A kind of glass batch material and its preparation method and a kind of glass and its preparation method

A batch, ultra-white glass technology, applied in the field of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

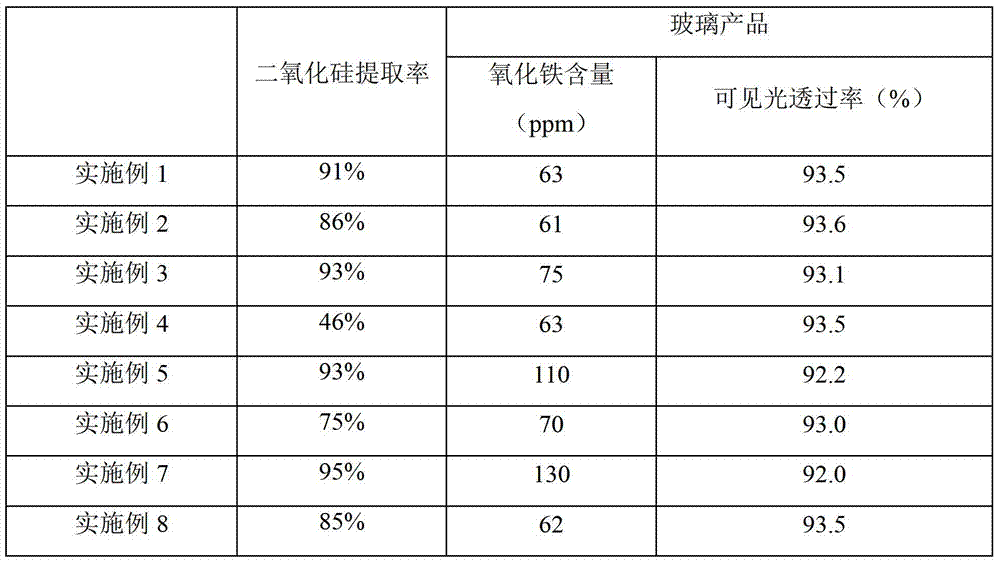

Examples

preparation example Construction

[0027] On the one hand, the present invention provides a kind of preparation method of glass batch material, and this method comprises:

[0028] (1) Remove the residual acid from the acid residue obtained after the fly ash is subjected to acid extraction of aluminum;

[0029] (2) Leaching with alkaline solution, solid-liquid separation to obtain leaching solution and leaching residue;

[0030] (3) Introduce carbon dioxide into the leaching solution for carbonation and decomposition, and then separate solid-liquid to obtain silicic acid precipitate and carbonate solution;

[0031] (4) Mix the silicic acid precipitate obtained in step (3) with calcium oxide and / or calcium oxide precursor, and optionally with sodium oxide and / or sodium oxide precursor to obtain a glass batch.

[0032] In the present invention, the glass batch refers to a glass batch whose ratio of soda-lime-silicon satisfies the glass composition.

[0033] In the present invention, the alkali solution is prefer...

Embodiment 1

[0077] This example is used to illustrate the preparation method of the glass batch material and the preparation method of glass of the present invention.

[0078] (1) Take the fly ash of the above composition and react under the conditions of sulfuric acid concentration of 98%, temperature of 260°C, time of 100min, and liquid-solid ratio of 4:1. Afterwards, unreacted sulfuric acid is filtered out, and the generated aluminum sulfate is in the filter residue, and part of the sulfuric acid is adsorbed. After roasting at 300°C to remove acid, add water to dissolve the dry residue for 30 minutes at a liquid-solid ratio of 6:1 to obtain aluminum sulfate solution and acid residue. The silicon dioxide content in the acid method residue was measured to be 72.8% by weight, the alumina content to be 13% by weight, and the iron oxide content to be 0.4% by weight.

[0079] (2) Roast the residue from the acid process at 800°C for 60 minutes, and wash it with water until neutral after cool...

Embodiment 2

[0086] This example is used to illustrate the preparation method of the glass batch material and the preparation method of glass of the present invention.

[0087] (1) The fly ash with the above composition is taken, and the iron oxide content is reduced to 0.7% by weight after iron removal by magnetic separation. Add 37% by weight hydrochloric acid for acid dissolution reaction, the ratio of hydrochloric acid to alumina in fly ash is 4.5:1, the reaction temperature is 200°C, and the reaction time is 2 hours. Solid-liquid separation to obtain aluminum chloride solution and acid residue. The silicon dioxide content in the acid method residue was measured to be 91.2% by weight, the alumina content to be 2.1% by weight, and the iron oxide content to be 0.2% by weight.

[0088] (2) Roast the residue from the acid process at 500°C for 120 minutes, and wash it with water until neutral after cooling. Then, the acid process residue was stirred and leached in 15% by weight sodium hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com