Composite type wood core gluing machine

A gluing machine and composite technology, which is applied to wood processing equipment, wooden veneer joints, lamination devices, etc., can solve the problems of long time occupying the machine, low machine working efficiency, and a large number of online workers, and achieve processing The effect of high quality, superior performance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

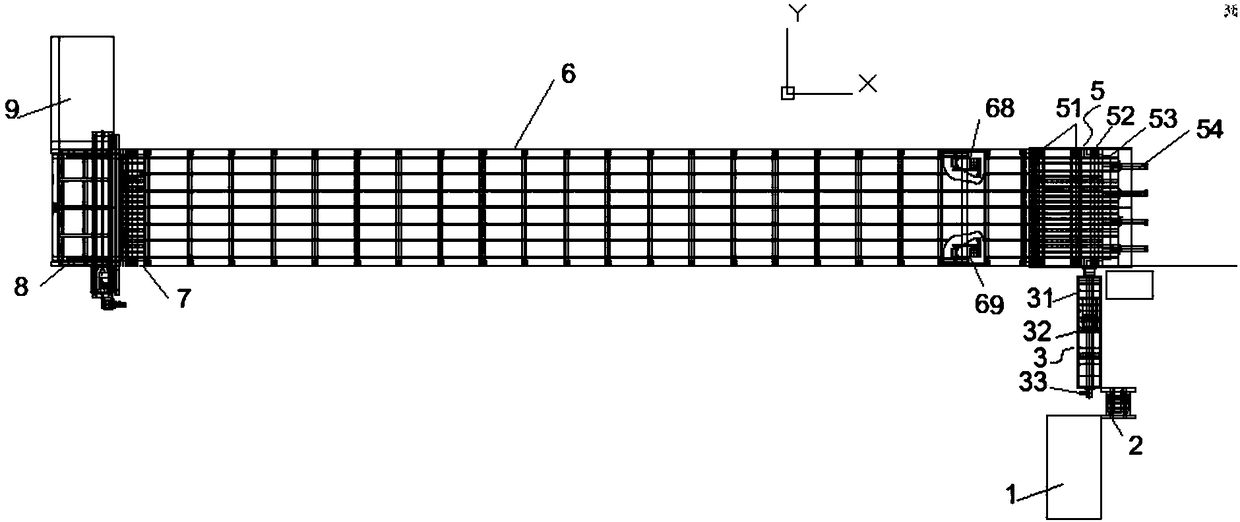

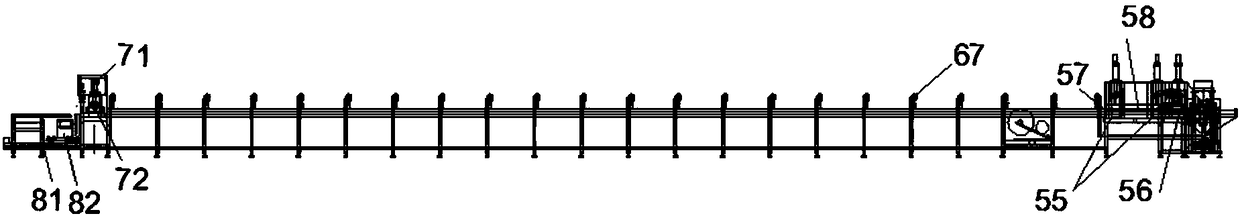

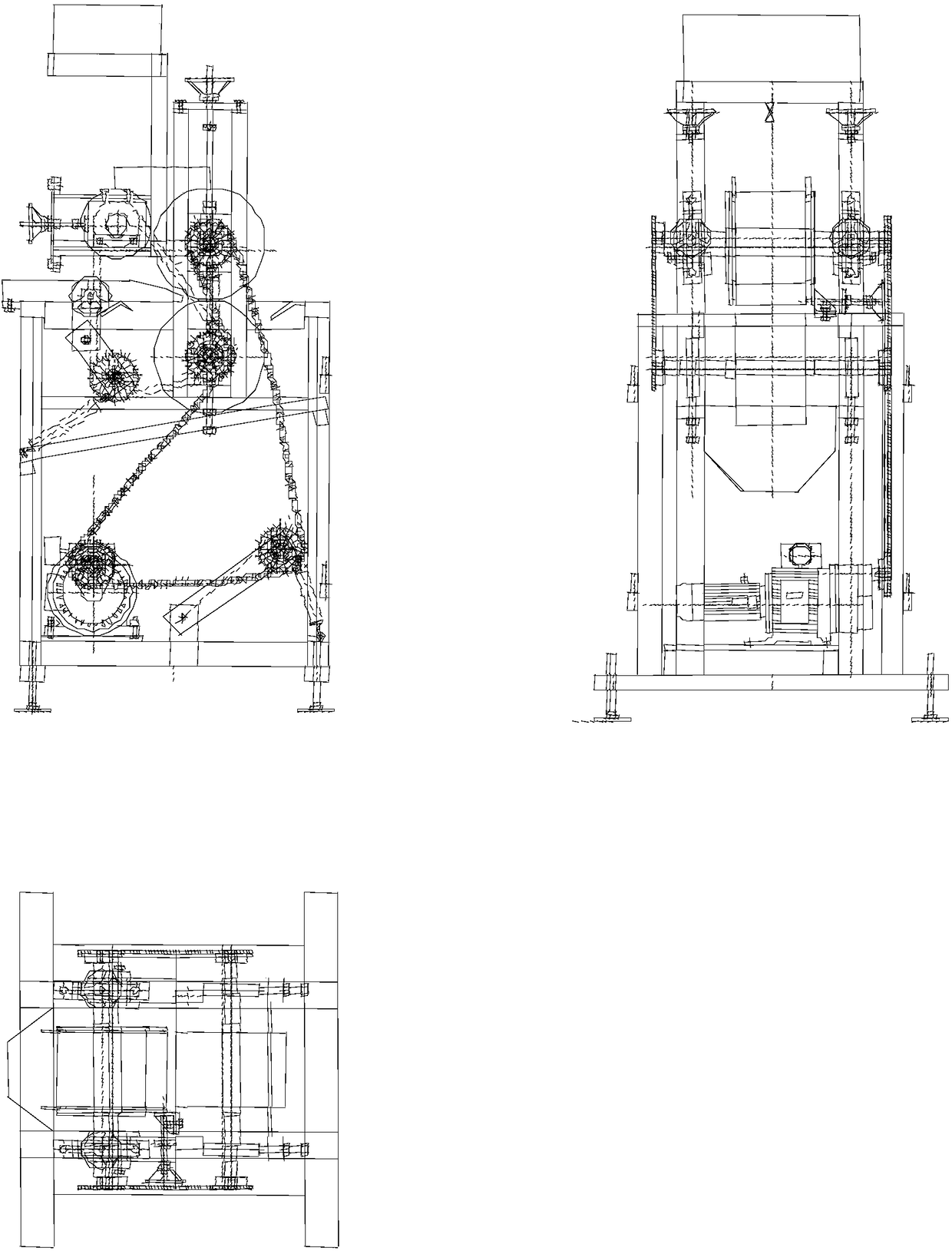

[0019] Such as Figure 1-7 As shown, the present invention discloses a composite wood core gluing machine, which includes a raw material placement area 1, an automatic gluing machine 2, a feeding push plate device 3, a composite machine head 5, a middle frame 6, and a tail plate holder 7. Cutting device 8 for machine tail sawing standard plate, finished product plate frame 9; said raw material placement area 1 is connected with automatic glue applicator 2, and said automatic glue applicator 2 is connected with feeding pushing plate device 3, and said feeding plate The material pushing plate device 3 is connected with the head 5 of the pressing machine, and the head 5 of the pressing machine is connected with the middle frame 6, and the middle frame 6 is connected with the tail platen frame 7, and the tail platen frame 7 It is connected with the cut-off device 8 of the tail saw target board, and the finished board connecting frame 9 is arranged on the side of the tail saw targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com