Patents

Literature

90results about How to "Increase the amount of coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light curing transparent priming paint and preparation method and use method thereof

ActiveCN102952455AReduce lossImprove product qualityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolyester

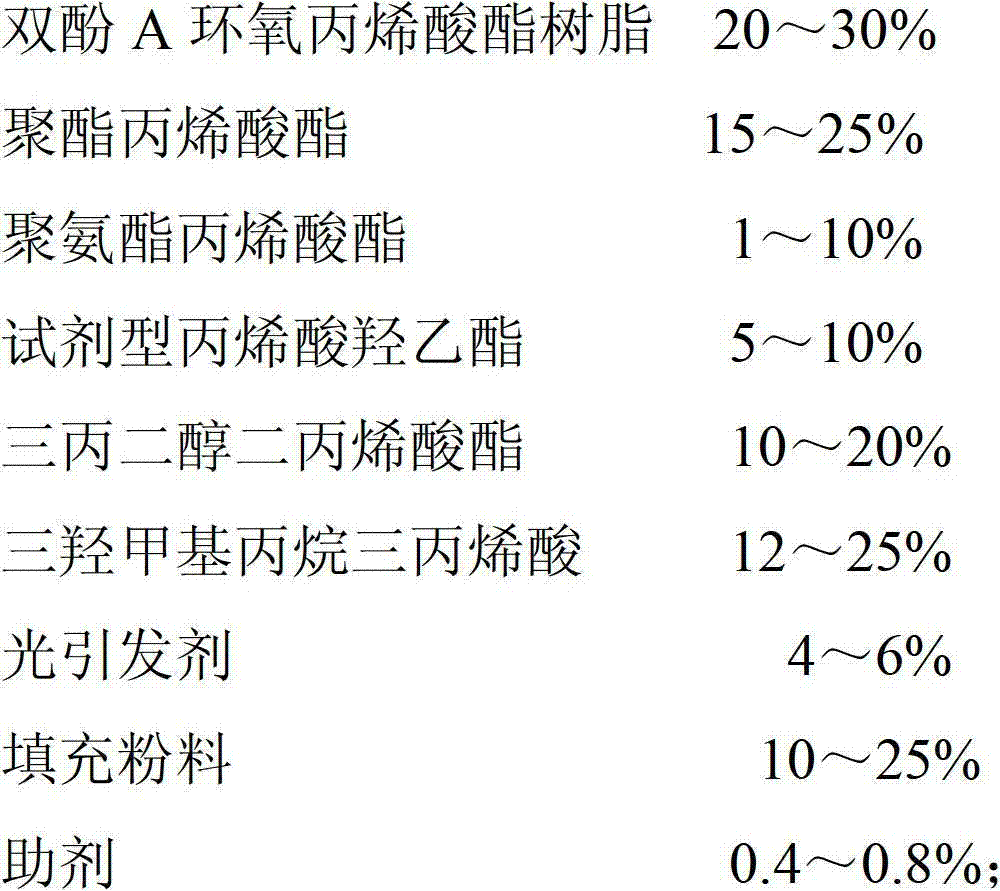

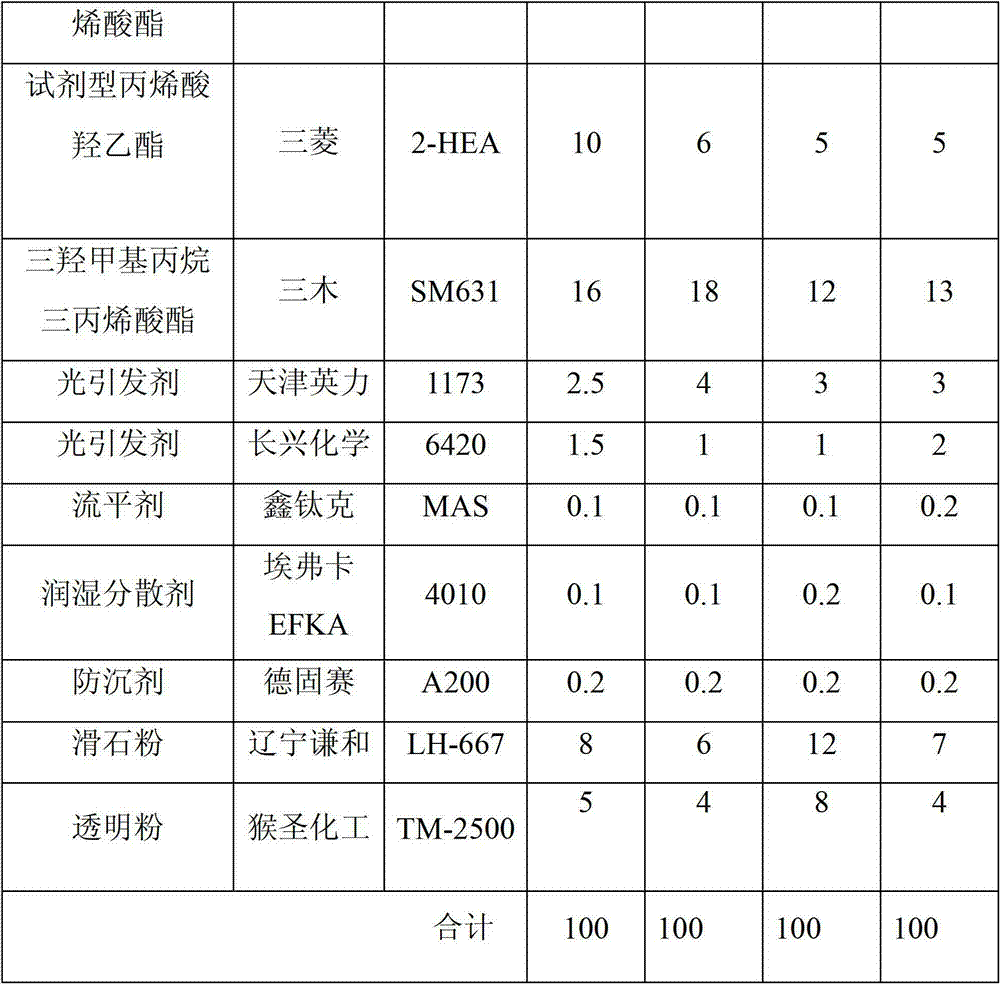

The invention discloses an ultraviolet light curing transparent priming paint and a preparation method and a use method thereof. The ultraviolet light curing transparent priming paint comprises the following components in percentage by weight: 20-30% of bisphenol A epoxy acrylate resin, 15-25% of polyester acrylate, 1-10% of urethane acrylate, 5-10% of reagent type hydroxyethyl acrylate, 10-20% of tripropylene glycol diacrylate, 12-25% of trimethylolpropane triacrylate, 4-6% of photoinitiator, 10-25% of filling powder and 0.4-0.8% of promotor. The ultraviolet light curing transparent priming paint is suitable for laser roller construction, has good grittiness and transparency, has the characteristics that sanding is not needed for semi-curing recoating between film layers and the like, and has thick coating performance and the performance that the surface is similar to a mirror surface, and compared with conventional roller coating, the coating weight is greatly increased, roller coating processes are saved, the priming paint is sanded by a sanding machine without large pressure and with a small number of sanded films, a workpiece has no bright spots, the fullness of a product is guaranteed, the product quality is improved, the loss of the machine is smallreduced, and the use amount of sanding belts is greatly reduced.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

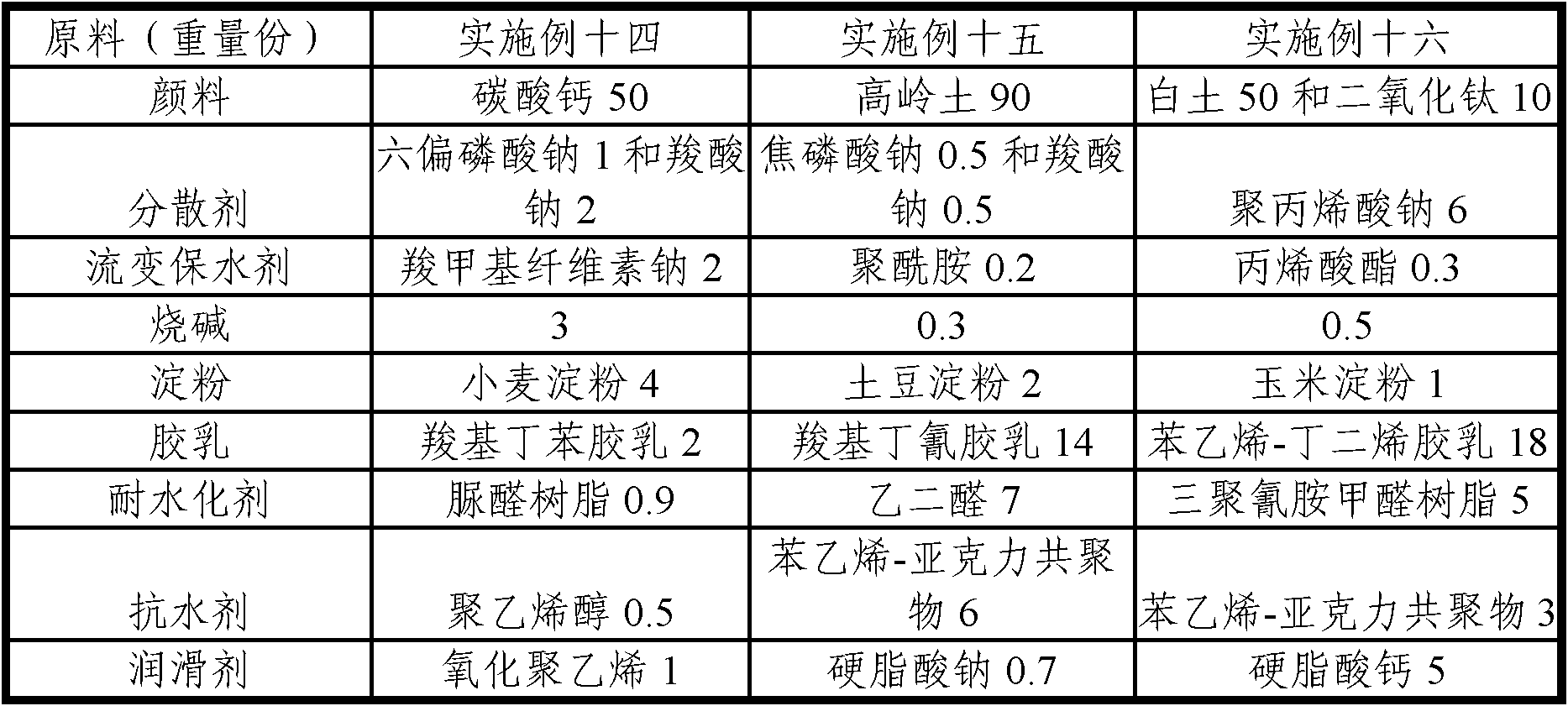

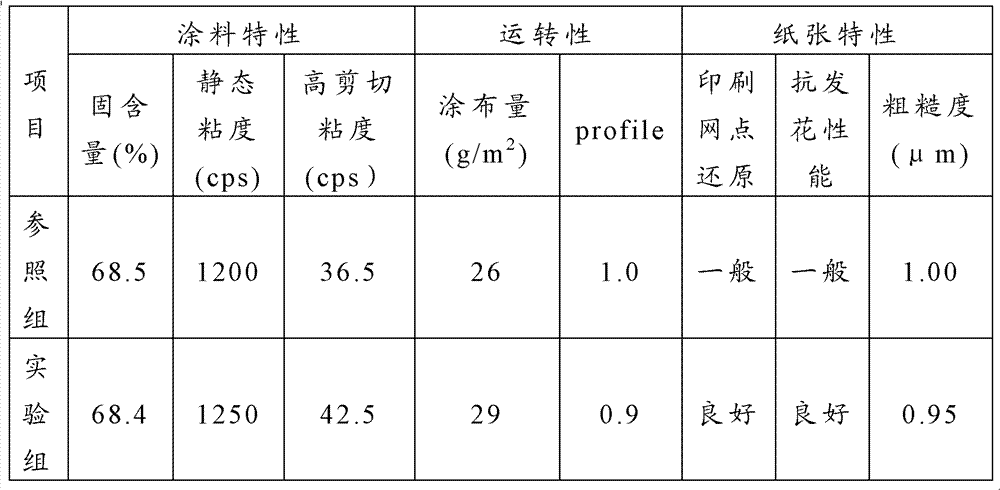

Copperplate board coating

ActiveCN102321997AHigh solid contentLose weightCoatings with pigmentsPaper/cardboardPapermakingSlurry

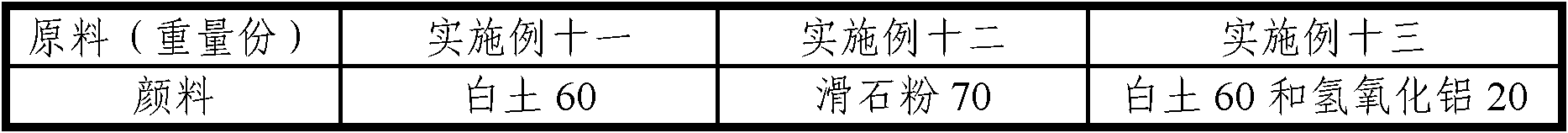

The present invention provides a new copperplate board coating. The copperplate board coating comprises the following raw materials, by weight, 5-100 parts of a pigment, 0-20 parts of starch, 0.2-5 parts of caustic soda, 0.05-3 parts of a rheology and water retaining agent, 1-30 parts of latex, 0.1-10 parts of a hydration resistant agent, 0.1-10 parts of a water repellent agent, 0.1-10 parts of alubricant and 0.1 to 8 parts of a dispersing agent. With the formula of the high solid content coating provided by the present invention, the gram weight of the base paper can be reduced in the context of production of the copper board with the same specification, such that the ratio of the base paper in the copper board is reduced, the slurry cost is decreased, the requirement of wood is reduced, the economic benefits and the social benefits are significantly improved; due to the reduction of the gram weight of the base paper, the speed can be improved during the base paper papermaking, the machine efficiency and the productivity can be improved; with the improvement of the coating amount, the paper covering and the smoothness are improved, such that the final product has a better printing effect.

Owner:HAINAN JINHAI PULP & PAPER

High-turning-speed multi-layer coating paint

InactiveCN104313939AFulfill development needsSatisfy the rheologyCoatings with pigmentsCoatingsKaolin clayPaper sheet

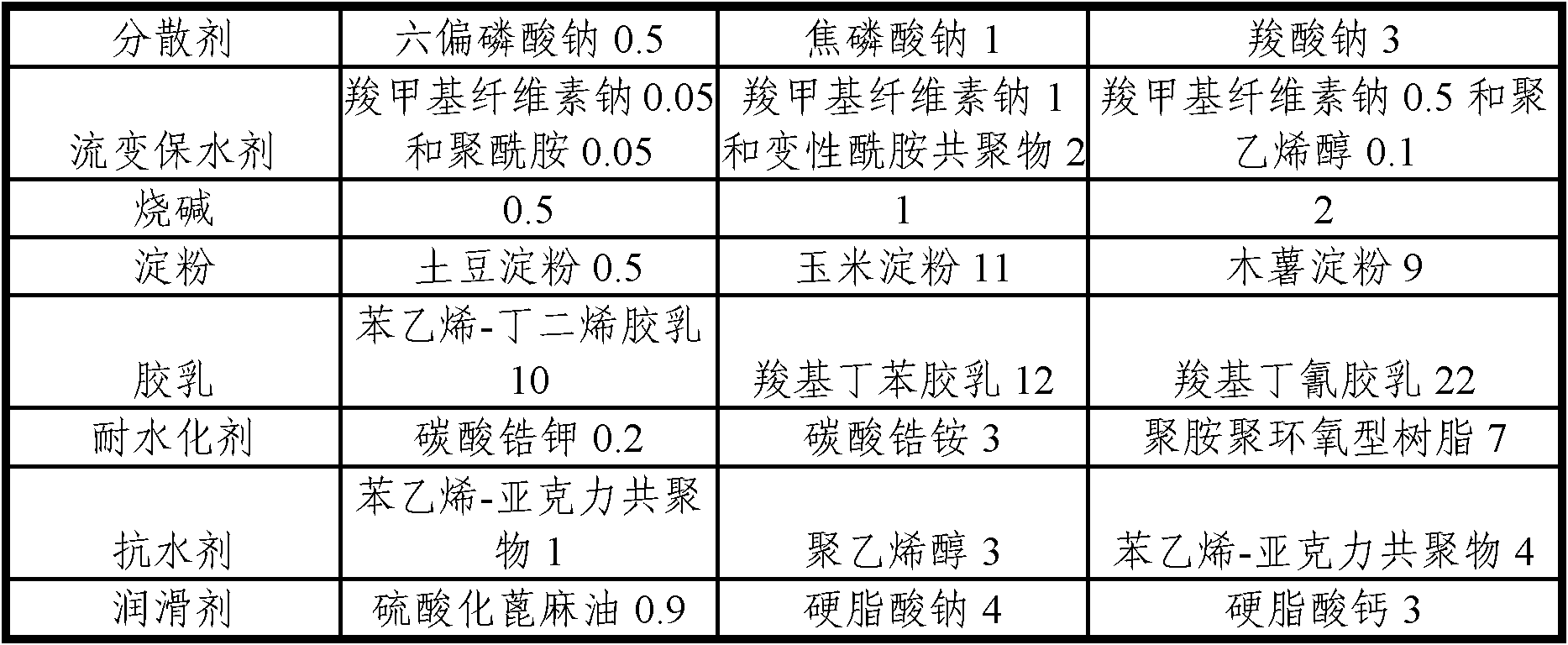

The invention discloses a high-turning-speed multi-layer coating paint. The paint formula mainly comprises precoating paint, middle-coating paint and surface-coating paint. The paint formula comprises the compositions in parts by weight: 70-100 parts of heavy calcium carbonate, 0-30 parts of kaolin, 5-12 parts of latex, 5-8 parts of coating starch, and 0.1-0.5 part of a thickening agent. Paper is subjected to machine coating by employing a coating manner of two layers of precoating, one layer of middle coating and one layer of surface coating or a coating manner of one layer of precoating, one layer of middle coating and one layer of surface coating. Bottom coating employs metered glue-applying coating, and the coating amount is relatively low; and the middle / surface coating employs scraper coating, and the coating amount is relatively high. The formula helps to effectively reduce resistance of paint during coating, and improve the smoothness and the glossiness of coated paper. The paint is applicable to machine coating, is capable of effectively improving coating amount, improving surface properties of finished paper, enabling the cost per ton of paper to be substantial reduced and improve the competitiveness of the product.

Owner:HAINAN JINHAI PULP & PAPER

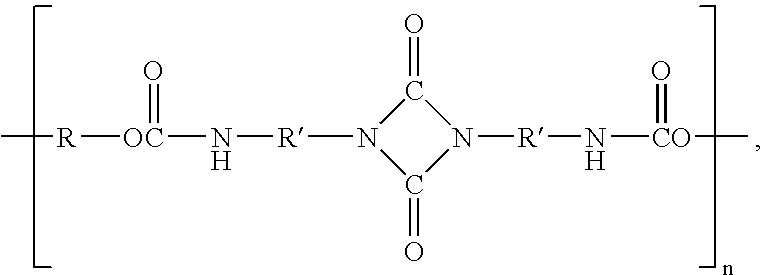

Method for making an aqueous coating with a solid crosslinking agent

InactiveUS20050113552A1Reduces regulated emissionIncrease the amount of coatingPolyurea/polyurethane coatingsPaints for electrolytic applicationsWater dispersibleHydrogen

An aqueous composition includes in dispersion an active hydrogen-functional resin and a uretdione compound. The uretdione compound is a crosslinker for the active hydrogen-functional resin. The uretdione compound does not release volatile by-products during the curing reaction, which reduces regulated emissions and increases the amount of coating solids weight converted to cured coating on the substrate. The aqueous dispersion coating may be made by combining a solid uretdione compound with a molten, water-dispersible resin, salting the water-dispersible resin if necessary, and dispersing the resin mixture in water. The molten, water-dispersible resin may have functionality reactive with the uretdione compound, or the coating composition may contain a further water-dispersible resin having functionality reactive with the uretdione compound. The coating composition of the invention is applied to a substrate and then cured to produce a cured coating layer on the substrate. In a particular embodiment, the coating composition of the invention is electrodepositable and is coated onto the substrate by electrodeposition.

Owner:BASF CORP

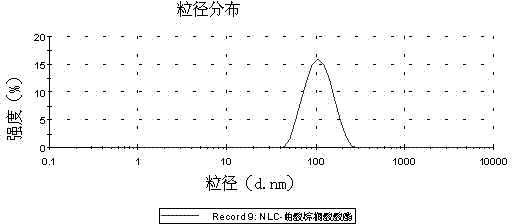

Nanometer solid lipid carrier covering kojic acid dipalmitate and preparing method thereof

A nanometer solid lipid carrier covering kojic acid dipalmitate is disclosed. The nanometer solid lipid carrier comprises 1-25% by weight of the kojic acid dipalmitate, 0.1-5% by weight of phospholipid, 2-15% by weight of solid lipid, 3-20% by weight of liquid lipid, 3-20% by weight of a solid emulsifying agent, 2-20% by weight of a polyalcohol additive and 0.01-0.8% by weight of a preservative, with the balance being deionized water. A preparing method of the nanometer solid lipid carrier is also provided. The preparing method includes: melting an oil phase comprising the kojic acid dipalmitate, the phospholipid, the solid lipid, the liquid lipid and the solid emulsifying agent at 75-95 DEG C and uniformly dispersing to obtain an oil phase; heating a water phase comprising the deionized water and the polyalcohol additive to 75-95 DEG C; stirring the water phase and adding the oil phase; performing high-pressure homogenization after uniform mixing; and stirring and cooling to form the nanometer solid lipid carrier. The nanometer solid lipid carrier and the preparing method promote permeation of the kojic acid dipalmitate on skin, increase the utilization rate, and enhance the whitening effect.

Owner:SHANGHAI INST OF TECH

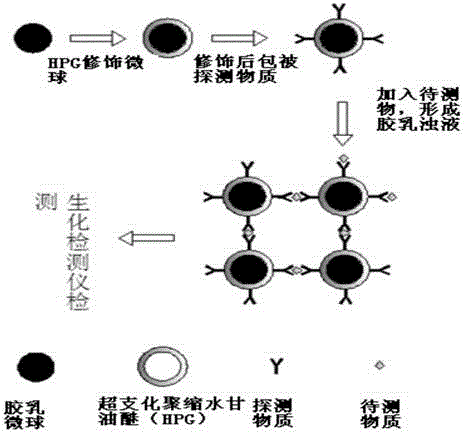

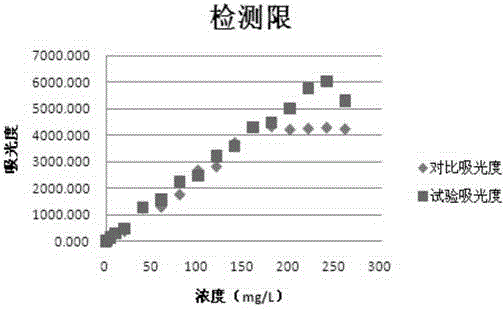

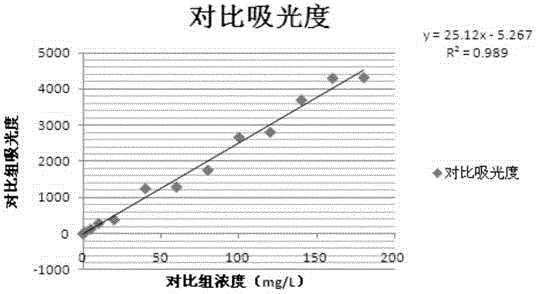

Hyperbranched polyglycerol modified latex microsphere enhanced immunoturbidimetry and application thereof

The invention discloses hyperbranched polyglycerol modified latex microsphere enhanced immunoturbidimetry and an application thereof. A latex microsphere material which is hydrophilic on surface and is rich in functional groups is prepared by using the hyperbranched polyglycerol modified latex microspheres. In actual use, when an immunoturbidimetric reagent of the hyperbranched polyglycerol modified latex microspheres is used, the reagent can be used for inhibiting nonspecific adsorption of proteins well and the antibody coupling rate is further higher than that of common commercialized latex microspheres. In project performance analysis, the latex microsphere reagent can be used for greatly enhancing reaction between antigens and antibodies. Compared with common commercialized latex microsphere reagents, the latex microsphere reagent has the advantages that the sensitivity and detection range are obviously improved and the hyperbranched polyglycerol modified latex microsphere enhanced immunoturbidimetry has excellent performances of relevance, stability and repeatability.

Owner:JILIN GETEIN BIOTECH CO LTD

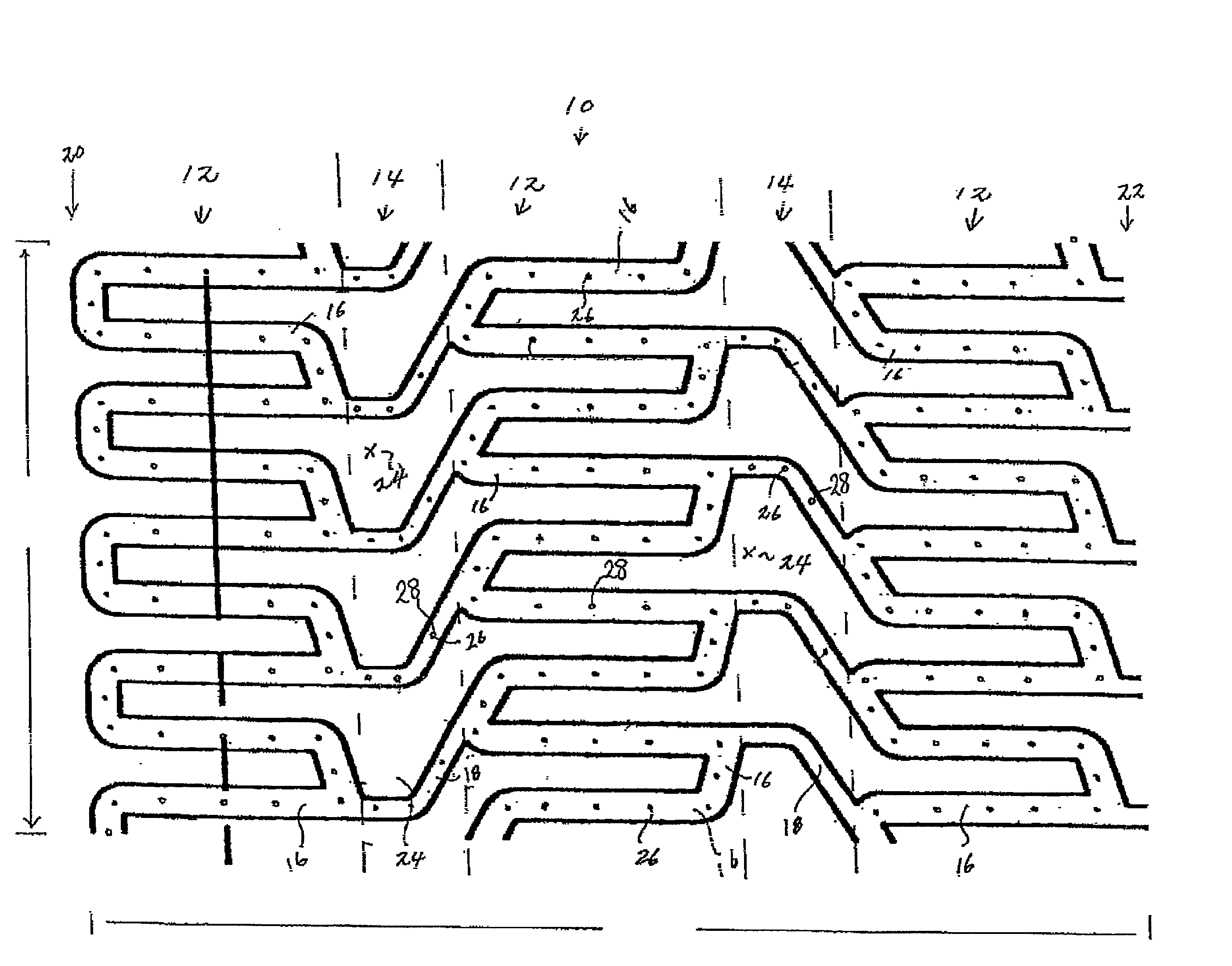

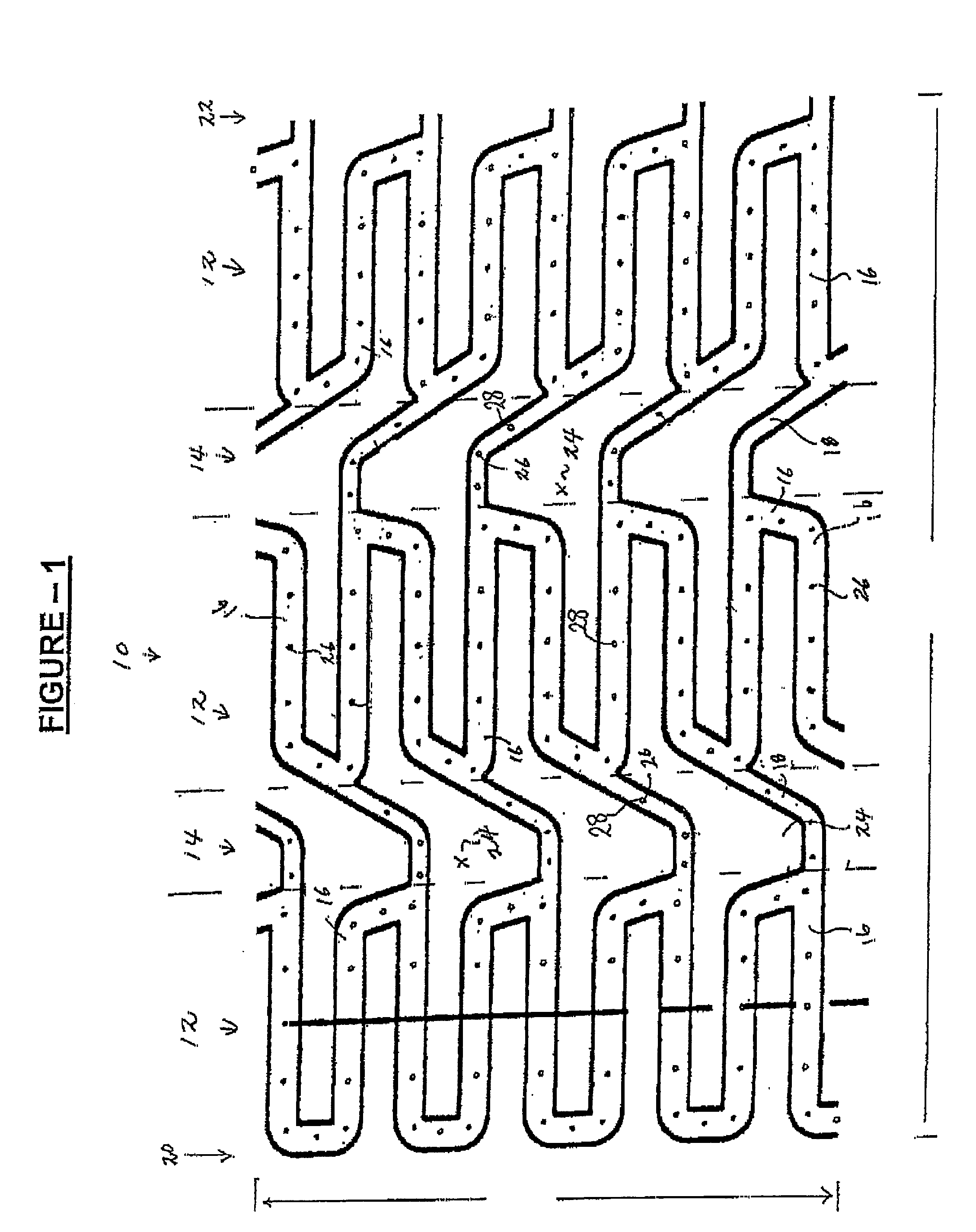

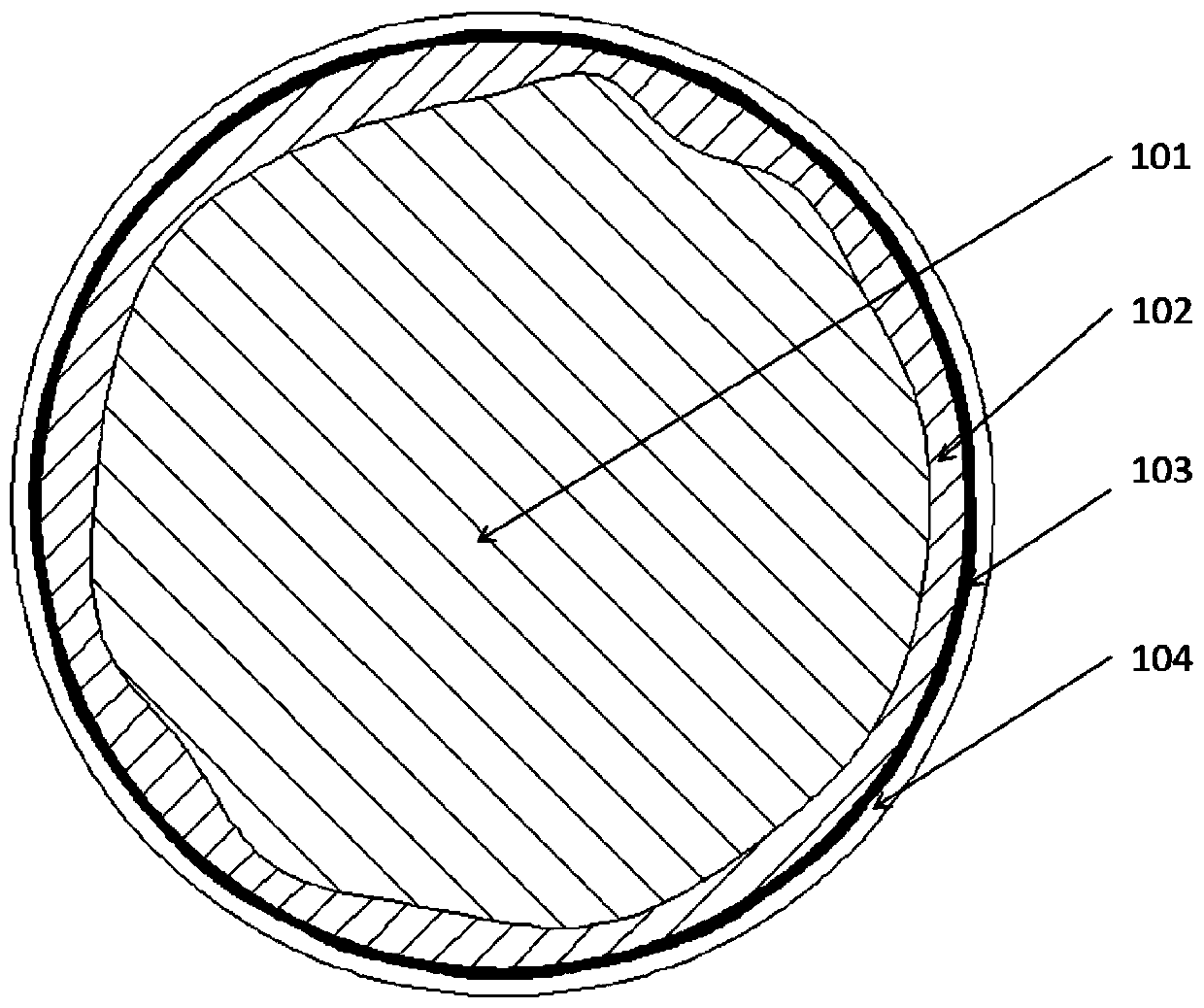

Extendible stent apparatus

InactiveUS20090254173A1Increase the amount of coatingStentsBlood vesselsBiomedical engineeringVascular wall

An expandable stent includes a tubular structure with an outer surface positionable adjacent to a vessel wall and an inner surface facing a lumen of a body passageway. The tubular structure further includes a plurality of expansion struts, connector struts and cells. The tubular structure has a first diameter which permits intraluminal delivery of the tubular structure into the body passageway, and a second expanded and deformed diameter which is achieved upon the application of a radially, outwardly extending force. A plurality of cavities are formed in the outer surface of the stent.

Owner:BOSTON SCI SCIMED INC

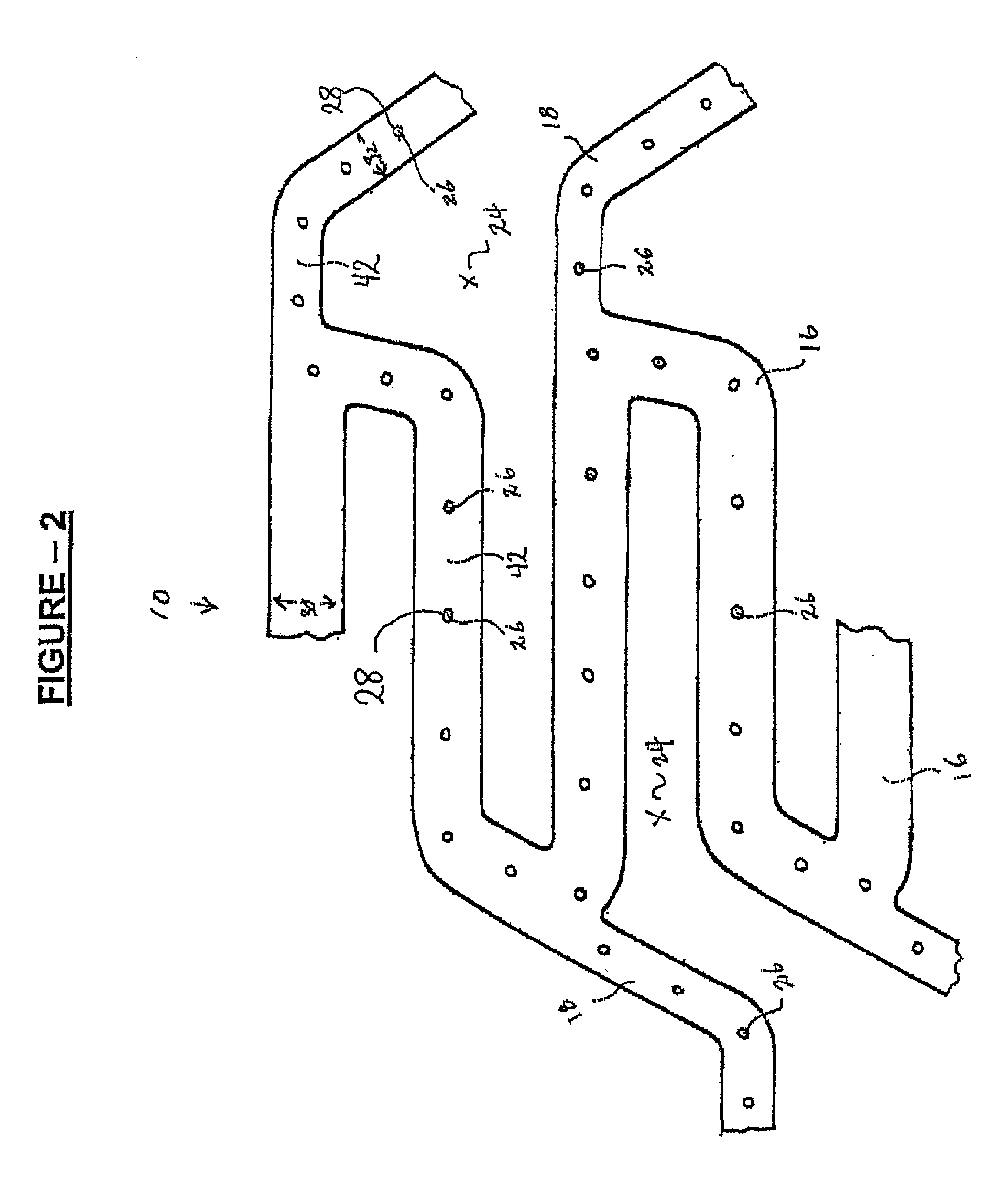

Preparation method of granulated graphite used in refractory castable

The invention belongs to the filed of refractory materials, and relates to a preparation method of granulated graphite used in a refractory castable. The granulated graphite is prepared from raw materials of, by mass: 34-52% of refractory raw material fine powder, 25-40% of flake graphite, 0-9% of solid-state phenol formaldehyde resin powder, 0-15% of an additive, and 22-31% of refractory raw material particles. Also, liquid-state phenol formaldehyde resin which takes 8.5-14.0% of the total weight of the solid raw materials is added. The preparation method comprises steps that: the refractory raw material fine powder, the flake graphite, the solid-state phenol formaldehyde resin powder and the additive are well mixed in a high-speed mixing granulator; a mixture is fetched for later use; the refractory raw material particles and the liquid-state phenol formaldehyde resin are well mixed in the high-speed mixing granulator according to the proportions; mixed powder obtained in the previous steps is placed in the high-speed mixing granulator; coating and granulating are carried out; an obtained material is dried in air, and is baked under a temperature of 100-200 DEG C, such that granulated graphite with a carbon content of 27.1-41.7wt% is obtained.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

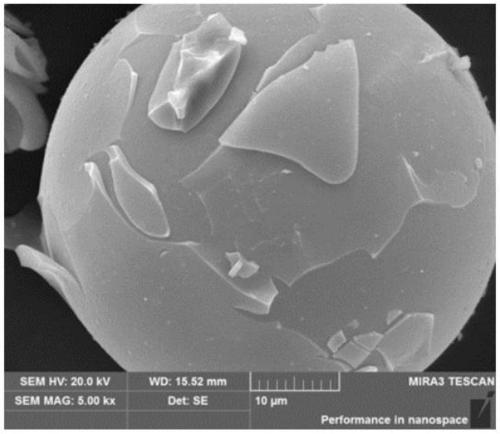

Hollow glass bead/titanium dioxide membrane composite material and preparation method thereof

ActiveCN108970599AImprove reflectivityReduce absorptionCoatingsMetal/metal-oxides/metal-hydroxide catalystsAcetic acidBiological activation

The invention provides a hollow glass bead / titanium dioxide membrane composite material and a preparation method thereof. The composite material is of a core-shell structure; and the thickness of a titanium dioxide membrane is 0.3-0.7 microns, the titanium dioxide exists in an anatase type, and the coating quantity is 5-25 percent. The method comprises the following steps of mixing and dissolvingabsolute ethyl alcohol, tetrabutyl titanate and glacial acetic acid, and then dropwise adding a mixed aqueous solution obtained by mixing the absolute ethyl alcohol, water and a pH regulator in a tetrabutyl titanate solution to prepare a titanium dioxide sol; performing ultrasonic cleaning on a hollow glass bead to remove impurities on the surface and perform alkali activation on the surface; andadding the activated hollow glass bead in the titanium dioxide sol, and performing standing and ageing to realize uniformity and compactness of coating of the surface of the hollow glass bead. The hollow glass bead / titanium dioxide membrane composite material and the preparation method solve the problems of low coating ratio of titanium dioxide, unevenness and looseness in a coating layer, low near-infrared band reflectivity and the like.

Owner:CENT SOUTH UNIV

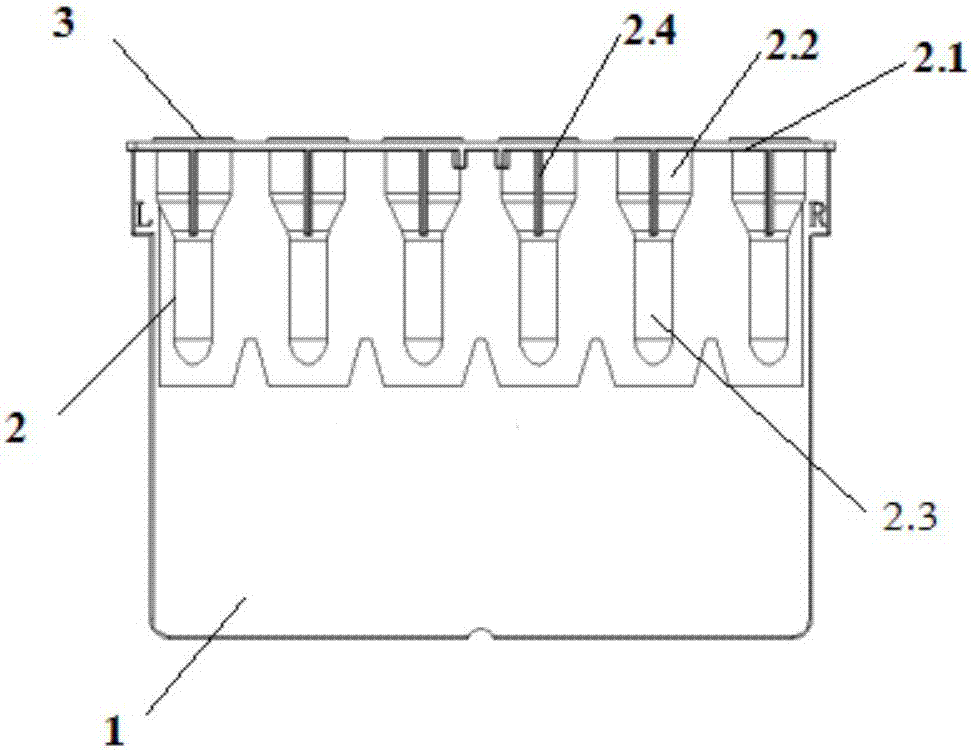

Platelet antibody detection kit and use method thereof

The invention provides a platelet antibody detection kit and a use method thereof. The platelet antibody detection kit comprises a detection plate (1), six gel tubes (2) and an opening sealing film (3), wherein the six gel tubes (2) are arranged at the top end of the detection plate (1) in a left and right arranging way; the opening sealing film (3) is arranged above the detection plate (1), and covers the top ends of the six gel tubes (2); each of six gel tubes (2) contains an anti-human globulin reagent and sephadex; the first gel tube and the sixth gel tube are respectively a positive contrast tube and a negative contrast tube, and the second gel tube, the third gel tube and the fourth gel tube are reaction tubes. The platelet antibody detection kit has the advantages that anti-human IgG and IgG sensitized erythrocyte are used as indication systems to replace anti-human IgG-coated aldehydated erythrocyte, the detection result is clear and accurate, and the repeatability is strong; the effect that detection result can be accurately judged by the naked eye and automatic robot at the same time, and the detection result is easily standardized.

Owner:北京乐普诊断科技股份有限公司

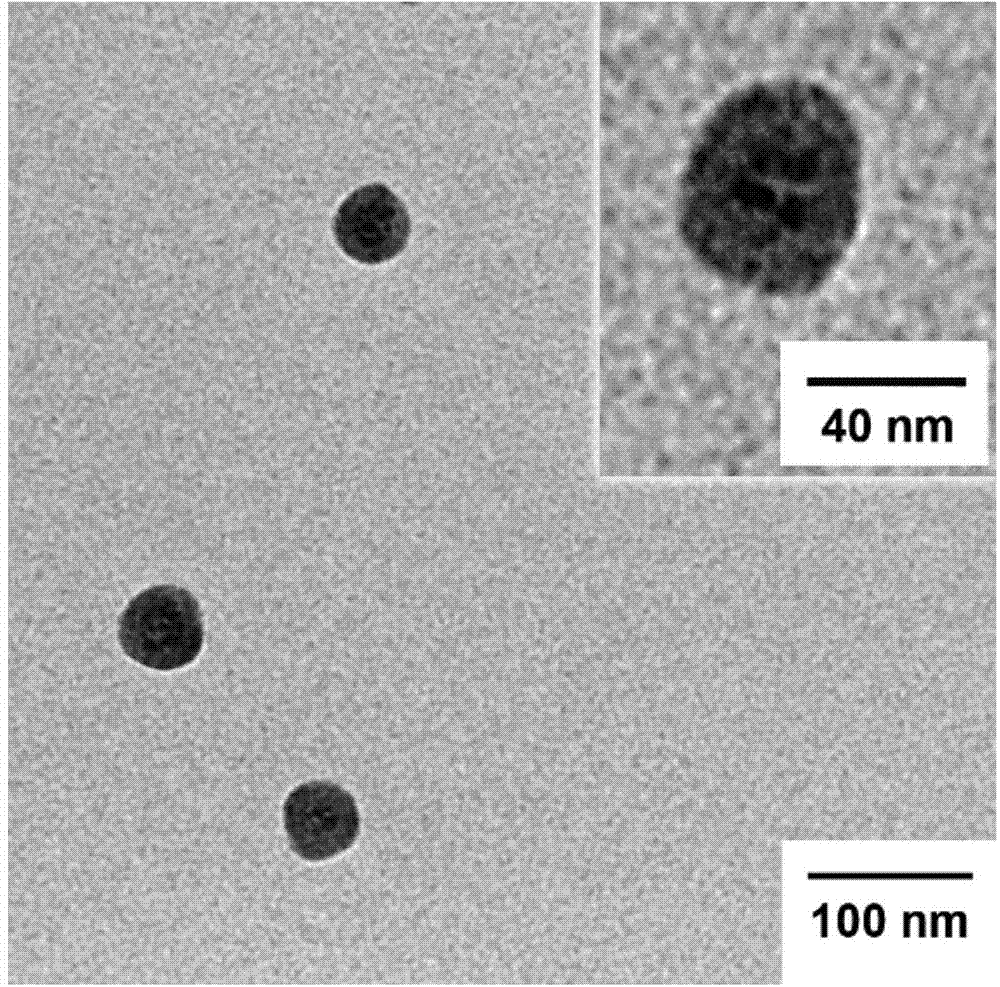

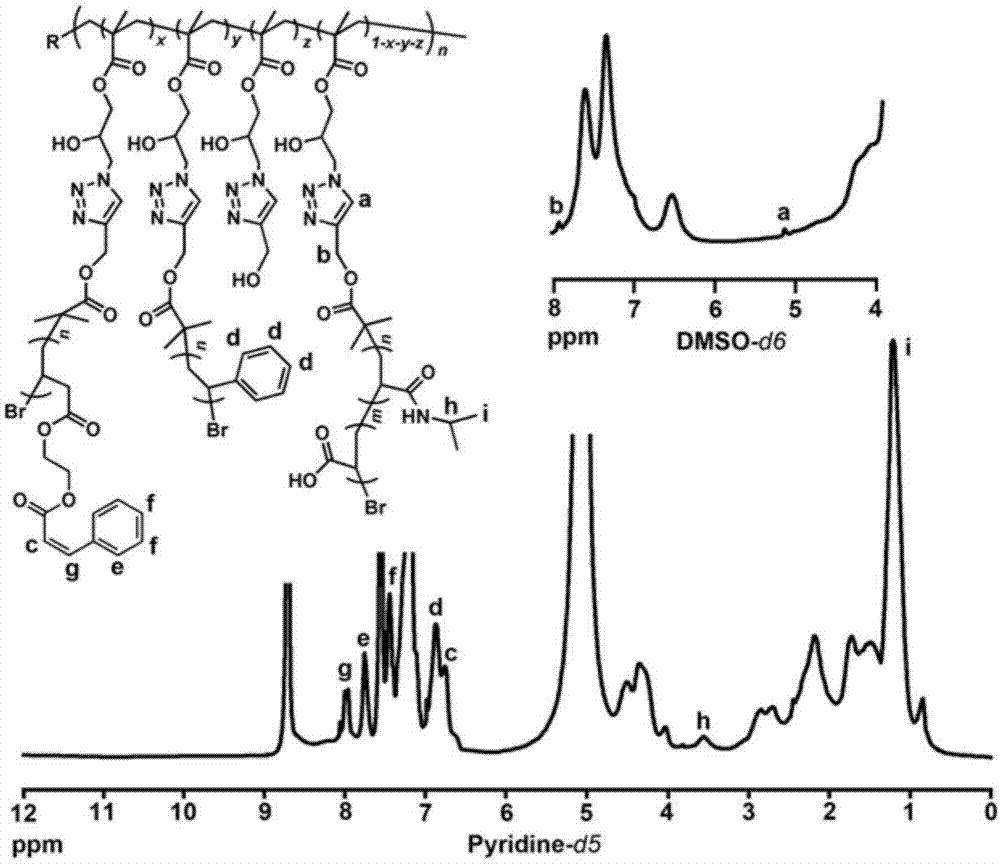

Ternary molecular brush polymer with double responsivenesses to pH and temperature and nano capsule prepared from ternary molecular brush polymer

ActiveCN103755968AThe saturation magnetic susceptibility is easy to adjust and controllableSolve the adjustmentEnergy modified materialsPharmaceutical non-active ingredientsEmulsionPhotoinitiator

The invention discloses a ternary molecular brush polymer with double responsivenesses to pH and temperature, and a nano capsule prepared from ternary molecular brush polymer with double responsivenesses to pH and temperature. The nano capsule is prepared by dispersing the ternary molecular brush polymer with double responsivenesses to pH and temperature in a two-phase system of oil and water, and performing lighting cross-linking or initiation reaction by using a photoinitiator. Difficulty that the conventional segmented copolymer is hard to effectively adjust or control the property and size of the nano capsule is solved, the size of the prepared nano capsule of the lighting cross-linking structure is easy to adjust and control, an emulsion self-assembling method adopted for preparing the nano capsule is simple to operate, the prepared hollow nano capsule is high in wrapping capability, the nano capsule disclosed by the invention is stable in structure, free of toxicity and harm due to adoption of the lighting cross-linking method, and is environment-friendly.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

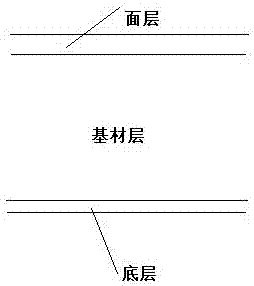

Formaldehyde-free solid wood composite floor and manufacturing method thereof

InactiveCN107310006AImprove filling abilityDoes not see throughLaminationLamination apparatusSolid woodSurface layer

The invention discloses a formaldehyde-free solid wood composite floor and a manufacturing method thereof. The formaldehyde-free solid wood composite floor comprises a surface layer, a base material layer and a bottom layer which are arranged from top to bottom. The base material layer is formed by sequentially bonding an upper layer body, a middle layer body and a lower layer body from top to bottom. The upper layer body and the lower layer body are both a two-layer board, and the middle layer body is a three-layer board. The two-layer board is composed of two layers of veneers with perpendicular texture, and the three-layer board is composed of three layers of veneers with perpendicular texture from top to bottom. All the veneers are bonded through YSD851 glue. The invention further provides the manufacturing method of the formaldehyde-free solid wood composite floor. The composite floor is free of formaldehyde and has no harm to human health; the glue is good in filling property, few in applied quantity, high in production efficiency and low in requirement for the hot-press time, temperature and pressure compared with other glue and saves cost; and the glue is long in active period and capable of being used for a long time.

Owner:兰州科天水性科技有限公司

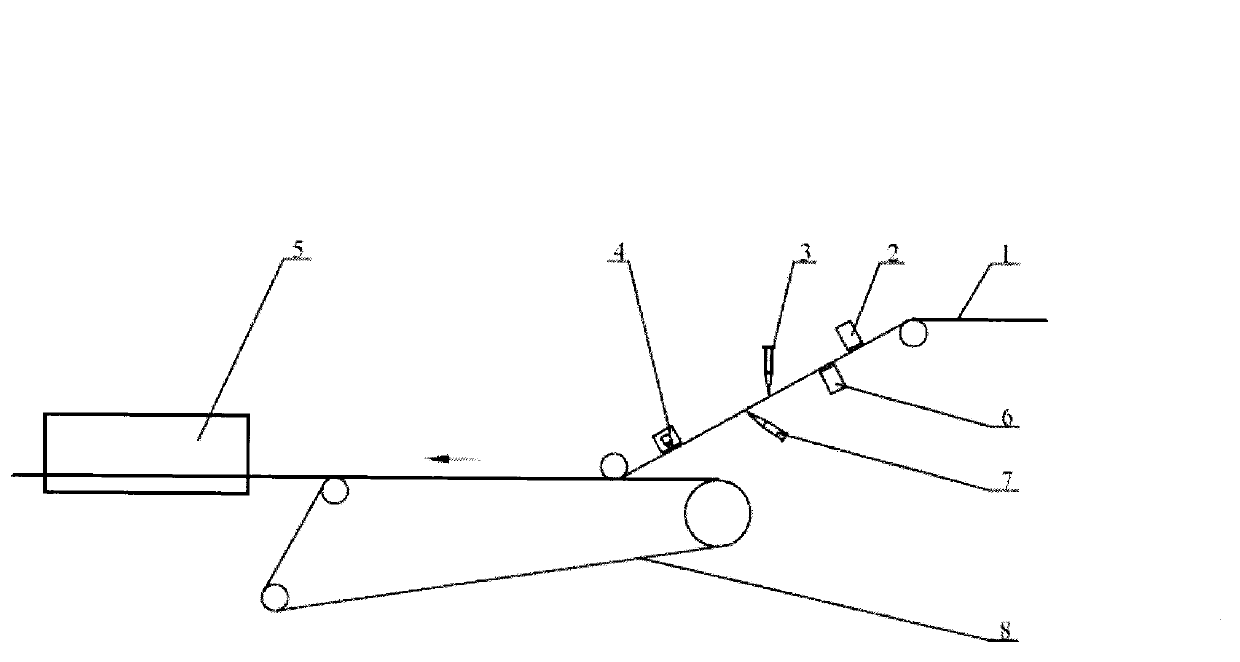

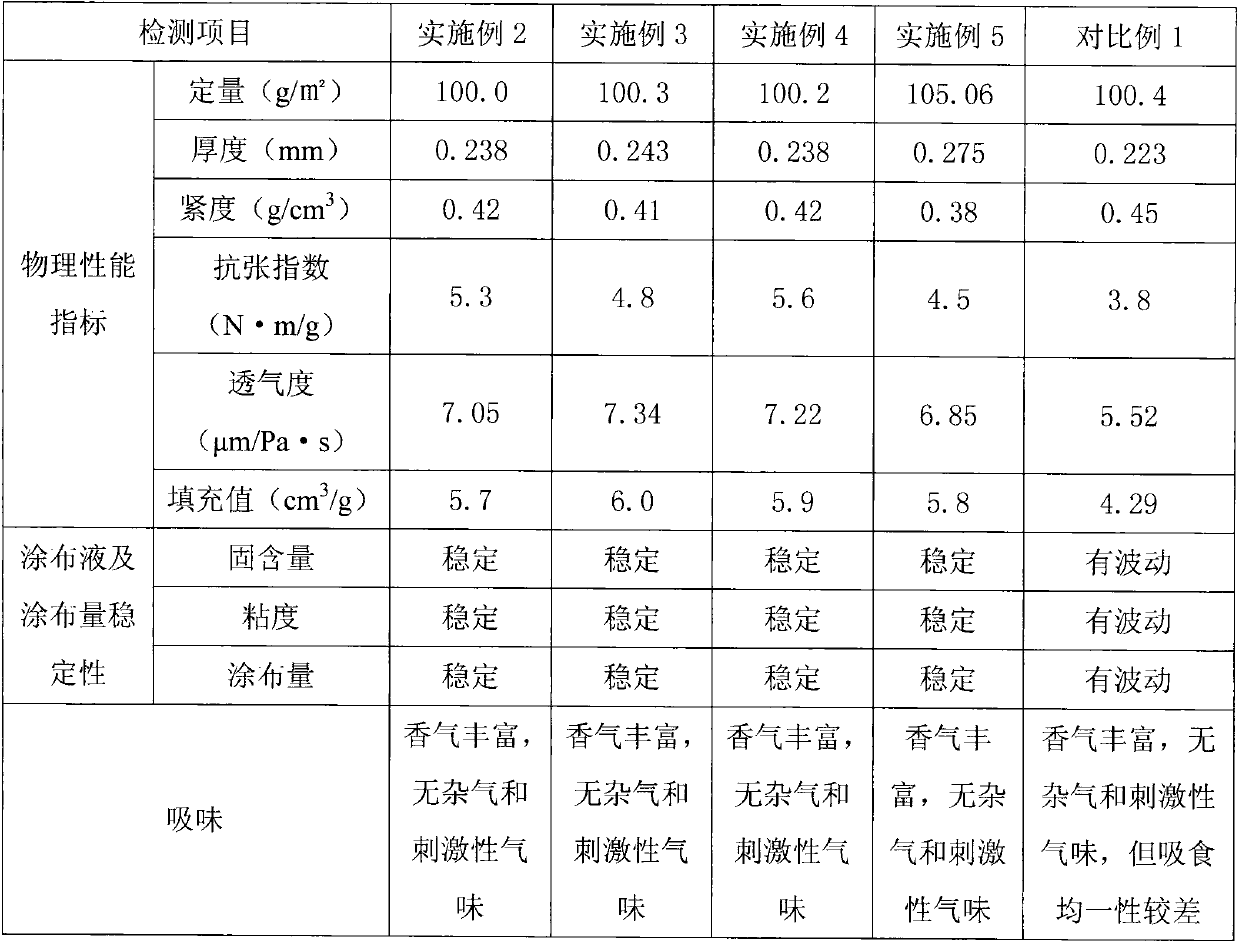

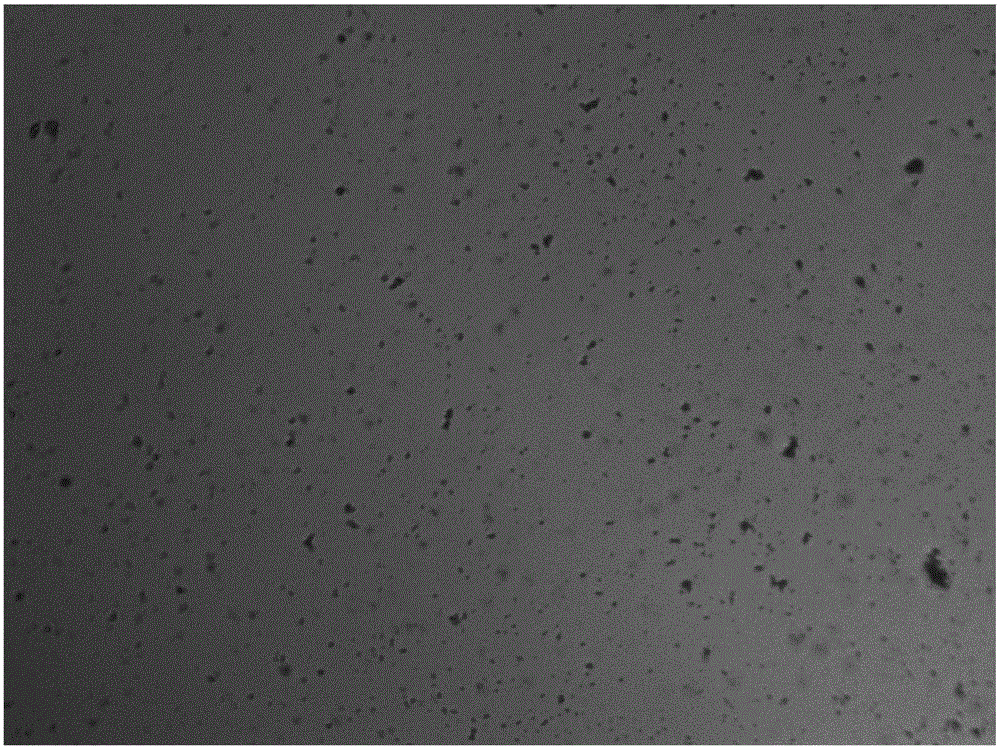

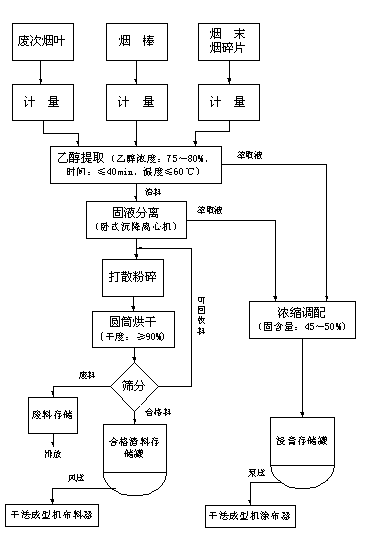

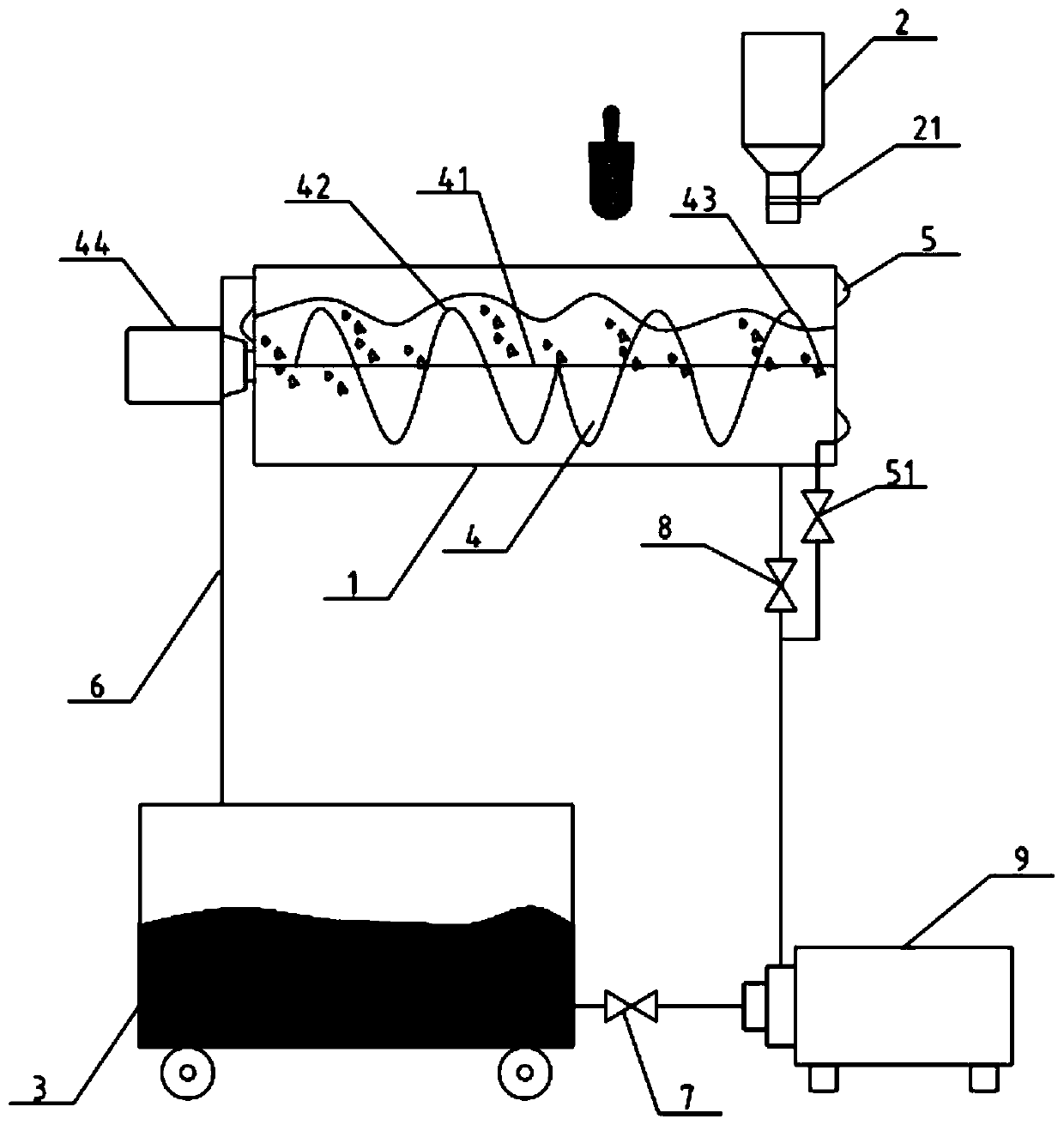

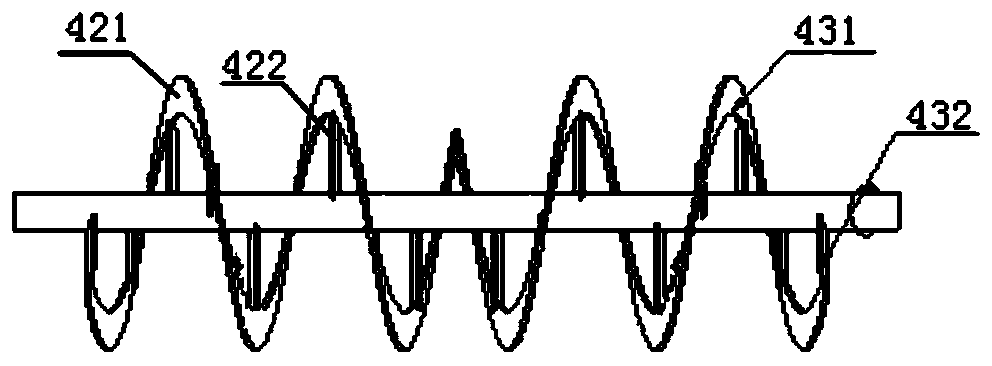

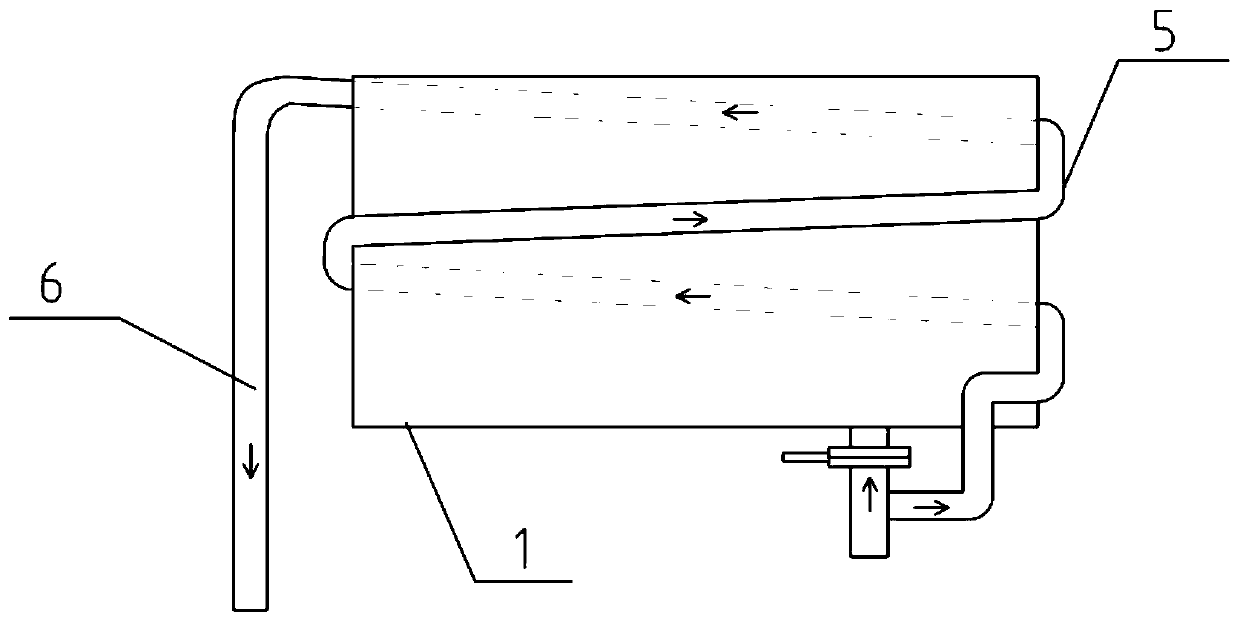

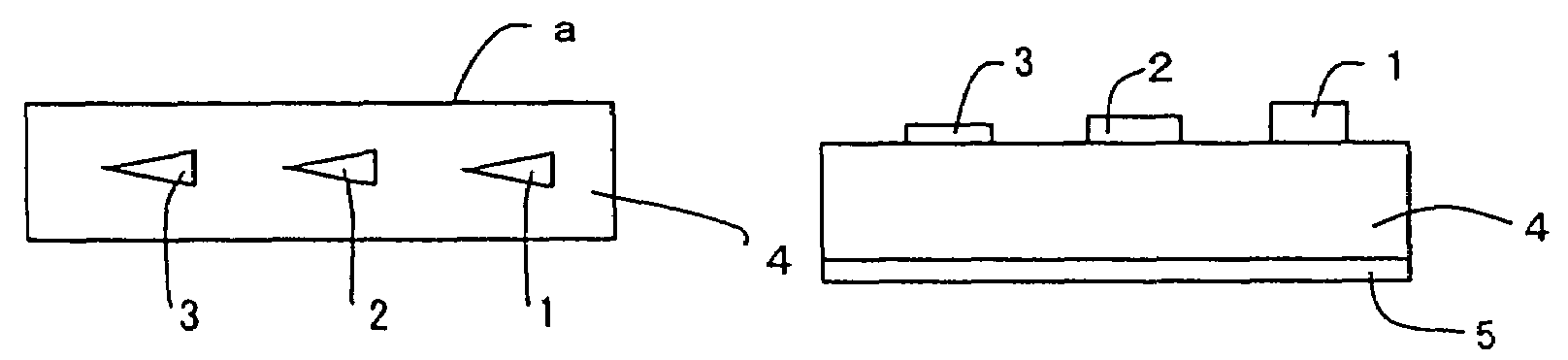

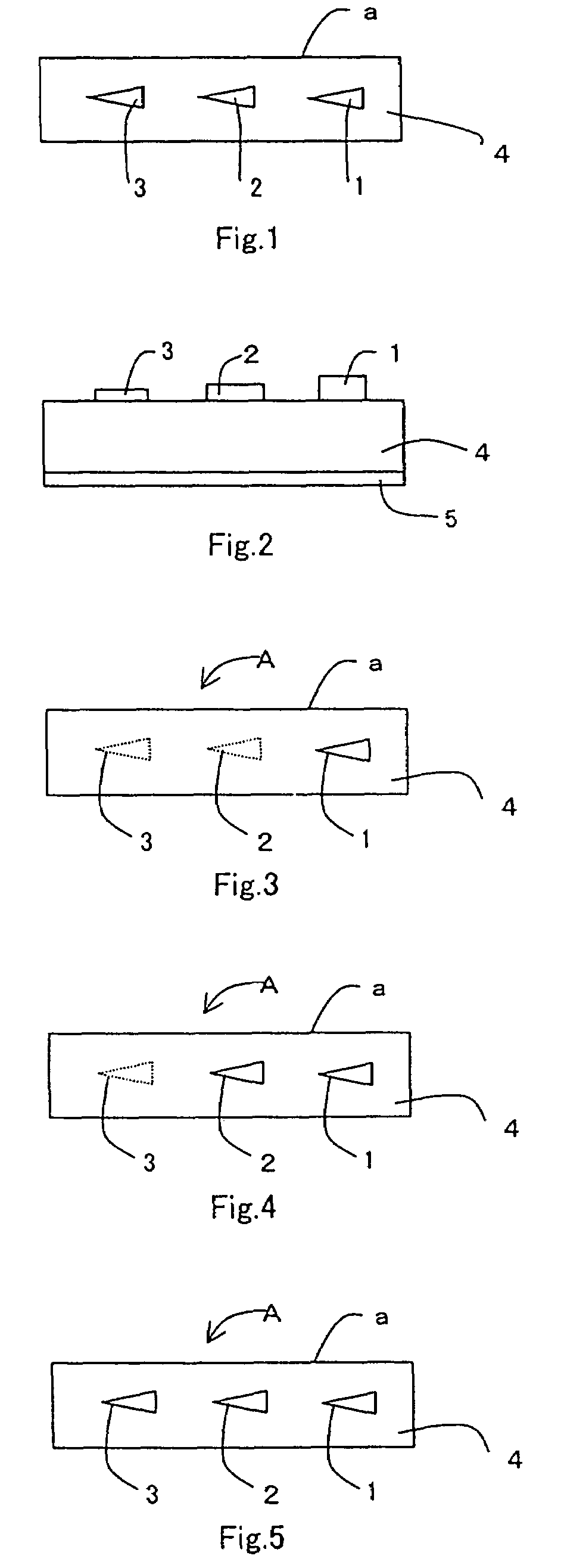

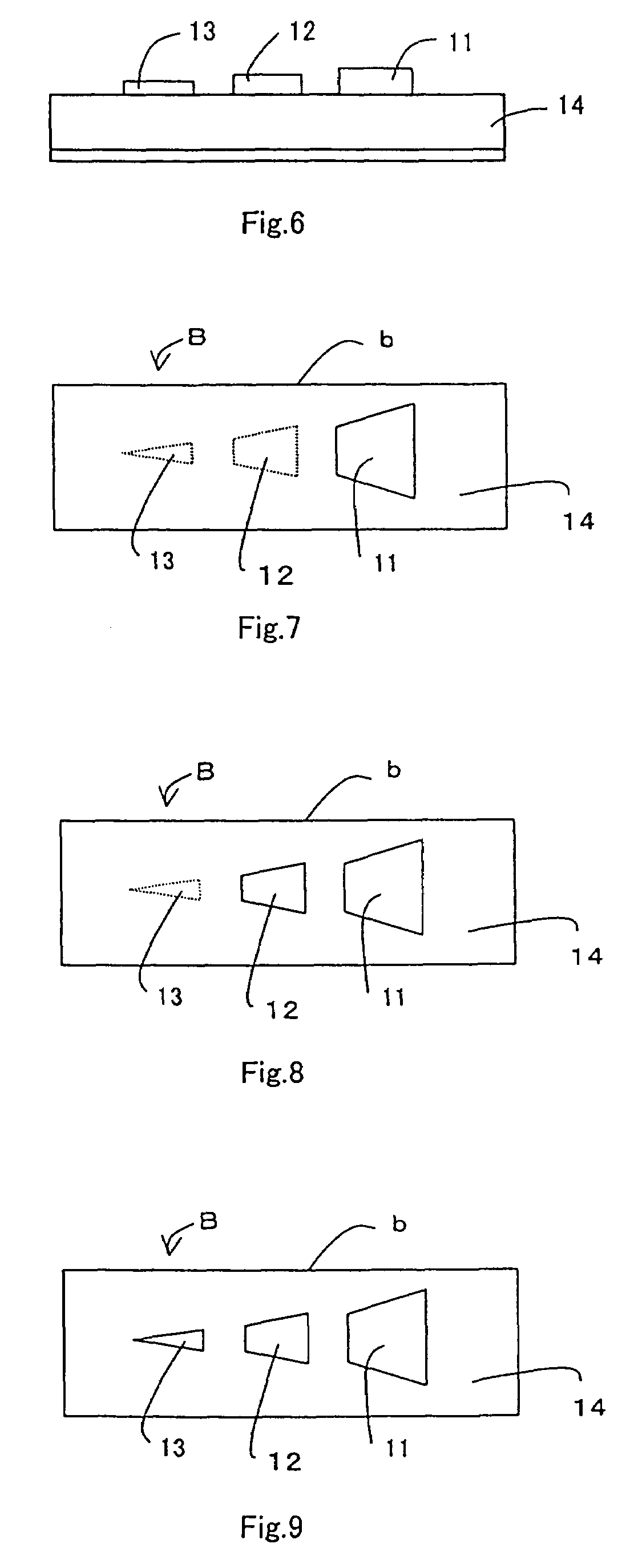

Device and method for producing tobacco sheets

ActiveCN103126052AIncrease the amount of coatingIncreasing the thicknessTobacco preparationPaper/cardboardEngineeringAcoustic wave

The invention provides a device and method for producing tobacco sheets. The production method of the tobacco sheets includes: tobacco raw materials are extracted in an extraction tank to be separated, insoluble substances are pulped and placed on a screen to be made into sheet bases, and obtained extract liquor is filtered through a filter screen and concentrated to obtain coating liquid; a part of coating liquid is foamed by using a foam generator to obtain foam coating liquid, the foam coating liquid is coated on the sheet bases by using a foam spraying process, and the other part of coating liquid is used for coating the sheet bases sprayed by foams again by using a mist spraying process to obtain wet sheet bases coated twice; sound wave or ultrasonic wave processing is performed on the wet sheet bases coated twice, vibration defoaming is performed on small foams to accelerate seepage of the coating liquid, and the coating liquid coated on the surfaces of the wet sheet bases is prevented from transferring to a nylon mesh belt; and the processed wet sheet bases are dried, and finished products of the tobacco sheets are manufactured after slitting of the sheet bases. The tobacco sheets manufactured by the method are large in coating quantity, high in coating evenness and good in air permeability.

Owner:CHINA HAISUM ENG

Chemical conversion treating agent and surface treated metal

InactiveUS20090065099A1Reduce ion concentrationReduce contentElectrophoretic coatingsSolid state diffusion coatingSilanesHydrolysate

It is an object of the invention to provide a chemical conversion treating agent containing no chromium and exhibiting high corrosion resistance and excellent stability.A chemical conversion treating agent comprising:zirconium; fluorine; (A) at least one compound selected from the group consisting of amino group-containing silane coupling agents, their hydrolyzed products, and their polymers; and (B) an amino group-containing water-borne phenol compound;wherein the content of zirconium in the chemical conversion treating agent is 25 to 2000 ppm on the metal equivalent basis, andthe mole ratio of the contents of fluorine and zirconium satisfies the following relation:3≦F / Zr≦6.

Owner:NIPPON PAINT CO LTD +1

Immunomagnetic bead and preparation method thereof

ActiveCN106405075AImprove magnetic propertiesStable in natureMaterial analysisBiotin-streptavidin complexMicrosphere

The invention provides an immunomagnetic bead and a preparation method thereof. The immunomagnetic bead comprises a magnetic microsphere and a biological ligand, wherein the structure of the magnetic microsphere is magnetic microsphere-biotin-streptavidin-biotin-biological ligand from inside to outside. The immunomagnetic bead provided by the invention is stable in property, good in magnetism and small in particle size. A connecting mode of biotin-streptavidin-biotin is adopted, and the biotinylated magnetic microsphere is firstly obtained through amidation reaction and then is combined with the streptavidin. As the combination of biotin-streptavidin has the characteristics of high affinity and specificity, the magnetic microsphere and the biological ligand can be directionally combined, cross-linking is not easy, and a change in the structure of the streptavidin is not easily caused. Meanwhile, the preparation method provided by the invention is simple and mild in reaction conditions, and the biological ligand can retain the biological activity.

Owner:SHANGHAI MAJORBIO BIO PHARM TECH

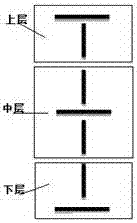

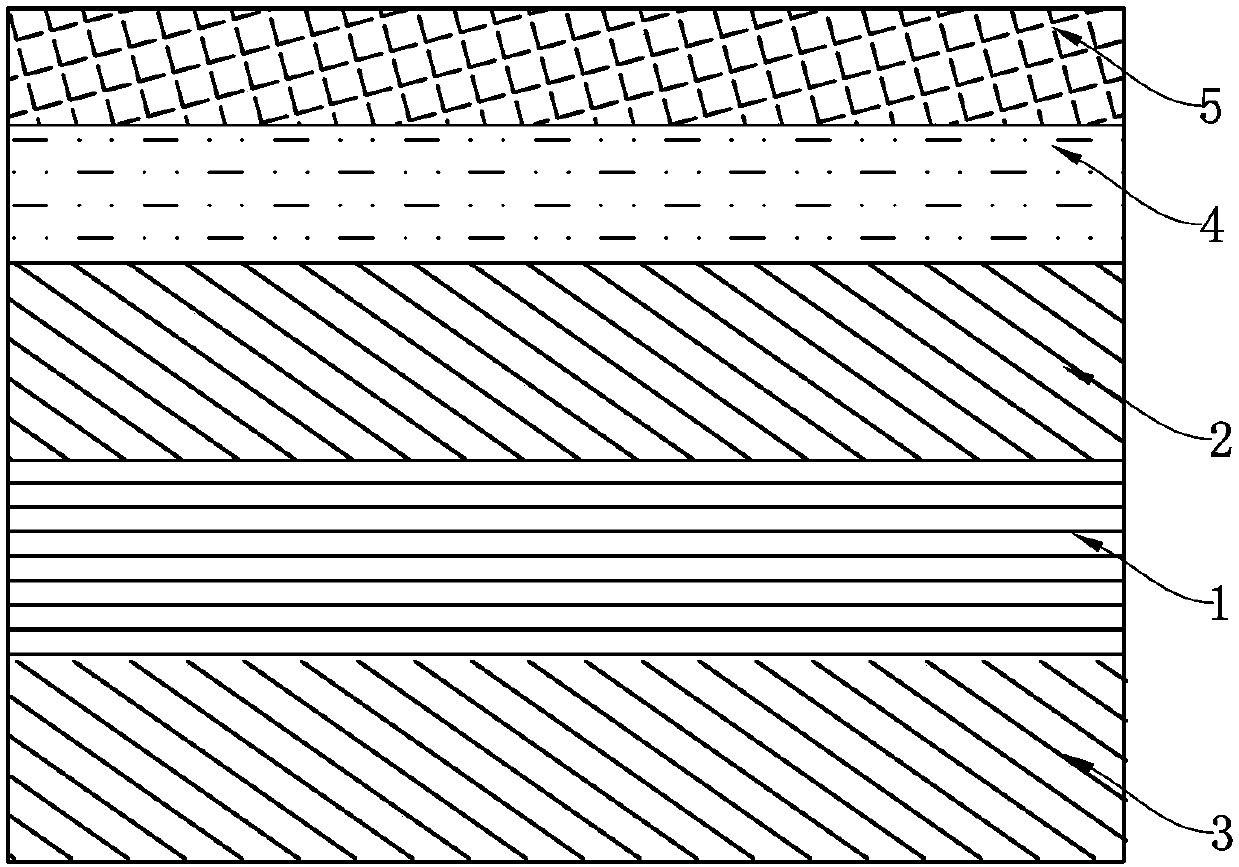

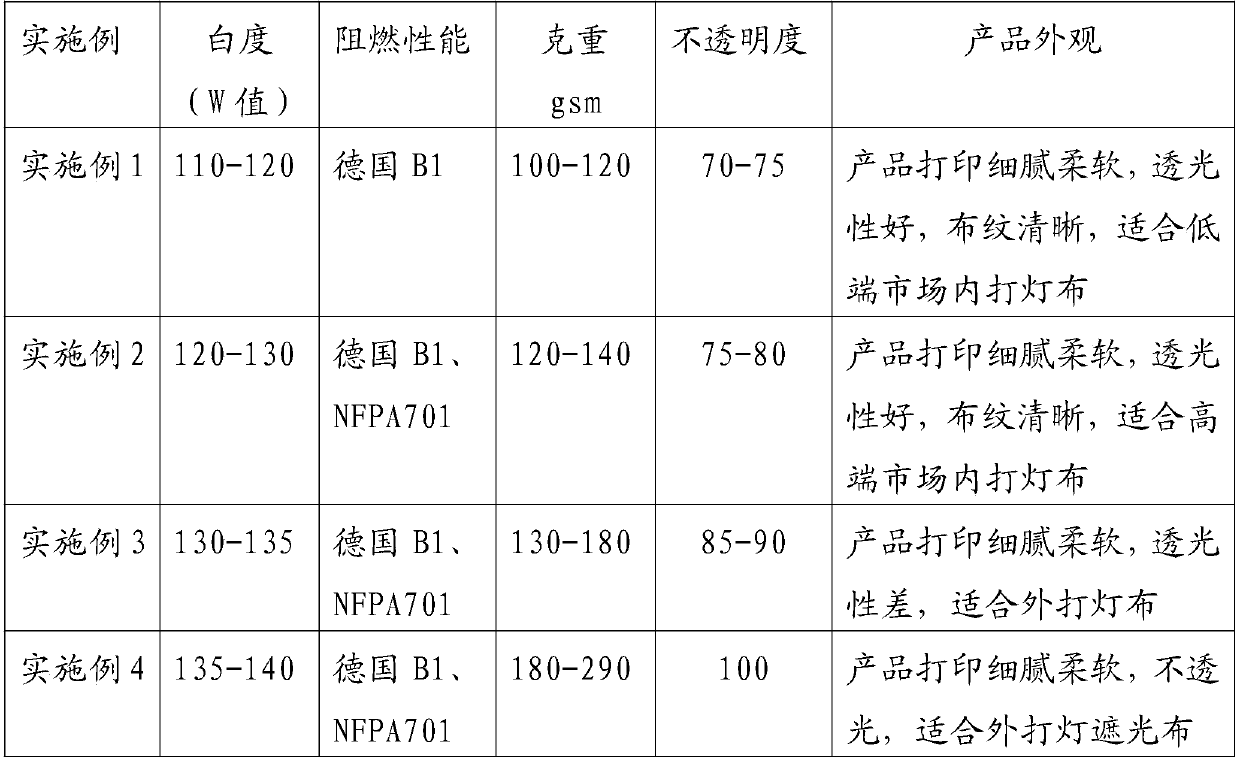

Foaming coating inner lighting advertising cloth and preparation technology thereof

ActiveCN107700232ALow densityReduce penetrationFireproof paintsTextiles and paperImaging qualityImage quality

The invention relates to an advertising cloth, especially to a foaming coating inner lighting advertising cloth. The foaming coating inner lighting advertising cloth comprises a base cloth layer, theupper side and lower side of the base cloth layer are respectively coated with a whitening waterproof layer, wherein the surface of a whitening waterproof layer on one side is coated with a foaming flame retardant coating, and the surface of the foaming flame retardant coating is coated with an ink absorption coating. The invention also discloses a preparation technology of the advertising cloth.The preparation technology includes coating of the whitening waterproof coating, coating of the foaming flame retardant coating, and coating of the ink absorption coating. The advertising cloth provided by the invention has the advantages of flame retardance, wrinkle resistance, light weight, good handfeel, and fine printed image quality.

Owner:柔识智能科技(山东)有限公司

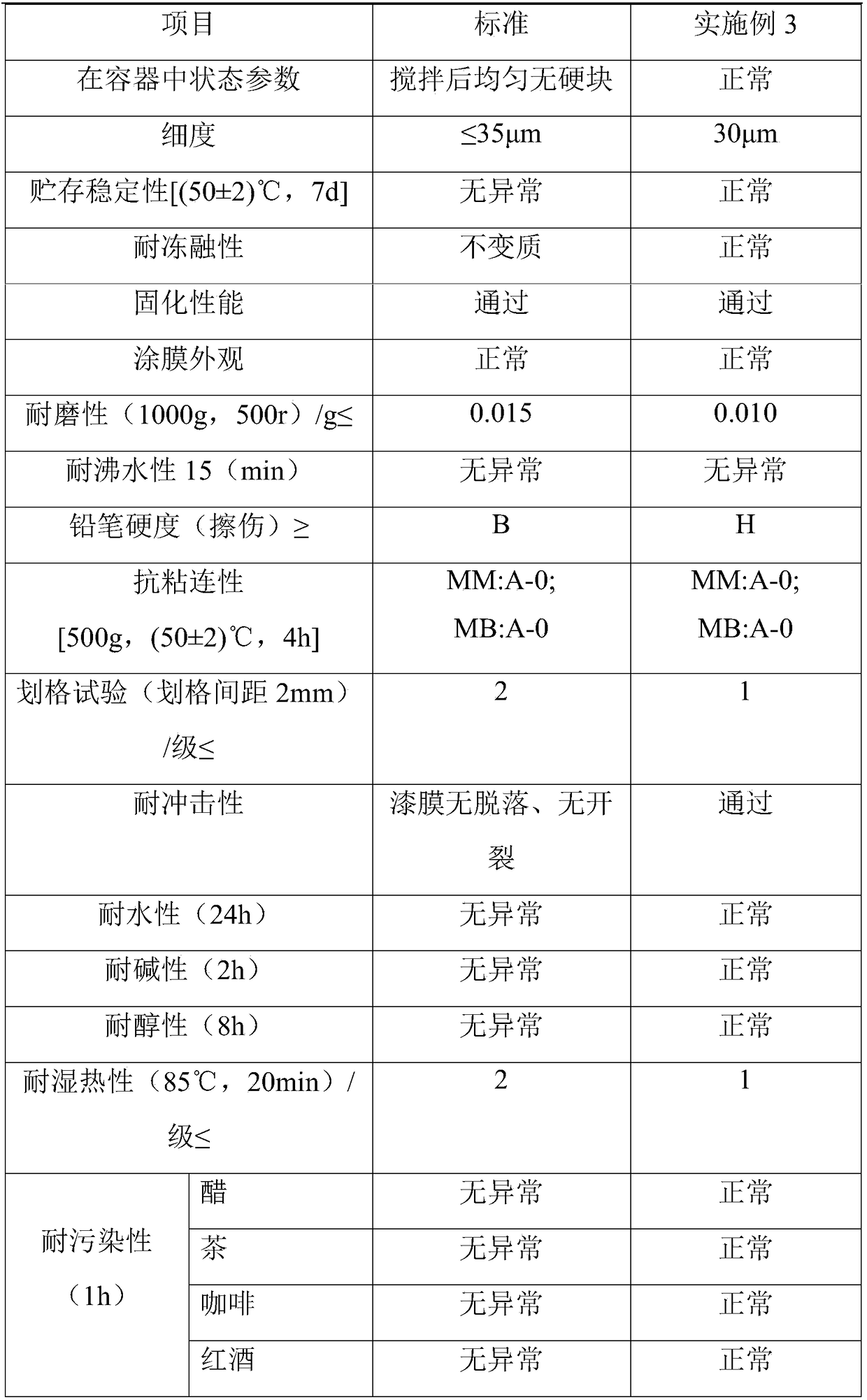

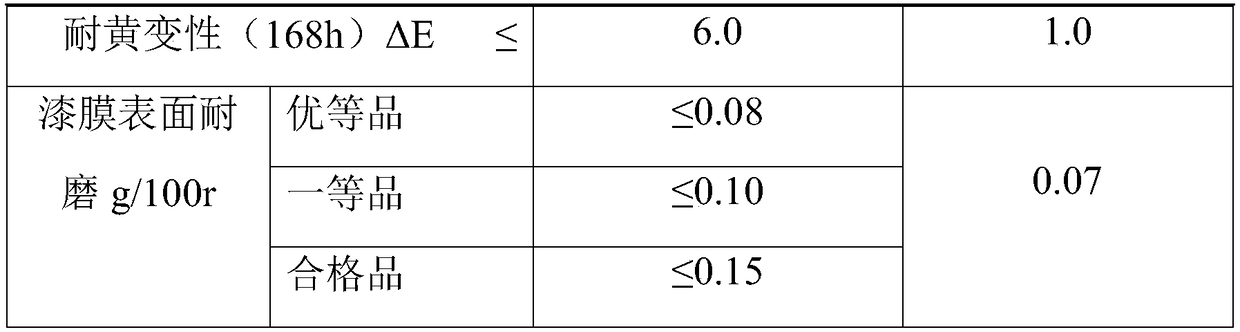

High-wear-resistance waterborne UV (ultraviolet) floor paint and preparation method thereof

InactiveCN109486394AMeet painting requirementsPerformance is not affectedPolyurea/polyurethane coatingsPolyurethane dispersionEmulsion

The invention relates to the technical field of paints, particularly to a high-wear-resistance waterborne UV floor paint and a preparation method thereof. The high-wear-resistance waterborne UV floorpaint is composed of, by weight part, 67-80 parts of waterborne UV polyurethane dispersion, 3-5 parts of waterborne alkali-soluble acrylic emulsion, 0.4-0.8 parts of defoamer, 0.3-0.6 part of wettingagent, 0-2 parts of solubilizer, 0.1-0.2 part of neutralizer, 0.1-0.5 part of in-tank bactericide, 0.2-1 part of rheologic additives, 0.5-2 parts of matting powder, 9-22 parts of deionized water and 1-3 parts of photoinitiator. Compared with the prior art, the h high-wear-resistance waterborne UV floor paint can meet floor painting requirements and achieve high wearing resistance, specifically, can firstly meet the requirements on floor painting roller construction and UV curing, and above all, by matching different types of resins, improves product viscosity without affecting paint film performance and increases single-roller coating capacity to achieve final painting effects.

Owner:上海展辰涂料有限公司 +3

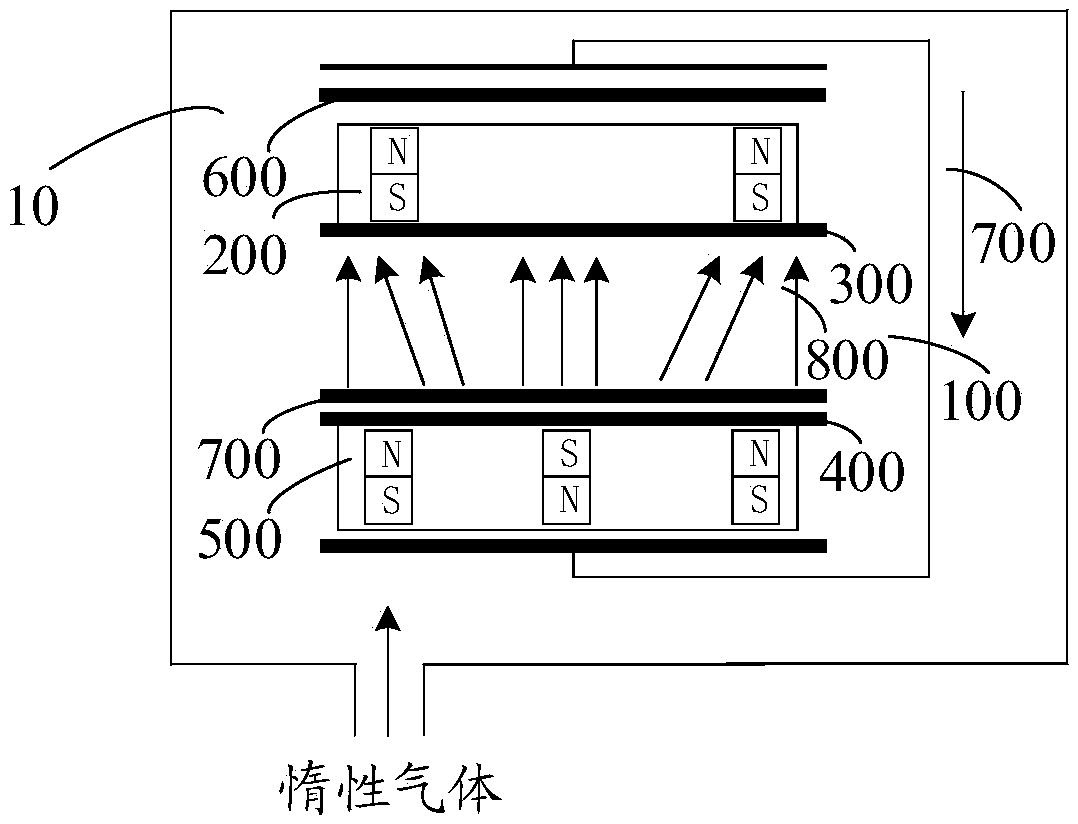

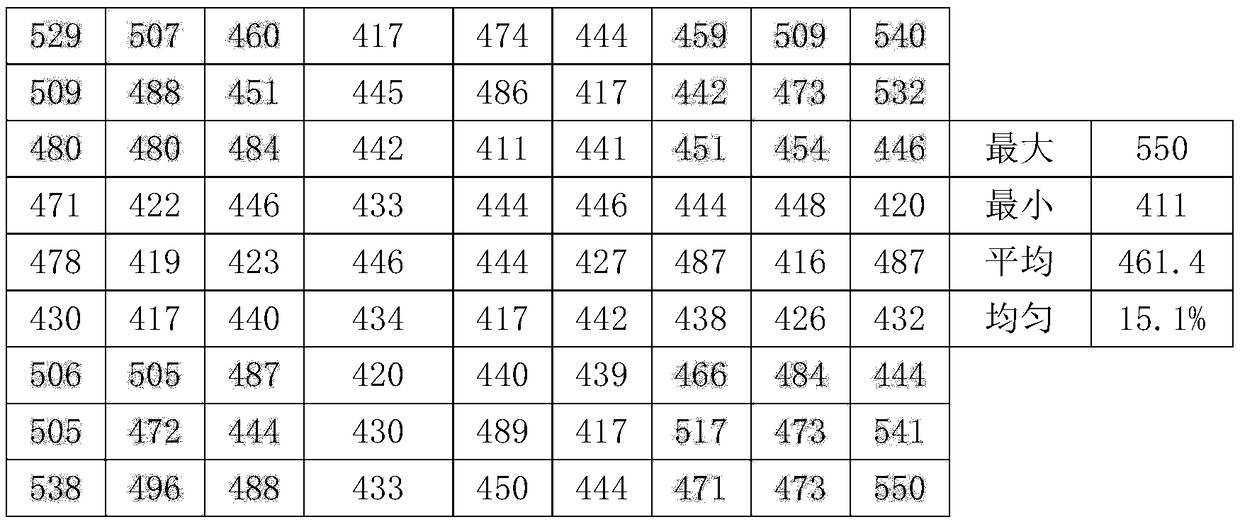

Plating system and plating glass manufacturing method

ActiveCN109161842AImprove uniformitySolve the problem of poor thickness uniformityVacuum evaporation coatingSputtering coatingElectric fieldGlass manufacturing

The invention relates to a plating system and a plating glass manufacturing method. The plating system comprises a vacuum chamber, a sputtering target, a substrate platform, an electric field device and a magnetic field device, wherein the sputtering target, the substrate platform, the electric field device and the magnetic field device are arranged in the vacuum chamber; the magnetic field devicecomprises a first magnetic field device and a second magnetic field device; the first magnetic field device, the substrate platform, the sputtering target and the second magnetic field device are positioned in an area of an electric field generated by the electric field device and are arranged in sequence in a direction of the electric field generated by the electric field device; the first magnetic field device is positioned inside an area with thin predicted plating thickness, and is right aligned to a glass substrate to be plated on a corresponding substrate platform. When plating is carried out, the plating quantity of the area with the thin predicted plating thickness can be intensified by using the first magnetic field device, and plated glass with good uniformity can be manufactured.

Owner:WGTECH JIANGXI

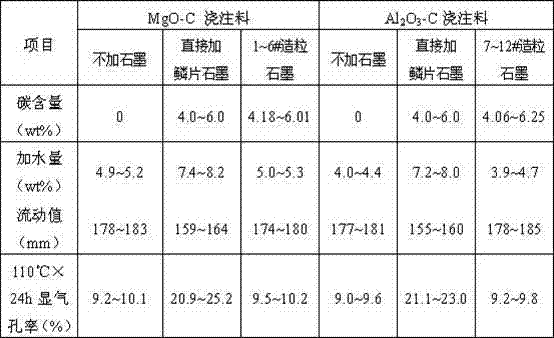

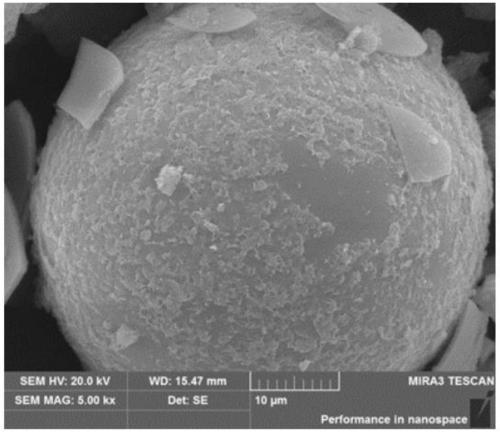

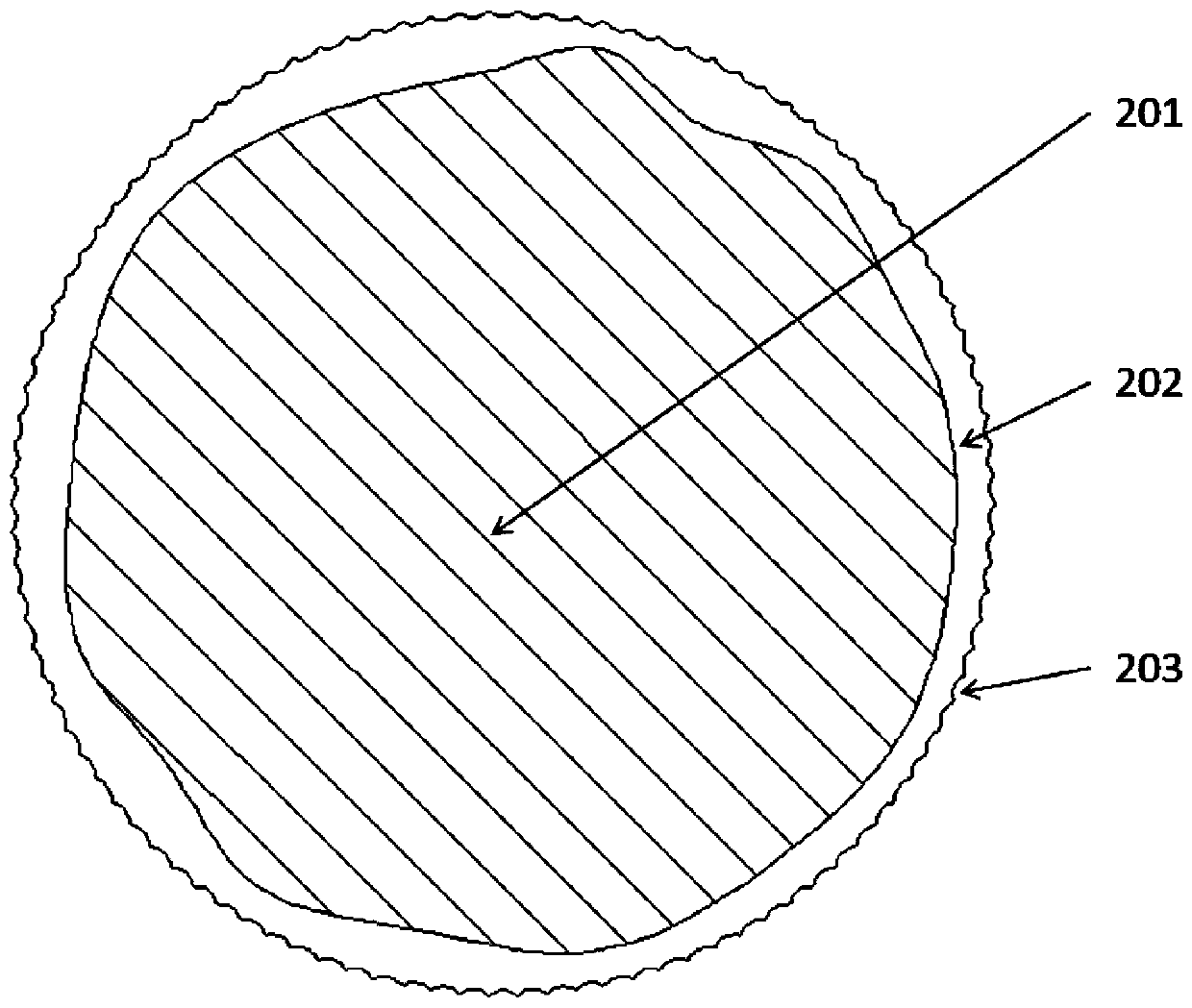

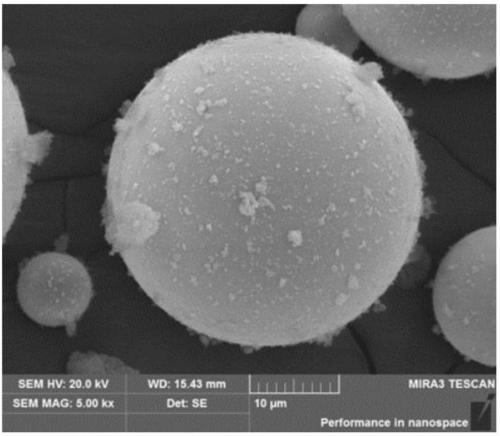

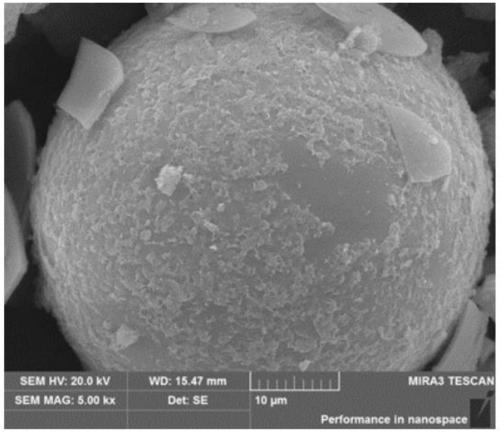

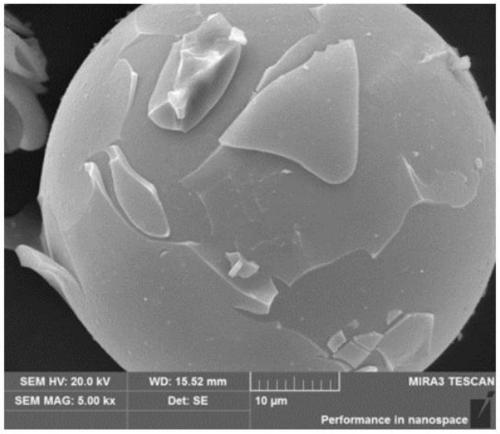

Graphene/ceramic composite microparticles used for spray molding and preparation method of composite microparticles

ActiveCN110526695AInhibit sheddingIncrease the amount of coatingMicroballoon preparationMicrocapsule preparationWater basedCeramic composite

The invention discloses graphene / ceramic composite microparticles used for spray molding and a preparation method of the composite microparticles. The graphene / ceramic composite microparticles are composed of ceramic microparticles, water-based polyurethane resin, graphene, and alcohol-soluble resin, the ceramic microparticles are used as core particles, and a water-based polyurethane resin layer,a graphene layer and an alcohol-soluble resin layer sequentially cover the core particles, wherein the thickness of the water-based polyurethane resin layer is 5-15 [mu]m, the thickness of the graphene layer is 0.15-0.75 [mu]m, and the thickness of the alcohol-soluble resin layer is 5-20 [mu]m. The preparation process of the composite microparticles includes the steps of ceramic microparticle pretreatment, low-temperature plasma treatment, graphene coating, and boiling spray coating drying. The graphene / ceramic composite microparticles provided by the invention have a consistent size and goodfluidity, and can be used for spray molding to control the dispersion range and dispersion effect of the graphene in a substrate; and the preparation method provided by the invention has the advantages of low costs, a simple and effective process and no pollution.

Owner:CHINA THREE GORGES UNIV

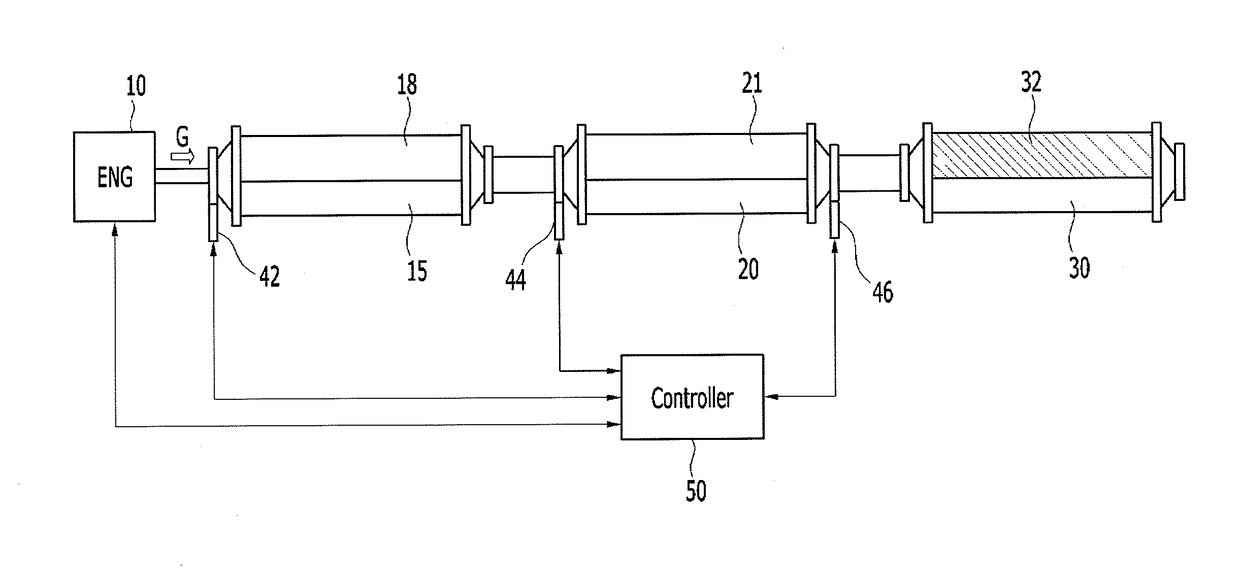

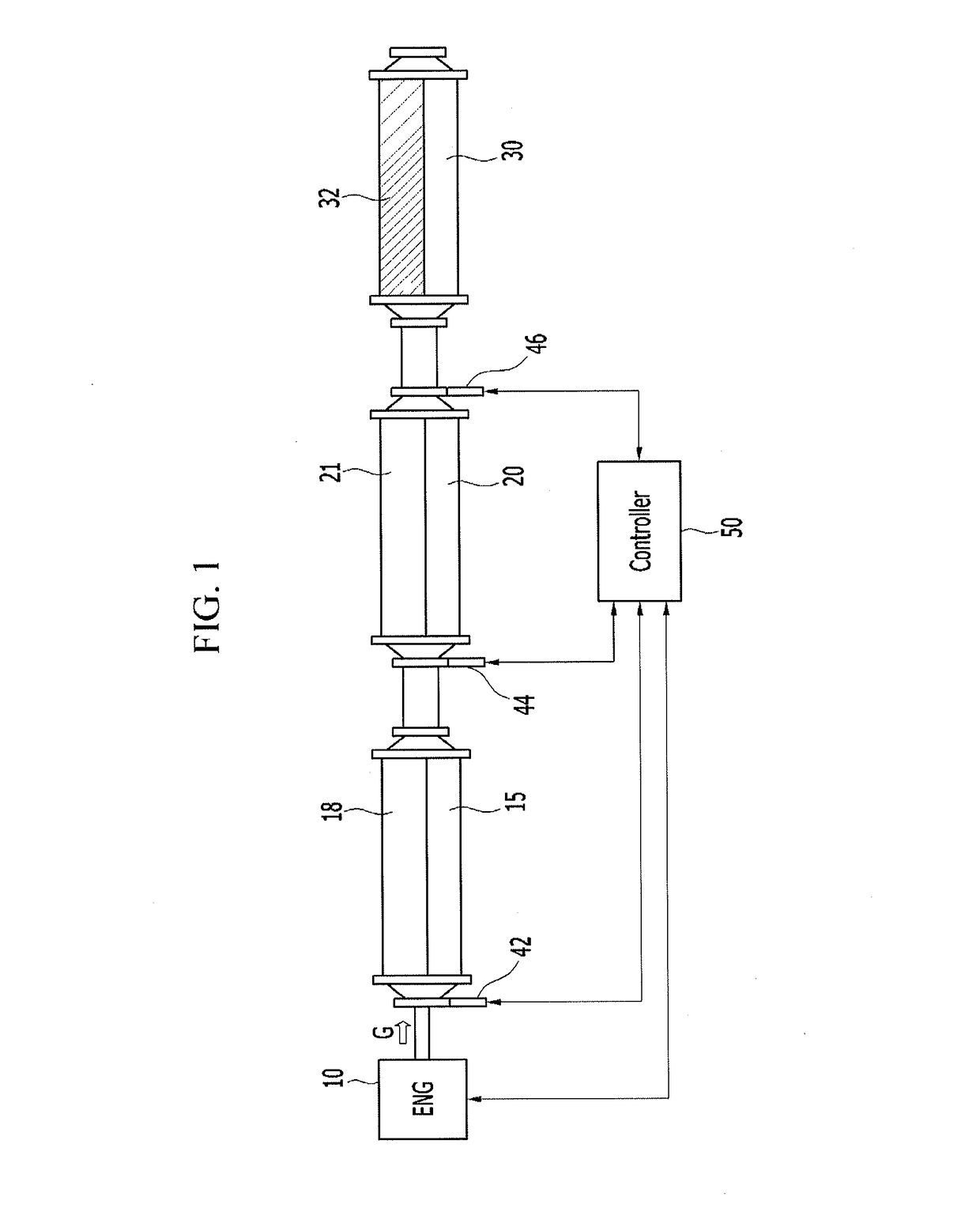

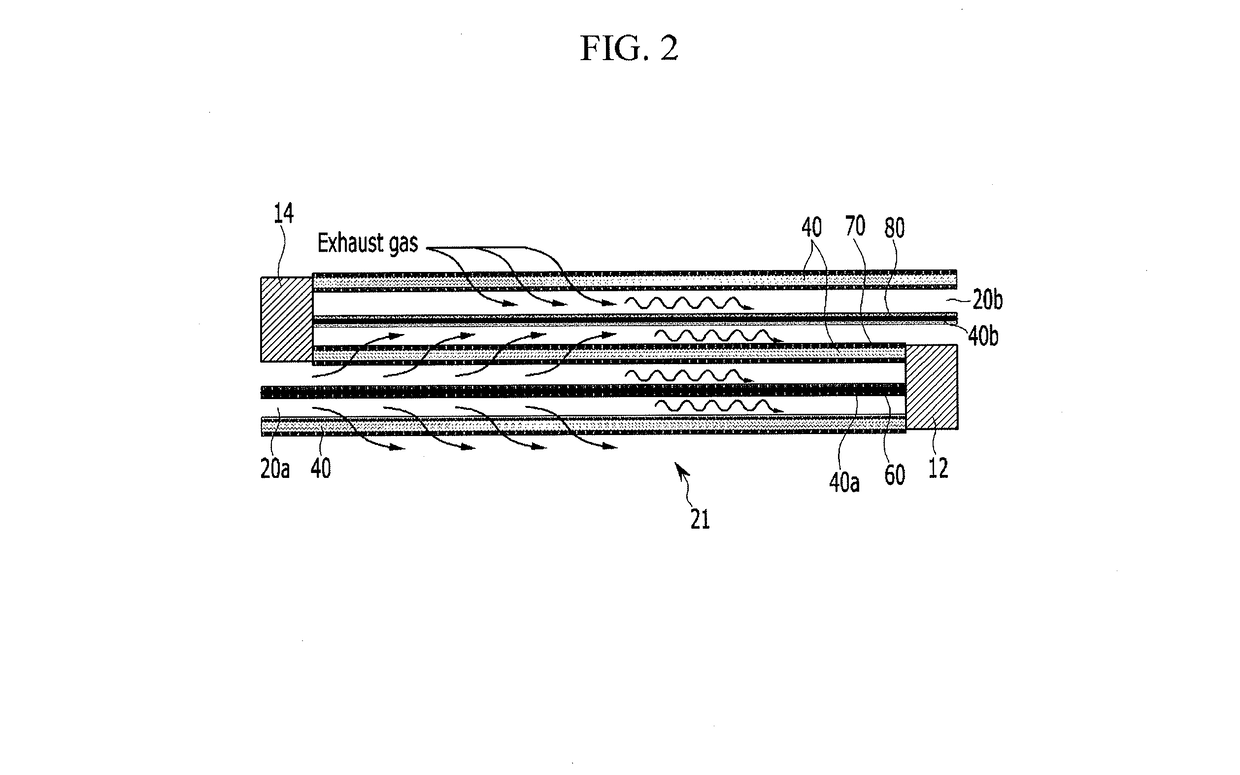

Exhaust system and control method of nitrogen oxide desorption

ActiveUS20180080357A1Improve exhaust gas purification performanceImprove efficiencyInternal combustion piston enginesSilencing apparatusNitrogen oxidesDesorption

An exhaust system may include first purification device disposed at a rear end portion of exhaust manifold and including Lean NOx Trap (LNT); second purification device disposed at rear end portion of the first purification device and including a diesel particulate filter (DPF); and a third purification device disposed at a rear end portion of the second purification device and including a selective catalytic reduction (SCR), wherein the DPF of the second purification device includes at least one inflow channel, at least one outflow channel, at least one wall disposed between the inflow channel and the outflow channel and extended in a longitudinal direction, and a support disposed inside of at least one of the inflow channel and the outflow channel, and at least one catalyst is coated on one of the inner wall of the inflow channel, the inner wall of the outflow channel, and the support.

Owner:HYUNDAI MOTOR CO LTD

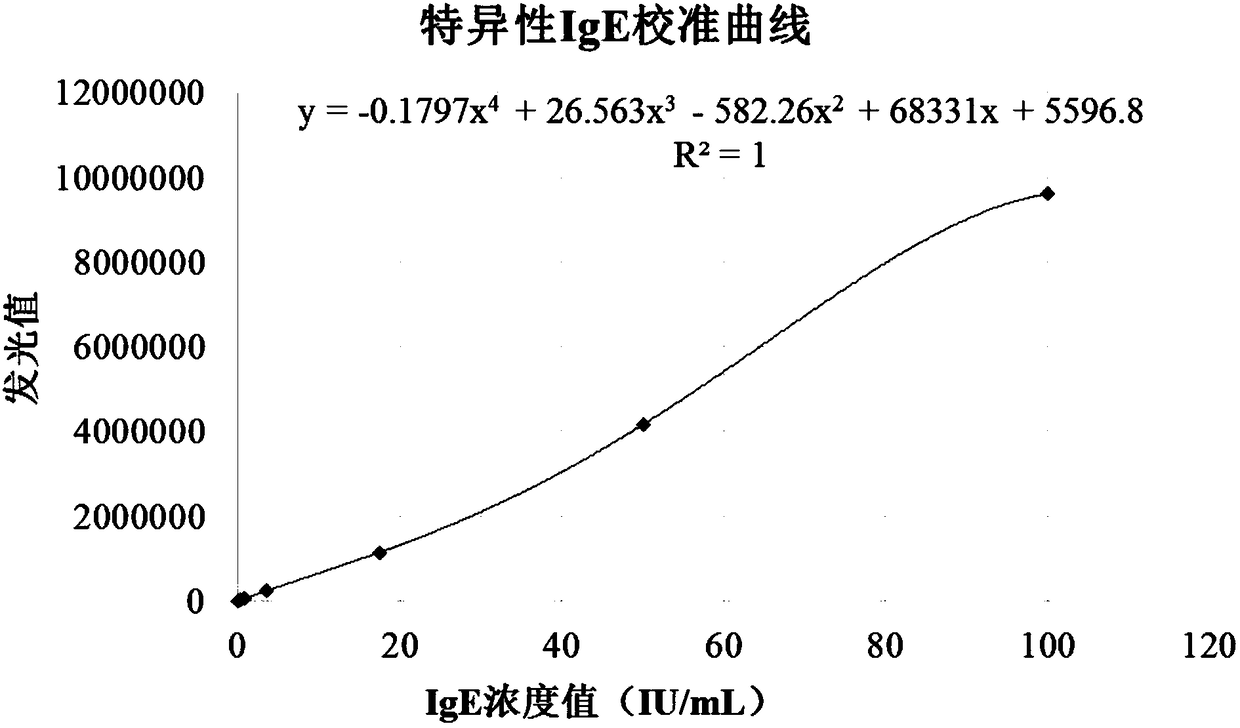

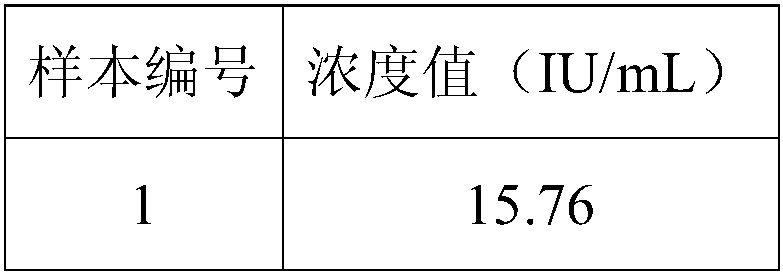

Food allergen specific IgE detection kit and application thereof

InactiveCN108333367AIncrease the amount of coatingImprove featuresBiological testingBiotinFood allergen

The invention provides a food allergen specific IgE detection kit and an application thereof. The kit includes magnetic micro-particles, a food allergen, an enzyme labeled anti human IgE antibody anda substrate, wherein the food allergen is modified with biotin, and the enzyme labeled anti human IgE antibody is modified with alkaline phosphatase. All the reagent components in the kit have good stability, and the kit has the advantages of long validity period, high sensitivity, good accuracy and short detection time.

Owner:AILEX TECH GRP CO LTD +1

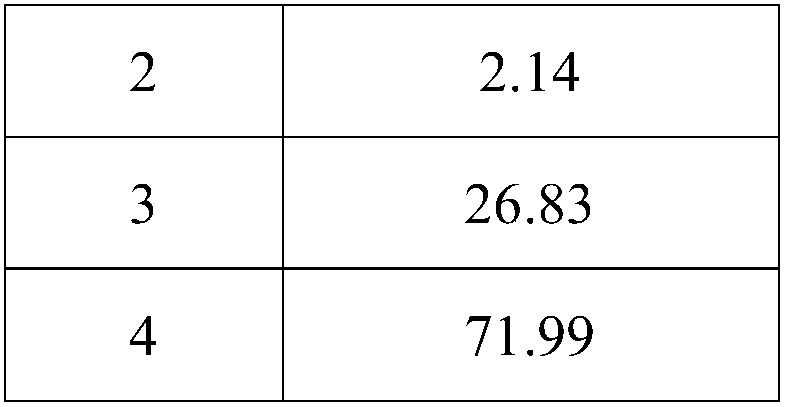

Raw material preparation method of dry method reconstituted tobacco

The invention provides a raw material preparation method of dry method reconstituted tobacco. An ethanol extraction method is adopted, lipid utmost fragrant substances in tobacco residuals such as tobacco powder, broken stalks and fragments are extracted out through a reverse alcohol extraction method and are used for preparing extracta, then, solid-liquid separation is carried out on slag charge, residual ethanol is extracted, remaining moisture is discharged out, and then the slag charge is screened and scattered, and dry method reconstituted tobacco raw materials are manufactured after being dried by a rotary drum dryer. Not only can intrinsic frangrance of natural tobacco be reserved to the maximum degree, but also the pollution of waste water to environment is reduced. The raw material preparation method of the dry method reconstituted tobacco is especially beneficial to accurate measuring of dry method paper-making process reconstituted tobacco equipment to raw materials in the process of manufacturing paper with pulp, and conducive to improving the filling value of the reconstituted tobacco.

Owner:GUANGDONG JINKE REFORGING TOBACCO LEAF CO LTD

Reflecting waterborne heat-insulating coating and preparation method thereof

ActiveCN109082181AGuaranteed uniformityReduce electrostatic repulsionAnti-corrosive paintsReflecting/signal paintsEmulsionAnti freezing

The invention provides reflecting waterborne heat-insulating coating and a preparation method thereof. The reflecting waterborne heat-insulating coating comprises an emulsion, a functional filler, a dispersant, a defoaming agent, a thickener, a film-forming aid, an anti-freezing agent, a pH regulator, a preservative and the balance of water. The functional filler is hollow glass microsphere / titanium dioxide film composite, having core-shell structure; titanium dioxide film is 0.3-0.7 mu m in thickness; titanium dioxide exists in anatase form, and has a coating quantity by weight of 5-25%. Thereflecting waterborne heat-insulating coating prepared herein has good uniformity, has high sunlight reflecting rate, and has small heat conductivity coefficient, good performance stability and excellent heat insulation.

Owner:YUEYANG CHANGLING EQUIP RES INST

Compound silicon dioxide and preparation method thereof and appliance in toothpaste

ActiveCN104944429AWith frictionAbsorbentCosmetic preparationsToilet preparationsChemical industryPhysical chemistry

The invention relates to the technical field of light industrial and chemical industry materials, in particular to a compound silicon dioxide and a preparation method thereof and an appliance in toothpaste. The method for preparing the compound silicon dioxide comprises the steps: 1 preparation of silica sols; 2 excitation of sodium carboxymethylcellulose; 3 surface coated reaction of silicon dioxide; and 4 post-processing of products. The method for preparing the compound silicon dioxide has the advantages of simple method, low production cost, no temperature, no special, complex and expensive equipment, and is suitable for mass production. The compound silicon dioxide which is prepared through the preparation method can be used as toothpaste abrasive agent, also can be used as toothpaste thickener, and has the functions of abrasive agent and thickener at the same time, thereby being capable of simplifying compositions of toothpaste, and saving cost.

Owner:ZHAOQING UNIV

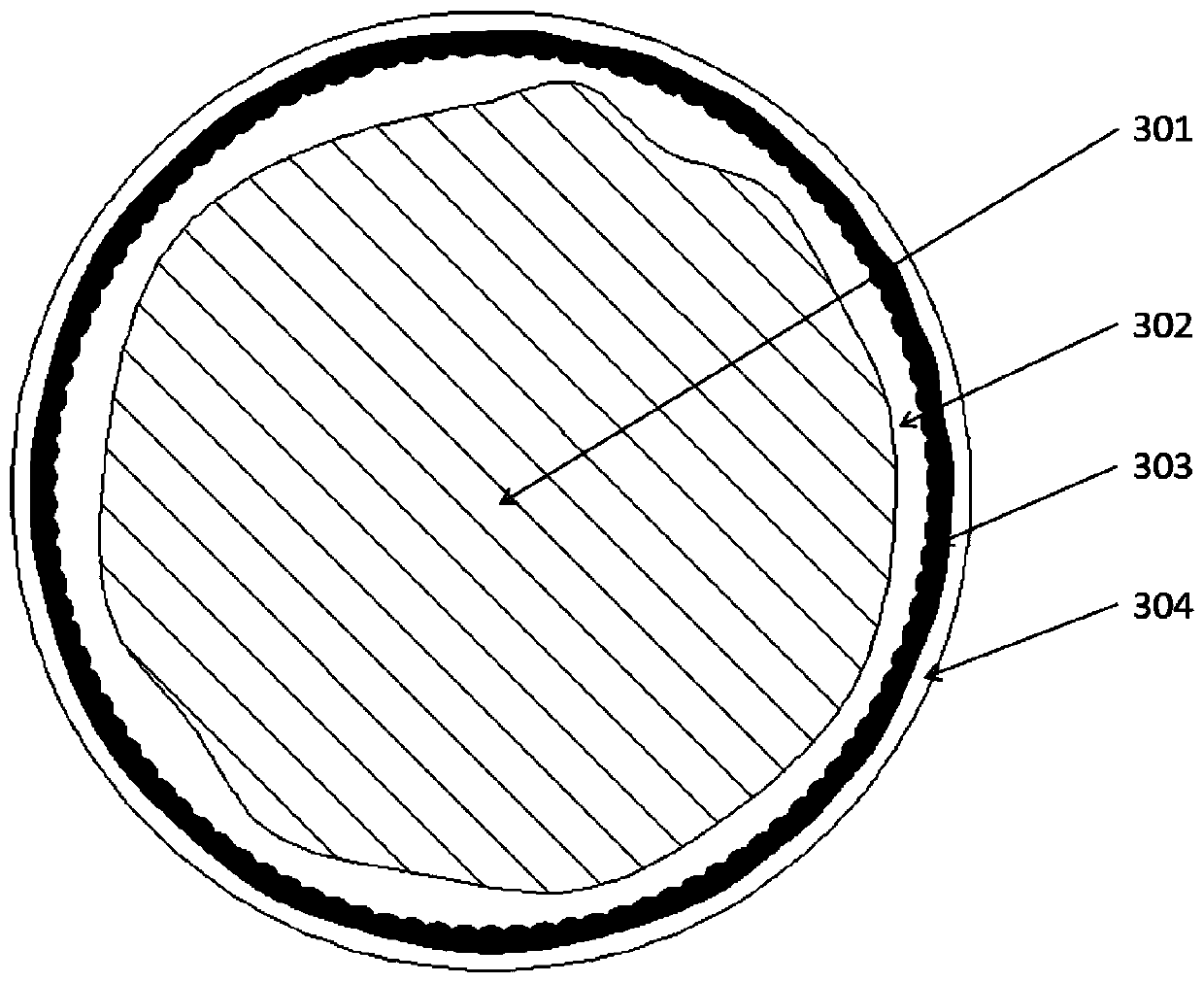

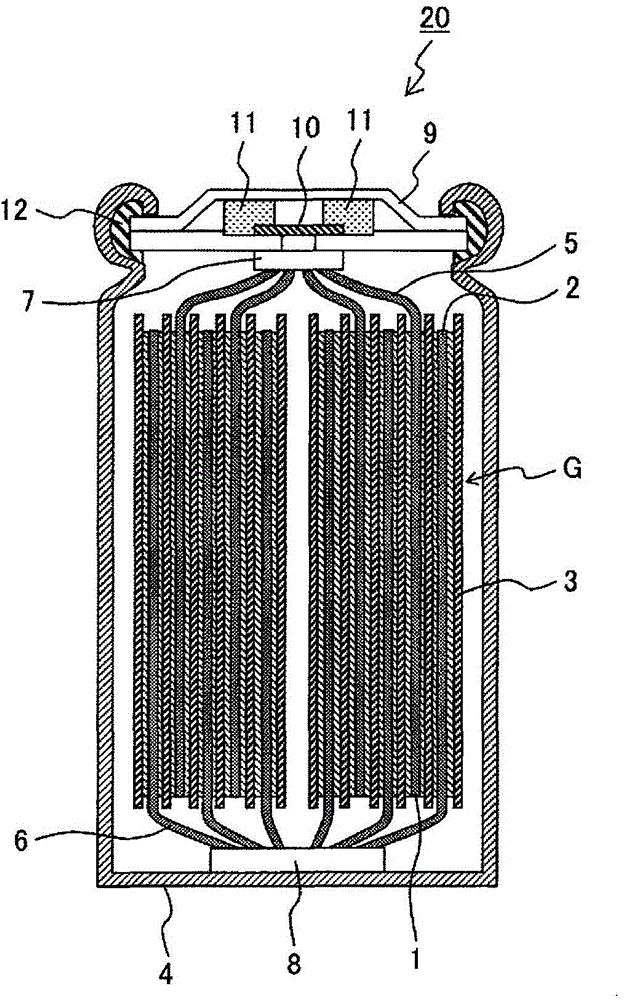

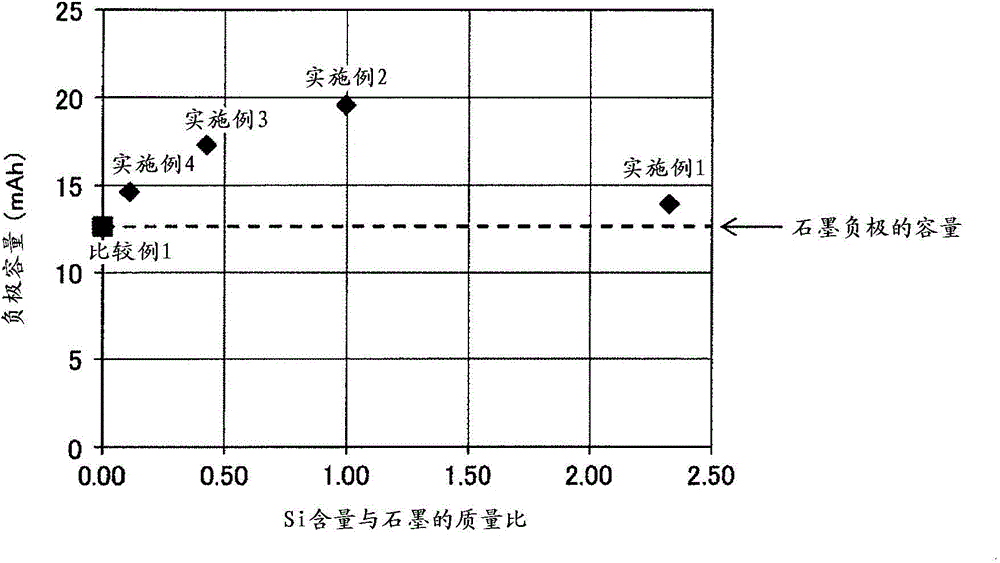

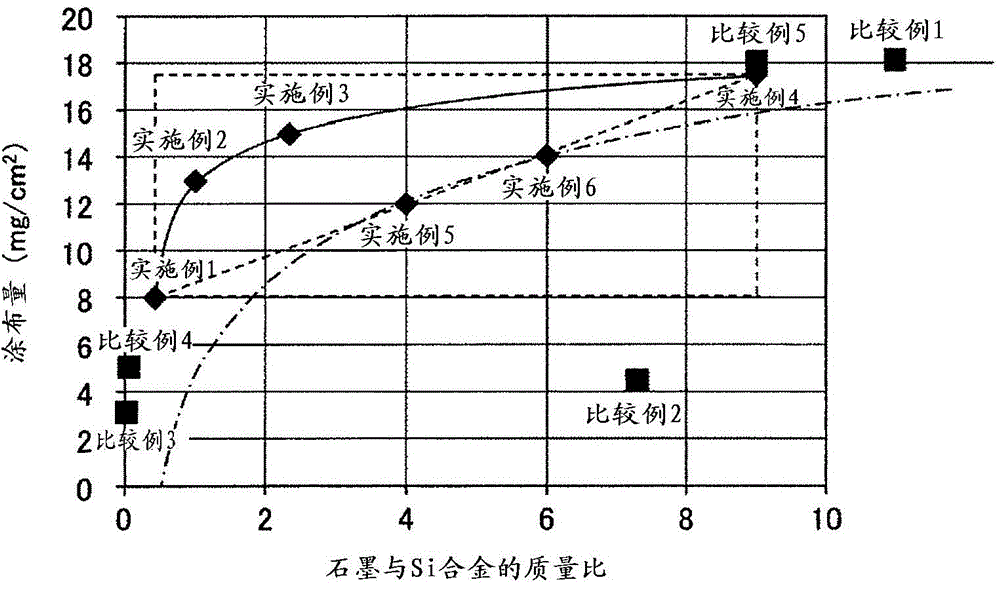

Lithium ion secondary battery

ActiveCN105322137AIncrease the amount of coatingHigh initial capacityCell electrodesSecondary cellsLithiumMass ratio

A lithium ion secondary battery includes: a positive electrode including a positive electrode active material; a negative electrode formed by coating a negative electrode active material mixture onto a surface of a negative electrode collector, the negative electrode active material mixture including a negative electrode active material, a conductive additive, and a binder; a separator interposed between the positive electrode and the negative electrode; and an electrolyte, in which the negative electrode active material includes graphite and an Si alloy, inequities of 0.43<=x<=9.0 and 8<=y<18 are satisfied when a mass ratio of the graphite and the Si alloy is defined as x and a coating amount of the negative electrode active material mixture is defined as y (mg / cm<2>). Thus, an initial capacity thereof can be increased and a capacity retention rate thereof can be improved in the lithium ion secondary battery which includes the Si alloy in the negative electrode.

Owner:HITACHI LTD

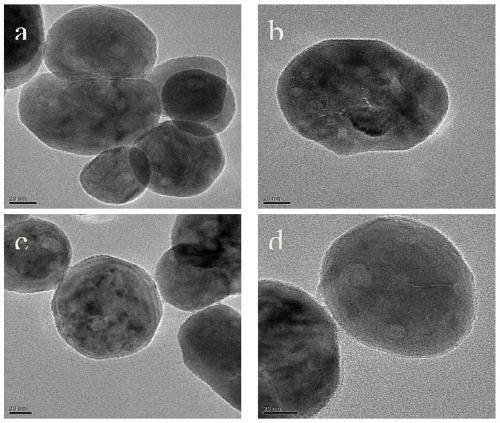

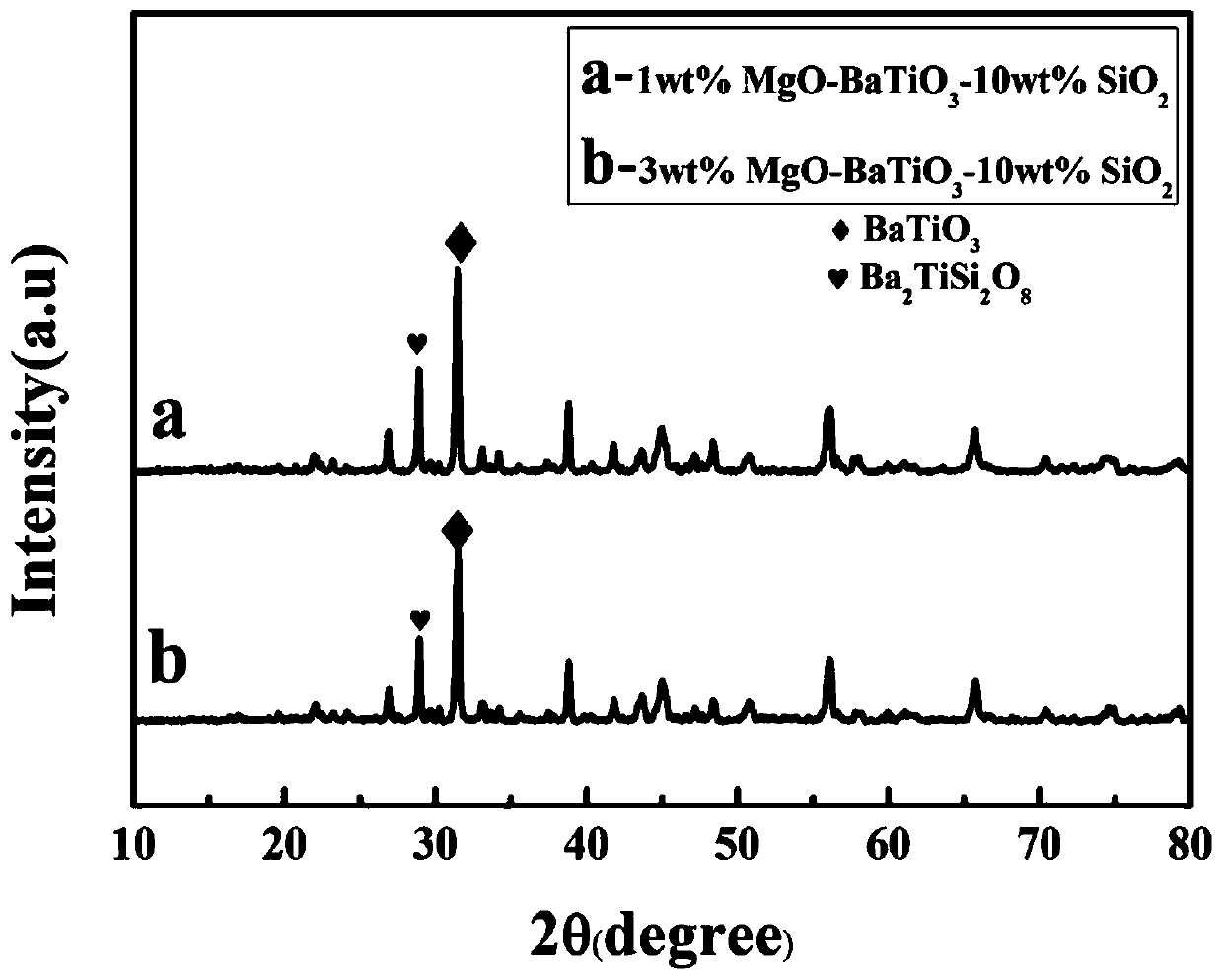

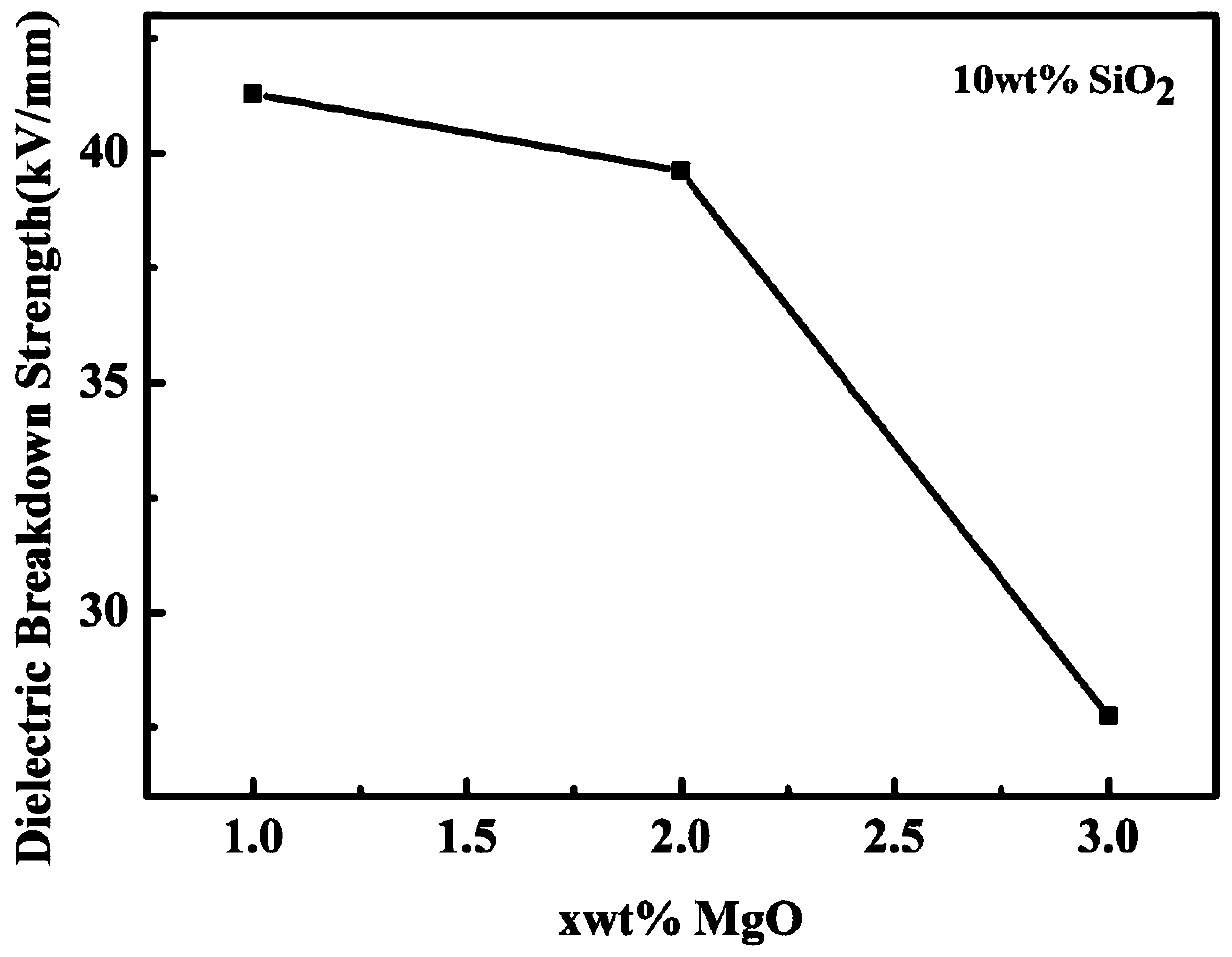

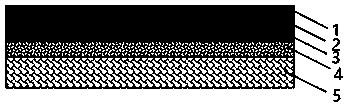

High-voltage-withstanding barium-titanate-based composite ceramic dielectric material and preparation method thereof

ActiveCN110117188AThe preparation process is simple and controllableGood repeatabilityComposite ceramicMetallurgy

The invention relates to a high-voltage-withstanding BaTiO3-based composite ceramic dielectric material and a preparation method thereof. The high-voltage-withstanding BaTiO3-based composite ceramic dielectric material comprises a ceramic material BaTiO3, a MgO coating layer and a SiO2 coating layer, wherein the MgO coating layer is arranged between the SiO2 coating layer and the ceramic materialBaTiO3. MgO coats the surface of BaTiO3 powder by means of a sol-coprecipitation method, SiO2 is added to the coated powder by means of a traditional solid phase method, and the SiO2 and MgO double-layer coated high-voltage-withstanding BaTiO3-based composite ceramic dielectric material is obtained. The BaTiO3-based dielectric material prepared by means of the method is high in voltage withstanding performance, and the direct current withstanding voltage can reach 41 kV / mm or above. In addition, the preparation process is controllable and simple, the repeatability is excellent, there are no special requirements for the granularity and particle size of the raw materials, and the cost is low.

Owner:WUHAN UNIV OF TECH

Special thermosensitive paper for ink jet

InactiveCN109112893AFast absorptionSolve pollutionSpecial paperDuplicating/marking methodsThermal energyThermal insulation

The invention relates to a special thermosensitive paper for ink jet. The special thermosensitive paper sequentially comprises a base paper layer, a prime coat layer, a temperature-resistant chromogenic layer, a protection layer and an absorption layer from bottom to top, wherein the prime coat layer, the temperature-resistant chromogenic layer, the protection layer and the absorption layer are respectively coated with different coating liquids. According to the present invention, the ink absorption speed of the special thermosensitive paper coating having the protection layer can be improved;the absorption layer is coated on the protection layer to achieve the rapid drying purpose, such that the problem of paper surface pollution or unclear pattern caused by difficult drying can be solved; the influence on the thermal insulation of the printing can be solved by additionally arranging the absorption layer; the prime coat layer uses a sufficient amount of the hollow spheres, and the coating amount is increased, such that the heat insulation effect can be improved; with the chromogenic layer, the chromogenesis cannot be affected by the drying temperature when the prefabricated bar code is dried; the protection layer does not require the adding of the organic filler so as to improve the heat transfer effect; and the absorption layer uses the inorganic filler with advantages of strong absorption and good heat transfer performance so as to easily transfer the heat.

Owner:JIANGSU WANBAO RUIDA HI TECH CO LTD

Chocolate, and coated frozen beverage and preparation method thereof

The invention discloses chocolate, and a coated frozen beverage and a preparation method thereof. The chocolate is prepared from sugar, milk powder, corn oil, butter, cocoa powder, cocoa mass, dextrinpowder, phospholipid, polyglycerol ricinoleate and lipase. According to the invention, the raw materials are reasonably proportioned, and in particular, the corn oil, butter and lipase are added intothe chocolate, so the viscosity of the chocolate is balanced, a crispy chocolate layer formed by the chocolate is not easy to crack and overflow, the viscosity of the chocolate is improved, the damping coefficient of the chocolate can be increased, and a settling speed is reduced.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Period indicator

InactiveUS7472667B2Improve the display effectEasy to observeStampsAnalysis using chemical indicatorsParticulatesRefractive index

A period indicator including a liquid-permeable substrate and an indicative section which is overlaid on a portion of the substrate and which is formed from a liquid-permeable material having a low light refractive index, the indicator containing a volatile liquid, wherein the indicative section is formed by coating a surface of the substrate with an indicative-section-forming material prepared by mixing a binder and finely divided particulate matter having a low light refractive index, the indicative section is composed of two or more regions, and the regions differ in height from one another as measured from the surface of the substrate, as the coating amounts per unit area of the indicative section forming material in respective regions differ from one another. Since the period indicator can indicate the chemical-containing state stepwise, it is useful for indicating the available period of use of a chemical such as a mothproofing agent, an insecticide, a deodorant, or a fragrance.

Owner:NIPPON PAPER PAPYLIA +1

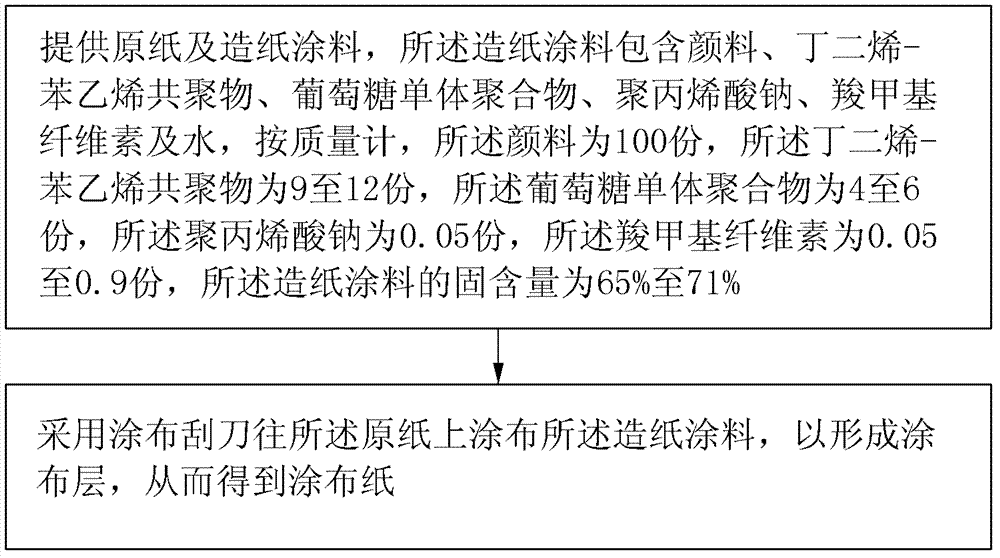

Papermaking coating, making method of coated paper using papermaking coating and coated paper

ActiveCN102817279AHigh through-thickness stressEvenly distributedCoatings with pigmentsReinforcing agents additionPapermakingMethyl cellulose

A papermaking coating comprises, by weight, 100 parts of pigment, 9-12 parts of butadiene-phenylethylene copolymer, 4-6 parts of glucose monomer polymer, 0.05 part of sodium polyacrylate, 0.05-0.9 part of carboxyl methyl cellulose, and water. The solid content of the papermaking coating is 65%-71%. The invention further provides a making method of coated paper using the papermaking coating, and the coated paper.

Owner:GOLD EAST PAPER JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com