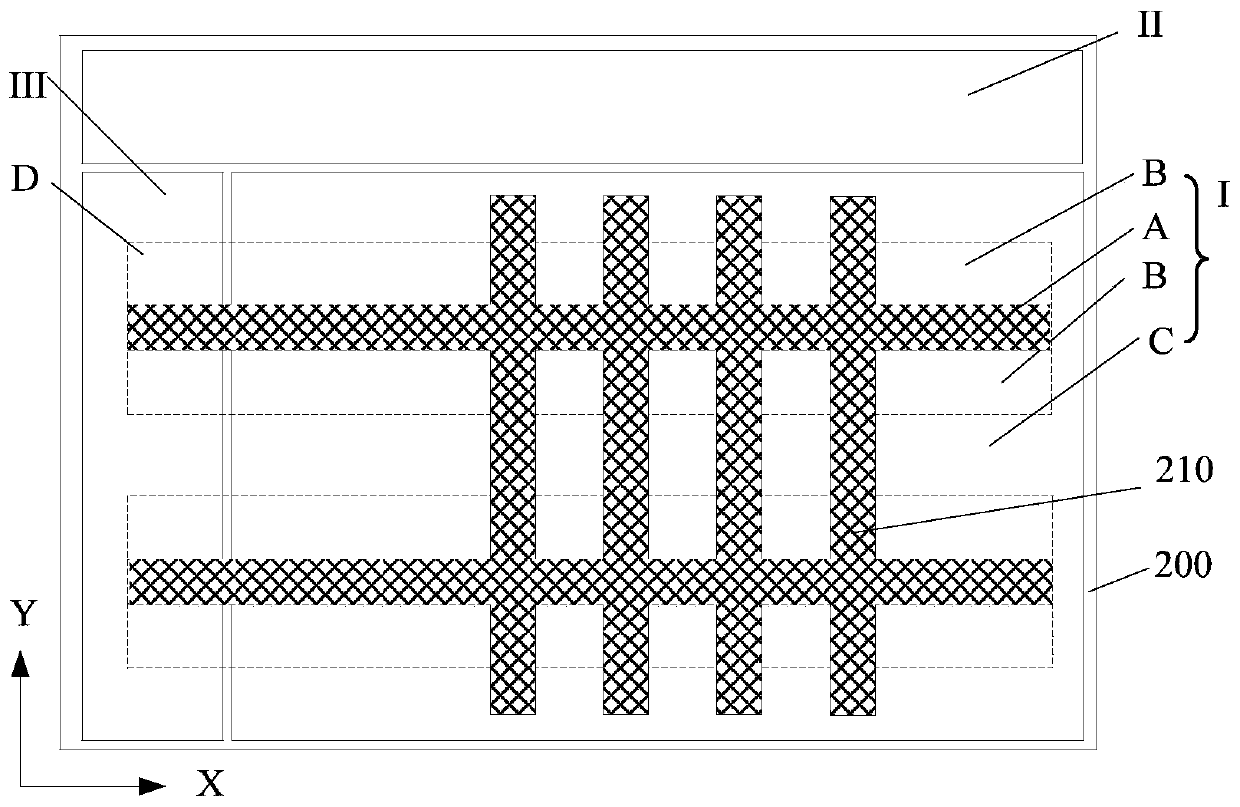

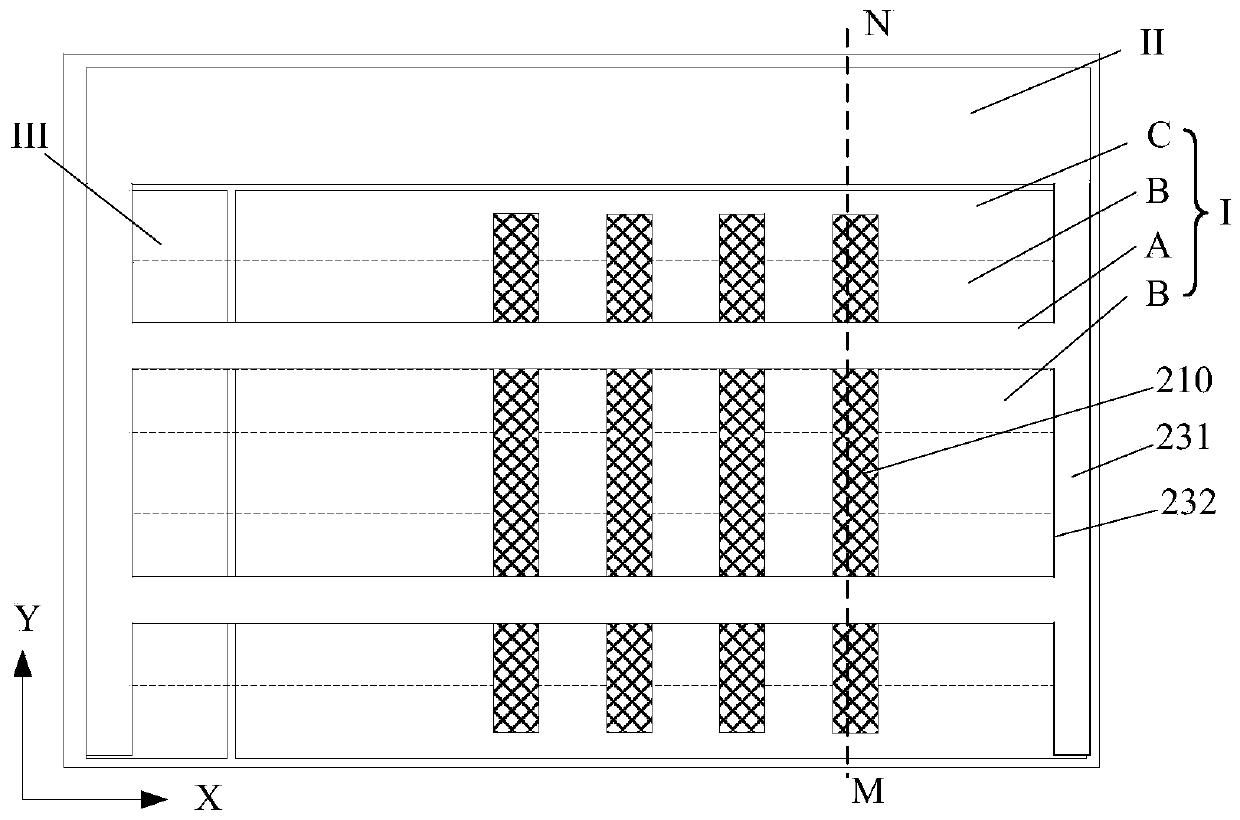

Memory and formation method thereof

ActiveCN109712981ASimple processReduced process flowSolid-state devicesSemiconductor devicesBit lineDielectric layer

A memory and a formation method thereof are disclosed. The method includes the following steps: a substrate is provided, the substrate includes erasure regions, floating gate regions and word line bitline regions, wherein the floating gate regions are located on both sides of the erasure regions, and the word line bit line regions are located on both sides of the erasure regions and the floatinggate regions; a floating grid electrode structure membrane and a dielectric layer located on the floating grid electrode structure membrane are formed on the substrate, and a first opening exposing the floating grid electrode structure membrane of the floating gate regions and the word line bit line regions are disposed in the dielectric layer; a first side wall is formed on the side wall of the first opening; a control grid electrode membrane is formed on the bottom of the first opening; a second side wall is formed on the side wall of the first side wall; the control grid electrode membraneand the floating grid electrode structure membrane exposed by the first side wall, the second side wall, and the dielectric layer are removed to form a floating gate structure layer, a control grid electrode layer and a second opening; the dielectric layer and the floating gate structure layer on the erasure regions are removed to form a third opening and a floating grid electrode structure; and an erasure grid electrode structure is formed in the third opening. The method enables the production efficiency of the memory to be improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Manufacture of water super-absorbing fiber and fiber thereby

InactiveCN1330801CImprove water absorptionGood physical and mechanical propertiesFilament/thread formingConjugated synthetic polymer artificial filamentsSodium AcrylateAqueous solution

An ultra-hydroscopic fibre is prepared from acrylic acid, sodium acrylate, acrylamide and hydroxypropyl methacrylate through copolymerizing in aqueous solution under triggering of polymerization trigger, providing polyvinyl alcohol as skin or core, composite extruding-out by compound extrusion noozle, hot-air dry spinning, and hot cross-linking. Its davantages are high hydroscopicity, better physical and mechanical properties and low cost.

Owner:CHINESE TEXTILE ACAD

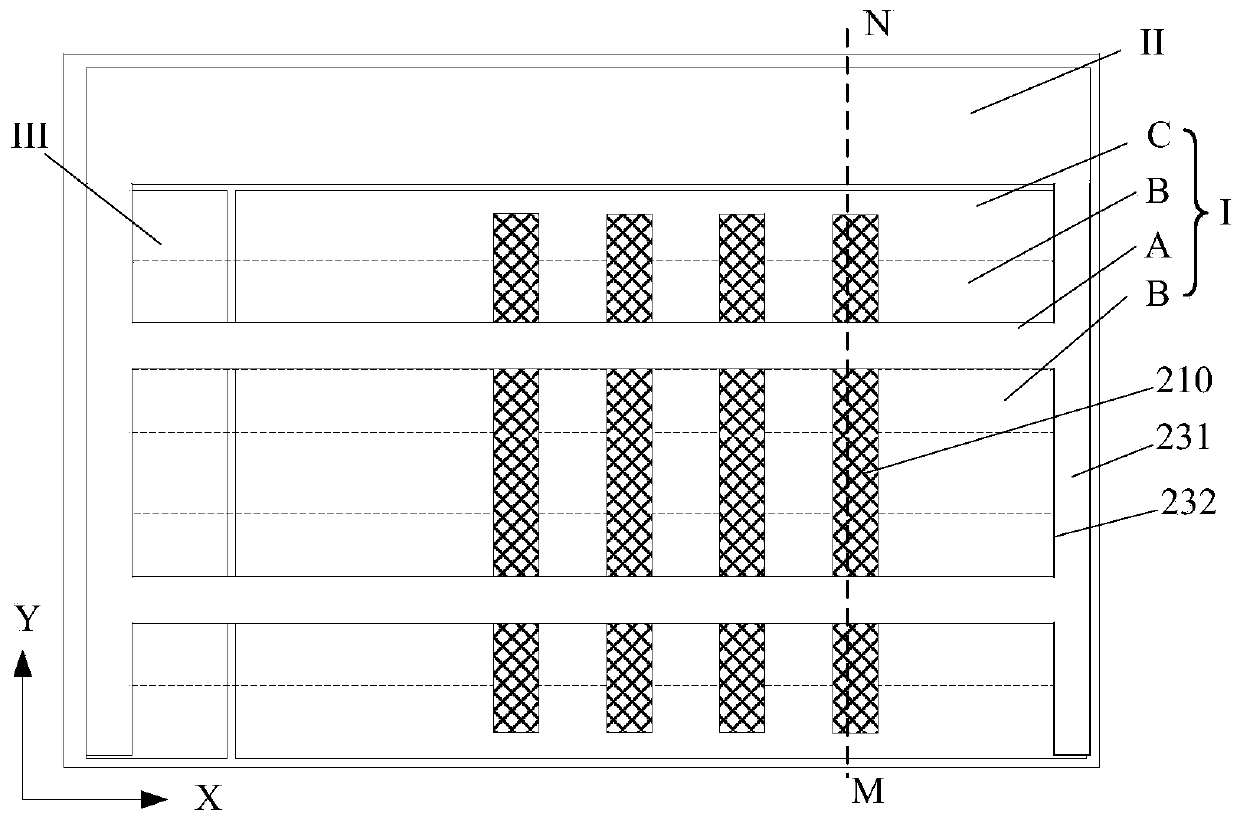

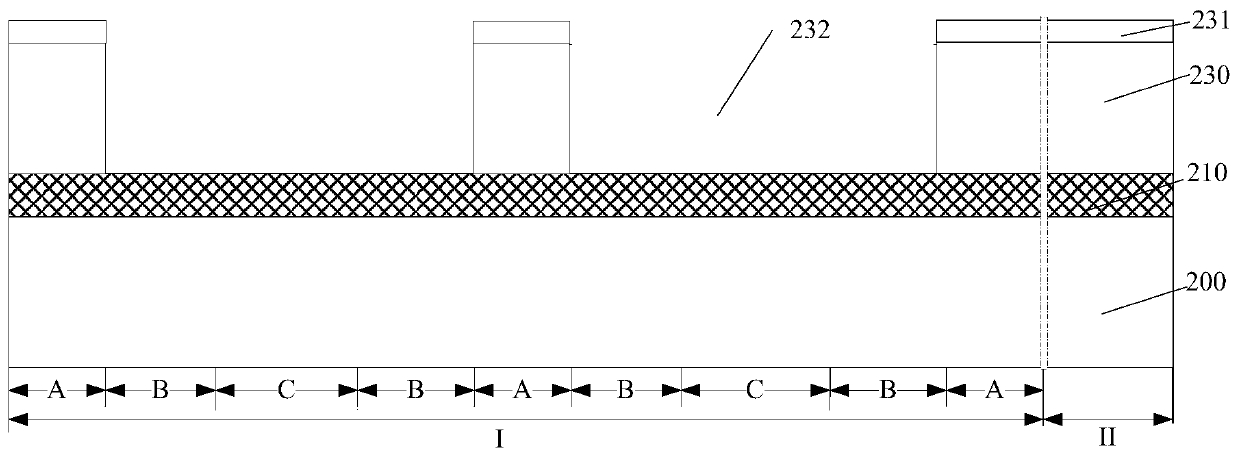

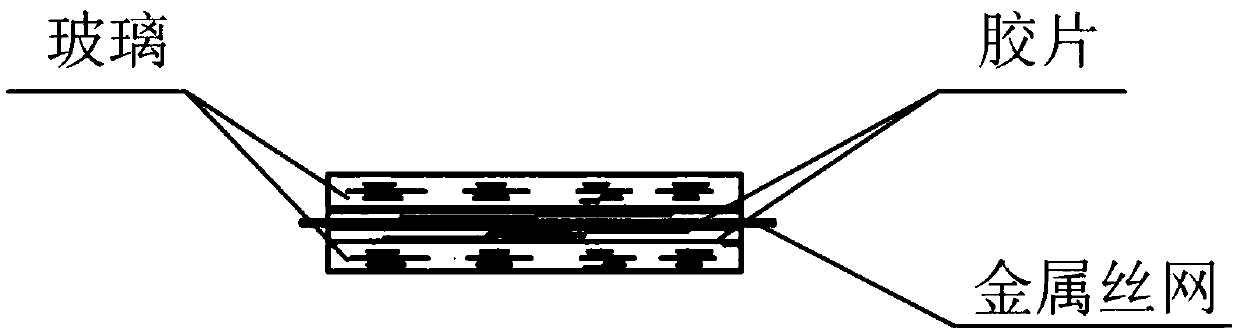

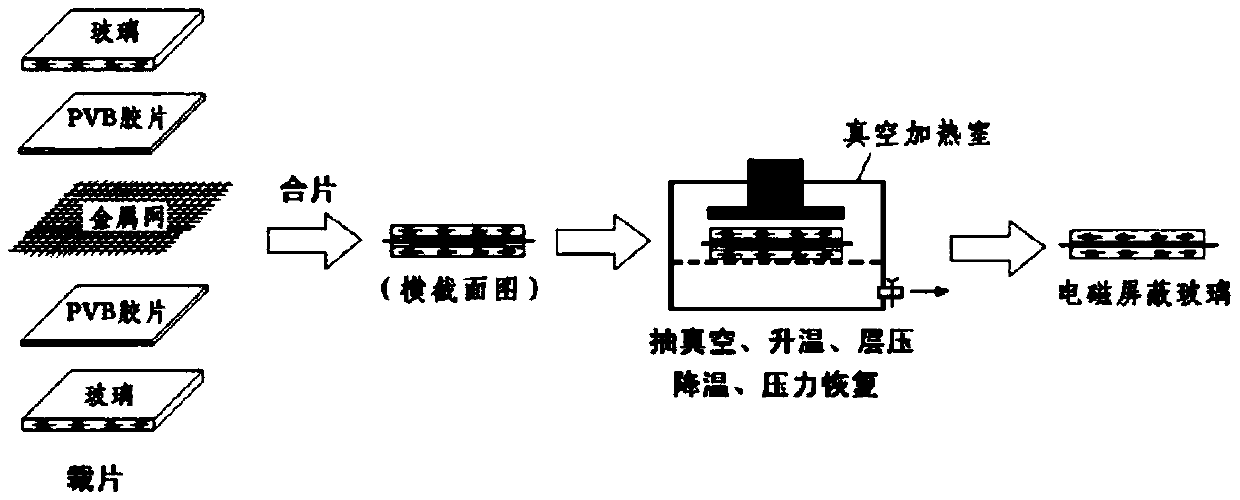

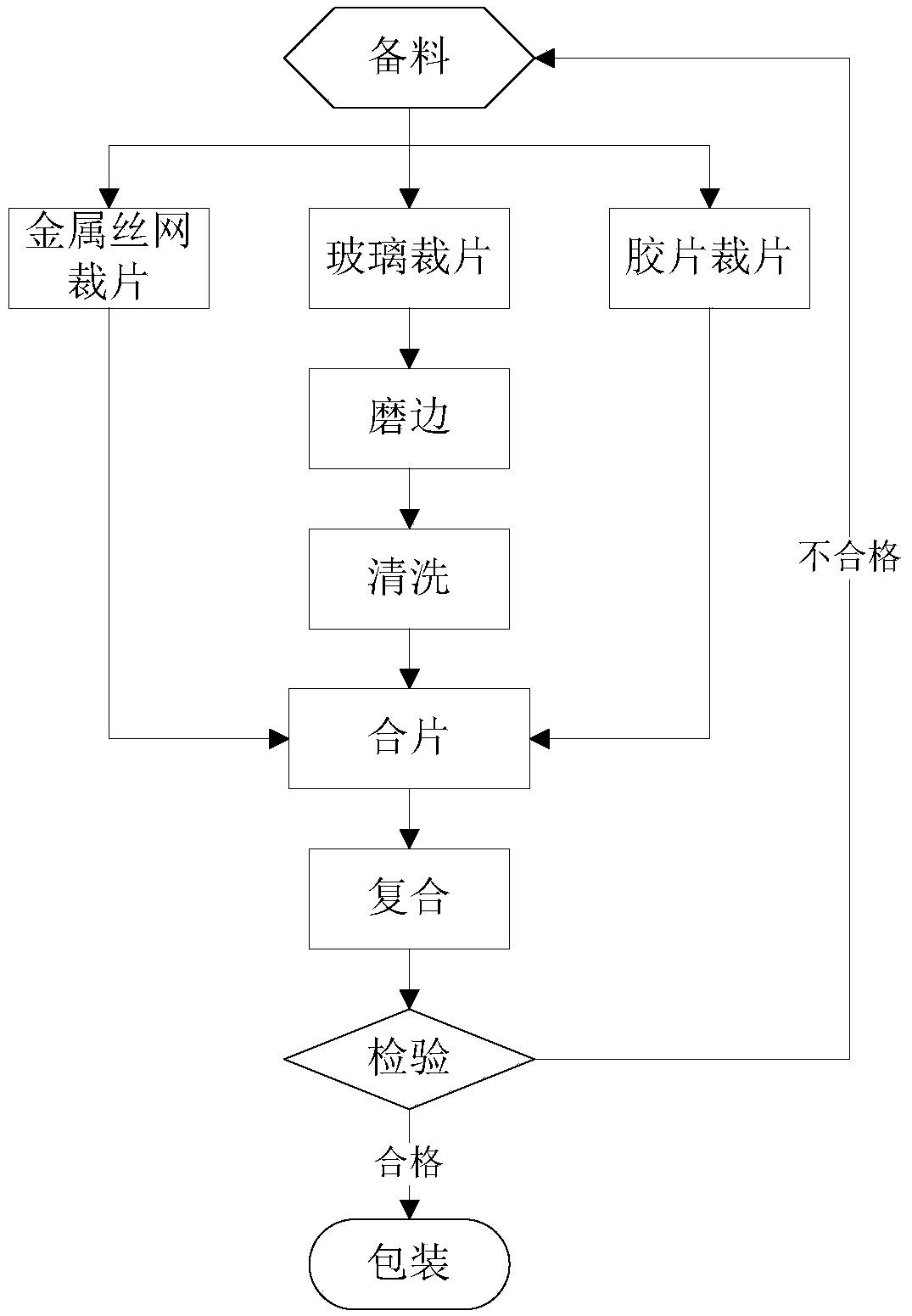

Electromagnetic shielding glass laser soldering structure and production process

InactiveCN109574479ALow environmental requirementsReduce the difficulty of production site managementMagnetic/electric field screeningGlass/slag layered productsElectromagnetic shieldingGlass sheet

The invention discloses an electromagnetic shielding glass laser soldering structure and a production process. The electromagnetic shielding glass laser soldering structure comprises glass sheets anda fine metal mesh clamped between the glass sheets, wherein the glass sheets and the metal mesh are soldered together by adopting a laser dissimilar material soldering process. Compared with the priorart, the electromagnetic shielding glass laser soldering structure has the beneficial effects: no adhesive film is used as adhesive between glass and metal mesh in the structure, thereby fundamentally preventing the quality problems of bubbles, impurity inclusions, edge shrinkage, adhesive overflow, degumming, delamination, yellowing and the like caused by the adhesive film; the processing process of the adhesive film and the product technological process can be reduced; the lamination process is simplified from four lamination steps to two lamination steps; the compositing process is replaced by laser soldering, so that the process difficulty is reduced; the defects of rupture, bubbles, edge cracking, pinholes, impurity inclusions, edge shrinkage, adhesive overflow and the like caused byimproper process control during the compositing can be avoided, and the rate of finished product is improved; and the compositing process in the kettle is cancelled, the production process of the product can be flow-operated, and the production smoothness can be improved.

Owner:NO 30 INST OF CHINA ELECTRONIC TECH GRP CORP +1

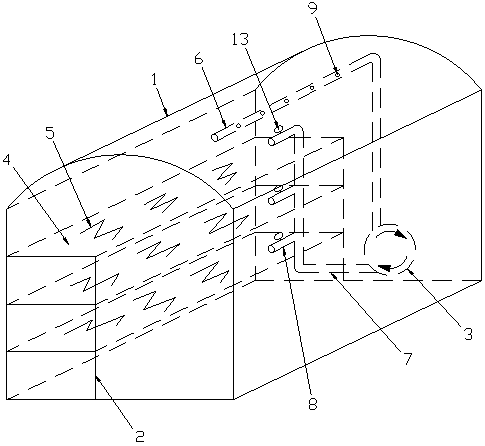

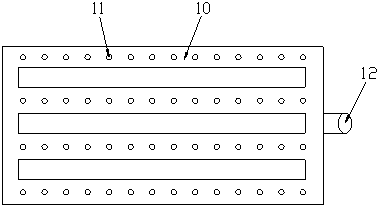

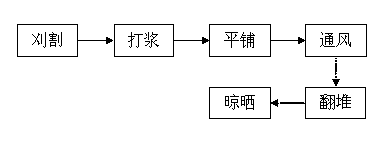

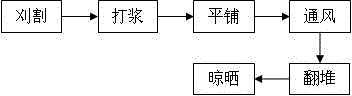

Chinese pennisetum drying method

InactiveCN103267404ASimple processImprove drying efficiencyDrying solid materials with heatDrying gas arrangementsGreenhousePulp and paper industry

The invention relates to a Chinese pennisetum drying method which is characterized in that a Chinese pennisetum drying device is provided. The Chinese pennisetum drying method includes steps of (1) mowing: Chinese pennisetum plants are mowed when Chinese pennisetum grows to be 1.5-2.5m high; (2) pulping: Chinese pennisetum is made to be grass pulp through a pulping machine without water; (3) flat laying: the grass pulp is flat laid on all layers of drying beds of drying bed frames, and the weight of the grass pulp on each drying bed frame is preferentially 5kg / m<2>-15kg / m<2>; (4) ventilating: upper layer hot air in a greenhouse is blown into grass pulp stacks for ventilating for 20-40 min by opening an air blower at the interval of 0.5-1.5 h; (5) turning: the grass pulp stacks are plowed and harrowed for one to three times every day; and (6) drying: the grass pulp stacks are dried for 3-7 days until the grass pulp is dried to be grass powder with 10-15% of water content, and then the grass powder can be stored or used. The Chinese pennisetum drying method has the advantages of being simple in process, high in drying efficiency, short in drying period and low in cost, being favorable for storing Chinese pennisetum nutrient substances and the like.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI

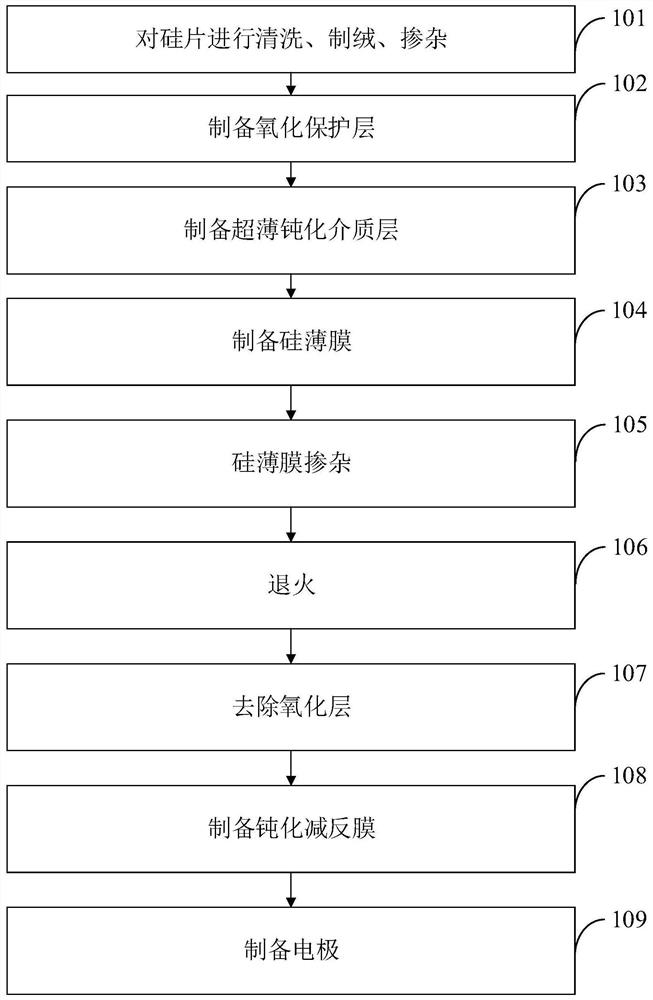

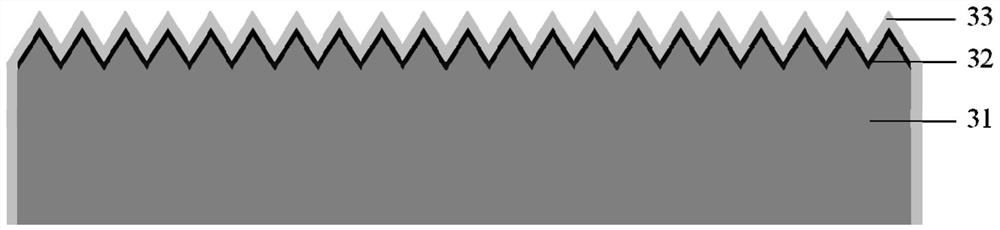

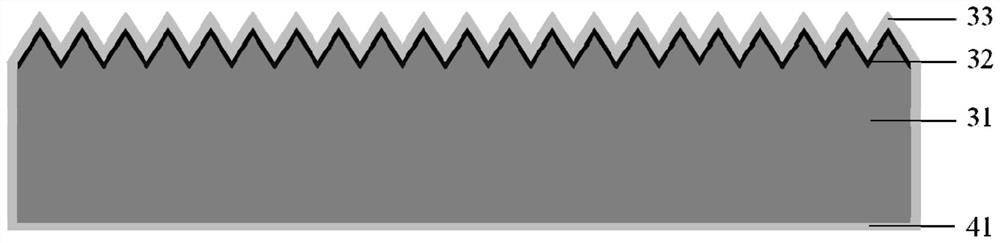

Preparation method of passivation contact solar cell

InactiveCN111816732AWill not polluteReduce leakageFinal product manufacturePhotovoltaic energy generationCell fabricationSolar battery

The invention relates to a preparation method of a passivation contact solar cell, and relates to the field of solar cell manufacturing. The method comprises the following step: forming an oxidation protection layer on a first surface of a doped silicon wafer, wherein the first surface of the silicon wafer comprises a doped surface of one surface of the silicon wafer and a side surface of the silicon wafer. According to the technical scheme provided by the invention, the process can be simplified, and the productivity of the solar cell can be improved.

Owner:JA SOLAR TECH YANGZHOU

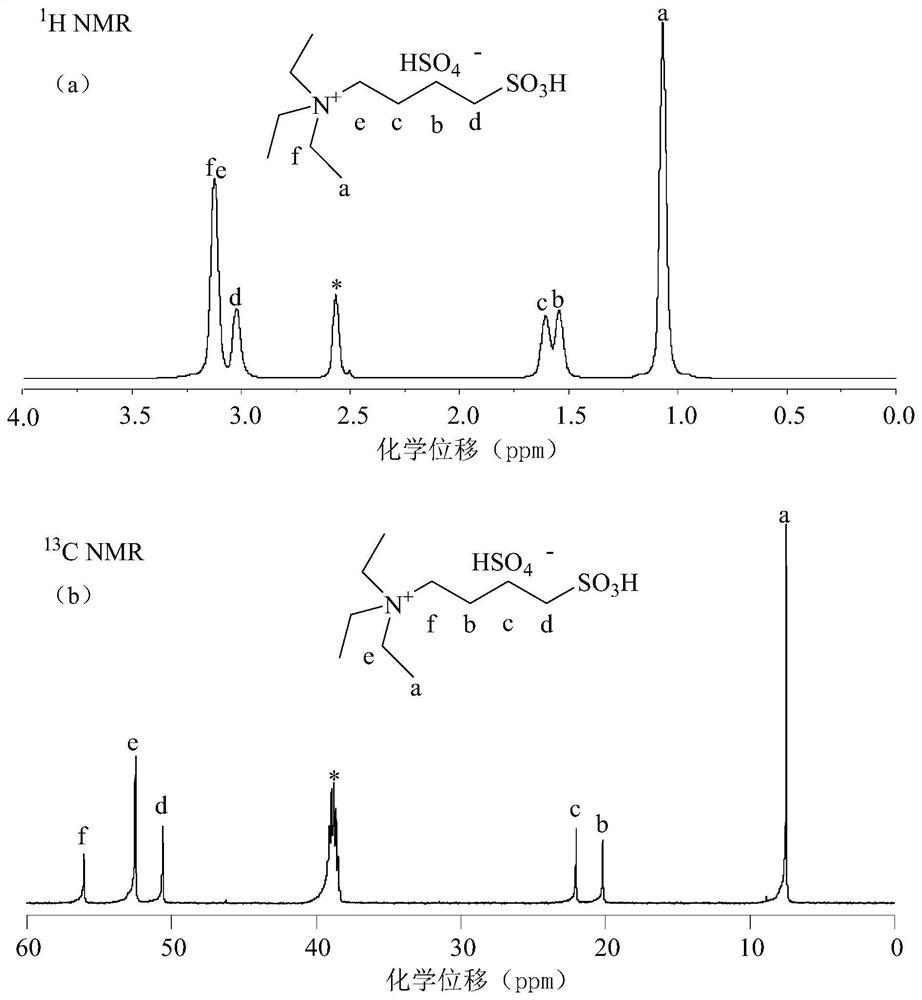

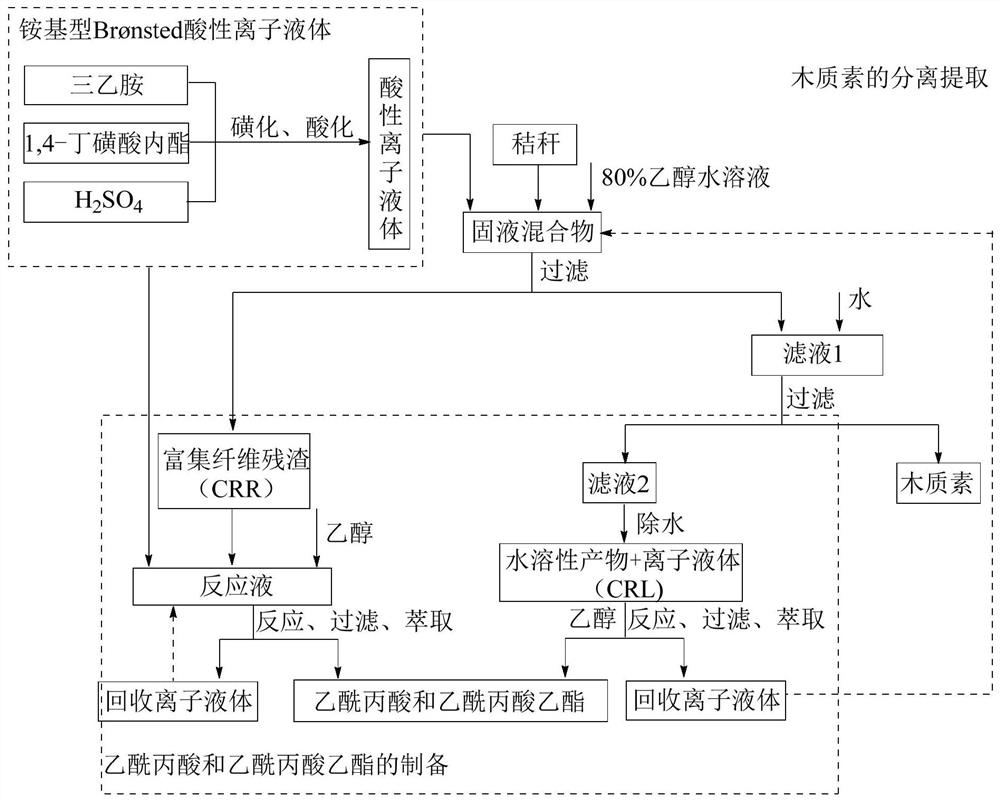

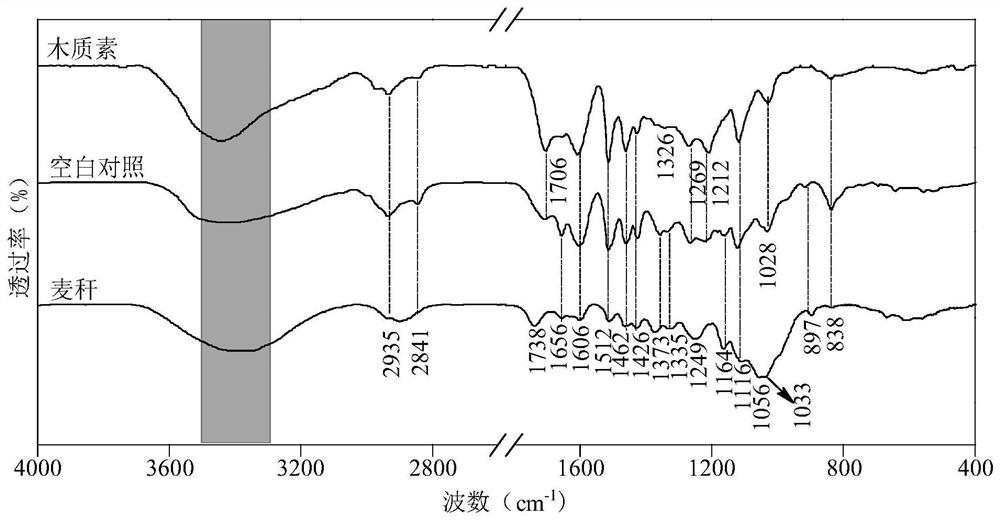

Method for promoting extraction of lignin in straw and catalytically preparing levulinic acid and ethyl ester thereof by using ammonium-based Brownst acidic ionic liquid

ActiveCN113999269AReduce dosageLow costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPropanoic acidPtru catalyst

The invention discloses a method for promoting extraction of lignin in straw and catalytically preparing levulinic acid and ethyl ester thereof by using ammonium-based Bronsted acidic ionic liquid. The method comprises the following steps: 1) by using pretreated straw powder as a raw material, adopting an organic solvent method and using the ammonium-based acidic ionic liquid as an accelerant, extracting lignin from the straw under proper reaction conditions; and 2) preparing levulinic acid and ethyl levulinate from cellulose-rich residue CRR and waste liquid CRL, which are generated after lignin is extracted from the straw, by using an ammonium-based acidic ionic liquid as a catalyst. The preparation method is simple and effective, low in cost, low in reaction temperature and low in toxicity, and the defects of complex process, high cost, high toxicity, high energy consumption, low product yield and the like in the prior art are overcome; and meanwhile, the ionic liquid has a very good effect on preparation of levulinic acid and ethyl levulinate through lignin extraction and catalytic degradation of carbohydrates.

Owner:CHINA UNIV OF MINING & TECH

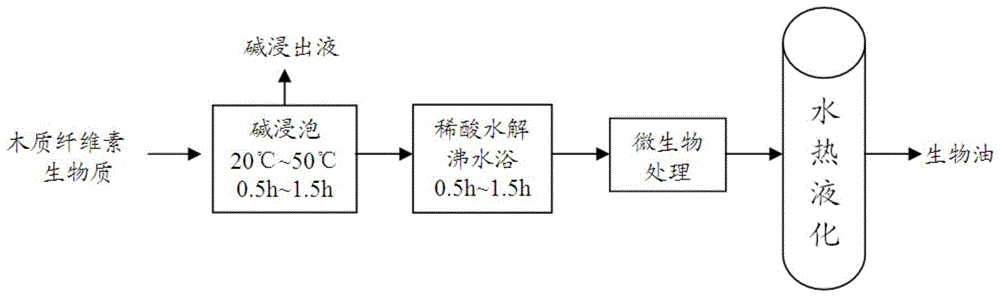

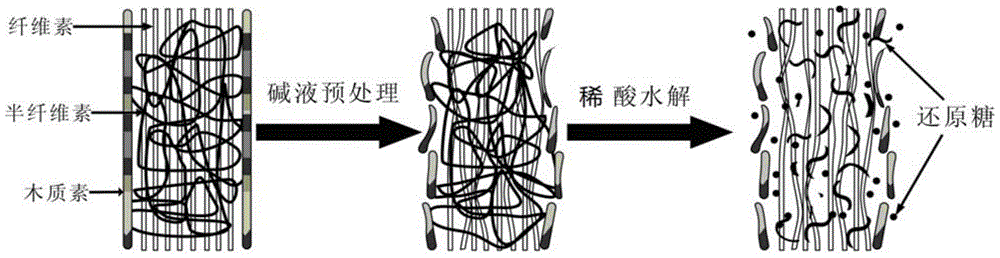

Method for preparing bio-oil reactant and bio-oil from lignocellulosic biomass

ActiveCN104004582BTake advantage ofReduce typesLiquid carbonaceous fuelsFatty-oils/fats productionWater bathsChemical composition

Owner:SHENYANG AEROSPACE UNIVERSITY

Autocatalytic denitrification process of sintering smoke and dust by coupling utilization of smoke dust waste heat

ActiveCN107321174AReduce the cost of denitrificationGuaranteed denitrification efficiencyGas treatmentDispersed particle separationSmall footprintHigh pressure

The invention relates to an autocatalytic denitrification process of sintering smoke dust by coupling utilization of smoke dust waste heat. According to the technical scheme, sintering smoke dust penetrates a sintering material layer, a bottom layer, a bottom grate of a sintering machine trolley and bellows under the trolley and enters a main flue under the draft action of a high-pressure blower; a sintering machine is divided into an ignition section, a machine head section, a smoke rapid heating section and a machine tail section in the traveling direction of the sintering machine trolley sequentially, the sintering smoke dust flows out of a main flue, passes through a denitrification smoke heat exchanger and a smoke heater sequentially and enters a fluidized bed denitrification reactor; liquid ammonia is sprayed into the bellows under the machine tail section, the bellows under the smoke rapid heating section and a smoke outlet pipe of the smoke heater, so that the sintering smoke dust is subjected to a denitrification reduction reaction with ammonia gas under the catalysis effect of particles which are rich in iron oxide and carried by the sintering smoke dust. The process has the advantages of simple process, no purchased catalyst, high recovery of waste heat, small floor area, low equipment investment and low operation cost, is energy saving and reduces consumption.

Owner:WUHAN UNIV OF SCI & TECH +2

Novel technique for preparing ethylene glycol

InactiveCN100381412CReduce utilizationIncrease productivityOrganic compound preparationHydroxy compound preparationSimulated moving bedSlurry

The invention discloses a new technology to manufacture ethandiol, which is characterized by the following: liquefying starch emulsion; saccharifying; filtering; decolouring; separating through simulated mobile chromatogramic separating system; obtaining DX 99-99.7% glucose slurry; evaporating DX value glucose slurry to 50% as dried material; adopting ruthenium or nickel as catalyst; proceeding hydrogenation reaction to obtain the sorbitol solution; hydrogenolyzing for certain time under one catalyst of Ru, Ni / Ru and Co / Re to produce compound with ethandiol, glycerin and propanediol; cooling multi-alcohol; sedimenting; filtering; separating; decolouring; separating ethandiol, glycerin and propanediol.

Owner:SHANDONG XIWANG SUGAR

Memory and method of forming the same

ActiveCN109712981BSimple processSave a patterning processSolid-state devicesSemiconductor devicesBit lineEngineering

A memory and its formation method. The method includes: providing a substrate. The substrate includes an erasure area, a floating gate area and a word line bit line area arranged along a first direction. The floating gate area is located on both sides of the erasure area, and the word line area is arranged along a first direction. The line bit line area is located on both sides of the erase area and the floating gate area; a floating gate structure film and a dielectric layer located on the floating gate structure film are formed on the substrate, and the floating gate area and word line are exposed in the dielectric layer The first opening of the floating gate structure film in the bit line area; forming a first spacer on the sidewall of the first opening; forming a control gate film at the bottom of the first opening; forming a second spacer on the sidewall of the first spacer ; Remove the control gate film and floating gate structure film exposed by the first sidewall, the second sidewall and the dielectric layer to form a floating gate structure layer, a control gate layer and a second opening; remove the dielectric on the erased area layer and a floating gate structure layer to form a third opening and a floating gate structure; an erasure gate structure is formed in the third opening. The method improves memory production efficiency.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Chlorinated polyethylene produced by one-step method and preparation method of chlorinated polyethylene

The invention provides chlorinated polyethylene produced by a one-step method and a preparation method of chlorinated polyethylene. The preparation method comprises the following steps: S1, dissolving high density polyethylene in water and carrying out chlorination reaction under a condition of an emulsifier, a dispersant, an initiator and chlorine; S2, adding calcium oxide into a reaction system in the S1 in batches to generate chlorinated polyethylene resin and a calcium chloride aqueous solution; S3, centrifugalizing and drying the chlorinated polyethylene in the S2 to obtain a product chlorinated polyethylene; and S4, concentrating and drying the calcium chloride aqueous solution in the S2 to prepare a byproduct calcium chloride. Compared to a conventional process, the process flow is reduced, the occupied area and the equipment investment are reduced, and the production cost is lowered; moreover, 15 tons of water per ton of CPE can be saved and 25 tons of industrial wastewater per ton of CPE can be reduced, the water resource is saved, and the social environmental benefit is remarkable. Waste acidic water is fully utilized to prepare the byproduct. The preparation method is high in clean production level and has a relatively good economical benefit.

Owner:SHANDONG LEJIANG BUILDING NEW MATERIALS CO LTD

Deuterium preparation method

ActiveCN109928364AReduce consumptionHigh purityHydrogen separationIsotope separationHydrogenPhysical chemistry

The invention discloses a deuterium preparation method, which sequentially comprises the following steps that 1, heavy water is subjected to impurity removal until the impurity is smaller than 10<-6>g / L; 2, the heavy water is pressurized and heated in a pressure kettle to become superheated water vapor being 1.5 atmospheric pressures and 403.15K; 3, the superheated water vapor and high-purity methane are simultaneously conveyed into a catalytic reactor; the mol ratio of the superheated water vapor to the high-purity methane is 3:1; the temperature in the reactor is controlled to be 1145 to 1155K, and the pressure is controlled to be 1.8 to 2.2 atmospheric pressure; the state is maintained for 30 to 40 minutes; 4, mixed gas is guided into a container; the temperature is lowered to 375.15K,and the pressure is lowered to 1.2 atmospheric pressures; 5, purification is performed through a purification tower; 6, the mixed gas is cyclically compressed into mixed liquid with the temperature being 19.8K; 7, the mixed liquid is fractionated; the temperature in a fractionating tower is maintained to be 21.5K; a gas ingredient of hydrogen and a liquid ingredient of deuterium are collected. The deuterium preparation method has the advantages that the energy source consumption of deuterium preparation is greatly reduced; the purity of obtained deuterium is high.

Owner:陈逸翔 +2

Chinese pennisetum drying method

InactiveCN103267404BSimple processImprove drying efficiencyDrying solid materials with heatDrying gas arrangementsPulp and paper industryWater content

The invention relates to a Chinese pennisetum drying method which is characterized in that a Chinese pennisetum drying device is provided. The Chinese pennisetum drying method includes steps of (1) mowing: Chinese pennisetum plants are mowed when Chinese pennisetum grows to be 1.5-2.5m high; (2) pulping: Chinese pennisetum is made to be grass pulp through a pulping machine without water; (3) flat laying: the grass pulp is flat laid on all layers of drying beds of drying bed frames, and the weight of the grass pulp on each drying bed frame is preferentially 5kg / m<2>-15kg / m<2>; (4) ventilating: upper layer hot air in a greenhouse is blown into grass pulp stacks for ventilating for 20-40 min by opening an air blower at the interval of 0.5-1.5 h; (5) turning: the grass pulp stacks are plowed and harrowed for one to three times every day; and (6) drying: the grass pulp stacks are dried for 3-7 days until the grass pulp is dried to be grass powder with 10-15% of water content, and then the grass powder can be stored or used. The Chinese pennisetum drying method has the advantages of being simple in process, high in drying efficiency, short in drying period and low in cost, being favorable for storing Chinese pennisetum nutrient substances and the like.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI

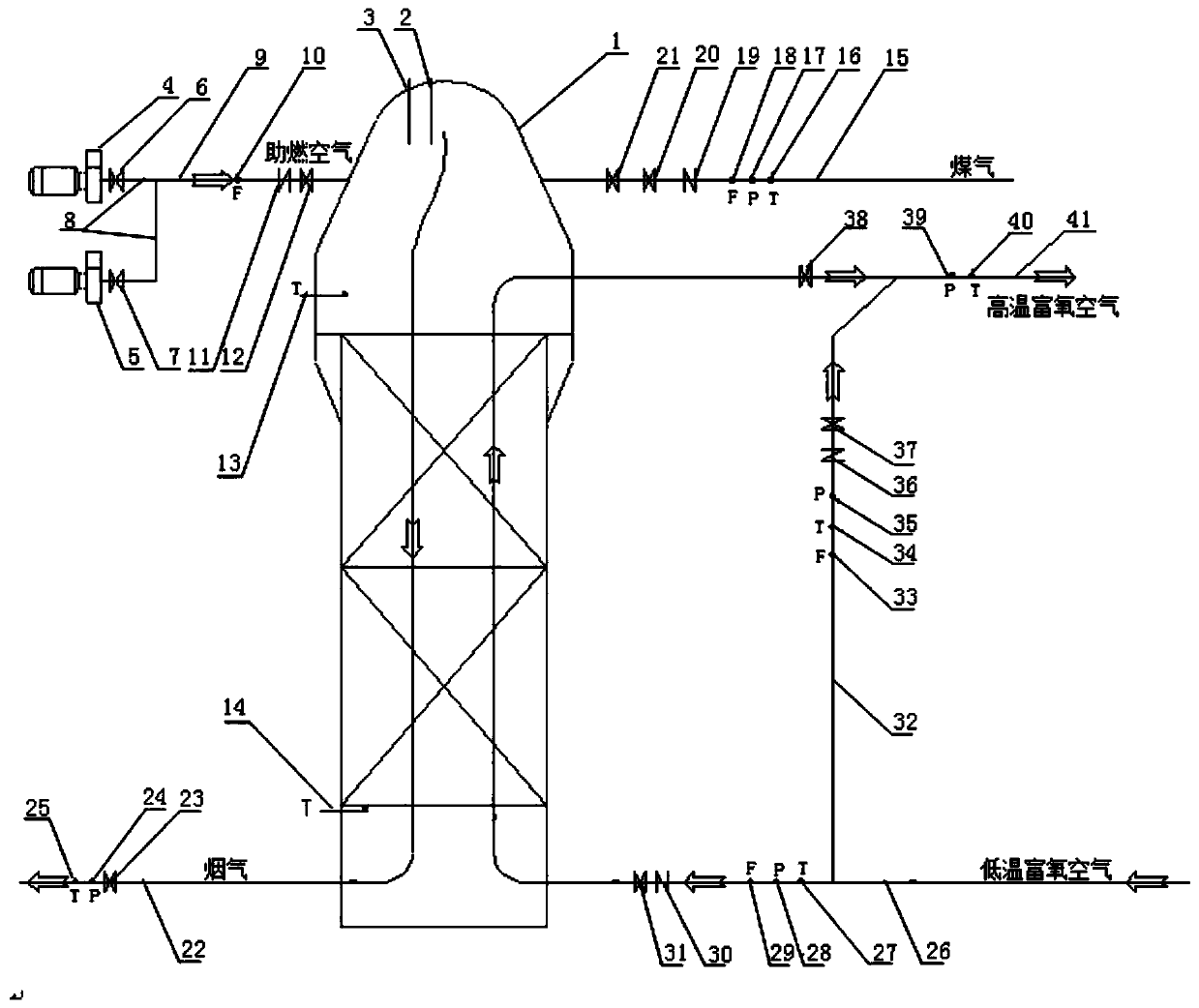

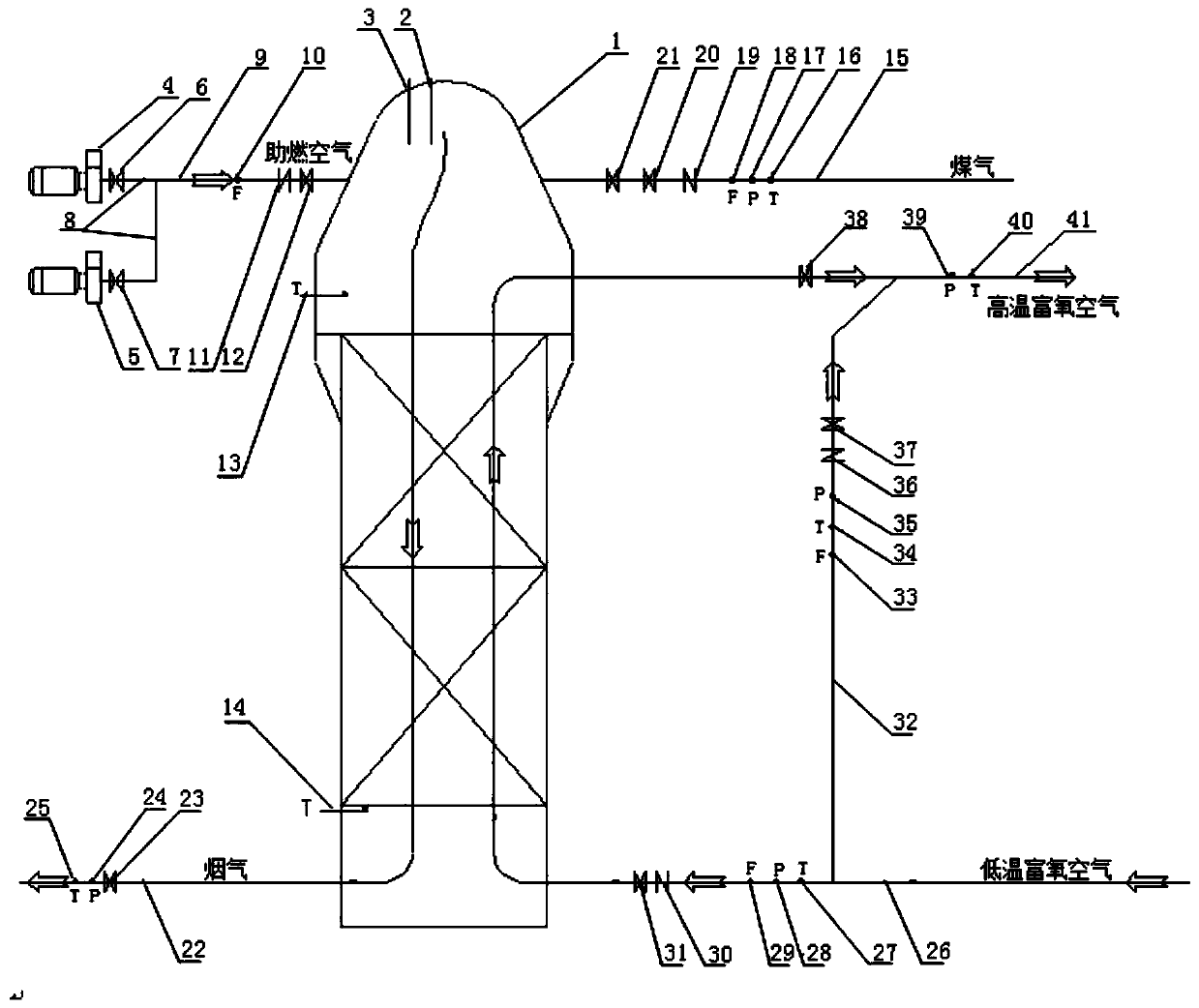

High-temperature oxygen-rich heating furnace for extracting vanadium and titanium from vanadium-titanium slag and operation method of high-temperature oxygen-rich heating furnace

PendingCN111174423ASimple structureRun smoothlyAir heatersProcess efficiency improvementPhysicsTitanium slag

The invention relates to a high-temperature oxygen-rich heating furnace for extracting vanadium and titanium from vanadium-titanium slag and an operation method of the high-temperature oxygen-rich heating furnace. The high-temperature oxygen-rich heating furnace comprises a heating furnace, a gas system, a combustion supporting air system, a smoke system and an oxygen-rich air system. The top of the heating furnace is provided with an auxiliary fire source and an electronic igniter. The heating furnace is provided with a combustion supporting air inlet connected with the combustion supportingair system and is provided with a gas inlet connected with the gas system. A smoke outlet is arranged and connected with the smoke system. An oxygen-rich air outlet is arranged and connected with an oxygen-rich air outlet pipeline, an oxygen-rich air inlet is arranged and connected with an oxygen-rich air inlet pipeline, and the oxygen-rich air inlet pipeline is connected with the oxygen-rich airoutlet pipeline through an oxygen-rich air branch pipe. The heating furnace is further provided with an upper thermometer, a lower thermometer and a heat storage body. By means of the high-temperatureoxygen-rich heating furnace for extracting vanadium and titanium from vanadium-titanium slag and the operation method of the high-temperature oxygen-rich heating furnace, the low-temperature oxygen-rich air can be heated into high-temperature oxygen-rich air needed for later vanadium extraction and titanium extraction, the integral technology requirement is met, finally, the vanadium and titaniumcontaining slag can be better resourcefully utilized, and environment pollution caused by metallurgy slag is reduced.

Owner:鞍钢集团工程技术有限公司

A self-catalytic denitrification system for sintering dust coupled with waste heat of sintering dust

ActiveCN107198962BReduce the cost of denitrificationGuaranteed denitrification efficiencyGas treatmentDispersed particle separationPtru catalystFlue gas

The invention relates to a sintering smoke self-catalyzing denitrifying system by coupling and utilizing residual heat of sintering smoke, which solves the problems of large investment, high running cost and lower denitrifying efficiency in the existing denitrifying system. The sintering smoke self-catalyzing denitrifying system adopts the technical scheme that the sintering smoke self-catalyzing denitrifying system comprises a sintering machine, wherein air bellows are arranged under a trolley of the sintering machine; an exit of the bottom part of each air bellow is communicated with a main flue; the sintering machine is sequentially provided with an ignition section, a machine head section, a flue gas quick heating section and a machine tail section along the moving direction of the trolley; the main flue is sequentially connected with a denitrifying reactor of a fluidized bed through a denitrifying flue gas heat exchanger shell or tube, and a flue gas heater; liquid ammonia spray nozzles are respectively arranged in the air bellows under the machine tail section to the flue gas quick heating section area, and in the flue gas exit pipeline of the flue gas heater. The sintering smoke self-catalyzing denitrifying system has the advantages that the system is simple, the additional purchase of the catalyst is avoided, the effective denitrifying and sintering process is realized, the recycling rate of residual heat is high, the energy-saving and consumption-reducing effects are realized, the land occupation area is small, and the equipment investment and running cost are low.

Owner:武汉钢铁有限公司 +2

One-step method for producing chlorinated polyethylene

The invention discloses a one-step production method of chlorinated polyethylene. The method comprises the following steps: adding 10-20 parts by mass of high-density polyethylene to 80-90 parts by mass of water to generate a chlorination in the presence of an emulgator, a dispersing agent, an initiator and chlorine gas, adding 5-7 parts by mass of calcium oxide in batches in the chlorination process, thus generating chlorinated polyethylene resin and an aqueous solution of calcium chloride, wherein the addition speed of calcium oxide has to ensure that the pH value of the reaction system is controlled to be between 7.0 and 8.5; centrifuging and drying the obtained chlorinated polyethylene resin to obtain a finished chlorinated polyethylene product; and concentrating and drying the aqueous solution of calcium chloride to obtain a byproduct calcium chloride. The one-step production method of chlorinated polyethylene has the advantages that the process flow is simplified, the space occupied by devices and investment in devices are reduced, and the production cost is lowered; in the preparation process of chlorinated polyethylene, waste acid water is made a full use and prepared into a byproduct, and therefore the clean production level is high and relatively high economic benefit can be created.

Owner:ANHUI RES INST OF CHEM IND

A self-catalyzed denitrification process of sintering dust coupled with waste heat of sintering dust

ActiveCN107321174BReduce the cost of denitrificationGuaranteed denitrification efficiencyGas treatmentDispersed particle separationPtru catalystEnvironmental geology

The invention relates to an autocatalytic denitrification process of sintering smoke dust by coupling utilization of smoke dust waste heat. According to the technical scheme, sintering smoke dust penetrates a sintering material layer, a bottom layer, a bottom grate of a sintering machine trolley and bellows under the trolley and enters a main flue under the draft action of a high-pressure blower; a sintering machine is divided into an ignition section, a machine head section, a smoke rapid heating section and a machine tail section in the traveling direction of the sintering machine trolley sequentially, the sintering smoke dust flows out of a main flue, passes through a denitrification smoke heat exchanger and a smoke heater sequentially and enters a fluidized bed denitrification reactor; liquid ammonia is sprayed into the bellows under the machine tail section, the bellows under the smoke rapid heating section and a smoke outlet pipe of the smoke heater, so that the sintering smoke dust is subjected to a denitrification reduction reaction with ammonia gas under the catalysis effect of particles which are rich in iron oxide and carried by the sintering smoke dust. The process has the advantages of simple process, no purchased catalyst, high recovery of waste heat, small floor area, low equipment investment and low operation cost, is energy saving and reduces consumption.

Owner:WUHAN UNIV OF SCI & TECH +2

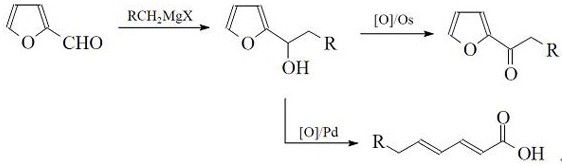

A kind of preparation method of gamma-substituted hexadienoic acid

ActiveCN112110812BAvoid techno-economic disadvantagesObvious cost advantageOrganic compound preparationCarboxylic compound separation/purificationFuranPtru catalyst

The invention relates to a preparation method of γ-substituted hexadienoic acid, which is characterized in that: (1) at 10-40°C, add a solvent, a catalyst, and a catalyst assistant to a reaction vessel, stir, and introduce oxygen, and add 1-( 2-furyl)-1-alkylcarbinol, control catalyst: catalytic promoter: the molar ratio of 1-(2-furyl)-1-alkylcarbinol is 0.0001~5:0.0001~3:100, and the reaction temperature is 0~200℃, pressure 0.1~20MPa, reaction 1~74h; solvent is a mixture of water phase and organic phase with a volume ratio of 1:0.01~3, the water phase is a phosphate acid solution, and the organic phase is a reaction inert solvent , the catalyst is a palladium compound, and the catalytic assistant is an amine or a phosphine compound; (2) cooling the reaction vessel to room temperature, adding an organic solvent for extraction, and performing vacuum distillation on the organic phase. The invention has the advantages of avoiding technical and economic disadvantages in the existing synthetic route, simplifying the technological process, reducing consumption and emission, reducing energy consumption and cost, and being suitable for industrialized production with expanded production capacity.

Owner:ANHUI JINGHE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com