Method for manufacturing steel hollow base

A manufacturing method and steel technology, applied in the manufacturing field of steel hollow base, can solve the problems of long production cycle, poor hollowing effect, high production cost, etc., and achieve the effect of short production cycle, durable structure and low total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

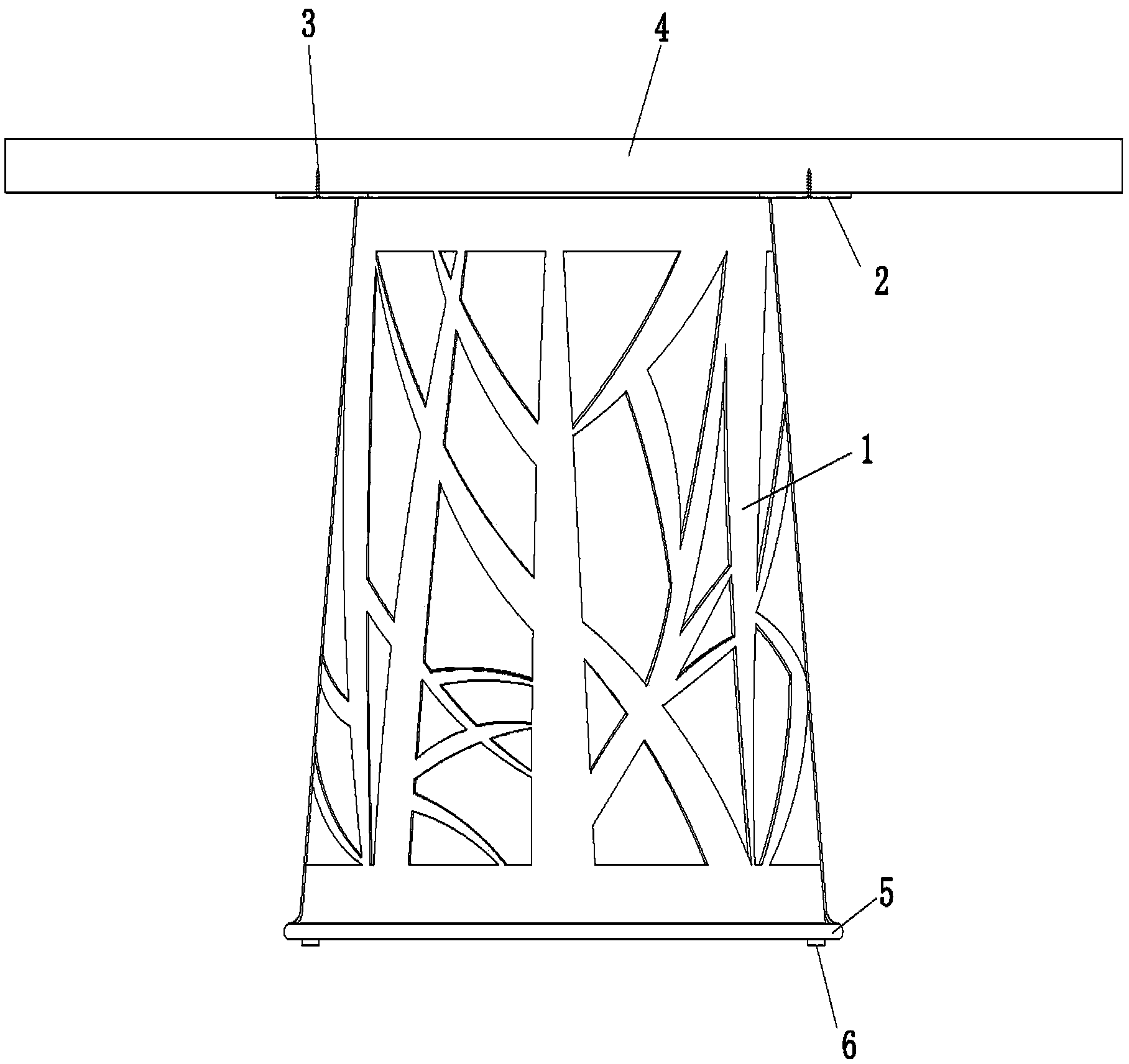

[0015] The invention discloses a manufacturing method of a steel hollow base, see figure 1 with figure 2 , which includes the following steps:

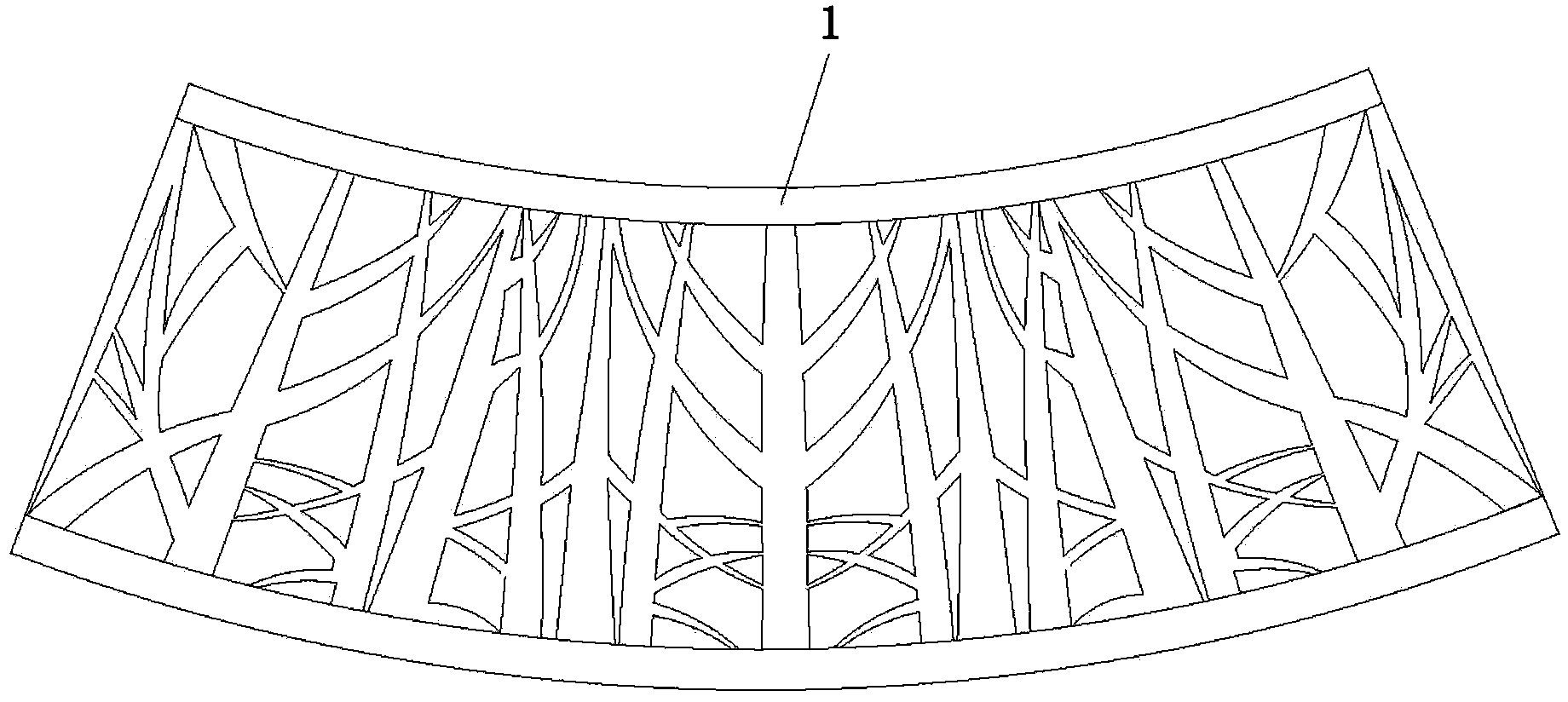

[0016] Step 1, select the steel plate 1, cut the four sides of the steel plate 1, laser cut the cut four sides of the steel plate 1, and hollow out the desired shape, figure 2 It shows an unfolded hollow steel plate, the two sides of the steel plate are hypotenuses, and the upper and lower sides are arc lines, so that the base after curling and forming is conical. If a cylindrical base is prepared, the expanded steel plate is rectangular;

[0017] Step 2, grinding the corners of the hollowed out part;

[0018] Step 3, curl the polished steel plate into a cylindrical base, and perform spot welding on the opposite sides of the steel plate. It should be pointed out that the cylindrical base not only includes figure 1 The conical shape in the table can also be a conical shape, or a polygonal cylinder, as long as it can support the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com