Energy-saving rotary kiln and furnace lining fireproof brick building slurry

A technology of refractory brick masonry and refractory bricks, which is applied in the field of industrial kilns, can solve the problems of personal safety hazards, increase enterprise costs, and the impossibility of being on the same level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

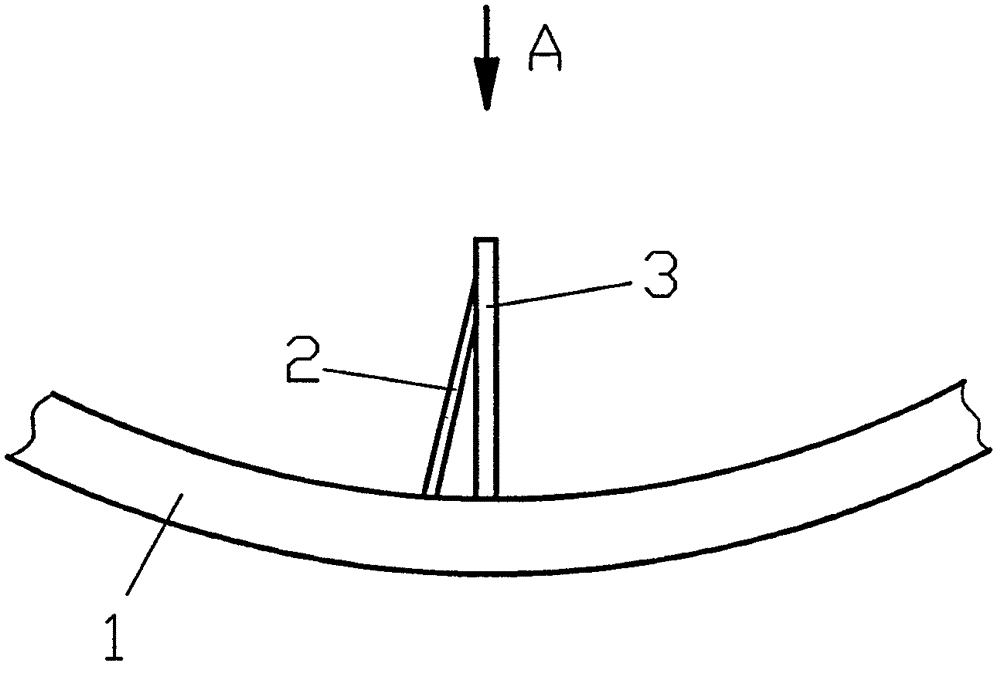

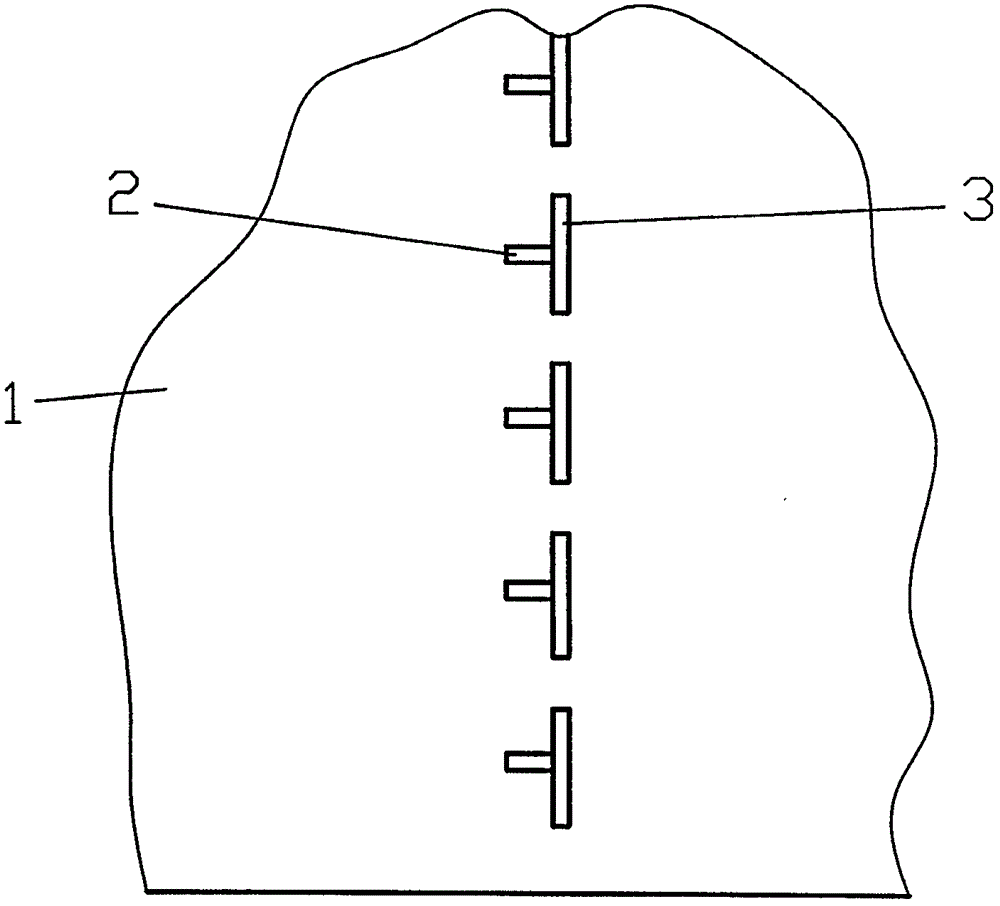

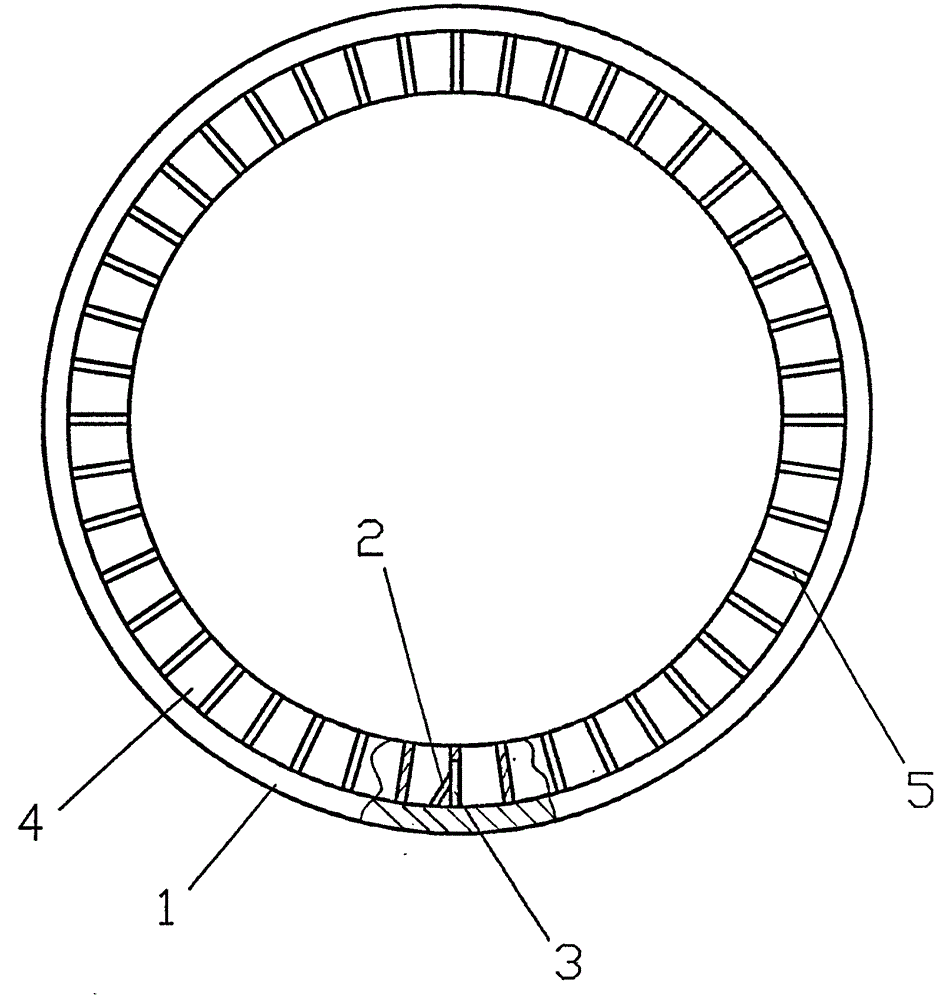

[0030] As shown in the figure, the energy-saving rotary kiln is composed of a cylindrical steel kiln shell 1, several high-temperature refractory brick steel plate molds 3, steel plate mold pillars 2, high-temperature refractory bricks 4, and refractory bricks during welding. Composed of mud 5; It is characterized in that: a high-temperature refractory brick steel plate form 3 that penetrates the overall structure is welded in the arc of the bottom of the steel body kiln shell 1, and one end of the high-temperature refractory brick steel plate form 3 is welded with a steel plate formwork pillar 2 , the other end of the steel plate formwork pillar 2 is welded inside the steel body kiln shell 1; the refractory brick masonry mud 5 is injected between the high temperature refractory bricks 4;

[0031] The height of the high-temperature refractory brick steel plate mold 3 is two-thirds of the height of the high-temperature refractory brick 4, the width of the high-temperature refrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com