Polyimide solar net plate and manufacturing method

A technology of polyimide and production method, which is applied in the field of solar screens, can solve the problems of cleanliness, temperature, and humidity requirements, high screen production costs, and insufficient yield, so as to save manpower, reduce EL defects, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described now in conjunction with accompanying drawing.

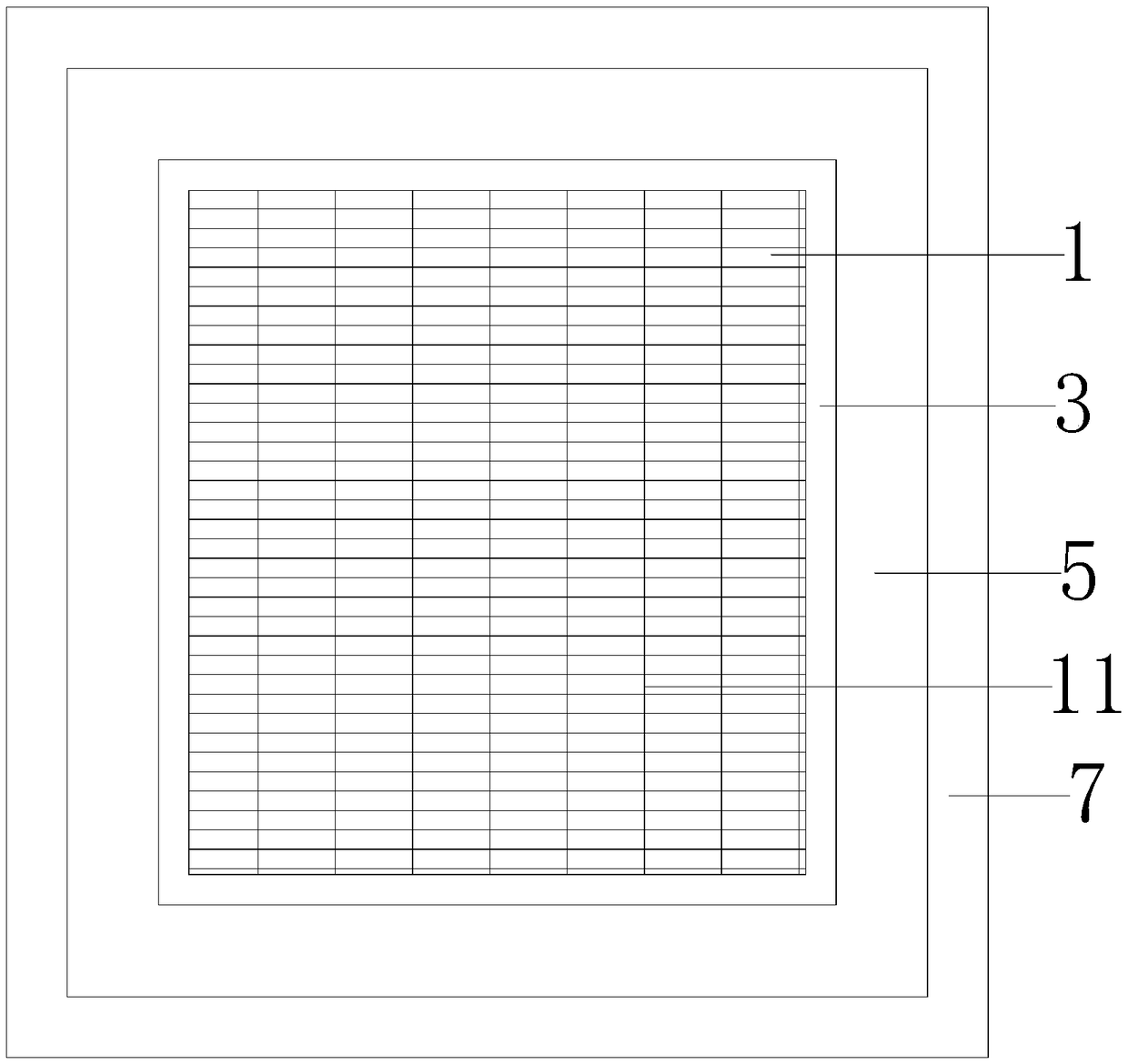

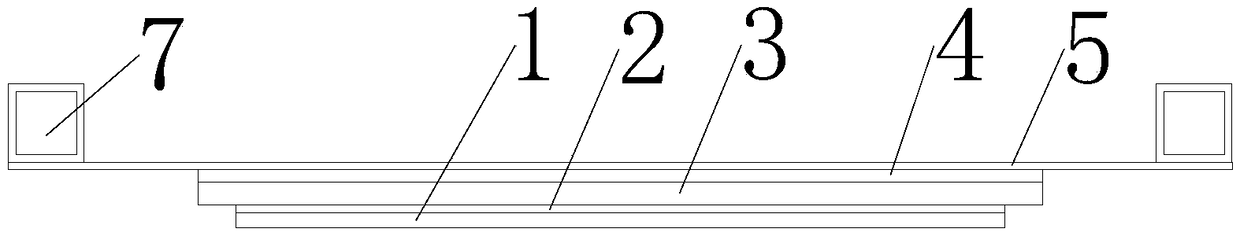

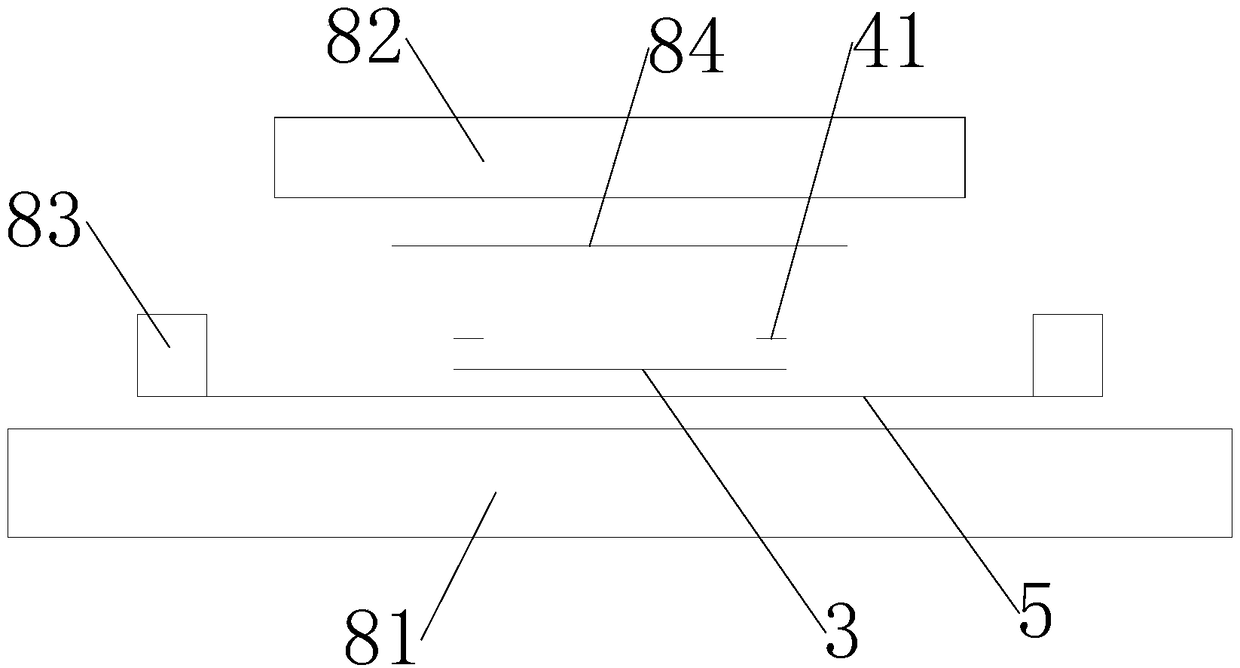

[0045] Such as figure 1 and figure 2 As shown, a polyimide solar screen plate includes a screen frame 7 and a polyester screen 5, the polyester screen 5 is stretched at the bottom of the screen frame 7, and the center of the polyester screen 5 is provided with a silk screen hole, Polyester screen 5 is back-shaped; also includes stainless steel screen 3 and polyimide film 1; polyimide film 1 is fixed on the bottom surface of stainless steel screen 3, polyimide film 1 and stainless steel screen 3 There is a high-temperature adhesive layer 2 between them, and a plurality of wire grooves 11 are arranged on the polyimide film 1, and the wire grooves 11 form a printing pattern; the top surface of the stainless steel wire mesh 3 is fixed on the polyester wire mesh 5, and the stainless steel wire mesh 3 is larger than the screen printing hole, the stainless steel screen 3 covers t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com