A kind of smelting method of phosphorus and copper alloy steel

A smelting method and alloy steel technology, applied in the field of alloy steel smelting, can solve the problem of high cost and achieve the effects of reducing smelting cost, reducing cost and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

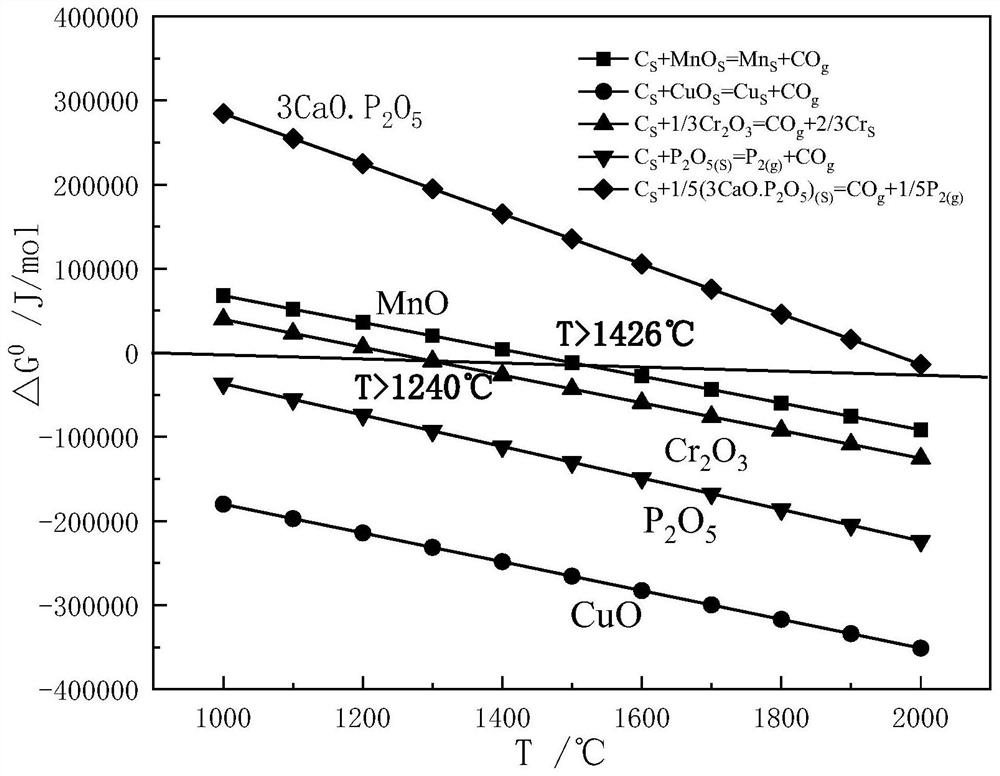

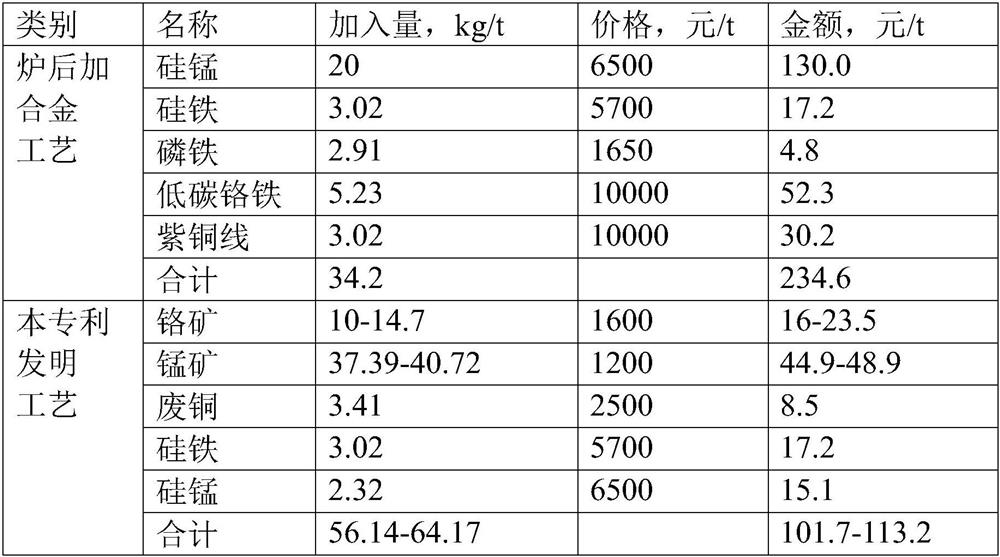

Method used

Image

Examples

Embodiment 1

[0061] Example 1, in the steelmaking process, molten iron with a higher phosphorus content is used, the weight of the molten iron is 38.0t, and the components of the molten iron are [C] 4.2%, [Si] 0.48%, [Mn] 0.40-0.56%, [P] 0.20 -0.28%, [S]0.01-0.023%, [Cu]0.008-0.012%, [V]0.008-0.011%, [Cr]0.008-0.01%, the rest is Fe and unavoidable impurities, T1300-1320℃. The amount of steel scrap added is 7t, including scrap copper, and the amount of scrap copper added is 130kg.

[0062] During the blowing process, add 1000kg of lime, 500kg of magnesium balls, 1640kg of manganese ore, and 525kg of chromium ore. Total blowing 14.0min, oxygen consumption is 2025m 3 . At the end of blowing, the molten steel temperature is 1640-1660°C, the carbon content is 0.10%, the phosphorus content is 0.098%, the slag basicity is 2.0, and the T.Fe content is 12%. After the end point of the converter (11-14.0min), strong blowing and stirring, the strength of bottom blowing gas supply is 0.13Nm 3 / (t·m...

Embodiment 2

[0066] In the process of steelmaking, molten iron with high phosphorus content is used. The weight of the molten iron is 40.0t. The composition of the molten iron is [C]4.1%, [Si]0.43%, [Mn]0.42%, [P]0.21%, [S]0.018 %, [Cu] 0.01%, [V] 0.008%, [Cr] 0.01%, the rest is Fe and unavoidable impurities, T1320℃. The amount of scrap steel added is 8t, including scrap copper, and the amount of scrap copper added is 140kg.

[0067] During the blowing process, add 1200kg of lime, 520kg of magnesium balls, 1800kg of manganese ore, and 460kg of chromium ore. Total blowing 13.6min, oxygen consumption is 2160m 3 . At the end of blowing, the molten steel temperature is 1648°C, the carbon content is 0.11%, the phosphorus content is 0.10%, the slag basicity is 1.9, and the T.Fe content is 11%. After the end point of the converter (11-14.0min), strong blowing and stirring, the bottom blowing gas supply intensity is 0.15Nm 3 / (t·min).

[0068] After the blowing is finished, 100kg of silicomanga...

Embodiment 3

[0071] In the steelmaking process, molten iron with a high phosphorus content is used. The weight of the molten iron is 37.0t, and the composition of the molten iron is [C]4.4%, [Si]0.52%, [Mn]0.45%, [P]0.25%, [S]0.019 %, [Cu] 0.01%, [V] 0.011%, [Cr] 0.01%, the rest is Fe and unavoidable impurities, T1310℃. The amount of steel scrap added is 7t, including scrap copper, and the amount of scrap copper added is 140kg.

[0072] During the blowing process, add 1350kg of lime, 460kg of magnesium balls, 1700kg of manganese ore, and 660kg of chromium ore. Total blowing 13.8min, oxygen consumption is 1987m 3 . At the end of blowing, the molten steel temperature is 1650°C, the carbon content is 0.13%, the phosphorus content is 0.093%, the slag basicity is 2.0, and the T.Fe content is 12%. After the end point of the converter (11-14.0min), strong blowing and stirring, the bottom blowing gas supply intensity is 0.12Nm 3 / (t·min).

[0073] After the blowing is finished, 103kg of silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com