Patents

Literature

153 results about "Vacuum gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

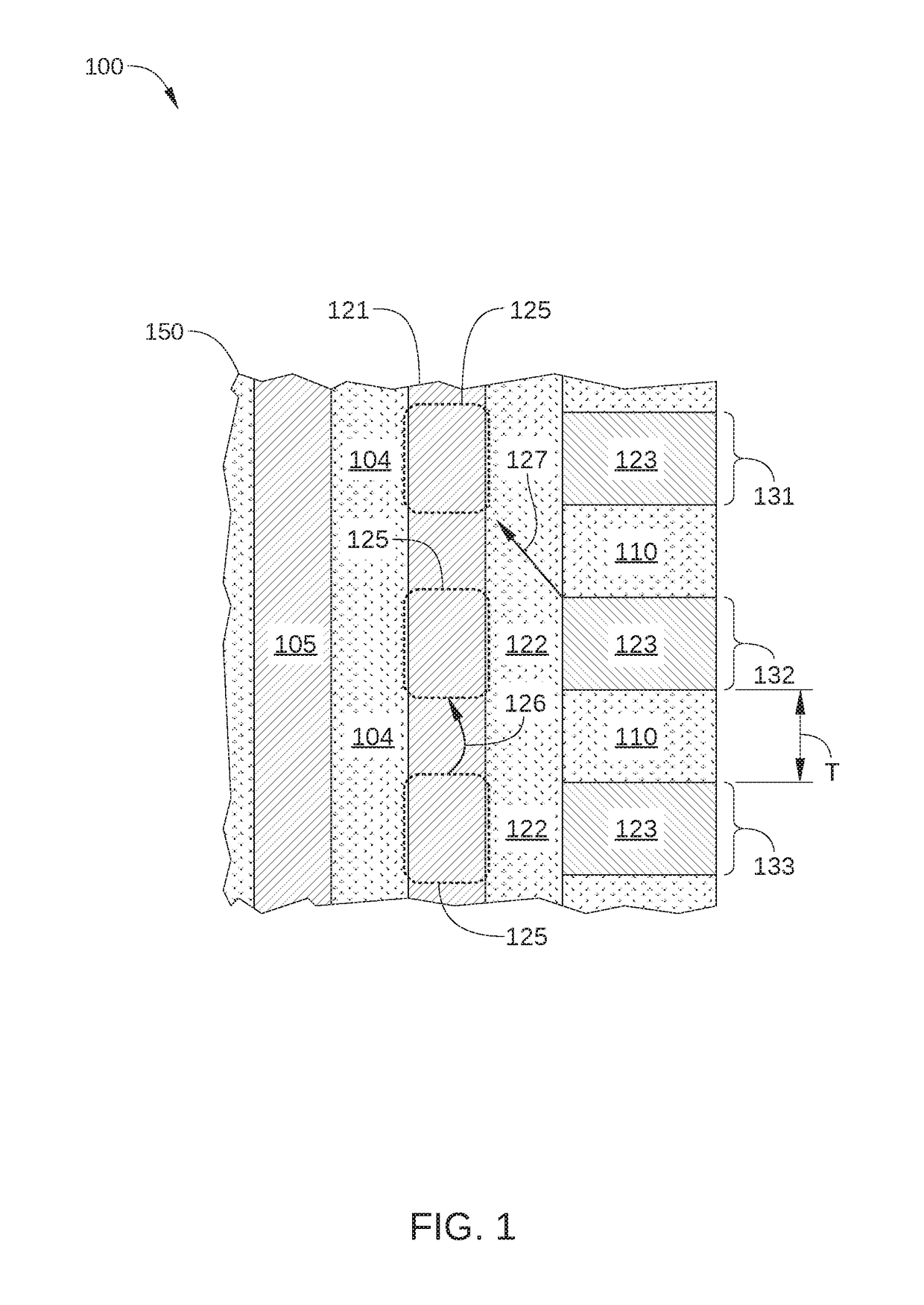

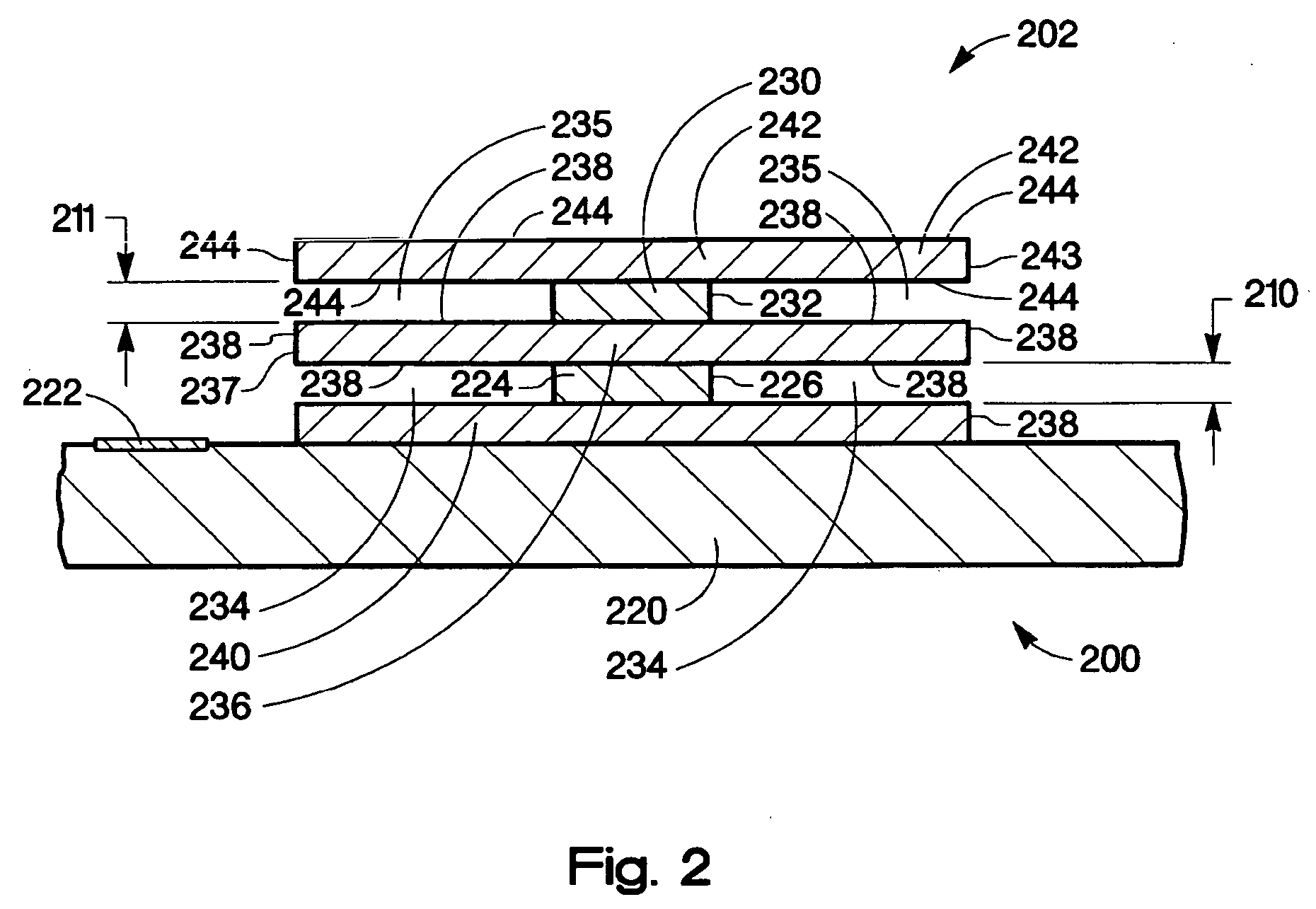

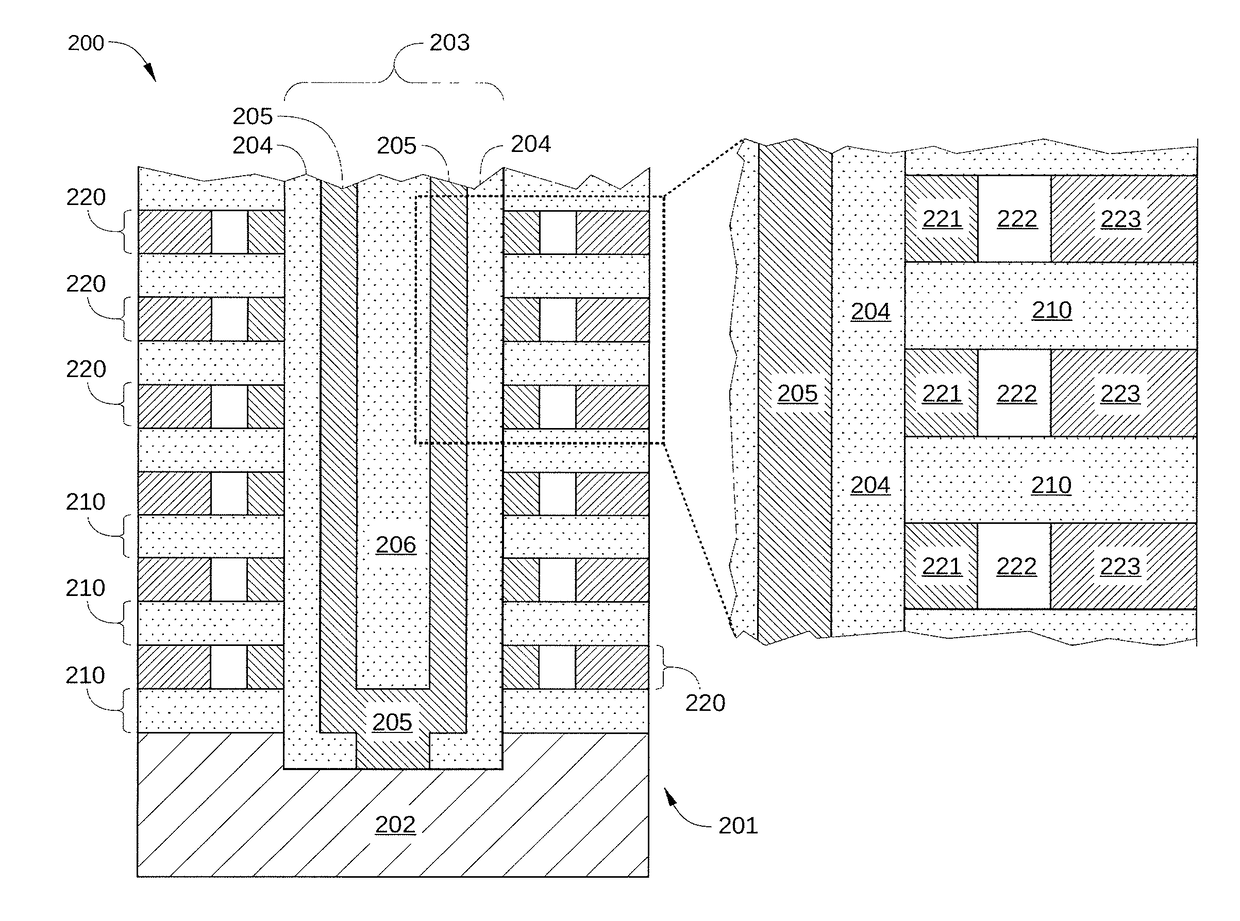

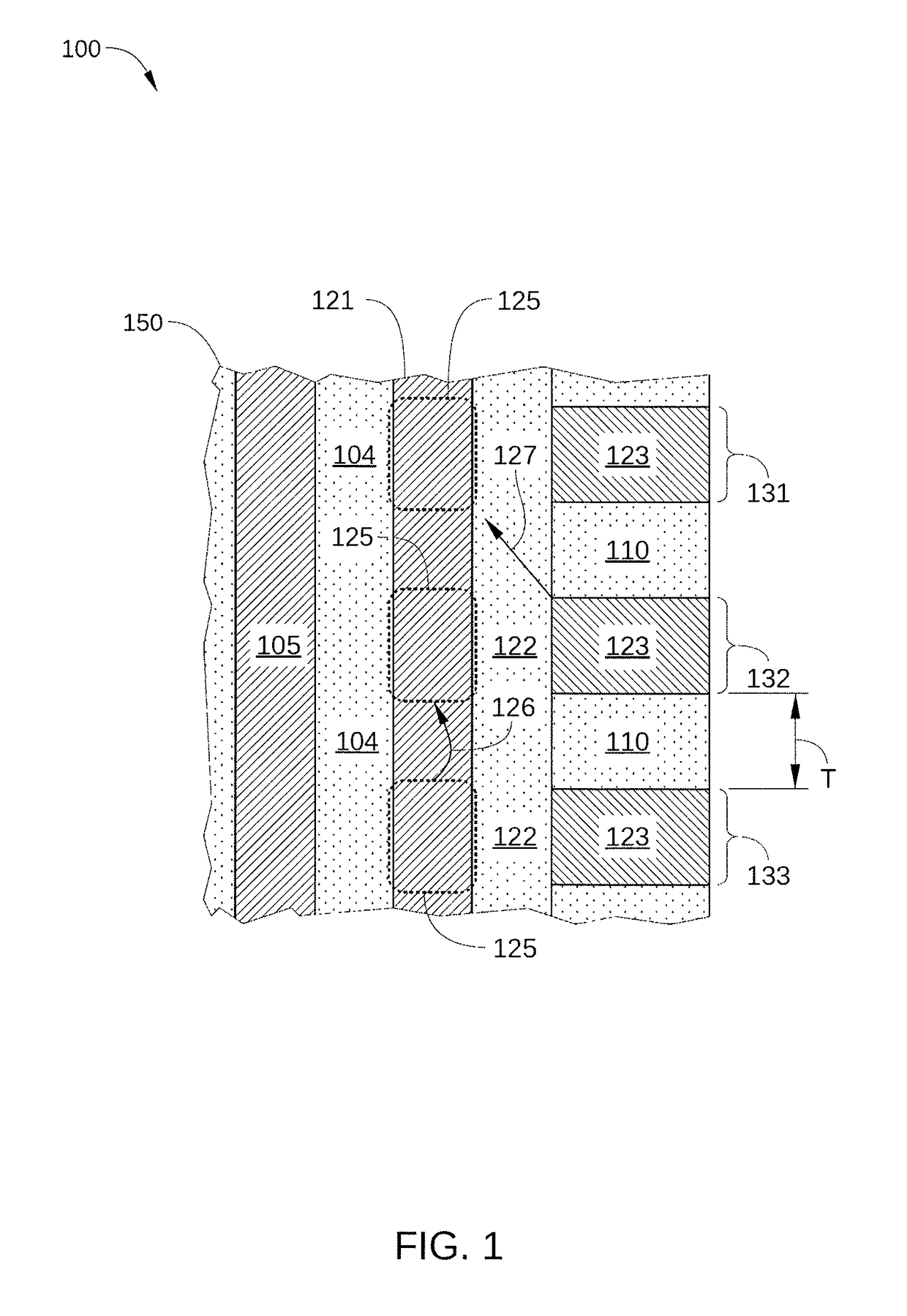

Charge-trap layer separation and word-line isolation for enhanced 3-D NAND structure

ActiveUS9960045B1Solid-state devicesSemiconductor/solid-state device manufacturingVacuum gapSilicon oxide

In a 3D NAND device, the charge trap region of a memory cell is formed as a separate charge-trap “island.” As a result, the charge-trap region of one memory cell is electrically isolated from charge-trap regions in adjacent memory cells. The charge trap region of one memory cell is separated from the charge trap regions of adjacent memory cells by a dielectric structure, such as a silicon oxide film. Alternatively, the charge trap region of a memory cell is separated from the charge trap regions of adjacent memory cells by an air, gas, or vacuum gap.

Owner:APPLIED MATERIALS INC

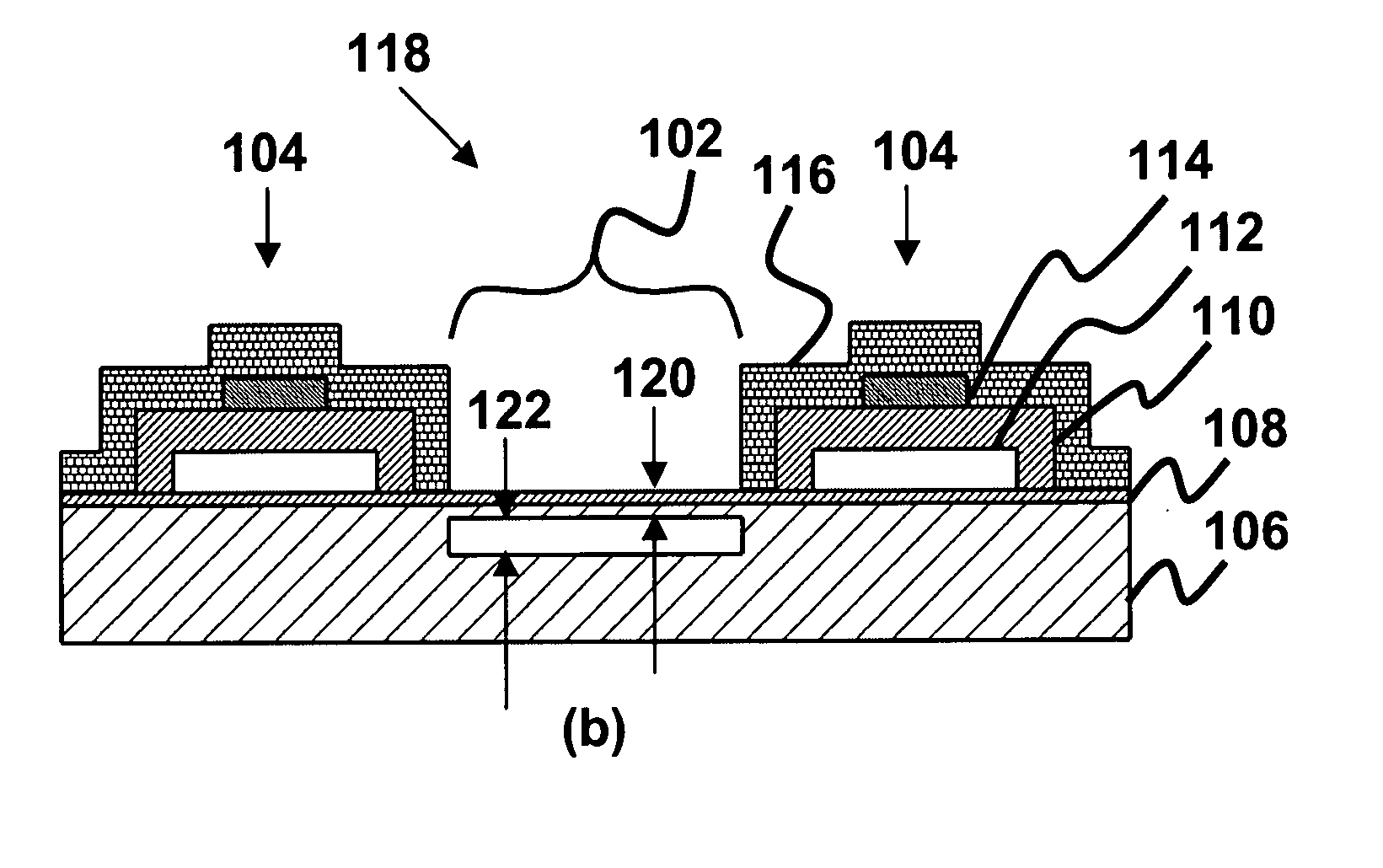

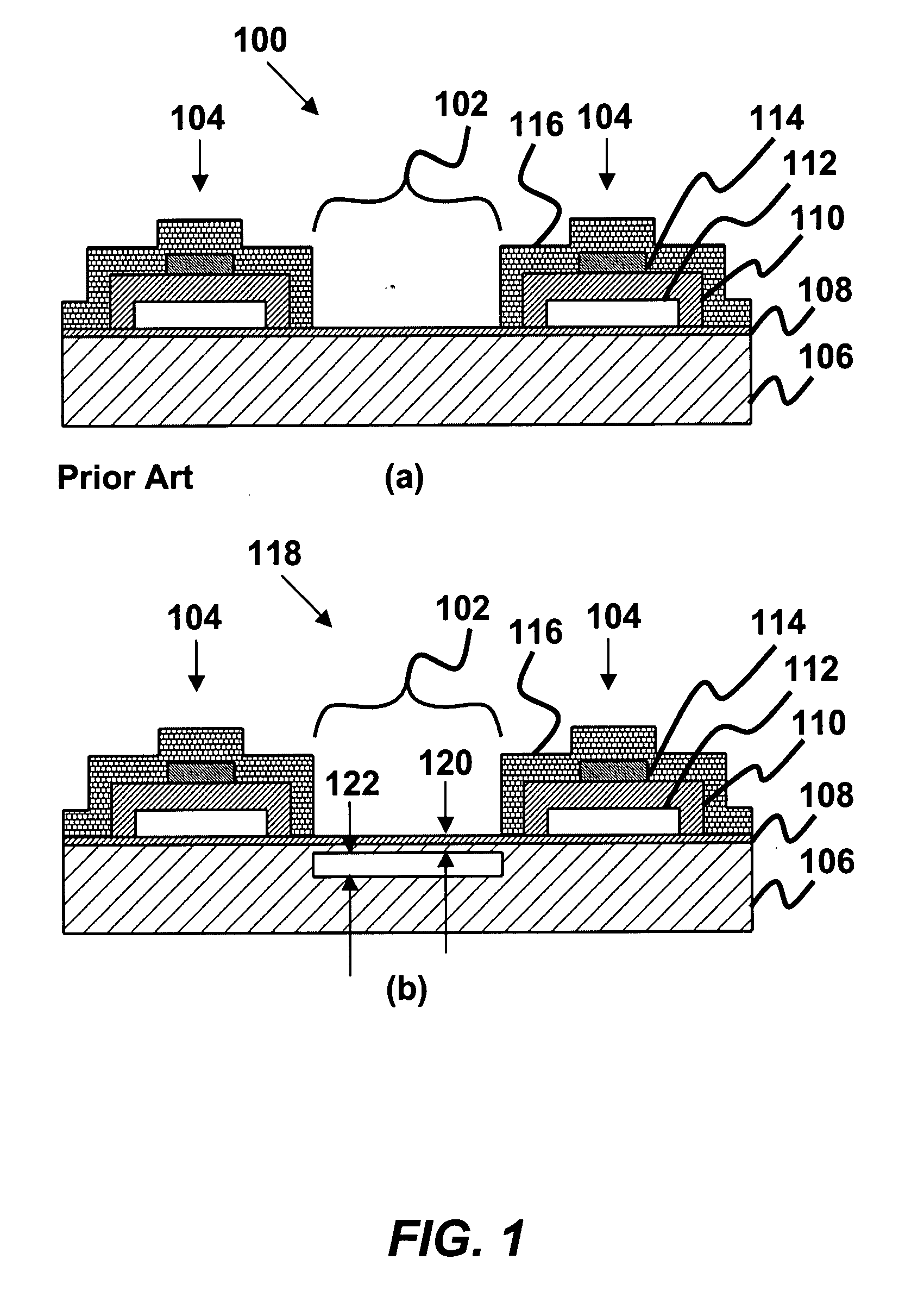

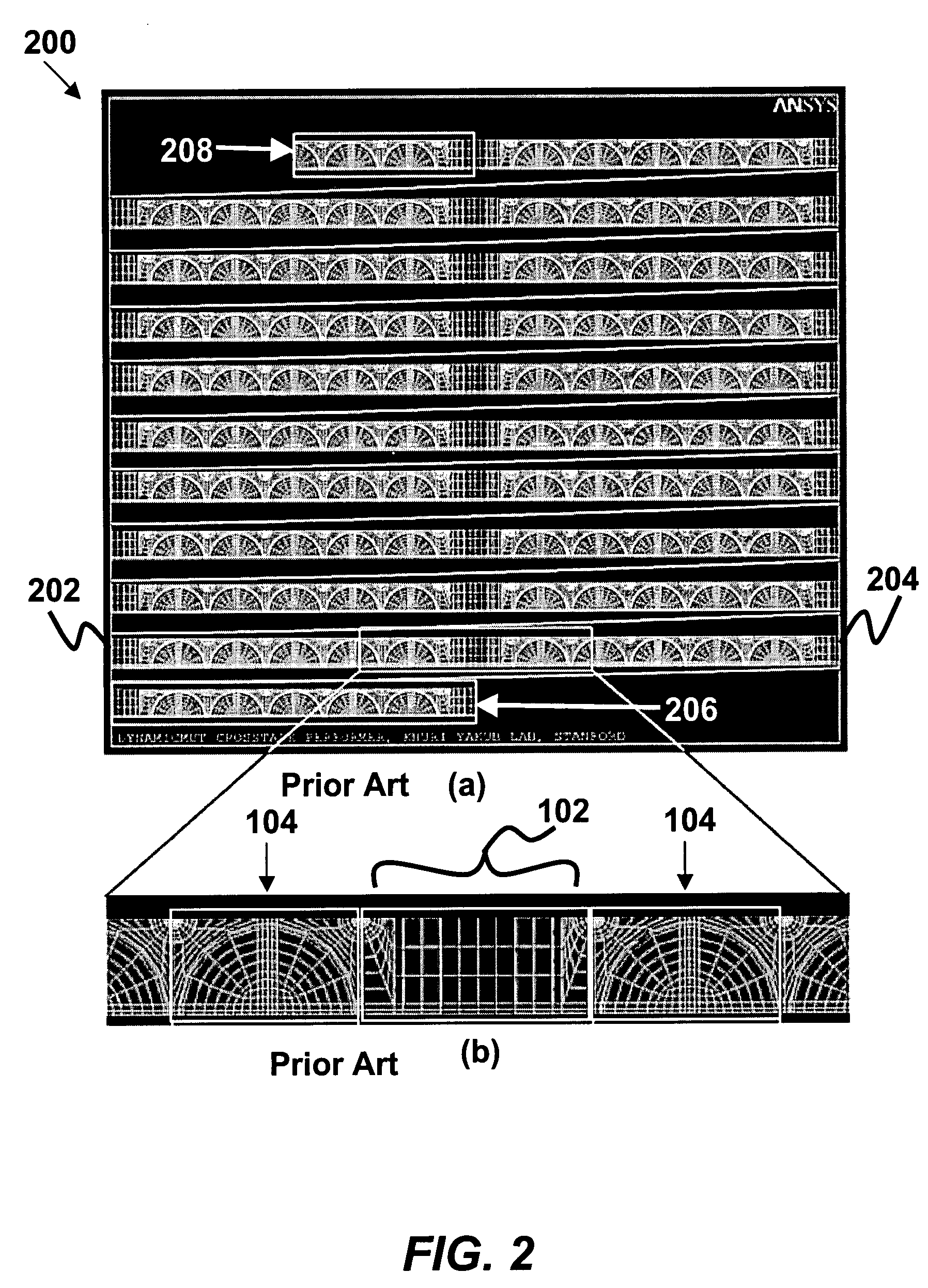

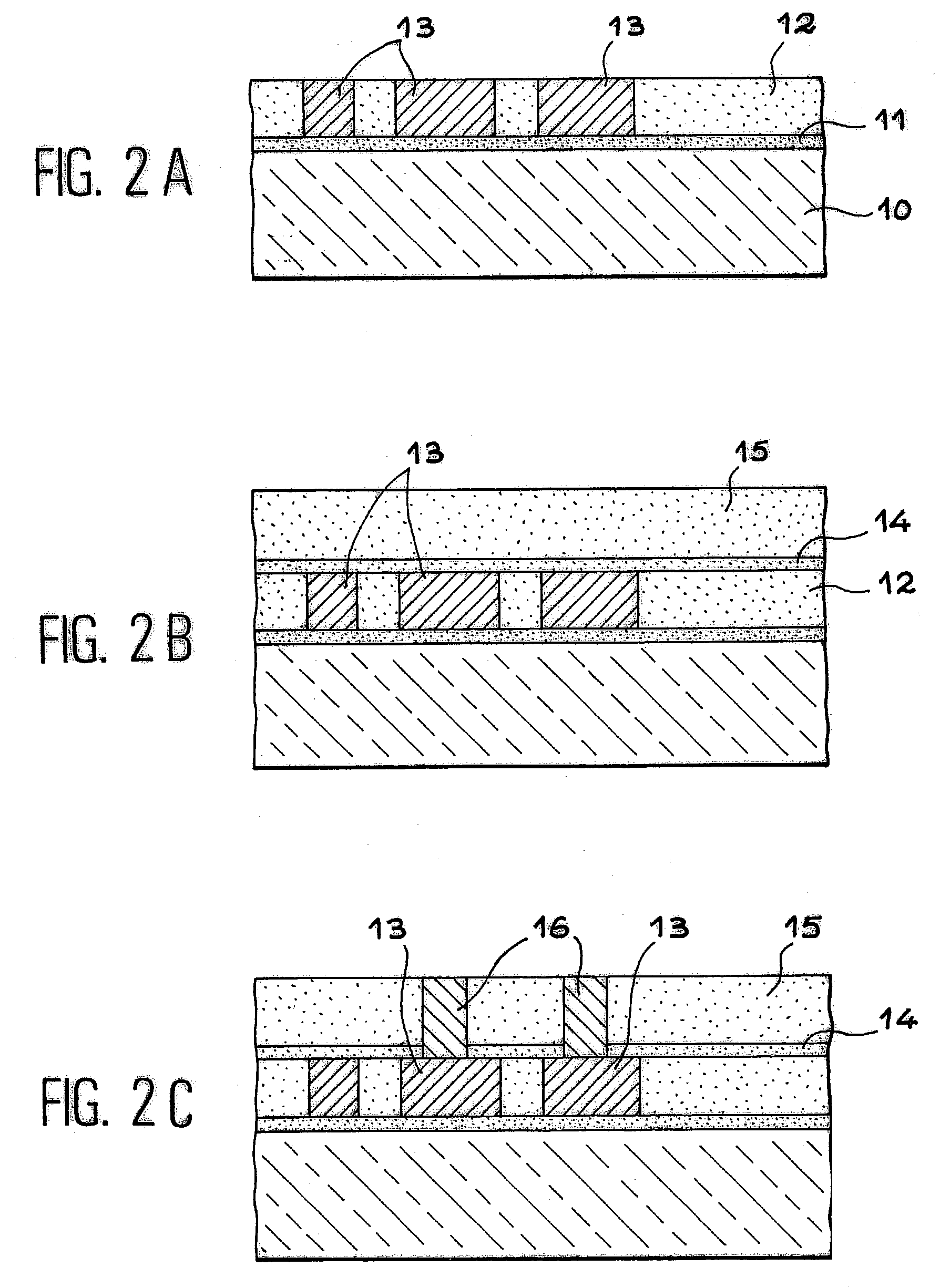

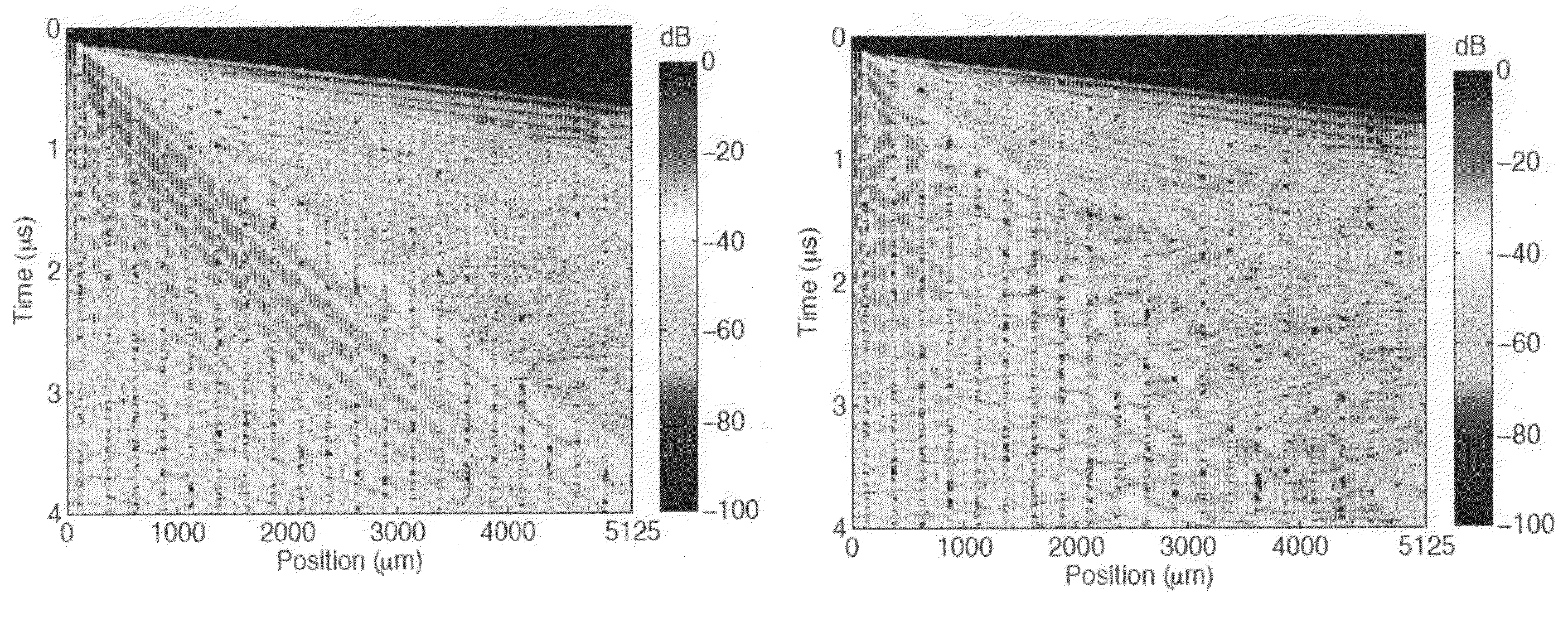

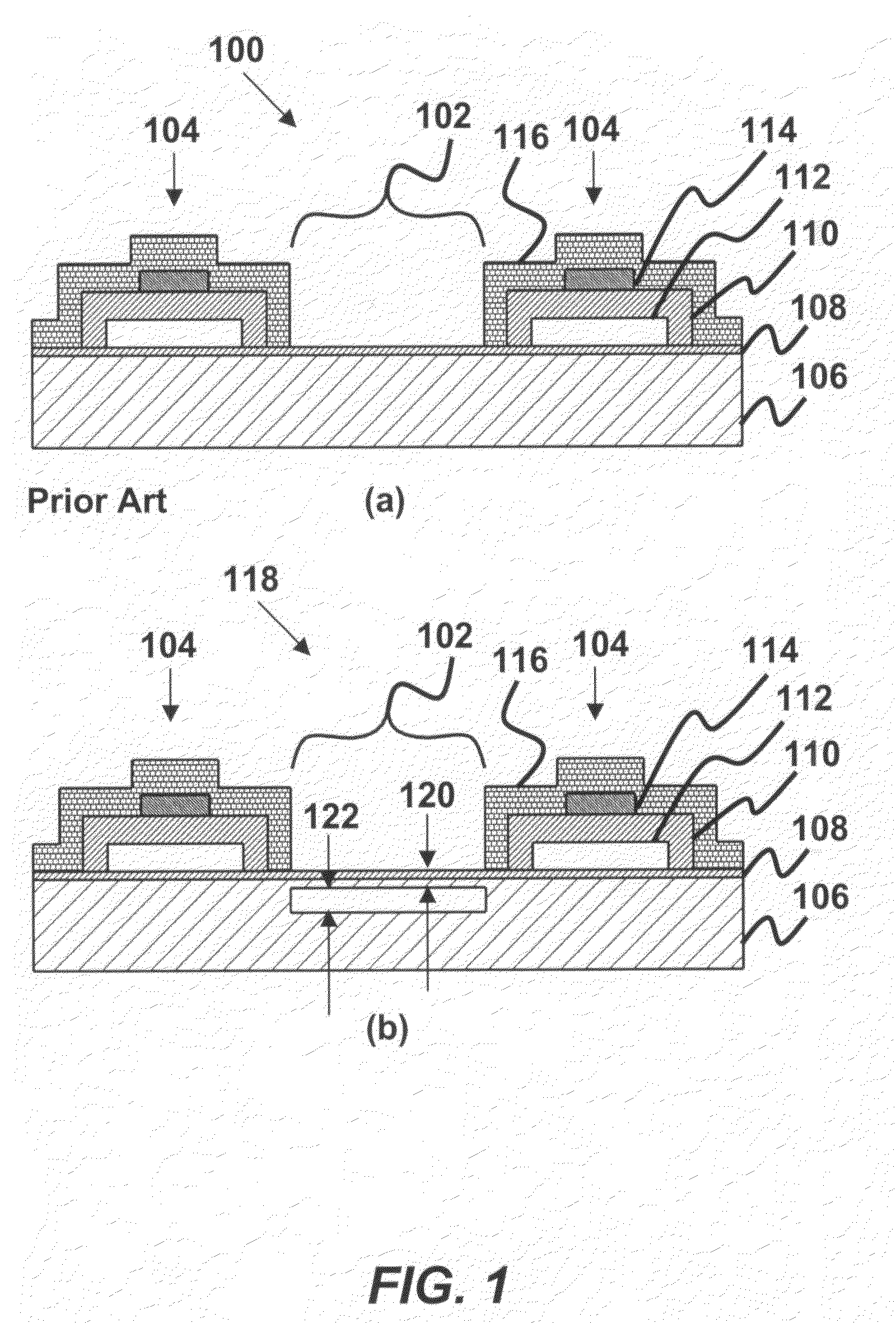

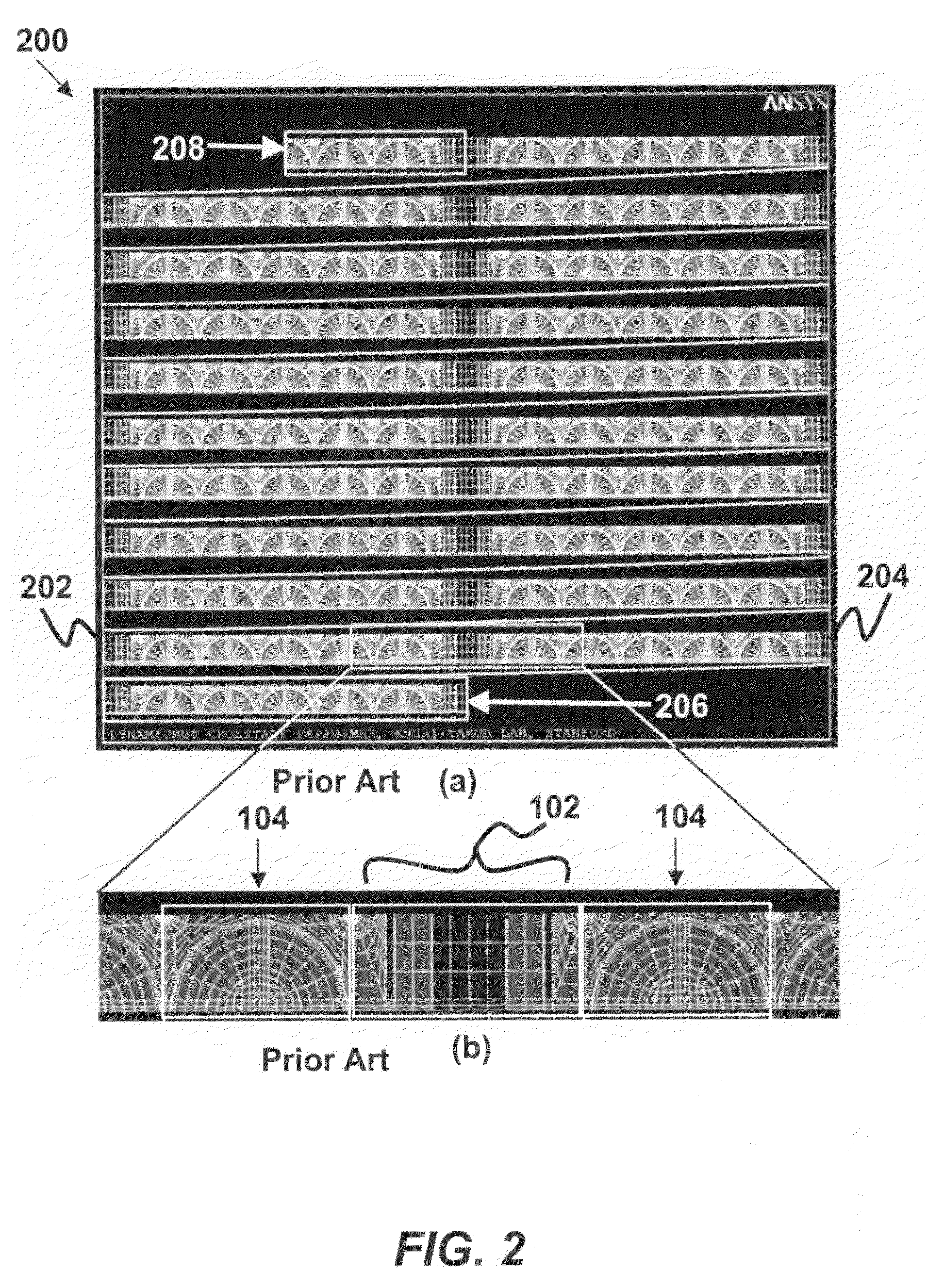

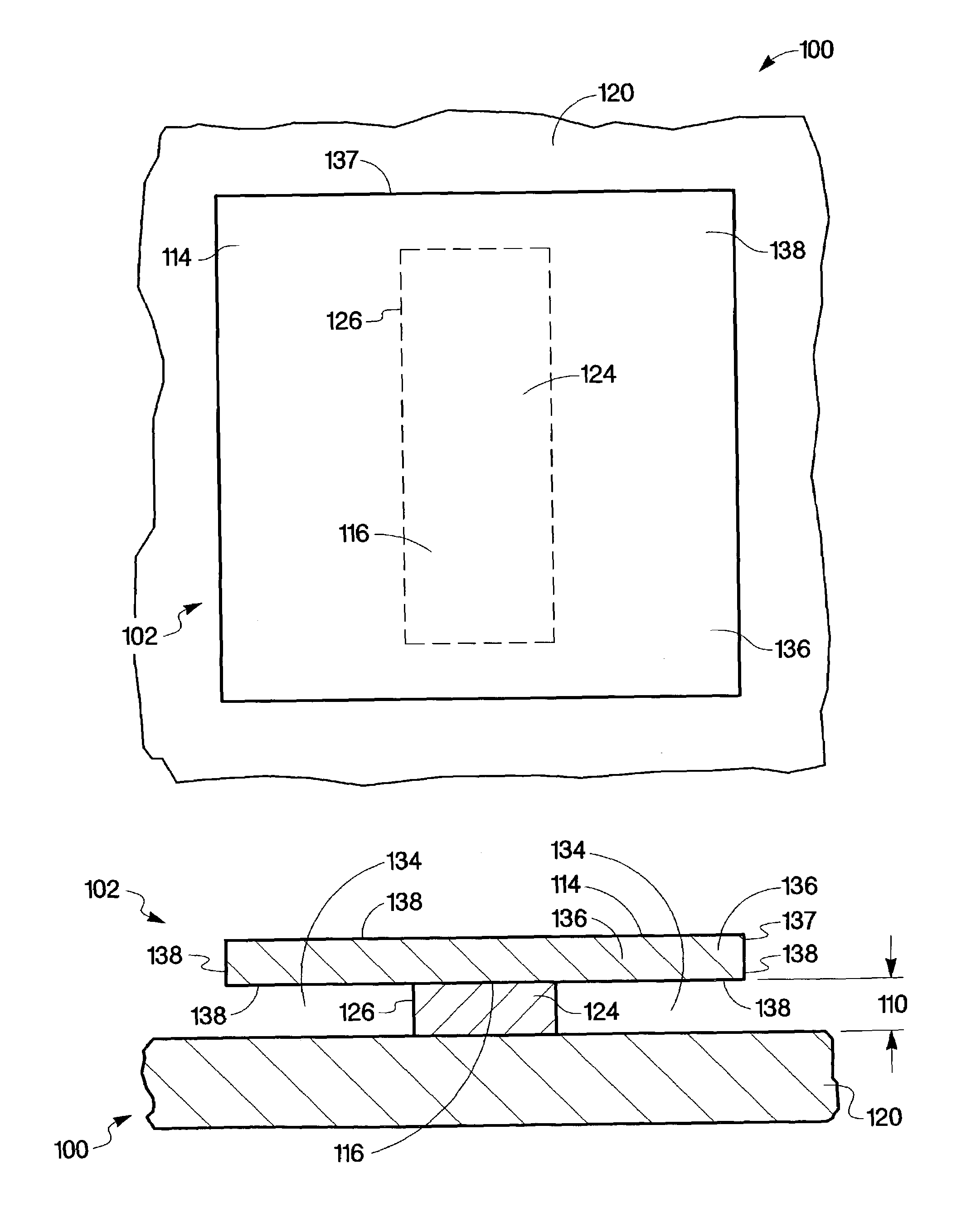

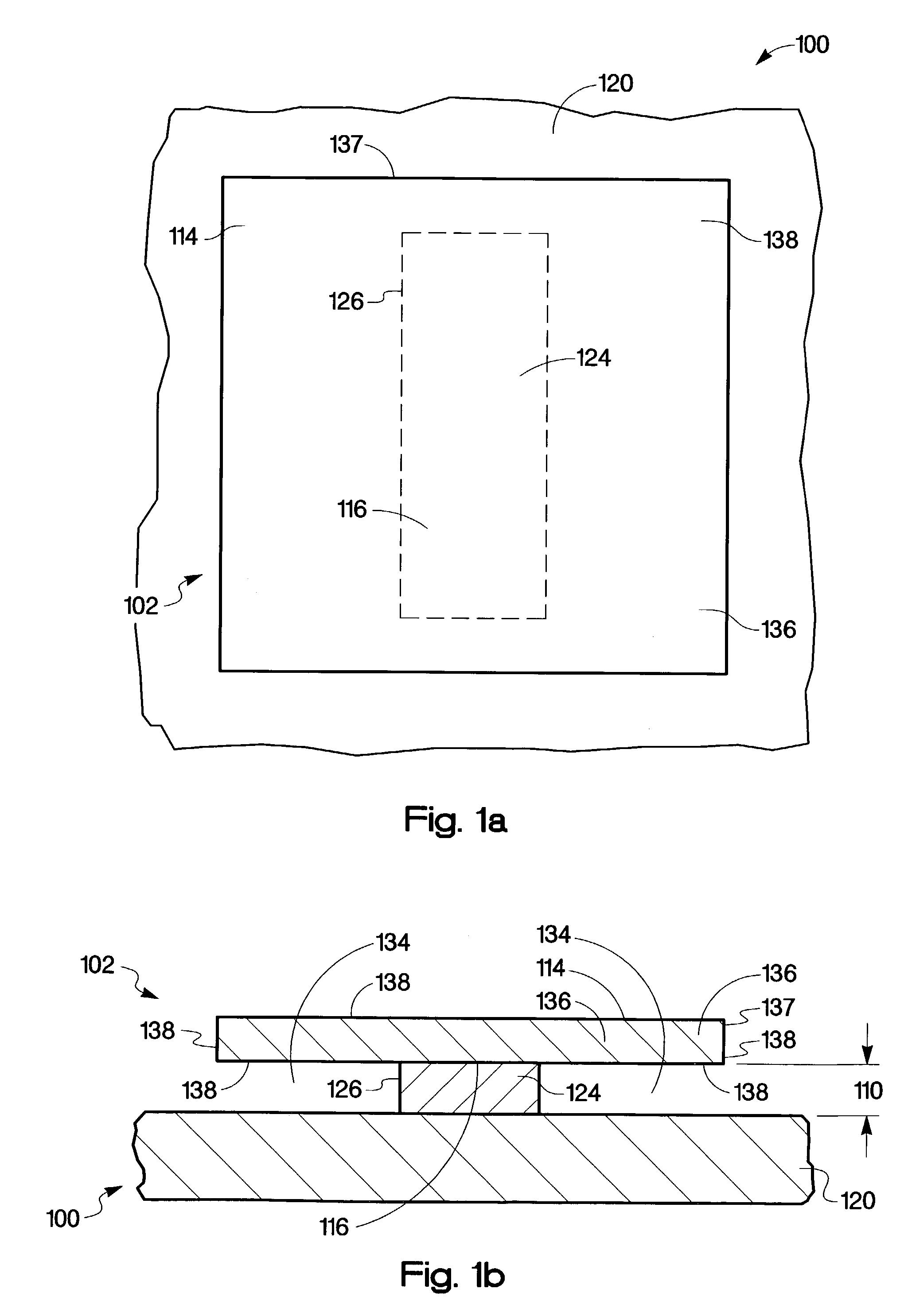

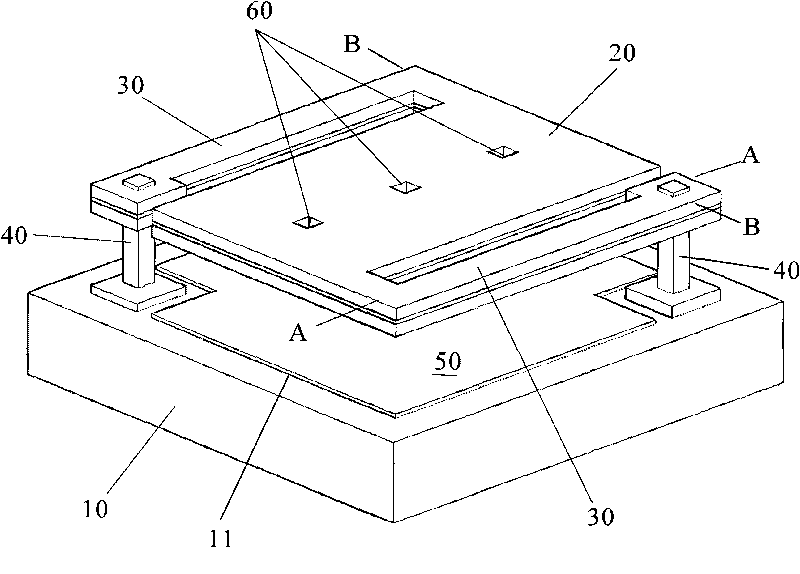

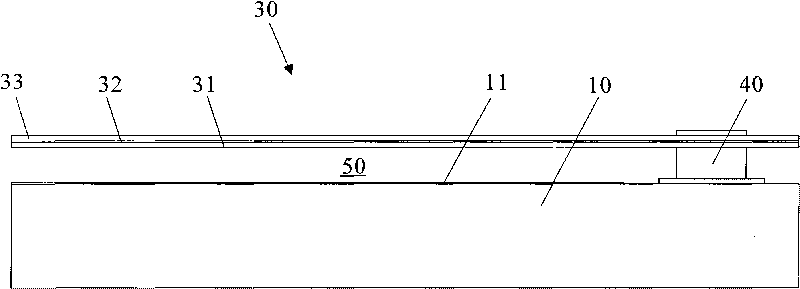

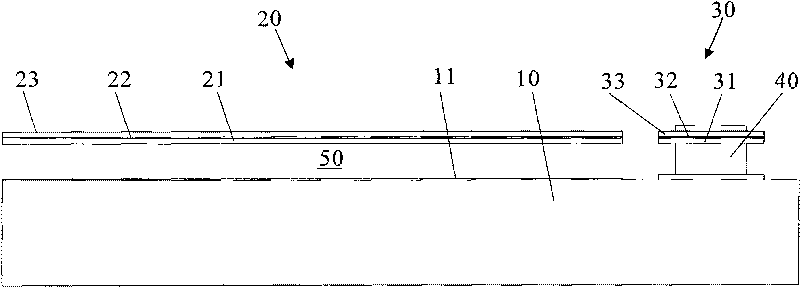

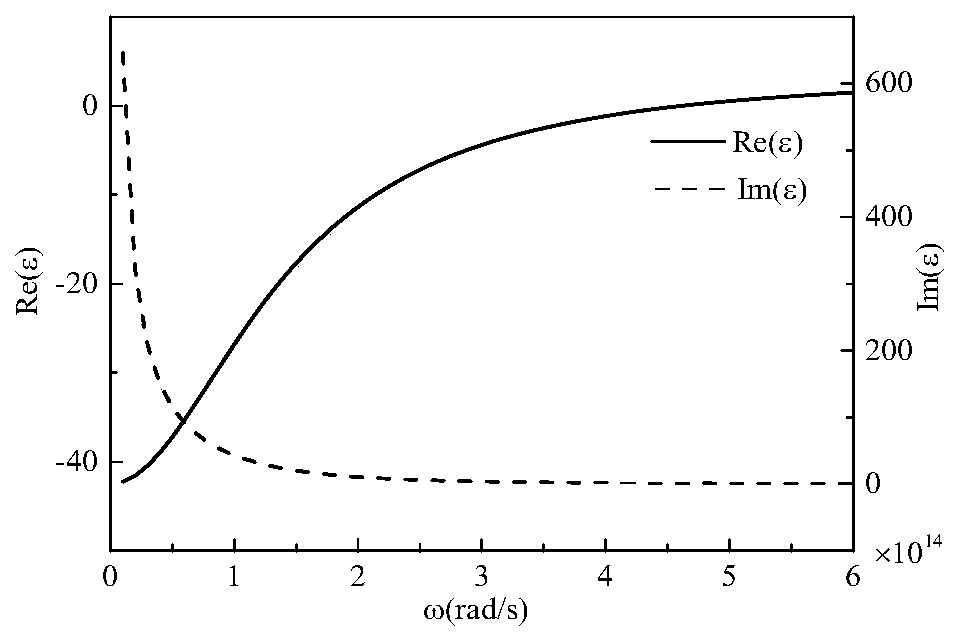

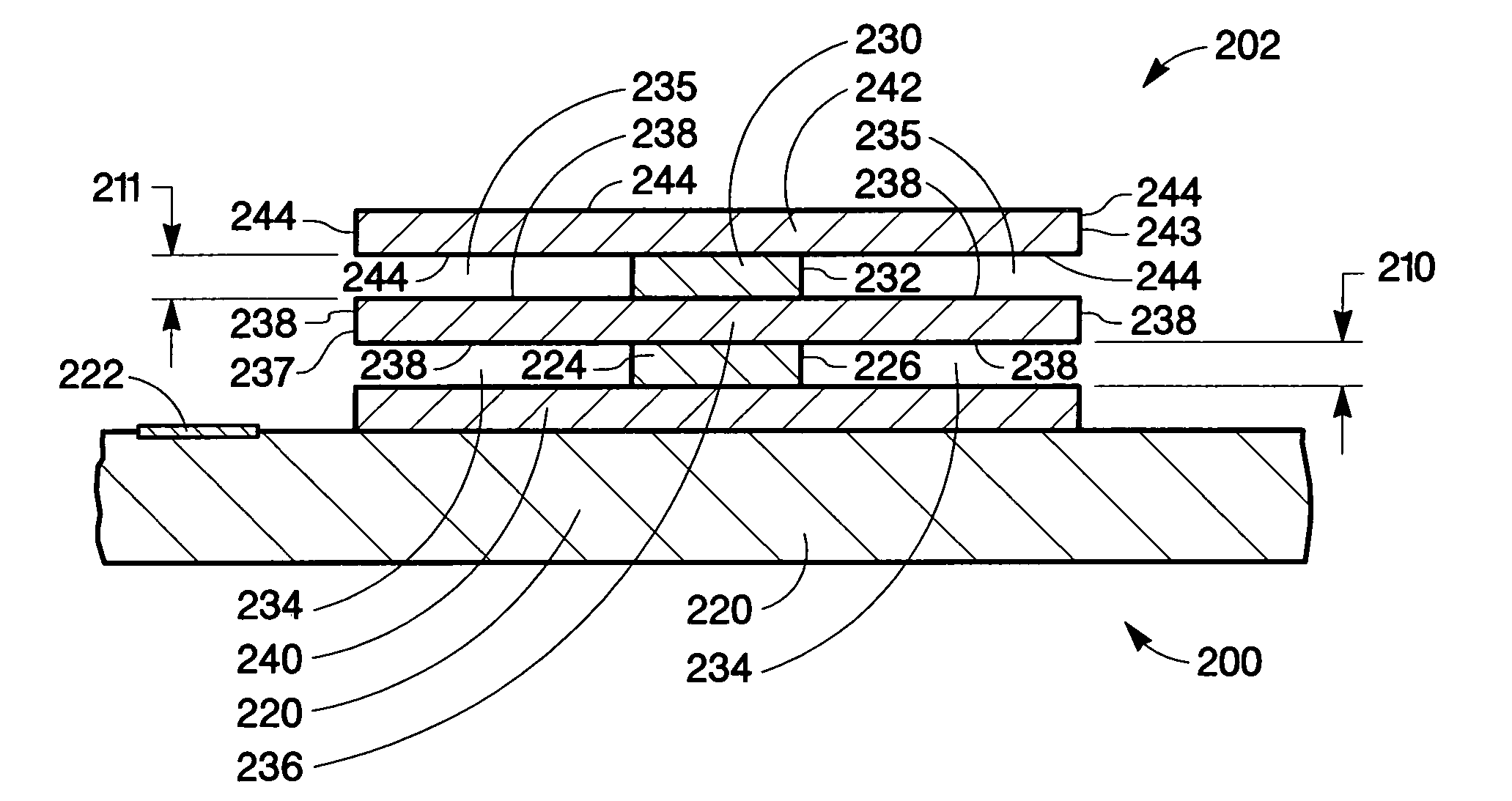

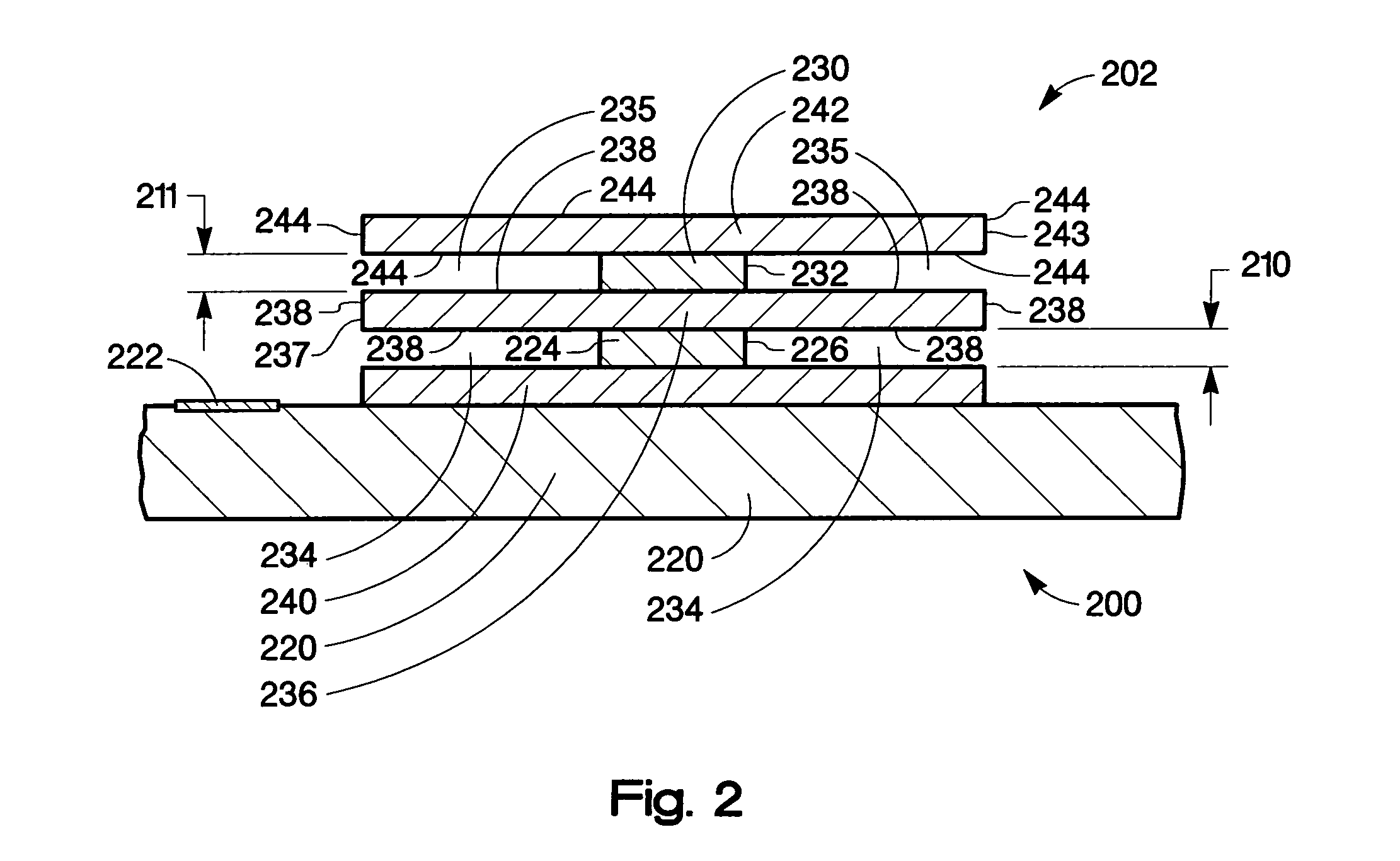

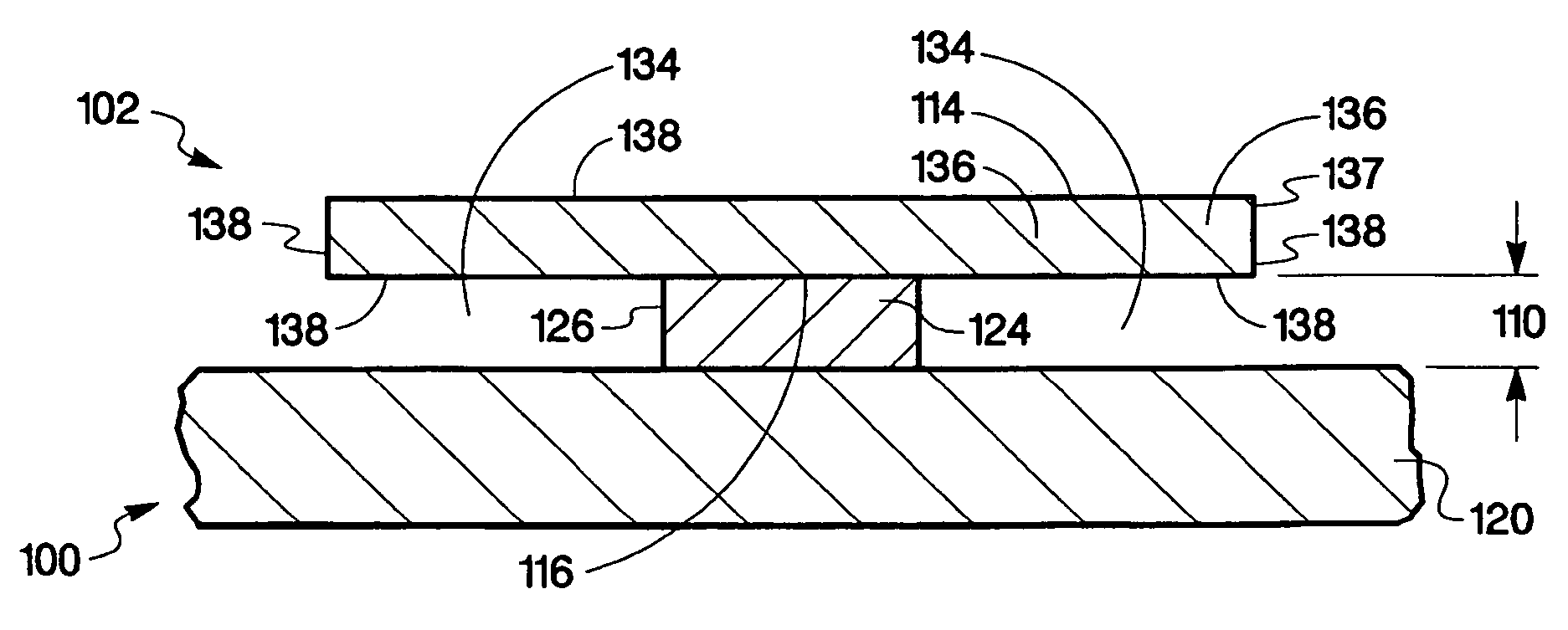

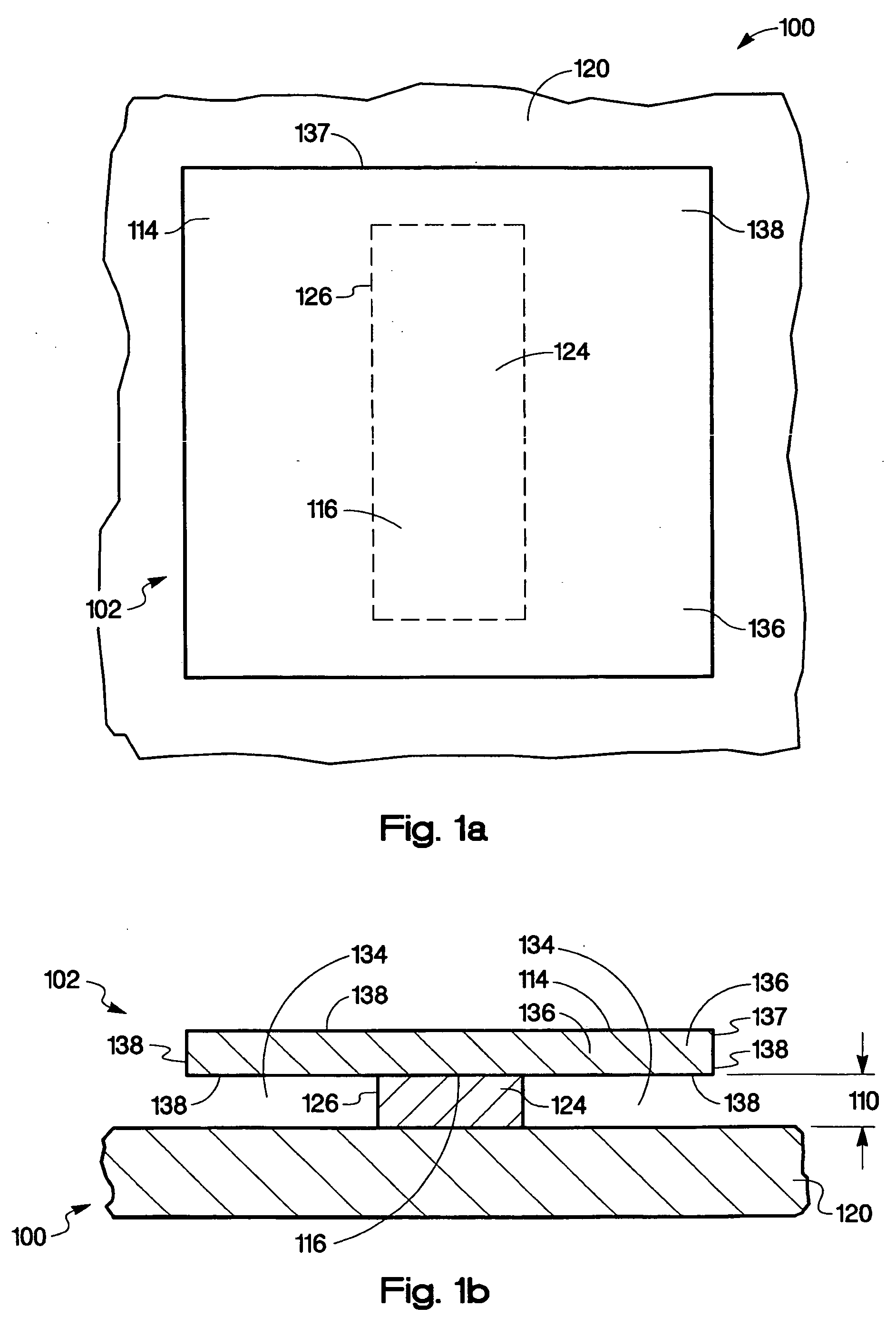

Acoustic crosstalk reduction for capacitive micromachined ultrasonic transducers in immersion

ActiveUS20080259725A1Reduce capacityReduce crosstalkPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationCapacitanceInsulation layer

A reduced crosstalk capacitive micromachined ultrasonic transducer (CMUT) array is provided. The CMUT array has at least two CMUT array elements deposited on a substrate, at least one CMUT cell in the array element, a separation region between adjacent CMUT array elements, and a membrane formed in the separation region. The membrane reduces crosstalk between adjacent array elements, where the crosstalk is a dispersive guided mode of an ultrasonic signal from the CMUT propagating in a fluid-solid interface of the CMUT array. Each cell has an insulation layer deposited to the substrate. A cell membrane layer is deposited to the insulation layer, where the cell membrane layer has a vacuum gap therein. The cells further have an electrode layer deposited to a portion of the membrane layer, and a passivation layer deposited to the electrode layer, the cell membrane layer and to the insulation layer.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

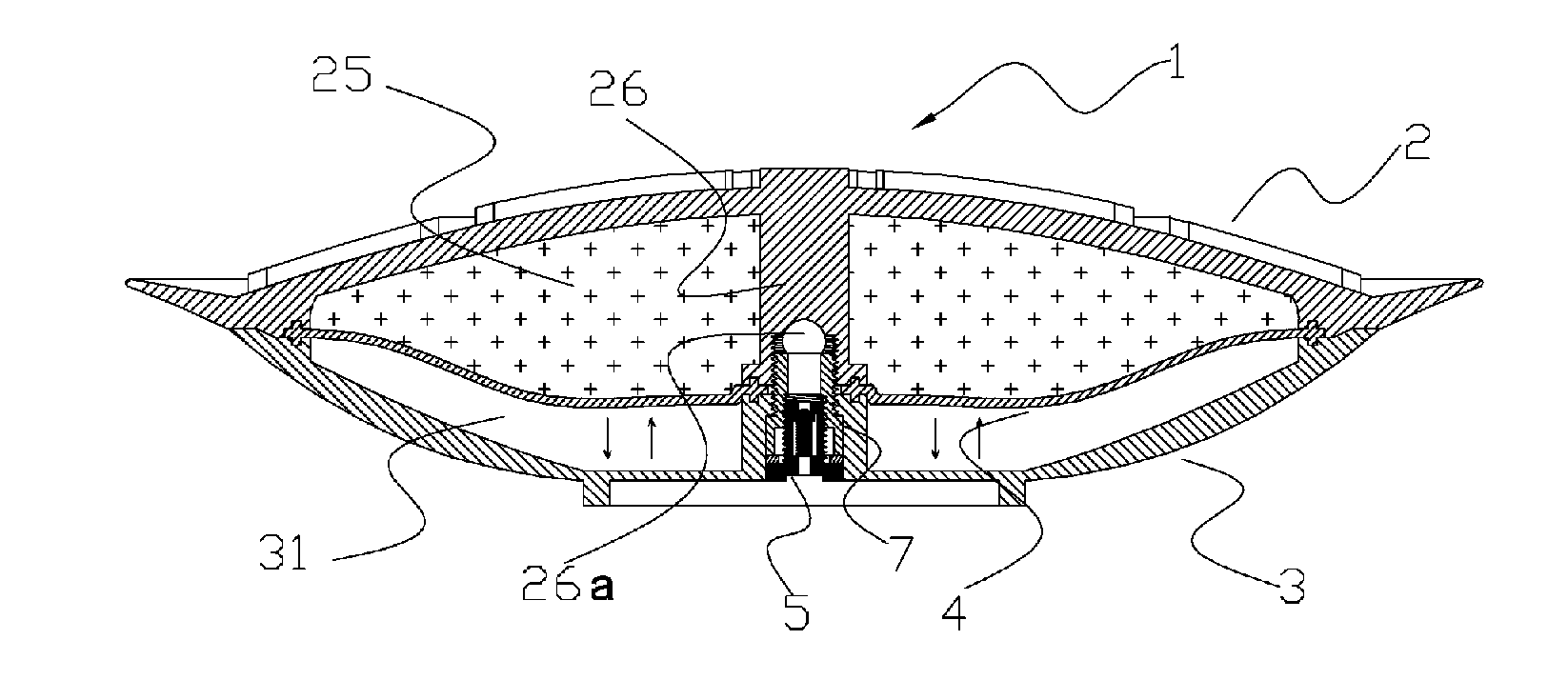

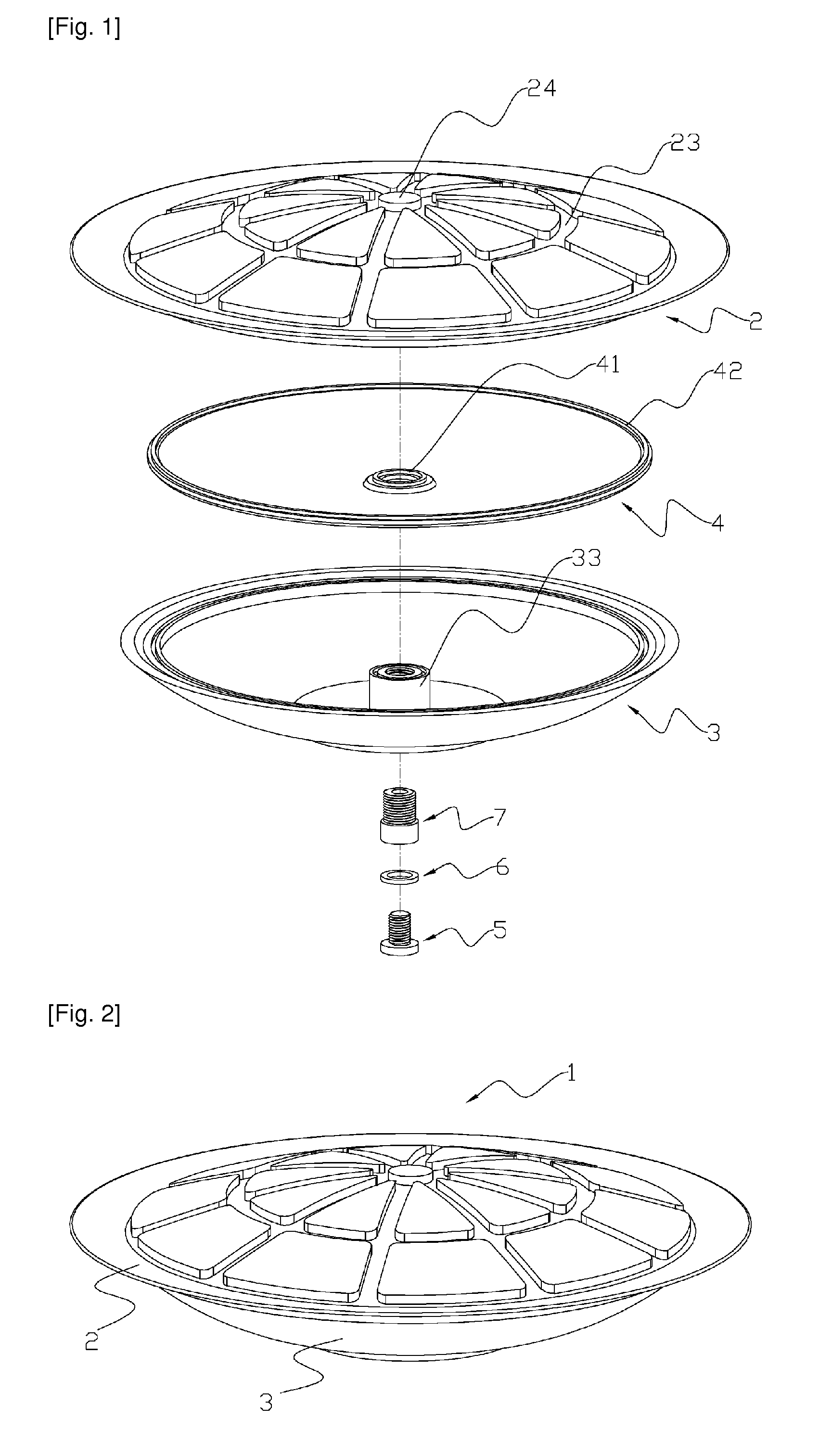

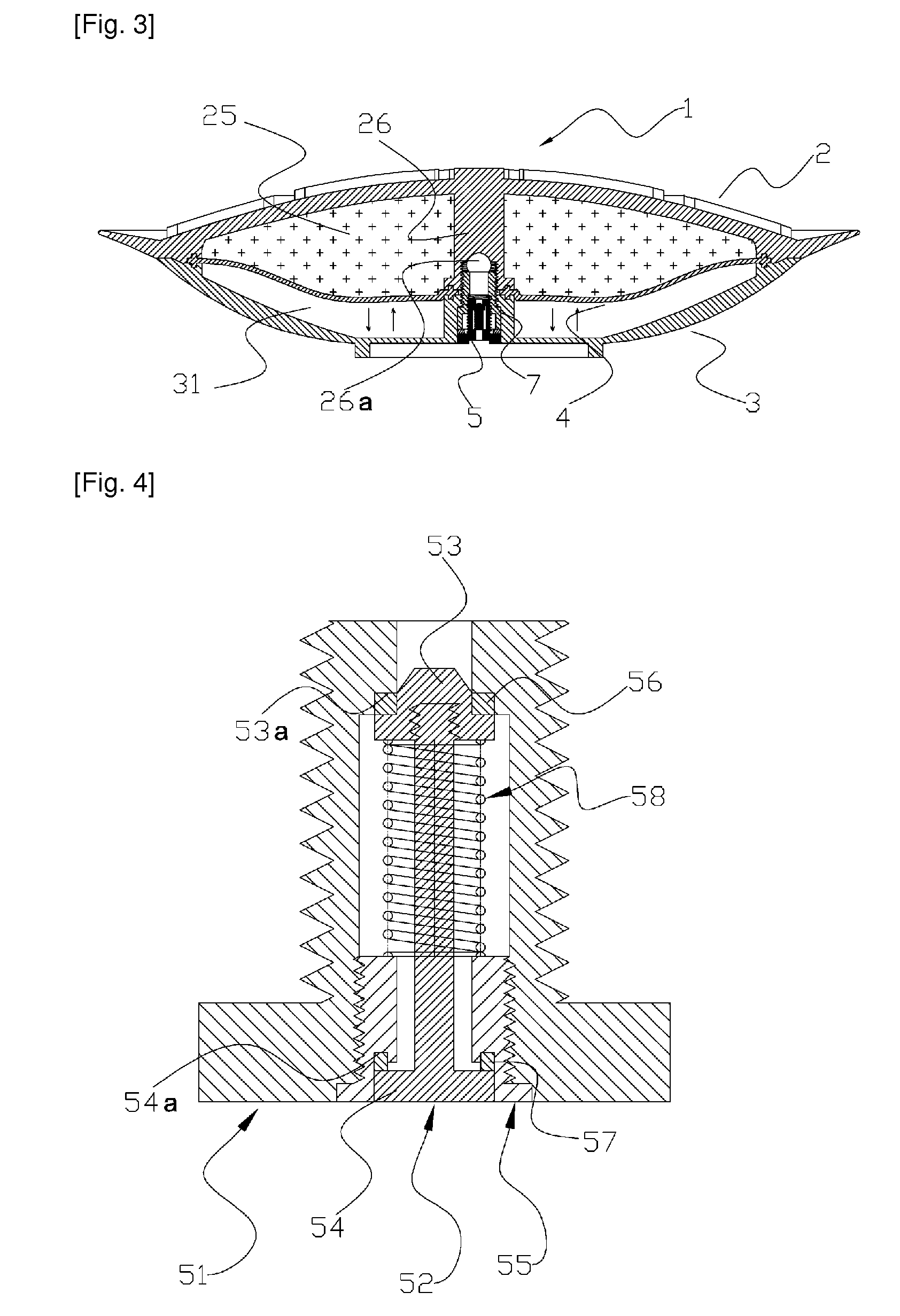

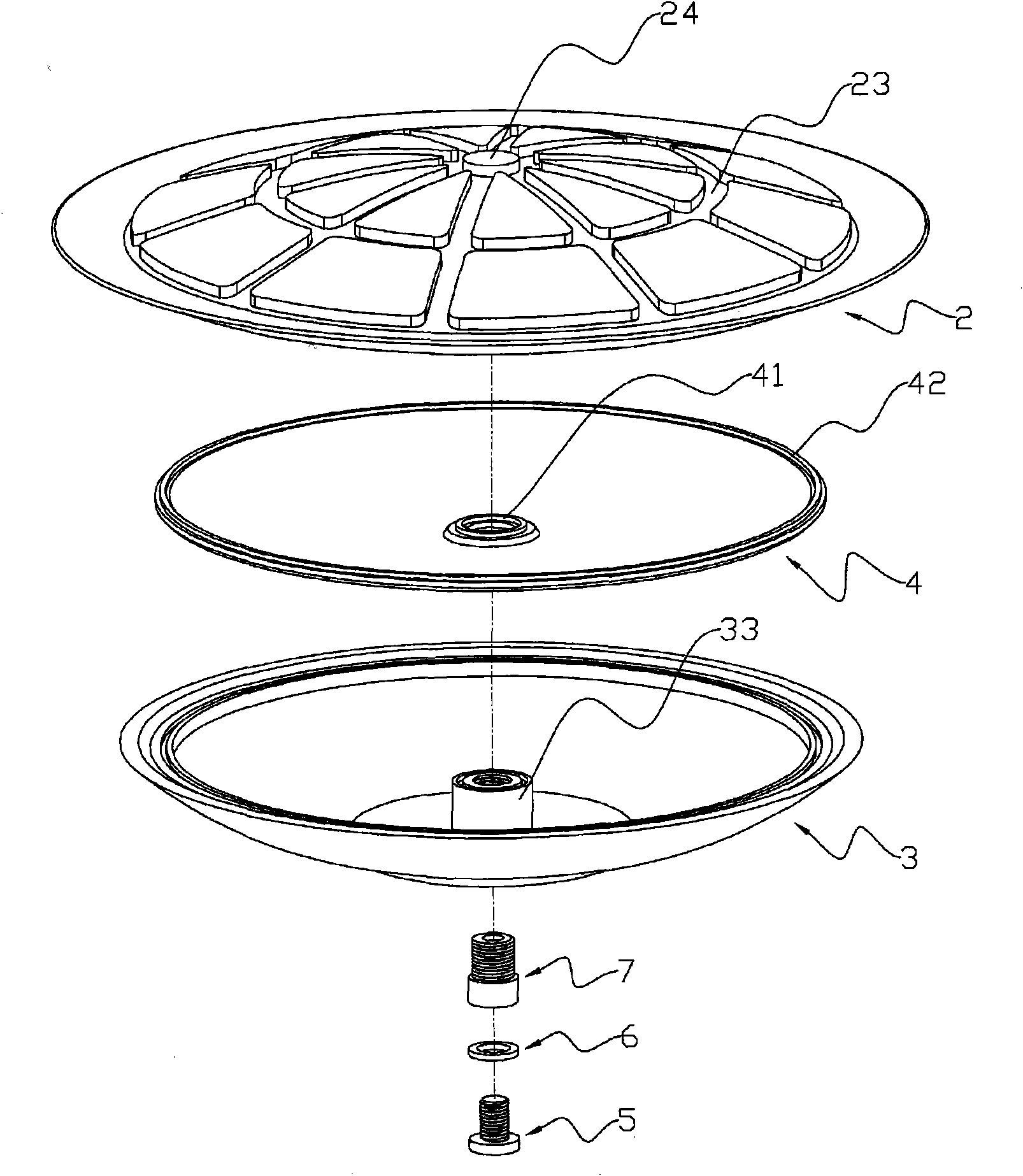

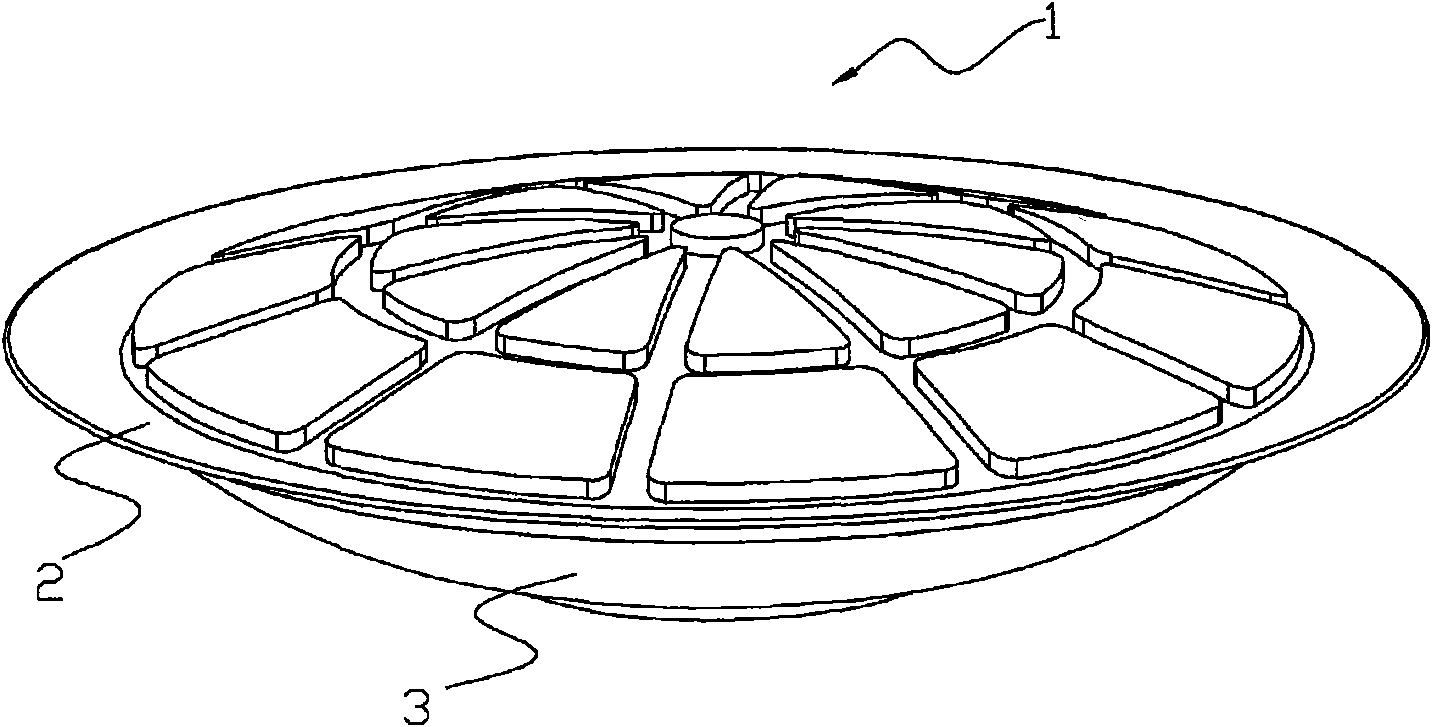

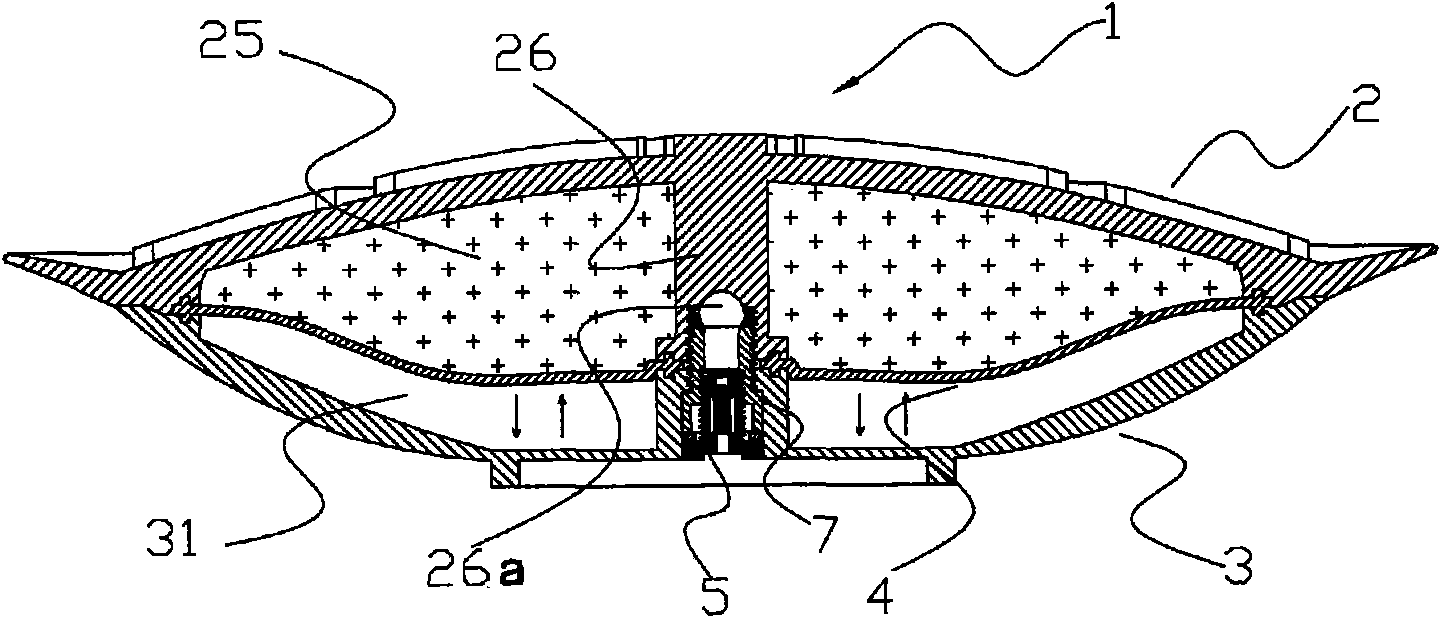

Freezing crack or distortion proof cooling utensil

InactiveUS20100147014A1Reduce manufacturing costSimple configurationLighting and heating apparatusPlatesVacuum gapEngineering

The present invention relates to a cooling utensil, which is a proof of freezing-crack and distortion. More particularly, an internal cavity of the utensil is fully filled the water to freeze in the freezer for cooling the serving food, such as a law fish, fruit, cold noodle or beer to feel fresh and tasty. For using the cooling bowl, the cooling cavity is filled the water or coolant for freezing. The cooling bowl is using for serving food. The cooling cavity is formed between the upper part and the lower part. The lower part is used a base to support the upper part. The upper part has same shape and size of the lower part for placing over the lower part. The elastic plate having flexibility and elastically restoring force is attached to the lower part, the upper part for assembling. Further, the cooling bowl having a cooling cavity is filled the water or coolant and freeze to use serving food. The lower part has built a dual wall to form a vacuum gap between the inner wall and the outer wall for insulation, so that the outer wall has no condensed water gained. The elastic tube (4k) having elastically restoring force is inserted through the water inlet (33). the plug bolt (5k) mounted at the mouth of the water inlet (33), for sealing the water filled cavity.

Owner:KIM EE

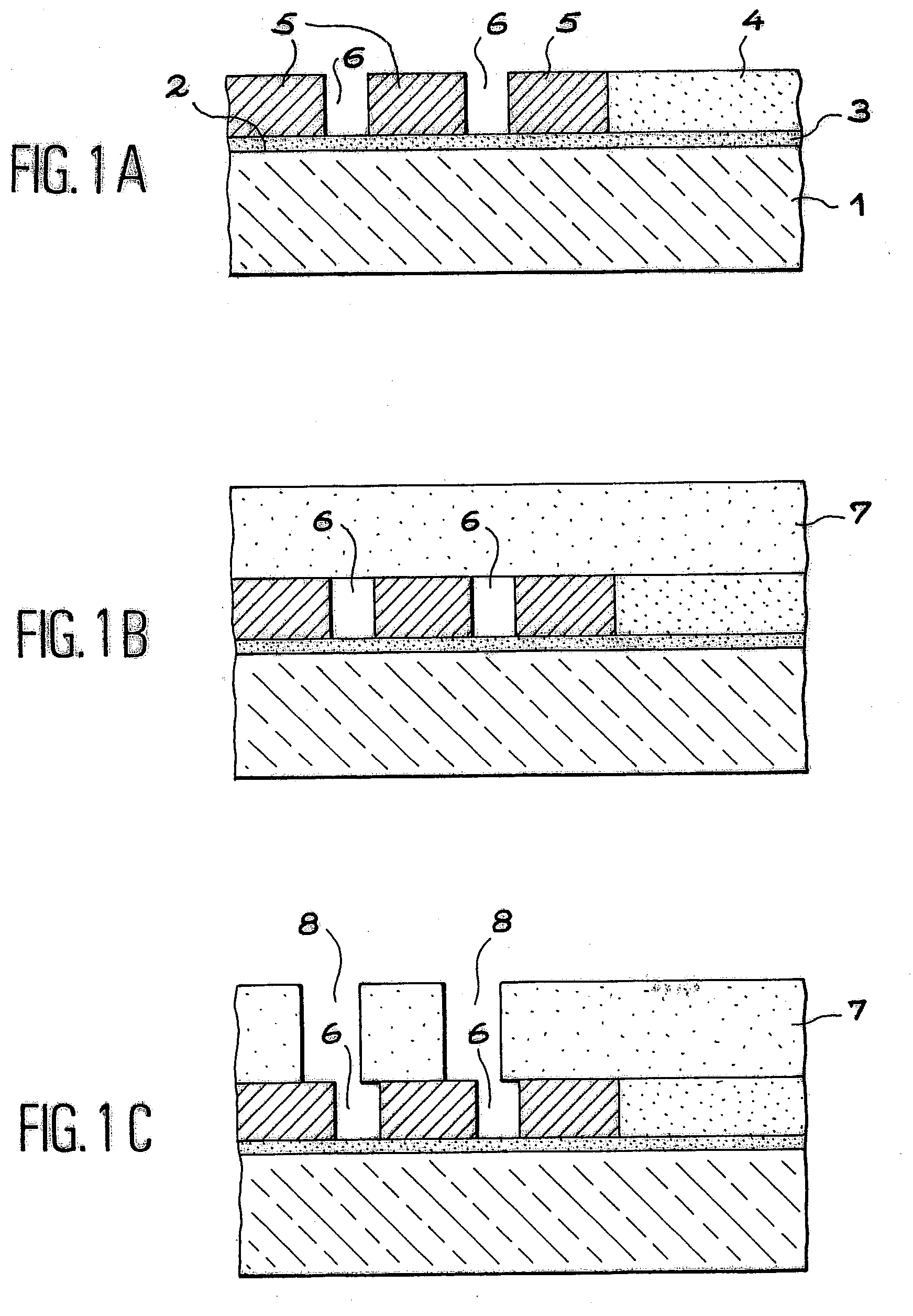

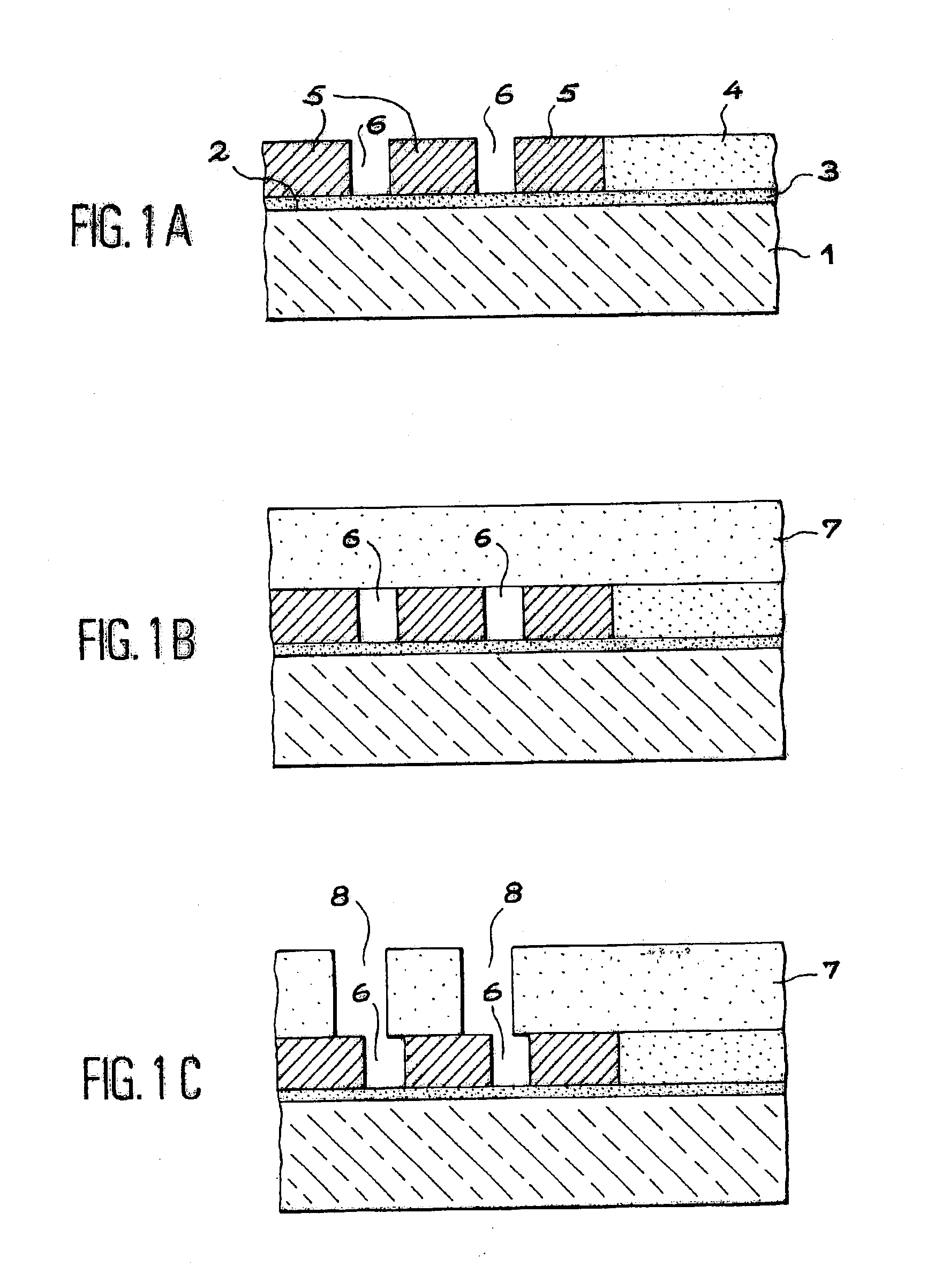

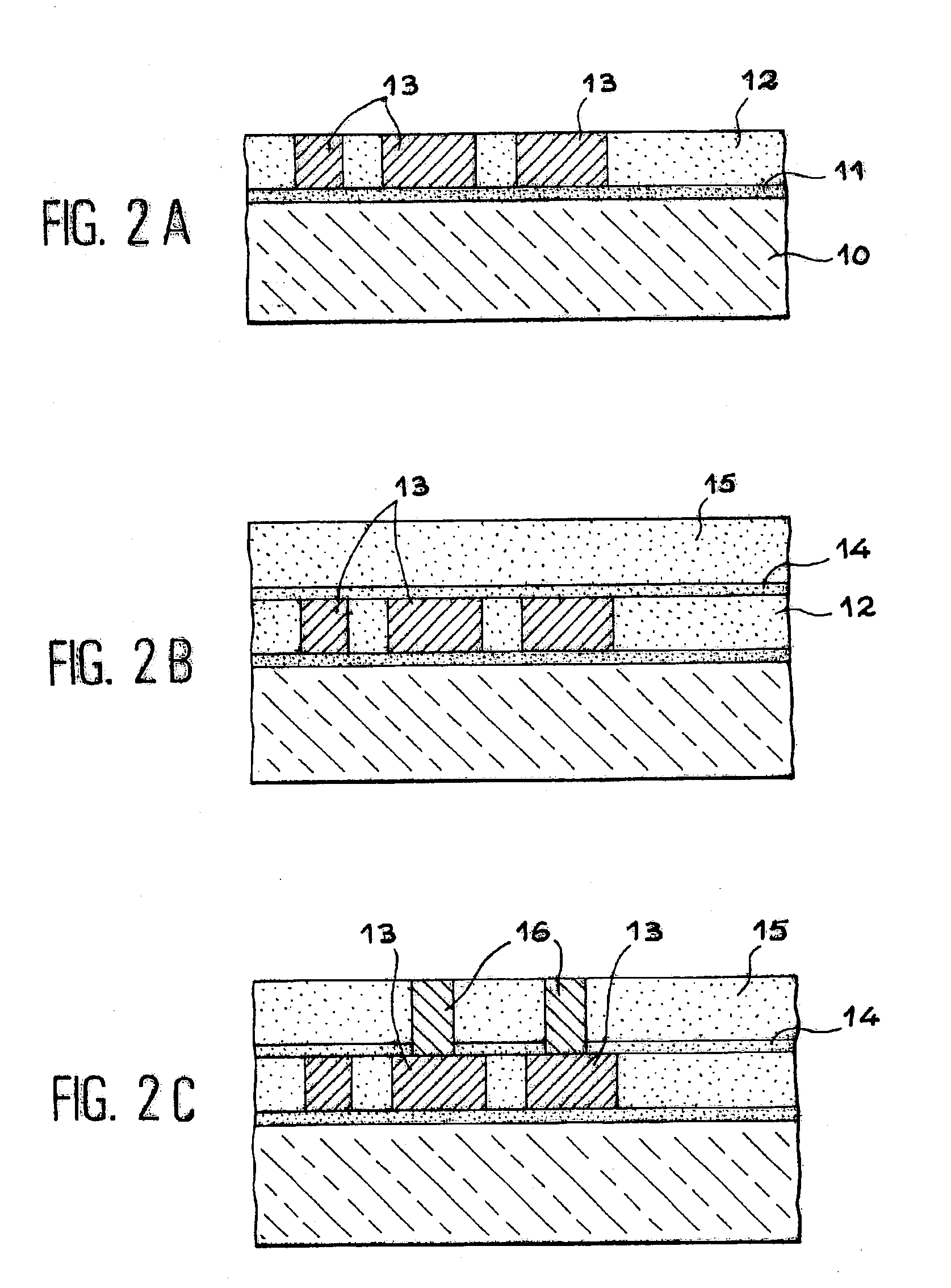

Interconnection structure with insulation comprising cavities

The invention concerns a method for fabricating a damascene type structure of interconnections on a semiconductor device. It includes the following steps: formation of a first level of conductors in a first electric insulating layer and of a second level of conductors in a second electric insulating layer, with the conductors in the first level being arranged with a pre-determined spacing in order to allow, in a later step, the formation of air or vacuum gaps between the conductors in the first level, elimination of the second electric insulating layer, elimination, at least partial, of the first electric insulating layer in order to eliminate at least some parts of the first layer corresponding to the gaps to be formed, deposit, over the structure thus obtained, of a material with low permittivity, with this deposit not filling the space between the conductors in the first level whose spacing has been planned to allow the formation of gaps.

Owner:STMICROELECTRONICS SRL +1

Acoustic crosstalk reduction for capacitive micromachined ultrasonic transducers in immersion

ActiveUS7745973B2Reduce crosstalkReduce capacityPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationCapacitanceVacuum gap

A reduced crosstalk capacitive micromachined ultrasonic transducer (CMUT) array is provided. The CMUT array has at least two CMUT array elements deposited on a substrate, at least one CMUT cell in the array element, a separation region between adjacent CMUT array elements, and a membrane formed in the separation region. The membrane reduces crosstalk between adjacent array elements, where the crosstalk is a dispersive guided mode of an ultrasonic signal from the CMUT propagating in a fluid-solid interface of the CMUT array. Each cell has an insulation layer deposited to the substrate. A cell membrane layer is deposited to the insulation layer, where the cell membrane layer has a vacuum gap therein. The cells further have an electrode layer deposited to a portion of the membrane layer, and a passivation layer deposited to the electrode layer, the cell membrane layer and to the insulation layer.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

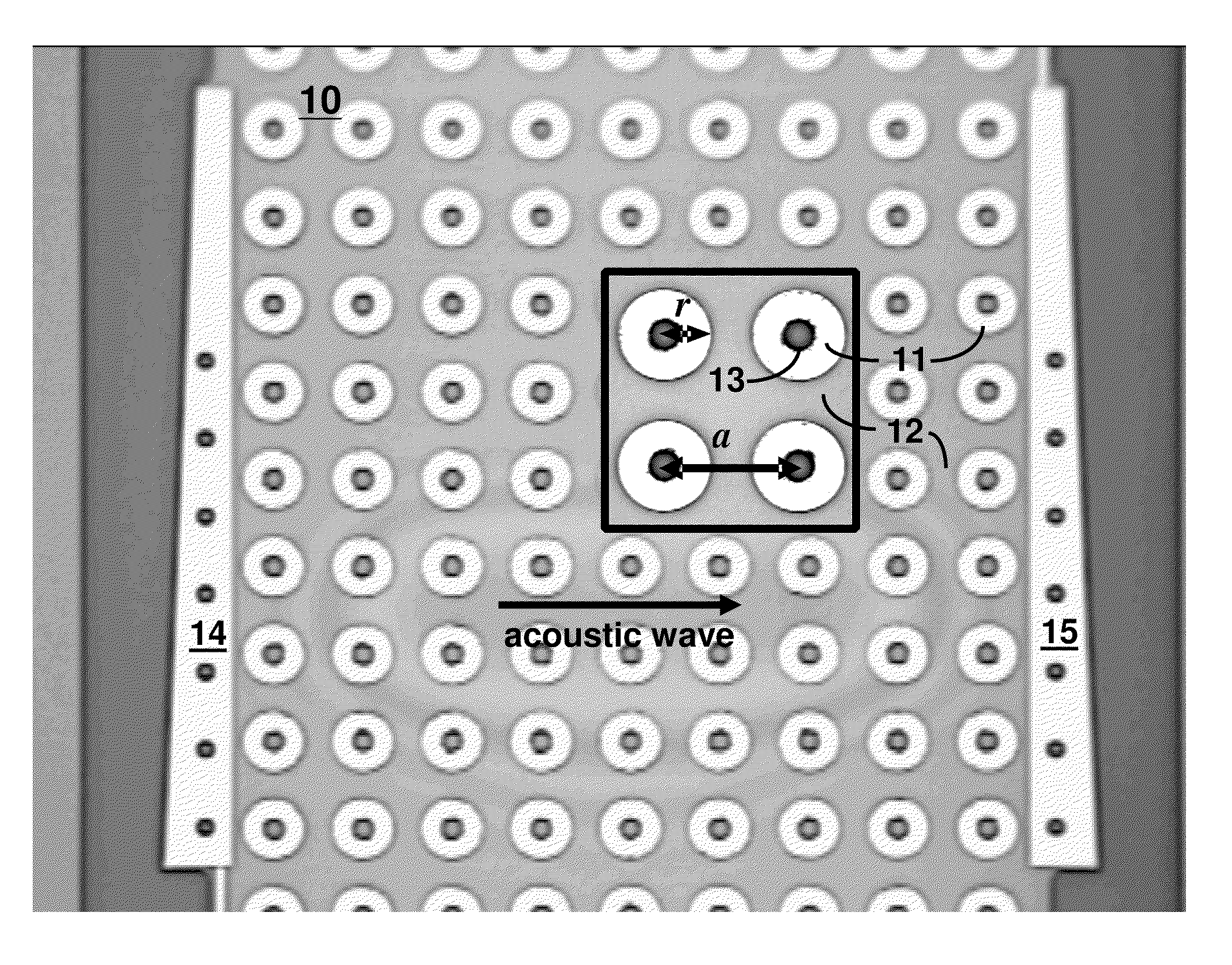

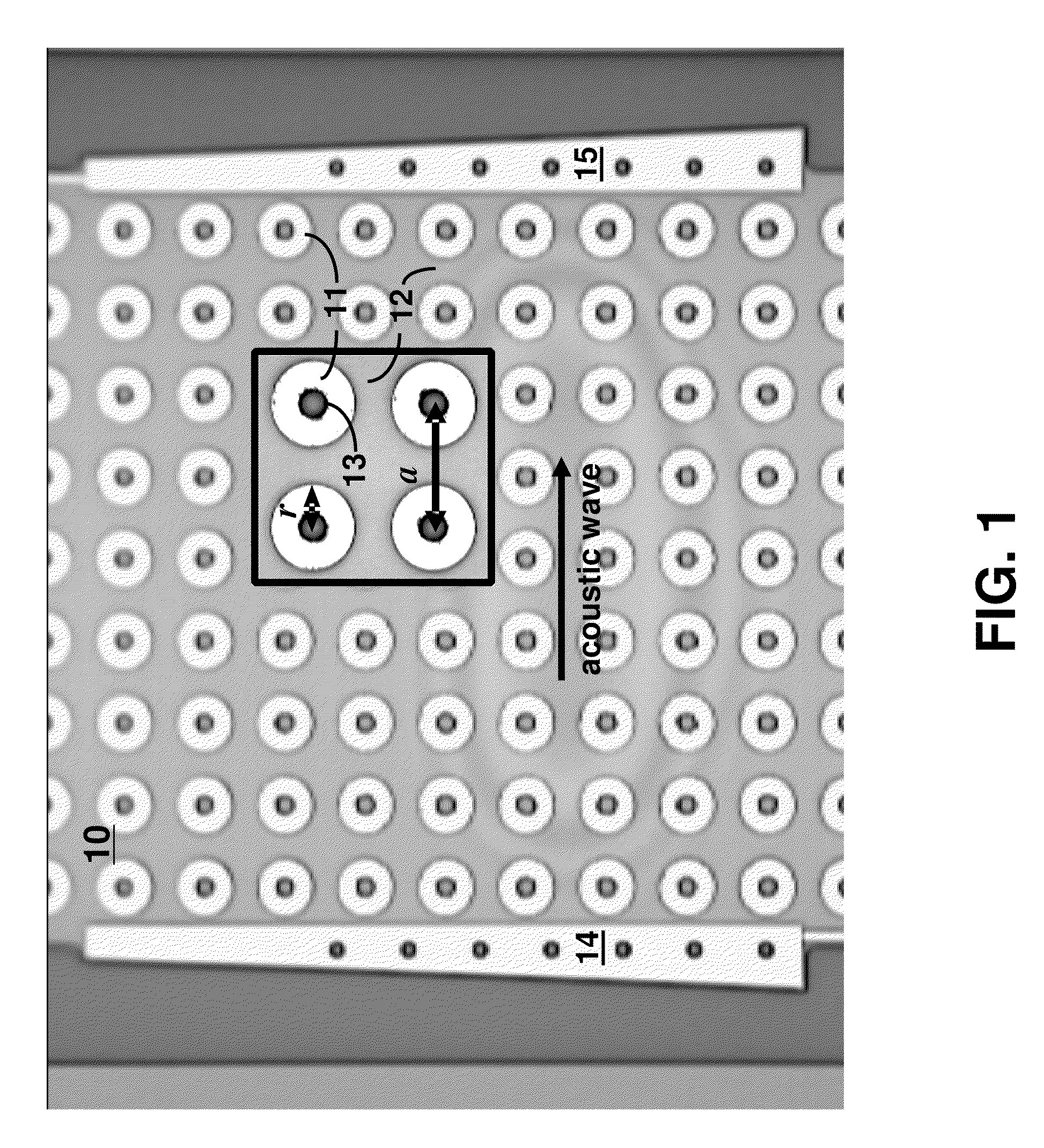

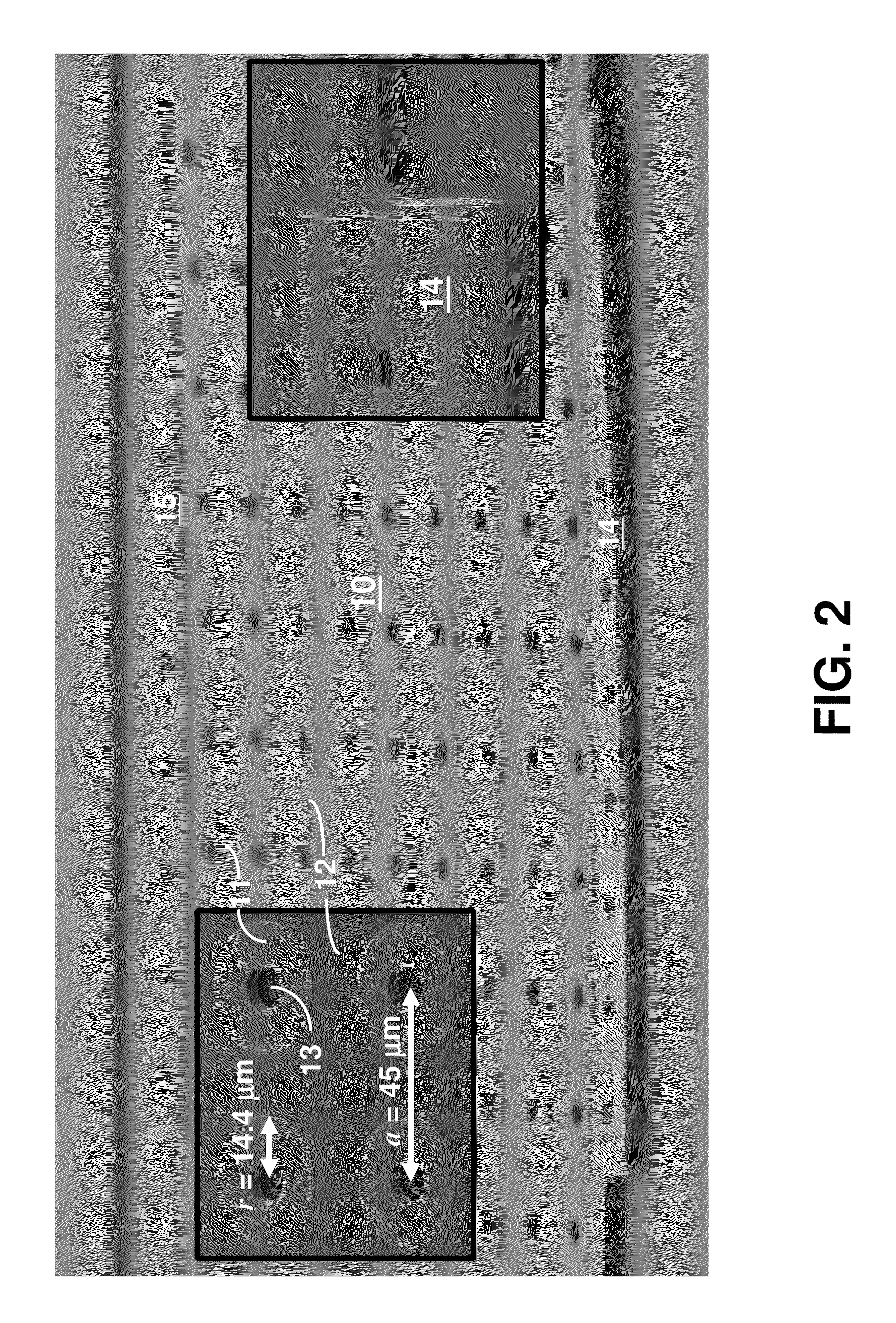

Microfabricated bulk wave acoustic bandgap device

ActiveUS7836566B1Piezoelectric/electrostrictive device manufacture/assemblyImpedence networksVacuum gapAcoustic wave

A microfabricated bulk wave acoustic bandgap device comprises a periodic two-dimensional array of scatterers embedded within the matrix material membrane, wherein the scatterer material has a density and / or elastic constant that is different than the matrix material and wherein the periodicity of the array causes destructive interference of the acoustic wave within an acoustic bandgap. The membrane can be suspended above a substrate by an air or vacuum gap to provide acoustic isolation from the substrate. The device can be fabricated using microelectromechanical systems (MEMS) technologies. Such microfabricated bulk wave phononic bandgap devices are useful for acoustic isolation in the ultrasonic, VHF, or UHF regime (i.e., frequencies of order 1 MHz to 10 GHz and higher, and lattice constants of order 100 μm or less).

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

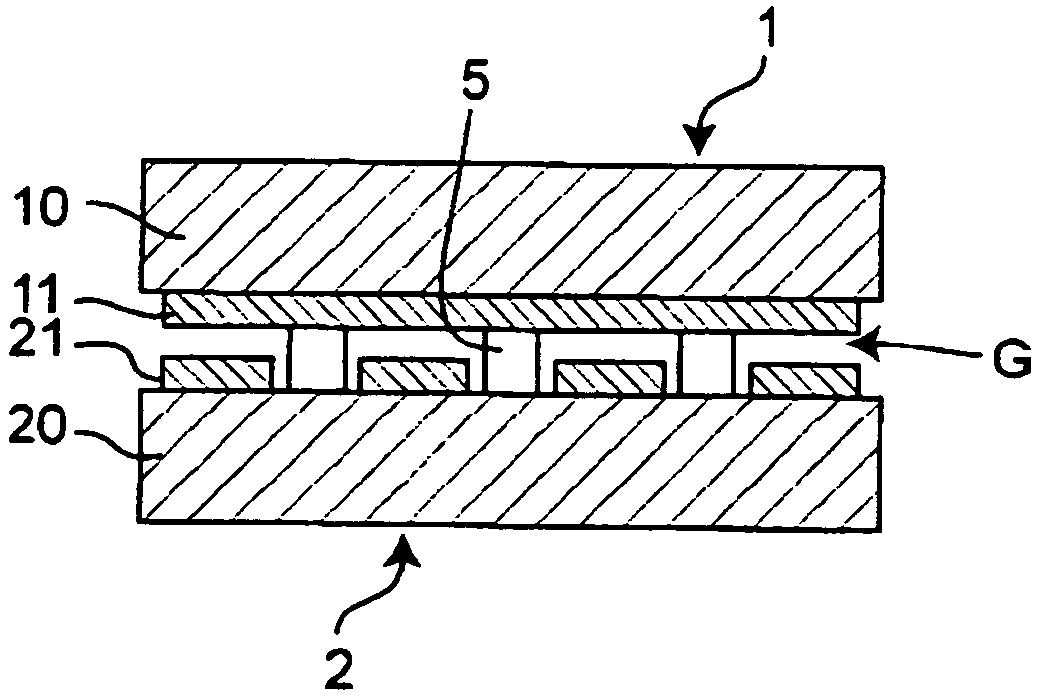

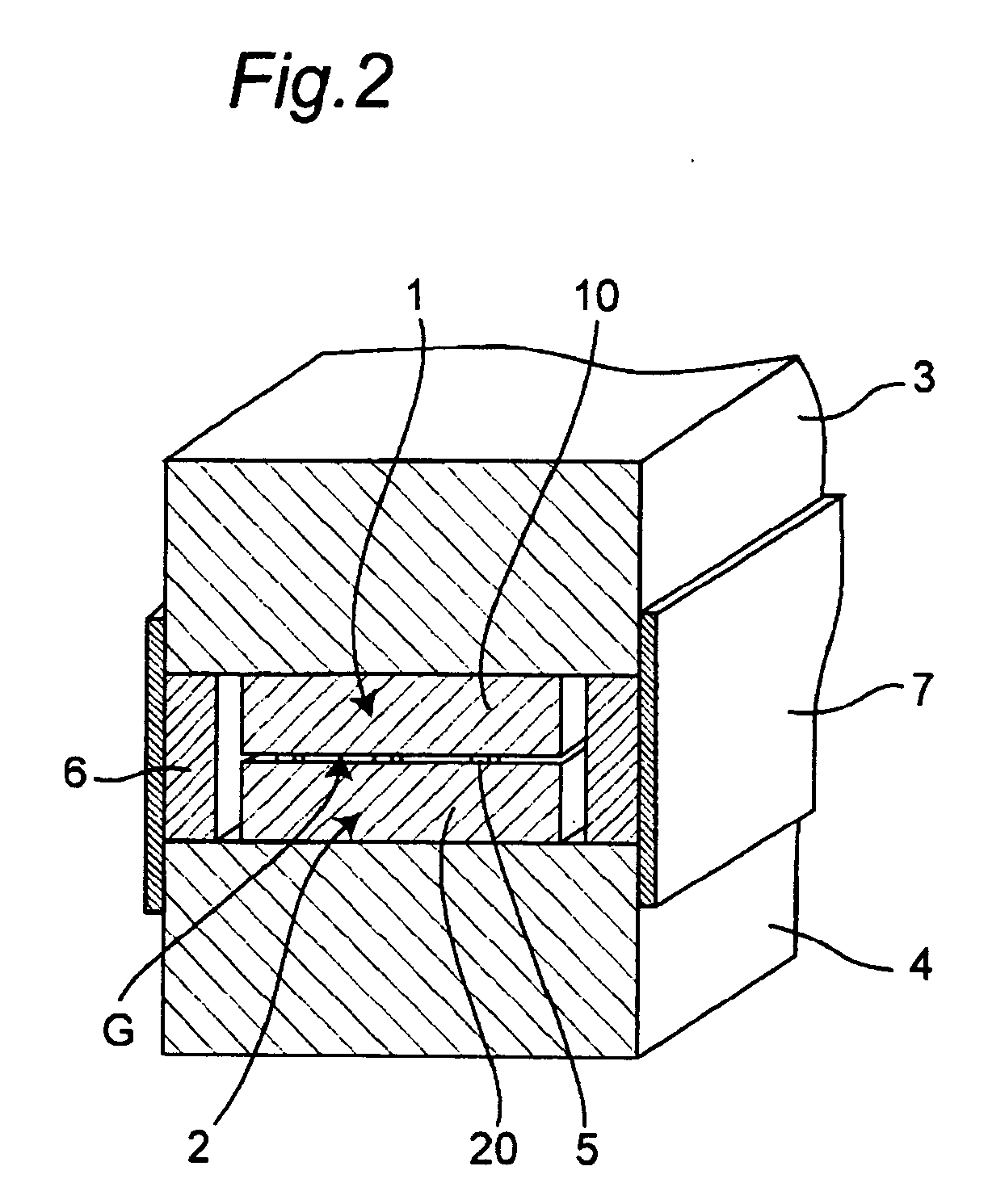

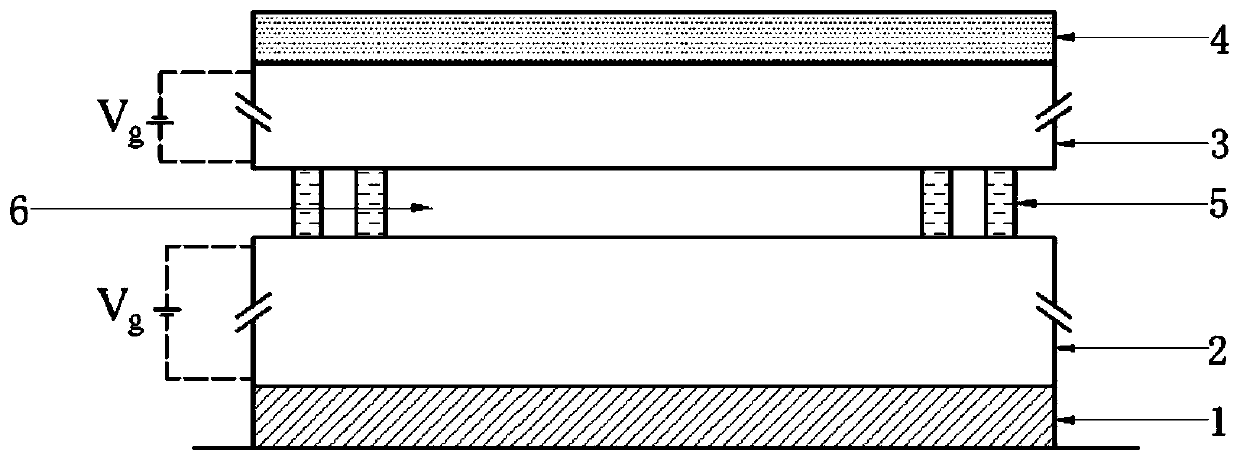

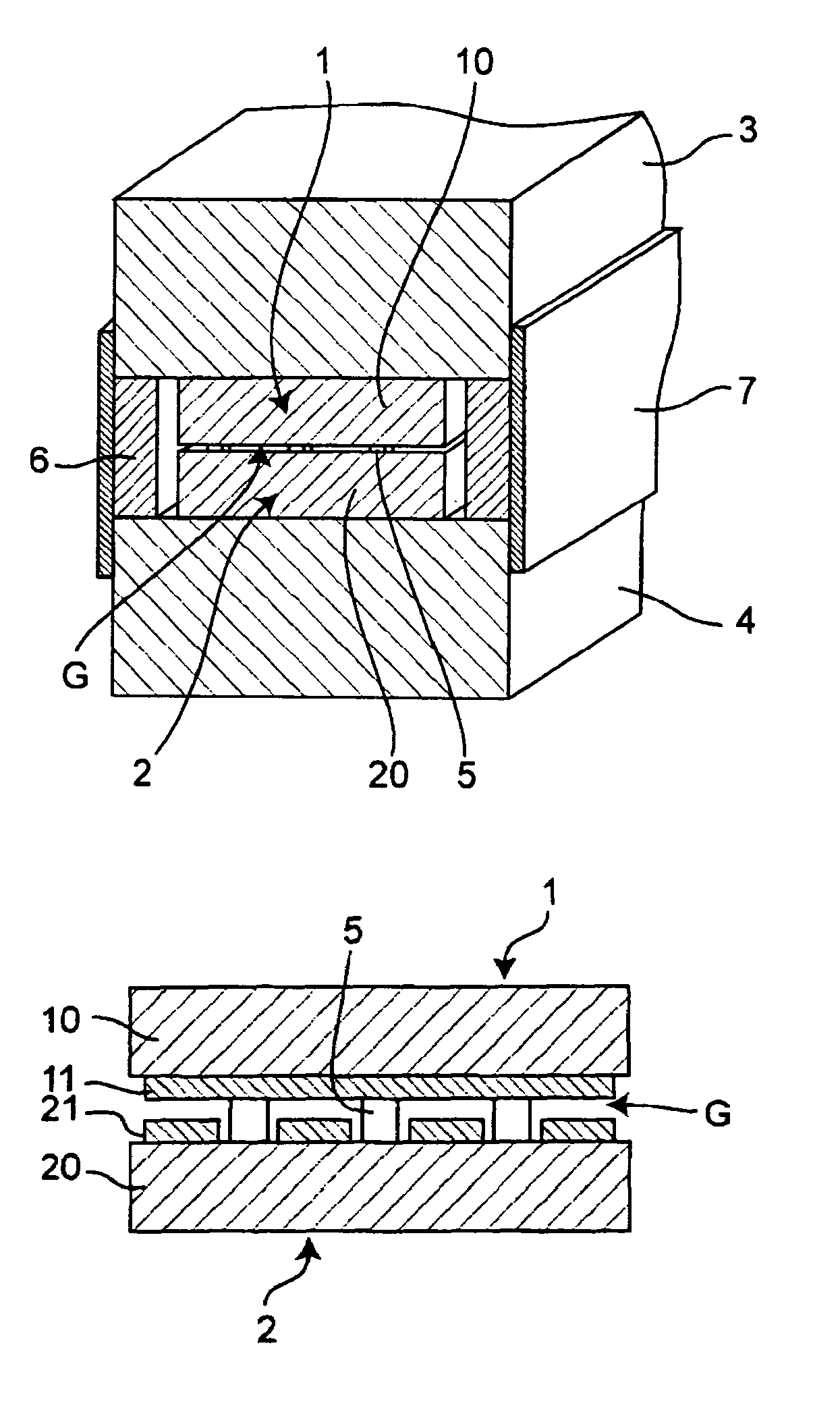

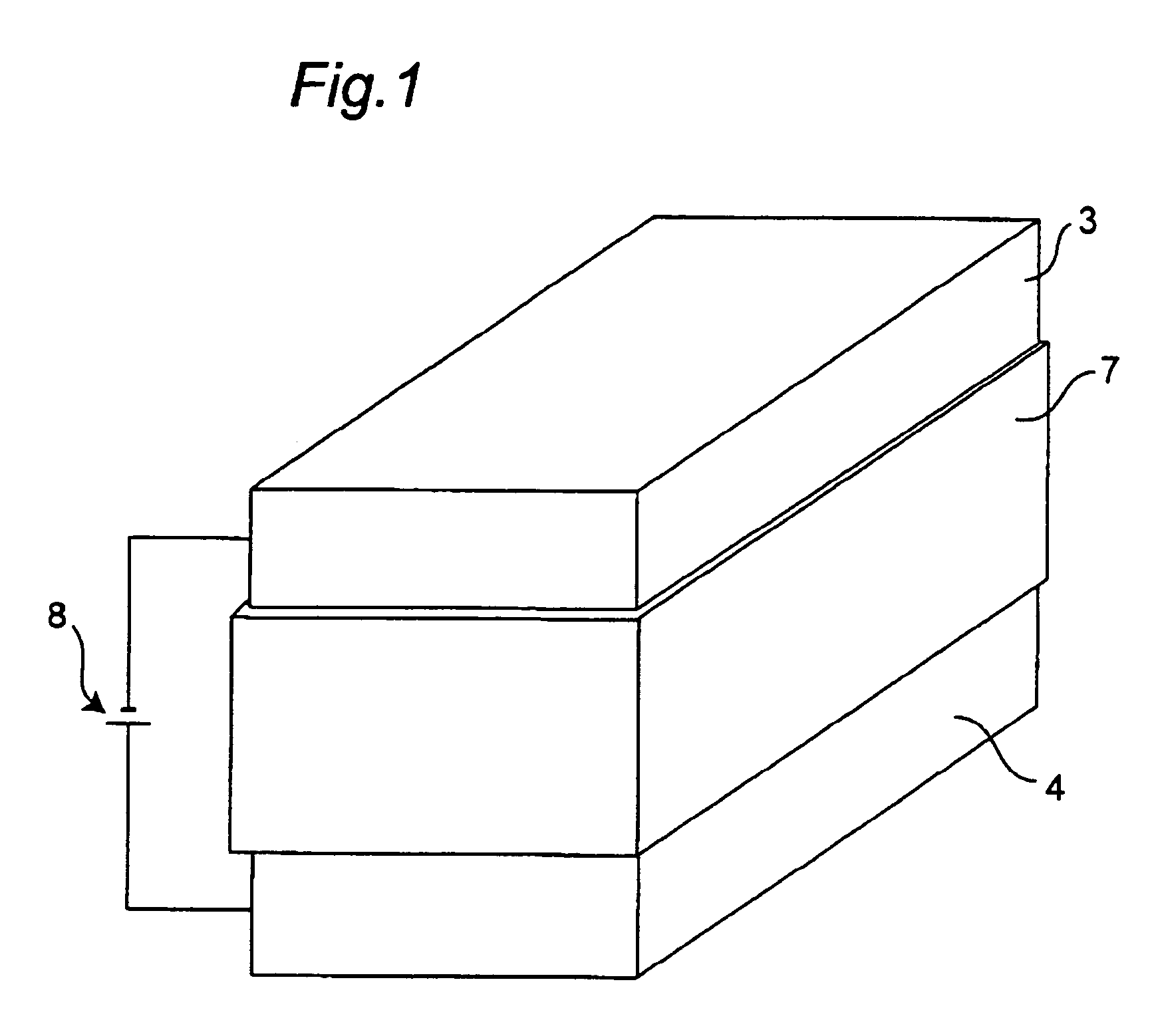

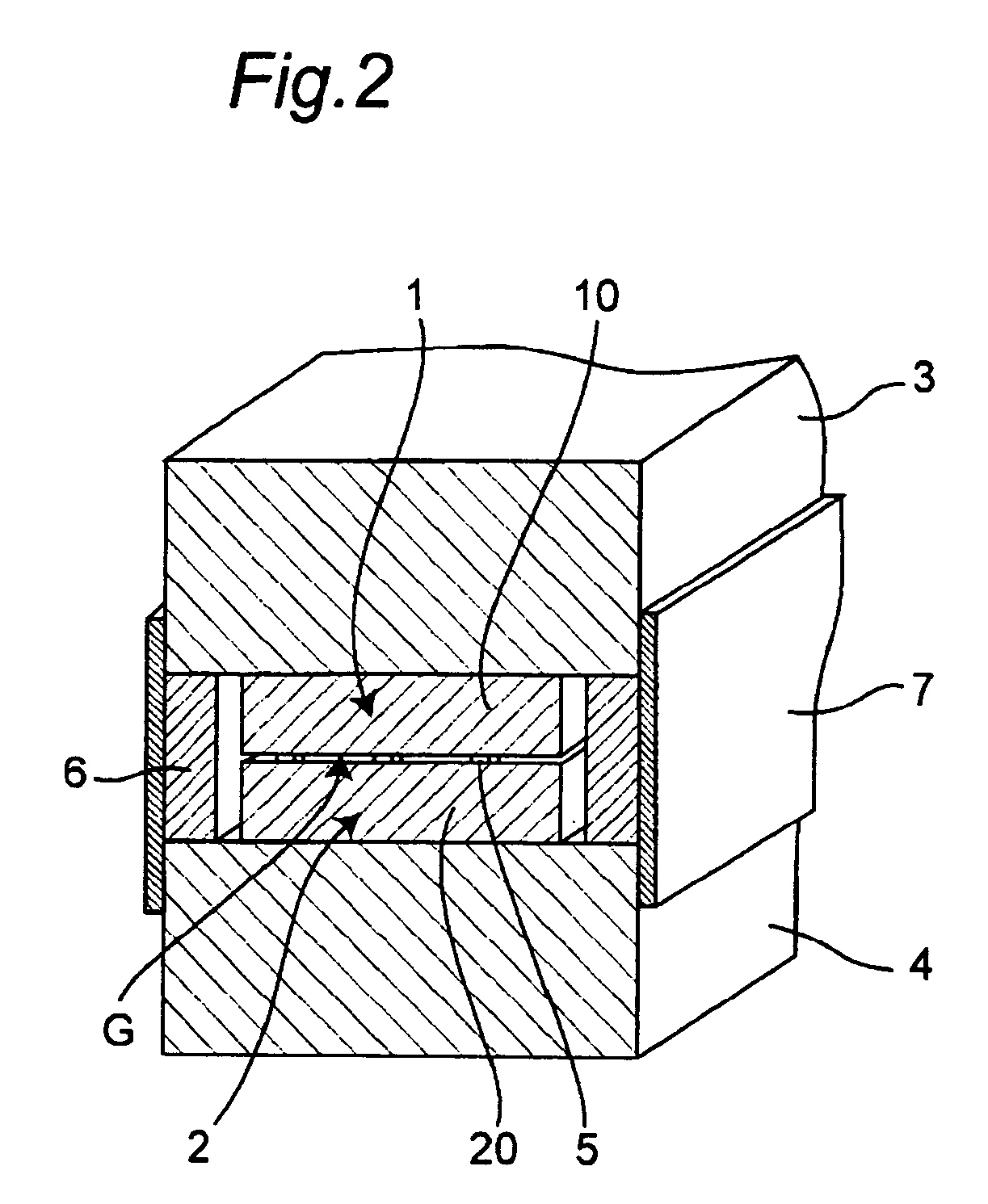

Electronic heat pump device, laser component, optical pickup and electronic equipment

InactiveUS20050110099A1Reduce amountLaser detailsSemiconductor/solid-state device detailsOptical pickupVacuum gap

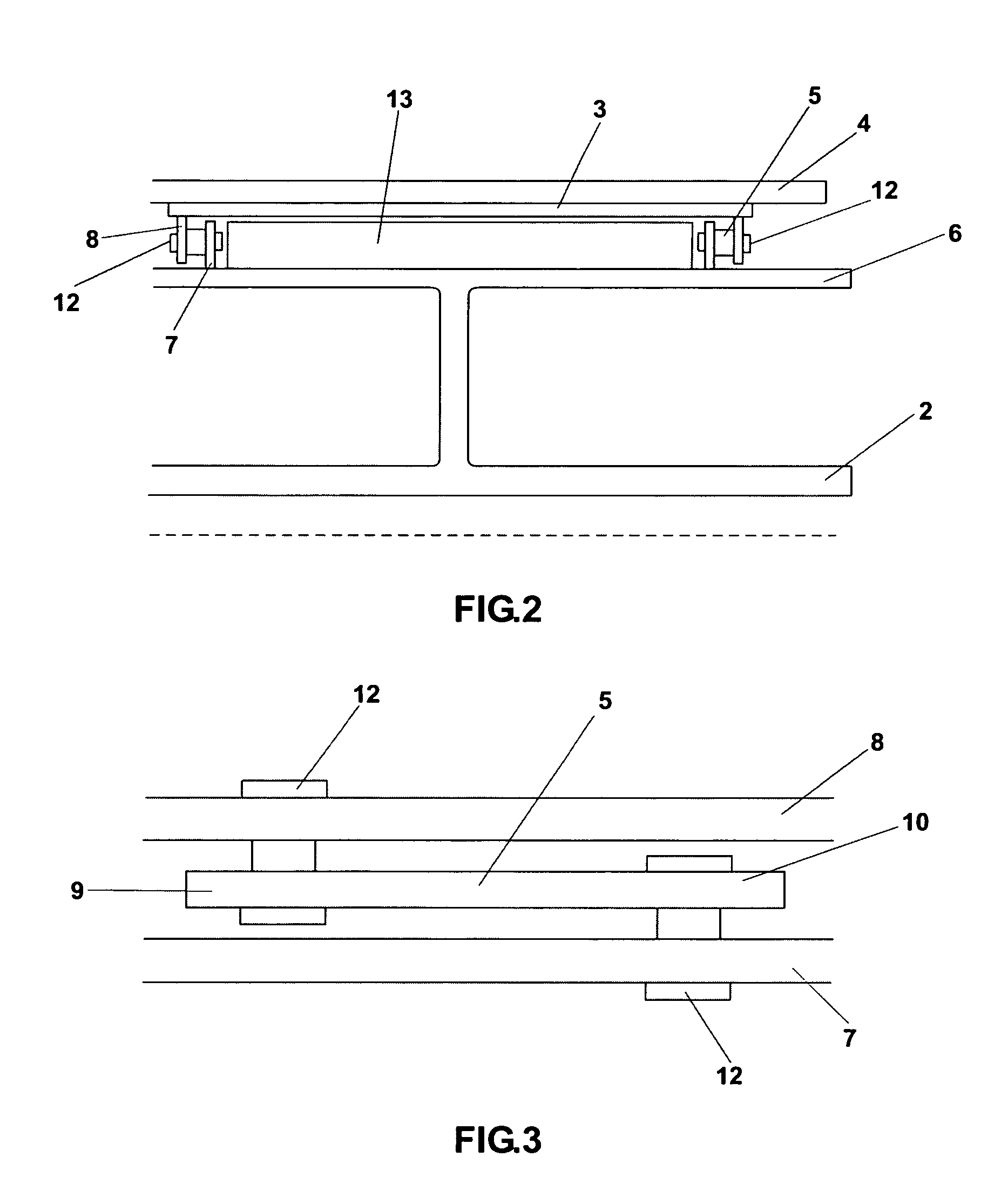

There is provided a small-size electronic heat pump device which is low in power consumption and which secures a vacuum gap without use of an additional circuit. The electronic heat pump device includes an emitter 1 and a collector 2. An electrically and thermally insulative spacer section 5 for keeping a space, i.e. vacuum gap G between an emitter electrode 11 and a collector electrode 21 constant is integrally formed in a semiconductor substrate 20 of the collector 2, which makes it possible to maintain the vacuum gap to be a specified space while a back flow of heat is prevented in a simple structure with a reduced number of component parts.

Owner:SHARP KK

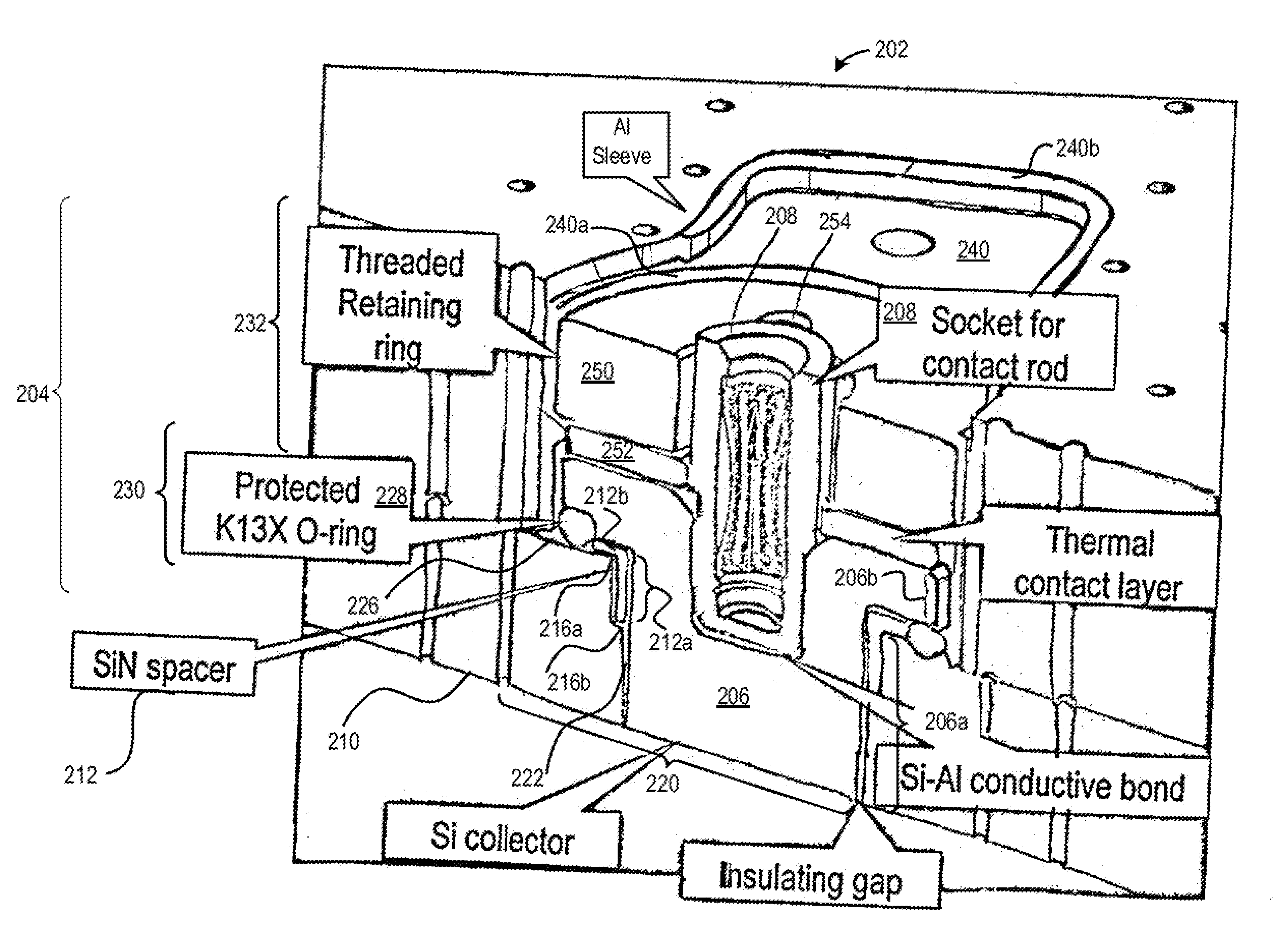

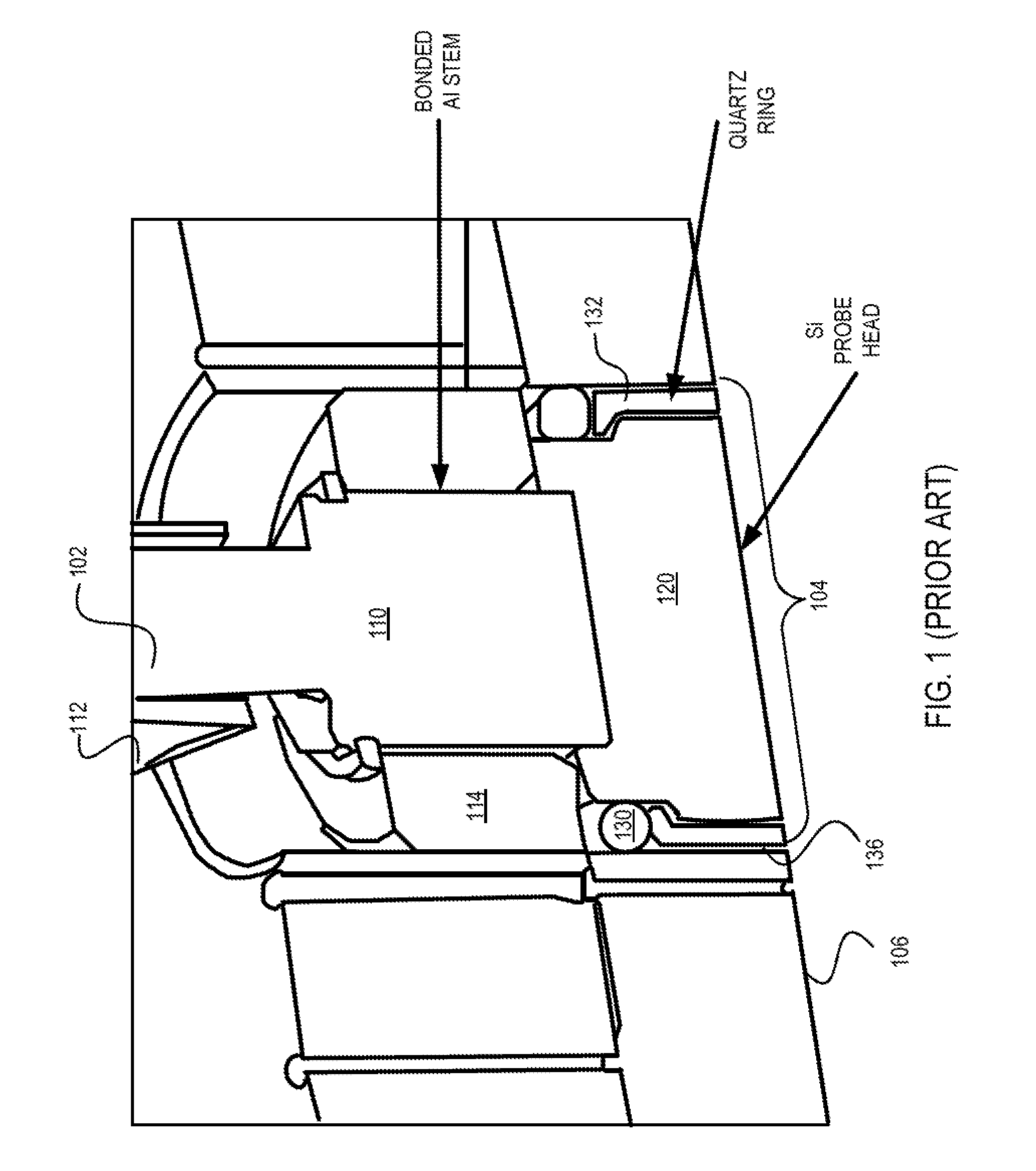

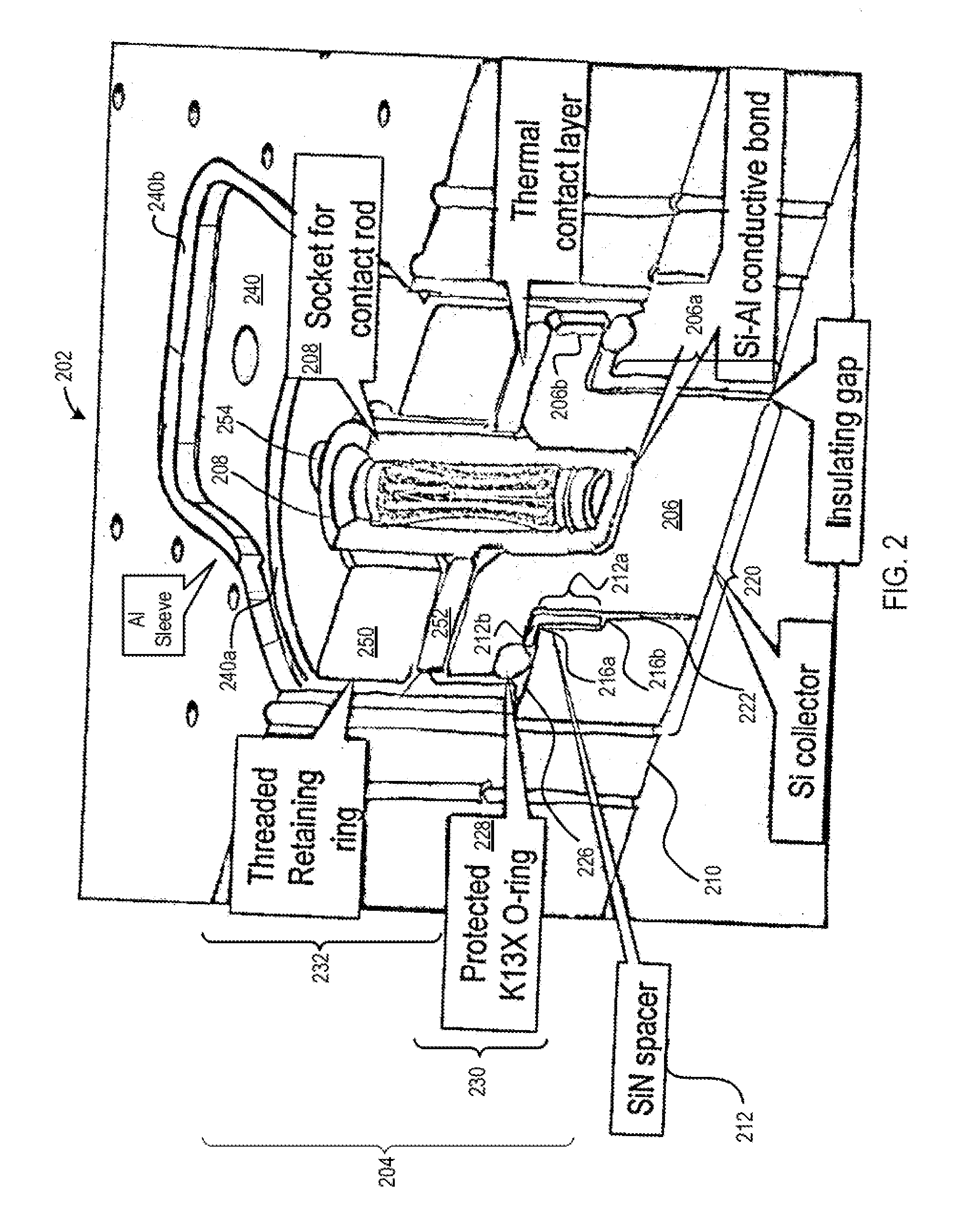

Plasma-facing probe arrangement including vacuum gap for use in a plasma processing chamber

ActiveUS20100007337A1Semiconductor/solid-state device testing/measurementCurrent/voltage measurementPlasma processingVacuum gap

An arrangement for measuring process parameters within a processing chamber is provided. The arrangement includes a probe arrangement disposed in an opening of an upper electrode. Probe arrangement includes a probe head, which includes a head portion and a flange portion. The arrangement also includes an o-ring disposed between the upper electrode and the flange portion. The arrangement further includes a spacer made of an electrically insulative material positioned between the head portion and the opening of the upper electrode to prevent the probe arrangement from touching the upper electrode. The spacer includes a disk portion configured for supporting an underside of the flange portion. The spacer also includes a hollow cylindrical portion configured to encircle the head portion. The spacer forms a right-angled path between the o-ring and an opening to the processing chamber to prevent direct line-of-sight path between the o-ring and the opening to the processing chamber.

Owner:LAM RES CORP

Vacuum device having a getter

A vacuum device, including a substrate and a support structure having a support perimeter, where the support structure is disposed over the substrate. In addition, the vacuum device also includes a non-evaporable getter layer having an exposed surface area. The non-evaporable getter layer is disposed over the support structure, and extends beyond the support perimeter, in at least one direction, of the support structure forming a vacuum gap between the substrate and the non-evaporable getter layer increasing the exposed surface area.

Owner:SAMSUNG ELECTRONICS CO LTD

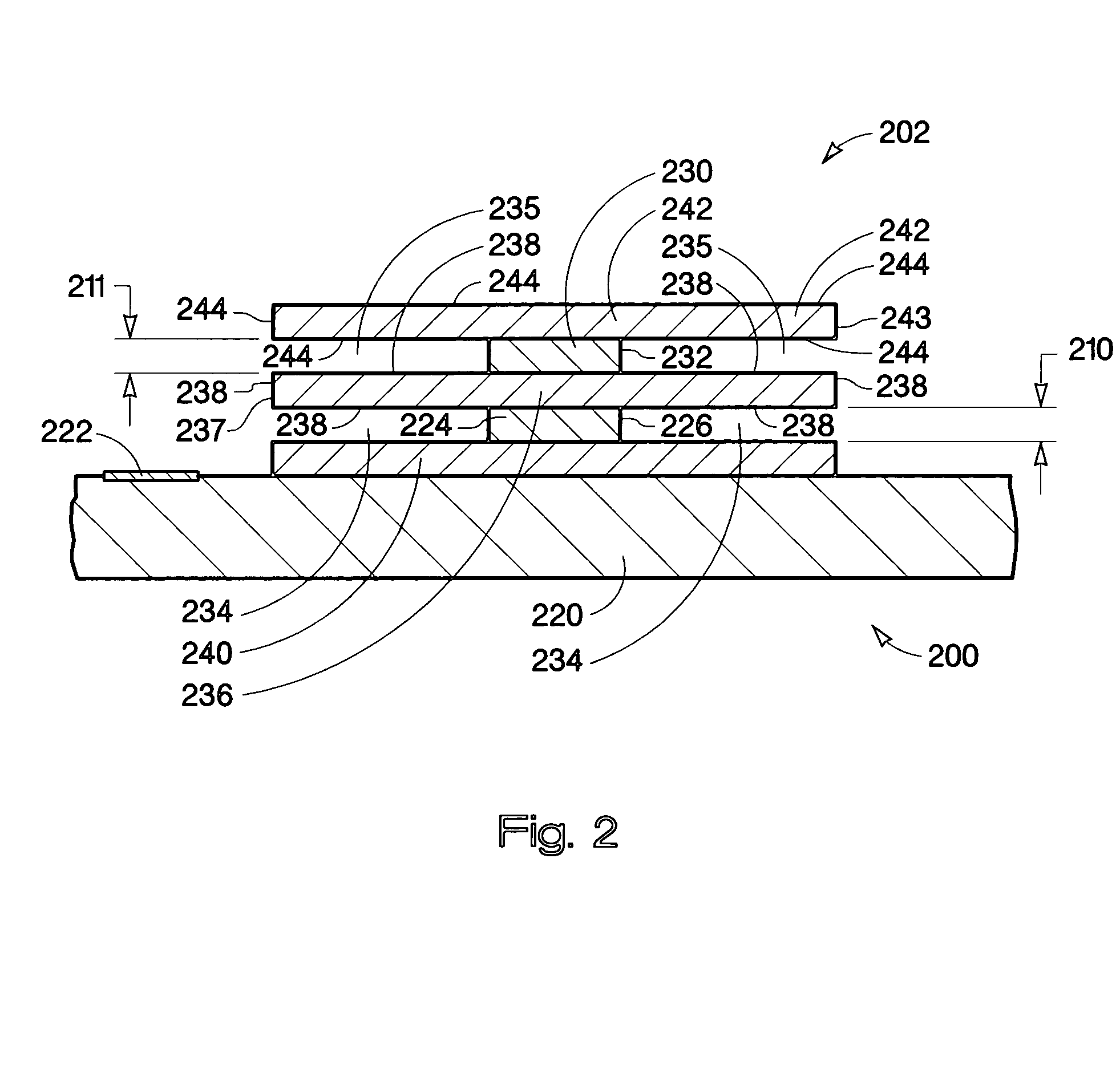

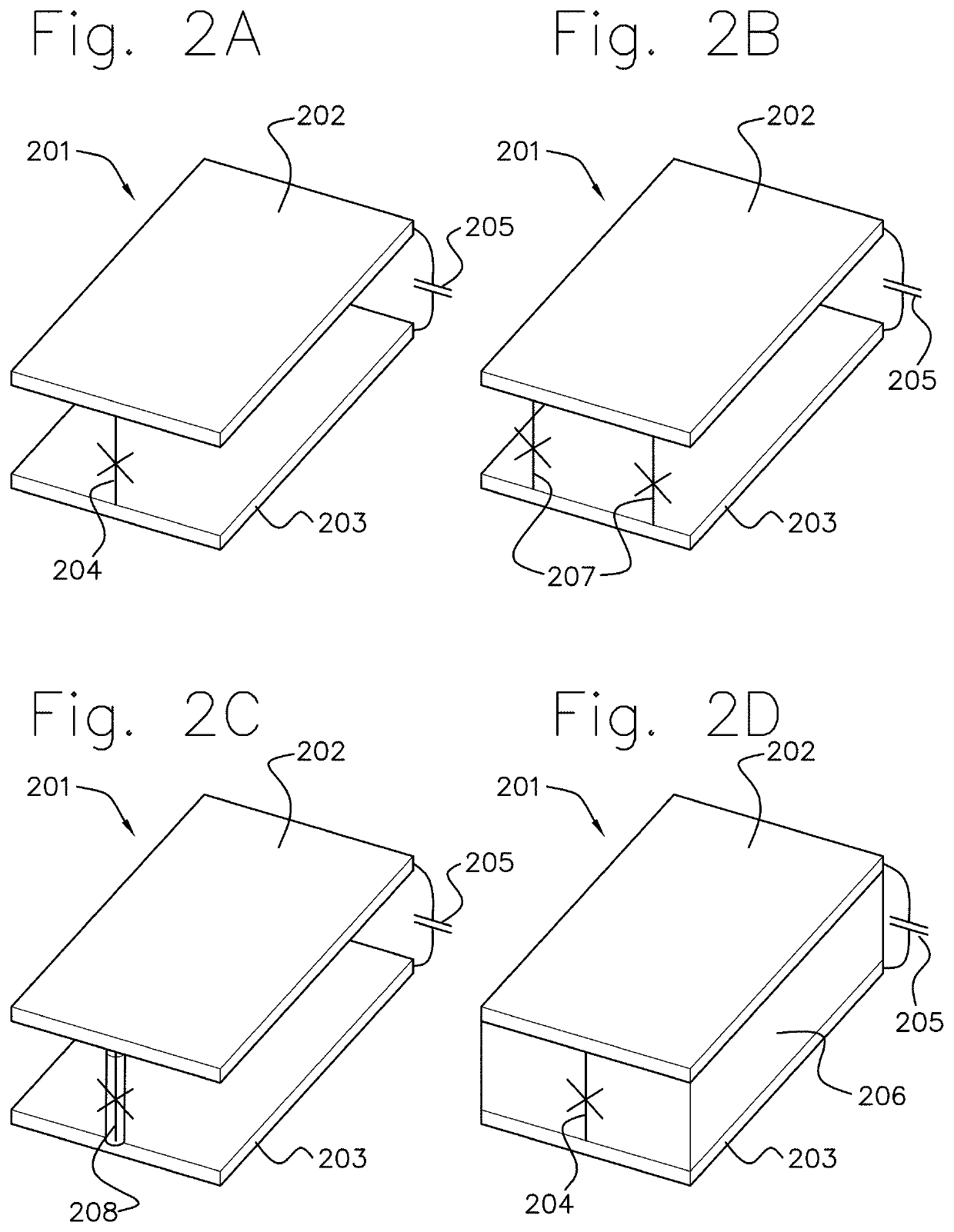

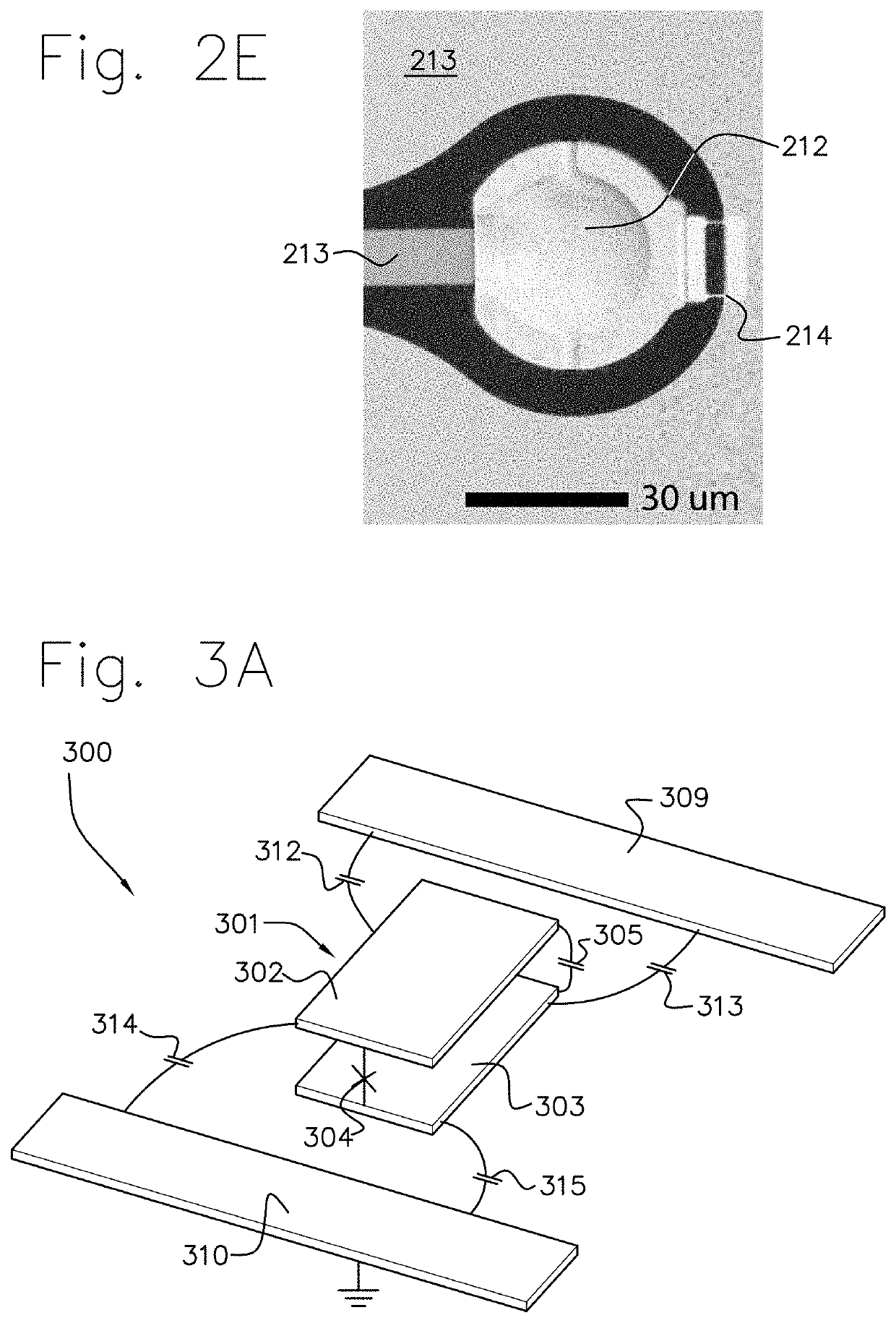

A qubit apparatus and a qubit system

ActiveUS20190385673A1Difficult to sizeEnhanced couplingQuantum computersSuperconductor detailsCapacitanceVacuum gap

A transmon qubit comprising a plate capacitor comprising a first plate (202) and a second plate (203) wherein the first plate is disposed opposite to at least a part of the second plate, wherein the first plate and the second plate are connected via a nonlinear inductance element (304), and a capacitance (205) formed between the first plate and the second plate, wherein the first plate and the second plate are configured to form a vacuum gap capacitor.

Owner:TECH UNIV DELFT

Method for fabricating a structure of interconnections comprising an electric insulation including air or vacuum gaps

The invention concerns a method for fabricating a damascene type structure of interconnections on a semiconductor device. It includes the following steps:formation of a first level of conductors in a first electric insulating layer and of a second level of conductors in a second electric insulating layer, with the conductors in the first level being arranged with a pre-determined spacing in order to allow, in a later step, the formation of air or vacuum gaps between the conductors in the first level,elimination of the second electric insulating layer,elimination, at least partial, of the first electric insulating layer in order to eliminate at least some parts of the first layer corresponding to the gaps to be formed,deposit, over the structure thus obtained, of a material with low permittivity, with this deposit not filling the space between the conductors in the first level whose spacing has been planned to allow the formation of gaps.

Owner:STMICROELECTRONICS SRL +1

Non-cooling type ultrared micrometering kampometer

ActiveCN101718587AStable structureWill not warpTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectricityVacuum gap

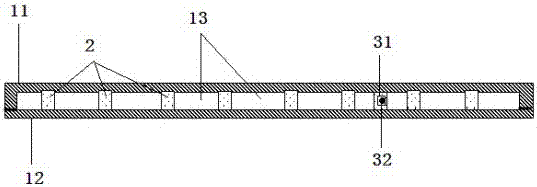

The invention provides a non-cooling type ultrared micrometering kampometer comprising a substrate base, a sheet bright surface and two L-shaped bridge arms arranged at the opposite sides of the bright surface. One end part of either bridge arm is electrically connected with the bright surface; the other end part is connected with the base by an electric connecting column; a vacuum gap layer is formed between the bright surface and the substrate base the upper surface of which is provided with a reflecting layer; the bright surface sequentially comprises an absorption layer, a heat-sensitive layer and a passivating layer from bottom to top; each bridge arm sequentially comprises a thermal resistance layer and a conductance layer from bottom to top; and the absorption layer and the passivating layer of the bright surface have the similar thickness of 2800-3200 so that crushing stress generated by the absorption layer and tensile stress generated by the passivating layer are easier to balance; and the structure of the bright surface is extremely stable to avoid warping, deforming, fracturing or demolding. The invention greatly lowers the process difficulty.

Owner:北方广微科技有限公司

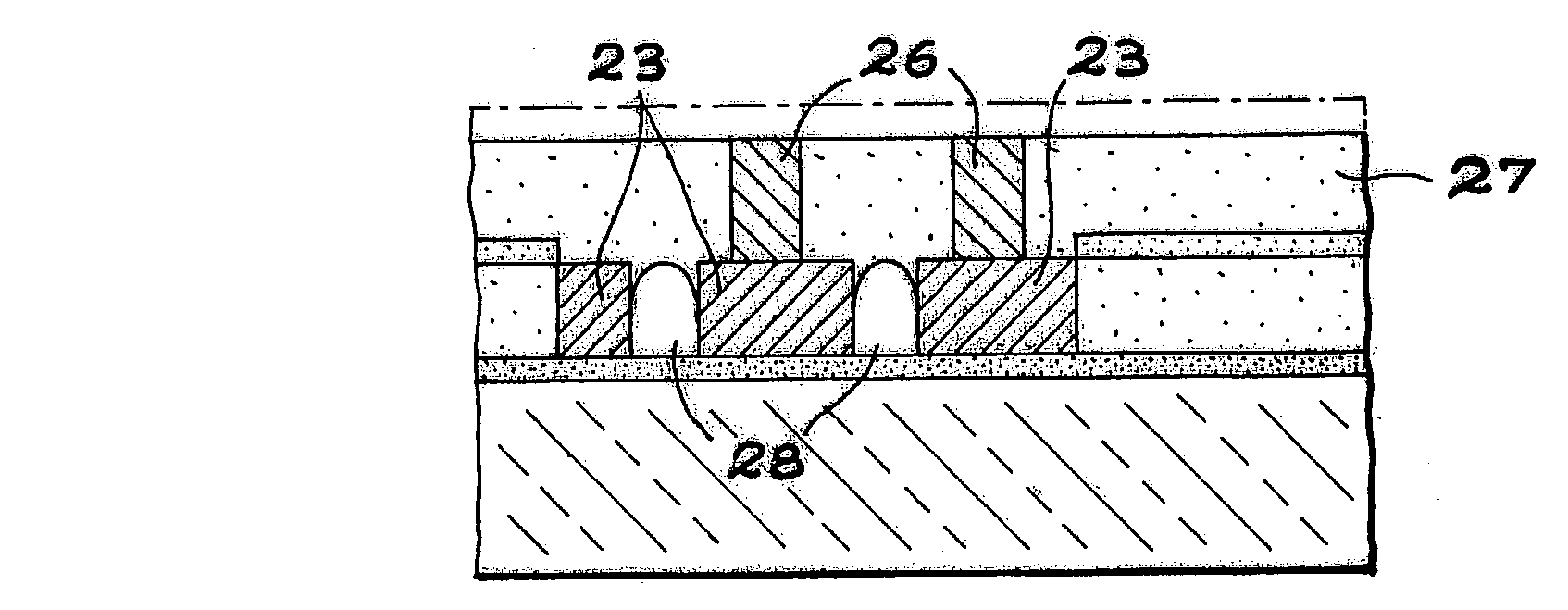

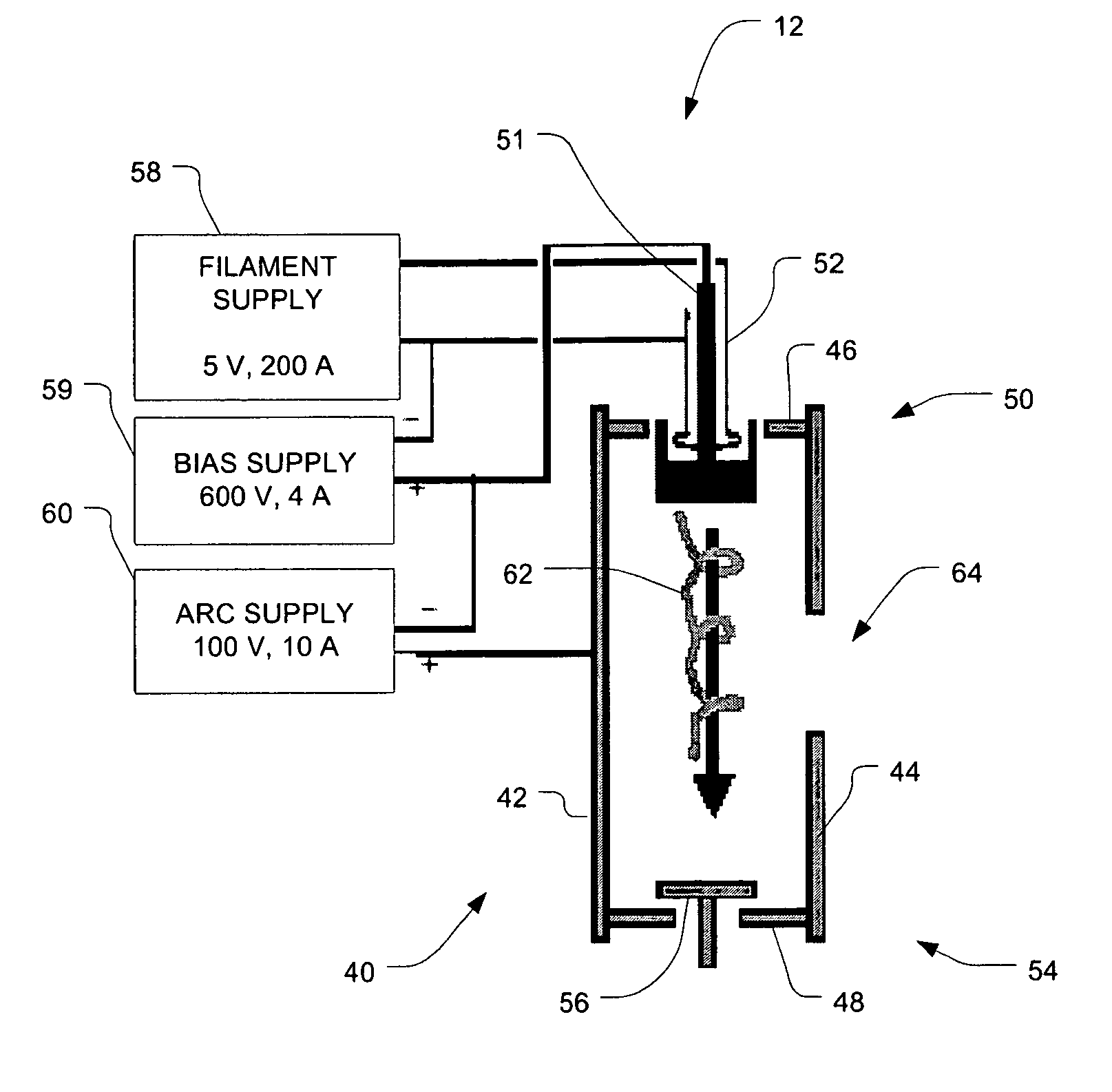

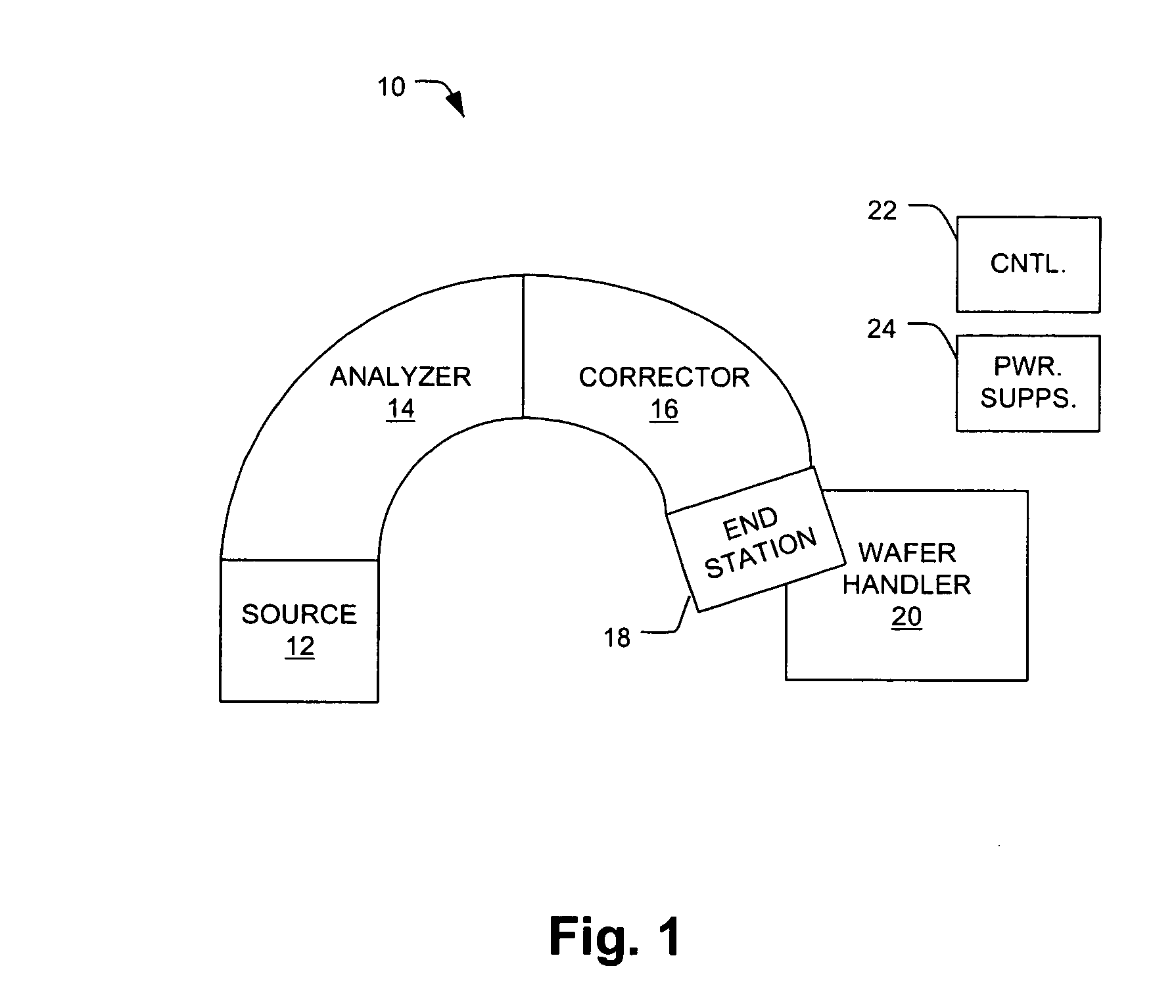

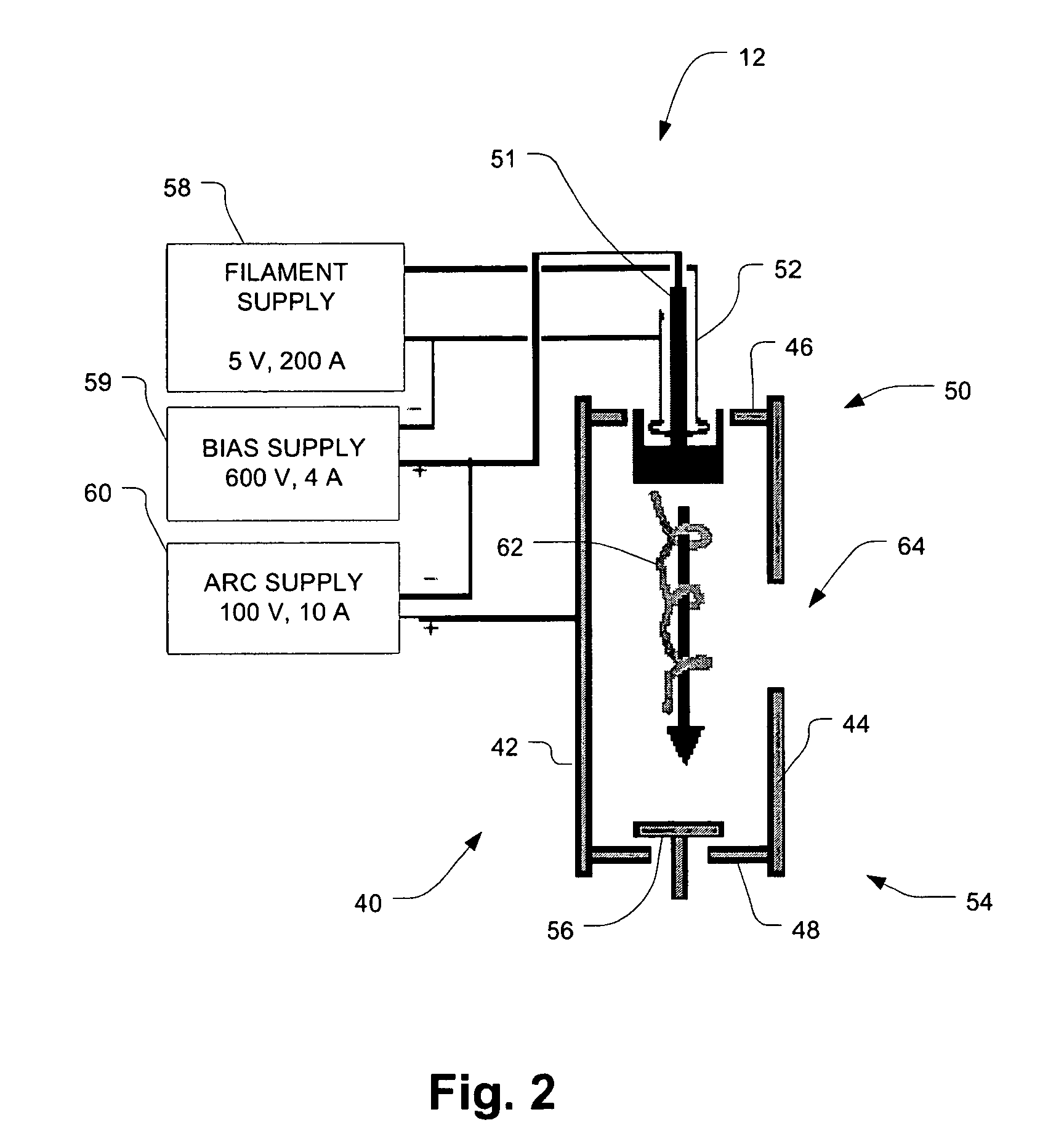

Source arc chamber for ion implanter having repeller electrode mounted to external insulator

ActiveUS7102139B2Low efficiencyReducing fractionationMaterial analysis by optical meansElectric arc lampsVacuum gapEngineering

An ion implanter has a source arc chamber including a conductive end wall at a repeller end of the arc chamber, the end wall having a central portion surrounding an opening. A ceramic insulator is secured to an outer surface of the end wall, such as by peripheral screw threads engaging mating threads at the periphery of a recessed area of the end wall. A conductive repeller has a narrow shaft secured to the insulator and extending through the end wall opening, and a body disposed within the source arc chamber adjacent to the end wall. The end wall, insulator and repeller are configured to form a continuous vacuum gap between the central portion of the end wall and (i) the repeller body, (ii) the repeller shaft, and (iii) the insulator. The insulator interior surface can have a ridged cross section.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Thermal control skin capable of adjusting equivalent emissivity by voltage and application thereof in spacecraft

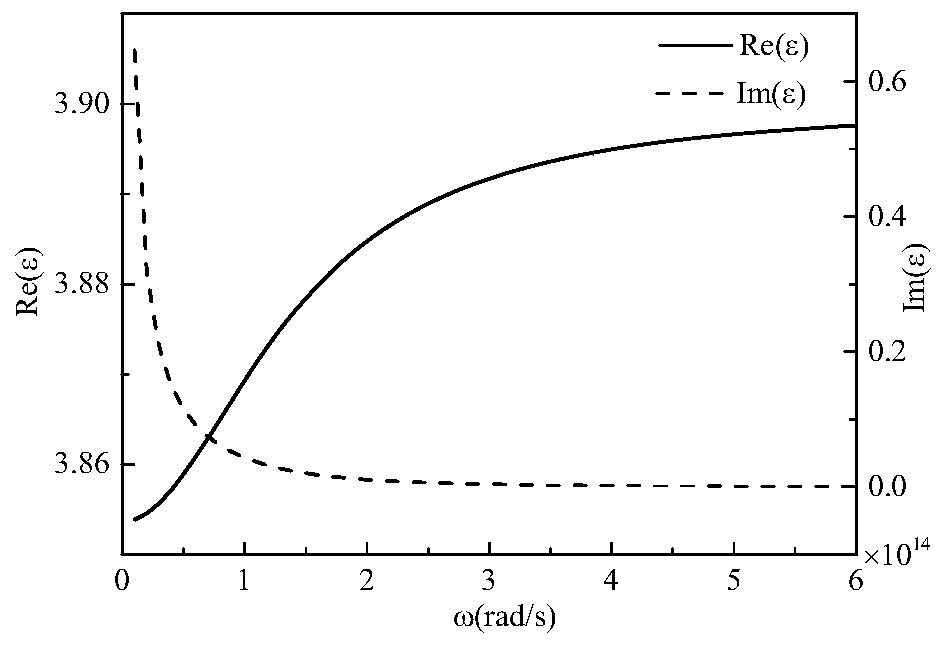

ActiveCN109870863AIncrease spaceIncrease freedomDoors/windowsNon-linear opticsMicro nanoSemiconductor structure

The present invention relates to a thermal control skin capable of adjusting equivalent emissivity by voltage and an application thereof in a spacecraft. The thermal control skin comprises a substrate, an inner layer, an outer layer and a protecting layer from bottom to top, and a spacer is arranged between the inner layer and the outer layer. The spacer forms a vacuum gap with a spacing of micro-nano scale between the inner layer and the outer layer. The inner layer and / or the outer layer comprises a metal-insulator-semiconductor structure, and direct current adjustable voltage is loaded between the semiconductor and the metal in the structure. The protecting layer has high infrared emissivity or both high infrared emissivity and low solar spectral absorptivity. On one hand, the thermal control skin has good adaptability to a space environment, and solves the problem of performance degradation caused by direct exposure of electrochromic material to the space environment, and on the other hand, the thermal control skin can provide a large emissivity adjustment range and can be applied to the spacecraft.

Owner:HARBIN INST OF TECH

Method of making a getter structure

A method of manufacturing a getter structure, including forming a support structure having a support perimeter, where the support structure is disposed over a substrate. In addition, the method includes forming a non-evaporable getter layer having an exposed surface area, where the non-evaporable getter layer is disposed over the support structure, and includes forming a vacuum gap between the substrate and the non-evaporable getter layer. The non-evaporable getter layer extends beyond the support perimeter of the support structure increasing the exposed surface area.

Owner:SAMSUNG ELECTRONICS CO LTD

Cooling container for the preventive frozen burst or shape alteration

The present invention relates to a cooling utensil, which is a proof of freezing-crack and distortion. More particularly, an internal cavity of the utensil is fully filled the water to freeze in the freezer for cooling the serving food, such as a law fish, fruit, cold noodle or beer to feel fresh and tasty. For using the cooling bowl, the cooling cavity is filled the water or coolant for freezing. The cooling bowl is using for serving food. The cooling cavity is formed between the upper part and the lower part. The lower part is used a base to support the upper part. The upper part has same shape and size of the lower part for placing over the lower part. The elastic plate having flexibility and elastically restoring force is attached to the lower part, the upper part for assembling. Further, the cooling bowl having a cooling cavity is filled the water or coolant and freeze to use serving food. The lower part has built a dual wall to form a vacuum gap between the inner wall and the outer wall for insulation, so that the outer wall has no condensed water gained. The elastic tube (4k) having elastically restoring force is inserted through the water inlet. The plug bolt mounted at the mouth of the water inlet, for sealing the water filled cavity.

Owner:金龙根

Method for preparing explosive composite pipe in local vacuum environment

PendingCN113231728AAvoid local defect problemsExplosive Freedom of ChoiceMetal working apparatusTubular articlesDetonatorTEX-explosive

The invention provides a method for preparing an explosive composite pipe in a local vacuum environment. The method comprises the following steps of: coaxially arranging a first to-be-composited pipe, a second to-be-composited pipe and a pvc pipe from inside to outside, and filling explosive and a detonator between the pvc pipe and the second to-be-composited pipe to form an explosive device of a to-be-welded pipe; sealing the two ends of a gap between the first to-be-composited pipe and the second to-be-composited pipe by using sealing strips, and vacuumizing to form a vacuum gap environment; and detonating the explosive device, and welding and combining the to-be-composited pipes by utilizing high pressure generated by explosion of the explosive to obtain the high-quality explosive composite pipe. According to the method for preparing the explosive composite pipe in the local vacuum environment, the phenomenon that in a traditional preparation method, large-area melting of a composite pipe bonding interface occurs due to the fact that gap air is not exhausted in time is effectively eradicated; the bonding strength of the explosive composite pipe is obviously improved; and compared with a traditional explosive welding method which needs to consider gap exhaust, the method has the advantage that the explosive velocity of the explosive can be selected more freely.

Owner:ANHUI UNIV OF SCI & TECH

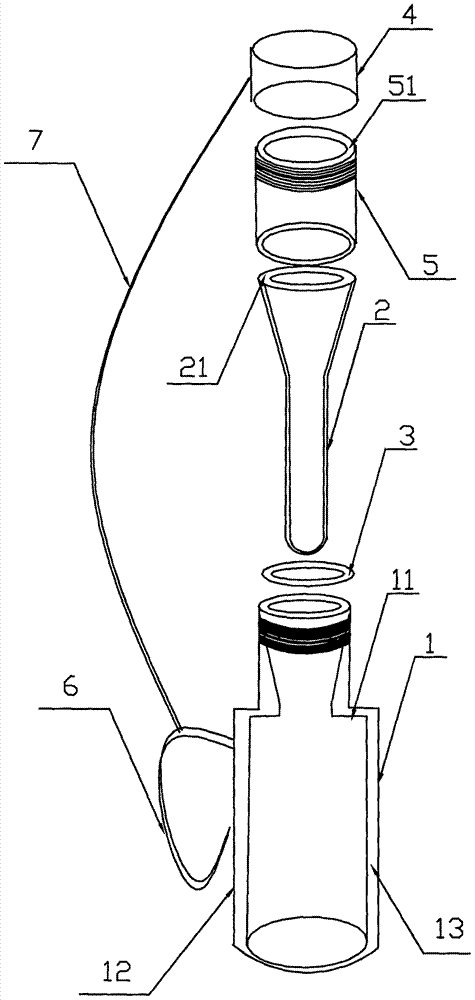

Heat preservation type semen collecting cup for dog

The invention relates to a heat preservation type semen collecting cup for a dog. The heat preservation type semen collecting cup comprises a cup body, a semen collecting tube, a seal ring, a top lid and a cup body neck sleeve. The cup body comprises a cup body inner container, a cup body shell and a vacuum gap between the cup body inner container and cup body shell. The lower portion of the cup body inner container is cylindrical, and the neck of the cup body inner container is a circular truncated cone shape with a wide upper portion and a narrow lower portion. The upper portion of the semen collecting tube is in a shape of a circular truncated cone and is matched with the neck of the cup body inner container in shape and size. The seal ring is a hollow cake-shaped rubber ring. The neck of the cup body shell is provided with a thread. The cup body neck sleeve and the neck of the cup body shell are matched in size and shape. The inner surface of the top lid is provided with a thread. The inner surface of the lower end of the cup body neck sleeve and the outer surface of the upper end of the cup body neck sleeve are respectively provided with threads. Compared with the prior art, the heat preservation type semen collecting cup is simple, small and exquisite in structure and convenient to use, and low-temperature damage caused in semen collecting operation processing by adopting a dog massaging method and in semen transporting process can be avoided.

Owner:QINGDAO AGRI UNIV

Electronic heat pump device, laser component, optical pickup and electronic equipment

InactiveUS7211891B2Reduce amountLaser detailsEnergy efficient heating/coolingOptical pickupElectricity

Owner:SHARP KK

Vacuum device having a getter

A vacuum device, including a substrate and a support structure having a support perimeter, where the support structure is disposed over the substrate. In addition, the vacuum device also includes a non-evaporable getter layer having an exposed surface area. The non-evaporable getter layer is disposed over the support structure, and extends beyond the support perimeter, in at least one direction, of the support structure forming a vacuum gap between the substrate and the non-evaporable getter layer increasing the exposed surface area.

Owner:SAMSUNG ELECTRONICS CO LTD

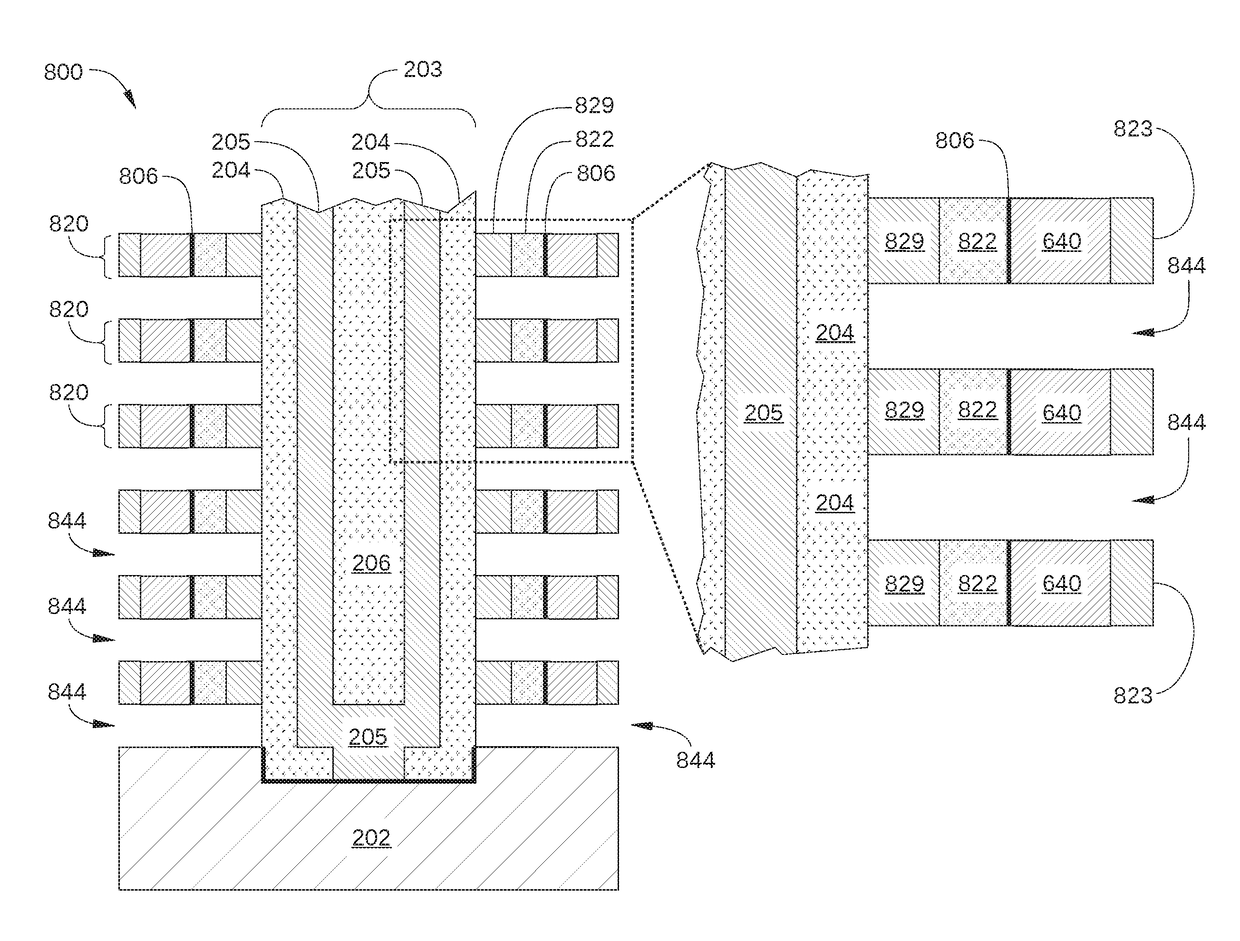

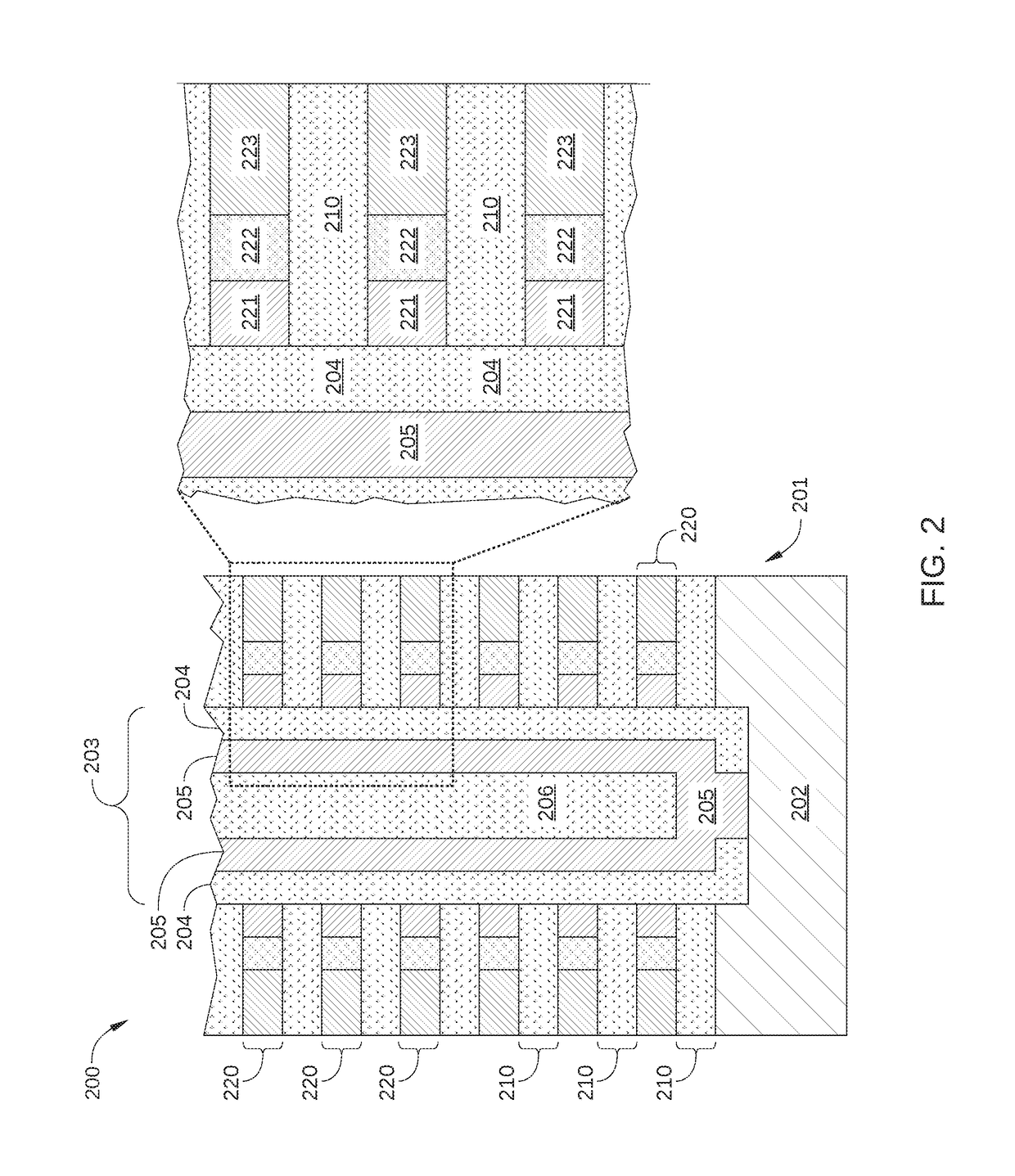

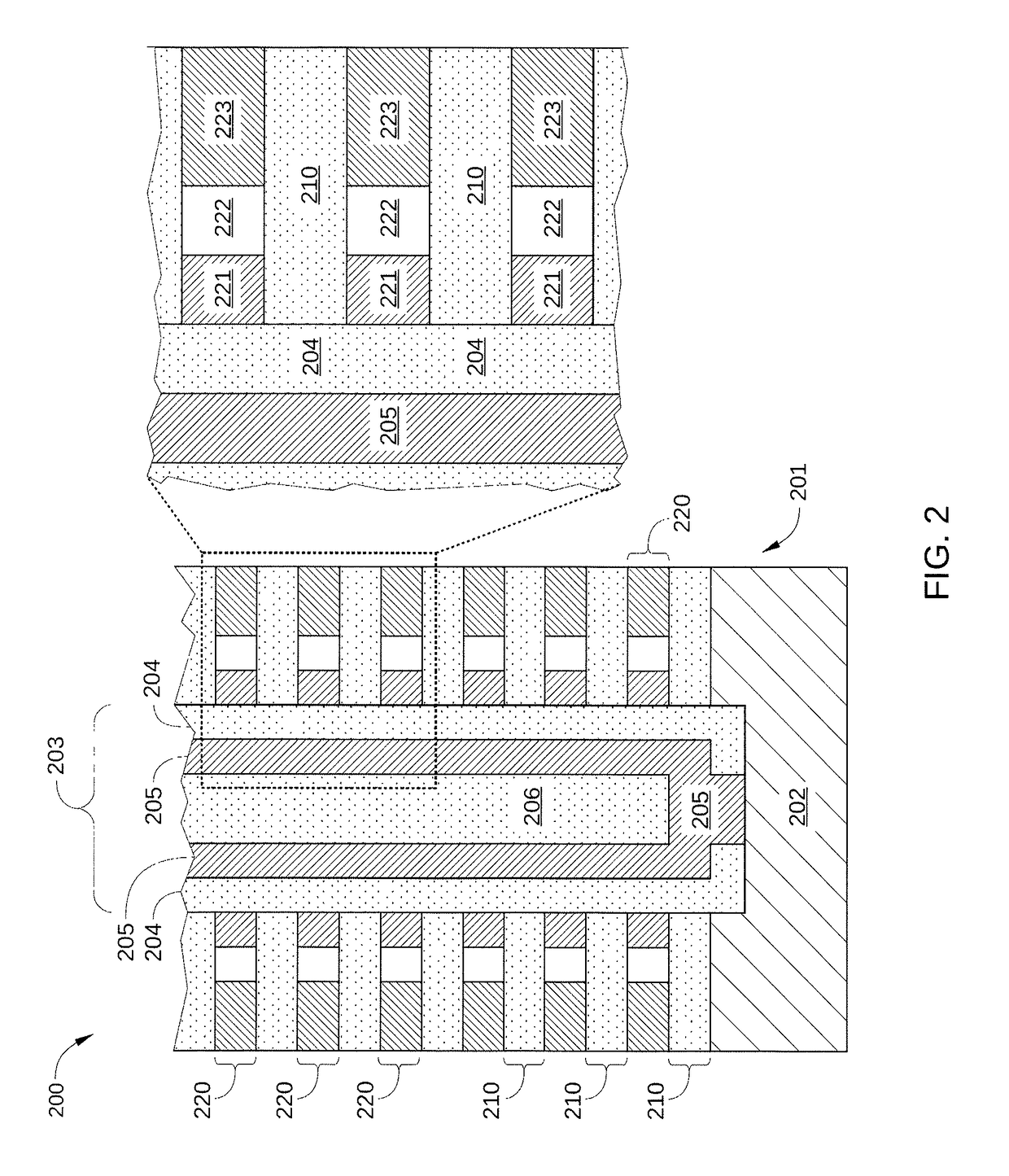

Charge-trap layer separation and word-line isolation in a 3-d NAND structure

ActiveUS20180254187A1Solid-state devicesSemiconductor/solid-state device manufacturingVacuum gapSilicon oxide

In a 3D NAND device, the charge trap region of a memory cell is formed as a separate charge-trap “island.” As a result, the charge-trap region of one memory cell is electrically isolated from charge-trap regions in adjacent memory cells. The charge trap region of one memory cell is separated from the charge trap regions of adjacent memory cells by a dielectric structure, such as a silicon oxide film. Alternatively, the charge trap region of a memory cell is separated from the charge trap regions of adjacent memory cells by an air, gas, or vacuum gap.

Owner:APPLIED MATERIALS INC

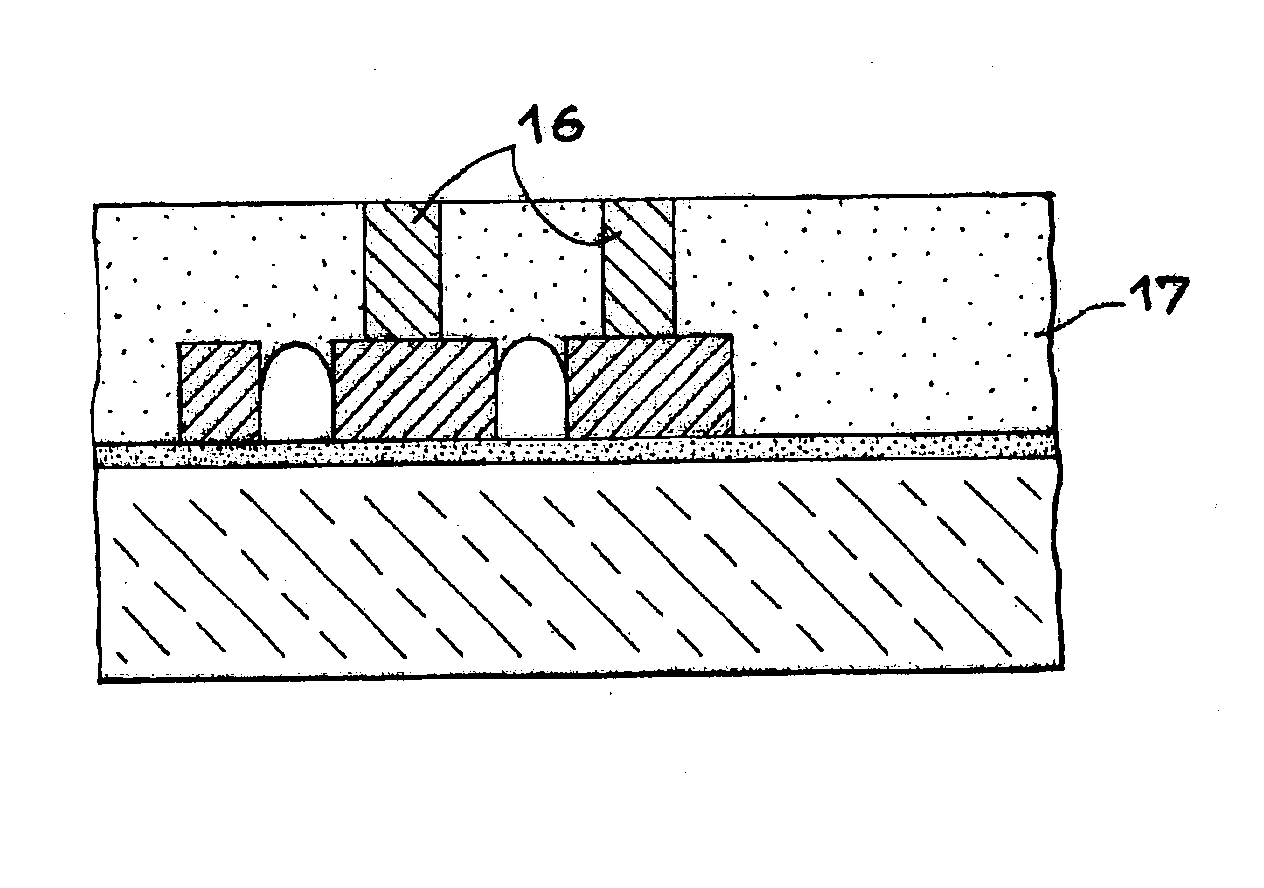

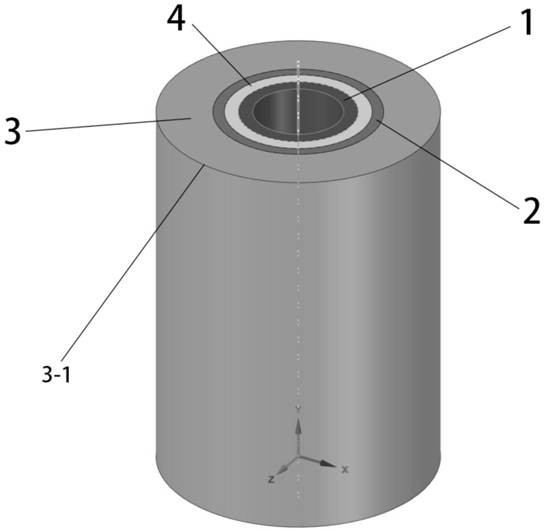

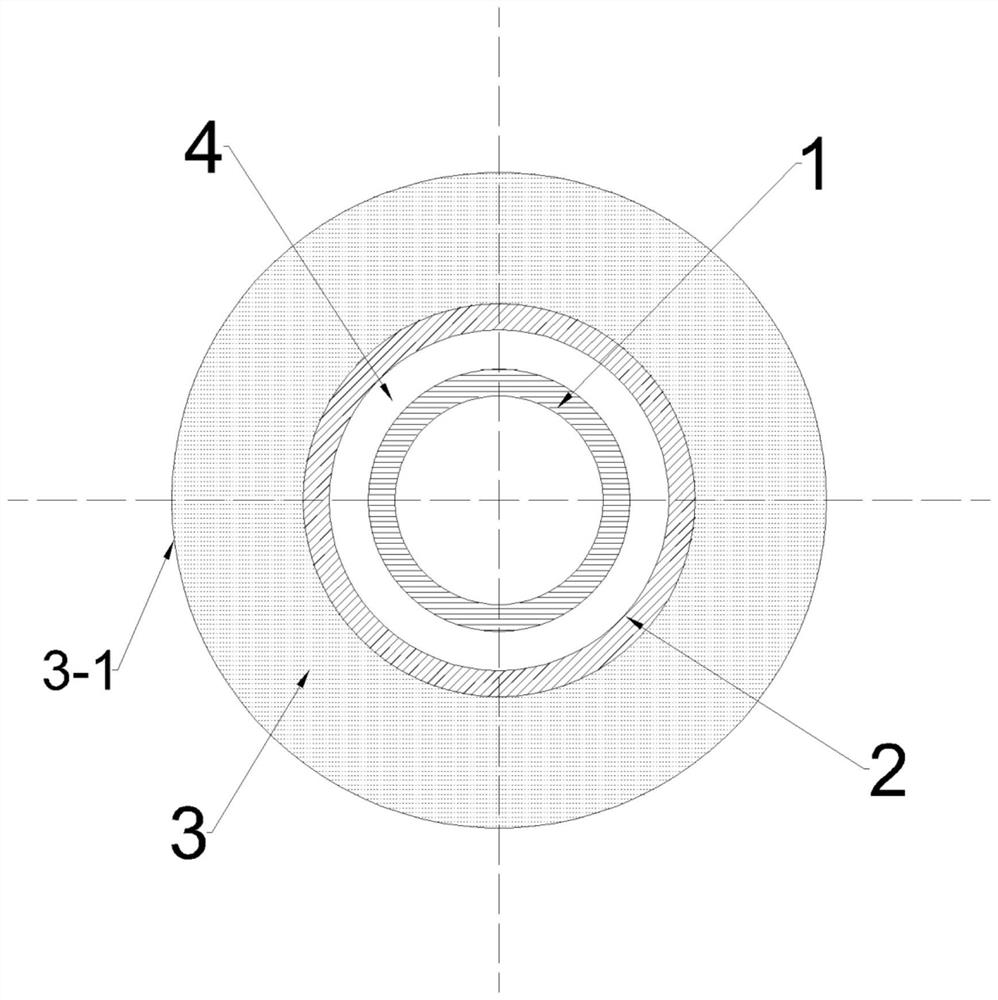

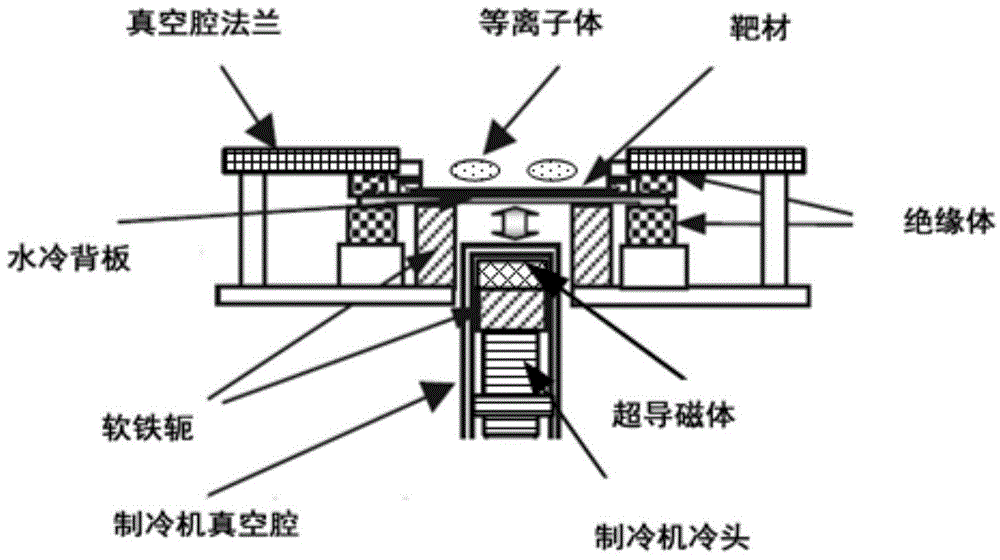

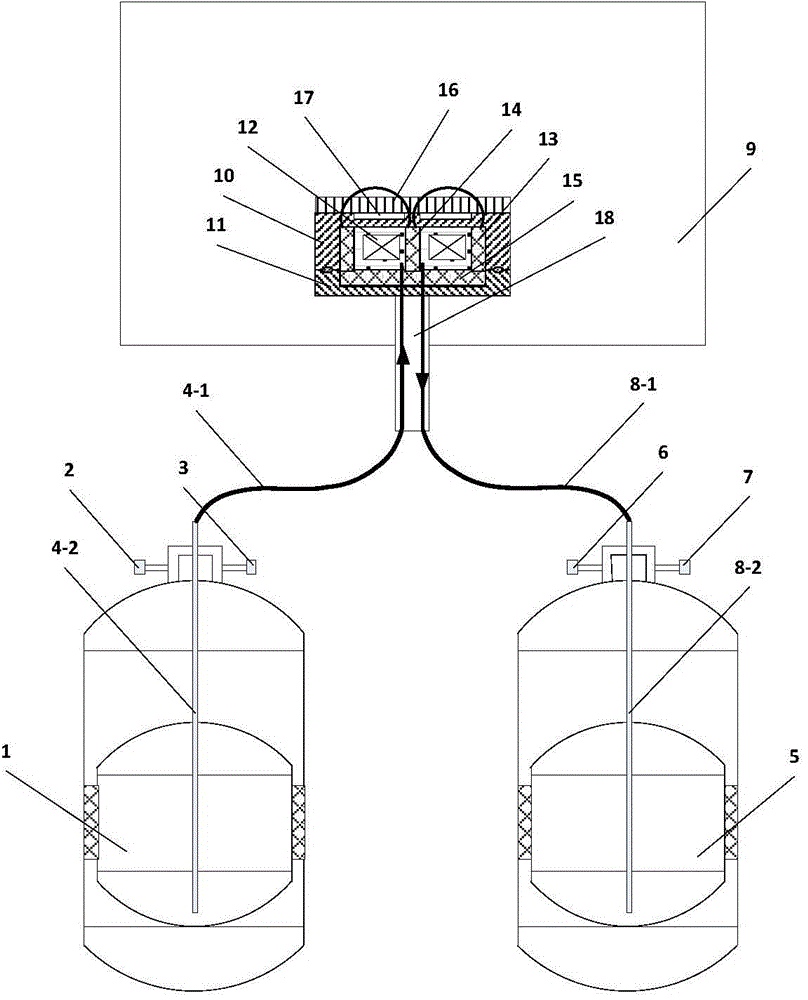

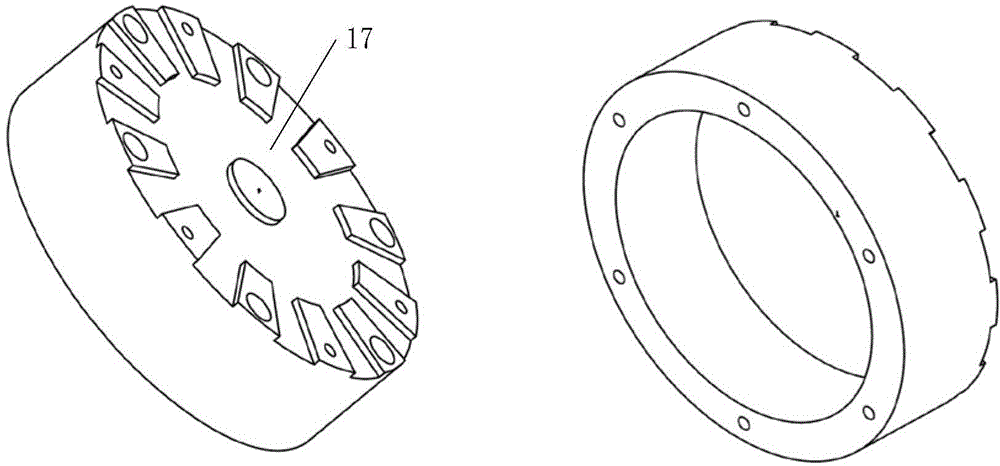

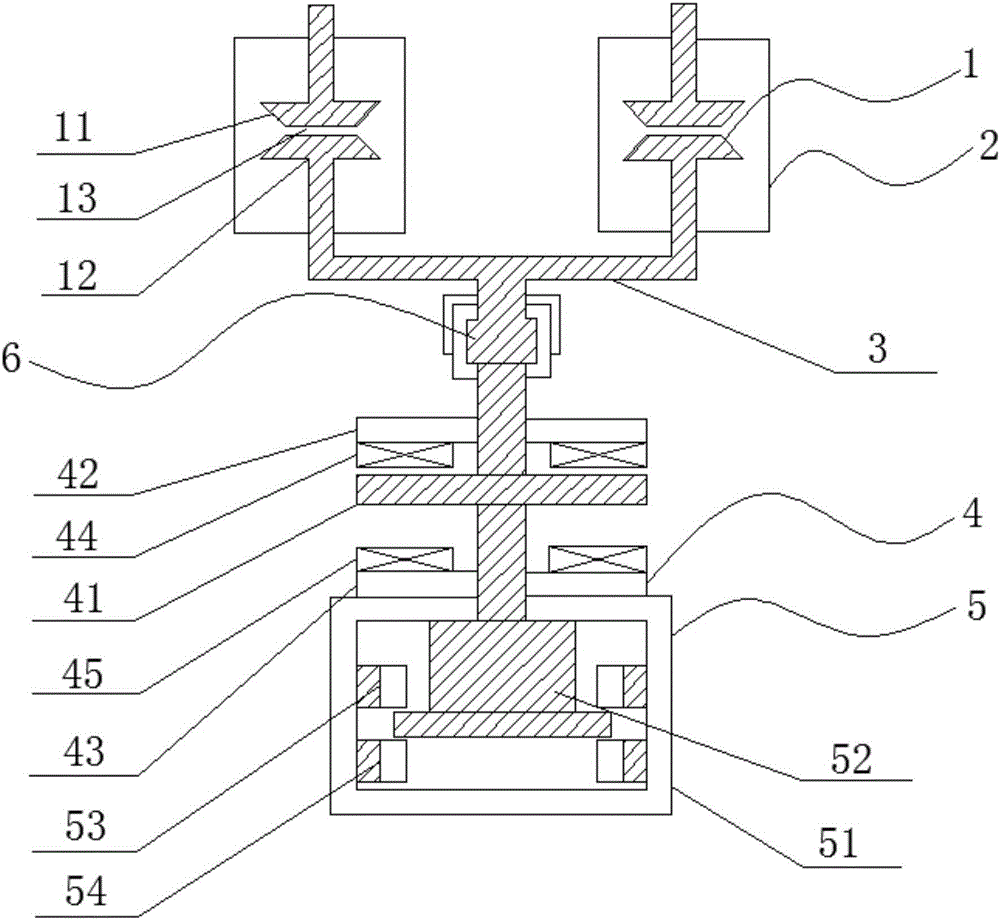

Low-temperature cooling system of superconduction high-intensity magnetic field magnetron sputtering cathode

The invention relates to a low-temperature cooling system of a superconduction high-intensity magnetic field magnetron sputtering cathode. The low-temperature cooling system is composed of two liquid nitrogen storage Dewars (1 and 5), pressure increasing valves (2 and 6), deflation valves (3 and 7), a first liquid transmitting pipe (4-1), a first liquid transmitting rod (4-2), a second liquid transmitting pipe (8-1), a second liquid transmitting rod (8-2), a vacuum cavity (9), a magnetic body Dewar upper cover (10) and a magnetic body Dewar base (11). A superconducting magnetic body (12), an outer magnetic yoke (13), an inner magnetic yoke (14) and a bottom magnetic yoke (15) are installed in closed space defined by the magnetic body Dewar upper cover (10) and the magnetic body Dewar base (11), the magnetic body Dewar upper cover (10) and a cathode target material (16) are fixed together, and part of a vacuum gap (17) is reserved between the magnetic body Dewar upper cover (10) and the cathode target material (16). Forced flowed cooling is carried out on the superconducting magnetic body (12) through liquid nitrogen; the two liquid nitrogen storage Dewars (1 and 5) alternatively work to cool the superconducting magnetic body (12) and the cathode target material (16).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

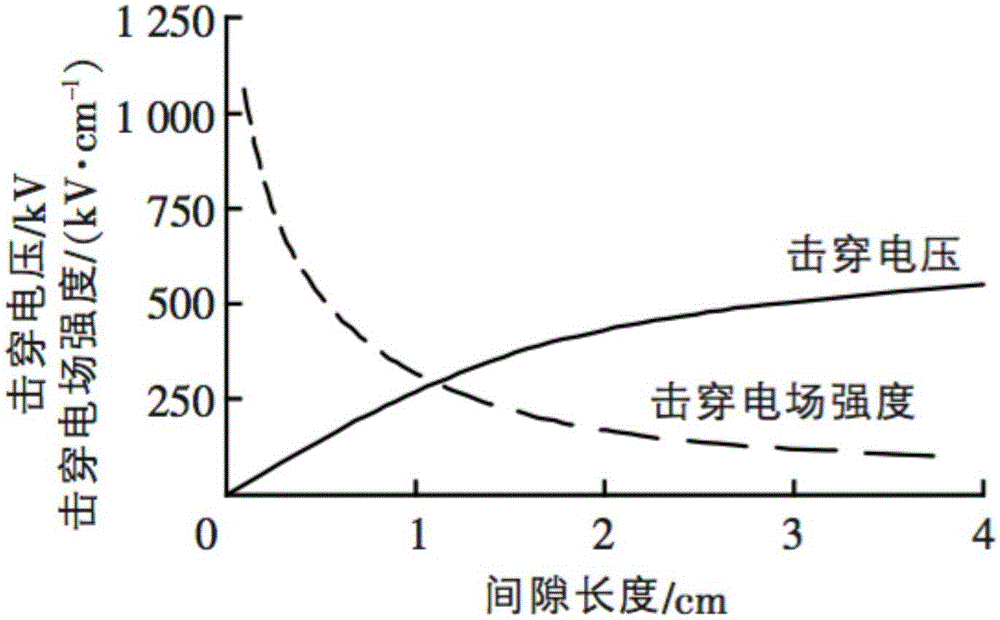

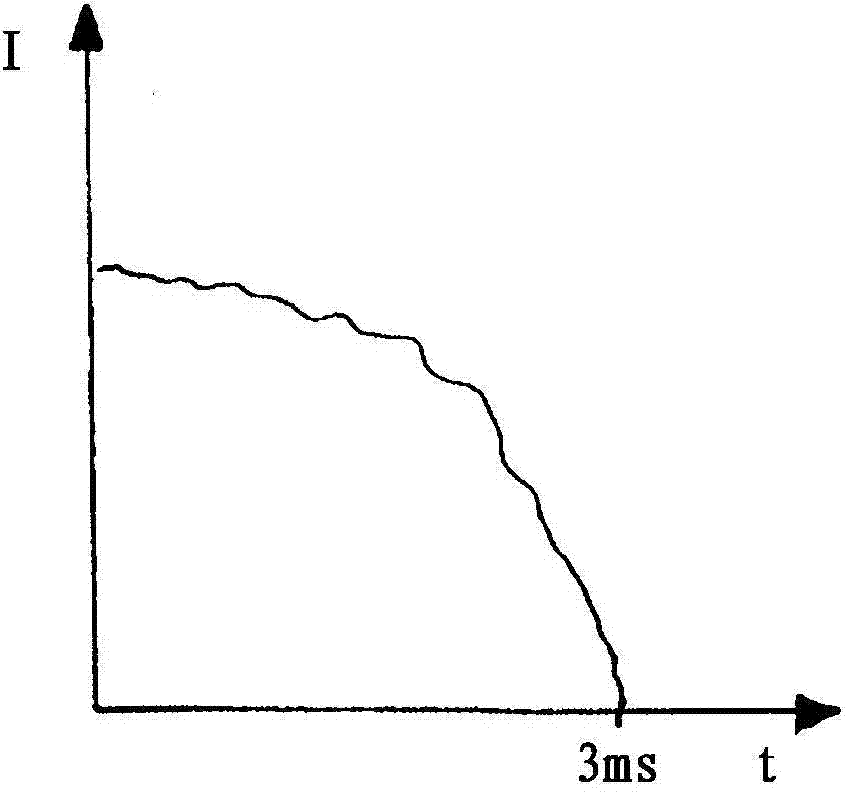

Double-break vacuum circuit breaker used for 66 KV

InactiveCN106449264ASolve the problem of not being able to meet the 66KV voltage levelNo pollutionHigh-tension/heavy-dress switchesAir-break switchesVacuum gapSynchronism

The invention provides a double-break vacuum circuit breaker used for 66 KV. The vacuum circuit breaker comprises two break devices with the same structure, each break device is arranged in a vacuum arc-extinguishing chamber, the break device comprises a static contact and a moving contact, a vacuum gap is reserved between the static contact and the moving contact, tail portions of the moving contacts at two sides are connected in series through a connecting rod, the connecting rod is provided with a bidirectional repulsive force mechanism and a permanent magnet maintenance mechanism in sequence, the bidirectional repulsive force mechanism comprises a metal repulsive force disc, the connecting rod is also provided with an upper fixing plate and a lower fixing plate parallel to the metal repulsive force disc, the metal repulsive force disc is located between the upper fixing plate and the lower fixing plate, the lower end surface of the upper fixing plate is fixedly connected with a switch-off coil, and the upper end surface of the lower fixing plate is provided with a switch-on coil. The beneficial effects of the vacuum circuit breaker are that the on-off 66 KV voltage level is realized through double breaks, the double breaks are linked by employing an electromagnetic repulsive force, a mechanical locking structure is avoided, fault sources are less, the usage reliability is high, the operation precision and the synchronism of the break devices are high, and the reaction can reach a microsecond level.

Owner:STATE GRID EAST INNER MONGOLIA ELECTRIC POWER CO LTD MAINTENANCE BRANCH +1

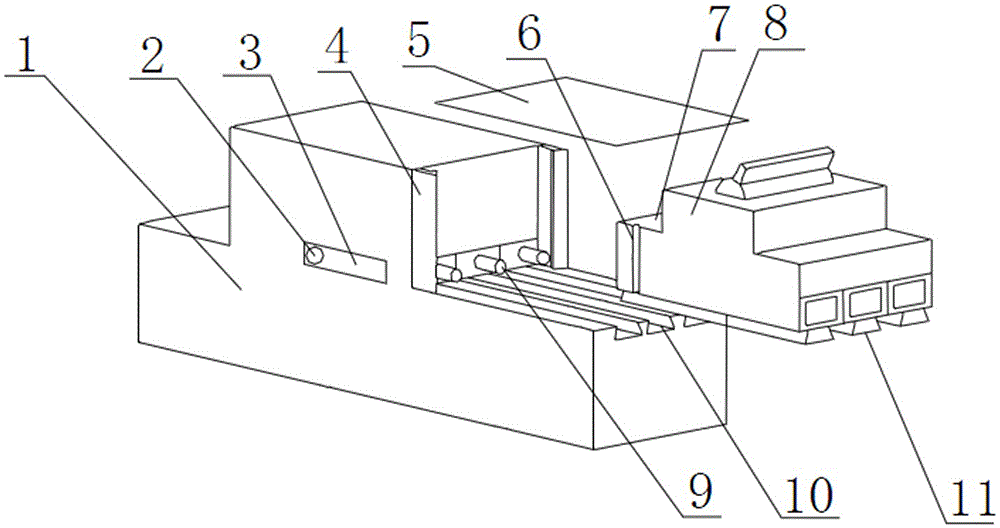

Combination switch for looped-network switch cabinet

InactiveCN105161374AProtective switch detailsEmergency protective device manufactureVacuum gapReciprocating motion

The invention discloses a combination switch for a looped-network switch cabinet. The combination switch comprises a circuit breaker, a shell, an operation rod and a circuit structure, wherein the circuit structure is arranged in the shell, the shell is provided with a sliding groove, the circuit breaker is provided with a sliding block adaptive to the sliding groove, the circuit structure is provided with a plug-in end outside the shell, the plug-in end can do axial reciprocating movement to be embedded onto the shell along the plug-in end, a sheath end is embedded into the circuit breaker and can be sheathed in and conducted with the plug-in end during the sliding process of the circuit breaker, an opening is formed on the side wall of the shell, the operation rod penetrates through the opening and is fixedly connected with the plug-in end, a groove is arranged at a position where the circuit breaker props against the shell, a sealing plate covers the upper part of the groove, and a vacuum gap is formed between the sealing plate and the groove. The vacuum gap has an effect of heat insulation, the influence of an exterior temperature environment to a connection part of the plug-in end and the sheath end can be prevented, so that the combination switch can be applicable for various working environments with high temperature.

Owner:扬中市佳旺华电器有限公司

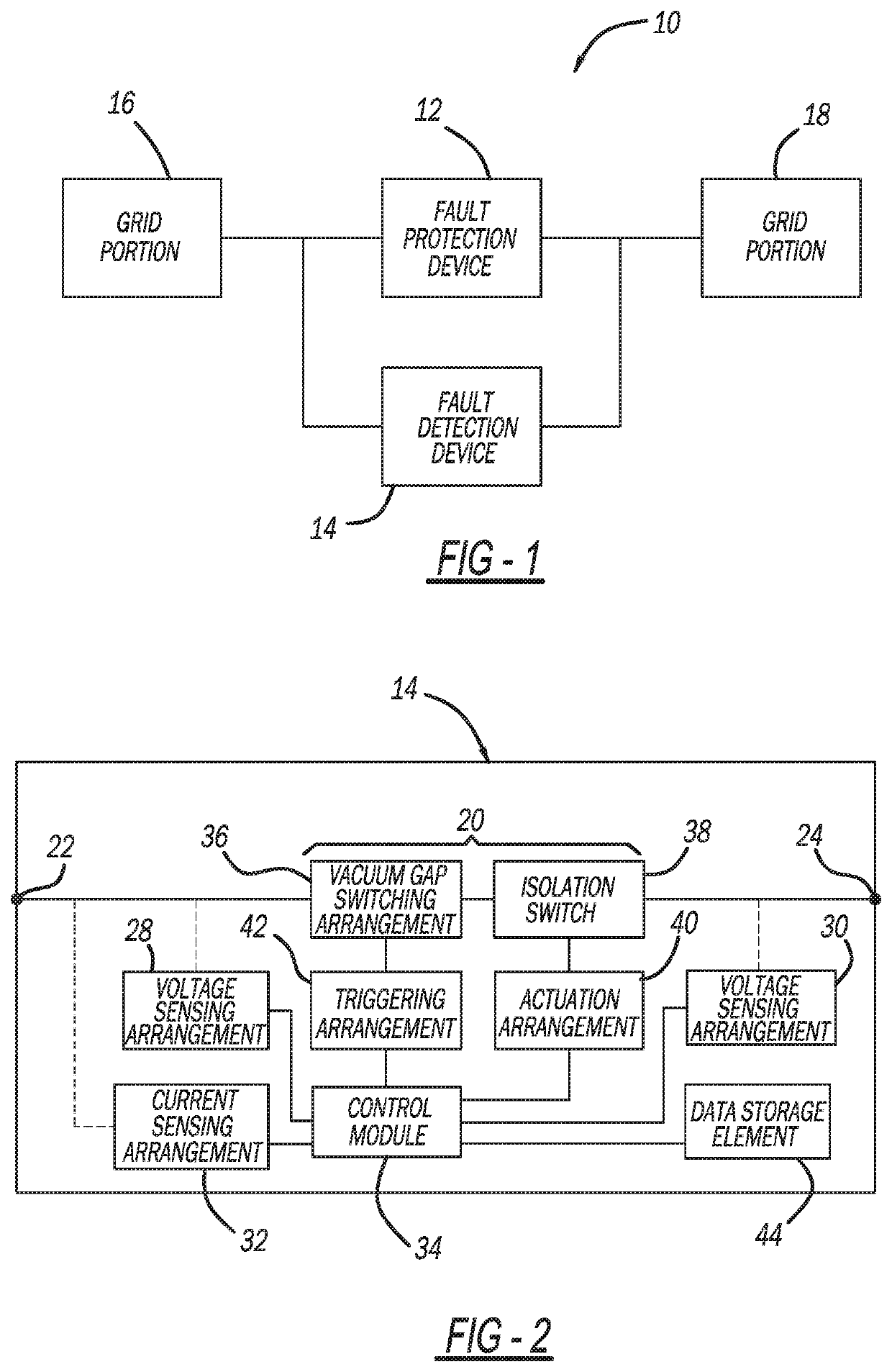

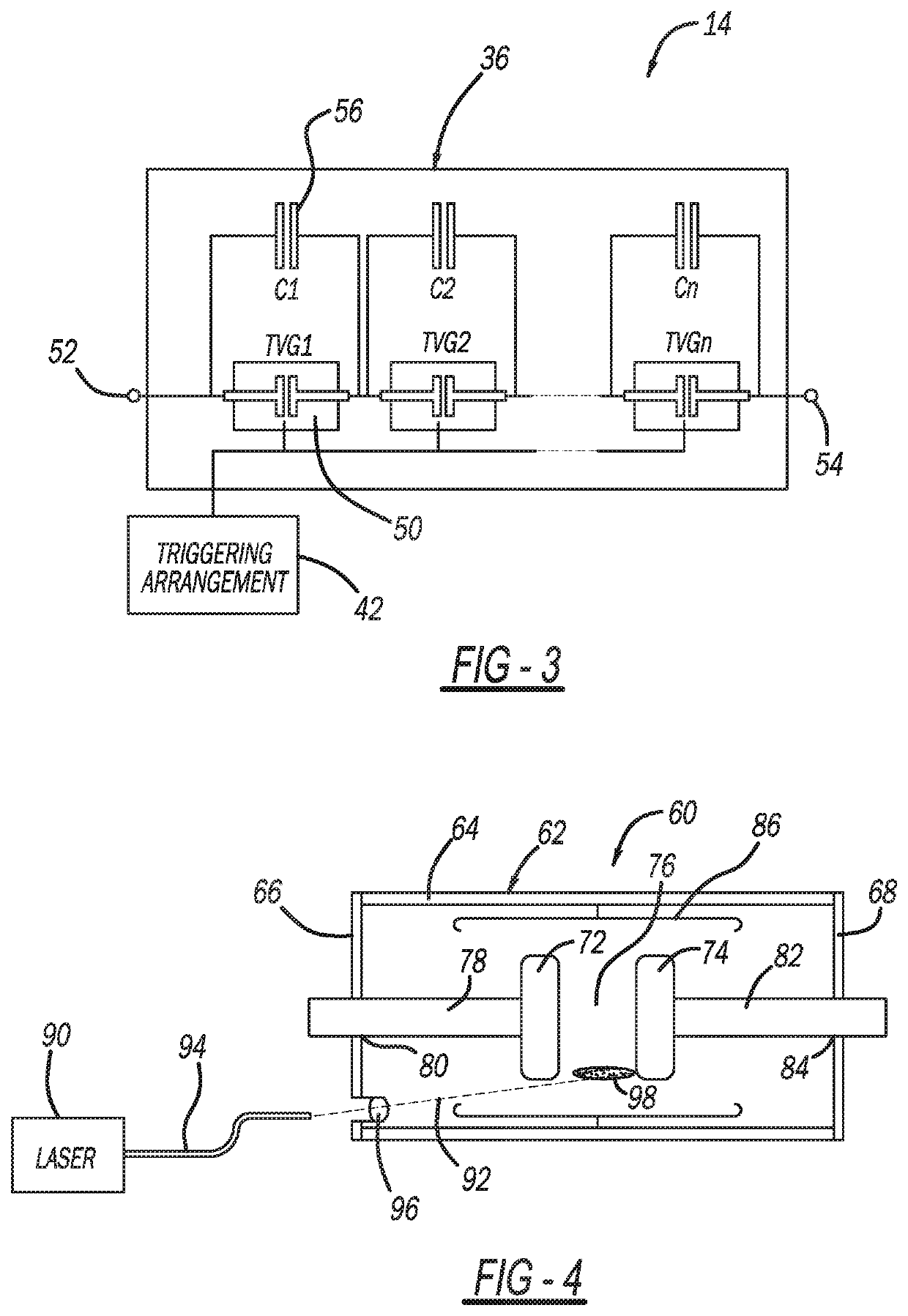

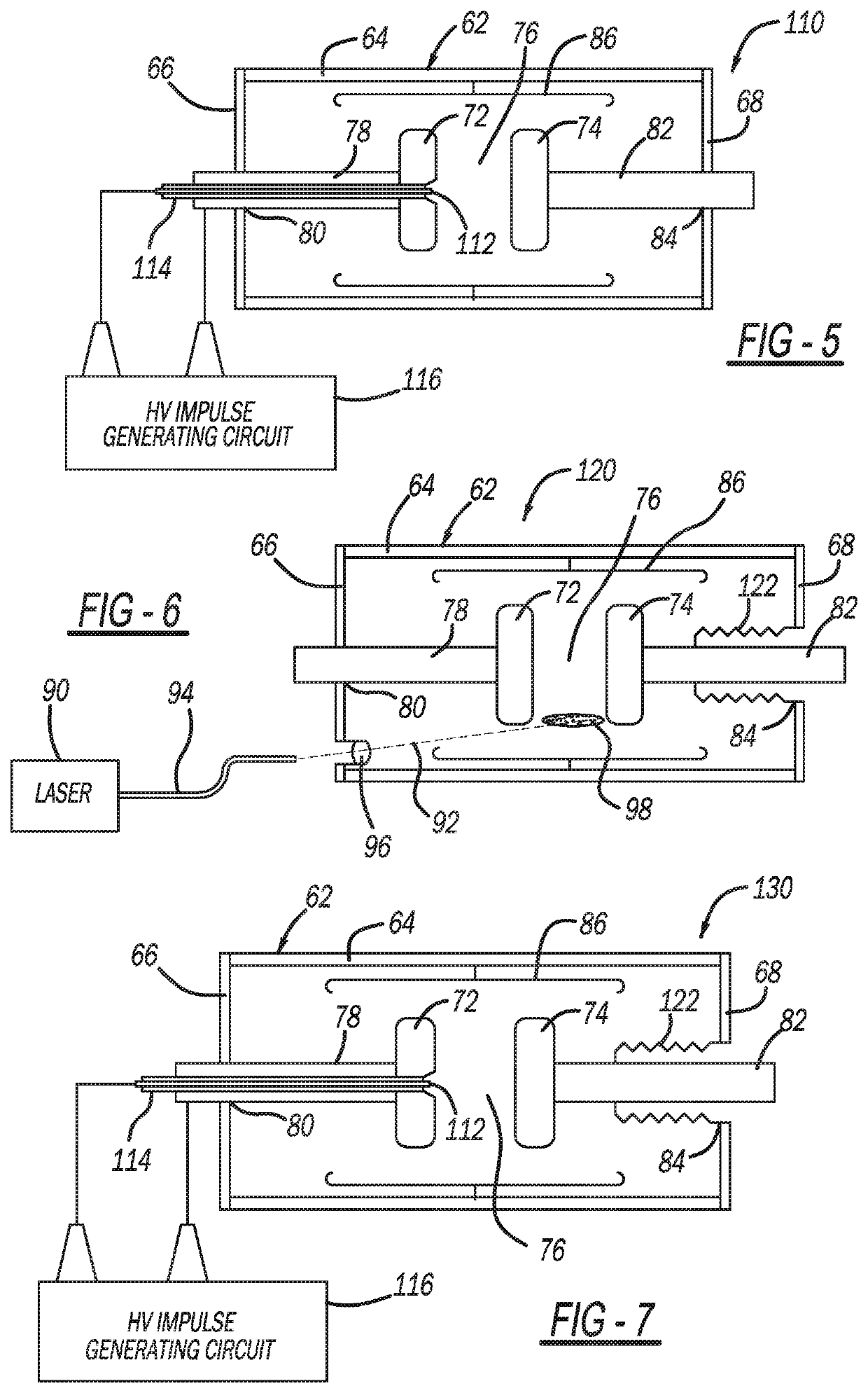

Triggered vacuum gap fault detection methods and devices

PendingUS20200191855A1Fault location by conductor typesCircuit interrupters testingVacuum gapComputational physics

A system and method for determining if a fault condition exists in an electrical network. The method includes determining that a fault protection device has been opened and monitoring a voltage angle of a voltage waveform across a vacuum gap switching arrangement if the fault protection device is open, where the vacuum gap switching arrangement includes at least one vacuum gap switching element. The method also includes triggering a breakdown of a vacuum gap in the at least one vacuum gap switching element when the voltage angle corresponds to a predetermined switching angle to enable a temporary current flow through the vacuum gap switching arrangement, measuring the current flow through the vacuum gap switching arrangement, and determining whether the fault condition exists based at least in part on the measured current flow.

Owner:S&C ELECTRIC

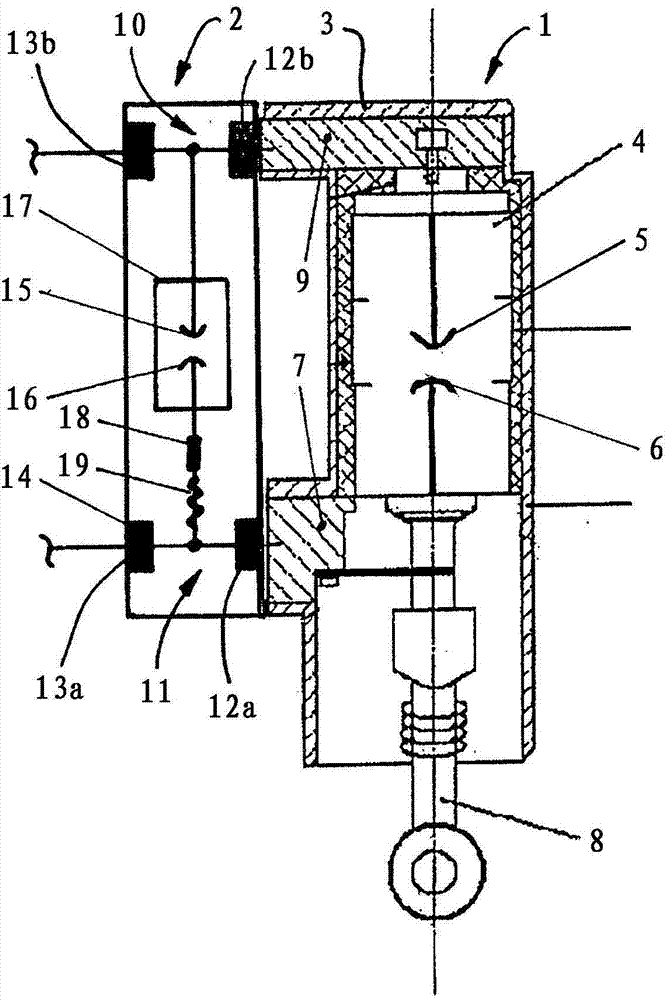

A pole part of a medium voltage circuit breaker arrangement comprising a triggered gap unit

A pole part (1) of a low-, medium- or high voltage circuit breaker arrangement comprising a pole housing (3) for accommodating a vacuum interrupter (4) with a pair of corresponding electrical contacts (5, 6), wherein a fixed electrical contact (5) is connected to an upper electrical terminal (9) and a movable electrical contact (6) is connected to a lower electrical terminal (7) and operated by a pushrod (8), and a triggered -vacuum gap or -gas gap or the combination of gas and vacuum gap connected in sereies unit (2) is parallel connected to the electrical contacts (5, 6) in order to avoid contacts welding, wherein the triggered vacuum gap or gas gap unit (2) is removable mounted between the upper electrical terminal (9) and the lower electrical terminal (7) arranged adjacent to the pole housing (3). Furthermore there is the possibility to trigger directly the vacuum interrupter device to get a similar effect to protect the vacuum interrupter device from inrush current load during the closing operation especially during capacitive switching.

Owner:ABB TECH AG

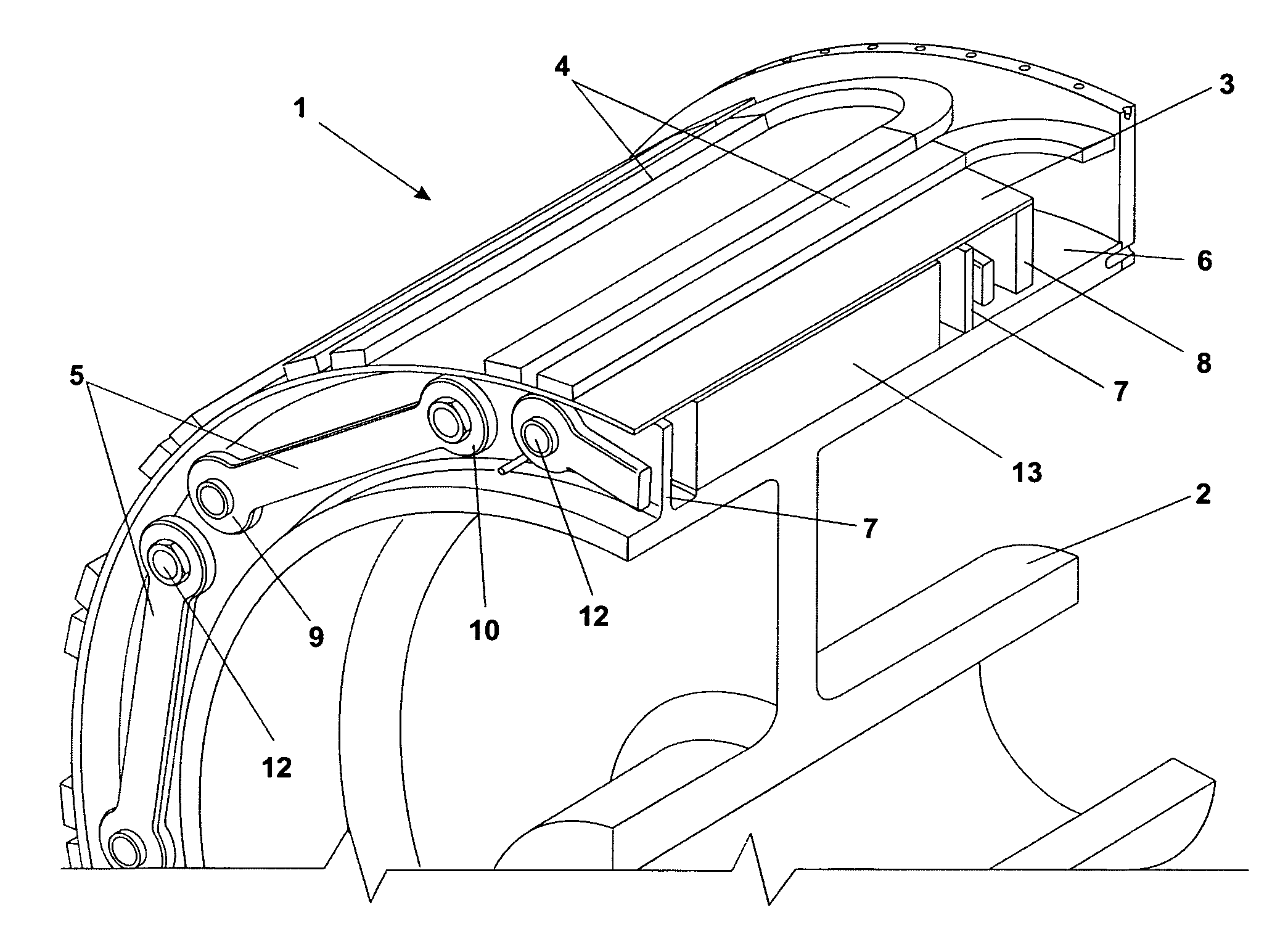

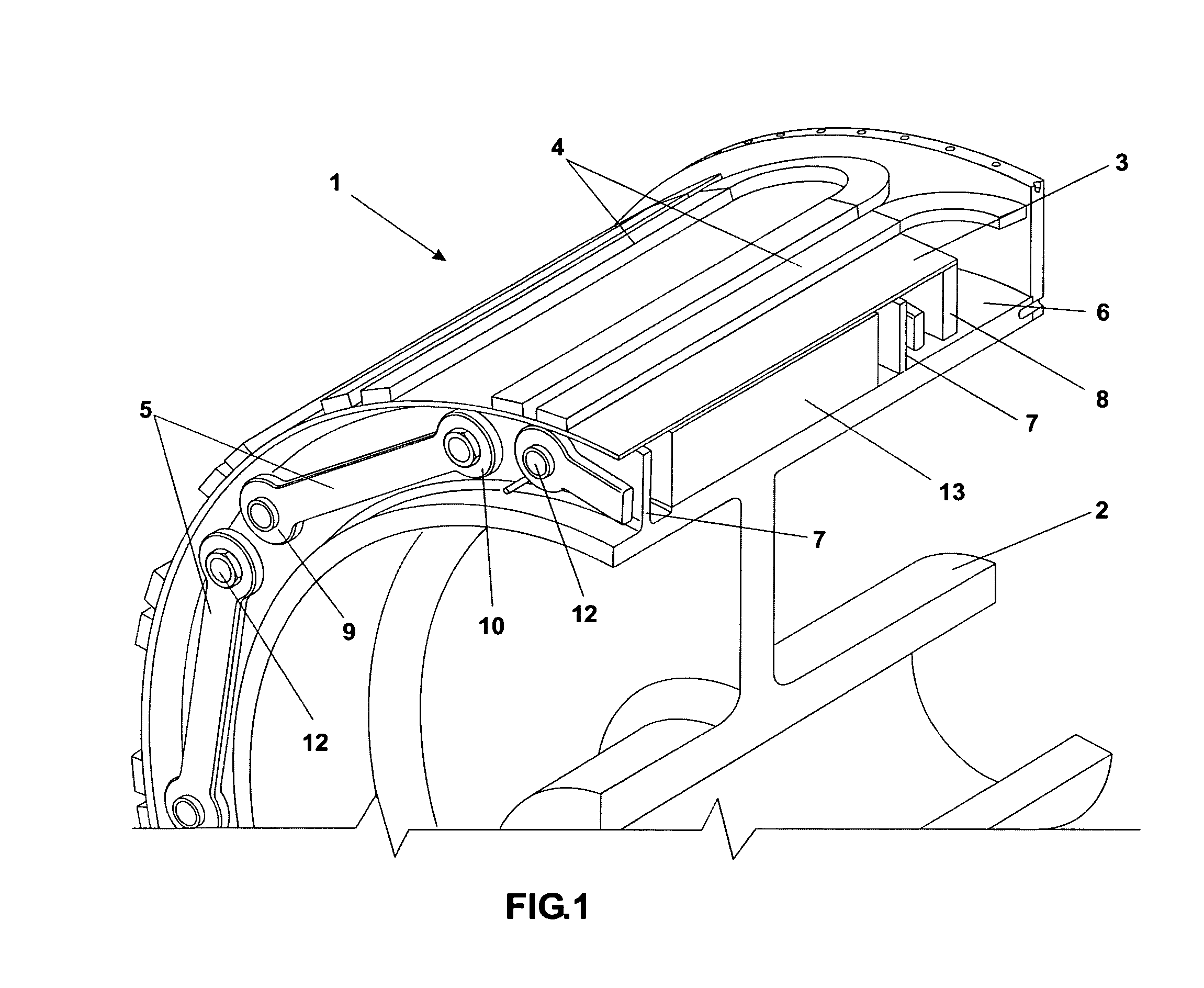

Rotor or a stator for a superconducting electrical machine

InactiveUS8692433B2Minimize flow of heatQuantity minimizationSynchronous generatorsWindingsVacuum gapCoupling

A rotor (or a stator) for a superconducting electrical machine includes a mounting that is maintained at substantially ambient temperature during operation of the electrical machine and a field coil support structure. A plurality of superconducting field coils are maintained at cryogenic temperatures during operation of the electrical machine and are supported by the field coil support structure. At least one coupling element is used to fix the field coil support structure to the mounting. The field coil support structure is preferably fixed to the mounting by a plurality of substantially circumferentially extending coupling elements at a first and second axial end of the field coil support structure and the mounting such that the mounting and field coil support structure are substantially separated over their axial lengths by a vacuum gap.

Owner:GE ENERGY POWER CONVERSION TECH

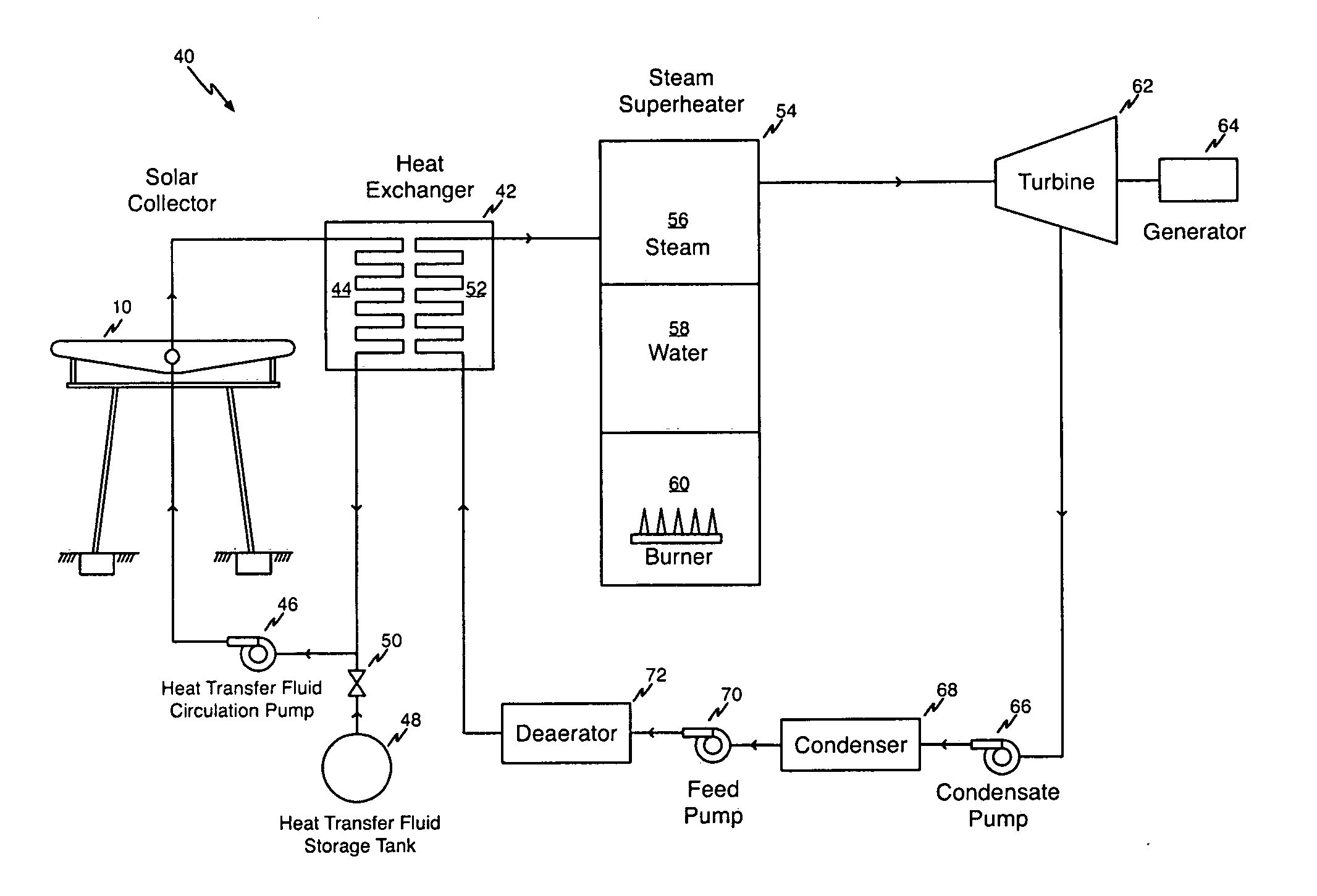

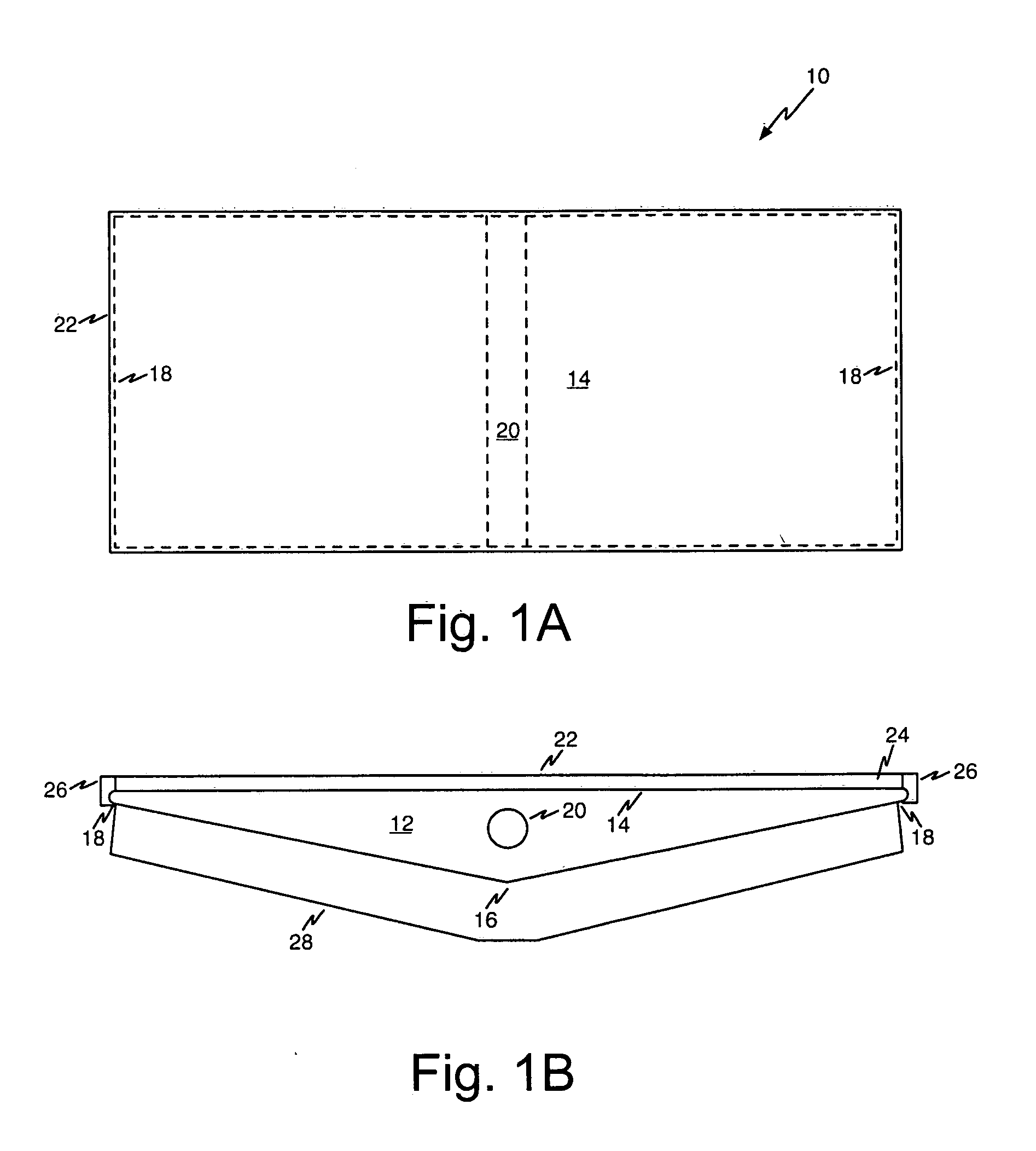

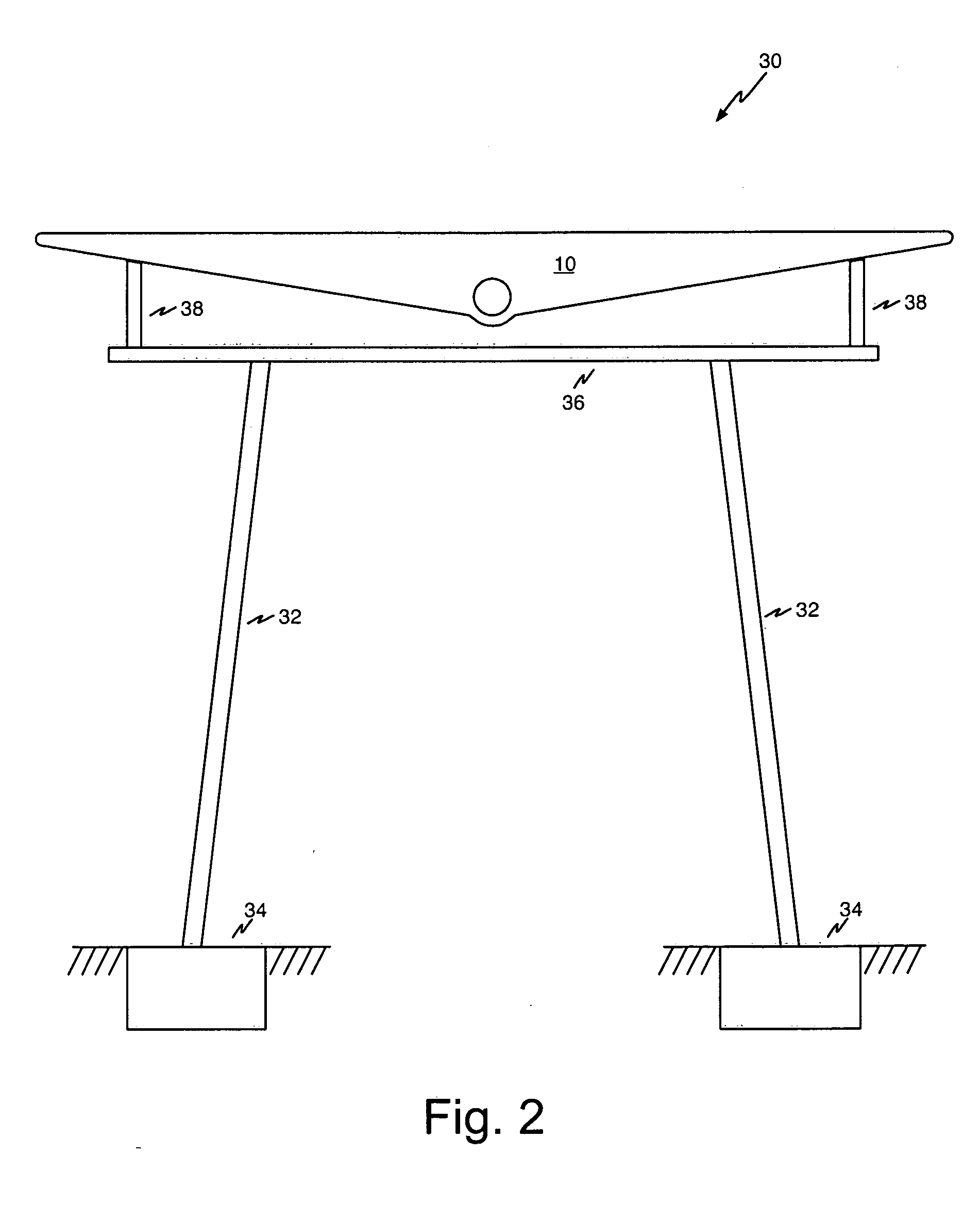

Dual Energy Solar Thermal Power Plant

InactiveUS20130081396A1Avoid heat conductionRemarkable effectAuxillary drivesSolar heating energyVacuum gapDual energy

A solar energy collector comprises a solid body having a substantially planar solar energy absorbing collecting surface. The solid body has a first thickness at a center portion tapering to a second thickness at each of a pair of opposing edge portions defining a width of the body. A bore extends completely through the body along its length and is aligned along an axis at the center portion. A window transparent at most solar radiation in the visible spectrum and near UV to infrared-red solar energy wavelengths is disposed at a distance from the collecting surface, the window sealed around a periphery of the collecting surface to define a sealed vacuum gap between the collecting surface and the bottom surface of the window. The solar energy collector is a major component of a large scale solar thermal power plant.

Owner:KUO CHANG

Solid state cooling or power generating device and method of fabricating the same

InactiveUS20070289315A1Improve efficiencyReduce manufacturing costNanomagnetismWave amplification devicesVacuum gapQuantum well

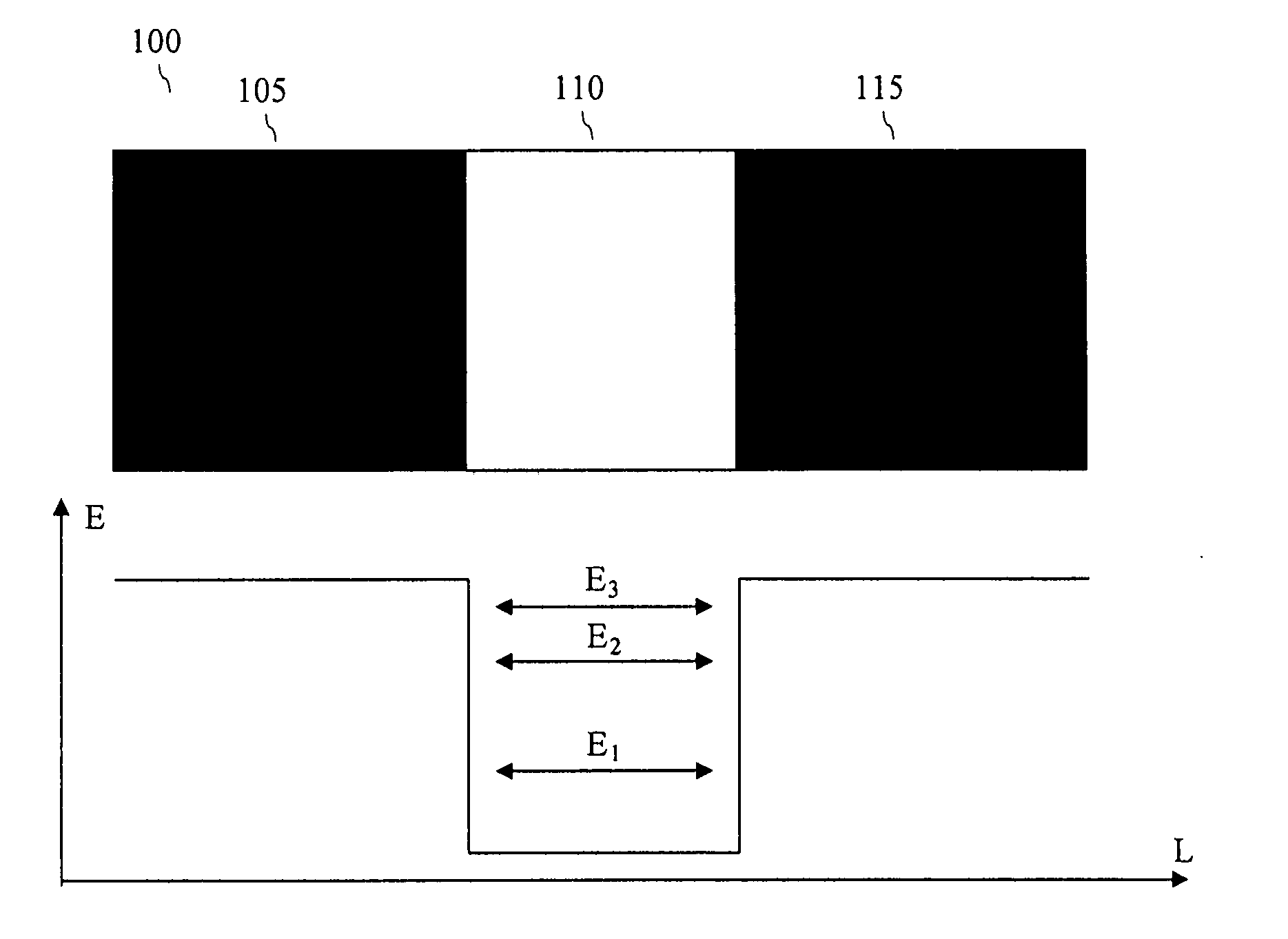

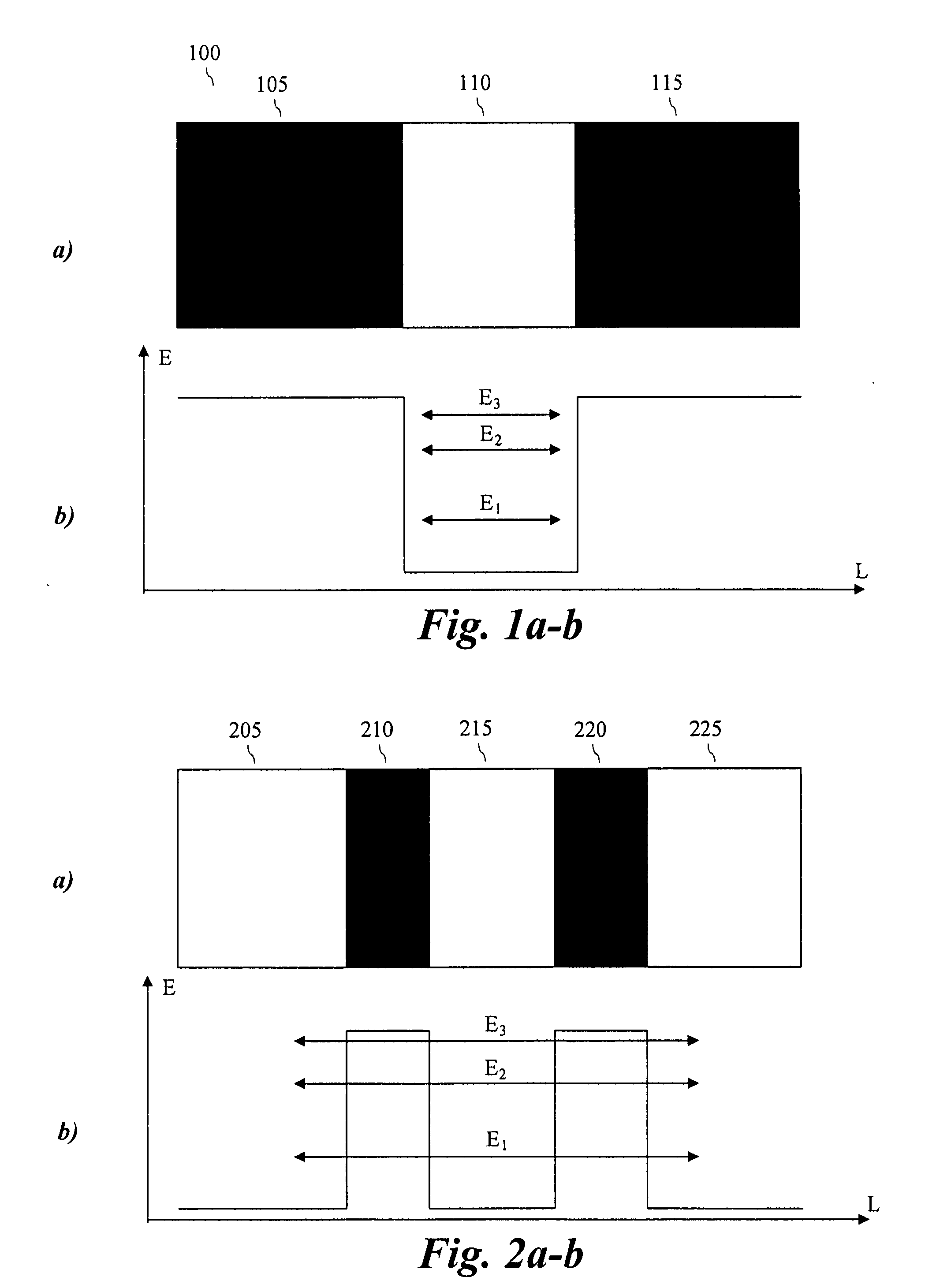

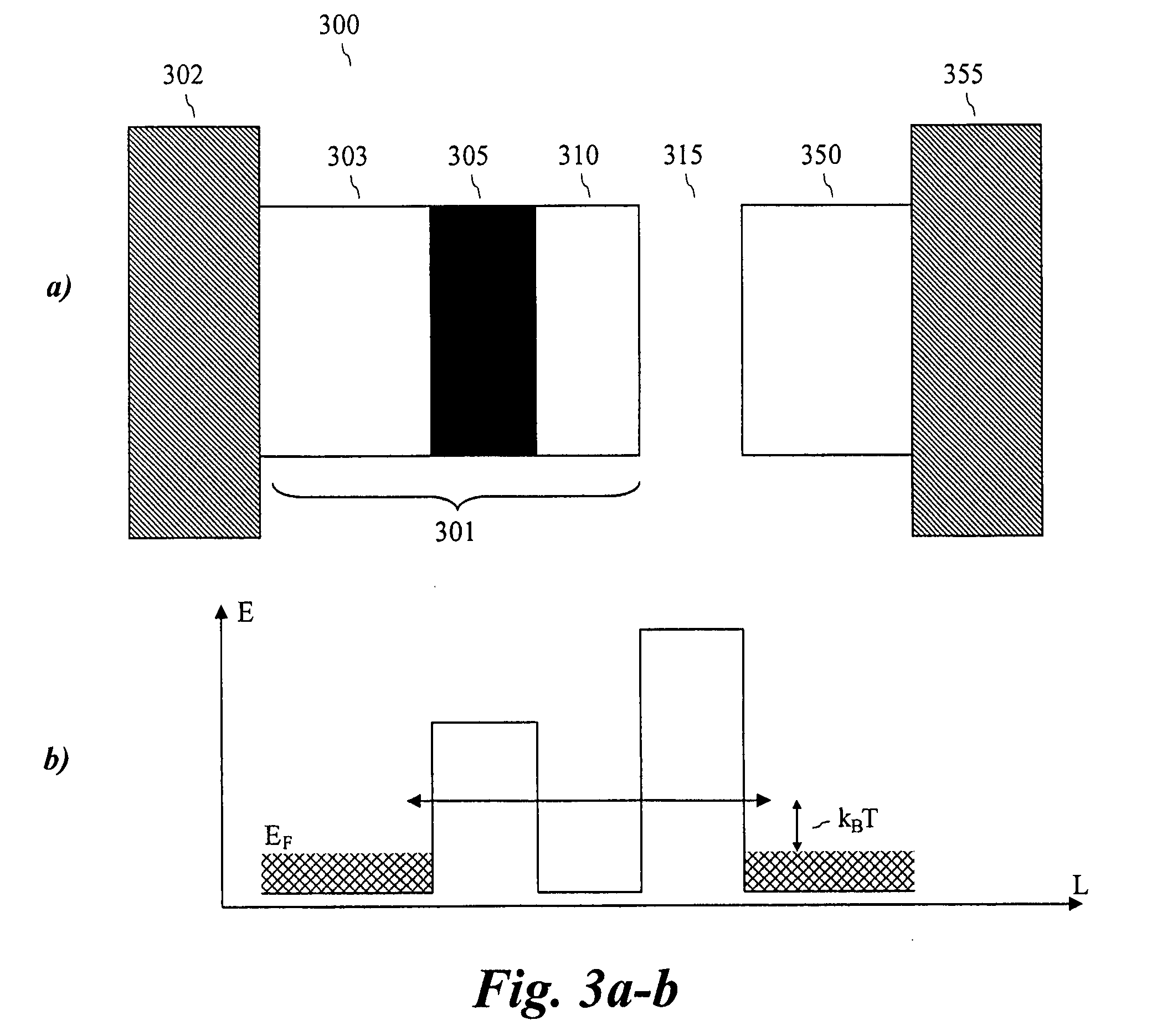

The present invention relates to a solid state cooling / power generating device is provided comprising a first and second electrode separated by a vacuum gap. According to the present invention at least one of the electrodes is provided with a nanoscaled heterostructure 301, which comprises at least one quantum well which in combination with the vacuum gap 315 forms a double barrier resonance structure providing conditions which allows resonant tunneling between the first and second electrode.

Owner:BEAKON TECH

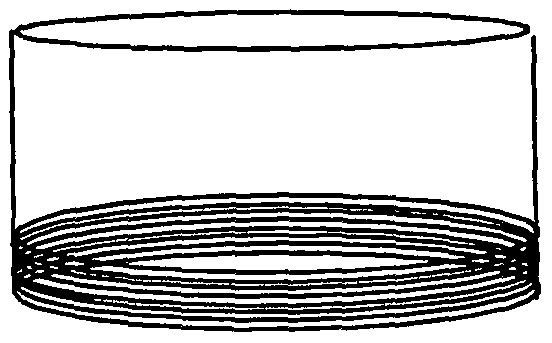

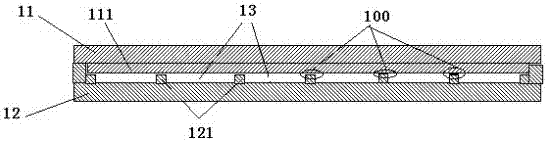

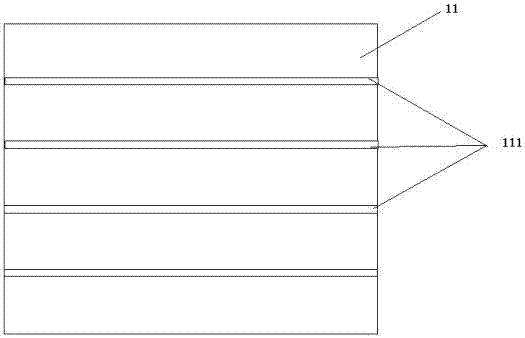

Vacuum glass and processing method thereof

PendingCN107216021ANot prone to air leaksAvoid defects that become leak pointsGlass reforming apparatusFlat glassVacuum gap

The invention discloses vacuum glass and a processing method thereof. The vacuum glass comprises two pieces of plate glass arranged in parallel, wherein a gap for vacuumizing is formed between the two pieces of plate glass; the periphery of the two pieces of plate glass is sealed through high temperature melting; a plurality of supporting strips formed from bulges on the inner side face of the plate glass are arranged on the inner side face of each piece of the plate glass; the inner side faces of the two pieces of plate glass are overlapped by virtue of the supporting strips in a staggered manner; the supporting strips are overlapped in a staggered manner so as to form a plurality of supporting surfaces; a vacuumizing gap is formed among the supporting strips on the inner side faces of each piece of the plate glass; the vacuumizing gaps between the two pieces of plate glass are communicated with one another. The product disclosed by the invention has the effects of saving energy and insulating heat and sound and has the advantages of high vacuum degree, long service life and the like. Particularly, long-lasting vacuum aging is maintained in a manner of enlarging the vacuum chamber, and the product quality problem caused by different materials of the supporting part and the plate glass is solved.

Owner:朱盛菁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com