Process for pretreating converter blowing end point steel slag by using calcium carbide CaC2

A converter blowing and pretreatment technology, applied in lime production, manufacturing converters, etc., can solve the problems of molten steel phosphorus return, achieve the effect of reducing slag, easy to popularize and apply, and improve the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The converter is 110 tons, and the loading capacity is 115 tons.

[0009] The converter is smelted according to the conventional process. After the converter blowing stops oxygen blowing, the gun is lifted and the oxygen gun is switched to the side of the nitrogen pipe. 1-6 kg / ton of calcium carbide is added to the furnace from the high-level silo, and the slag is stirred with nitrogen 50-120 Second. The nitrogen stirring pressure is 0.8-1.4MPa, and the nitrogen flow rate is 300-700m3 / min. In this test furnace, stop blowing and take samples before and after nitrogen stirring.

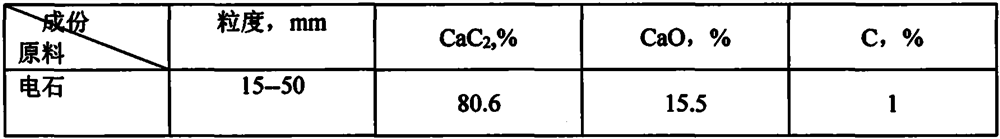

[0010] Table 1 is the calcium carbide parameters used in the test

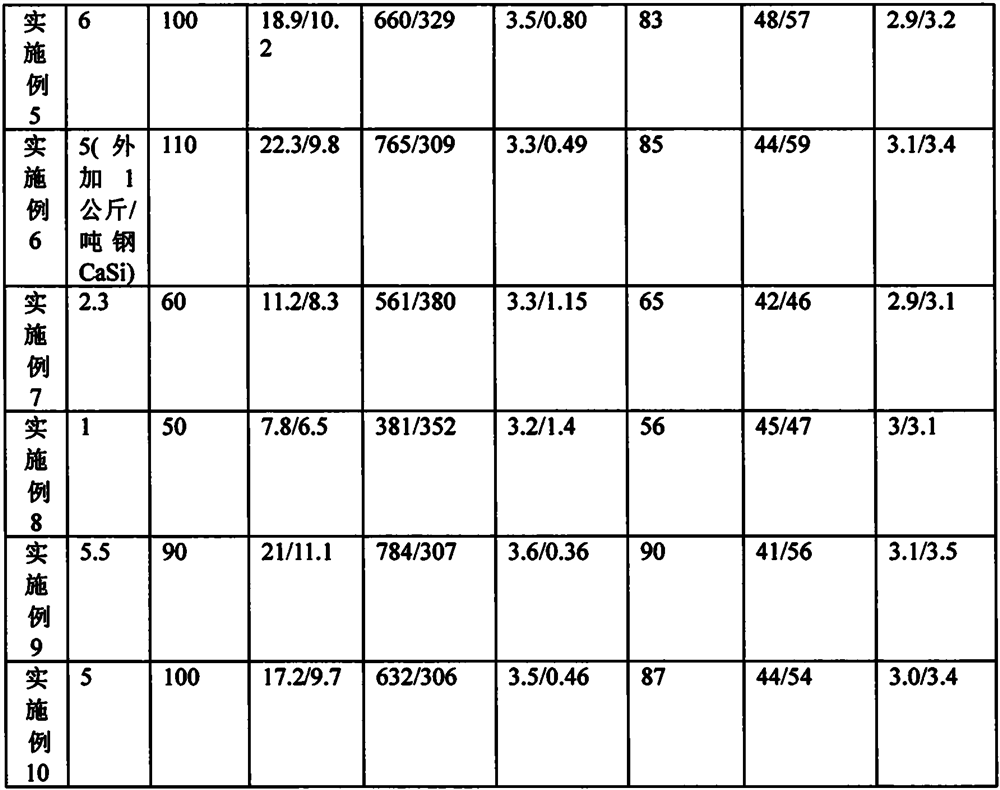

[0011] Table 2 shows the 110-ton converter test plan and its implementation effect

[0012] Table 1 The calcium carbide particle size and main component parameters used in the test

[0013]

[0014] Table 2 120-ton converter test plan and implementation effect

[0015]

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com