Refractory castable for lime spray gun as well as preparation method and application of refractory castable

A technology of refractory castables and spray guns, applied in the field of refractory materials, can solve problems such as short service life, achieve the effects of improving service life, optimizing construction performance and comprehensive performance, and reducing the amount of water added in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

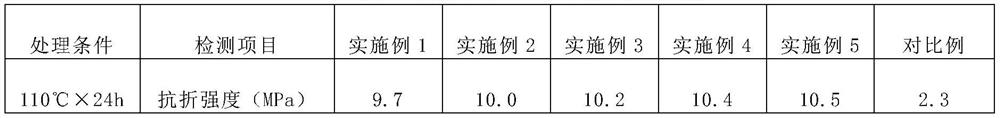

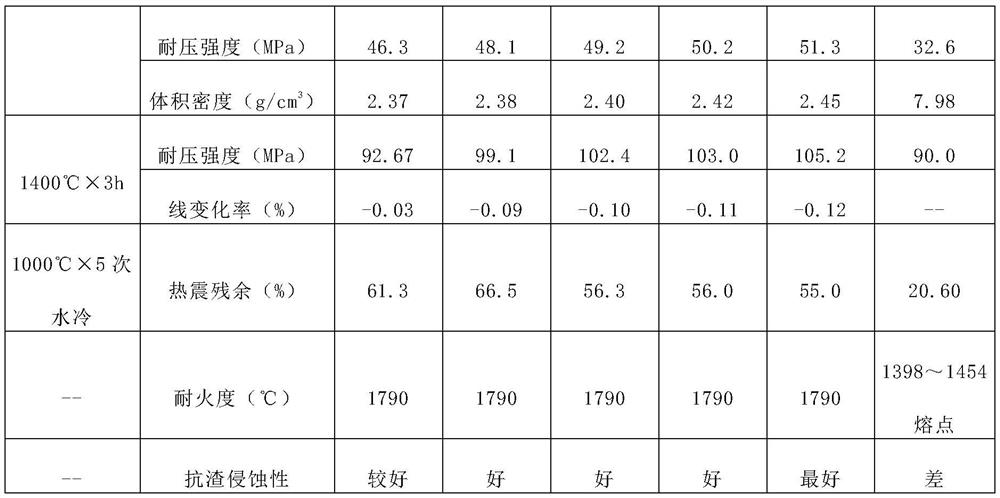

[0061] As shown in Table 1, the refractory castable for lime spray gun provided in the present embodiment includes raw material and water reducing agent; the raw material includes the following components by weight percentage:

[0062] M70 sintered mullite: 28%, particle size is 0.044~5mm;

[0063]Burnt gemstone: 40%, particle size ≤8mm;

[0064] Calcium titanate aluminate: 7%, particle size is 0.044~3mm;

[0065] Ceramic micropowder: 15%, particle size D 50 = 1 μm;

[0066] Waxstone: 10%, particle size is 1~3mm;

[0067] Pure calcium aluminate cement: 0.7%, particle size ≤180 mesh;

[0068] Microsilica: 1.5%, particle size D 50 ≤0.5μm;

[0069] The water reducing agent is an inorganic water reducing agent sodium tripolyphosphate, which is 0.030wt% of the total raw materials.

[0070] In the refractory castable for lime spray gun in this embodiment, the mass percentage content of alumina is 70-72%, and the content of iron oxide is less than or equal to 0.5wt%;

[0071]...

Embodiment 2

[0073] As shown in Table 1, the refractory castable for lime spray gun provided in the present embodiment includes raw material and water reducing agent; the raw material includes the following components by weight percentage:

[0074] M70 sintered mullite: 30%, particle size is 0.044~5mm;

[0075] Burnt gemstone: 38%, particle size ≤8mm;

[0076] Calcium titanate aluminate: 7%, particle size is 0.044~3mm;

[0077] Ceramic micropowder: 14%, particle size D 50 = 1 μm;

[0078] Waxstone: 10.5%, particle size is 1-3mm;

[0079] Pure calcium aluminate cement: 1.0%, particle size ≤180 mesh;

[0080] Silicon micropowder: 1.6%, the particle size is D50≤0.5μm;

[0081] The water reducing agent is an inorganic water reducing agent sodium tripolyphosphate, which is 0.032wt% of the total weight of the raw materials.

[0082] In the refractory castable for lime spray gun in this embodiment, the mass percentage content of alumina is 70-71%, and the content of iron oxide is less than ...

Embodiment 3

[0085] As shown in Table 1, the refractory castable for lime spray gun provided in the present embodiment includes raw material and water reducing agent; the raw material includes the following components by weight percentage:

[0086] M70 sintered mullite: 28%, particle size is 0.044~5mm;

[0087] Burnt gemstone: 37%, particle size ≤8mm;

[0088] Calcium titanate aluminate: 7%, particle size is 0.044~3mm;

[0089] Ceramic micropowder: 13%, particle size D 50 = 1 μm;

[0090] Waxstone: 11%, particle size is 1-3mm;

[0091] Pure calcium aluminate cement: 1.2%, particle size ≤180 mesh;

[0092] Microsilica: 1.7%, particle size D 50 ≤0.5μm;

[0093] The water reducing agent is an inorganic water reducing agent sodium tripolyphosphate, which is 0.034wt% of the raw material.

[0094] In the refractory castable for lime spray gun in this embodiment, the mass percentage content of alumina is 70-72%, and the content of iron oxide is ≤0.5wt%

[0095] Sample detection: the raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com