Electromagnetic shielding glass laser soldering structure and production process

An electromagnetic shielding and glass laser technology, applied in glass manufacturing equipment, magnetic/electric field shielding, manufacturing tools, etc., can solve the problems of high production cost, product color spots, and multiple steps in the composite process, and reduce material costs and time cycles. cost, reduce the difficulty of production site management, and reduce the effect of product process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

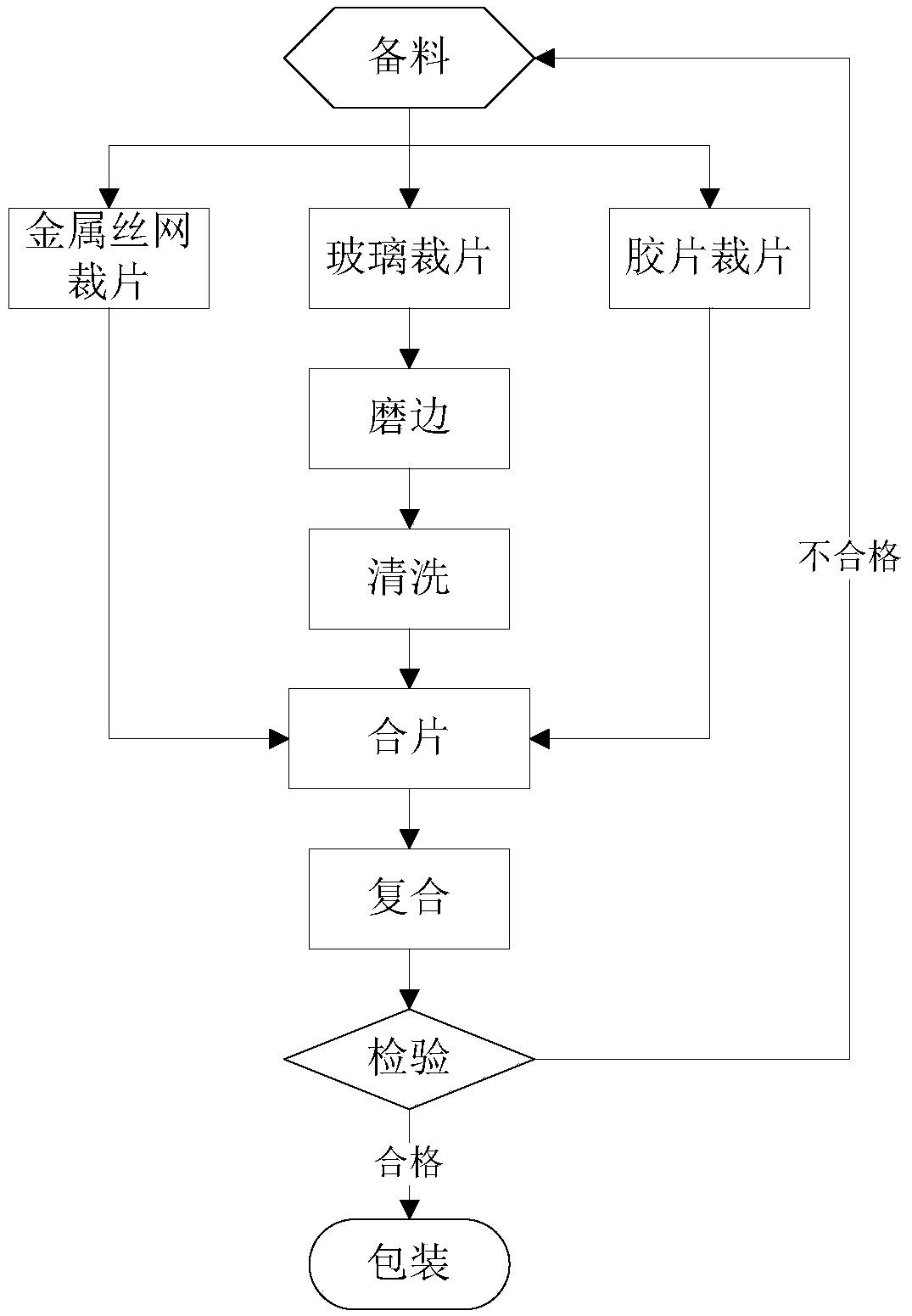

[0051] (1) The fine metal nickel mesh (100 mesh) is firmly clamped between the tempered glass sheets, and then fixed together on the laser welding platform;

[0052] (2) Set the laser welding process parameters, the laser wavelength is 1064nm, the pulse width is 40 nanoseconds, the average laser power is 200W, and the welding scanning rate is 50mm / s. Along the set welding path, it is collected on the CNC laser welding machine , In the air, the above tempered glass sheet and fine metal nickel mesh are welded together to obtain electromagnetic shielding glass with high strength, high light transmittance and high shielding efficiency.

Embodiment 2

[0054] (1) The fine metal stainless steel mesh (150 mesh) is firmly clamped between ordinary silicate glass sheets, and then fixed together on the laser welding platform;

[0055] (2)) Set the laser welding process parameters, the laser wavelength is 1064nm, the pulse width is 1 nanosecond, the average laser power is 50W, and the welding scanning rate is 2mm / s. Along the set welding path, the above-mentioned common silicic acid The salt glass sheet and the fine metal stainless steel mesh are welded together to obtain electromagnetic shielding glass with high strength, high light transmittance and high shielding efficiency.

Embodiment 3

[0057] (1) The fine stainless steel mesh (150 mesh) is firmly clamped between the tempered glass sheets, and then fixed together on the laser welding platform;

[0058] (2) Set the laser welding process parameters. The laser wavelength is 1065nm, the pulse width is 45 picoseconds, the average laser power is 250W, and the welding scanning rate is 150mm / s. Along the set welding path, it is collected on the CNC laser welding machine , In the air, the above tempered glass sheet and fine stainless steel mesh are welded together to obtain electromagnetic shielding glass with high strength, high light transmittance and high shielding efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com