Patents

Literature

120results about How to "Good slag resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterless stemming and preparation method thereof

The invention relates to waterless stemming and a preparation method thereof. The waterless stemming is a fireproof, corrosion-resistant, washing-resistant and wear-resistant material for blocking an iron notch and filling iron notch gaps and cracks having various shapes. The waterless stemming has the advantages that 1, the waterless stemming does not yellow, does not produce black smoke, reduces benzpyrene content to a value less than 0.01% and has good filling performances, contractibility and sintering properties, 2, strength is high and stable blast furnace conditions are kept, 3, iron is produced stably, the iron notch can be opened easily, the pore is not broadened, melt iron flow and flow velocity can be effectively controlled, and strong slag resistance, erosion resistance and washing resistance are obtained, 4, the hearth is protected, crack is not produced in fast heating and high bonding strength of novel and old stemming is high, 5, opening performances are good and a boring process can be carried out easily by a tapping machine drill bit, 6, plasticity is good and clay gun operation and iron notch mud drum formation are convenient, and 7, a certain micro-expansion performance is obtained at a high temperature, gas permeability is good, strength is high and molten iron seepage caused by stemming contraction is avoided.

Owner:阜康市三工河乡樟兴新型耐火材料厂

Aluminum/zinc composite ultralow-carbon alumina-magnesite carbon brick for ladle lining

The invention discloses an aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick for a ladle lining. The aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick is made by the following steps of: mixing raw materials, aging, molding, carrying out heat treatment at 180-250 DEG C and curing for 16-36 hours. The aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick comprises the following raw materials in percentage by weight: 40-60% of magnesite granule, 5-15% of magnesia alumina spinel granule, 25-35% of magnesite fine powder, 3-8% of aluminum / zinc metallic composite powder, 0-1% of crystalline flake graphite, 0.5-2% of boracic antioxidant and 3-4% of organic bond. The volume density of the aluminum / zinc composite ultralow-carbon alumina-magnesite carbon brick is greater than or equal to 3.0g / cm<3>, the apparent porosity is not more than 5%, the cold compressive strength is not lower than 45 MPa, the carbon-embedded high-temperature folding strength at 1400 DEG C is not lower than 25MPa, the content of MgO is not less than 75%, and the carbon content is not more than 2%.

Owner:ZHENGZHOU UNIV

Periclase-silicon carbide-carbon composite materials and method for preparing same

InactiveCN1884202AHigh melting pointHigh thermal conductivityCarbon compositesHexamethylenetetramine

The invention discloses a periclase-carborundum-carbon composite material and preparing method, which comprises the following steps: blending 60-90% electric melting or sintered magnesite, 5-35% carborundum, 2-15 % graphite, 0.5-5% carbon black and 0.5-6% additive; mixing 3-9% binder and 0-1%hexamethylenetetramine hardener; stirring; moulding; baking at 150-350 deg.c for 2-24 h. The invention improves oxidation resistance of material and penetrability and aggressivity resistance of melting waste and metal fusion, which fits melting furnace and container liner widely.

Owner:WUHAN UNIV OF SCI & TECH

Magnesia carbon brick and preparation method thereof

The invention provides a magnesia carbon brick and a preparation method thereof, belonging to the field of refractory materials. The raw materials of the magnesia carbon brick include 30-80 parts of waste magnesia carbon brick grains, 3-40 parts of magnesia grains, 6-12 parts of graphite, 5-15 parts of magnesia powder, 3-15 parts of micro powder additives, 2.2-3.5 parts of organic bonds by weight. The preparation method is characterized by sorting, hydrating, drying and grinding the waste magnesia carbon bricks from the steel mills and then mulling the waste magnesia carbon brick grains with other raw materials, forming and carrying out heat treatment to prepare the magnesia carbon brick. The energy-saving and environment-friendly aluminium-magnesia carbon brick prepared by the invention has high compression strength, low porosity, good resistance to molten steel corrosion and service life reaching or exceeding the service lives of the traditional aluminium-magnesia carbon bricks. In the invention, the waste aluminium-magnesia carbon bricks are rationally utilized and consumption of the mineral resources is reduced.

Owner:ZHENGZHOU DONGFANG SANLI REFRACTORY MATERIALS

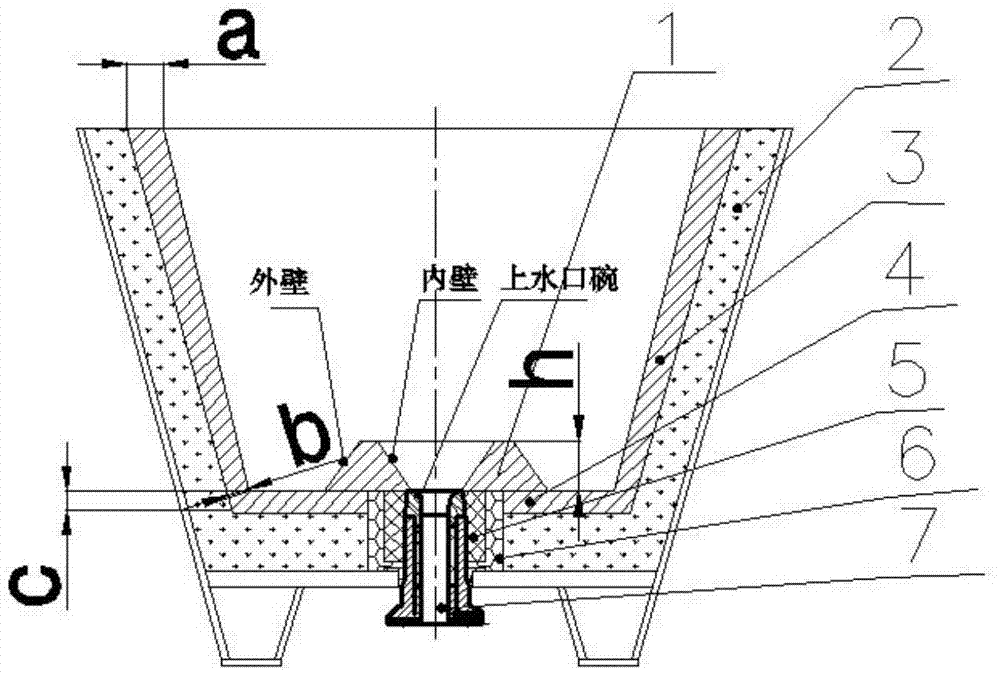

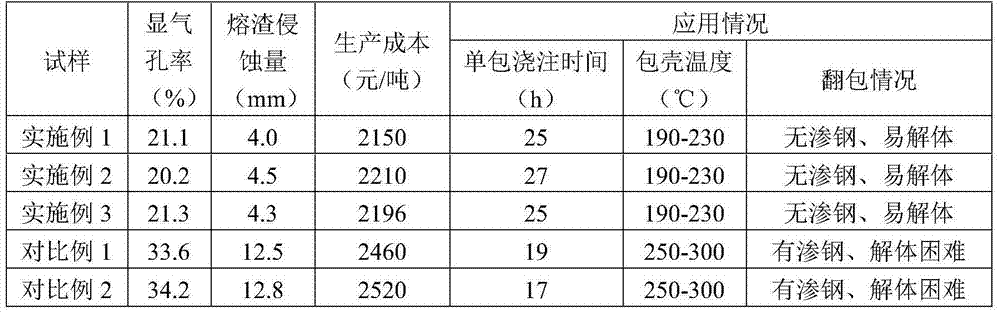

Recycled magnesia carbon coating material with strong slag-corrosion resistance and application thereof

InactiveCN104774020APrevent penetrationReduce manufacturing costWaste processingSolid waste disposalSilica fumeCarbon coating

The invention relates to a recycled magnesia carbon coating material with strong slag-corrosion resistance and an application thereof. The coating material is composed of the following materials by weight percentage: 10-15% of waste magnesia carbon brick regenerated granule material with the granularity of not less than 3mm and not more than 5 mm, 25-30% of waste magnesia carbon brick regenerated granule material with the granularity of not less than 1 and not more than 3 mm, 30-35% of magnesite clinker with the granularity of not less than 0.083 mm and not more than 1 mm, 10-12% of fused magnesite micro powder with the granularity of less than or equal to 0.047mm, 3-5% of alpha-Al2O3 micro powder with the granularity of less than or equal to 0.047 mm, 3.5-5% of alumina-magnesia spinel micro powder with the granularity of less than or equal to 0.047 mm, 3.5-4.0% of soft clay, 1.5-2.5% of silica powder, 0.2-0.5% of sodium tripolyphosphate, 0.5-1.0% of metal silicon powder with the granularity of less than or equal to 0.074 mm, 0.7-1.2% of silicon carbide powder with the granularity of less than or equal to 0.074 mm, and 0.1-0.3% of refractory fiber. The recycled magnesia carbon coating material with strong slag-corrosion resistance, provided by the invention, is good in slag-corrosion resistance and long in service life, the problems of penetration of steel in the recycled magnesia carbon coating material, the penetration of steel between the upper nozzle and the brick cup, the high cladding temperature of the tundish and the bad disassembly performance are solved, the single packet pouring time is increased by 6h or above and the cladding temperature of the tundish is reduced by 60 DEG C or above.

Owner:武治宏

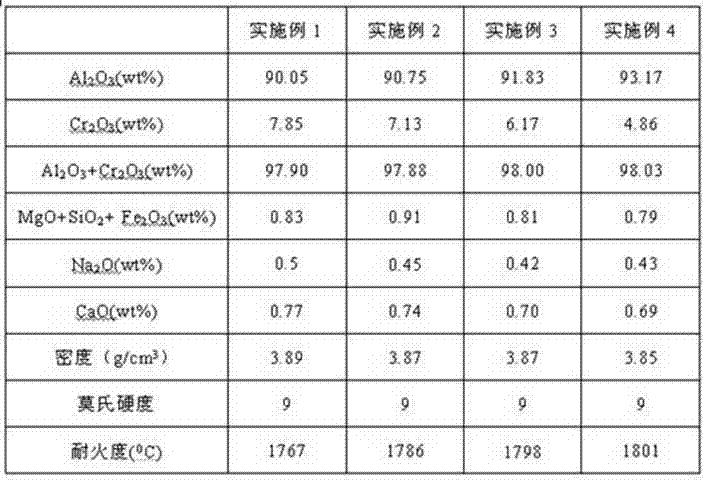

Chromium corundum material and production method thereof

The invention relates to a chromium corundum material and a production method thereof. The chromium corundum material consists of 90wt%-94.5wt% of aluminum oxide, 3wt%-8wt% of chromic oxide and less than and equal to 2.5wt% of total impurities. The production method comprises the steps of uniformly mixing aluminum-chromium slag having a particle size less than and equal to 20mm, aluminum oxide having a particle size less than and equal to 1mm, petroleum coke having a particle size less than and equal to 20mm and aluminum fluoride, heating bitumen and spraying to the mixture, pressing into ball materials, drying, and adding the dried ball materials to an electric-arc furnace; smelting, pouring smelted liquid in a slag pot, removing the calcium fluoride floating on the upper part of the liquid material and standing; and separating from the slag pot, crushing, selecting chromium metal reduced by carbon and finishing to obtain the chromium corundum material. The chromium corundum material has the advantages that the problem of aluminum chromium slag solid waste is solved by taking aluminum chromium slag as raw materials, environmental friendliness is achieved, the raw material cost is lowered, the contents of Al2O3 and Cr2O3 are improved and the high-temperature performance, slag resistance and corrosion resistance of the chromium corundum material are ensured.

Owner:锦州集信高温材料有限公司

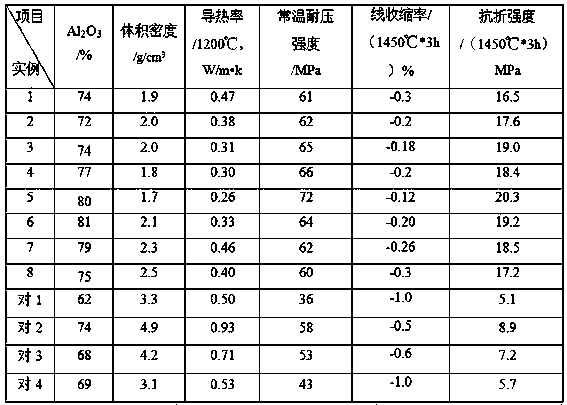

High-alumina refractory castable and preparation method thereof

The invention belongs to the technical field of refractory materials, in particular to a high-alumina refractory castable and a preparation method thereof. The high-alumina refractory castable is prepared from the following raw materials in parts by weight: 50-70 parts of high bauxite, 8-13 parts of andalusite, 11-23 parts of floating bead, 15-20 parts of silicon carbide, 10-15 parts of silicon nitride, 7-12 parts of alpha-Al2O3 micro powder, 3-9 parts of silica-alumina colloid powder, 1-5 parts of attapulgite clay, 10-25 parts of calcium aluminate cement, water reducer and aluminium silicatefiber, wherein the water reducer occupies 0.1-0.3% of total mass of the above raw materials, and the aluminium silicate fiber occupies 0.05-0.12% of total mass of the above raw materials. The high-alumina refractory castable has the advantages of high Al2O3 content, light weight, low heat conductivity and high castable strength.

Owner:黎文泰

Slide board refractory containing titanium carbo-nitride and its preparing method

The present invention relates to one kind of slide board refractory containing titanium carbonitride and its preparation process. The slide board refractory is prepared with alumina 75-90 wt%, magnesia 0-10 wt%, zirconium oxide 0-15 wt%, titanium carbonitride 0.5-30 wt%, boron carbide 0- 5 wt%, silicon carbide 0-5 wt%, metal aluminum 0-6 wt%, metal silicon 0-6 wt%, graphite 4-10 wt%, and organic binding agent 2-6 wt%, and through mixing, forming, and heat treatment at 100-300 deg.C or sintering at 1100-1500 deg.C. The slide board refractory of the present invention has the features of high antioxidant effect, high strength at high temperature, high slagging resistance and high heat shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

Tap hole reclaimed material recycled quick-dry anti-explosion castable

The invention discloses a tap hole reclaimed material recycled quick-dry anti-explosion castable which comprises the following components in parts by mass: 15-30 parts of electrically-fused dense corundum, 5-10 parts of brown fused alumina fresh material, 3-5 parts of brown fused alumina reclaimed material, 5-10 parts of mullite fresh material, 3-5 parts of mullite reclaimed material, 4-8 parts of silicon carbide, 4-6 parts of graphite, 2-5 parts of binding agent which is a mixture of pure calcium aluminate cement and nanometer silica-alumina gel powder, 3-8 parts of polycarboxylate superplasticizer, and 0.5-2 parts of compound anti-explosion agent. The tap hole reclaimed material recycled quick-dry anti-explosion castable has the beneficial effects that by adopting brown fused alumina reclaimed material and mullite reclaimed material, waste materials can be sufficiently utilized so as to reduce the cost of industrial products in the iron and steel industry, the condensation time can be effectively controlled by specially proportioning aggregate materials with different properties and particles and adding additional additives, the hardening time of the castable can be shortened, the quick-dry anti-explosion properties are good, the construction efficiency is improved, on-schedule tapping of a blast furnace can be guaranteed, and the service life of the castable can be prolonged.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

Lining patching material of iron-smelting blast furnace

The invention discloses a lining patching material of the iron-smelting blast furnace. The lining patching material is prepared from the following raw materials by weight percent: 50-70% of aluminum oxide powder with the purity of 88%, 2-5% of aluminum oxide powder with the purity of 95%, 15-25% of silicon carbide powder, 3-13% of mullite powder, 2-4% of activated alpha-A12O3 powder, 3-6% of purecalcium aluminate cement and 3-5% of silica micropowder. When used, the patching material is weighted according to the area and part of the lining to be parched, water is added to mix, and a spray-repair device is used to perform hot spray-repair to the lining of the blast furnace. The lining patching material of the invention has the advantage that mullite powder, silicon carbide powder, aluminum oxide powder and alpha-A12O3 powder are used as the aggregate and base material of the hot patching material of the blast furnace and pure calcium aluminate cement and silica micropowder are used asthe bonding agents, thus ensuring that the patching material has good fire resistance and slag resistance when the operating temperature is above 1400 DEG C; and the cost of the patching material andthe construction cost can be reduced, thus greatly reducing the maintenance cost of smelting enterprises for patching the blast furnace.

Owner:郑州九环科贸有限公司

Refractory composition and process for forming article therefrom

ActiveUS20150197450A1Easy to optimizeImprove corrosion resistanceSolid waste managementPhosphorus compoundsSlagRefractory

Refractory compositions and methods of forming articles therefrom are provided that include a plurality of aggregate particles and a binder intermixed with the aggregate particles. The binder composition includes sintered crystalline chromium metaphosphate or chromium-aluminum metaphosphate, or combinations of the two distributed in the binder. The provided compositions are free of chromium oxide yet exhibit excellent slag resistance and are easily disposed of.

Owner:STELLAR MATERIALS

Environment-friendly castable for blast furnace iron runners

The invention belongs to the field of refractory materials, and mainly relates to an environment-friendly castable for blast furnace iron runners. The castable is composed of, by weight, 50 parts to 85 parts of corundum raw materials, 8 parts to 30 parts of silicon carbide based raw materials, 1 part to 10 parts of palletized carbon black, 2 parts to 6 parts of silica fume, 1 part to 5 parts of calcium aluminate cement, 0.3 part to 3 parts of antioxidants, 0.1 part to 0.3 part of water reducing agents, 0.01 part to 0.2 part of wetting agents and 3.2 parts to 5 parts of water. The environment-friendly castable has the advantages of being low in water addition, high in carbon content, compact in structure, large in hot strength and excellent in anti-scouring performance, not causing site environment pollution in a construction utilization process, and being environment-friendly.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Al4SiC4-Al2O3 composite refractory materials and preparation method thereof

The invention relates to a composite refractory material of Al4SiC4 and Al2O3 and a method for preparing the same. The adopted technical proposal is as follows: firstly, 50 to 65 weight percent of bauxite and 35 to 50 weight percent of industrial carbon powder are mixed; and the mixture is added with 3 to 10 weight percent of bonding agent to be stirred for 5 to 25 minutes, is pressed to be shaped, and is dried for 12 to 36 hours under the condition of between 60 and 110 DEG C or naturally dried for 24 to 48 hours indoors; and secondly, the mixture is sintered for 2 to 6 hours under argon atmosphere and under the condition of between 1,600 and 1,800 DEG C, and is cooled naturally to obtain the composite refractory material of the Al4SiC4 and the Al2O3. The composite refractory material has the characteristics of rich raw material resource, low production cost and easy industrialized production. The composite refractory material of the Al4SiC4 and the Al2O3 prepared by the method not only has excellent performance, but also can prolong the service life, is suitable for a furnace lining material for nonferrous metal and iron and steel smelting equipment, and particularly suitable for producing ladle inside lining and refining furnace lining of clean steel such as low carbon steel, ultra-low carbon steel and so on.

Owner:WUHAN UNIV OF SCI & TECH

Aluminum-magnesium casting material for ladle liner and preparation method thereof

The invention relates to an aluminum-magnesium casting material for a ladle liner and a preparation method thereof. ACcording to the technical scheme, the method comprises the following steps: preparing 50-65wt% of microporous alumina particles serving as aggregate; preparing 10-15wt% of fine corundum particles, 15-30wt% of fine corundum powder, 2-8wt% of magnesium oxide powder, 2-8wt% of alpha-A12O3 powder and 2-8wt% of aluminum powder silica gel which are used as base materials; adding water which accounts for 3-10wt% of the sum of the aggregate and the base materials; evenly agitating, and molding in a vibrating manner; carrying out heat preservation at 100-150 DEG C for 12-36 hours, so as to prepare the aluminum-magnesium casting material for the ladle liner. The aluminum-magnesium casting material for the ladle liner prepared by the method has excellent slag resistance and thermal shock stability, and the service life of the aluminum-magnesium casting material for the ladle liner can be effectively prolonged.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of granulated graphite used in refractory castable

The invention belongs to the filed of refractory materials, and relates to a preparation method of granulated graphite used in a refractory castable. The granulated graphite is prepared from raw materials of, by mass: 34-52% of refractory raw material fine powder, 25-40% of flake graphite, 0-9% of solid-state phenol formaldehyde resin powder, 0-15% of an additive, and 22-31% of refractory raw material particles. Also, liquid-state phenol formaldehyde resin which takes 8.5-14.0% of the total weight of the solid raw materials is added. The preparation method comprises steps that: the refractory raw material fine powder, the flake graphite, the solid-state phenol formaldehyde resin powder and the additive are well mixed in a high-speed mixing granulator; a mixture is fetched for later use; the refractory raw material particles and the liquid-state phenol formaldehyde resin are well mixed in the high-speed mixing granulator according to the proportions; mixed powder obtained in the previous steps is placed in the high-speed mixing granulator; coating and granulating are carried out; an obtained material is dried in air, and is baked under a temperature of 100-200 DEG C, such that granulated graphite with a carbon content of 27.1-41.7wt% is obtained.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Energy-saving rotary kiln and furnace lining fireproof brick building slurry

The invention discloses an energy-saving rotary kiln and furnace lining fireproof brick building slurry. The energy-saving rotary kiln consists of a cylindrical steel body kiln shell, a plurality of high-temperature fireproof brick steel plate dies, and steel plate die supporting columns, high-temperature fireproof bricks and fireproof brick building slurry which are welded together, wherein the fireproof brick building slurry is high in filling property, contractibility and sintering performance. The intensity is high, and the furnace condition of a blast furnace can be kept stable (the depth of an iron notch, the fluctuation of the smelting time and the full-blast plugging rate), so that the yield of the blast furnace is increased; the slag resistance performance is high, and the energy-saving rotary kiln can resist corrosion and scouring; no crack is generated during quick heating, so that the combination strength is high; the energy-saving rotary kiln has certain contractibility under high temperature and is high in ventilation property and high in intensity, so that the phenomenon that the fireproof bricks are broken due to expansion in a high-temperature environment is avoided.

Owner:NINGXIA SAIDI BURDEN TECH DEV CO LTD

Corundum-magnesium aluminate spinel refractory material

The invention relates to a refractory material, and in particular relates to a corundum-magnesium aluminate spinel refractory material which is prepared from raw materials, including corundum, magnesium aluminate spinel, fused magnesite and alpha-Al2O3 micro powder. The corundum-magnesium aluminate spinel refractory material is relatively high in refractoriness and strength, good in anti-erosion property, anti-stripping property and anti-slag property, good in thermal vibration stability and long in service life, thereby being a corundum-magnesium aluminate spinel refractory material with excellent quality.

Owner:QINGDAO YONGTONG ELEVATOR ENG

Refractory brick of ladle slag line

The invention discloses a refractory brick of a ladle slag line. The refractory brick is prepared from the following raw materials in parts by weight: 24-26 parts of waste magnesia brick, 46-48 parts of fused magnesite, 1-2 parts of -20mesh graphite powder, 3-5 parts of -100mesh silicon carbide, 15-17 parts of -100mesh zirconium oxide, 6-8 parts of -150mesh fused millite, 8-10 parts of magnesite powder, 2-3 parts of asbestos fibers, 4-6 parts of Suzhou bentonite, 10-12 parts of zirconium boride, 1.5-2.5 parts of -200mesh boron nitride, 2.5-3.5 parts of -200mesh cerium oxide, 2-3 parts of asphalt powder, 1-2 parts of phenolic resin, 3-5 parts of sodium hexametaphosphate and 16-18 parts of water, wherein the waste magnesia brick of which the granularity is -20 mesh to +40 meshes accounts for 50%; the waste magnesia brick of which the granularity is -40 mesh to +100 meshes accounts for 25%; the waste magnesia brick of which the granularity is -100 mesh to +200 meshes accounts for 25%; the fused magnesite of which the granularity is -5 mesh to +18 meshes accounts for 35%; the fused magnesite of which the granularity is -18 mesh to +80 meshes accounts for 35%; and the fused magnesite of which the granularity is -80 mesh to +150 meshes accounts for 30%.

Owner:偃师市诚鼎耐火材料有限公司

Anti-slag-adhesion spray coating

ActiveCN107235733AExcellent high temperature resistance and anti-sticking slag performanceGood slag resistanceSilica fumeSlag

The invention relates to an anti-slag-adhesion spray coating, which comprises the following raw materials in weight percent: 10%-13% of bauxite granules in grain size of 0-1mm, 20%-24% of bauxite powder in grain size of 325-800 meshes, 13%-18% of silica powder in grain size of 280-325 meshes, 35%-45% of silica powder in grain size of 600-1000 meshes, 1.5%-2.5% of metal silicon powder in grain size of 180-260 meshes, 0.5%-3% of zirconium oxide in grain size of 325-400 meshes, 2%-5% of silicon carbide in grain size of 180-280 meshes, 1.5%-3% of silica powder, 0.2%-0.5% of sodium tripolyphosphate, 0.3%-0.5% of sodium hexametaphosphate and 35%-40% of water. The anti-slag-adhesion spray coating has an excellent anti-slag-adhesion effect, a slag pot and a slag ladle are free from slag adhesion and the service life of the slag pot and the slag ladle is greatly prolonged.

Owner:巩义市金利炉料厂

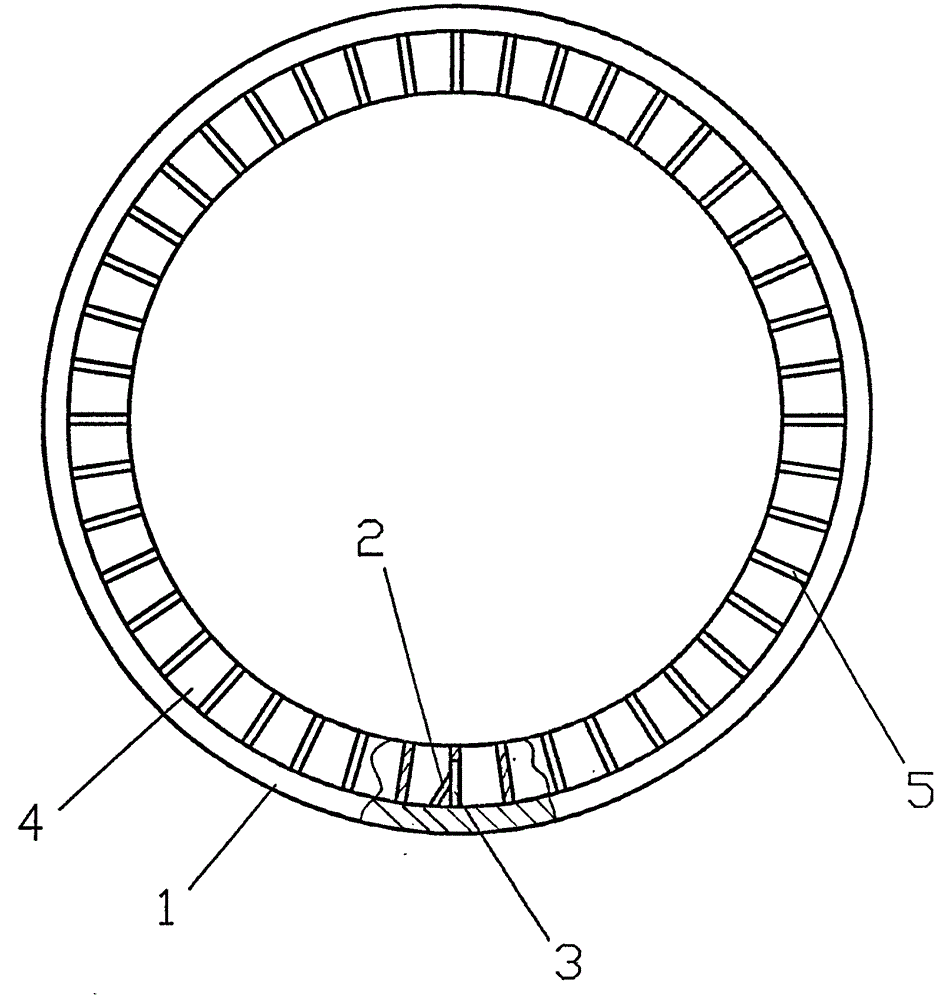

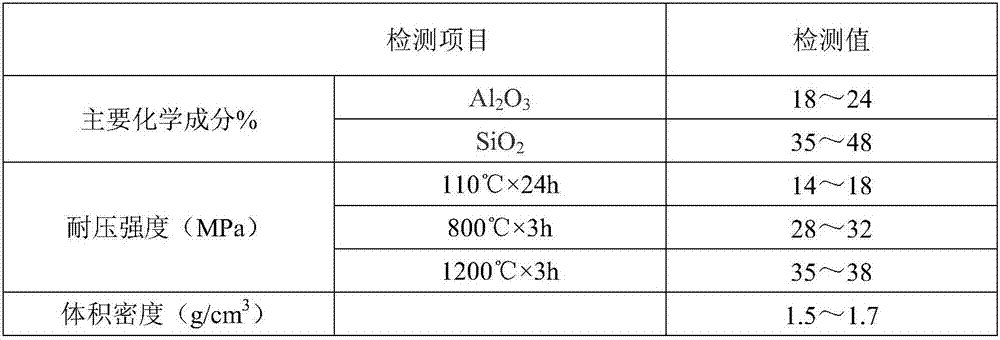

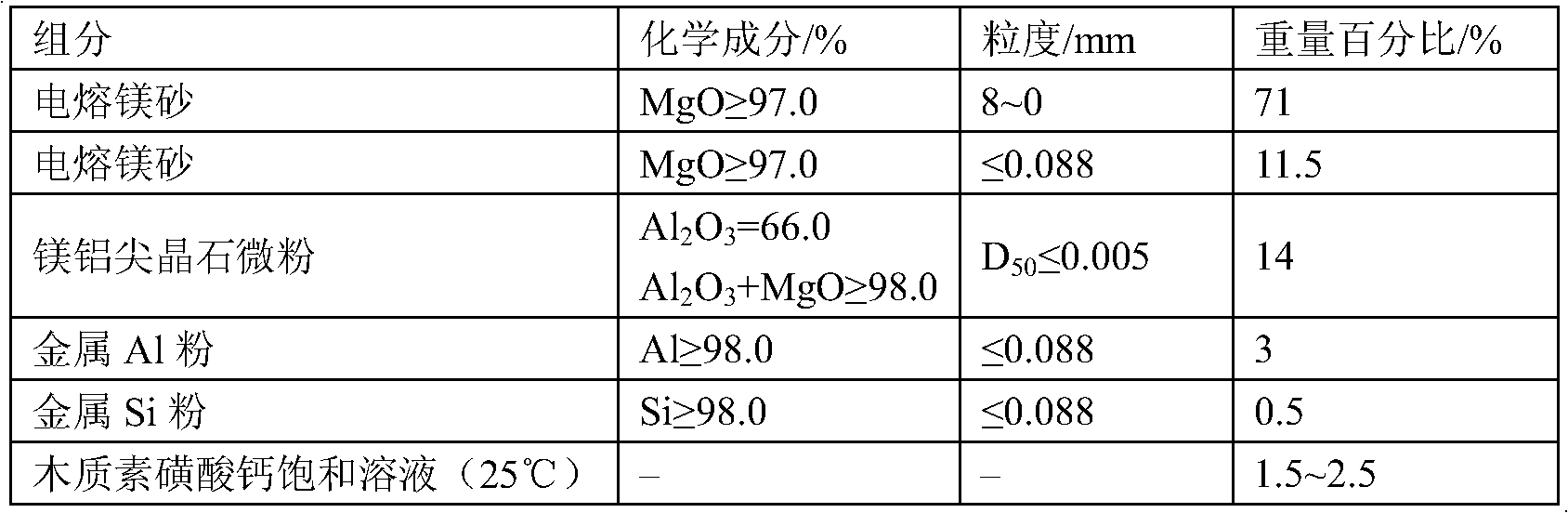

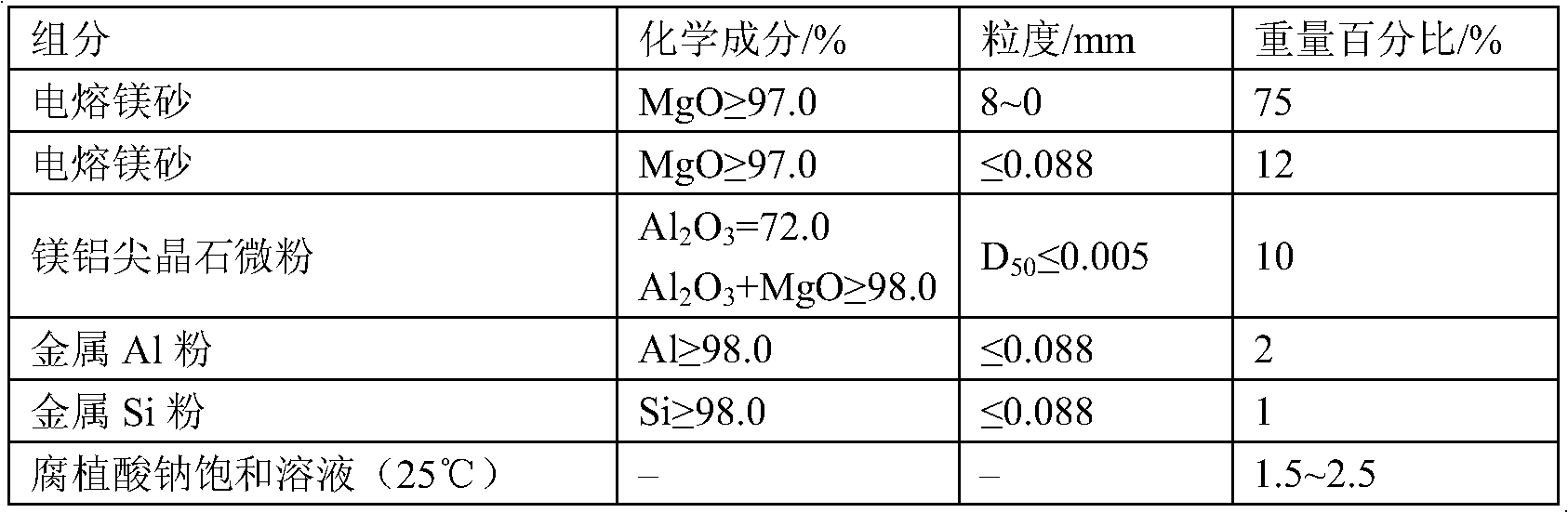

Magnesium spinel brick, production method of magnesium spinel brick, and method for preparing RH furnace circulation pipe by using magnesium spinel brick

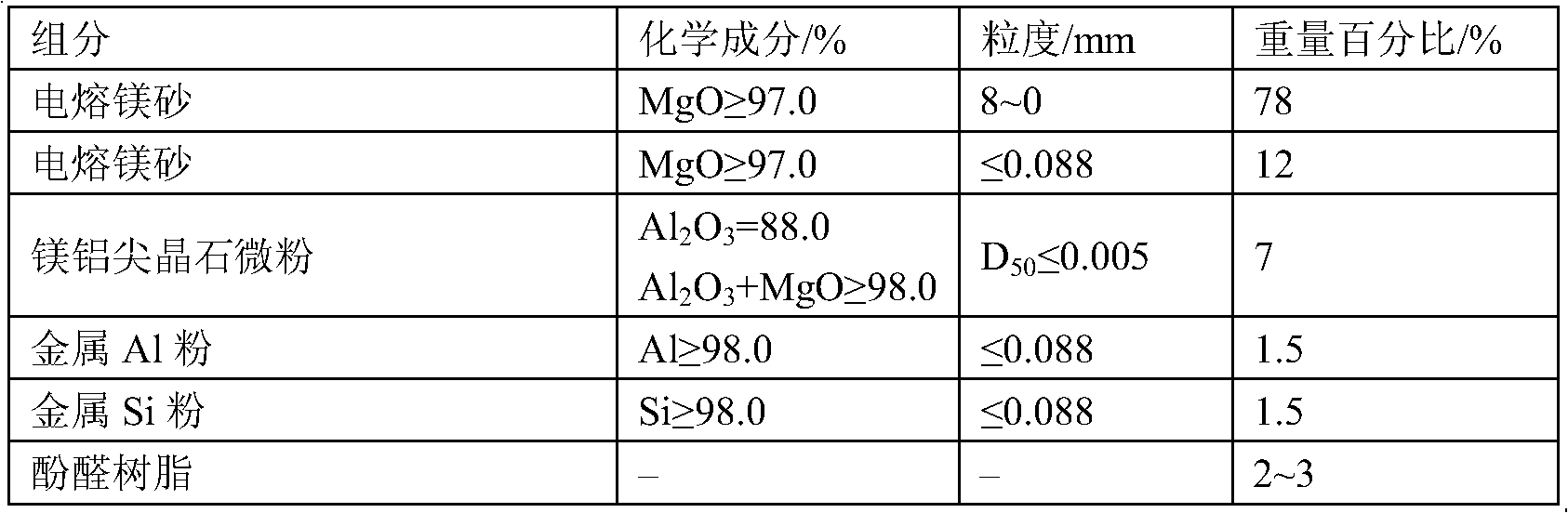

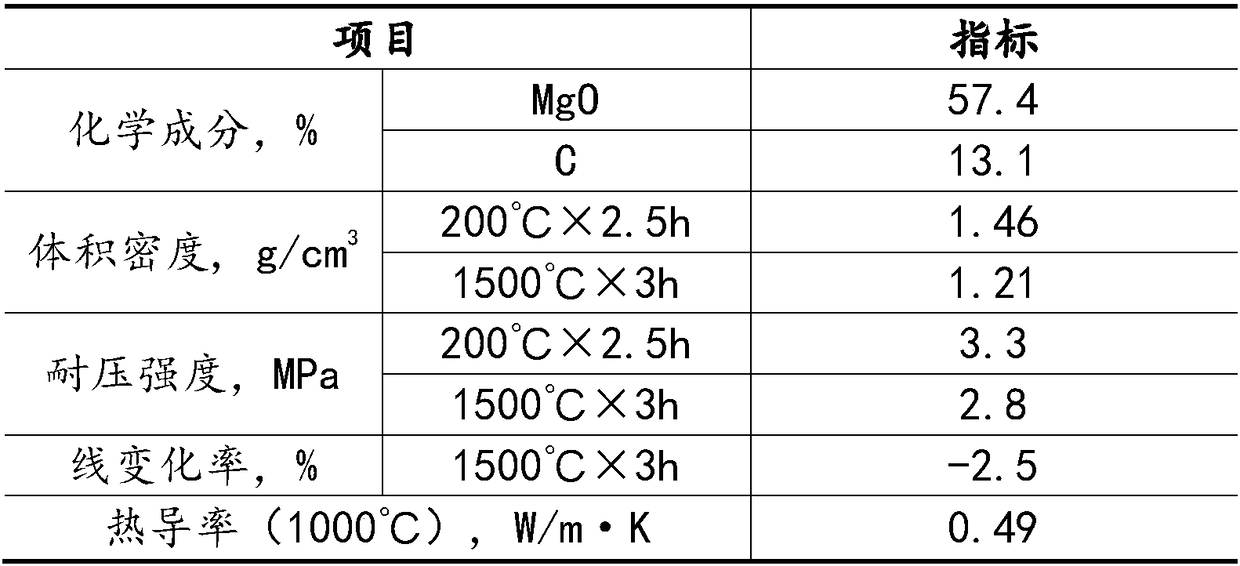

The invention discloses a magnesium spinel brick. The brick is prepared by raw materials consisting of the following components: 71 wt%-78 wt% of fused magnesia having a particle size of 8-0mm; 8 wt%-12 wt% of fused magnesia having a fineness which is less than or equal to 0.088mm; 7 wt%-14 wt% of magnesium-aluminum spinel micro power having a fineness of D50 which is less than or equal to 5mum; 1 wt%-3 wt% of metal Al power having a fineness which is less than or equal to 0.088mm; 0.5 wt%-1.5 wt% of metal Si power having a fineness which is less than or equal to 0.088mm; and an organic bonding agent accounting for 2%-5% of the total weight of the above mentioned components. The method for preparing the magnesium spinel brick of the invention comprises the following steps: accurately weighting the fused magnesia, the magnesium-aluminum spinel micro power, the metal Al power, the metal Si power and the organic bonding agent in the proportion described above, and uniformly mixing and grinding the components in a wet grinding machine; shaping the mixture by compressing the mixture in a press; and performing baking at a temperature of 180 DEG C-250 DEG C to obtain a finished magnesium spinel brick product. After the finished magnesium spinel brick products are abraded, the abraded products are bonded into a ring by using magnesium-aluminum chamotte, and the ring is hooped firmly by using an iron hoop on the outside of the ring. A RH furnace circulation pipe prepared by using the magnesium spinel bricks of the invention has a good melting loss resistance performance, has service life which is synchronized with that of an impregnating tube, and realizes long life effect of the whole RH furnace.

Owner:ZHEJIANG ZILI CORP LTD

Light tundish working lining and method for preparing same

ActiveCN108530090AImprove corrosion resistanceObvious volume shrinkage (≤-4.0%) phenomenonCeramic materials productionClaywaresFiberBrick

The invention discloses a light tundish working lining and a method for preparing the same. Ingredients for the light tundish working lining comprise waste magnesia-carbon bricks, magnesite tailing, aluminum oxide, fibers, compound bonding agents and additives. The method for preparing the light tundish working lining includes dry vibration forming or wet smearing forming. The light tundish working lining and the method have the advantages that the light tundish working lining prepared by the aid of the method is low in volume density, erosion rate, cost and consumption and long in service life, energy can be saved, and the like. Besides, the problem of excessive consumption of resources of existing refractory raw materials (including waste magnesia-carbon brick reclaimed materials and thelike), the problems in the aspects of energy conservation and heat preservation and the like can be solved by the aid of the light tundish working lining and the method.

Owner:PUYANG REFRACTORIES GRP CO LTD

Preparation method of slag line magnesia carbon brick for steel ladle

The invention discloses a preparation method of a slag line magnesia carbon brick for a steel ladle. The preparation method comprises the following steps: (1) placing 28-32 parts of 5-20-mesh low-silicon fused magnesia, 22-26 parts of 20-50-mesh low-silicon fused magnesia, 8-12 parts of 50-200-mesh low-silicon fused magnesia and 1-3 parts of -200-mesh low-silicon fused magnesia into a mixing machine to mix for 30-40min; (2) then, adding 0.8-1.2 parts of -20-mesh graphite powder, 1-2 parts of -100-mesh zinc powder, 1-2 parts of -100-mesh aluminum powder, 0.5-1 part of -200-mesh borne nitride, 0.5-1 part of -200-mesh boron carbide, 1-2 parts of -200-mesh cerium oxide and 0.5-1.5 parts of asphalt powder to mix for 60-90min; (3) next, adding 3.5-4.5 parts of phenolic resin to remix for 60-90min; (4) forming by using a press and drying a green brick at the temperature of 200 DEG C for 24h.

Owner:WUXI CHENGBO SCI & TECH DEV

Al4SiC4-Al2OC composite refractory materials and preparation method thereof

The invention relates to a composite refractory material of Al4SiC4 and Al2OC and a method for preparing the same. The technical proposal adopted by the invention is as follows: firstly, 30 to 70 weight percent of bauxite, 10 to 45 weight percent of industrial carbon powder, and 20 to 55 weight percent of metallic aluminium powder are mixed; and the mixture is added with 3 to 10 weight percent of bonding agent to be stirred for 5 to 25 minutes, is pressed to be shaped, and is dried for 12 to 36 hours under the condition of between 60 and 110 DEG C or naturally dried for 24 to 48 hours indoors; and secondly, the mixture is sintered for 2 to 6 hours under argon atmosphere and under the condition of between 1,600 and 1,800 DEG C, and is cooled naturally to obtain the composite refractory material of the Al4SiC4 and the Al2OC. The composite refractory material has the characteristics of rich raw material resource, low production cost and easy industrialized production. The composite refractory material of the Al4SiC4 and the Al2OC prepared by the method not only has excellent performance, but also can prolong the service life, is suitable for a novel furnace lining material for nonferrous metal and iron and steel smelting equipment, and particularly suitable for producing ladle inside lining and refining furnace lining of clean steel such as low carbon steel, ultra-low carbon steel and so on.

Owner:WUHAN UNIV OF SCI & TECH

Al2O3-Cr2O3 refractory material for smelting reduction iron smelting furnace

The invention belongs to the field of refractory materials for smelting reduction iron smelting and provides an Al2O3-Cr2O3 refractory material for a smelting reduction iron smelting furnace. The Al2O3-Cr2O3 refractory material for the smelting reduction iron smelting furnace comprises the following raw material components in percentage by mass: 60-70% of aggregate and 30-40% of matrix; content of Cr2O3 in the Al2O3-Cr2O3 refractory material is 30-55%; the aggregate comprises alumina-chrome particles and a zirconium-containing raw material; the zirconium-containing raw material is one of zirconium mullite particles and zirconite particles or combination of the two particles; addition amount of zirconium mullite and zirconite is 2-15% of the total mass of the raw material; the matrix is fine powder and micro powder, the fine powder comprises chromium oxide green and alumina-chrome fine powder; and the micro powder is zirconia micro powder and sintered alumina micro powder or activated alumina micro powder. The Al2O3-Cr2O3 refractory material for the smelting reduction iron smelting furnace has the advantages that thermal shock resistance of the material is effectively improved while guaranteeing excellent sintering effect and slag resistance of the material and operation cost is saved.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

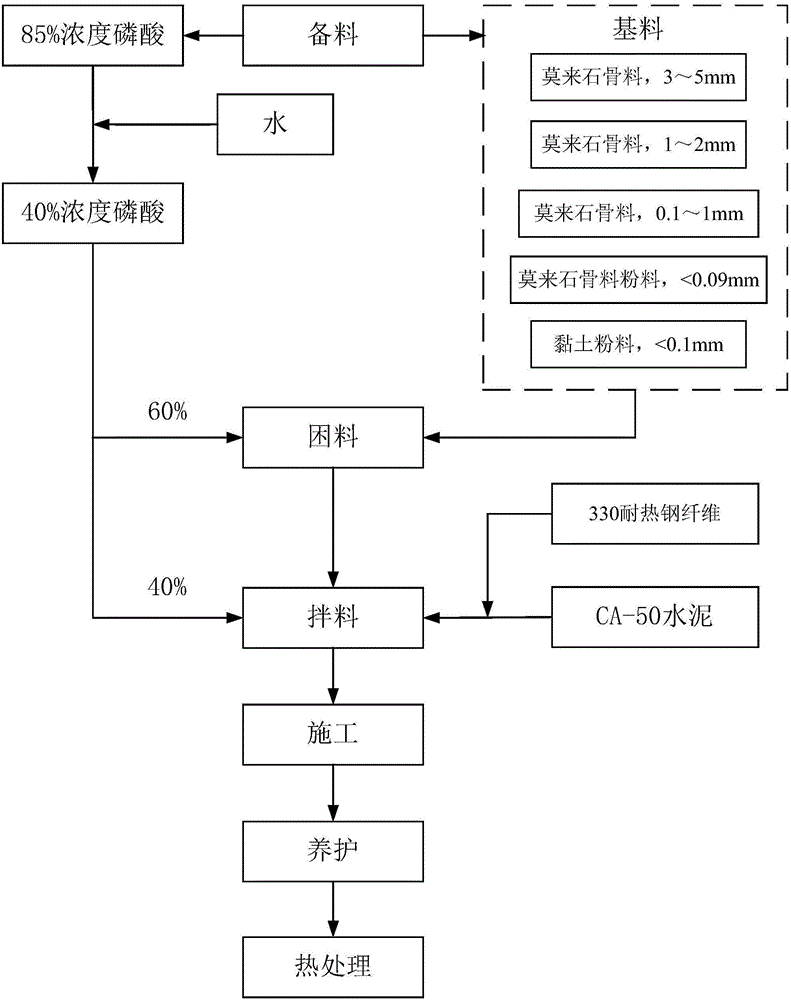

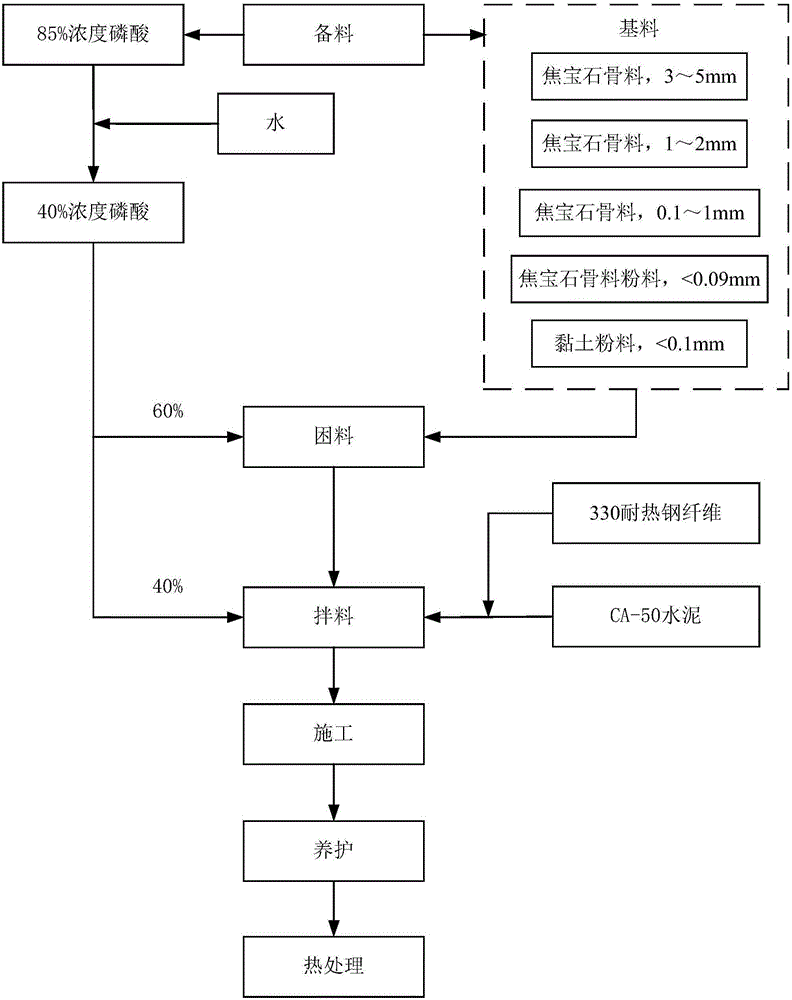

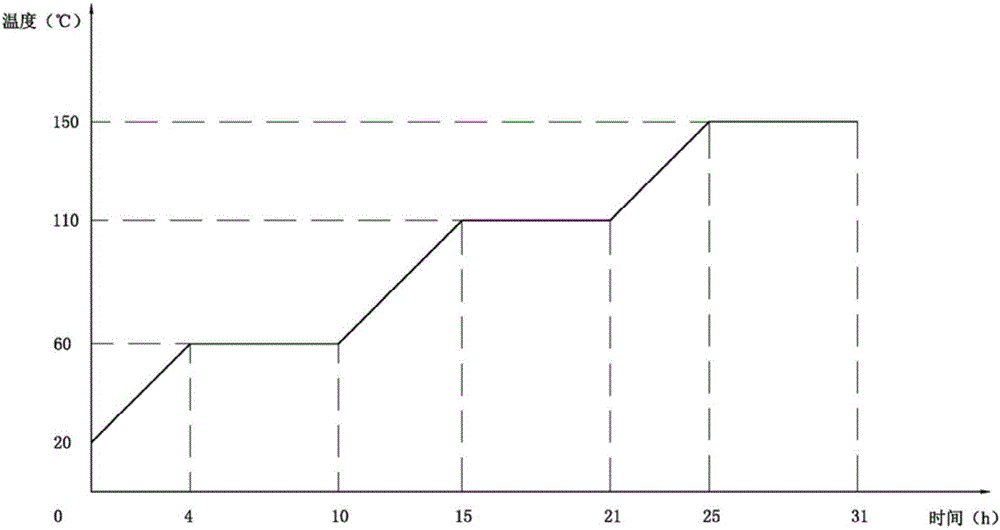

Mullite phosphate and chamotte phosphate refractory ramming material and preparation method thereof

InactiveCN105948765ASolve the problem of fire resistance and heat insulationImprove fire resistanceFiberPhosphate

A preparation method of a phosphate mullite refractory ramming material comprises the following steps: preparing a base material: preparing a base material: according to the mass percentage, weighing 30-40% of a mullite aggregate with the particle size of 3-5 mm, 15-25% of a mullite aggregate with the particle size of 1-2 mm, 5-10% of a mullite aggregate powder with the particle size of 0.1-1 mm, 15-25% of a mullite powder with the particle size of less than 0.09 mm and 5-15% of a clay powder with the particle size of less than 0.1 mm; then stirring evenly the weighed raw materials; and preparing a phosphoric acid solution with the amount 5-15% of the total amount of the base material; preparing a wet material: adding 40-70% of the total amount of the phosphate solution into the base material, and continuing to stir; ageing the material: sealing the prepared wet material in a sealed container, and allowing air not to be left in the container; and blending the material: again adding 1-5% of CA-50 cement into the wet material, stirring evenly, then adding the remaining phosphoric acid solution, at the same time, sprinkling steel fibers with the amount 1-5% of the total amount of the base material, and stirring for 3-5 minutes.

Owner:JIANGXI RONGEN ENERGY TECH CO LTD

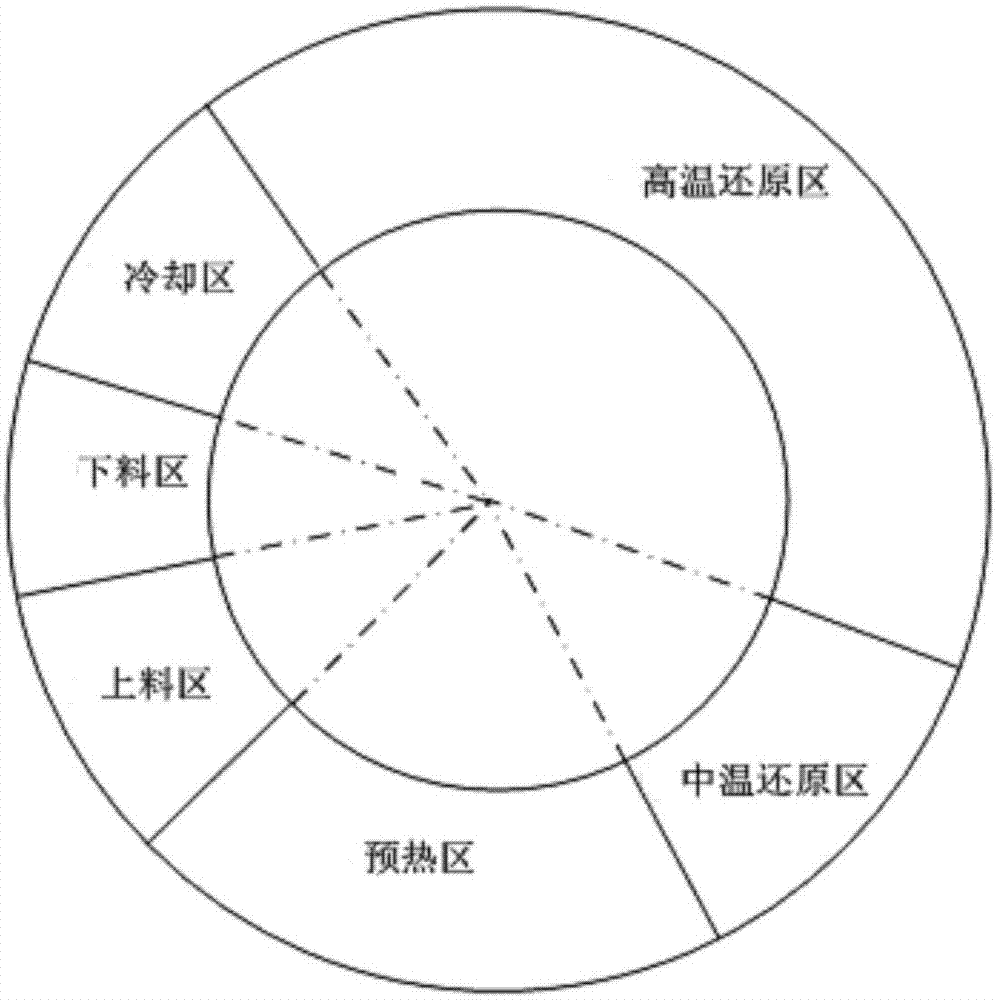

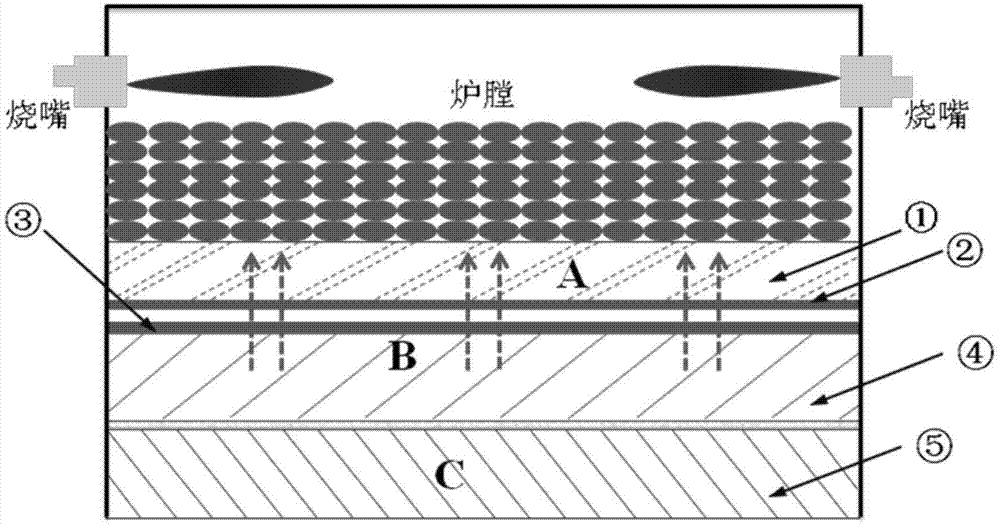

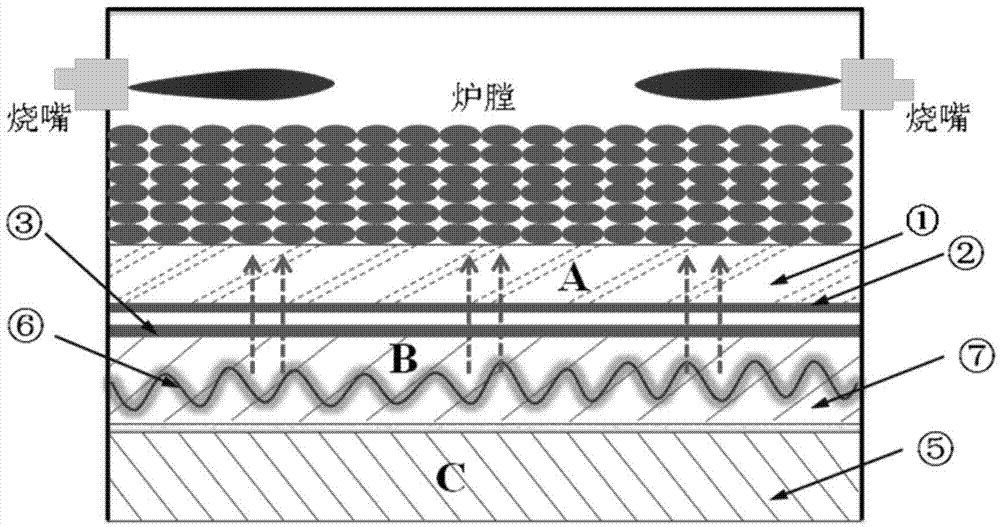

Furnace bottom structure capable of realizing reduction of deep bed for rotary hearth furnace

The invention provides a furnace bottom structure for a rotary hearth furnace. The furnace bottom structure comprises a heat preserving layer, a heating layer and an anti-slag-corrosion heat transfer layer in sequence from bottom to top, wherein the heat preserving layer and the heating layer are fixed; the anti-slag-corrosion heat transfer layer can rotate relative to the heat preserving layer and the heating layer; resistance wires are buried in the heating layer; the inside of the rotary hearth furnace is partitioned into a plurality of regions; the quantity of the resistance wires in the heating layer correspondsing to each region is set in advance; a layer of second steel plate is fixed on the upper part of the heating layer; a layer of first steel plate is fixed on the lower part of the anti-slag-corrosion heat transfer layer; a certain gap is kept between the first steel plate and the second steel plate, so that radiation heat transfer can be realized, and friction is prevented. By adopting the furnace bottom structure for the rotary hearth furnace provided by the invention, effective heat transfer and rapid reduction of a deep bed in a reduction process can be realized.

Owner:SHENWU TECH GRP CO LTD

Binding agent powder for magnesian castable and preparation method thereof

The invention relates to binding agent powder for a magnesian castable and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: firstly, uniformly stirring 30-65wt% of silicon oxide fine powder and 35-70wt% of magnesian fine powder as raw materials, putting the powder in a ball-milling tank, and then adding 2-10wt% of an additive and 150-300wt% of water based on the weight of the raw materials into the ball-milling tank to be ball-milled for 1-3h to prepare pulp; conserving the pulp for 12-84h at 25-80 DEG C, and grinding the pulp till the grain size is smaller than 75mu m to prepare pre-prepared powder; and keeping the temperature of the pre-prepared powder at 150-650 DEG C for 2-8h to obtain the binding agent powder for magnesian castable. The application result of the binding agent powder for magnesian castable prepared by the preparation method shows that the strength of the magnesian castable is improved remarkably, and the burst resistance and slag resistance of the magnesian castable are enhanced remarkably.

Owner:WUHAN UNIV OF SCI & TECH

Spinel castables for coal water slurry gasification furnace and using method thereof

The invention relates to spinel castables for a coal water slurry gasification furnace and a using method thereof. The spinel castables comprise, by weight, 55-72% of magnesium aluminate spinel particles, 0-15% of tabular corundum particles, 4-10% of magnesium aluminate spinel fine powder, 2-5% of magnesium aluminate spinel micro powder, 4-6% of alpha-Al2O3 micro powder, 0.5-1.5% of Y2O3 micro powder, 0.5-1.5% of CeO2 micro powder, 0.2-1% of TiO2 micro powder, 1-7% of pure calcium aluminate cement, 2-12% of CMA cement, 0.03-0.1% anti-explosion fibers, and 0.1-0.3% of FS series water reducer. The using method comprises the steps of pouring water which accounts for 4.8-6.2%, by weight, of the castables in the castables, stirring evenly, and carrying out forming, conservation, demoulding and baking. Products prepared through the spinel castables for the coal water slurry gasification furnace have the advantages of being environmentally friendly, good in coal slag permeation resistance and anti-corrosion performance, capable of saving energy, high in strength and good in thermal shock stability, and thus demands of the production of the coal water slurry gasification furnace are met.

Owner:湖南立达高新材料有限公司

Magnesium-silicon hydrate binding agent based on salt lake brine and preparation method of magnesium-silicon hydrate binding agent

InactiveCN108358213ANo emissionsEfficient use ofMagnesium silicatesAlkali metal chloridesEnvironmental resistanceFiltration

The invention relates to a magnesium-silicon hydrate binding agent based on salt lake brine and a preparation method of the magnesium-silicon hydrate binding agent. The binding agent adopts a technical scheme as follows: firstly, a silicate solution in a molar concentration ratio of magnesium ion to silicon ion being (0.6-2.0):1 is added to the salt lake brine and stirred uniformly, and a mixed solution is obtained; then, the mixed solution is left to stand for 10-91 hours at 25-90 DEG C, washed and subjected to suction filtration, and a solid product and a filtrate are obtained respectively;next, the solid product is dried at 45-120 DEG C and ground, and the magnesium-silicon hydrate binding agent based on the salt lake brine is prepared. The filtrate is evaporated and crystallized, andone or two by-products of potassium chloride, sodium chloride and lithium carbonate is or are obtained. The method has the characteristics of being simple in process, high in yield, safe, environmentally friendly and short in period; the prepared magnesium-silicon hydrate binding agent based on the salt lake brine has high purity, excellent thermal stability and good use effect, and can be widelyused in the fields of magnesium refractory castables, environment-friendly concrete building materials and the like.

Owner:WUHAN UNIV OF SCI & TECH

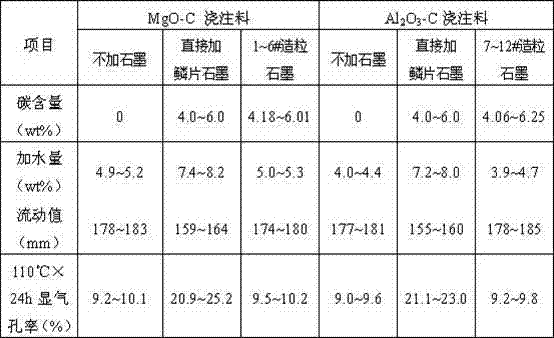

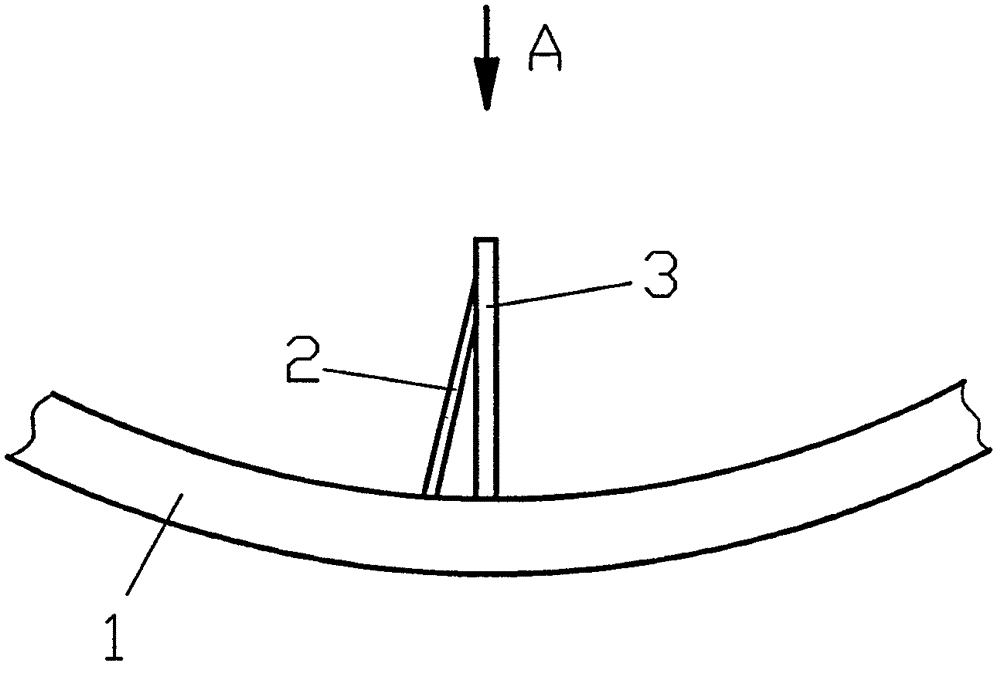

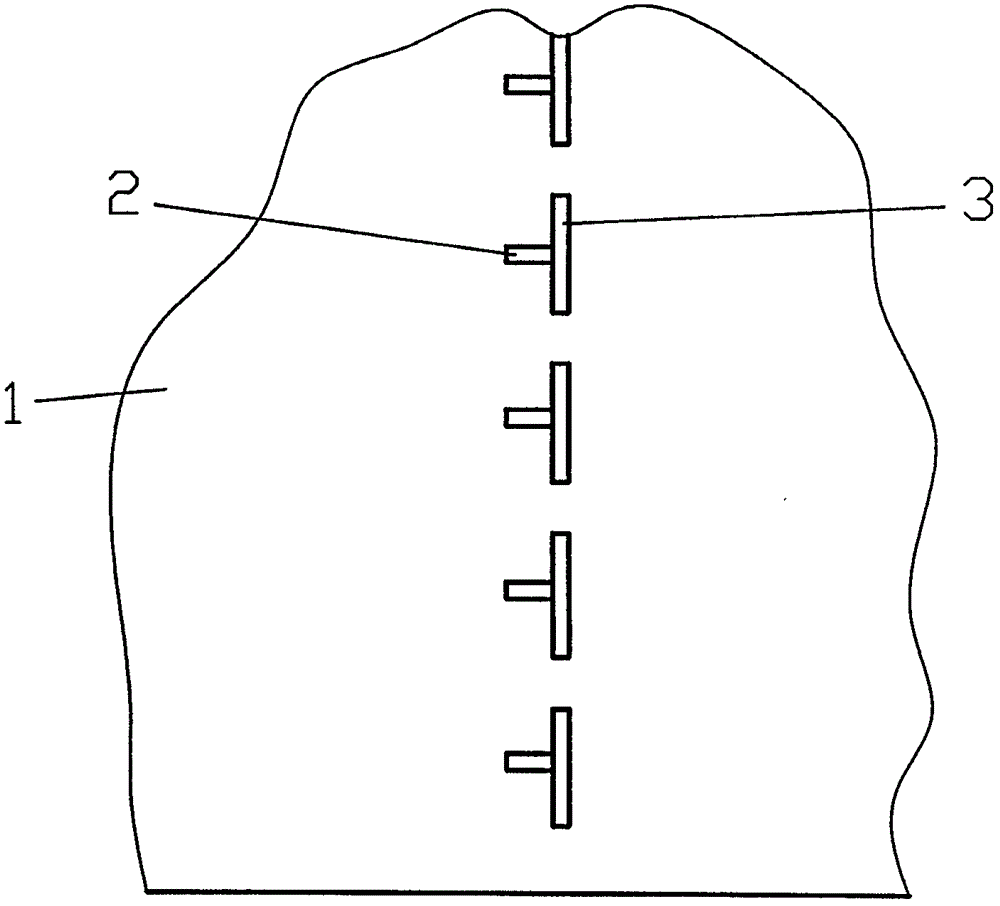

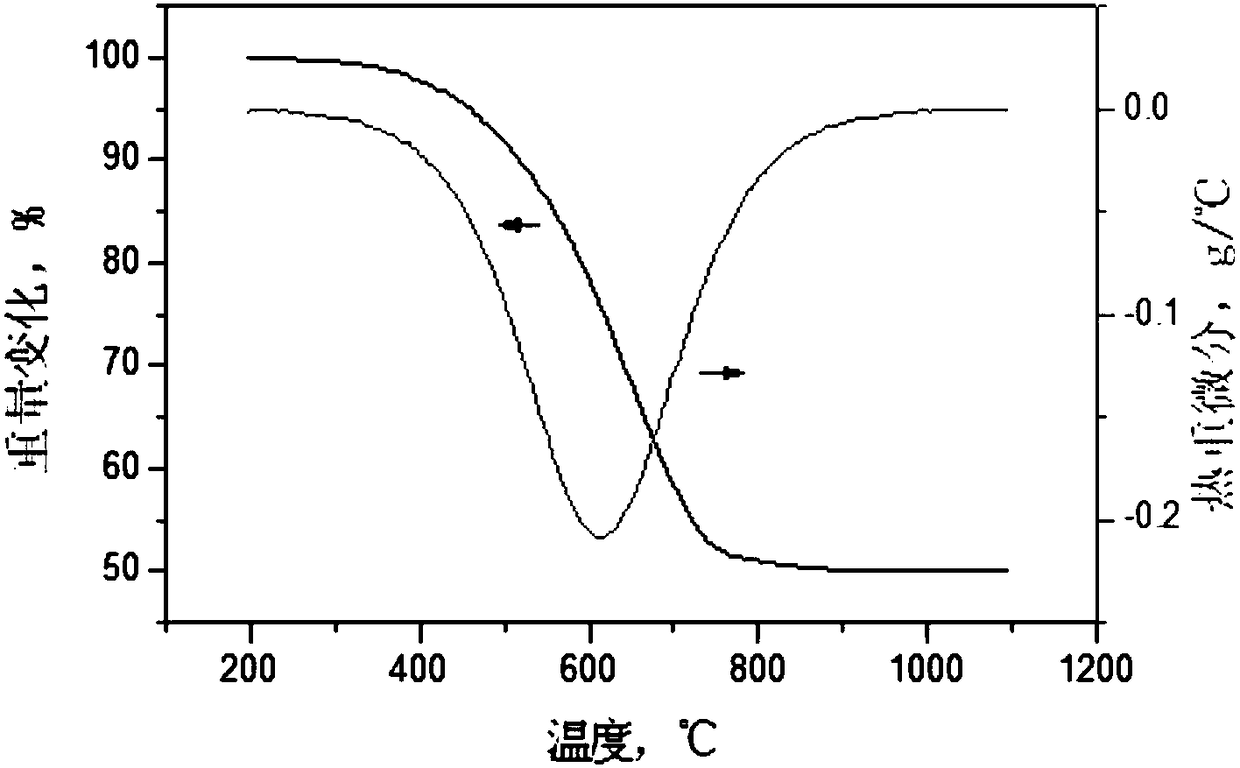

Preparation method of MgO-C castable

The invention relates to a preparation method of a MgO-C castable, comprising the following steps of: using granulation flake graphite as a carbon source, adding an appropriate additive, uniformly dispersing graphite in a castable, and unconspicuously increasing the amount of water for stirring the castable to finally obtain the MgO-C castable with high carbon content (3.0-7.3 wt%), high strength, uniform and compact structure and excellent slag resistance. The raw materials used contain: by weight, a fused magnesia aggregate consisting of 14-22 parts of an aggregate 5-3mm, 10-20 parts of an aggregate 3-1mm and 12-16 parts of an aggregate 1-0.088mm; 29-33 parts of a fused magnesia fine powder with its particle size being less than 0.088mm; 10-18 parts of granulation graphite; 2-5 parts ofsilicon ash; and an additional additive consisting of 0.7-2.0 parts of an antioxidant, 0.1-0.7 part of a wetting agent and 0.1-0.3 part of a dispersant.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com