A pole part of a medium voltage circuit breaker arrangement comprising a triggered gap unit

A technology for triggering gap and pole components, which is used in high-voltage air circuit breakers, electrical components, overvoltage arresters using spark gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

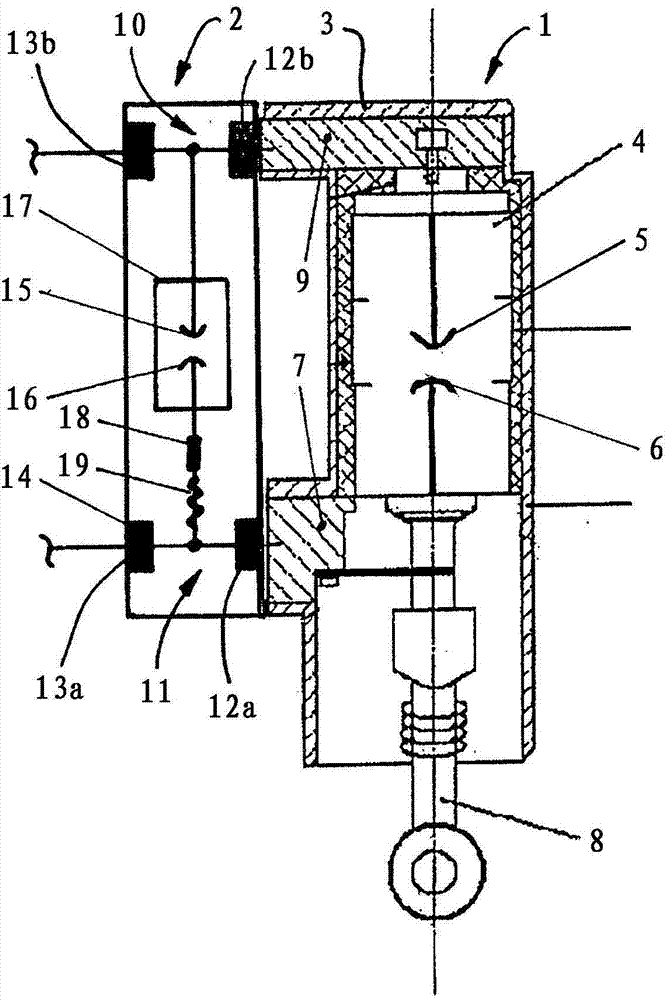

[0019] according to figure 1 , a medium voltage circuit breaker device usually consists of a pole part 1 and a vacuum trigger gap or spark trigger gap (or multi-gap) unit 2. It is possible to provide a multi-gap configuration consisting of a series connection of vacuum gap and gas gap or as described above as a vacuum or gas multi-gap configuration. A vacuum-triggered gap and / or spark-triggered gap (multi-gap) unit 2 is arranged adjacent to the pole part 1 as an auxiliary device.

[0020] The pole part 1 comprises a pole housing 3 made of epoxy resin or thermoplastic material for accommodating a vacuum interrupter 4 . The vacuum interrupter 4 contains a corresponding pair of electrical contacts 5 and 6 . The stationary electrical contact 5 is connected to an upper electrical terminal 9 molded in the pole housing 3 . The opposite movable electrical contact 6 is connected to the lower electrical terminal 7 of the pole housing 3 and is operated by a push rod 8 in order to inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com