Backplane components and backlight modules

A backplane assembly and backlight module technology, applied in optics, light guides, light sources, etc., can solve the problems of optical uniformity and brightness drop, extruded backplane, easy expansion of the light guide plate, etc., and achieve the effect of good light output efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

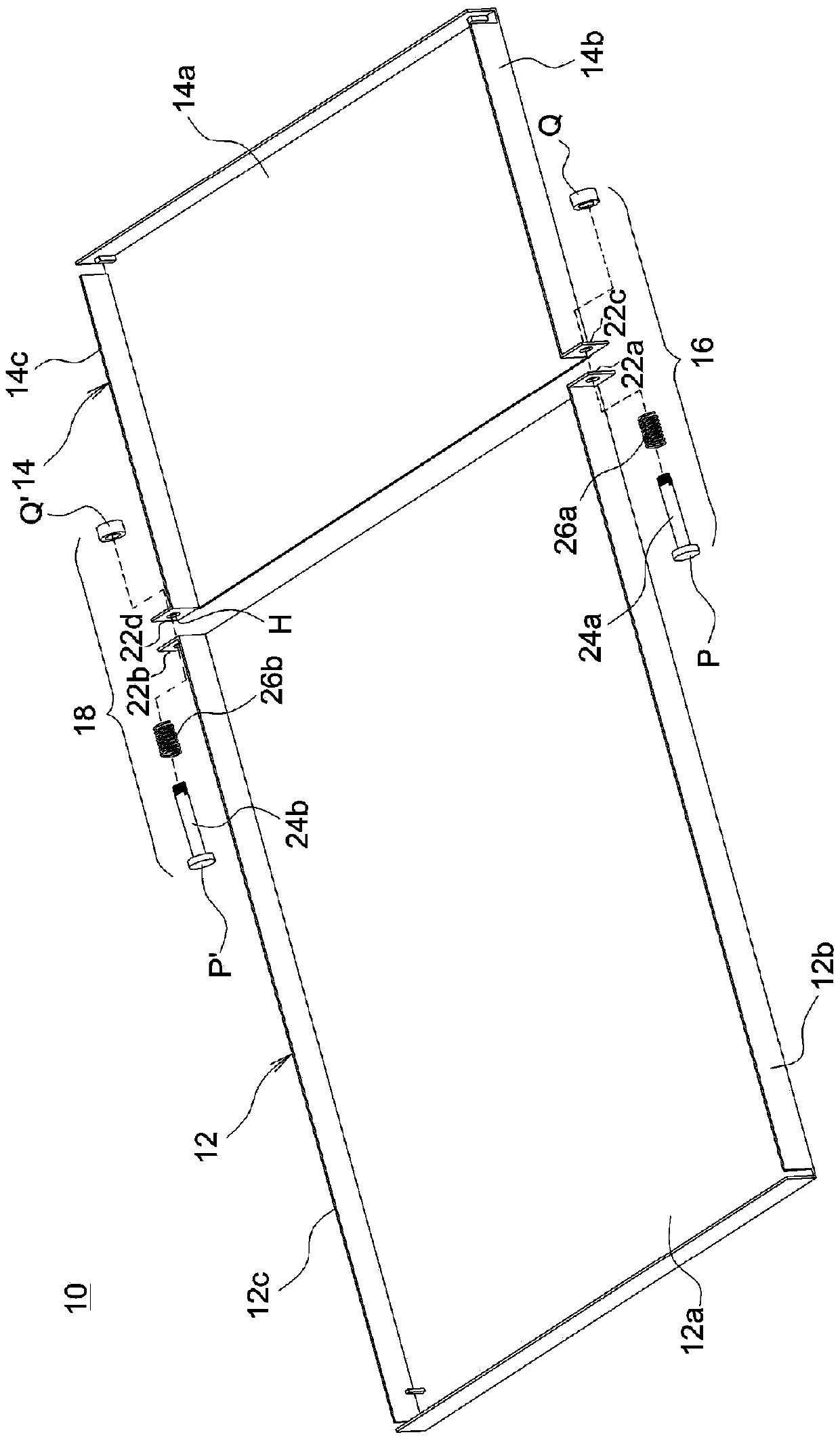

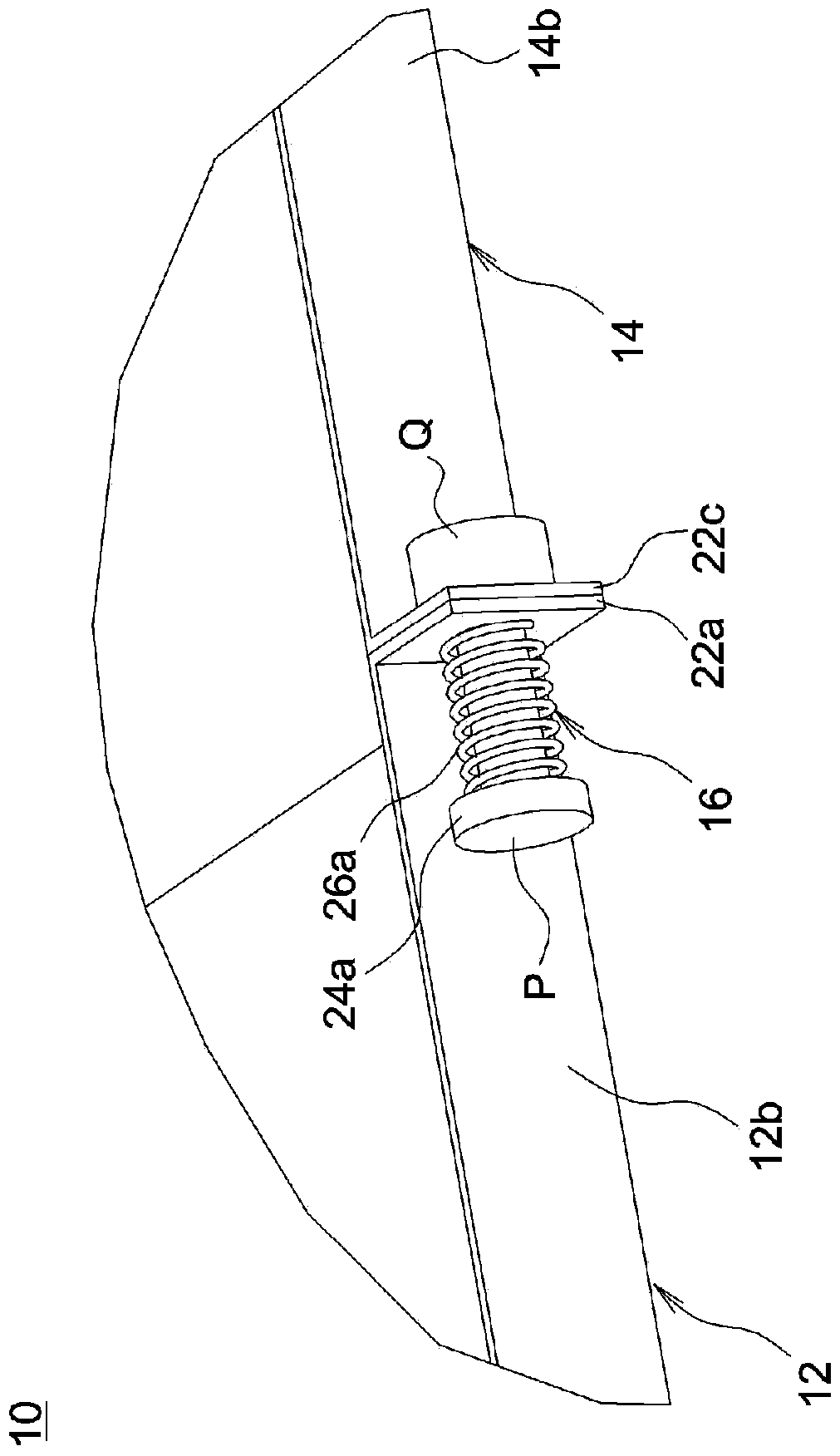

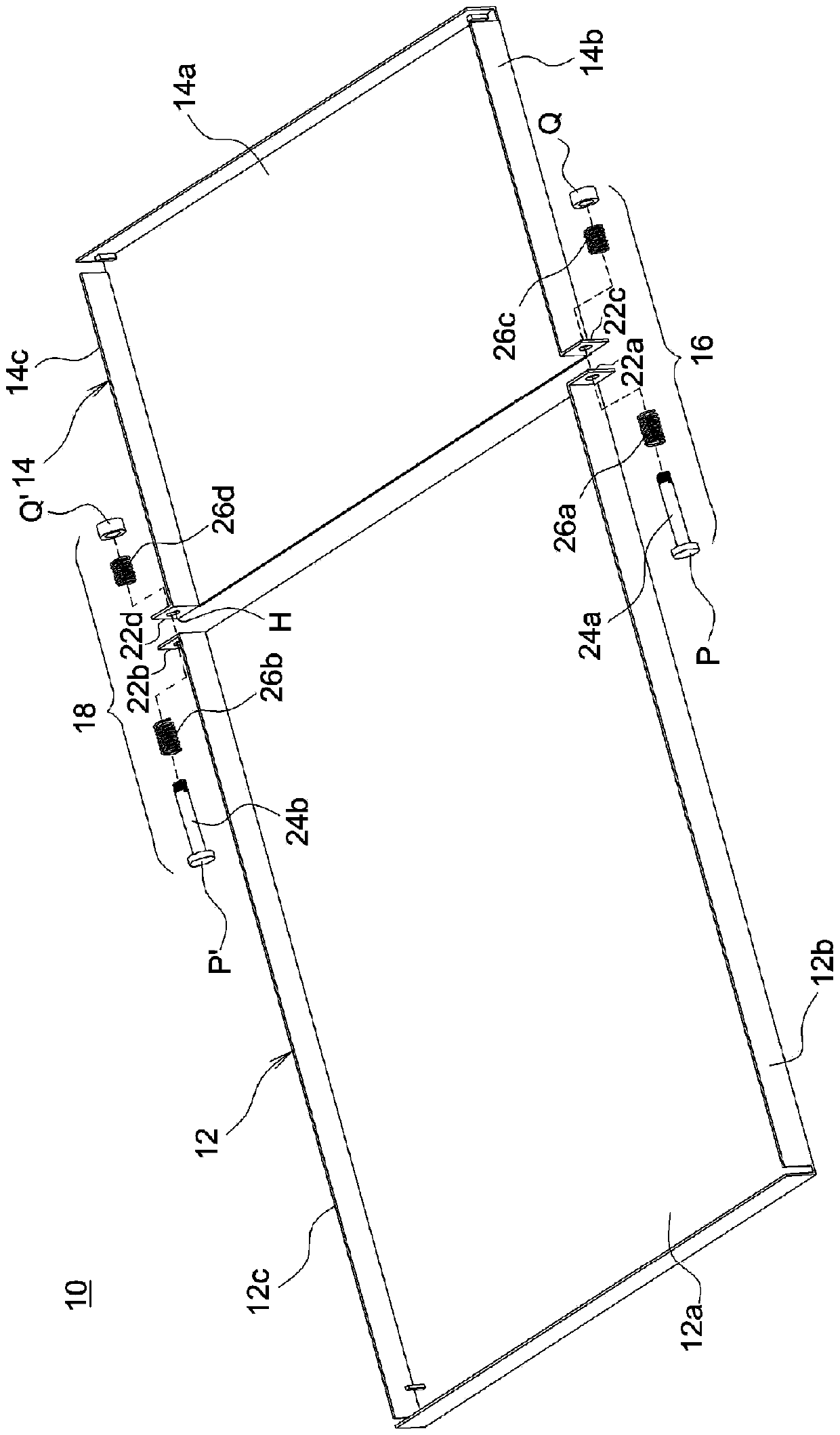

[0021] figure 1 is an exploded view of the components of the backplane assembly according to an embodiment of the present invention, figure 2 for figure 1 The partially enlarged schematic diagram of the backplane assembly after assembly. Please also refer to figure 1 and figure 2 The backplane assembly 10 includes at least a first backplane block 12 and a second backplane block 14 , a first fixing structure 16 , and a second fixing structure 18 . In this embodiment, the first back panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com