Patents

Literature

498results about How to "Downgrade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

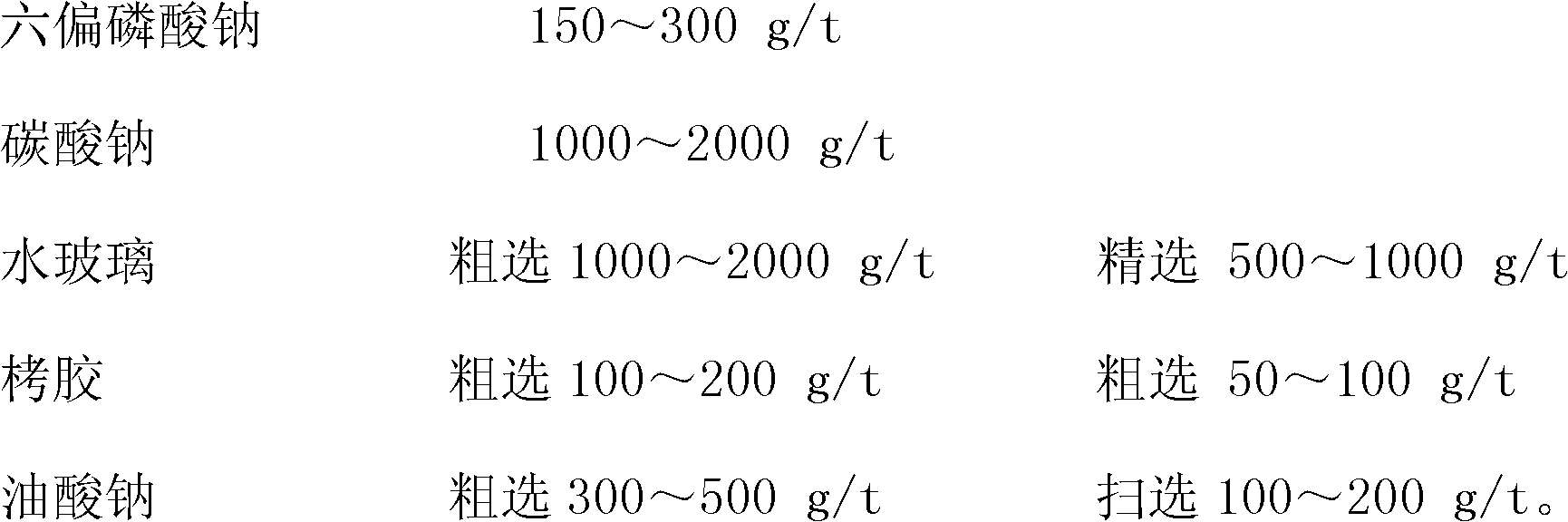

Processing technology for molybdenum and tungsten oxidized ore

InactiveCN101224441AHigh recovery rateResolve recovery rateSievingScreeningLaboratory testFatty acid

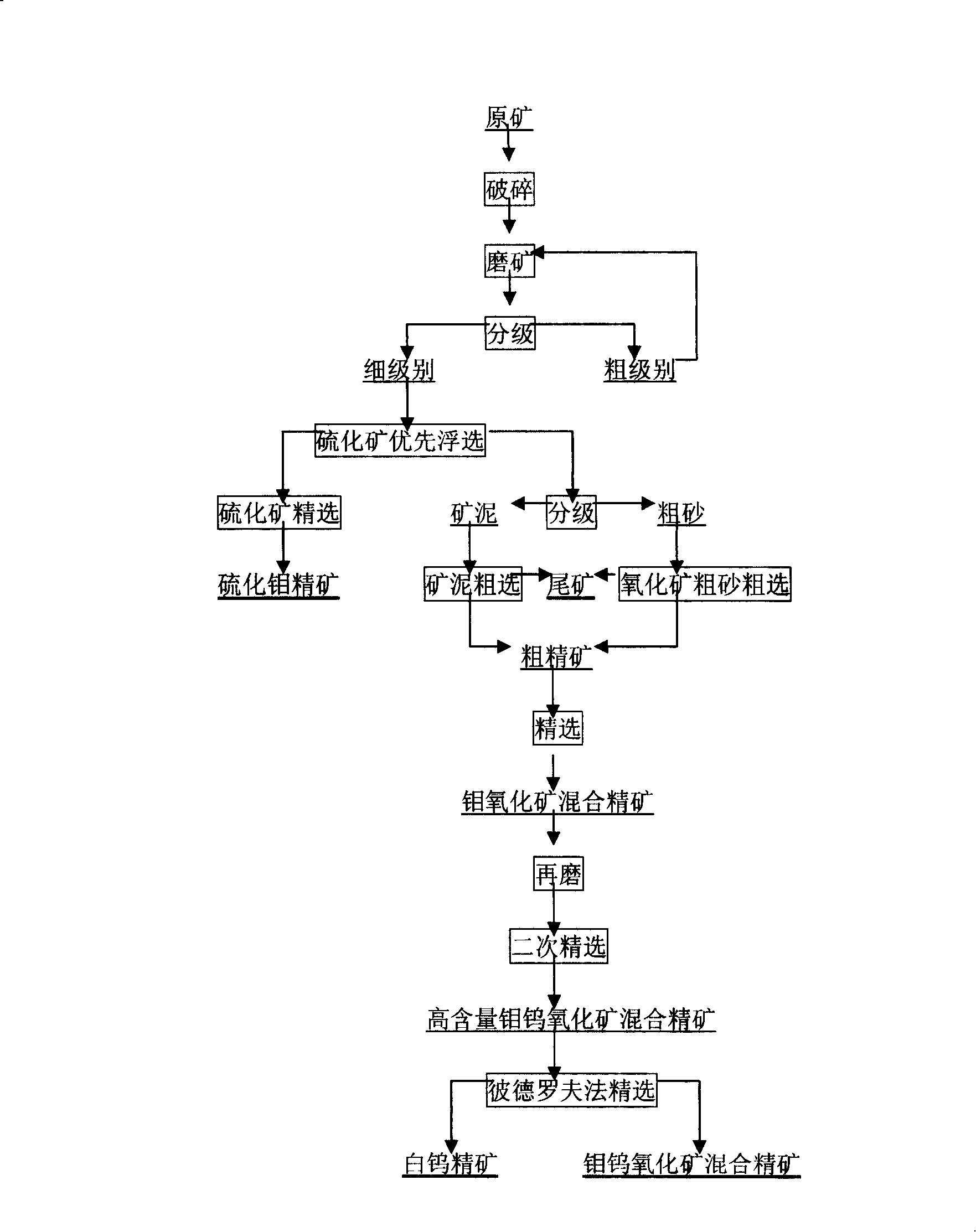

The invention discloses a beneficiation process of a molybdenum-tungsten oxide ore. The process of which is that: the liberation degree of ore crushing is higher than or equal to 70%; the flotation of molybdenum sulfide is preferred; the floatation tailing is classified and then a separation of slime and sand is carried out, wherein a slime and sand system takes alkali as the conditioning agent, sodium silicate as the depressant, and emulsified fatty acid as the collecting agent. The rough concentrate obtained from the separation of slime and sand is concentrated after being blended to obtain molybdenum-tungsten oxide ore collective concentrate. The collective concentrate is grounded again and added with the depressant, then a secondary concentrate can be gained through the concentration; the secondary concentrate is concentrated by means of Peter Roph method to obtain scheelite ore and oxidized molybdenum-tungsten beneficiation concentrate. The invention has the advantages that: 1. the invention discloses a beneficiation process flow for treating molybdenum-tungsten oxide ore; 2. the invention solves the difficulty of lowe technical specification of molybdenum - tungsten oxide ore beneficiation; 3. the invention completes laboratory tests and researches and fulfills industrialized implementation for the first time in China.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

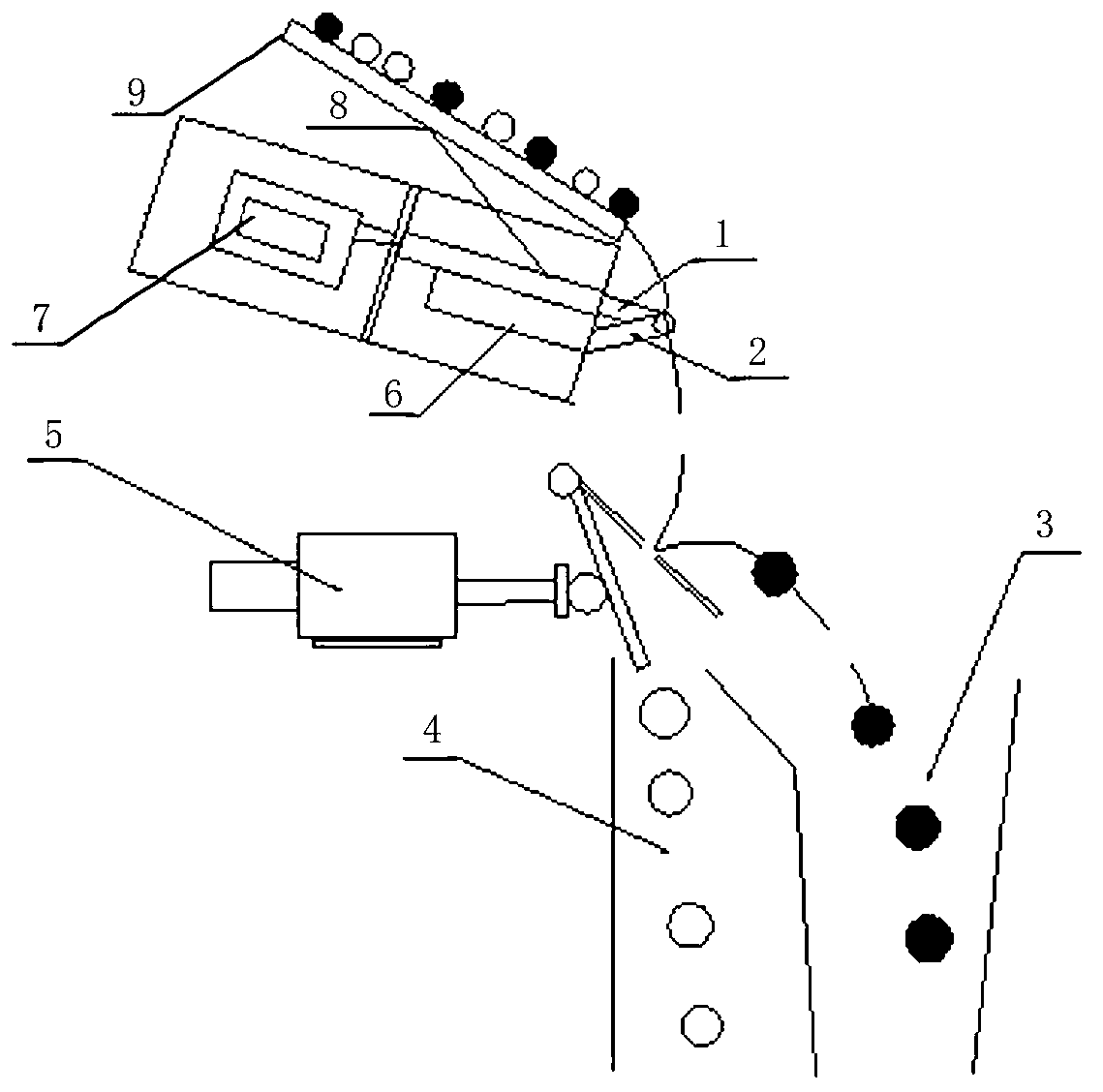

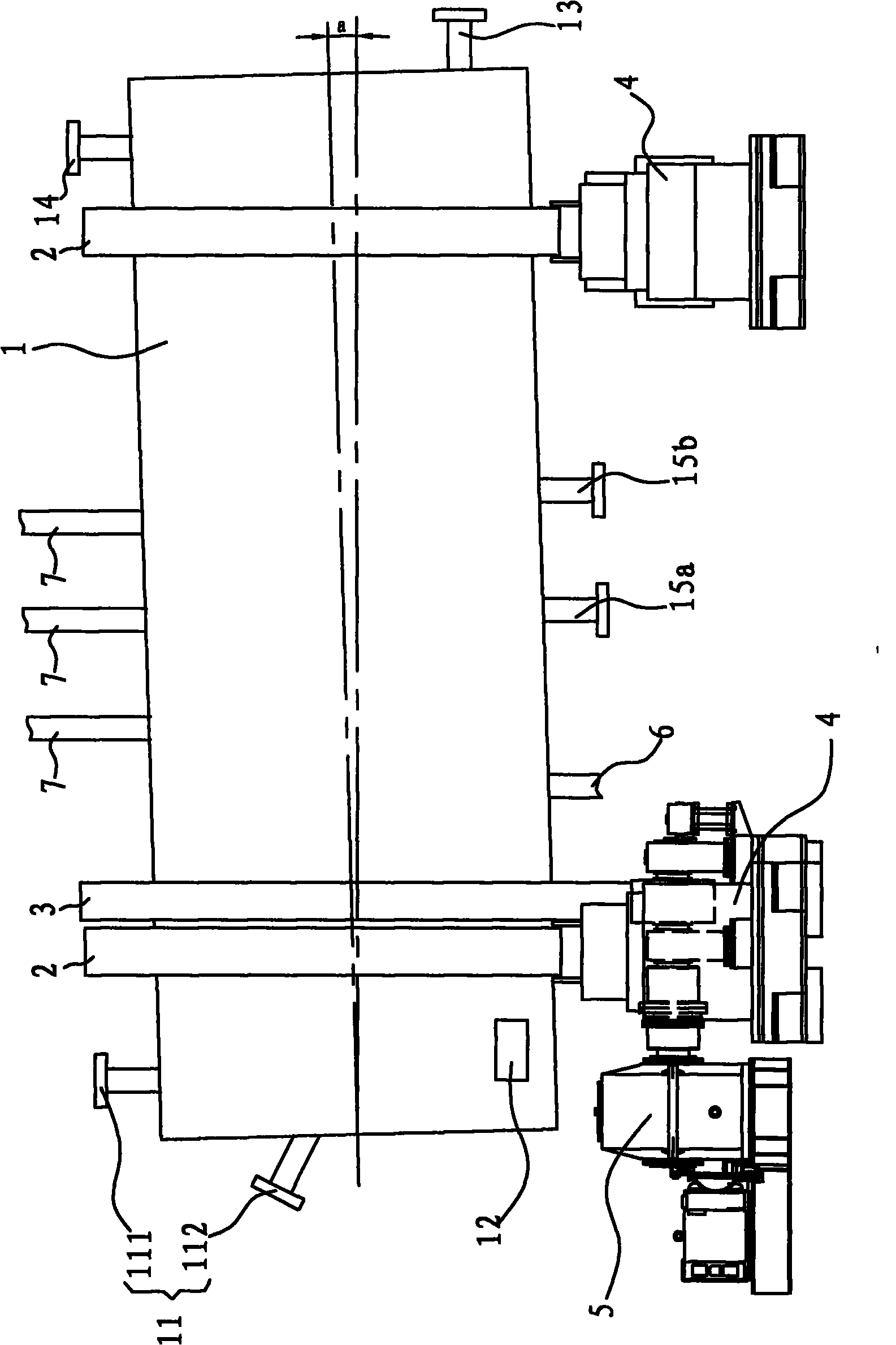

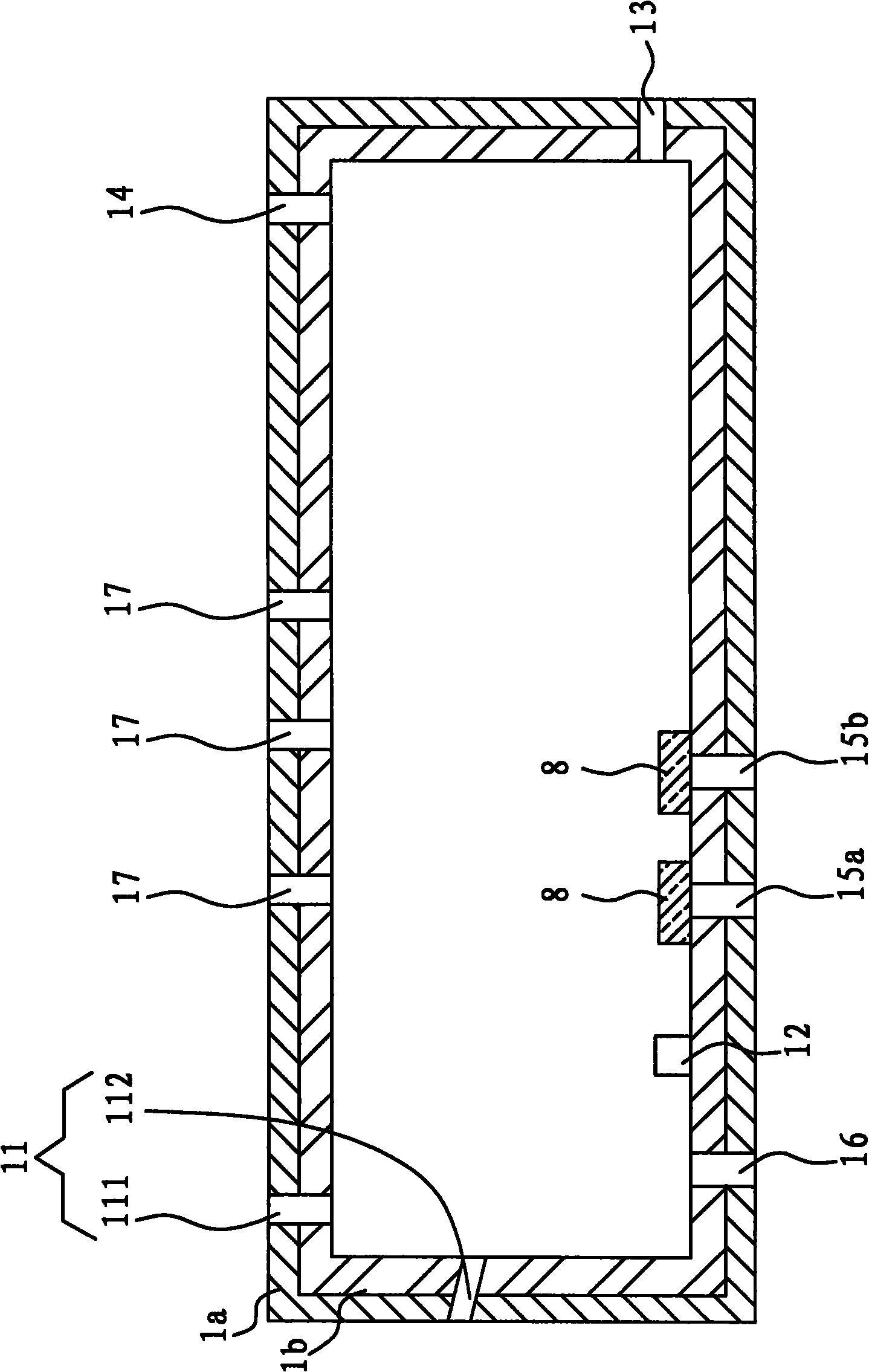

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

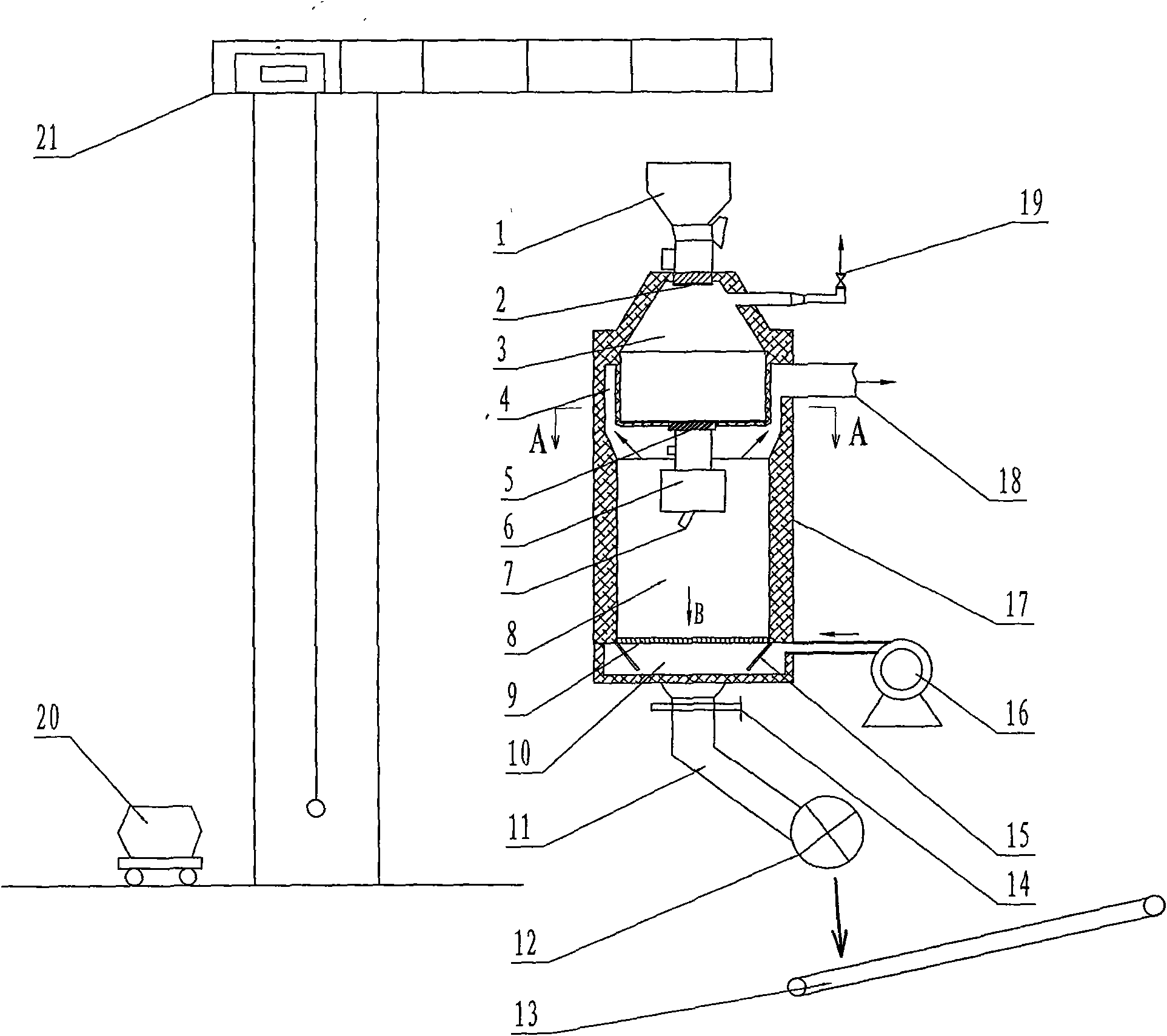

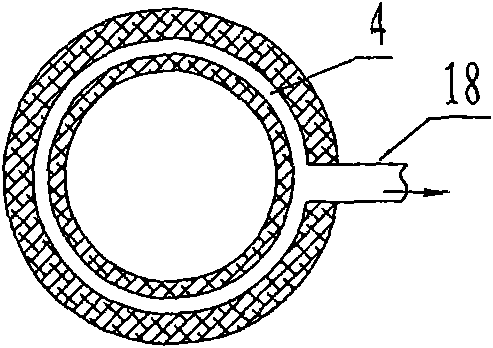

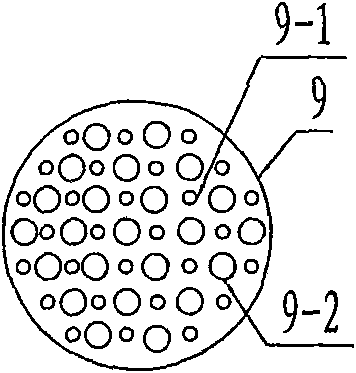

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

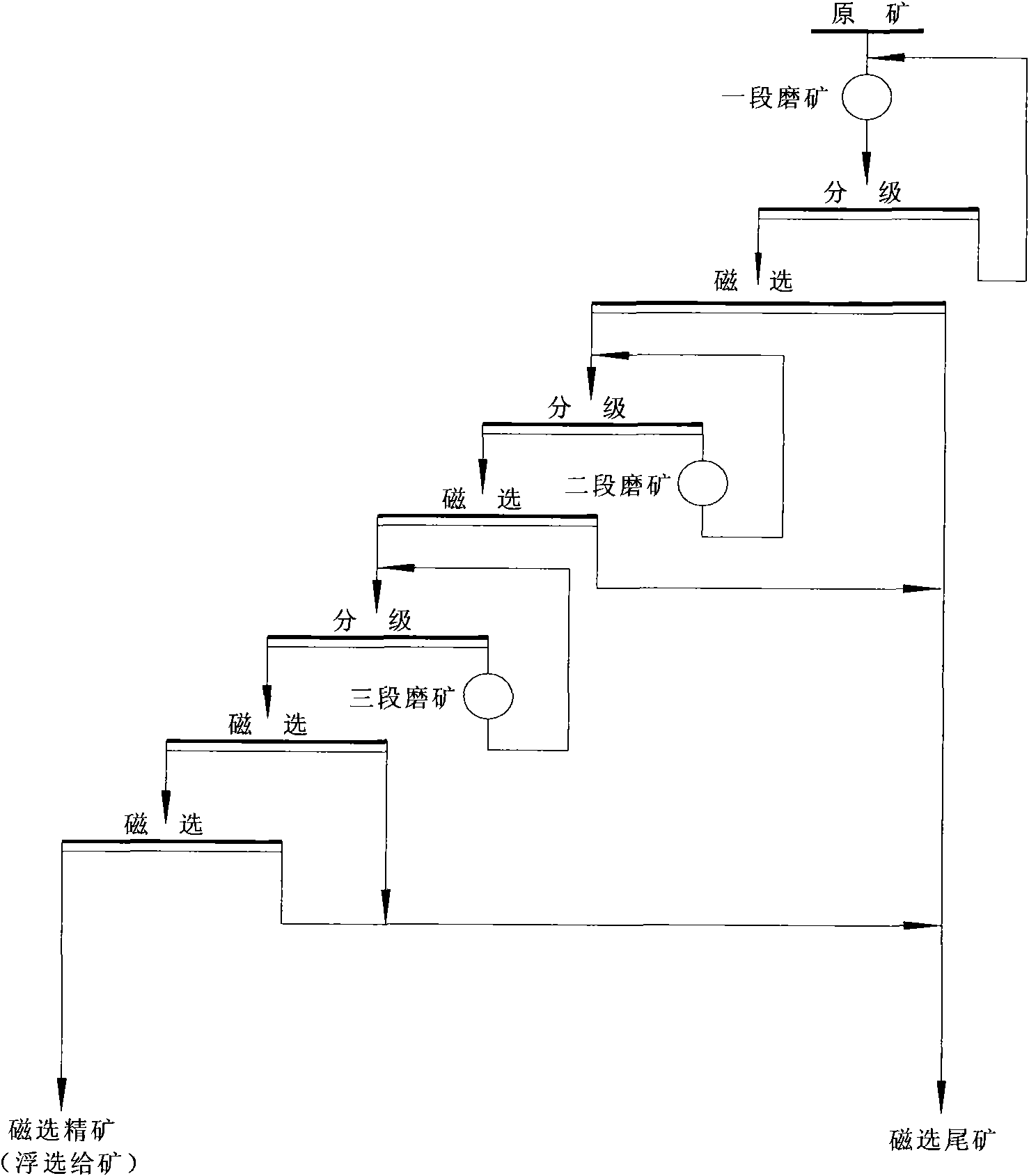

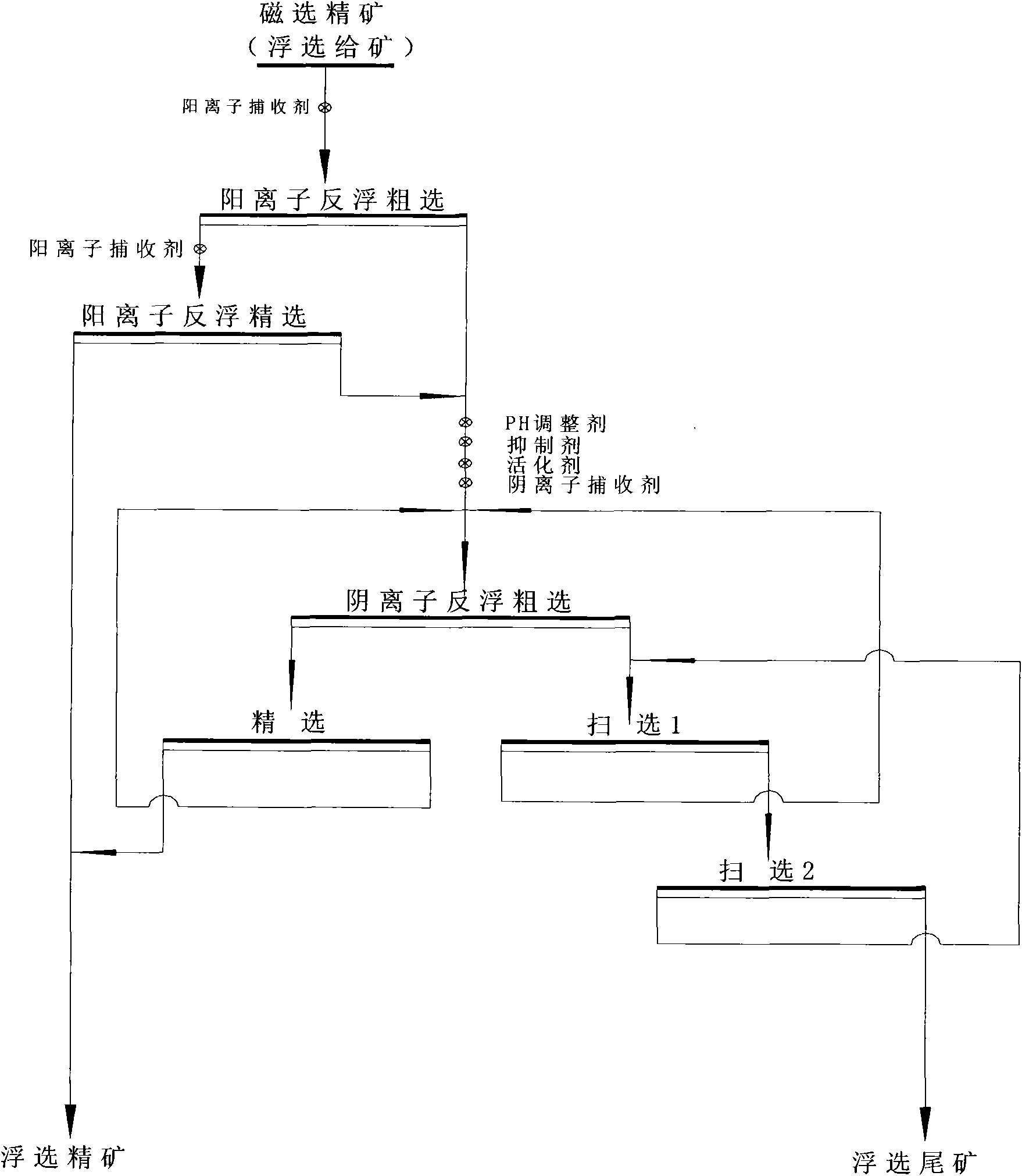

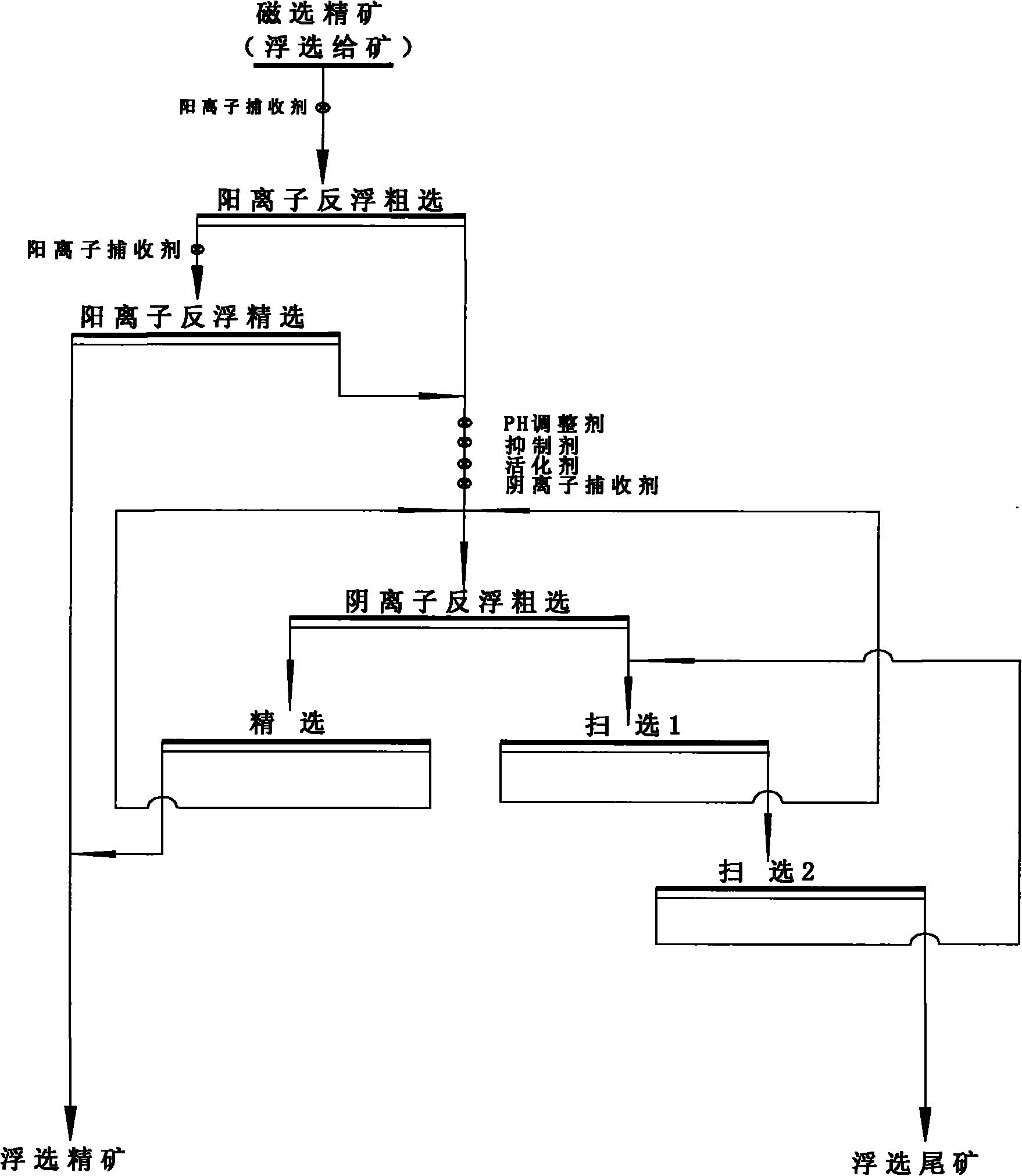

Beneficiation method for producing high-quality iron ore concentrate by low-grade magnetic iron ore

The invention discloses a beneficiation method for producing high-quality iron ore concentrate by low-grade magnetic iron ore, which comprises the following steps that a stage grinding-stage magnetic separation discarding tailing beneficiation process is adopted to produce magnetic separation ore concentrate with the iron ore concentrate grade TFe of 62-66%; a positive ion collector reverse flotation process is adopted on the magnetic separation ore concentrate to obtain positive ion collector reverse flotation iron ore concentrate and middling; a negative ion collector reverse flotation process is adopted on the middling obtained by positive ion collector reverse flotation to obtain negative ion collector reverse flotation iron ore concentrate; and the positive ion collector reverse flotation iron ore concentrate and the negative ion collector reverse flotation iron ore concentrate are combined to obtain the ultimate high-quality iron ore concentrate. The invention has the advantages of high grade of iron ore concentrate, high iron recovery rate, small loss of fine iron minerals, low beneficiation energy consumption and small consumption of medicaments, can relieve the industry difficulty of difficult filtration caused by adding starch into fine concentrate, greatly optimizes concentrate filtration operation, can be used for the sorting of magnetite ore, and can also be used for the sorting of weakly magnetic iron minerals such as hematite and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

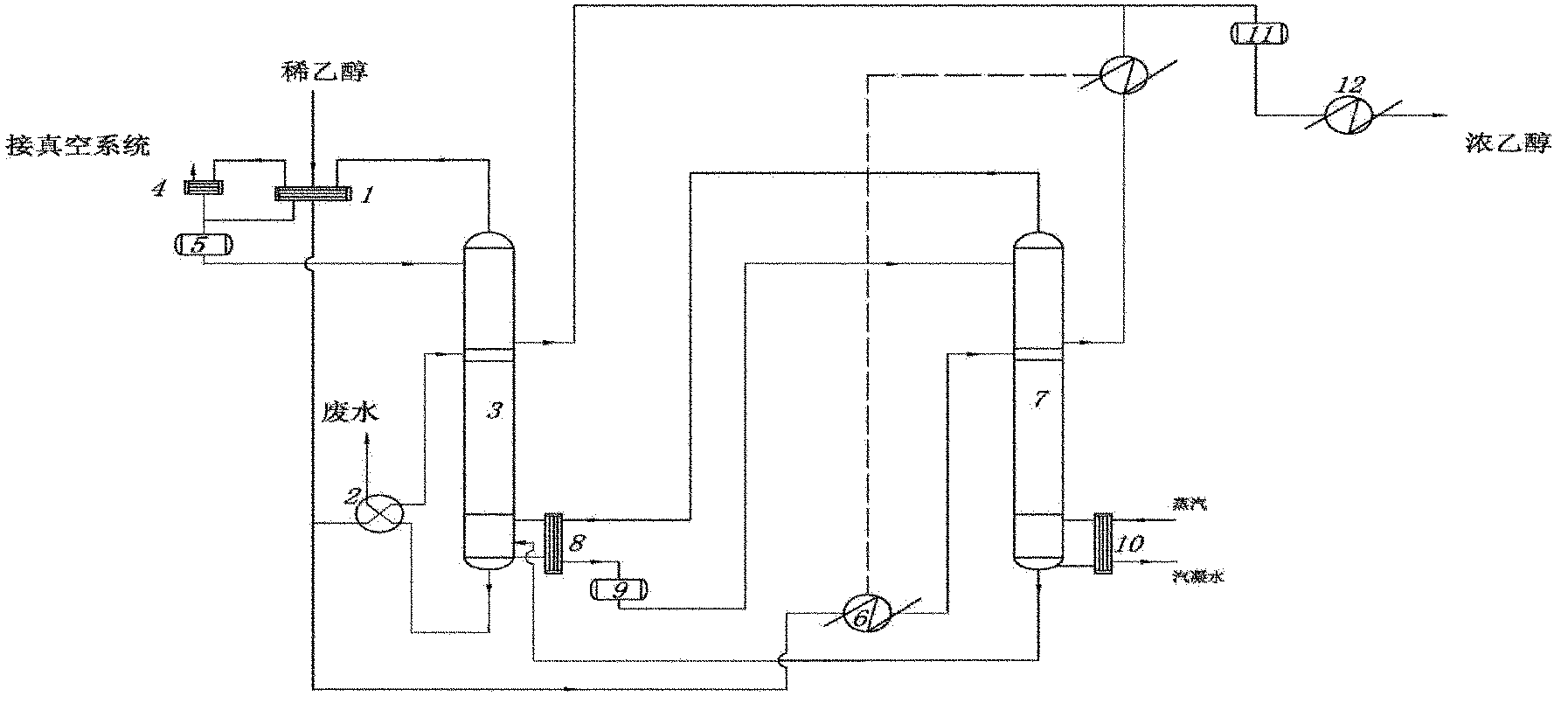

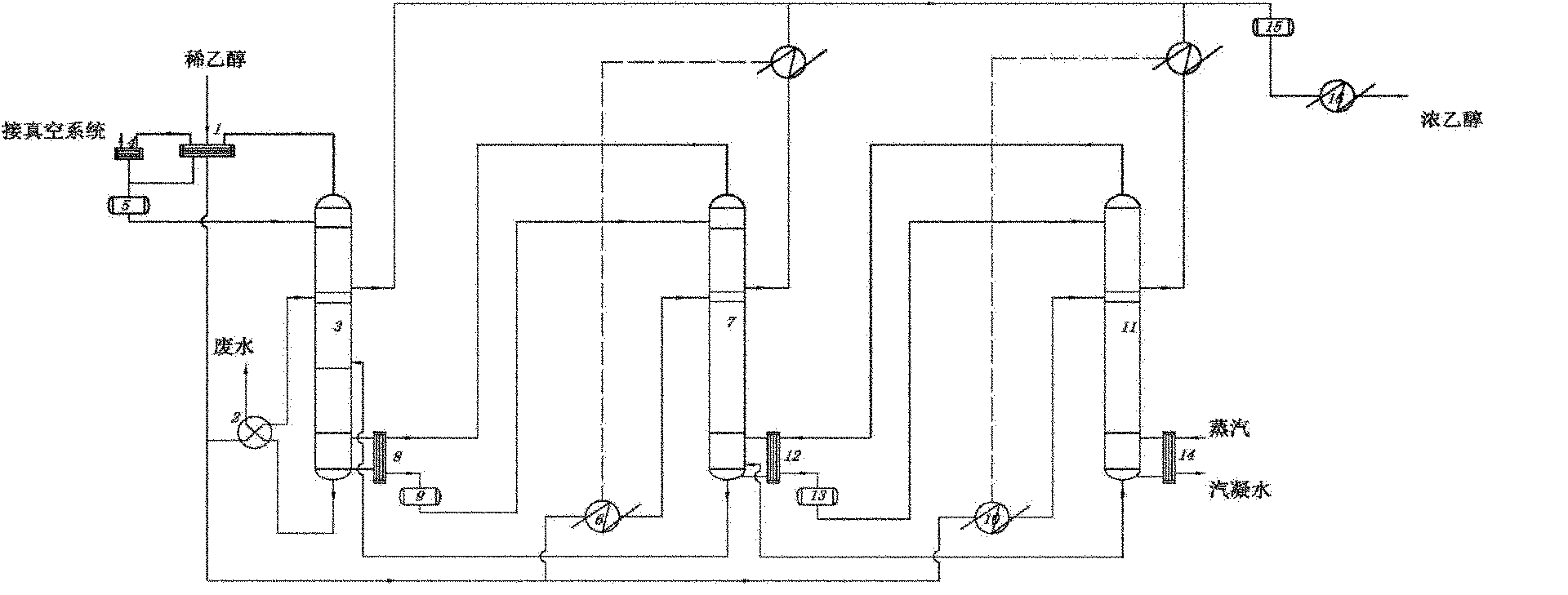

Low-pressure ethanol recovery device and method with triple effect rectification

ActiveCN102091429AReduce energy consumptionReduce lossesOrganic compound preparationHydroxy compound preparationRecovery methodReboiler

The invention discloses a low-pressure ethanol recovery device and method with triple effect rectification. The low-pressure ethanol recovery device with triple effect rectification comprises a first rectifying tower, a second rectifying tower, a third rectifying tower, a rectifying tower reboiler, a rectifying tower feed preheater, a condenser, a return tank, a dilute ethanol feed preheater, a temporary finished product storage tank and a finished product cooler. In the ethanol recovery method with triple effect rectification, by controlling the recovery of the finished ethanol in the second rectifying tower, the content of ethanol in tower bottom wastewater of the second rectifying tower is 5wt%-30wt%, the temperature of the tower bottom wastewater is 100-120 DEG C, and the working pressure of the third rectifying tower is 250-400kPa. The invention adopts the low-pressure triple effect rectification technique and reduces energy loss in the technical process, thus greatly reducing the energy consumption; and the operating pressure and temperature of the third rectifying tower are greatly reduced, and the requirements on the high temperature resistant and corrosion resistant properties of equipment are reduced, thereby reducing the equipment investment and the maintenance cost.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Casinghead gas corrosion resistant pumping rod steel and manufacturing method thereof

InactiveCN101440461AImproved corrosion cracking performanceGood plasticityTemperature control deviceFurnace typesNiobiumManganese

The invention provides steel for a pumping rod resisting casinghead gas corrosion and a manufacture method thereof. The steel comprises the following chemical compositions by mass percentage: 0.05 to 0.25 percent of carbon, 0.50 to 2.00 percent of silicon, 1.10 to 2.50 percent of manganese, 0.02 to 0.50 percent of molybdenum, 0.02 to 0.50 percent of nickel, 0.50 to 1.50 percent of chromium, 0.01 to 0.10 percent of vanadium, 0.005 to 0.050 percent of aluminum, 0.02 to 0.10 percent of niobium, 0.05 to 0.50 percent of copper, 0.01 to 0.10 percent of titanium, less than or equal to 0.015 percent of sulphur, less than or equal to 0.020 percent of phosphorus, and the balance being ferrum. The method is to manufacture a pumping rod wire through a design of adding the niobium and other trace alloy elements and corresponding compositions into steel, and controlled rolling and controlled cooling organization control technology. The pumping rod manufactured by the wire has excellent oilwell medium corrosion resistance, proper strength, excellent plastic tenacity and excellent welding performance, thereby improving the service life and reliability of the pumping rod, and improving the whole stability of pumping equipment, and further solving the problem that the prior pumping rod has repeated stress failure caused by endurance of complex casinghead gas corrosion.

Owner:BAOSHAN IRON & STEEL CO LTD +1

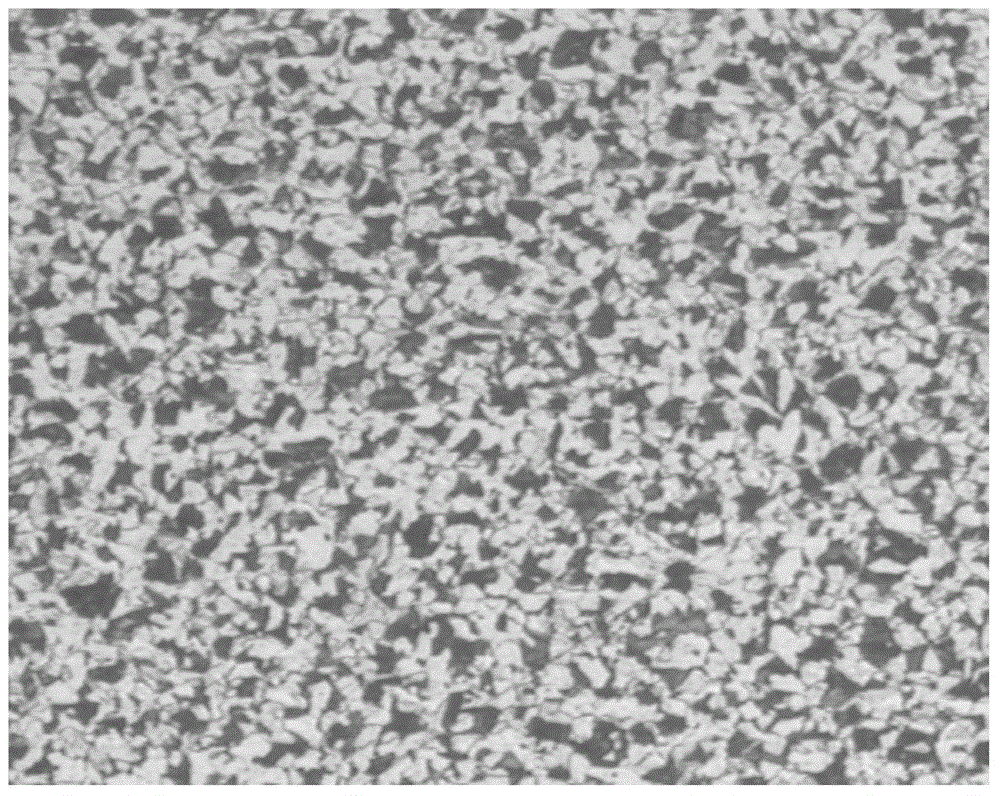

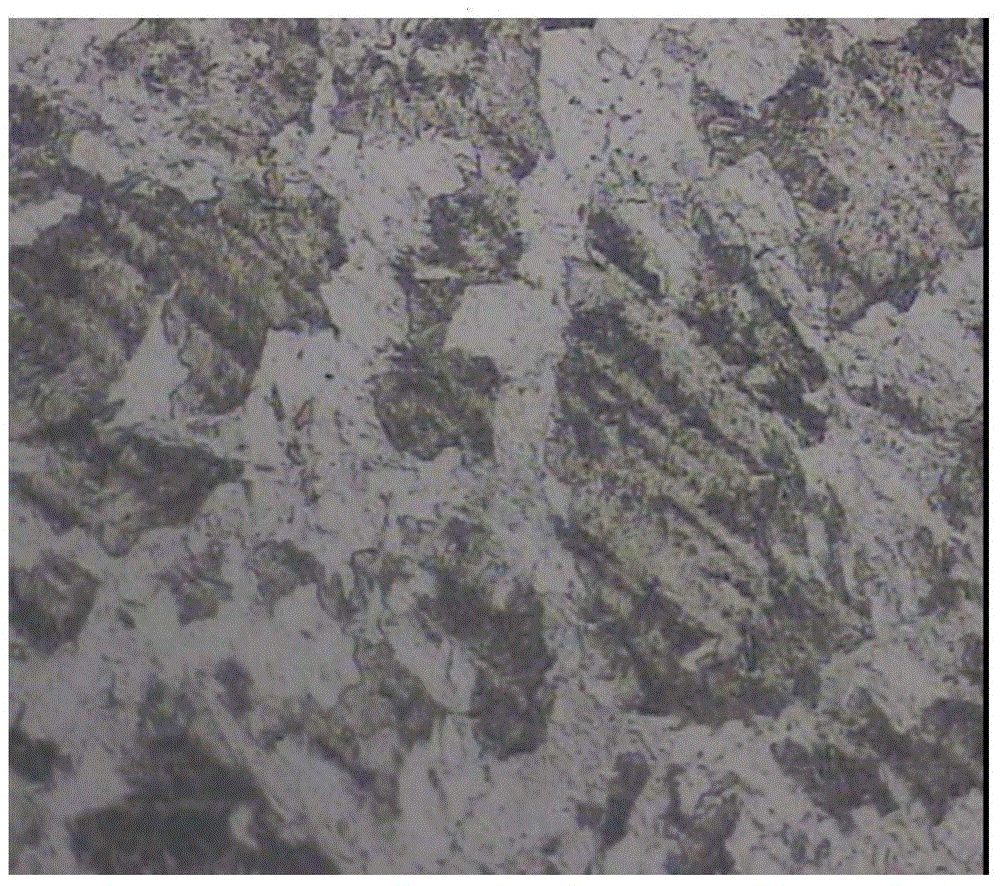

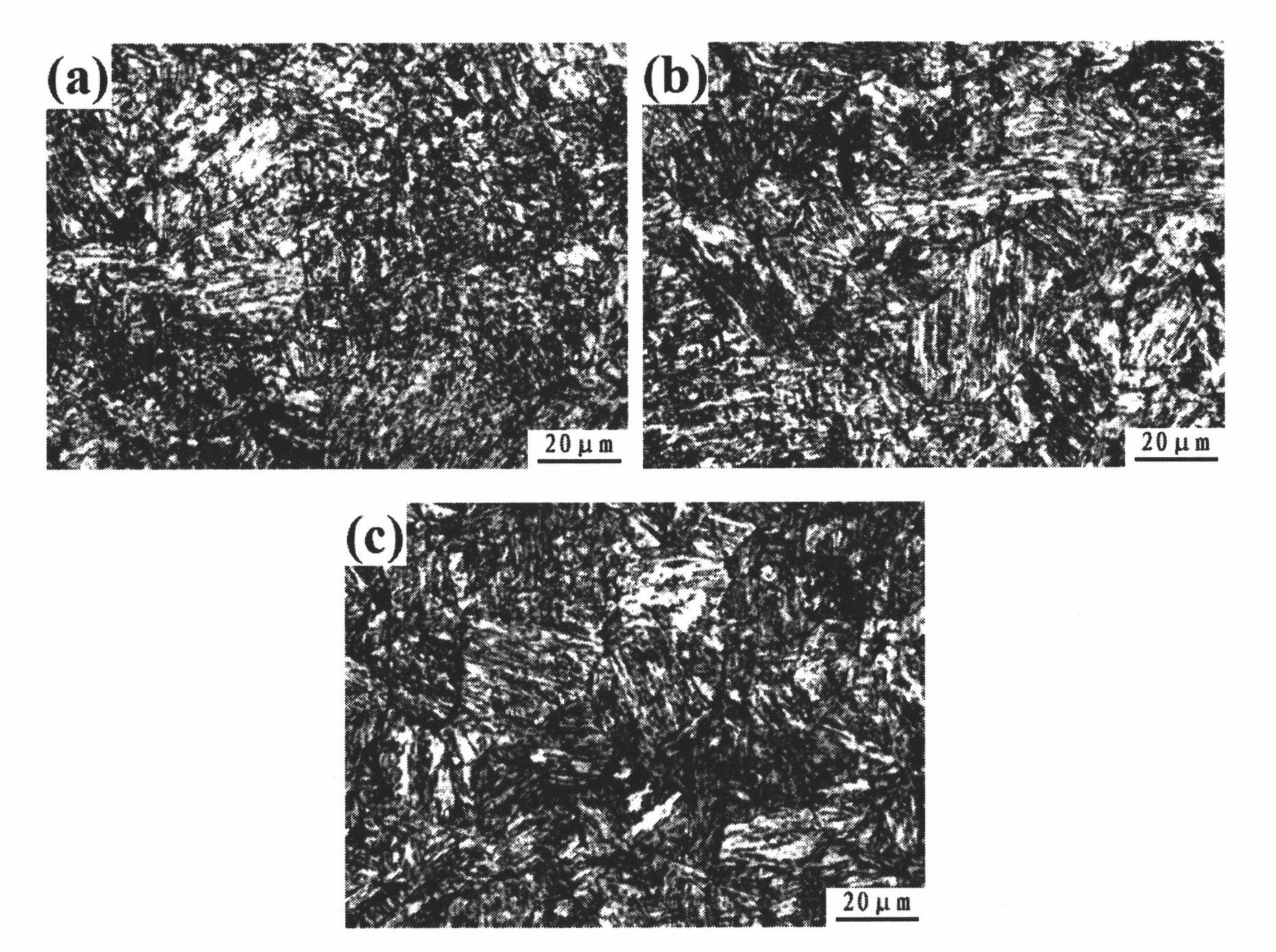

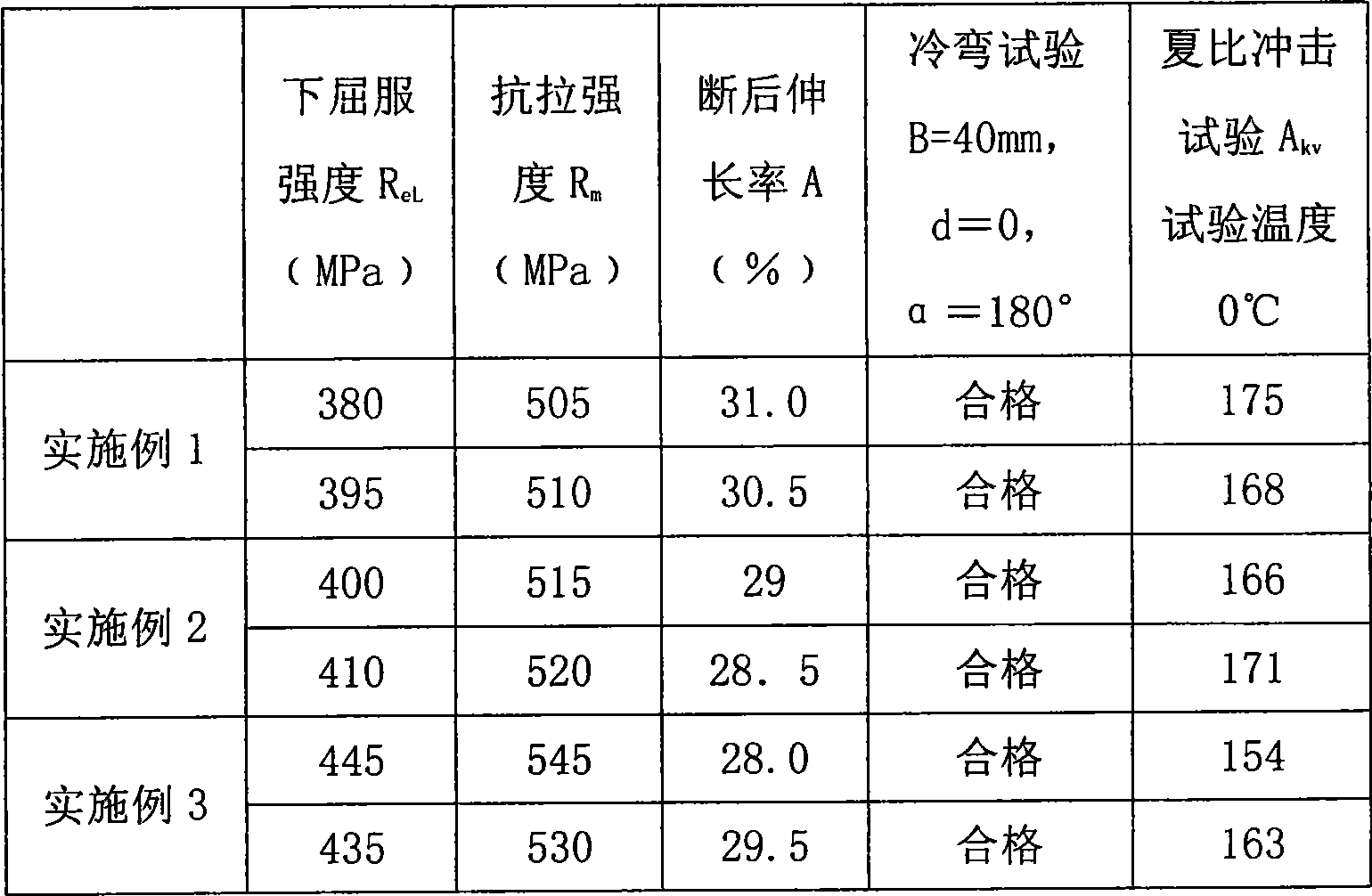

CrNiMo high-strength pinion steel and preparation method thereof

ActiveCN104372258AImprove heat treatment effectGuaranteed mechanical propertiesProcess efficiency improvementPinionUltimate tensile strength

The invention relates to a CrNiMo high-strength pinion steel and a preparation method thereof. The pinion steel comprises the following chemical components in percentage by mass: 0.19%-0.25% of C, 0.17%-0.37% of Si, 0.70%-1.00% of Mn, at most 0.030% of P, at most 0.030% of S, 0.85%-1.25% of Cr, 0.40%-0.70% of Ni, 0.30%-0.40% of Mo, 0.015%-0.050% of Al, at most 2.5*10<-4>% of H, 30*10<-4>%-80*10<-4>% of N, at most 15*10<-4>% of T.O, and the balance of Fe and inevitable impurities. The invention also provides a preparation method of the pinion steel. The nickel molybdenum alloy is added to improve the heat treatability of the material, thereby ensuring the mechanical properties of the material. The hardenability of the material is enhanced, and the material satisfies the performance requirements for large module pinions.

Owner:SHANDONG IRON & STEEL CO LTD

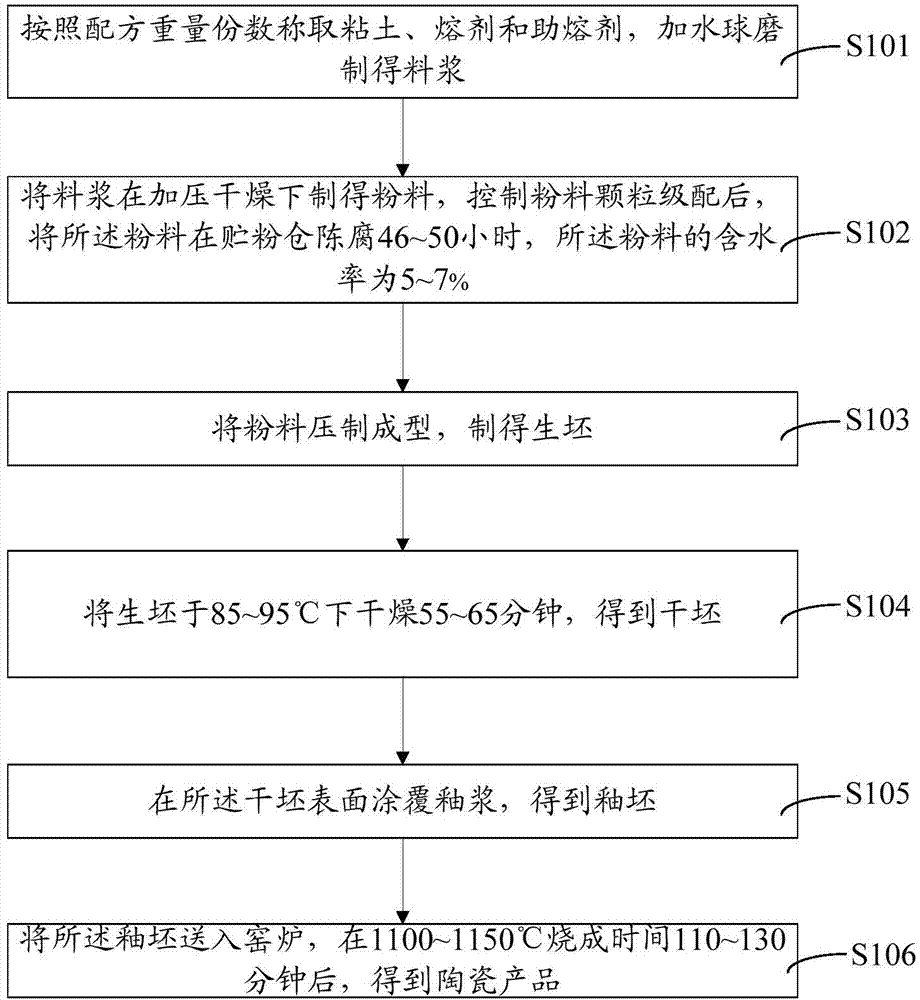

Ceramic formula and preparation method for ceramic product

The invention provides a ceramic formula, comprising, by weight, 55 to 65 parts of clay, 20 to 30 parts of a flux and 15 to 23 parts of a fluxing agent, wherein the clay is a mixture of purple sandshale and china clay mixed according to a weight ratio of 0.67 to 2.0, the flux is shale, and the fluxing agent is one or more selected from the group consisting of limestone, calcite, diopside, wollastonite, dolomite, talcum and industrial waste residue. A preparation method for a ceramic product comprises the following steps: weighing the clay, the flux and the fluxing agent according to the formula, carrying out crushing and screening with a 250-mesh sieve, wherein the weight of screen residue is 1 to 1.5%, adding water, carrying out blending to obtain slurry and then carrying out drying and granulation so as to obtain powder; grading particles and then carrying out molding so as to prepare a green body; carrying out drying so as to prepare a dry body; and carrying out firing so as to prepare a seasonal ceramic body. According to the ceramic formula and the preparation method for the ceramic product in the invention, raw materials are cheap, process is simple, firing temperature is reduced, production cost is decreased, investment for production equipment is lowered down, production efficiency is improved, and energy consumption is reduced.

Owner:怀化市亿智陶瓷有限公司

Smelting production method of low activation martensitic steel for fusion reactor

InactiveCN101328522AReduce manufacturing costMeet the design requirementsIncreasing energy efficiencyQuality levelSteel bar

The invention relates to a method for producing a low-activation martensitic steel for a fusion reactor by melting. The method comprises: step one, a charging material is smelted in a vacuum induction furnace: (1) when a vacuum degree is between 0.1 and 10 Pa, argon gas is passed through the vacuum induction furnace till the vacuum degree is between 0.005 and 0.08MPa, and a smelting temperature is between 1450 and 1650 DEG C; (2) alloys are added in sequence: firstly, pure Fe is melted; Cr and W are added into the furnace; then Ta and V are added into the furnace, and finally C and Mn are added into the furnace; simultaneously, the level of an oxygen content in the pure Fe is observed; before Cr is added, a little of C is added into the furnace for carrying out deoxidation treatment; (3) on-line detection is carried out to the compositions of alloy elements; the alloy elements are added according to a detection result; and (4) after the compositions are qualified, a mixture is cast under the vacuum at a casting temperature of between 1450 and 1550 DEG C. Step two, according to the compositions and the inner quality level of a cast ingot which is obtained by vacuum induction and melting, whether the cast ingot is remelted and refined in a vacuum electroslag remelting furnace or a common electroslag remelting furnace with argon protection. Step three, a needed CLAM steel bar material is prepared by the production of forging, cogging and hot rolling. The method has the characteristics of simple smelting operation, stable process and low production cost; the compositions and impurities of the produced CLAM steel meet the design requirement; and the method has no aliquation of the compositions and tissues and high degree of purity and is suitable for the application of the fusion reactor.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

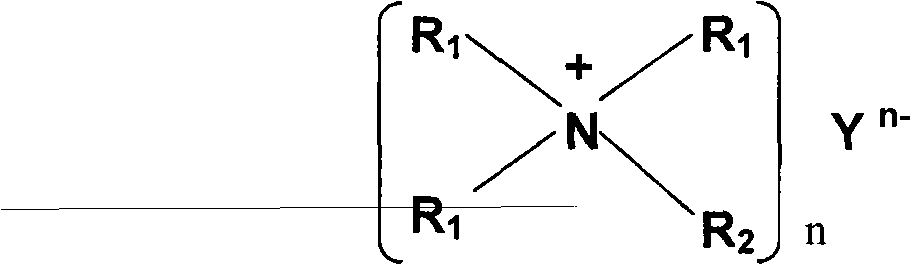

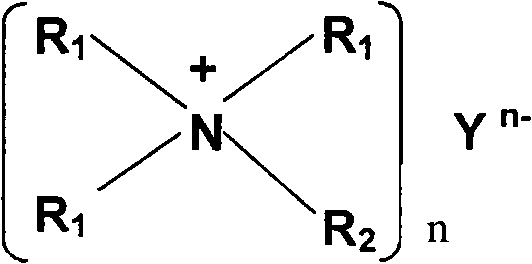

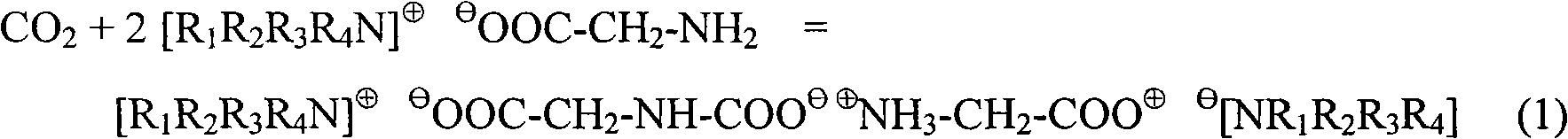

Special MDEA formula solution activated by functional ion liquid for CO2 gas absorption separation

InactiveCN101804292AReduce lossOvercome the disadvantage of high energy consumptionDispersed particle separationBy chemical separationSulfolanePoly(ethylene glycol) dimethyl ether

The invention relates to a special N-methyldiethanolamine formula solution activated by ion liquid for CO2 gas absorption separation, which consists of the following ingredients in mass percent: 35 to 50 percent of N-methyldiethanolamine, 5 to 20 percent of low-viscosity kalescent functional ion liquid, 15 to 30 percent of dimethyl ether of polyethlene glycol and / or sulfolane and 15 to 30 percent of water, wherein cations of the low-viscosity kalescent functional ion liquid are tetraalkylammonium ions, and anions of the low-viscosity kalescent functional ion liquid are amino acid radicals or organic carboxylate anions. The formula solution of the invention has the advantages that the high mass transfer performance of the absorption-desorption process is improved, the material consumption in the use process is low, the defect of high energy consumption because a large amount of water vapor is brought away during the absorbing agent regeneration, and the invention belongs to an energy-saving formula with high green degree. The regeneration temperature of the solution is lower than that of the traditional absorbing liquid, the grade of a heat source required to be provided in the regeneration process is reduced, energy sources can be saved, the stability of the absorbing agent solution in the operation is high, the consumption of each absorption-desorption circulation is low, and in addition, the cost is low.

Owner:NANJING UNIV

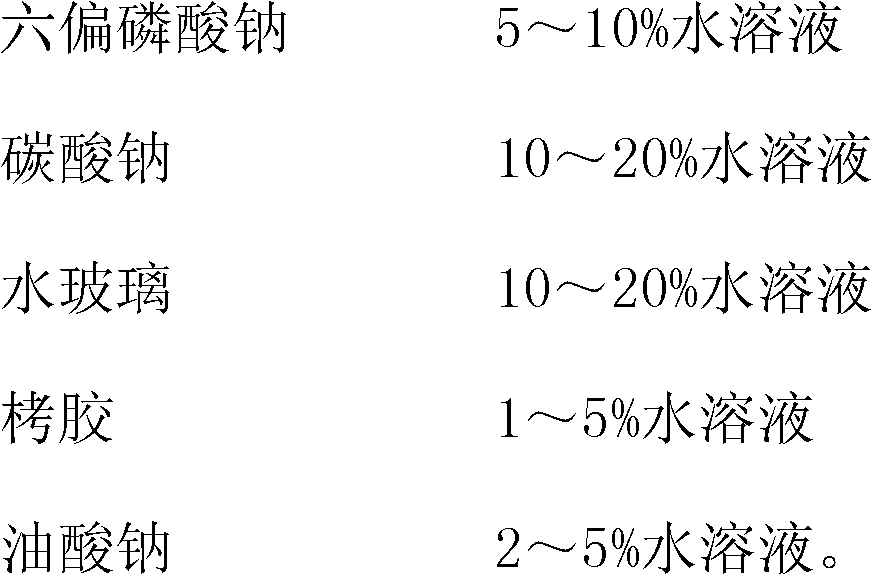

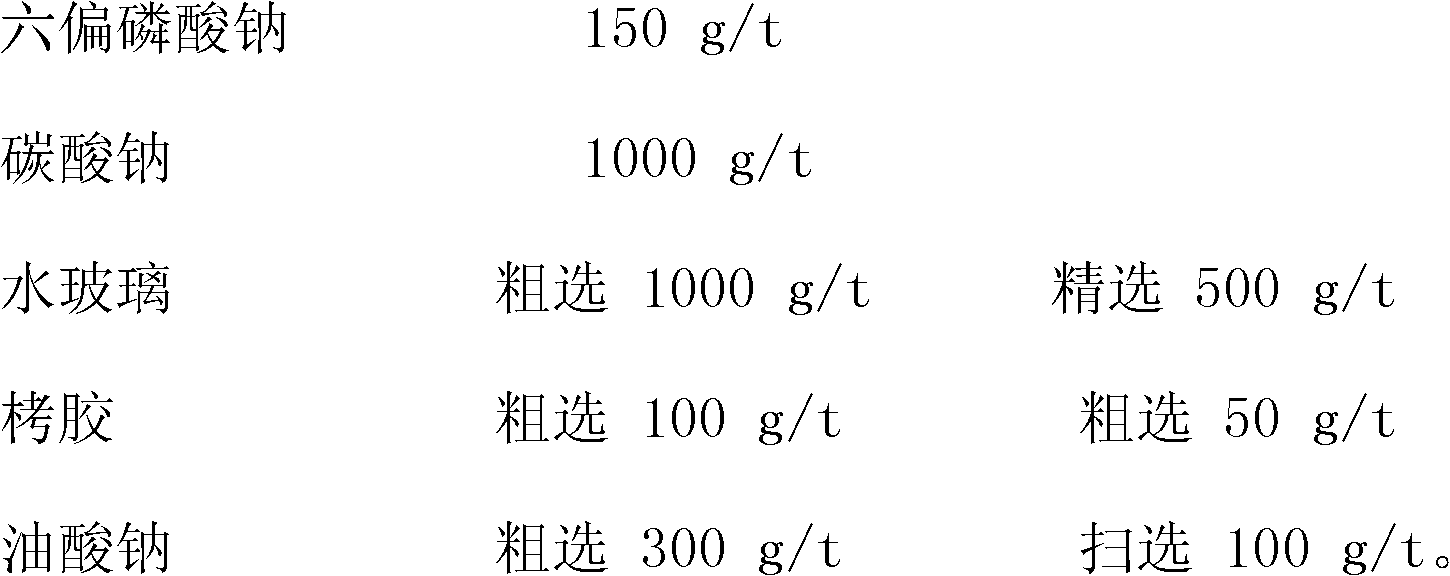

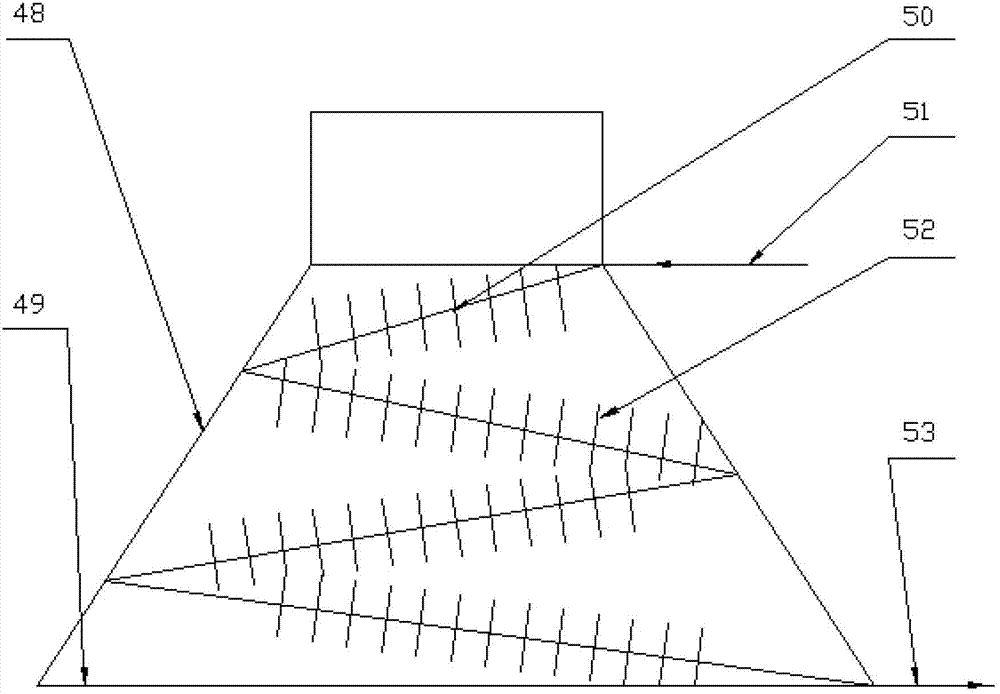

Method for recovering fine mud cassiterite

The invention discloses a method for recovering fine mud cassiterite. The method comprises the following steps of dispersing a fine mud cassiterite mineral in an agitator by using sodium hexametaphosphate as a dispersing agent, grading the fine mud cassiterite mineral by using a high frequency fine screen, recovering the graded fine mud cassiterite mineral through gravity separation by using a fine mud cassiterite table concentrator to obtain fine mud rough concentrates in different particle sizes, and combining the fine mud rough concentrates in different particle sizes and performing floatation recovery on the fine mud cassiterite to obtain a cassiterite concentrate. By the method, the fine mud cassiterite can be effectively recovered, and the fine mud cassiterite concentrate of which the cassiterite grade is 45.87-46.21 percent and the recovery rate is 52.51-56.75 percent can be obtained under the condition that the fed mineral has the cassiterite grade of 0.37-0.45 percent.

Owner:广西华锡集团股份有限公司

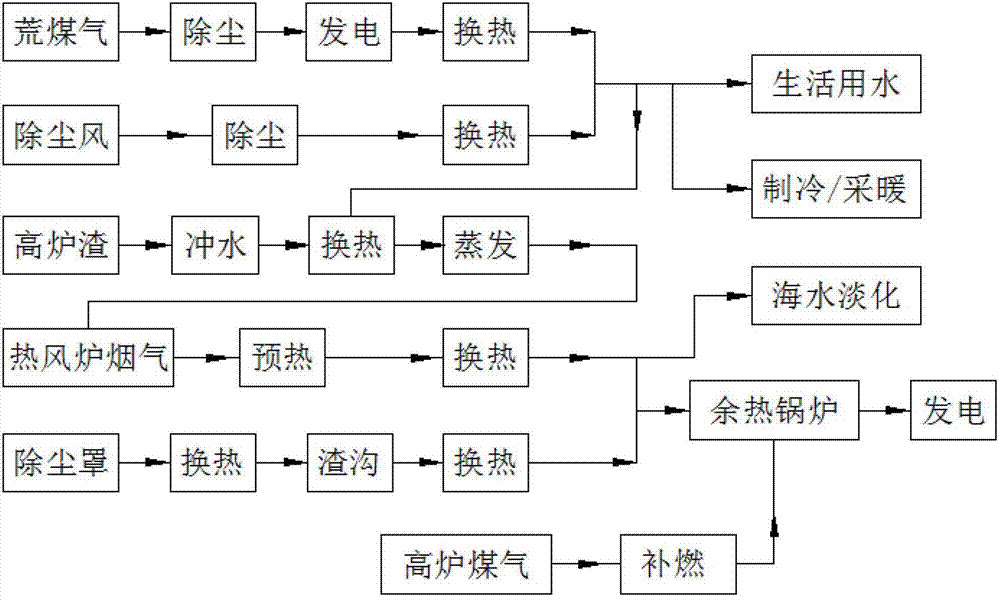

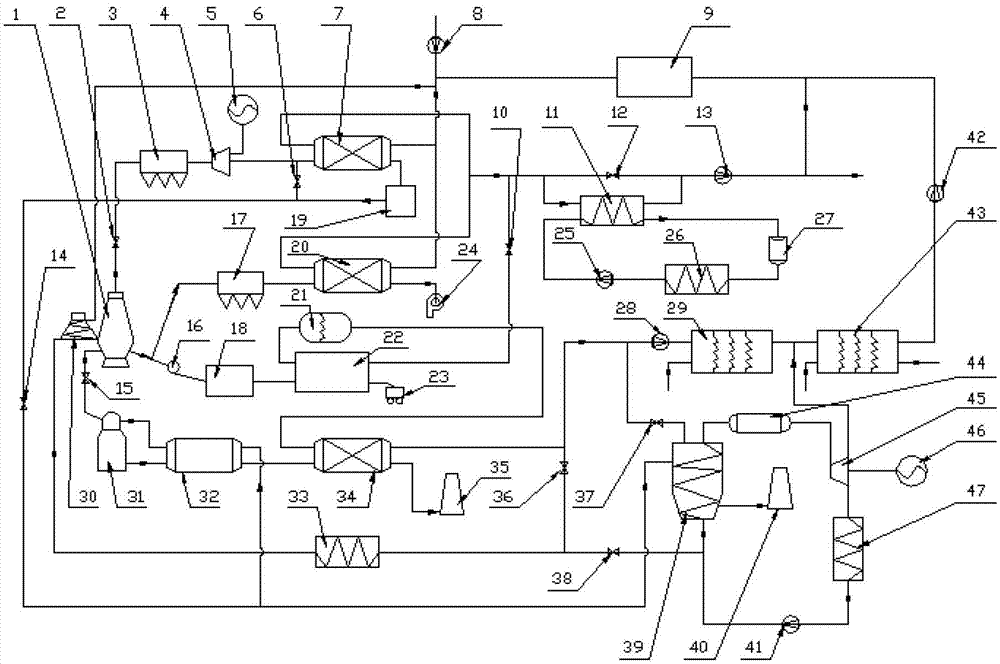

Steelmaking residual heat step recycling method

ActiveCN102851420ASolve effective useEnable fair useBlast furnace detailsIncreasing energy efficiencySteelmakingDitch

The invention discloses a steelmaking residual heat step recycling method. The invention belongs to the technical field of steel industry iron-making residual heat and residual energy utilization. The method is adopted under a condition for further utilizing iron-making low-grade residual heat, and comprises step recycling and high-efficiency utilizations of blast furnace gas residual heat, dust removal air residual heat, water slag residual heat, hot air furnace low-temperature flue gas waste heat, and dust cover and slag ditch residual heat. According to the technical scheme, blast furnace gas residual heat and dust removal air residual heat obtained after furnace top residual pressure power generation are connected in parallel, and are supplied for domestic water, cooling, or heating. Recycled water slag residual heat and flue gas residual heat obtained after hot air furnace gas heat exchanger are connected in parallel, and are used for supplying a heat source for low-temperature seawater desalination. Recycled dust cover residual heat and slag ditch surface radiation heat are connected in parallel, and are supplied for blast furnace gas supplementary firing residual heat boiler power generation. After powder generation, high-temperature seawater desalination is realized by a steam method. Cooling water and domestic water are treated and are adopted as inlet water replenishment. Through step recycling and graded utilization of the low-grade residual heat and residual energy, steel system comprehensive energy consumption can be reduced to a maximal extent, and energy resource reasonable utilization and comprehensive optimized utilization can be realized.

Owner:SHOUGANG CORPORATION

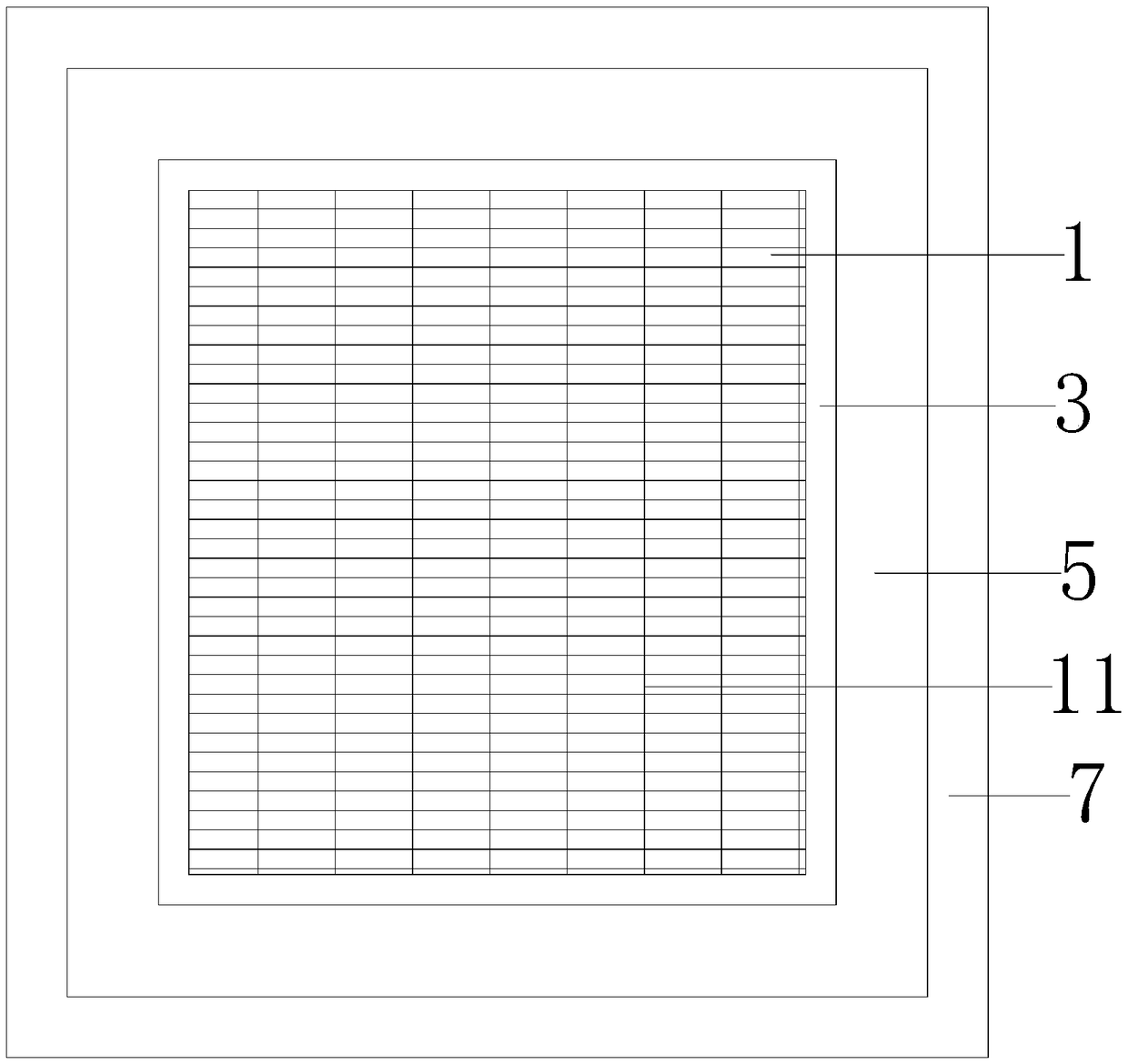

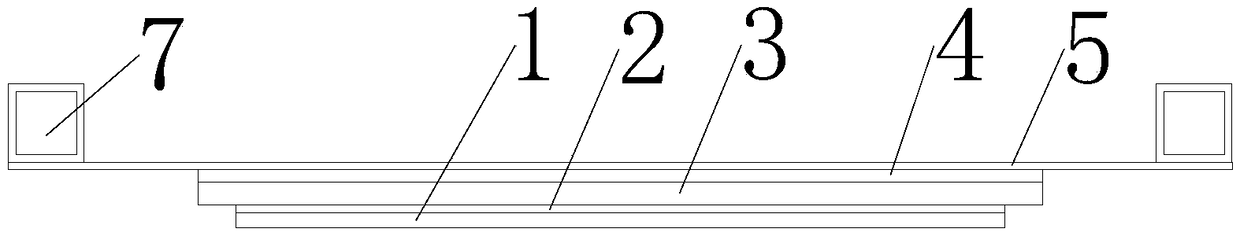

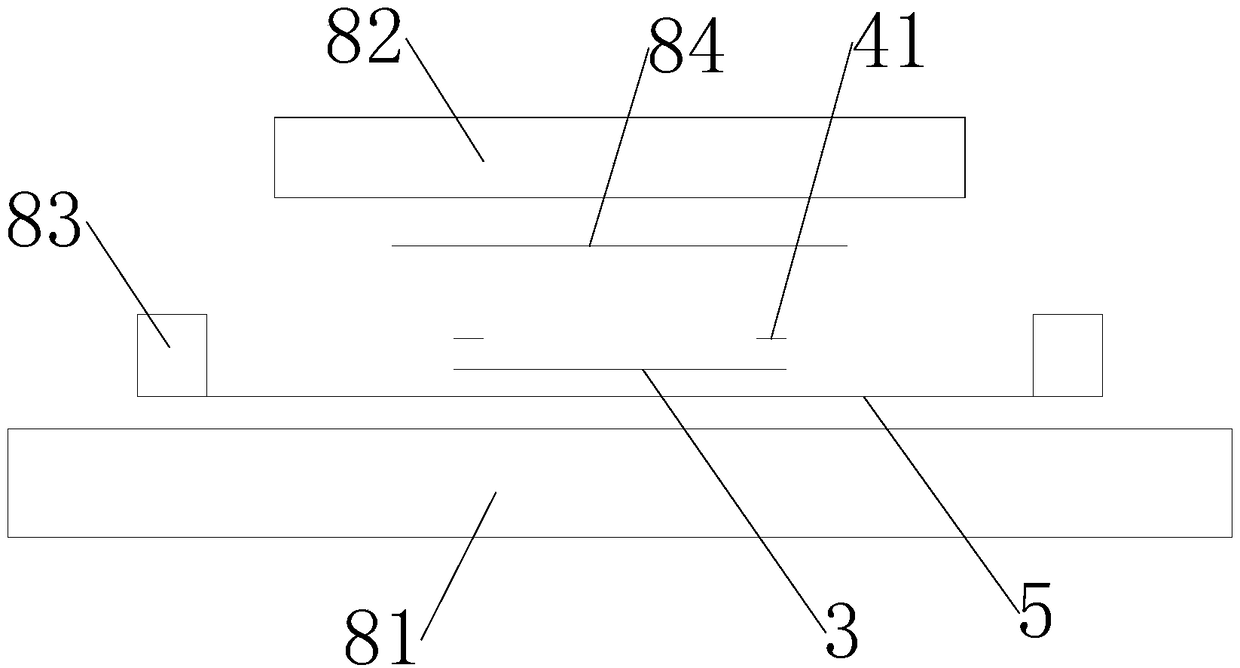

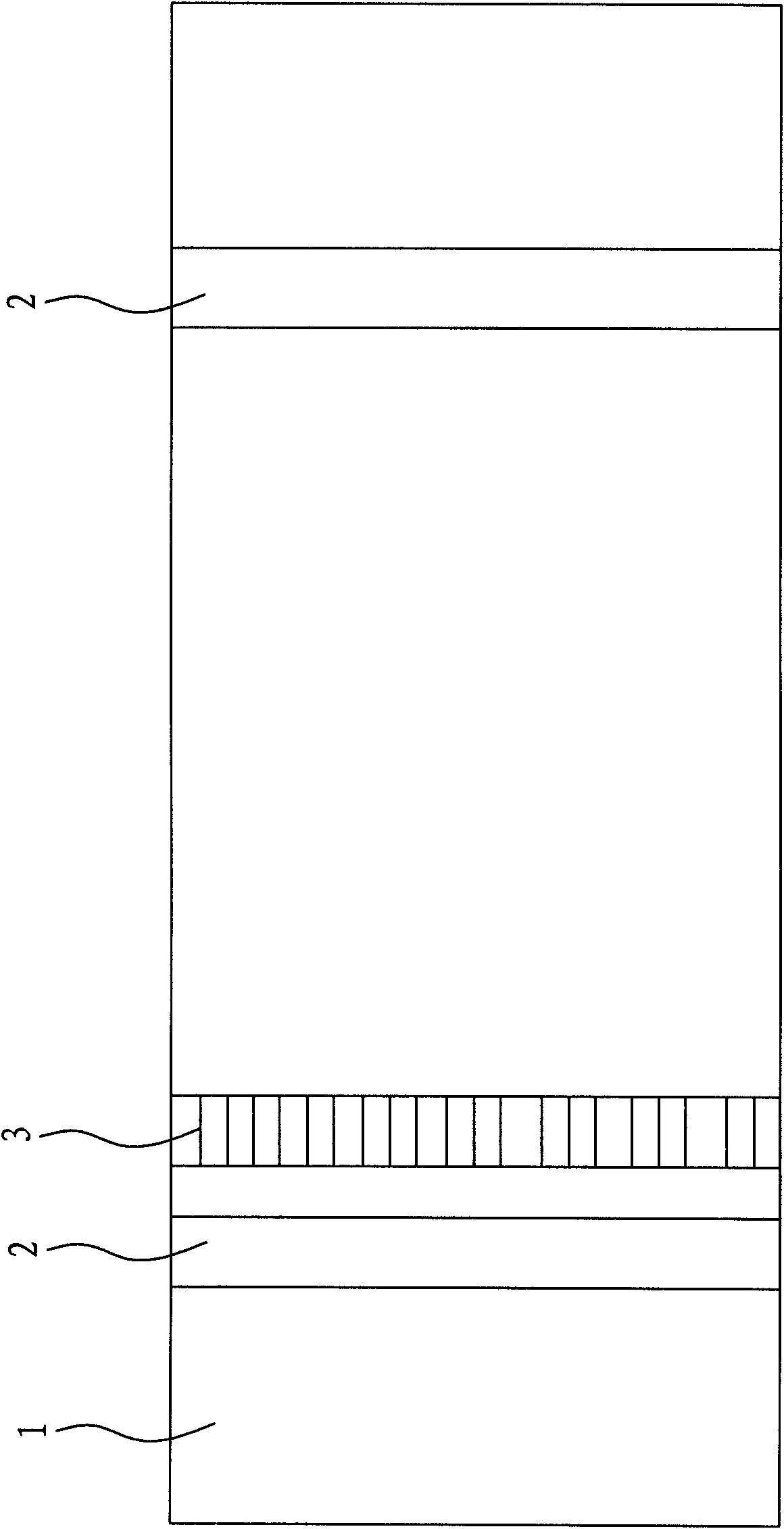

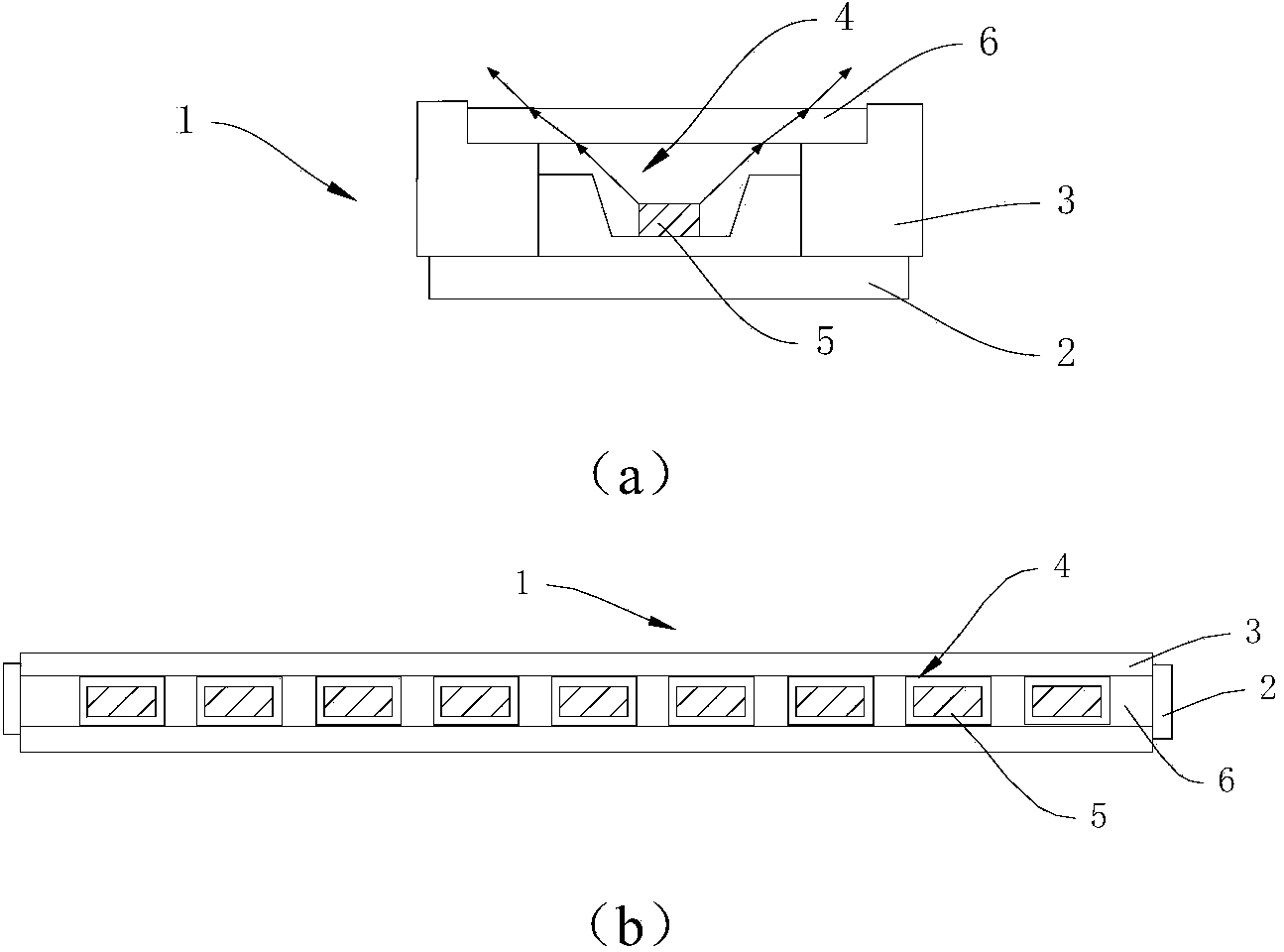

Polyimide solar net plate and manufacturing method

PendingCN108749276ADowngradeReduce manufacturing costScreen printersSynthetic resin layered productsWire gauzeScreen printing

The invention relates to a solar net plate, in particular to a polyimide solar net plate. The polyimide solar net plate comprises a net frame and a polyester wire net. The polyester wire net is tied to the bottom of the net frame. A silk screen printing hole is formed in the center of the polyester wire net, and the polyester wire net is in a concentric square shape. A stainless steel wire net anda polyimide film are further included. The polyimide film is fixed to the bottom face of the stainless steel wire net. A high-temperature glue layer is arranged between the polyimide film and the stainless steel wire net. The polyimide film is provided with a plurality of wire grooves, and a printing pattern is composed of the wire grooves. The top face of the stainless steel wire net is fixed tothe polyester wire net. The stainless steel wire net is larger than the silk screen printing hole and covers the silk screen printing hole, and a hot melt glue layer is arranged between the stainlesssteel wire net and the polyester wire net. The net plate manufacturing technology is simple, the manufacturing cost is low, the yield is high, the service life of the net plate is long, and frictionresistance and cross section sharpness are obviously improved; and the service life reaches 100,000 times or more, and the purchasing cost of printing net plates is reduced for battery piece manufacturers.

Owner:昆山良品丝印器材有限公司

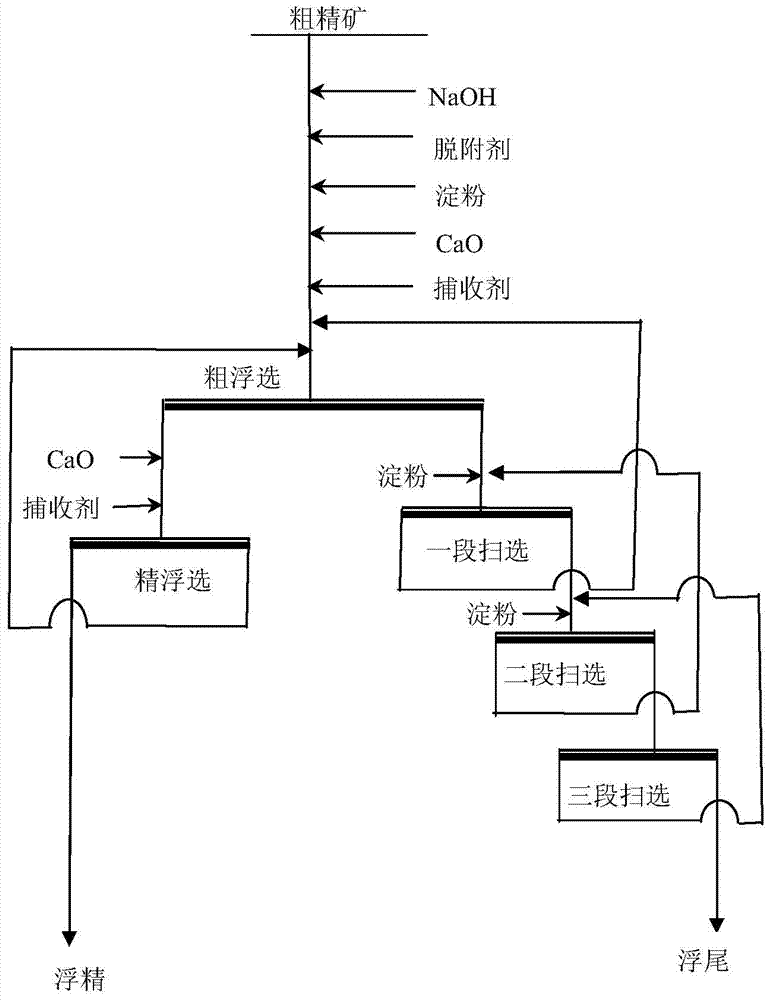

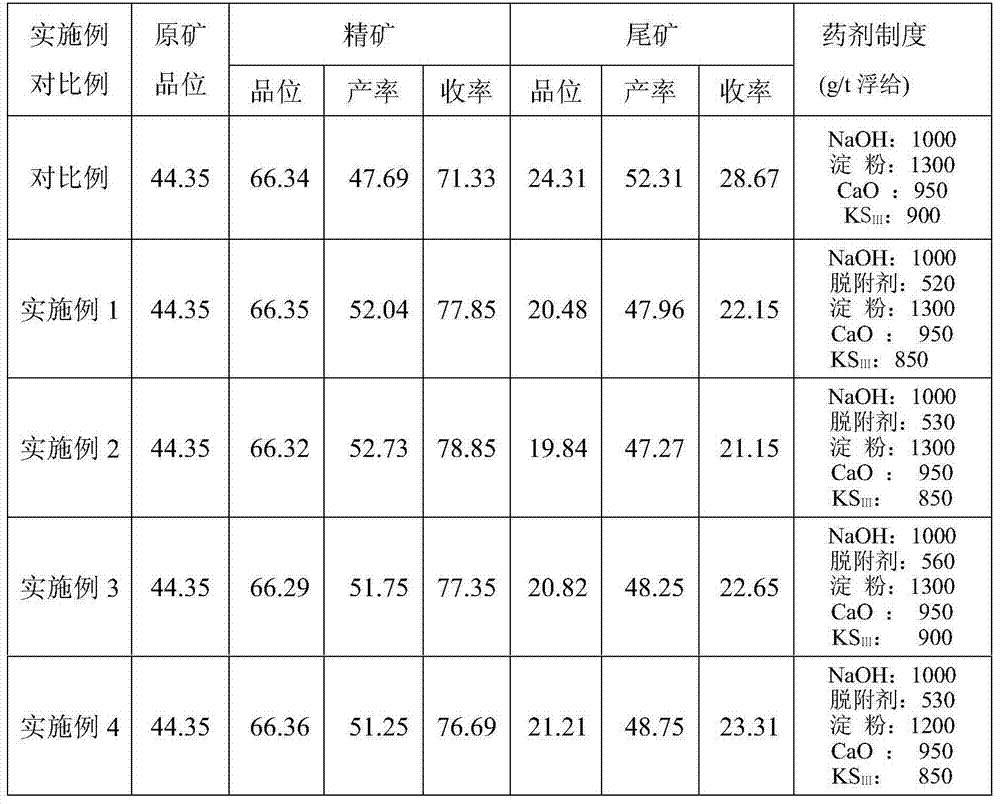

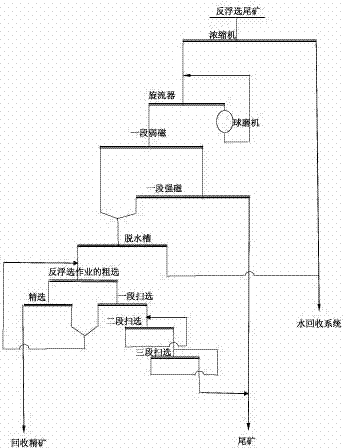

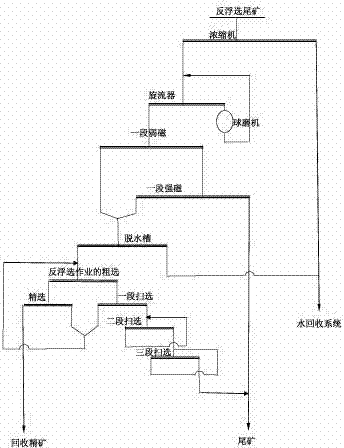

Agent for reverse flotation of iron ore and combination use method

The invention provides an agent for reverse flotation of iron ore and a combination use method. The agent is composed of pH regulator sodium hydroxide, desorption agents, inhibitor causticity corn starch, activator calcium oxide and fatty acid collectors and is characterized in that the desorption agents are composed, by weight, of 40-42 parts of water glass, 4-6 parts of carboxymethyl cellulose and 7-9 parts of polycarboxylate. When the desorption agents are used, all raw material components are dissolved respectively according to the weight proportion and mixed, water is added, and therefore a desorption agent solution with the mass concentration of 0.04-0.06% is prepared. The desorption agents are applied to a reverse flotation process including one-time rough separation, one-time fine separation and three-time scavenging and a stage agent addition manner is adopted, so that the selective inhibition function on iron minerals by inhibitors in an original reverse flotation process is obviously enhanced, selectivity of the collectors is obviously enhanced, the tailing grade is reduced, the metal recovery rate is improved, fine-grain metal losses are reduced, emission reduction, yield increasing and efficiency increasing are achieved, the resource utilization rate is improved, and a new approach is provided for improvement of the micro-fine-particle iron ore reverse flotation technical index.

Owner:ANSTEEL GRP MINING CO LTD

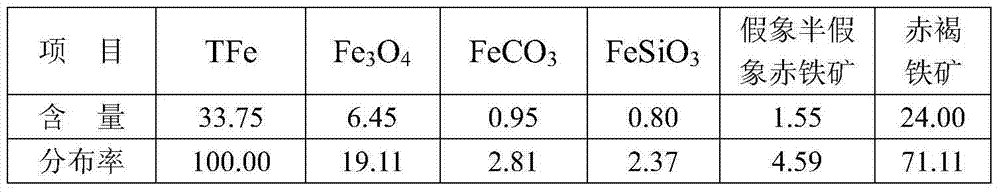

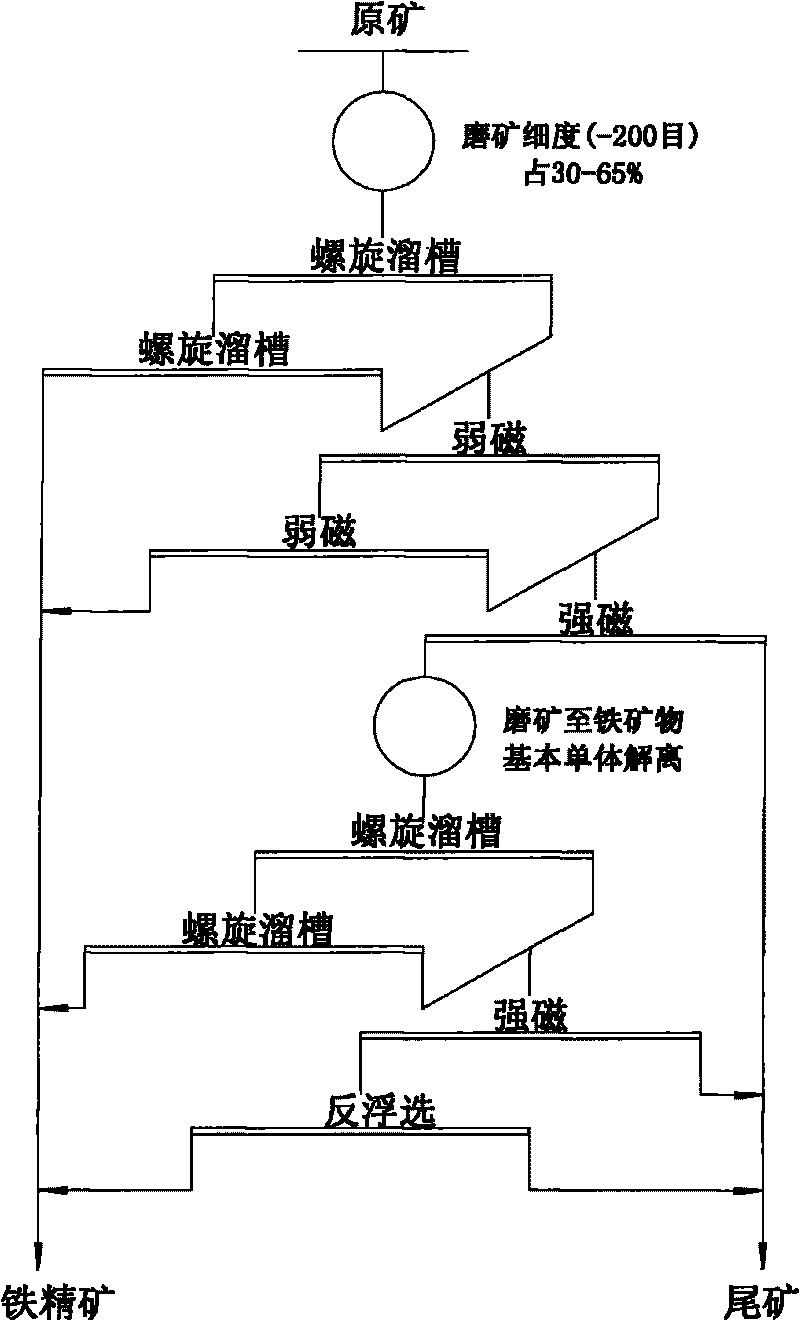

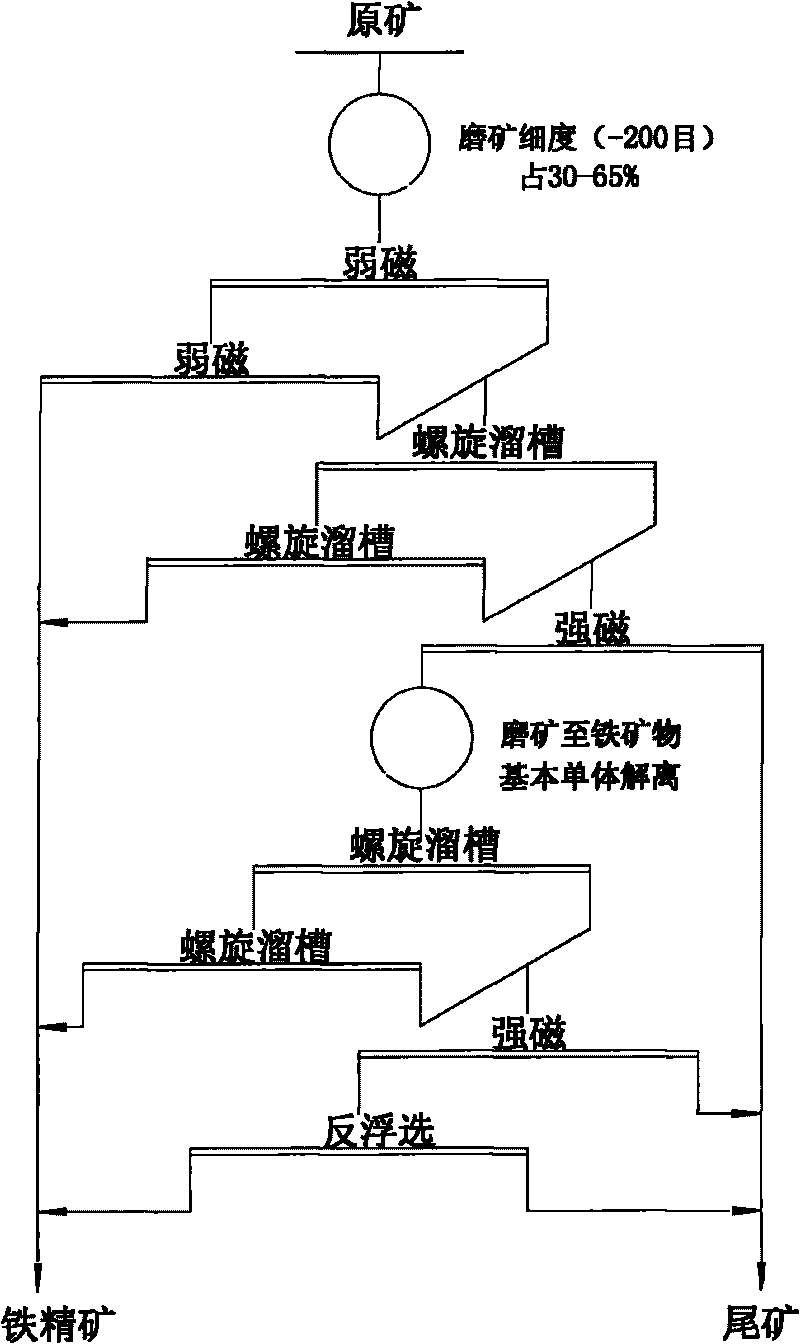

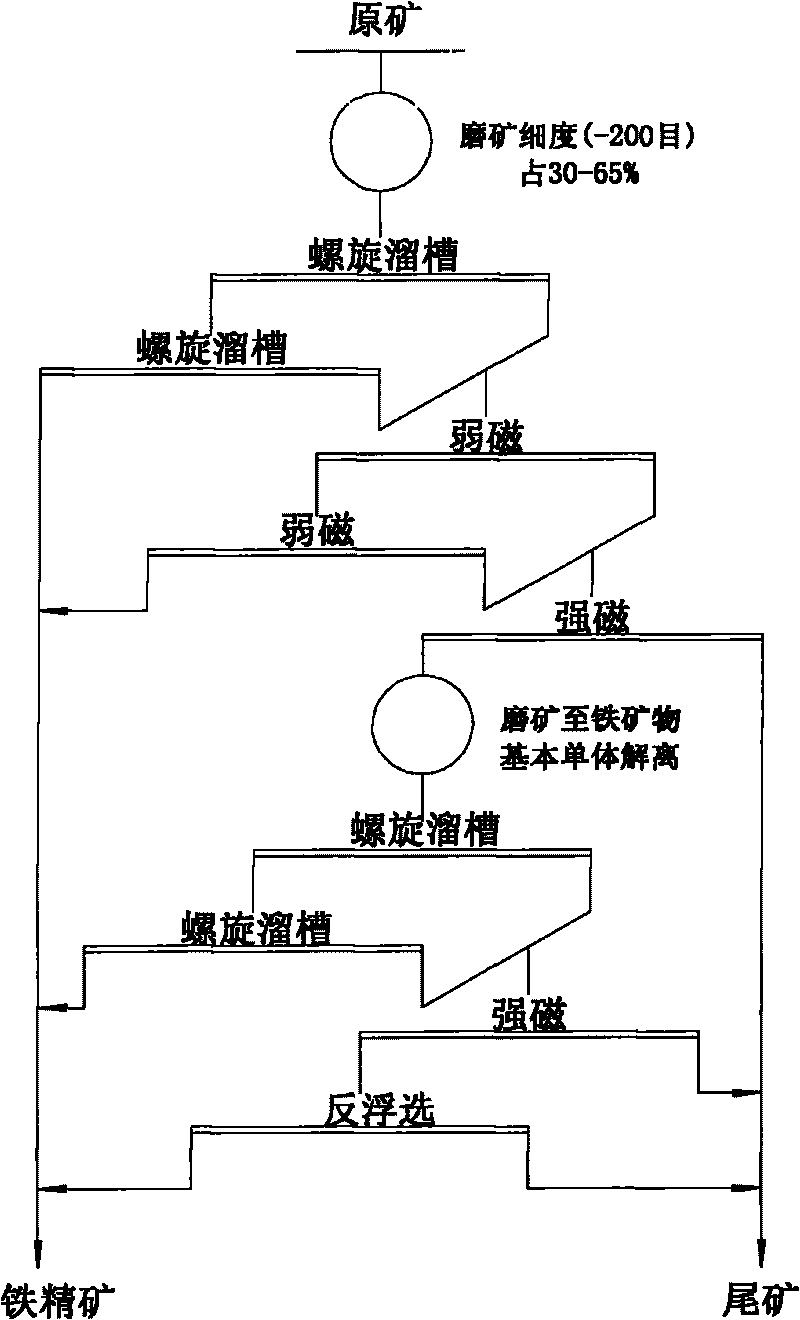

Mineral benefication method for specularite

ActiveCN101716551AAchieve economyRealize environmental protection utilizationFlotationMagnetic separationHigh intensityEngineering

The invention relates to a mineral benefication method for specularite, comprising recycling the iron ore concentrate in the specularite by first-stage coarse grinding, spiral chute sorting, low-intensity magnetic separating, high-intensity magnetic separating, second-stage ore-grinding, spiral chute sorting, high-intensity magnetic separating and reverse flotation separating process, or first-stage coarse grinding, low-intensity magnetic separating, spiral chute sorting, high-intensity magnetic separating, second-stage ore-grinding, spiral chute sorting, high-intensity magnetic separating and reverse flotation separating process. The method has the characteristics of simple process and structure, low investment cost, low production cost, economy and environment protection, and strong flexibility; when the mineral property changes, the iron minerals are sorted and recycled by properly regulating the method.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

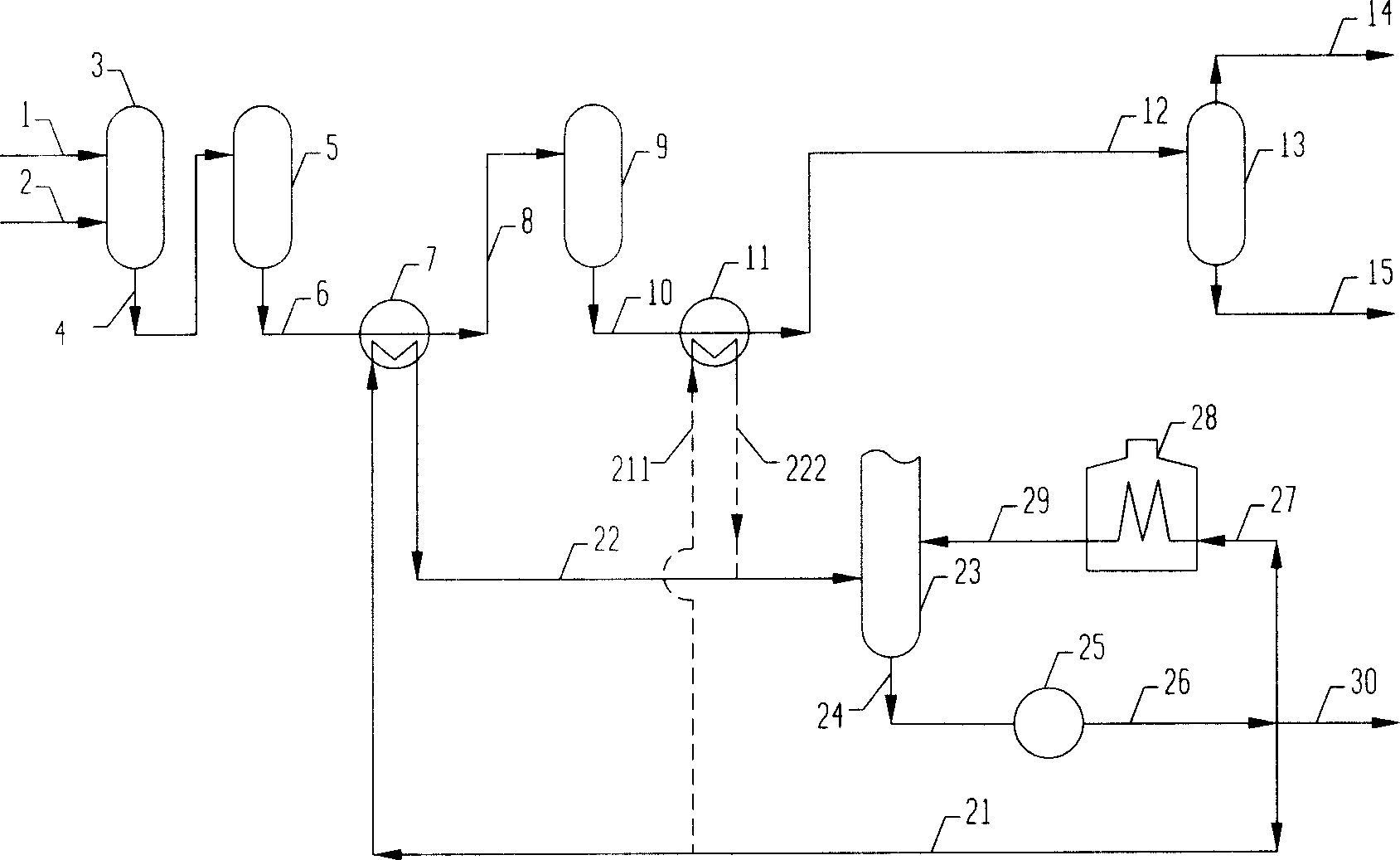

Method of recovering heat in hydrocarbon hydrogenating conversion process

InactiveCN101067095AReduce consumptionSmall scaleExothermal chemical reaction heat productionExothermal chemical reactions for heatingThermal energyHydrogen

The present invention relates to method of recovering heat in hydrocarbon hydrogenating conversion process. The low temperature heat absorbing oil and the reaction resultant are heat exchanged to form high temperature heat absorbing oil, which enters to the bottom of the fractionating tower so as to mix with the liquid phase material flow inside the fractionating tower before being shunt into low temperature heat absorbing oil for reuse. The process is especially suitable for hydrogenating conversion of coal tar, and has the advantages of high heat utilizing rate, reduced hydrogen circulating system scale and reduced the scale of reboiling furnace in the fractionating tower. In addition, the heat absorbing oil heat exchanger may be used as the heater for starting the reactor or sulfurizing to reduce heat load of the heating furnace.

Owner:何巨堂 +1

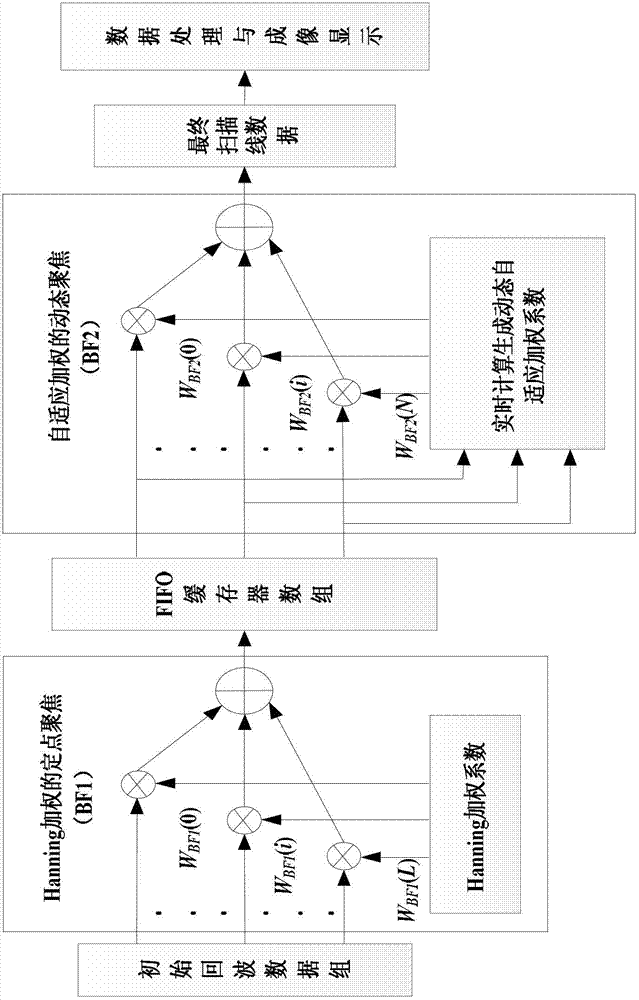

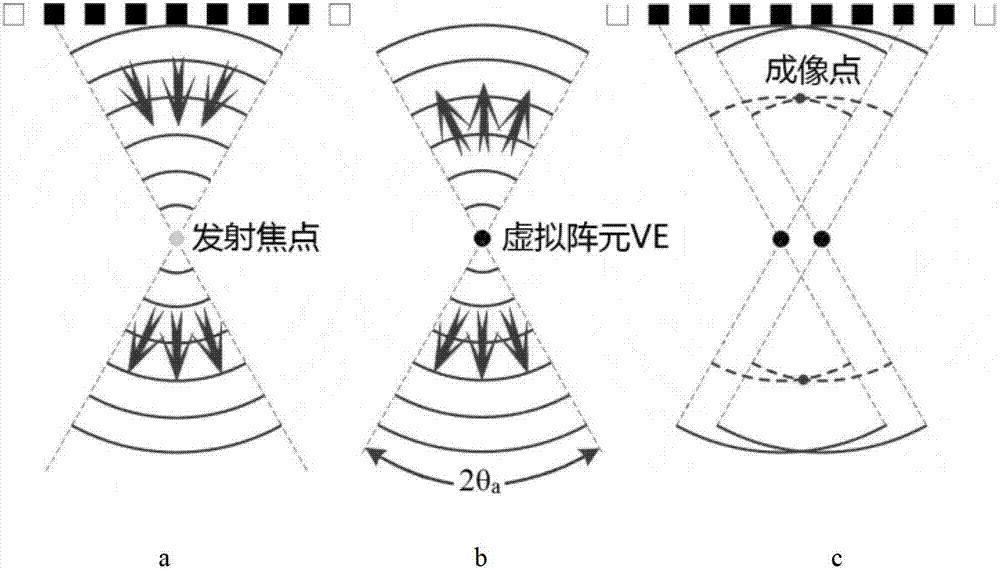

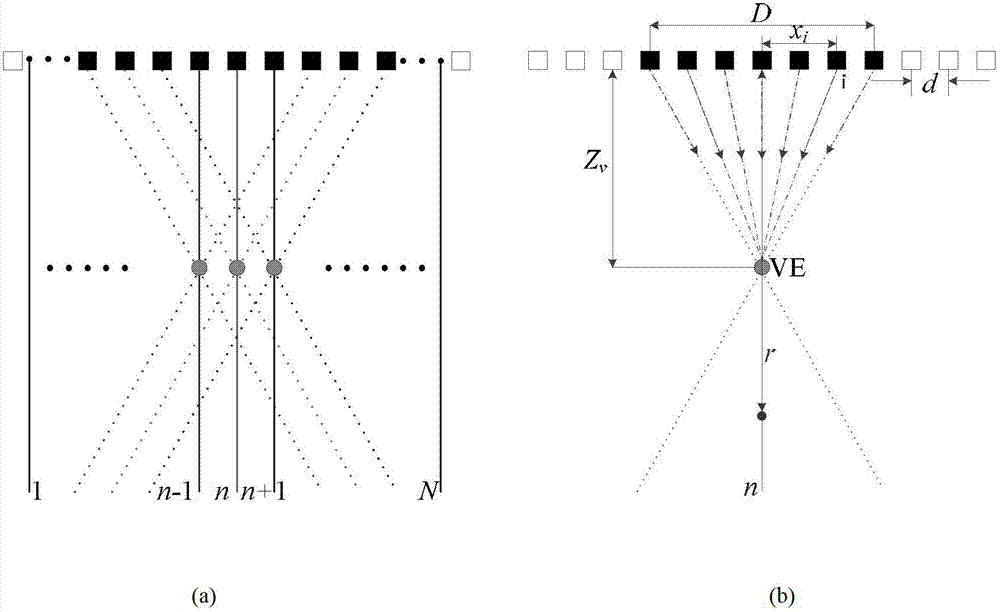

Double-focusing beamforming method based on self-adaptive weighting

InactiveCN102895000AHigh-resolutionLarge detection depthUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSelf adaptiveBeamforming algorithm

The invention discloses a double-focusing beamforming method based on self-adaptive weighting. An amplitude apodization technology, a virtual array element technology and a self-adaptive weighting method are introduced into an ultrasonic imaging system, and ultrasonic imaging of self-adaptive weighting double-focusing beamforming is realized by two-times delay superposition on the basis of a dynamic focusing technology. The double-focusing beamforming method comprises the following steps of: firstly, extracting effective information of a plurality of superposed sound fields by using the virtual array element technology; secondly, performing fixed-point focusing after performing amplitude apodization on the extracted information during first focusing; and finally, generating self-adaptive weighting coefficients by using a self-adaptive beamforming algorithm according to beamforming signals of the first focusing, and performing self-adaptive weighting beamforming focusing on the beamforming signals of the first focusing again so as to obtain data of finally imaged scanning lines. By the method, the shortcoming that a near-field region has severe pseudomorphism when the traditional double-focusing method based on virtual array elements is implemented is overcome, and an ultrasonic imaging effect is remarkably improved.

Owner:CHONGQING UNIV

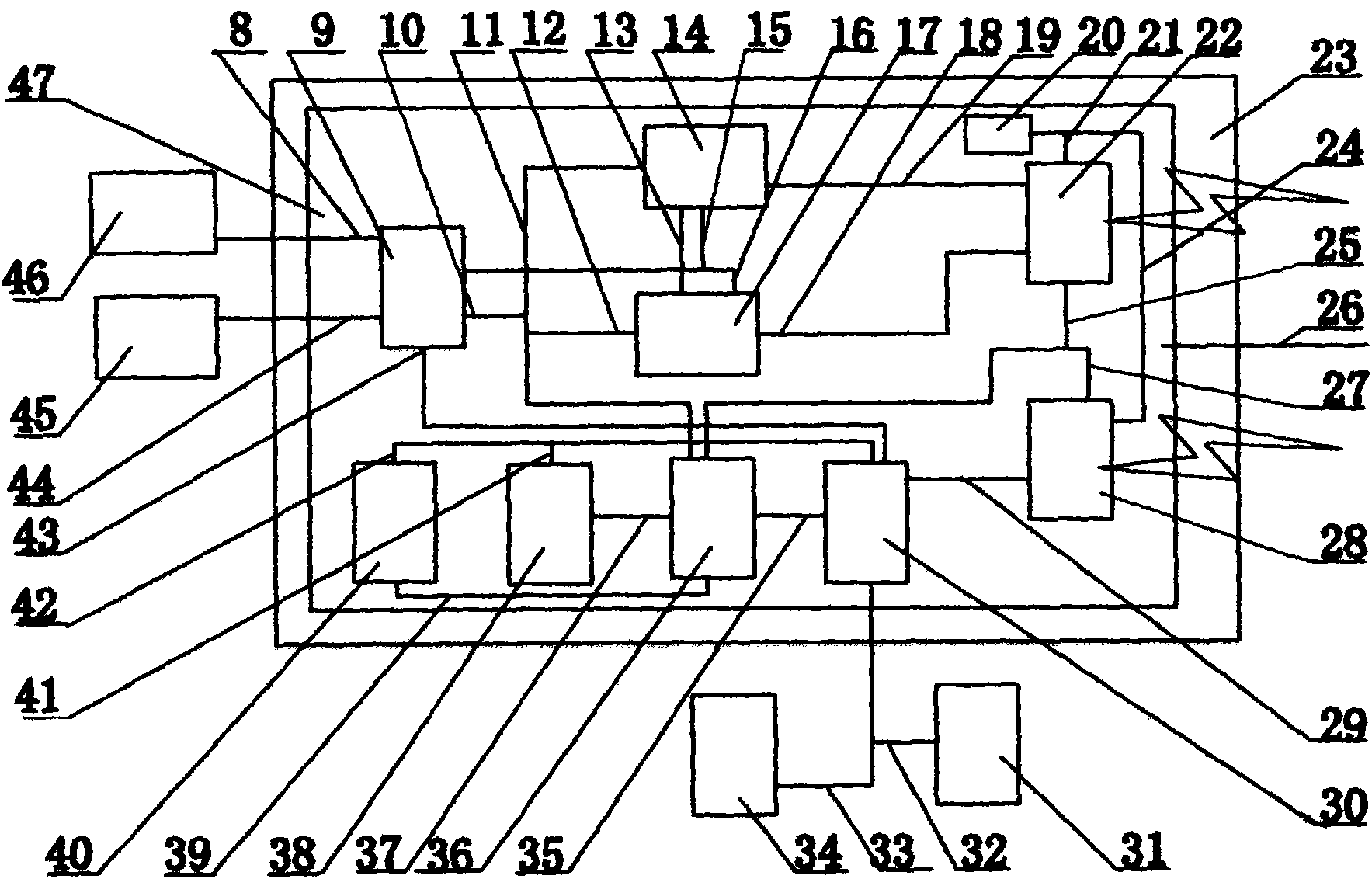

Intelligent theft-robbery resistant and fatigue-driving resistant system for vehicle

InactiveCN101628568ASolve crimes quicklyReduce traffic accidentsAnti-theft devicesElectric/fluid circuitDriver/operatorAutomatic braking

The invention is an intelligent theft-robbery resistant and fatigue-driving resistant system for a vehicle, and relates to the collecting, analyzing, confirming and alarming of information of a driver and the vehicle and automatic braking control of the vehicle. The system comprises a vehicle speed sensor (VSS), an engine working senor, a vehicle-mounted information machine, a wireless (mobile) communication network, a data (information) processing center, an ignition circuit control switch of an engine, a vehicle automatic braking device, a 110 alarm center, an accident center of an insurance company and information of a vehicle owner. When the vehicle is in theft and robbery, the controlled state of the vehicle can be judged by comparing the head portrait of the driver with the driving license of the driver and confirming the owner of the vehicle; if the vehicle is not controlled, the data (information) processing center issues braking control instruction and alarming information that the vehicle is stolen, and the vehicle can realize remote control and prompt alarming by automatic braking and (or) disconnecting the ignition circuit of the engine. The system in the invention is applicable to various vehicles (ships).

Owner:郭炼光

Hematite reverse flotation tailings re-election process

The invention relates to the technical field of hematite reverse flotation tailings, in particular to a hematite reverse flotation tailings re-election process, which is characterized in that the stage grinding of lean hematite, magnetic separation-gravity separation-anion reverse The reverse flotation tailings in the flotation combined process are re-selected, that is, the reverse flotation tailings are concentrated, then ground to a particle size of -320 mesh with a content of more than 90%, and then subjected to weak magnetic separation, strong magnetic separation-reverse flotation Operation, recovery of magnetic minerals in the reverse flotation tailings, the advantages of the present invention: firstly, the reverse flotation tailings are concentrated and defoamed to reduce the foam in the pulp, which is beneficial to the subsequent sorting operation. The reverse flotation tailings after concentration and defoaming undergo regrinding, weak magnetic, strong magnetic, reverse flotation operations of roughing, selection and three-stage sweeping to decompose the coarse-grained intergrowth monomers in the reverse flotation tailings Separation, separation and recovery of metals in reverse flotation tailings, reducing metal loss and lowering the final tailings grade. The process is simple, the number of equipment is small, and the occupied area is small.

Owner:ANSTEEL GRP MINING CO LTD

Process for producing thick plate of plastic die steel

The invention discloses a process for producing a thick plate of plastic die steel. The thick plate of the plastic die steel is obtained by the following steps of: pouring by using an open-close type water-cooled die casting machine, performing reasonable heating system, rolling and normalizing and annealing after rolling. Low temperature pouring and a pouring process of feeding on bottom pouring are performed, so molten steel is quickly solidified by forced cooling of circulating water; the molten steel is not born any shrinkage resistance so as to ensure that a wide surface of the die casting blank does not have any crack; the heating temperature of a steel ingot does not exceed 1,280 DEG C, so that alloy elements are fully dissolved; the rough rolling temperature is 1,100 to 1,200 DEG C, and a rough rolling stage is performed at the high temperature under high pressure; after a fine rolling stage is performed at the temperature of 950 DEG C, the finishing temperature is greater than or equal to 920 DEG C; the discharging temperature after rolling is 750 to 830 DEG C, and the steel plate is cooled in pile for 72 hours after rolling; the steel plate is normalized and annealed; and the solution temperature is about 870 DEG C, and the aging temperature is 500 to 550 DEG C, so that the thick age-hardened plastic die steel plate is obtained. After flaw detection, each performance index of the plastic die steel produced by the invention meets the requirement.

Owner:NANJING IRON & STEEL CO LTD

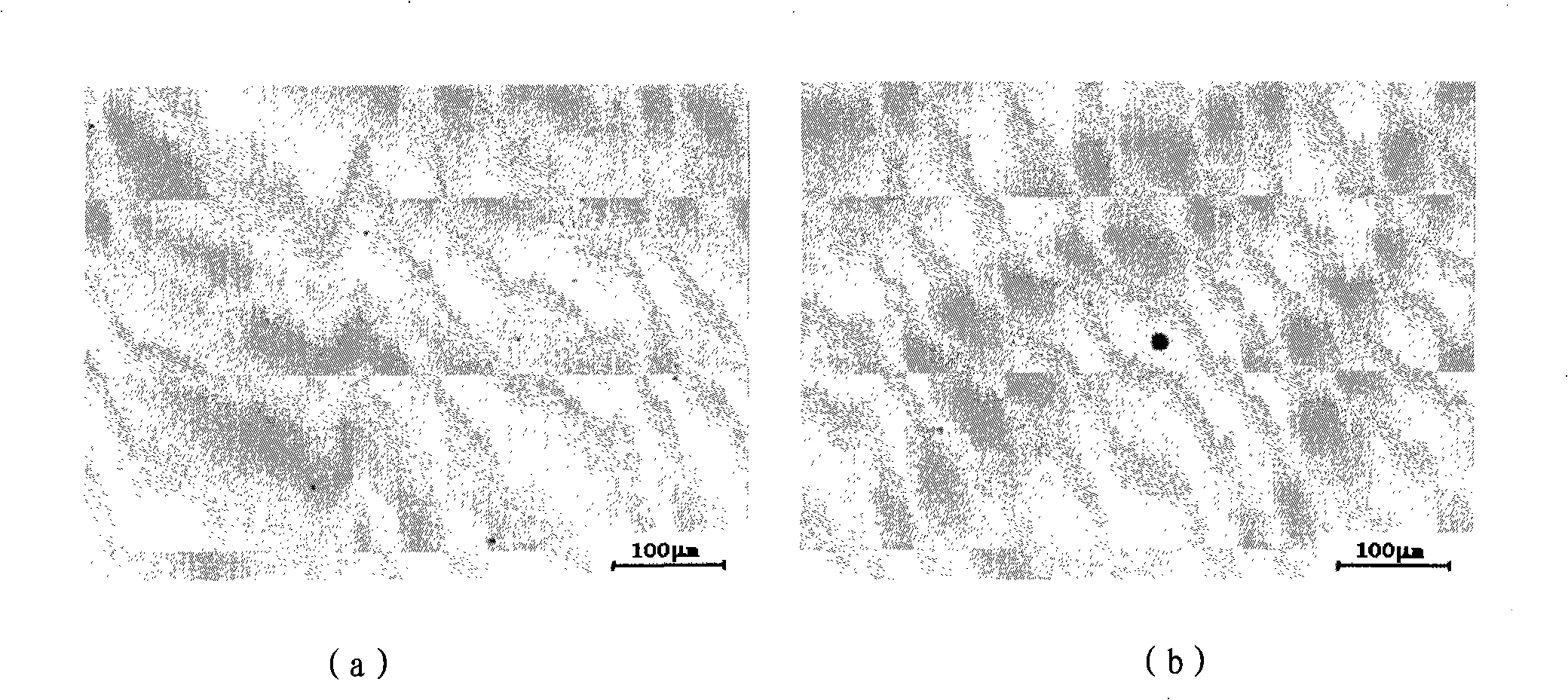

Calcium treatment method for molten steel in steelmaking

The invention relates to a calcium treatment method for molten steel in steelmaking, which is the method for carrying out calcium treatment in two process steps in the steelmaking process route flow, and the steelmaking adopts the process route of pretreatment of molten iron plus smelting in a converter plus refining in an LF furnace plus RH refining plus continuous casting; the whole steelmaking process route adopts two times of calcium treatment; the first calcium treatment is to feed a calcium line into the molten steel to carry out the calcium treatment after finishing the LF treatment in the process step of refining in the LF furnace; and the second calcium treatment is to feed the calcium line into the molten steel to carry out the calcium treatment after finishing vacuum treatment in the process step of the RH refining. The application of the calcium treatment method for the molten steel in the steelmaking can respectively control the mass fractions of total oxygen and sulfur in a steel ball to be (5-20) multiplied by 106 and (2-30) multiplied by 106 respectively, most of inclusion in the steel ball is spherical, the equivalent diameter of the inclusion is (1-10) mu m, the qualified rate of the fault detection of a steel plate after rolling is larger than 99%, the B type inclusion grading is reduced as a whole, the proportion of the grade below grade 1 is 97%, and the control level of the inclusion is significantly improved.

Owner:NANJING IRON & STEEL CO LTD

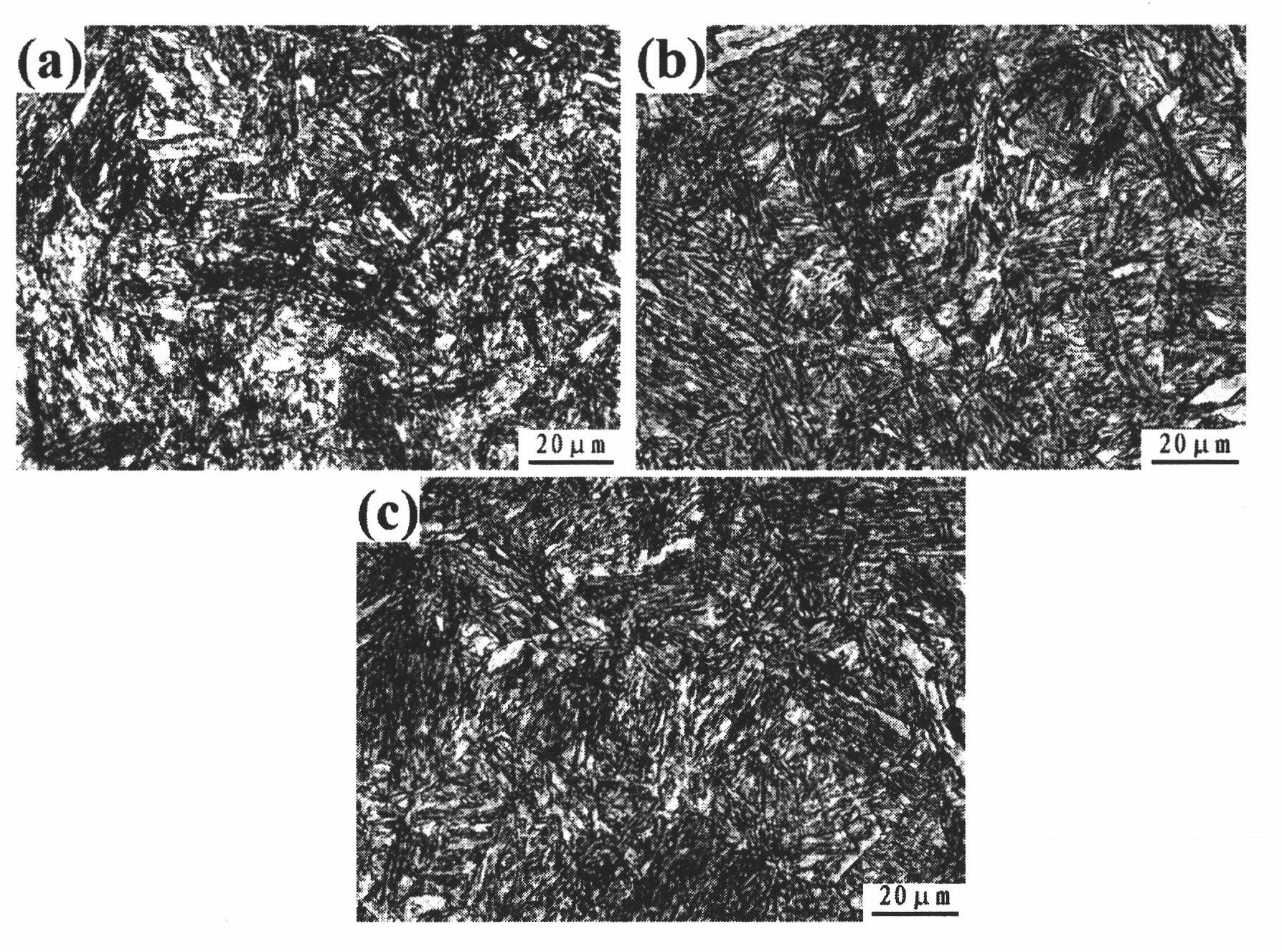

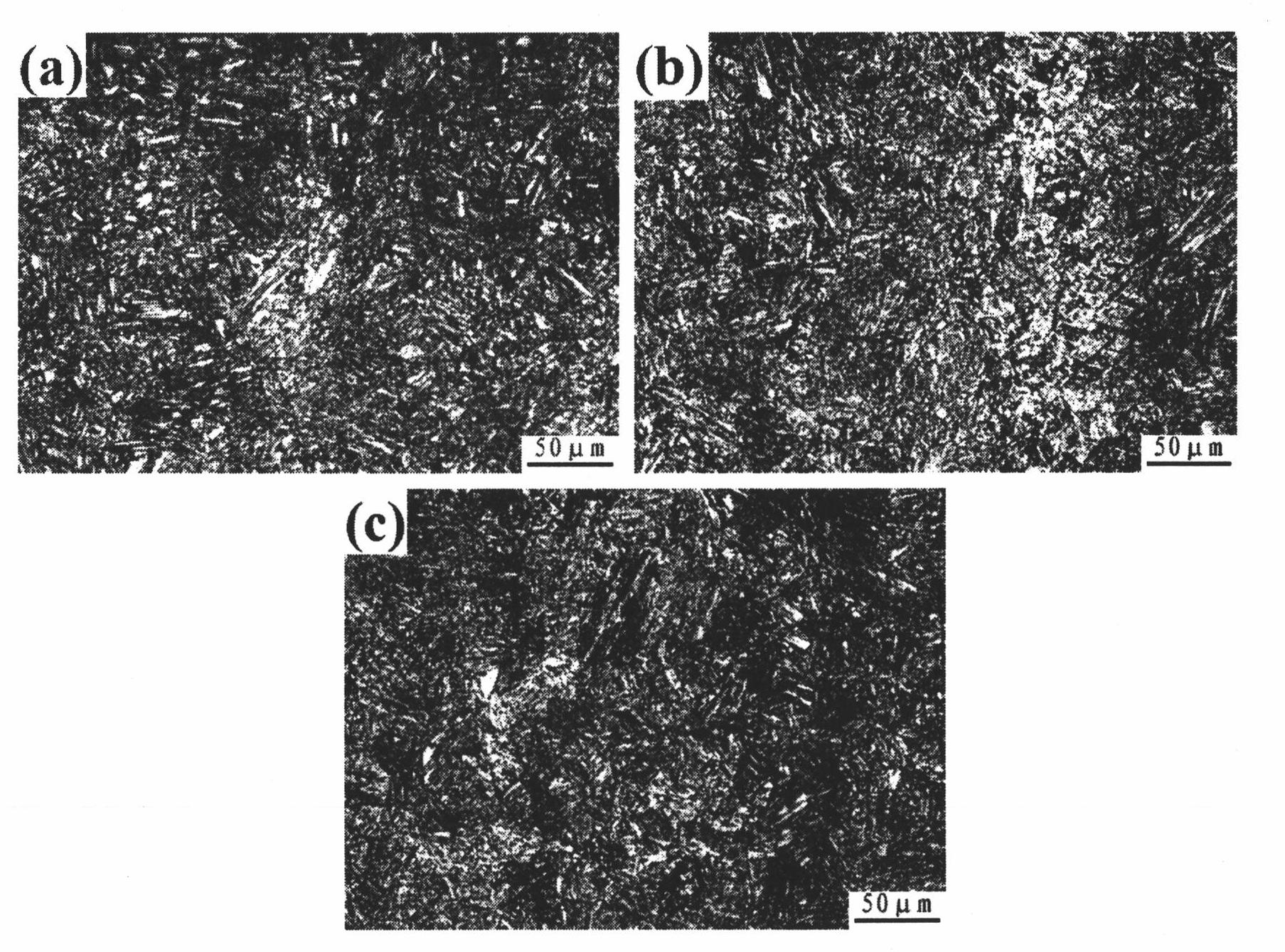

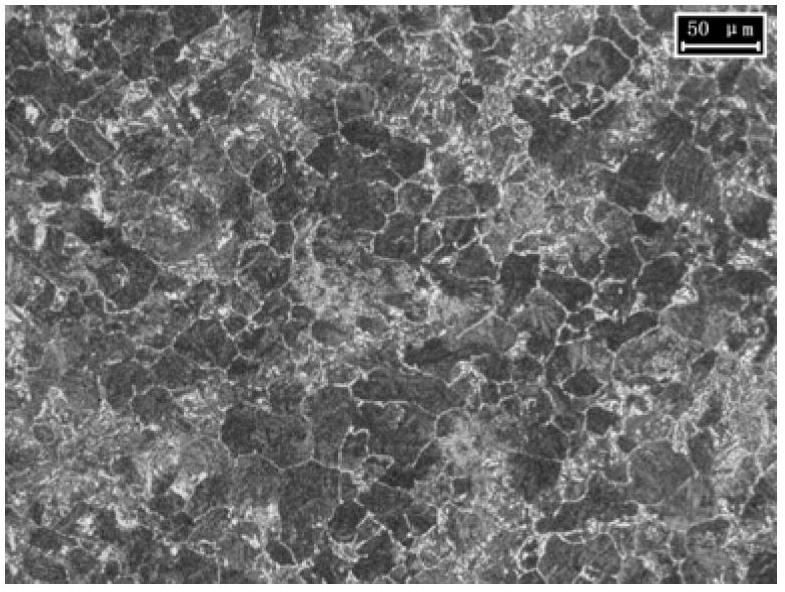

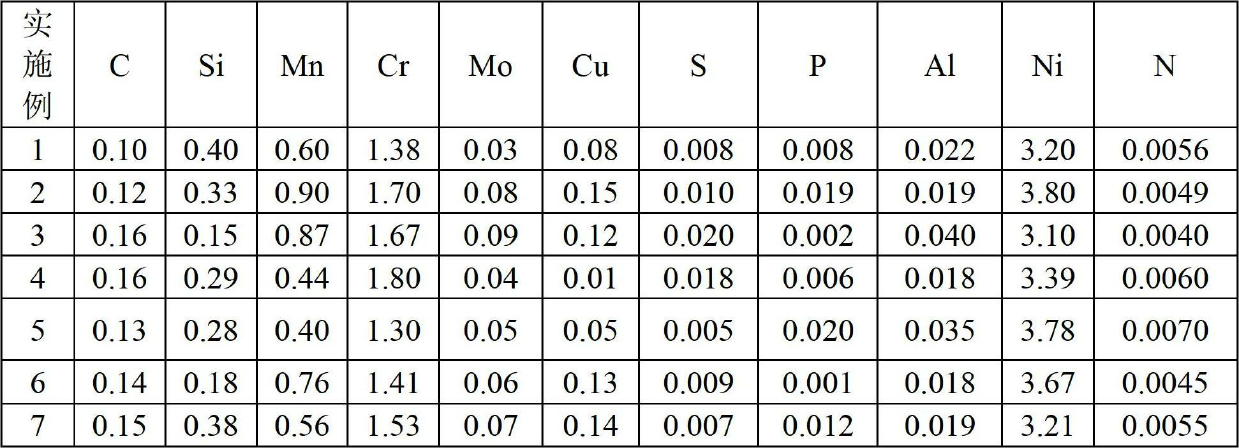

Carburizing bearing steel

The invention discloses a carburizing bearing steel, which comprises the following chemical elements in percentage by mass: 0.10-0.16% of carbon, 0.40-0.90% of manganese, 0.15-0.40% of silicon, 1.30-1.80% of chromium, 3.10-3.80% of nickel, 0.02-0.09% of molybdenum, 0.015-0.040% of aluminum and 0.0040-0.0070% of nitrogen, less than or equal to 0.0010% of oxygen, less than or equal to 0.020% of phosphorus, 0.005-0.020% of sulfur, less than or equal to 0.0020% of titanium, less than or equal to 0.15% of copper, less than or equal to 0.025% of tin, less than or equal to 0.015% of antimony, less than or equal to 0.030% of arsenic, and the balance of Fe and inevitable impurities, wherein the ratio of aluminum / nitrogen is more than or equal to 3. The carburizing bearing steel disclosed by the invention is easy for carburizing surface treatment, and has excellent strength and toughness.

Owner:宝钢特钢有限公司

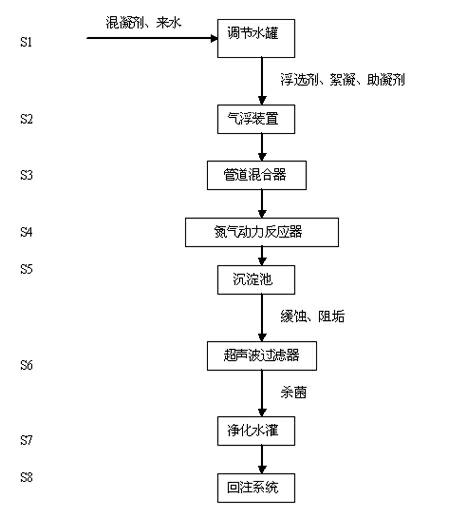

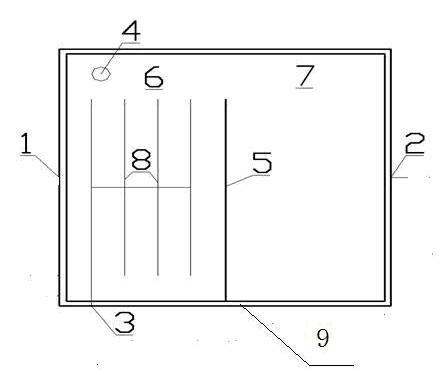

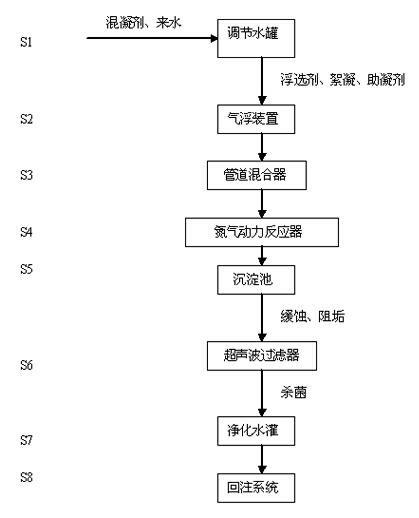

Process for treating oil field produced water

ActiveCN102153221AEasy to handleHigh degreasing efficiency at one timeWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentFiltrationNitrogen

The invention belongs to a process for treating oil field produced water and belongs to the field of oil field produced water treatment, in particular relates to the process for treating the oil field produced water. In the process, at least a regulating water tank, an air flotation device, a pipeline mixer, a nitrogen power reactor, a sedimentation tank and an ultrasonic filter are adopted and the oil field produced water is treated by adopting a mode of combining air flotation oil and suspended matter removal, nitrogen preparation and ultrasonic filtration. The process for treating the oil field produced water has good treatment effect, high oil removing efficiency, corrosion resistance and low cost and has good effect in the actual application.

Owner:XIAN CHANGQING TECH ENG

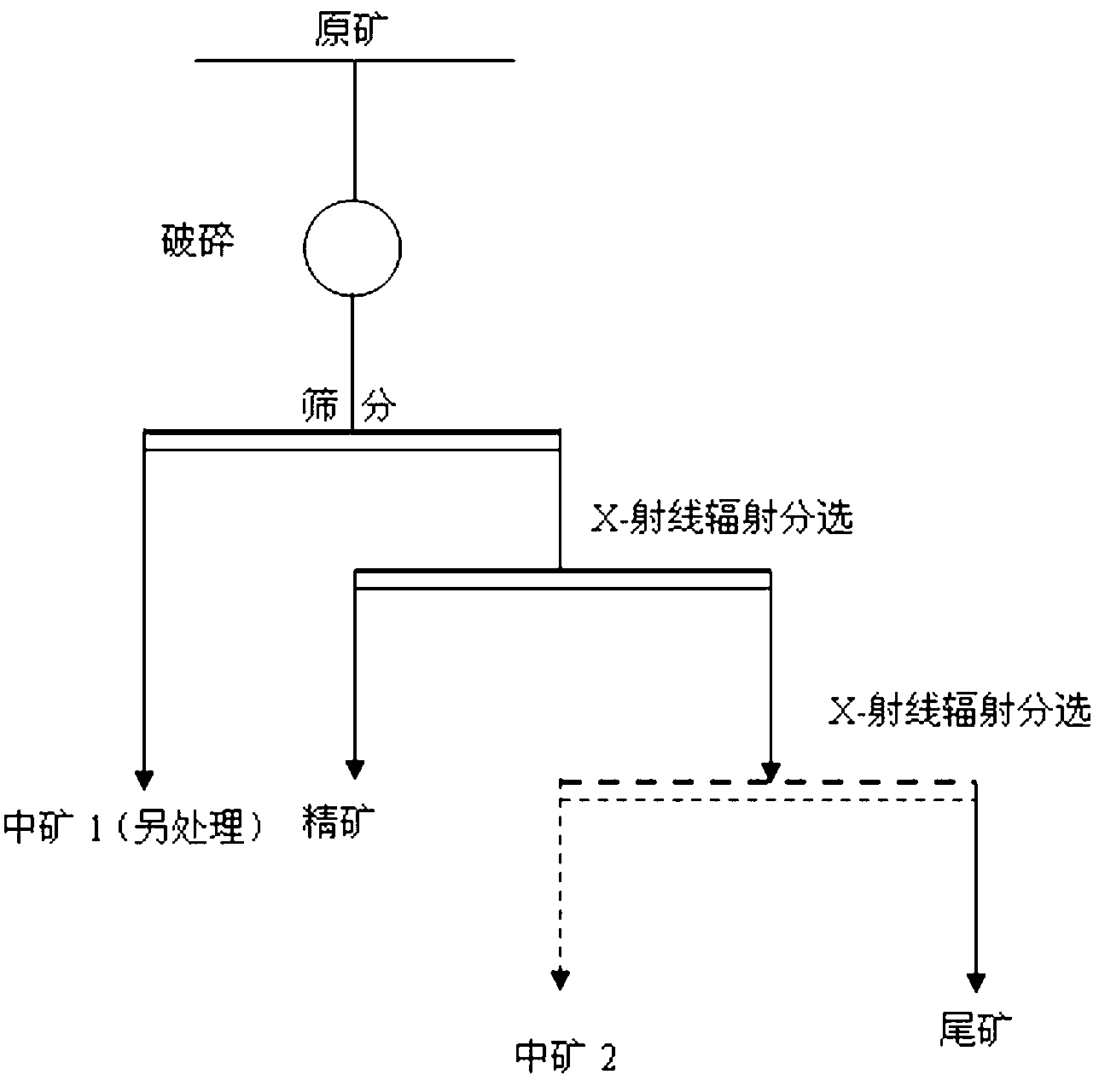

Method for sorting and pre-enriching lean hematite by using X-ray radiation

The invention relates to a method for sorting and pre-enriching lean hematite by using X-ray radiation. The invention belongs to the technical field of mineral processing. The method comprises the steps that: copper-containing ores are crushed to a size below 150mm by using a crusher; the crushed material is sieved by using a sieving machine with a mesh size greater than or equal to 20mm; on-sieve material is delivered to an X-ray radiation sorting machine through a feeder; a sorting threshold is set in the control system of the X-ray radiation sorting machine according to the iron content in crude ore; and after the sorting of the X-ray radiation sorting machine, concentrate and tailings are obtained. The method provided by the invention is domestically initiative. Target component grade of processed ore is low, mechanical and automation degrees are high, ore-sorting cost is saved, the grade of selected material iron of a concentrator is greatly improved, and equipment utilization rate is substantially improved. Also, the process provided by the invention has the advantages of reasonable technology and stable running. With the method, industrialization of lean hematite pre-sorting can be easily realized, and concentrator economic and technical indicators and comprehensive benefits can be greatly improved.

Owner:NORTHEASTERN UNIV

Calcium treatment process of rod wire alloy steel

The invention belongs to the technical field of metallurgy of iron and steel, and particularly relates to a calcium treatment process of rod wire alloy steel. The invention adopts a converter smelting-LF (ladle furnace) refining-RH refining-square billet continuous casting production technique. The calcium treatment process is implemented in a way that: after the LF refining finishes, feeding an iron calcium wire, silico-calcium wire or solid calcium wire into molten steel at the linear speed of 50-250m / min to control the mass percent of calcium aluminum in the molten steel at 0.08-0.16%; after the soft blow, carrying out RH treatment; after the RH treatment finishes, carrying out calcium carbonate treatment, and feeding the iron calcium wire, silico-calcium wire or solid calcium wire into molten steel at the linear speed of 50-250m / min to control the mass percent of calcium aluminum in the molten steel at 0.04-0.08%; and carrying out soft blow, and casting. When the treatment process is used for producing high-quality steel, the inclusion level can not deteriorate, the castability of the molten steel is good, the number of continuous casting furnaces is increased, the calcium content of the molten steel is low but does not influence the casting performance, and the treatment process plastifies the inclusions and improves the mechanical properties of steel.

Owner:NORTHEASTERN UNIV +1

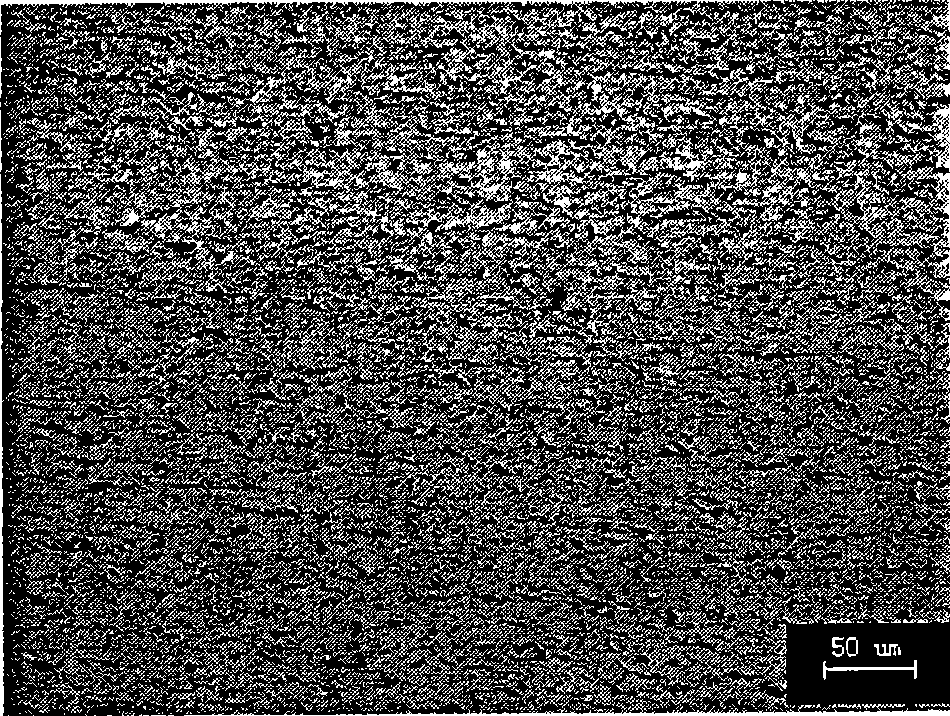

Thick specification hot-rolled steel sheet for roll forming high intensity metal sheet pile and manufacturing technology

ActiveCN101451216AAvoid formingMeet demanding requirementsTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention relates to a high strength hot rolled plate and a production process thereof, in particular to a heavy gauge hot rolled steel plate for a roll bending forming high strength steel plate pile and a production process thereof. The invention mainly solves the technical problems of inadequate thickness, and lowcold bending performance and absorbed-in-fracture energy in the prior high strength heavy gauge steel plate. The technical proposal comprises: the heavy gauge hot rolled steel plate for the roll bending forming high strength steel plate pile comprises the following chemical components by weight percentage: 0.08 to 0.15 percent of C, 0.10 to 0.40 percent of Si, 0.30 to 0.90 percent of Mn, 0.020 to 0.040 percent of Nb, 0.010 to 0.030 percent of Ti, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S, and the balance being Fe. The microscopic structures can be fine grain ferrites, and pearlitic structures plus a small amount of bainite structures which are dispersed; the grain size level is 11 to 14; and the banded structure level is less than 0.5. The high strength hot rolled plate is mainly used for producing the steel plate pile.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

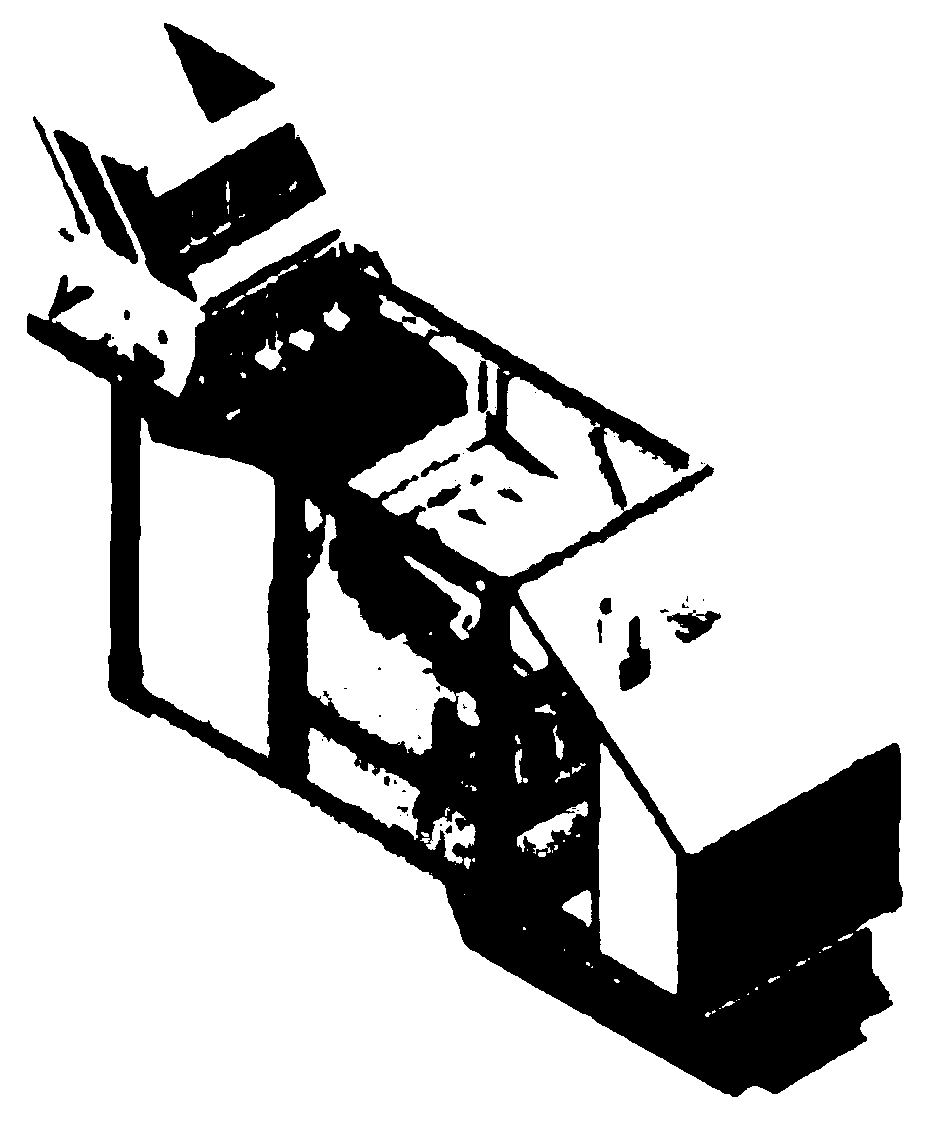

Electrothermal copper-smelting slag depleted furnace

ActiveCN101839631ADowngradeHigh recovery rateRotary drum furnacesProcess efficiency improvementSiphonElectricity

The invention discloses an electrothermal copper-smelting slag depleted furnace, which comprises a furnace body, supports, an oxygen lance and electrodes; the furnace body comprises a furnace shell defining a furnace chamber and a refractory material layer arranged on the inner wall of the furnace shell, the furnace body is provided with a feed inlet for feeding copper-smelting slag and vulcanizing agent into the furnace chamber, a siphon inlet for discharging copper matte, a waste slag-discharging outlet, electrode plugholes, a smoke outlet and an oxygen lance plughole, wherein the oxygen lance plughole is formed at the bottom of the furnace shell; the furnace body is supported by the supports; the oxygen lance is plugged into the oxygen lance plughole; and the electrodes are plugged into the furnace body via the electrode plugholes. When the electrothermal copper-smelting slag depleted furnace is used for bottom-blowing electrothermal copper-smelting slag depletion, the copper content in waste slag can be reduced, and electricity consumption can be decreased.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for flotation after acid etching pretreatment of high-calcium fluorite

The invention discloses a method for flotation after acid etching pretreatment of high-calcium fluorite. Acid is added into high-calcium fluorite pulp before flotation, inhibitors are added while the acid is added, and acid etching pretreatment is carried out; pH regulators and collecting agents are sequentially added after pretreatment is completed, and then air agitation pulp mixing is carried out; foam flotation is carried out after pulp mixing is completed, and rough concentrate is obtained; and the rough concentrate is further subjected to concentration to obtain high-quality fluorite concentrate. The method is clean, environmentally friendly, efficient and low in cost, and the obtained fluorite concentrate is high in grade and recovery rate.

Owner:CENT SOUTH UNIV

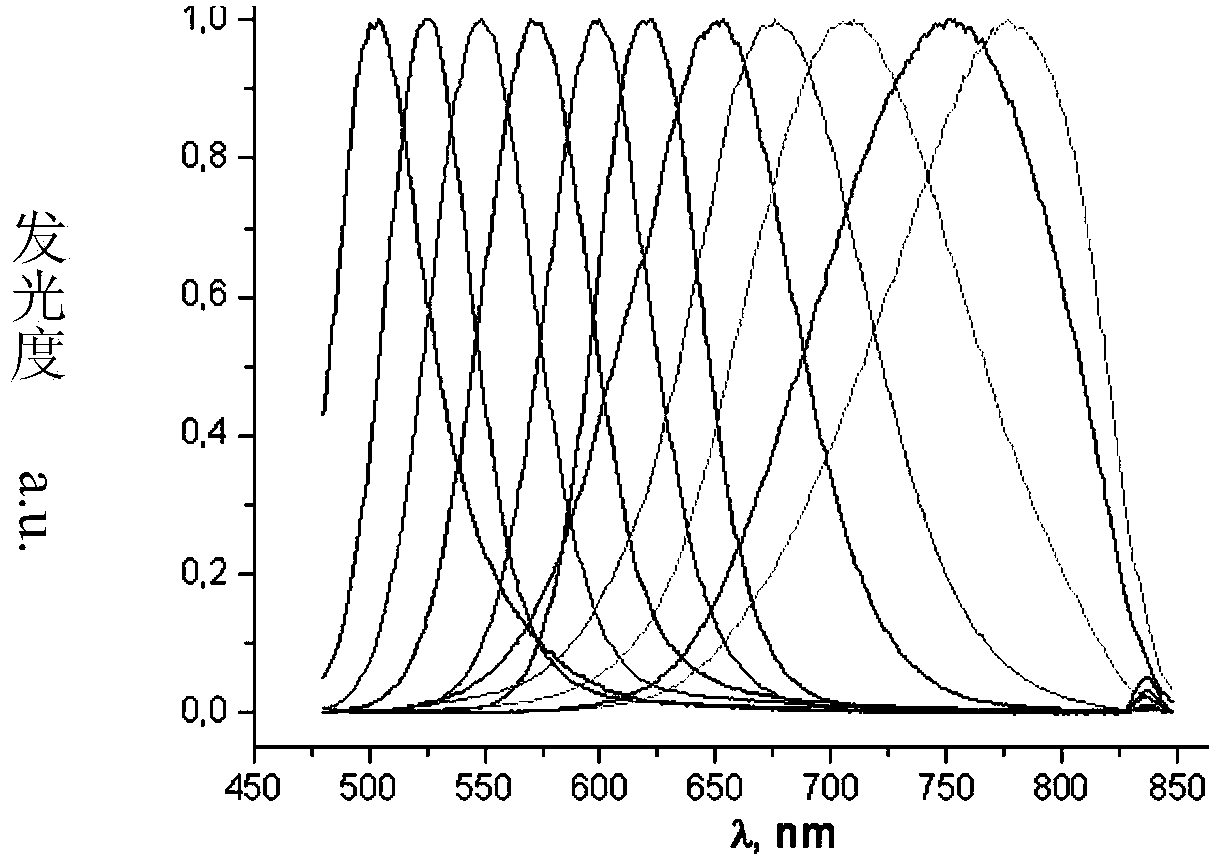

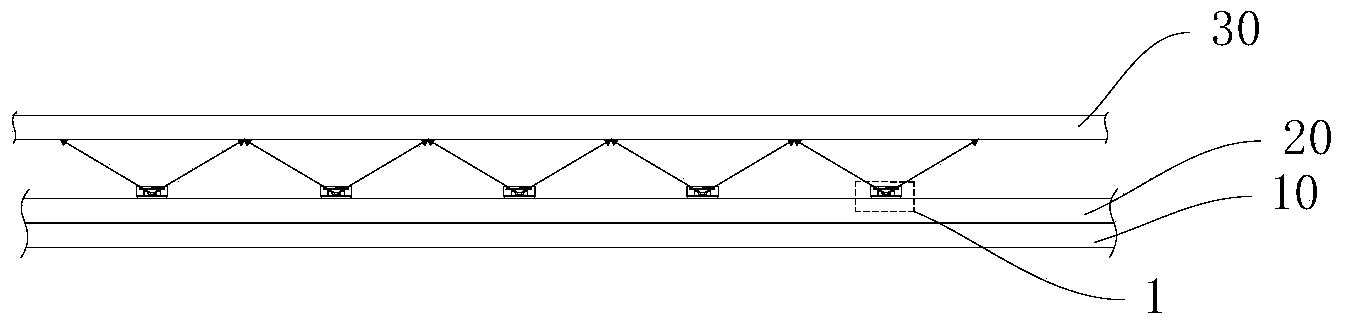

Light source with quantum dots and manufacturing method and application of light source with quantum dots

InactiveCN103672609AIncrease the light output angleReduce in quantityNon-linear opticsRefractorsDiffusionLiquid-crystal display

The invention relates to the technical field of liquid crystal display, in particular to a structural improvement on a directly-down-type backlight source, and provides a light source with quantum dots. The light source comprises a substrate, a lamp bar and light mixing bodies arranged around the lamp bar are installed on the substrate, quantum dot stick blocks are arranged at the tops of the light mixing bodies, light emitted by the lamp bar is refracted by the quantum dot stick blocks to go out, and the light outgoing faces of the quantum dot stick blocks are curved surfaces. The invention further provides a manufacturing method of the quantum dot stick blocks and the novel directly-down-type backlight source assembled with the quantum dot stick blocks. According to the light source with the quantum dots, due to the fact that the light outgoing faces of the quantum dot stick blocks are the curved surfaces through the structural improvement on the quantum dot stick blocks, the light diffusion angle formed after the light emitted by the lamp bar passes through the quantum dot stick blocks is increased, and finally the light outgoing angle of the light source is increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

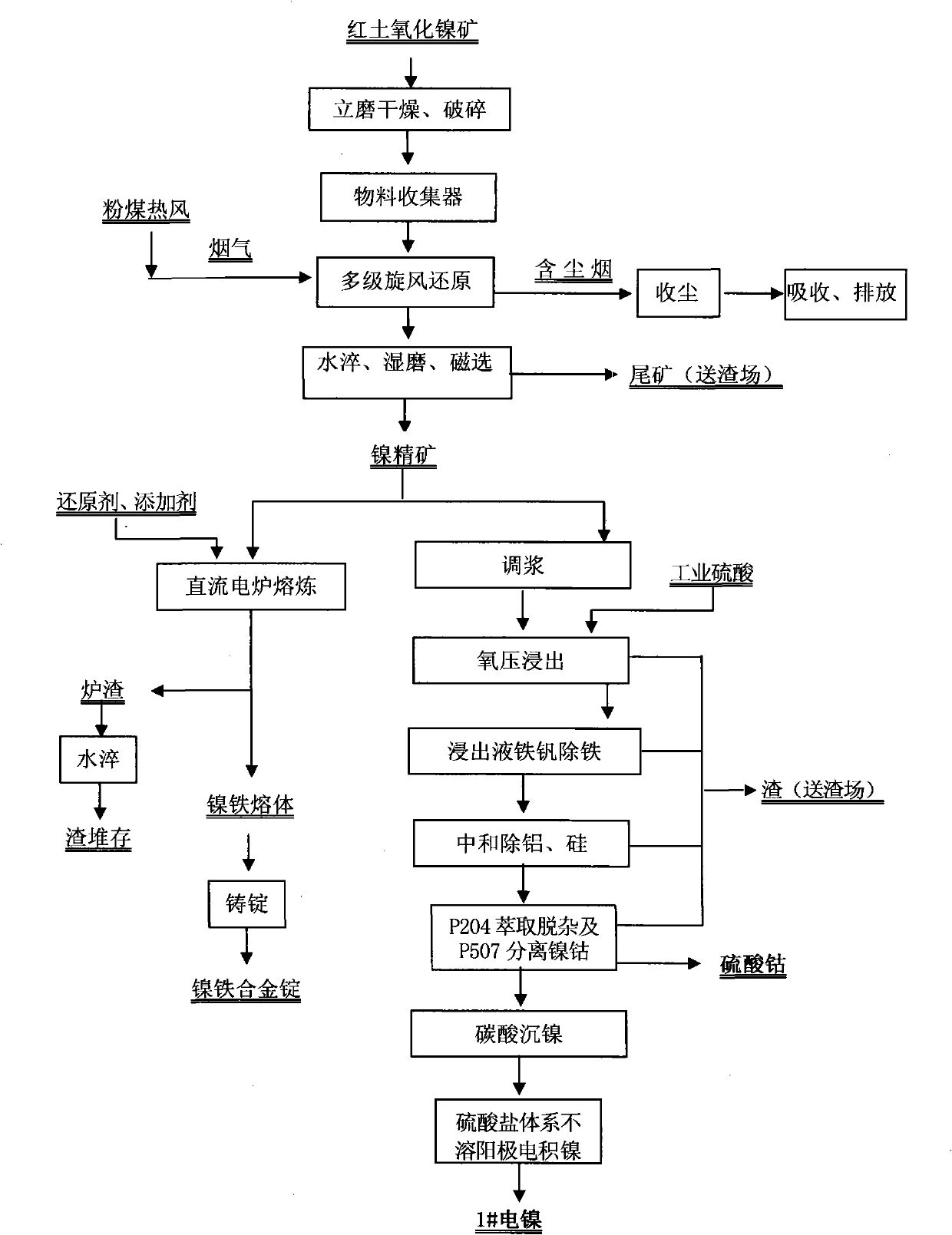

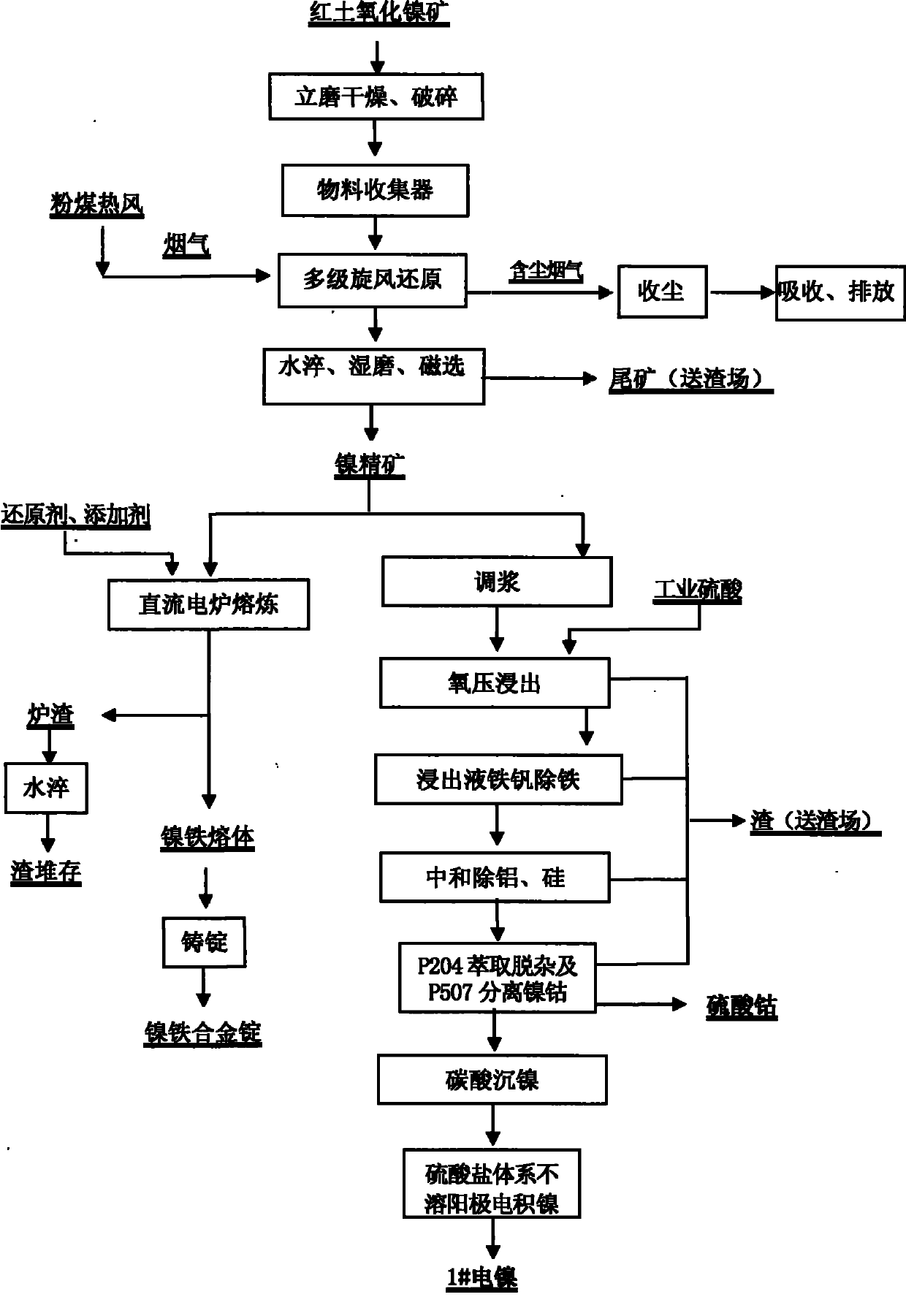

Integrated approach to enriching nickel from nickel oxide laterite ore

The invention relates to an integrated approach to enriching nickel from nickel oxide laterite ore, comprising the following steps of: breaking the nickel oxide laterite ore into 100-320-mesh specification by a vertical mill; and feeding into a multistage cyclone to successively dry, calcine and reduce; meanwhile, injecting coal, coke or carbon black solid reductant into the multistage cyclone for prereduction roasting, wherein the amount of the added coal, coke or carbon black solid reductant accounts for 1-13wt% of the nickel oxide laterite ore; circulating and returning smoke discharged by prereduction roasting back to the vertical mill for drying materials; carrying out water quenching and wet ore grinding to the reduced materials; and carrying out magnetic separation under the magnetic field intensity of 3000-5000 Gaussians to obtain nickel ore concentrates of which the grade is 5-15wt%. The method can be used for processing different types of nickel oxide laterite ore and has the characteristics of strong adaptability to raw materials, flexible production technology and products, high nickel and cobalt recovery rate, low energy consumption, environment-protection performance and the like.

Owner:YUNNAN TIN GROUP HLDG

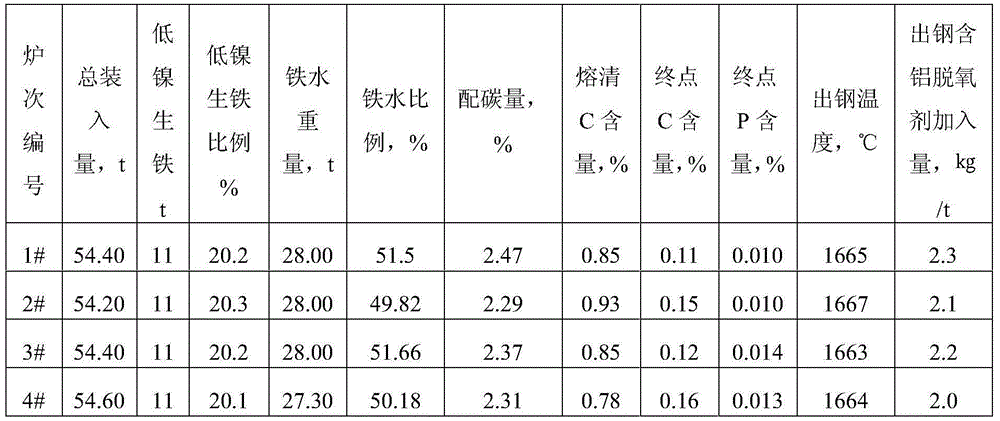

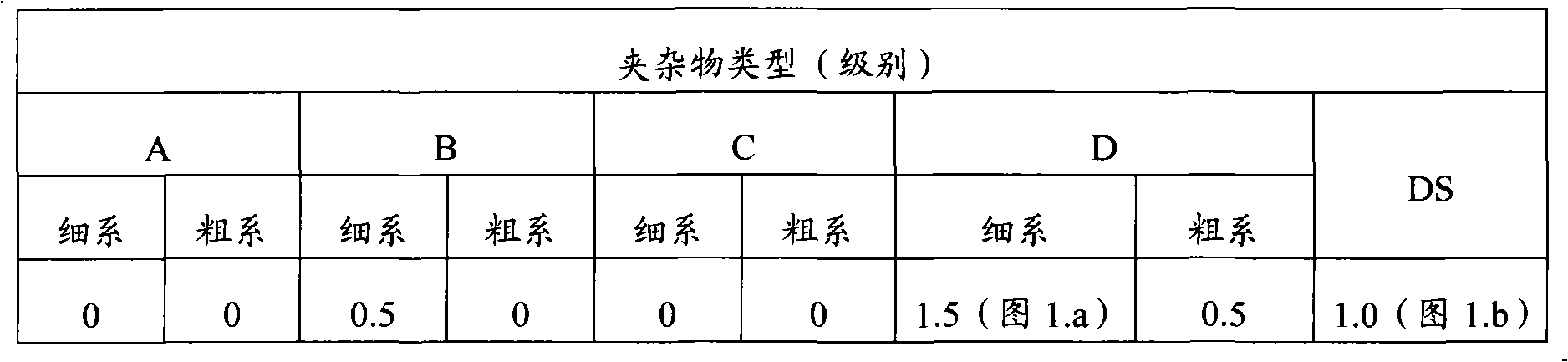

Inclusion control method for rod and wire alloy steel

The invention relates to the technical field of metallurgy, in particular to an inclusion control method for rod and wire alloy steel, which solves the problem of inclusion standard exceeding of the rod and wire material alloy steel, improves the molten steel cleanness and improving the molten steel casting performance. The method has the technical scheme that a production process of converter smelting, laser fusion (LF) refining, relative humidity (RH) refining and square blank continuous casting is adopted, the molten steel is subject to the calcium treatment after the LF refining completion during the production, and the RH treatment is then carried out after the soft blowing. The concrete steps are as follows: (1) the molten steel smelted by the converter is deoxidized by aluminum; (2) calcium wires are fed into the molten steel after the LF refining completion; (3) argon soft flowing is carried out on the molten steel after the wire feeding completion; (4) the molten steel is subject to RH vacuum treatment; (5) argon soft flowing is carried out on the molten steel after the RH vacuum treatment completion; and (6) tundish covering agents are added, and the continuous cast steel long nozzle argon blowing protection casting is adopted. The inclusion control method has the advantages that the production cost is greatly saved, and in addition, the inclusion grade is obviously reduced through being compared with that of the original process.

Owner:NORTHEASTERN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com