Magnesium spinel brick, production method of magnesium spinel brick, and method for preparing RH furnace circulation pipe by using magnesium spinel brick

A technology of magnesia spinel and brick products, which is applied in the field of magnesia spinel circulating pipes for RH furnaces and its manufacture, can solve the problems of high melting loss rate, unsuitable life of dipping pipes, and affecting the longevity of RH furnaces, etc. Achieve the effects of low production energy consumption, good thermal strength and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

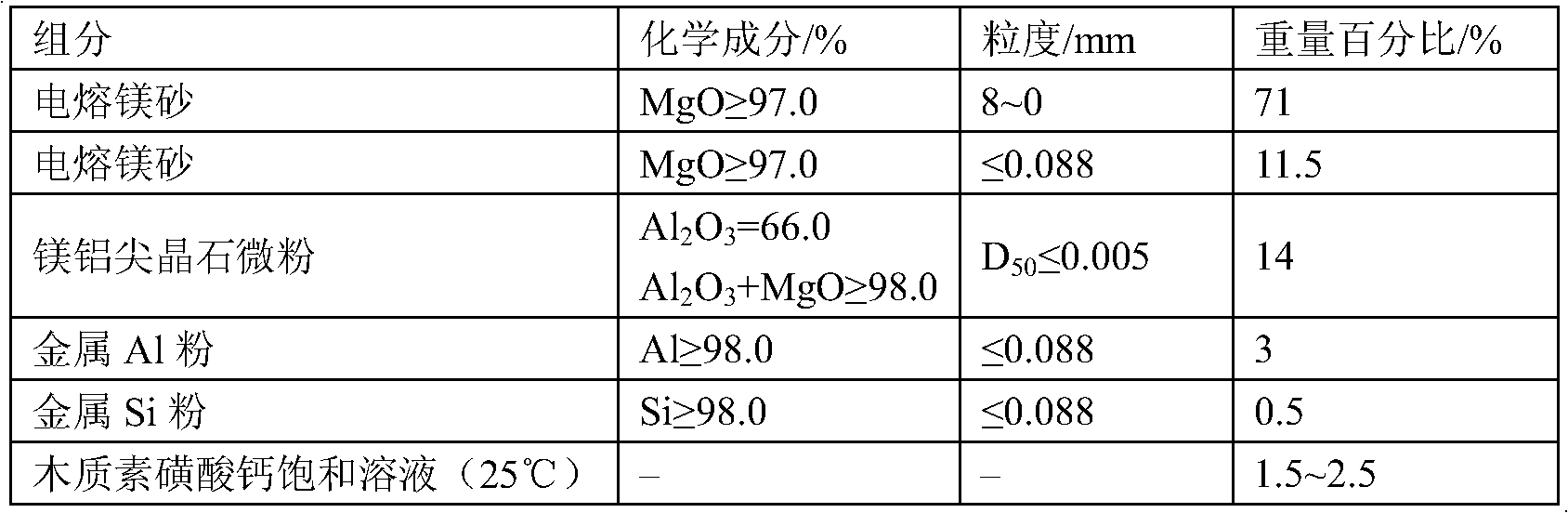

[0028] A kind of magnesia spinel brick, the preparation raw material of this brick is made up of the raw material component of following table:

[0029]

[0030] Accurately weigh magnesia, magnesia-aluminum spinel powder, metal Al powder, metal Si powder and saturated calcium lignosulfonate solution (25°C) according to the ratio in the above table and mix them evenly in a wet mill , machine-pressed, and baked at 180°C-250°C to prepare magnesia spinel bricks, then polish the magnesia spinel bricks, and use magnesia-aluminum fireclay to bond them into a ring, and use iron hoops on the outside prison.

[0031] The magnesium spinel circulation tube produced by this formula is used in the RH furnace of a steel factory. The original working layer thickness is 180mm. After smelting 60 furnaces, the residual thickness is 110mm-120mm, which is synchronized with the life of the dipping tube; while the magnesium The residual thickness of the chromium circulation tube after reaching t...

Embodiment 2

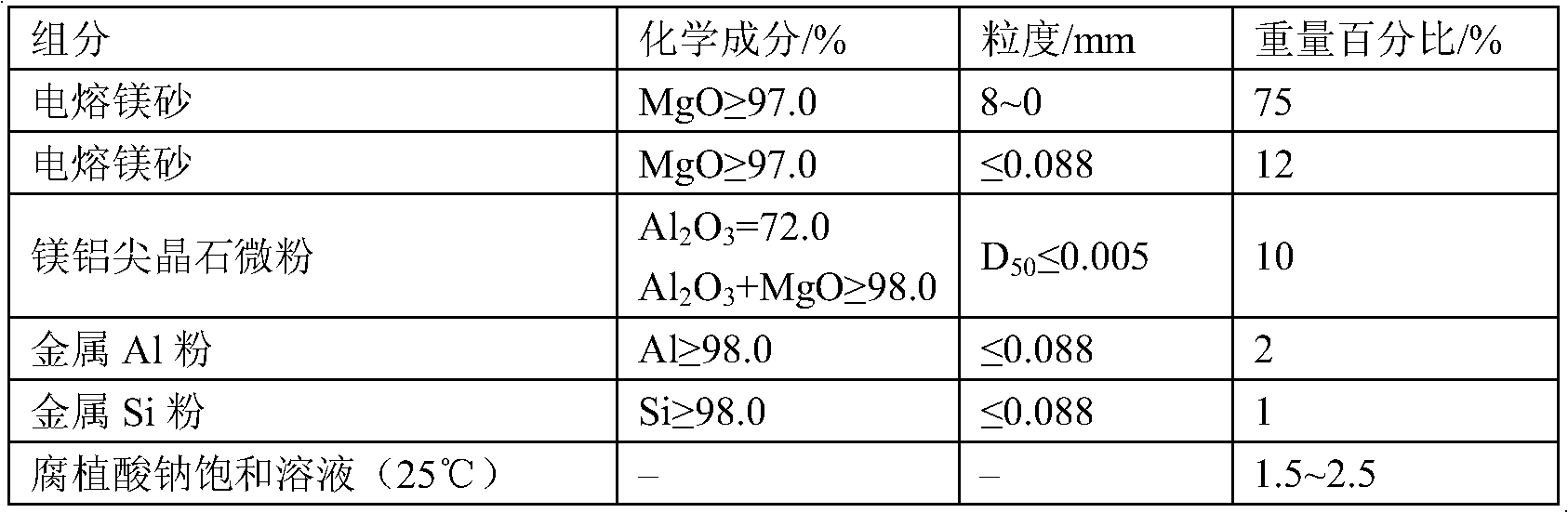

[0033] Magnesium spinel circulation tube for RH furnace, the weight percentage of each component is:

[0034]

[0035] The magnesia, magnesium aluminum spinel micropowder, metal Al powder, metal Si powder and sodium humate saturated solution (25°C) with different particle sizes are accurately weighed according to the proportion, mixed and rolled evenly in a wet mill, and machine pressed into shape. And baked at 180°C-250°C to prepare magnesia spinel bricks, then polish the magnesia spinel bricks, and use magnesia-aluminum fireclay to bond into a ring, and the outside is fastened with iron hoops.

[0036] The magnesium spinel circulation tube produced by this formula is used in the RH furnace of a steel factory. The original working layer thickness is 150mm. The residual thickness of the chromium circulation tube after reaching the same service life is 90mm-100mm, while the corundum spinel circulation tube can only be used in 90 furnaces, and the residual thickness of the of...

Embodiment 3

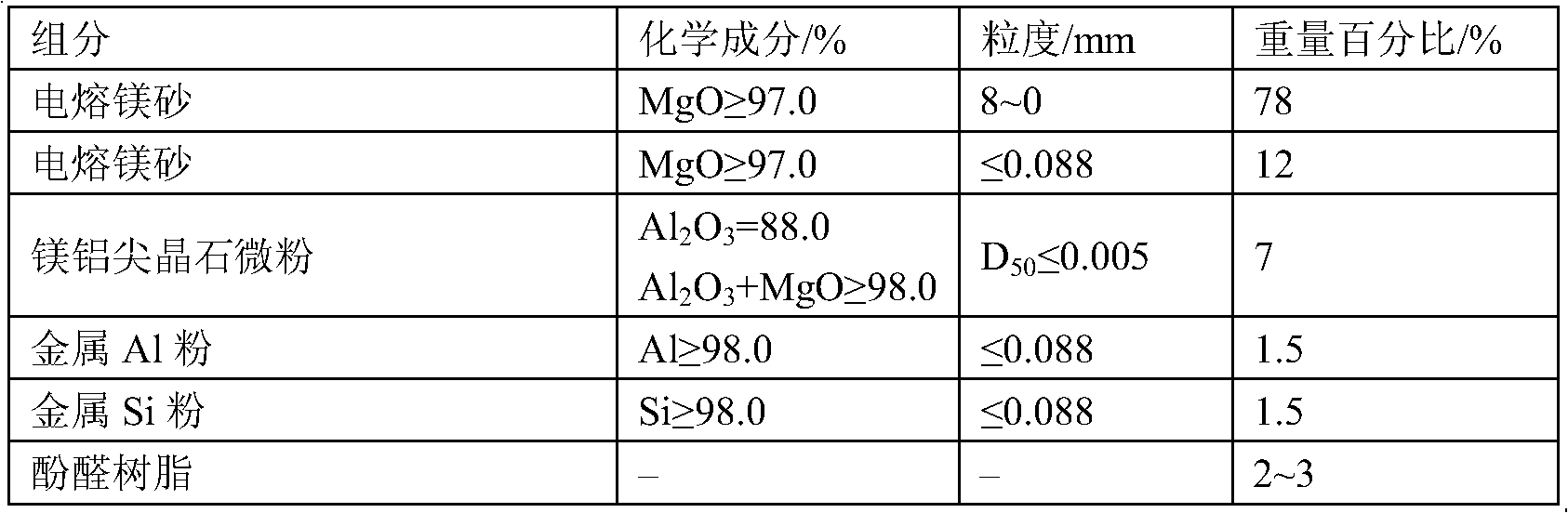

[0038] Magnesium spinel circulation tube for RH furnace, the weight percentage of each component is:

[0039]

[0040] The magnesia, magnesia aluminum spinel powder, metal Al powder, metal Si powder and phenolic resin with different particle sizes are accurately weighed according to the ratio, and then mixed and rolled evenly in a wet mill, machine pressed and formed, and subjected to 180°C-250°C Bake to prepare magnesia spinel bricks, then polish the magnesia spinel bricks, and use magnesia-aluminum fireclay to bond them into a ring, and use iron hoops to fasten the outside.

[0041] The magnesia spinel circulation tube produced by this formula is used in the RH furnace of a steel factory. The original working layer thickness is 200mm. After smelting 80 furnaces, the residual thickness is 110mm ~ 120mm, reaching the same service life as the magnesium chromium circulation tube. The residual thickness after the off-line is equivalent to the life of the dipping tube; the coru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com