Manufacturing method for light-emitting diode (LED) lamp strip using sapphire as chip support

A technology of LED light bar and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of small light emitting angle and low light output efficiency, and achieve the effects of increased light output efficiency, good light transmission performance, and improved packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

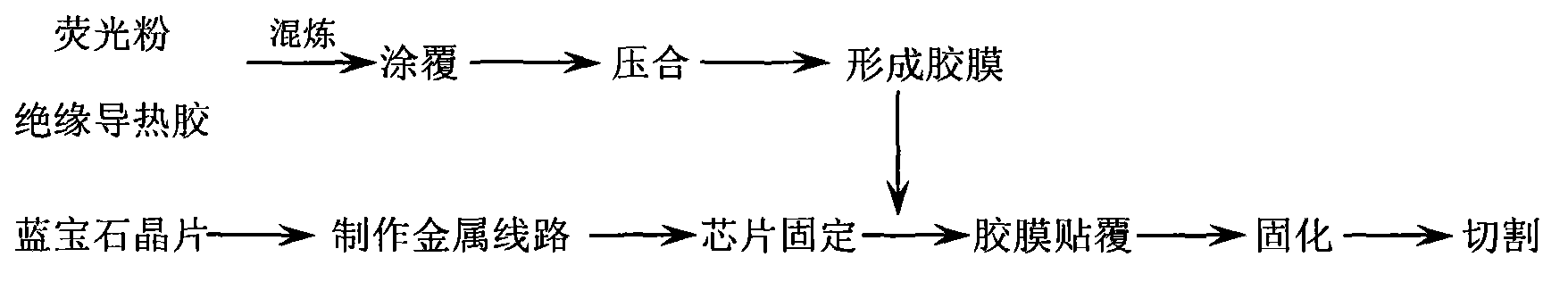

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] combine figure 1 , In this embodiment, the LED lamp power is designed to be 3W, and three light bars are pre-installed in each lamp. The power of each chip is 0.05W, so each light bar needs to arrange 20 chips. According to the size of the chip and the chip and the reserved size at both ends, the length of the light bar needs to be 25mm. According to the required width of the light bar, make a sapphire wafer with an end face size of 25×50mm and a thickness of 0.2-2mm. The surface of the sapphire wafer is plated with an aluminum metal film layer, and etched to form a connecting circuit, the width of the aluminum conductor is 80 μm, and the thickness of the circuit is 60 μm. After dispensing, solid crystal, and welding processes, the chip is fixed on the sapphire wafer in the form of flip chip. The fluorescent powder and silica gel w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com