Patents

Literature

39results about How to "Reduce iron oxide content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-resistant corrosion-resistant coating

The invention discloses a flame-resistant corrosion-resistant coating. The flame-resistant corrosion-resistant coating is an amorphous flame-resistant corrosion-resistant coating for protecting the surface of a liner of an industrial furnace. The flame-resistant corrosion-resistant coating is characterized in that fine powder of tabular corundum and magnesium aluminate spinel, calcined alpha-Al2O3 micro-powder, pure calcium aluminate cement as a curing agent, sodium hexametaphosphate as a sintering assistant, and a phosphoric acid or aluminum dihydrogen phosphate solution as a binder are blended into the flame-resistant corrosion-resistant coating. The flame-resistant corrosion-resistant coating can resist corrosion produced by a high-concentration fluoride and a high-concentration hydrogen fluoride atmosphere, and has the advantages of high purity, good heat stability, application convenience, smooth and compact surface and relatively low cost. The flame-resistant corrosion-resistantcoating is suitable for the surface of a liner of a furnace with fluorides and a hydrogen fluoride atmosphere and also is suitable for the surface of a liner of a high-temperature and low-oxygen content furnace with a strong reduction atmosphere.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

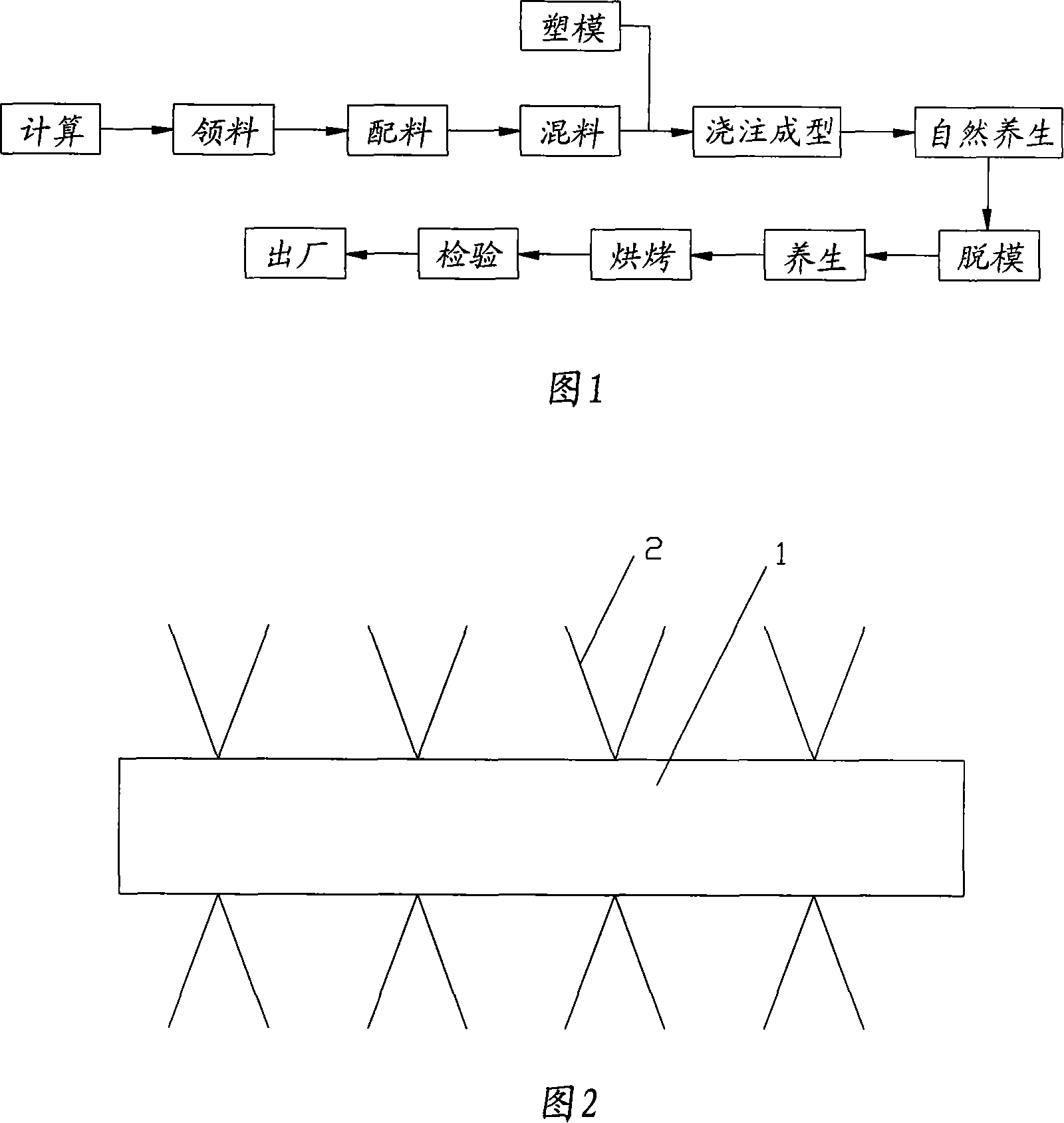

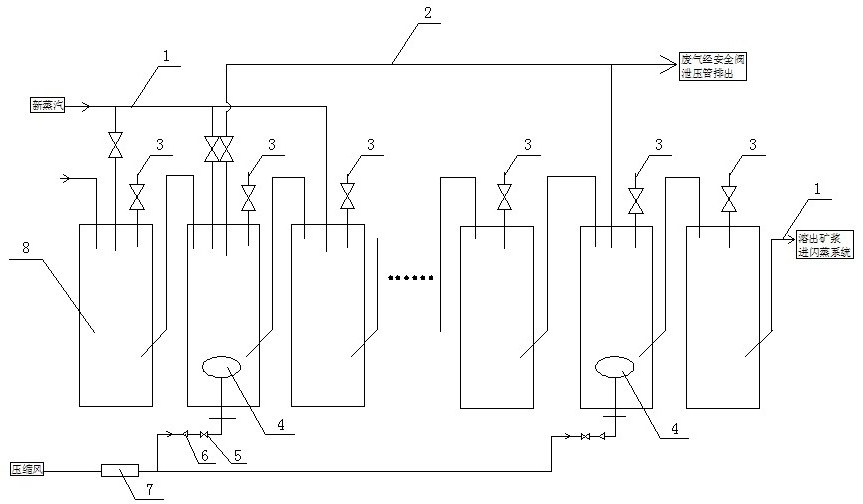

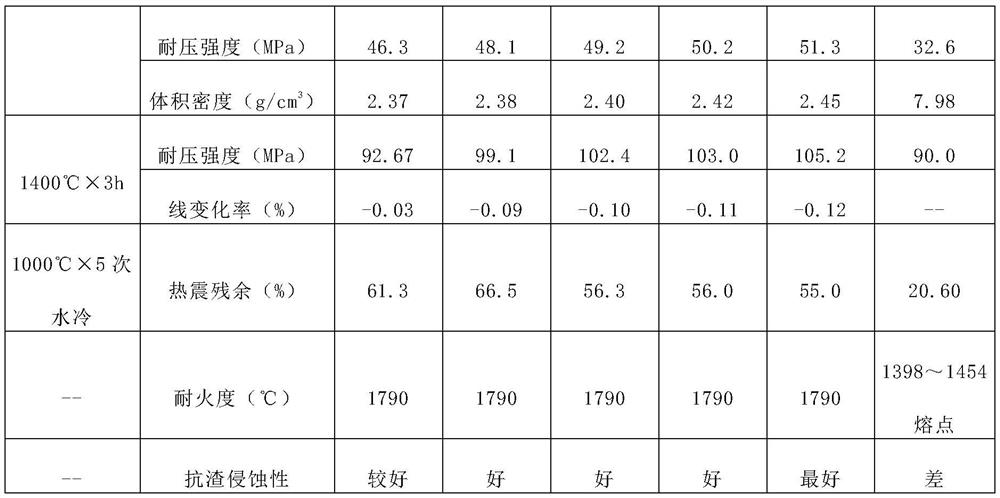

Fire resistive material for desulfurization spray gun and producing technique for the desulfurization spray gun

The present invention discloses one kind of refractory material for desulfurizing spray gun, and the refractory material has the main raw materials including electrocast mullite, andalusite, alundum powder, fine alpha-Al2O3 powder, fine SiO2 powder, kyanite, steel fiber, 95# flake graphite, cement and fine spinelle powder. The refractory material is cast to desulfurizing spray gun vertically in two sections, one slag line section and one non-slag line section. The spray gun thus produced has high heat stability, low reburning shrinkage, high mechanical strength, excellent wear resistance, compact structure, low ferric oxide content, great high temperature strength and long service life.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

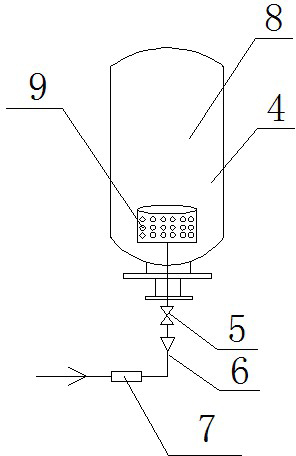

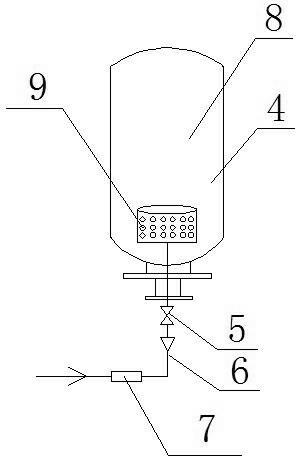

Method for producing aluminum oxide by high sulfur bauxite

InactiveCN102616821AReduce manufacturing costNegative divalent sulfur concentration decreasedAluminium oxide/hydroxide preparationSulfate radicalsAluminium hydroxide

The invention discloses a method for producing aluminum oxide by high sulfur bauxite, which comprises the processes of raw material preparation, high-pressure digestion, settling separation and washing, aluminum hydroxide seed decomposition, aluminum hydroxide washing and calcination, and mother liquor evaporation. The high-pressure digestion process comprises a low-temperature section, a medium-temperature section and a high-temperature section; compressed air is fed into a high-temperature section reaction kettle in the high-pressure digestion process, so as to finally oxidize S2- in pulp into SO42-; and SO42- is combined in sodium-silicon slag in red mud and discharged with the red mud. By adopting the technical scheme, the concentration of negative bivalent sulfur in dissolution pulp liquid phase is obviously reduced, the concentration of thiosulfate in the dissolution pulp liquid phase is not increased obviously, the concentrations of negative bivalent sulfur and ferric oxide in circulating mother liquor are obviously reduced, the concentration of negative bivalent sulfur in fine liquor is obviously reduced, the concentration of thiosulfate is not increased obviously, the content of ferric oxide in the fine liquor is reduced, the contents of ferric oxide in aluminum hydroxide and aluminum oxide meet the primary standard of the national standard, and all production links return to normal.

Owner:洛阳香江万基铝业有限公司

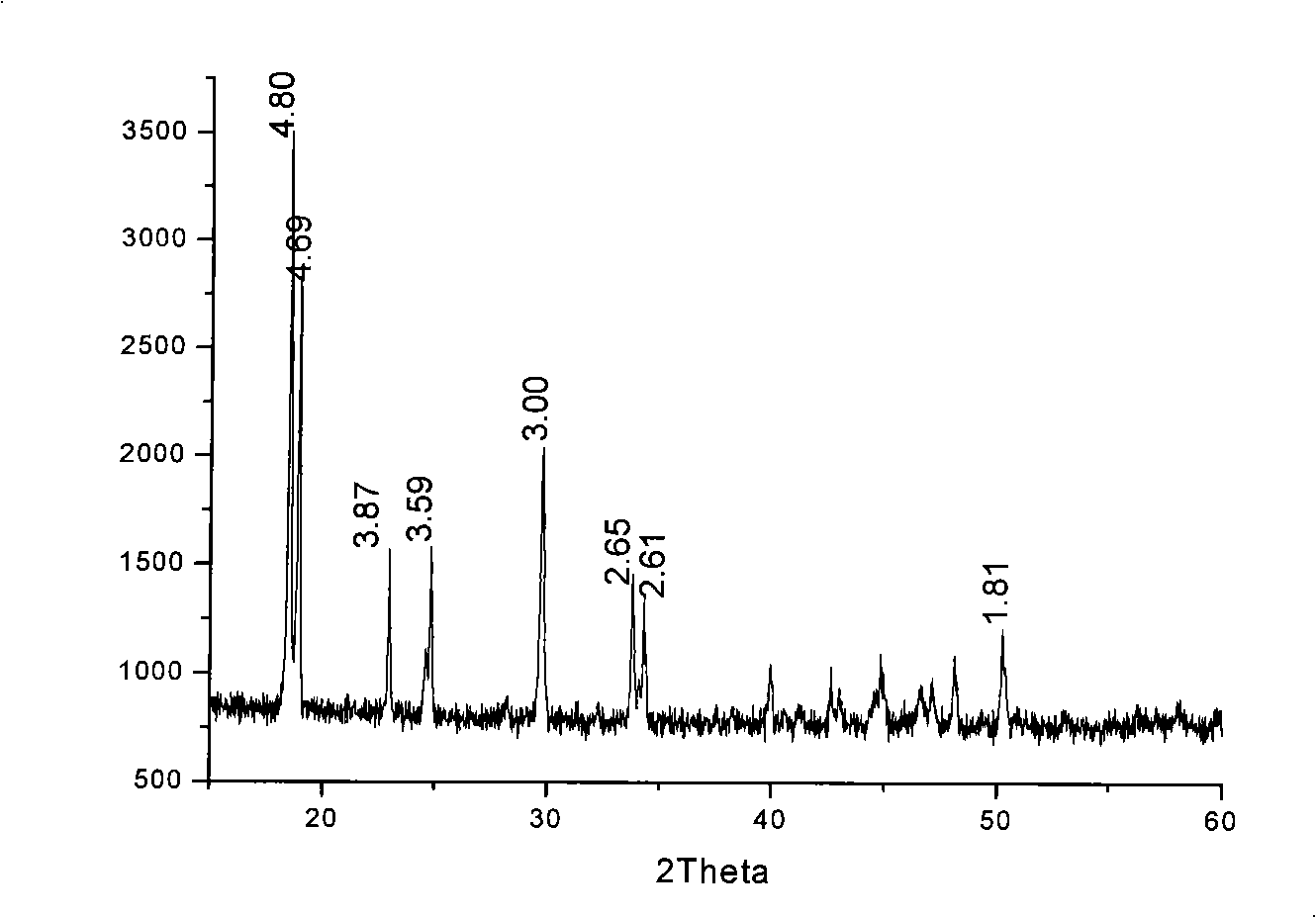

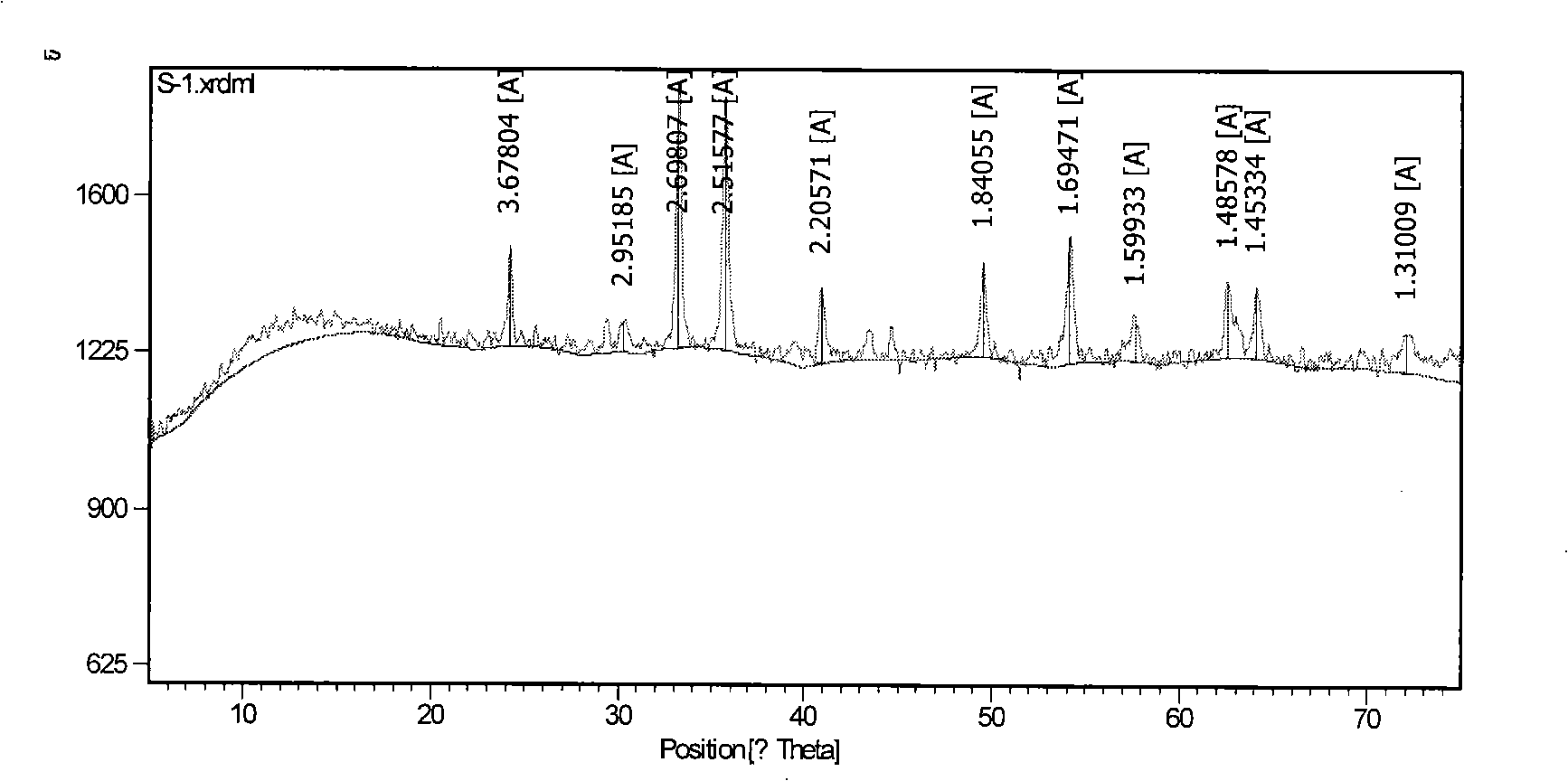

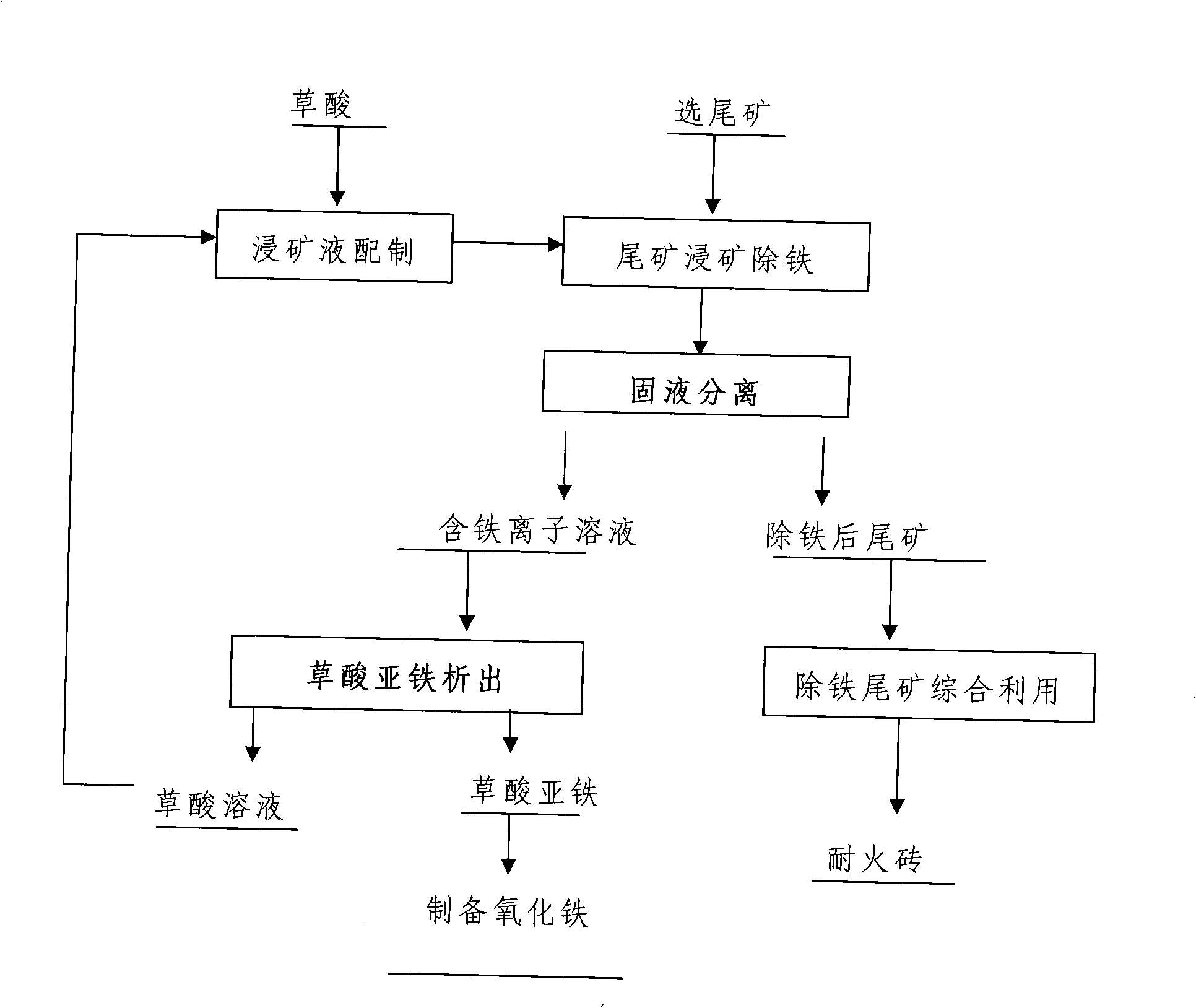

Process for preparing clay firebrick by flotation tailing of bauxite

InactiveCN101306953AReduce iron oxide contentDoes not destroy the crystal structureOxalateFire brick

A method for the treatment of bauxite flotation tailings relates to a method for making clay fire brick by means of bauxite flotation tailings and reclaiming the iron mineral in the tailings to make ferrous oxalate and ferric oxide. The method is characterized in that: firstly, the making process adopts oxalic acid leach bauxite cradling tailings iron mineral so as to remove iron; then, tailings is filtered and separated to make clay fire bricks. The method removes most impurity iron in the tailings at first so as to ensure that the content of ferric oxide in the tailings drops to less than 1.5 percent; meanwhile, only less than 1 percent of aluminum is leached out, and the crystal structure of the aluminum mineral in the tailings is not damaged basically; moreover, the flotation tailings with iron removed can be used to make qualified clay fire bricks.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

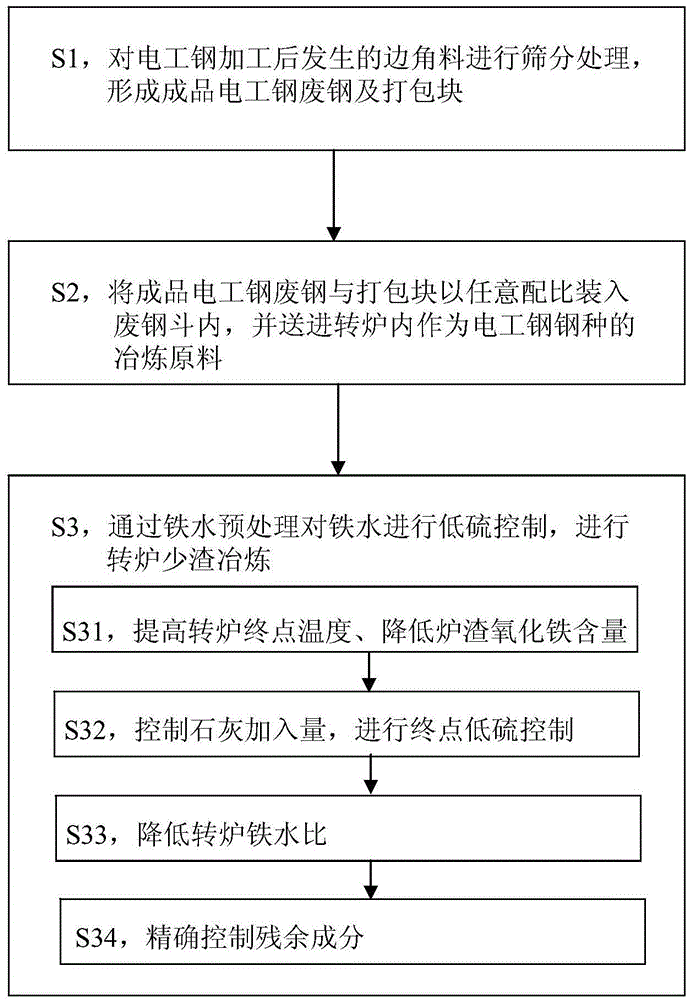

Electrical steel scrap recovery treatment method

InactiveCN104975129ARealize less slag smeltingIncrease temperatureManufacturing convertersRecycling and recovery technologiesElectrical steelSulfur

The invention provides an electrical steel scrap recovery treatment method, which relates to a steel scrap treatment method and solves the problem of inadequate electrical steel heavy slash resources. The method comprises the following steps: carrying out screening treatment on the scrap generated after electrical steel processing to form an electrical steel scrap finished product and a packaged block; adding the electrical steel scrap finished product and packaged block into a steel scrap hopper in any ratio, and sending into a converter as smelting raw materials of the electrical steel grade; and carrying out molten iron pretreatment to perform low-sulfur control on the molten iron, and carrying out converter low-slag smelting. The smelting process comprises the following steps: enhancing the final temperature of the converter, lowering the iron oxide content of furnace slag, controlling the addition of lime, carrying out end point low-sulfur control, lowering the molten iron ratio of the converter, and accurately controlling the residual component. According to the method, the electrical steel scraps with different specifications are classified or packaged into the pressed block, and the electrical steel scraps and pressed block are used as the electrical steel smelting raw materials to perform electrical steel low-slag smelting, so that the steel scrap rate of the converter is enhanced to 10% or above, thereby reducing the consumption of precious metals and lowering the smelting cost.

Owner:BAOSTEEL RESOURCES

Ultra high power direct-current arc furnace deoxidation furnace-protective agent, making method and use thereof

InactiveCN101302569AImprove the yield of all ironIncrease viscosity and alkalinityProcess efficiency improvementElectric furnaceScrapSmelting process

The invention relates to a deoxidation furnace protective agent for an ultrahigh power direct current electric arc furnace, a method for manufacturing the same and an application of the deoxidation furnace protective agent. The deoxidation furnace protective agent comprises the following compositions in percentage by weight: 15 to 25 percent of total carbon, 38 to 55 percent of MgO, 15 to 25 percent of SiC, more than or equal to 3 percent of metallic aluminum, 4 to 10 percent of CaO, more than or equal to 6 percent of metallic iron and 0.05 to 0.2 percent of H2O; the manufacturing process is simple and comprises the following steps that: firstly, materials are weighed according to the mixture ratio, added with 7 to 9.5 weight percent of wedding agent and molded by a ball forming mill to manufacture a rugby-shaped product with a density of more than or equal to 1.8 g / cm<3>. In proportioning, aluminium scraps, carborundum, sponge iron and graphite adopt a parallel mode and have a weight mixture ratio of 1:4 - 6:1 - 2: 4- 6; in the whole smelting process, the deoxidation furnace protective agent is added for three times according to a proportion of 4 to 3 to 3 in order that the total iron content in the slag is reduced from average 40 percent to 10 to 15 percent around, thereby prolonging the service life of a furnace brick lining and a furnace cover and reducing elecrictiy consumption.

Owner:上海柯瑞冶金炉料有限公司

Converter tapping, slag washing and refining process

InactiveCN110804685AReduce manufacturing costReduce in quantityManufacturing convertersSteelmakingCastability

The invention relates to a converter tapping, slag washing and refining process, and belongs to the technical field of steelmaking. In terms of strong desulphurization and deoxidization of the process, during converter tapping, when molten steel is fully laid at the bottom of a ladle, a slag washing material and small lime slag are continuously and evenly put into the steel ladle through an alloychute; when converter tapping is carried out for 1 minute, aluminum particles are added for strong deoxidization, and the addition amount of the aluminum particles is 1.5-2.5 kilograms per tonnage ofsteel; in the tapping process, the flow of argon blown at the bottom of the steel ladle is larger than or equal to 500 ML / min; when tapping ends, aluminum particles are added to the slag side of the steel ladle for slag deoxidization, and the addition amount is 0.3-0.5 kg / t; and the steel slag oxidability (FeO+MnO) is smaller than or equal to 2%. The desulphurization and deoxidization are realizedthrough the tapping and slag washing process without a refining furnace, impurities in steel are effectively removed, the continuous casting castability is improved, and the cleanliness of a castingblank is improved.

Owner:唐山瑞丰钢铁(集团)有限公司

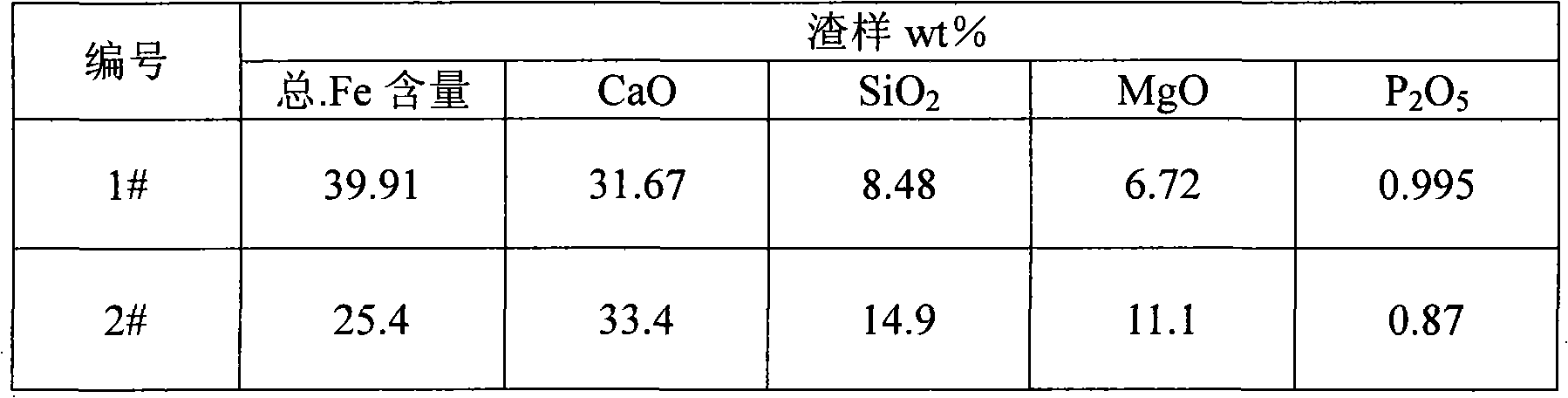

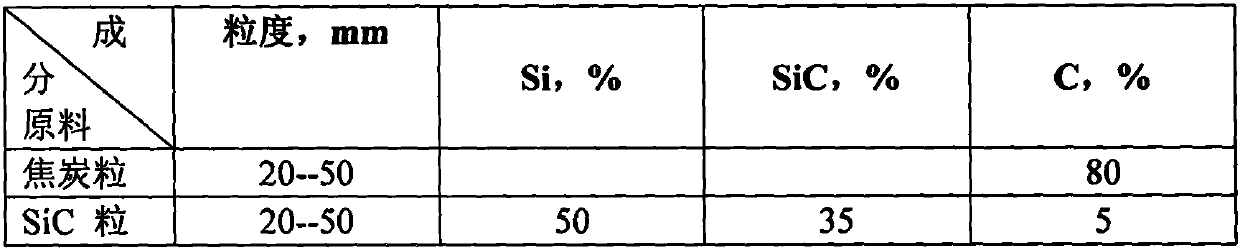

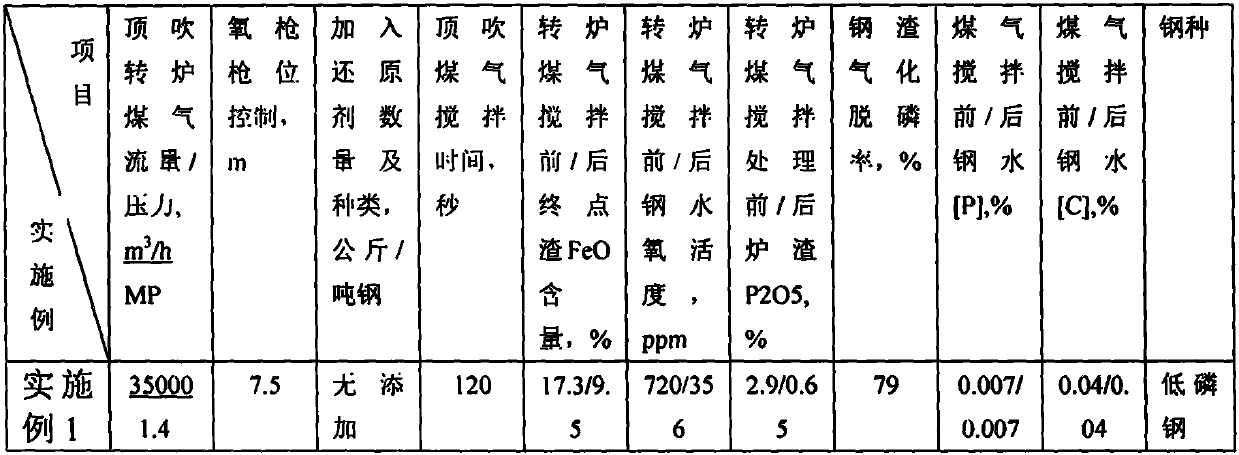

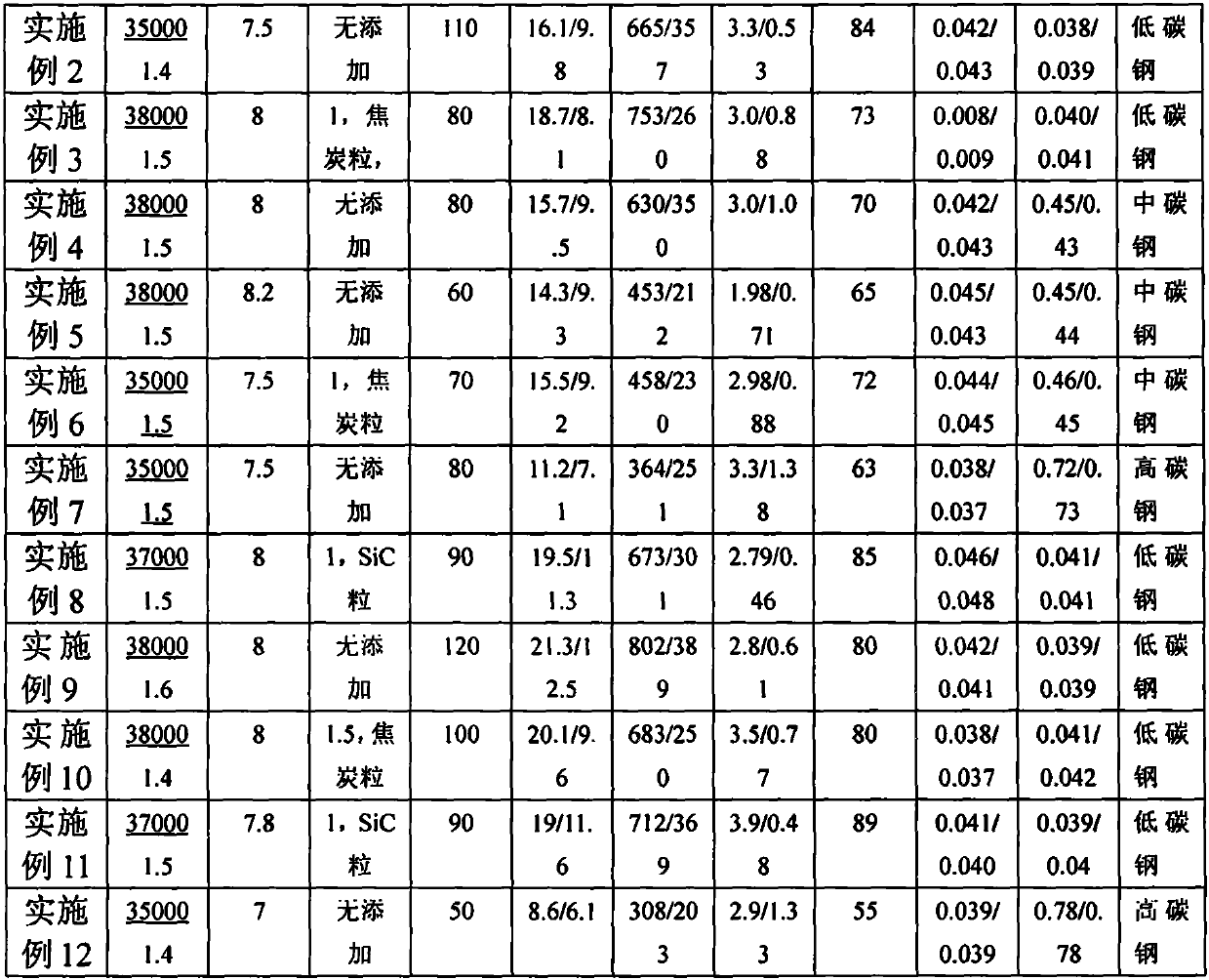

Novel pretreatment process for converter blowing end point steel slag

InactiveCN109593906AReduce iron oxide contentEmission reductionManufacturing convertersSteelmakingEconomic benefits

The invention discloses a novel pretreatment process for converter blowing end point steel slag. The process comprises the step of immediately blowing converter gas instead to the top slag surface for40-120 seconds at the end of the oxygen blowing at the converter blowing end point. With the technical solution, the process is simple and the cost is low. Steel slag is gasified and dephosphorized to obtain lower iron oxide content, the yield of molten steel is increased, and the consumption of a deoxidizer and alloy is reduced. The process is beneficial to the whole slag-retaining operation andslagless steelmaking, is beneficial to smelting low-phosphorus steel and ultra-low-phosphorus steel, is beneficial to slag stopping and slag splashing for protection of a converter, and has great economic benefits.

Owner:王虎

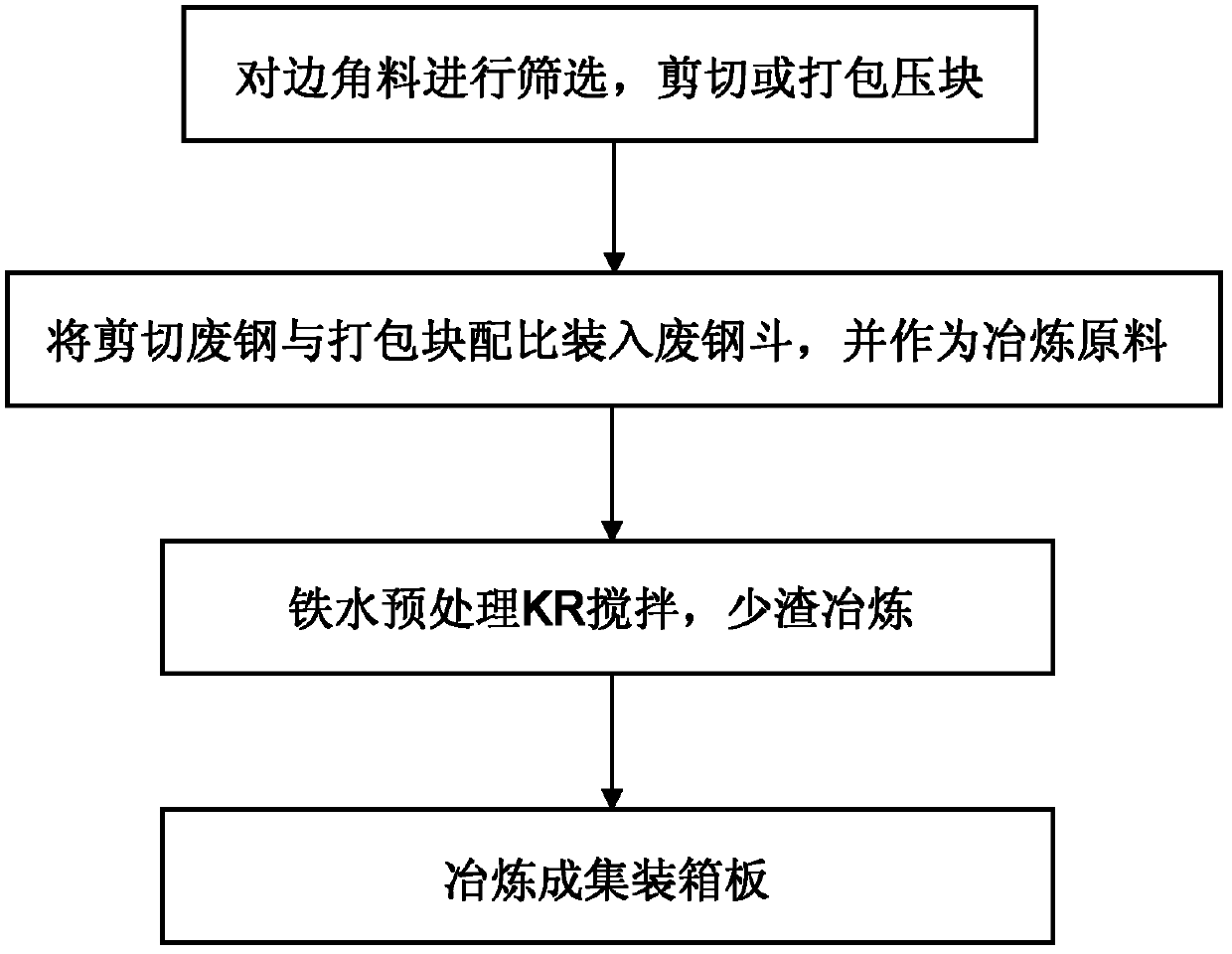

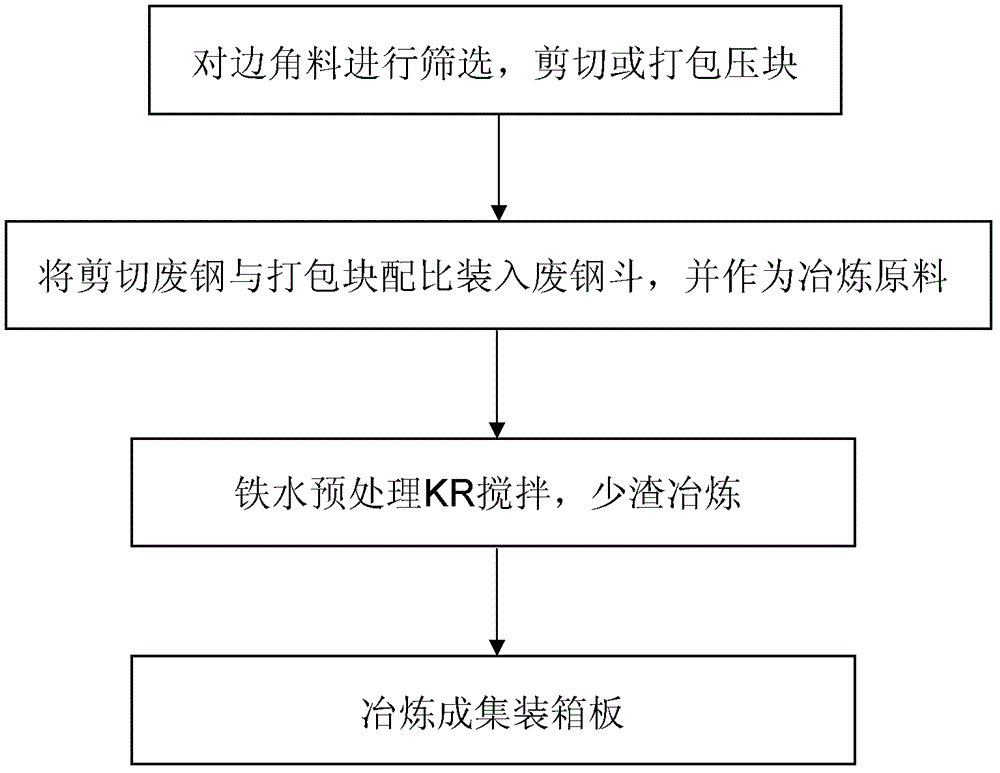

Recovery processing method of leftover materials of container plate

InactiveCN103374654ARealize less slag smeltingIncrease temperatureManufacturing convertersProcess efficiency improvementLead smeltingEconomic benefits

The invention discloses a recovery processing method of leftover materials of a container plate. The method comprises the following steps of: cutting or packaging and briquetting on the leftover materials of the container plates with different specifications, and proportioning and taking the leftover materials as smelting raw materials of the container plates; smelting; and adopting means of improving the final temperature of a converter, reducing the content of iron oxide of furnace slag, controlling the adding amount of lime, carrying out hyperphosphate control of a terminal point, controlling an iron-water ratio of the converter, accurately controlling nickel and copper components and the like. Therefore, less-slag smelting of the container plate is realized and the consumption of noble metal can also be reduced; and the smelting cost is reduced and huge economic benefits are brought to enterprises.

Owner:BAOSTEEL RESOURCES +1

Iron-carbon synthesized block and its application

The invention relates iron-carbon compound block made by iron powder and carbon powder, using to improve carbon content in the course of electric-arc steel furnace, converter, tapping and refining treatment. The proportion by weight is following: 33-90% iron powder, 10-67% carbon powder, 10-80mm particle diameter, 3.0-5.5g / cm3 denseness, 2-4% binding agent. Using the method, the molten steel carbon content is increased by 0.03-0.04%, the dissolved oxygen content is decreased by more than 50ppm; the iron oxide content in steel slag is decreased by 6-8%, after tapping,silicon and aluminium content increased by 12-15%; the steel cost per ton is decreased by 5.3 yuan. The method guarantees the safety in production, and shorts the refining treatment cycle.

Owner:卞安生

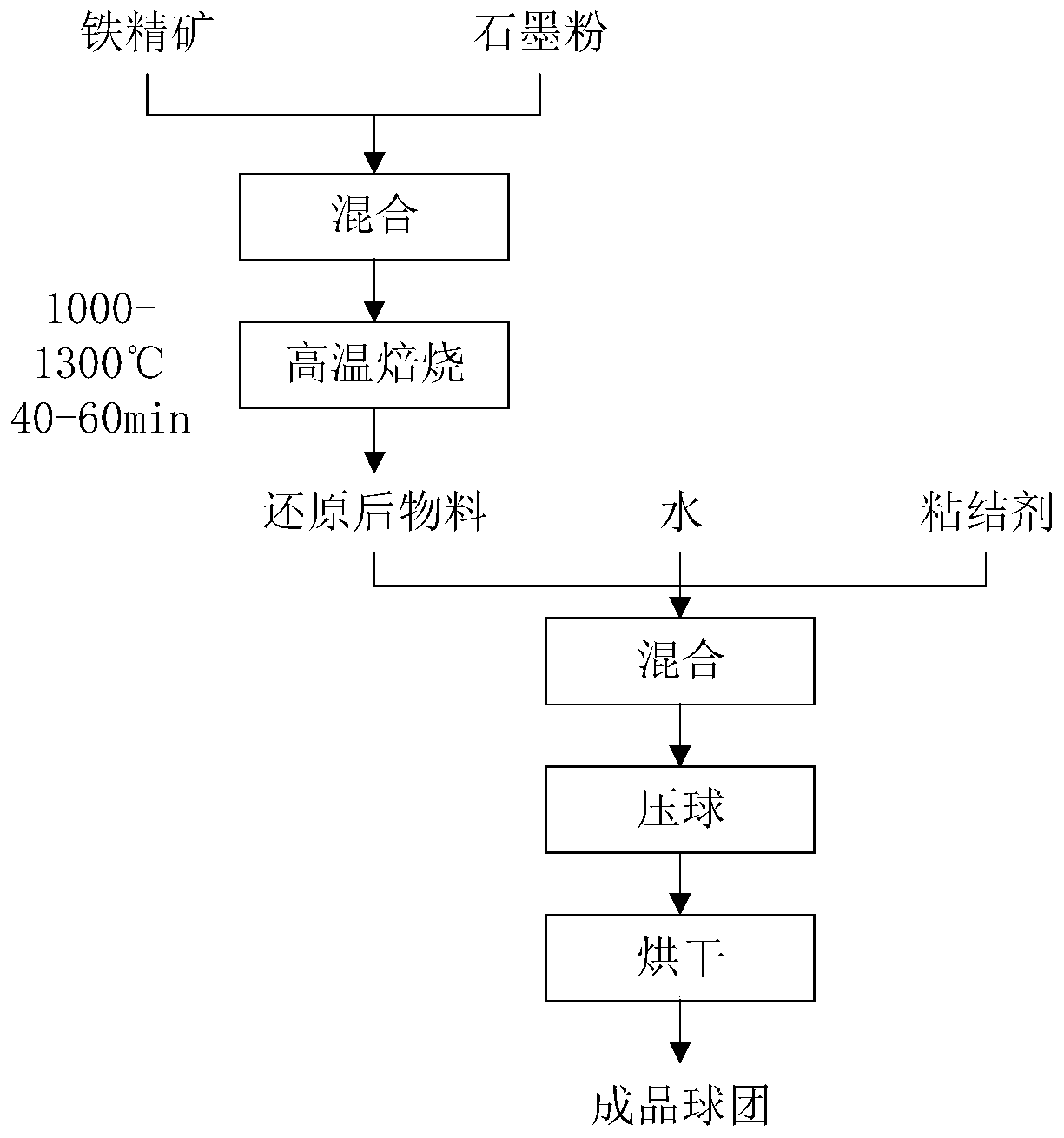

Prepraiton method of high-carbon metallized pellets for electric furnace

The invention discloses a preparation method of high-carbon metallized pellets for electric arc furnace smelting. The preparation method comprises the steps that carbon-containing powder is added intoiron concentrate for material preparation according to the mass ratio of carbon to iron of 1.5-2:1, prereduction is carried out at a reduction temperature of 1000-1300 DEG C for 40-60min, the reduction product is ground to 0.4-0.5 mm granularity, 4-6% of a binding agent and 9-12% of water are added, the mixture is mixed evenly, pressed into pellets and dried at the temperature of 120-140 DEG C for 60-90min, the high-carbon metallized pellets are obtained, and the pellets can reach the falling strength of 3-4 and reach the density of 2.6-3.3g / cm<3>. Molten steel can be stably and efficiently recarburized by the pellets below the slag-steel interface, the problems that the density of conventional carburant is insufficient, the carburant rapidly floats on the surface of furnace slag after being added, and the carburizing effect is poor are solved, meanwhile, the pellets can perform a good carbon-oxygen reaction below the slag-steel interface to remove inclusions and gas, formation of a large amount of foam slag is promoted, electric arc is stabilized, smelting time is shortened, iron loss is effectively reduced, steel material consumption is remarkably reduced, the metal yield is improved, and the smelting cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING

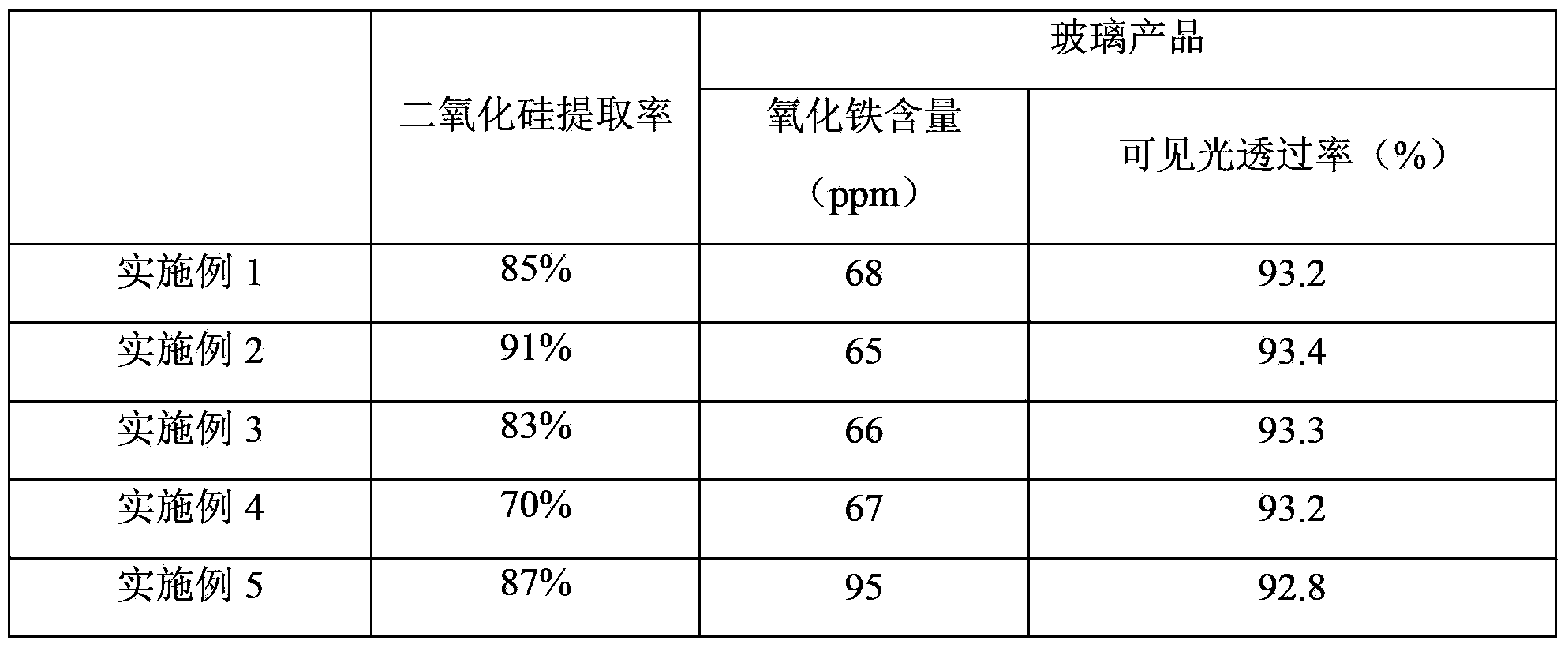

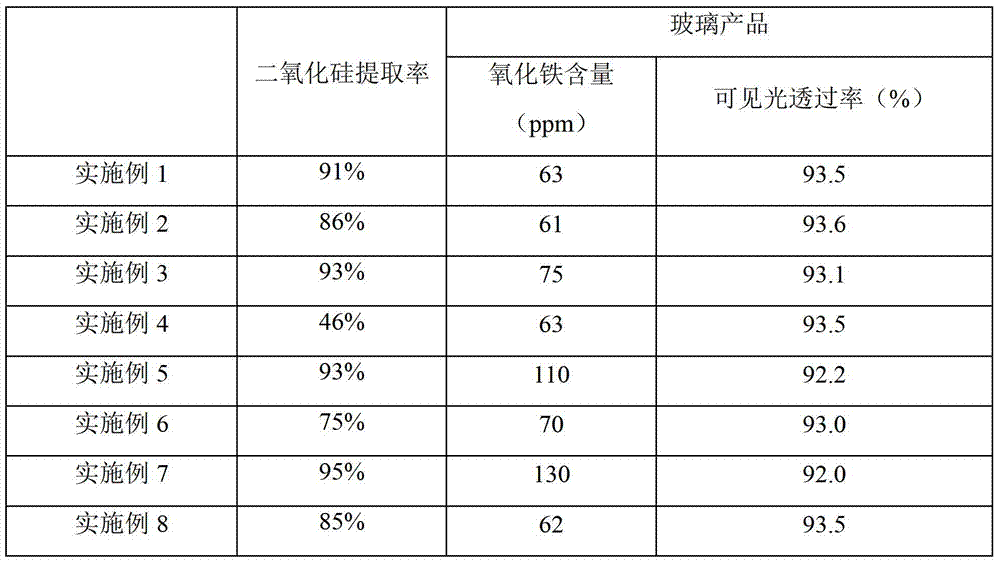

Glass batch, preparation method of glass batch, glass, and preparation method of glass

The invention discloses a preparation method of a glass batch. The method includes the following steps: 1, removing residual acid from residues obtained after acid process aluminum extraction of fly ash; 2, mixing the residual acid removed residues with carbonate, and roasting to obtain a roasted clinker; 3, leaching the roasted clinker by using water or an alkali solution, and carrying out solid-liquid separation to obtain a leaching solution and leaching residues; 4, introducing carbon dioxide to the leaching solution in order to carry out carbonation decomposition, and carrying out solid-liquid separation to obtain a silicic acid precipitate and a carbonate solution; and 5, mixing the silicic acid precipitate obtained in step 4 with calcium oxide and / or a calcium oxide precursor, and optionally mixing with sodium oxide and / or a sodium oxide precursor to obtain the glass batch. The invention also discloses the glass batch prepared through the preparation method, a preparation method of glass, and the glass prepared through the glass preparation method. The glass contains an extremely low quantity of iron oxide, has high visible light transmittance, can achieve ultra clear glass standards, and can greatly improve the overall economy of the acid process aluminum extraction of the fly ash.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Control method for converter double-slag smelting

The invention relates to a control method for converter double-slag smelting. The control method comprises the following steps that 1, the furnace slag of an upper furnace is partially or totally leftto a current furnace; 2, the early-stage total oxygen consumption of the current furnace is calculated; 3, oxygen supply is stopped when the oxygen supply amount reaches the total oxygen consumptionof the earlier stage or the carbon monoxide concentration is greater than 15%; 4, nitrogen is immediately blown into the furnace through the oxygen lance after the oxygen supply is stopped; 5, after the nitrogen is supplied to the furnace, slags are poured into the furnace; and 6, the oxygen is continuously supplied into the furnace after the slag discharge is ended until the blowing is completed.According to the method, splashing during early-stage oxygen supply can be effectively avoided, later slag foam formation is good, the slag discharge amount can be finally increased, the total iron content of furnace slag during early-stage slagging can be reduced, and the metal material loss is reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

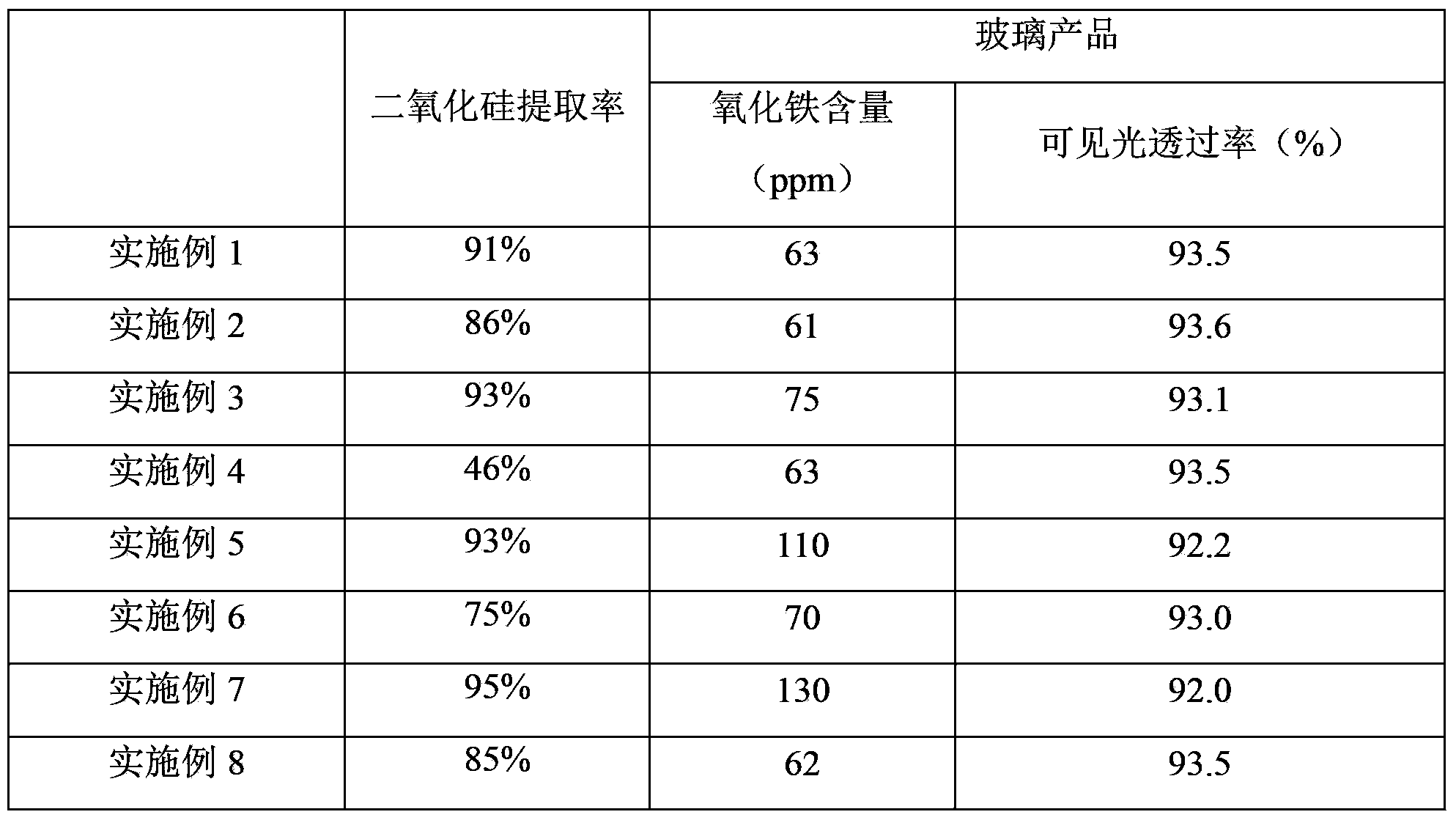

Glass batch, preparation method of glass batch, glass, and preparation method of glass

The invention discloses a preparation method of a glass batch. The method includes the following steps: 1, removing residual acid from residues obtained after acid process aluminum extraction of fly ash; 2, leaching by using an alkali solution, and carrying out solid-liquid separation to obtain a leaching solution and leaching residues; 3, introducing carbon dioxide to the leaching solution in order to carry out carbonation decomposition, and carrying out solid-liquid separation to obtain a silicic acid precipitate and a carbonate solution; and 4, mixing the silicic acid precipitate obtained in step 3 with calcium oxide and / or a calcium oxide precursor, and optionally mixing with sodium oxide and / or a sodium oxide precursor to obtain the glass batch. The invention also discloses the glass batch prepared through the preparation method, a preparation method of glass, and the glass prepared through the glass preparation method. The glass contains an extremely low quantity of iron oxide, has high visible light transmittance, can achieve ultra clear glass standards, can greatly improve the overall economy of the acid process aluminum extraction of the fly ash, reduces industrial solid wastes generated in the acid process aluminum extraction, and realizes recycling and environmentally friendly application of the fly ash.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

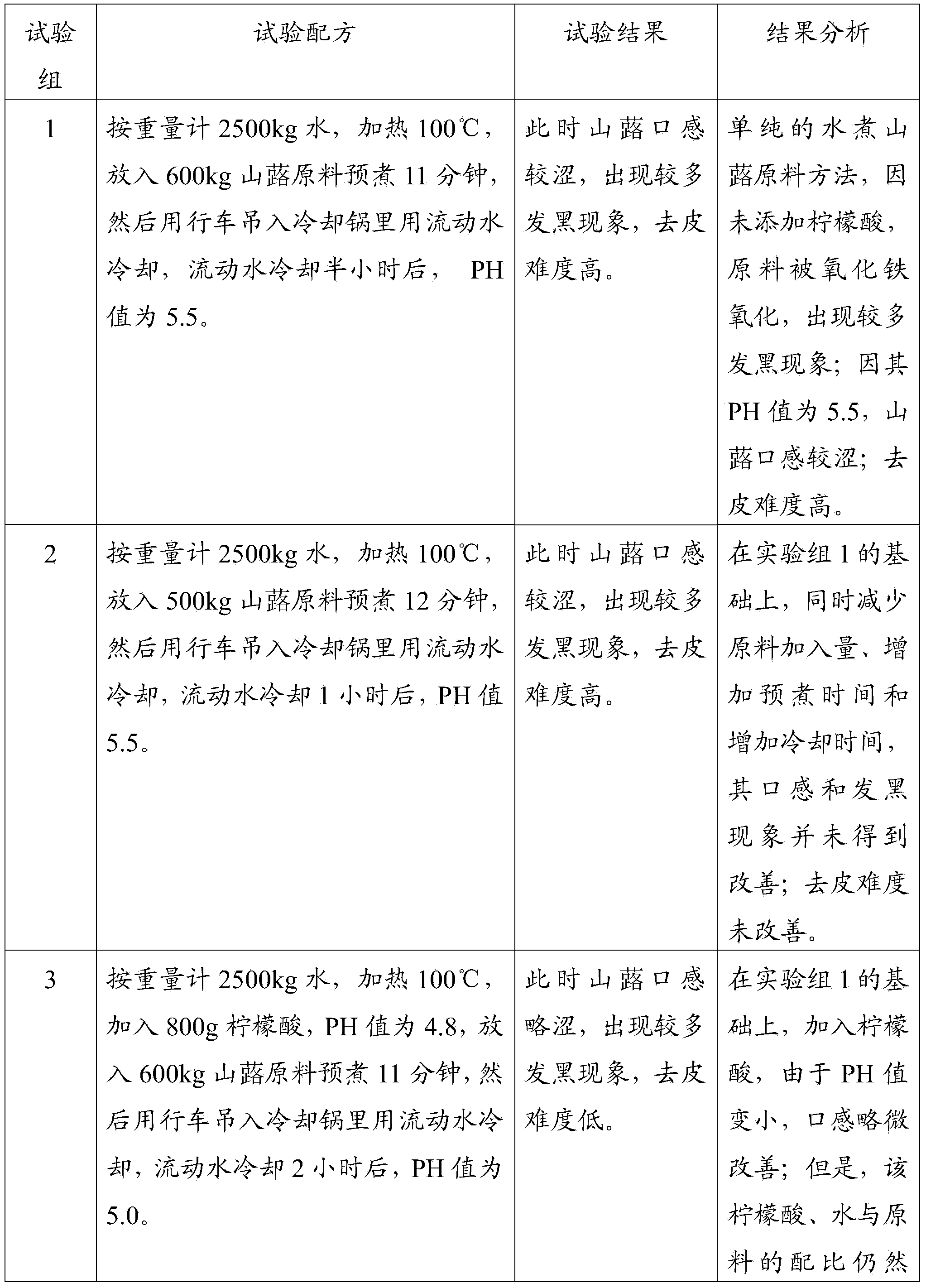

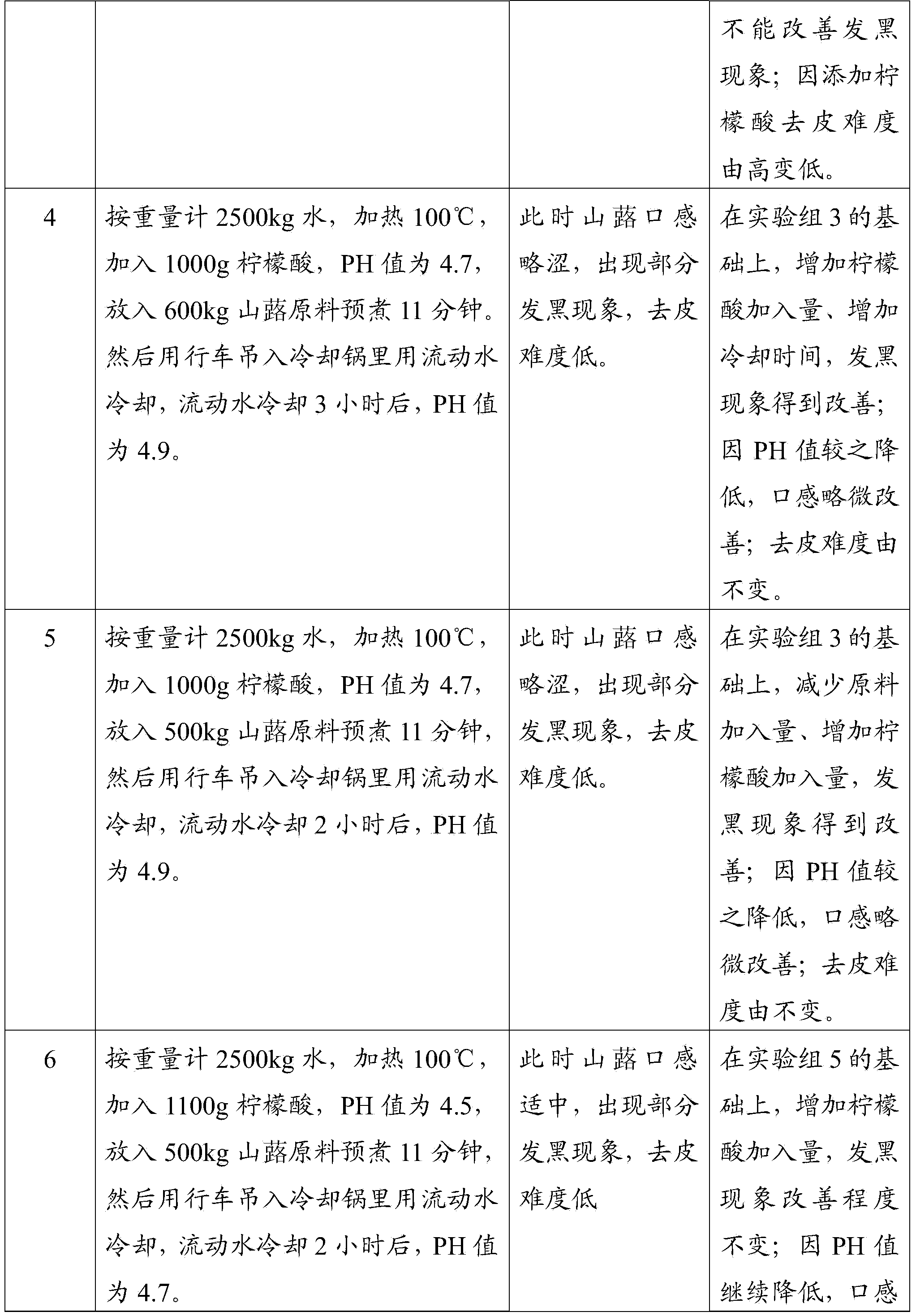

Processing method of boiled petasites tatewakianus

ActiveCN103976307AReduce iron oxide contentImprove darkeningFood ingredientsFood preparationCitric acidChemistry

The invention relates to a processing method of boiled petasites tatewakianus. The processing method comprises the step of adding petasites tatewakianus raw materials into a citric acid solution for sufficiently precooking for 7-12min, wherein the citric acid solution is prepared by adding 520-560g of citric acid into every 1000kg of water, the mass ratio of the petasites tatewakianus raw materials to the water in the citric acid solution is 1:5, the temperature of the citric acid solution is 95-100 DEG C, and the pH value is 3.9-4.3. The canned boiled petasites tatewakianu prepared by using the processing method of the boiled petasites tatewakianu, provided by the invention, has the advantages of petasites tatewakianus raw material blackening phenomenon improvement, petasites tatewakianus taste improvement, low petasites tatewakianus skin viscidity, high toughness as well as simplicity and easiness for peeling.

Owner:FUJIAN SANXIN FOOD STUFFS

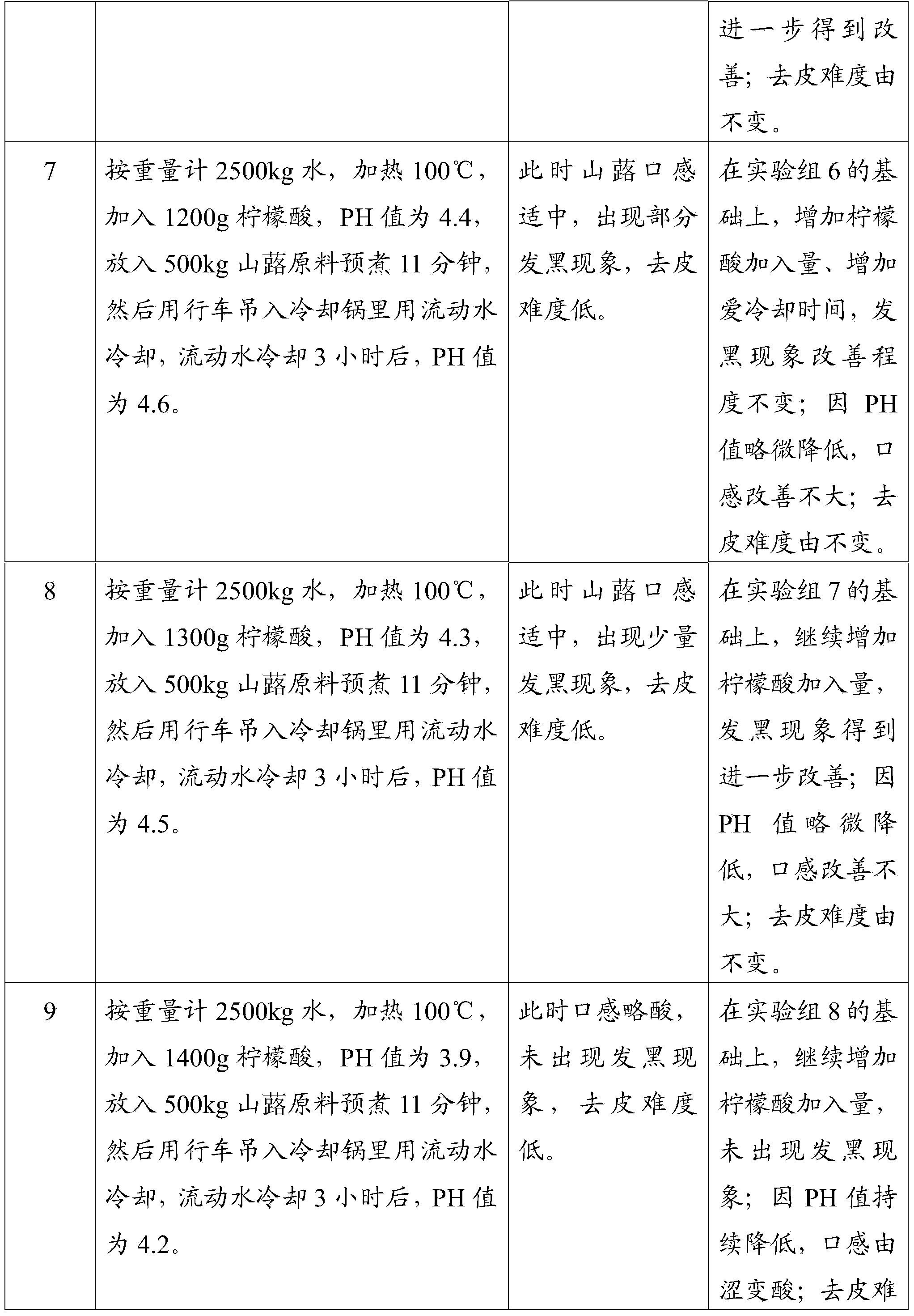

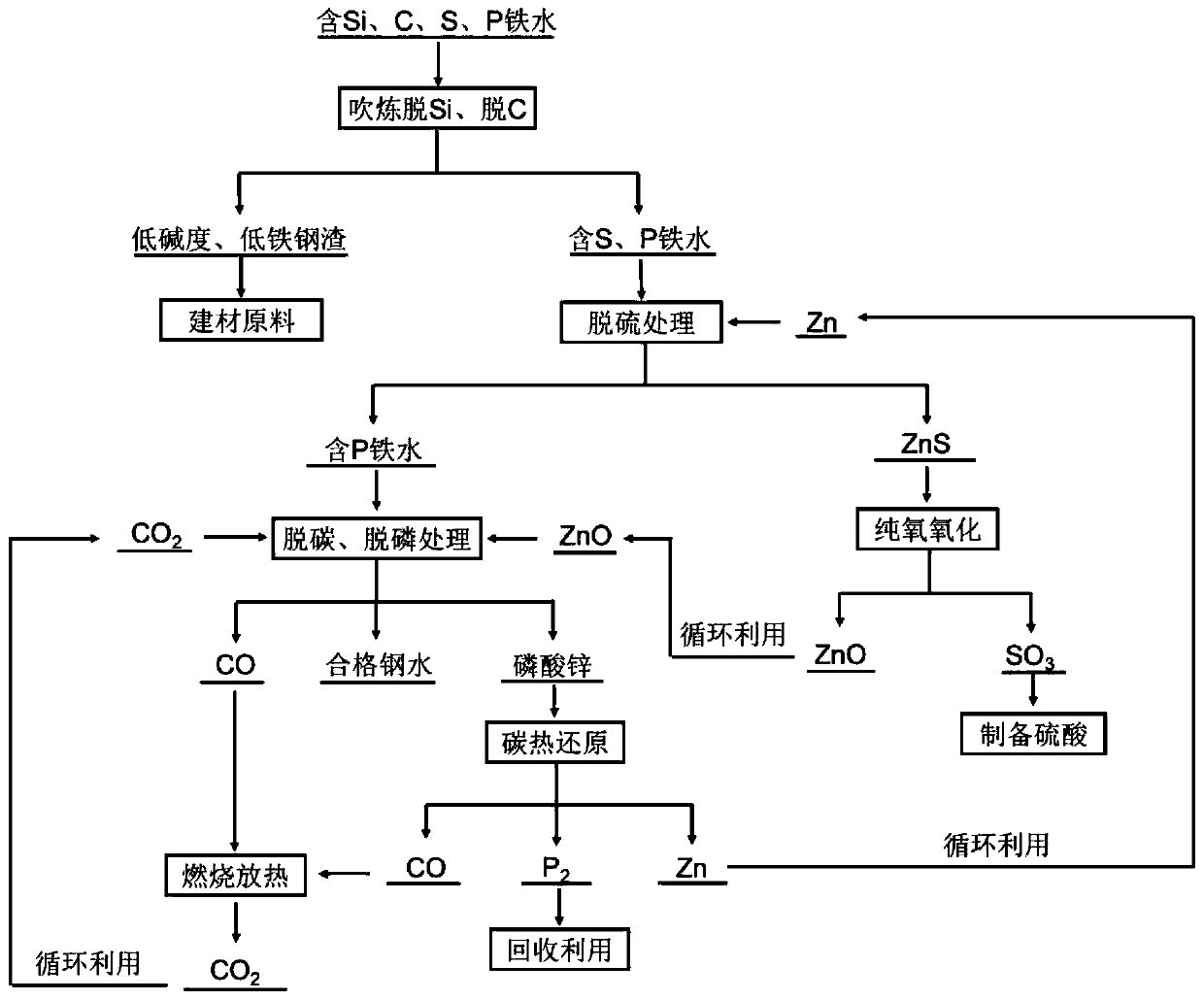

Sulfur and phosphorus deep removal method of slagless steelmaking

ActiveCN111471832AReduce consumptionReduce iron oxide contentProcess efficiency improvementPhosphorus preparationSteelmakingZinc phosphate

The invention relates to a sulfur and phosphorus deep removal method of slagless steelmaking, and belongs to the technical field of steelmaking. With the sulfur and phosphorus deep removal method of slagless steelmaking, the problem that in the prior art, much steel slag is generated, and the steel slag is difficult to utilize is solved. The sulfur and phosphorus deep removal method of slagless steelmaking comprises the steps that first, alkaline flux is added into molten steel to carry out desilicication and decarburization, and steel slag and molten steel which are low in alkalinity and ironcontent are obtained; second, a desulfurizer Zn is used to desulfurize the molten steel to obtain desulfurized molten steel; third, deep decarburization is carried out on the desulfurized molten steel, and when the carbon content in the molten steel is lower than 0.5%, and the molten steel is dephosphorized by utilizing CO2 gas containing ZnO powder to obtain zinc phosphate flux and dephosphorized molten steel; and fourth, the zinc phosphate flux is reduced by utilizing solid carbon to obtain phosphorus and metal zinc, phosphorus is recycled, and the metal zinc returns to the second step as the desulfurizer. With the sulfur and phosphorus deep removal method of slagless steelmaking, much less steel slag is generated, the content of free CaO and the content of iron in the steel slag are reduced, the use ratio of the steel slag is increased, and the problem about stacking storage of the steel slag is solved completely.

Owner:CENT IRON & STEEL RES INST +1

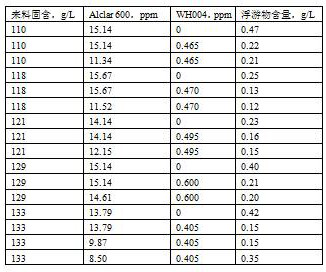

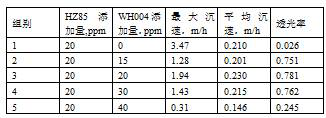

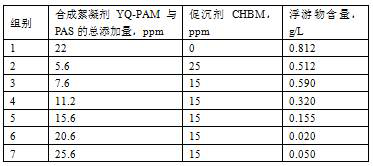

Chemical treatment method for improving red mud settling separation effect

The invention relates to the technical field of red mud settling separation, in particular relates to a chemical treatment method for improving red mud settling separation effect. The treatment methodis characterized by comprising the following steps of: for dissolved red mud with higher iron oxide content, when the content of ferric oxide in the dissolved red mud solid phase is greater than or equal to 20%, a non-ionic settling agent and a synthetic flocculant are combined for treatment; when the content of ferric oxide in the dissolved red mud solid phase is less than 20%, a cationic settling accelerator and a synthetic flocculant are combined for treatment. The chemical treatment method for improving the red mud settling separation effect has the advantages of simple method, high settling efficiency, good settling effect, low treatment cost, improvement of the recovery rate of aluminum oxide and caustic alkali and the like.

Owner:威海汉邦生物环保科技股份有限公司

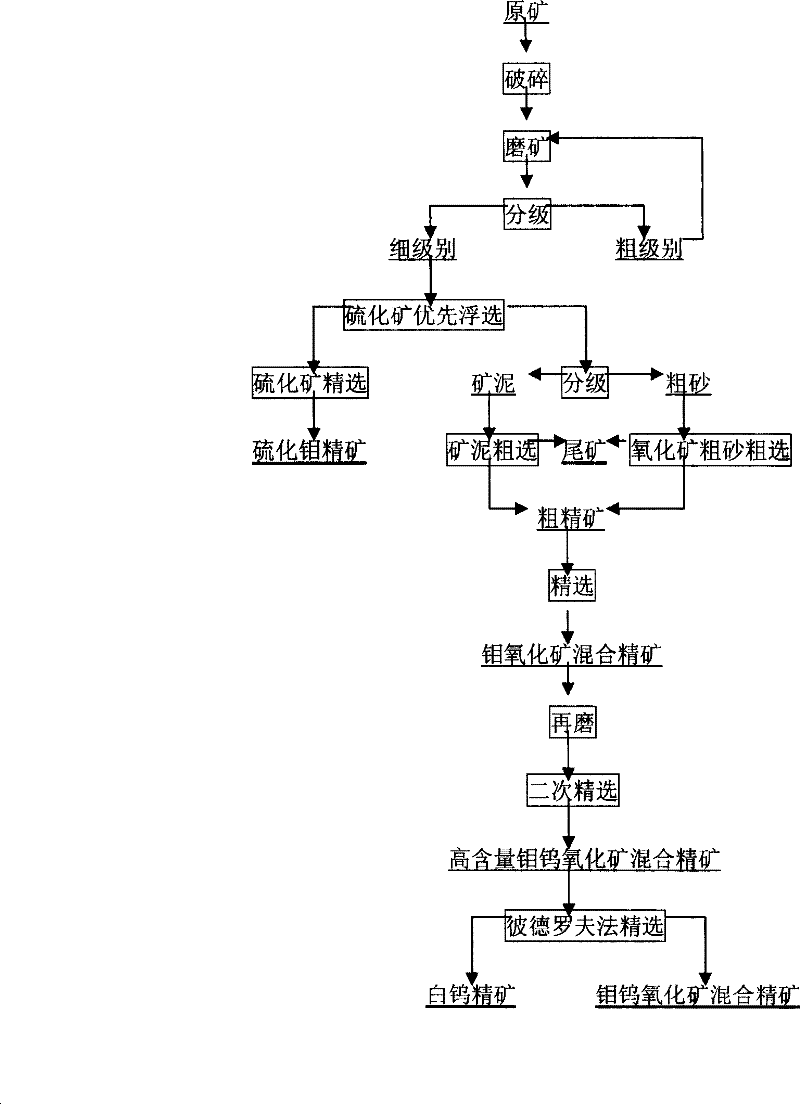

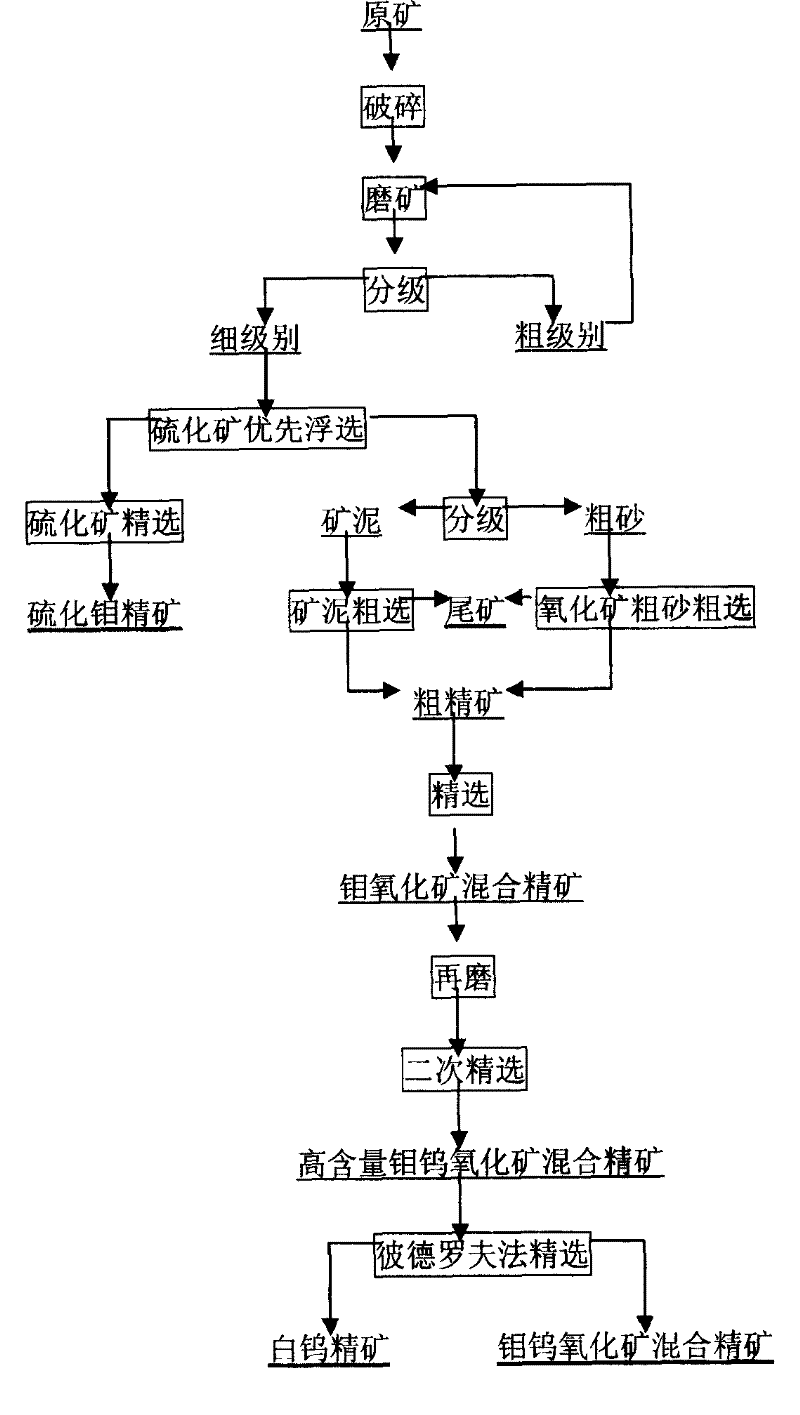

Processing technology for molybdenum and tungsten oxidized ore

The invention discloses a beneficiation process of a molybdenum-tungsten oxide ore. The process of which is that: the liberation degree of ore crushing is higher than or equal to 70%; the flotation of molybdenum sulfide is preferred; the floatation tailing is classified and then a separation of slime and sand is carried out, wherein a slime and sand system takes alkali as the conditioning agent, sodium silicate as the depressant, and emulsified fatty acid as the collecting agent. The rough concentrate obtained from the separation of slime and sand is concentrated after being blended to obtainmolybdenum-tungsten oxide ore collective concentrate. The collective concentrate is grounded again and added with the depressant, then a secondary concentrate can be gained through the concentration;the secondary concentrate is concentrated by means of Peter Roph method to obtain scheelite ore and oxidized molybdenum-tungsten beneficiation concentrate. The invention has the advantages that: 1. the invention discloses a beneficiation process flow for treating molybdenum-tungsten oxide ore; 2. the invention solves the difficulty of lowe technical specification of molybdenum - tungsten oxide ore beneficiation; 3. the invention completes laboratory tests and researches and fulfills industrialized implementation for the first time in China.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

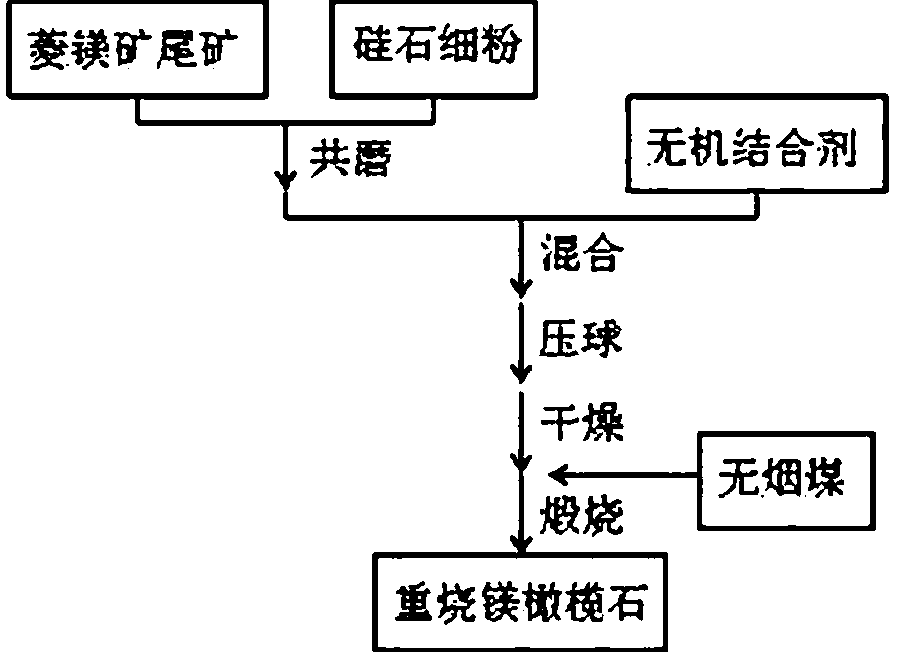

Method for preparing sintered forsterite by re-firing magnesite tailings

InactiveCN111017941AEfficient use ofAlleviate ecological and environmental problemsMagnesium silicatesRefractoryAnthracite

The invention relates to a method for preparing sintered forsterite by re-firing magnesite tailings, and belongs to the field of magnesite comprehensive utilization and refractory material calcination. The sintered forsterite is prepared from magnesite tailings, silica fine powder and anthracite as raw materials and an additional binding agent according to a certain ratio through steps of co-grinding, ball pressing, drying and firing. Compared with the method in the prior art, the method of the invention has the beneficial effects that the magnesite tailings are effectively utilized so as to relieve the ecological environment problem caused by accumulation of the magnesite tailings, the magnesite tailings and the silica fine powder are adopted as raw materials, the sintered forsterite is produced through a reburning method, the enrichment effect of the silicon dioxide in the magnesite flotation tailings is fully utilized, and the produced forsterite refractory material is low in iron oxide content and good in fire resistance compared with natural forsterite.

Owner:HAICHENG CITY ZHONGHAO MAGNESIUM CO LTD

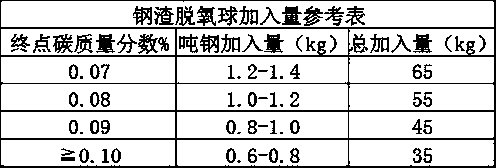

Method for manufacturing steelmaking converter steel slag deoxidization balls

InactiveCN108842035ATake away lower utilizationQuality improvementManufacturing convertersSteelmakingOxygen

The invention discloses a method for manufacturing steelmaking converter steel slag deoxidization balls. Coke powder, fluorite powder and a binder are used as raw materials, a mixing device is used for even mixing, the raw materials are pressed into finished products with the diameter being 15-20 mm through a ball pressing machine, and the finished products are naturally dried for standby use. After gun lifting of converter steelmaking, the deoxygenation balls are added into the converter through a feeding system, since the density of the deoxygenated balls is approximate to that of steel slag, the deoxygenated balls float on the surface of the steel slag, carbonaceous materials in the deoxygenated balls react with oxygen in steel, carbon dioxide is produced and removed, and the fluorite powder in the deoxidization balls can effectively inhibit formation of foam slag during the reaction. Compared with the deoxidization method, the steelmaking steel slag deoxidization balls do not causesecondary pollution during the deoxidization process, the manufacturing cost is low, molten steel is not polluted either, the manufacturing method is simple and rapid, and the metal loss in the steelmaking production process can be effectively reduced, the adding amount of light burnt dolomite is decreased, the corrosion resistance of a slag splashing protection layer is improved, thereby the steelmaking cost is reduced, and the quality of steelmaking molten steel is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Recovery processing method of leftover materials of container plate

InactiveCN103374654BRealize less slag smeltingIncrease temperatureMetal recyclingManufacturing convertersSlagEconomic benefits

The invention discloses a recovery processing method of leftover materials of a container plate. The method comprises the following steps of: cutting or packaging and briquetting on the leftover materials of the container plates with different specifications, and proportioning and taking the leftover materials as smelting raw materials of the container plates; smelting; and adopting means of improving the final temperature of a converter, reducing the content of iron oxide of furnace slag, controlling the adding amount of lime, carrying out hyperphosphate control of a terminal point, controlling an iron-water ratio of the converter, accurately controlling nickel and copper components and the like. Therefore, less-slag smelting of the container plate is realized and the consumption of noble metal can also be reduced; and the smelting cost is reduced and huge economic benefits are brought to enterprises.

Owner:BAOSTEEL RESOURCES +1

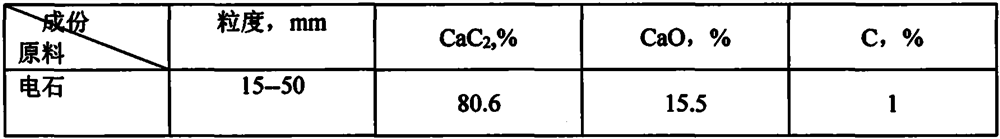

Process for pretreating converter blowing end point steel slag by using calcium carbide CaC2

PendingCN113122673AReduce iron oxide contentReduce consumptionManufacturing convertersLime productionSteelmakingAlloy

The invention discloses a process for pretreating converter blowing end point steel slag by using calcium carbide CaC2. The process can gasify and dephosphorize the steel slag at the blowing end point, reduce the iron oxide content of the steel slag, improve the molten steel yield, reduce the oxygen content of the molten steel and the consumption of a deoxidizer and alloy, thereby reducing the impurities of the molten steel and improving the quality of the molten steel. CaO generated by CaC2 reduction reaction and CaO brought in by calcium carbide enable the alkalinity of the slag to be improved. Full slag remaining operation is facilitated, consumption of slag such as lime and steel materials is reduced, and less slag steelmaking is achieved. The remaining end slag becomes a good dephosphorizing agent, so that great and rapid dephosphorization in the earlier stage of converter smelting is facilitated, and low-phosphorus steel and ultra-low-phosphorus steel smelting is realized. Slag at the end point is sticky, so that slag stopping and slag splashing furnace protection operation are facilitated. In the steelmaking process, only part of low-alkalinity initial slag needs to be poured out, the poured-out slag amount is reduced, the content of CaO and the content of iron in the poured-out initial slag are greatly reduced, and the poured-out low-alkalinity slag is more beneficial to high-added-value utilization.

Owner:王虎

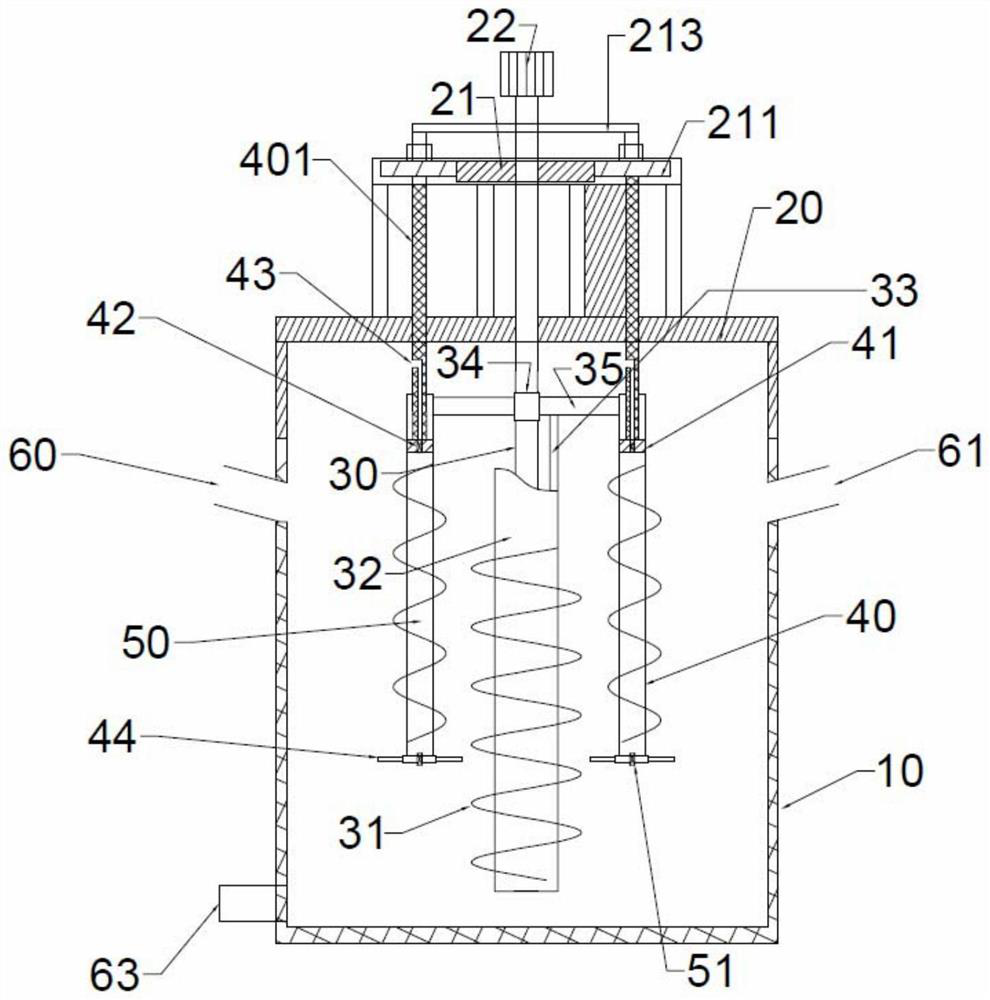

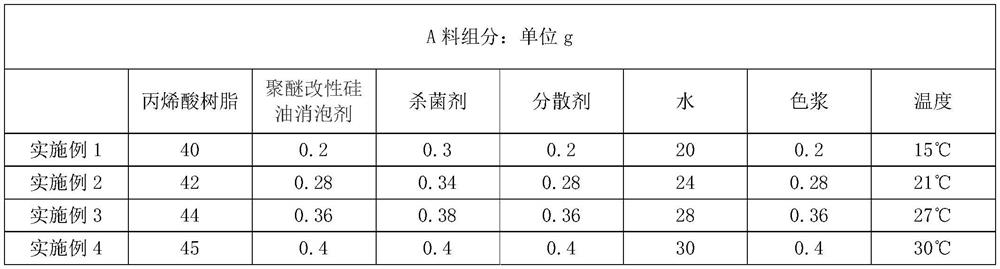

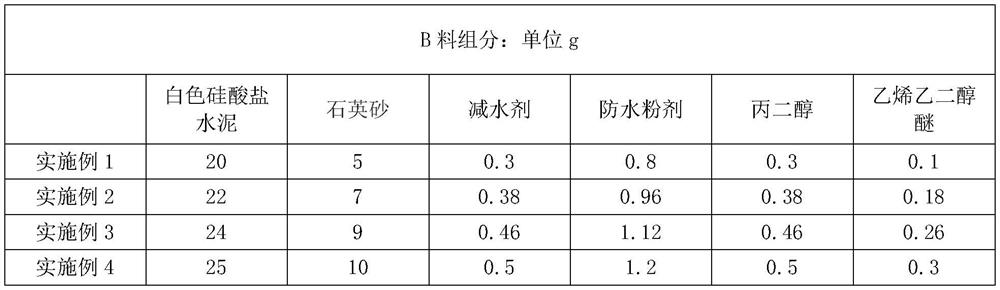

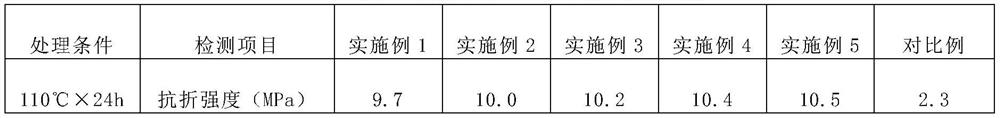

High-permeability two-component polymer cement-based waterproof coating

InactiveCN114133807AGood tensile and compressive strengthStrong toughnessCement coatingsPolymer scienceAcrylic resin

The invention relates to the technical field of building materials, and particularly discloses a high-permeability two-component polymer cement-based waterproof coating which is prepared by the following steps: pouring acrylic resin and water into a dispersion machine, adjusting the rotating speed of the dispersion machine to 900 revolutions per minute, stirring for 5 minutes, then adding a dispersing agent, and stirring for 10 minutes; adjusting the rotating speed of the dispersion machine to 500 revolutions per minute, then sequentially adding the bactericide and the color paste without stopping stirring in the adding process, and then stirring for 10 minutes; adjusting the rotating speed of the dispersion machine to 300 revolutions per minute, adding a silicone oil defoaming agent without stopping stirring in the adding process, and then stirring for 10 minutes; pouring the white Portland cement into a dry powder stirrer, stirring for 5 minutes, adding the quartz sand without stopping stirring in the adding process, and then stirring for 10 minutes; the water reducing agent and the waterproof powder are sequentially added, stirring is not stopped in the adding process, and stirring is conducted for 10 min; propylene glycol and ethylene glycol ether are sequentially added, and stirring is not stopped in the adding process;

Owner:贵州文泰防水技术有限公司

A Chemical Treatment Method for Improving the Sedimentation and Separation Effect of Red Mud

Owner:威海汉邦生物环保科技股份有限公司

Refractory castable for lime spray gun as well as preparation method and application of refractory castable

The invention discloses a refractory castable for a lime spray gun as well as a preparation method and application of the refractory castable. The refractory castable for the lime spray gun comprises raw materials and a water reducing agent, the raw materials comprise the following components in percentage by weight: 28-30% of M70 sintered mullite; 35-40% of flint clay; 5-7% of titanium calcium aluminate; 11 to 15% of ceramic micro powder; 10 to 12 percent of agalmatolite; 0.7%-1.2% of pure calcium aluminate cement; 1.5 to 2.0 percent of silica powder; and the water reducing agent accounts for 0.03-0.06 wt% of the raw materials. By designing the components and proportion of the refractory castable for the lime spray gun, the lime spray gun can have good high-temperature mechanical strength, thermal shock resistance stability and slag corrosion resistance at the temperature of 1350-1400 DEG C, so that the refractory castable has good service life.

Owner:BAOSHAN IRON & STEEL CO LTD

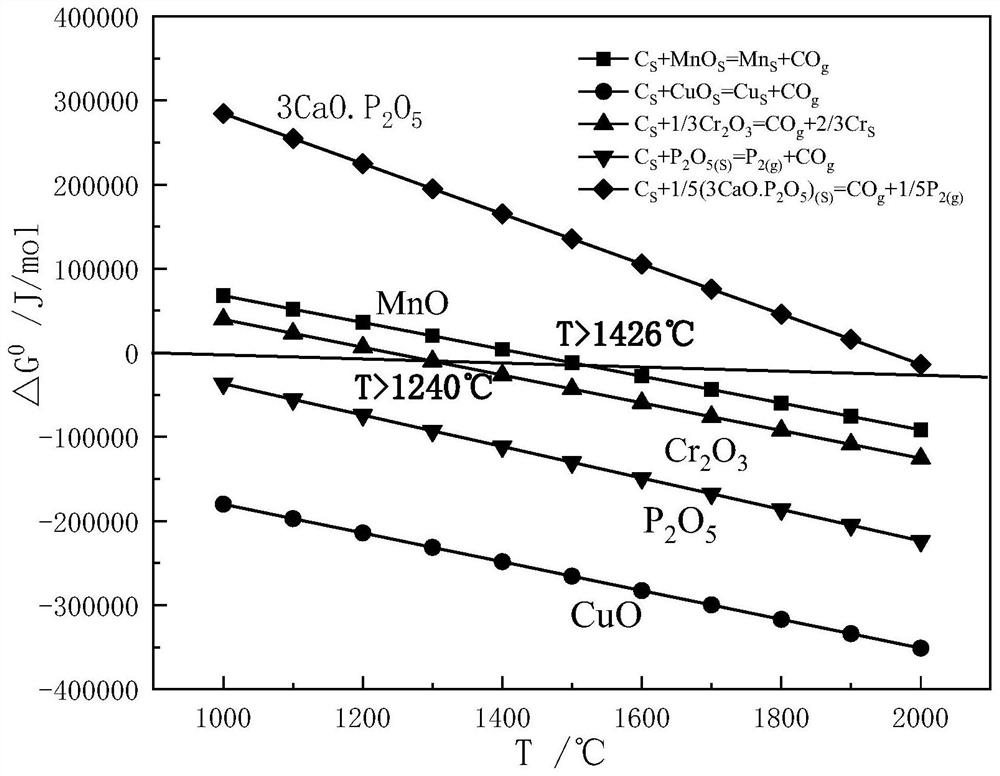

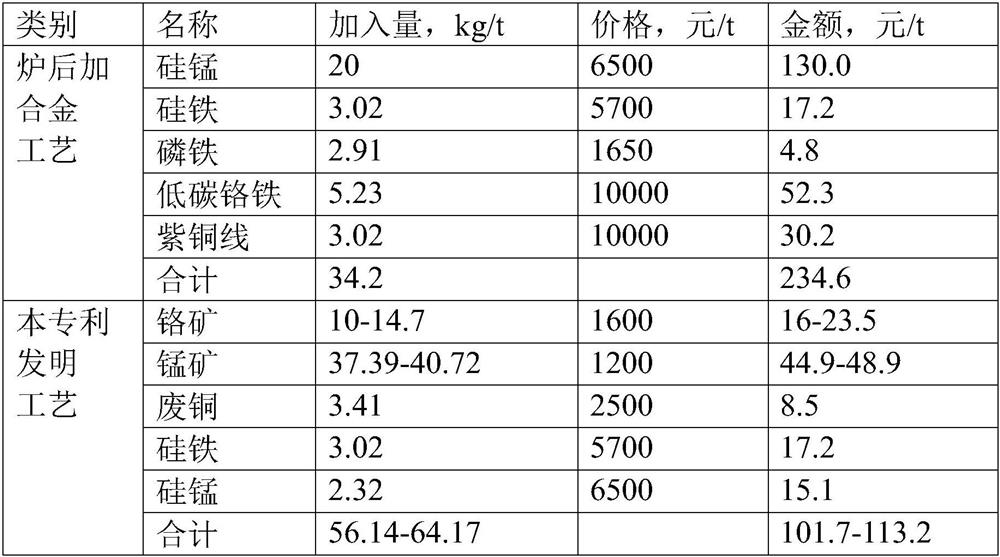

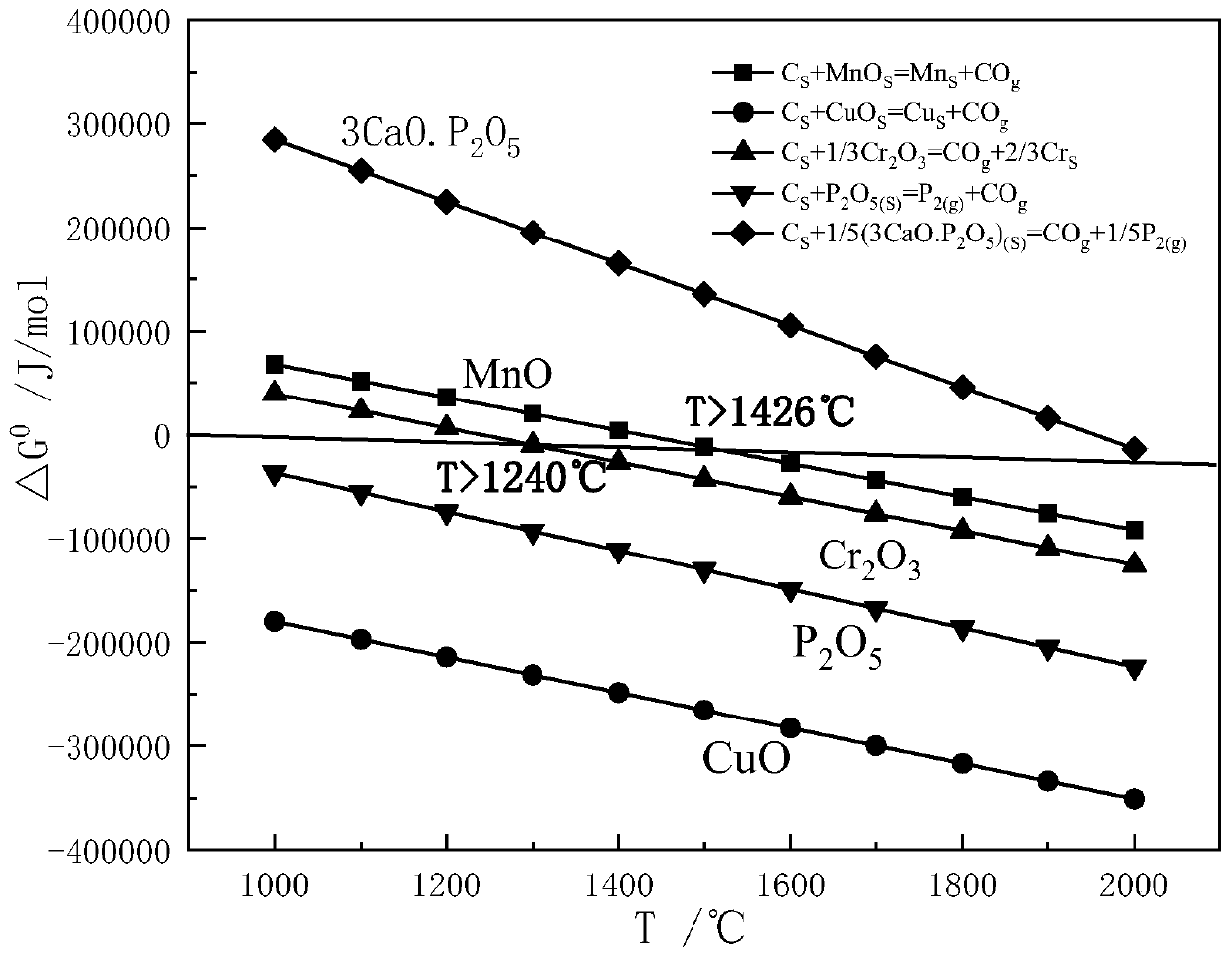

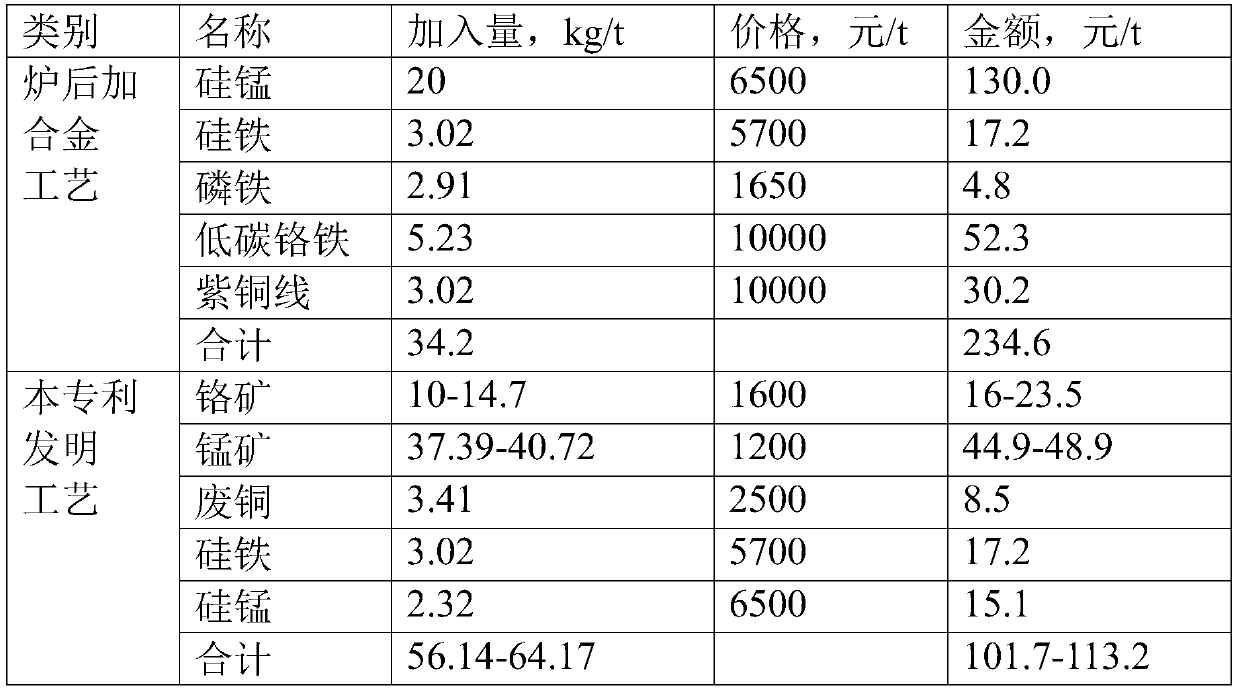

A kind of smelting method of phosphorus and copper alloy steel

ActiveCN111206181BRestoredHigh priceManufacturing convertersProcess efficiency improvementSlagMetal alloy

The invention discloses a method for smelting phosphorus- and copper-containing alloy steel, which belongs to the technical field of alloy steel smelting and solves the problem of high cost caused by adding metal alloy during smelting in the prior art. The smelting method of the present invention comprises the following steps: step 1. using molten iron with a phosphorus content of more than 0.2% as raw material during converter smelting; step 2. adding scrap steel and scrap copper; step 3. controlling oxygen supply, final slag alkalinity, Increase the T.Fe content of the slag, and increase the bottom blowing stirring intensity at the end of the converter to perform dephosphorization; Step 4. During the tapping process, add alloys to adjust the content of other elements. The invention greatly reduces the smelting cost of phosphorus and copper alloy steel.

Owner:CENT IRON & STEEL RES INST

Smelting method of alloy steel containing phosphorus and copper

ActiveCN111206181ARestoredHigh priceManufacturing convertersProcess efficiency improvementMetal alloySmelting process

The invention discloses a smelting method of alloy steel containing phosphorus and copper, belongs to the technical field of alloy steel, and solves the problem in the prior art that the cost is higher due to adding of metal alloy during the smelting process. The smelting method comprises the following steps: 1, during converter smelting, taking molten iron containing more than 0.2% of phosphorusas the raw material; 2, adding scrap steel and scrap copper; 3, carrying out dephosphorization through controlling the oxygen supply amount, the final slag alkalinity, and T.Fe content of furnace slagand improving the bottom blowing stirring strength at the end point of the converter; and 4, during the steel tapping process, adding alloy to adjust the contents of other elements. With adoption ofthe smelting method, the smelting cost of alloy steel containing phosphorus and copper is greatly reduced.

Owner:CENT IRON & STEEL RES INST

A kind of glass batch material and its preparation method and a kind of glass and its preparation method

The invention discloses a preparation method of a glass batch. The method includes the following steps: 1, removing residual acid from residues obtained after acid process aluminum extraction of fly ash; 2, leaching by using an alkali solution, and carrying out solid-liquid separation to obtain a leaching solution and leaching residues; 3, introducing carbon dioxide to the leaching solution in order to carry out carbonation decomposition, and carrying out solid-liquid separation to obtain a silicic acid precipitate and a carbonate solution; and 4, mixing the silicic acid precipitate obtained in step 3 with calcium oxide and / or a calcium oxide precursor, and optionally mixing with sodium oxide and / or a sodium oxide precursor to obtain the glass batch. The invention also discloses the glass batch prepared through the preparation method, a preparation method of glass, and the glass prepared through the glass preparation method. The glass contains an extremely low quantity of iron oxide, has high visible light transmittance, can achieve ultra clear glass standards, can greatly improve the overall economy of the acid process aluminum extraction of the fly ash, reduces industrial solid wastes generated in the acid process aluminum extraction, and realizes recycling and environmentally friendly application of the fly ash.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A kind of method for reducing iron oxide content in vanadium slag

ActiveCN110904347BReduce iron oxide contentRaise the gradeManufacturing convertersSlagPhysical chemistry

The invention relates to a method for reducing the content of iron oxide in vanadium slag. The method comprises: after the vanadium extraction and blowing in a converter is completed, adding additives to the furnace and reacting in a protective atmosphere to obtain vanadium slag. By the method provided by the invention, the iron oxide in the vanadium slag is reduced to generate elemental iron and carbon monoxide, wherein the elemental iron enters the semi-steel, and the carbon monoxide is discharged with the furnace gas. By adopting the operation of blowing protective gas and pulling the gun, the stable state of vanadium slag in the furnace is destroyed, the discharge of carbon monoxide is accelerated, and the reduction reaction is promoted. Finally, the purpose of reducing the iron oxide content in the vanadium slag is achieved.

Owner:HEBEI IRON AND STEEL

Method for reducing content of ferric oxide in vanadium slag

The invention relates to a method for reducing the content of ferric oxide in vanadium slag. The method comprise the steps of: after vanadium extraction blowing through a converter is finished, addingan additive into the converter, and performing reacting in a protective atmosphere to obtain the vanadium slag. According to the method provided by the invention, ferric oxide in the vanadium slag isreduced to generate iron elementary substance and carbon monoxide, the iron elementary substance enters the semisteel, and the carbon monoxide is discharged along with furnace gas. By adopting protective gas blowing and gun drawing operation, the stable state of the vanadium slag in the converter is destroyed, the discharge of carbon monoxide is accelerated, and the reduction reaction is promoted. Finally, the purpose of reducing the iron oxide content in the vanadium slag is achieved.

Owner:HEBEI IRON AND STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com