Thermal control skin capable of adjusting equivalent emissivity by voltage and application thereof in spacecraft

A technology of equivalent emissivity and voltage adjustment, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of poor chemical stability, inability to withstand erosion, and small range of material choices, achieving large degrees of freedom and high spatial stability , to ensure the effect of space stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

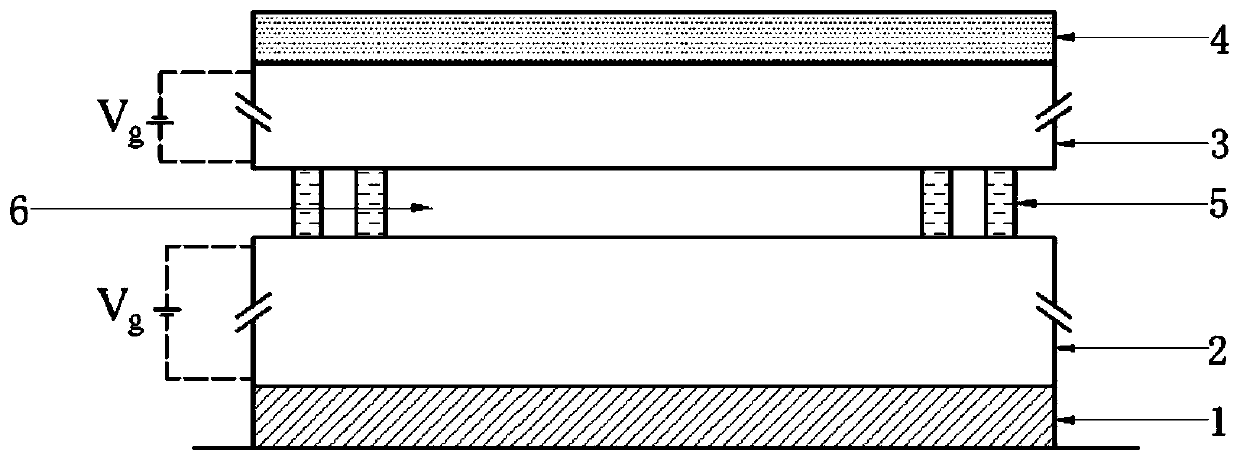

[0061] A thermal control skin, comprising base 1, inner layer 2, outer layer 3 and optical solar reflector 4 from bottom to top, with spacer 5 between inner layer 2 and outer layer 3, said spacer 5 makes inner layer 2 A vacuum gap 6 is formed between the outer layer 3 and the outer layer 3, and the inner layer 2 is a metal-insulator-semiconductor structure.

[0062] Specifically, the material of substrate 1 is SiO 2 ; The inner layer 2 is a metal-insulator-semiconductor structure, the metal layer in the structure is an Ag film with a thickness of 1 μm, the insulator layer is a SiC film with a thickness of 1 μm, and its breakdown voltage is 300V, and the semiconductor layer is an ITO film with a thickness of 10nm, and the semiconductor layer in the structure is adjacent to the vacuum gap 6, and a forward DC adjustable voltage is applied between the semiconductor layer and the metal layer; the outer layer 3 is a 10μm thick Al film substrate + a 10nm thick ITO film, coated on an ...

Embodiment 2

[0065] A thermal control skin, comprising base 1, inner layer 2, outer layer 3 and optical solar reflector 4 from bottom to top, with spacer 5 between inner layer 2 and outer layer 3, said spacer 5 makes inner layer 2 A vacuum gap 6 is formed between the outer layer 3 and the outer layer 3, and the inner layer 2 is a metal-insulator-semiconductor structure.

[0066] Specifically, the material of substrate 1 is SiO 2 ; The inner layer 2 is a metal-insulator-semiconductor structure, the metal layer in the structure is an Ag film with a thickness of 1 μm, the insulator layer is a SiC film with a thickness of 1 μm, and its breakdown voltage is 300V, and the semiconductor layer is an ITO film with a thickness of 10nm, and the semiconductor layer in the structure is adjacent to the vacuum gap 6, and a forward DC adjustable voltage is applied between the semiconductor layer and the metal layer; the outer layer 3 is a 10μm thick Al film substrate + a 10nm thick p-type doped silicon fi...

Embodiment 3

[0069] A thermal control skin, comprising base 1, inner layer 2, outer layer 3 and optical solar reflector 4 from bottom to top, with spacer 5 between inner layer 2 and outer layer 3, said spacer 5 makes inner layer 2 A vacuum gap 6 with a pitch of micronano scale is formed between the outer layer 3 and the outer layer 3 is a metal-insulator-semiconductor structure.

[0070] Specifically, the material of substrate 1 is SiO 2 The inner layer 2 is a 10 μm thick Al substrate+10nm thick ITO film; the outer layer 3 is a metal-insulator-semiconductor structure, and the metal layer in the structure is an Ag film with a thickness of 1 μm, which is coated on the inner surface of the optical solar mirror 5, and the insulator The layer is a SiC film with a thickness of 1 μm, its breakdown voltage is 300V, the semiconductor layer is an ITO film with a thickness of 10nm, and the semiconductor layer in the structure is adjacent to the vacuum gap 6, and a positive direct current can be added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breakdown electricity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com