Light source with quantum dots and manufacturing method and application of light source with quantum dots

A production method and technology of quantum dots, which are applied in electric light sources, optics, nonlinear optics, etc., can solve the problems of high cost of quantum dot production, uneconomical benefits, etc., to save resources, save quantity, and increase the angle of light output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

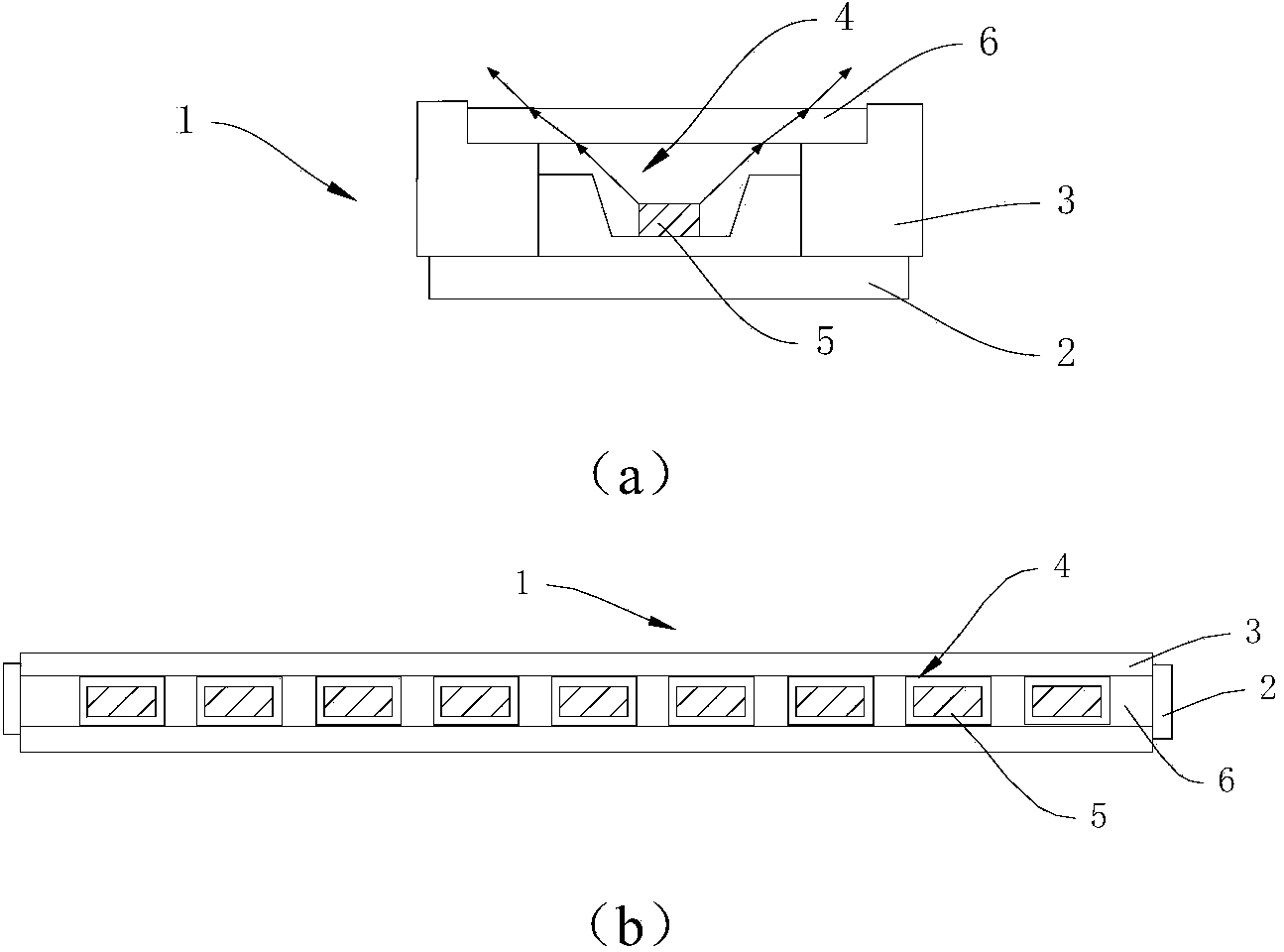

[0043] Figure 4 The figure shows the short-axis cross-sectional structure of the light-emitting source 40 using quantum dots provided in this embodiment. The light emitting source 40 includes: a substrate 41 on which a light bar 43 and a light mixing body 42 arranged around the light bar 43 are installed. Wherein, the light bar 43 may specifically be composed of an LED light 44 and a circuit board thereof. A quantum dot bar 45 is erected on the top of the light mixing body 42, and the emitted light of the light bar 43 is refracted by the quantum dot bar 45 and then emerges. Surface) is a curved surface, so that the emitted light is further diverged and emitted through the quantum dot bar 45, and the light emitting angle can reach 150°-160°, which effectively increases the light emitting angle of the light source.

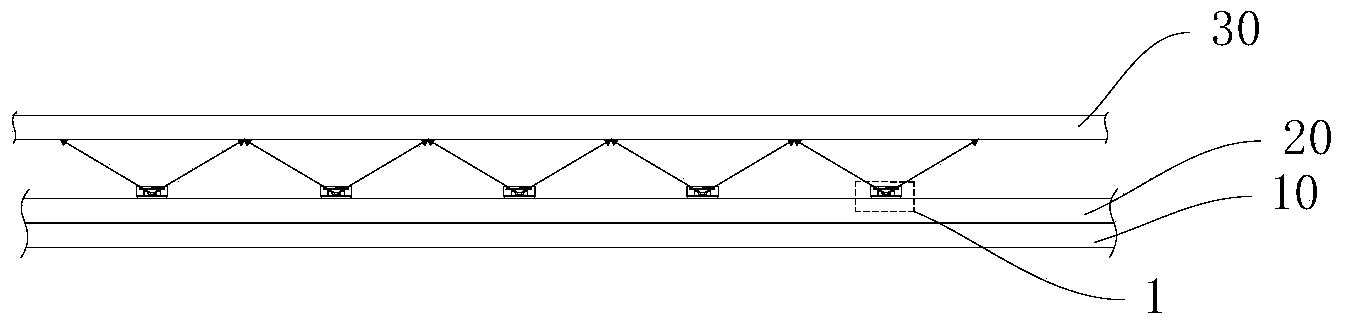

[0044] By assembling this light source 40 into an existing direct-lit backlight source, obvious beneficial effects can be obtained. see image 3 As shown, the ...

Embodiment 2

[0050] This embodiment is a further improvement or change to the quantum dot bar structure and manufacturing method. The light emitting surface of the quantum dot bar in this embodiment has concave grooves. For example, if Figure 7 As shown, a groove 48 can be formed on the top of the quantum dot bar 45a obtained in Example 1, so that the obtained light-emitting surface is not a smooth transition arc surface, and a new quantum dot bar 45c is formed. Further, in order to uniformly disperse the emitted light from the light bar (not shown in the figure) from the center, the groove 48 preferably corresponds to the light emitting center of the light bar.

[0051] The above-mentioned quantum dot bar 45c can be obtained by the first manufacturing method in Embodiment 1, and the obtained quantum dot bar light path diagram is as follows Figure 7 As shown, the purpose of the invention of increasing the light emitting angle of the light emitting source can also be achieved.

[0052]...

Embodiment 3

[0054] In this embodiment, the structure of the quantum dot bar provided in Example 2 is further improved, and the shape of the groove on the light-emitting surface of the quantum dot bar can also be changed along with the change of the curved surface pattern of the light-emitting surface of the quantum dot bar. Such as Figure 9 As shown, the short-axis section of the light-emitting surface of the quantum dot bar 45e in this embodiment is in the shape of double arches juxtaposed left and right. In order to disperse the emitted light from the light bar (not shown in the figure) evenly from the center, the juxtaposed arches are arranged symmetrically, and the groove 48a formed by the double arches corresponds to the light emitting center of the light bar.

[0055] Similarly, the quantum dot bar 45e of this embodiment can be obtained by the first preparation method provided in Embodiment 1, and its structure and optical path diagram are as follows Figure 9 shown.

[0056] It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com