Foaming coating inner lighting advertising cloth and preparation technology thereof

A foam coating and preparation process technology, applied in the field of advertising cloth, can solve the problems of incapable of high coating amount, poor printing quality, easy to produce wrinkles, etc., achieving easy control of coating amount, fine printing quality, Low permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

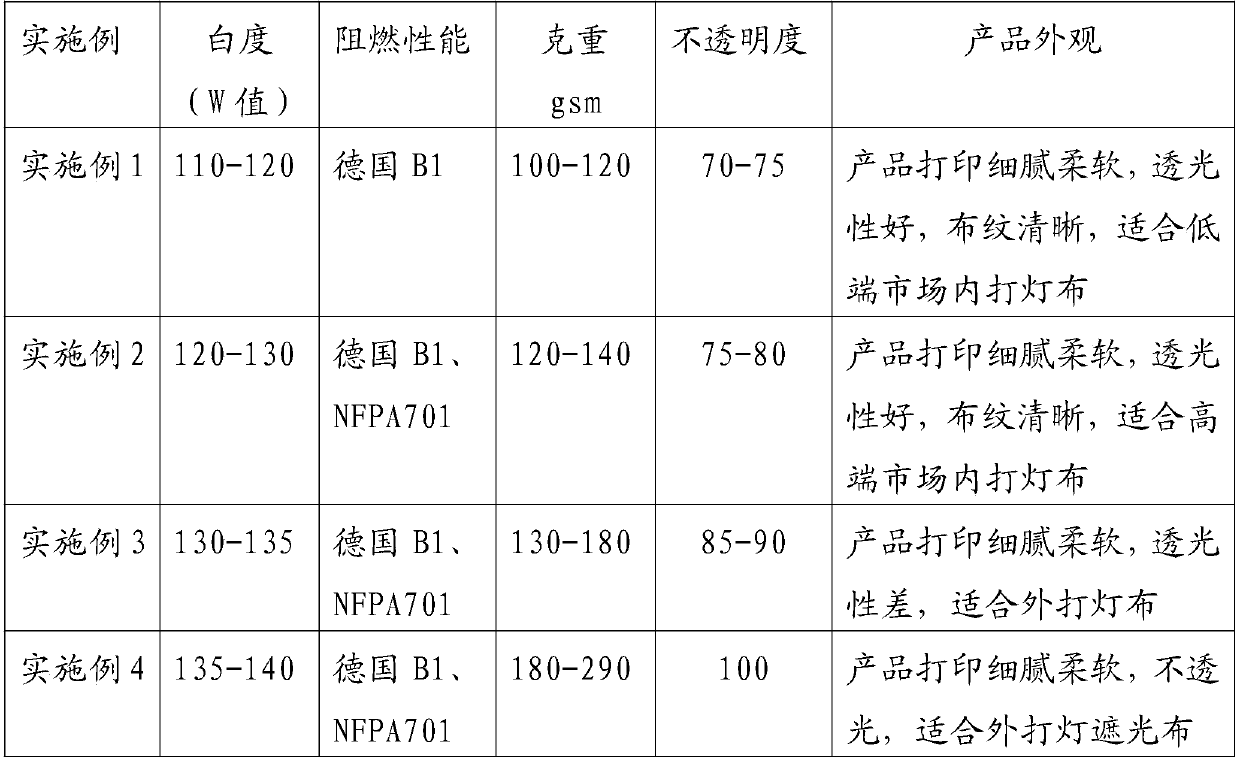

Embodiment 1

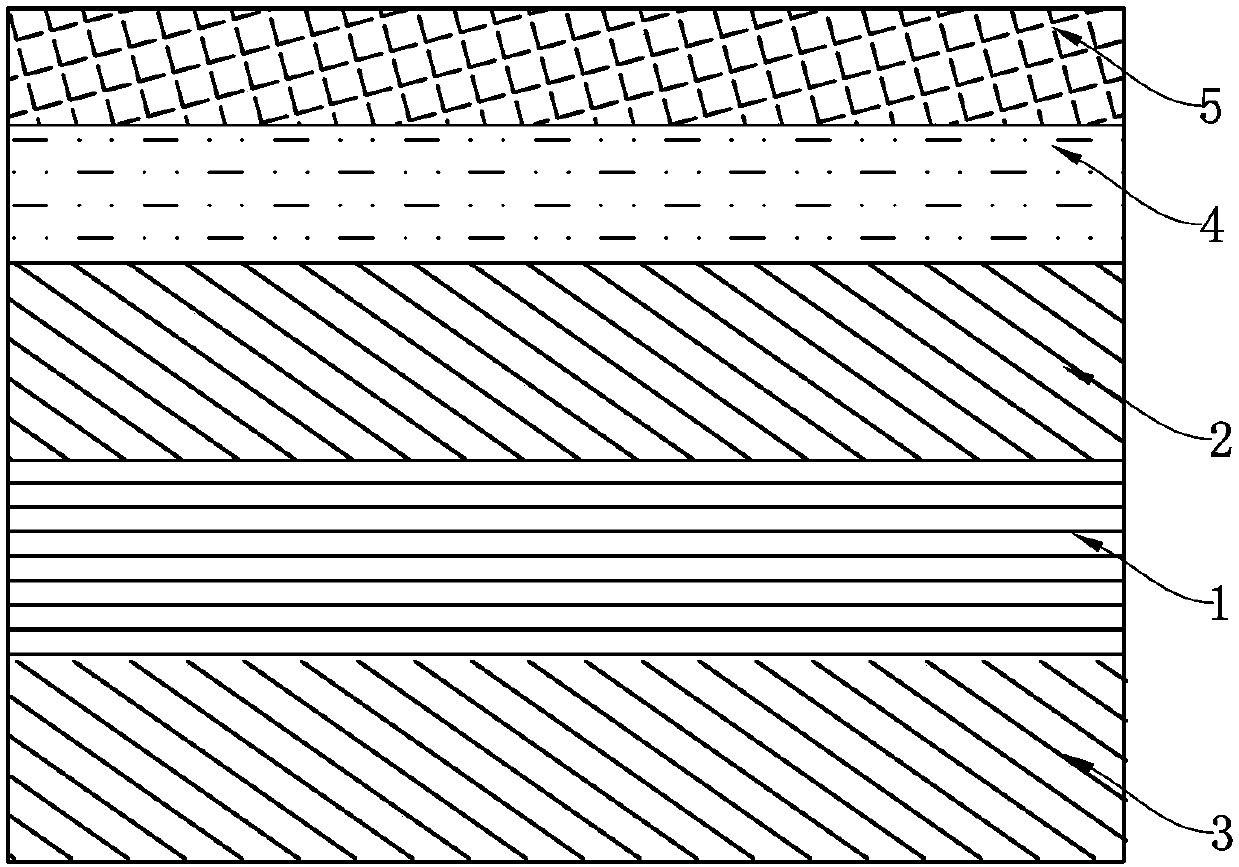

[0037] A foam-coated inner lighting advertising cloth, such as figure 1 As shown, the base fabric layer 1 (polyester chemical fiber cloth) is included, and the upper and lower sides of the base fabric layer 1 are coated with a whitening and waterproof layer 2 respectively, and the surface of the whitening and waterproof layer 2 on one side is coated with a foaming flame-retardant Coating 4, the surface of the foaming flame-retardant coating 4 is coated with an ink-absorbing coating 5;

[0038] Among them, the foaming flame retardant coating is 50 parts of textile emulsion, 10 parts of foaming agent (sodium lauryl sulfate), 40 parts of foam stabilizer (ammonium stearate), 2 parts of talcum powder, 10 parts of kaolin, nanocarbonic acid 2 parts of calcium, 10 parts of titanium dioxide dispersion, 40 parts of composite flame retardant (10 parts of antimony trioxide and 30 parts of ammonium polyphosphate) are compositely coated on the surface of the whitening waterproof layer to fo...

Embodiment 2

[0049] A foam-coated inner lighting advertising cloth, such as figure 1 As shown, the base fabric layer 1 (polyester chemical fiber cloth) is included, and the upper and lower sides of the base fabric layer 1 are coated with a whitening and waterproof layer 2 respectively, and the surface of the whitening and waterproof layer 2 on one side is coated with a foaming flame-retardant Coating 4, the surface of the foaming flame-retardant coating 5 is coated with an ink-absorbing coating 5;

[0050] Among them, the foaming flame retardant coating is 65 parts of textile emulsion, 12 parts of foaming agent (sodium lauryl sulfate), 45 parts of foam stabilizer (ammonium stearate), 4 parts of talcum powder, 15 parts of kaolin, nanocarbonic acid 5 parts of calcium, 15 parts of titanium dioxide dispersion, 50 parts of composite flame retardant (20 parts of antimony trioxide and 30 parts of aluminum trioxide) are compositely coated on the surface of the whitening waterproof layer to form a ...

Embodiment 3

[0061] A foam-coated inner lighting advertising cloth, such as figure 1 As shown, the base fabric layer 1 (polyester chemical fiber cloth) is included, and the upper and lower sides of the base fabric layer 1 are coated with a whitening and waterproof layer 2 respectively, and the surface of the whitening and waterproof layer 2 on one side is coated with a foaming flame-retardant Coating 4, the surface of the foaming flame-retardant coating 4 is coated with an ink-absorbing coating 5;

[0062] Among them, the foaming flame retardant coating is 70 parts of textile emulsion, 13 parts of foaming agent (sodium lauryl sulfate), 53 parts of foam stabilizer (ammonium stearate), 6 parts of talcum powder, 18 parts of kaolin, nanocarbonic acid 8 parts of calcium, 18 parts of titanium dioxide dispersion, 60 parts of composite flame retardant (30 parts of aluminum oxide and 30 parts of ammonium polyphosphate flame retardant) are compositely coated on the surface of the whitening waterproo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com