Processing technology for reducing Guangdong big-leaf green tea bitterness

A processing technology and technology of big-leaf green tea, which is applied in the field of processing technology for reducing the bitterness of Guangdong big-leaf green tea, can solve the problems of reducing the bitterness of Guangdong big-leaf green tea and the bitter taste of tea soup, so as to alleviate the bitterness and reduce the Bitterness, content reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

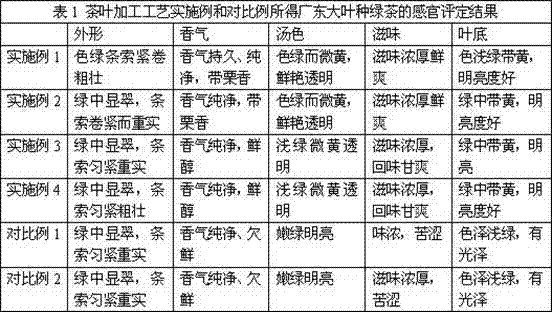

Examples

Embodiment 1

[0031] A tea processing technique for reducing the bitterness and astringency of Guangdong big-leaf green tea, comprising the following steps:

[0032] S1. Picking and spreading of fresh leaves: pick freshly stretched fresh leaves of one bud and one leaf tea tree from the big-leaf tea tree in Liannan, Guangdong, and spread the picked fresh tea greens for 4 hours until the water content of the tea greens is 75%;

[0033] S2. Green fixation: raise the temperature of the green fixer to 230°C, then put the green tea in S1 into the green fixer, and finish it for 15 minutes;

[0034] S3. Spreading and airing: take out the tea green after S2 is finished and then spread it to dry. The thickness of spreading is 4 cm, and the spreading time is 1.5 hours. During this period, flip once every 30 minutes;

[0035] S4. Kneading: Put the green tea leaves from S3 into a kneading machine for kneading. The kneading is carried out in the order of no pressure air kneading, light kneading, and no p...

Embodiment 2

[0041] A tea processing technique for reducing the bitterness and astringency of Guangdong big-leaf green tea, comprising the following steps:

[0042] S1. Picking and spreading of fresh leaves: picking freshly stretched fresh leaves of one-bud and two-leaf tea trees from the big-leaf tea tree in Liannan, Guangdong, and spreading the picked fresh tea greens for 6 hours until the water content of the tea greens is 70%;

[0043] S2. Green fixation: raise the temperature of the green fixer to 250°C, then put the green tea in S1 into the green fixer, and finish it for 10 minutes;

[0044] S3. Spreading and airing: take out the tea green after S2 is finished and then spread it to dry. The thickness of spreading is 5 cm, and the spreading time is 2 hours. During this period, flip once every 30 minutes;

[0045] S4. Kneading: Put the green tea leaves of S3 into a kneading machine for kneading. Kneading is carried out in the order of no pressure air kneading, light kneading, and no pr...

Embodiment 3

[0051] A tea processing technique for reducing the bitterness and astringency of Guangdong big-leaf green tea, comprising the following steps:

[0052] S1. Picking and spreading of fresh leaves: picking freshly stretched fresh leaves of one-bud and one-leaf tea tree from the large-leaf tea tree in Guangdong group, and spreading the picked fresh tea greens for 5 hours until the water content of the tea greens reaches 75% ;

[0053] S2. Green fixation: raise the temperature of the green fixer to 240°C, then put the green tea in S1 into the green fixer, and finish it for 15 minutes;

[0054] S3. Spreading and airing: take out the tea green after S2 is finished and then spread it to dry. The thickness of spreading is 4 cm, and the spreading time is 1.5 hours. During this period, flip once every 30 minutes;

[0055]S4. Kneading: Put the green tea leaves from S3 into a kneading machine for kneading. The kneading is carried out in the order of no pressure air kneading, light kneadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com