Patents

Literature

74 results about "AMMONIUM STEARATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

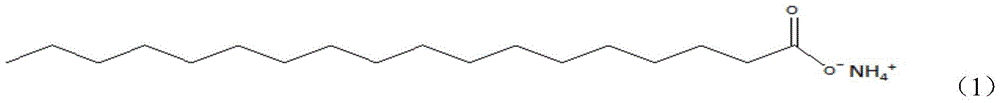

AMMONIUM STEARATE has weak oxidizing or reducing powers. Redox reactions can however still occur. The majority of compounds in this class are slightly soluble or insoluble in water .

Ammonium stearate emulsion and producing method thereof

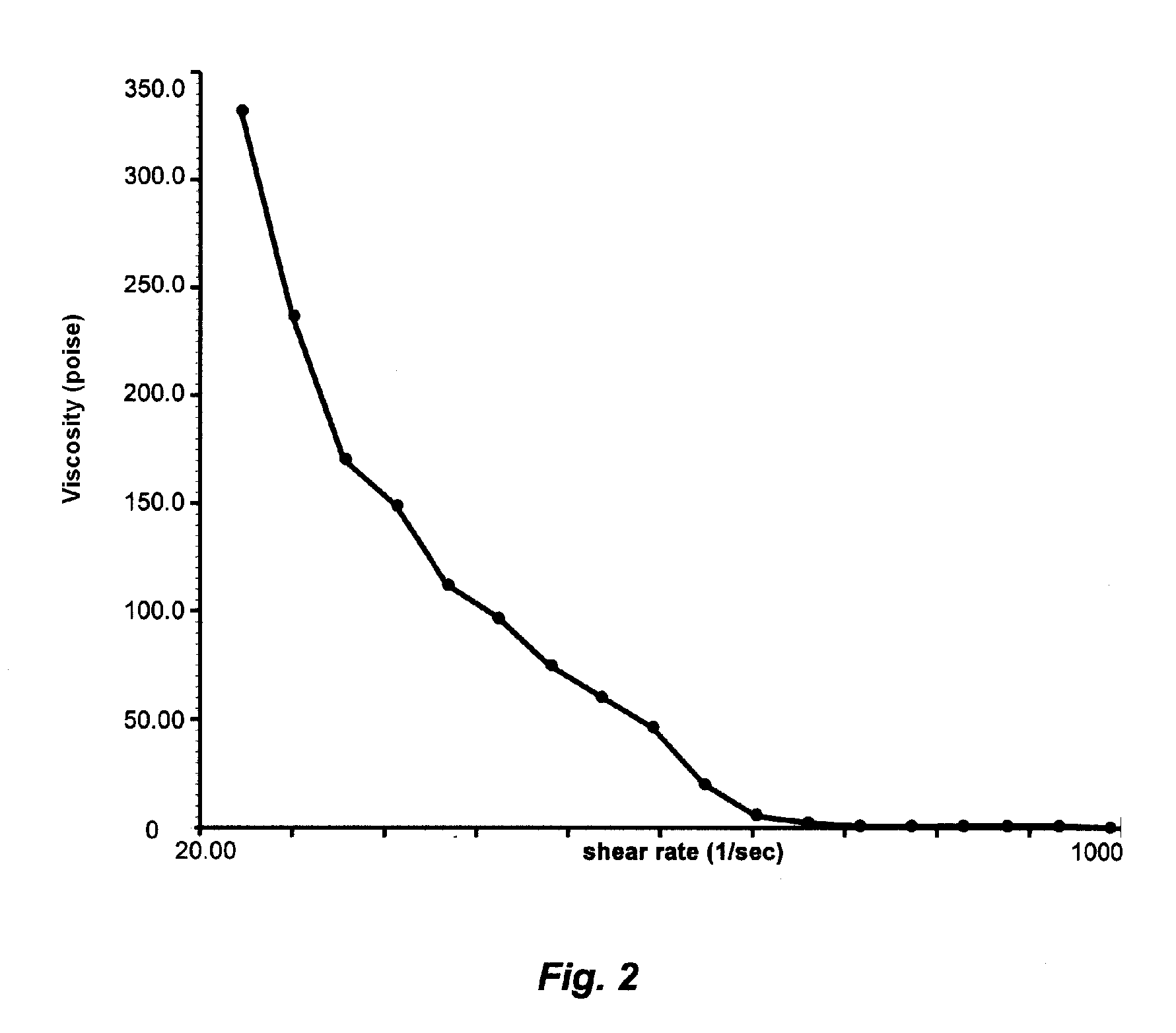

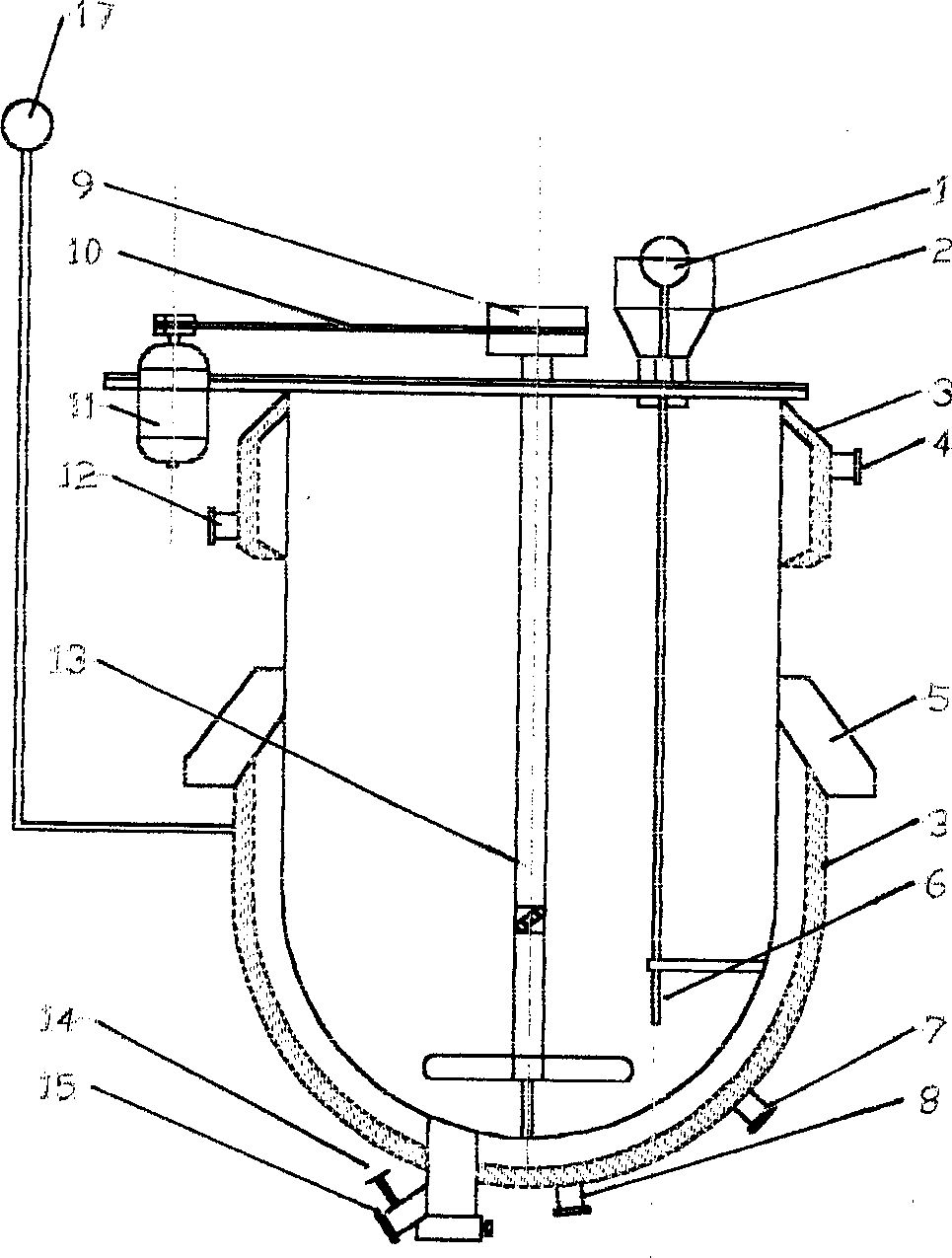

The invention relates to ammonium stearate emulsion and a producing method thereof, belonging to the technical field of auxiliary chemicals. The ammonium stearate emulsion comprises the following components with the weight percentage: 15-35% of stearic acid, 6-14% of 20% ammonia water, 1-3% of lauryl sodium sulfate and the rest of water. The production technique is that a reaction vessel is sequentially added with the stearic acid, the lauryl sodium sulfate and the water according to the formulation amount, the temperature is regulated to be 10-25 DEG C; after being evenly stirred, the mixture in the reaction vessel is added with the ammonia water, and the mixing speed is adjusted; the prepared ammonium stearate liquid is absorbed into an emulsifying tank for emulsification, stands still for 1-2h, and then is filtered, so that the ammonium stearate emulsion is obtained. The invention is suitable for large scale continuous production, ensures the reaction to be very safe under normal temperature and pressure, and has the advantages of simple input equipment, saved cost, no pollution and emission in the whole production process, silvery white and lustrous finished products, excellent fluidness and stability, low product viscosity (being lower than or equal to 350cps), high purity, good dispersion effect and convenient use. The ammonium stearate emulsion can be fully dispersed in waterborne liquid, has about six-month shelf life and is hard to become thick after being placed for a long time.

Owner:海宁市树桥纺织科技有限公司

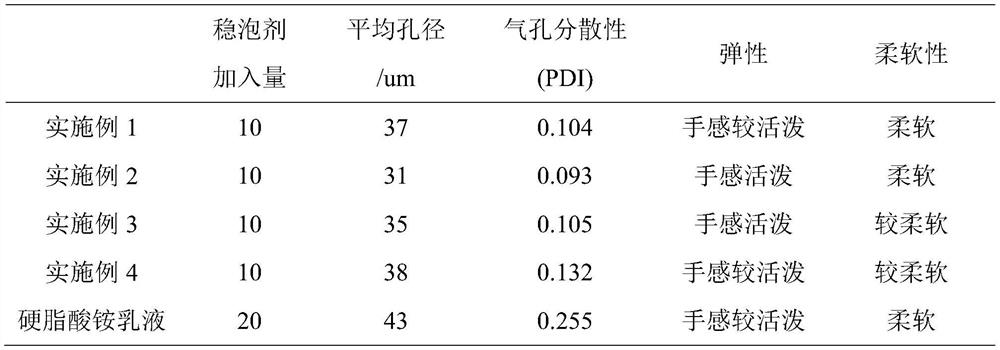

Reinforced cement foaming board and preparation method thereof

InactiveCN103172327AGuaranteed carbonization indexStrength does not shrinkCeramic shaping apparatusCeramicwareFiberPolymer science

The invention relates to a reinforced cement foaming board and a preparation method thereof. The reinforced cement foaming board comprises the following components in percentage by weight: 27.00-35.50% of water, 28.0-61.0% of Portland cement, 0-32.70% of coal ash at grade I or a mixture of coal ash and recycled filler, 0-2.00% of wollastonite powder, 0.10-0.30% of fiber, 0.37-0.65% of ammonium stearate, 1.00-2.00% of a mixture of 10 parts of calcium sulphate and 1 part of calcium formate, 0.10-0.20% of naphthalenesulfonate formaldehyde condensation compound, 0.90-1.20% of hydrogen peroxide and reinforcement net. The reinforced cement foaming board provided by the invention has the advantages of low apparent density, low heat conductivity coefficient, good noise reduction effect, high strength, no crack and shock resistance.

Owner:上海中驰建筑工程有限公司

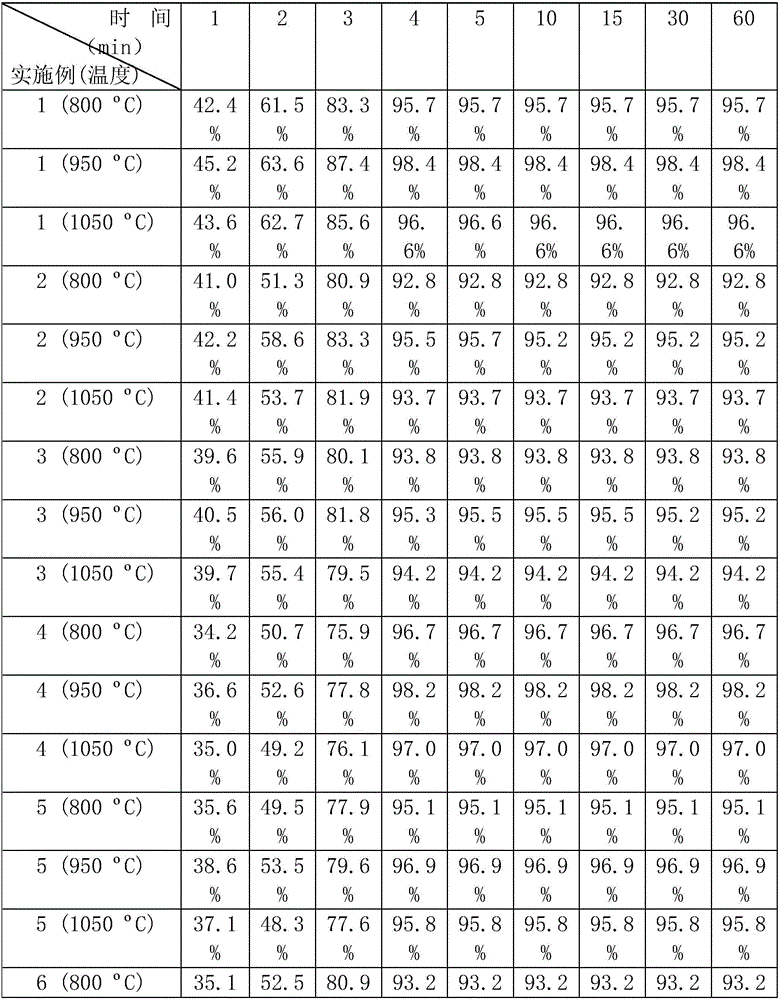

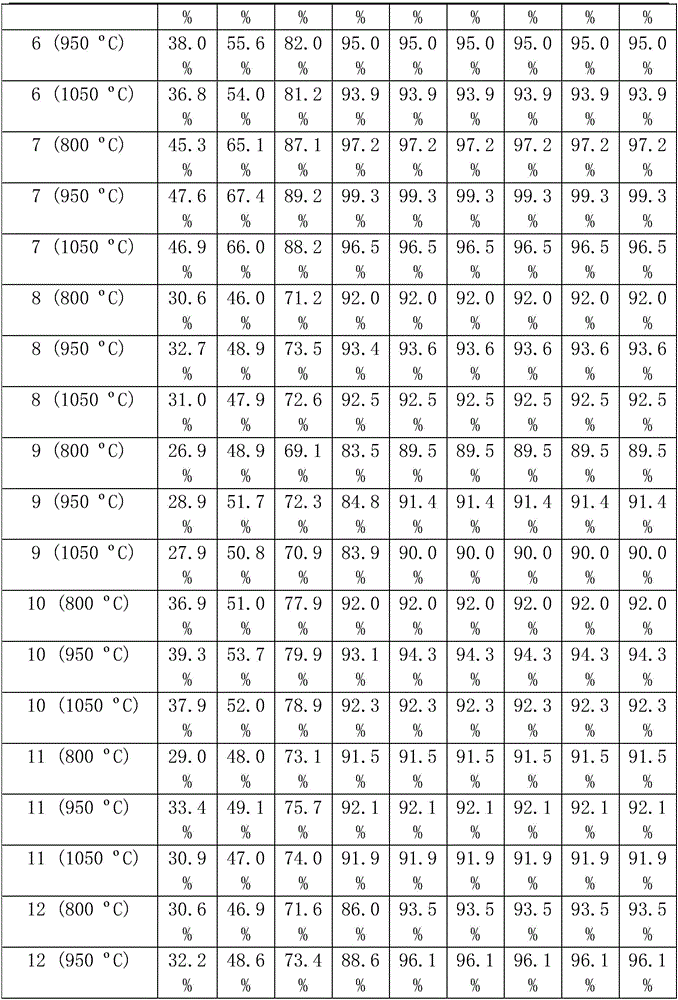

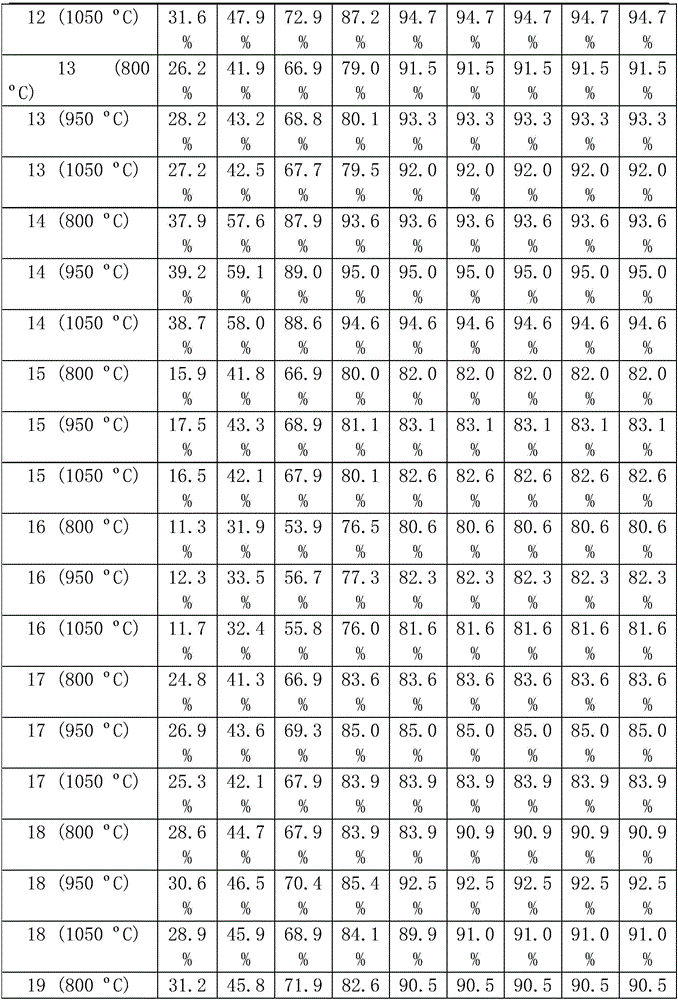

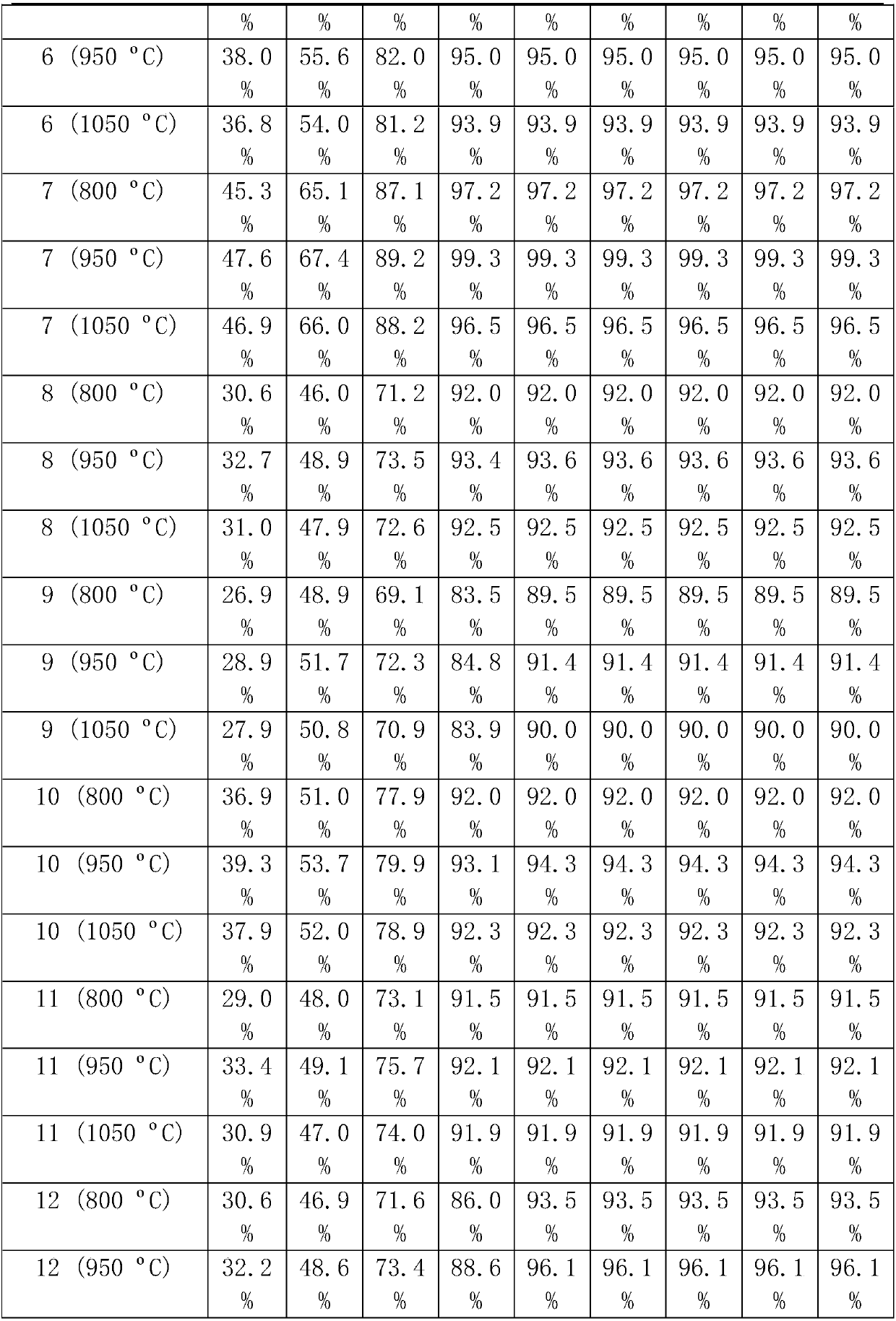

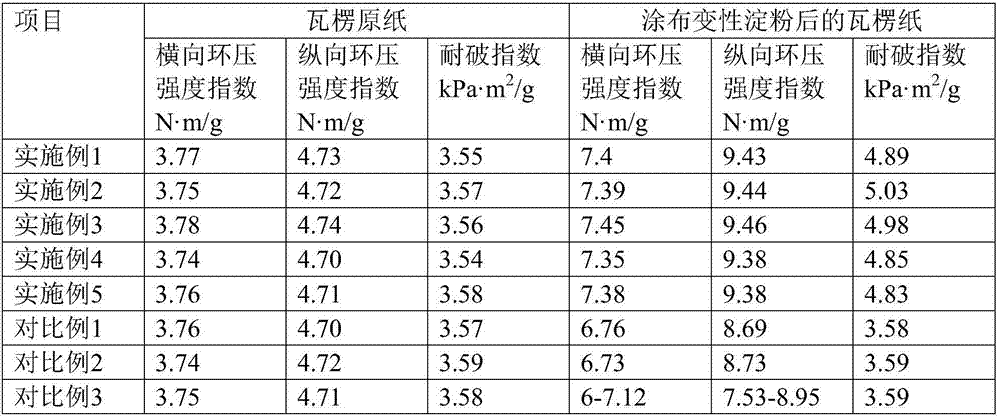

High-polymer denitration agent and preparation method thereof

The invention discloses a composite denitration agent. The composite denitration agent is characterized by comprising the following components comprising the three parts all in parts by mass: (1) 30.0-99.0 parts of an ammonium / amine source which takes at least one of urea, ammonium carbonate, ammonium bicarbonate, ammonium acetate, ammonium sulfate, melamine and benzene substituted melamine, (2) 1.0 to 70.0 parts of a synergistic polymer which comprises polyacrylic acid salts and / or polyalkyl acrylates and / or polyacrylamides as well as copolymer polymer carriers and / or polymer fillers, and (3) 0 to 10.0 parts of other components which at least comprise the power comprising one of the following components: ammonium stearate, magnesium stearate, calcium stearate, a mould inhibitor, precipitated calcium carbonate, magnesium oxide and zeolite. The denitrification rate of the denitration agent can reach 82.3% to 99.3% at the temperature of 800 to 1050 DEG C. The composite denitration agent is simple in preparation method and can be widely used in high-temperature gas denitration situations of a thermal power plant, a waste incineration plant and the like.

Owner:SHENZHEN HUAMING ENVIRONMENTAL PROTECTION TECH CO LTD

Admixture for improving marine concrete impervious and anti-cracking performance

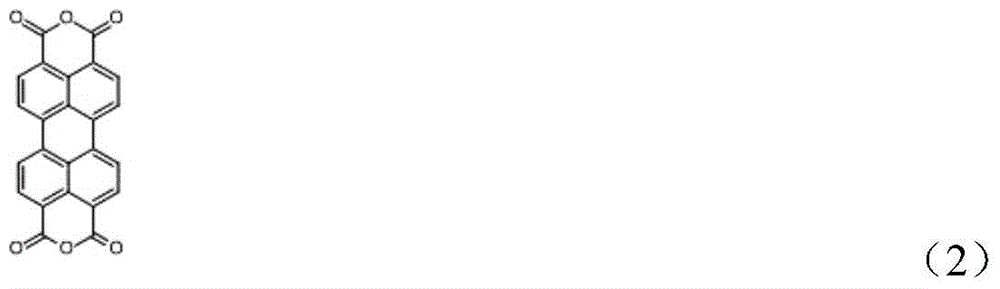

ActiveCN105669073AIncrease in sizeIncrease the probability of cross-linking fusionCelluloseWork Performances

The invention discloses an admixture for improving marine concrete impervious and anti-cracking performance. The admixture is prepared from an ammonium stearate emulsion, 3, 4, 9, 10-perylenetetracarboxylic acid anhydride (PAT), a nano-silica dispersion solution, an ultra-dispersed shrinkage-reducing type water reducer, micron-sized modified absorbent cotton cellulose and water in proportion. According to the invention, the ammonium stearate emulsion is employed to form a thin complex adsorptive layer of insoluble calcium soap in marine concrete capillary pores to block concrete capillary pores. And a PAT optimized pore structure is utilized to improve the impervious performance and work performance of marine concrete. The nano-silica dispersion solution is employed to enhance the mechanical properties of marine concrete. The ultra-dispersed shrinkage-reducing type water reducer is utilized to reduce concrete shrinkage and improve the work performance. The micron-sized modified absorbent cotton cellulose is utilized to enhance the anti-cracking performance of marine concrete. The admixture provided by the invention does not contain nitrite, chromate and the like, is chlorine-free and environment-friendly, and can greatly enhance the durability of concrete serving in a marine environment.

Owner:HAINAN RUIZE NEW BUILDING MATERIAL +1

Foam stabilizer and producing method thereof

ActiveCN101016427AQuality improvementImprove performanceLiquid surface applicatorsTransportation and packagingWarm waterCoconut oil

The invention discloses a foam stabilizer to be used to foaming coating and foaming flocked pile, which comprises the following steps: adding 20-35% ammonium stearate, 1-5% dodecyl sodium sulfate, 1-10% coconut oil acetal acidamide into reacting vessel sequentially; adding into warm water; controlling the temperature at 20-28 deg.c; stirring evenly; adding into ammonia water; capping 20-40 min till presenting pasty state; stirring continually; capping and placing 12-18 h; stirring with high speed; getting the product. This invention possesses simple craft, jade white product, good flow ability and low viscosity, which assured quality time can reach 6 month.

Owner:海宁市名人居纺织有限公司

Graphene-organosilicon modified urethane resin synthetic leather

InactiveCN106702750AGood high and low temperature resistanceLower surface energyPolyurea/polyurethane coatingsTextiles and paperWater basedAMMONIUM STEARATE

The invention relates to a graphene-organosilicon modified urethane resin synthetic leather, which is prepared from the following ingredients: graphene-organosilicon modified urethane resin, fluorine-modified alkide resin, propylene glycol n-butyl ether, a flatting agent, a thickening agent, a foaming agent, a filler, a water-based color paste, a plasticizer, an ammonium stearate emulsion and de-ionized water, wherein the graphene-organosilicon modified urethane resin is prepared through reaction of polyisocyanate, polyhydric alcohol, a polybasic amine chain extender, oligomer polyhydric alcohol, dimethylolpropionic acid, organosilicon, graphene, a neutralizer and de-ionized water; the synthetic leather prepared by the invention is capable of effectively preventing statical electricity, and has the characteristics of good abrasion resistance, high crosslinking density, good chemical resistance and no pollution.

Owner:康伦国

Precoated sand accelerating casting part forming and preparation method thereof

InactiveCN107096871ASpeed up moldingImprove molding qualityFoundry mouldsFoundry coresTetramineSand casting

The invention relates to the field relative to precoated sand casting technologies, in particular to precoated sand accelerating casting part forming. The precoated sand is prepared from the following components of a silica sand body, a ceramsite sand body, a magnetite sand body, thermoplastic phenolic resin, modified polyester resin, hexamethylene tetramine, ammonium acetate, calcium stearate, ceramic glaze powder, ammonium stearate and a forming agent. According to the precoated sand accelerating casting part forming, the problem that a majority of precoated sand is low in forming speed and poor in forming effect is solved, the forming agent is added into the precoated sand, and the specific precoated sand preparation technology is matched, so that through the preparation method of the precoated sand, the casting part forming speed can be increased, and the casting part forming quality can be improved, and casting efficiency is improved.

Owner:李吕军

Making method for high-tap-density surface-modified silver powder

The invention relates to a manufacturing method for high-tap-density surface-modified silver powder. The manufacturing method for the high-tap-density surface-modified silver powder comprises the following steps that zirconium balls and a surface treatment agent are ball-milled, so that a layer of surface treatment agent is evenly attached to the surfaces of the zirconium balls to obtain modified zirconium balls, wherein the surface treatment agent is selected from at least one of ammonium stearate, oleic acid and palmitic acid; after the modified zirconium balls and silver powder are ball-milled for 20-120 minutes, the high-tap-density surface-modified silver powder is obtained. The high-tap-density surface-modified silver powder manufactured through the manufacturing method is high in tap density.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

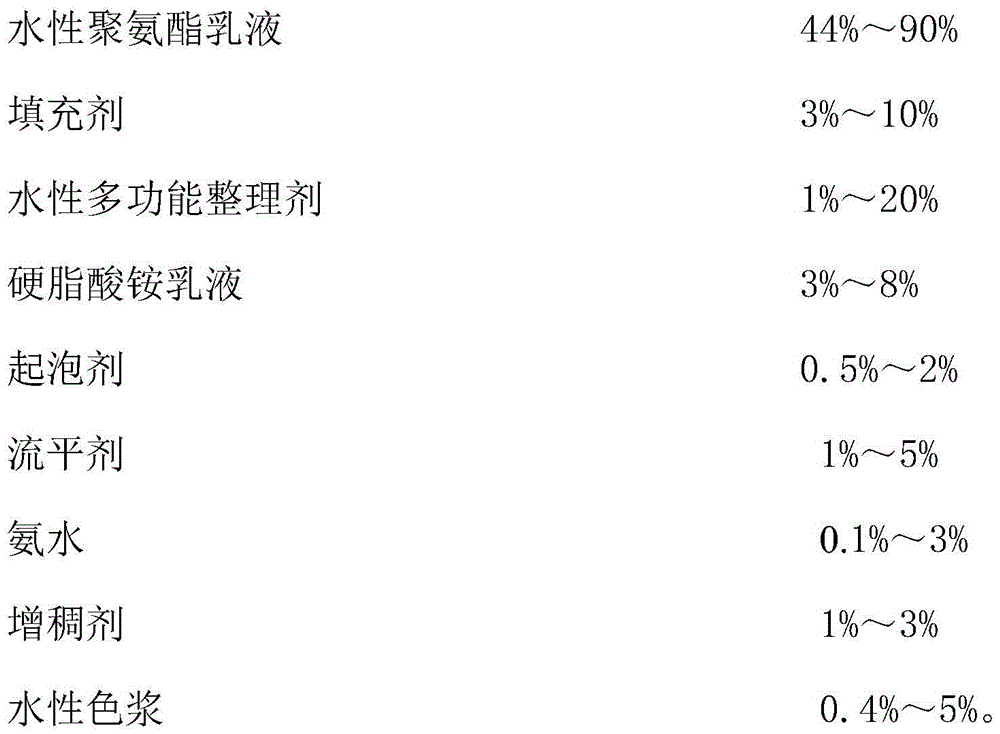

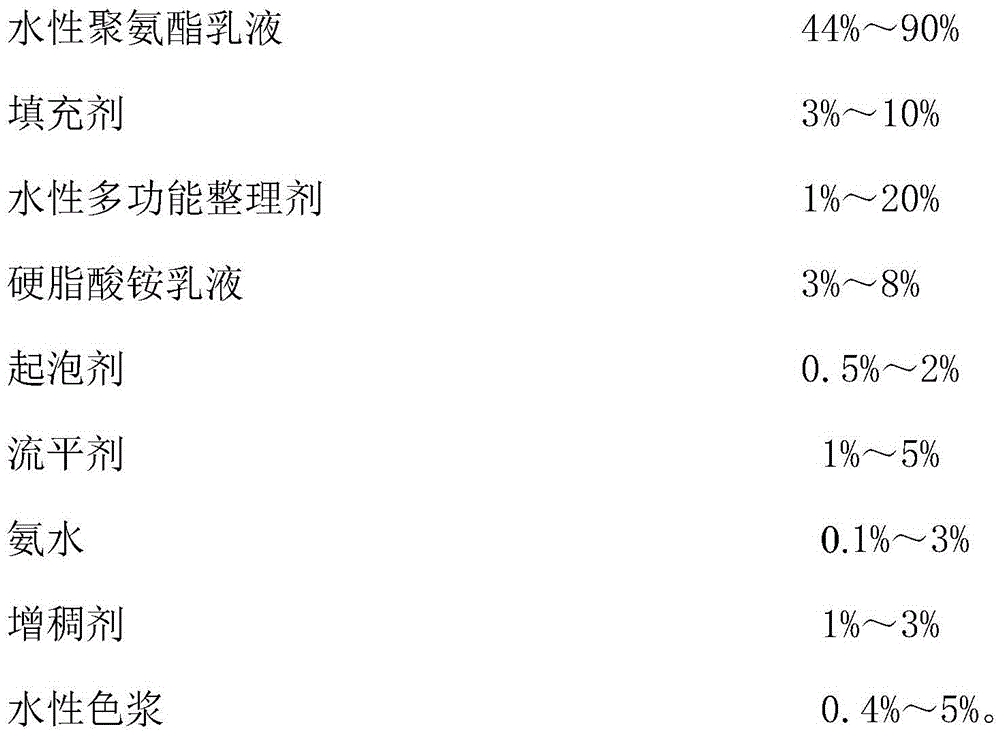

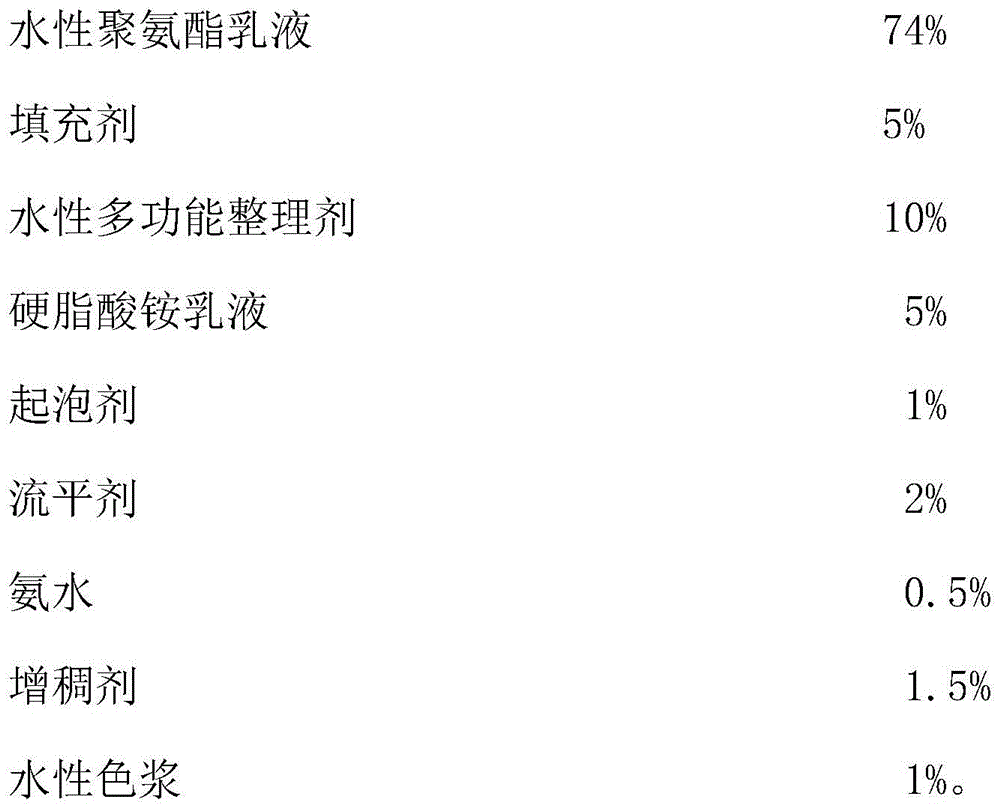

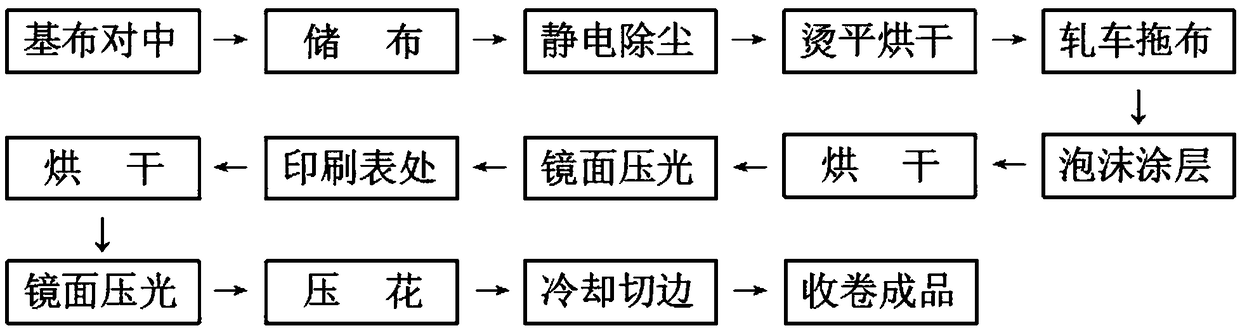

Formula and process for producing multifunctional synthetic leather from waterborne polyurethane intumescent coating

The invention discloses a formula for producing a multifunctional synthetic leather from a waterborne polyurethane intumescent coating. The formula includes a coating liquid; the coating liquid comprises the following components: 44%-90% of waterborne polyurethane emulsion, 3%-10% of a filler, 1%-20% of an aqueous multifunctional finishing agent, 3%-8% of ammonium stearate emulsion, 0.5%-2% of a foaming agent, 1%-5% of a leveling agent, 0.1%-3% of aqueous ammonia, 1%-3% of a thickener and 0.4%-5% of an aqueous color paste. A process is as below: preparing a coating solution; preparing a coating foam, and then applying the coating foam to a leather fabric through precise control of the coating amount by the computer; drying in an oven; and conducting post-treatment to obtain the multifunctional synthetic leather. The product has strong skin feel, soft handle and good peeling resistance and fastness; the coating solution has low water content, and significantly reduces drying energy and water resource; and the entire production process does not produce any sewage or exhaust emission, and is in line with environmental requirements.

Owner:宋婷婷

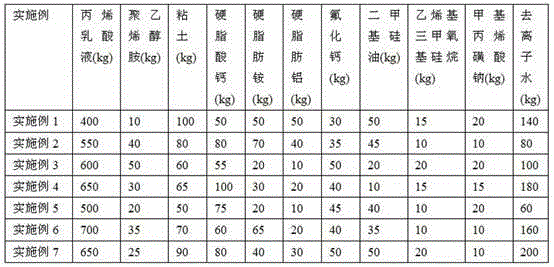

Building waterproof agent

The present invention provides a safe and non-toxic building waterproof agent, and belongs to the field of building additives. The building waterproof agent of the present invention comprises, by weight, 40-70 parts of an acrylic acid emulsion, 1-5 parts of polyvinyl alcohol amine, 5-10 parts of clay, 5-10 parts of calcium stearate, 2-7 parts of ammonium stearate, 1-5 parts of aluminum stearate, 3-5 parts of calcium fluoride, 1-5 parts of dimethyl silicone oil, 1-2 parts of vinyltrimethoxysilane, 1-2 parts of sodium methyl acryl sulfonate, and 6-20 parts of deionized water. The preparation method comprises: uniformly mixingan an acrylic acid emulsion, polyvinyl alcohol amine, clay, calcium stearate, ammonium stearate, aluminum stearate, calcium fluoride and sodium methyl acryl sulfonate to obtain a mixture, heating to a temperature of 30-50 DEG C, stirring dimethyl silicone oil, vinyltrimethoxysilane and deionized water to obtain a mixed material, and slowly adding the mixed material to the mixture. The building waterproof agent of the present invention has characteristics of inexpensive raw materials, simple preparation method and significant waterproof effect.

Owner:QINGDAO WINCHANCE TECH

Calcium stearate production method

InactiveCN102875356AQuality improvementNo emissionsCarboxylic acid salt preparationDecompositionReaction temperature

The invention discloses a calcium stearate production method. The calcium stearate production method is characterized by including steps of firstly, subjecting ammonium stearate and calcium hydroxide to reaction to generate calcium stearate and ammonia water; secondly, when calcium hydroxide turbid liquid is insufficiently added, stearic acid is excessive, subjecting the stearic acid and the ammonia water to reaction to generate the ammonium stearate, and preparing the ammonium stearate required in the first step; and when calcium hydroxide turbid liquid is slightly excessively added, subjecting the ammonium stearate and the calcium hydroxide to reaction and generating calcium stearate and ammonia water, wherein the ammonia water is freed and is decomposed to generate ammonia gas on the condition of the pH (potential of hydrogen) value of 9-9.5 of the reaction system at the temperature of 65-85 DEG C, and filtrate is composed of water and precious little calcium hydroxide soluble in water. The calcium stearate production method is simple in process and is low in reaction temperature and energy consumption and low in requirements for equipment as compared with a double decomposition process, no reflux reaction is needed in the later stage of reaction, even general double decomposition process production equipment can produce products, economic benefits are evident, and accordingly, the calcium stearate production method is applicable to further popularization.

Owner:NANTONG XINBANG CHEM

Dispensible brazing paste

InactiveUS20050211017A1Avoid problemsWelding/cutting media/materialsSoldering mediaOrganic solventWater soluble

A dispensable brazing paste useful in lamp manufacturing includes a brazing powder and a water soluble vehicle that has water, glycerin, a binder, and a dispersant that includes ammonium stearate and ammonium citrate. Preferably, the brazing powder is 84-87 wt % of the paste, the water is 3-5 wt %, the glycerin is 3-4 wt %, the binder is 1-2 wt %, and the dispersant is 4-6 wt %, and a weight of the water is within a range of 60-90% of a weight of the dispersant. The brazing paste does not include the troublesome organic solvents of the prior art.

Owner:GLOBAL TUNGSTEN & POWDERS CORP

Efficient controlled release fertilizer used for pollution-free fruit mulberries and preparation method thereof

InactiveCN106518304APromote absorptionPromote growthBio-organic fraction processingAnimal corpse fertilisersSlagOyster shells

The invention discloses an efficient controlled release fertilizer used for pollution-free fruit mulberries. The efficient controlled release fertilizer comprises, by weight, oyster shells, polylactic acid, graphene, activated nano zeolite, marine microalgae slag, selenium and germanium-enriched spirulina slag, chlorella slag, kelp slag, bacillus subtilis, saccharomycetes, ferrous sulfate, boric acid, calcium ammonium nitrate, soy isoflavone, ammonium stearate, ammonium molybdate, ferrous sulfate, a proper amount of hydrogen peroxide, a proper amount of ammonia water and a proper amount of water. According to the efficient controlled release fertilizer, the marine microalgae slag, the selenium and germanium-enriched spirulina slag, the chlorella slag and the kelp slag are adopted to be matched with nutrient substances, and the coated controlled release fertilizer is prepared after enzymolysis and zymotechnics. The fertilizer is rich in fermentation micromolecule organic matter and microelements, the nutrition is rich and can be absorbed and utilized by the fruit mulberries conveniently, and growth of the fruit mulberries can be facilitated. The selenium and germanium nutrition is increased, and pollution-free cultivation of the fruit mulberries is guaranteed. A coating layer capable of supplying oxygen and dynamically adjusting pores is adopted, organic matter nutrients can be released for a long time, efficient cultivation of the fruit mulberries can be realized, and the efficient controlled release fertilizer can be widely applied and popularized.

Owner:高鹏

High-flame-retarding low-smoke modified polyvinyl ethylene cable material and preparation method thereof

InactiveCN104817788AImprove flame retardant performanceGood flexibilityPlastic/resin/waxes insulatorsInsulated cablesPhosphateAntimony trioxide

The invention discloses a high-flame-retarding low-smoke modified polyvinyl ethylene cable material, which is characterized by being prepared from following raw materials, by weight, 100-120 parts of polyvinyl ethylene resin, 8-12 parts of ethyleneglycol polyadipate glycol, 3-6 parts of antimonous oxide, 4-5 parts of paraffin chloride, 8-10 parts of aluminum hydroxide, 30-40 parts of dioctyl terephthalate, 10-14 parts of trimethylbenzene phosphate, 5-7 parts of an organic tin stabilizing agent, 4-8 parts of an anti-oxygen agent TPP, 6-9 parts of nano kaolin, 7-10 parts of epoxy soybean oil, 9-13 parts of tetrabromophthalate, 7-8 parts of an ultraviolet absorbent, 4-5 parts of pentaerythritol ammonium stearate, 5-6 parts of white oil, 6-8 parts of mica powder, 7-9 parts of calcium ricinoleate, 5-9 parts of electric-conductive carbon black and 10-12 parts of nano silicon dioxide. In the invention, by means of a synergistic effect between the added antimonous oxide and the paraffin chloride, polyvinyl ethylene is enhanced in flame retarding performance. The added trimethylbenzene phosphate has an effect as a condensed phase and the added plasticizer, the dioctyl terephthalate, can improve toughness of the cable, and the added other filling materials can improve the physical and chemical performances of the cable, thereby ensuring a stable mechanical performance and also achieving an effect of inhibiting smoke.

Owner:邹文君

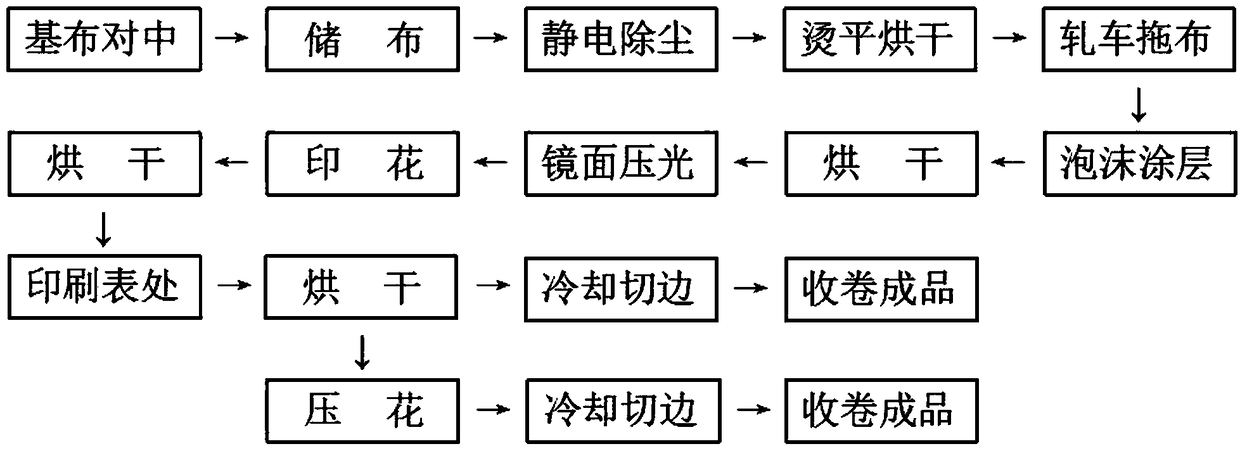

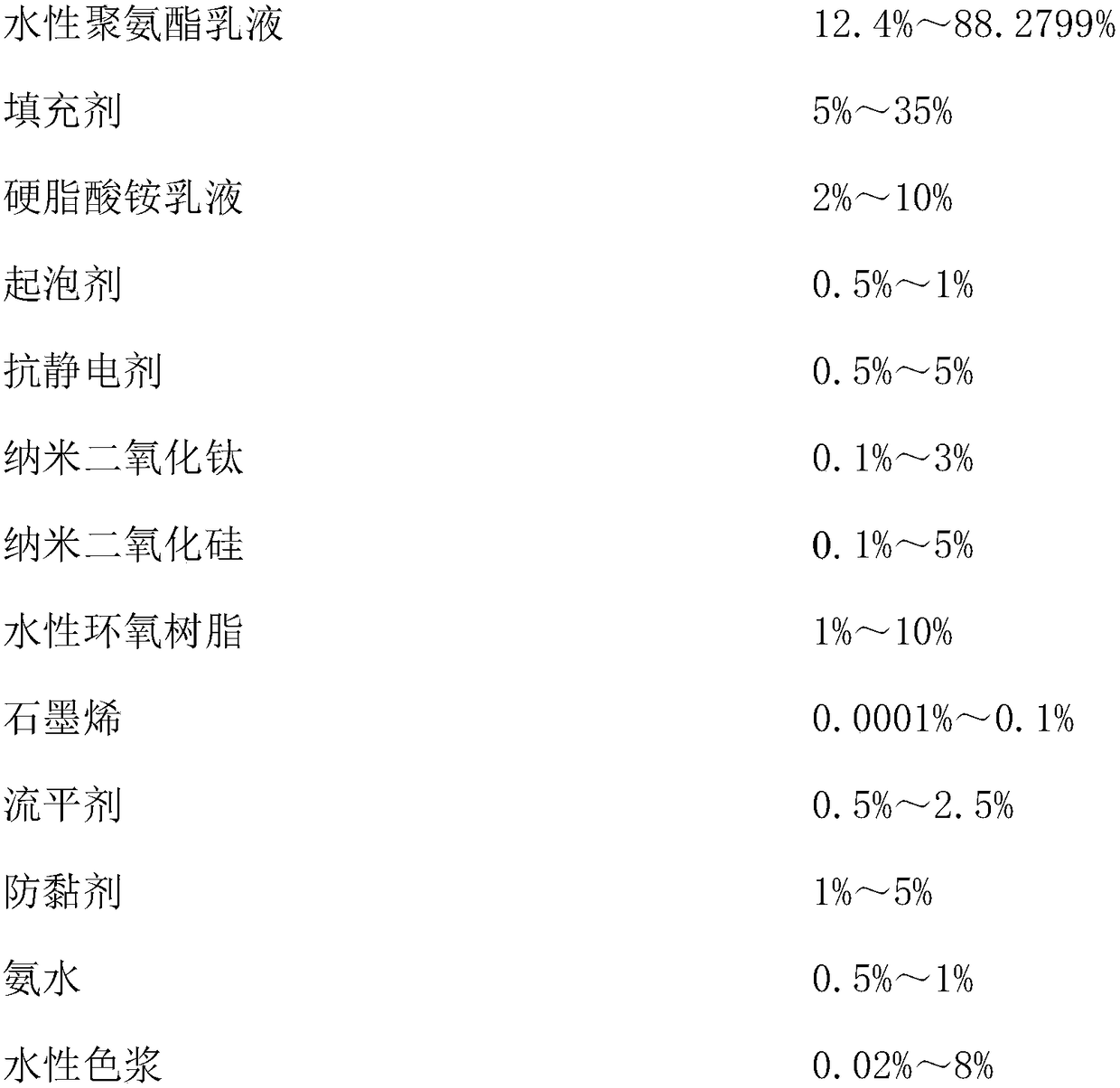

Formula and process of antibacterial photocatalyst aqueous polyurethane synthetic leather

InactiveCN108587425AImprove abrasion fastnessExtended service lifeFireproof paintsAntifouling/underwater paintsUltravioletPolymer chemistry

The invention discloses a formula of an antibacterial photocatalyst aqueous polyurethane synthetic leather. The antibacterial photocatalyst aqueous polyurethane synthetic leather comprises a coating liquid, which comprises 12.4-88.2799% of an aqueous polyurethane emulsion, 15-35% of a filler, 3-10% of an ammonium stearate emulsion, 0.5-1% of a foaming agent, 0.5-3% of nanometer titanium dioxide, 1-5% of nanometer silica, 0.0001-0.01% of graphene, 0.5-2.5% of a leveling agent, 1-3% of an anti-sticking agent, 0.5-1% of ammonia water, 0.02-8% of an aqueous pigment paste, and 0.5-1.5% of a thickener. The preparation process comprises: adding the raw materials of the formula, stirring, filtering, and adjusting the viscosity to obtain a coating liquid; preparing a coating foam body from the coating liquid, and coating a leather base cloth with the coating foam body; drying; and carrying out post-treatment and surface treatment to obtain the finished product. According to the present invention, with the preparation process, the obtained synthetic leather has advantages of self-cleaning property, ultraviolet resistance and antibacterial ability, and the fastness and the hand feeling of thesynthetic leather are not affected.

Owner:宋金火

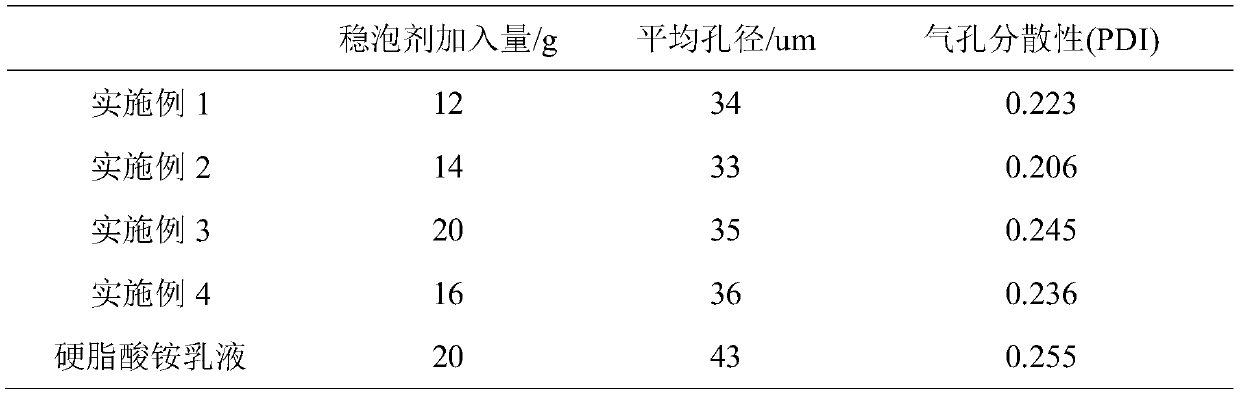

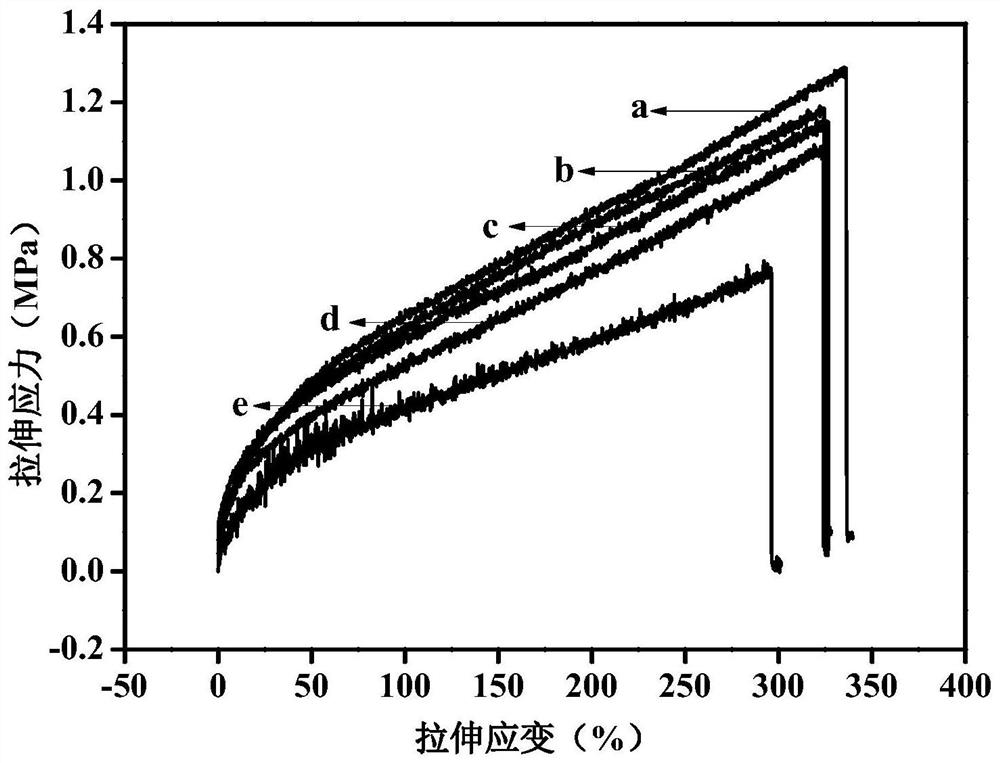

Particle foam stabilizer and preparation method and application thereof

ActiveCN111253779AImprove stabilitySolve the problem of white solid precipitationPolyurea/polyurethane coatingsPigment treatment with macromolecular organic compoundsPolymer sciencePhysisorption

The invention discloses a particle foam stabilizer and a preparation method and application thereof. The particle foam stabilizer comprises hydrophilic solid particles with a particle size of 0.1-5 [mu]m, and the surface of the particle foam stabilizer is modified with a hydrophobic molecular chain through a physical adsorption effect. The preparation method comprises the steps: firstly, adding hydrophilic solid particles into an ethanol-water solution to prepare a solid particle suspension; then adding a modifier containing a hydrophobic molecular chain, and stirring to modify the surface ofthe hydrophilic solid particle with the hydrophobic molecular chain; and finally, carrying out suction filtration and separation on the obtained product, and drying the solid-phase material to obtainthe particle foam stabilizer. The particle foam stabilizer can effectively improve the foam stability, has good stability, is convenient to prepare, has no pungent smell and is more environmentally friendly; the particle foam stabilizer is used in a polyurethane foaming coating layer, on one hand, the particle foam stabilizer can replace a traditional ammonium stearate foam stabilizer, and on theother hand, solid particles can also serve as a filler or a functional additive of the polyurethane foaming coating layer, so that the production cost is reduced while the coating layer performance isimproved.

Owner:YANGZHOU UNIV

Formula and technology of waterborne polyurethane foaming velvet and silk sense synthetic leather

InactiveCN105839425AOver wear resistanceExceeds scratch resistanceTextiles and paperFiltrationHeat resistance

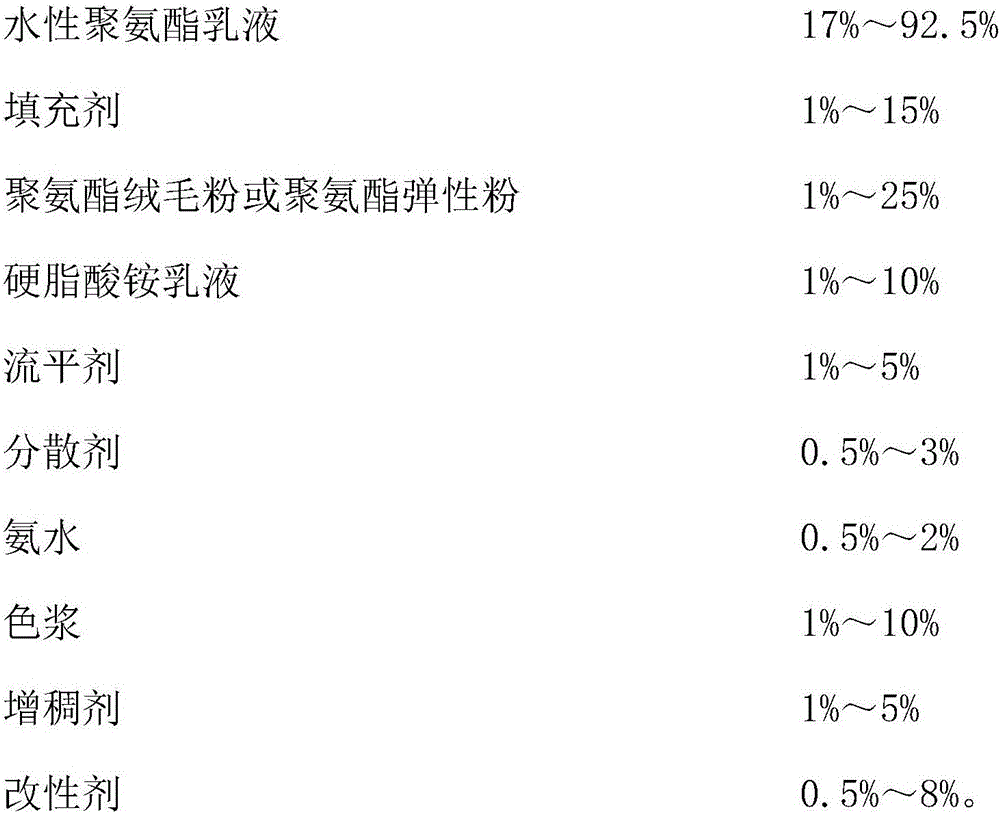

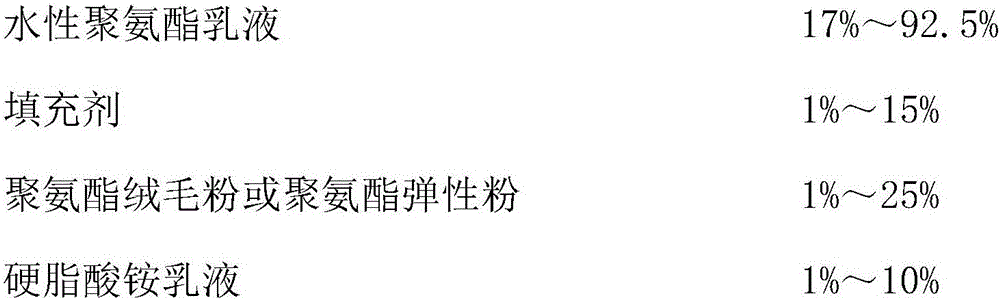

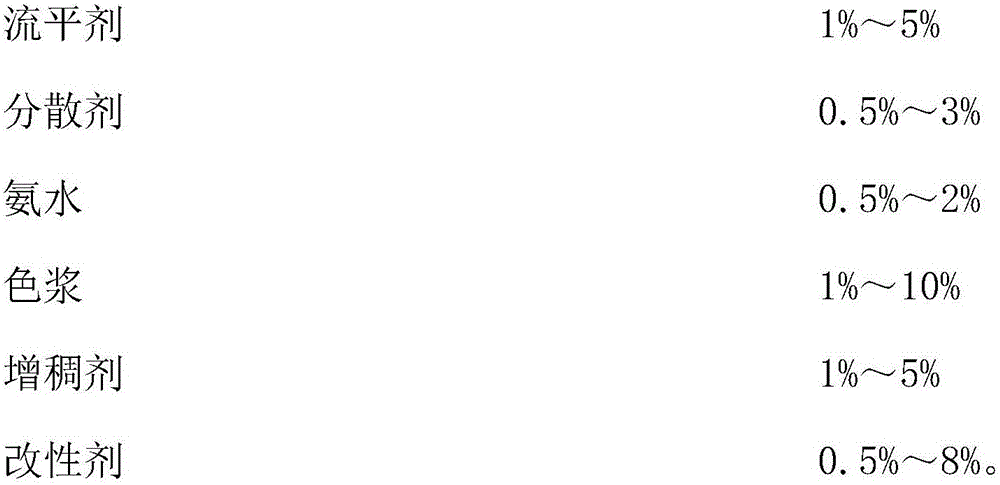

The invention discloses a formula of water-based polyurethane foamed velvet-like silk-like synthetic leather, which comprises a coating liquid; the coating liquid comprises the following component ratios: 17%-92.5% of water-based polyurethane emulsion; 1%-15% of filler; Polyurethane fluff powder or polyurethane elastic powder 1%~25%; ammonium stearate emulsion 1%~10%; leveling agent 1%~5%; dispersant 0.5%~3%; ammonia water 0.5%~2%; color paste 1% to 10%; thickener 1% to 5%; modifier 0.5% to 8%. Process: Add formula raw materials, stir and filter, adjust viscosity to obtain coating liquid; make coating foam into coating foam, and apply it to leather base cloth; dry to obtain foaming velvet feel and silk feel bass; post-processing and Surface treatment, polyurethane foam velvet feel silky synthetic leather. The wear-resistant and scratch-resistant properties of the invention far exceed the film fastness of traditional synthetic leather, and the air permeability is very good, and it also has certain solvent resistance and heat resistance, and has good environmental protection performance.

Owner:宋婷婷

Anticorrosive metal primer

InactiveCN105440876APrevent surface discolorationHigh peel strengthAnti-corrosive paintsPolyester coatingsDiacetone alcoholCis-Butenedioic Acid

The invention discloses an anticorrosive metal primer. The anticorrosive metal primer is prepared from, by weight, 10-23 parts of amino resin, 14-42 parts of polyester resin, 10-18 parts of 1,2-propylene glycol-1-monobutyl ether, 11-28 parts of diethyl carbonate, 35-52 parts of 2,2-di(4-hydroxyphenyl)propane, 9-21 parts of cethyl trimethyl ammonium bromide, 13-27 parts of isoprene, 2-13 parts of ammonium stearate, 8-20 parts of triethyl acetocitrate, 5-10 parts of tetraethylenepentamine, 5-15 parts of maleic anhydride, 14-22 parts of diacetone alcohol, and 8-27 parts of ethyl alcohol. The paint prepared from the metal primer is environmentally friendly, free of toxicity, harmless to people, capable of being well combined with the metal primer and a finishing coat, high in water resistance, capable of preventing color change of a metal surface, improving the peel strength of a paintcoat and guaranteeing the anticorrosive effect, and long in anticorrosive time.

Owner:TONGLING MINGCHENG FOUNDRY

Preparation method of pigment used for nitrocotton solvent ink

The invention discloses a preparation method of a pigment used for nitrocotton solvent ink, which comprises the following steps: beating 800 parts of water, 98 parts of hydrochloric acid and 60 parts of 3,3'-dichlorobenzidine, adding 132 parts of sodium nitrite solution at the temperature below -3 DEG C, stirring at the temperature of 0 DEG C, regulating the end point with sulfamic acid until KI starch test paper is slightly blue, and adding activated carbon and red oil solution to obtain a solution I; adding 19.4 parts of acetic acid and 2-60 parts of 12-hydroxy ammonium stearate in 350 parts of water, heating to be transparent, regulating water to reduce the temperature, and filtering the solution into a coupling tank; dissolving 136 parts of sodium hydroxide and 102 parts of AAMX in 800 parts of water to be transparent to obtain a solution II; adding the solution II into an acetic acid solution for anti-acidification, and stopping acid eduction when the pH is 4.8 to obtain a solution III; combining the solution II and the solution I into the solution III to couple for 50-60 minutes, convecting and adding convection alkali when the pH is 4.5 until coupling is ended, raising the temperature to 95 DEG C, adding 200 parts of sodium hydroxide, adding 5-52.5 parts of rosin solution, adding 100 parts of hydrochloric acid, regulating the pH to 5, adding 2-30 parts of WB-101, stirring, reducing the temperature below 60 DEG C, filtering by pressing, flushing, and drying to obtain the pigment used for nitrocotton solvent ink. The nitrocotton solvent ink prepared from the pigment used for solvent ink has low viscosity, high gloss, high transparency and high strength.

Owner:LONGKOU UNION CHEM

A kind of polymer denitration agent and preparation method thereof

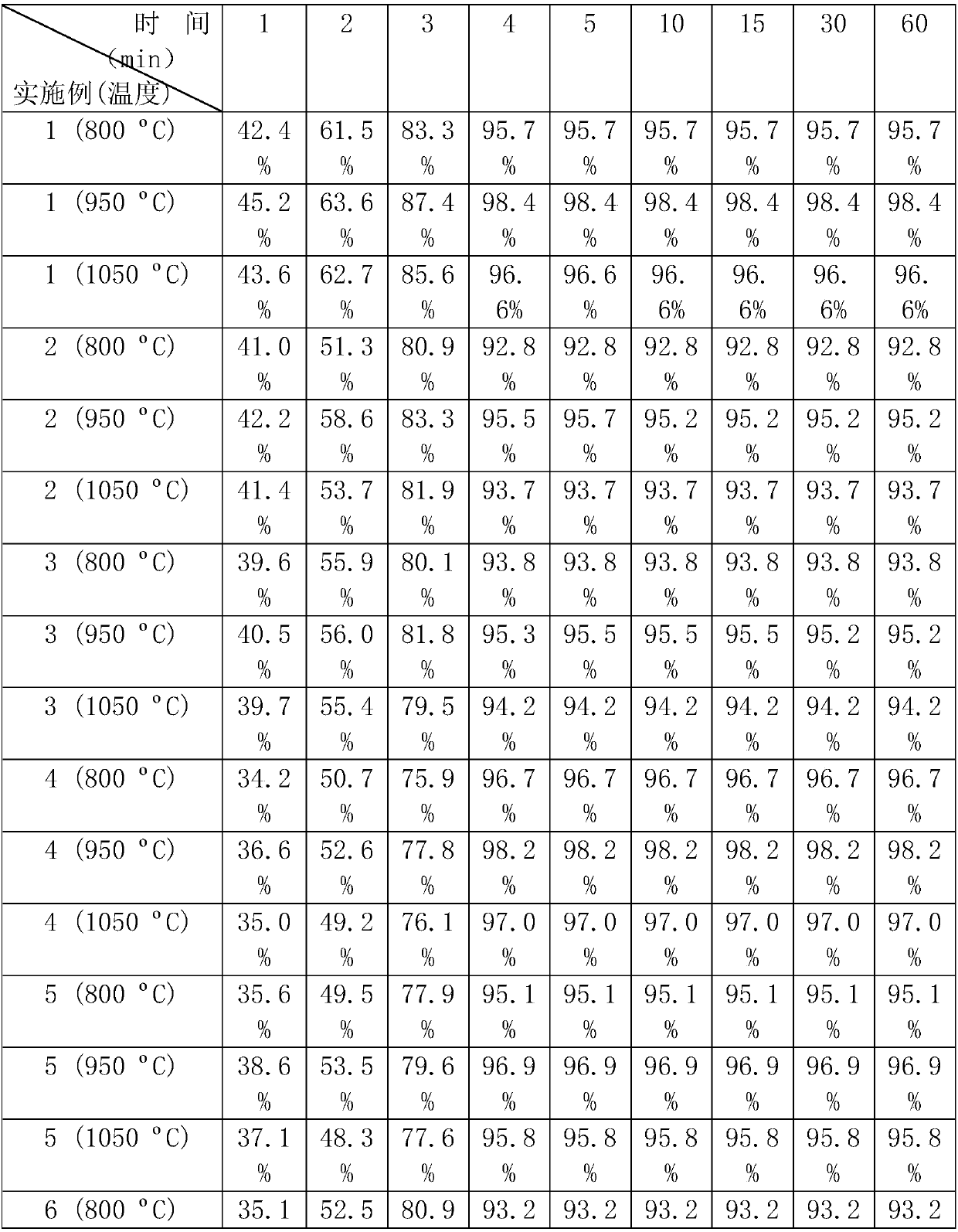

The invention discloses a composite denitration agent. The composite denitration agent is characterized by comprising the following components comprising the three parts all in parts by mass: (1) 30.0-99.0 parts of an ammonium / amine source which takes at least one of urea, ammonium carbonate, ammonium bicarbonate, ammonium acetate, ammonium sulfate, melamine and benzene substituted melamine, (2) 1.0 to 70.0 parts of a synergistic polymer which comprises polyacrylic acid salts and / or polyalkyl acrylates and / or polyacrylamides as well as copolymer polymer carriers and / or polymer fillers, and (3) 0 to 10.0 parts of other components which at least comprise the power comprising one of the following components: ammonium stearate, magnesium stearate, calcium stearate, a mould inhibitor, precipitated calcium carbonate, magnesium oxide and zeolite. The denitrification rate of the denitration agent can reach 82.3% to 99.3% at the temperature of 800 to 1050 DEG C. The composite denitration agent is simple in preparation method and can be widely used in high-temperature gas denitration situations of a thermal power plant, a waste incineration plant and the like.

Owner:SHENZHEN HUAMING ENVIRONMENTAL PROTECTION TECH CO LTD

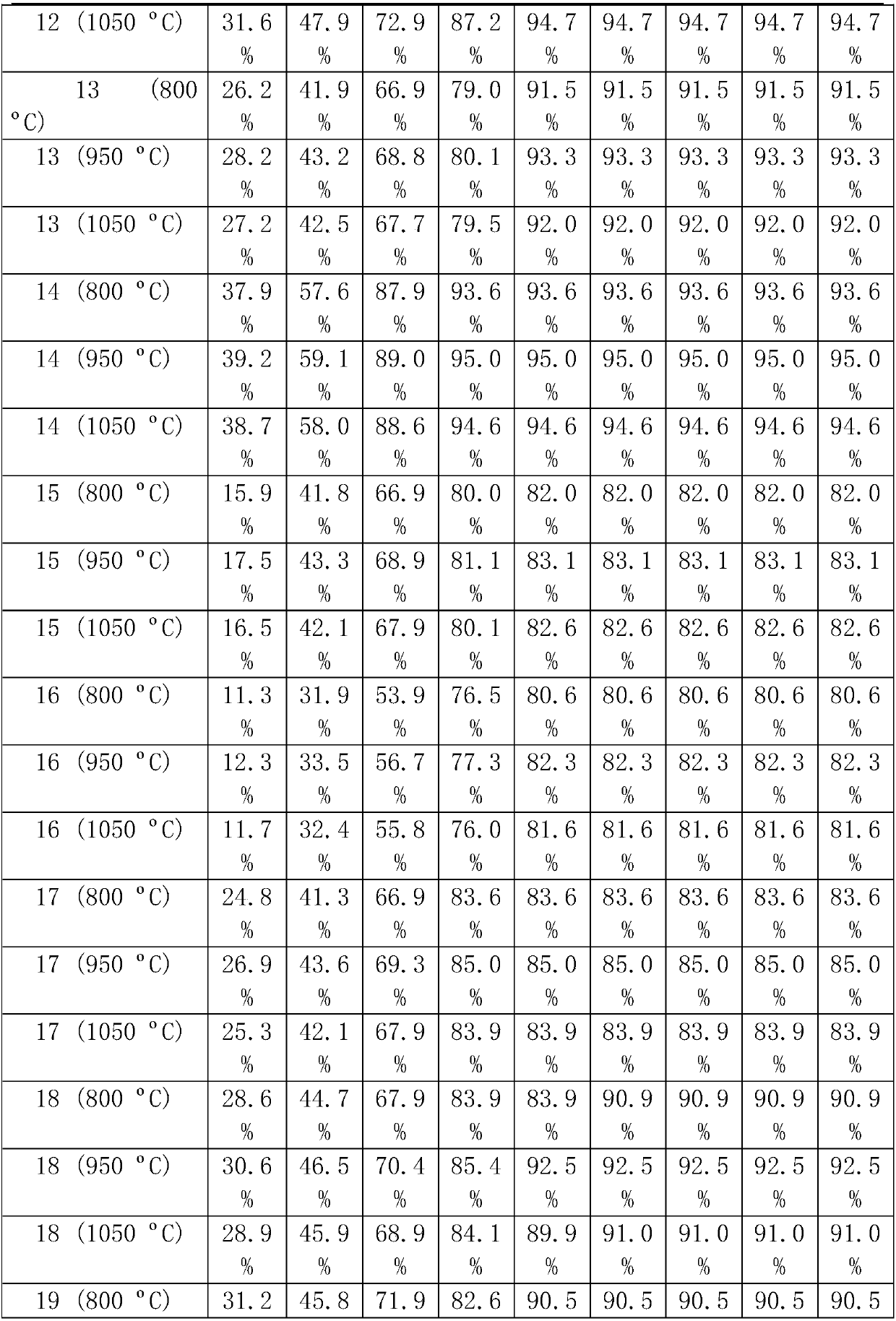

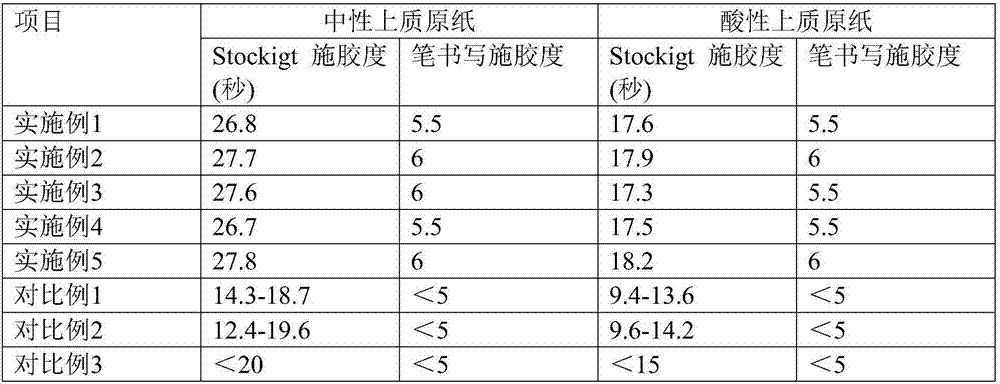

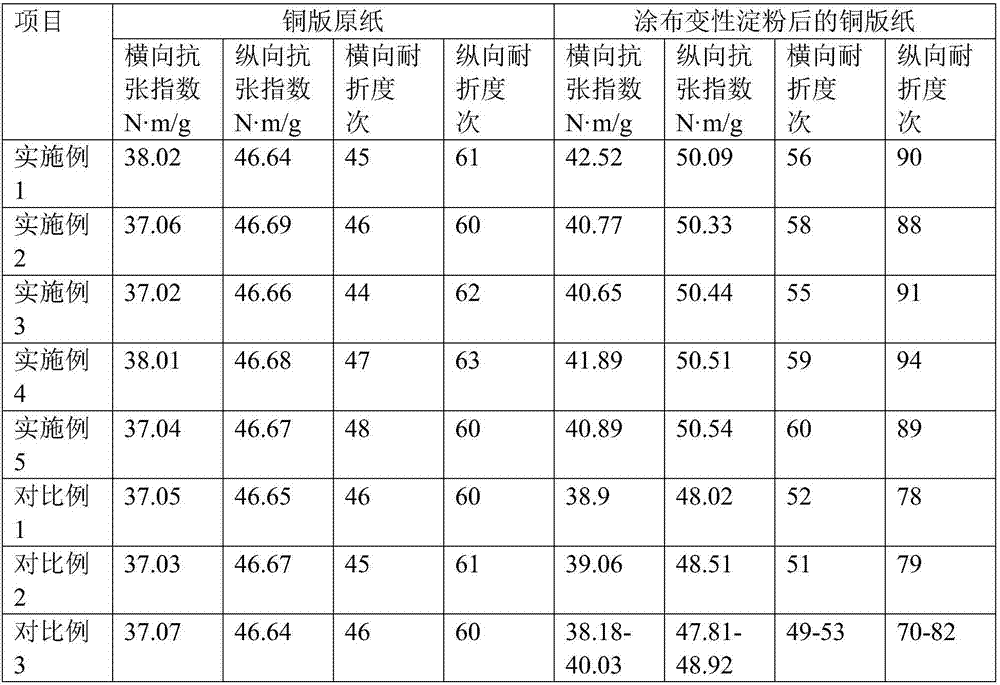

Waterproof sizing starch preparation process

ActiveCN106905487AFast waterproofingImprove performanceWater-repelling agents additionPaper coatingBoric acidAqueous solution

The invention discloses a waterproof sizing starch preparation process, and belongs to the technical field of starch. According to the process, starch serves as raw materials and modified. The preparation process includes the steps: A, adding starch and aluminum sulfate into a reaction kettle, and controlling the temperature of the reaction kettle to be 30 DEG C-50 DEG C; B, adding acryl amide aqueous solution and ammonium persulfate aqueous solution into the reaction kettle under stirring conditions, and performing reaction for 10-15min in a stirring manner; C, adding ammonium stearate and ferrite into the reaction kettle, and performing reaction for 20-30min; D, adding boric acid into the reaction kettle to react; E, cooling and discharging to obtain the waterproof sizing starch. The preparation process is simple, mild and stable and simple to operate, and the prepared waterproof sizing starch is good in hydrophobicity and high in whiteness.

Owner:晋州市大成变性淀粉有限公司

Polypropylene plastic used for cable guide tube in underground cable

InactiveCN104327371AGood chemical resistanceImprove antibacterial propertiesEthylene-propylene-diene-monomerPotassium

The invention discloses a polypropylene plastic used for a cable guide tube in an underground cable and belongs to the technical field of plastics. The polypropylene plastic comprises following components: polypropylene, potassium silicoaluminate, graphite, paraffin, ammonium stearate, ethylene propylene diene monomer, a sterilizing agent, a dispersing agent and an anti-oxidant. The polypropylene plastic is excellent in chemical-resistant performance, is good in anti-bacterial performance, is easy to process and mould, is excellent in anti-shock performance and is long in service live.

Owner:QINGDAO DTCN NEW MATERIAL TECH DEV

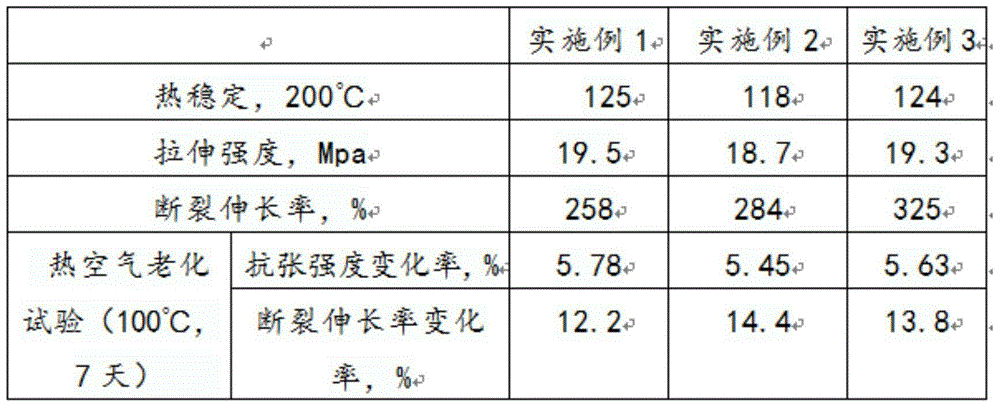

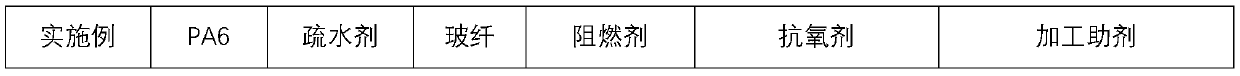

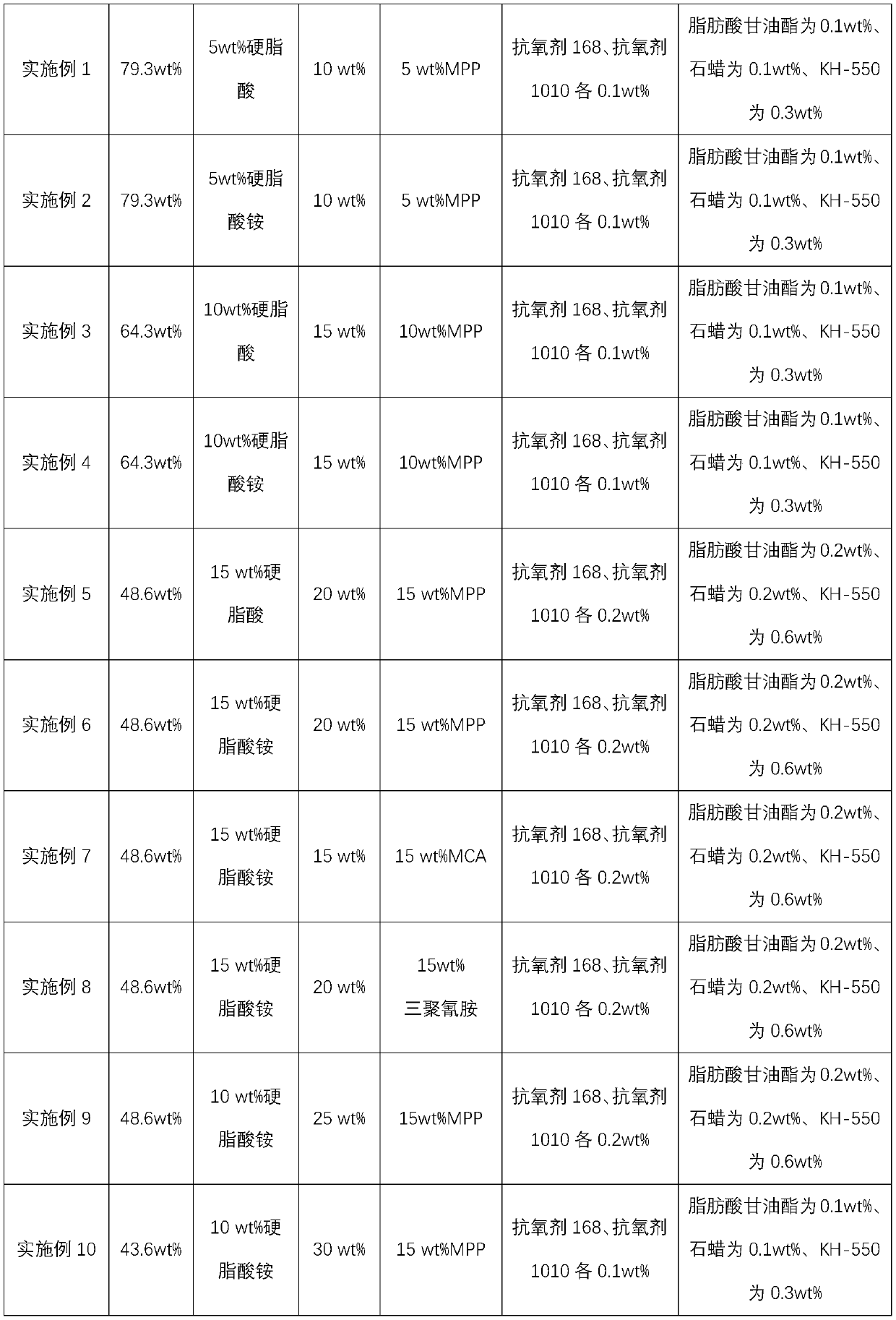

Low-water-absorption flame-retardant glass fiber reinforced PA6 (polyamide 6) composite and preparation method thereof

The invention belongs to the field of high polymer materials and discloses a low-water-absorption flame-retardant glass fiber reinforced PA6 (polyamide 6) composite and a preparation method thereof. The low-water-absorption flame-retardant glass fiber reinforced PA6 composite is prepared from components in parts by weight as follows: 43.6-99.3 parts of PA6, 5.0-15.0 parts of a water repellent agent, 10.0-30.0 parts of glass fiber, 5.0-20.0 parts of a flame retardant, 0.2-0.4 parts of an antioxidant and 0.5-1 part of a processing aid. A forming process of the low-water-absorption flame-retardant glass fiber reinforced PA6 composite is optimized, the hydrophobic performance of a PA6 matrix is improved by use of stearic acid and ammonium stearate, the flame retardance of the composite is improved by use of MPP (modified polypropylene), mechanical properties such as impact strength, tensile strength, elongation at break and the like of PA6 are improved by adding glass fiber, wherein stearic acid and ammonium stearate can increase the compatibility of MPP and PA6, and separation is inhibited; and besides, the water repellent agent has a gas-phase flame retardance function while producing gas through thermal decomposition, melamine groups in the MPP structure has certain hydrophobic property, and the water repellent agent and the melamine groups have synergistic flame retardant and hydrophobic effects.

Owner:横店集团得邦工程塑料有限公司

Polyurethane-polyurea aqueous dispersion for synthetic leather as well as preparation method and application thereof

The invention provides a polyurethane-polyurea aqueous dispersion containing a tertiary amine group as well as a preparation method and an application thereof. The dispersion is mainly prepared from the following reaction raw materials: a) at least one amine which contains the tertiary amine group and has the functionality of 1; b) at least one polyol having the functionality of 2 to 4 and a number average molecular weight of 500 g / mol to 15000 g / mol; c) at least one polyisocyanate component; d) at least one non-ionic polyol having the number average molecular weight of 500 g / mol to 10,000 g / mol, which is different from component b); and optionally other components. The polyurethane-polyurea aqueous dispersion provided by the invention can be used as synthetic leather foaming resin, is especially suitable for a foaming system containing ammonium stearate (STA), and has the characteristic of inhibiting stearic acid precipitation.

Owner:WANHUA CHEM GRP CO LTD +2

Waterproof powder producing process

The present invention relates to waterproof powder producing process. The waterproof powder consists of basic grains with sintered industrial slag as core and calcium stearate as coating. The production process includes mixing sintered industrial slag with calcium hydroxide homogeneously; adding ammonium stearate solution via stirring to form paste; and stoving to obtain the waterproof powder. The present invention has the advantages of firm structure, less influence of outer humidity and temperature, stable performance, powerful waterproof performance, light weight, and low cost.

Owner:长春市交通建筑安装工程公司

Polytetrafluoroethylene coating and preparation method thereof

InactiveCN104263120AStrong adhesionGood physical propertiesEpoxy resin coatingsEpoxyDiacetone alcohol

The invention discloses a polytetrafluoroethylene coating and a preparation method thereof. The polytetrafluoroethylene coating comprises the following components: polytetrafluoroethylene, epoxy resin, organic silicon resin, silver powder, benzyldimethyl ketal, ammonium stearate, 2-((2-hexyloxy)ethoxy)ethanol, calcium dodecylbenzene sulfonate, ammonia water, aluminum oxide, copper powder, graphite powder, diacetone alcohol, tributyl phosphate, dimethyldiallylammonium chloride and epoxy chloropropane. The preparation method comprises the following steps of adding polytetrafluoroethylene, epoxy resin, organic silicon resin, the silver powder, ammonium stearate, the copper powder, the graphite powder, aluminum oxide, tributyl phosphate and 2-((2-hexyloxy)ethoxy)ethanol into a reaction kettle, heating and uniformly stirring; then, discharging after grinding by using a grinder to obtain a mixture I; stirring and uniformly mixing the rest components, and grinding to form a mixture II with the particle size same as that of the mixture I; and finally, mixing the mixture I and the mixture II.

Owner:山东瑞特新材料有限公司

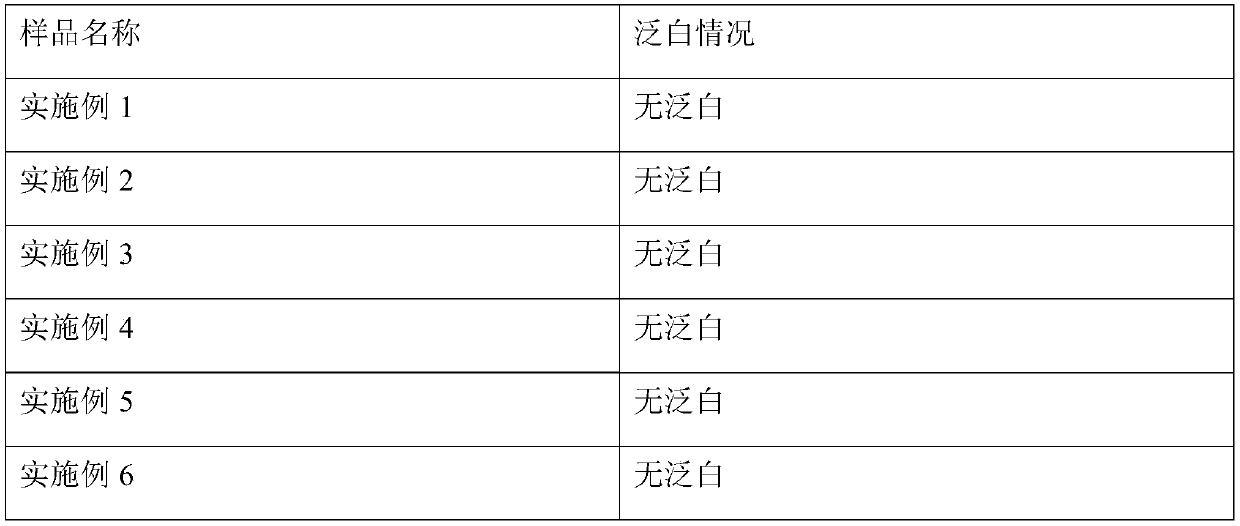

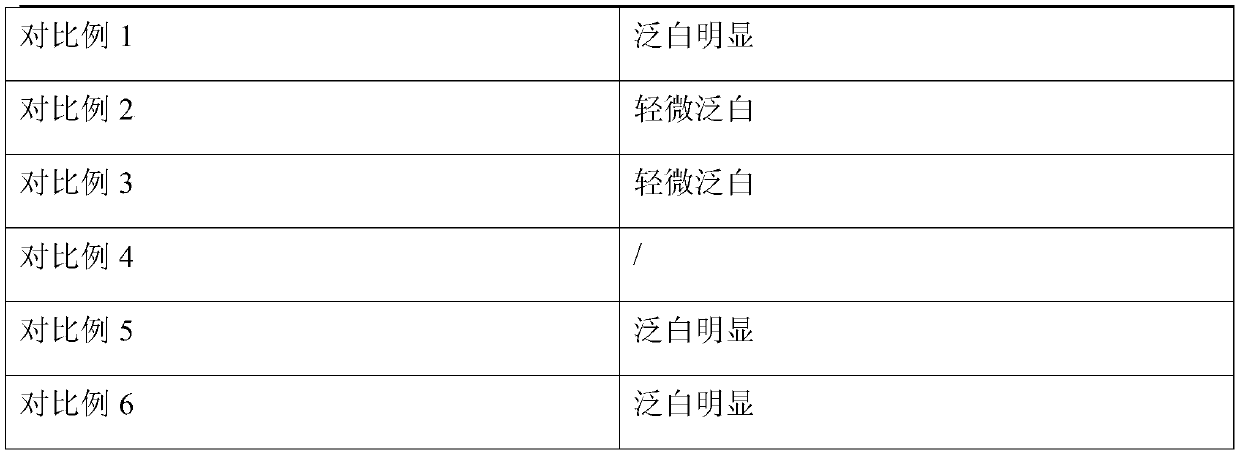

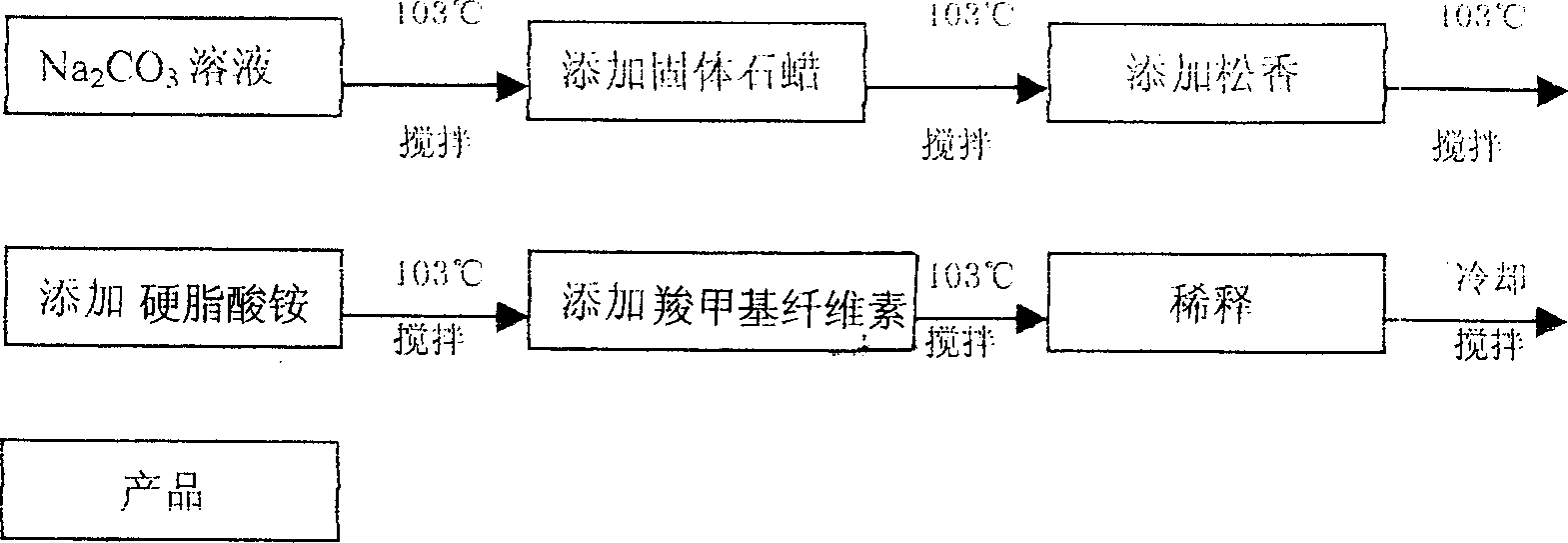

Water-proof additive speically for pulp moulding and its producing method

The waterproof additive specially for pulp molding consists of paraffin, rosin and water, and includes liquid waterproof additive and solid waterproof additive in different water content. It features that the composiion also includes anhydrous sodium carbonate and ammonium stearate and carboxyl methyl cellulose. The molded paper product with the said waterproof additive may be dried in the sun or in the air, and has excellent waterproof effect. The molded paper product with the said waterproof additive is the ideal substitute of foamed polystyrene product.

Owner:DONGLU PULP MOLDING PROD SHANGHAI

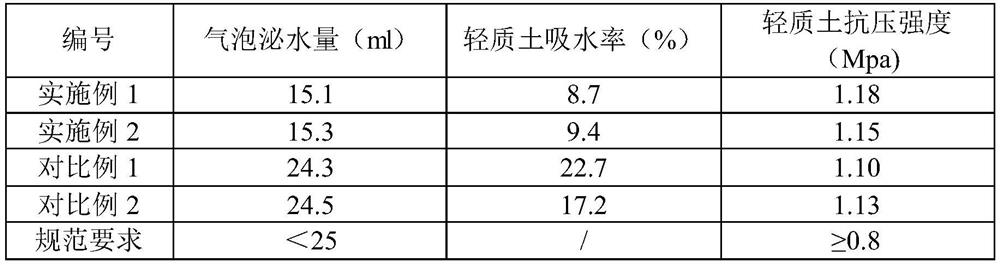

Foaming agent capable of reducing water absorption rate of foamed mixed light soil

The invention discloses a foaming agent capable of reducing the water absorption rate of bubble mixed light soil. The foaming agent is prepared by compounding a modified cardanol-based surfactant anda modified ammonium stearate emulsion. The preparation method comprises the following steps of: performing sulfonation reaction on cardanol; carrying out neutralization reaction by utilizing N-methyldiethanolamine and sodium ethoxide until an alkaline condition is reached; and introducing oxa naphtheneto carry out a polyetherification reaction. The obtained modified cardanol-based surfactant hasgood foaming performance and foam stabilizing performance, has good compatibility with the modified ammonium stearate, and can play a role in a superimposed mode, so that the obtained foaming agent has good foaming performance, foam stabilizing performance and waterproof performance at the same time, and the waterproof performance and using performance of obtained foamed light soil are effectivelyconsidered. The preparation method of the foaming agent is simple, low in cost and suitable for popularization and application.

Owner:THE FIRST SINCERITY CONSTR TECH CO LTD

Solid-liquid mixed type foam stabilizer and preparation method thereof

ActiveCN112647306APrevent coalescencePrevent disproportionationTextiles and paperSodium stearatePotassium hydroxide

The invention discloses a solid-liquid mixed type foam stabilizer and a preparation method thereof. The solid-liquid mixed type foam stabilizer is prepared from emulsion and solid particles, wherein the emulsion is potassium stearate emulsion and / or sodium stearate emulsion, and the solid particles are calcium carbonate particles with stearic acid molecules chemically grafted on the surfaces. The solid-liquid mixed type foam stabilizer is prepared by reacting raw materials containing stearic acid, sodium hydroxide and / or potassium hydroxide and calcium carbonate particles. The preparation method comprises the following steps that an organic solvent, stearic acid and calcium carbonate particles are added into a reaction kettle, the temperature is adjusted to 40-65 DEG C, and mixing and stirring are carried out; an aqueous alkali solution is continuously dropwise added, and reacting is carried out for 2-4 hours after dropwise adding is finished; after the reaction is finished, a sufficient amount of water is supplemented into the reaction kettle; and shearing and emulsifying are carried out at high speed to obtain a final product. According to the solid-liquid mixed foam stabilizer, the problem of poor foam stabilizing performance of traditional sodium soap and potassium soap emulsions is solved, the foam stabilizing performance of the obtained mixed foam stabilizer is significantly improved, and the mixed foam stabilizer is better than traditional ammonium stearate emulsions.

Owner:YANGZHOU UNIV

Production technology of wrapping paper

InactiveCN109468886AImprove plasticityGood flexibilityFlexible coversWrappersProduction lineReusability

The invention discloses a production technology of wrapping paper. The production technology comprises the following steps: step one, preparing raw materials: sorting impurities, viscose paper, binding needles and packaging tape of a raw pulp plate or waste recycled paper for later use; step two, repulping: repulping the raw materials by an aquapulper; step three, preparing pulp: putting the repulped raw materials into a pulp blending pool, adding a wet strength agent, oxidized starch and ammonium stearate and fully stirring a mixture by using a pulp stirrer mounted on the pulp blending pool;step four, supplying the pulp: transporting the pulp to molding equipment on a production line through a pulp supplying pump; step five, manufacturing paper with pulp: manufacturing the pulp, adding to a net, squeezing, drying, calendaring and coiling; and step six, molding: processing the paper into a needed shape through a die-cutting machine. The wrapping paper produced by the production technology disclosed by the invention has relatively high plasticity and flexibility; the wear resistance, folding resistance and anti-aging degree of the wrapping paper are improved; and meanwhile, the reusability of waste paper resources is also improved.

Owner:东莞市江高包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com