Polyurethane-polyurea aqueous dispersion for synthetic leather as well as preparation method and application thereof

A technology of polyurethane and dispersion, which is applied in the field of polyurethane-polyurea aqueous dispersion and its preparation, and can solve the problems of oiliness and staining on the surface of the foam layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

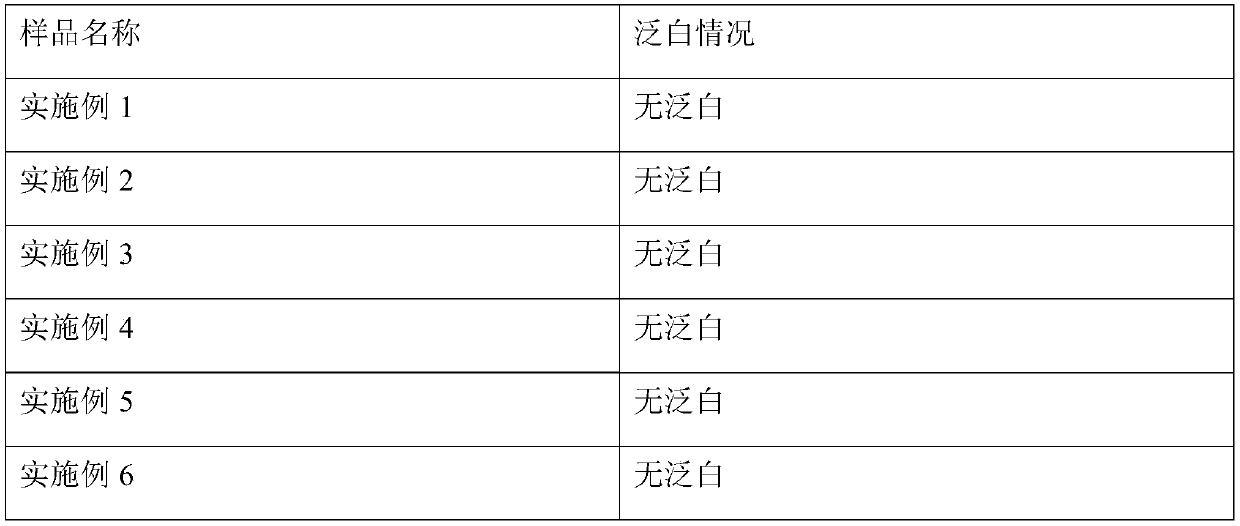

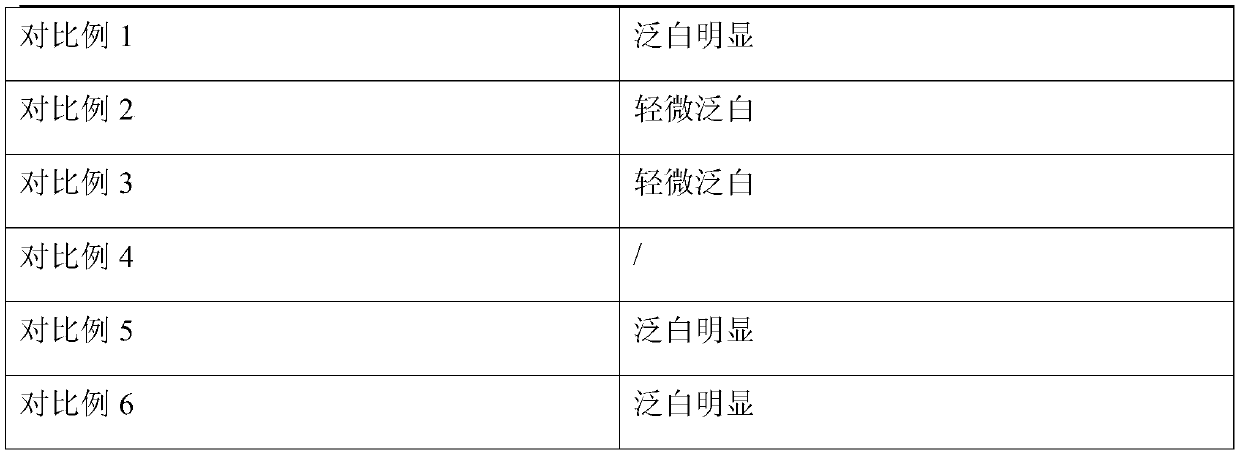

Examples

Embodiment 1

[0061] 110g dehydrated polyether polyol PTMEG2000 (component b), 120g polyether polyol PPG (component b), 15.0g HDI (component c), 42.9g MDI-50 (component c), 4.0 g After dehydration treatment MPEG1200 (component d)), 4.6g 1,4-butanediol (component f) and 40g acetone were added to a 1L four-neck round bottom flask equipped with nitrogen inlet and outlet, and stirred at 60~90℃ This mixture is until -NCO reaches 2.38 wt%. Add 460g of acetone to dilute and cool to 40-45°C and add 47.6g of water diluted 5.6g of sodium ethylenediaminoethyl sulfonate (50% aqueous solution) (component e), 10.0g of N-aminoethylmorpholine ( Component a) react for about 15 minutes, add 1.54g of light stabilizer TINUVIN 292 (component h) and stir evenly, add 468g of deionized water to disperse under rapid stirring. After separating the acetone by distillation, a solvent-free polyurethane-polyurea dispersion was obtained. It has a solid content of 40% by weight, an average particle size of 170 nm, and a ...

Embodiment 2

[0063] 240g of dehydrated polyether polyol PTMEG2000 (component b), 11.5g HDI (component c), 49g MDI-50 (component c), 6.0g dehydrated MPEG1200 (component d), 4.5g 1 ,4-Butanediol (component f) and 38g of acetone were added to a 1L four-neck round bottom flask equipped with nitrogen inlet and outlet, and the mixture was stirred at 60-90°C until -NCO reached 2.21wt%. Add 400g of acetone to dilute and cool to 40-45℃ and add 6g of sodium ethylenediaminoethyl sulfonate (50% aqueous solution) diluted with 48g of water (component e), 6.1g of N-aminoethylmorpholine (component a) React with 2g IPDA (component g) for about 15 minutes, add 3.23g light stabilizer TINUVIN 292 and stir evenly, add 490g deionized water to disperse under rapid stirring. After separating the acetone by distillation, a solvent-free polyurethane-polyurea dispersion was obtained. It has a solid content of 40% by weight, an average particle size of 131 nm, and a pH of 8.7.

Embodiment 3

[0065] 160g of dehydrated PTMEG2000 (component b), 170g of PPG (component b), 23g of HDI (component c), 35g of MDI-50 (component c), 6.0g of dehydrated MPEG1200 (component d) Add 48 g of acetone to a 1 L four-neck round bottom flask equipped with nitrogen inlet and outlet, and stir the mixture at 60-90° C. until -NCO reaches 2.08 wt%. Add 400g of acetone to dilute and cool to 40-45℃ and add 6g of sodium ethylenediaminoethyl sulfonate (50% aqueous solution) diluted with 50g of water (component e), 8g of N-aminoethylmorpholine (component a) ) After reacting for about 15 minutes, add 6.12g of light stabilizer TINUVIN 292 and stir evenly, and add 618g of deionized water for dispersion under rapid stirring. After separating the acetone by distillation, a solvent-free polyurethane-polyurea dispersion was obtained. It has a solid content of 40% by weight, an average particle size of 144 nm, and a pH of 8.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com