Aluminum dihydrogen phosphate-silicon carbide refractory ramming material and preparation method thereof

A technology of aluminum dihydrogen phosphate silicon carbide and ramming material, which is applied in the field of refractory ramming material preparation, and achieves the effect of simple production process, good refractoriness, and solving the problem of refractory and heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

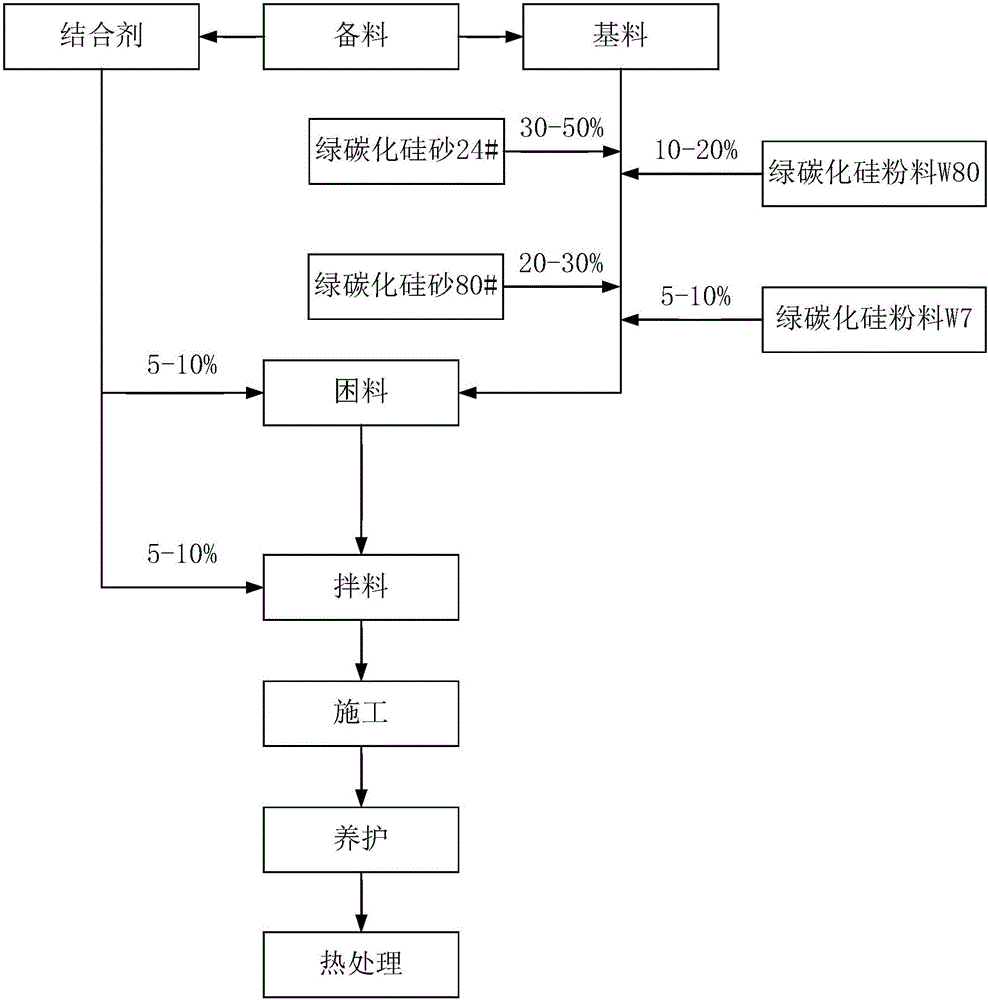

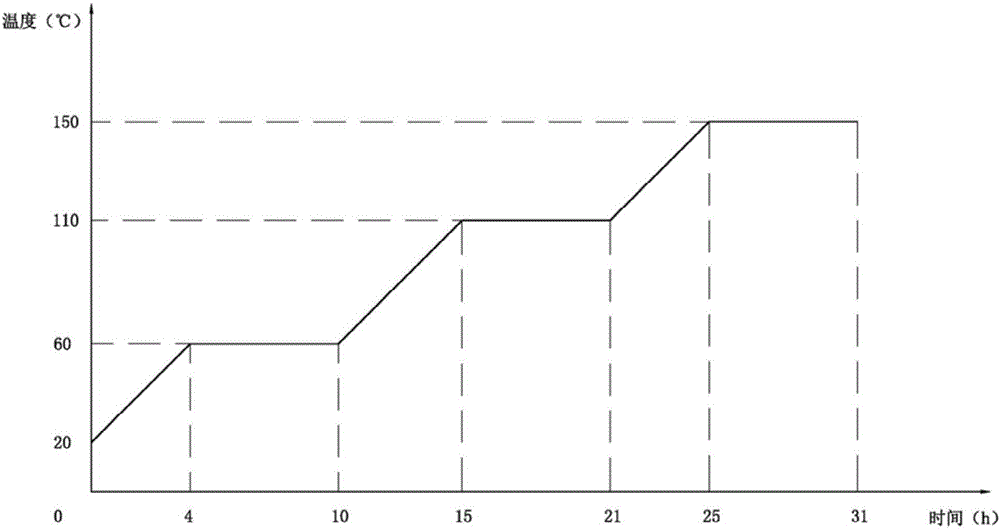

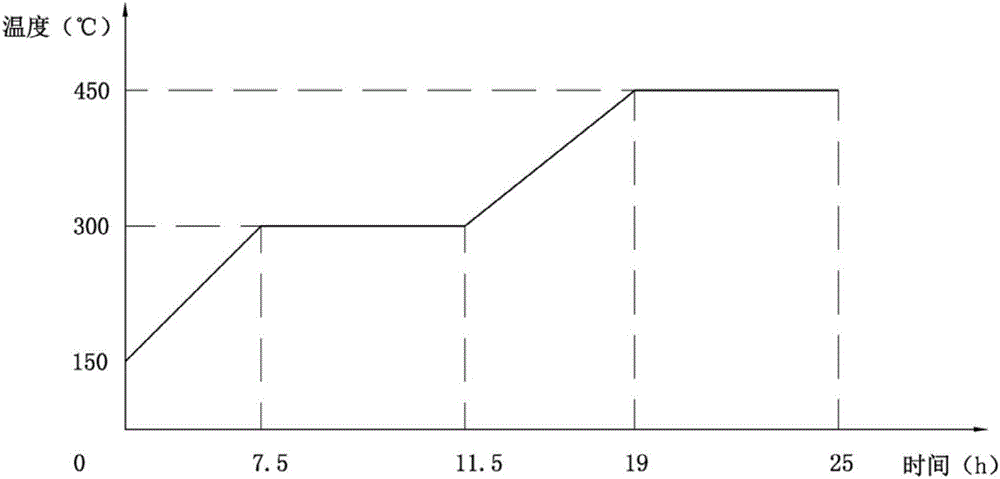

[0028] Below will combine each preferred embodiment and appended Figure 1-3 The refractory aluminum dihydrogen phosphate silicon carbide ramming material proposed by the present invention and its preparation method are described in more detail.

[0029] The present invention provides an aluminum dihydrogen phosphate silicon carbide refractory ramming material. The percentage of raw materials and the test parameters of the finished product are shown in Table 1 below. materials and binders such as figure 1 Shown, its preparation method step is as follows: First, prepare base material 1000kg, the mass percentage of the raw material component of described base material is:

[0030]

[0031] Then, weigh 400kg of green silicon carbide sand of 24# granularity, 300kg of green silicon carbide sand of 80# granularity, 200kg of green silicon carbide powder of W80 granularity, 100kg of green silicon carbide powder of W7 granularity; Put it into a horizontal mortar mixer, mechanicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com