Patents

Literature

32results about How to "Will not warp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

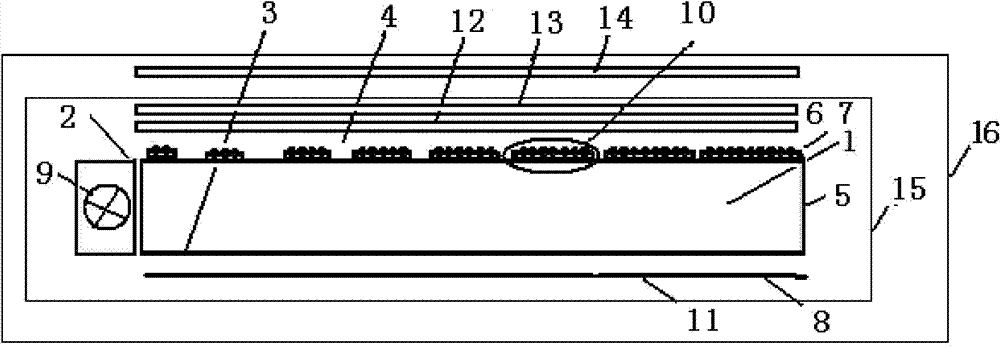

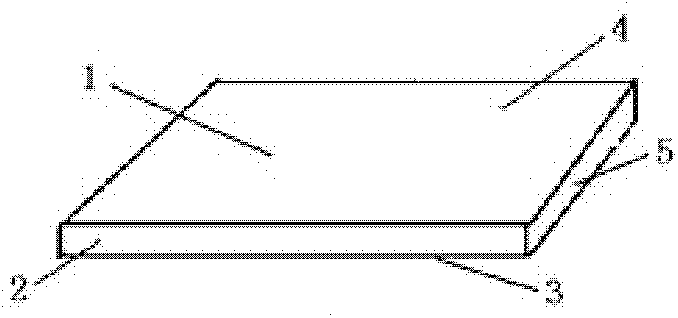

Light guide plate, planar light emitting device, liquid crystal display device, liquid crystal display terminal equipment and manufacturing method of light guide plate

InactiveCN103499853AReduce lossIncrease profitMechanical apparatusPoint-like light sourceLiquid-crystal displayLight guide

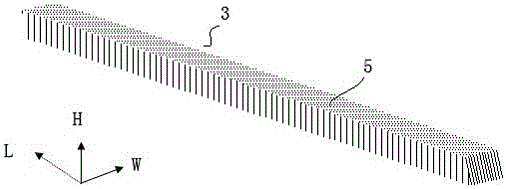

The invention discloses an efficient energy-saving microstructural light guide plate, a planar light emitting device provided with the light guide plate, a liquid crystal display device, liquid crystal display terminal equipment and a manufacturing method of the light guide plate. A scattering pattern structure on the bottom plane of the light guide plate is formed by providing a colorless and transparent adhesive glue pattern layer on the bottom plane of the substrate, a stereoscopic microstructural scattering pattern layer is obtained by planting and sticking a plurality of mini scattering particles on the adhesive glue pattern layer, all or part of the planted and stuck mini scattering particles is bared and protrudes at the surface of the adhesive glue pattern layer, a part of the mini scattering particles, which is bared and protrudes at the surface of the adhesive glue pattern layer, is embedded into the colorless and transparent adhesive glue pattern layer, and is firmly bonded by the adhesive glue, and the other part of the mini scattering particles is bared and protrudes outside the colorless and transparent adhesive glue pattern layer. After adopting the light guide plate, a brightness increase rate of the planar light emitting device is more than 20%. According to the light guide plate prepared by the invention, the light guide plates in small, middle and big sizes can be manufactured at high quality, and the brightness increase rate of the light guide plate is fully realized.

Owner:HANGZHOU RUIHUI OPTOELECTRONICS TECH

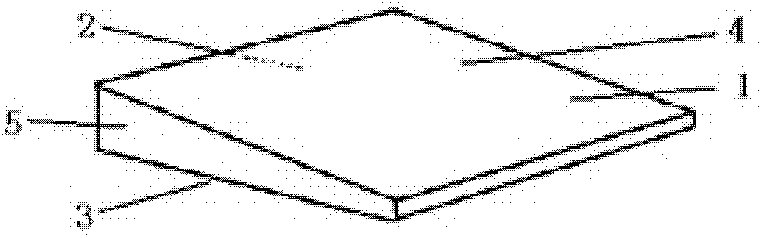

Lightweight plastic-wood composite sheet and preparation method thereof

The invention relates to a lightweight plastic-wood composite sheet and a preparation method thereof. The preparation method comprises the following steps of: firstly stirring PVC particles and tribasic lead sulfate evenly in a stirred tank, and then adding wood flour, LDPE-g-GMA, hollow glass beads, chlorinated polyethylene, ethylene bisstearamide and hard fatty acid butyl ester to the tank, heating up and stirring evenly, cooling and taking out the mixture, and then stirring the mixture evenly with baking soda and citric acid at room temperature, extruding out and molding. The lightweight plastic-wood sheet has the advantages of convenient production and manufacture, high degree of mechanization in the production process, low production cost, low density, light weight, easy installation and maintenance, less use of timber and plastic, turning waste into treasure, being recyclable and not destroyed by insects, no aging and discoloration as well as cracking, no buckling deformation and high impact strength, with the function of adsorbing gas. The lightweight plastic-wood sheet can be applied to a plurality of occasions such as office buildings, hotels and home offices, can be made into products such as photo frames, picture frames, foot lines, and hoisting and fastening boards, and can also be used as suspended beams, pergolas, and the like.

Owner:江苏森诺塑胶科技有限公司

Method for producing thick-core plywood by using aldehyde-free biomass soy protein adhesive

ActiveCN105563571AStress reliefUniform thicknessLaminationLamination apparatusAfter treatmentAdhesive

The invention discloses a method for producing thick-core plywood by using aldehyde-free biomass soy protein adhesive, belongs to the technical field of wood processing, and solves such problems as large back surface cracks, moreburrs, high thickness deviation and easiness in deformation and bending. The production method comprises wood block pretreatment, rotary cutting, drying, plasma treatment, veneer surface scratch treatment, gluing, prepressing, hot pressing and after-treatment. The method is suitable for producing the aldehyde-free thick-core plywood, largely reduces the production cost, and improves the production efficiency.

Owner:SHANDONG XINGANG ENTERPRISE GRP CO LTD

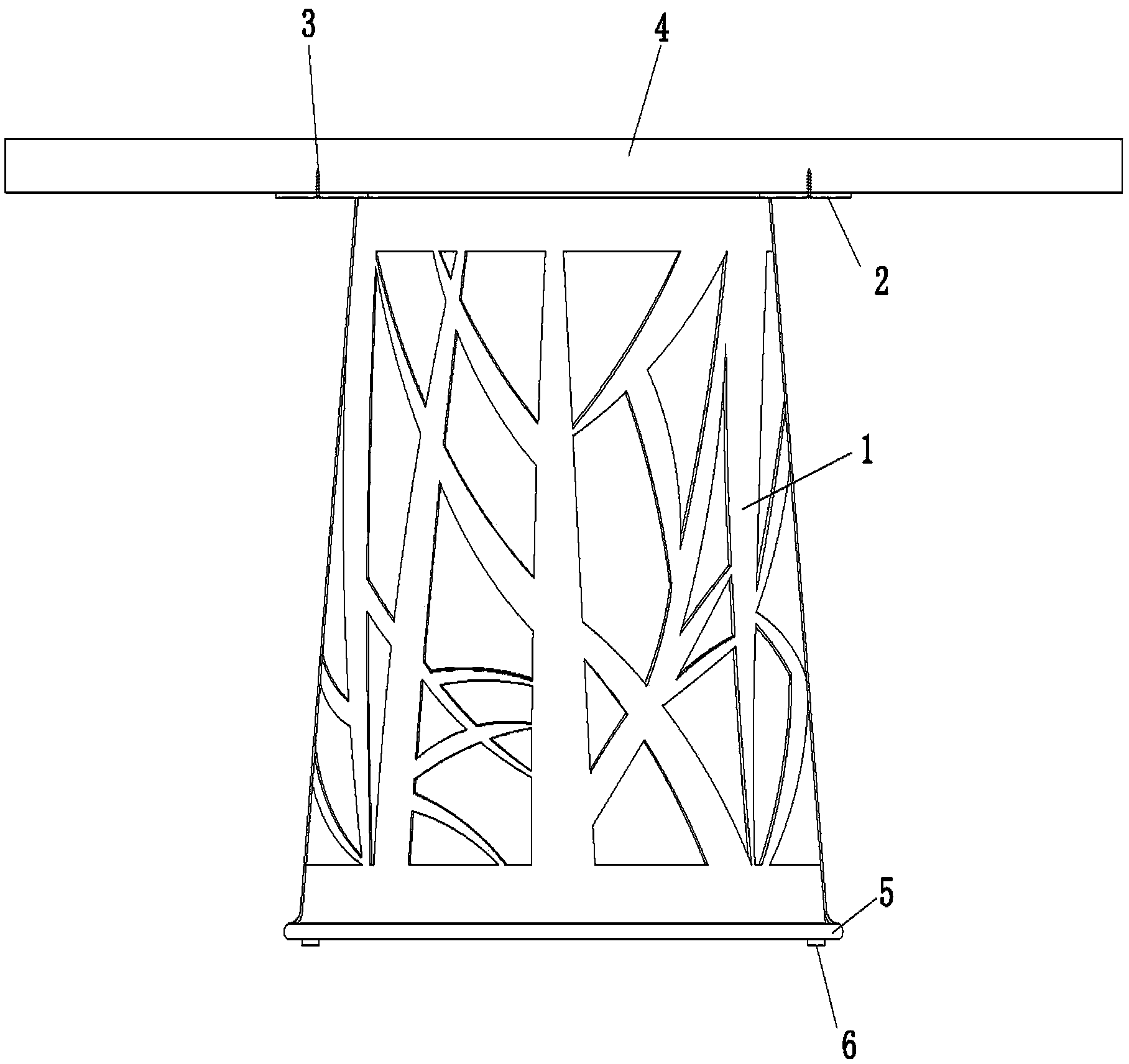

Method for manufacturing steel hollow base

The invention discloses a method for manufacturing a steel hollow base. The method includes the following steps that (1) the four edges of a steel plate are clipped, laser cutting is performed on the steel plate, and a needed shape is formed in a hollow mode; (2) grinding treatment is performed on corners of hollow positions; (3) the grinded steel plate is rolled to be the cylindrical base, and spot welding connection is performed on opposite positions of the two side edges of the steel plate; (4) the grinding treatment is performed on spot welding connection positions, and polishing is performed on the surface of the whole steel plate; (5) coloring treatment is performed on the polished steel plate to form the hollow base. The base of a desk is made of steel, due to the fact that the steel is high in strength and good in tenacity, various kinds of models can be manufactured, and a good artistic effect is achieved. A laser cutting technology is adopted in quantity, machining is easy and convenient, and the production cycle is short. The cut leftover material can be recovered and smelted, therefore, material is saved, and overall cost is low. The steel base is little affected by weather, all the connection parts can not deform in a buckling mode, and the whole structure is firm and durable.

Owner:FUJIAN SENYUAN FURNITURE CO LTD

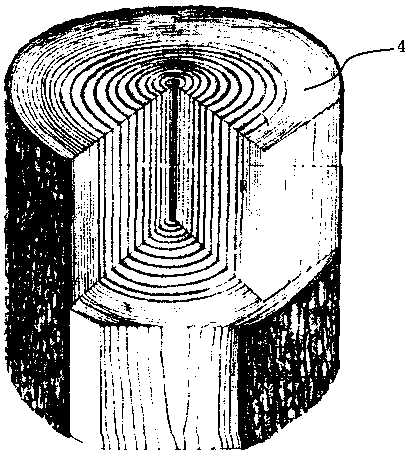

Longitudinal bamboo glue board and fabricating method

A fly-bamboo with longitudinal surface is made up of bamboo through providing bamboo, splitting to become bamboo strips, shaping according to its design, transversely adhering to become a bamboo board, cutting to become board strips, longitudinal adhering and hot pressing. Its advantages are high utilization rate of bamboo, high physical stability and beautiful appearance.

Owner:陈晓岗

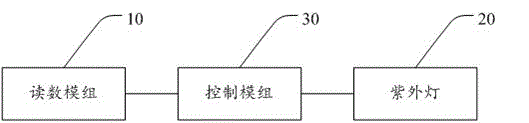

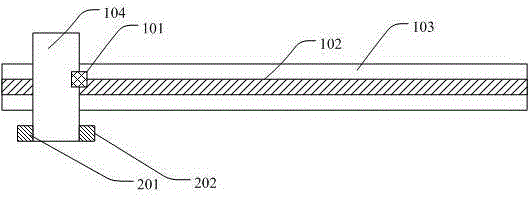

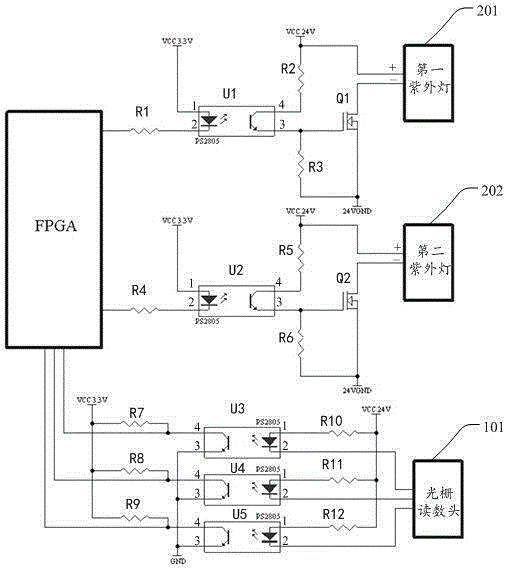

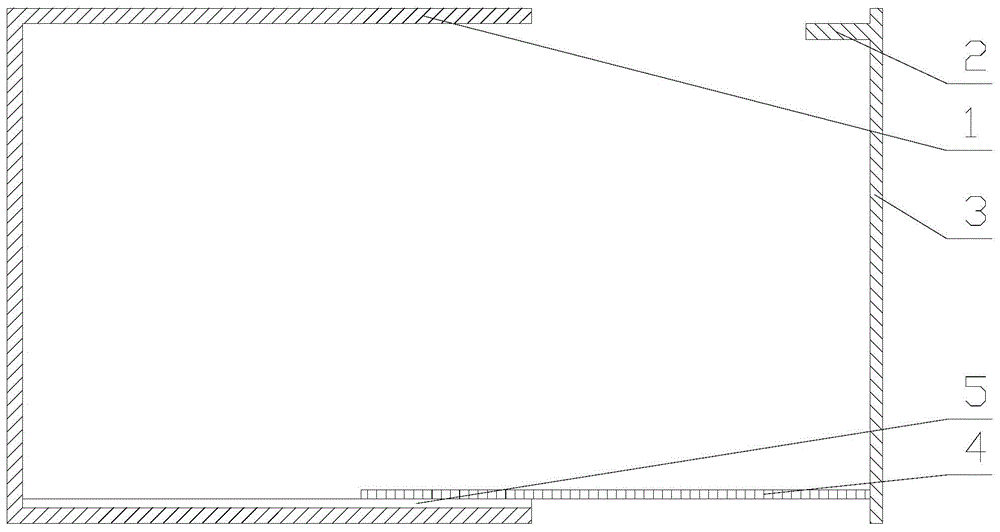

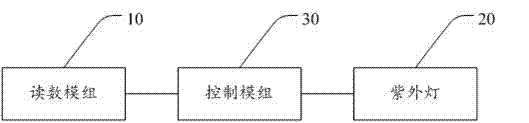

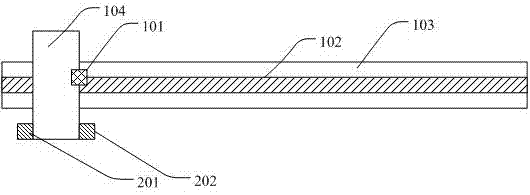

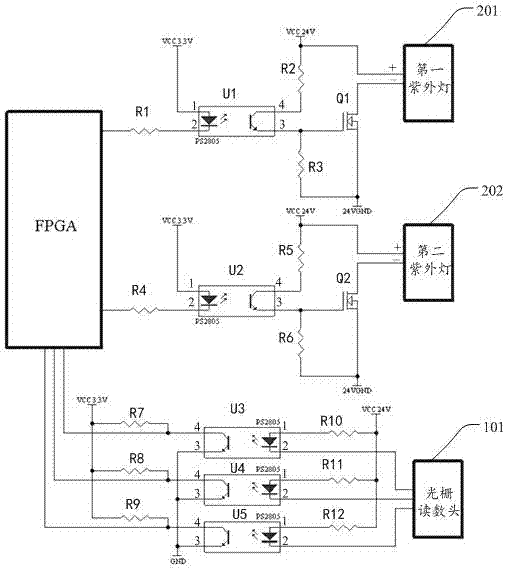

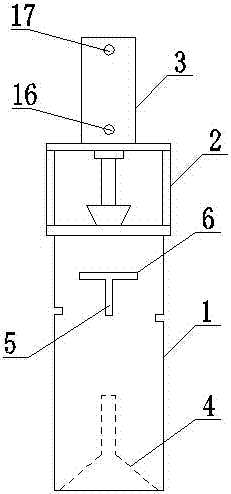

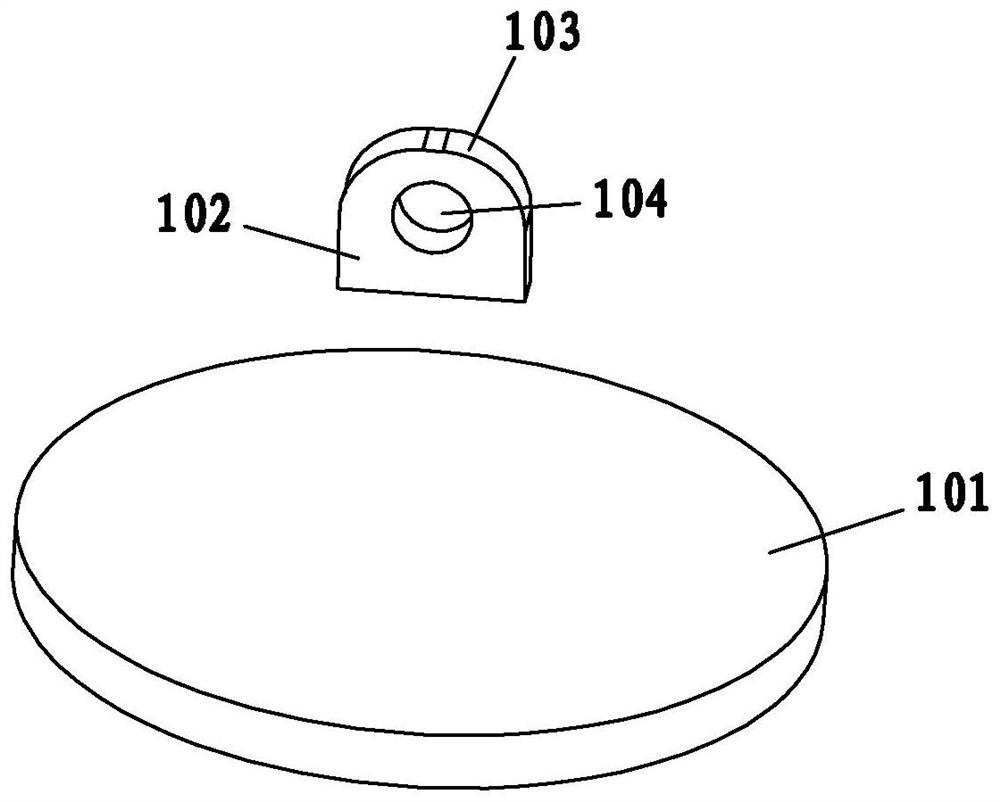

Ultraviolet lamp curing device and curing method thereof

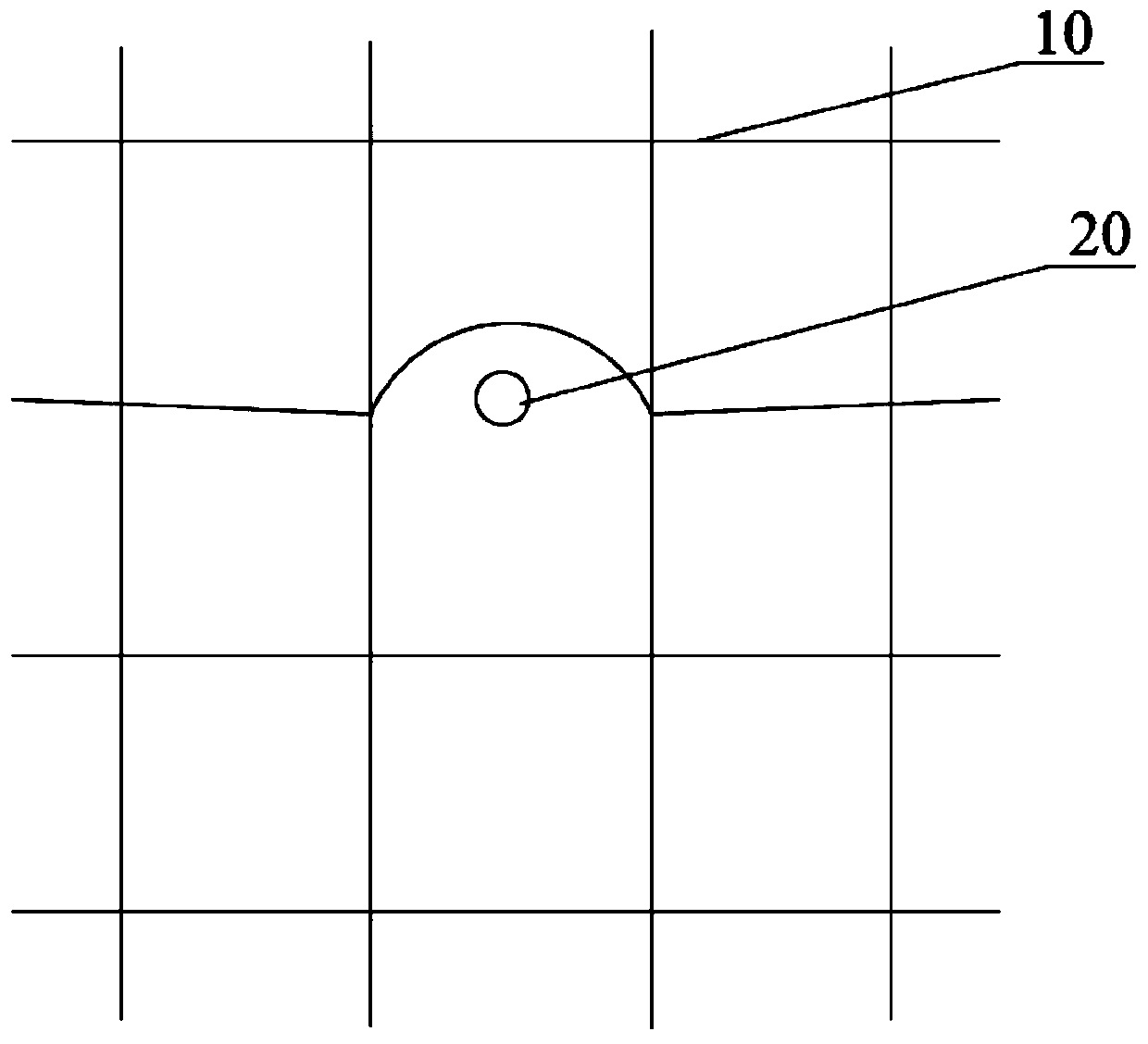

ActiveCN105172392AWill not warpTo achieve the purpose of energy savingOther printing apparatusHigh energyUltraviolet

The invention discloses an ultraviolet lamp curing device and a curing method thereof. The ultraviolet lamp curing device comprises a reading module, at least one ultraviolet lamp and a control module, wherein the reading module reads a coordinate position of a printing module; the control module judges whether the ultraviolet lamp is positioned in an image area according to the coordinate position of the printing module; if the ultraviolet lamp is positioned in the image area, the control module controls the ultraviolet lamp to be turned on; and if the ultraviolet lamp is outside the image area, the control module controls the ultraviolet lamp to be turned off. Thus, the on-off state of the ultraviolet lamp can be accurately controlled according to the size of a printed image, the curing is started where the image exists, the ultraviolet lamp is turned off immediately where no image exists, and a situation that the ultraviolet lamp is turned on when the ultraviolet lamp is not necessary is avoided. The ultraviolet lamp is high-energy equipment, so that the energy-saving purpose is achieved in this way, the curing effect is good, and printing media can not be subjected to buckling deformation.

Owner:SHENZHEN HANDTOP TECH

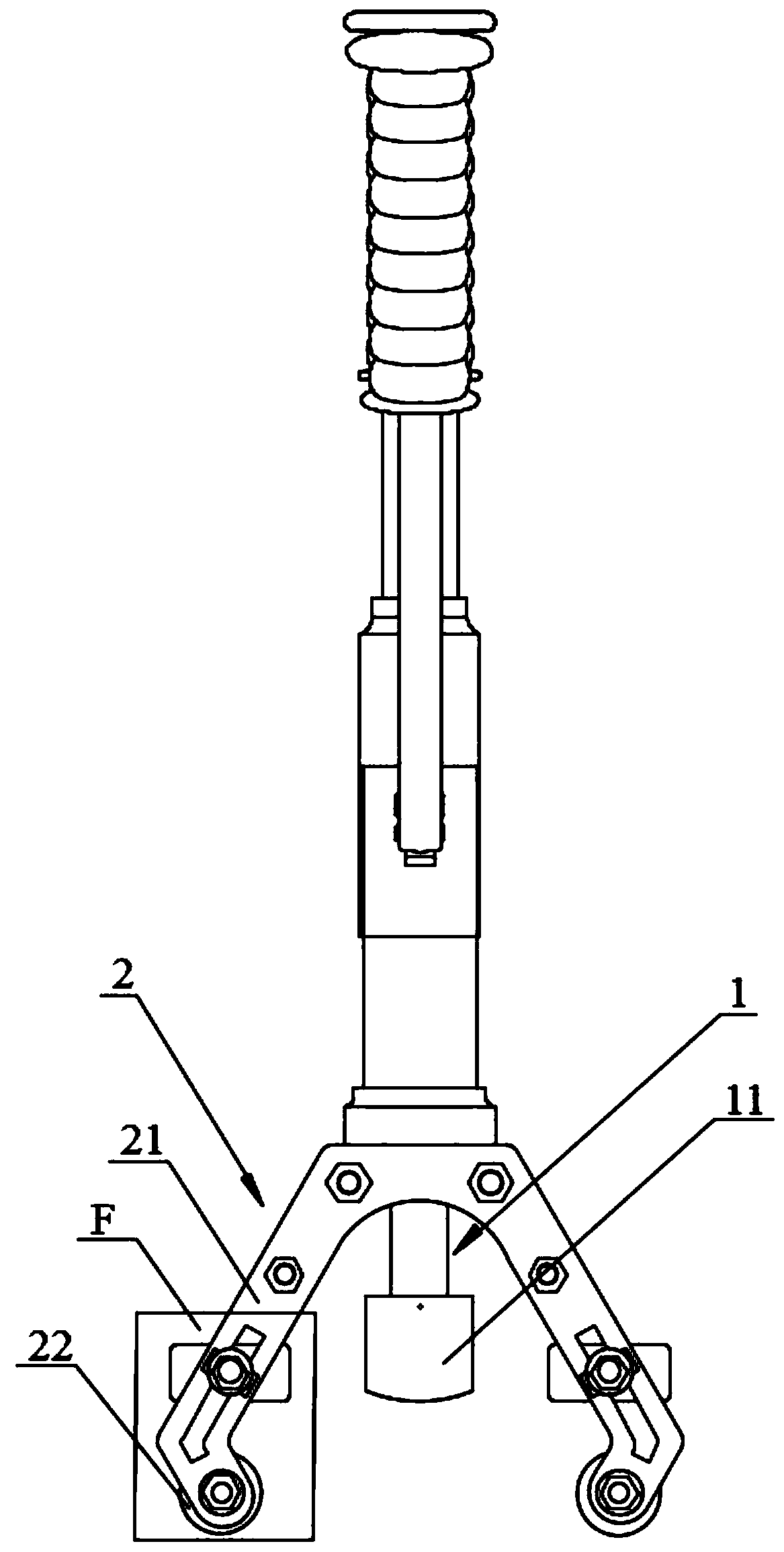

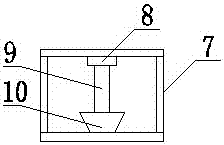

Reinforcing steel bar bending structure, reinforcing steel bar bending device and reinforcing steel bar bending method

The invention discloses a reinforcing steel bar bending structure. The reinforcing steel bar bending structure comprises a pushing rod and a supporting frame; the supporting frame comprises two fixingarms; the pushing rod penetrates through the supporting frame and is located between the two fixing arms; sliding wheels are arranged at the ends of the fixing arms; and pressing blocks correspondingto the sliding wheels are further arranged on the fixing arms. Besides, the invention further relates to a reinforcing steel bar bending device utilizing the reinforcing steel bar bending structure and a reinforcing steel bar bending method. The reinforcing steel bar bending structure, the reinforcing steel bar bending device and the reinforcing steel bar bending method have the beneficial effects that through cooperation of the pressing blocks and the sliding wheels, under the action force of the pushing rod, two ends of a reinforcing steel bar are pressed by the pressing blocks, thus the two ends are kept horizontal all the time, and the condition that the strength of a reinforcing steel bar mesh is affected due to the fact that the two ends of the reinforcing steel bar are deformed byforce to pull the adjacent reinforcing steel bar mesh is avoided; and besides, the pressing blocks can slide on the fixing arms, so that reinforcing steel bars in different diameters can be bent by the structure, and the applicability is improved.

Owner:CHONGQING ZHONGKE CONSTR GROUP

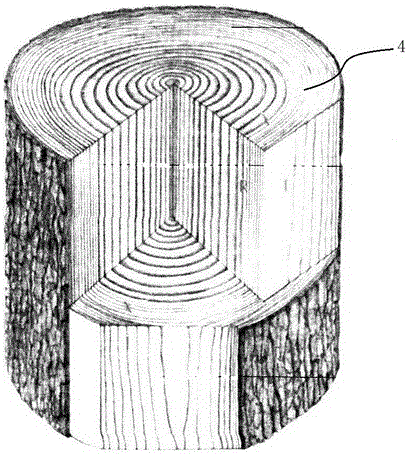

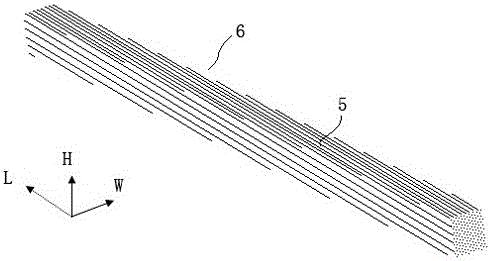

High-strength formwork free of layer separation and method for manufacturing high-strength formwork

ActiveCN105155839AHigh strengthImprove mechanical propertiesSynthetic resin layered productsLaminationHigh intensityMechanical property

The invention discloses a high-strength formwork free of layer separation and a method for manufacturing the high-strength formwork. The high-strength formwork and the method have the advantages that the length directions of battens a are consistent with the growth direction of wood, the height directions of battens b are consistent with the growth direction of the wood, accordingly, sufficient adhesive steeping and mechanical bracing effects can be realized, a core is extremely high in mechanical property in the vertical direction and the horizontal direction and is low in deformation, layer separation phenomena inside the machined core can be prevented, the high-strength formwork is high in modulus, and buckling deformation of the formed formwork can be prevented; the mechanical properties of the formwork can be improved by the aid of continuous fiber reinforcement composite surface layers, the high-strength formwork is light, waterproof and anticorrosion, is high in strength and recycling frequency, and can be easily released from forms, the recycling frequency of the high-strength formwork can reach a hundred at least, accordingly, the service life of the building formwork can be greatly prolonged, and the single-service cost can be reduced.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

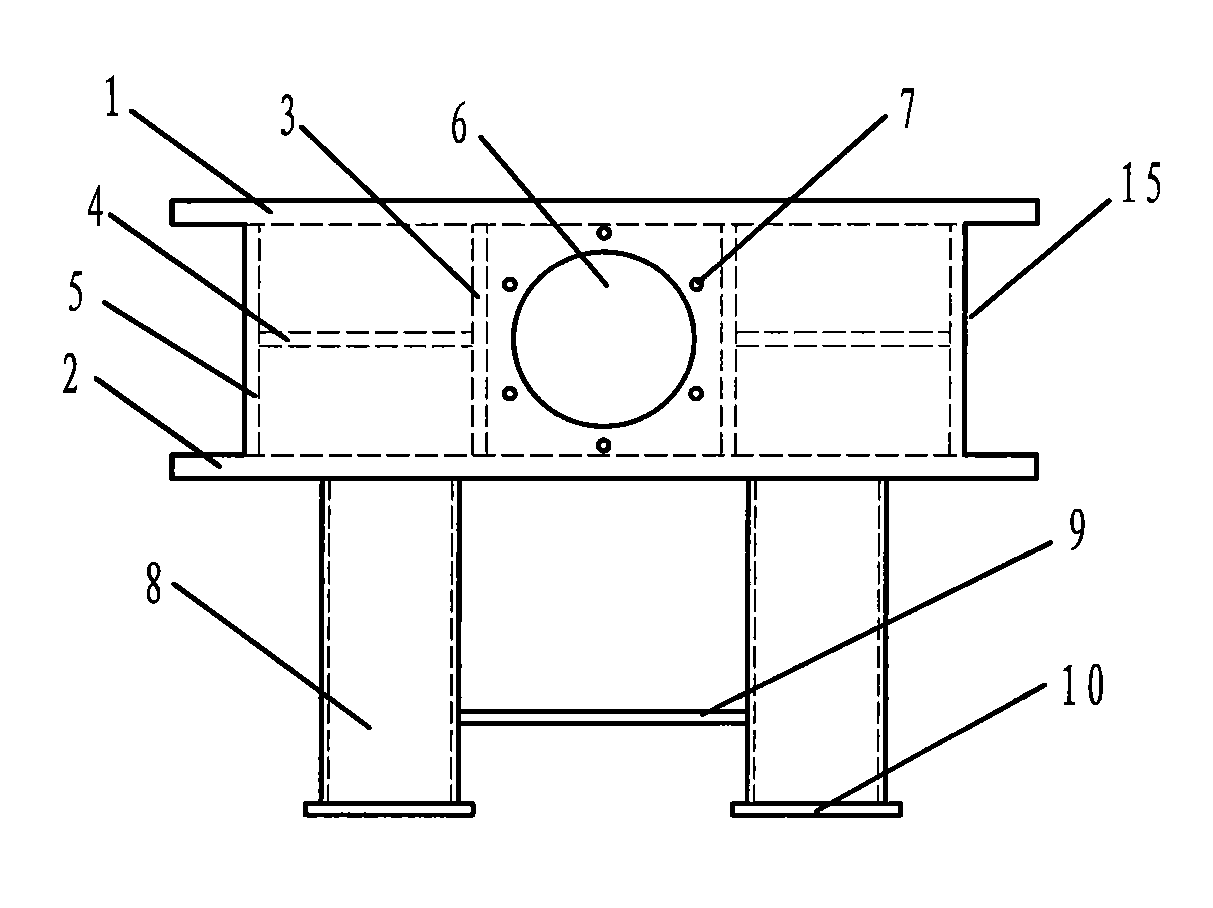

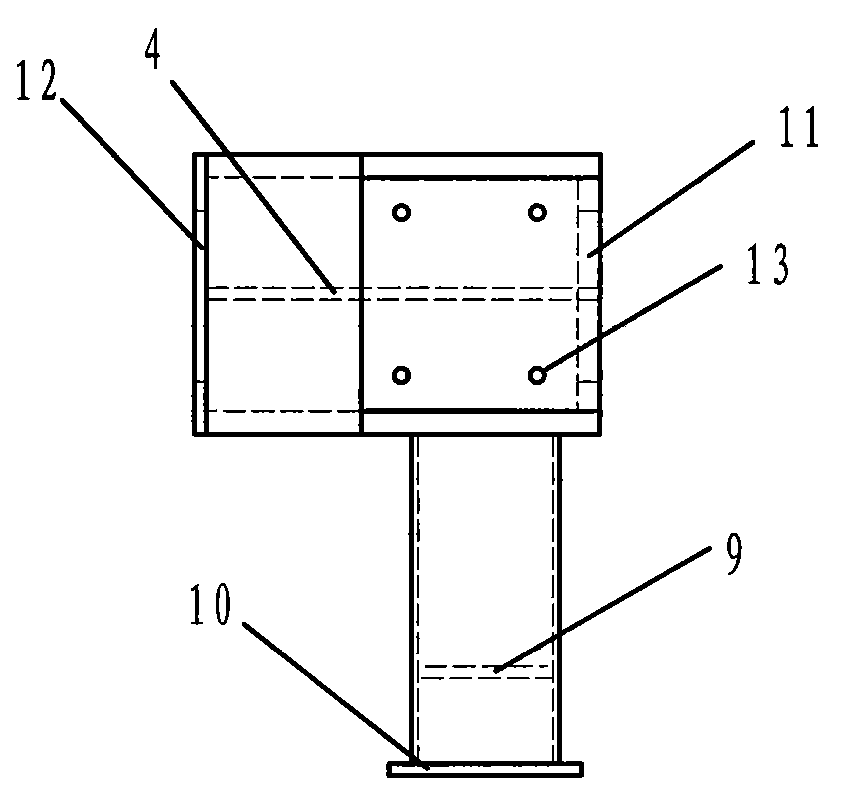

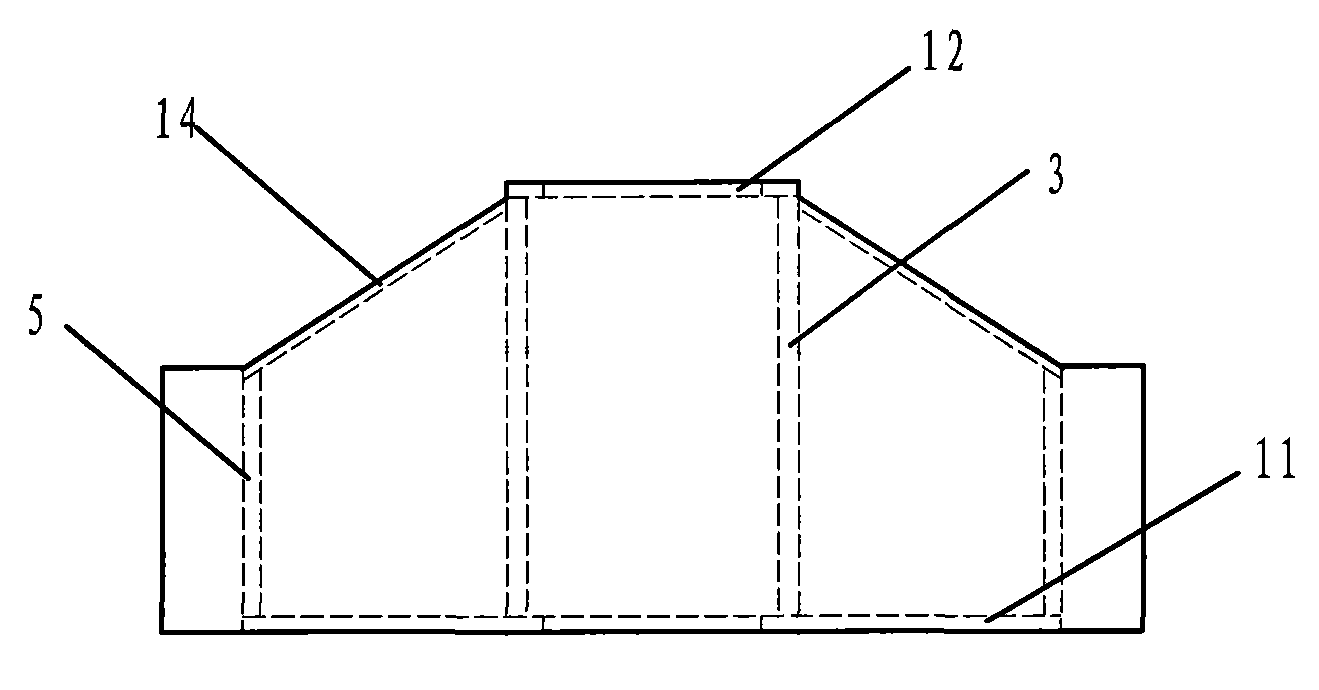

Van body type oil cylinder seat of filter press

InactiveCN103316513ASafe and reliable structureReasonable structureFiltration separationTubes typesHigh pressure

The invention provides a van body type oil cylinder seat of a filter press. The van body type oil cylinder seat is provided with an upper main plate and a lower main plate; middle parts of the upper main plate and the lower main plate are welded with a vertical rib plate and a transverse rib plate to form an oil cylinder seat main body; the two ends of the oil cylinder seat are welded with baffles to form a main beam groove; a front panel and a rear panel are welded at the two ends of the main body; the front panel and the rear panel are provided with oil cylinder body holes; closing plates are welded at the rear two sides of the main body to form the van body type oil cylinder seat; a square tube type supporting leg is arranged at the lower end of the oil cylinder seat; a transverse pull rod is arranged in the middle of the supporting leg; the lower end of the supporting leg is welded with a bottom plate. According to the van body type oil cylinder seat disclosed by the invention, the structure is reasonable and the bearing strength is great; the structure is tightly pressed by hydraulic pressure and high pressure and the fatigue durability is strong; when the van body type oil cylinder seat is tightly pressed and stressed, the oil cylinder seat is not warped and can not deform; a main beam is firmly mounted, and a pressing plate and a thrust plate reach designed parallelism; when materials are filtered, a filtering plate does not leak materials; the arranged supporting leg is welded with a transverse pull plate and a bottom plate and is mounted stably, so that the van body type oil cylinder seat is firm is structure and is safe to use.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

Preparation method of twisted-earth ceramic

The invention relates to a preparation method of twisted-earth ceramic, and belongs to the technical field of twisted-earth ceramic. The porcelain clay is aged by milk, and a coloring agent is added,so that plasticity is improved, and a cracking phenomenon caused by poor plasticity is reduced; a double-sided multi-directional hand rolled sheet shaped like a Chinese character "mi" is adopted, andthickness and uniformity, and trend of grains are controlled, so that the grains and the body cannot be warped and deformed; a mud strip mechanism is used to manufacture geometric continuous patterns,the length of mud strips can reach several meters, and the mud strips can be used to manufacture large-area twisted-earth ceramic or inserted ceramic; geometric patterns are different in change and uniform in rule; waste of corner mud materials is effectively avoided, and zero loss can be almost realized; a printing blank or mud plate forming method is adopted, so that blank repairing is not needed, and waste is avoided. Therefore, raw material cost is reduced, resources are saved, the environment is protected, and meanwhile, a great of resources and manpower are saved. Meanwhile the rate offinished products is improved to the maximum extent, the efficiency is higher than efficiency of manual production of twisted earth, the completion degree of images is higher than the completion degree of hand painting, and low-cost manufacturing or batch production is realized.

Owner:洪张良

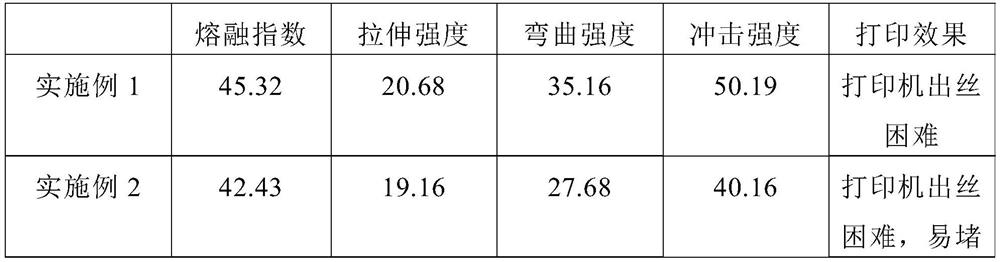

Carbon fiber/PET composite material as well as preparation method and application thereof

PendingCN112480615AGood dispersionReduce joinAdditive manufacturing apparatusPolytetramethylene terephthalatePolyethylene terephthalate glycol

The invention relates to a carbon fiber / PET composite material as well as a preparation method and application thereof. The carbon fiber / PET composite material is prepared from the following raw materials in parts by weight: 60-90 parts of polyethylene glycol terephthalate, 10-40 parts of polybutylene terephthalate, 5-20 parts of chopped carbon fibers, 1-15 parts of a compatilizer, 10-30 parts ofa flexibilizer, 0.1-1 part of a nucleating agent and 0.1-10 part of other assistants. According to the carbon fiber / PET composite material, the nucleating agent adheres to the compatilizer and the flexibilizer, dispersion of the nucleating agent is facilitated, then the nucleating agent, PET, PBT, chopped carbon fibers and other auxiliaries are mixed according to the formula and then added into adouble-screw extruder to be extruded and granulated, modified granules are dried and then extruded through a single-screw extruder, and the wire suitable for the FDM printer is obtained. And the prepared wire and the printed product have smooth and flat surfaces, and do not warp or deform in the printing process. The nucleating agent can be used for well adhering the heated compatilizer, so that the nucleating agent can be well dispersed in the subsequent mixing process, the addition of a dispersing agent can be reduced, and the cost is saved.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

A wood-plastic composite material board with cross-linked microporous structure and preparation method thereof

Owner:扬州润友复合材料有限公司

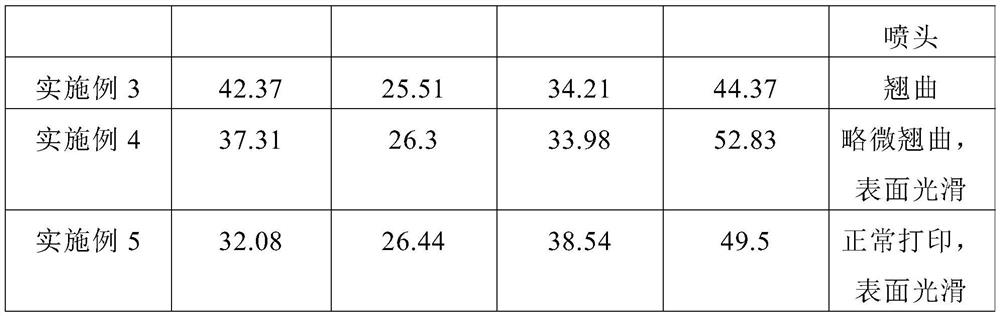

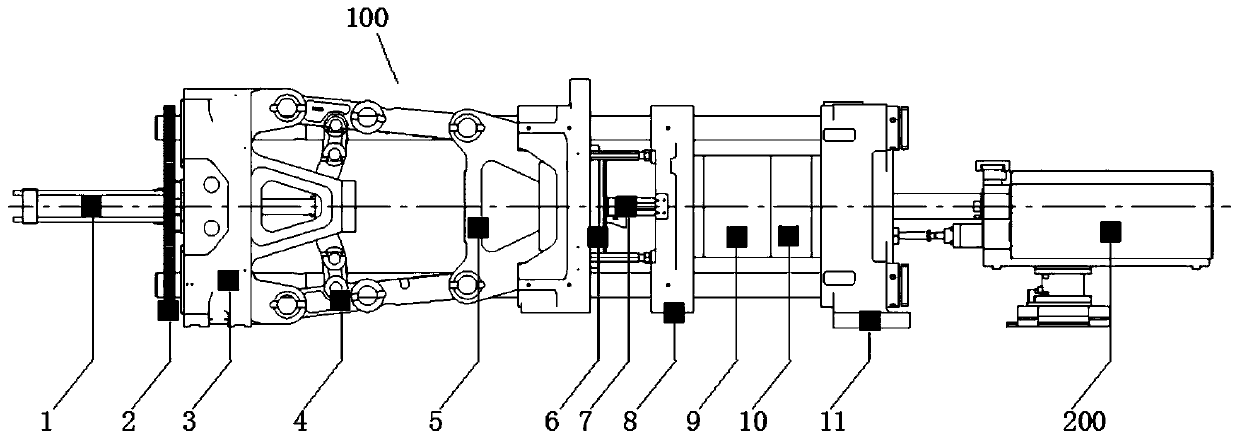

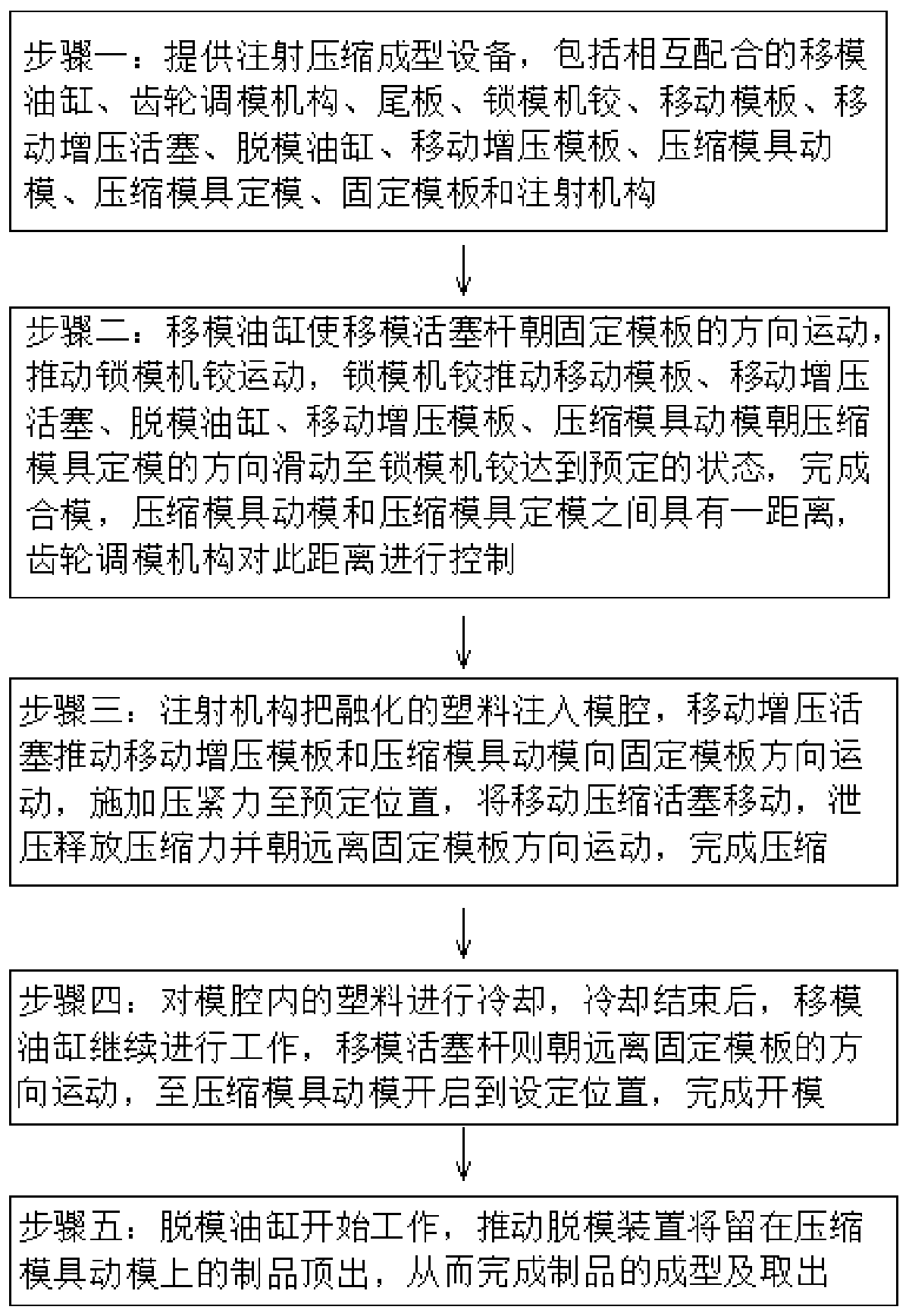

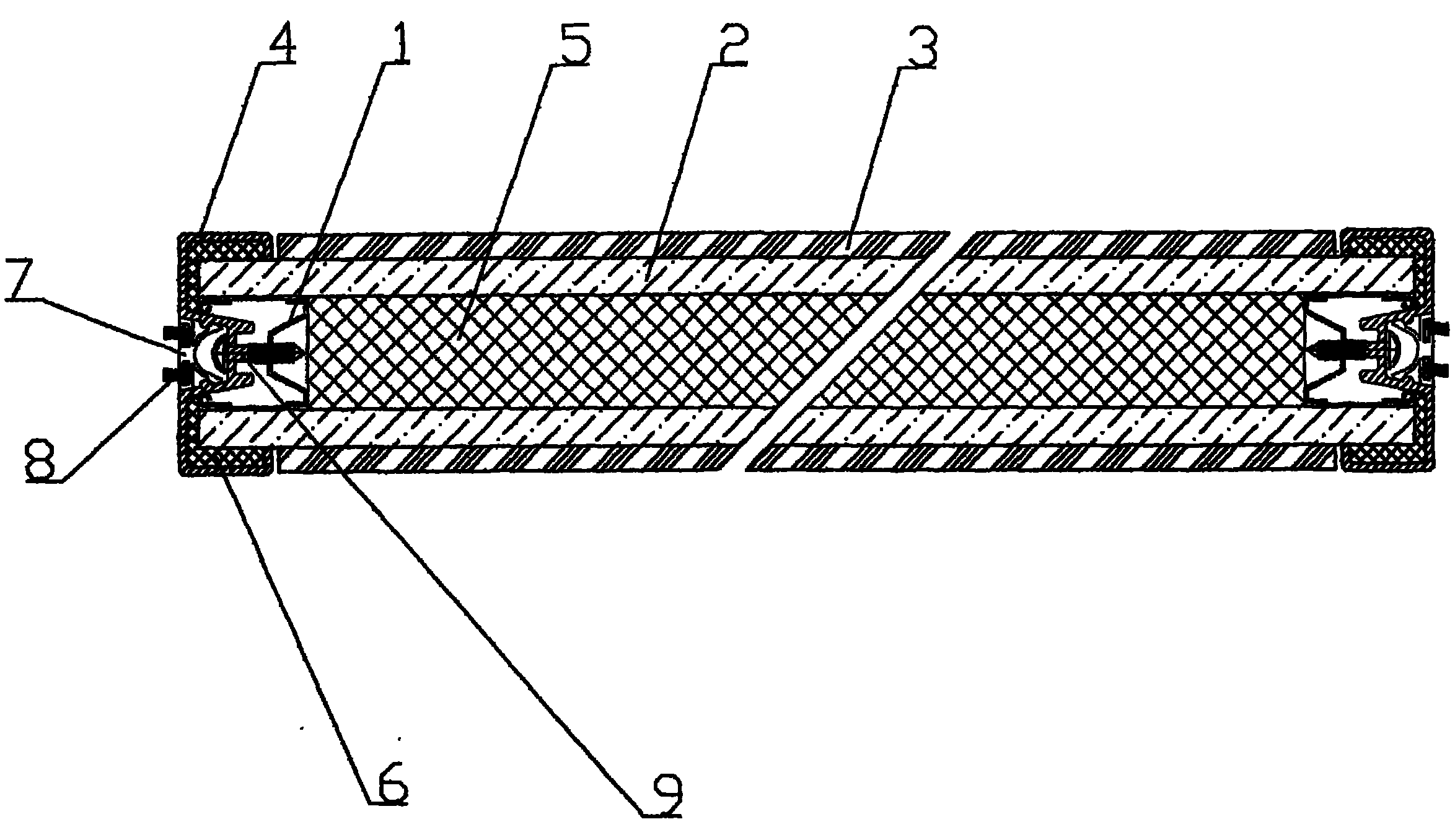

Injection compression molding process and equipment

The invention discloses an injection compression molding process and equipment. According to the injection compression molding process and equipment, a mold moving oil cylinder makes a mold moving piston rod move, a mold locking machine hinge is pushed to move, the mold locking machine hinge pushes a moving mold plate, a moving pressurizing piston, a demolding oil cylinder, a moving pressurizing mold plate and a compression mold moving mold to slide until the mold locking machine hinge reaches a predetermined state to finish mold closing, a distance exists between the compression mold moving mold and a compression mold fixed mold, a mold cavity is formed between the compression mold moving mold and the compression mold fixed mold, an injection mechanism injects melted plastic into the moldcavity, the moving pressurizing piston pushes the moving pressurizing mold plate and the compression mold moving mold to move to the direction of a fixed mold plate, a compression force is applied tothe inner portion of the mold cavity, and then the melted plastic inside the mold cavity is compressed until to a predetermined position, then a moving compression piston is moved, pressure relief isperformed to release the compression force inside the mold cavity and moving away from the direction of the fixed mold plate is performed, a compression process is finished, product warping deformation is avoided, and the accuracy is guaranteed.

Owner:何兆洪

Lightweight plastic-wood composite sheet and preparation method thereof

The invention relates to a lightweight plastic-wood composite sheet and a preparation method thereof. The preparation method comprises the following steps of: firstly stirring PVC particles and tribasic lead sulfate evenly in a stirred tank, and then adding wood flour, LDPE-g-GMA, hollow glass beads, chlorinated polyethylene, ethylene bisstearamide and hard fatty acid butyl ester to the tank, heating up and stirring evenly, cooling and taking out the mixture, and then stirring the mixture evenly with baking soda and citric acid at room temperature, extruding out and molding. The lightweight plastic-wood sheet has the advantages of convenient production and manufacture, high degree of mechanization in the production process, low production cost, low density, light weight, easy installation and maintenance, less use of timber and plastic, turning waste into treasure, being recyclable and not destroyed by insects, no aging and discoloration as well as cracking, no buckling deformation and high impact strength, with the function of adsorbing gas. The lightweight plastic-wood sheet can be applied to a plurality of occasions such as office buildings, hotels and home offices, can be made into products such as photo frames, picture frames, foot lines, and hoisting and fastening boards, and can also be used as suspended beams, pergolas, and the like.

Owner:江苏森诺塑胶科技有限公司

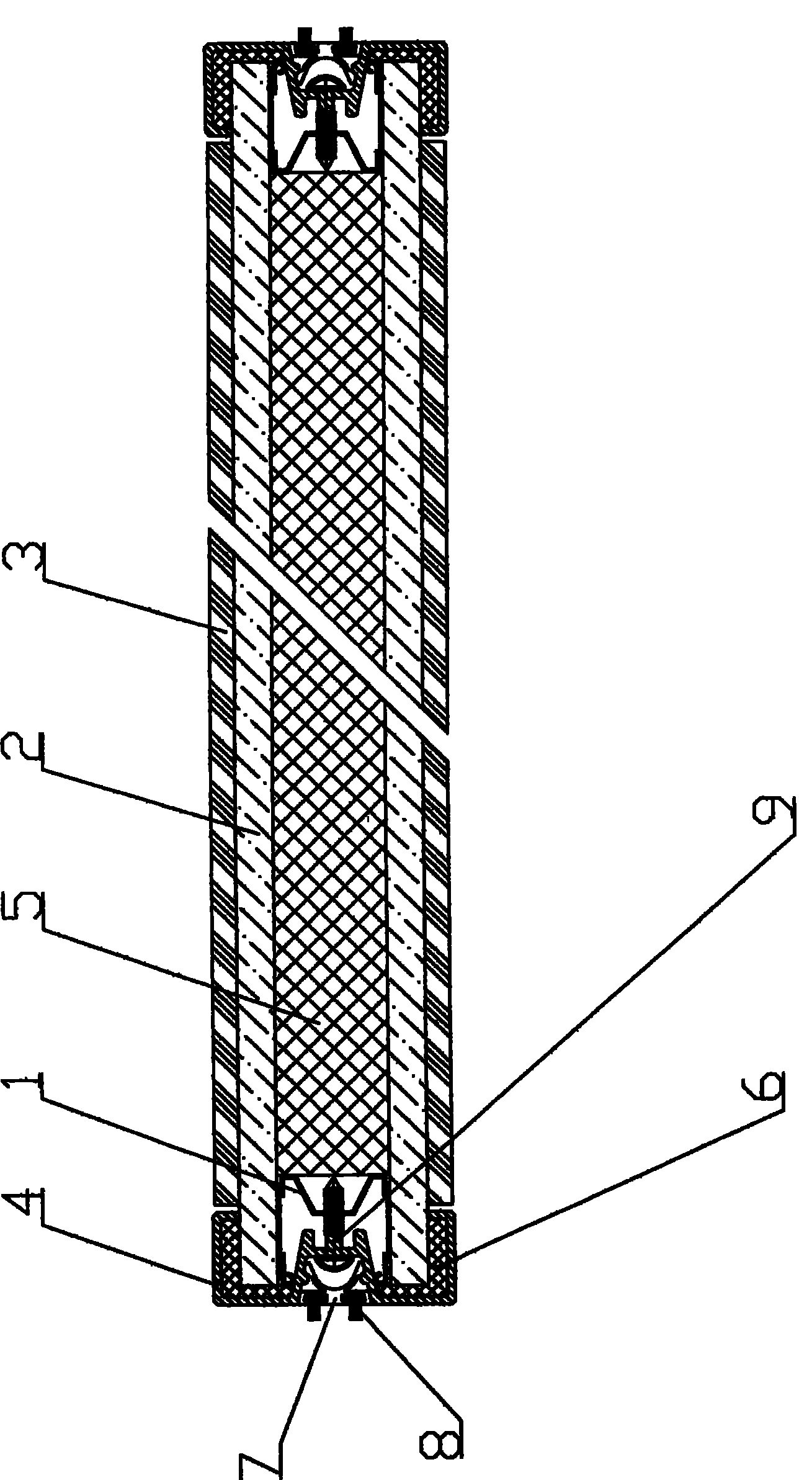

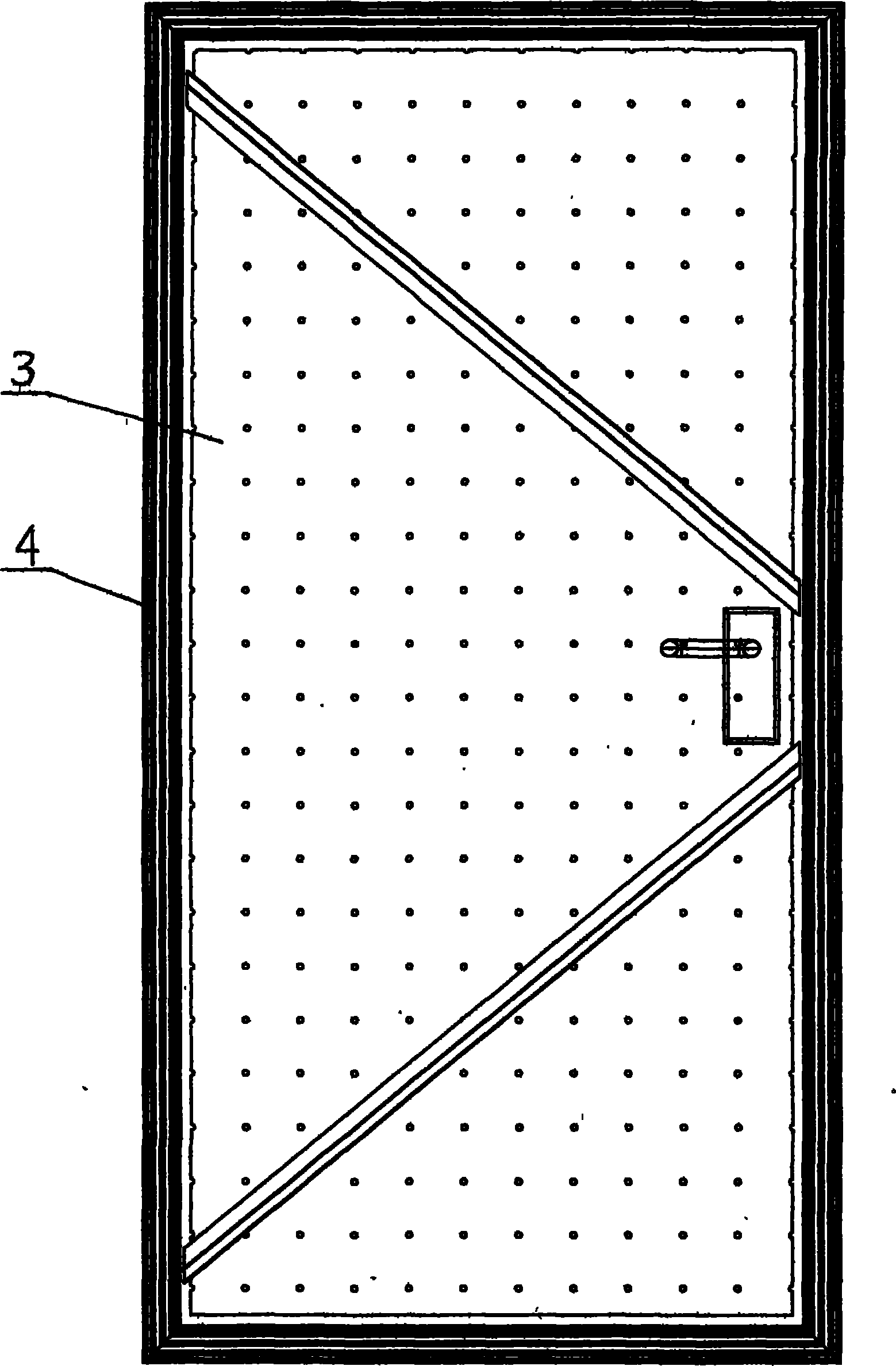

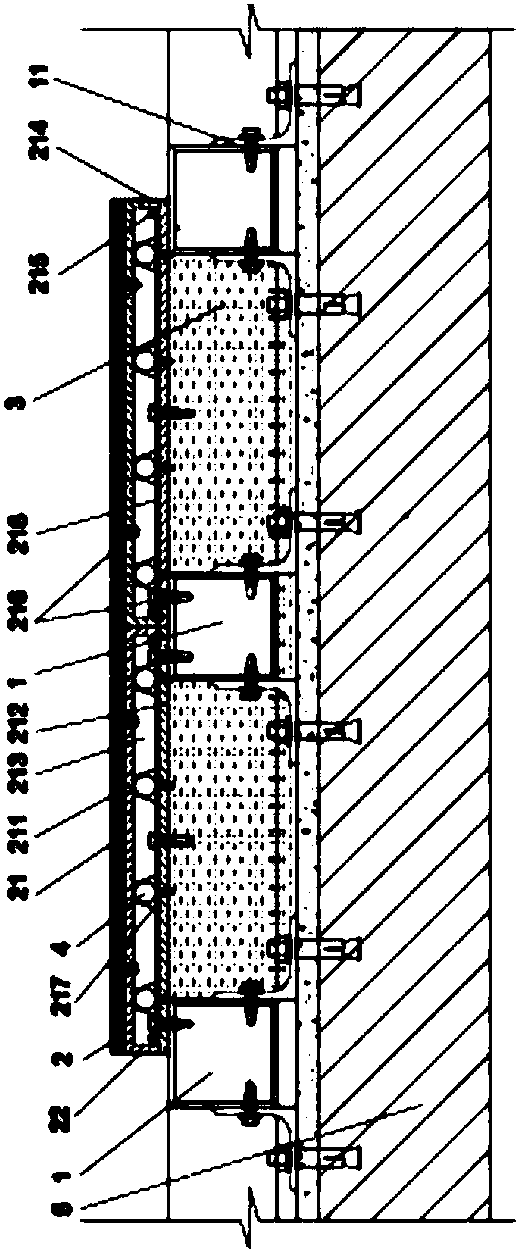

Indoor composite door

InactiveCN101418663BImprove fire performanceImprove insulation effectFireproof doorsSealing arrangementsThermal insulationSteel frame

The invention relates to an indoor composite door, which is composed of a door frame, door bottom plates, door panels, a door jamb, fillings, end caps, door jamb press strips, sealing wool tops and fasten nails. The door is characterized in that two door bottom plates made of plasterboard parallelly clamp the door frame made of light steel frame, fillings are filled therebetween and are made fromrock wool and glass wool material, the end caps made of rubber wrap the peripheral edges of the door bottom plates; the door jamb made of aluminium alloy is fixedly connected with the door frame through the metal fasten nails, and the door bottom plates, the door frame, and the door jamb are fixed into one body; the two door panels are respectively attached to two door base plates which are made of fireproof decorative plate; and the door jamb press strips with the sealing wool tops buckle on the door jamb to combine the indoor composite door. The indoor composite door has excellent fireproofperformance, thermal insulation performance, sound insulation performance, and will not generate warpage because of environmental influence in use.

Owner:王志峰

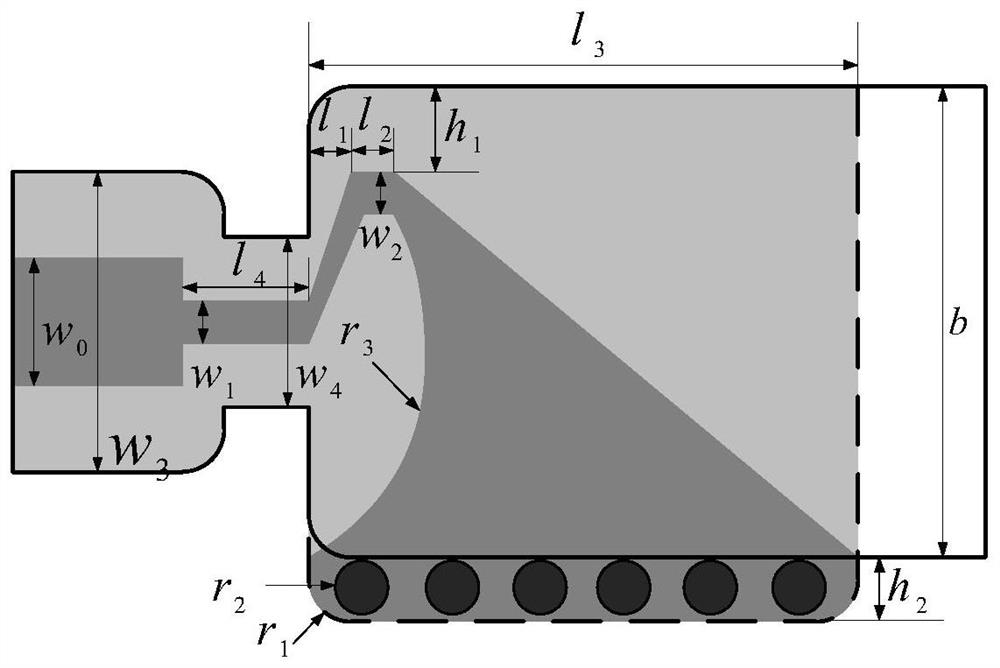

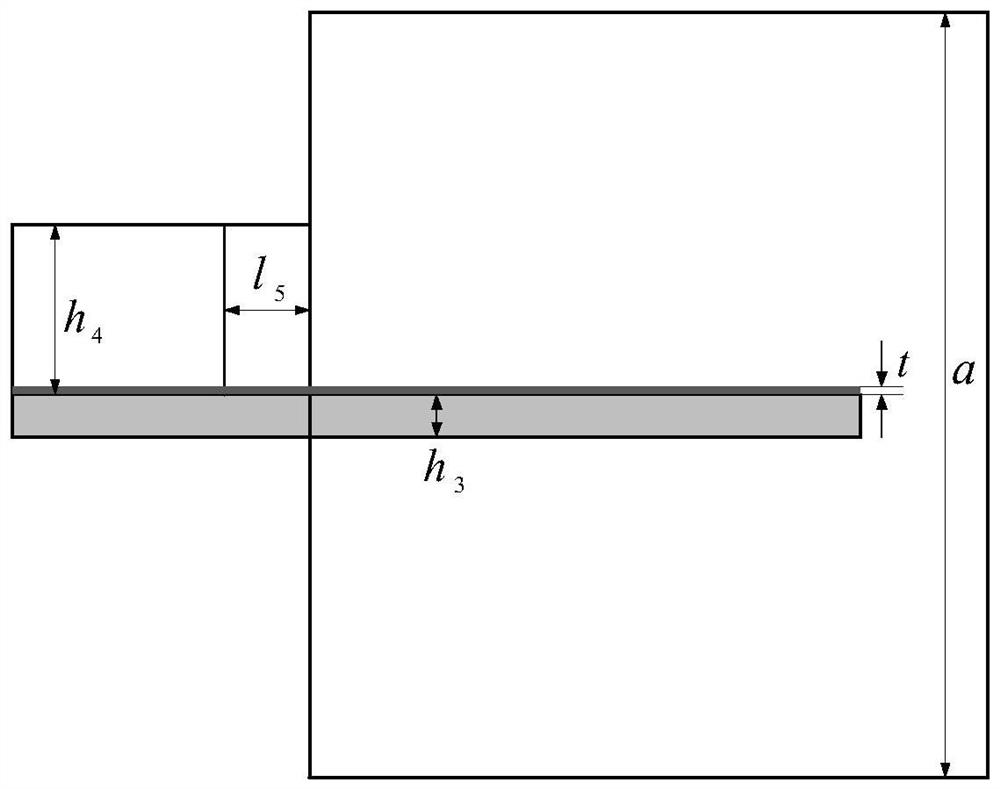

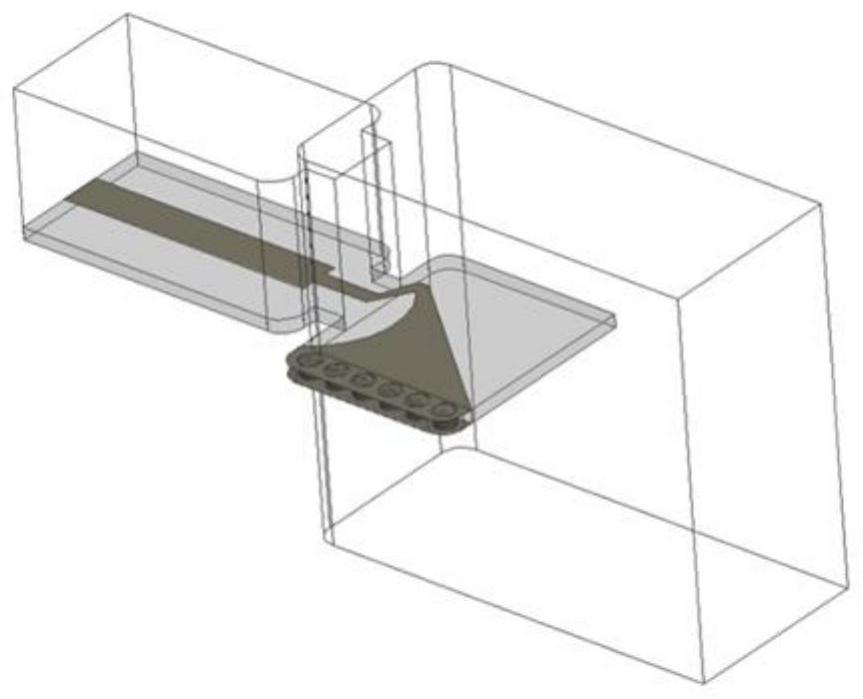

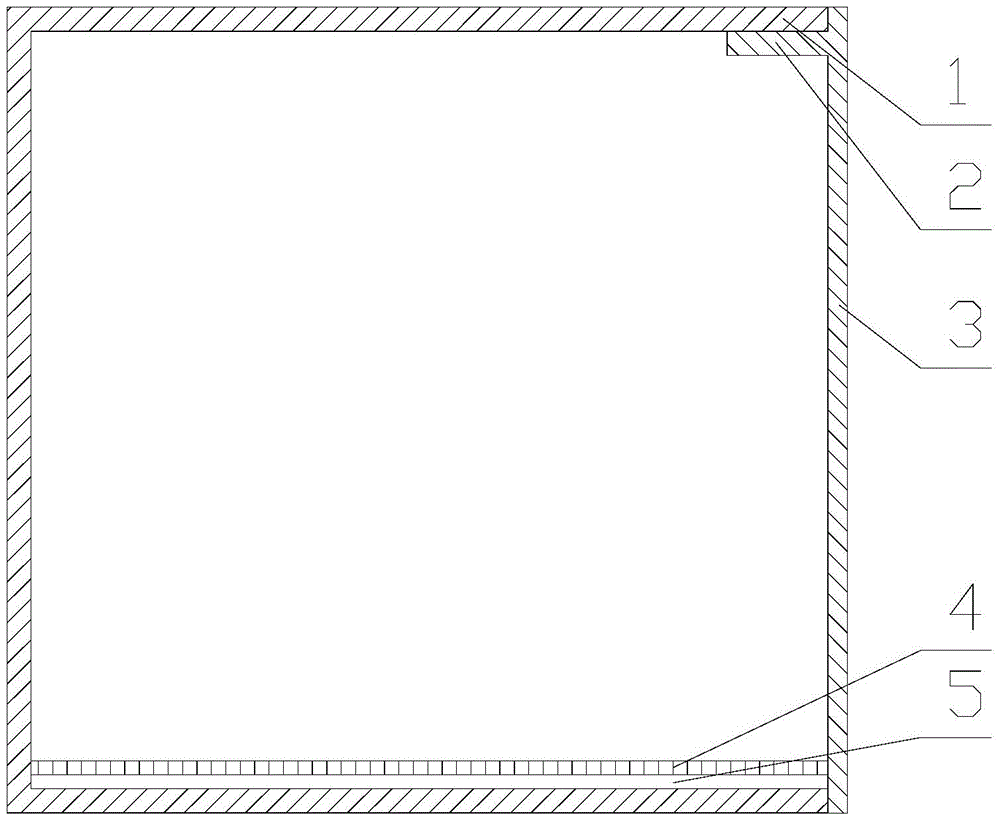

A small size ka-band broadband end-fed waveguide microstrip conversion structure

ActiveCN106450632BSmall standing waveImproving Impedance MatchingCoupling devicesBroadbandingWaveguide

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

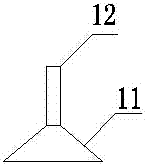

Side-opening packing box

InactiveCN104691891ANo need to worry about smashingWill not warpDrawer-and-shell containersSlide plateEngineering

The invention provides a side-opening packing box and relates to a packing box body for goods with large size and weight. The side-opening packing box is characterized in that a box body adopts five sealed surfaces, and a side-opening cover is mounted on an opening surface of the box body to form a sealed box body; the opening surface of the box body is the side part of the box body; a slideway is mounted at the inner bottom of the box body; a sliding plate matched with the slideway is mounted on the side-opening cover and is mounted on the slideway; a stop plate is mounted at the upper part of the side-opening cover. The side-opening packing box has the characteristics of being novel in structure, simple and convenient in machining, convenient to use, safe, reliable and the like, thereby being a novel side-opening packing box integrating economy and practicality.

Owner:DALIAN YUREN DESIGN

Compound foamed plastic-wood composite material plate and preparation method thereof

The invention relates to a compound foamed plastic-wood composite material plate and a preparation method thereof. The preparation method comprises the following steps: adding polyvinyl chloride and dibasic lead phosphite into a stirring kettle, and evenly mixing at high temperature; adding wood powder, kaolin powder, accelerator, azobisformamide, calcium stearate and chlorinated polyethylene into the stirring kettle, heating, evenly mixing, and cooling; adding o-toluenesulfonhydrazide and dibutyl phthalate into the kettle, heating, evenly mixing, cooling, taking out the mixture, and granulating by extrusion; and after finishing the granulation, carrying out extrusion molding on the granules. The invention has the advantages of high manufacturing convenience, low cost, light weight, low brittleness, excellent ductility, excellent shock resistance, favorable surface tactile sensation, sound insulation, heat insulation, aging resistance, discoloring resistance and no buckling deformation, is convenient to mount and maintain, and can adsorb toxic gas; and the invention consumes less plastic, is environment-friendly and can be recycled. The invention can be used in office buildings, families and other occasions, and can be made into door plates, photo frames, picture frames, skirting plates, suspended pinch plates, suspended beams, pergolas and the like.

Owner:扬州润友复合材料有限公司

Ultraviolet lamp curing device and curing method thereof

ActiveCN105172392BWill not warpTo achieve the purpose of energy savingOther printing apparatusHigh energyEngineering

The invention discloses an ultraviolet lamp curing device and a curing method thereof. Wherein, the ultraviolet lamp curing device includes a reading module, at least one ultraviolet lamp and a control module, the coordinate position of the printing module is read by the reading module, and the control module judges whether the ultraviolet lamp is located in the image area according to the coordinate position of the printing module Medium; when the UV lamp is in the image area, control the UV lamp to turn on; when the UV lamp is outside the image area, control the UV lamp to turn off, so that the switch of the UV lamp can be precisely controlled according to the size of the printed image, and the curing can be started where there is an image , Turn off the UV lamp immediately where there is no image, and avoid turning on the UV lamp when it is not necessary, because the UV lamp is a high-energy device, which can achieve the purpose of energy saving, and the curing effect is good, and the printing medium will not warp and deform.

Owner:SHENZHEN HANDTOP TECH

Geothermal solid wood floor board

InactiveCN109113301AThe overall thickness is thinImprove moisture resistanceLighting and heating apparatusFlooring insulationsSolid woodKeel

The invention relates to a geothermal solid wood floor board which comprises a keel and a solid wood board, and the solid wood board is erected on the keel, the solid wood board is characterized in that the solid wood board is a metal-based solid wood board, and the upper layer of the metal-based solid wood board is a thin-sheet layer with the thickness of 2-5 mm, and the lower layer of the metal-based solid wood board is a metal substrate layer with the thickness of 5-8 mm; the middle or the lower surface of the metal substrate layer is provided with a pipeline channel for the pipeline to pass through. The solid wood floor board has the advantages that the structure is compact, and the overall thickness of the geothermal solid wood floor is relatively thin; the floor board is damp-proofing, good in fireproof performance, resistant to worm damage and free of harmful gas, free of warping and deformation, and is firm and durable; the heat utilization rate is up to 70%, is far higher thanthat of a traditional geothermal solid wood floor board, and has relatively good application value.

Owner:XIAN GAIWO THERMAL ENERGY TECH

A steel pipe pile device with outrigger

ActiveCN105544507BImprove vertical load carrying capacityImprove stabilityBulkheads/pilesEngineeringWire rope

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LIANYUNGANG POWER SUPPLY CO +3

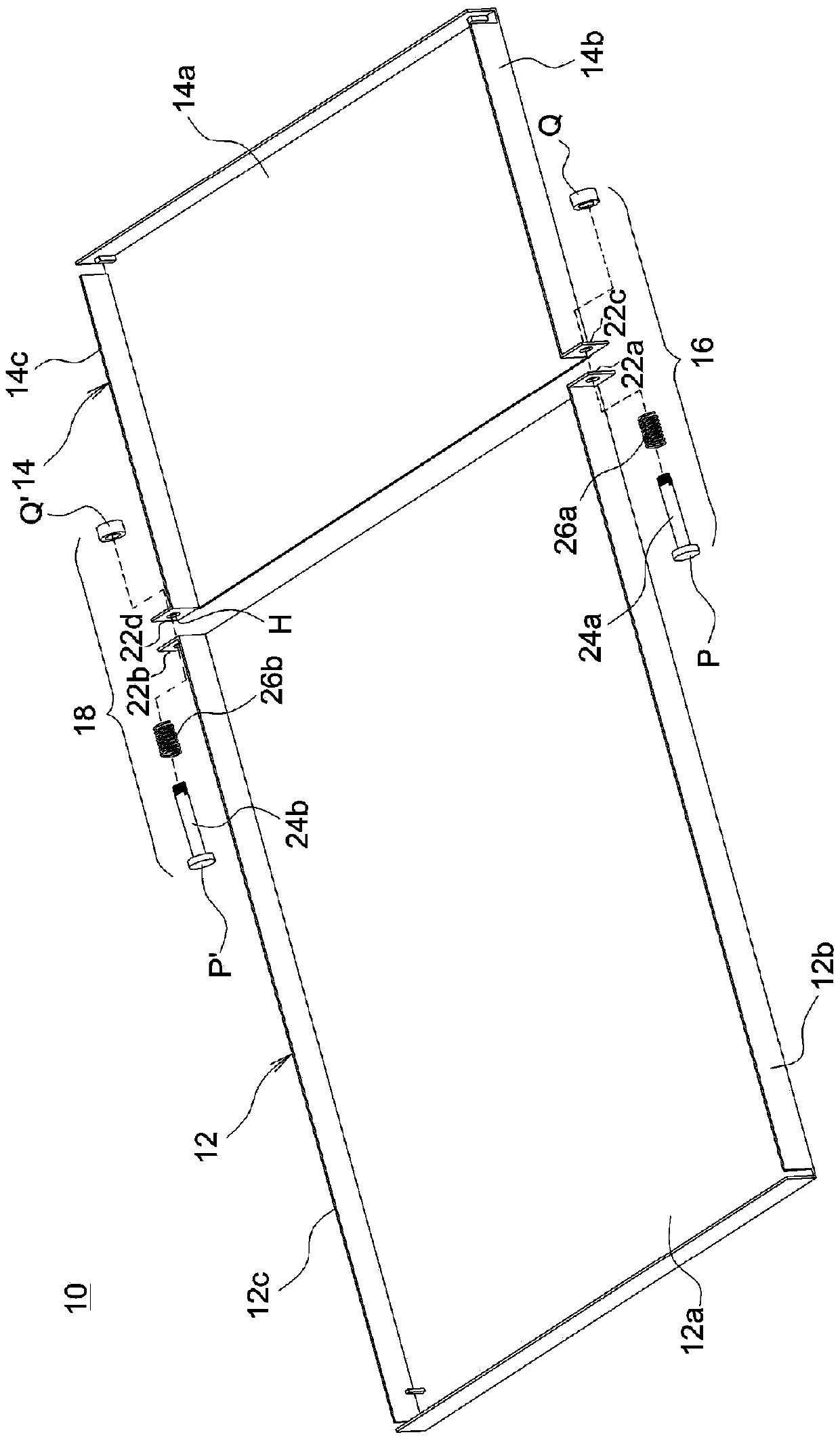

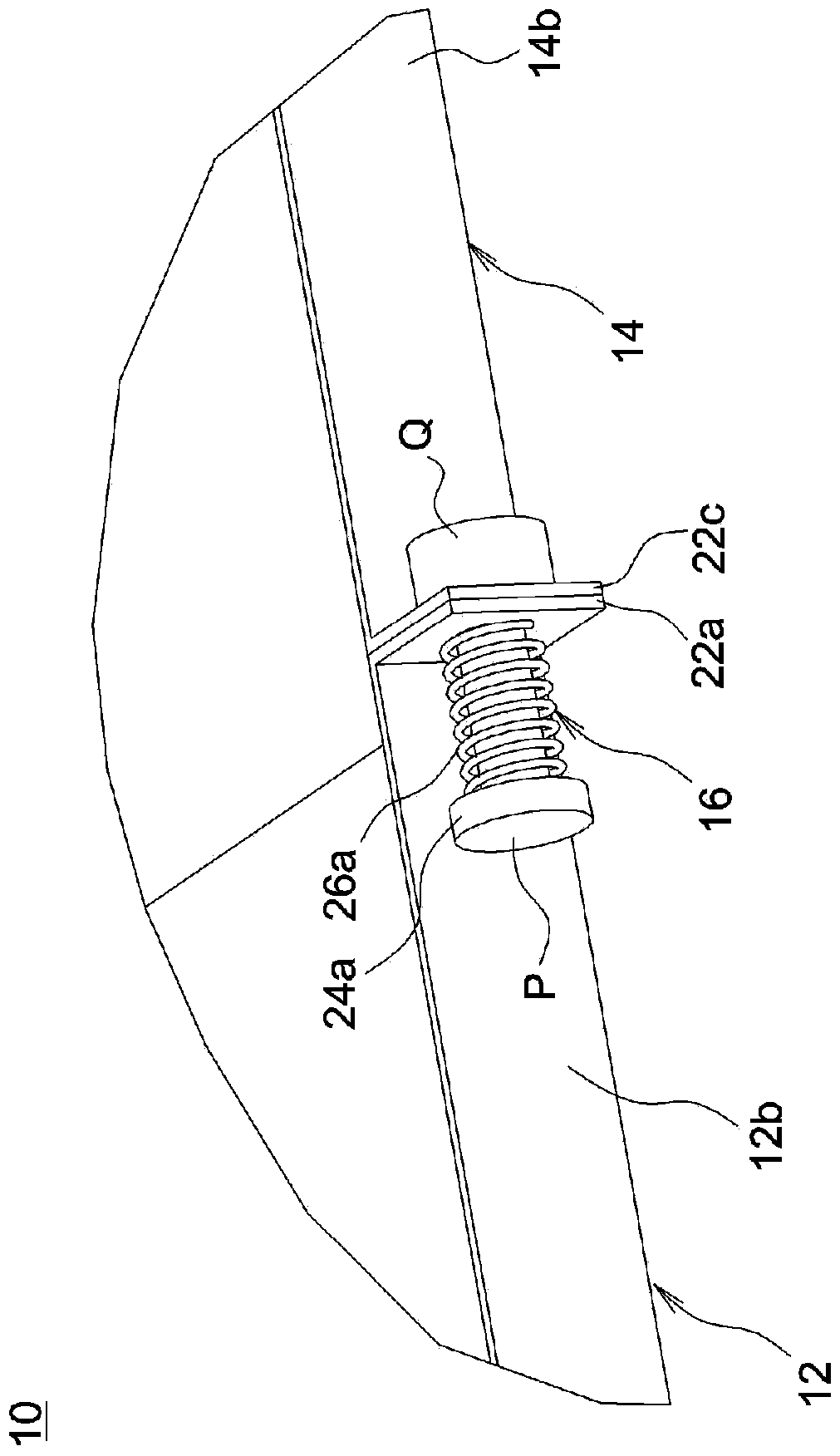

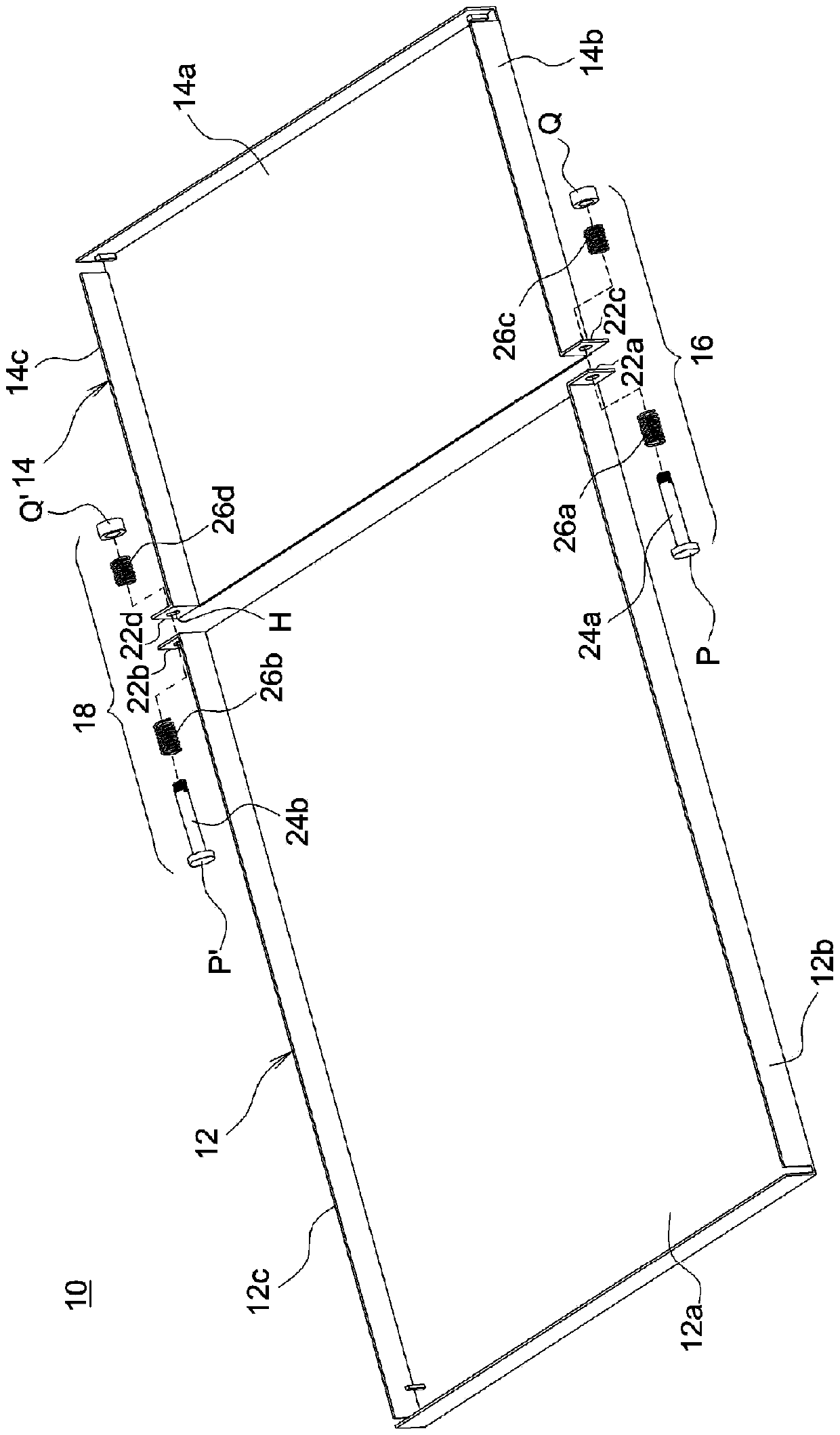

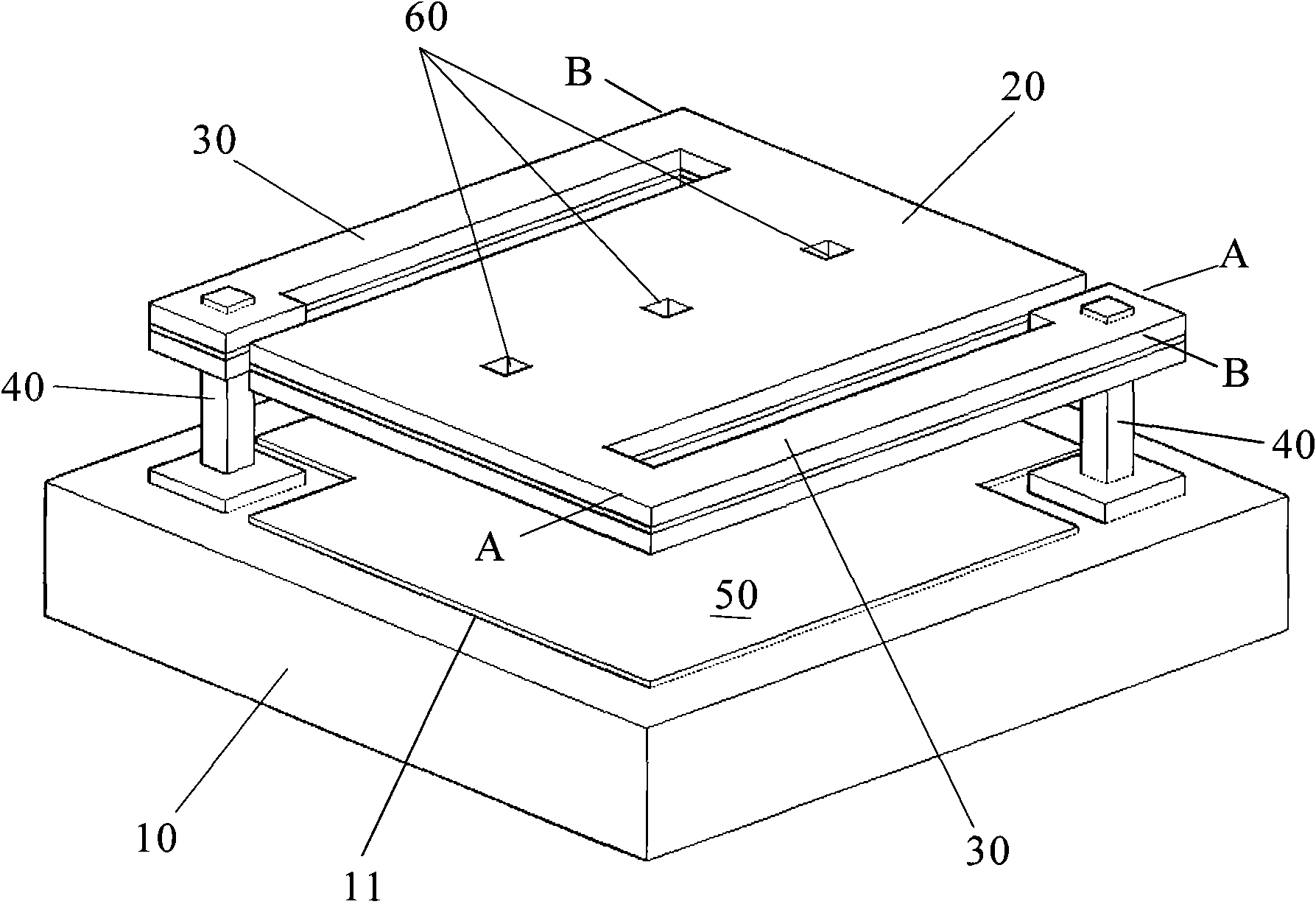

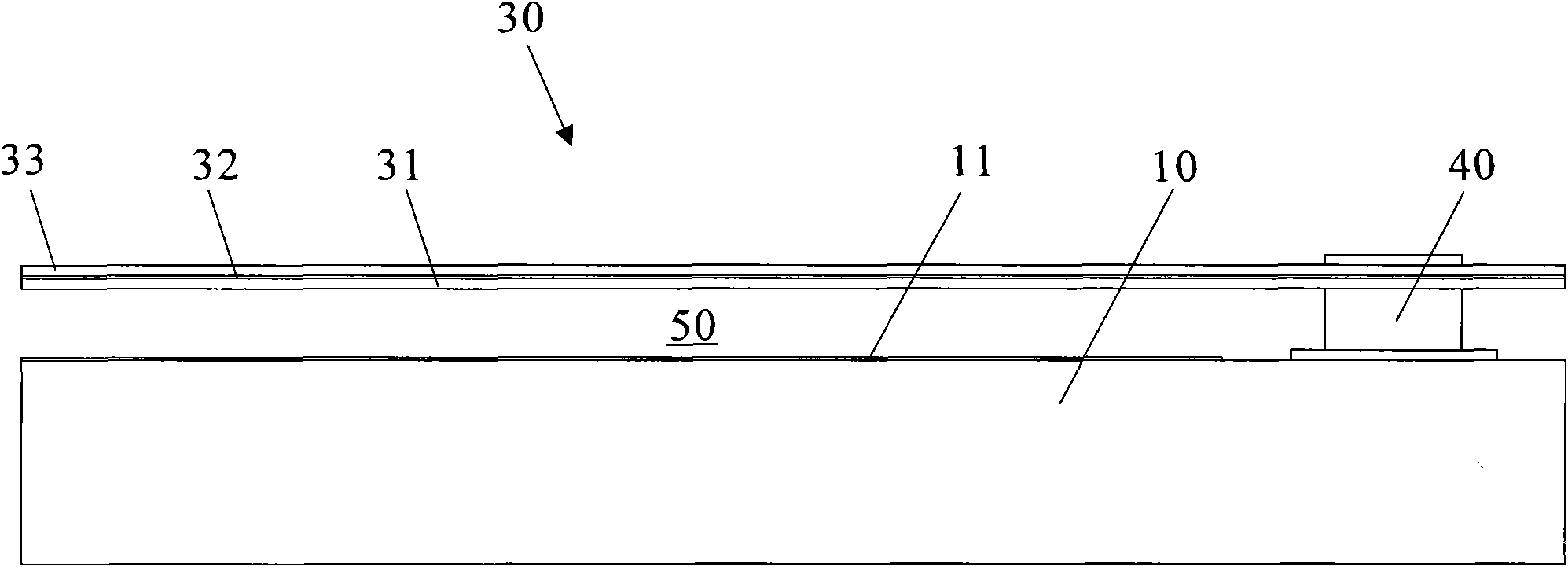

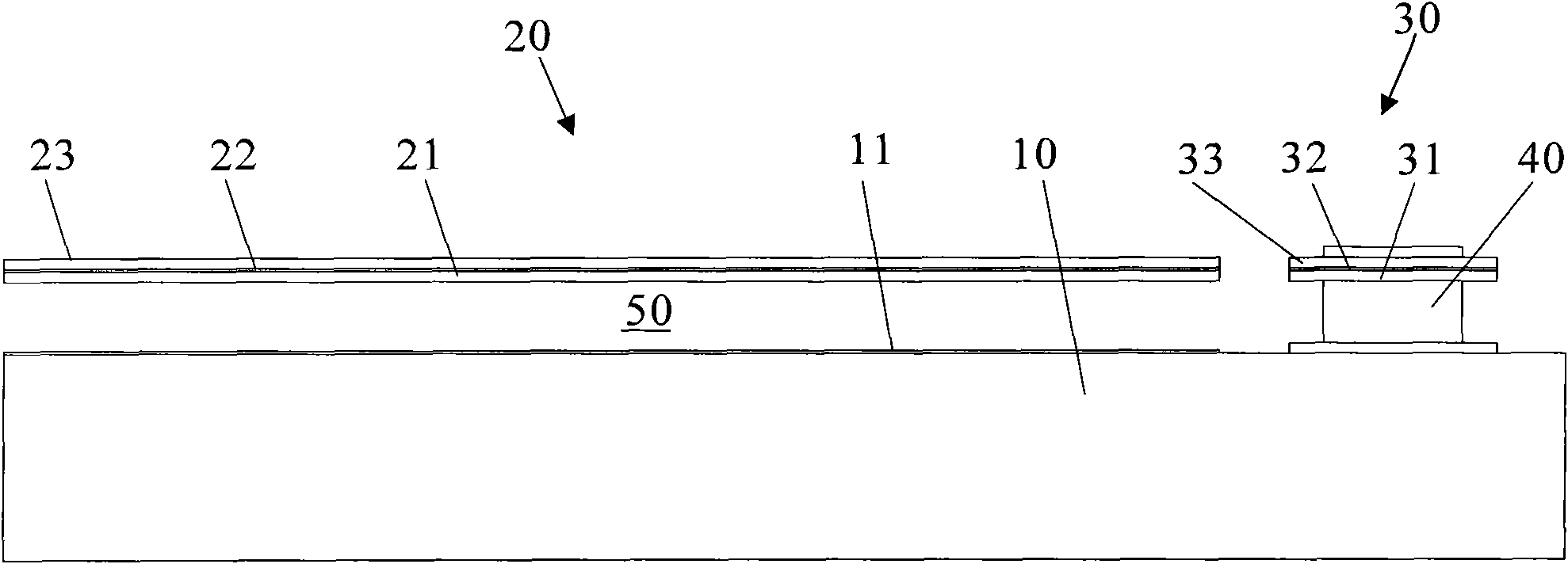

Backplane components and backlight modules

InactiveCN104864367BWill not warpConstant spacingMechanical apparatusLighting support devicesEngineeringMechanical engineering

Owner:CORETRONIC (SUZHOU) CO LTD

A high-strength non-delamination template and its preparation method

ActiveCN105155839BHigh strengthImprove mechanical propertiesSynthetic resin layered productsHigh intensityMechanical property

The invention discloses a high-strength formwork free of layer separation and a method for manufacturing the high-strength formwork. The high-strength formwork and the method have the advantages that the length directions of battens a are consistent with the growth direction of wood, the height directions of battens b are consistent with the growth direction of the wood, accordingly, sufficient adhesive steeping and mechanical bracing effects can be realized, a core is extremely high in mechanical property in the vertical direction and the horizontal direction and is low in deformation, layer separation phenomena inside the machined core can be prevented, the high-strength formwork is high in modulus, and buckling deformation of the formed formwork can be prevented; the mechanical properties of the formwork can be improved by the aid of continuous fiber reinforcement composite surface layers, the high-strength formwork is light, waterproof and anticorrosion, is high in strength and recycling frequency, and can be easily released from forms, the recycling frequency of the high-strength formwork can reach a hundred at least, accordingly, the service life of the building formwork can be greatly prolonged, and the single-service cost can be reduced.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

Method for producing thick-core plywood using formaldehyde-free biomass soybean protein adhesive

ActiveCN105563571BStress reliefUniform thicknessLaminationLamination apparatusAfter treatmentAdhesive

The invention discloses a method for producing thick-core plywood by using aldehyde-free biomass soy protein adhesive, belongs to the technical field of wood processing, and solves such problems as large back surface cracks, moreburrs, high thickness deviation and easiness in deformation and bending. The production method comprises wood block pretreatment, rotary cutting, drying, plasma treatment, veneer surface scratch treatment, gluing, prepressing, hot pressing and after-treatment. The method is suitable for producing the aldehyde-free thick-core plywood, largely reduces the production cost, and improves the production efficiency.

Owner:SHANDONG XINGANG ENTERPRISE GRP CO LTD

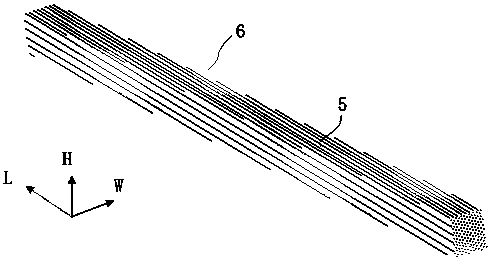

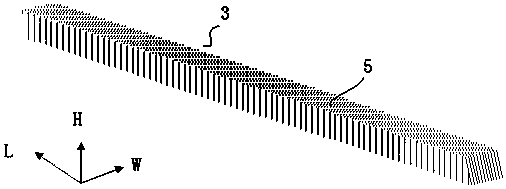

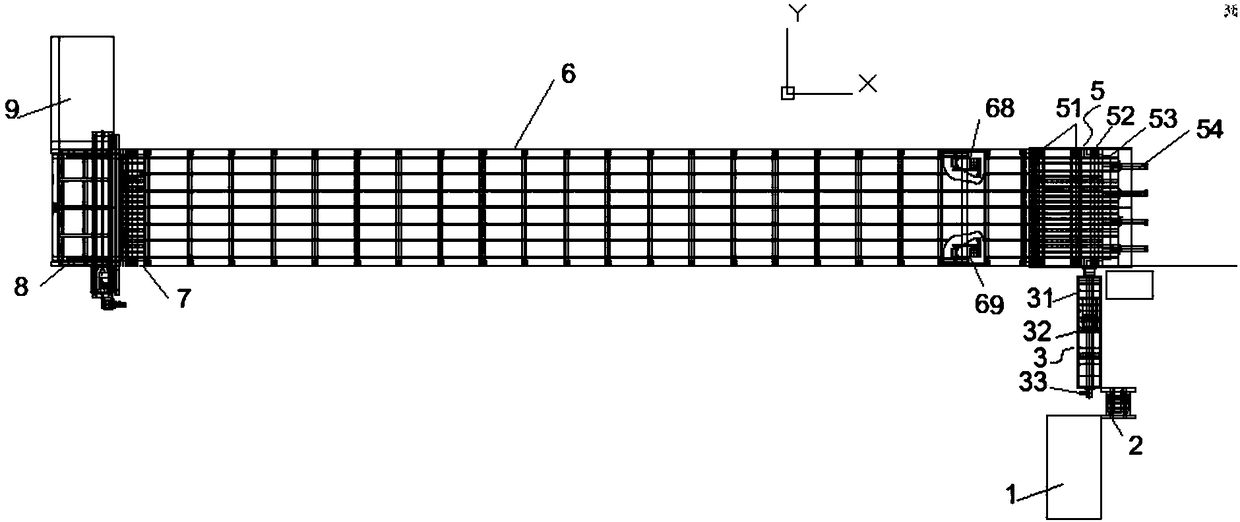

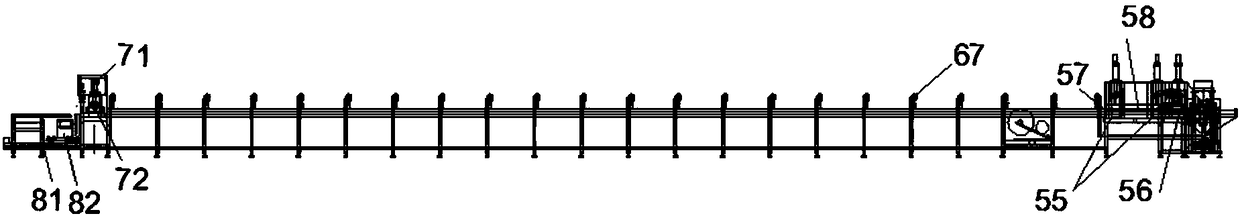

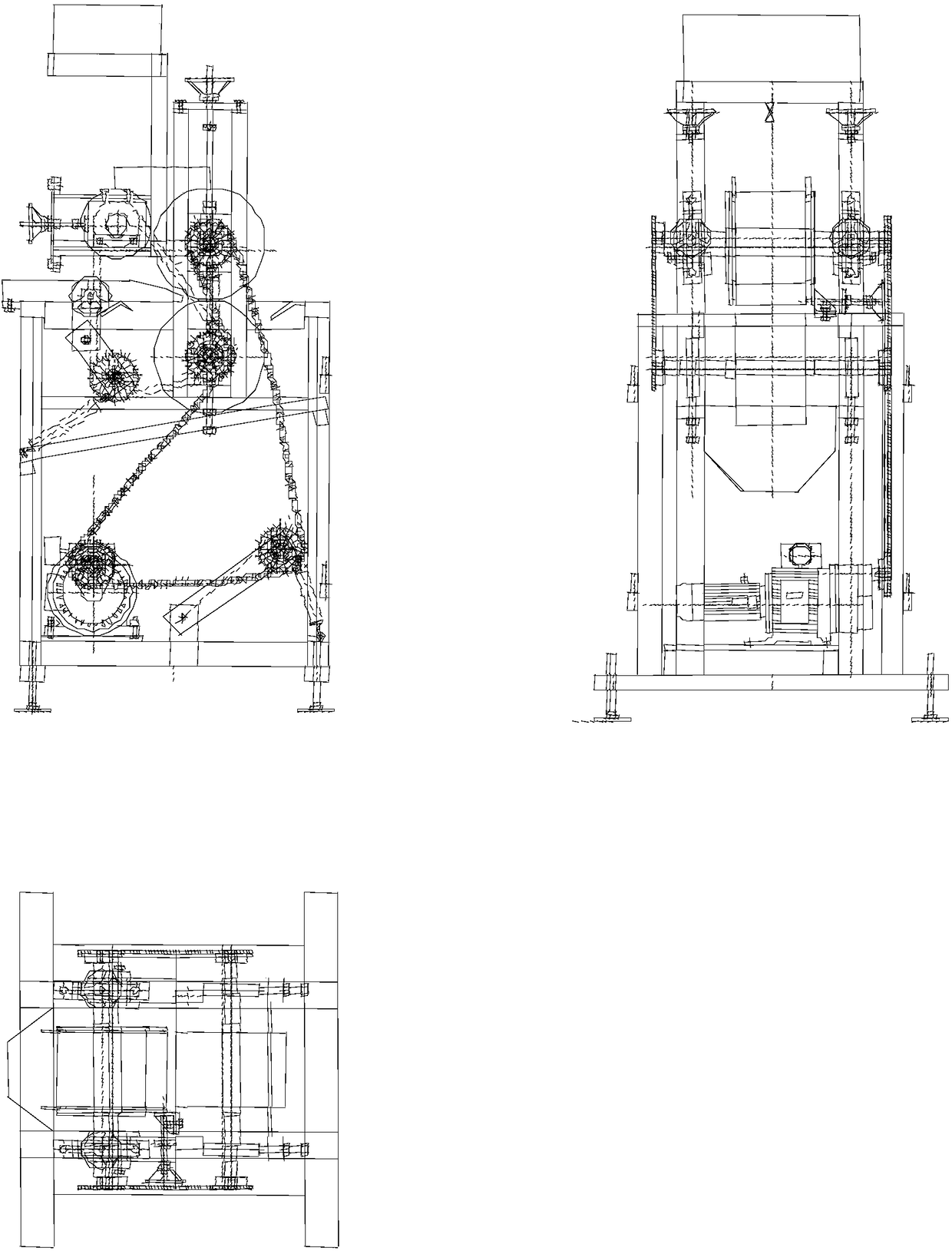

Composite type wood core gluing machine

PendingCN108437104AImprove processing qualityShorten the setting timeLaminationLamination apparatusPulp and paper industryUltimate tensile strength

The invention discloses a composite type wood core gluing machine. The composite type wood core gluing machine comprises a raw material placing region, an automatic glue coating machine, a feeding push plate device, a compounding machine head, a middle rack, a machine tail sawing mark plate cutting device, a machine tail pressing plate frame and a finished product receiving plate frame; and the raw material placing region, the automatic glue coating machine, the feeding push plate device, a laminating machine head, the middle rack, the machine tail pressing plate frame, the machine tail sawingmark plate cutting device, the machine tail sawing mark plate cutting device and the finished product receiving plate frame are sequentially connected. The composite type wood core gluing machine disclosed by the invention realizes gluing, lamination and side cutting functions of wood cores and is excellent in performances. Compared with the traditional processing equipment, the composite type wood core gluing machine disclosed by the invention is small in floor area and high in processing efficiency. By adopting pressure-maintaining and temperature-maintaining adhesion, the glue solidification time is shortened; the adhesive strength is high; moreover, a wood bar is prevented from warping deformation in a glue solidification process, so the processed wood is flat and straight and high inprocessing quality.

Owner:LIUZHOU WUXIN WOOD WORKING MACHINERY

Non-cooling type ultrared micrometering kampometer

ActiveCN101718587BStable structureWill not warpTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectricityVacuum gap

Owner:北方广微科技有限公司

On-line embossed high-strength antiskid plastic-wood composite material plate and preparation method thereof

InactiveCN111234551AReduce the waterproof effectHigh degree of mechanizationPlastic materialsStearic acid

A on-line embossed high-strength antiskid plastic-wood composite material plate is prepared from high-density polyethylene plastic particles, a substituted benzamide nucleating agent TMB-5, oily woodflour, modified graphene, calcium carbonate powder, terpene resin, butyl stearate and oxidized polyethylene. The plate is prepared by following steps: uniformly mixing the high-density polyethylene plastic particles with the substituted benzamide nucleating agent TMB-5, carrying out melt extrusion to form a crystalline plastic material flow; uniformly mixing high-density polyethylene plastic particles, oily wood powder, modified graphene, calcium carbonate powder, terpene resin, butyl stearate and oxidized polyethylene, carrying out melt extrusion to obtain a plastic-wood material flow; uniformly mixing the two material flows in a mixing machine head, extruding to form a plastic-wood plate; and rolling and embossing the plastic-wood plate for two times at a certain temperature. The production is convenient, the mechanization degree is high in the production process, the required labor force is little, the cost is low, and the plate is environment-friendly, strong in wood texture, freeof deformation, water resistant, aging resistant, mildew resistant, cracking resistant and worm damage resistant, strong in modifiability, good in stability and anti-skid.

Owner:江苏福瑞森塑木科技股份有限公司

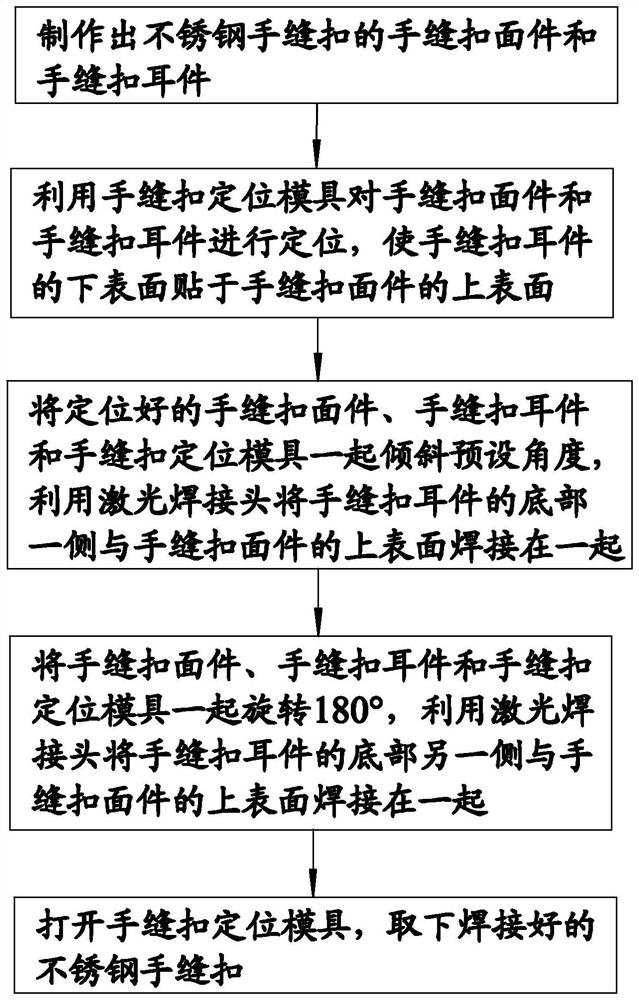

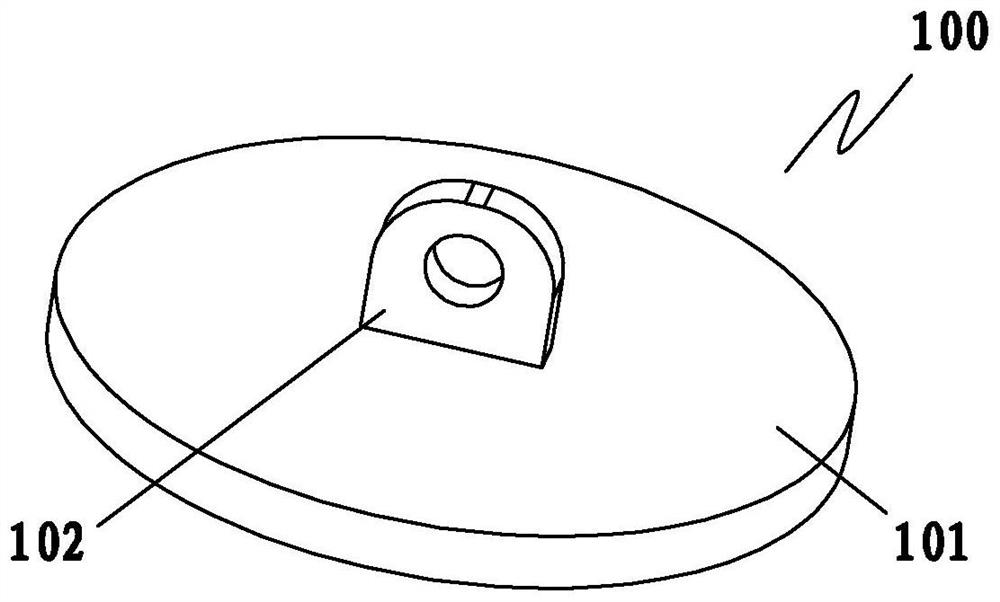

Production method of stainless steel hand sewing buckle

PendingCN114346620AEasy to operateGuaranteed positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesLaser solderingEngineering

The invention provides a production method of a stainless steel hand sewing buckle. A hand sewing buckle surface piece and a hand sewing buckle ear piece of the stainless steel hand sewing buckle are manufactured; positioning the hand sewing buckle surface piece and the hand sewing buckle lug piece by using a hand sewing buckle positioning mold, so that the lower surface of the hand sewing buckle lug piece is attached to the upper surface of the hand sewing buckle surface piece; the positioned hand sewing buckle surface piece, hand sewing buckle lug piece and hand sewing buckle positioning mold are inclined together by a preset angle, and one side of the bottom of the hand sewing buckle lug piece and the upper surface of the hand sewing buckle surface piece are welded together through a laser welding head; rotating the hand sewing button surface piece, the hand sewing button ear piece and the hand sewing button positioning mold together by 180 degrees, and welding the other side of the bottom of the hand sewing button ear piece and the upper surface of the hand sewing button surface piece together by using a laser welding head; and opening the hand sewing buckle positioning mold, and taking down the welded stainless steel hand sewing buckle. The device has the advantages that the investment of personnel and the labor intensity of operators can be reduced, meanwhile, the production efficiency can be greatly improved, the productivity is improved, and the production quality is guaranteed.

Owner:晋江市东盛服饰配件有限公司

Micro-foamed high-strength plastic-wood composite material plate and preparation method thereof

The invention relates to a micro-foamed high-strength plastic-wood material plate and a preparation method thereof. The preparation method comprises the following steps: mechanically evenly mixing polyvinyl chloride plastic granules and tribasic lead sulfate, adding wood powder, wollastonite powder, accelerator, azobisformamide, composite auxiliary foaming agent, zinc oxide, dibutyl phthalate and acrylic acid, heating while stirring, cooling and taking out; granulating the mixture by extrusion by using an extruding machine; and after finishing the granulation, carrying out extrusion molding on the granules by using the extruding machine. The invention has the advantages of high production convenience, low production cost, low density, lower plastic and wood consumption, environment friendliness, strong wood sensation, aging resistance, discoloring resistance, no buckling deformation and strong modificability, is convenient to mount and maintain, and can be recycled. The invention can be widely used in office buildings, families and many other occasions, can be made into door plates, photo frames, picture frames, skirting plates, suspended pinch plates, partitions, roofs and other products, and can also be used as suspended beams, pergolas, outdoor veranda plates and the like.

Owner:江苏明天材料科技有限公司

Light guide plate, planar light emitting device, liquid crystal display device, liquid crystal display terminal equipment and manufacturing method of light guide plate

InactiveCN103499853BReduce lossIncrease profitMechanical apparatusPoint-like light sourceLiquid-crystal displayLight guide

The invention discloses an efficient energy-saving microstructural light guide plate, a planar light emitting device provided with the light guide plate, a liquid crystal display device, liquid crystal display terminal equipment and a manufacturing method of the light guide plate. A scattering pattern structure on the bottom plane of the light guide plate is formed by providing a colorless and transparent adhesive glue pattern layer on the bottom plane of the substrate, a stereoscopic microstructural scattering pattern layer is obtained by planting and sticking a plurality of mini scattering particles on the adhesive glue pattern layer, all or part of the planted and stuck mini scattering particles is bared and protrudes at the surface of the adhesive glue pattern layer, a part of the mini scattering particles, which is bared and protrudes at the surface of the adhesive glue pattern layer, is embedded into the colorless and transparent adhesive glue pattern layer, and is firmly bonded by the adhesive glue, and the other part of the mini scattering particles is bared and protrudes outside the colorless and transparent adhesive glue pattern layer. After adopting the light guide plate, a brightness increase rate of the planar light emitting device is more than 20%. According to the light guide plate prepared by the invention, the light guide plates in small, middle and big sizes can be manufactured at high quality, and the brightness increase rate of the light guide plate is fully realized.

Owner:HANGZHOU RUIHUI OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com