Admixture for improving marine concrete impervious and anti-cracking performance

A technology of marine concrete and crack resistance, applied in the field of building materials, can solve problems affecting the durability of concrete, degradation of cohesiveness, and aggravation of concrete, so as to improve impermeability and work performance, improve work performance, and improve mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

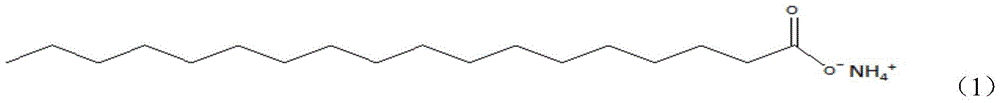

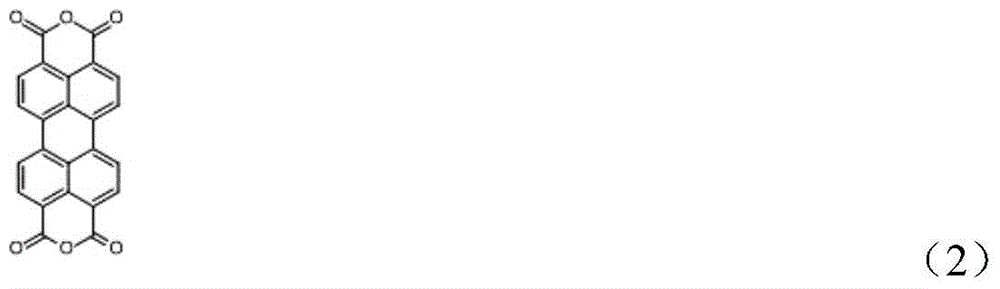

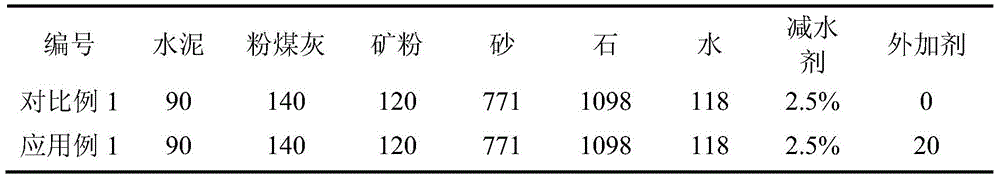

[0044] An admixture for improving the anti-seepage and anti-crack performance of marine concrete. The mass percentage of each raw material is: ammonium stearate emulsion 60%, 3,4,9,10-perylenetetracarboxylic anhydride 3%, nano-dioxide Silicone dispersion 4% (mass concentration 20%), ultra-dispersed shrinkage reducing water reducer 10%, micron modified absorbent cotton cellulose 4%, water 19%.

[0045] In the present embodiment, the preparation method of the ammonium stearate emulsion comprises the following steps: 1) heating water to 60° C., dissolving anhydrous sodium carbonate and potassium hydroxide in water, and maintaining a constant temperature to obtain a mixed solution I; 2) Put stearic acid in a three-necked flask, heat and melt at 58°C, and keep the temperature at a constant temperature after raising the temperature to 65°C to obtain a stearic acid solution; 3) Dissolve the emulsifier fatty acid methyl ester ethoxylate evenly in the mixing solution I, then slowly add...

Embodiment 2

[0059] An admixture for improving the anti-seepage and anti-crack performance of marine concrete. The mass percentage of each raw material is: ammonium stearate emulsion 65%, 3,4,9,10-perylenetetracarboxylic anhydride 3%, nano-dioxide Silicone dispersion 3% (mass concentration 30%), ultra-dispersed shrinkage reducing water reducer 9%, micron modified absorbent cotton cellulose 4%, water 16%.

[0060] In the present embodiment, the preparation method of the ammonium stearate emulsion is roughly the same as that in Example 1, except that the volume percentages of the raw materials in the ammonium stearate emulsion are: water 91%, stearic acid 4% , ammonia 3.5%, anhydrous sodium carbonate 0.2%, potassium hydroxide 0.8%, emulsifier 0.5%.

[0061] The difference between the preparation method of the ultra-dispersed shrinkage-reducing water-reducer and Example 1 is: ultra-disperse slump-preserving polycarboxylate water-reducer A55%, shrinkage-reducing polycarboxylate water-reducer B...

Embodiment 3

[0069] An admixture for improving the anti-seepage and anti-crack performance of marine concrete. The mass percentage of each raw material is: ammonium stearate emulsion 55%, 3,4,9,10-perylenetetracarboxylic anhydride 5%, nanometer dioxide 4% silicon dispersion (mass concentration 20%), 10% ultra-dispersed shrinkage reducing water reducer, 4% micron modified absorbent cotton cellulose, 22% water.

[0070] In the present embodiment, the preparation method of the ammonium stearate emulsion is roughly the same as that in Example 1, the difference being that the volume percentages of the raw materials in the ammonium stearate emulsion are: water 89%, stearic acid 5% , ammonia water 4%, anhydrous sodium carbonate 0.3%, potassium hydroxide 1%, emulsifier 0.7%.

[0071] The difference between the preparation method of the ultra-dispersed shrinkage-reducing water-reducer and Example 1 is: ultra-disperse slump-retaining polycarboxylate water-reducer A50%, shrinkage-reducing polycarboxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com