Mullite phosphate and chamotte phosphate refractory ramming material and preparation method thereof

A ramming material and mullite technology, which is applied in the field of refractory ramming material preparation, can solve the problems affecting product quality, material deformation, softening, melting, interruption of material service period, etc. Simple process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

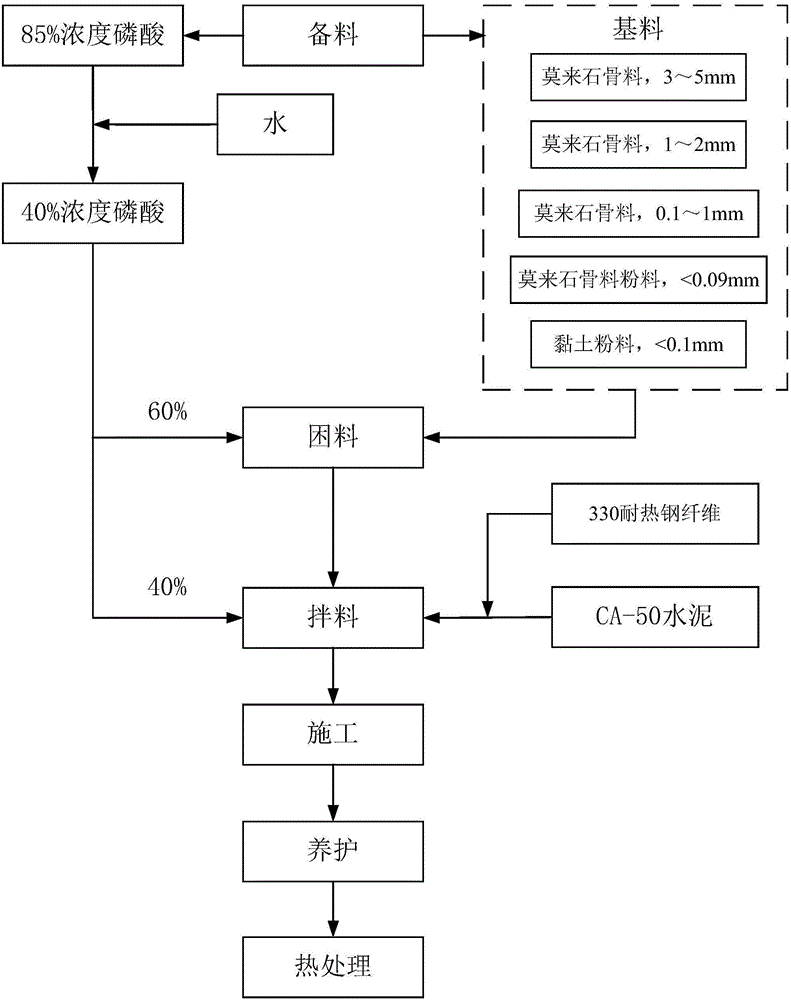

[0046] Embodiment 1: The present invention provides a kind of mullite phosphate refractory ramming material, its raw material percentage and the test parameter of finished product are shown in the following table 1 for details, it is used as burner and gas pipe liner in entrained bed pulverized coal gasification equipment, The outer lining of the lower outlet of the equipment body, which includes base material, steel fiber and bonding agent, such as figure 1 Shown, its preparation method steps are as follows:

[0047] At first, prepare base material 1000kg, the mass percentage content of the raw material component of described base material is as follows:

[0048]

[0049]

[0050] The steel fiber accounts for 1-5% of the total base material; the binder is a phosphoric acid solution with a concentration of 40%, and the binder accounts for 5-15% of the total base material;

[0051] Furthermore, weigh 380kg of mullite aggregate with a particle size of 3-5mm, 200kg of mull...

Embodiment 2

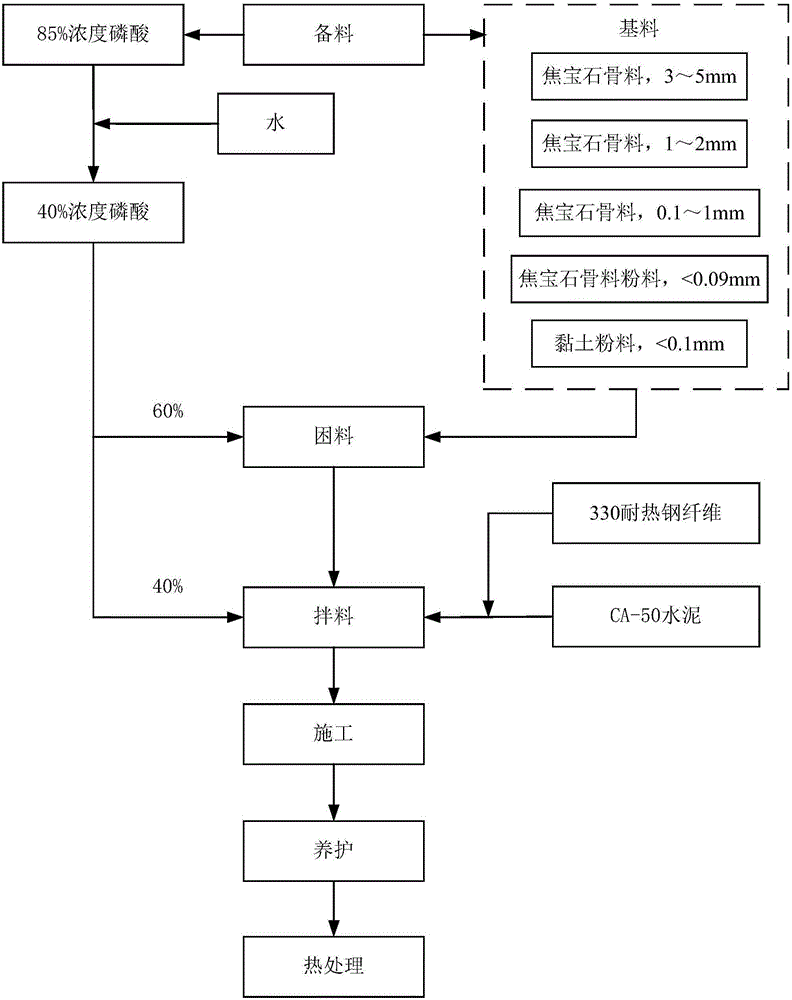

[0058] Embodiment 2: The present invention provides a kind of phosphoric acid coke gemstone refractory ramming material, its raw material percentage and the test parameter of finished product are shown in the following table 2 for details, it is used as burner and gas pipeline lining, equipment in entrained bed pulverized coal gasification equipment The outer lining of the lower outlet of the main body, which includes base material, steel fiber and bonding agent, such as figure 2 Shown, its preparation method steps are as follows:

[0059] At first, prepare base material 1000kg, the mass percentage content of the raw material component of described base material is as follows:

[0060]

[0061] The steel fiber accounts for 1-5% of the total base material; the binder is a phosphoric acid solution with a concentration of 40%, and the binder accounts for 5-15% of the total base material;

[0062] Furthermore, weigh 380 kg of burnt gemstone aggregates with a particle size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com