Patents

Literature

115results about How to "Speed up molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low dielectric constant insulating film and method for forming the same

InactiveUS8828886B2Improve resistance to damageLow dielectric constantSemiconductor/solid-state device manufacturingChemical vapor deposition coatingArea ratioPolymer

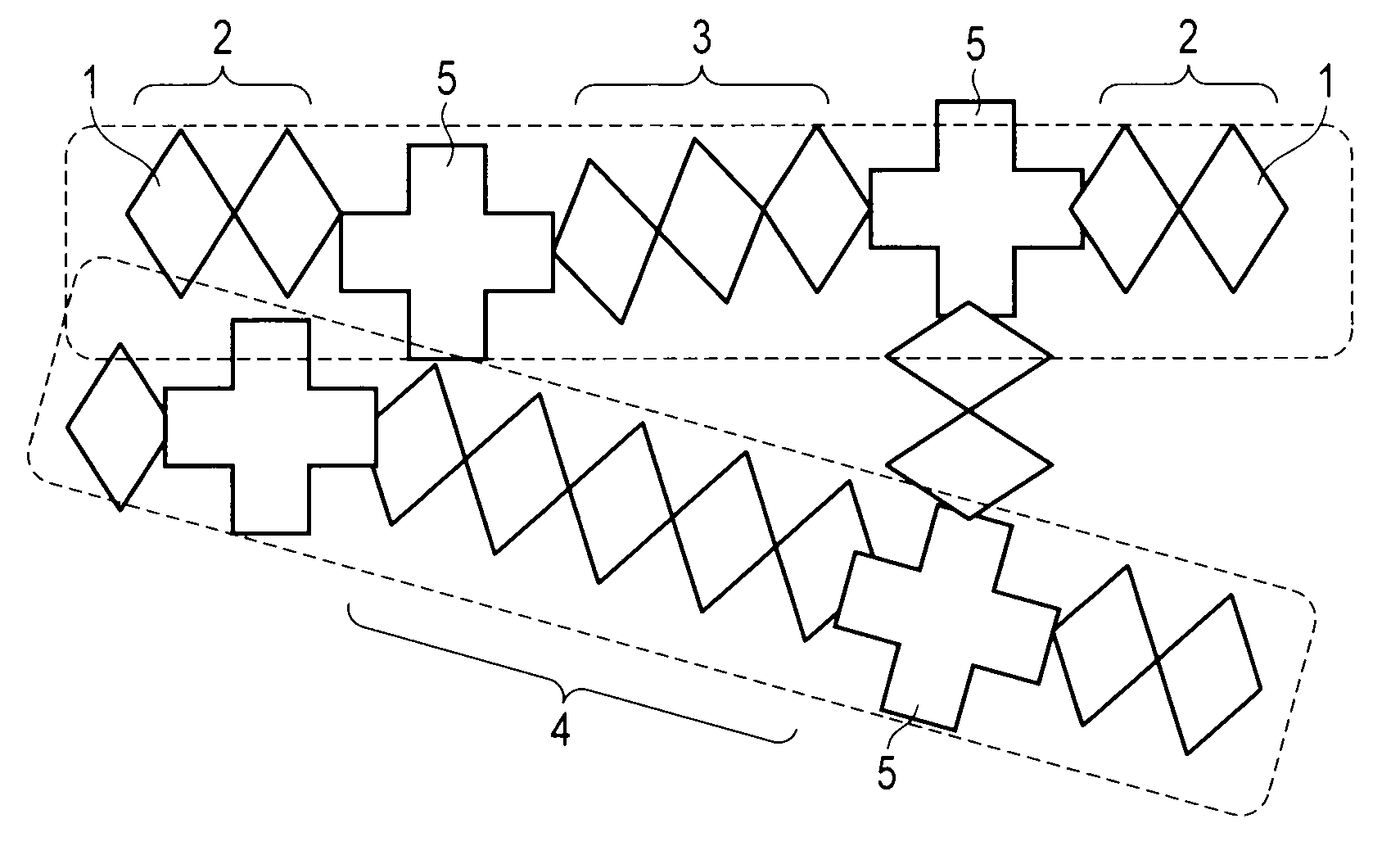

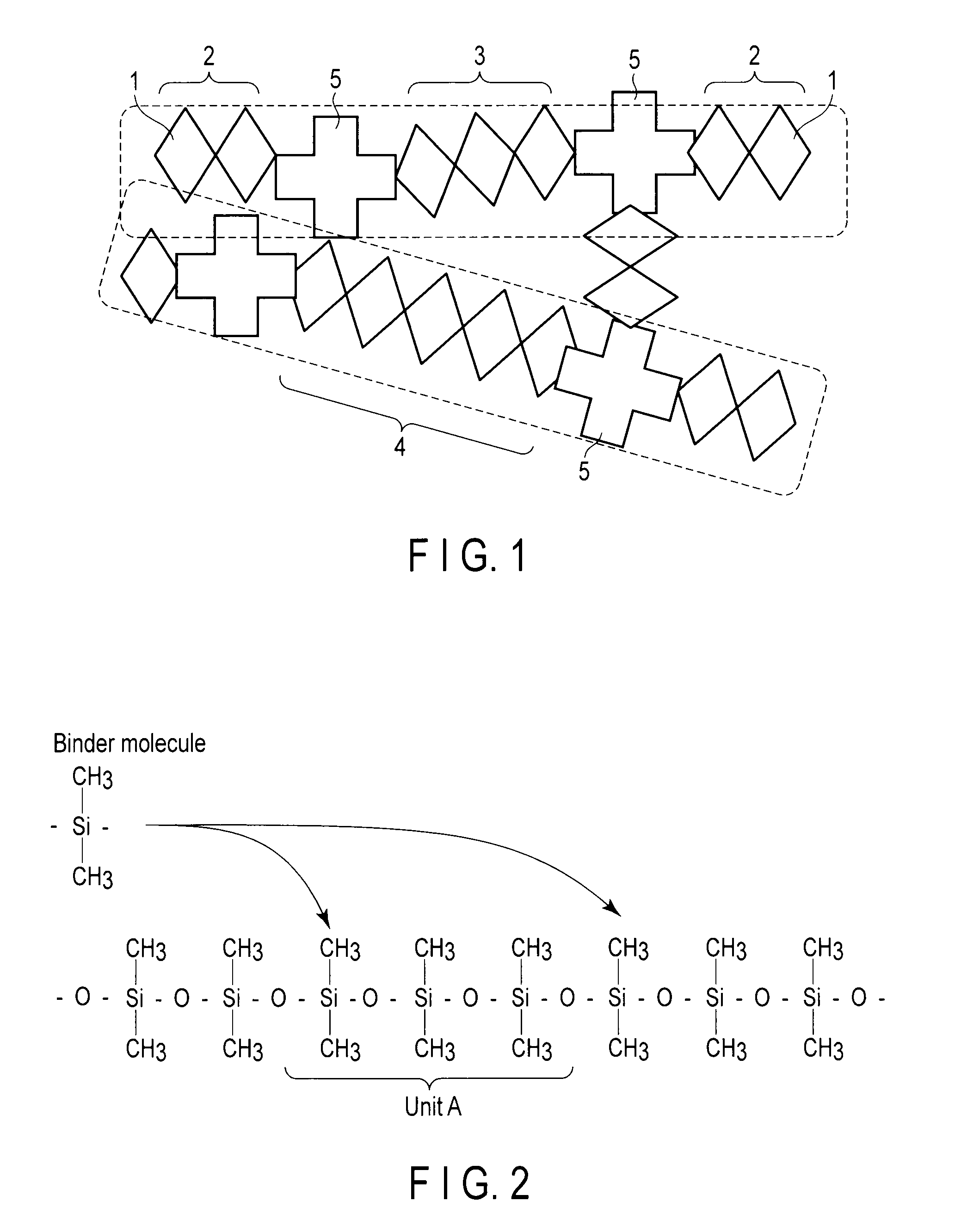

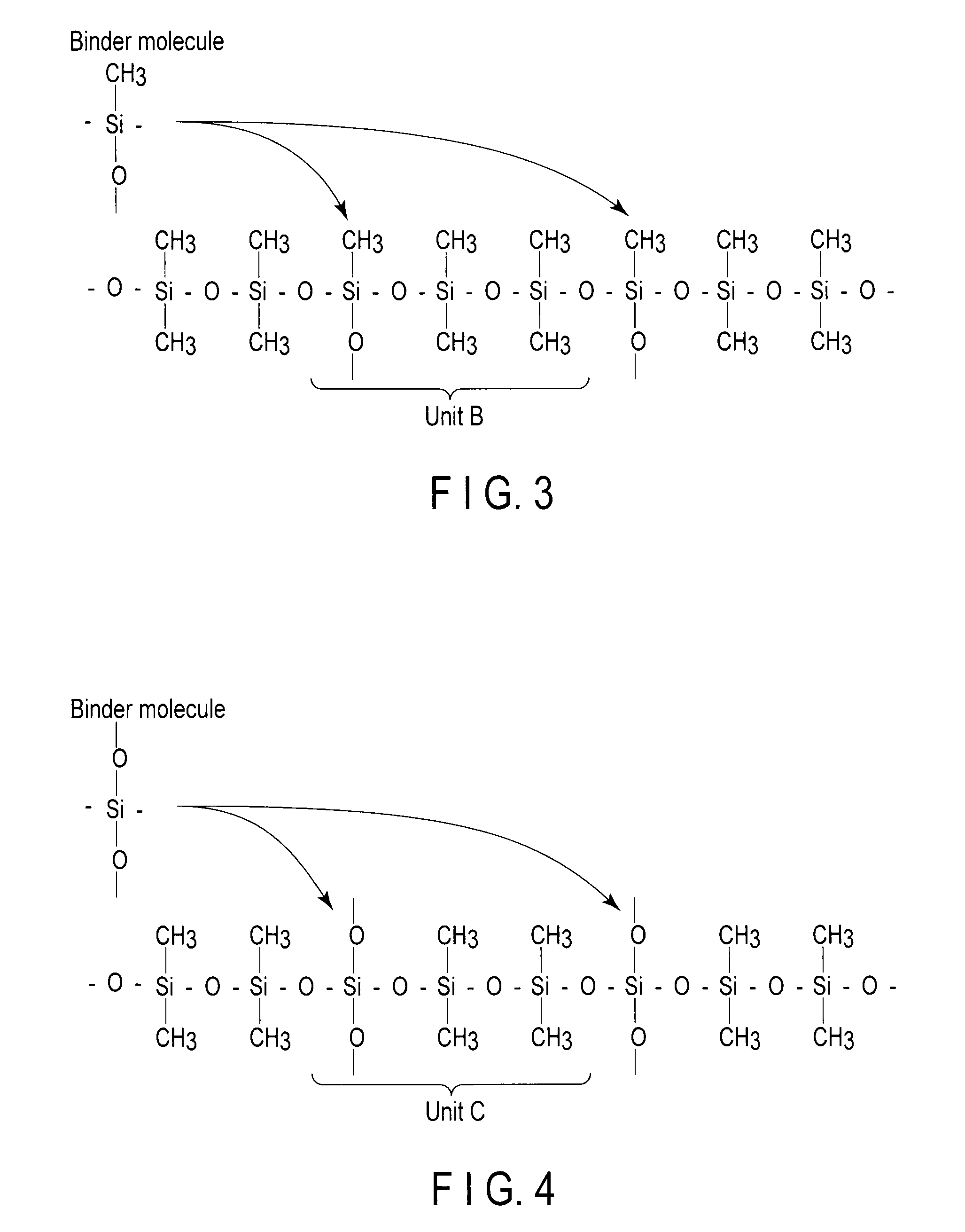

Disclosed is a low dielectric constant insulating film formed of a polymer containing Si atoms, O atoms, C atoms, and H atoms, which includes straight chain molecules in which a plurality of basic molecules with an SiO structure are linked in a straight chain, binder molecules with an SiO structure linking a plurality of the straight chain molecules. The area ratio of a signal indicating a linear type SiO structure is 49% or more, and the signal amount of the signal indicating Si(CH3) is 66% or more.

Owner:TOHOKU UNIV

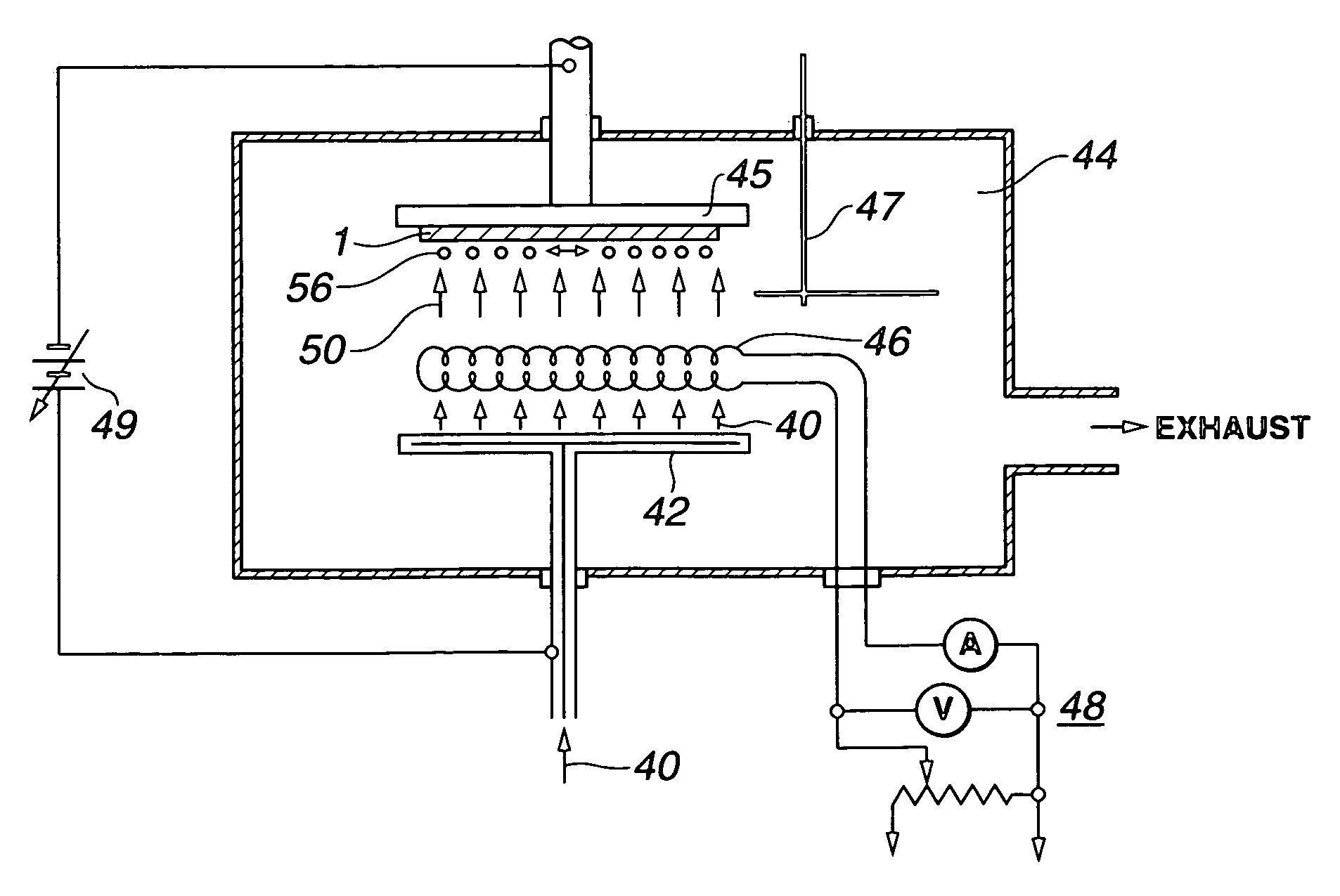

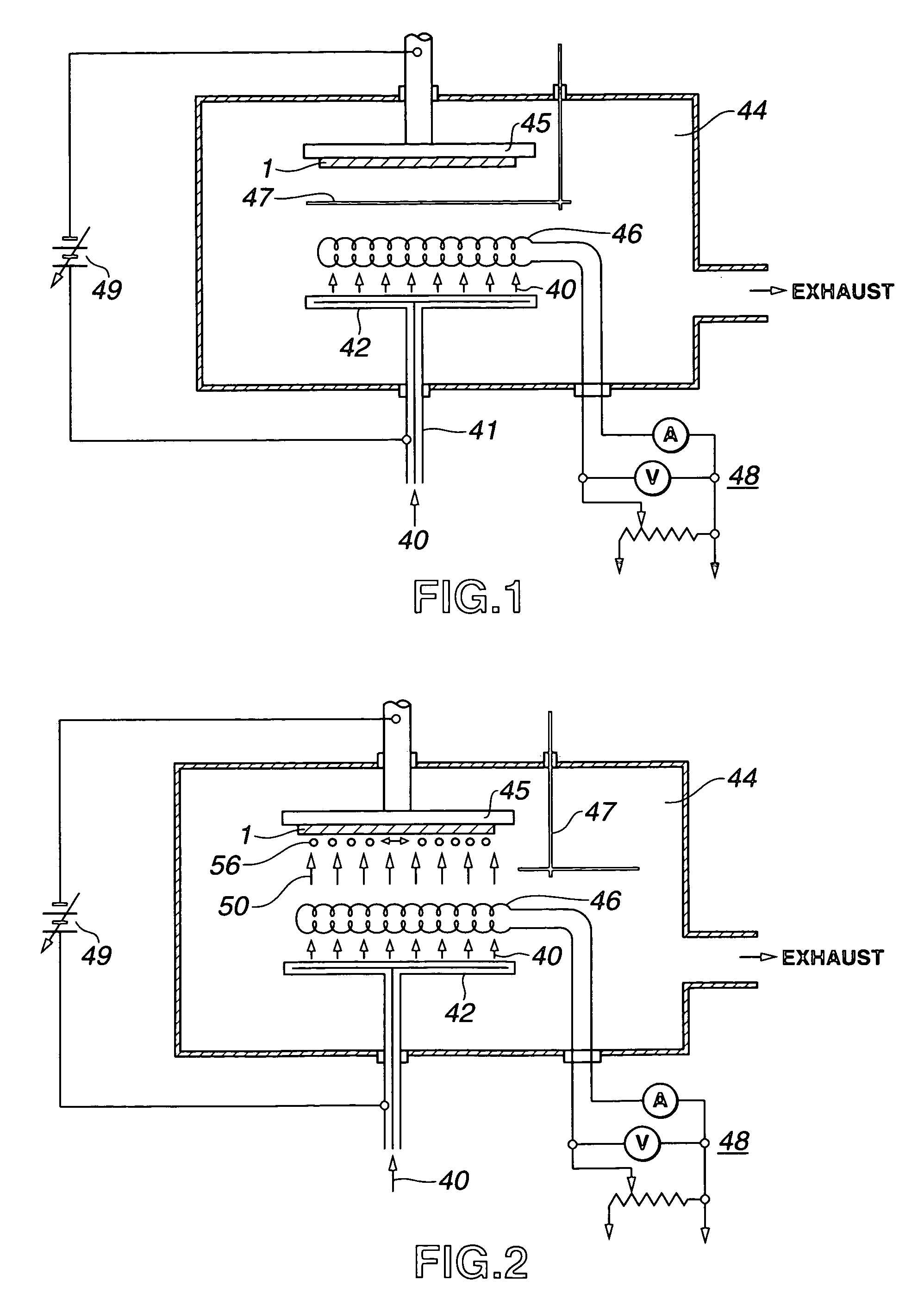

Method and apparatus for film deposition

InactiveUS7011866B1Increase contactHigh densitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenSilanes

A reaction gas made of a hydrogen-based carrier gas and a silane gas or the like is brought in contact with a heated catalyzer of tungsten or the like, and a DC voltage not higher than a glow discharge starting voltage or a voltage produced by superimposing an AV voltage or an RF voltage on the DC voltage is applied on the produced reactive species, so as to provide kinetic energy and carry out vapor growth of a predetermined film on a substrate, thereby providing a film of high quality.

Owner:SONY CORP

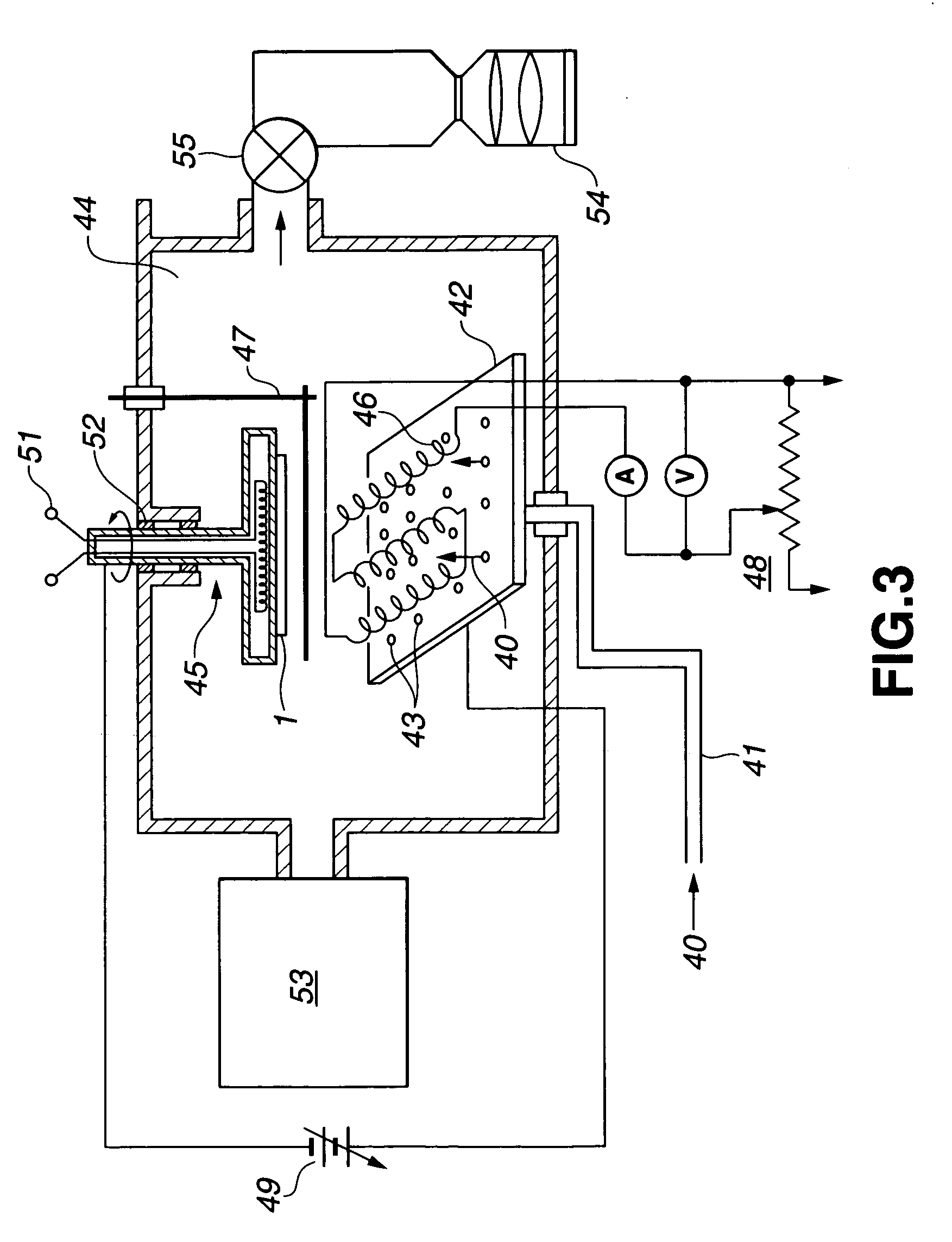

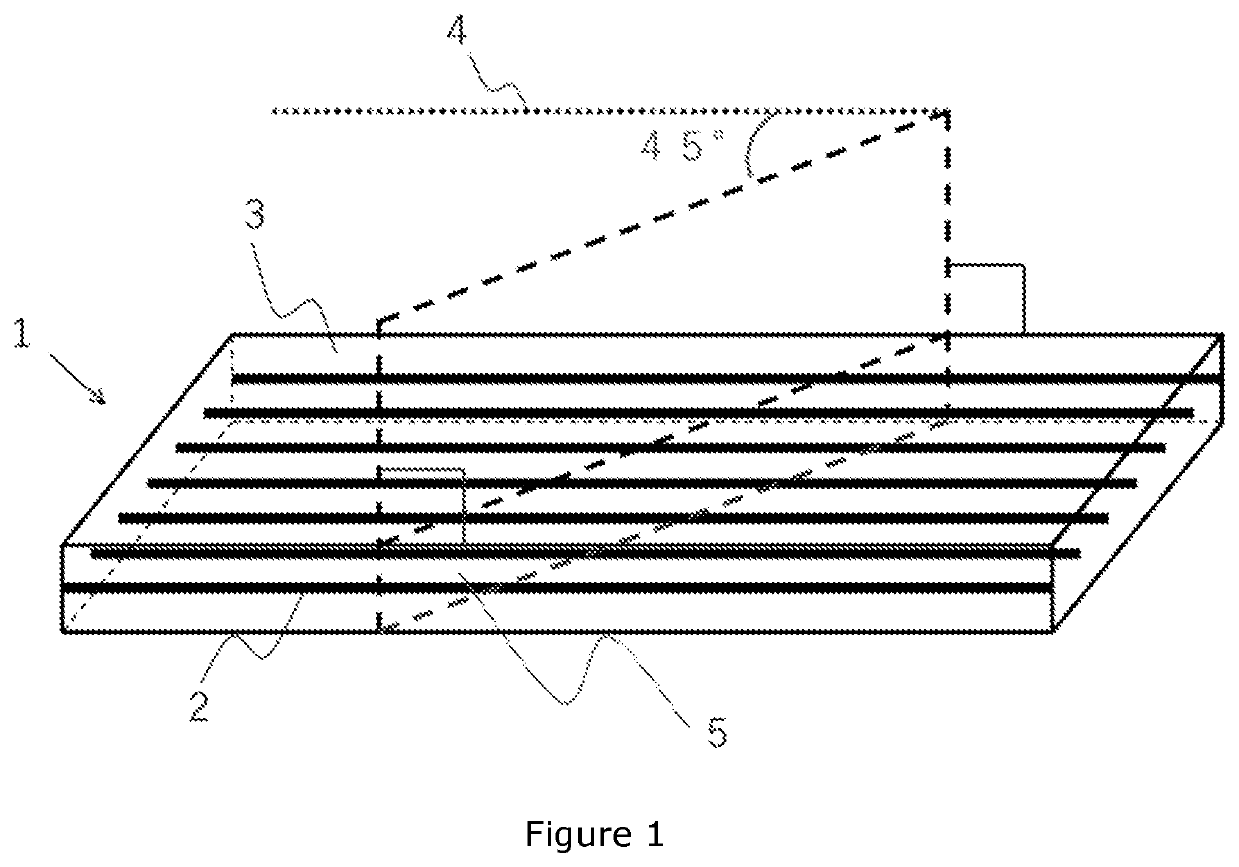

Laser rapid-forming method based on contour scanning of coated powder materials

InactiveCN1827281AGuaranteed accuracyHigh precisionComputer controlSpecial data processing applicationsSurface finishSplit lines

The invention relates to a laser quick molding method based on coating powder material figure scanning, belonging to the laser quick molding technique. The invention first uses the computer, according to the z-direction layered figure information of three-dimensional CAD mold, to control the laser beam to scan the figure of coating powder material; the coating powder material scanned by laser beam is heated and increases temperature to the solid temperature of said powder material; the outer surface coating layer of said powder material loses the solidify property, to form the ineffective division line consistent with the figure; then the piston of workbench decreases one layer to be laid with powder and scan figure until finishing the three-dimensional figure scanning; at last, heating the whole of coating powder while the attained solidified element is separated at the bound of three-dimensional figure which has lost the solidify property, to attain the three-dimensional solid. The invention can quickly make complex three-dimensional solid, with high efficiency, compactness, strength, accuracy and surface fineness.

Owner:DALIAN UNIV OF TECH

Precoated sand accelerating casting part forming and preparation method thereof

InactiveCN107096871ASpeed up moldingImprove molding qualityFoundry mouldsFoundry coresTetramineSand casting

The invention relates to the field relative to precoated sand casting technologies, in particular to precoated sand accelerating casting part forming. The precoated sand is prepared from the following components of a silica sand body, a ceramsite sand body, a magnetite sand body, thermoplastic phenolic resin, modified polyester resin, hexamethylene tetramine, ammonium acetate, calcium stearate, ceramic glaze powder, ammonium stearate and a forming agent. According to the precoated sand accelerating casting part forming, the problem that a majority of precoated sand is low in forming speed and poor in forming effect is solved, the forming agent is added into the precoated sand, and the specific precoated sand preparation technology is matched, so that through the preparation method of the precoated sand, the casting part forming speed can be increased, and the casting part forming quality can be improved, and casting efficiency is improved.

Owner:李吕军

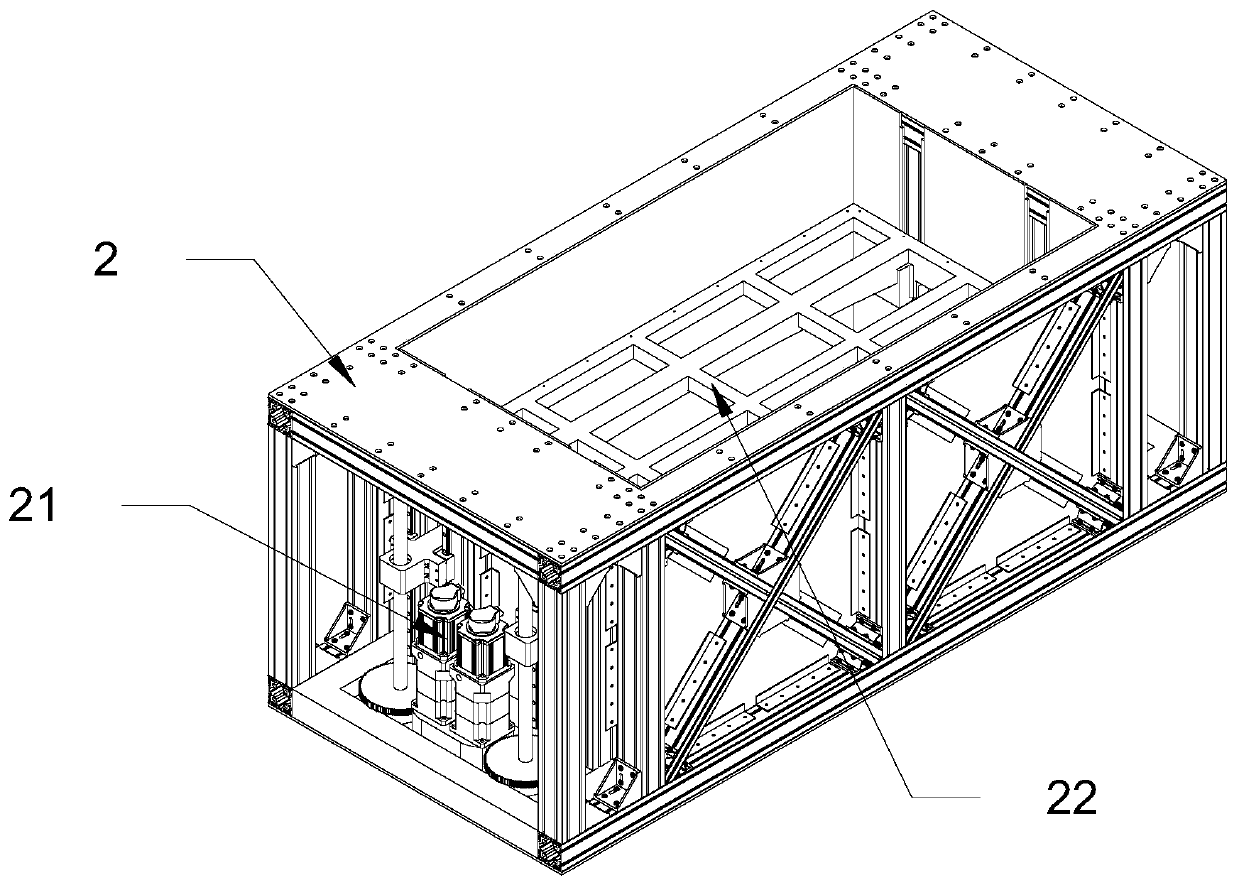

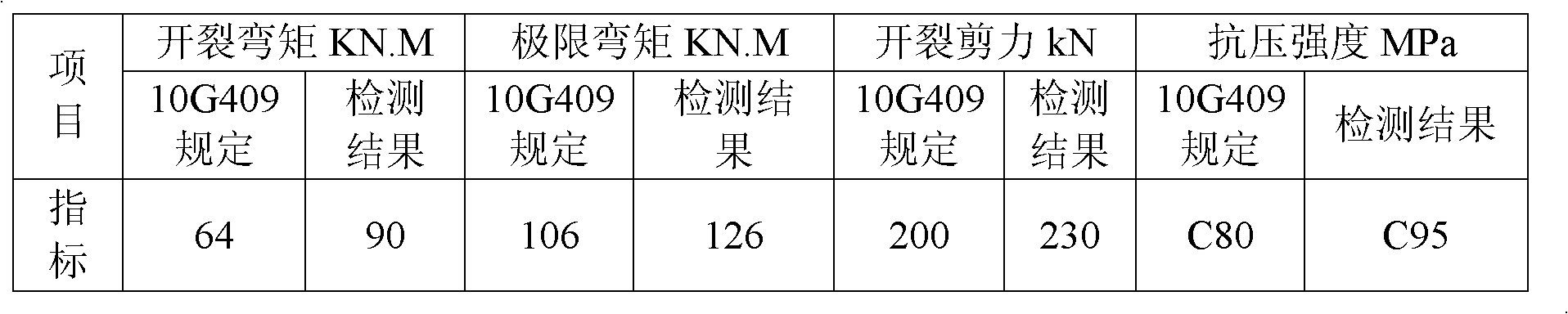

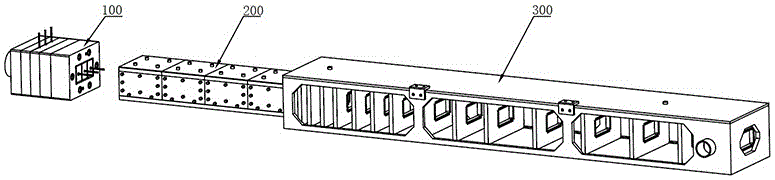

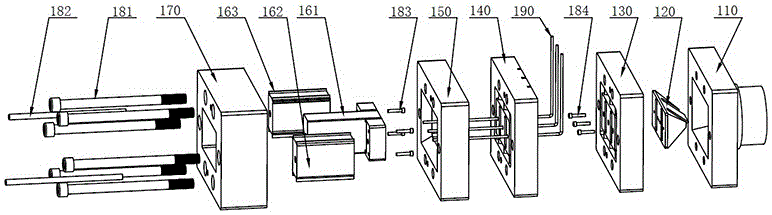

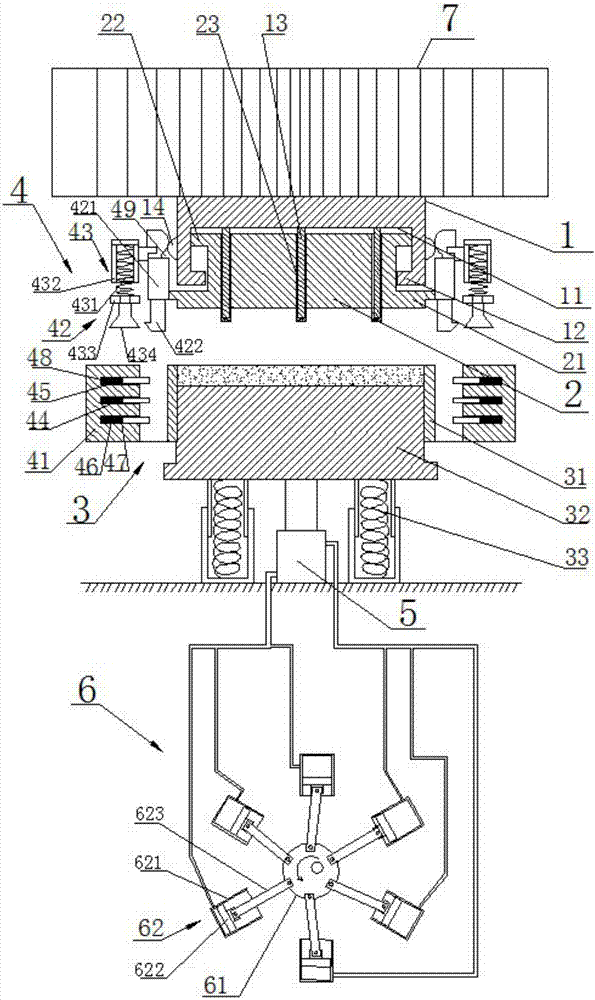

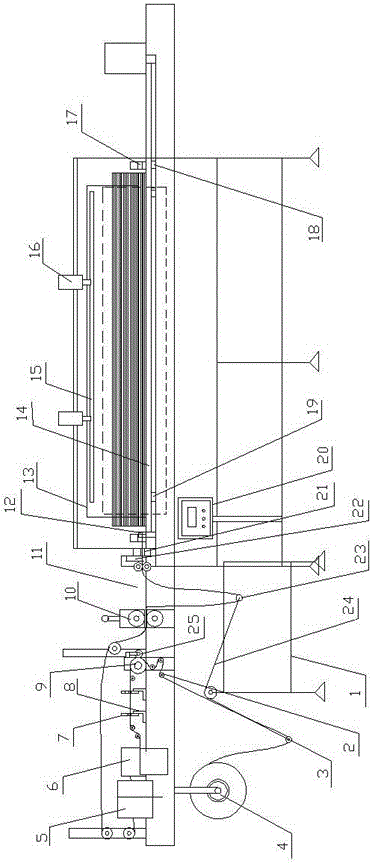

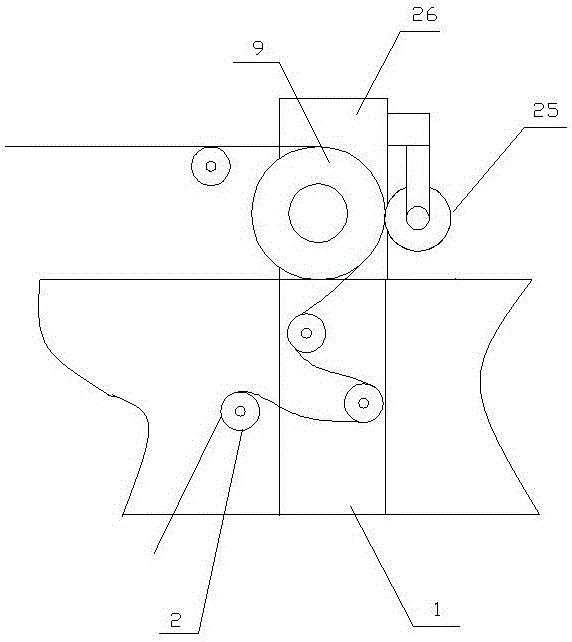

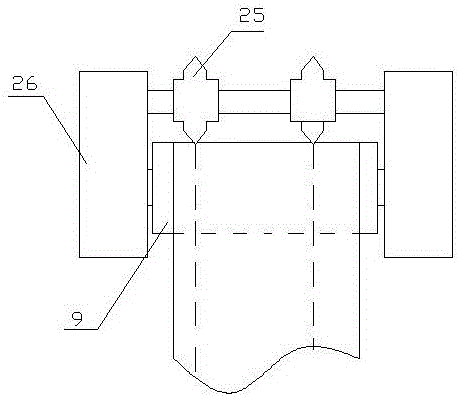

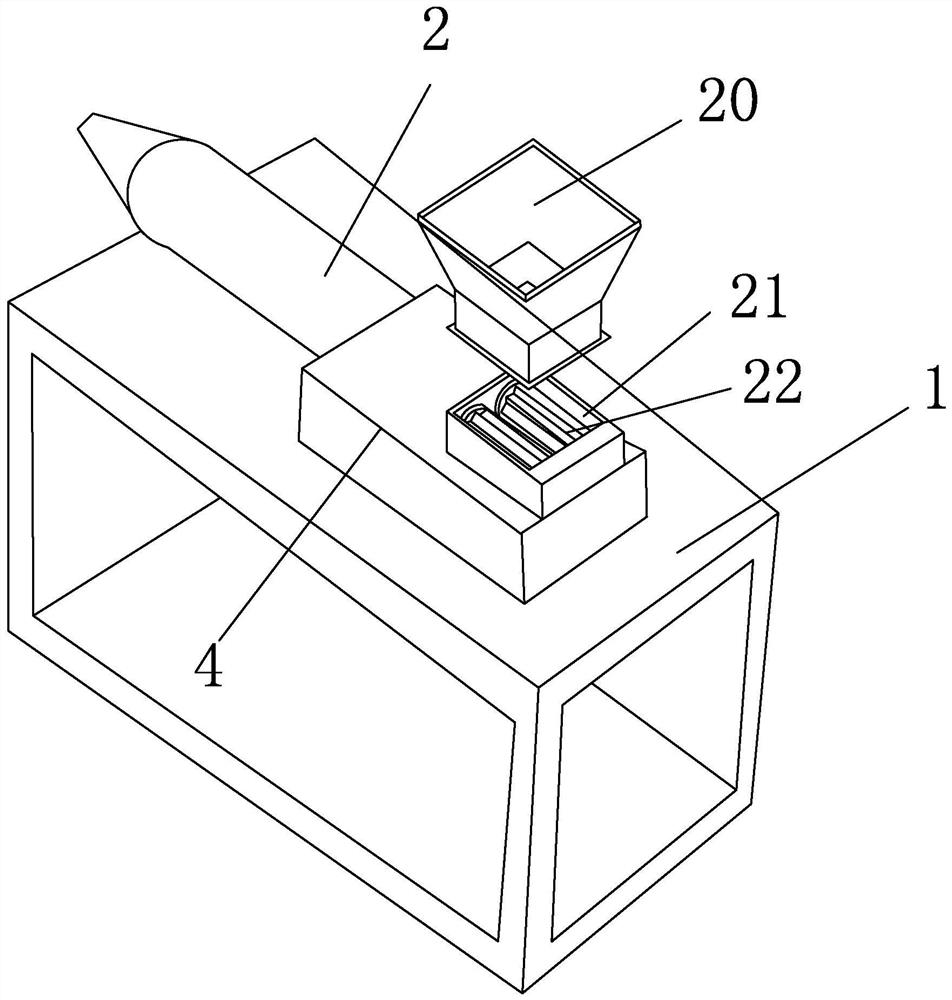

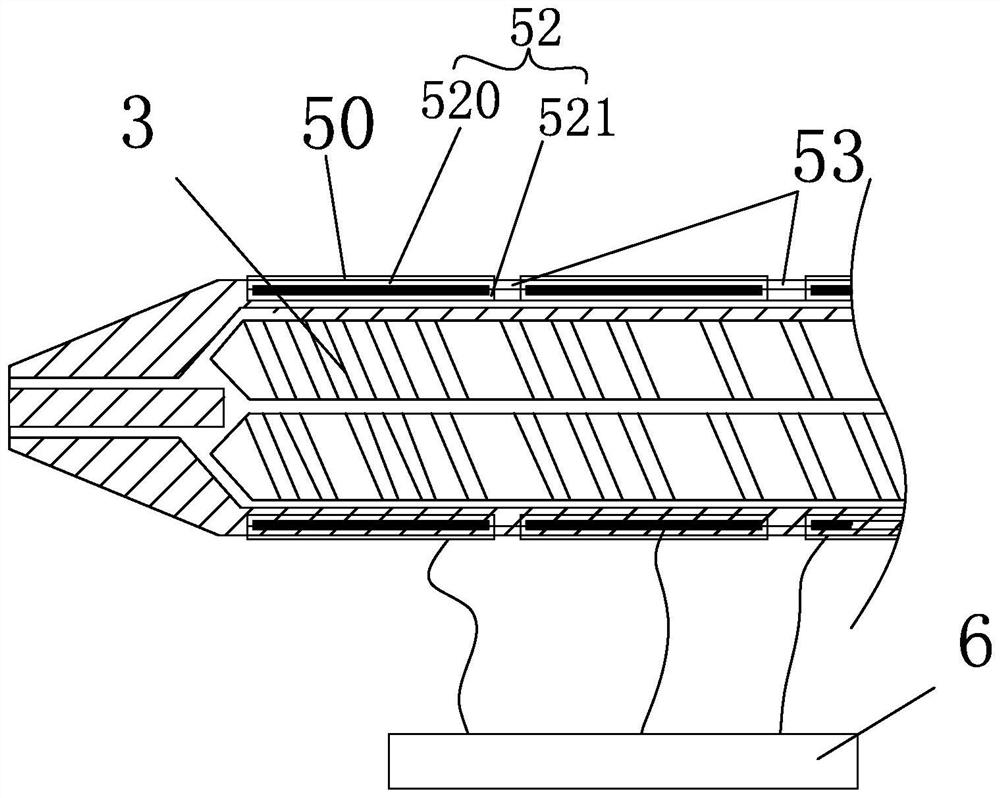

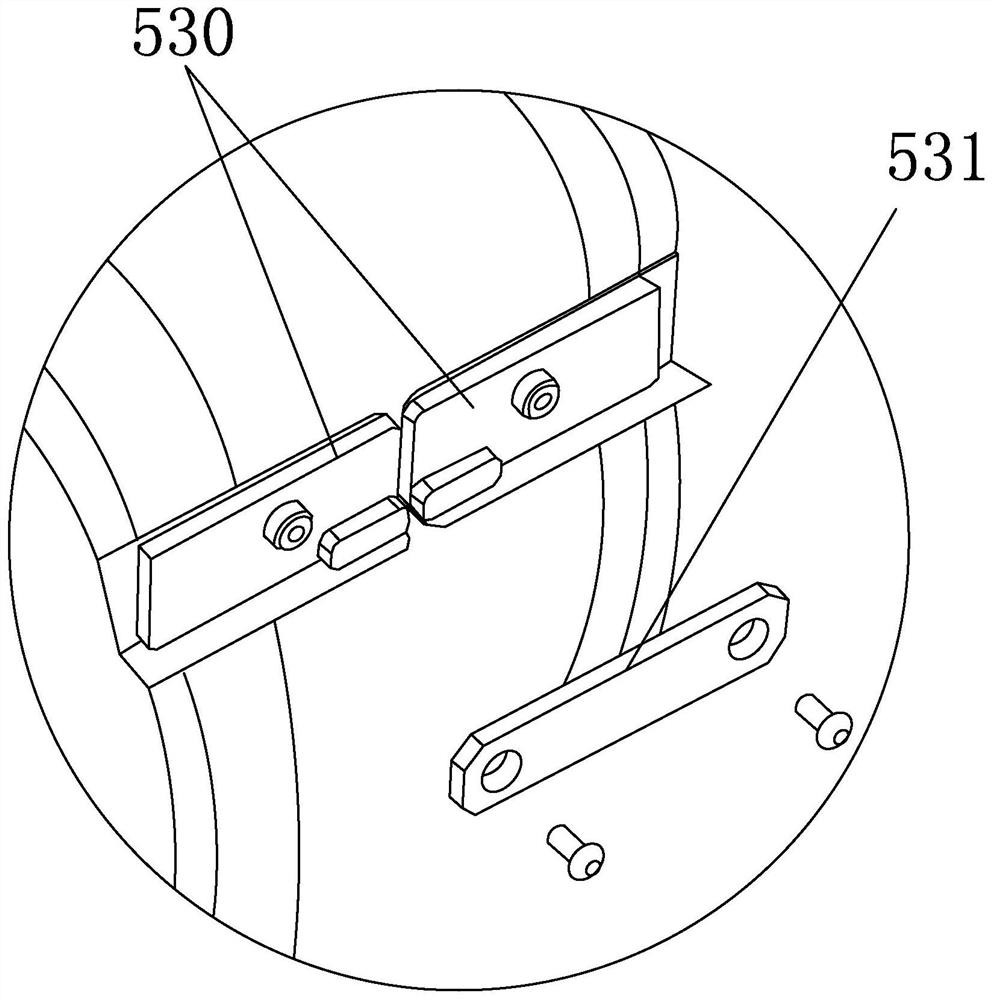

Laser 3D printer capable of finishing high-precision sand mold manufacture at one step

ActiveCN106001416AImprove molding speed and efficiencyHigh dimensional accuracyAdditive manufacturing apparatusFoundry mouldsLaser printingEngineering

A laser 3D printer capable of finishing high-precision sand mold manufacture at one step comprises a printing device, a feeding device, a material distribution device and a drying device, wherein the printing device comprises a base, a lifting device is arranged on the base for controlling the rise and fall of a lifting platform, a sand paving platform is arranged on the lifting platform, and a laser printing head is arranged above the sand paving platform; the feeding device comprises a sand box and a feeding pipeline; the material distribution device comprises a hopper and a sand pushing plate, the hopper is located at the bottom end of the feeding pipeline and used for distributing sand provided by the feeding device on the sand paving platform, and the sand pushing plate is used for uniformly pushing the sand flat; the laser printing head is used for printing patterns on a sand surface; and the drying device is used for drying a printed sand mold. The laser 3D printer can effectively increase molding speed and efficiency and can strictly control printing sizes, so that the size precision of molded components is high. By adopting the printer, sand molds with various sizes and complicated curvy surfaces can be printed, and the range of applications is wide.

Owner:辽宁森远增材制造科技有限公司

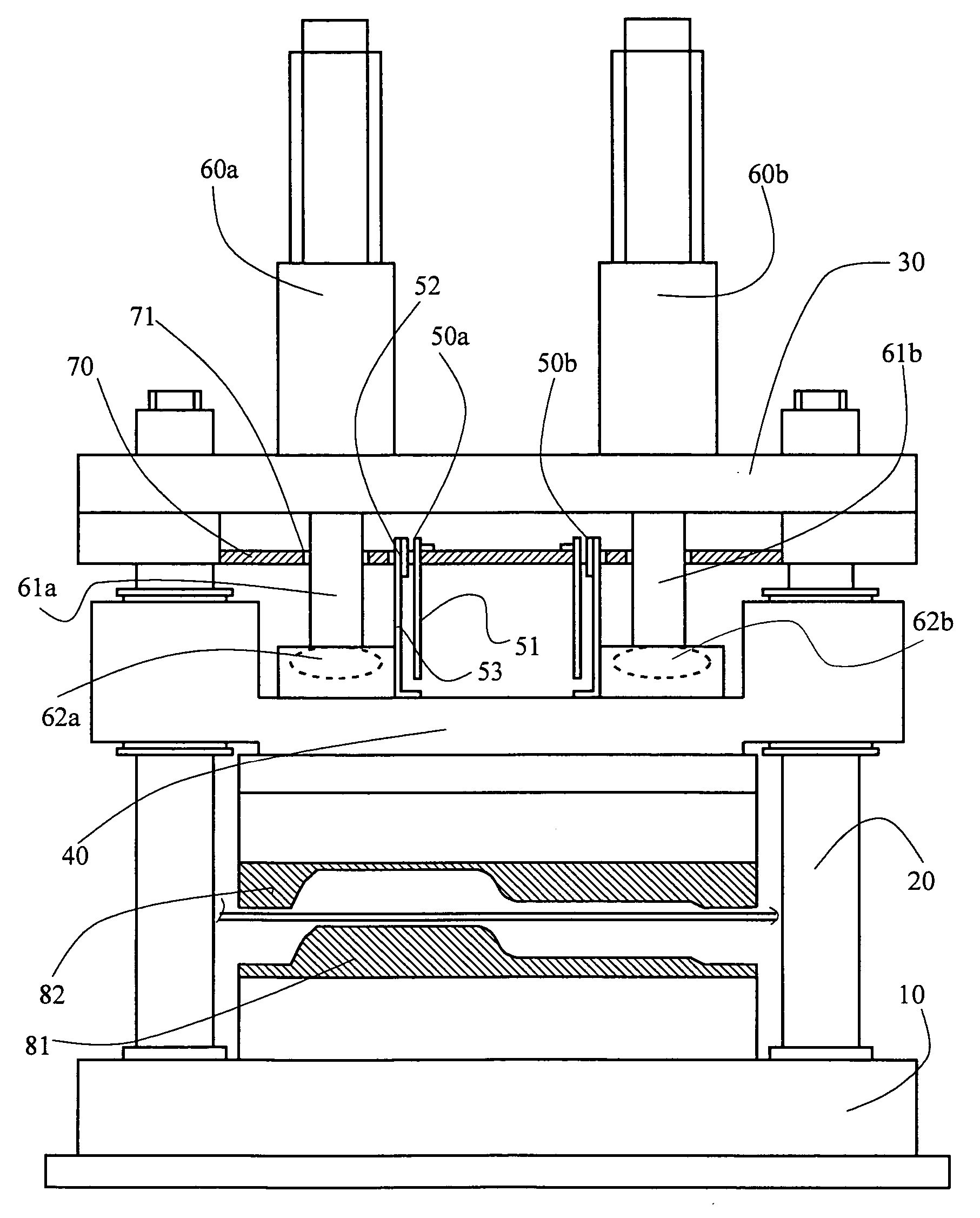

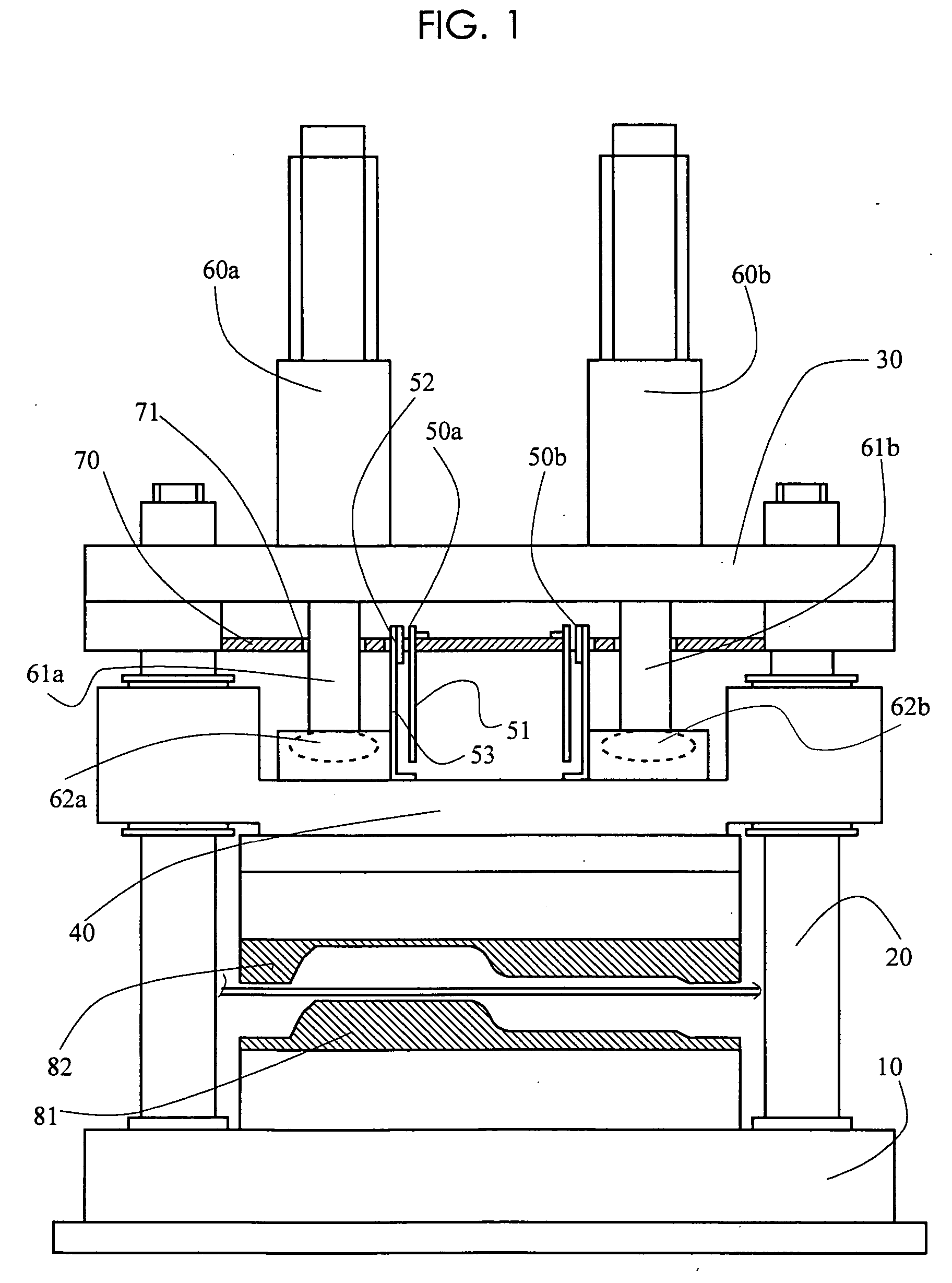

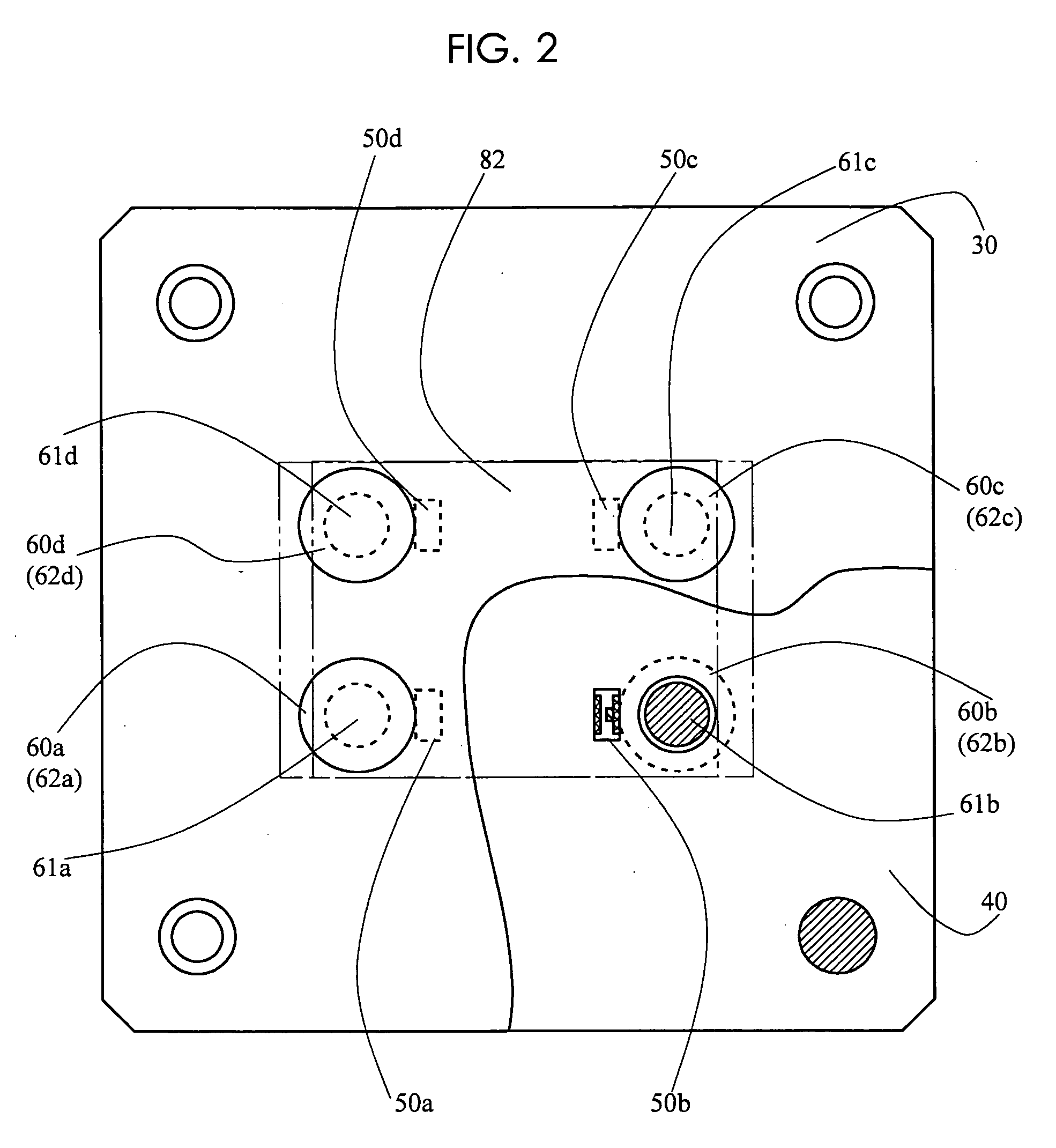

Press forming method

InactiveUS20050257697A1Speed up moldingSuitable for mass productionShaping safety devicesHammer drivesMotor driveHigh volume manufacturing

A press forming method is disclosed, wherein press forming can be effected at high speed while maintaining the horizontal state of a slide plate in press-forming work by a press machine. A press machine is used in which the slide plate is pressed by a plurality of servo-motor drive sources. In trial forming, the slide plate is sufficiently slowly moved to measure the delay of each drive source. According to the magnitude of the delay of each drive source or according to the difference between the trial forming speed and the production forming speed, the respective speeds of the drive sources are corrected, and trial forming is repeated on the basis of the corrected speed to derive conditions that enable press forming at high forming speed suitable for mass production while maintaining the horizontal state of the slide plate to the extent of ensuring sufficient product accuracy.

Owner:HODEN SEIMITSU KAKO

High-precision 3D sand mold printing equipment

InactiveCN110860651AHigh degree of automationEasy to collectAdditive manufacturing apparatusFoundry mouldsElectric machineryEngineering

The invention relates to high-precision 3D sand mold printing equipment. The high-precision 3D sand mold printing equipment comprises a support frame, a sand box, an ink jet assembly and a sand feeding assembly, wherein sliding rails and lifting mechanisms are arranged at the two outer ends of the sand box; a mould lifting frame connected with the lifting mechanisms is arranged in the sand box; the ink jet assembly comprises an ink jet trolley, a first guide rail and second guide rails; the ink jet trolley is connected with the first guide rail; the two ends of the first guide rail are connected with the second guide rails; the second guide rails are arranged at the upper end of the support frame; the sand feeding assembly comprises a sand storage tank, a spiral rod, a scraper and a vibration motor; the two ends of the sand storage tank are slidably connected with third guide rails; the spiral rod is arranged inside the sand storage tank; and the scraper and the vibration motor are respectively arranged on the two sides of the bottom of the sand storage tank. According to the printing equipment provided by the invention, through the cooperation of the ink jet assembly, the sand feeding assembly and the sand box, the actions of automatic sand spreading, printing, sand surface sedimentation, residual sand collection and the like can be realized, the automation degree is high, andthe rapid forming of any complex part can be realized.

Owner:郑州中兴三维科技有限公司

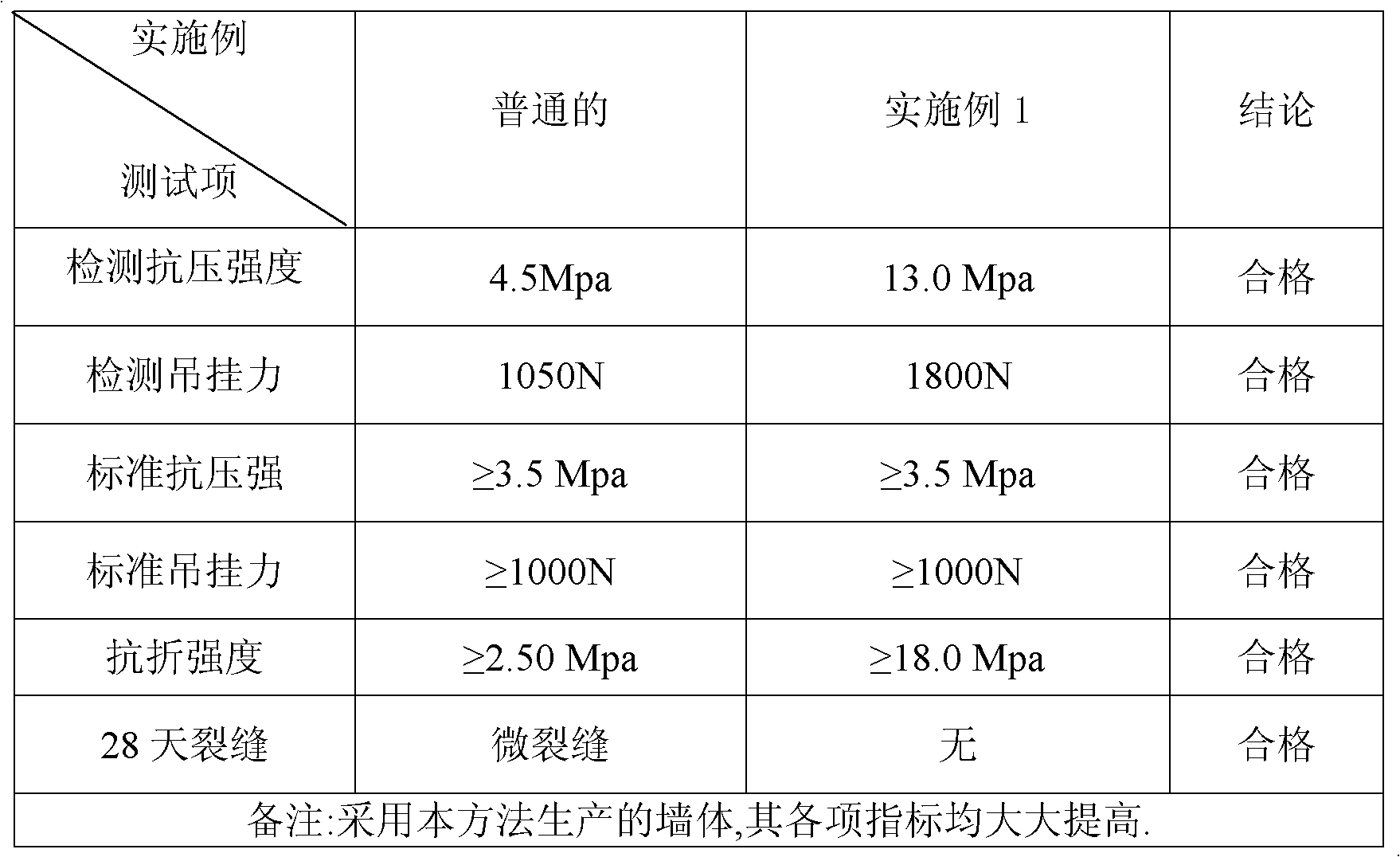

Method for preparing high-performance concrete and application

The invention discloses a method for preparing high-performance concrete and application. The method comprises the following steps of: designing a concrete mixing proportion; sequentially adding fine aggregate, engineering fibers and gel material into a stirrer, and stirring till the engineering fibers are uniformly distributed; and adding water to prepare mortar, adding coarse aggregate, stirring uniformly, and adding an admixture to obtain the high-performance concrete required by design. The prepared high-performance concrete can be used for preparing high-performance concrete products. The method is simple and convenient for processing; the length of the utilized engineering fibers is easily controlled, so that the concrete has good workability, the forming velocity and the production efficiency are improved, the concrete has the advantages of tensile resistance, shearing resistance, cracking resistance, fatigue resistance, high toughness and the like, and concrete cracks caused by temperature stress can be reduced; the microstructure of the cement slurry is improved, and the compactness of the concrete is increased, so that the strength and the durability of the concrete are improved, and the service life of the concrete is prolonged; and the concrete has good safety and economic and social benefits.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

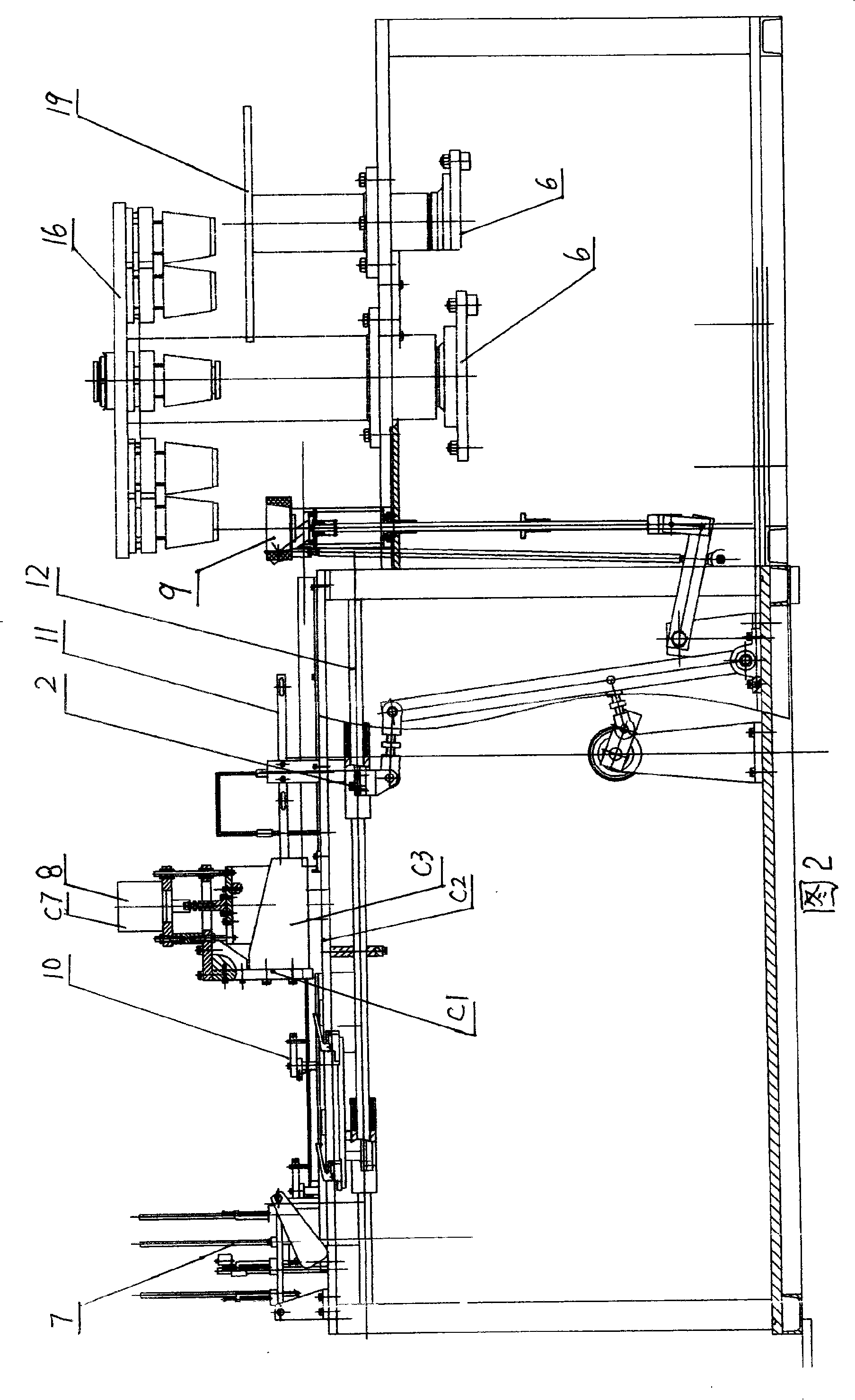

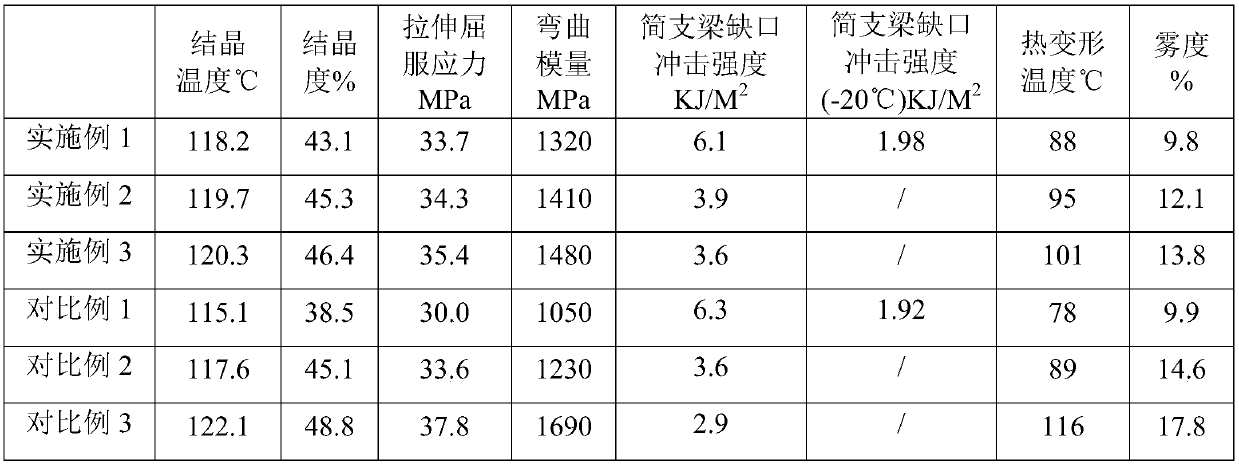

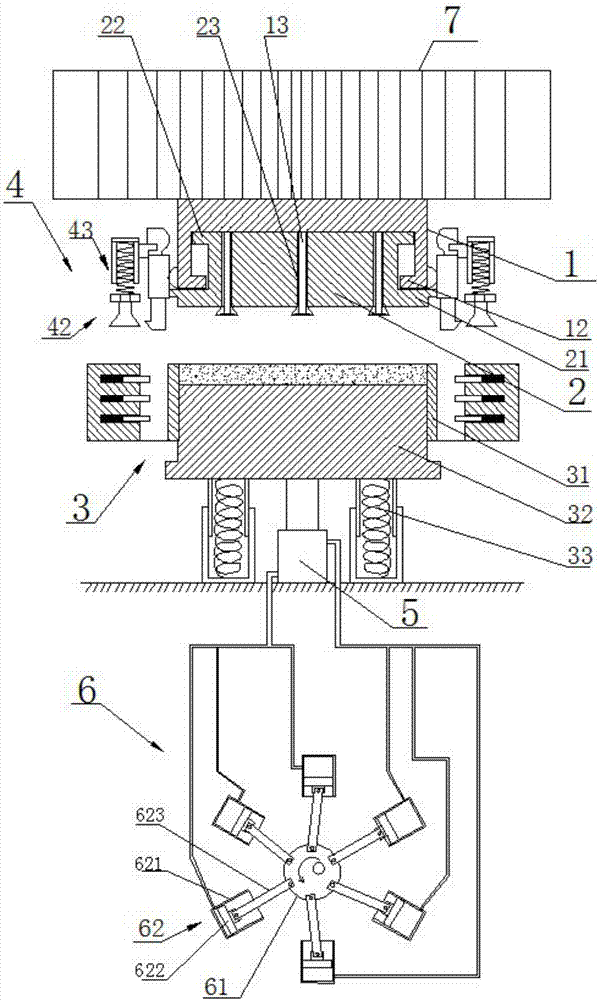

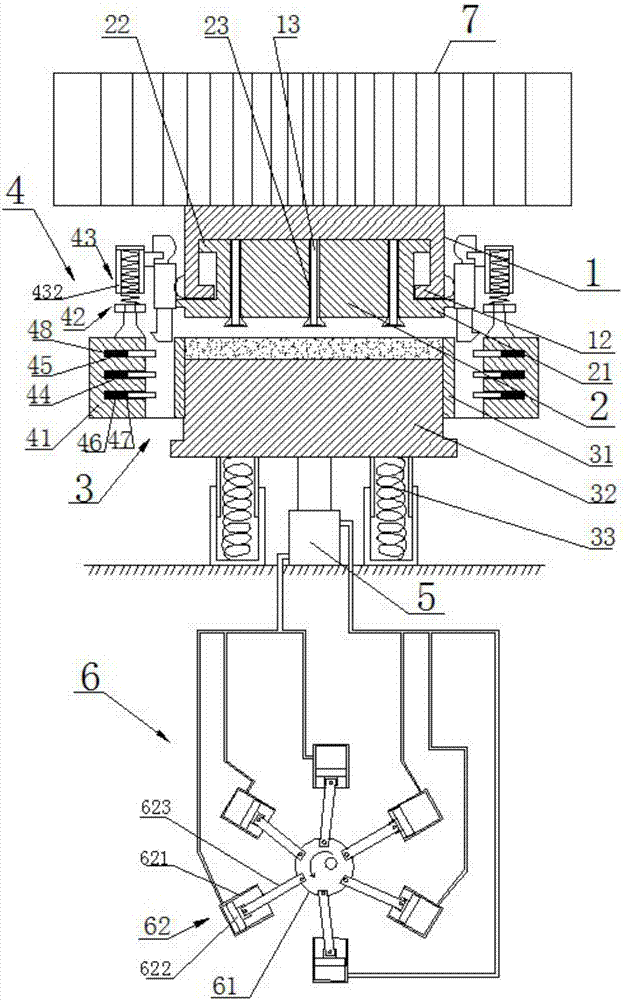

High speed full automatic paper bowl and paper cup shaping machine

InactiveCN101186124AOvercome scratch defectsQuality improvementPaper/cardboard wound articlesHuman–machine interfaceSeparation technology

The invention provides a high-speed fully automatic paper bowl and paper cup forming machine, which adopts unique bottom and mouth separation technology, overcomes the shortage of combination between the bottom and the mouth of the traditional equipment and overcomes the defect of unclear printed patterned by the rotation of a die; a dual-station heating technology greatly improves the quality and forming speed of a forming product, with the forming speed reaching 70 / min; unique hot wind heating melting technology well ensures the melting quality and avoids poor bonding and burning phenomena; a cup bottom paper punching mechanism (3) adopts a bottom paper servo system, thus avoiding the waste of the bottom paper and improving the utilization ratio of the raw material; a rotary disc indexing mechanism (6) greatly improves the positioning precision of the rotary disc; unique cotton ginning die protection structure is adopted in order to fully avoid the abrasion of the cotton ginning die; the application of a special PLC micro-computer control system and an LCD visual man-machine interface implements automation of the working process of the whole machine, and the intelligent operation is implemented by arranging the parameters of products through the interface when different products are replaced.

Owner:四川索牌科技股份有限公司

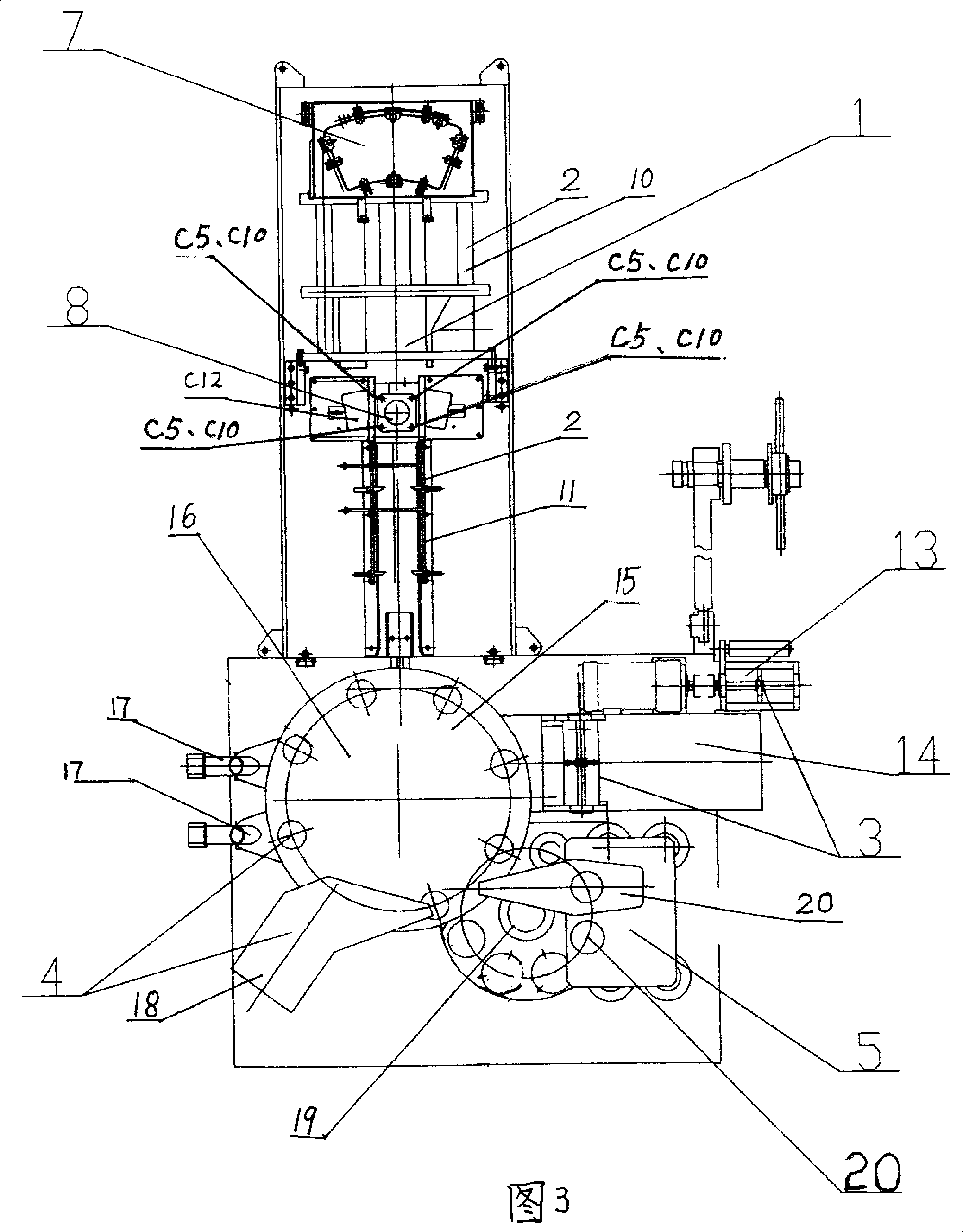

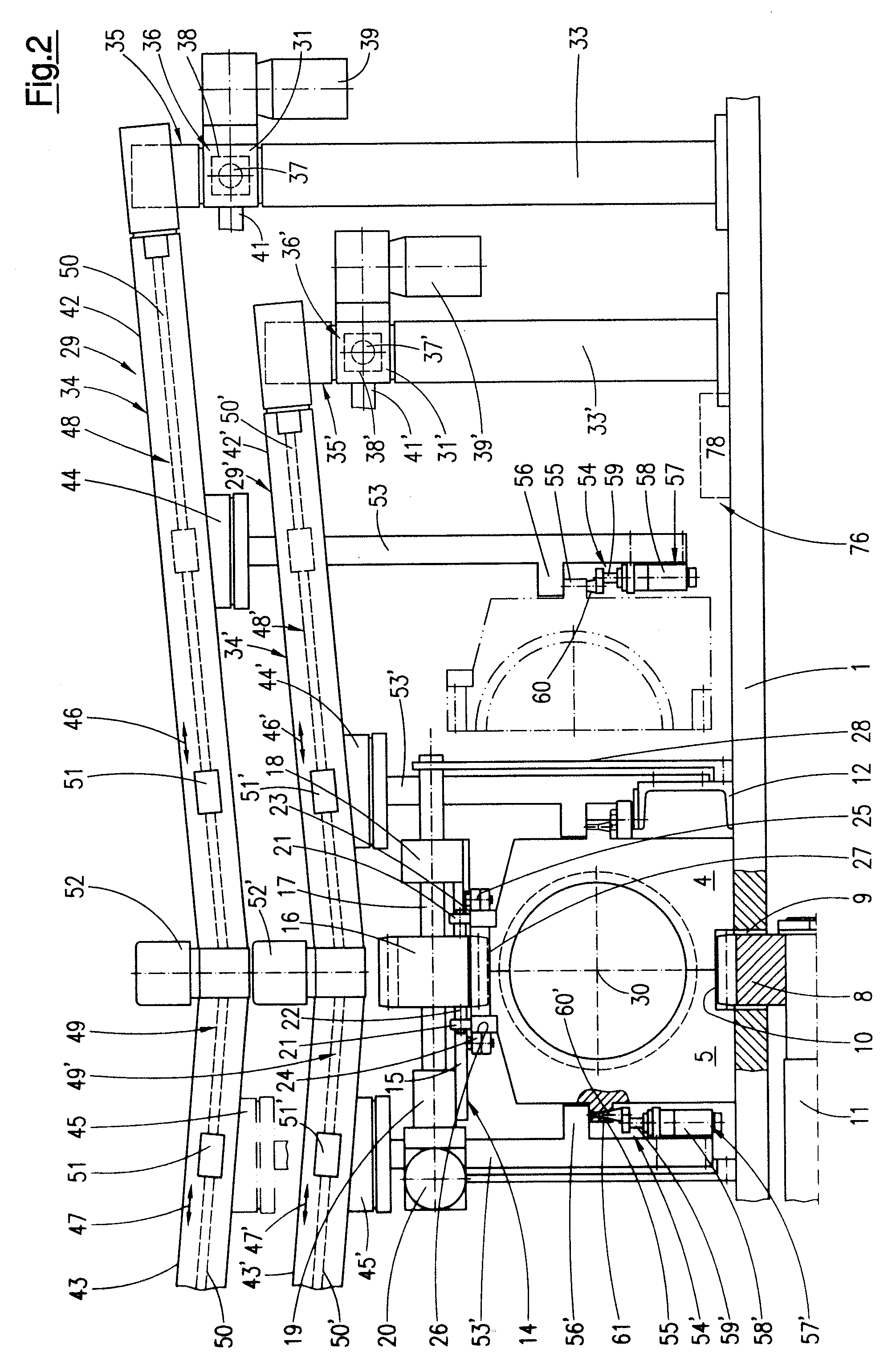

Method and apparatus for producing pipes having a transverse profile from thermoplastic material

InactiveUS20090091055A1High speedIncrease production speedTailstocks/centresHollow filament manufactureGantry craneMechanical engineering

In a method and an apparatus for producing pipes having a transverse profile from thermoplastic material, mold segment halves are used on a molding path and are circulated in pairs. A main conveying device is provided for returning the mold segment halves, the main conveying device being designed like a gantry crane. A conveying bridge encompassing the molding path is provided with two conveying carriages which are displaceable at right angles to a direction of production and in opposite directions relative to each other and to which is in each case attached a downwards facing conveying arm comprising a holding device for in each case one mold segment half. Downstream of the downstream end of the molding path are provided parking positions for additional mold segment halves. Disposed downstream of the molding path is an auxiliary conveying device which is provided for removing the additional mold segment halves from the molding path in order to subsequently return them to the parking positions.

Owner:HEGLER RALPH PETER

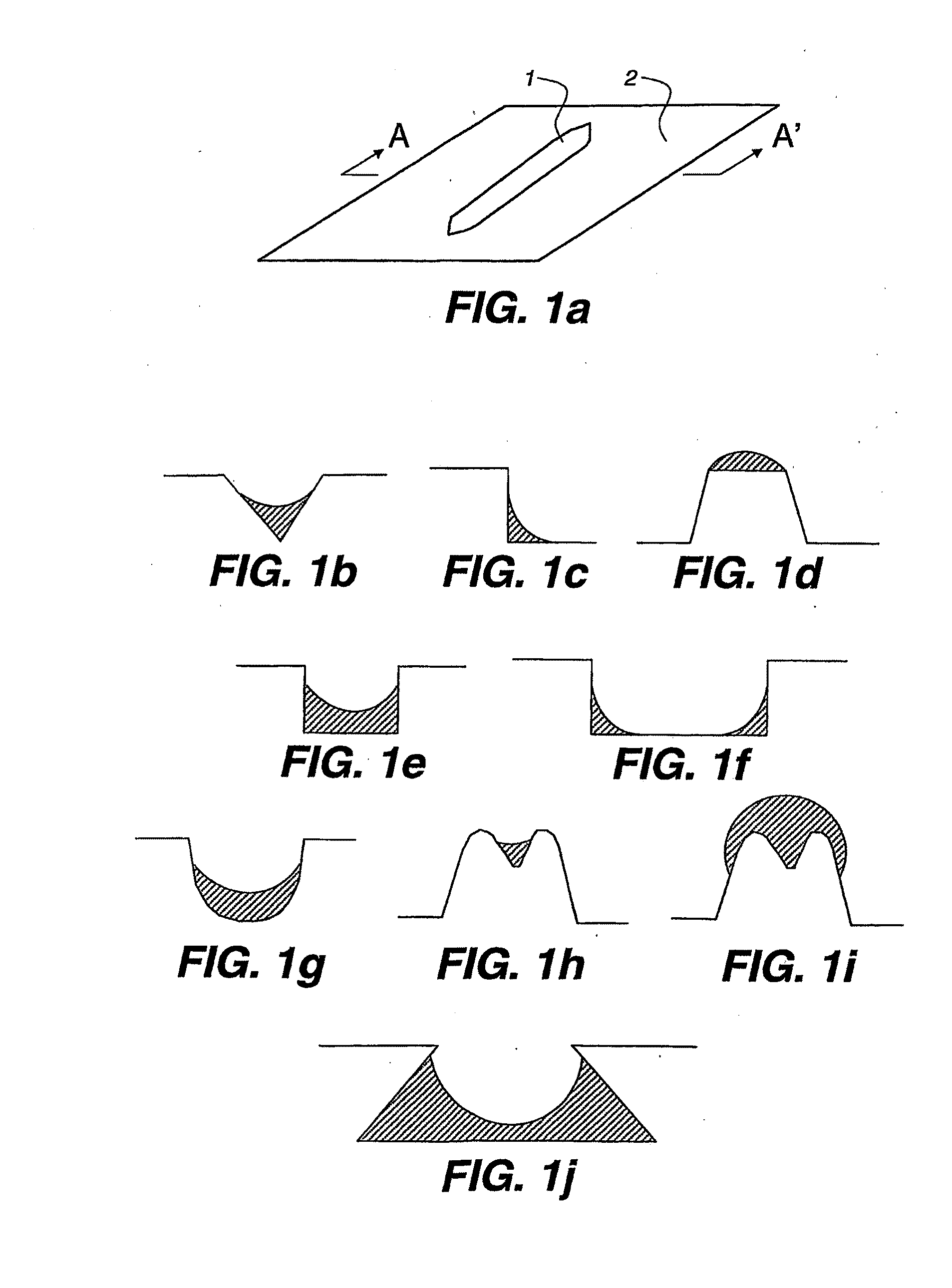

Patterning method

InactiveUS20110159250A1Precise alignmentReduce parasitic capacitanceLayered productsDecorative surface effectsElectrical and Electronics engineeringContact angle

The invention provides a method of patterning flowable material on a surface. The method comprises providing the surface with at least one channel and at least one deposition region connected to the at least one channel, the width of the channel being less than the width of the deposition region, and depositing flowable material in the deposition region such that when the material makes contact with the channel the material is directed into said channel by capillary forces, the receding contact angle of the flowable material in the deposition region being less than 30°.

Owner:EASTMAN KODAK CO

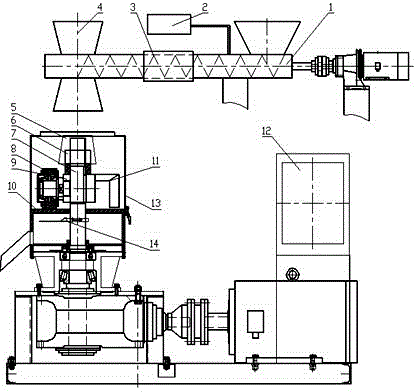

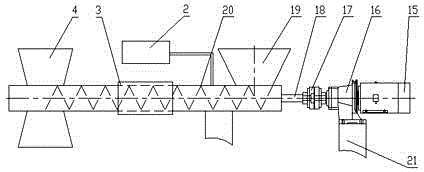

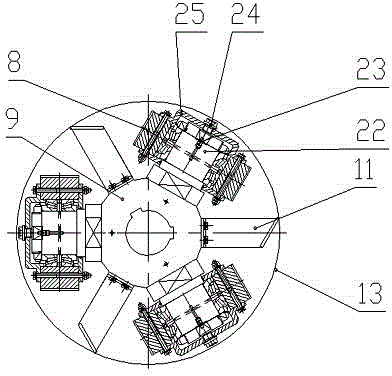

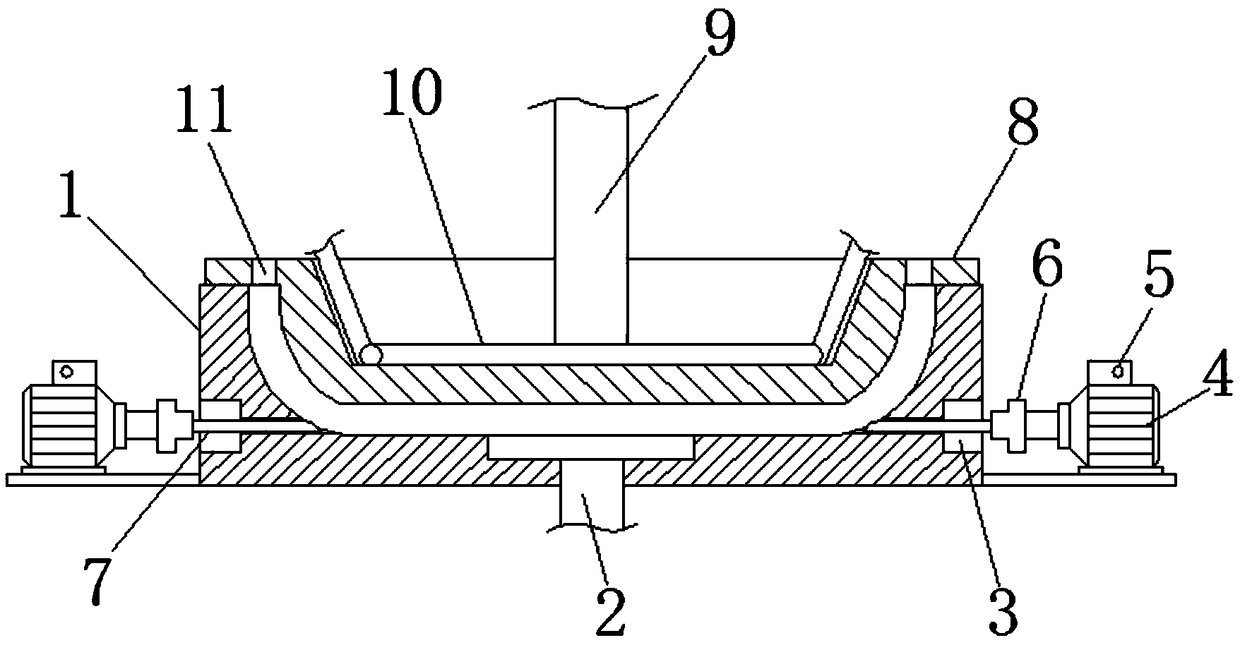

Flat-mold biomass granulating apparatus with raw material pre-optimization function

ActiveCN104959076AEasy to splashEvenly distributedGranulation by pressingFeed devicesEngineeringPre treatment

The invention discloses a flat-mold biomass granulating apparatus with a raw material pre-optimization function, belonging to the technical field of biological energy machinery. The flat-mold biomass granulating apparatus comprises a granulator and a controller; a material paddle-type conveyer is arranged before the granulator; automatic temperature-adjusting and automatic humidity-adjusting devices are arranged on the paddle-type conveyer; a feed inlet of the granulator is connected with a discharge outlet of the conveyer; the granulator comprises a main shaft; a pressure roller rack is in upward-and-downward sliding connection with the main shaft through keys and provided with a pressure roller shaft which is perpendicular to the direction of the main shaft; pressure rollers are rotatably connected with the pressure roller shaft through bearings; a mold is fixedly arranged below the pressure roller; a self-pressure adjusting device is arranged above and connected with the pressure roller rack; a rotary material distributing device is mounted on the part of the pressure roller rack between two pressure rollers; and a main shaft drive unit is connected with the main shaft. The flat-mold biomass granulating apparatus can pretreat a feed, improves molding speed and molding quality and has reduced dependence on auxiliary equipment.

Owner:ANYANG GEMCO ENERGY MACHINERY

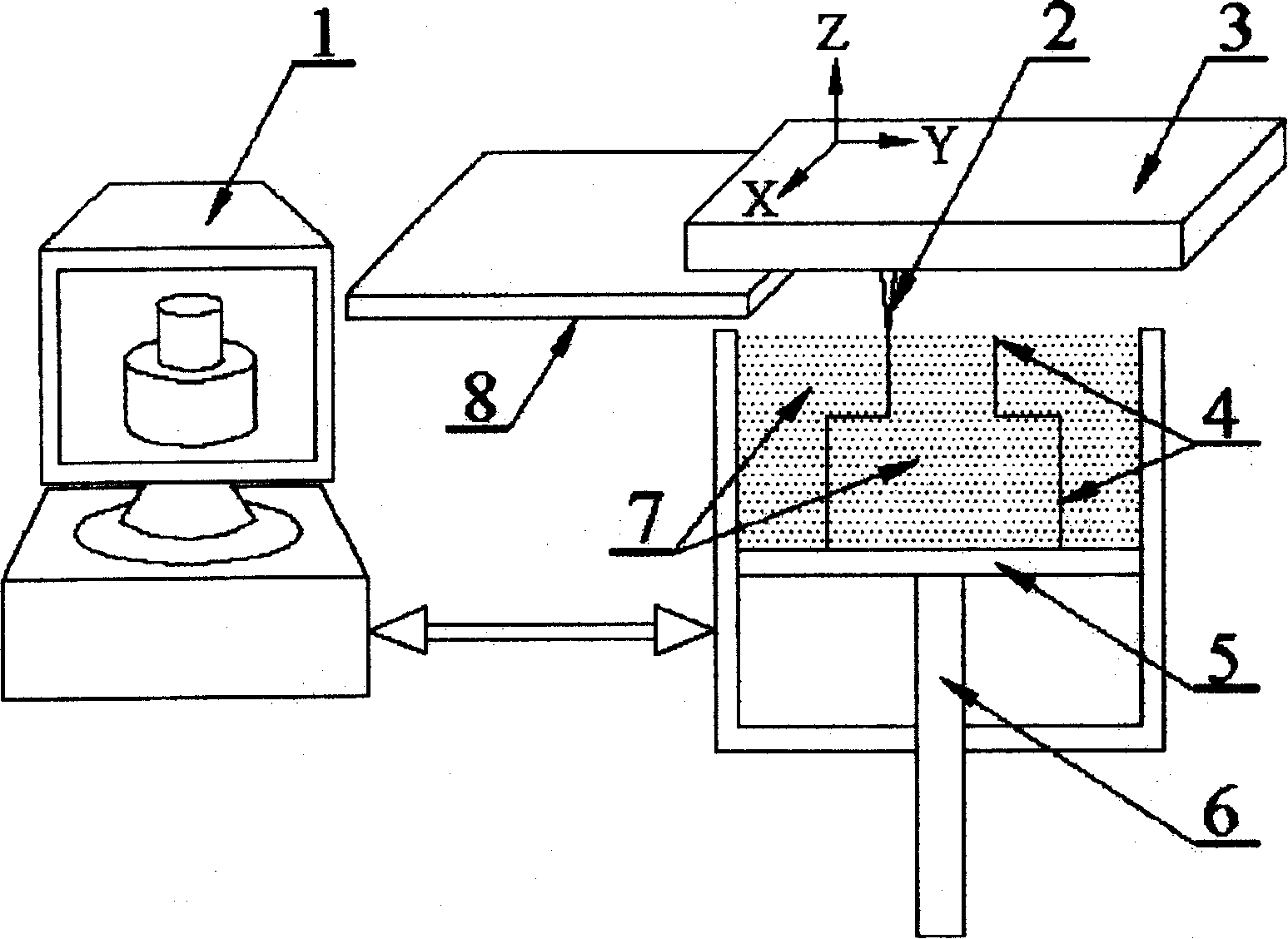

Laser rapid-forming method based on contour scanning of coated powder materials

InactiveCN100386173CHigh precisionSpeed up moldingComputer controlSpecial data processing applicationsSurface finishSplit lines

The invention relates to a laser quick molding method based on coating powder material figure scanning, belonging to the laser quick molding technique. The invention first uses the computer, according to the z-direction layered figure information of three-dimensional CAD mold, to control the laser beam to scan the figure of coating powder material; the coating powder material scanned by laser beam is heated and increases temperature to the solid temperature of said powder material; the outer surface coating layer of said powder material loses the solidify property, to form the ineffective division line consistent with the figure; then the piston of workbench decreases one layer to be laid with powder and scan figure until finishing the three-dimensional figure scanning; at last, heating the whole of coating powder while the attained solidified element is separated at the bound of three-dimensional figure which has lost the solidify property, to attain the three-dimensional solid. The invention can quickly make complex three-dimensional solid, with high efficiency, compactness, strength, accuracy and surface fineness.

Owner:DALIAN UNIV OF TECH

Quick cooling type production mould for pedal main body of sea farming net cage

InactiveCN106079358AAvoid deformationGuaranteed molding effectFlat articlesVacuum coolingVacuum pumping

The invention relates to the technical field of production moulds, in particular to a quick cooling type production mould for a pedal main body of a sea farming net cage. The quick cooling type production mould comprises an extrusion mould head, a vacuum cooling and molding mould and a vacuum molding water tank, which are sequentially connected. According to the quick cooling type production mould, an inner rib and an inner wall of the pedal main body are cooled by a metal air guide tube of the extrusion mould head, vacuum-pumping is carried out by utilizing a ring-shaped vacuum slot of the vacuum cooling and molding mould, and frozen water is injected to quickly cool and mould the outer wall of the pedal main body, and finally, continuous cooling and vacuum-pumping are carried out in the vacuum molding water tank for strengthening molding. According to the quick cooling type production mould, integral molding and cooling speed of a pedal is increased, production efficiency is improved, and dimension and performance of the pedal main body are guaranteed to meet standard requirements.

Owner:HESHAN LESSO IND DEV

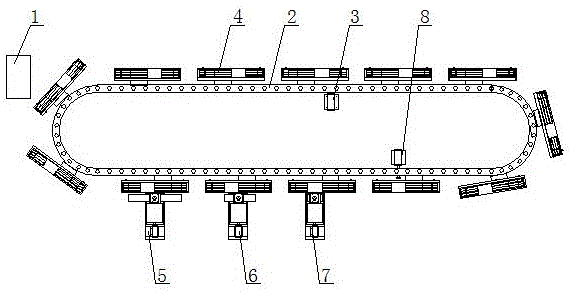

Automatic steel bar bent hoop forming device

The invention relates to an automatic steel bar bent hoop forming device, and belongs to the technical field of building machines. The forming device comprises a program control box, a rack, a transmission track chain, a stepping motor, stirrup female dies, a forming press A, a forming press B, a forming press C and an unloading push head. The transmission track chain is annularly arranged on the rack through the stepping motor. The multiple stirrup female dies are arranged on the transmission track chain at intervals. The forming press A, the forming press B, the forming press C and the unloading push head are arranged on the inner side of one side of the transmission track chain at intervals. The forming device is simple in structure and high in practicability. In the work process, the stirrup female dies intermittently move along with the transmission track chain, downward pressing is conducted one by one through the forming press A, the forming press B and the forming press C, and accordingly steel bar bent hoop manufacturing is finished. Compared with an existing hoop bending machine, the steel bar bent hoop pressing steps are reduced, the bent hoop forming speed and quality are improved, and the labor intensity of workers is lowered; and the automatic steel bar bent hoop forming device is particularly suitable for being used for steel bar bent hoop forming.

Owner:YANGTZE UNIVERSITY

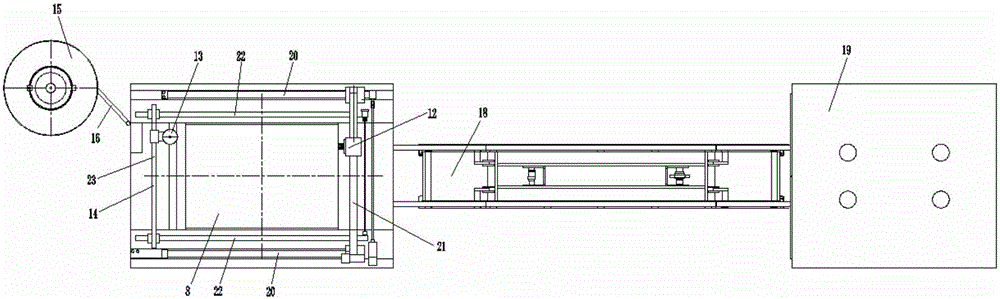

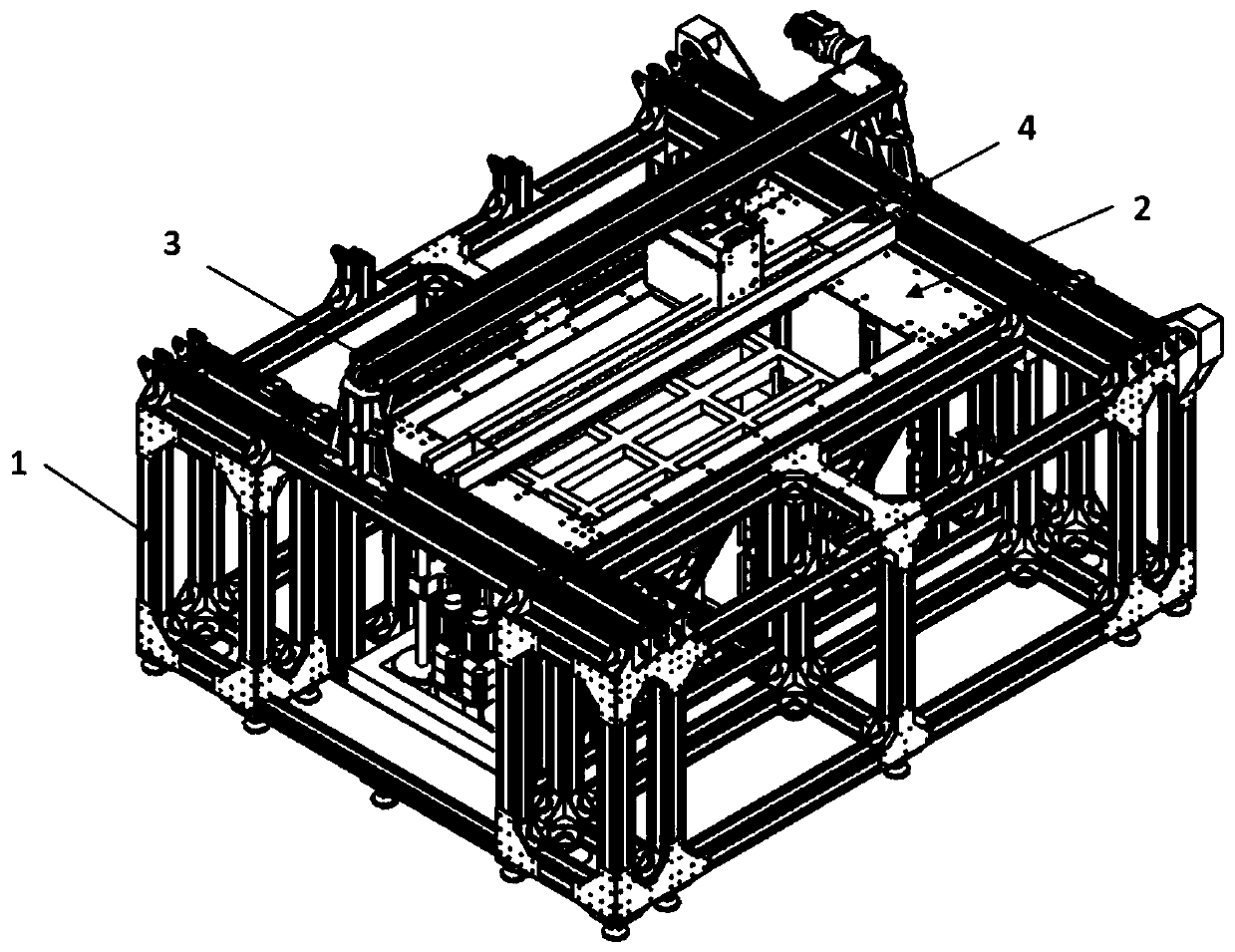

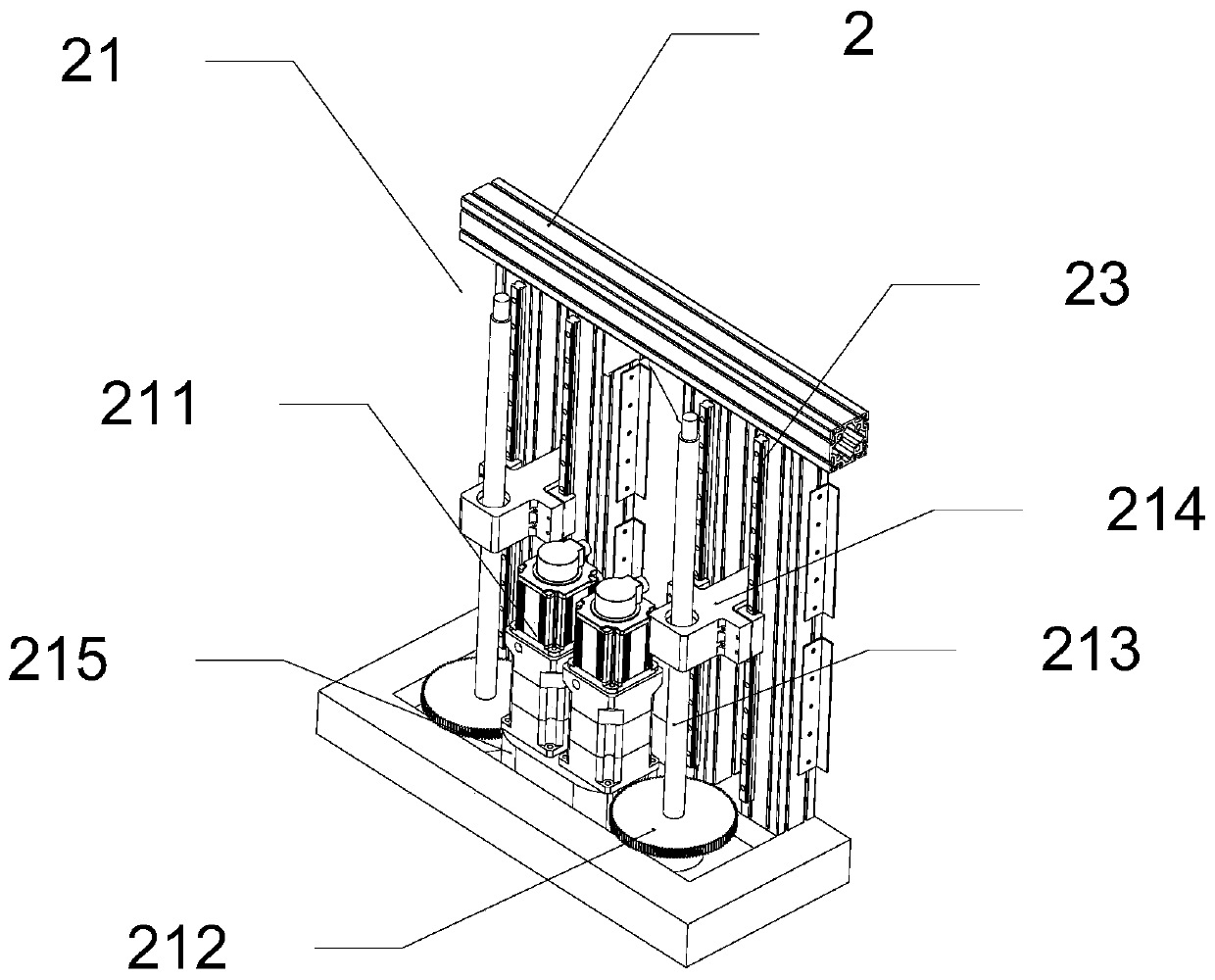

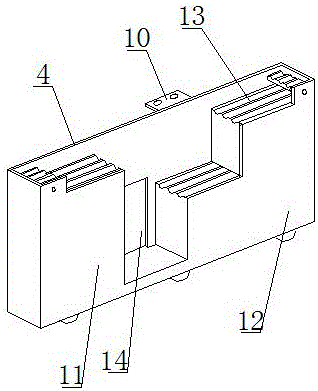

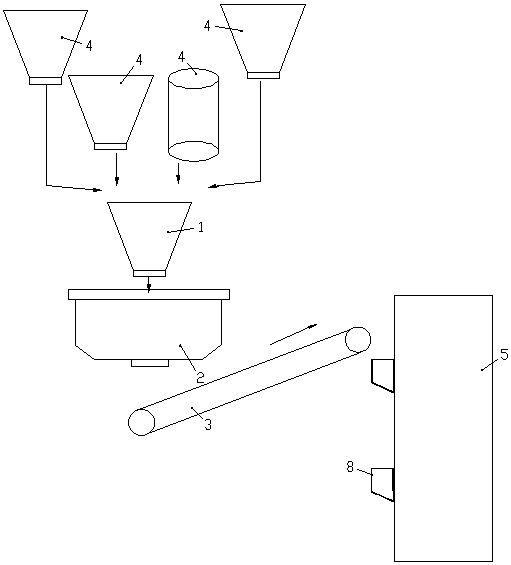

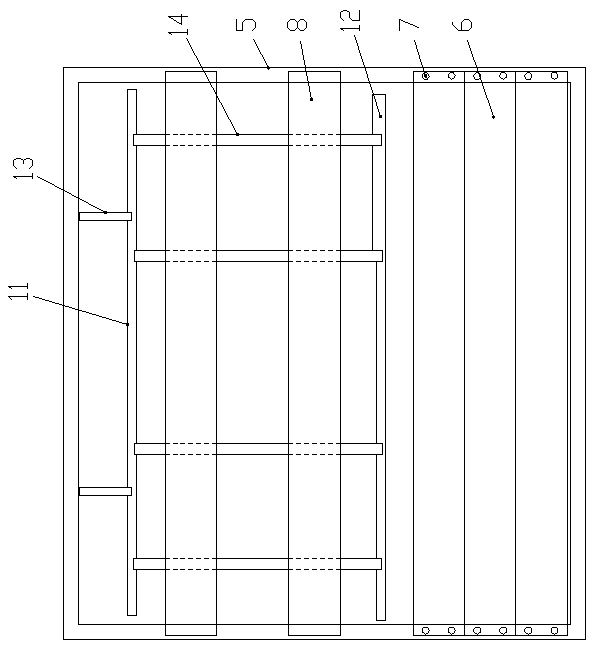

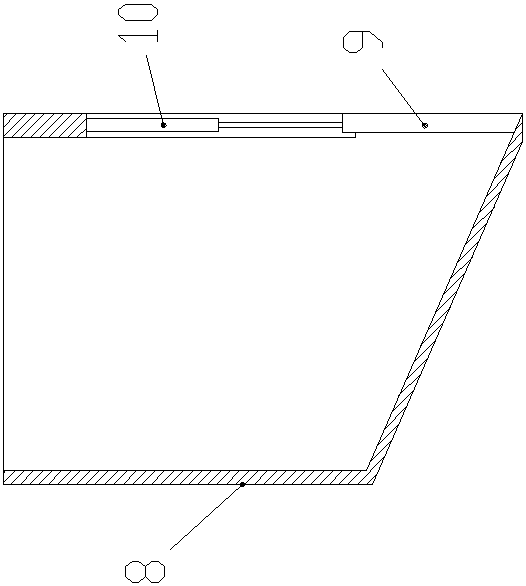

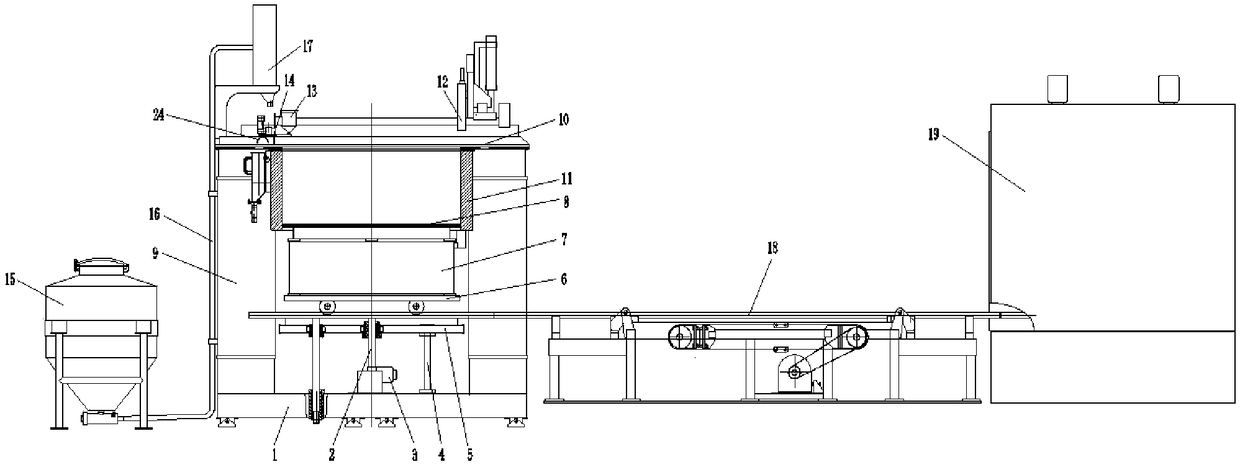

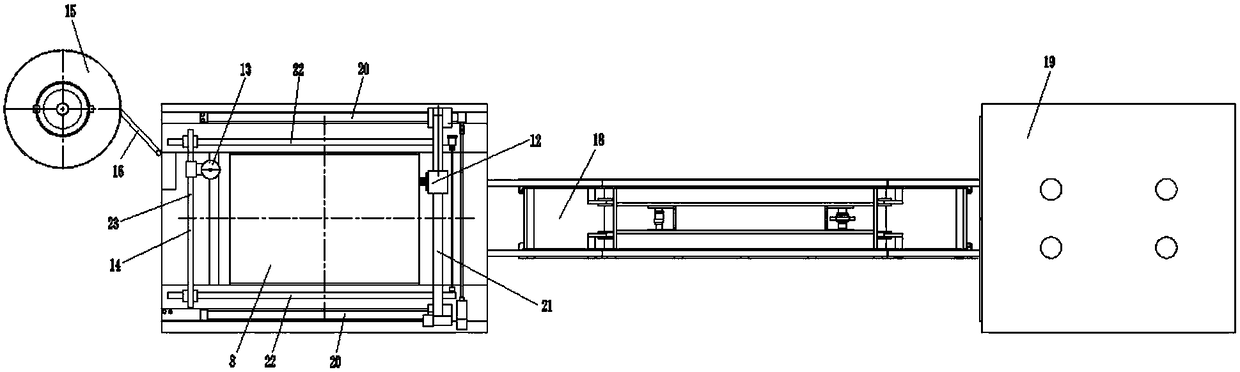

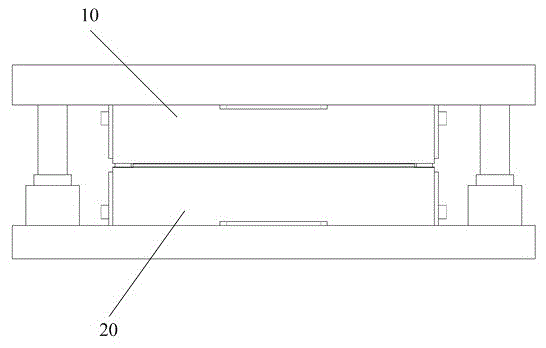

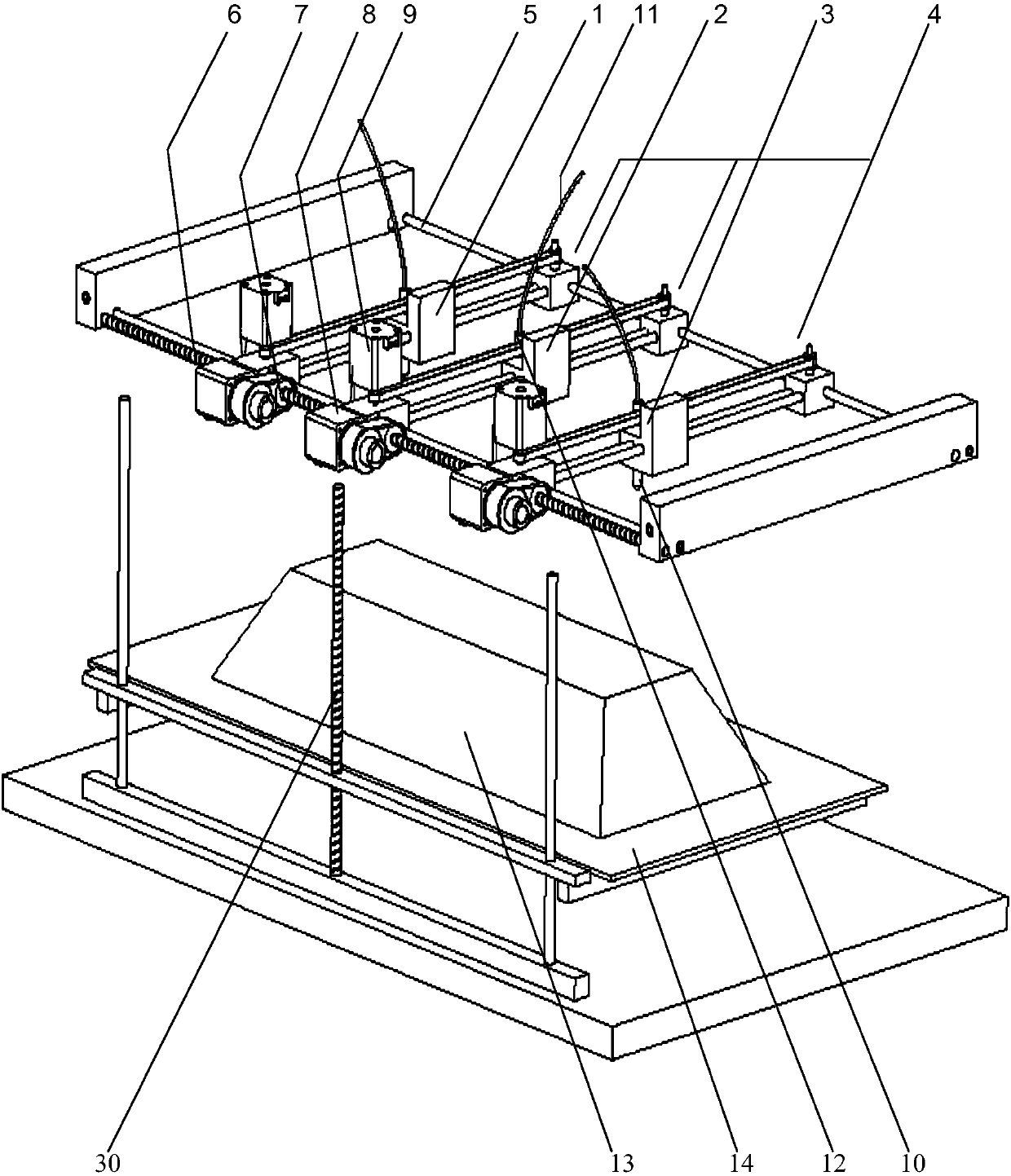

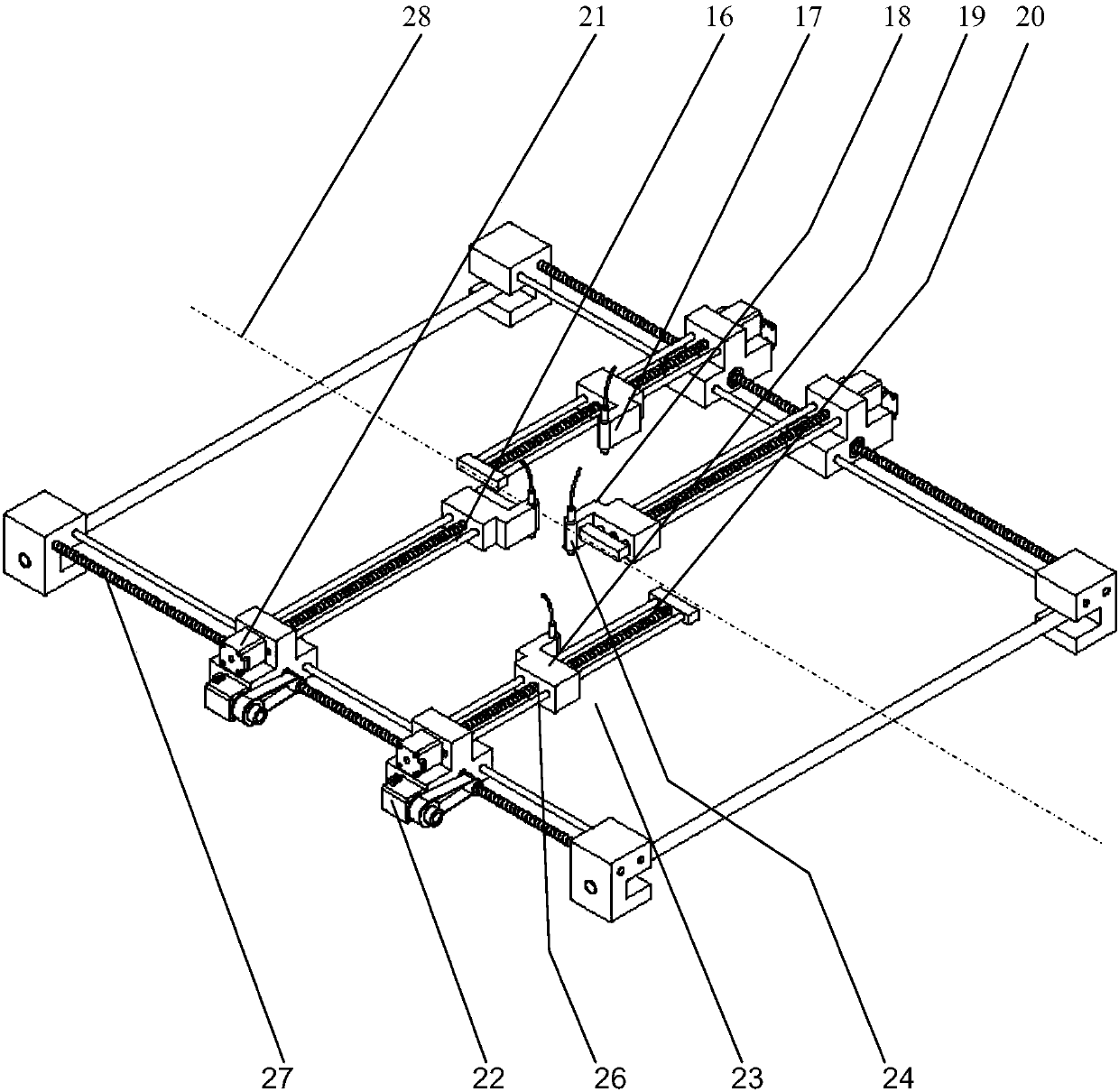

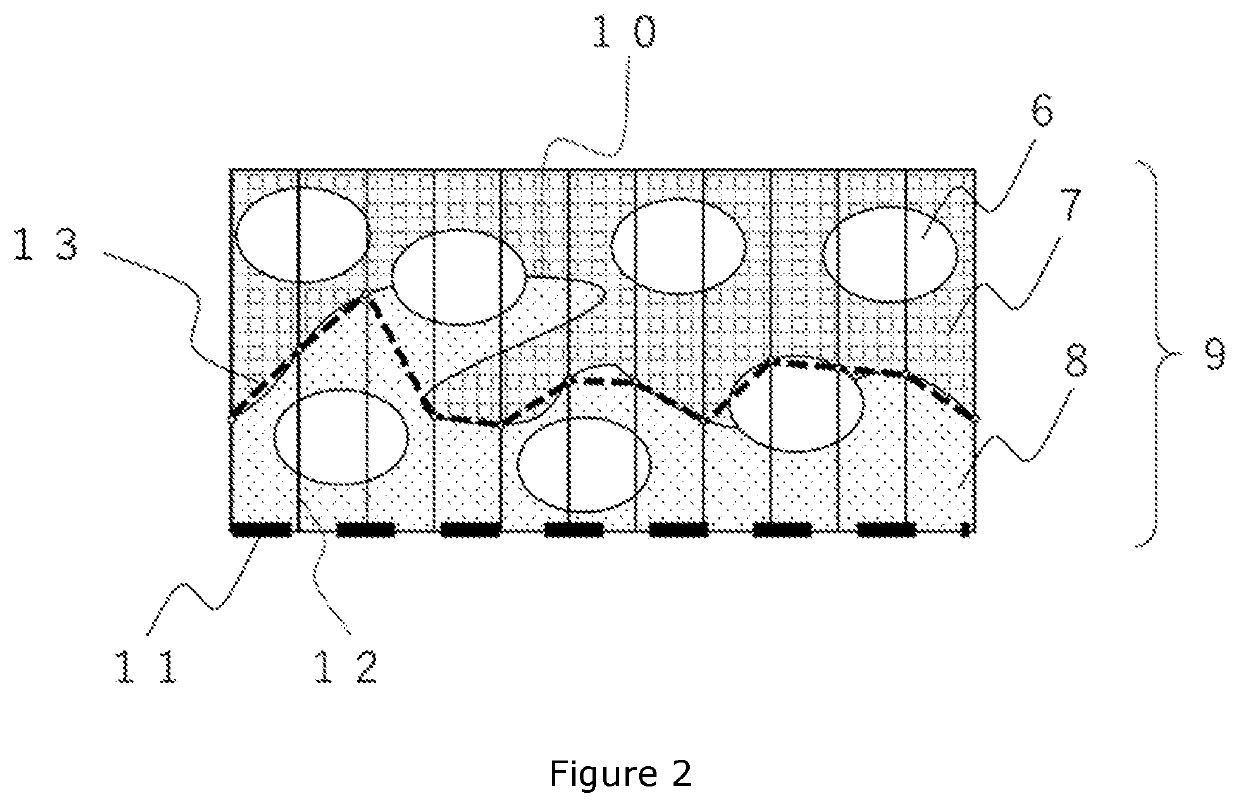

Automatic laying device for similar material simulation test and application method thereof

InactiveCN109291216AImprove molding qualitySpeed up moldingPreparing sample for investigationFeeding arrangmentsTest chamberUltimate tensile strength

The invention discloses an automatic laying device for a similar material simulation test. The automatic laying device comprises a weighing hopper, a stirrer, an elevation type belt conveyor, a similar material test chamber and multiple material bins. Discharging openings of the multiple material bins are connected with a feeding opening of the weighing hopper. A discharging opening of the weighing hopper is connected with a feeding opening of the stirrer. The automatic laying device has the beneficial effects that a series of technological improvement is conducted based on the laying and tamping method adopted in the similar material model production process; by means of the weighing hopper and the stirrer, all materials are mixed and stirred according to certain ratios, and molding quality of a similar material model is greatly improved; after stirring, the materials are conveyed into the similar material test chamber through the belt conveyor and then compacted through pressing plates; and labor intensity is lowered, in addition, the molding speed of the similar material model can be remarkably increased, the molding quality of the similar material model can be remarkably improved, and consistency of the similitude ratio of the simulation stratum thickness to strength obtained after molding can be remarkably improved.

Owner:HENAN POLYTECHNIC UNIV

Laser 3D printer that completes high-precision sand mold production at one time

ActiveCN106001416BHigh dimensional accuracyRealize layered printingAdditive manufacturing apparatusFoundry mouldsEngineeringMaterial distribution

Owner:辽宁森远增材制造科技有限公司

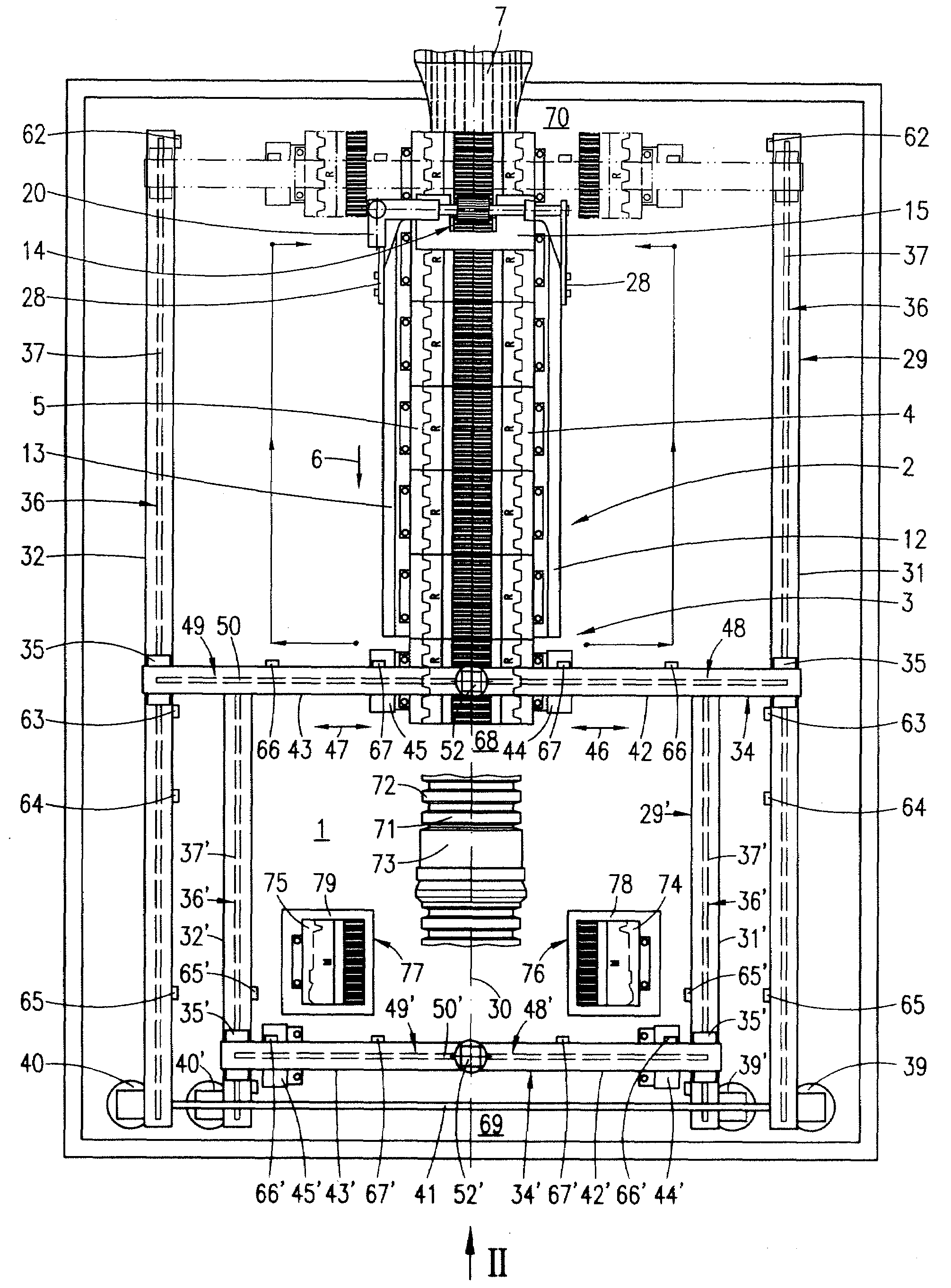

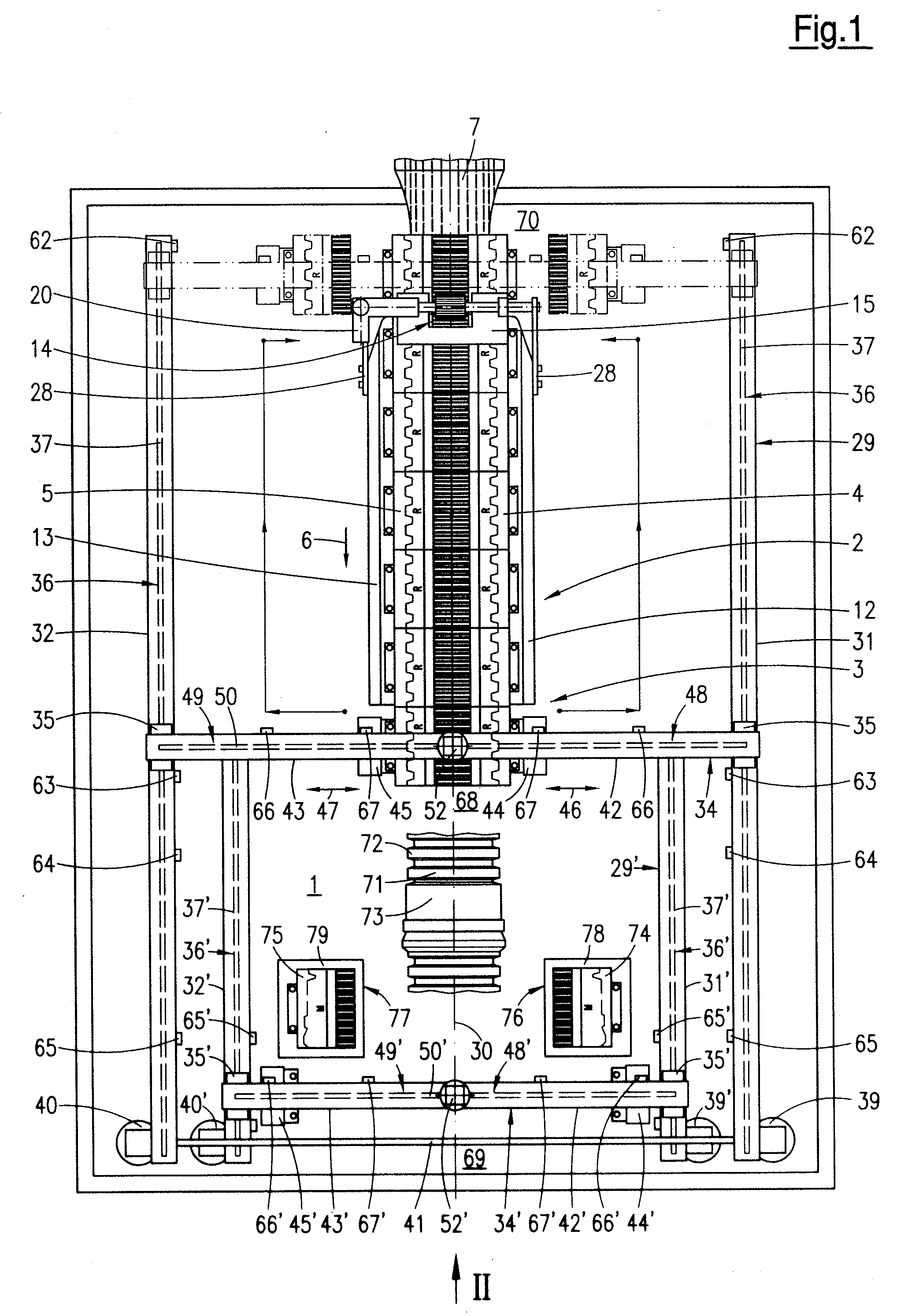

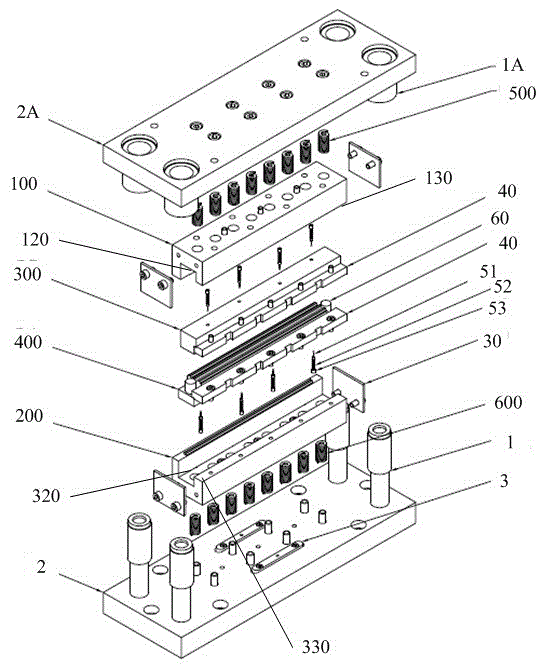

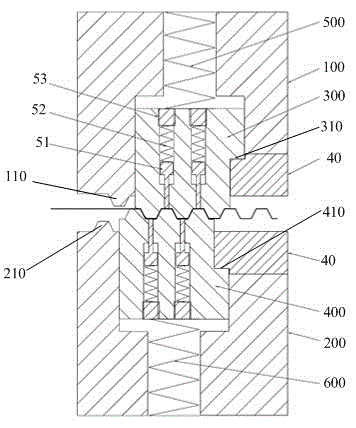

Punch forming method and punch forming die for corrugated metal foil

ActiveCN105033005AGood size consistencyStable mechanical propertiesShaping toolsMetal foilEngineering

The invention provides a punch forming method and punch forming die for corrugated metal foil. The punch forming die comprises an upper rack die and a lower rack die, wherein the upper rack die comprises an upper forming tooth base, an upper forming tooth arranged on the upper forming tooth base and an upper shaping rack capable of moving relative to the upper forming tooth base; the upper forming tooth base is connected with the upper shaping rack through a limiting component so as to limit the upper shaping rack to the degree of freedom of moving in a die assembly direction; the lower rack die comprises a lower forming tooth base, a lower forming tooth and a lower shaping rack and has the same connection and structural position relation as the upper rack die; the upper forming tooth and the lower forming tooth are arranged asymmetrically; a sectional punch stroke is formed through the asymmetric motion of the upper shaping rack and the lower shaping rack during a die assembly process in combination with the corresponding forming teeth; and the sectional punch stroke comprises a first punch stroke for punching a material strip to bend the material strip to one side and a second punch stroke for punching the material strip to bend the material strip to the other side.

Owner:SHENZHEN CANSINGA TECH CO LTD

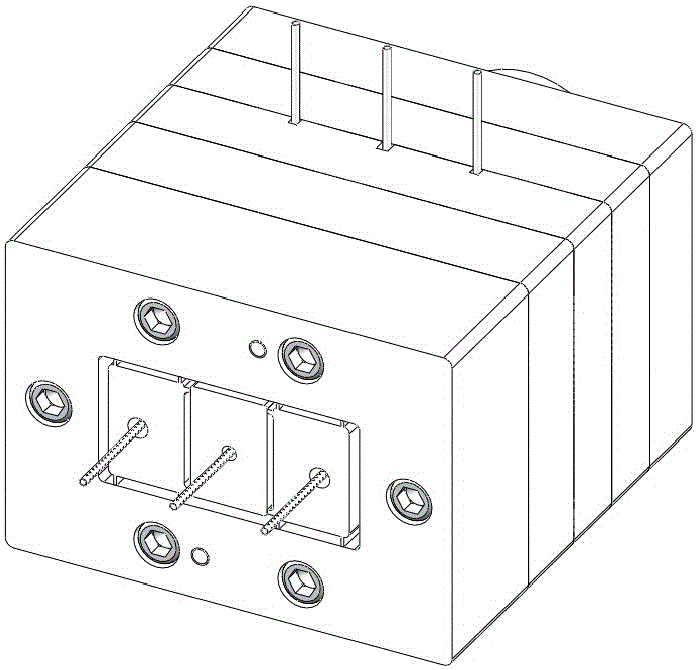

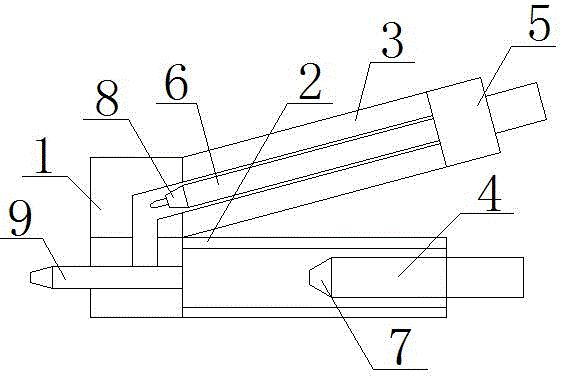

Novel injection device for injection molding machine

The invention relates to the technical field of injection molding machines, and in particular relates to a novel injection device for an injection molding machine. The novel injection device comprises a connecting body, a material storing cylinder, an injection material barrel, a material pushing plug, an injection oil cylinder and an injection screw rod; the connecting body is connected with the material storing cylinder; the injection material barrel is arranged on the material storing cylinder; the material pushing plug is arranged in the material storing cylinder; the injection oil cylinder is arranged at one end of the injection material barrel; the injection screw rod is arranged in the injection material barrel; a material supply gluing device is arranged at the front end of the material pushing plug; a gluing device is arranged at the front end of the injection screw rod; and an injection nozzle is arranged on the connecting body. The novel injection device for the injection molding machine is simple in structure, practical and convenient, improves the synchronization, reduces the plasticizing period, accelerates the formation speed, improves the production efficiency of a product, ensures the injection precision of the injection molding machine, improves the quality of the product, solves the phenomena of glue leaking and material blocking, and is beneficial for application and popularization.

Owner:南京荣欣化工有限公司

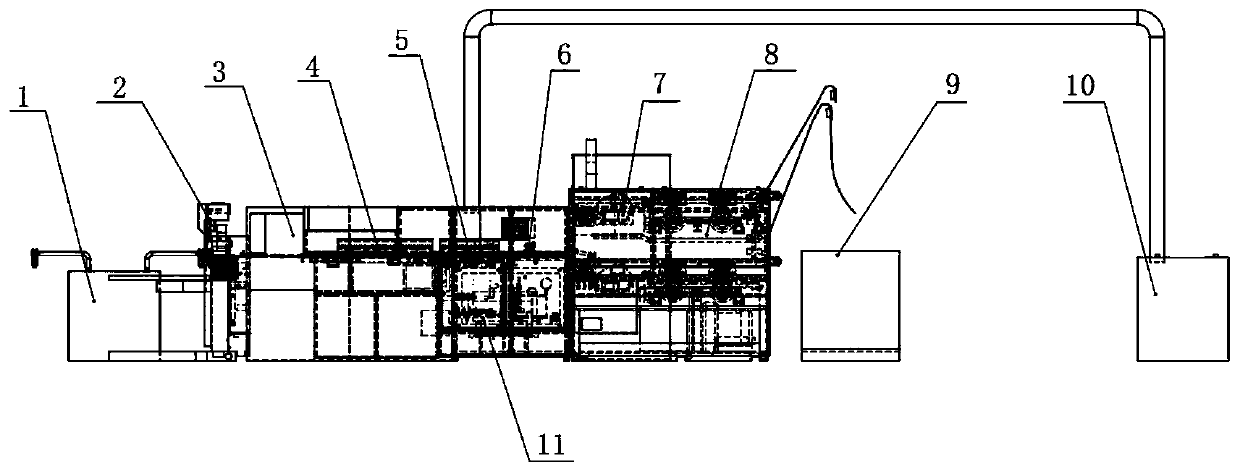

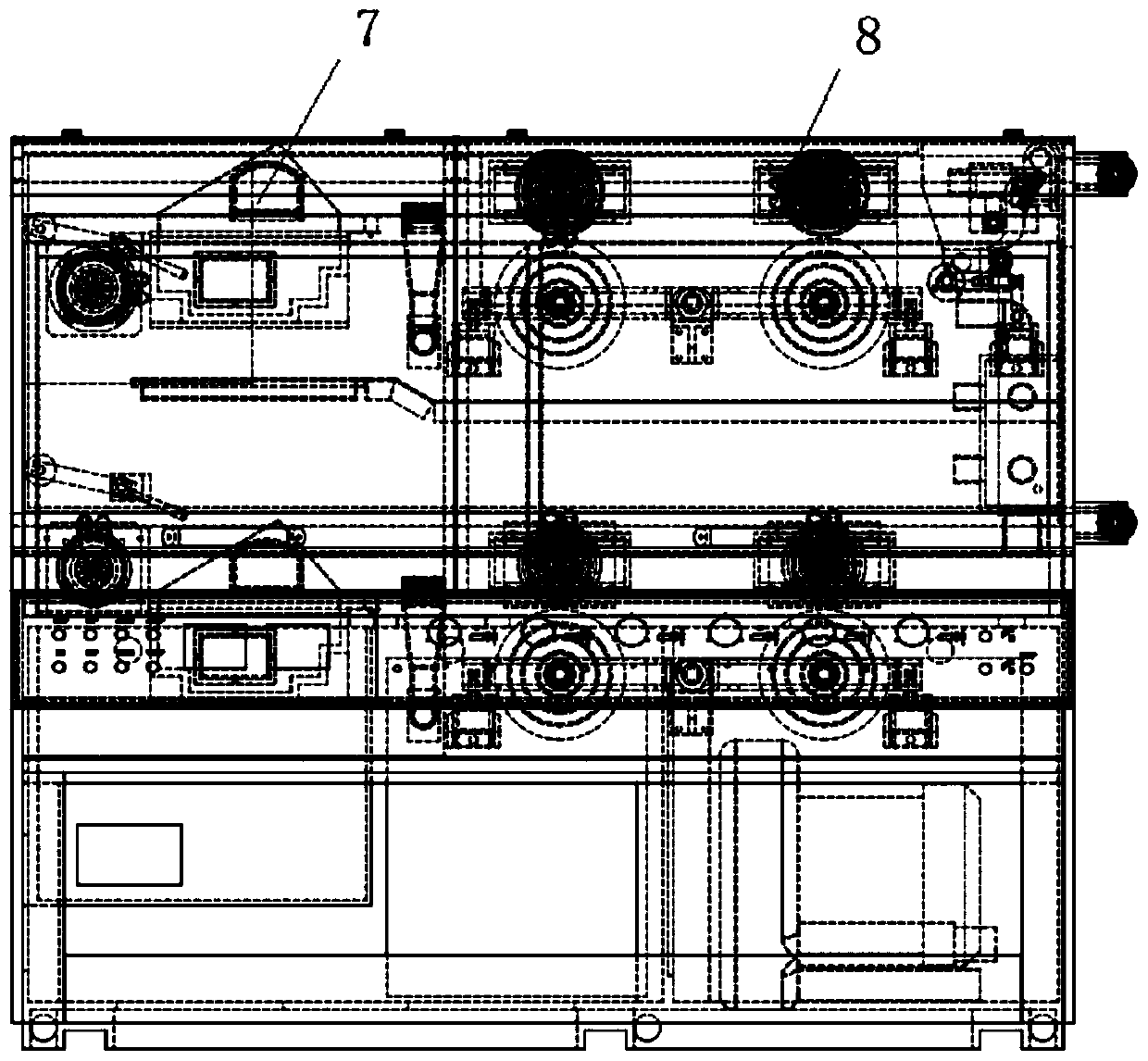

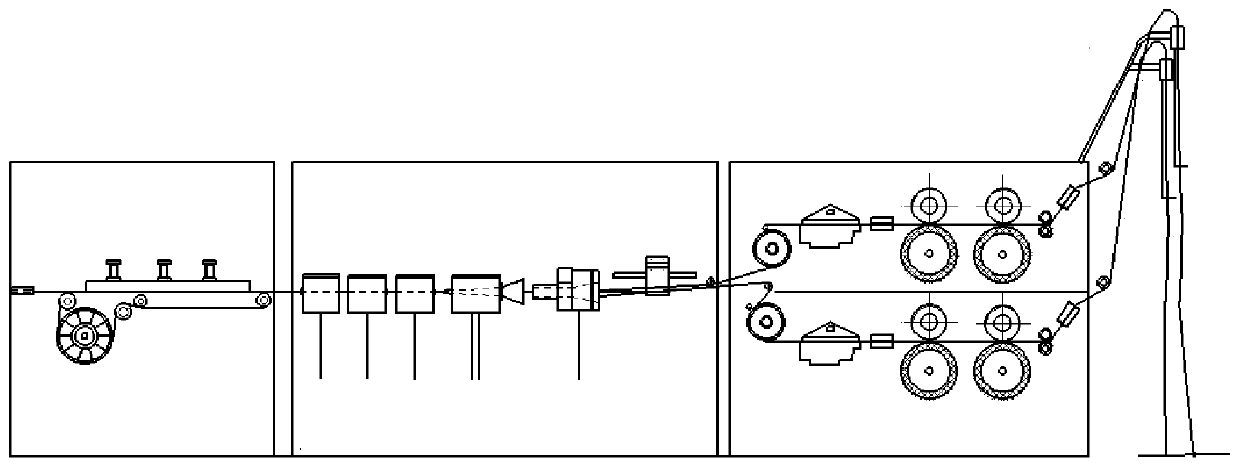

Drawing type preparation equipment and preparation method of hollow filter stick

The invention discloses drawing type preparation equipment and method for a hollow filter stick, and the preparation equipment comprises an opener which is a double-layer opener and comprises an upper-layer opening mechanism and a lower-layer opening mechanism; a high-pressure pipe tobacco feeder which is located on the downstream of the opener and comprises a high-pressure nozzle, wherein the high-pressure nozzle is of a hollow cylindrical structure, a core rod is located on the central axis of the high-pressure nozzle, an annular cavity is formed in the high-pressure nozzle, a through hole is formed in the inner side wall of the annular cavity, and the annular cavity is connected with a compressed air source; a forming module which is located on the downstream of the high-pressure pipe tobacco feeder, a conical flow guide part, a forming hot die and a forming cold die assembly are sequentially arranged in the moving direction of the pipe tobacco bundle, the forming hot die is connected with a steam source, and the forming cold die is connected with a cold air source. The equipment can be matched according to the hardness and quality requirements of the filter stick, and the effect of forming the filter stick is ensured.

Owner:山东将军烟草新材料科技有限公司

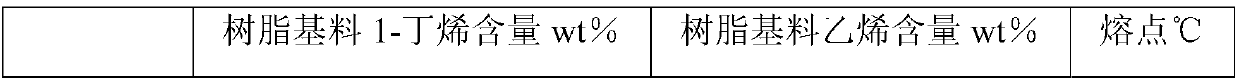

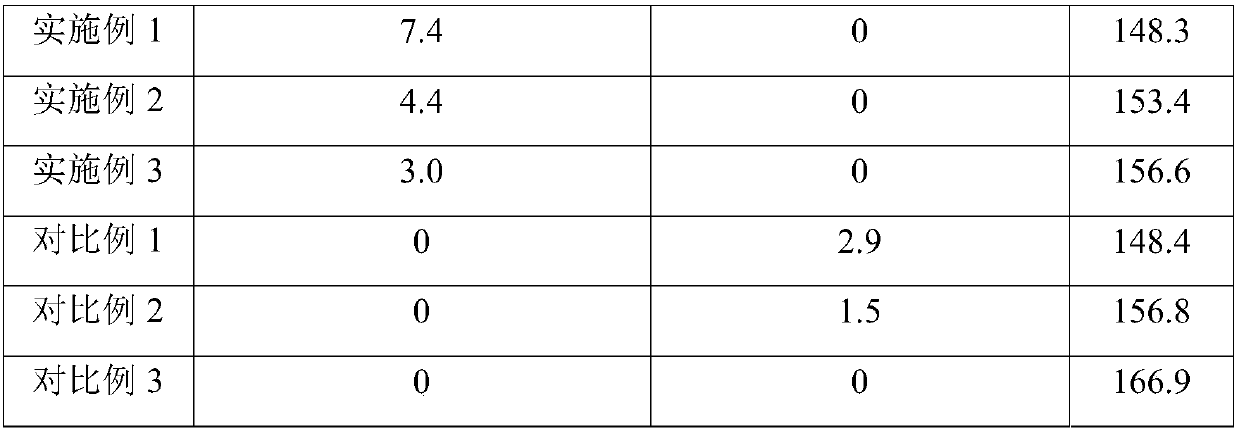

Polypropylene resin for hot filling bottles

The invention provides a polypropylene resin for hot filling bottles. The polypropylene resin comprises a polypropylene resin base material, an antioxidant, a nucleating agent and an acid neutralizer,wherein the polypropylene resin base material is propylene / 1-butene random copolymer polypropylene, the butene content of the polypropylene resin base material is 1-10wt%, the melting temperature is140-165 DEG C, and the melt flow rate is 3.0-25.0g / 10min. Compared with an existing ethylene / propylene random copolymer polypropylene, the propylene / 1-butene random copolymer polypropylene obtained bythe invention has the advantages of better crystallization capacity, higher heat resistance and rigidity, the thermal deformation temperature reaches 80-90 DEG C, the flexural modulus reaches 1200-1400 MPa, and the polypropylene resin is suitable for injection stretch blow molding and can be applied to hot filling beverage bottles.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for processing circular single dovetail grooves in back surfaces of ceramic tiles

InactiveCN107053432APrevent infiltrationSimple and effective pressure retentionDischarging arrangementShaping press ramPneumatic pressureCeramic tiles

The invention relates to a processing device and a processing method for a circular single dovetail groove on the back of a ceramic tile. The processing device includes a hollow pressure seat lifting cover fixed at the lower end of an air hammer and a pressure seat sliding sleeve matching with the pressure seat lifting cover. seat; the upper end of the lifting cover of the press seat is provided with a cover surface, and the lower end is provided with a lifting arm extending inward; And the lifted arm located in the cover of the pressure seat lifts; the lifted arm is limited and slid in the cavity formed by the cover surface and the lifting arm; the pressure seat is evenly distributed with a plurality of vertical hollow holes Cylinder; the upper end of the hollow cylinder is flush with the top of the press seat, and the lower end protrudes downward from the press seat, and the part protruding from the press seat is formed by sequentially overlapping a plurality of first fan-shaped pressing pieces that can be turned inside and outside; the The processing device and processing method for the circular single dovetail groove on the back of the ceramic tile can effectively, quickly and stably form the circular single dovetail groove.

Owner:郑小华

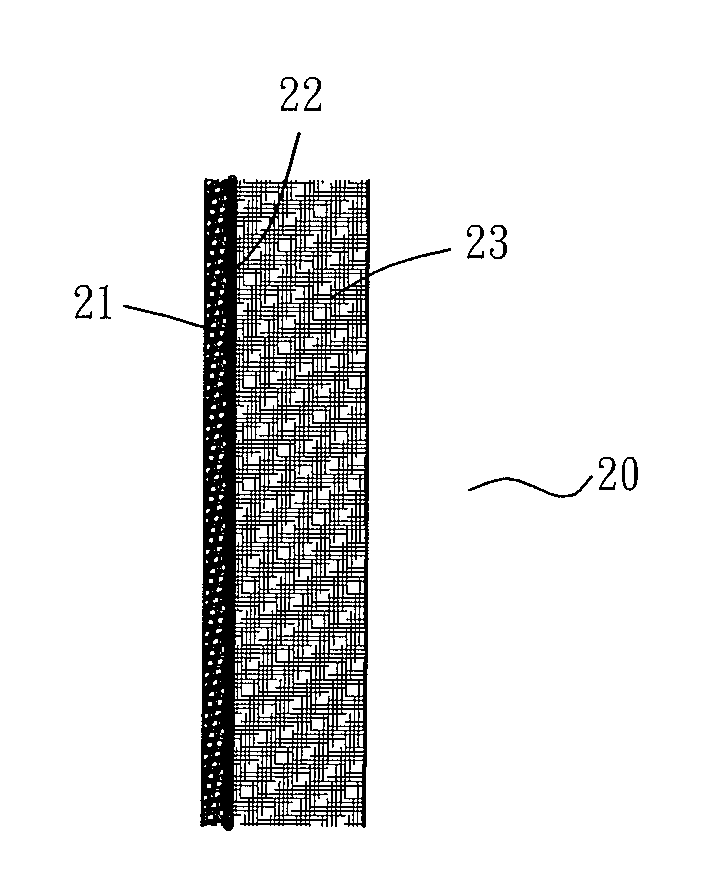

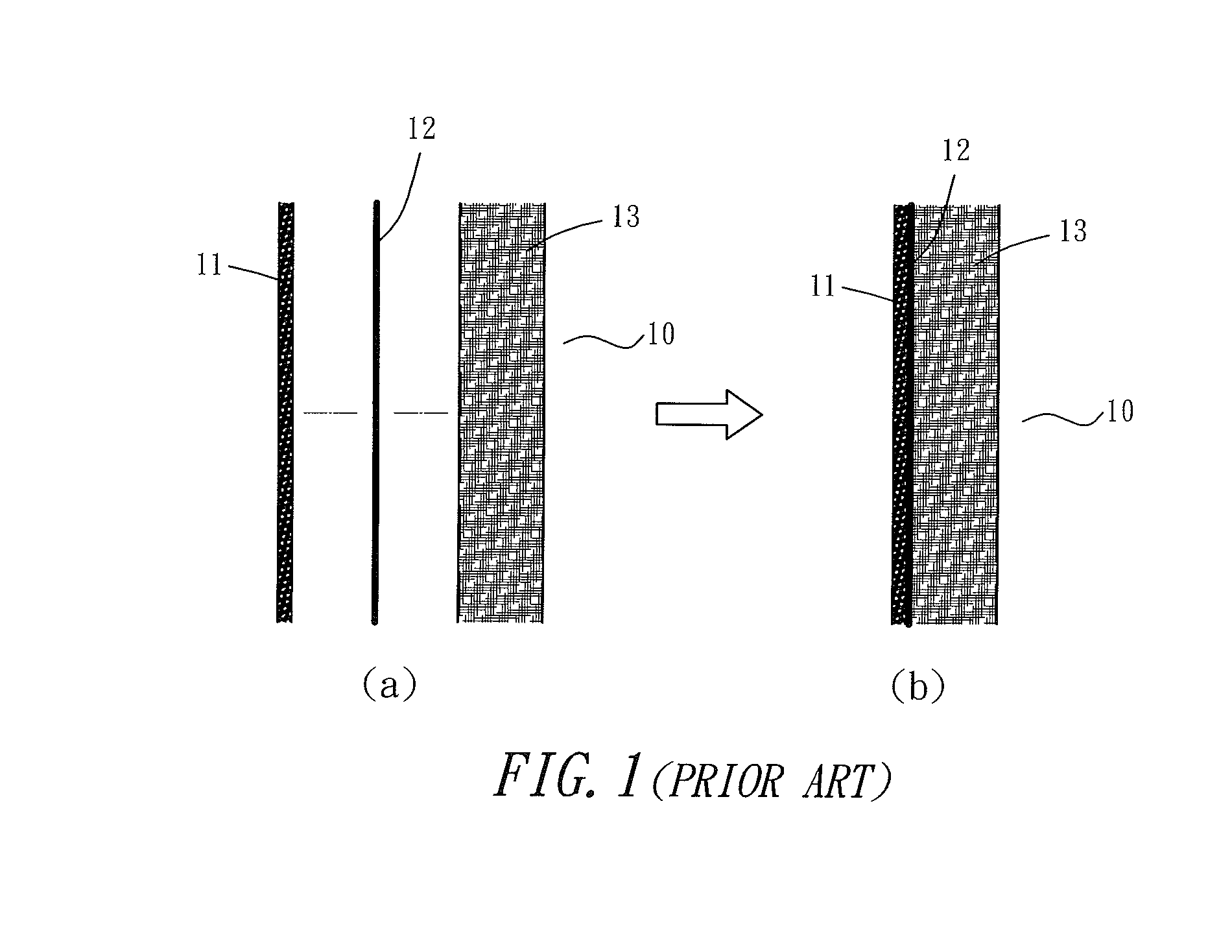

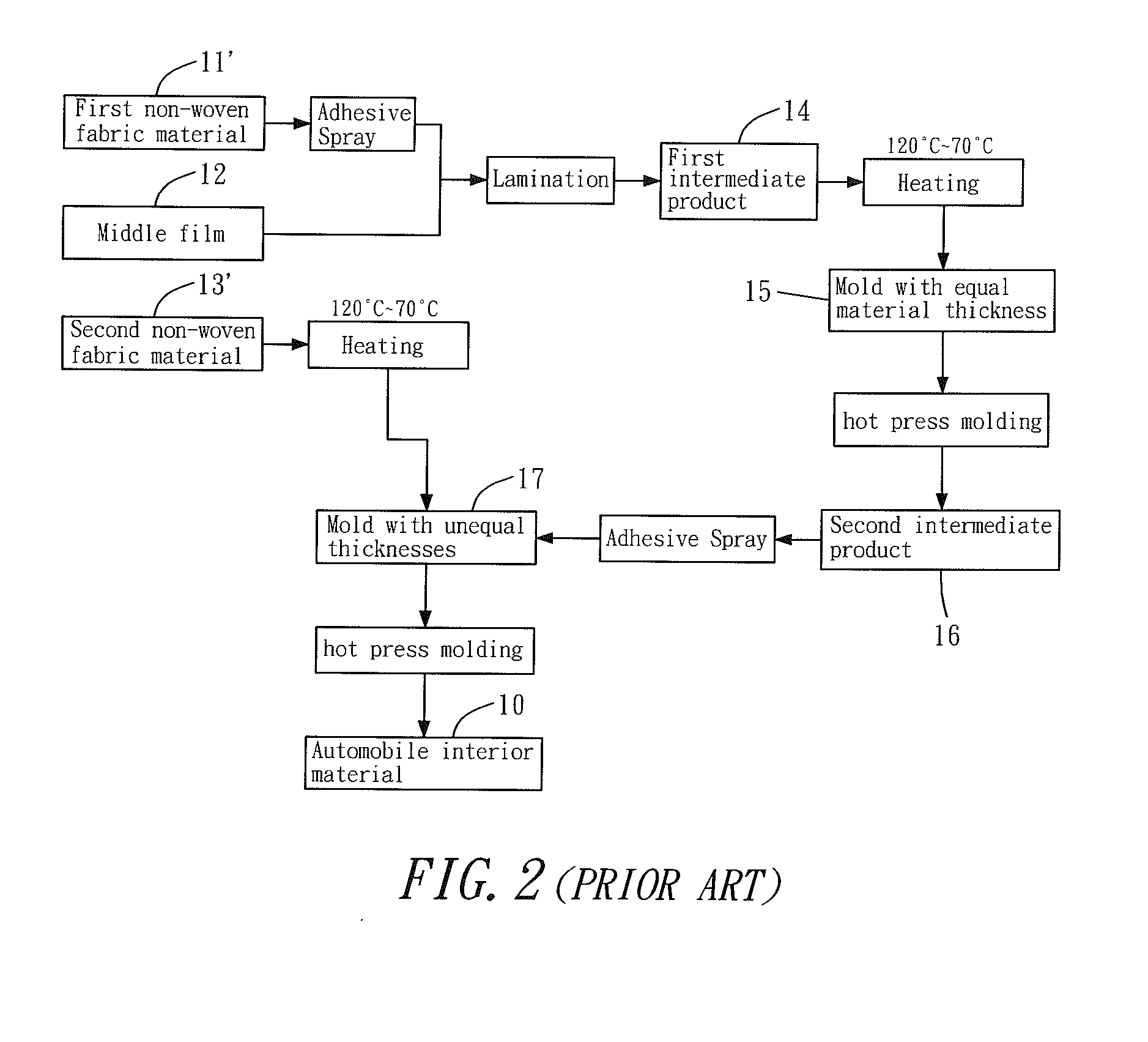

Method for Manufacturing Non-Woven Composite Layer Product with Different Hardnesses

InactiveUS20150054194A1Reduce equipment costsSimple manufacturing processLayered product treatmentLaminationSoft layerHot melt

Disclosed is a method for manufacturing a non-woven composite layer product with different hardnesses, the non-woven composite layer product at least consisting of a hard layer with a thickness of between 2-7 mm and a weight of between 600-1200 g / m2, and a soft layer with a thickness of between 15-40 mm and a weight of between 600-1200 g / m2. The manufacturing method mainly comprises the steps of: sticking at least a first non-woven material to be pre-formed into a hard layer and a second non-woven material to be pre-formed into a soft layer to become an intermediate, and then feeding the intermediate into a baking oven at a constant temperature to heat at a heating temperature of 180±20° C. over a duration of longer than at least 200 seconds (inclusive), such that the first non-woven material and the second non-woven material are fully heated to softening, and the contact surfaces are bound by hot melting; and then feeding into a mold with different material thicknesses for a one-time hot-press molding, so as to obtain a non-woven composite layer product containing a hard layer and a soft layer with required specifications.

Owner:SAN SHIANG TECH

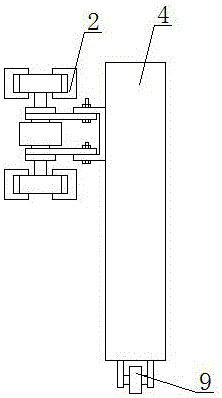

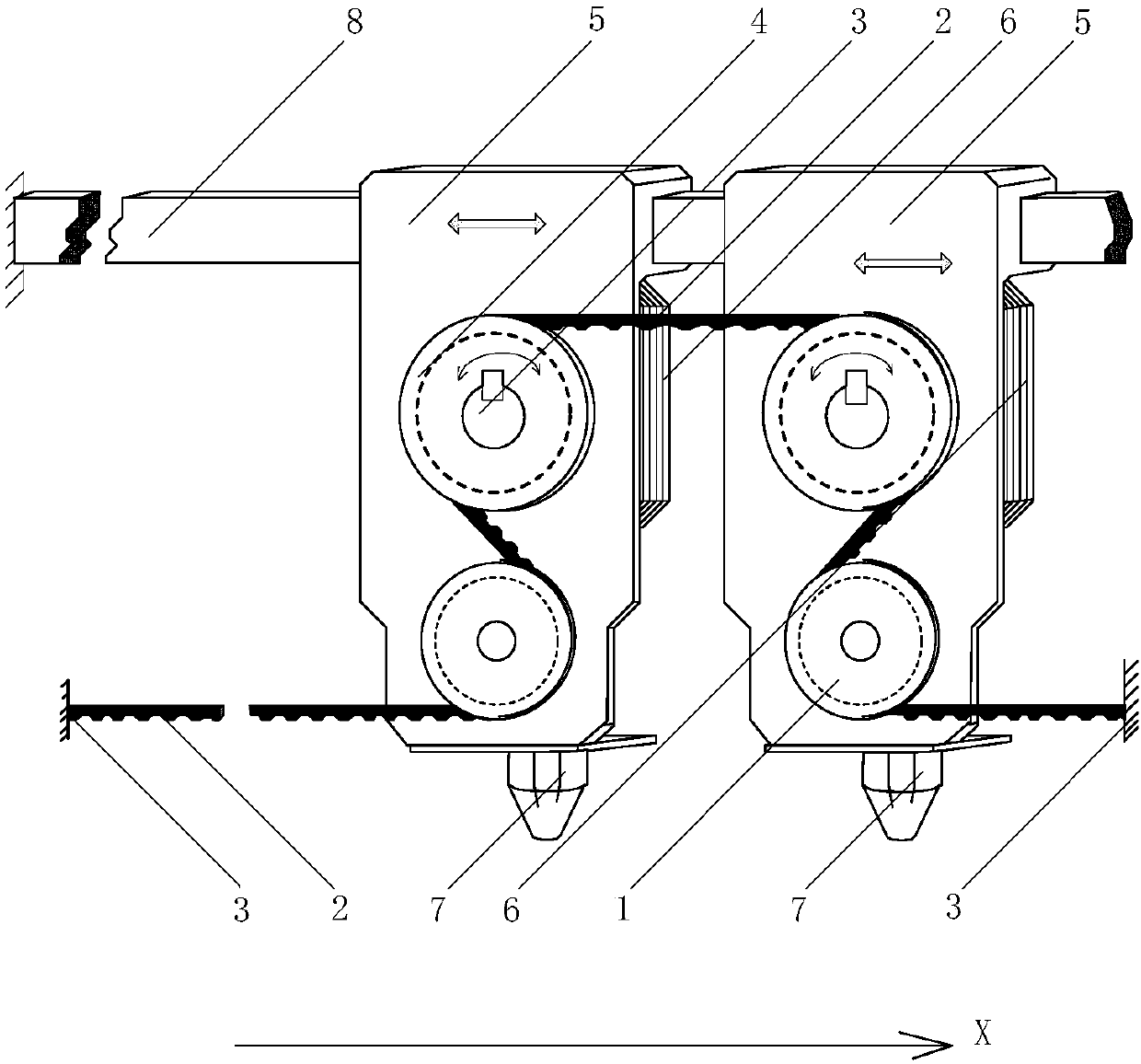

Multi-sprayer FDM-3D printer with belt-idler drive

PendingCN108115929AHigh speedSpeed up moldingManufacturing driving means3D object support structuresSprayerGear wheel

A multi-sprayer FDM-3D printer with belt-idler drive is composed of 2-100 extruder assemblies, a belt-idler drive constructed mechanical device or gear / rack or lead screw / nut conveying mechanism carrying the extruder assemblies to move in the two-dimension horizontal X-axis direction and Y-axis direction, a printing platform, a lifting mechanism, an electric control system, an operation panel anda structure shell. The arrangement of a multi-extruder assembly system is divided into the single X arrangement splicing manner and the multi-row Y arrangement splicing manner. The extruder assemblies are used for pavement of one part of a section of a component slice and jointly finish pavement of the whole section of the product component slice. After one layer of section is formed, a workbenchrelatively descends by a certain height, pavement of the next layer is conducted, finally, a three-dimensional product component is formed, and the forming speed is greatly improved.

Owner:罗天珍

Preparation method of precise casting wax mold repair wax

InactiveCN108788010AHigh hardnessStrong regulationFoundry moulding apparatusWaxVolumetric Mass Density

The invention discloses a preparation method of precise casting wax mold repair wax. The preparation method comprises the following steps that a, firstly, selected raw materials are processed; b, auxiliary materials are prepared after the step a is finished; c, after the step b is completed, and then heating and fusing are carried out by utilizing a stirrer; d, after the step c is finished, the preparation of the repair wax is carried out; and e, after the step d is completed, finally the repair wax is collected. According to the preparation method, in the process of manufacturing the repair wax, the auxiliary materials are added on the conventional raw materials, white vaseline, rosin, petrochemical engineering resin and stearic acid in the auxiliary materials are utilized, the overall hardness of the repair wax can be increased according to the proportioned proportion, and the adjusting degree is higher, and therefore, different repairing requirements can be met, and the production cost can be effectively controlled; and cooling equipment can be provided for gradually cooling when mechanical fusion is carried out, so that the formation of internal air holes is avoided on the premise that the adhesion performance is improved, the forming speed and the overall density are increased, and popularization and use are facilitated.

Owner:山东景阳岗金属设备有限公司

Integrated forming machine for honeycomb blind

Provided is an integrated forming machine for a honeycomb blind. The machine comprises a frame, on which a unreeling rack, a guide mechanism, a forming mechanism, a heat setting mechanism, a gluing device and a fixed-length cutting mechanism. One side of the fixed-length cutting mechanism is provided with a cloth groove. An overturn mechanism is arranged between the cloth groove and the fixed-length cutting mechanism. An adhering compaction mechanism is arranged above the cloth groove.The integrated forming machine for the honeycomb blind has following beneficial effects: through the unreeling rack, unreeling speed of cloth is automatically adjusted; under effect of embossing wheels, two embossing lines running in parallel with cloth-feeding direction of cloth of support rolls are pressed and guided by folding through folding holes in forming and guide pieces to make honeycomb-shaped cloth strips so that a better forming effect of cloth is ensured. By automatic gluing and fixed-length cutting of a cloth-feeding track, machining speed is increased. Under effect of the overturn mechanism, cut honeycomb-shaped cloth strips are arranged in the cloth groove. Through the adhering compaction mechanism, the honeycomb blind is made so that forming speed and efficiency are increased.

Owner:连云港市汉恒节能窗饰有限公司

Prepreg, laminate, and molding

PendingUS20220324184A1High bonding strengthHigh compressive strengthLayered productsElectrical equipmentFiberPolymer science

An object of the present invention is to provide a prepreg and a laminate for producing a laminate suitable as a structural material, which have excellent compressive strength and interlaminar fractural toughness values, and can be firmly integrated with another structural member by welding. The present invention provides a prepreg including the following structural components [A] reinforcing fibers, [B] a thermosetting resin, and [C] a thermoplastic resin, in which [B] has a rubbery state elastic modulus of 10 MPa or more at a temperature obtained by adding 50° C. to a glass transition temperature in a state in which a degree of cure is 90% or more, [C] is present in a surface of the prepreg, and the reinforcing fibers [A] are present, which are included in a resin area including {B] and a resin area including [C] across an interface between the two resin areas.

Owner:TORAY IND INC

Injection mold for automobile bonnets

InactiveCN108748889AReduce your weightManually control the size of the opening and closingEngineeringControl switch

The invention discloses an injection mold for automobile bonnets. The injection mold comprises a lower die, an electric push rod, an upper die and a disc, wherein a push device is fixedly installed inthe bottom center of the lower die, a push hole is formed in the bottom of the side of the lower die, the electric push rod is fixed to the side of the lower die, a signal control switch is installedon the electric push rod, a connecting rod is perpendicularly connected to the edge of the electric push rod, an ejector pin is arranged on the connecting rod, the ejector pin is located in the pushhole, the upper die is located just above the lower die, a lifting rod is fixedly connected to the top center of the upper die, an injection hole is formed in the top edge of the upper die, a chute isreserved in the side of the injection hole, the disc is arranged in the chute, a sliding block is connected to the top of the disc, and the sliding block is located above the chute. According to theinjection mold for the automobile bonnets, the product ejection smoothness is increased, the product ejection deformation damage is reduced, and additionally, the product forming quality and speed areincreased.

Owner:刘福芳

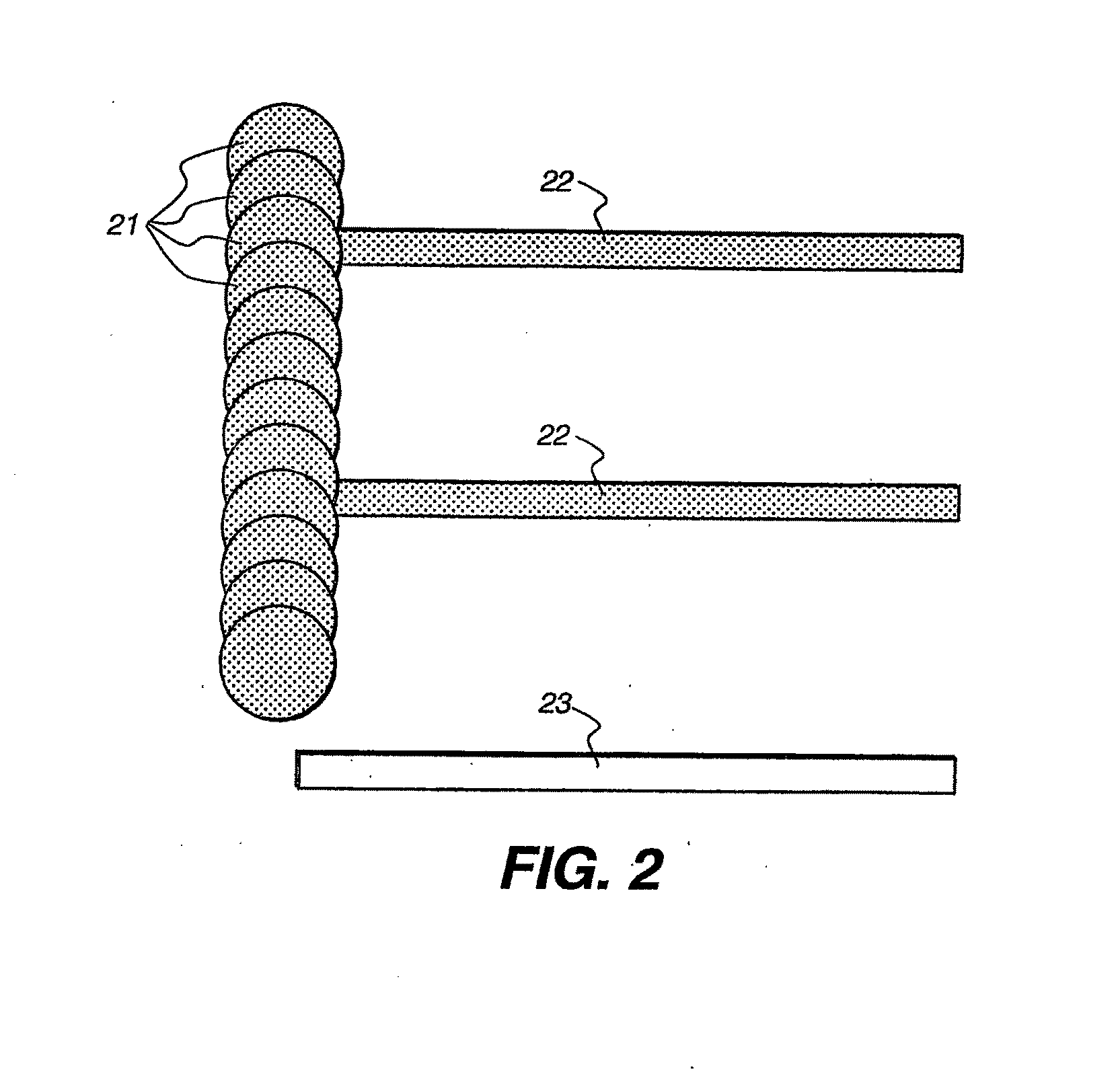

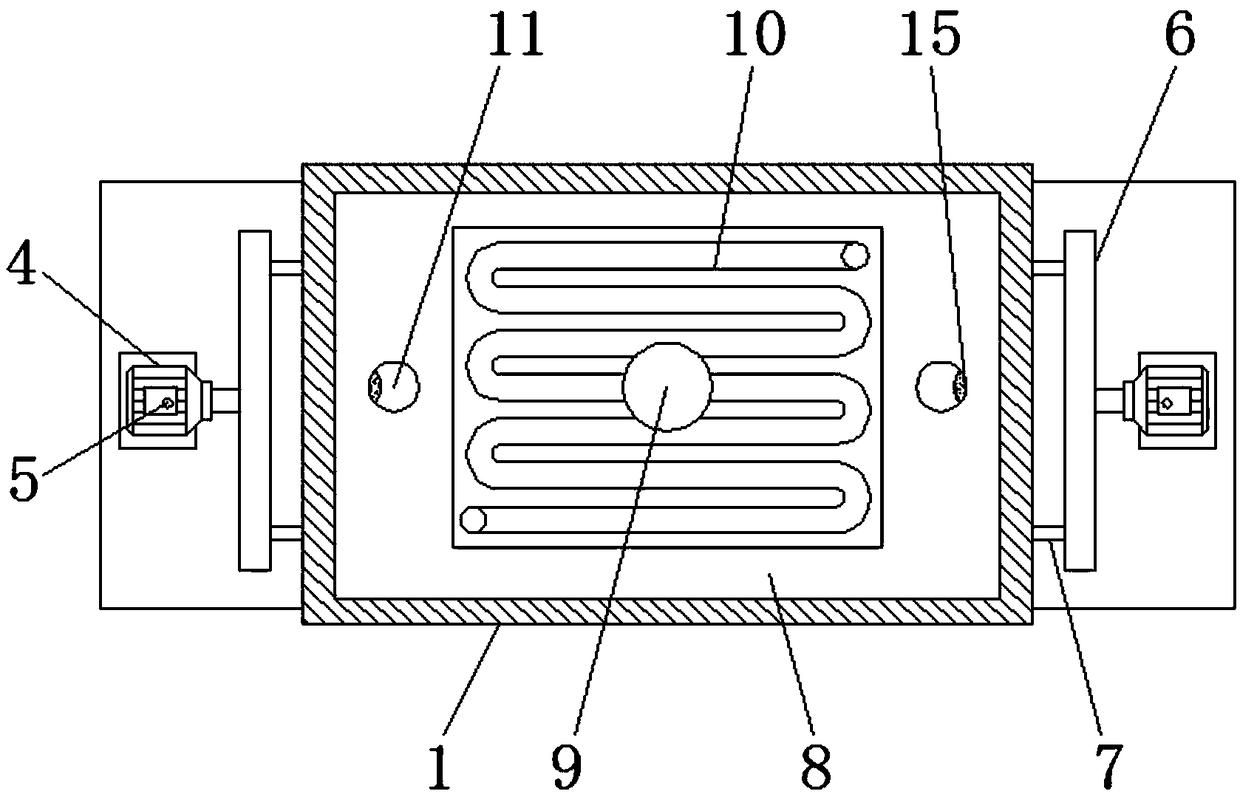

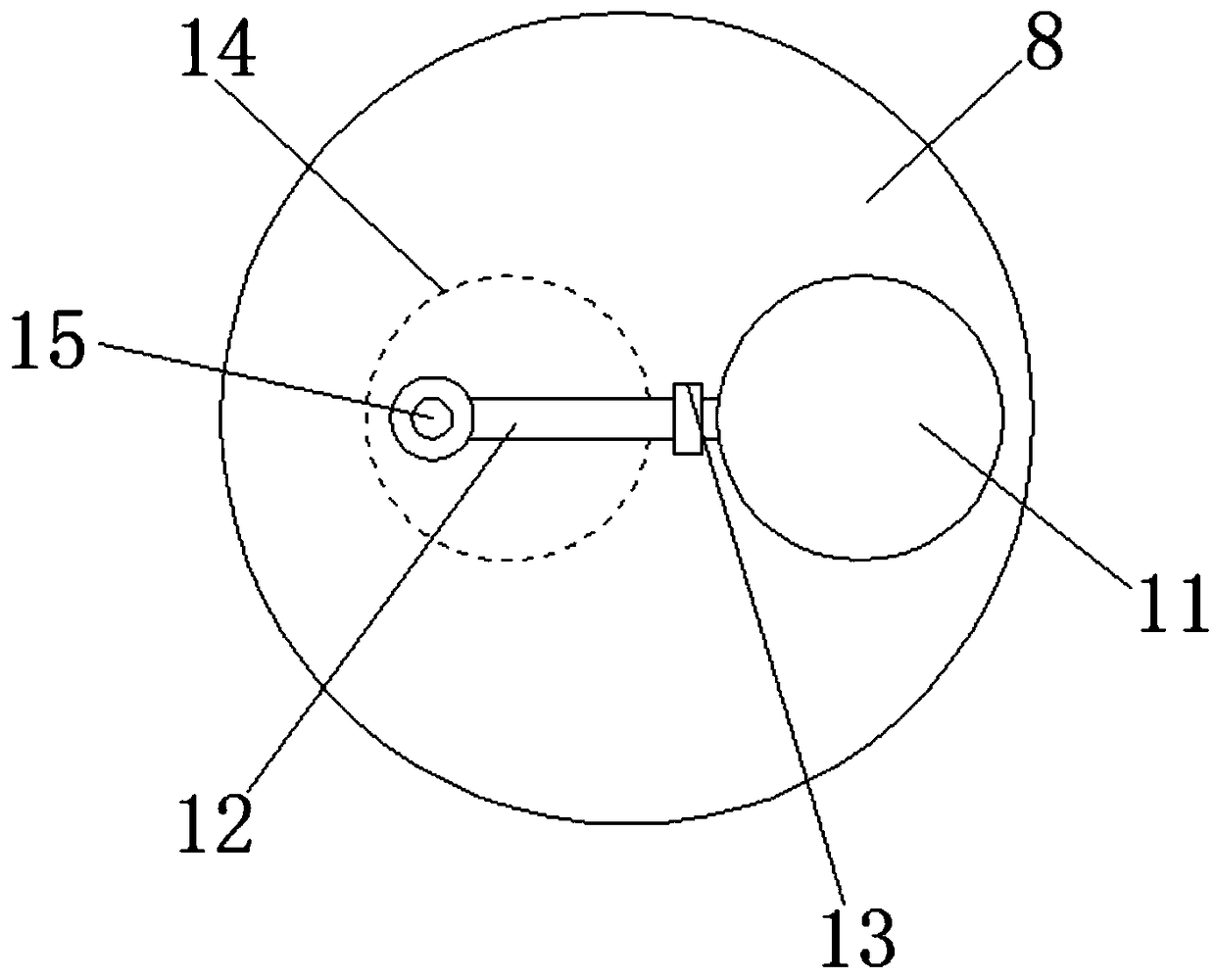

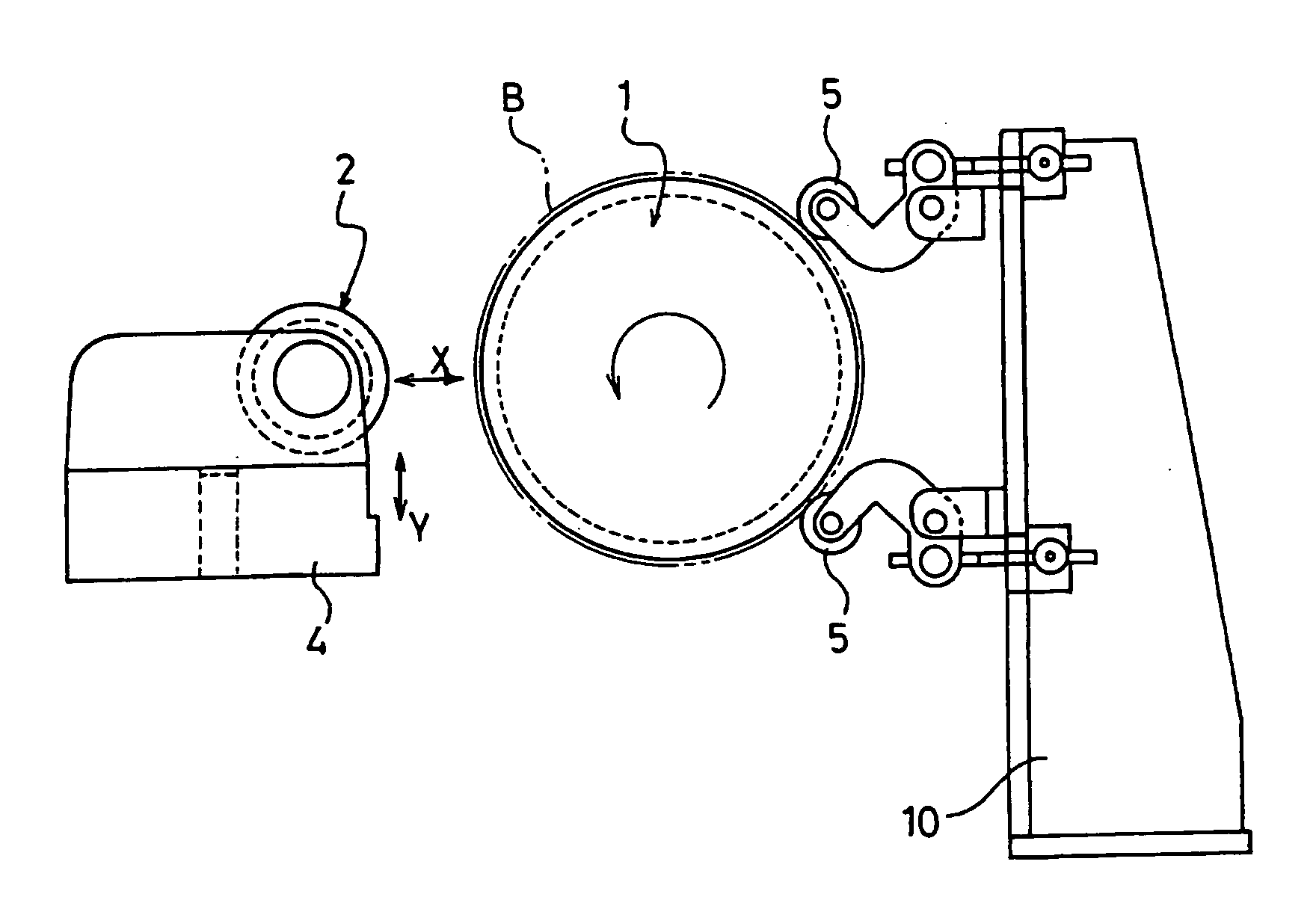

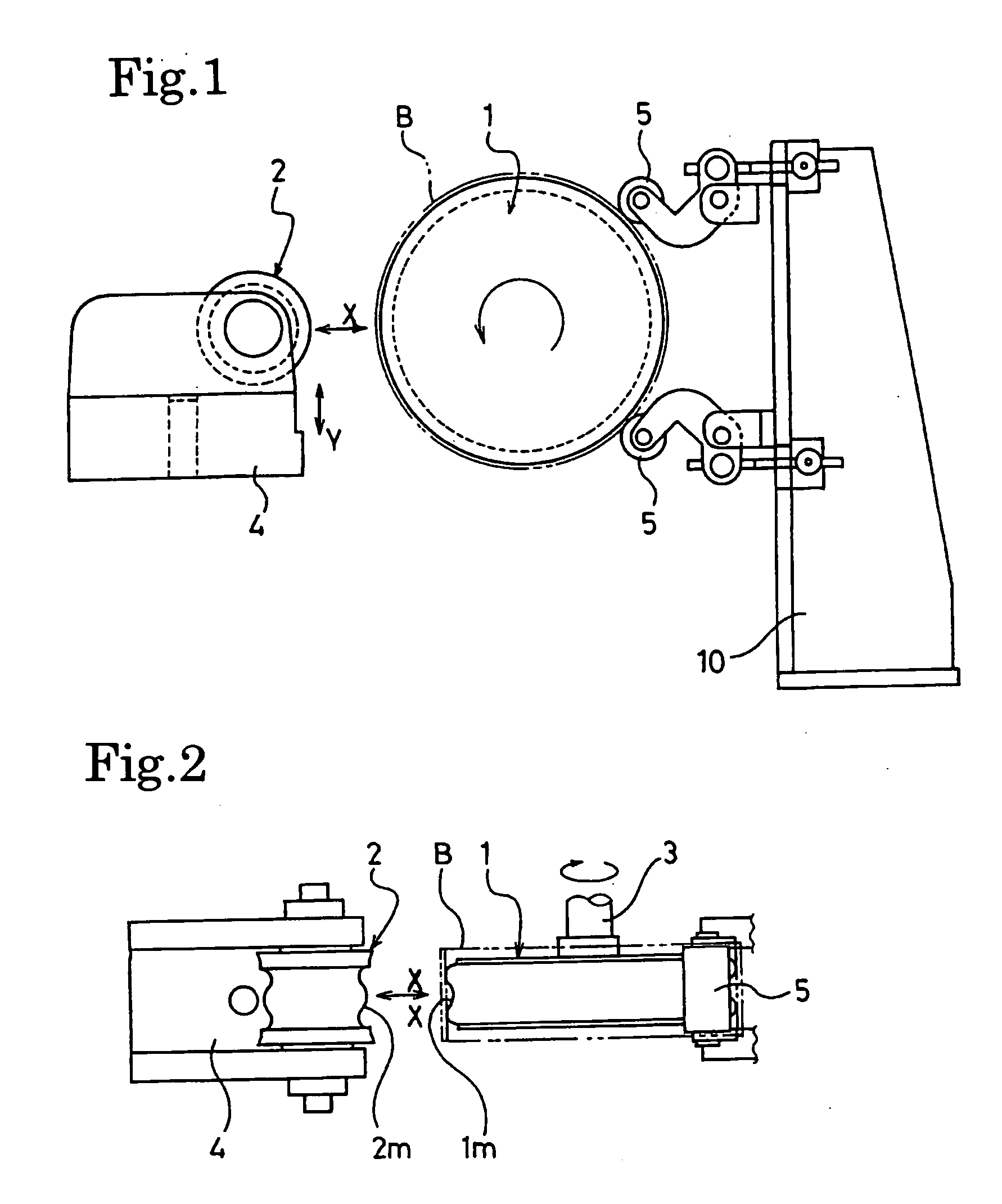

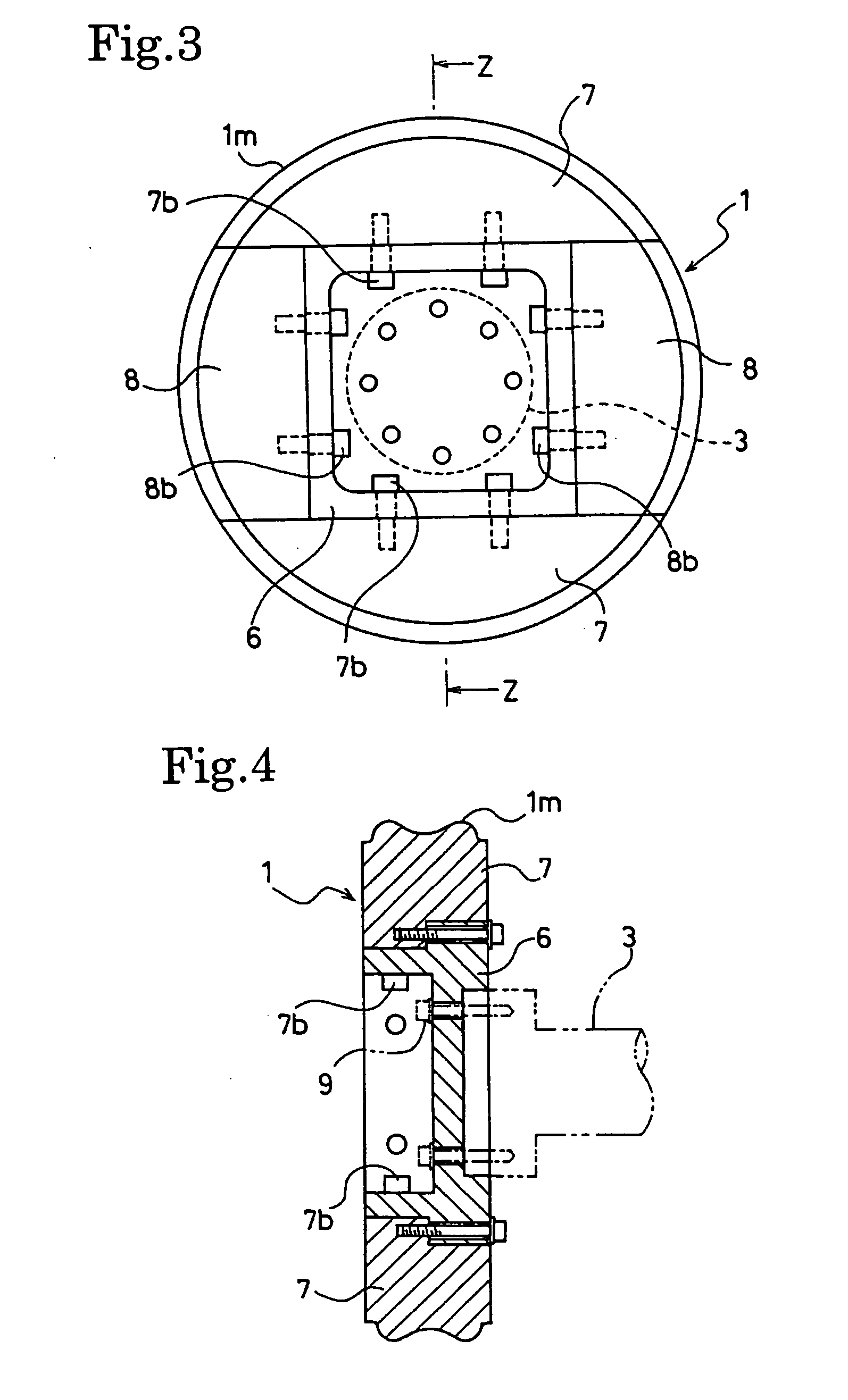

Method and device for manufacturing support body for run flat

A method of manufacturing a support body for run flat, wherein in a case where the circumferential wall of a tubular blank B is pressingly held between inner and outer molding rollers 1 and 2 and where the molding rollers 1 and 2 are rotated to form at least one circumferentially continuous protruding part on the circumferential wall of the tubular blank B to process the tubular blank B into an annular shell, a molding roller having the maximum outer diameter that is substantially the same as the inner diameter of the tubular blank B is used as the inner molding roller 1.

Owner:YOKOHAMA RUBBER CO LTD

A PVC pipe extrusion acceleration device and its control method

The invention discloses a PVC pipe extrusion acceleration device and its control method, aiming to provide a PVC pipe extrusion acceleration device with good molding effect, simple structure and strong practicability. Equipped with a multi-stage heating device, the multi-stage heating device is mainly composed of a feedback circuit, a casing and several heaters located in the casing. The heater is composed of several heating tubes connected by connecting pieces. The heating tube is composed of Composed of inner tube and outer tube, between the inner tube and the outer tube is a vacuum gap structure filled with working fluid, there is a temperature detector between each heating tube and the barrel, adopts a multi-stage heating structure, and each heating tube The temperature is independent of each other. Through the above-mentioned structural setting, when the barrel is heated, the temperature of the material can be ensured when the material flows, the flow effect of the material can be improved, and the extrusion speed can be ensured. This invention is suitable for PVC pipe processing equipment technology field.

Owner:YUHUAN JINLONG KLOE SANITARY WARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com