Patents

Literature

187results about How to "Emerald green color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of barley seedling powder and product thereof

The invention relates to a production process of chewable tablets of barley shoot powder and a product thereof and belongs to the deep processing technology field of agricultural products. The production process is characterized in that the barley shoot powder is main base material, and the chewable tablets of the barley shoot powder with smooth appearance, green color and crispness and freshness is made after the processes of composite stabilizer, making soft material, granulation, drying, tabletting, sterilization and packing. The method has the advantages of simple process, higher industrialization degree, low production cost, realizing the full utilization of the barley shoot and promoting the added value of the barley shoot. The chewable tablets of the barley shoot powder produced by the invention which is leisure-base health care food can fully enhance physique and body immune, simultaneously has the function of catharsis, reducing blood lipid and preventing cerebral thrombosis and coronary heart disease.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for cultivating tea

InactiveCN1663350ARich biodiversityImprove the ecological environmentCultivating equipmentsDry seasonTea plantation

The invention discloses a method for cultivating tea comprising the steps of, tea plantation sun screening, planting deciduous arbor around the tea plantation and between the tea trees, covering the tea plantation through rice straw and planting bean green manure, applying special-purpose fertilizer for organic tea, inoculating beneficial soil organisms and soil creatures including right amount of earthworm, finally carrying out irrigation through mini- sprinkling irrigation system in high temperature dry seasons.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

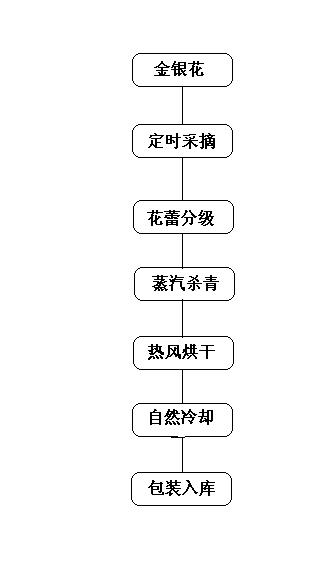

Processing method of honeysuckle tea

InactiveCN102356794ARapid inhibitory activityAvoid decompositionTea substituesCold airChlorogenic acid

A processing method of honeysuckle tea has a technical scheme that the method comprises the following steps of picking at regular time, bud grading, enzyme deactivation by steam, hot air drying, natural cooling, packaging and warehousing; the beneficial effect is that: honeysuckle buds are picked at 8:30-11:00 in the morning everyday, which can ensure that fresh flowers contain the most beneficial components and dew is prevented; grading of the buds can ensure uniform processing; enzyme deactivation by steam can rapidly inhibit the activity of polyphenol oxidase, and effectively prevent the decomposition of honeysuckle chlorogenic acid; direct hot air drying is performed after enzyme deactivation without cooling or cold air dehumidification, which can rapidly remove residual water contained in fresh flowers, destroys the activity of polyphenol oxidase, and allows the honeysuckle tea to be maintained to be undeteriorated for a long time; the honeysuckle tea processed by the method has a jade green color, and a lifelike shape; nutrient components can be maintained to be less lost; the infused tea has a bright and clear soup color, and a complete flower shape; the invention can greatly increase the drinking value and appearance quality of honeysuckle tea.

Owner:重庆市秀山红星中药材开发有限公司

Green tea and processing method thereof

ActiveCN104186736AImprove freshnessImprove quality foundationPre-extraction tea treatmentGreen teasProcess engineering

The invention relates to a processing method of green tea. The processing method comprises the processing steps of raw material selection, picking, spreading, fixation, spreading, rolling, shaping, baking and the like, wherein the types of selected raw materials are strictly controlled to be Nanjiang #1, Zaobaijian #5 or Fuding Dabai tea; the raw materials are required to be picked in a harmless ecological tea garden at the elevation of 550-650m in sunny days in the middle of March under the temperature of 20-25 DEG C. The processing method is executed by the processing technologies such as high-quality raw material selection and optimized spreading, so that the quality of the green tea is improved.

Owner:CHONGQING YUNLING TEA IND TECH

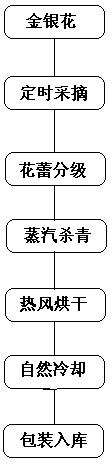

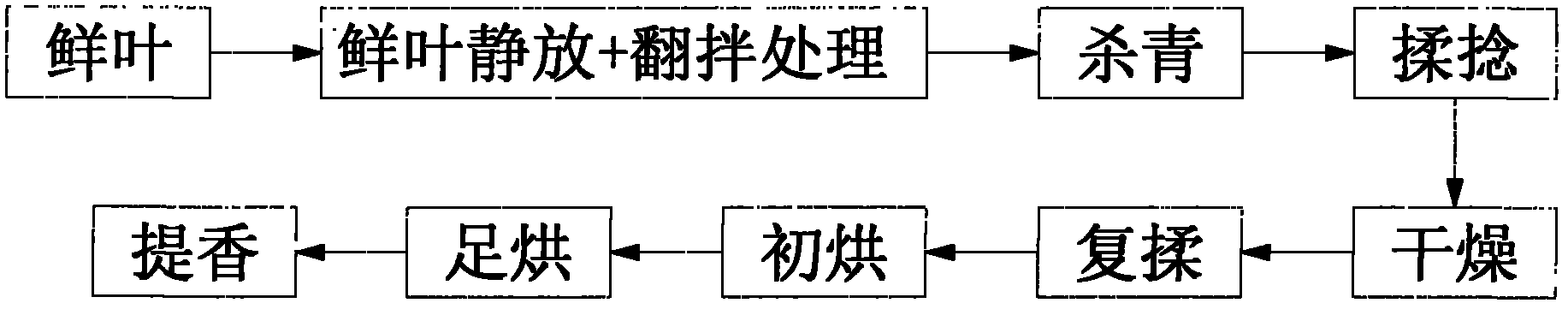

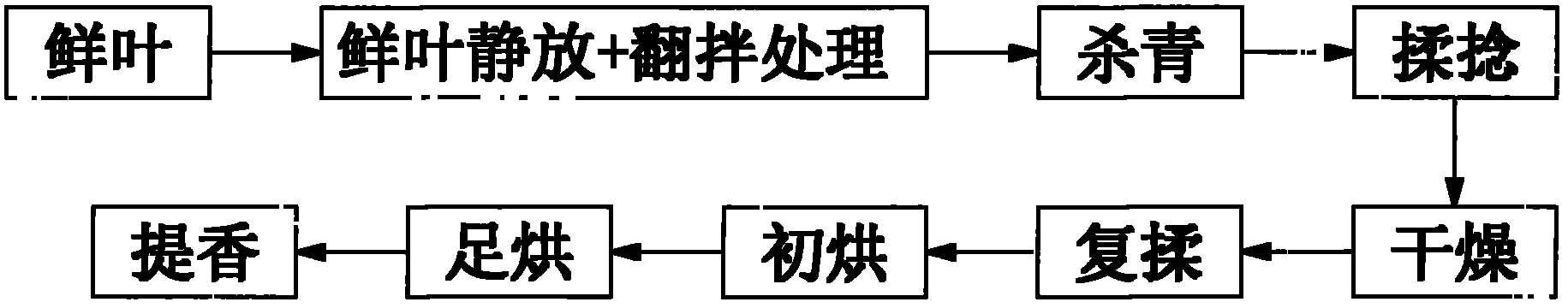

Processing method of chestnut-flavor green tea

ActiveCN102613321AImprove qualityThe shape of the tea sticks is tight, thin and evenPre-extraction tea treatmentFood flavorGreen tea

The invention discloses a processing method of chestnut-flavor green tea, comprising the following processing flows of: a, picking fresh leaves; b, standing, turning and stirring the fresh leaves; c, de-enzyming; d, rolling; e, drying; f, secondarily rolling; g, primarily baking; h, sufficiently baking; and I, extracting flavor. Compared with the prior art, the chestnut-flavor green tea produced by using the processing method has the advantages of high quality, compact, fine and uniform tea strip appearance, bright green and lubricant color and luster, strong and durable chestnut flavor, dark green and bright liquor color, fresh, mellow, refreshing and sweet taste as well as light green and uniform-brightness leaf back.

Owner:成都市碧涛茶业有限公司

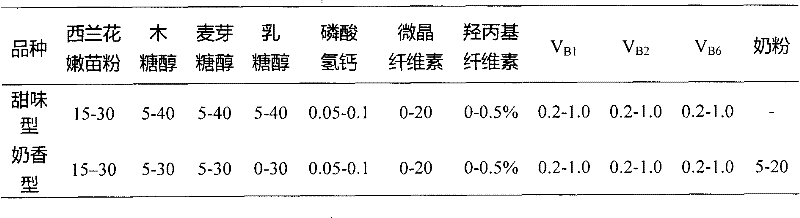

Process for preparing brassica vegetable seedling powder chewable tablets and brassica vegetable seedling powder chewable tablet product

InactiveCN102511753ASmooth appearanceEmerald green colorFood shapingFood preparationBrassica creticaBroccoli raab

The invention relates to a process for preparing brassica vegetable seedling powder chewable tablets and a brassica vegetable seedling powder chewable tablet product, belonging to the technical field of deep processing of agricultural products. The process is characterized by comprising the following steps of: with brassica vegetable seedling powder, such as broccoli and the like as a main basic stock, compounding, preparing a soft material, granulating, drying, tabletting, sterilizing and packing to prepare the brassica vegetable seedling powder chewable tablet with the advantages of clean appearance, green color and crispness. The process for preparing the brassica vegetable seedling powder chewable tablet, disclosed by the invention, is simple, has high industrial degree and can realize complete utilization on the brassica vegetable seedling, such as broccoli and the like, thereby increasing the additional value of the brassica vegetable seedling. The brassica vegetable seedling powder chewable tablets, including the broccoli and the like, prepared by the process disclosed by the invention have functions of resisting oxidation, slowing aging and resisting inflammation and cancer and the like of human bodies, and is a kind of casual healthcare food. According to the product of the process for preparing the brassica vegetable seedling powder chewable tablets, disclosed by the invention, the content of 4-methylsulfinylglucosinolate is up to 185.0-413.0mg / 100g, and the content of sulforaphane provided by each chewable tablet is equal to that provided by 30-75g of fresh brassica vegetable, such as broccoli and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

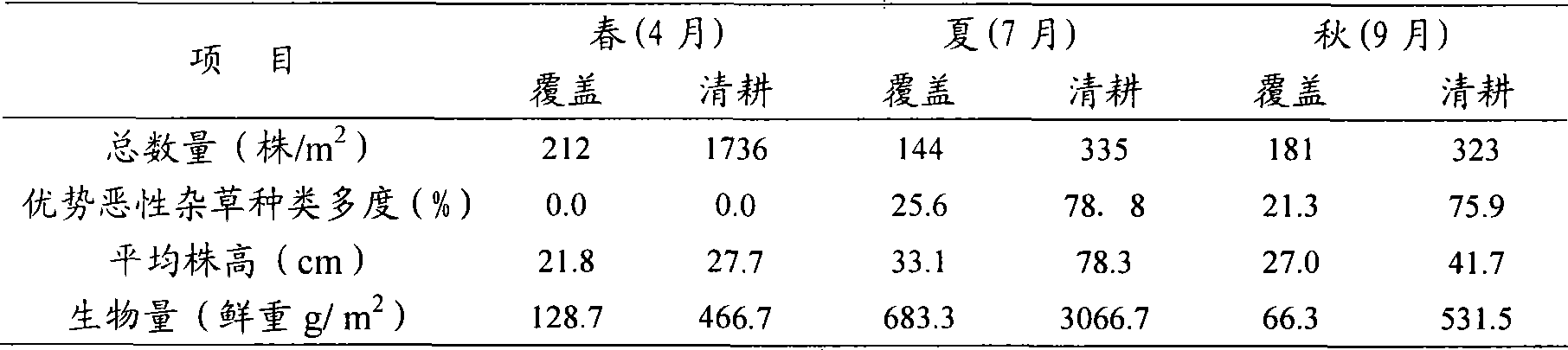

Control method of weed in tea garden

InactiveCN101379926ASmall temperature fluctuationsHinder photosynthesisFertilising methodsWeed killersAlligatorTea leaf

The invention discloses a method for controlling weeds in a tea garden, which comprises the following steps: first, plowing is carried out on the ground between tea plant rows in winter to remove root systems of the weeds such as nutgrass flatsedge, alligator alternanthera, greenbrier, chinaroot greenbrier, cogongrass, smartweed, lygodium and the like; a high-quality organic fertilizer is applied in spring: a certain amount of rape seed cake fertilizer is broadcast; the ground is covered with rice straws in spring: after the rape seed cake fertilizer is broadcast, all tea plant rows in the garden are immediately evenly covered with a certain amount of the rice straws; the high-quality organic fertilizer is applied in summer: a proper amount of the rape seed cake fertilizer is broadcast at a certain time; and the ground is covered with the rice straws in summer: after the rape seed cake fertilizer is broadcast, all tea plant rows are immediately evenly covered with a certain amount of the rice straws. The method enriches biodiversity of the tea garden, improves the ecological condition of the tea garden, increases tea yield, improves the quality of tea leaves; in addition, the method has the advantage of simple operation, is easy to be accepted by tea growers and has great popularization and application prospect.

Owner:HUNAN XIANGFENG TEA

Composite barley green solid beverage and production process thereof

InactiveCN102511894ASolve the reconciliationSolving Dispersion ProblemsFood preparationFreeze-dryingBARLEY GRASS

The invention relates to composite barley green solid beverage and a production process thereof and belongs to the technical field of deep processing of agricultural products. The invention is characterized in that: the composite barley green solid beverage is prepared by using fresh barley grass juice and barley green powder as main raw materials and adding barley grass dreg powder, spiral seaweed powder, xanthan gum, sorbitol, sodium alginate, maltodextrin and sodium carboxymethylcellulose through procedures of sterilizing and packaging, wherein the fresh barley grass juice is used for performing biological green protection by using flammulina velutipes extracting solution; and the barley green powder is prepared through vacuum freeze drying. The composite barley green solid beverage have the characteristics of simple production process, high utilization rate of the raw materials and the like, can be produced industrially, has high nutritional value and high drinking performance and is ideal natural health-care beverage.

Owner:NANJING AGRICULTURAL UNIVERSITY

Green tea processing technology in summer

InactiveCN106035773AImprove qualityAmino acid highPre-extraction tea treatmentCooking & bakingPolyphenol

The invention provides a processing technology of green tea, which specifically includes picking, green tea spreading, killing green tea, spreading cold, rolling, initial frying, re-frying, drying, aroma enhancer to enhance the aroma, and the green tea produced has good quality and amino acid The higher the content, the lower the content of tea polyphenols, and the smaller the ratio of phenol to ammonia. The aroma of the finished finished tea lasts for a long time, the water content of the tea leaves is less than 5%, that is, the water content is low, the storage time is long, the color is emerald green, the appearance is even and the pekoe is exposed, the cord is curled, and the tea quality is good; the taste is mellow, the aftertaste is sweet, The soup is clear, and the bottom of the leaves is bright green.

Owner:遵义凤龙茶业有限公司

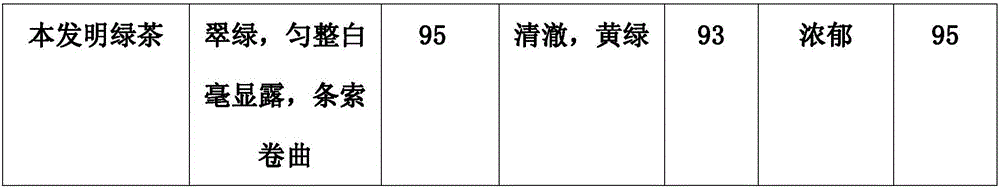

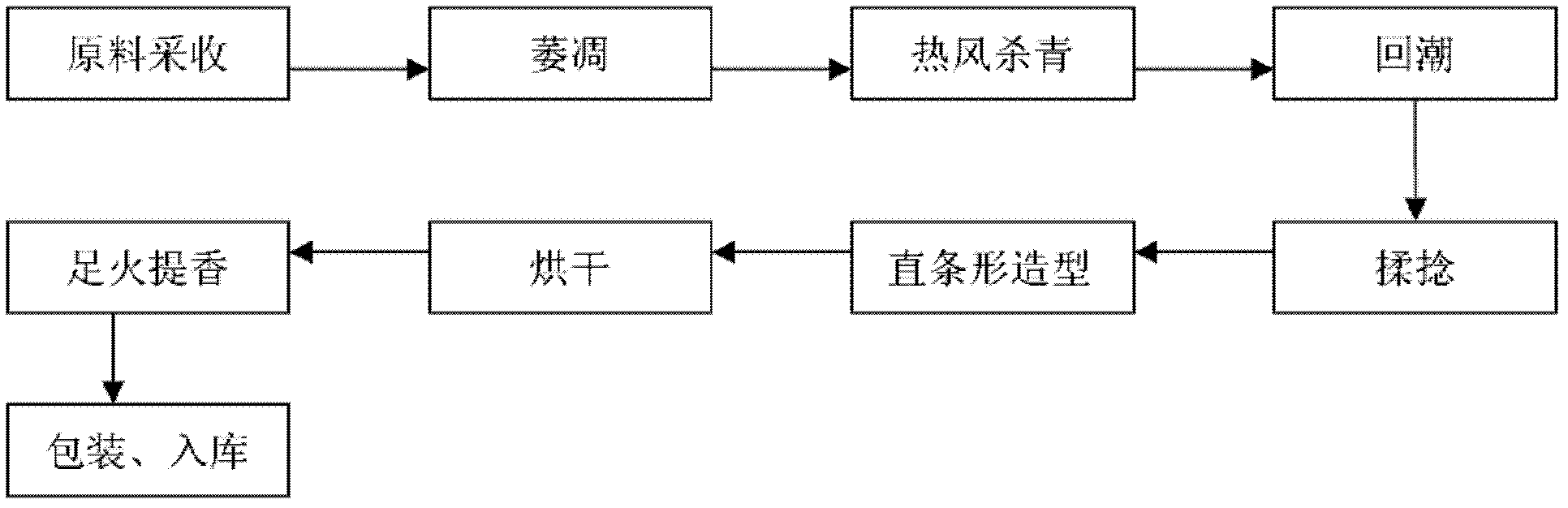

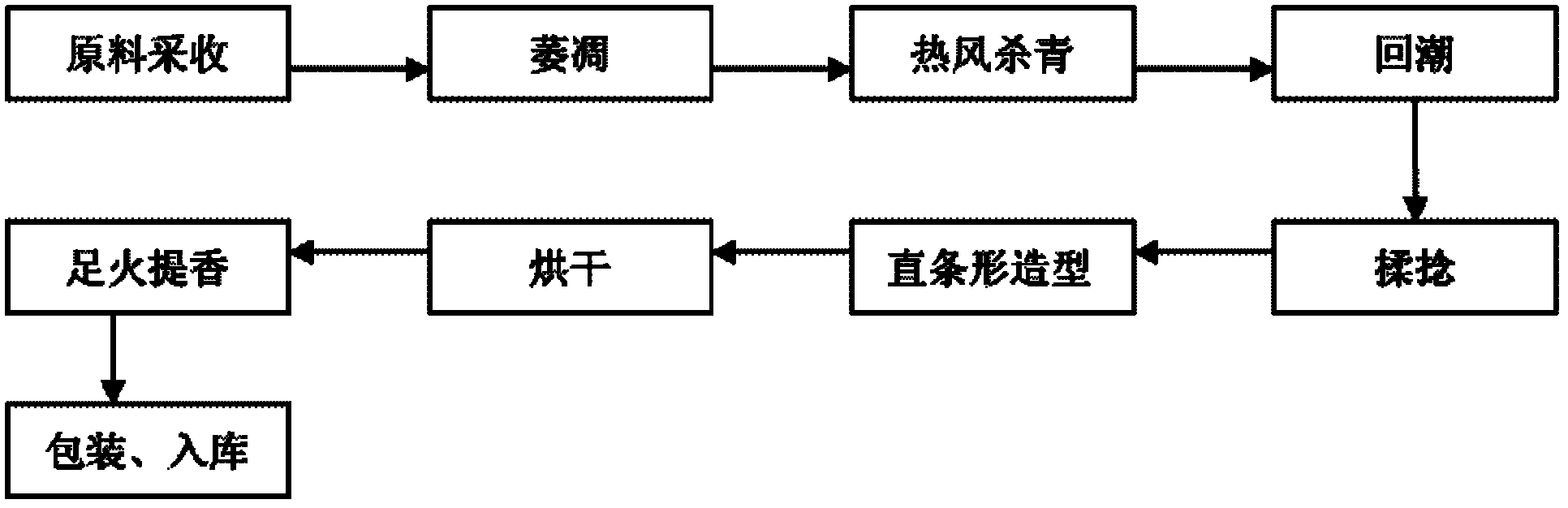

Processing technique for Guire No. 1 green tea

InactiveCN102613324APretty in appearanceEmerald green colorPre-extraction tea treatmentVertical barMoisture regain

The invention discloses a processing technique for Guire No. 1 green tea, which comprises the steps of raw material harvesting, wilting, deactivation of enzymes by hot wind, moisture regain, rolling, vertical-bar shaping, drying, perfuming by complete fire, wherein the three critical steps that guarantee the unique quality of the Guire No. 1 green tea are as follows: fresh leaves are purchased strictly in accordance with the standard of one bud one leaf, the temperature for the deactivation of the enzymes by the hot wind is 280-320 DEG C, the sorting temperature is strictly controlled to be 40-50 DEG C, and the sorting time is controlled to be 8-10 minutes. With the application of the technique, the standardized and scale production of the Guire No. 1 green tea is realized, the processed Guire No. 1 green tea is good in appearance, bright green in color, blooming, yellow green and bright in liquor color, and mellow and sweet in taste, the castanea mollissima fragrance is persistent, leaf bases are light green and even, and the requirements of tea lovers on high-quality tea can be met.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Processing method of green tea

InactiveCN105494699ASimple processing methodConsistent qualityPre-extraction tea treatmentBudGreen tea

The invention discloses a processing method of green tea. The method includes the steps of picking, withering, fixation, spreading and cooling, rolling, drying and packaging. Fresh leaves of tea trees with three leaves on one bud or four leaves on one bud are picked to serve as raw materials, vacuum anaerobic treatment is conducted on the tea leaves, hot wind withering is conducted, withered leaves are put into a fixation machine, the tea leaves are placed on a screen to be spread and cooled, the spread and cooled leaves are put into a rolling machine to be rolled, the rolled leaves are dried for 10-15 min at the temperature of 110-130 DEG C, the leaves are cooled to the normal temperature and dried for 20-25 min at the temperature of 80-100 DEG C, and the dried tea leaves are sealed, packaged, frozen and subjected to fragrance increase, and the finished product is obtained. The tea leaves processed through the method are firm in appearance, jade green in color and luster, stable in quality, durable in fragrance and thick and fresh in taste, and after the tea leaves are brewed into tea, the liquor color is transparent and bright, leaf bottoms are green and tender, and the taste is pure.

Owner:GUANGXI ZHAOPING NINGXIANGCUI TEA FACTORY

Barley seedling powder solid beverage and production technology thereof

InactiveCN101214079AEmerald green colorStrong aromaFood preparationL&D processSodium carboxymethylcellulose

The invention discloses barley seedling powder solid beverage and a production process thereof, belonging to the agricultural product deep processing technology field. The beverage includes barley seedling powder, barley malt powder, spirulina, xanthan gum, sucrose ester powder, sodium alginate and sodium carboxymethyl cellulose and amorphous silica and is obtained after the procedures of pretreatment, drying, crushing, complex formulation, sterilization and packaging. The dietary fibers with high quality in barley seedlings are used in the solid beverage. The nutrition materials in the barley seedlings are reserved. With the advantages of nice taste, good stirring performance and simple process, the invention overcomes a plurality of disadvantages of the present process, including complication, etc.

Owner:兴化市绿禾食品有限公司

Process for producing green tea

The invention discloses a green-tea production technique, comprising the following steps: spreading, de-enzyming, rolling, stir-drying and shaping, characterized in that: the tea leaves are stirred to be 90% dry before stir-drying and shaping step and then the 'roasting' step is performed after shaping, namely the black material on the surface of tea leaves is removed by the friction between the tea leaves and the boiler inner wall at 120-130degree for 4.0-4.5hour then the tea leaves become celadon and rich in lustrousness and the water content is reduced to below 3.5%. In addition, the green-tea becomes jade green and uniform; and the tea liquor is dark green, bright and clear; and the aroma is clear and long; and the flavor is clear and heavy, fragrant, smooth and sweet after taste under the strong thermochemistry action such as high temperature, long-time stir-frying, therefore the special shape and intrinsic quality are formed.

Owner:诸秋莲

Manufacturing method of Jinshan green-buds tea leaves

The invention discloses a manufacturing method of Jinshan green-buds tea leaves, and provides the complete manufacturing method from a cultivating process to a processing process, wherein the cultivating process comprises selection and reclamation of garden plot, selection and breeding of tea seedlings and garden management, and the processing process is from plucking and selecting of raw materials to picking, rejecting and warehousing finally. The finished product of the processed tea leaves is flat, firm and sharp in shape, bright green in color, tippy in state, uniform in size, brisk and mellow in taste, light green and bright in tea soup color, and the elaborate tea leaves with fine work, high quality and prominent characteristic meet demands of tea fans with high-quality requirements.

Owner:句容谷歌庄园现代农业科技发展有限公司

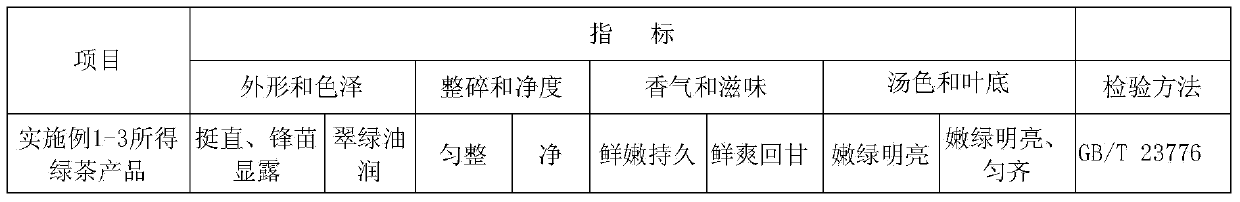

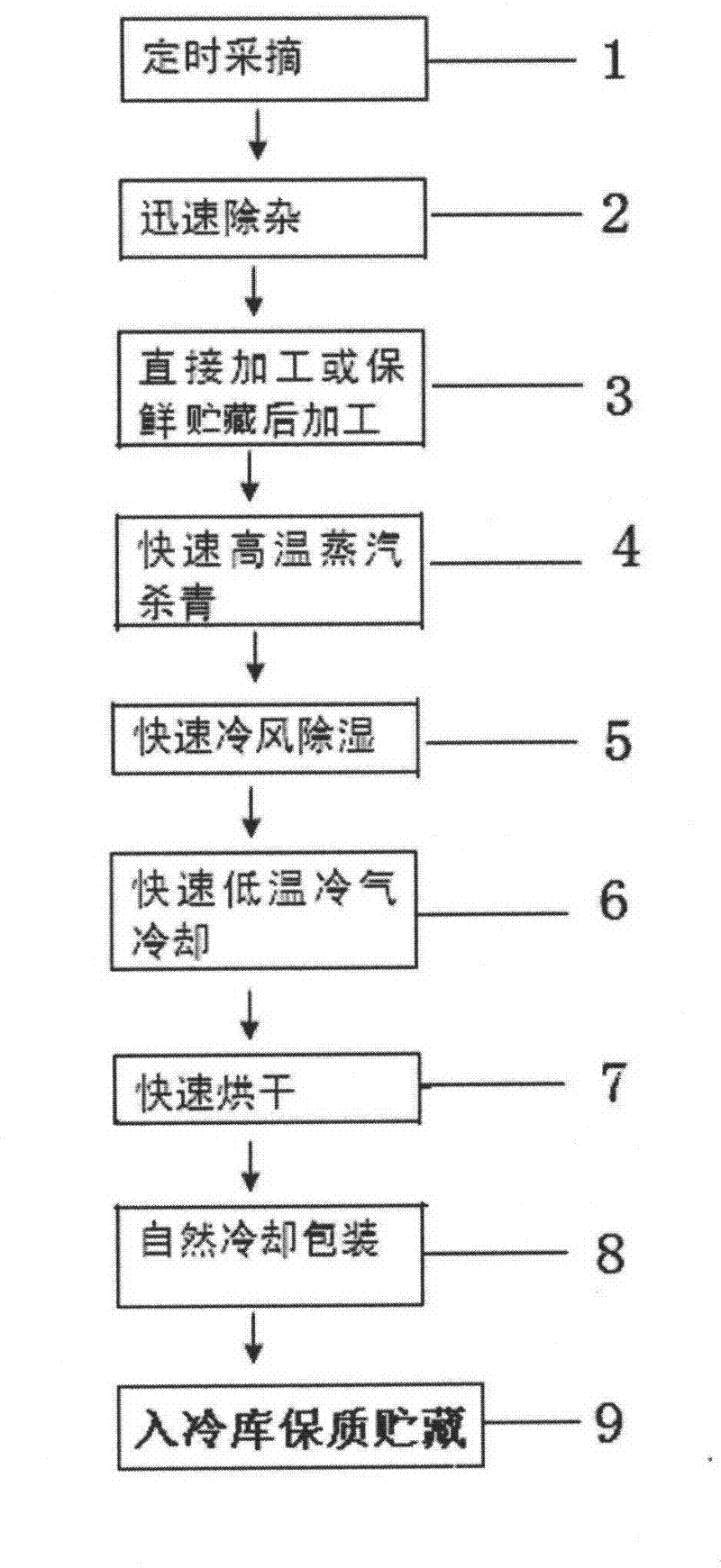

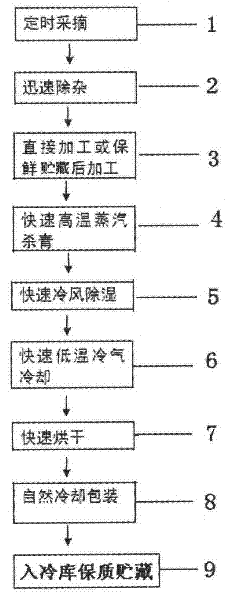

Production method of wild honeysuckle flower tea

InactiveCN102326648AFull flower shapeComplete flower shapeTea substituesChlorogenic acidDecomposition

The invention discloses a production method of wild honeysuckle flower tea. By adopting the production method, the original color and shape of wild honeysuckle flower can be kept unchanged and stable chlorogenic acid content can be ensured. The production method specifically comprises the following steps: picking at regular time; rapidly removing impurities; directly processing; carrying out rapid enzyme deactivation by high-temperature steam; rapidly dehumidifying by cold air; rapidly cooling by low-temperature cold air; rapidly drying by high-temperature hot air; naturally cooling and packaging; and warehousing for storage so as to guarantee quality. The production method has the beneficial effects of rapidly destroying activity of polyphenol oxidase in the wild honeysuckle flower, effectively avoiding decomposition of the beneficial substance namely chlorogenic acid contained in the wild honeysuckle flower, preventing the wild honeysuckle flower from browning, avoiding the procedures of turnover as well as pickup and placement, and ensuring that the appearance of the wild honeysuckle flower is not damaged and the flower shape is complete. The wild honeysuckle flower tea processed by the method has the advantages of green color, new shape and less loss of the chlorogenic acid; and the brewed wild honeysuckle flower tea has the advantages of light green and bright and clean color, delicious taste as well as complete and lifelike flower shape. Therefore, the drinking value and appreciation grade of the wild honeysuckle flower tea are obviously improved by adopting the production method.

Owner:XIUSHAN SHENGDA AGRI DEV

Production process of asparagus tea

The invention discloses a production process of asparagus tea, which comprises the following steps of: (1) picking; (2) cleaning and air drying; (3) enzyme deactivation; (4) rolling; (5) drying. The production process of asparagus tea of the invention is characterized in that: (1) a potassium permanganate solution is used for sterilization, and sterile air is used to dry fresh asparagus tips (buds), which ensures that the asparagus tips (buds) are not contaminated by bacteria, ensures that nutritional components are not destroyed, and ensures that the asparagus tea does not contain peculiar smell caused by bacterial fermentation; (2) enzyme deactivation is performed after the leaves wither, which facilitates thorough and uniform deactivation, improves the toughness of the asparagus tea, allows tea juice to be not easy to be squeezed out during enzyme deactivation, maintains the emerald green color of finished tea, allows chemical components which exhibit green tea smell in fresh leaves to be volatilized and transformed, and improves the purity of the aroma of finished tea. The asparagus tea prepared by the process of the invention has the efficacy of cancer prevention and cancer resistance, has therapeutic effect on cardio cerebrovascular diseases, and has health care effect of aging resistance and human immunity improvement.

Owner:劳子明

Honeysuckle green tea and production method thereof

ActiveCN104222399AAvoid destructionOvercome the problems of dull color and poor product qualityTea extractionMicrowaveBud

The invention relates to a honeysuckle green tea and a production method thereof. The method comprises picking honeysuckle buds of the three-green period, radiating the buds through a film with infrared rays of the rate of power of 5kW for 20-30 seconds and then water-removing the buds through microwaves for 2 minutes at a temperature of 80-90 DEG C, and during the microwave water-removing process, adjusting the moisture removal according to the color and the water content of the water-removed buds; timely blowing and cooling the water-removed buds for 20-30 minutes; rolling the buds for 8-10 minutes in a gentle and short-time mode; drying the buds through microwaves for 2-3 minutes at a temperature of 80-85 DEG C; flavoring the buds for 30-60 minutes to obtain the honeysuckle green tea. The honeysuckle green tea comprehensively improves the appearance and the color as well as internal qualities such as fragrance and taste of honeysuckle substituting tea and accordingly is a novel honeysuckle green tea product integrating high quality, health care and ornamental value.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

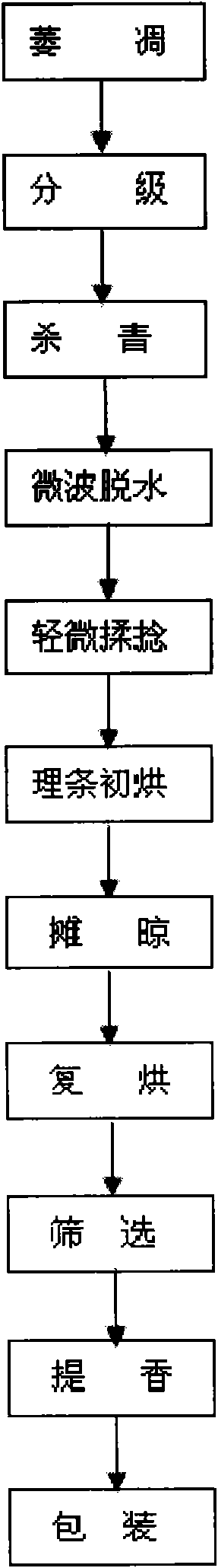

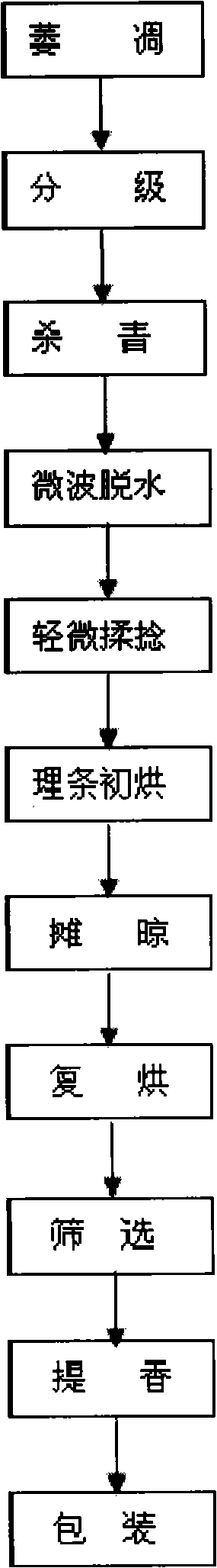

Process flow for preparing Tai Lake jade-green tea

InactiveCN101878824AEmerald green colorFresh and mellow tastePre-extraction tea treatmentLong lastingChemistry

The invention discloses a technical process for preparing Tai Lake jade-green tea, which comprises the steps of withering, grading, enzyme inactivation, microwave dehydration, slight twisting, carding, primary drying, spreading and drying in the air, secondary drying, screening, fragrance improving and the like. The Tai Lake jade-green tea prepared by the process has bamboo leaf-like flat shape, jade-green and oleosus color and luster, a full and fresh taste, pure and long-lasting fragrance, light green and uniform brewed leaves and a unique style. When brewed in a cup, the light green tea leaves expand slowly into bamboo leaf-like shapes to make clear and bright team.

Owner:WUXI DONGTIANXIUZHU TEA

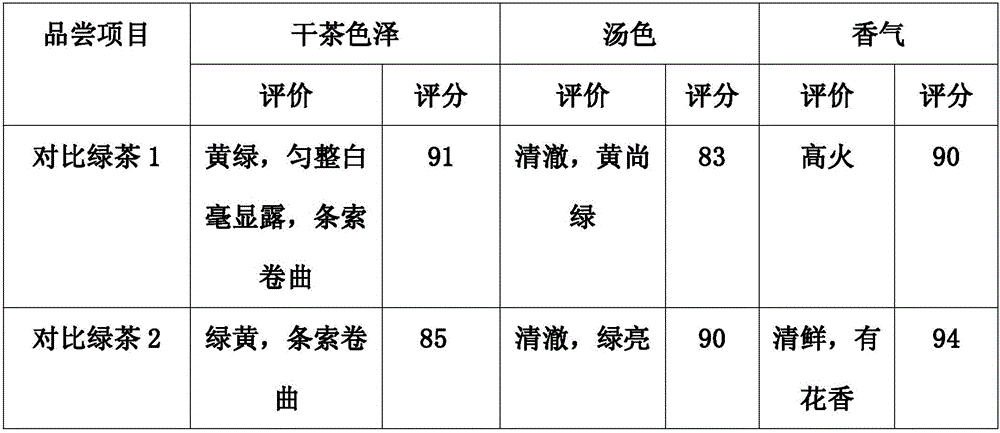

Aroma extracting method of green tea and preparation method of highly-aromatic and chestnut flavor type green tea

ActiveCN102960485ALow costTight, fine, straight and beautifulPre-extraction tea treatmentBiotechnologyGreen teas

The invention discloses an aroma extracting method of green tea. The aroma extracting method comprises the following steps of: a, extracting the aroma by final spanning; and b, extracting the aroma by far infrared ray. The invention also discloses a preparation method of highly-aromatic and chestnut flavor type green tea and prepared highly-aromatic and chestnut flavor type green tea. By adopting the aroma extracting method, the green tea long-lasting in thick highly-aromatic and chestnut flavor can be prepared; the preparation method is simple to operate, and low in cost; the green tea prepared by the preparation method disclosed by the invention is tight, fine, uniform, straight and nice in appearance, emerald green and smooth in color and gloss, dark green and bright in tea water, long-lasting in thick highly-aromatic and chestnut flavor, fresh, thick, delicious and sweet after taste, emerald green and uniformly bright in the bottom of the leaf and high in quality, and brings high economic benefit.

Owner:CHENGDU JINCHUAN TEA

Processing and making method of lotus leaf tea

The invention provides a processing and making method of lotus leaf tea. The method comprises the following nine steps: picking, leaf peeling, green leaf spreading, fixation, air drying, twisting, sieving, flavour extracting and dehydration. The method has the beneficial effects that fresh and tender lotus leaves are picked in proper season and then leaf stalks and coarse veins are peeled, so that pureness of the lotus leaf tea can be maintained; the water steam of the leaf stalks and the coarse veins is adopted for steam fixation, so that the pureness of the aroma of the lotus leaf tea can be further ensured; fixation and air drying are carried out on a conveyor belt, so that the leaf shapes can be maintained and trabes formed by the leaf shapes are uniform; the tea is twisted while the tea is hot, so that the tea can be better shaped and the astringent tastes in lotus leaves are removed, and the astringent tastes can be further covered up after flavour extracting; therefore, the produced lotus leaf tea has orderly appearance, bright green color and pure and thick aroma; the tea soup has dark green and transparent color, tastes fresh, tender and mellow and smells elegant and aromatic; the quality of the lotus leaf tea product is greatly improved.

Owner:高文靓

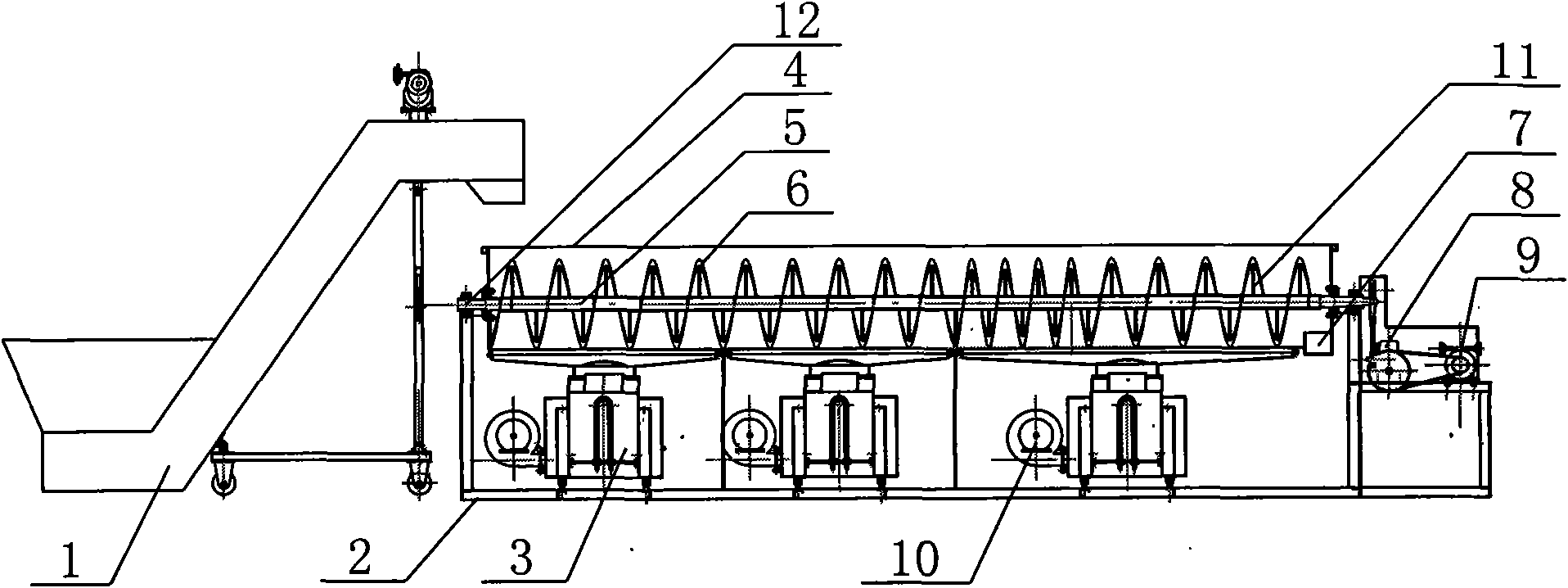

Continuous baking machine device for tea leaves

ActiveCN101647503ADissipate quicklyImprove qualityPre-extraction tea treatmentCooking & bakingEngineering

The invention provides a continuous baking machine device for tea leaves and relates to a continuous type shaping, tippy showing, baking and fragrance extracting device for Quhao teas, belonging to amachine for processing tea leaves. The device comprises hot air generators and a stand, wherein a strip-shaped baking groove is arranged on the stand, a rotary shaft with a screw panel is arranged inthe baking groove, small holes are lined at the bottom of the baking groove, the tail end of the baking groove is used as a tea outlet, and the rotary shaft is supported on the stand through a bearing; more than two heat blowers are lined below the baking groove, and the rotary shaft is driven by a power device. The invention overcomes the defect that the baking process is completed manually in the past, provides a technology for processing Quhao teas, provides a continuous and automatic processing device and sets different temperatures at different stages. With the advantages of reasonable structure, favorable air permeability, simple operation, rapid water dissipation and high tea baking quality, the device can enhance the quality of tea leaves to a great extent. The baked tea leaves arejade green in color, bright in soup color, clear in fragrance, bright in leave bottom and good in quality.

Owner:ZHEJIANG ZHUFENG MACHINERY

Method for making flat green tea

ActiveCN102696794AReduce breakage rateImprove integrityPre-extraction tea treatmentGreen teasEngineering

The invention discloses a method for making flat green tea. The method comprises the steps of spread cooling of fresh leaves, green killing, spread cooling, reshaping, spread cooling and air drying, fragrance increasing and handpicking, wherein at the spread cooling and air drying step, the reshaped tea leaves are taken out of the pan and uniformly spread in a spread cooling slot, the thickness of the tea leaves is 1 to 2cm, the air is continuously blown to dry the tea leaves until the water content of the tea leaves reaches 8 to 9 percent, and finally the spread cooling and air drying process is completed. By the spread cooling method of air-blow drying, the water content of the tea leaves is greatly lowered, therefore the method has the advantages that (1) by the processing method, the broken tea and tea dust generated in the drying process are reduced, and the breaking rate of bud-tea shoot tips is lowered, so that the integrity of the bud-tea is improved; (2) the processing cost is lowered by nearly 25 percent and the energy is saved by nearly 30 percent; and (3) the color of green tea is brightened, and because the spread cooling and air drying process is adopted in the drying process, the color of green tea is kept all the time, and the influence of fluctuating temperature in the drying process on the quality of tea leaves is completely avoided.

Owner:湄潭银柜山茶业有限公司

Green eucommia tea and preparation method thereof

ActiveCN101617730AEmerald green colorImprove water leaching rateTea substituesFood preparationCoffeaCaffeine

The invention relates to green eucommia tea and a preparation method thereof. The preparation method comprises the following steps: (1) removing water: eucommia fresh leaves are taken, and a microwave water-removing and drying machine is adopted to remove water for 1-2 minutes by controlling a water loss ratio of the eucommia fresh leaves of 30-40 percent; (2) kneading and cutting: the water-removed eucommia leaves are processed by a rotor type tea kneading and cutting machine, kneading and smashing processes are finished once within 2-3 minutes, and output materials of a material outlet are fine particle broken tea type semi-finished products; (3) drying: the semi-finished products of the step (2) are treated by a far infrared tea aroma raising machine for 8-12 minutes, and the output materials of the material outlet are the finished eucommia tea; and (4) spread cooling and packaging. The process has simple production working procedure, high efficiency and high leaching yield of effective constituents. The green eucommia tea prepared by the processing method is natural green, tea water is brilliant green, and the leaves are light green. The green eucommia tea does not contain theophylline, has no caffeine, contains abundant protein and amino acid and is easy to absorb and beneficial to health.

Owner:MICANGSHAN TEA GROUP

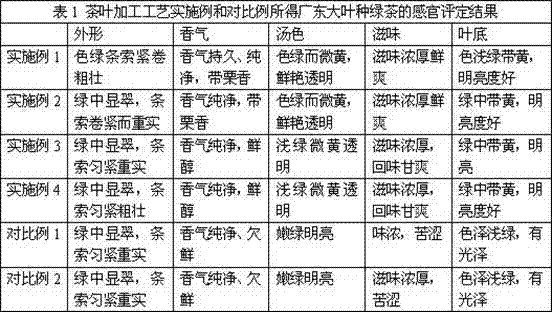

Processing technology for reducing Guangdong big-leaf green tea bitterness

InactiveCN107047835AShorten the time for finishingShorten the timePre-extraction tea treatmentTanninCaffeine

The invention belongs to the field of tea processing, and particularly relates to a processing technology for reducing Guangdong big-leaf green tea bitterness. The technology comprises the steps that fresh picked tea leaves are spread for 4-6 h till the water content of the tea-green color is 70-80%, the tea leaves are put into a fixation machine with the temperature increased to 230-260 DEG C to perform fixation; the tea leaves are spread and aired for 1-2 h after fixation is performed for 1-2 h, non-pressure empty rolling and light rolling are adopted, non-pressure light sequential rolling is performed for 20-30 min, and deblocking is performed; the tea leaves obtained after rolling need to be stacked for 1-2 h, and the stacking thickness is 10-20 cm; initial drying is performed, and the tea leaves are taken out and spread till the water content of the tea leaves is 20-30%, the water inside the tea leaves is distributed again, the stacking thickness is 2-4 cm, and drying is performed after stacking is performed for 20-40 min till the water content is not larger than 6%. According to the processing procedures, the probability that extra bitterness of the tea leaves is generated is lowered, the tea leaves are instantly in contact at high temperature during fixation, spreading is performed after fixation, and stacking is performed after rolling is performed, so that the content of caffeine and tea tannin in tea leaves is lowered, and therefore the bitterness of the tea leaves and tea soup is lowered.

Owner:TEA RES INST GUANGDONG ACAD OF AGRI SCI

Process for drying green tea

ActiveCN102763738AKeep the shape and colorIncrease aromaPre-extraction tea treatmentFlavorFreeze-drying

The invention discloses a process for drying green tea, comprising the steps of low-temperature vacuum drying and hot-air drying. The process is characterized by comprising the following steps: putting the green tea which is rolled by adopting the conventional techniques into a vacuum freeze-drying machine directly, heating to dehydrate in the vacuum environment, taking the green tea out of the vacuum freeze-drying machine after the content of the moisture in the green tea is reduced to 20-28%, and drying by adopting the traditional hot-air drying method until the content of the moisture in the green tea is reduced to 6% or lower. The low-temperature vacuum drying mode and the hot-air drying mode are both used, the advantages of the two drying modes are absorbed, and the disadvantages are discarded. The green tea can be kept green in appearance and tastes more aromatic, and the bitter and puckery flavor of the green tea is improved. The product is emerald green, has mild or chestnut and flower fragrance and mellow taste. The green tea water is greenish yellow and bright, and the tea leaves are green and bright. Due to the adoption of the process, the quality of the product is improved greatly, and the production efficiency is improved. The process is easy and convenient to operate and practical.

Owner:广西昭平县古书茶业有限公司

Production method of green tea

InactiveCN104222331AEmerald green colorParticles round and tightPre-extraction tea treatmentGreen teaEpigallo-catechin gallate

The invention provides a production method of green tea. The production method comprises the following steps: after picking fresh leaves, sequentially carrying out paving and airing, selection, fixation, primary rolling, primary drying, secondary rolling, secondary frying, primary filtering, tertiary drying and secondary filtering to obtain finished-product tea. According to the production method of the green tea, the prepared green tea has bright green color and luster, round and compact grains, slight pekoes, pure aroma, fresh and rich taste, and clear and bright soup color, is crimped spirally and has complete leaf bottoms; and the problems in an existing production process that long-time mechanical rolling and drying are carried out under the conditions of high temperature and high oxygen content so that shapes, colors, tastes and nutritional components of the tea are damaged, and the color and aroma of the tea are greatly influenced when the tea is brewed with hot water are solved.

Owner:郎溪县白阳岗瑞草魁茶厂

Preparation process of green tea

InactiveCN104171058AEmerald green colorParticles round and tightPre-extraction tea treatmentChemistryEnzyme

The invention relates to a preparation process of green tea. The preparation process sequentially comprises the processes of material selecting, washing, enzyme deactivation, fixation, secondary rolling, triple drying, and shaping, wherein the secondary drying process is carried out after the secondary rolling is finished and comprises the concrete steps of drying at the temperature of 130-150 DEG C and with the large air volume by using a dryer, and overturning while drying; and the three-time drying processes are all finished under a low-oxygen or oxygen-free condition. After the process is adopted, the shape of the green tea is curled as a whorl, and the green tea is jade green in color and luster, round and compact in particle, capable of being shown like pekoe slightly, pure in fragrance, fresh and strong in taste, clear and bright in decoction color and complete in leaf base.

Owner:ANHUI MINGZHENTANG HEALTH ARTICLE

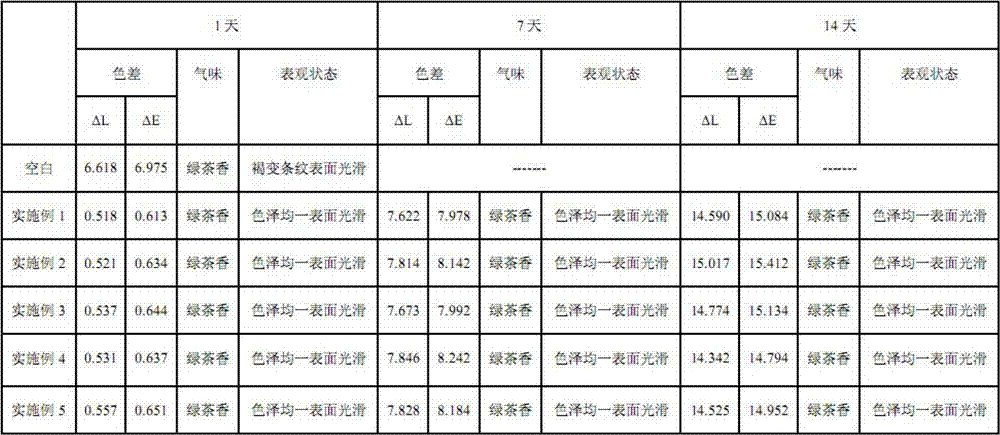

Green tea fresh noodle and method for making same

InactiveCN102813131AExtended shelf life at room temperatureGood color protectionFood preparationAdditive ingredientPhosphate

The invention discloses a green tea fresh noodle and a method for making the same. The green tea fresh noodle is the fresh noodle which takes wheat flour and green tea powder as main ingredients, and further contains salt, citric acid, sodium alga acid, guar gum, compound phosphate, water and other ingredients. The method for making the noodle comprises the steps of: taking the wheat flour to be subjected to sterilization and enzyme deactivation, mixing the ingredients of the green tea fresh noodle with other raw materials uniformly, standing the formed green tea dough at a room temperature, sequentially rolling and shredding the green tea dough, and packaging the obtained noodle product in a protective atmosphere. The green tea fresh noodle has the advantages of green color, smooth surface, smooth and chewy taste, rich nutrition, pleasant green tea taint scent, no preservative addition, stable quality, safety, no toxicity and quality guarantee period of 14 days at the room temperature; and the method for making the noodle is simple and convenient to operate and low in cost.

Owner:JIANGNAN UNIV

Processing method of green tea

ActiveCN104430956ASolid shapeEmerald green colorPre-extraction tea treatmentGreen teaComputer science

The invention discloses a processing method of green tea, relating to the technical field of tea processing. The processing method comprises the following steps: picking tea leaves, tedding, fixing, performing moisture regaining, primarily rolling, roasting at a low temperature, performing secondary rolling and high-temperature roasting, parameters in all the steps are controlled, the green tea obtained by adopting the processing technology is firm in appearance, brightly green in color, stable in quality, lasting in aroma, the taste is strong in strength and freshness, and after the tea is brewed into tea water, soup is transparent and clear, infused leaf is tender and the taste is unadulterated.

Owner:广西西林九龙山茶业有限公司

Cactus health care tea and its preparation method

The present invention relates to green beverage and is especially health cactus tea and its production process. Edible cactus as material is produced into the health cactus tea through cleaning, slicing, soaking, drying and frying or through cleaning, slicing, soaking, dewatering and stoving, and the product is sealed and packed. During the production, aweto, glossy ganoderma, wolfberry fruit, chrysanthemum, gingko leaf, American ginseng and other health Chinese medicinal materials may be added. The production process can keep the nutritive components of cactus, and the health cactus tea is verdure, and has pure taste, fragrance and obvious health functions.

Owner:朱胜一

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com