Patents

Literature

1702results about How to "Fully heated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

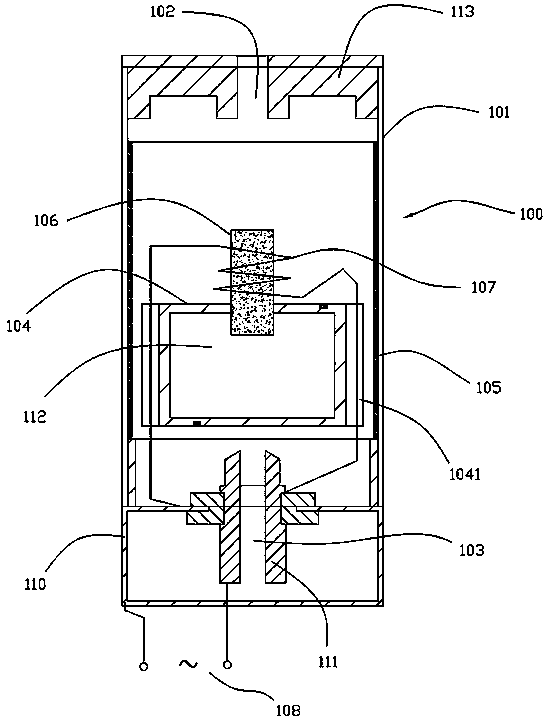

Smoke generator and electronic cigarette with same

InactiveCN103689812ASimple structureFully heatedTobacco devicesElectronic cigaretteAlternating current

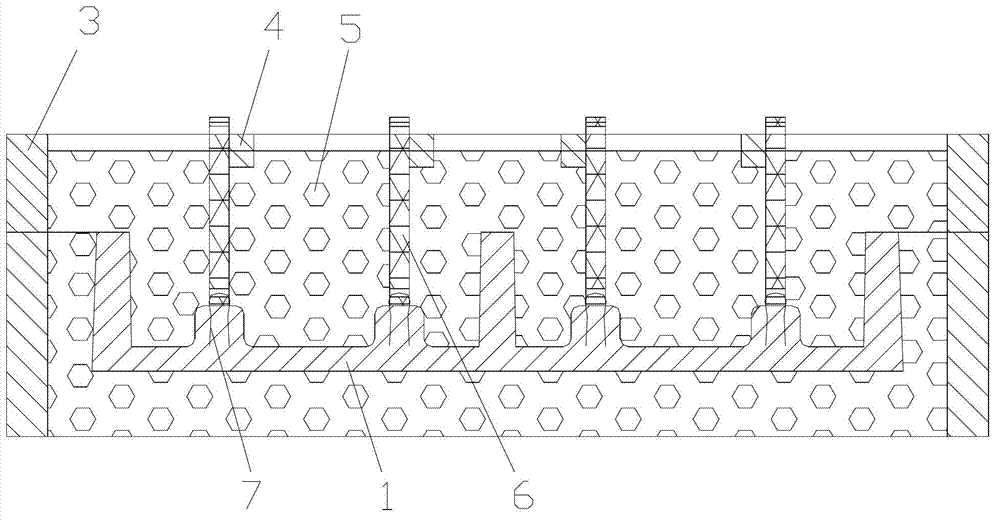

The invention discloses a smoke generator and an electronic cigarette with the same. The smoke generator comprises a shell and a heating component. The shell is provided with a smoke inlet hole and a smoke outlet hole, and the heating component is arranged in the shell. The shell is further provided with an accommodating area used for storing smoke generating materials. The heating component comprises a metal component and an induction coil wound on the periphery of the metal component. Two ends of the induction coil are connected with an alternating-current power source. The heating component is used for directly heating the smoke generating materials in the accommodating area or permeating from the accommodating area to enable the smoke generating materials to generate smoke which is then exhausted from the smoke outlet hole. Compared with smoke generators with conventional atomizing modes, the smoke generator has the advantages that the smoke generating materials are atomized by a heating mode in which vortexes are generated through electromagnetic induction, so that the smoke generator is large in heating area, full in atomization and the like.

Owner:SHENZHEN FIRST UNION TECH CO LTD

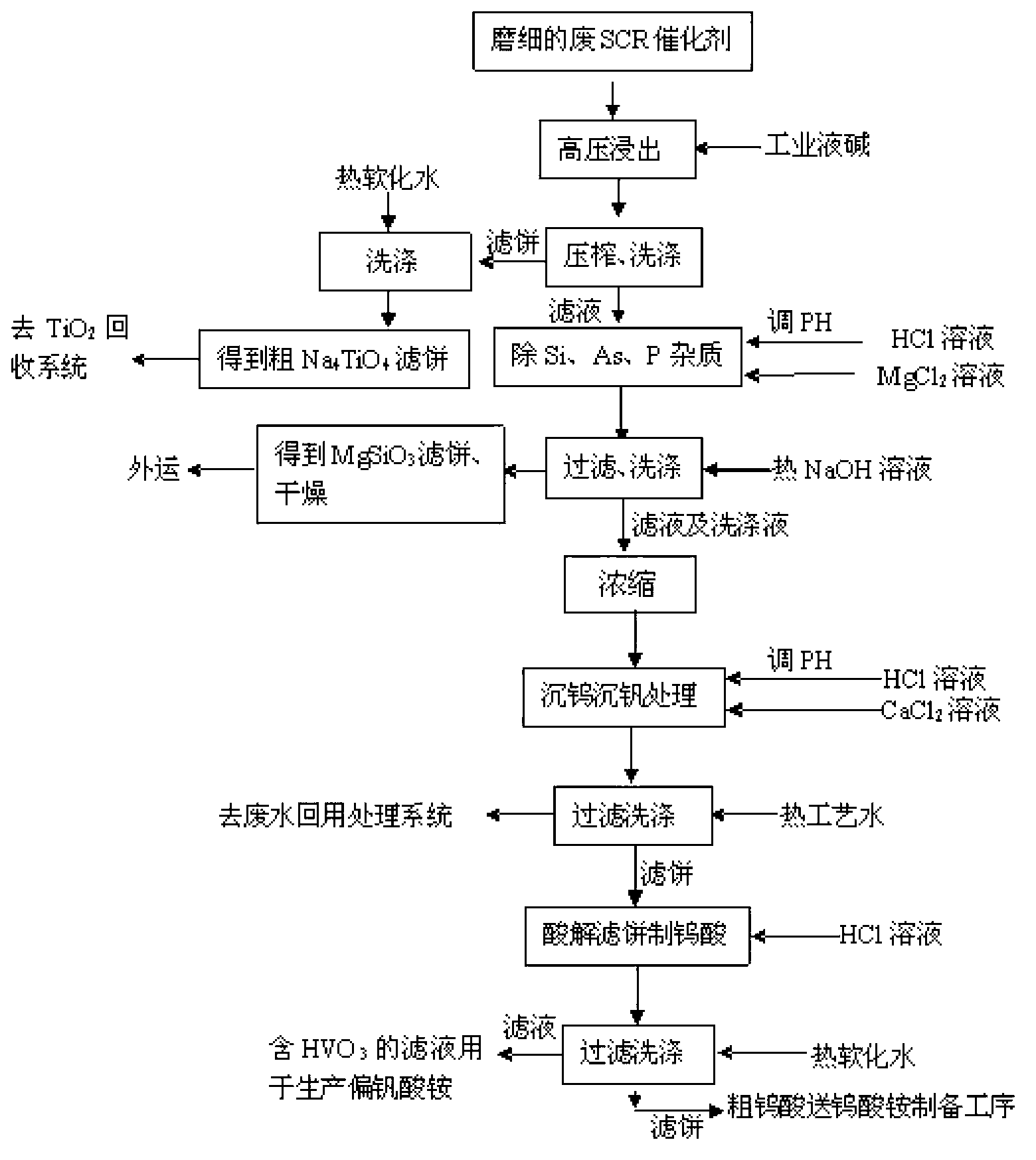

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

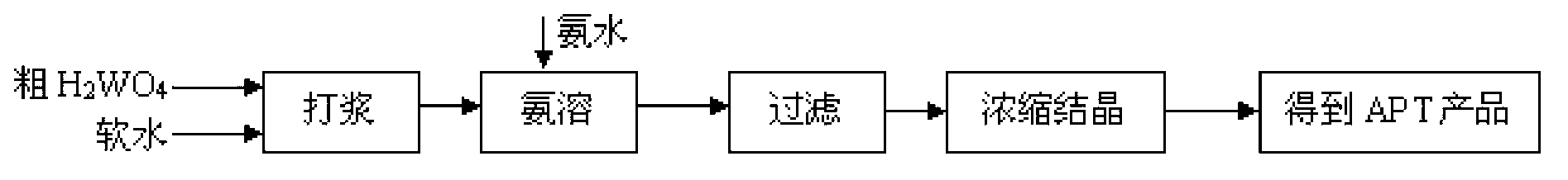

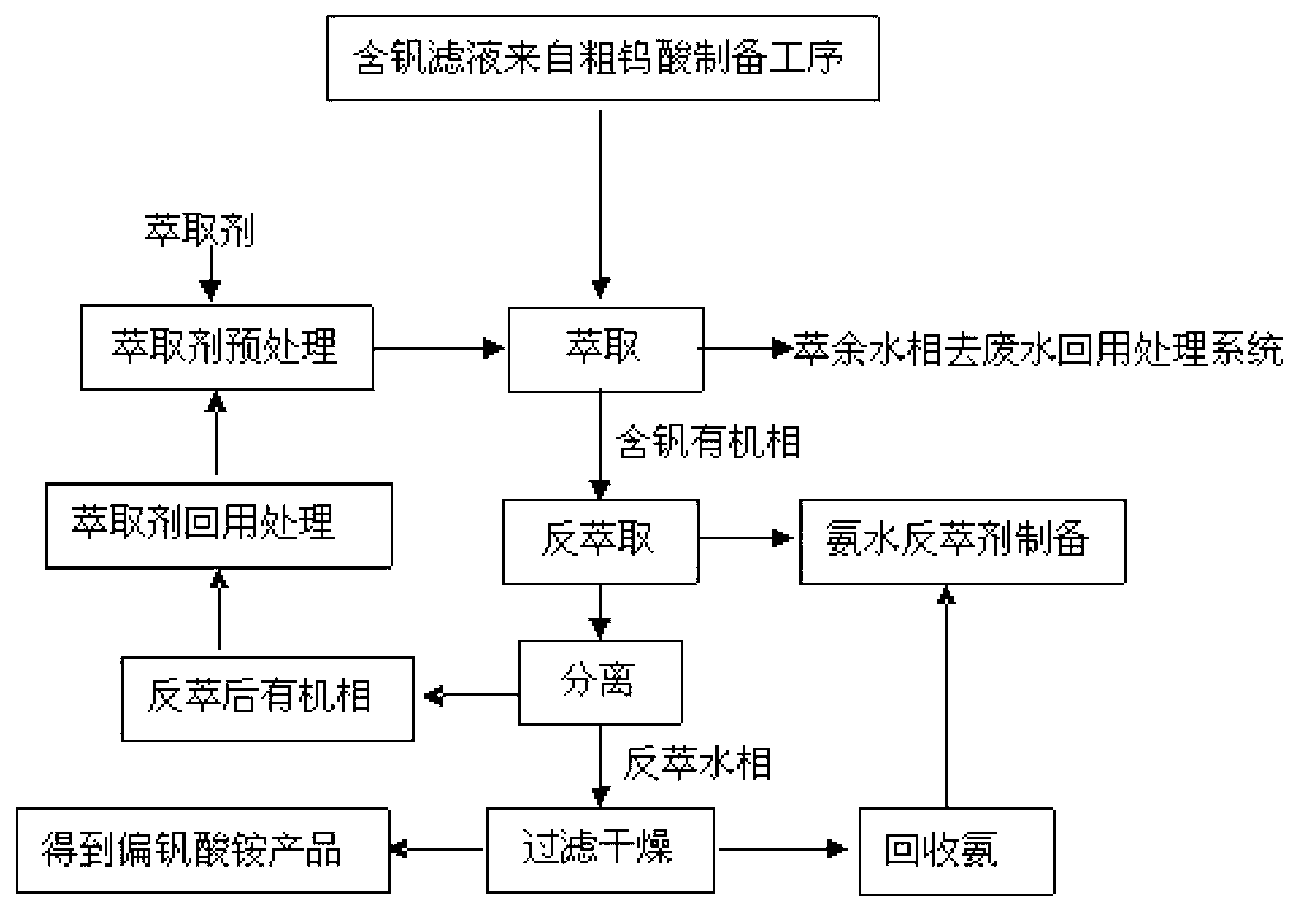

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

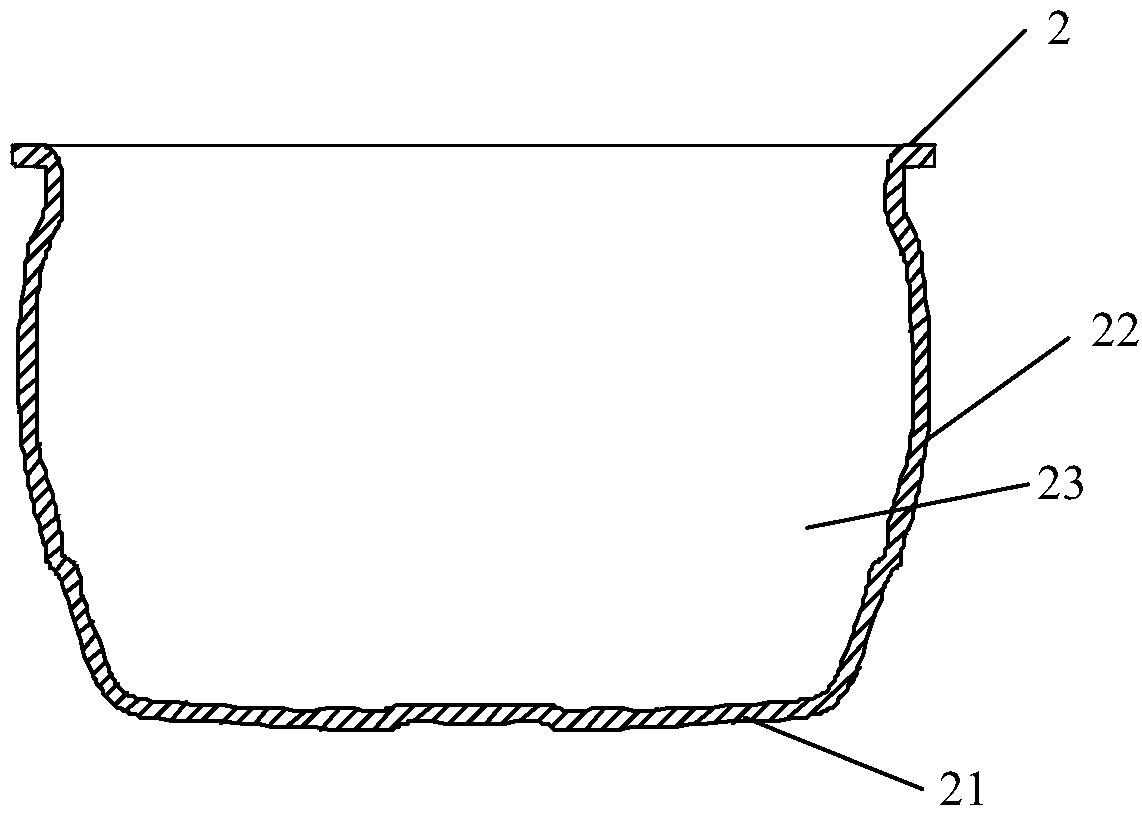

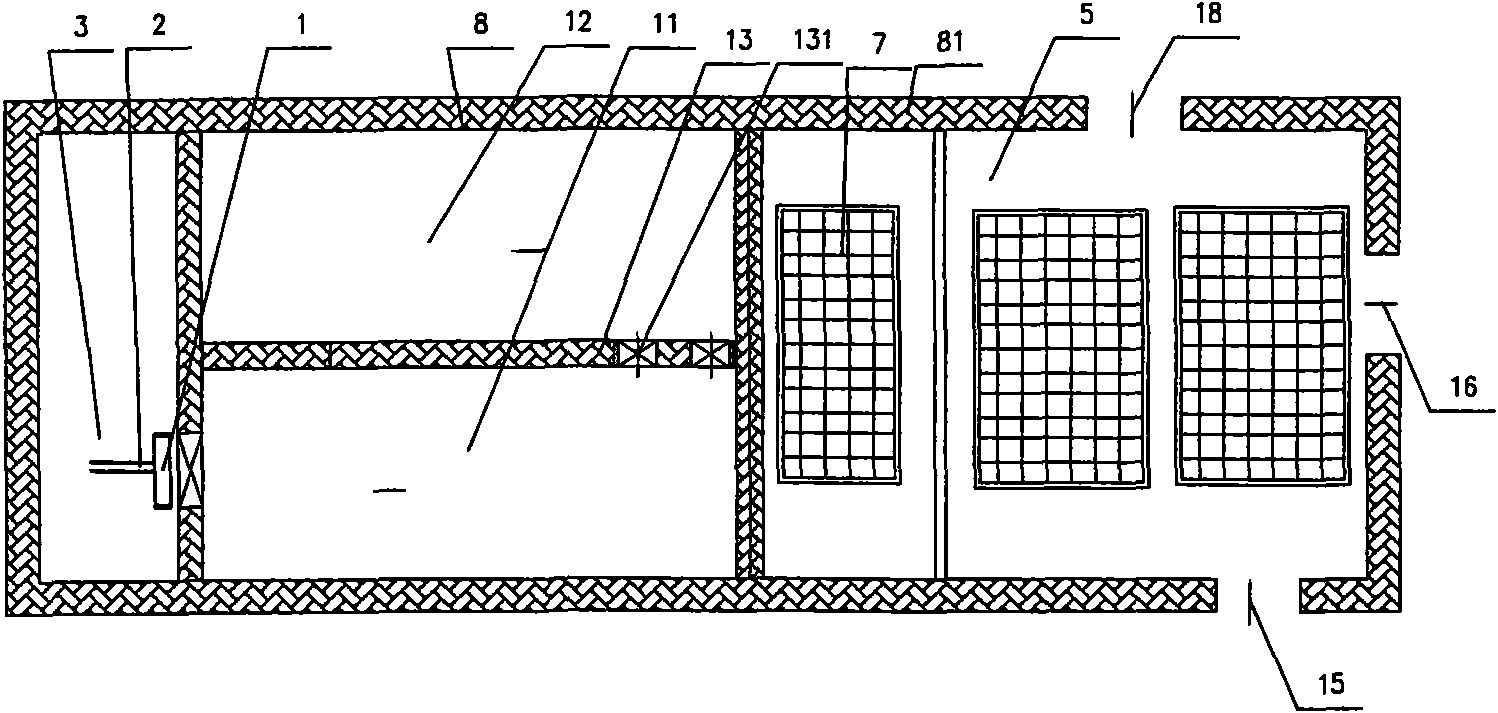

Cooking device

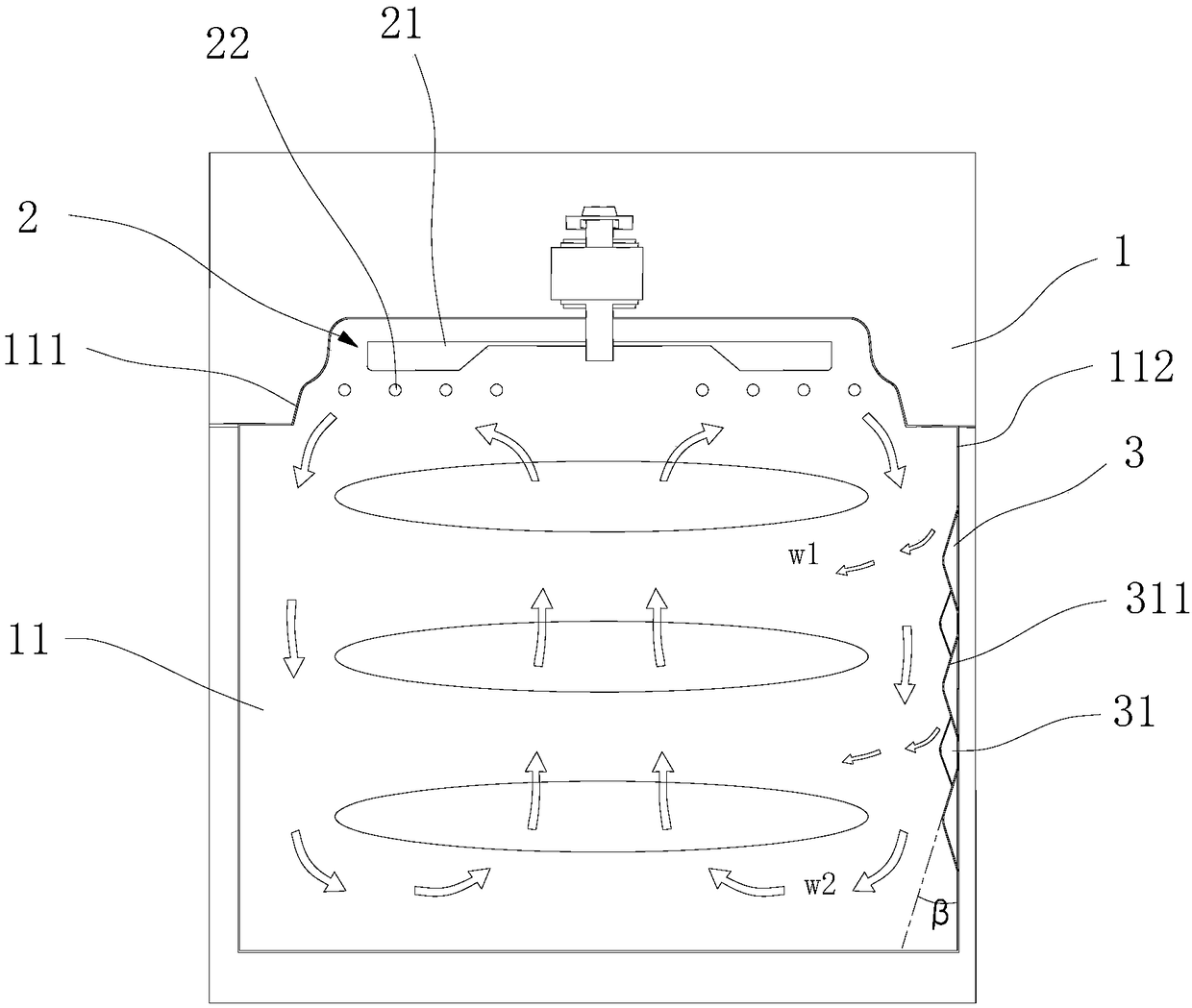

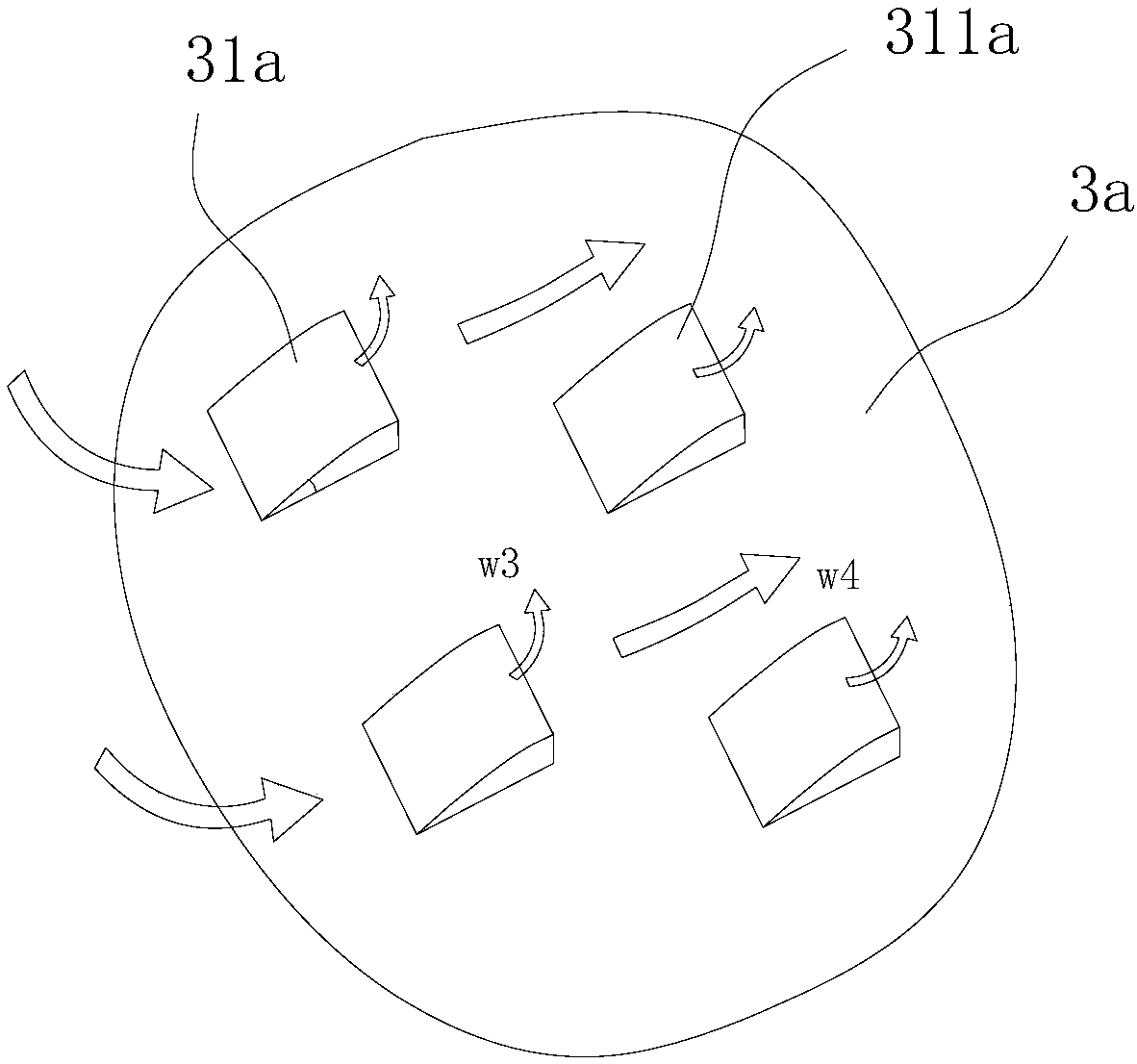

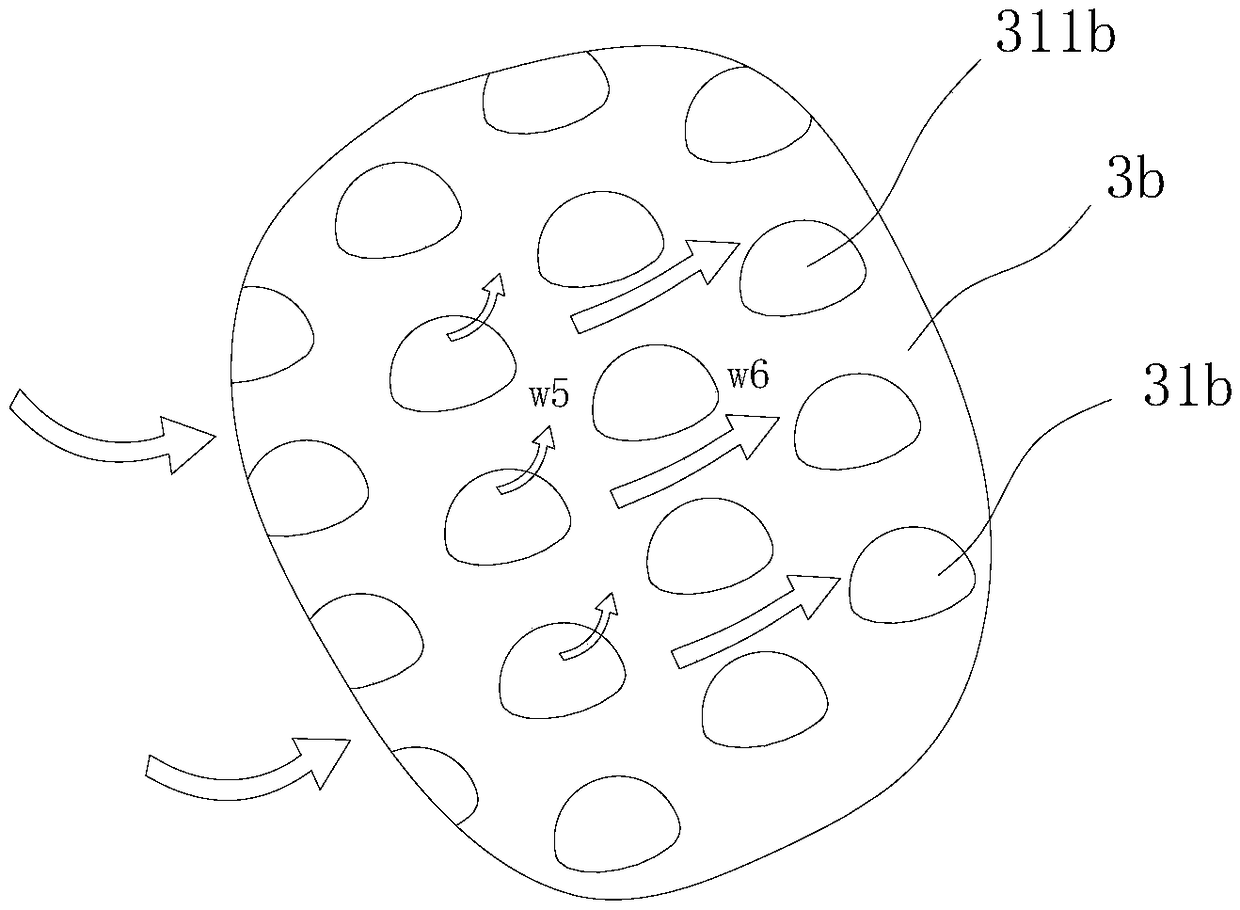

PendingCN108703675AFully heatedImprove cooking resultsRoasting apparatusRoasters/grillsProcess engineeringAirflow

Owner:FOSHAN SHUNDE KUFU ELECTRIC APPLIANCES CO LTD

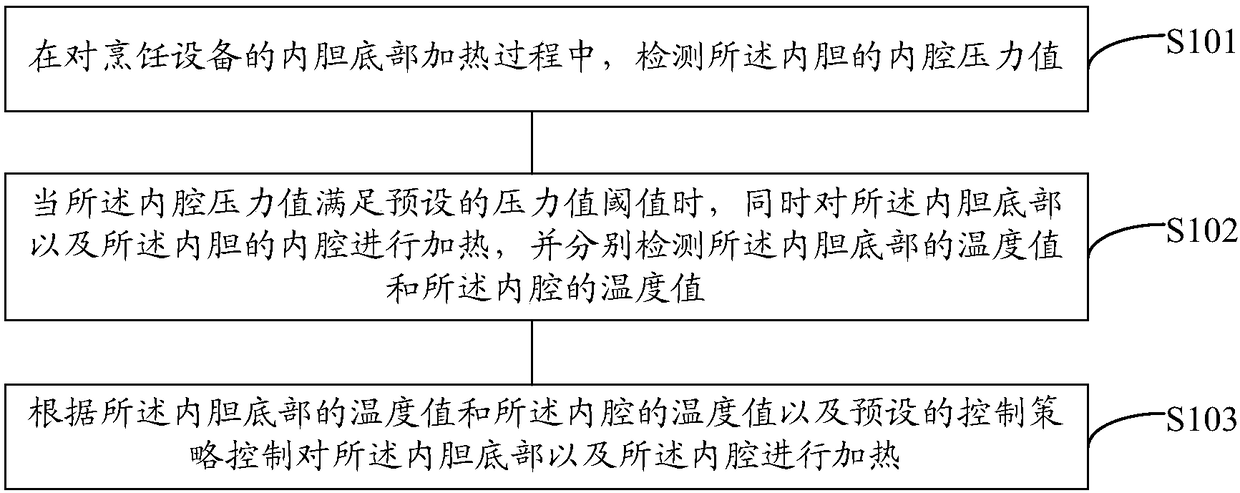

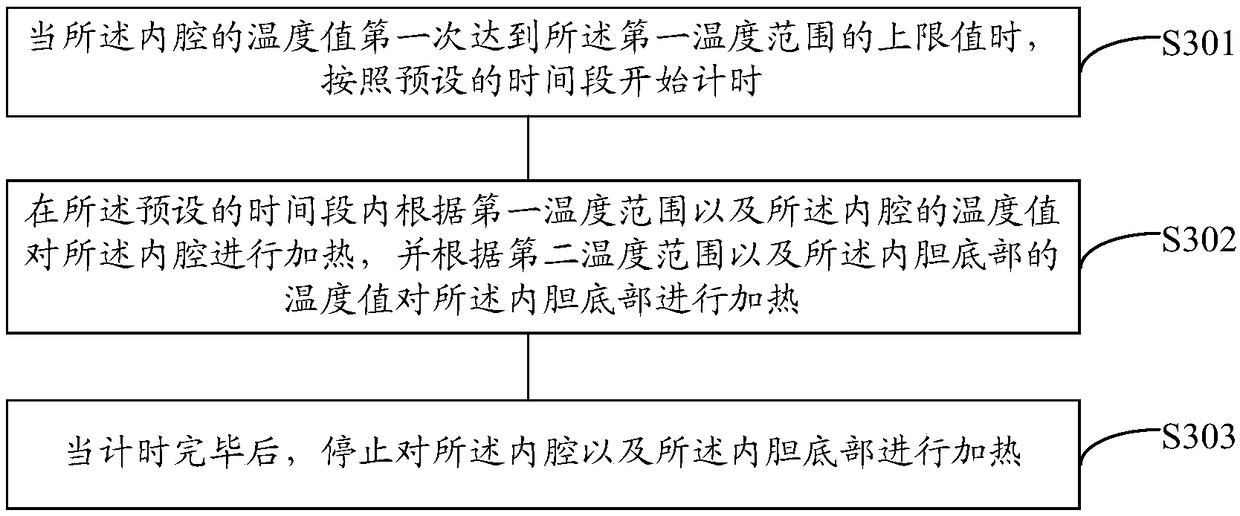

Control method and device

PendingCN108720577AGreat tasteImprove efficiencyRoasters/grillsPressure-cookersProcess engineeringCavity pressure

The embodiment of the invention discloses a control method and device. The control method can include the steps that in the process that the bottom of an inner container of a cooking device is heated,an inner-cavity pressure value of the inner container is detected; when the inner-cavity pressure value meets a preset pressure threshold value, the bottom of the inner container and an inner cavityof the inner container are simultaneously heated, and a temperature value of the bottom of the inner container and a temperature value of the inner cavity are detected respectively; according to the temperature value of the bottom of the inner container, the temperature value of the inner cavity and the preset control strategy, the bottom of the inner container and the inner cavity are controlledto be heated. Whole cooking food materials can be heated accordingly, the decocting, baking and roasting function of an electric pressure cooker for the cooking food materials is achieved, the taste of the cooking food materials can also be better than that of common cooking food materials, and the using efficiency and the cooking effect of the electric pressure cooker are improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

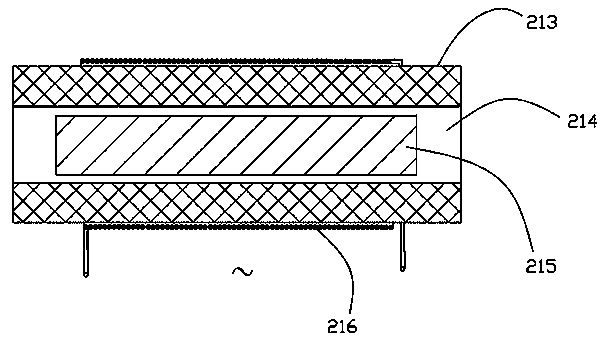

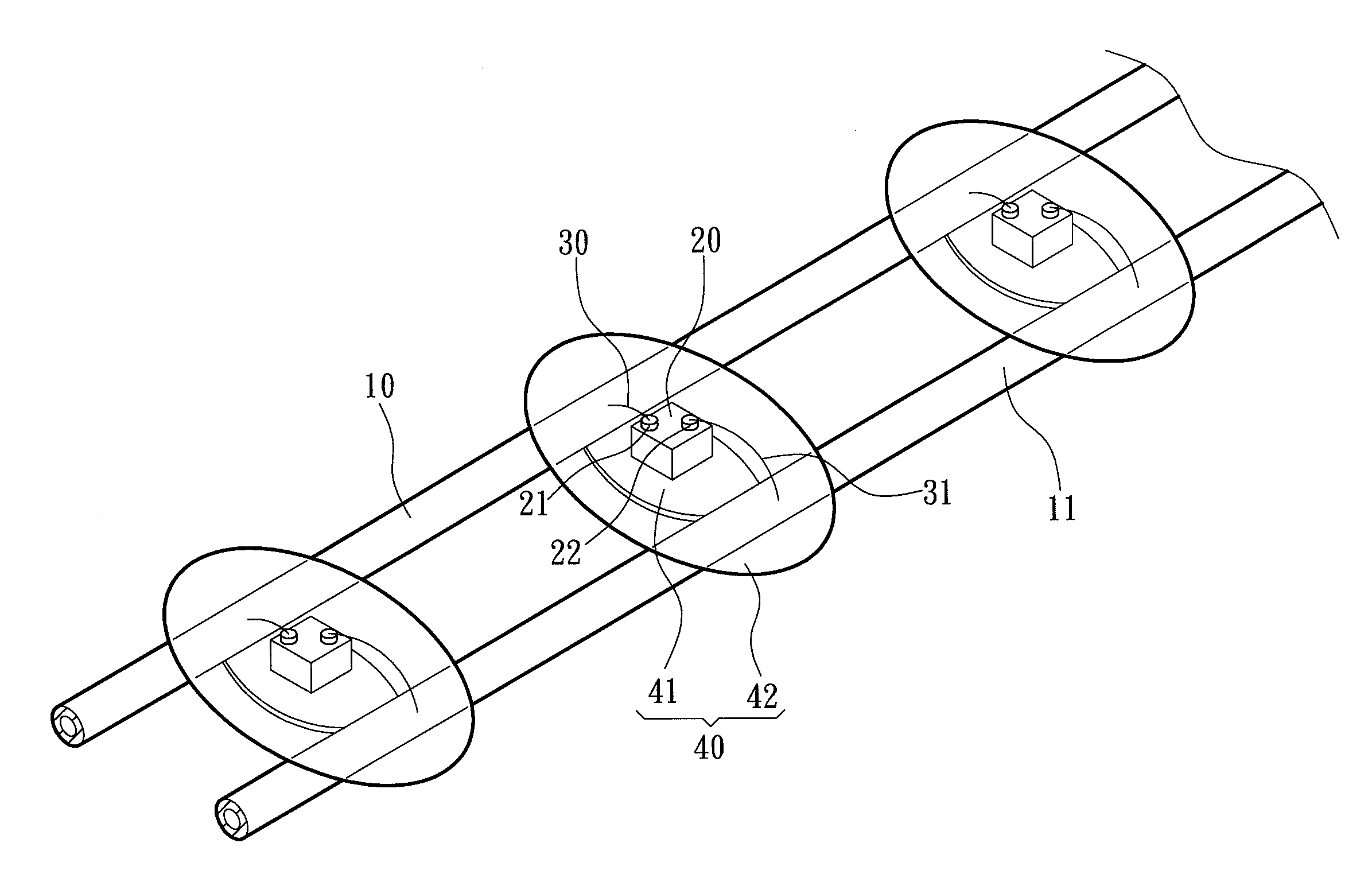

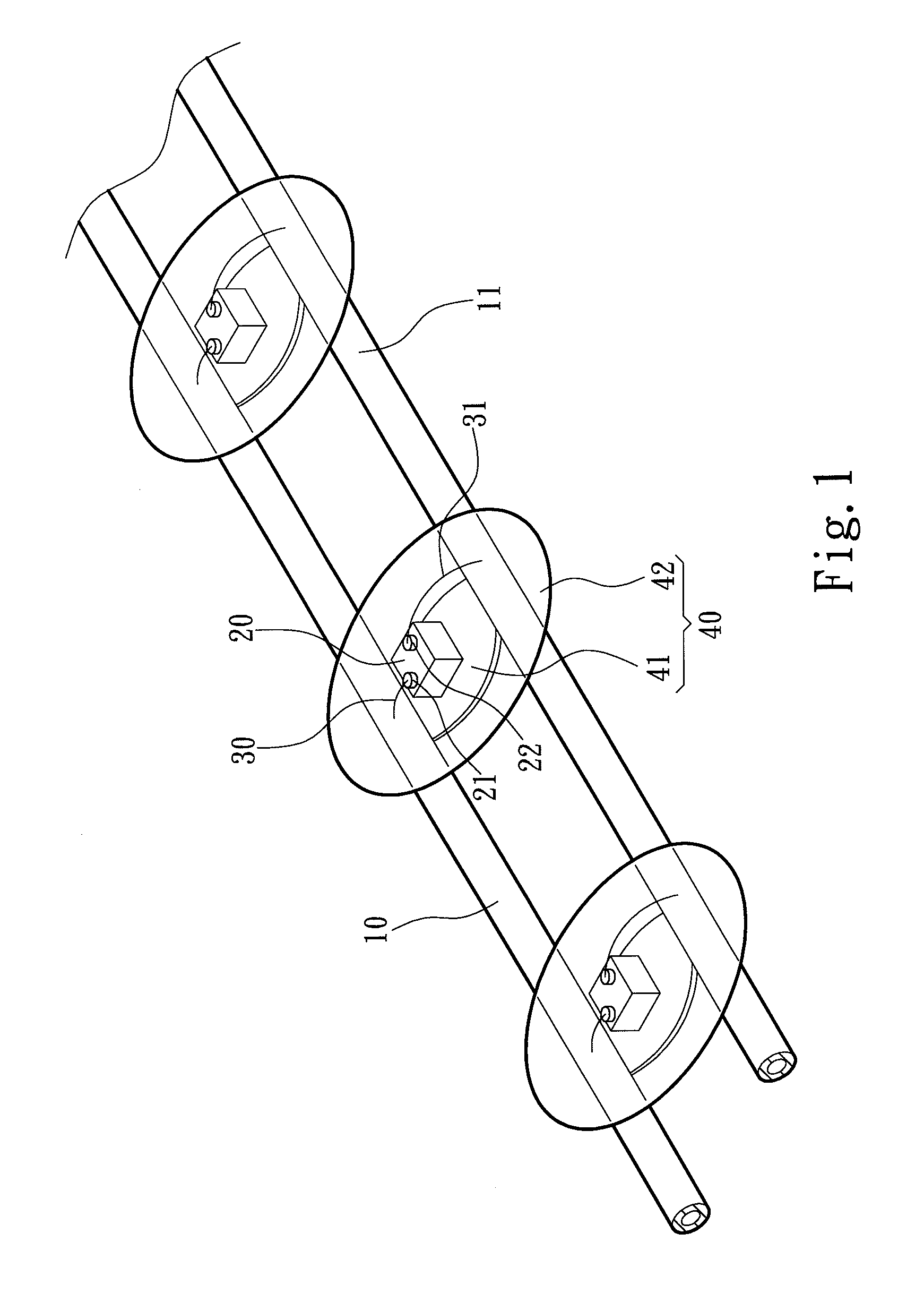

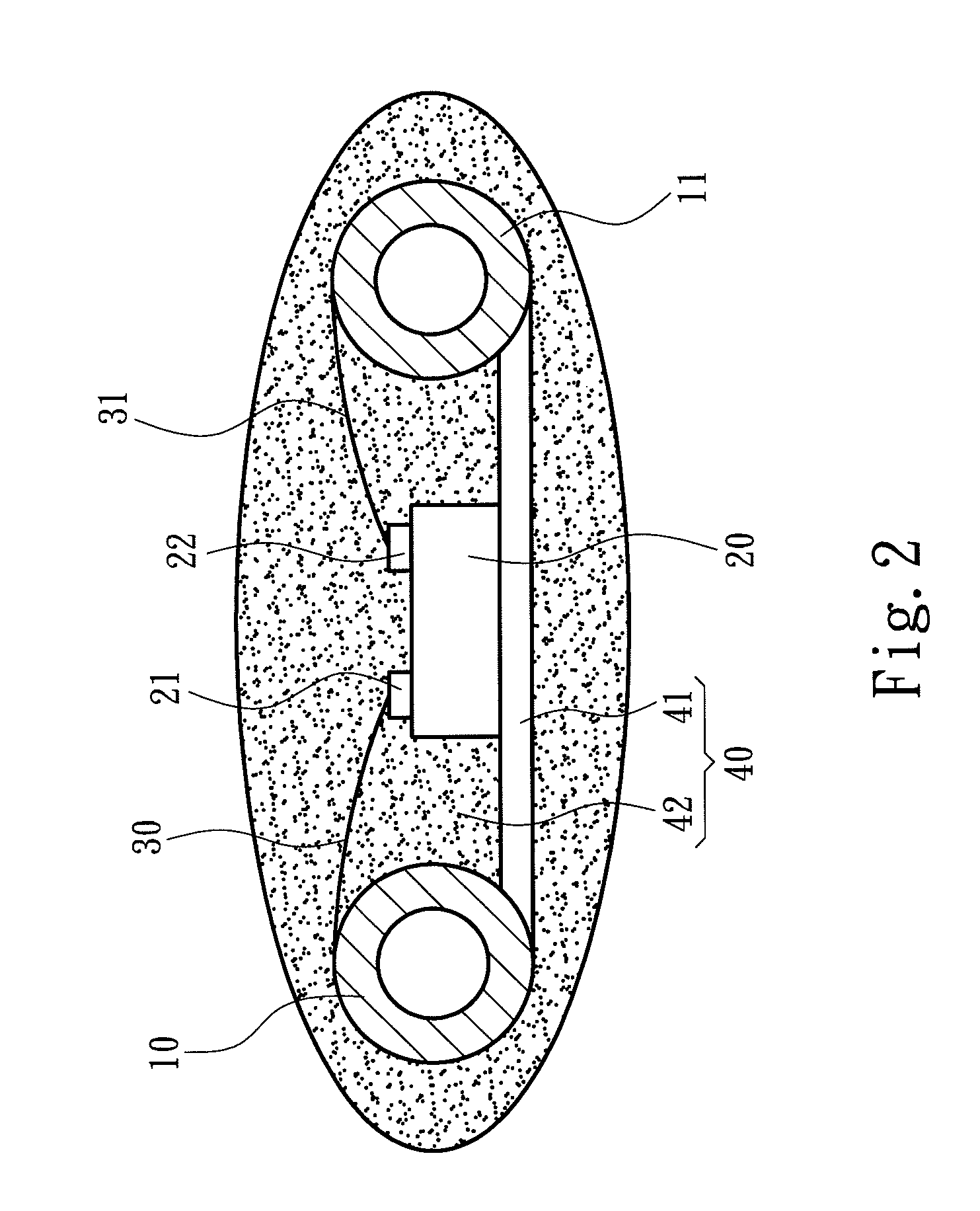

Lamp string structure for emitting light within wide area

InactiveUS20120275157A1Shorten production timeFully heatedPoint-like light sourceLighting support devicesConductive filamentElectricity

A lamp string structure for emitting light within wide area includes a first conductive wire and a second conductive wire parallel with each other, and at least one lighting element located between the first and second conductive wires. The lighting element has a first conductive filament and a second conductive filament electrically connected to the first and second conductive wires respectively. The lighting element is encased by a package body which has an insulation holding layer to hold the lighting element and an insulation covering layer connected to the insulation holding layer to cover the lighting element. The insulation holding layer and insulation covering layer are light transparent. Thus the lighting element can emit light radially without being constrained by light emission angles and also dissipate heat generated by the lighting element during light emission to reduce heat accumulation.

Owner:HSU YU MOU

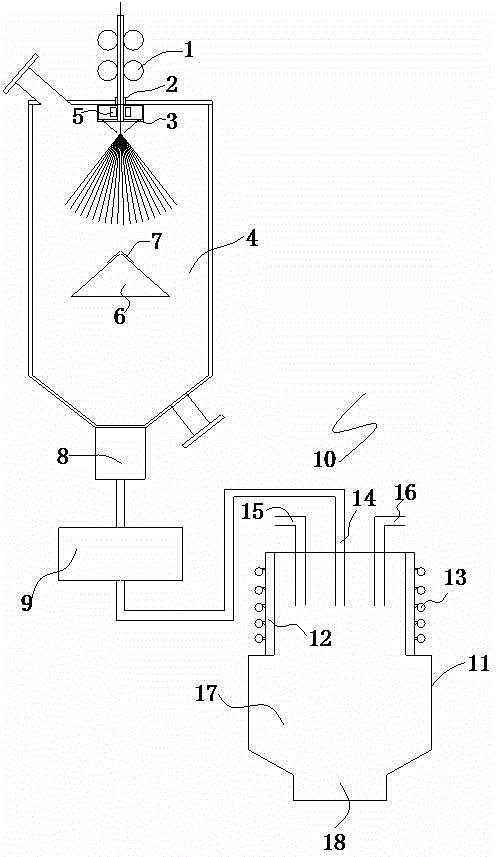

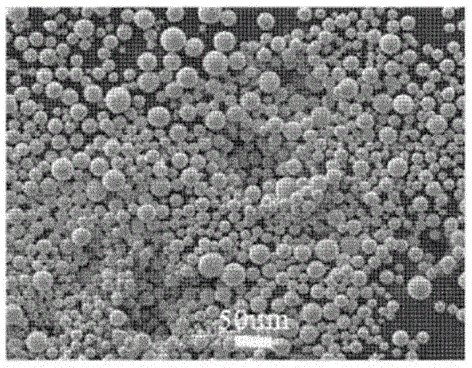

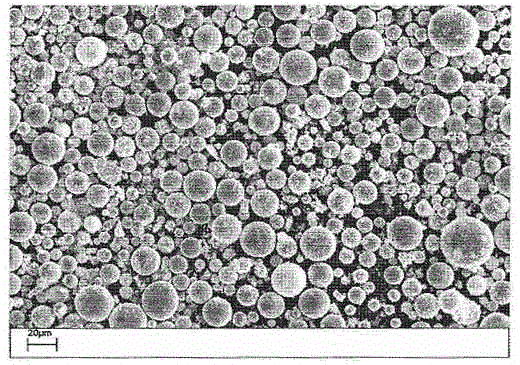

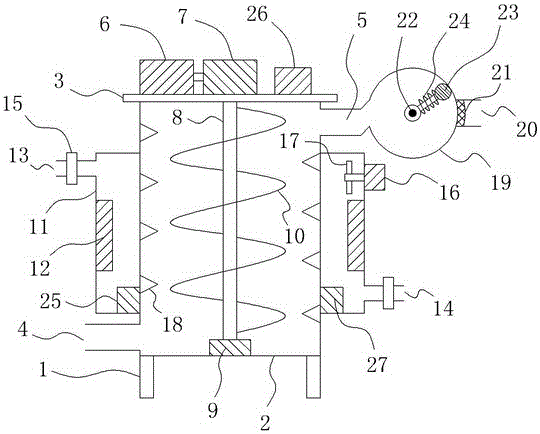

Device and method for preparing superfine micro-spherical titanium powder for 3D printing

InactiveCN105057689AGood sphericityHigh purityAdditive manufacturing apparatusPlasma torchRadio frequency plasma

The invention relates to a device for preparing superfine micro-spherical titanium powder for 3D printing. The device for preparing the superfine micro-spherical titanium powder for 3D printing comprises an automatic feeding system, an insulation dynamic seal unit, an annular gas atomization nozzle, an atomization chamber, an arc cathode smelting well, a radiating cover, a protection cover, a powder collection tank, a supersonic gas crushing mill and a radio frequency plasma reactor. The invention further relates to a method for preparing the superfine micro-spherical titanium powder for 3D printing. The method comprises the steps that firstly a gas atomization unit is used for performing initial powder production on raw titanium powder; then crushing is used for further reducing the granularity of the titanium powder; a plasma unit is used for further processing the titanium powder; the high-energy characteristic of radio frequency plasma is used for injecting carrying gas for irregular-shaped titanium powder particles into a plasma torch, the irregular titanium powder is heated rapidly and melted, the melted particles form drops with high sphericity degree under the action of surface tension, and the drops are solidified rapidly under an ultra-high temperature gradient to form the superfine micro-spherical titanium powder good in sphericity degree, high in purity and low in oxygen content.

Owner:SHANXI ZHUOFENG TITANIUM IND

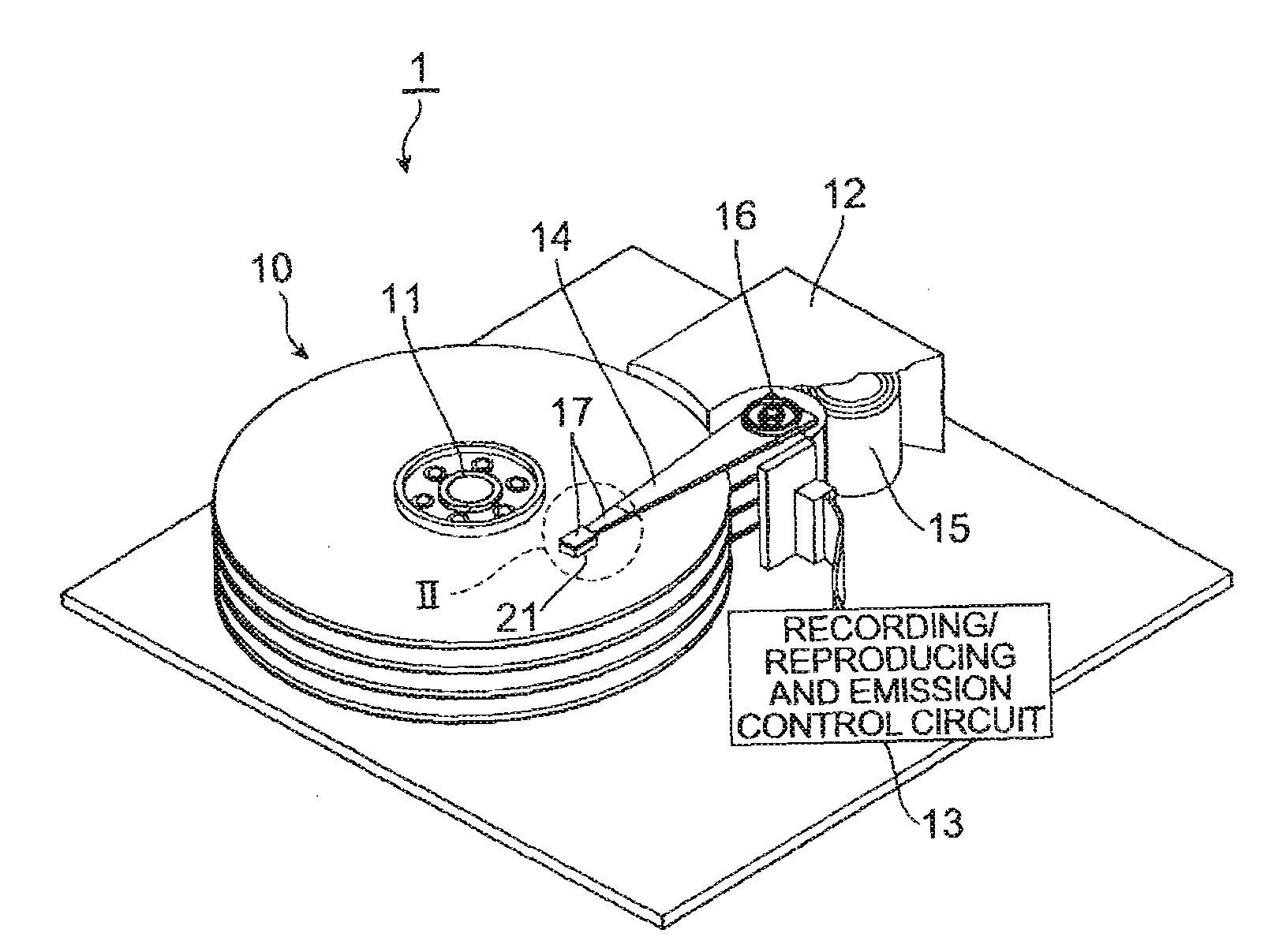

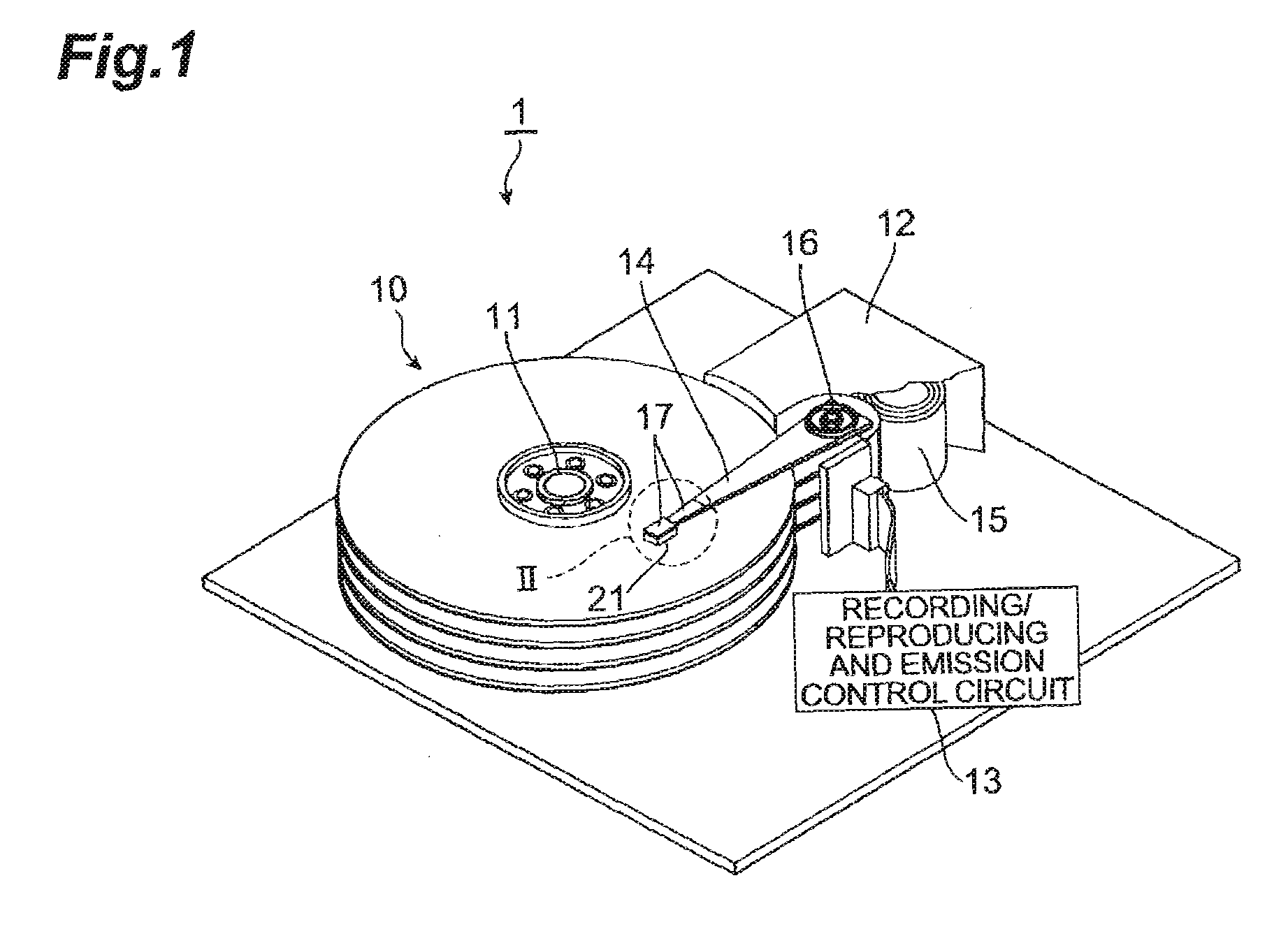

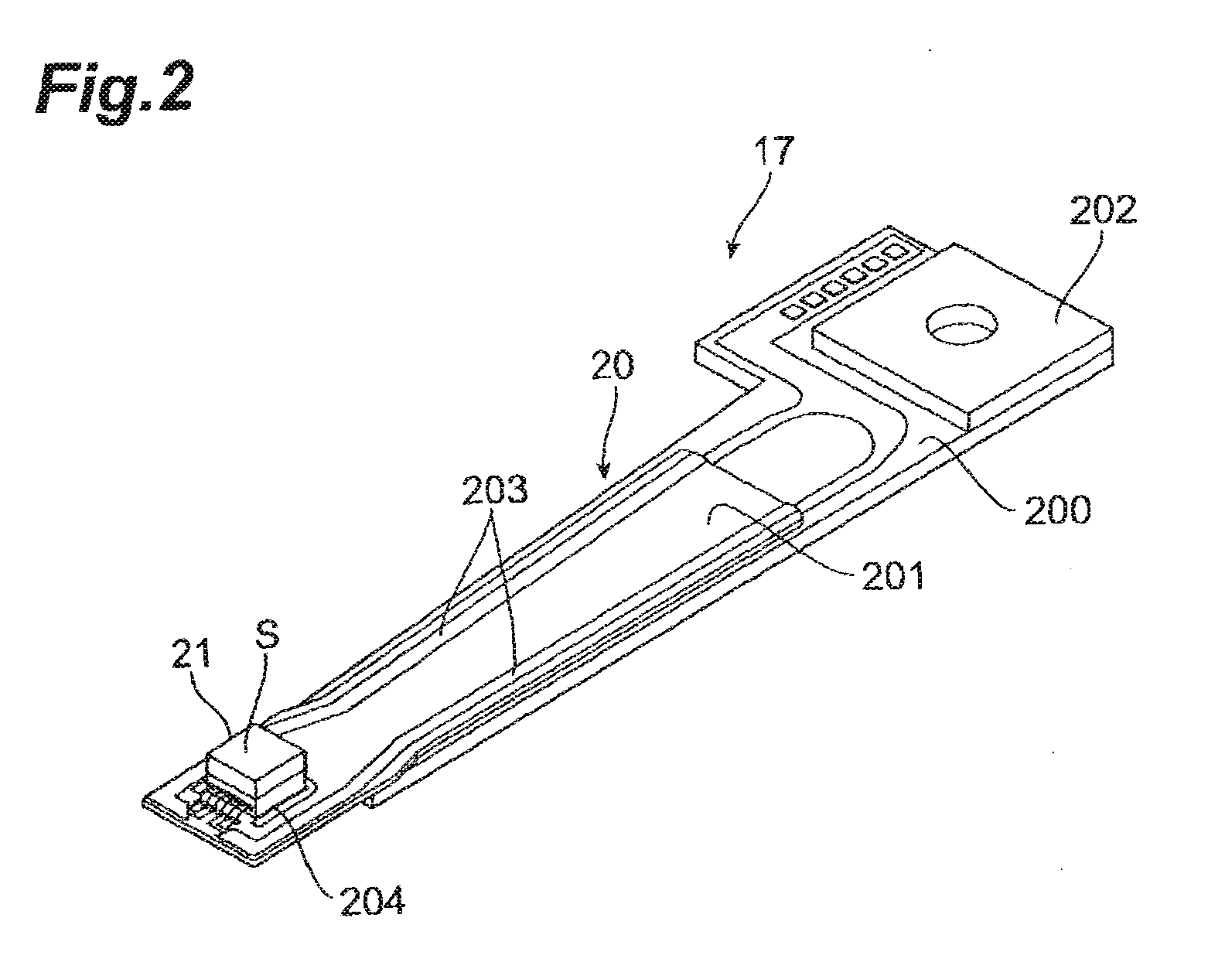

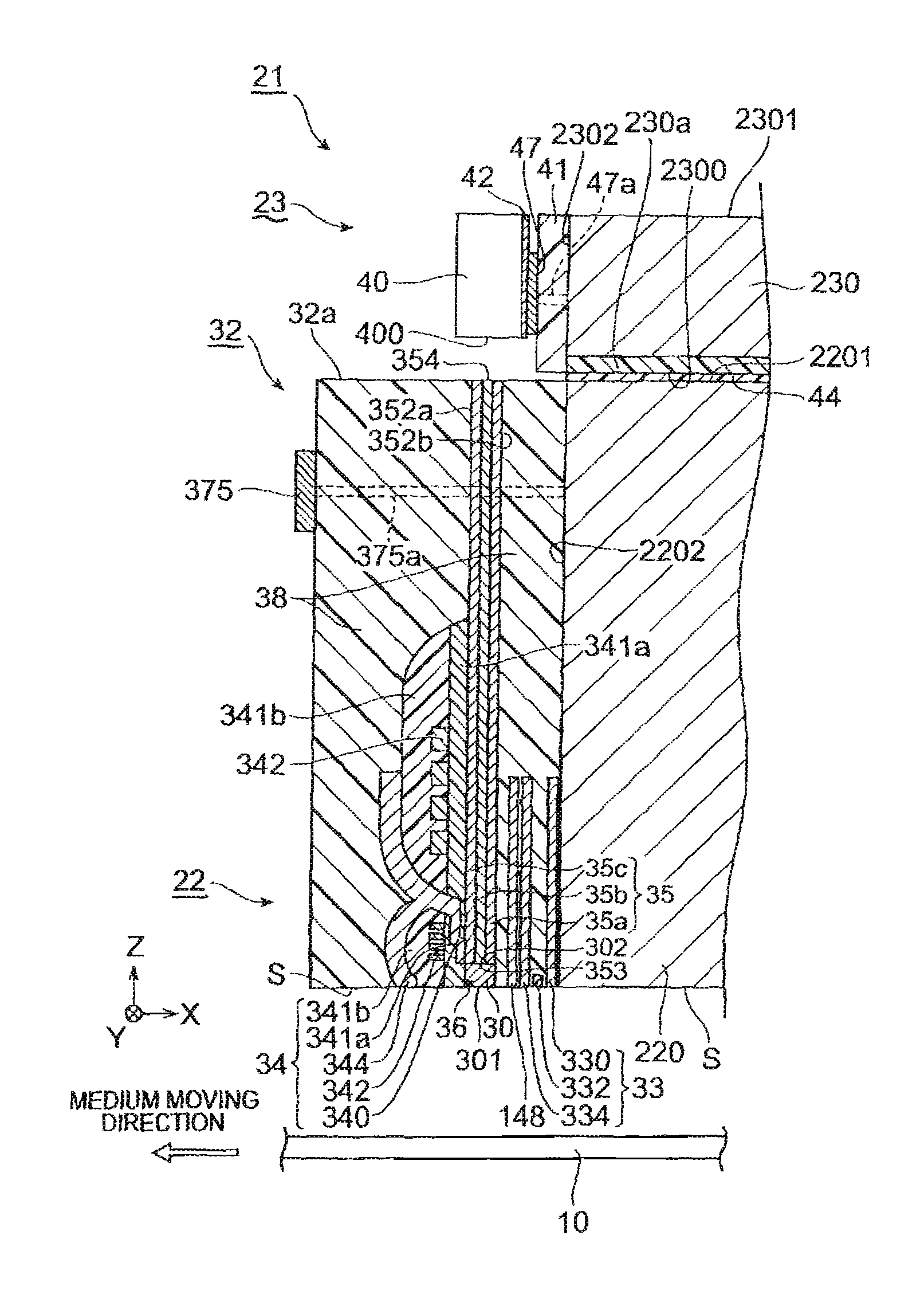

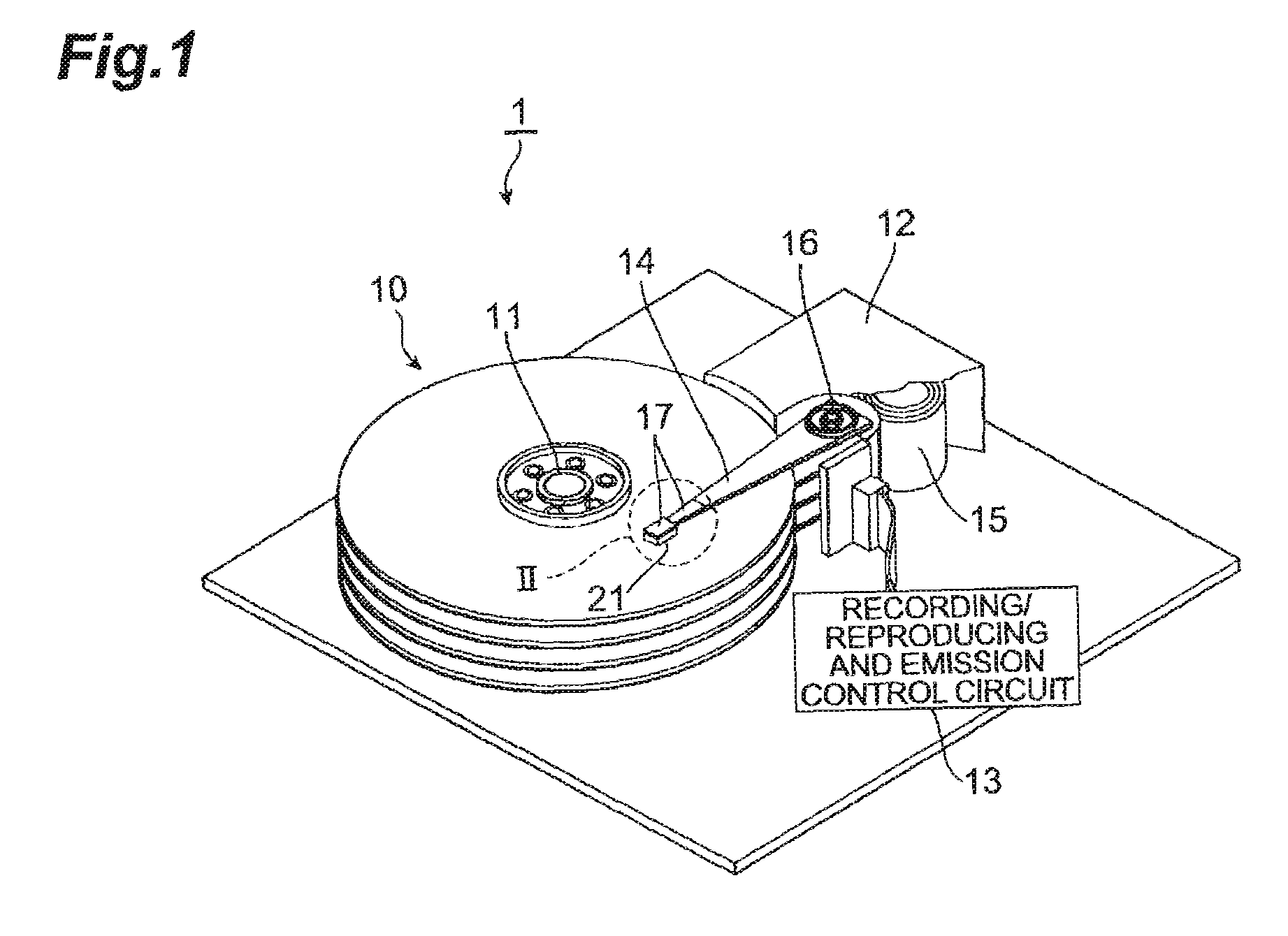

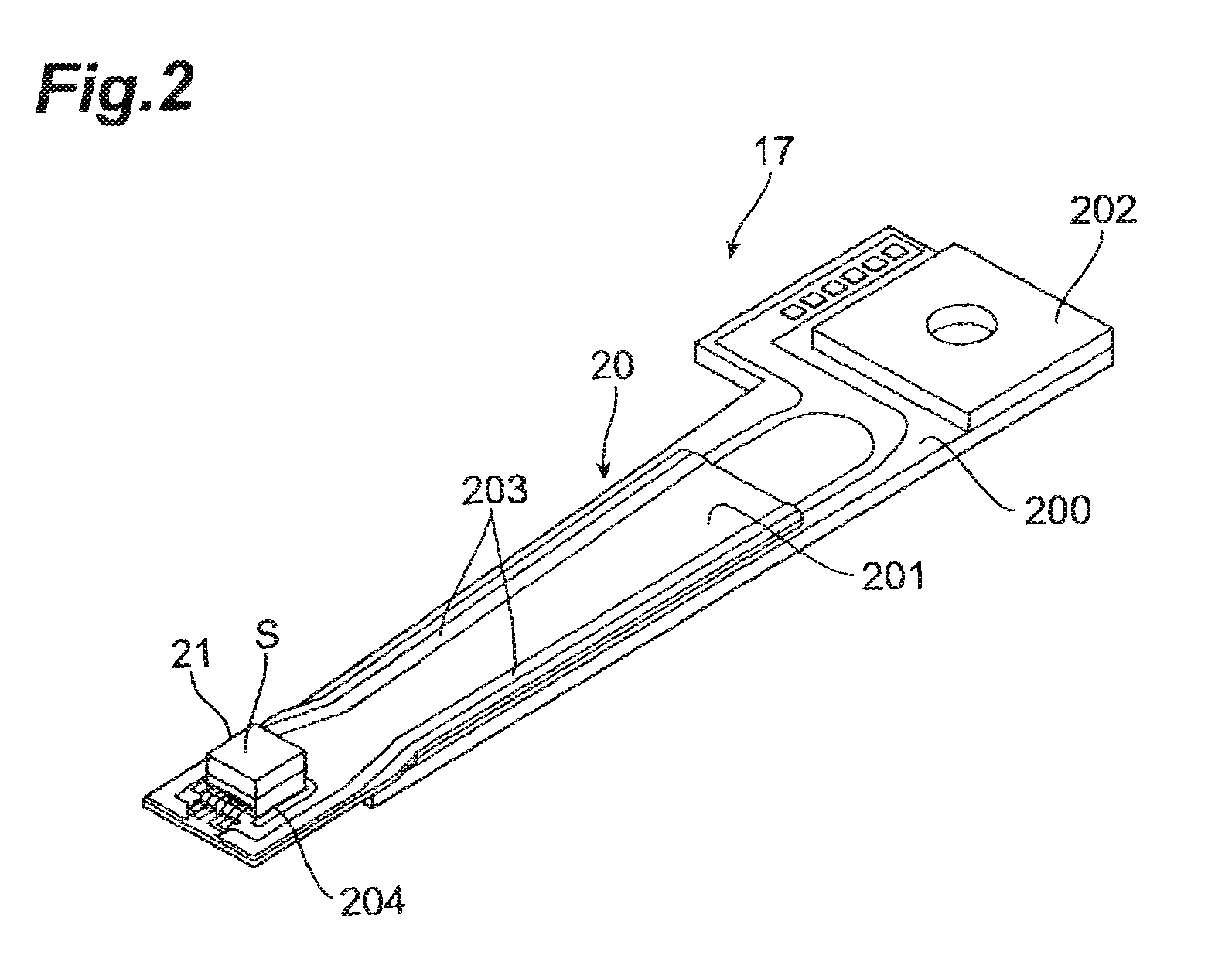

Thermally assisted magnetic head, head gimbal assembly, and hard disk drive

ActiveUS20080239541A1Low coercivityHeat the recording areaCombination recordingRecord information storageHard disc driveMagnetic poles

The thermally assisted magnetic head comprises a medium-opposing surface; a magnetic recording device whose distance from a main magnetic pole to a medium is set longer than a distance from the medium-opposing surface to the medium; a first core for receiving light; and a second core positioned between a first light exit surface of the first core and the medium-opposing surface, having a second light exit surface on the medium side; while a distance between positions where an optical intensity distribution center within the first light exit surface and a center of the main magnetic pole are orthographically projected onto a reference plane including the second light exit surface is greater than a distance between an optical intensity distribution center within the second light exit surface and the position where the center of the leading end of the main magnetic pole is orthographically projected onto the reference plane.

Owner:TDK CORPARATION

Infrared energy-saving coating with anti-corrosion and anti-coking functions and preparation method thereof

InactiveCN102585571AStress reliefLow shrinkageAnti-corrosive paintsInorganic adhesivesBoron nitrideManganese(III) oxide

The invention relates to an infrared energy-saving coating with anti-corrosion and anti-coking functions, which is prepared from a component A and a component B according to the weight ratio of 1: 1-2. The particle size of powder materials in the component A is not less than 280 meshes and the component A is prepared from the following powder materials according to the weight ratio: 40-60 parts of spinel structure infrared composite darkening agent, 10-30 parts of corundum powder and 3-10 parts of high-temperature binding agent. The component A further comprises an anti-coking agent, and the anti-coking agent is prepared from the following powder materials according to the weight ratio: 3-10 parts of graphite, 0-10 parts of boron nitride and 1-5 parts of manganese sesquioxide. The component B is of a film-forming substance and prepared from the following raw materials according to the weight ratio: 60-80 parts of water glass, 10-30 parts of silica sol and 0-20 parts of water-borne resin solution. The invention further discloses a preparation method of the coating. The coating provided by the invention has the advantages: corrosion prevention, capability of reducing coking, high temperature resistance and excellent infrared radiation performance.

Owner:KING STRONG MATERIAL ENG LTD

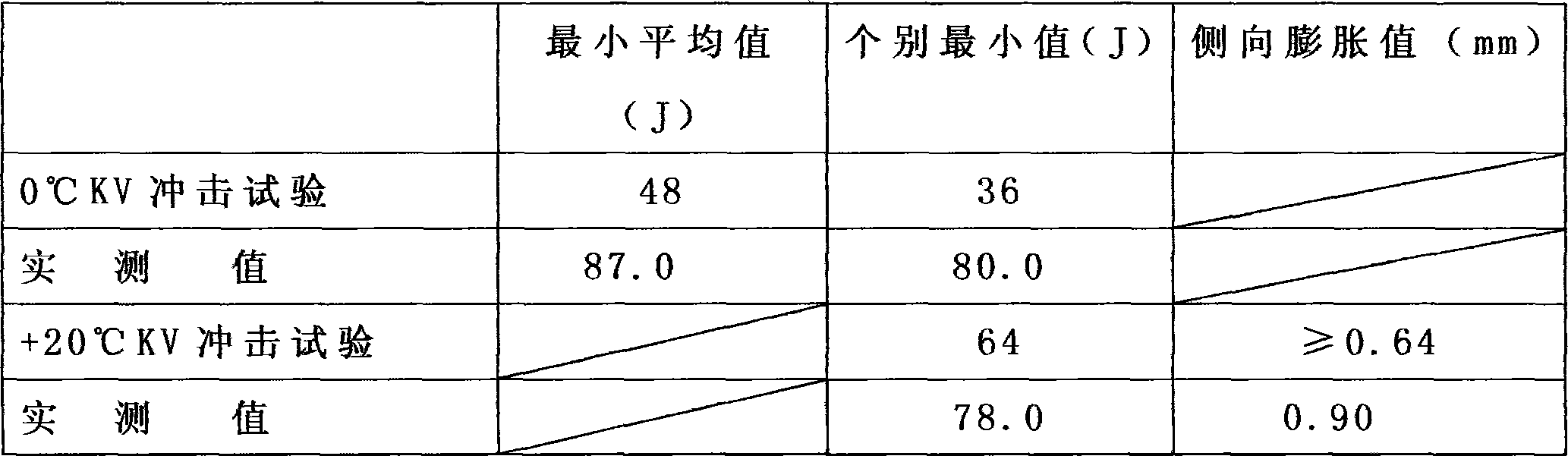

Million - kilowatts class nuclear power station reactor main bolt production process

ActiveCN101169150AUniform tissueFully heatedNuclear energy generationScrewsNuclear engineeringNuclear power

The invention discloses a pile main bolt manufacturing technique of a million kilowatt grade nuclear power station. The manufacturing technique includes material-selecting, melting, heating, forging, cooling, after-forging heat treatment, defect-detecting, and forging capability heat treating. When selecting the material, the microelement content of the materials is controlled, the heat preserving duration in the intermediate temperature stage is prolonged, the heat raising and the heat preserving duration in the high temperature stage are reduced, the distortion volume in the course of the forging is controlled between 30 percent and 70 percent, the forging rate reaches 5 above; after-forging heat treatment, ultrasonic defect detecting, and forging capacity heat treating are conducted when the forging is finished. The main bolt produced according to the manufacturing technique of the invention can improve the impact value under the circumstance that the intensity keeps unchanged, theproduct can meet the RCC-M standard requirements completely, and the reliability and the safety of the pile pressure container using the main bolt of the million kilowatt grade nuclear power station can be ensured.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

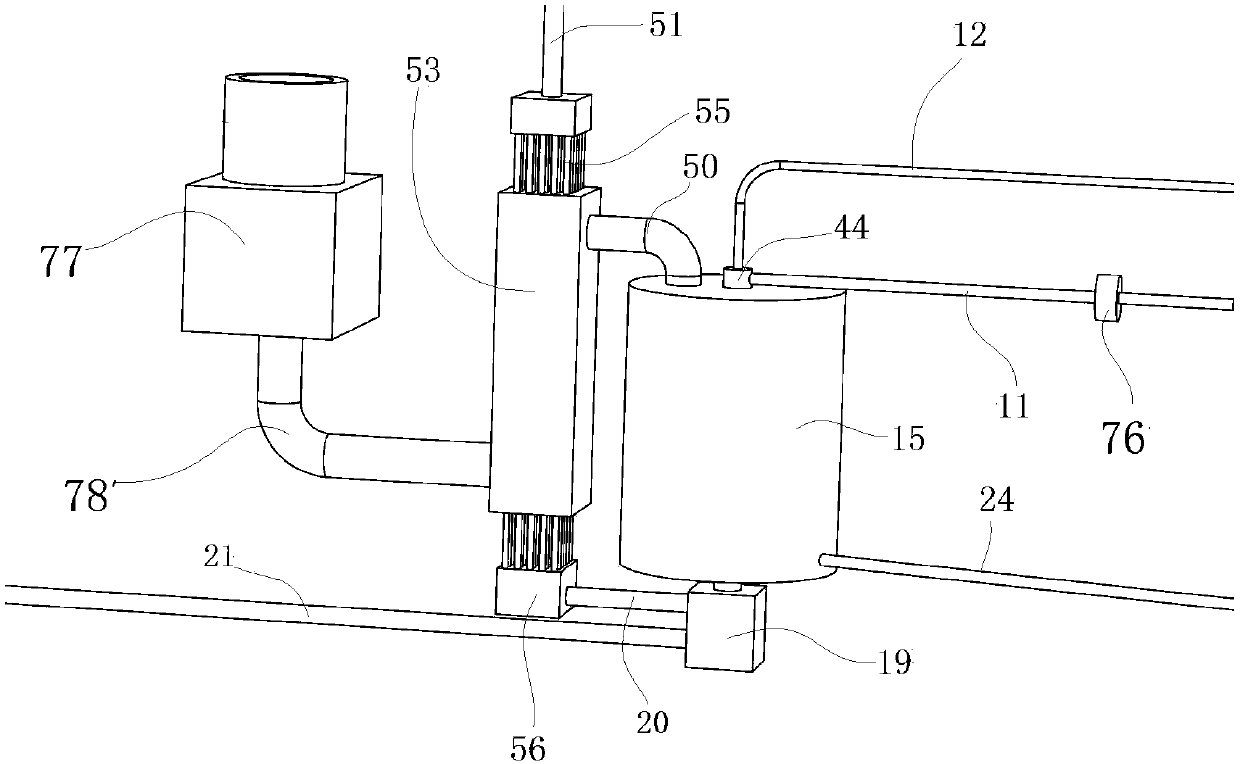

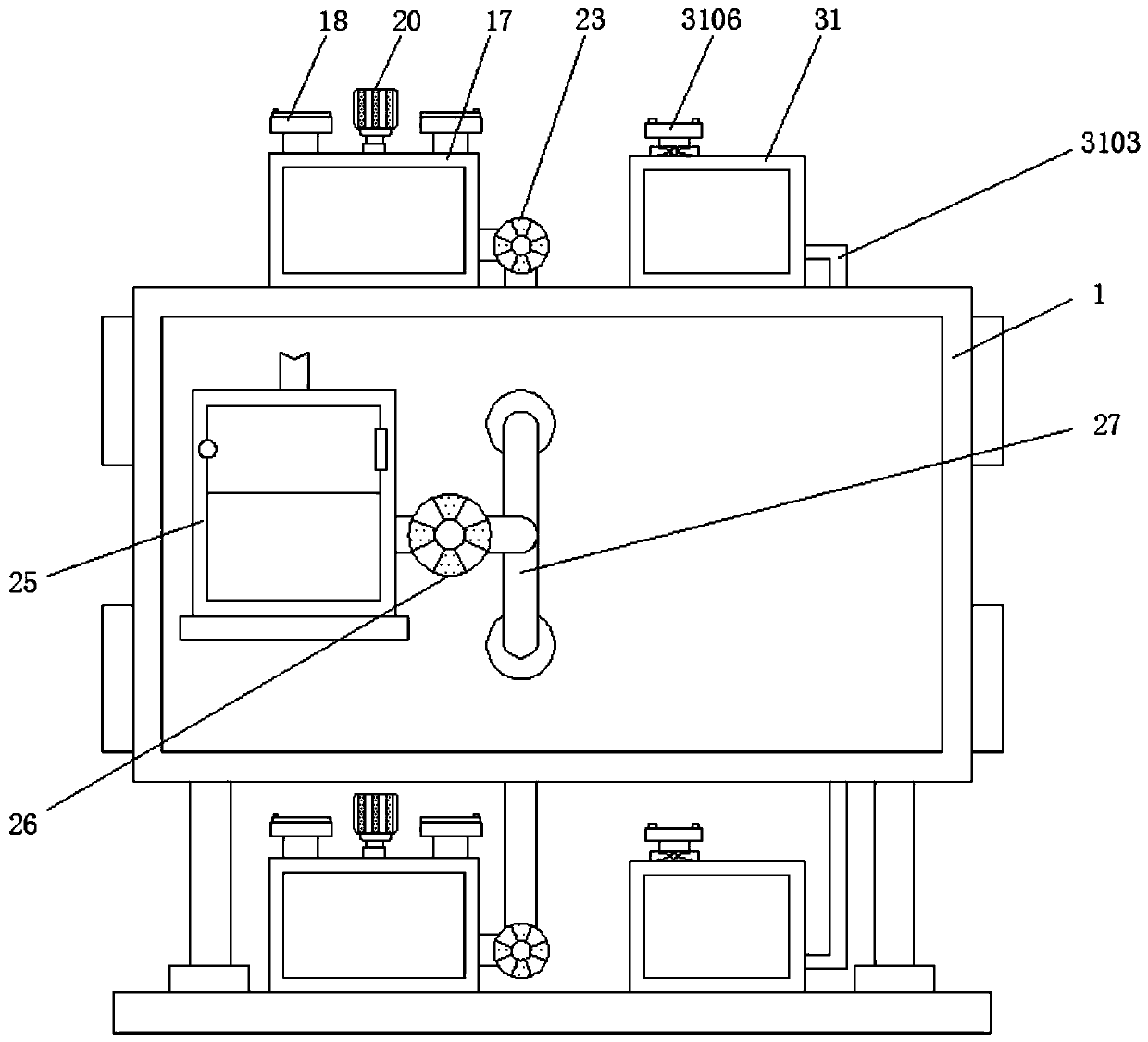

Combustion furnace based on liquid ethanol-natural gas composite fuel and method thereof

ActiveCN108050509AFully heatedHeating evenlyCombustion using gaseous and pulverulent fuelLiquid fuel feeder/distributionCombustion chamberEngineering

The invention discloses a combustion furnace based on liquid ethanol-natural gas composite fuel. The combustion furnace comprises a combustion furnace body, and the combustion furnace body comprises acomposite fuel combustion furnace which is of a cone-shaped circular platform structure with a thin end facing down; the lower end of the composite fuel combustion furnace is coaxially provided witha flame nozzle, and the firing direction of the flame nozzle is vertical upwards; the upper end of the composite fuel combustion furnace is a smoke exhaust wall, and the smoke exhaust wall is providedwith a plurality of smoke outlets; and the combustion furnace is simple in structure, the cone-shaped circular platform type combustion chamber is adopted and matched with an ethanol gasification cone to guide ordinary natural gas jet flames into a trumpet shape, and the flames go forwards by being attached to a heating pipe distributed in a conical spiral form, so that the heating area of the flames is enlarged.

Owner:谢丽萍

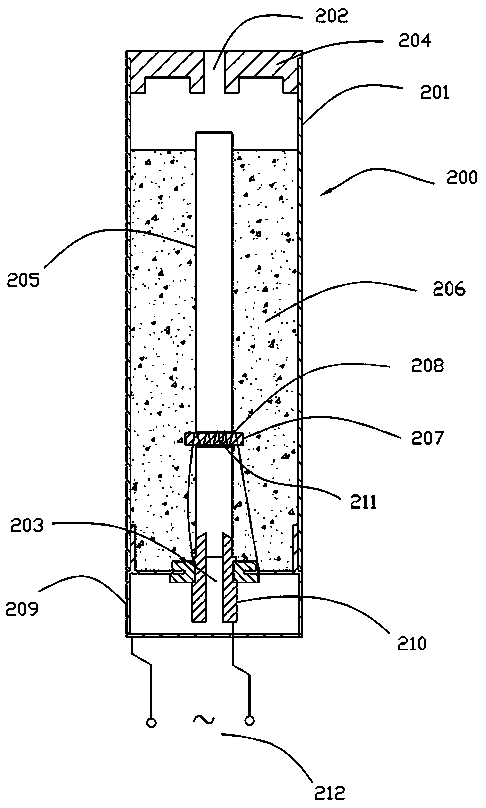

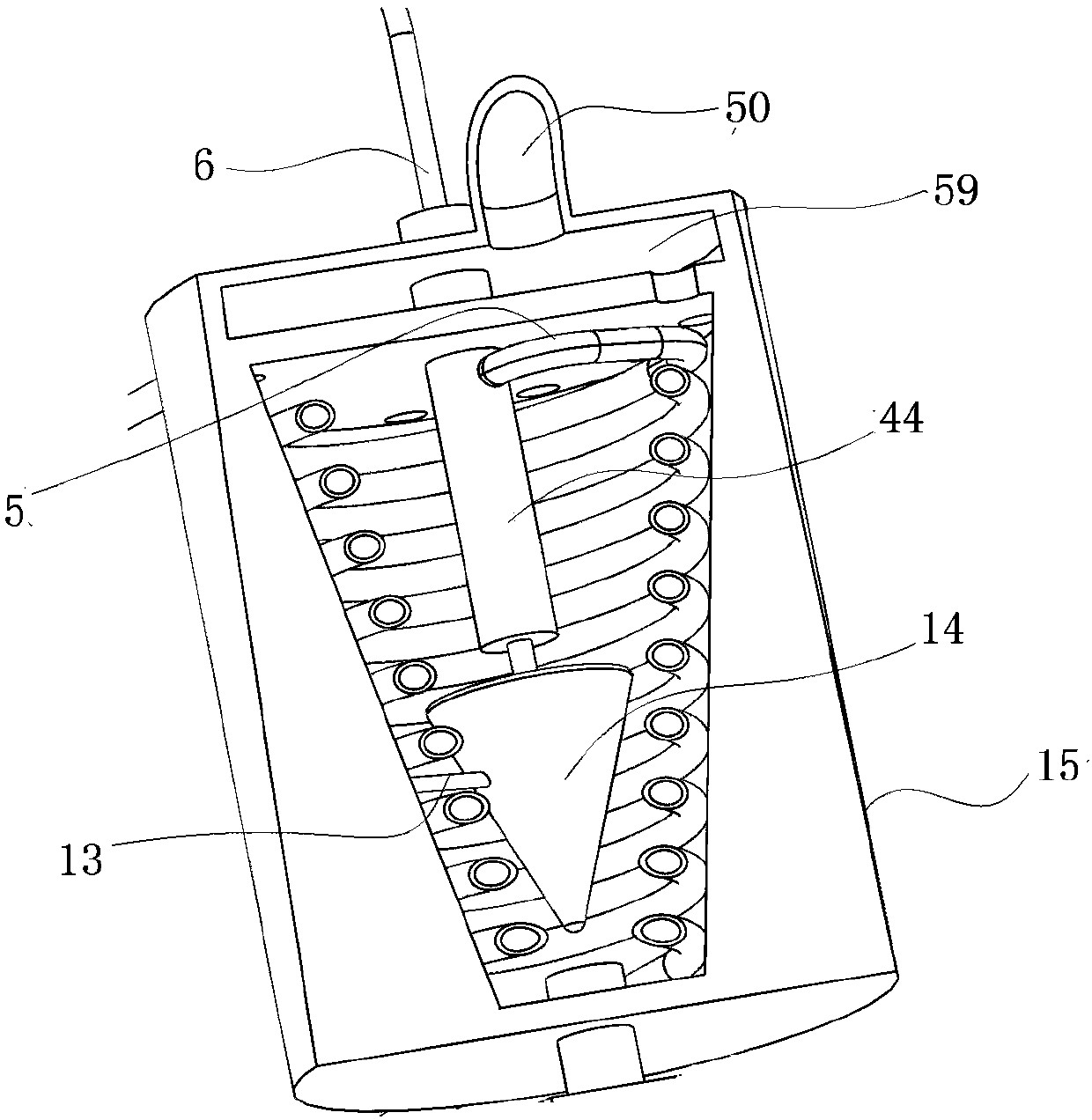

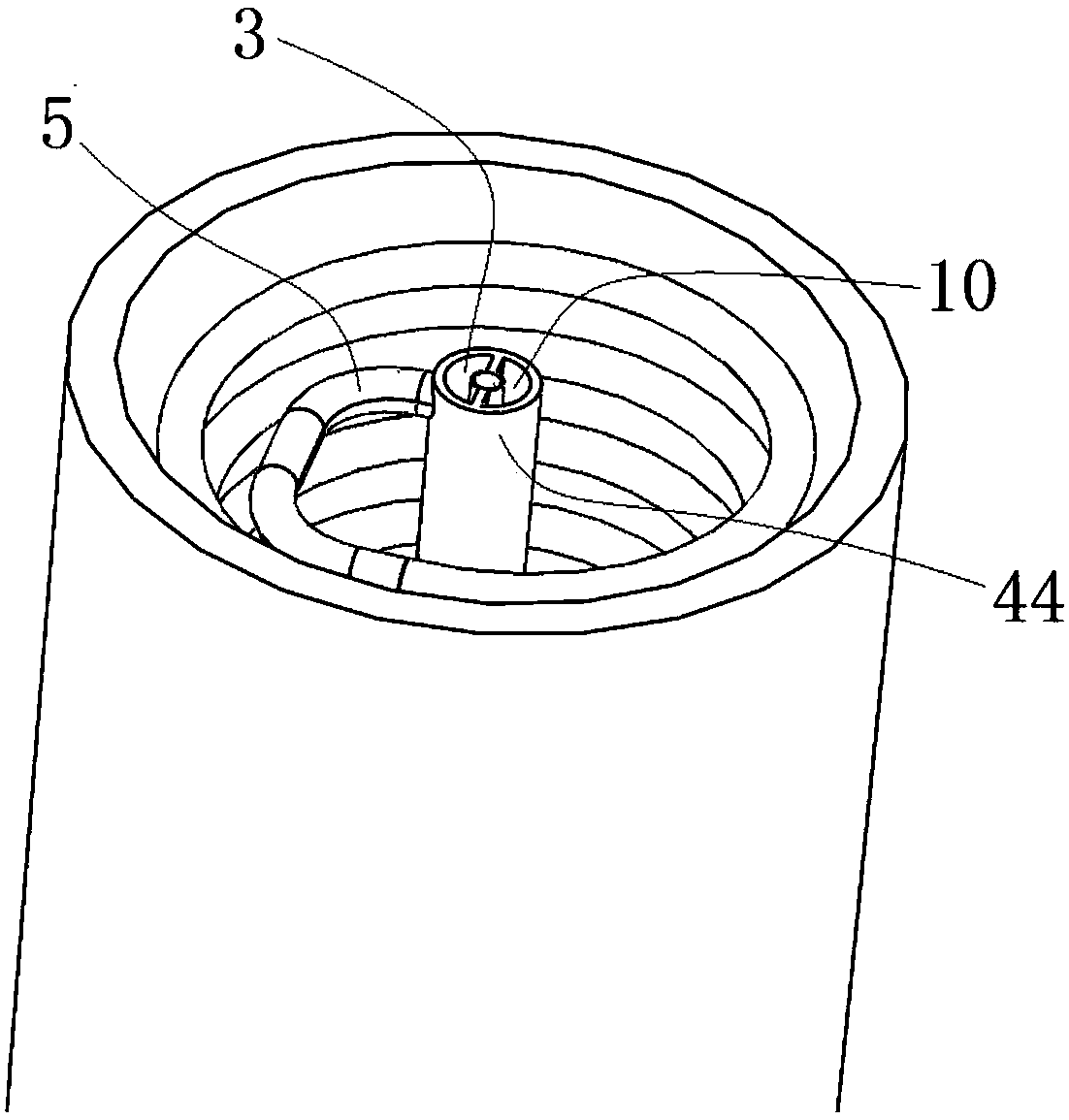

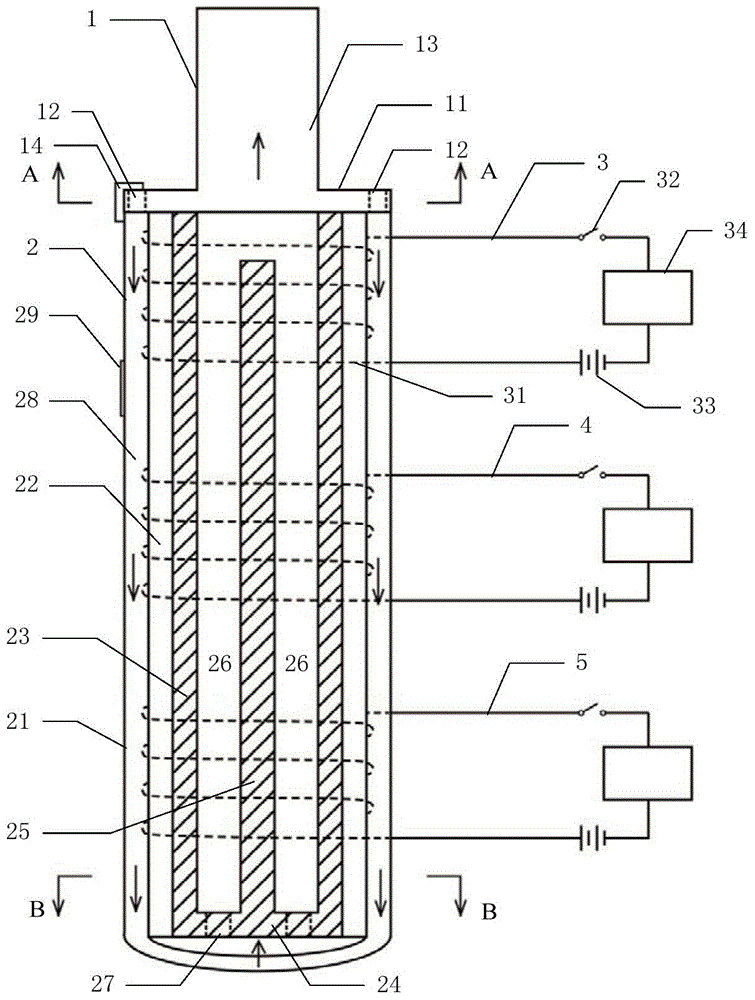

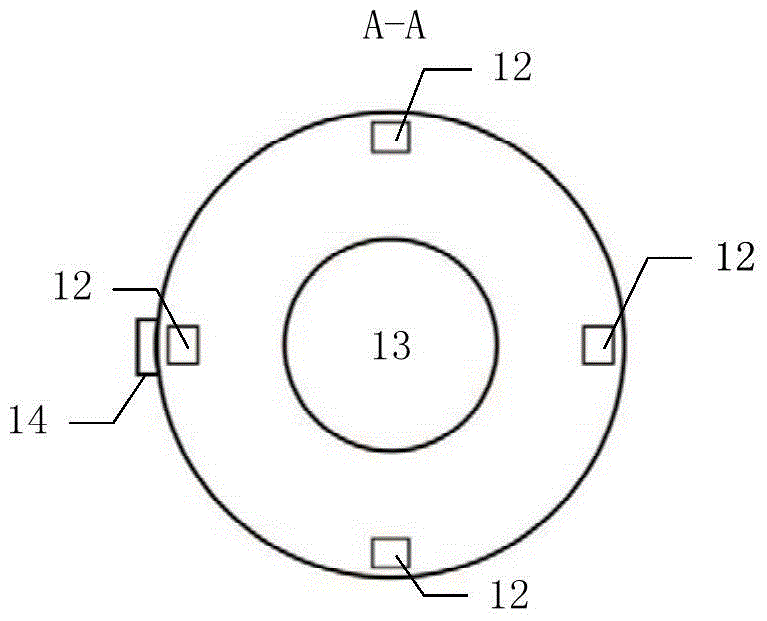

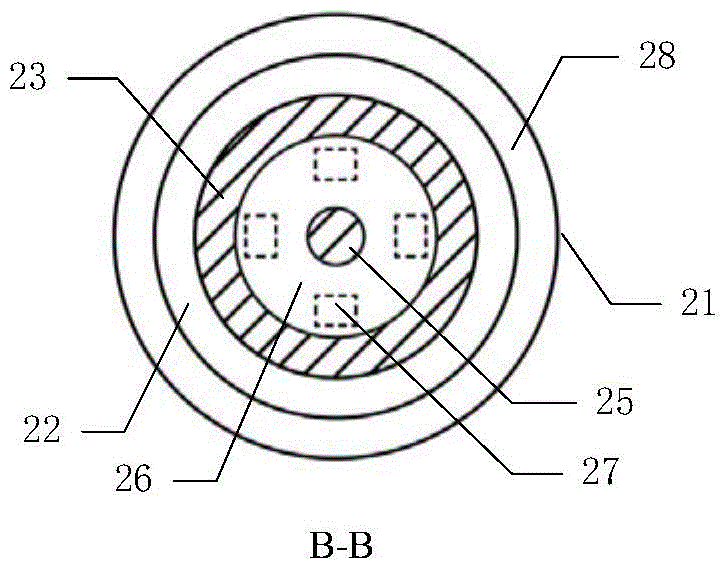

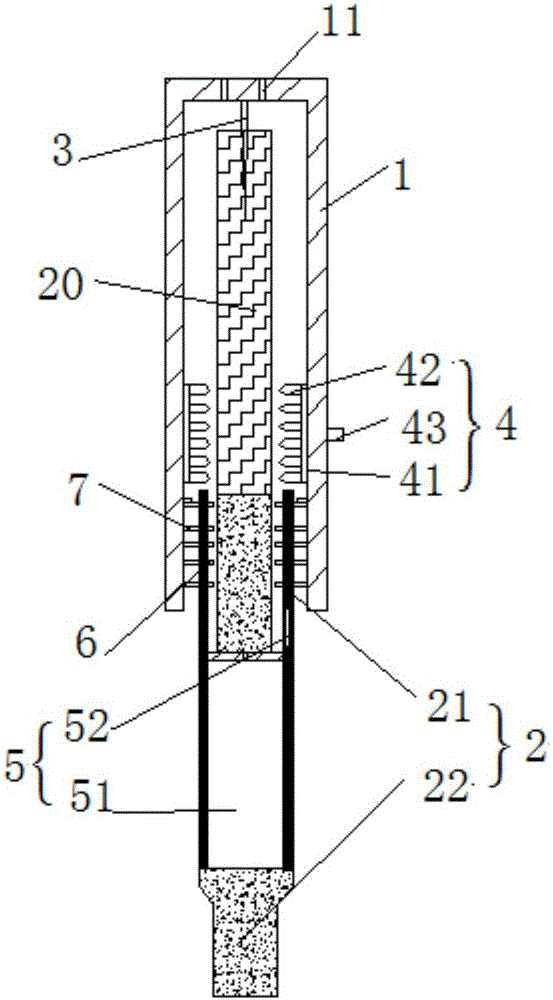

Tobacco suction system based on electromagnetic heating

The invention discloses a tobacco suction system based on electromagnetic heating, which is characterized in that it comprises an end cover (1), a heater (2) and an electromagnetic induction system, and the end cover (1) is detachably connected to the heater ( 2) above; the end cap (1) includes a round cover (11) and a filter tip (13); the heater (2) includes a shell (21), an inner tank (23) and a chassis (24) and a cylindrical Iron core (25); the electromagnetic induction system includes a heating liner (23), a chassis (24), a cylindrical iron core (25), an induction coil and a temperature control circuit. The present invention can increase the heating speed and high thermal efficiency through the electromagnetic induction system to heat the liner, the chassis and the cylindrical iron core, and can also realize instantaneous heating, so as to better meet the needs of the suction taste; the cylindrical iron core The setting can realize the uniform heating of the tobacco products, so that the tobacco products can be fully heated, which can prevent the waste caused by insufficient heating of the tobacco products, and is suitable for popularization and use.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

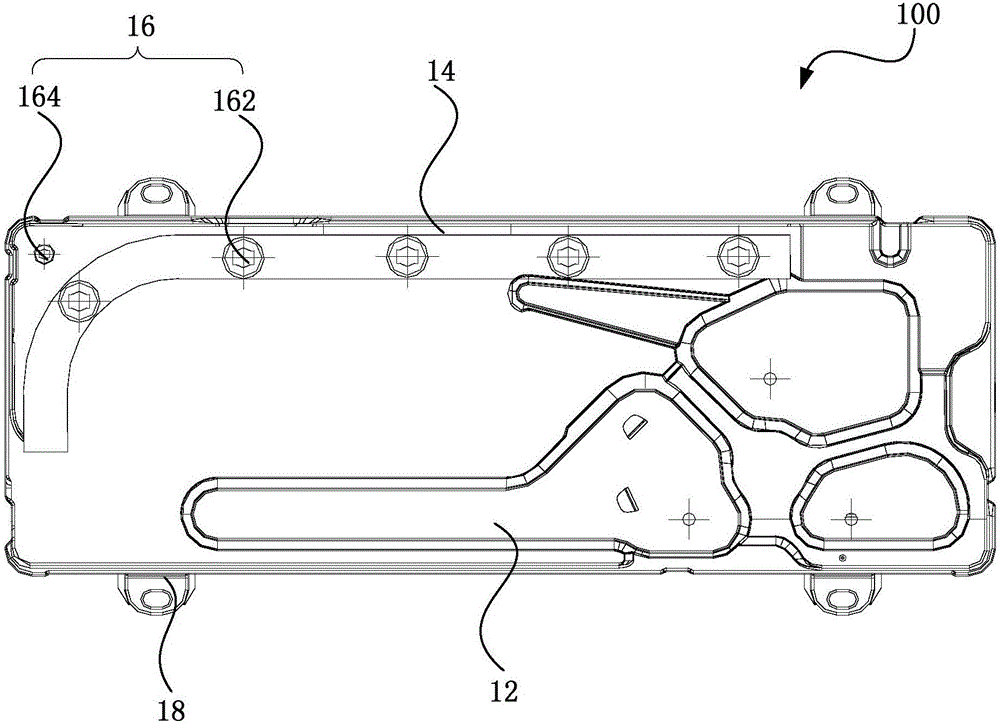

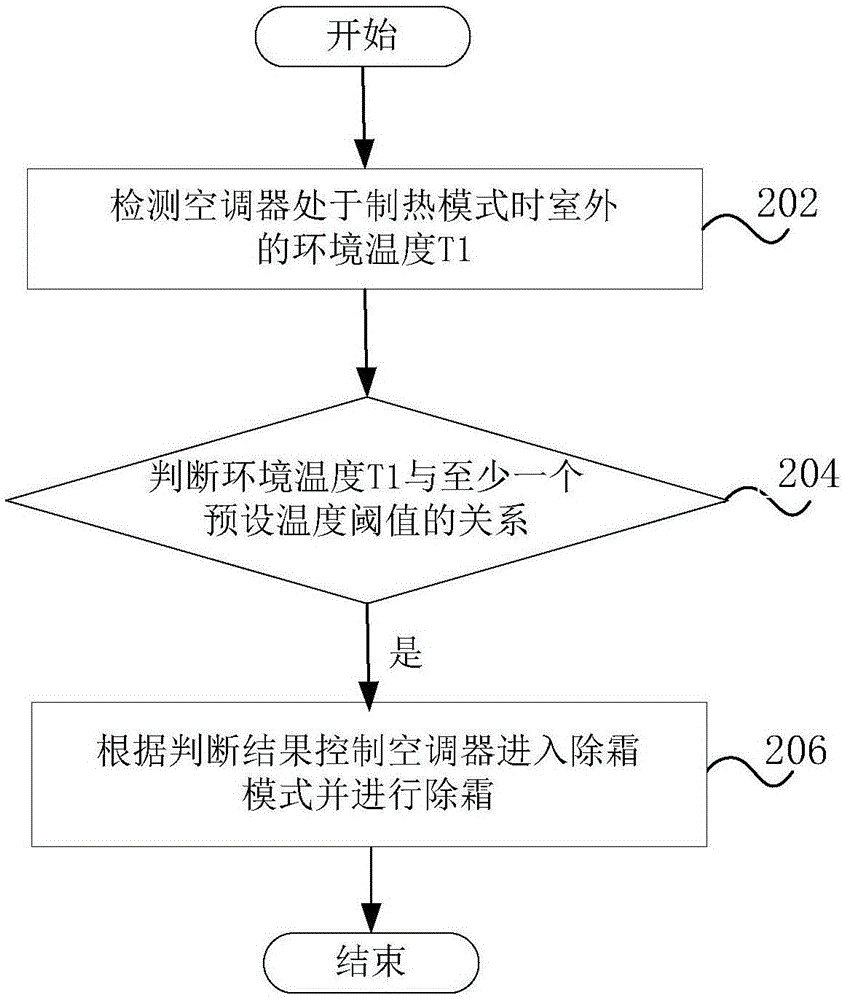

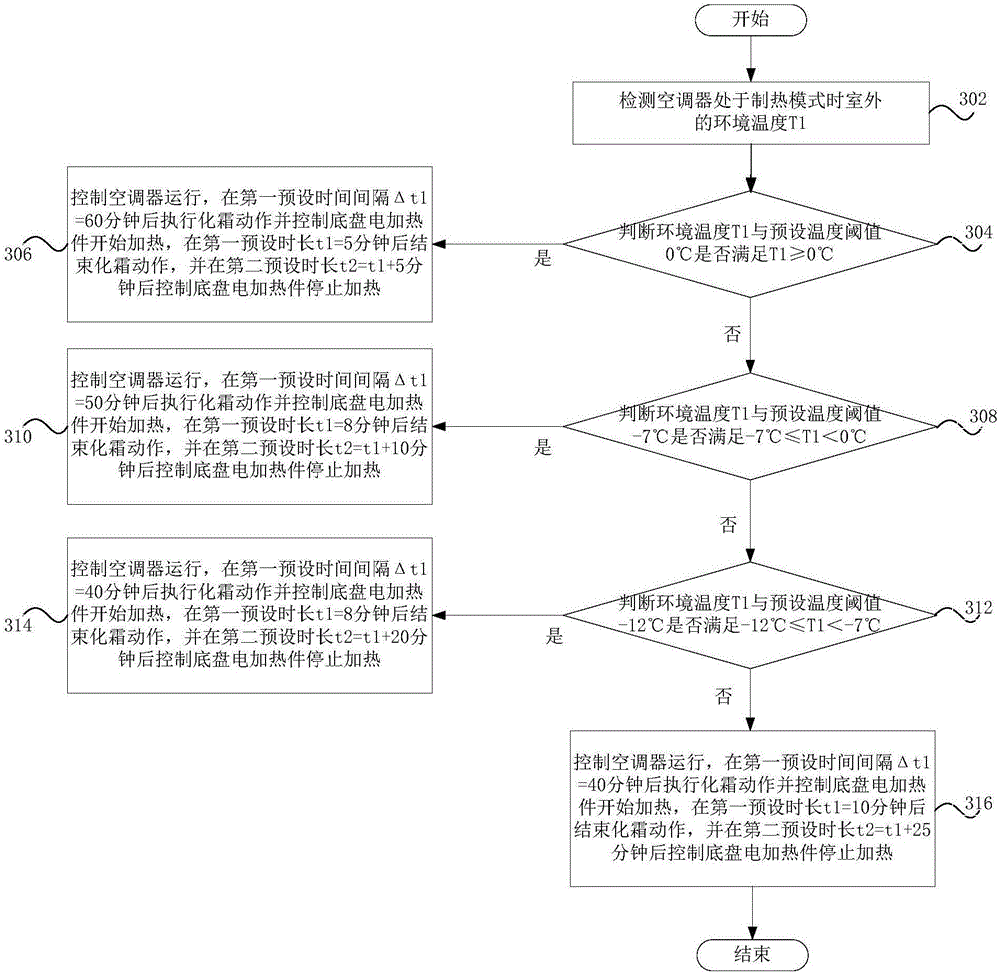

Base plate structure, air conditioner and defrosting control method for air conditioner

PendingCN106352443AHigh speedImprove defrosting efficiencyMechanical apparatusSpace heating and ventilation safety systemsFrostEngineering

The invention provides a base plate structure for an outdoor unit of an air conditioner, the outdoor unit of the air conditioner, the air conditioner and a defrosting control method for the air conditioner. The base plate structure for the outdoor unit of the air conditioner comprises an outdoor unit base plate, a base plate electric heating element and a drainage part, wherein a compressor fixing support is arranged on the outdoor unit base plate, and a condenser is installed on the outdoor unit base plate; the base plate electric heating element is arranged at the bottom of the condenser and located above the outdoor unit base plate; and the drainage part is arranged on the outdoor unit base plate and comprises at least one main drainage port, and the main drainage port is located below the base plate electric heating element. By adopting the base plate structure, when the air conditioner is heated for defrosting at a lower outdoor temperature, frost on the condenser and the outdoor unit base plate can be quickly and thoroughly thawed, and the thawed water quickly and smoothly flows out of the main drainage port, so the frost is thawed cleanly and thoroughly, the temperature of an indoor air port is improved, a good heating effect is guaranteed, and the market competitiveness of the product is improved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

Spraying device for building material machining

ActiveCN110653110AAvoid occlusionPlay a limiting effectPretreated surfacesCleaning using toolsConstruction engineeringStructural engineering

The invention discloses a spraying device for building material machining. The spraying device for building material machining comprises a device body, material supplying boxes and treating boxes; connecting plates are arranged at the inner ends of first hydraulic telescopic rods; cleaning rolls are rotatably connected to the inner side walls of first U-shaped frames, second rotation shafts penetrate through the back side walls of the first U-shaped frames, and the second rotation shafts on the left sides are connected with second motors; the treating boxes are arranged on the front side faceand the back side face of the device body and arranged on the left sides of first motors; first fans are arranged on the right sides of the treating boxes and connected with suction pipes; and secondhydraulic telescopic rods are arranged on the upper side wall and the lower side wall of the device body, second U-shaped frames are arranged at the inner ends of the second hydraulic telescopic rods,and flattening rolls are rotatably connected to the inner side walls of the second U-shaped frames. According to the spraying device for building material machining, a coating in the material supplying boxes is sprayed to building plates through spraying pipes at the upper end and the lower end, and the two faces of the building plates can be simultaneously sprayed.

Owner:徐州思达新技术开发有限公司

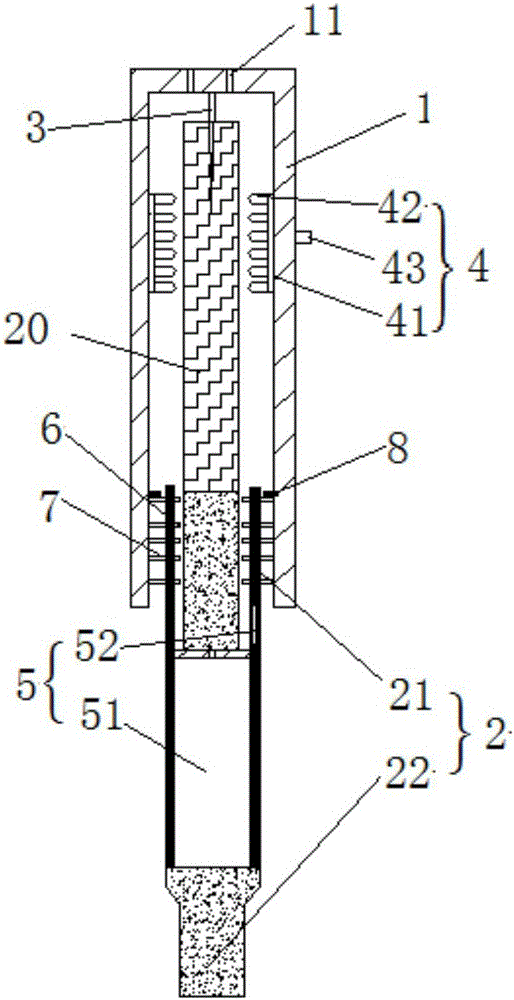

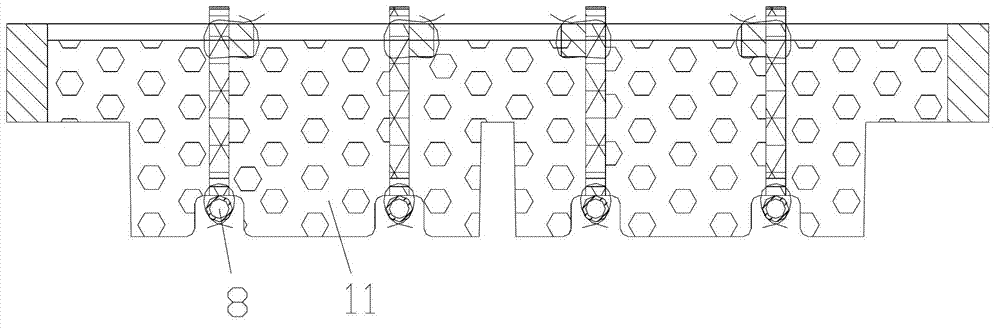

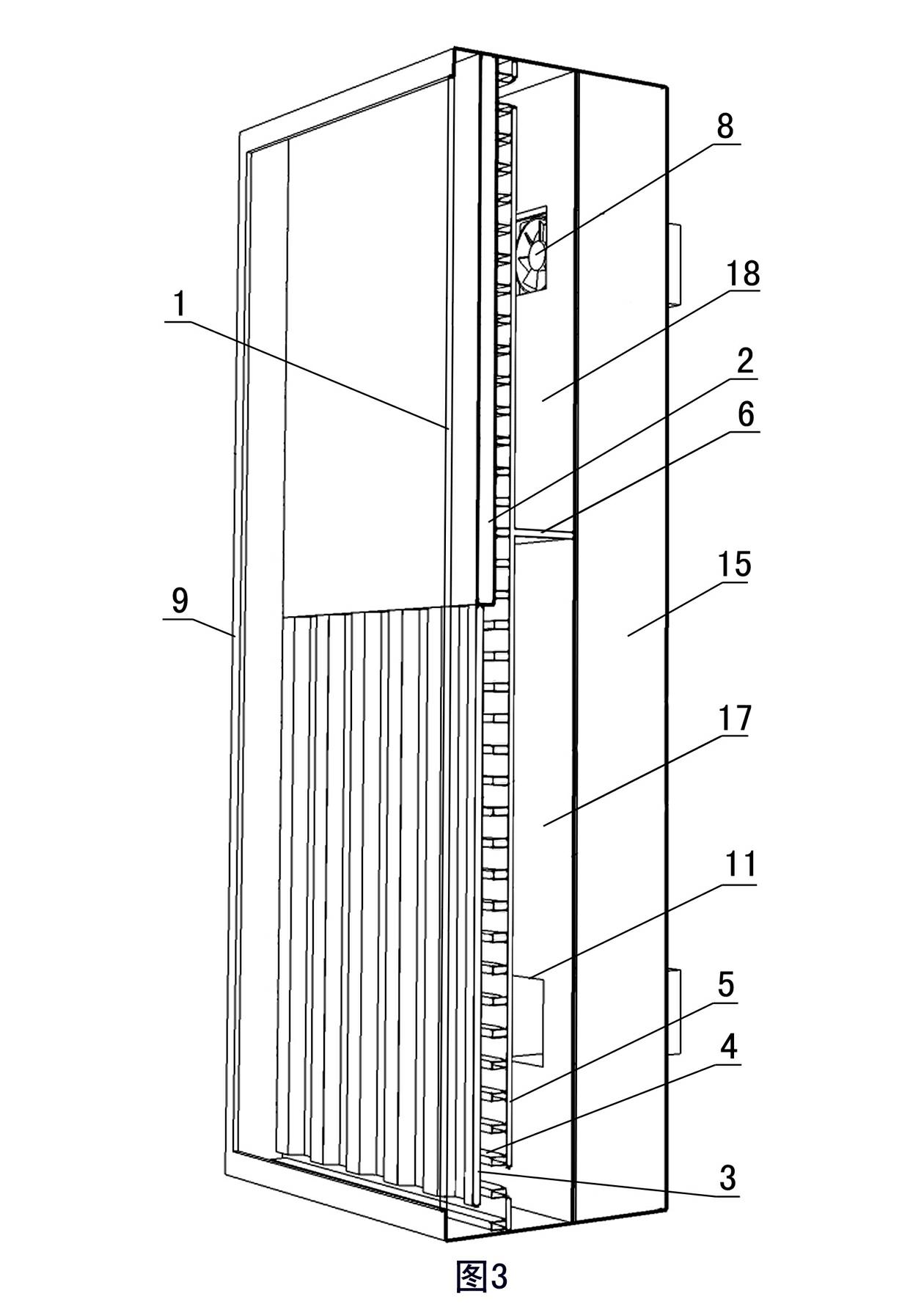

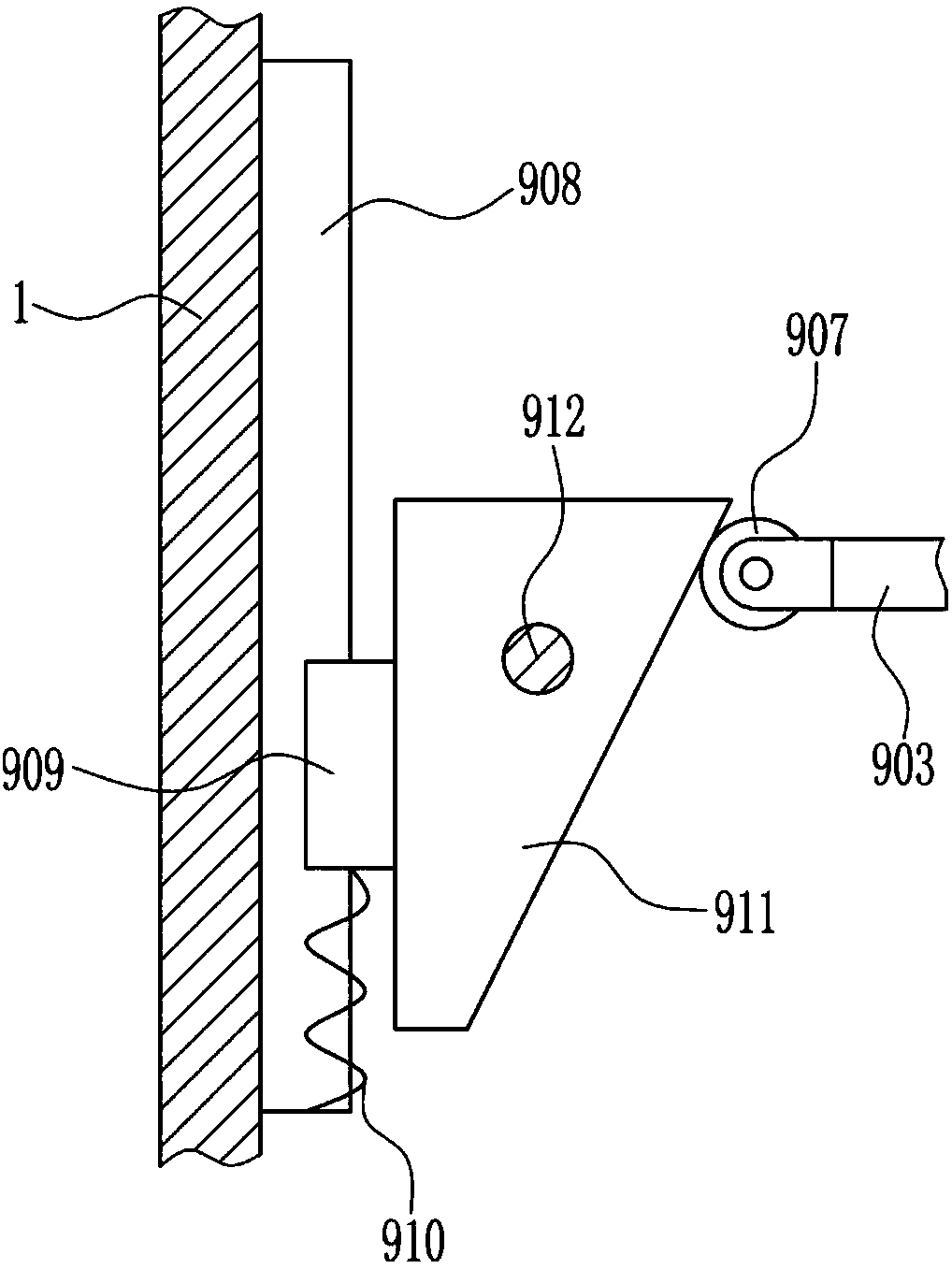

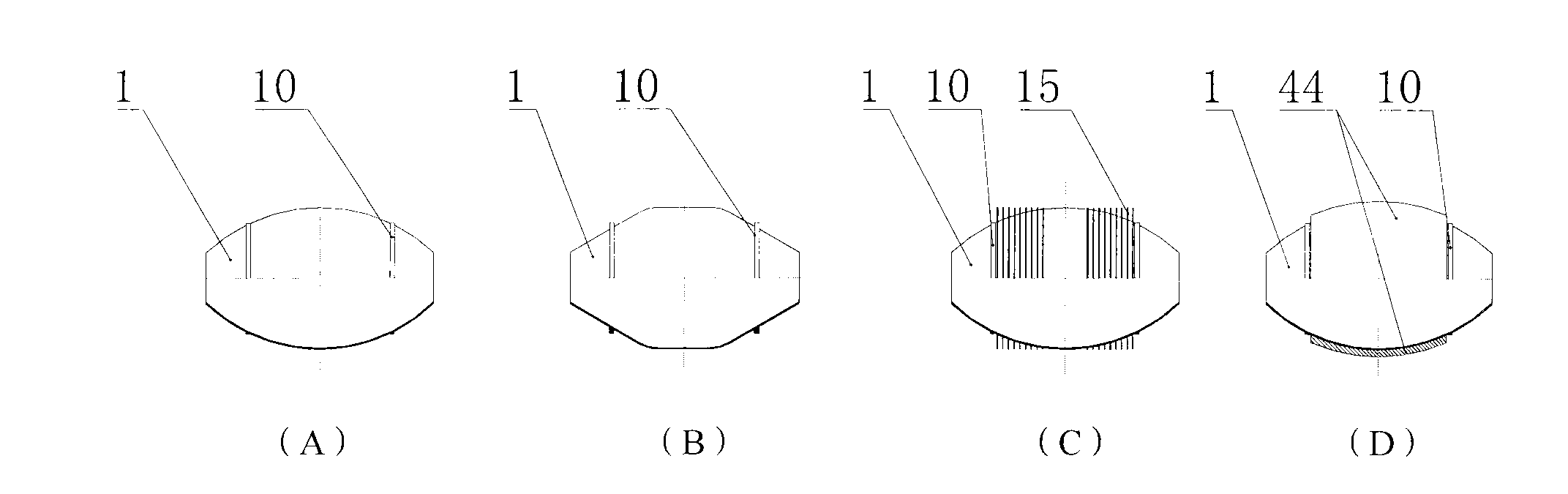

Unfired cigarette heating device

The invention discloses an unfired cigarette heating device which comprises a hollow heating casing with one end opening and further comprises a circuit control carrier. A vent hole is molded in the heating casing; a piercing internal-heating structure and an annular external-heating structure are arranged in an inner cavity of the heating casing, the piercing internal-heating structure is arranged at the bottom of the heating casing, and the annular external-heating structure is arranged on the annular cavity wall of the heating casing. A cigarette clamp part is arranged at one end of the circuit control carrier, a smoking part which is in gas-flow circulation with the cigarette clamp art is arranged at the other end of the circuit control carrier, the cigarette clamp part is inserted in the inner cavity of the heating casing and is in sealed connection with the same; an airflow actuator used for starting the piercing internal-heating structure and the annular external-heating structure to heat cigarettes is also arranged in the circuit control carrier. During smoking by the smoking part of the circuit control carrier, the piercing internal-heating structure and the annular external-heating structure are started to simultaneously heat the cigarettes. The cigarettes are heated from all sides by means of combination of the piercing internal-heating structure and the annular external-heating structure; meanwhile, air pollution caused by leaked smoke can be reduced in use of the unfired cigarette heating device; and by the unfired cigarette heating device, the whole cigarettes can be heated uniformly with low requirement for heating temperature.

Owner:CHINA TOBACCO GUANGXI IND

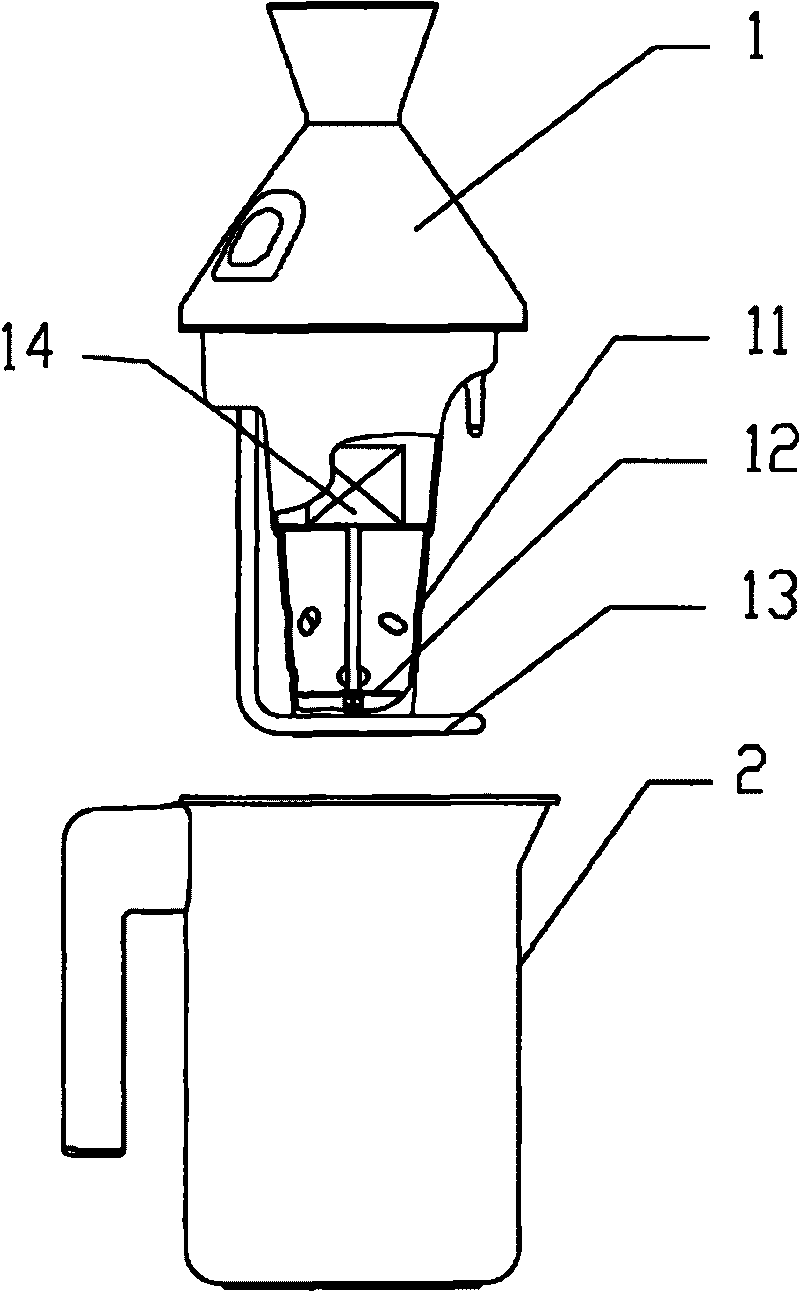

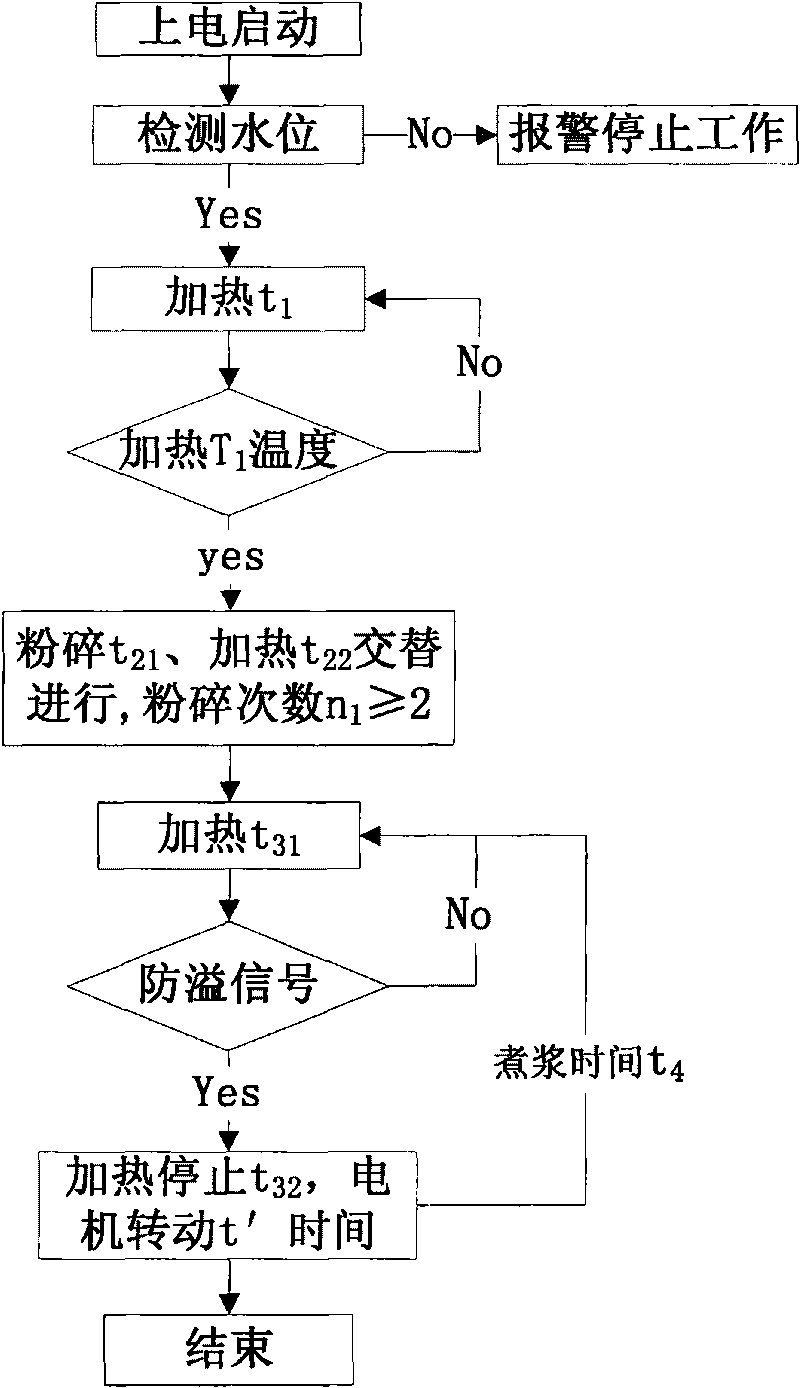

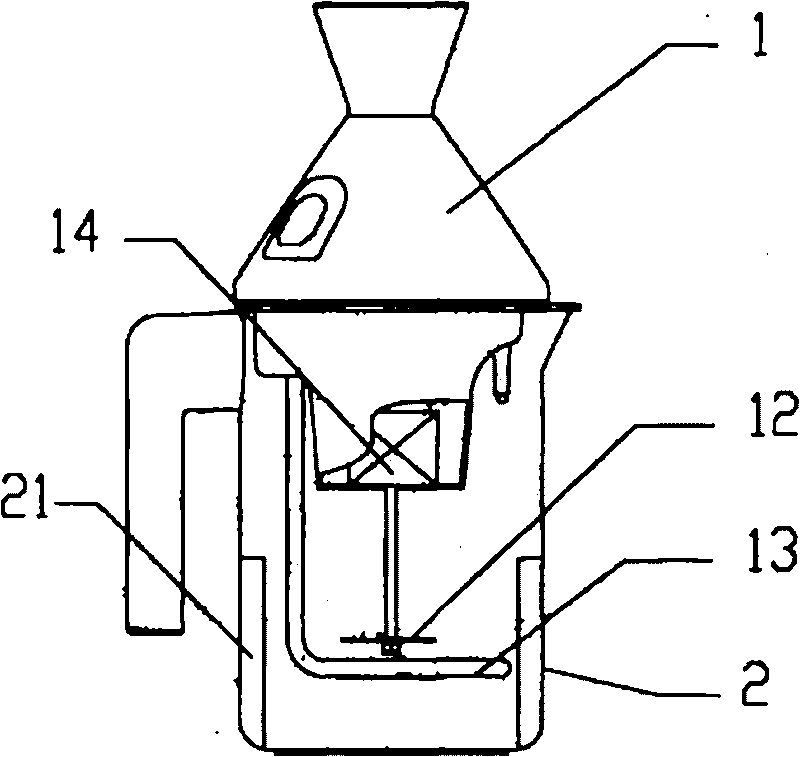

Quick pulping method of soymilk maker

ActiveCN101715835AMeet needsFully heatedBeverage vesselsMilk substitutesPulp and paper industryMouthfeel

The invention relates to a method for preparing soymilk, in particular to a quick pulping method of a soymilk maker, which comprises a heating process, a pulverization process and a boilout process, wherein the pulverization process comprises a stage that a pulverization cutter is driven by a motor to pulverize materials and a stage of motor stop; the boilout process comprises a stage of heating the materials and water by a heating device and a stage of stopping heating; and the time of the heating process is t1, the time of the pulverization process is t2, the time of the boilout process is t3, the total time of pulping is T, and T is less than 900 seconds and is more than t1+t2+t3. The soymilk maker realizing the quick pulping method comprises a maker head, a cup body, the motor, a pulverization device and the heating device, wherein the pulverization device comprises the pulverization cutter. The pulping working procedure of the soymilk maker comprises the quick pulping method of the soymilk maker in any item from 1 to 9 of patent claim. The invention provides a pulping method capable of preparing the soymilk with good mouthfeel quickly and efficiently.

Owner:JOYOUNG CO LTD

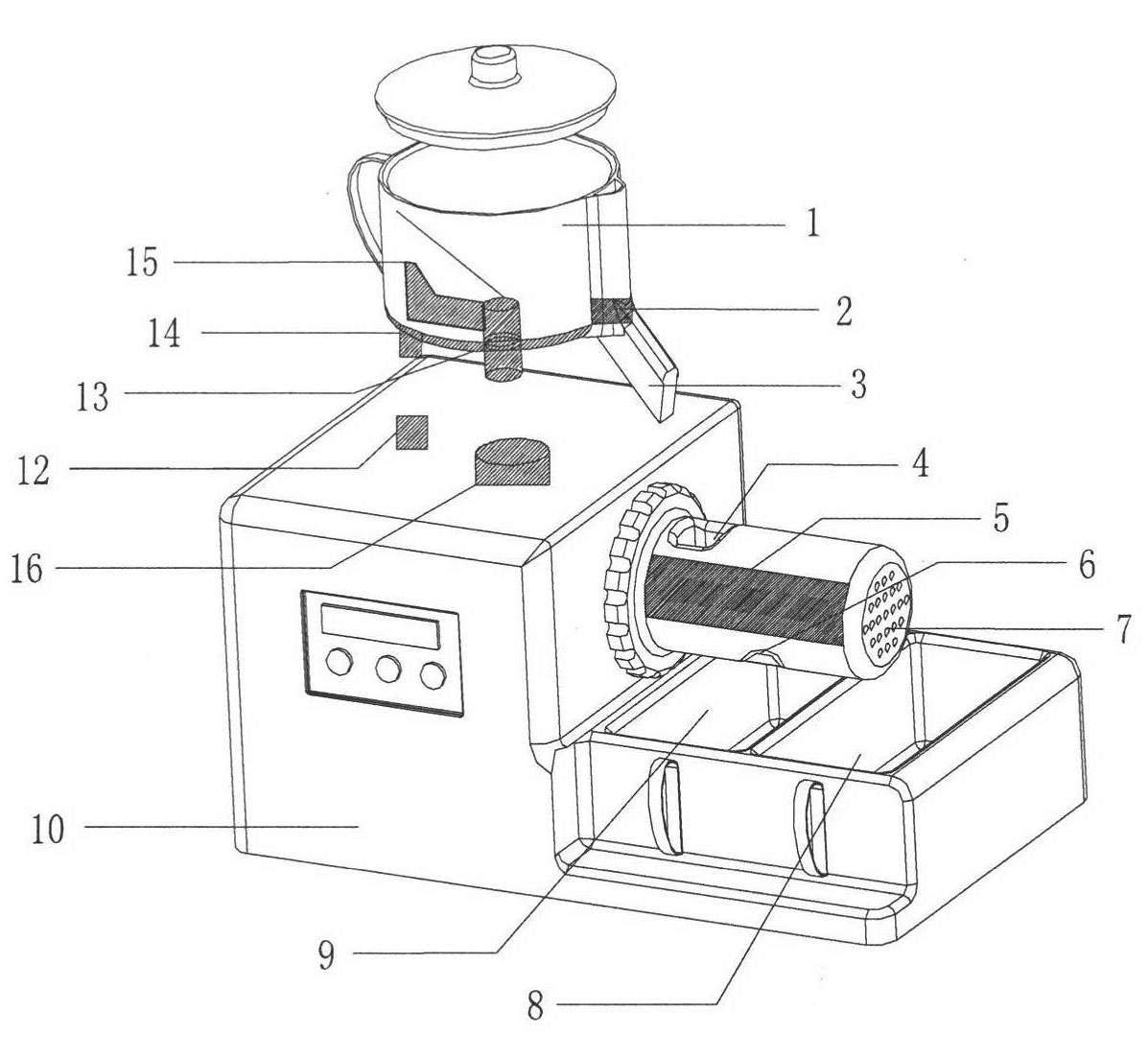

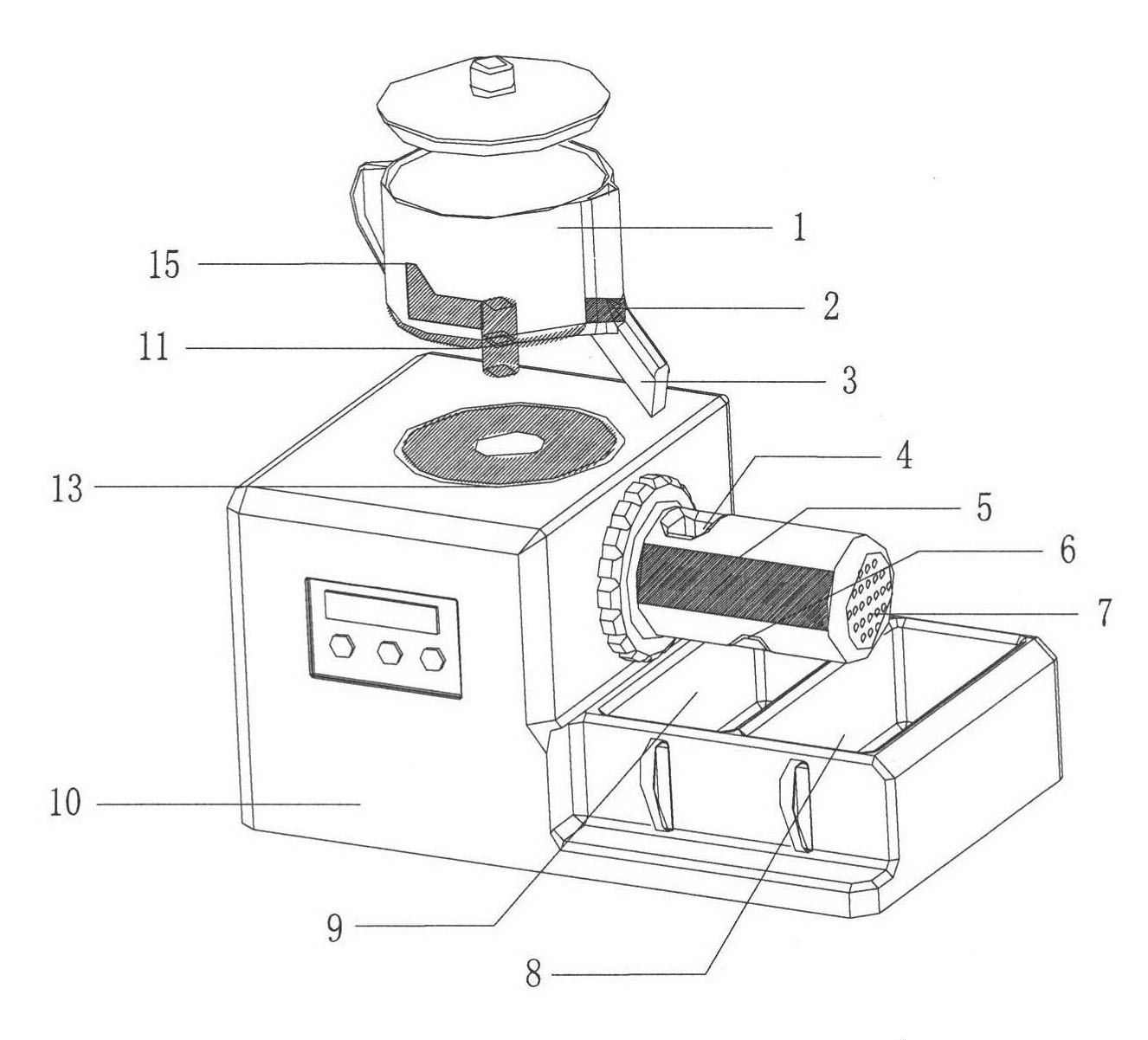

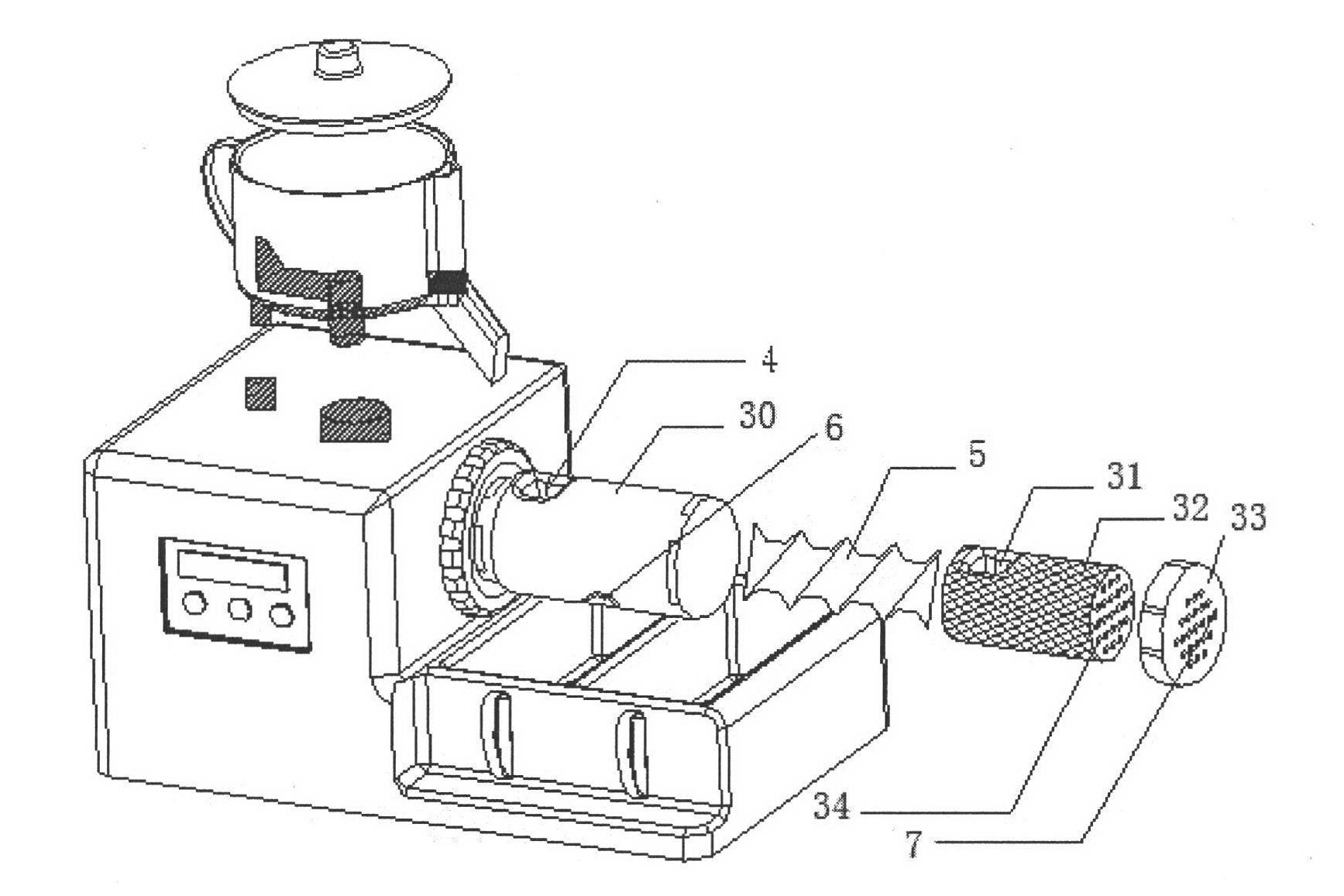

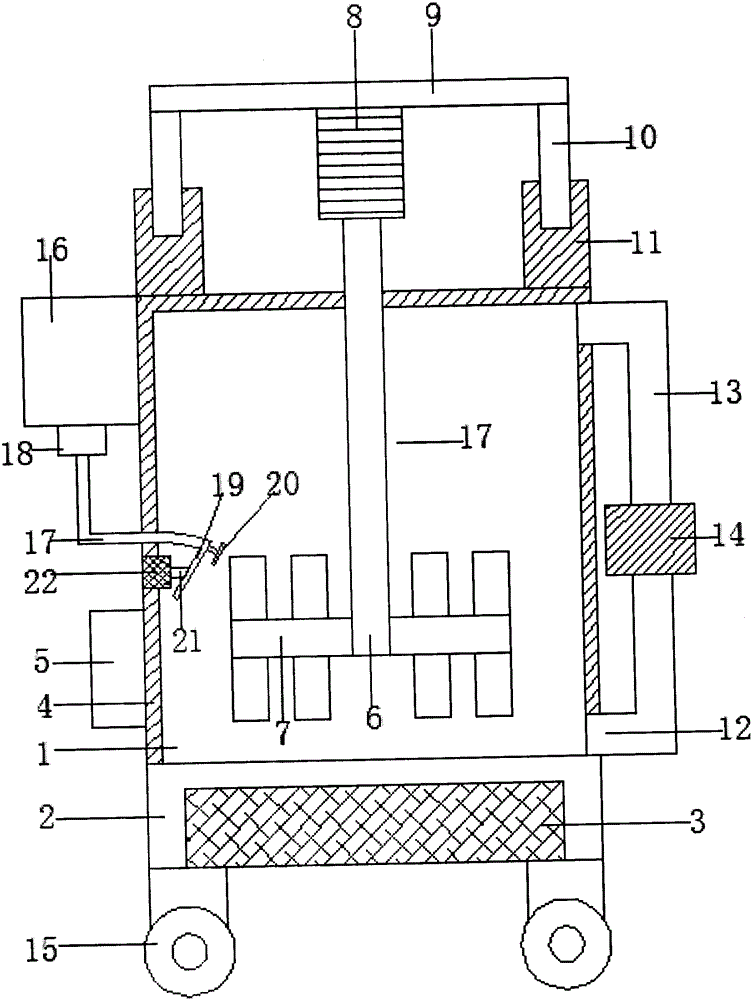

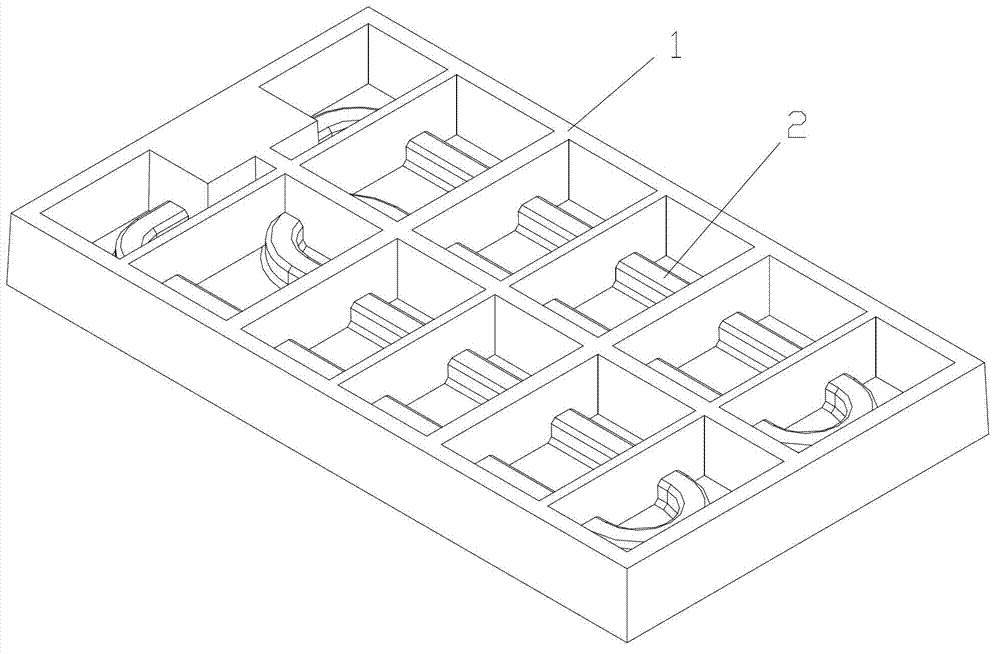

household automatic oil press

A domestic automatic oil press, including a machine base, a heating element, a feeding cup, an oil pressing assembly and a collection tank; the feeding cup and the machine base are in a detachable joint structure, and the joint between the machine base and the feeding cup is equipped with a heater for heating the feeding cup Components; the inner base of the feeding cup is also equipped with a stirring knife, the central axis of the stirring knife extends to the outside of the feeding cup, and the motor driving the stirring knife is placed in the machine base. When the feeding cup is combined with the machine base, the central axis of the stirring knife is connected to the motor; There is a discharge port at the bottom of the feeding cup, and there is a solenoid valve at the discharge port to control its opening and closing. The discharge port is aligned with the feed port of the oil pressing assembly, which is placed outside the machine base; The screw rod, the oil outlet and the slag outlet have an oil collection groove and a slag collection groove arranged on the machine base below the oil outlet and the slag outlet. The process of heating, feeding and oil extraction can be completed automatically, and the whole process is simple and convenient.

Owner:李文庆

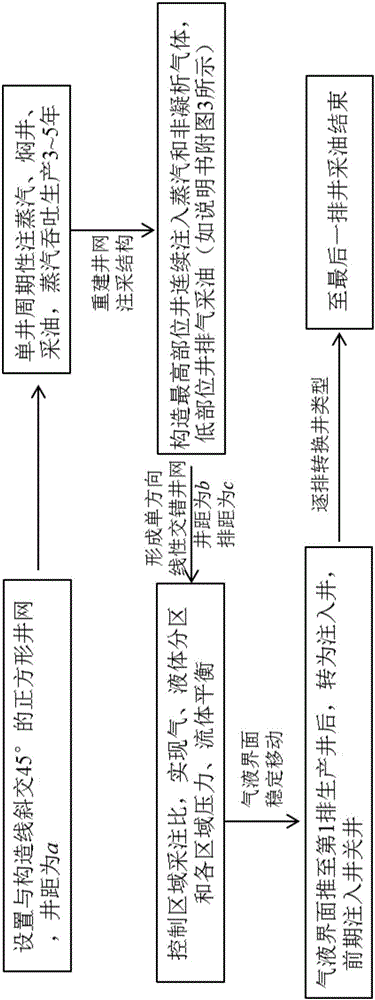

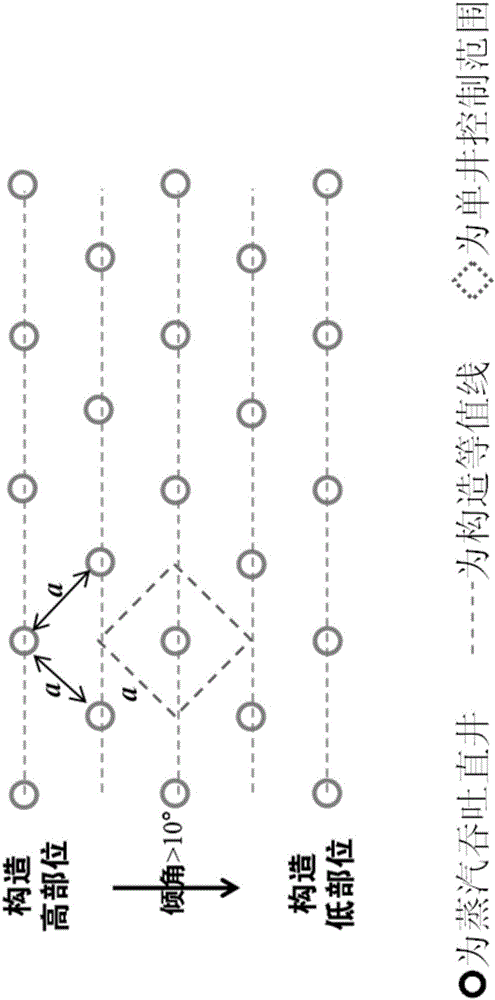

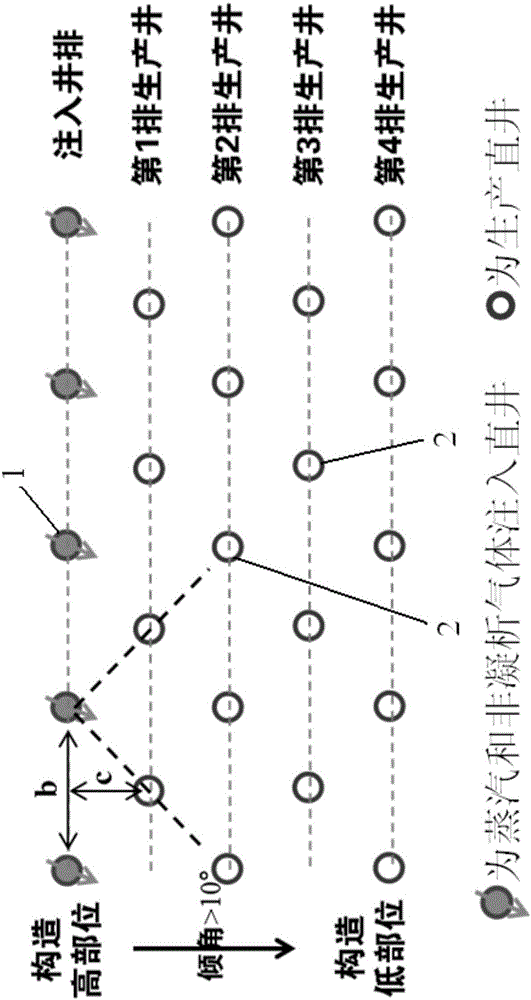

Method for exploiting high-inclined-angle heavy oil reservoir by plane gravity displacement

ActiveCN107435535AGuaranteed one-way advancementImprovement factorFluid removalDensity differenceHot Temperature

The invention provides a method for exploiting a high-inclined-angle heavy oil reservoir by plane gravity displacement. According to the method for exploiting the high-inclined-angle heavy oil reservoir by plane gravity displacement, a plane gravity oil displacement mode using steam injection as a major measure and non-condensable gas injection as an auxiliary measure is designed. Steam and non-condensable gas are proportionally injected; high-temperature hot water and non-condensable gas in the stratum can easily form a secondary gas cap and a secondary water zone with the obvious spatial variation effects due to the density differences; the high-temperature secondary water zone provides a heating resource for a downstream cold oil zone; and the breakthrough of the injection gas towards a production well in a low structure position is prevented. Meanwhile, the oil reservoir integral scaled development is realized; the unidirectional linear staggered well network development is used; and the plane conformance coefficient and the recovery efficiency are improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Self-cleaning efficient stirrer

InactiveCN105056808AAvoid Stirring Dead AngleEasy to moveRotary stirring mixersHollow article cleaningHydraulic cylinderPulp and paper industry

The invention discloses a self-cleaning efficient stirrer. The self-cleaning efficient stirrer comprises a stirrer body, a heat insulation material layer and hydraulic cylinders; a heating cavity is formed in the lower side of the stirrer body and internally provided with a heating furnace, the outer wall of the stirrer body is covered with the heat insulation material layer, a control panel is arranged on the outer wall at the left side of the stirrer body, a stirring rotating shaft is vertically arranged in the stirrer body, and stirring paddles are symmetrically arranged on outer walls at the two sides of the bottom end of the stirring rotating shaft. The self-cleaning efficient stirrer is good in lifting stirring effect and high in efficiency, in the stirring process, materials at the bottom in the stirrer are circularly pumped into the top to be mixed, the stirring effect and efficiency are greatly improved, and no dead angle exists in the stirring process; the materials are heated in the stirring process, the heat efficiency is high, the heat insulation effect is good, after stirring is finished, a nozzle is driven by a motor to rotate to clean the inside of the stirrer, the cleaning effect is good, and manual operation difficulty and intensity are reduced; in addition, the stirrer is convenient and fast to move and high in convenience.

Owner:岑立强

Technique for embedding stainless steel tube in large-size aluminum alloy casting blank

The invention relates to a technique for embedding a stainless steel tube in a large-size aluminum alloy casting blank, belonging to the technical field of casting. The technique comprises the following steps: manufacturing a wood mold with a pipe chase according to a drawing, and putting the wood mold into a sand box to manufacture inner and outer sand molds; halving the pipe chase according to the distribution and position characteristics of the pipe chase in the inner sand mold; inserting a connecting rod, of which the upper and lower ends are penetrated by binding wires, into the inner sand mold via a fraction distance point, connecting the upper end of the connecting rod to the sand box, and connecting the lower end of the connecting rod to a water pipe; closing the box, and casting; after the solution becomes solidified and cooled, removing the connection between the upper end of the connecting rod and the sand box to discharge; and cleaning by removing the exposed part of the binding wire at the lower end of the connecting rod, and taking out the connecting rod to produce the stainless steel tube embedded casting blank, wherein the connecting rod is preserved for later use. The invention is mainly used for casting home appliance mold casting blanks, has the advantages of low production cost and high casting blank yield, enhances the service performance of the molds, and greatly prolongs the service life of the molds.

Owner:CHUZHOU JINNUO INDAL

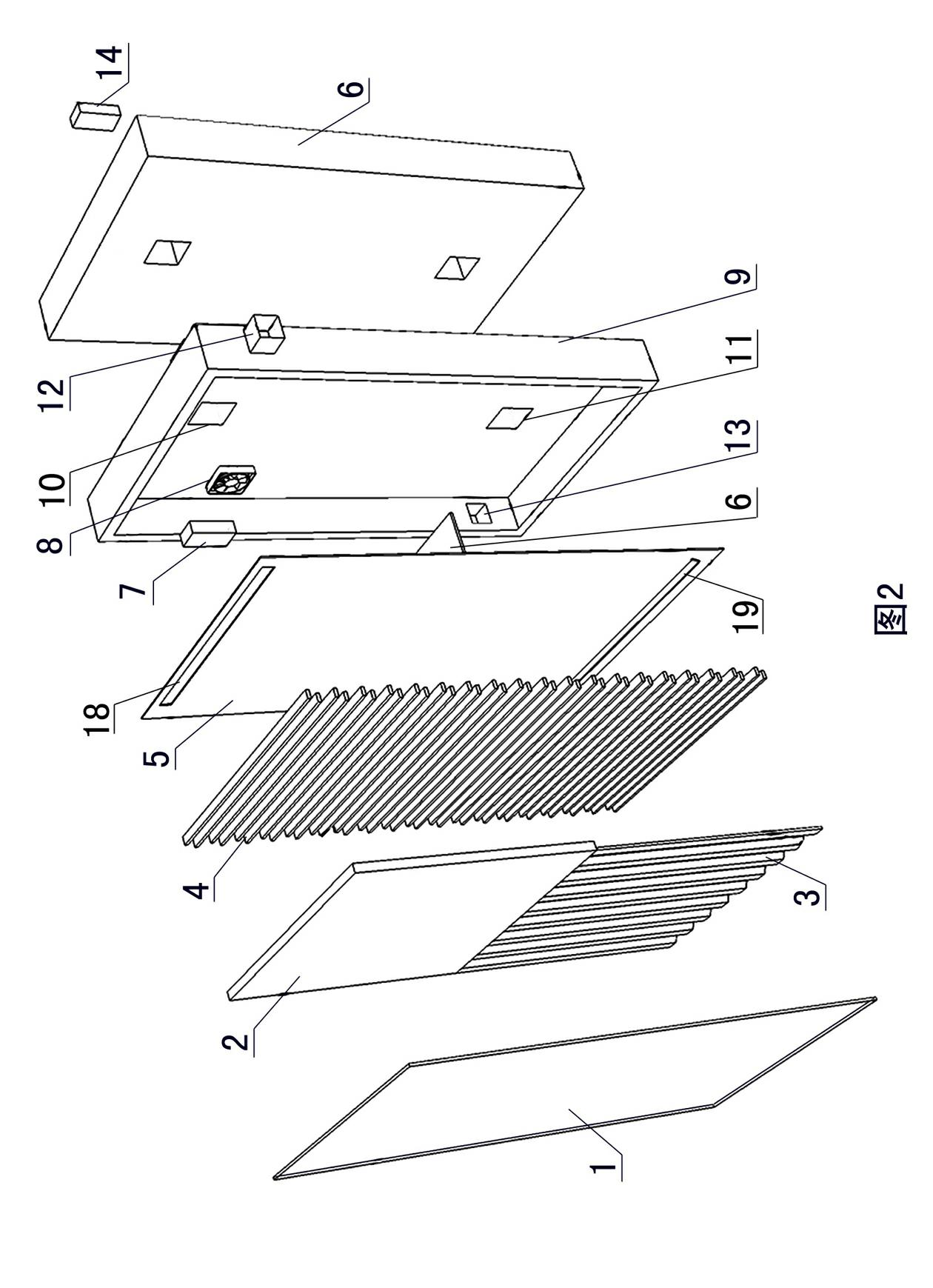

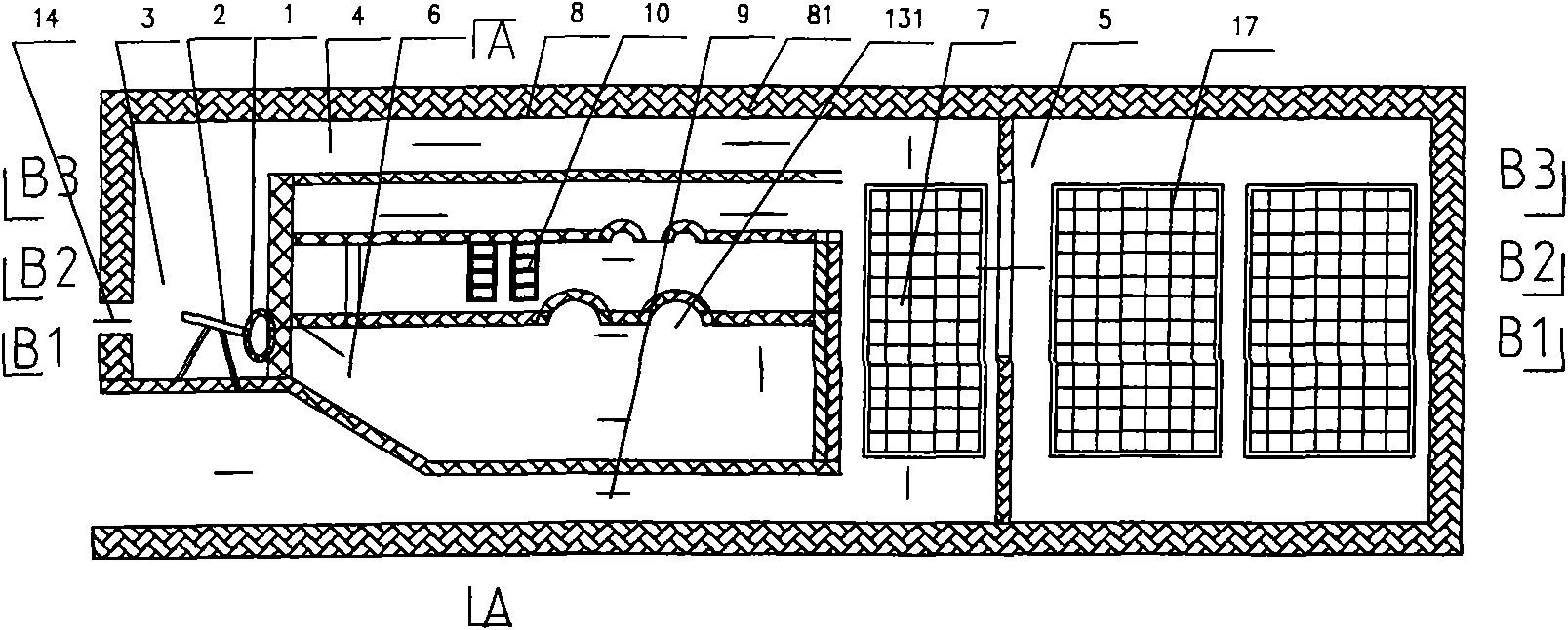

Photovoltaic drive solar air collector

InactiveCN102322695AReduce use costImprove economySolar heating energySolar heat devicesAerospace engineeringPhotovoltaics

The invention provides a photovoltaic drive solar air collector which comprises a collector cavity and a collecting plate arranged in the collector cavity, wherein the collector cavity is also internally provided with a solar photovoltaic plate, an S-shaped air channel, a wind guide plate and a partition plate; the wind guide plate divides the collector cavity into a front cavity and a back cavity, the partition plate is arranged in the back cavity and divides the back cavity into a back upper cavity and a back lower cavity, the solar photovoltaic plate and the collecting plate are connected together and the solar photovoltaic plate is arranged above the collecting plate, meanwhile, the solar photovoltaic plate and the collecting plate are arranged in the front cavity and divide the front cavity into a sunny cavity and a shaded cavity, and the S-shaped air channel is arranged in the shaded cavity. The collector has the advantages of complete heat exchange, good heat exchange effect, high heat utilization, low use cost and high economy.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

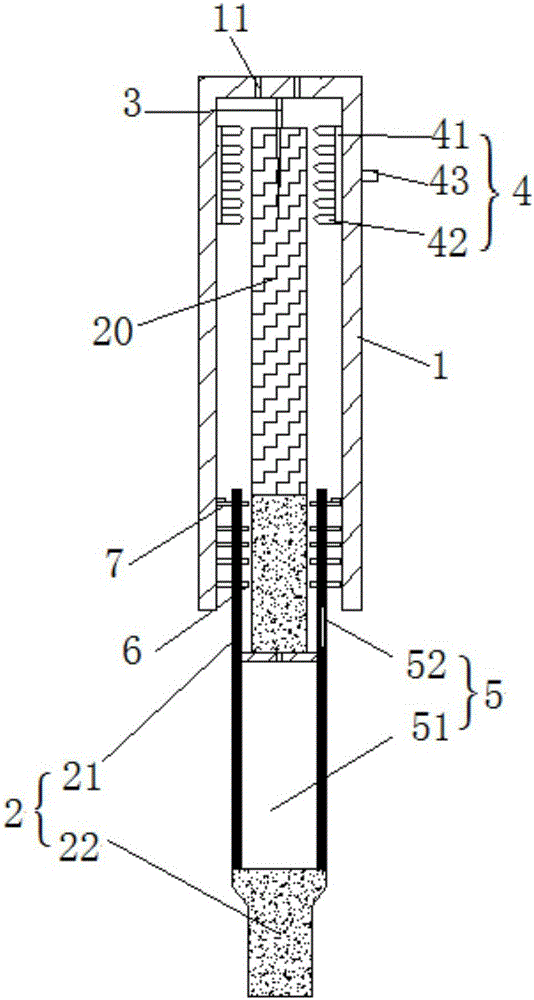

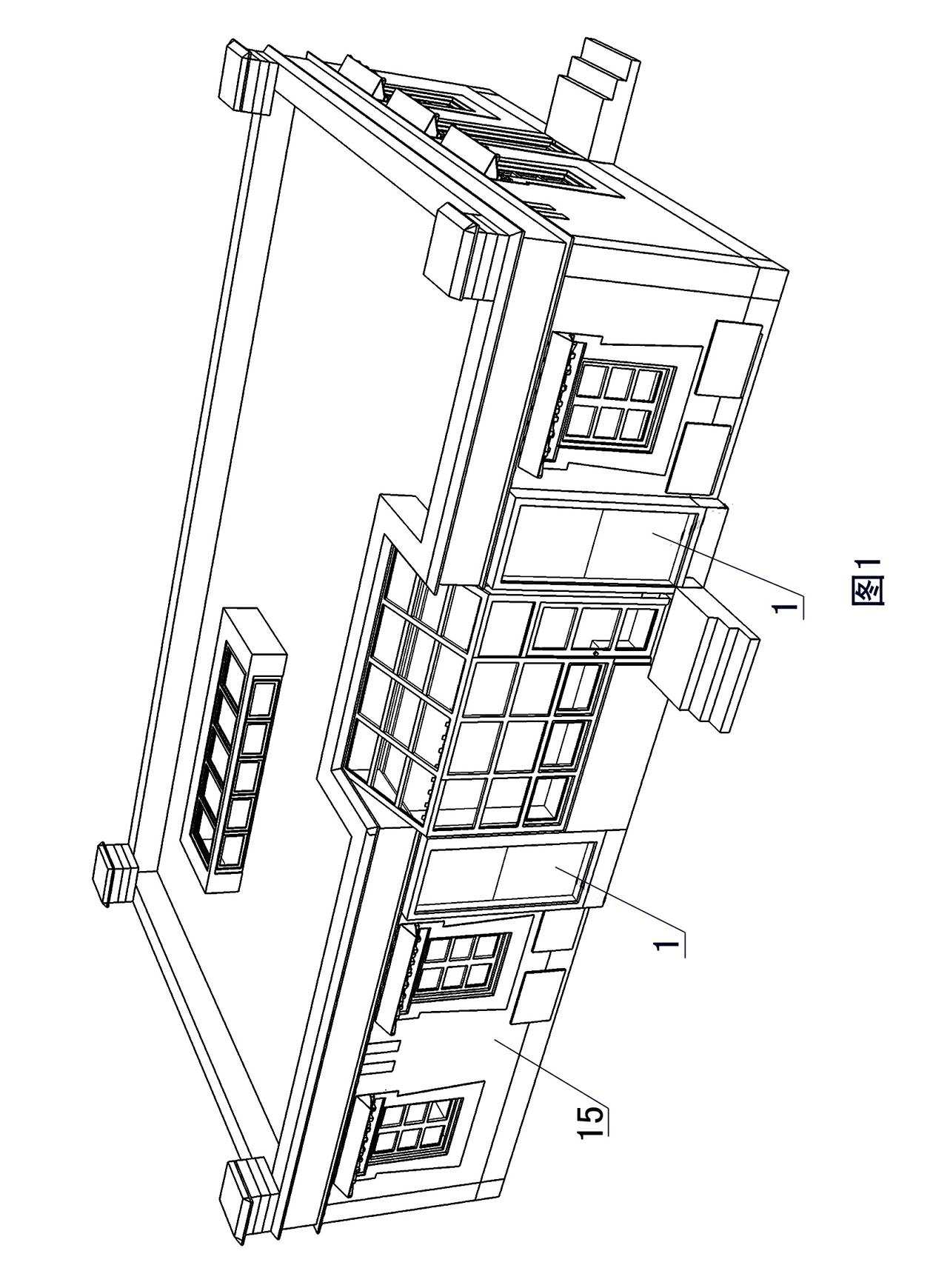

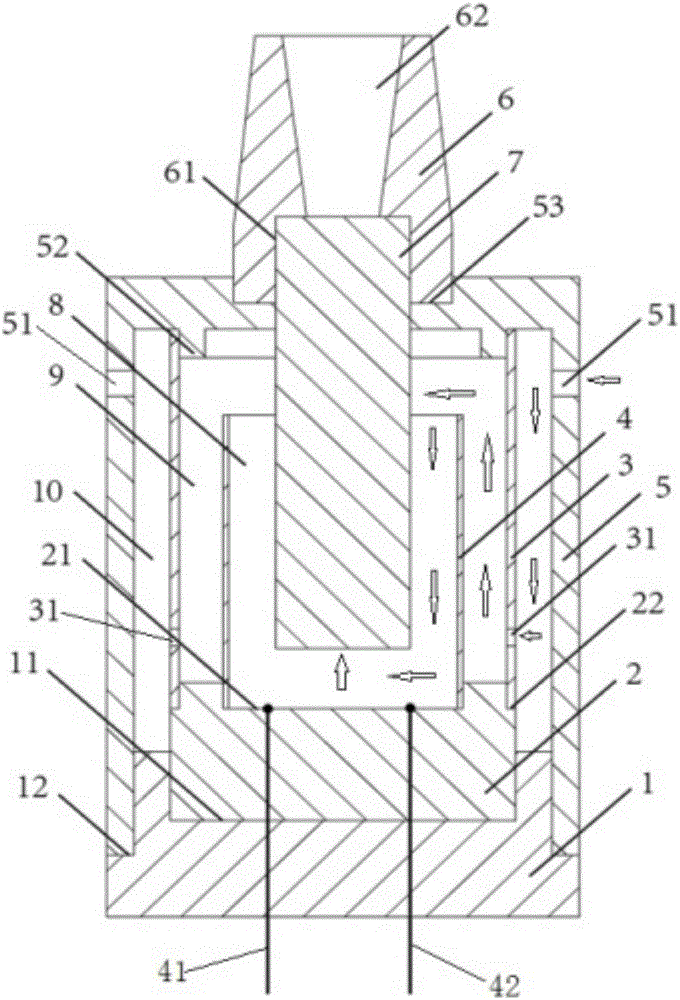

Low temperature tobacco smoking set heated by hot air

A low temperature tobacco smoking set heated by hot air comprises a base (1), an insulating seat (2), a tubular heating element (4), a strip top plate and a shell (5), wherein the base (1) is provided with a first outer ring bearing platform (12) and a first upper part center groove (11); the insulating seat (2) is mounted in a first round center groove; a second upper part round center groove (21) is arranged at the upper part of the insulating seat (2); the tubular heating element (4) is mounted in the second upper part round center groove (21); the strip top plate is located on the first outer ring bearing platform (12); a round bearing platform (53) is formed in the center of the top of the shell (5); a suction nozzle (6) provided with a gas guide channel (62) in the center is mounted on the round bearing platform in an insertion manner; an insertion hole, into which a cylindrical tobacco material (7) can be inserted, is formed in the center of the bottom of the suction nozzle; and a positive electrode (41) and a negative electrode (42) of the heating element respectively penetrate through the insulating seat and are connected with a power supply device. The smoking set has the advantages that the heating uniformity of the tobacco material can be improved, aroma components are promoted to be uniformly and fully released, the suction experience feeling is improved, and charring of the tobacco material is avoided, so as to reduce the generation of harmful substances.

Owner:云南拓宝科技有限公司

Thermally assisted magnetic head, head gimbal assembly, and hard disk drive

ActiveUS8295010B2Low coercivityHeat the recording areaCombination recordingRecord information storageHard disc driveMagnetic poles

The thermally assisted magnetic head comprises a medium-opposing surface; a magnetic recording device whose distance from a main magnetic pole to a medium is set longer than a distance from the medium-opposing surface to the medium; a first core for receiving light; and a second core positioned between a first light exit surface of the first core and the medium-opposing surface, having a second light exit surface on the medium side; while a distance between positions where an optical intensity distribution center within the first light exit surface and a center of the main magnetic pole are orthographically projected onto a reference plane including the second light exit surface is greater than a distance between an optical intensity distribution center within the second light exit surface and the position where the center of the leading end of the main magnetic pole is orthographically projected onto the reference plane.

Owner:TDK CORPARATION

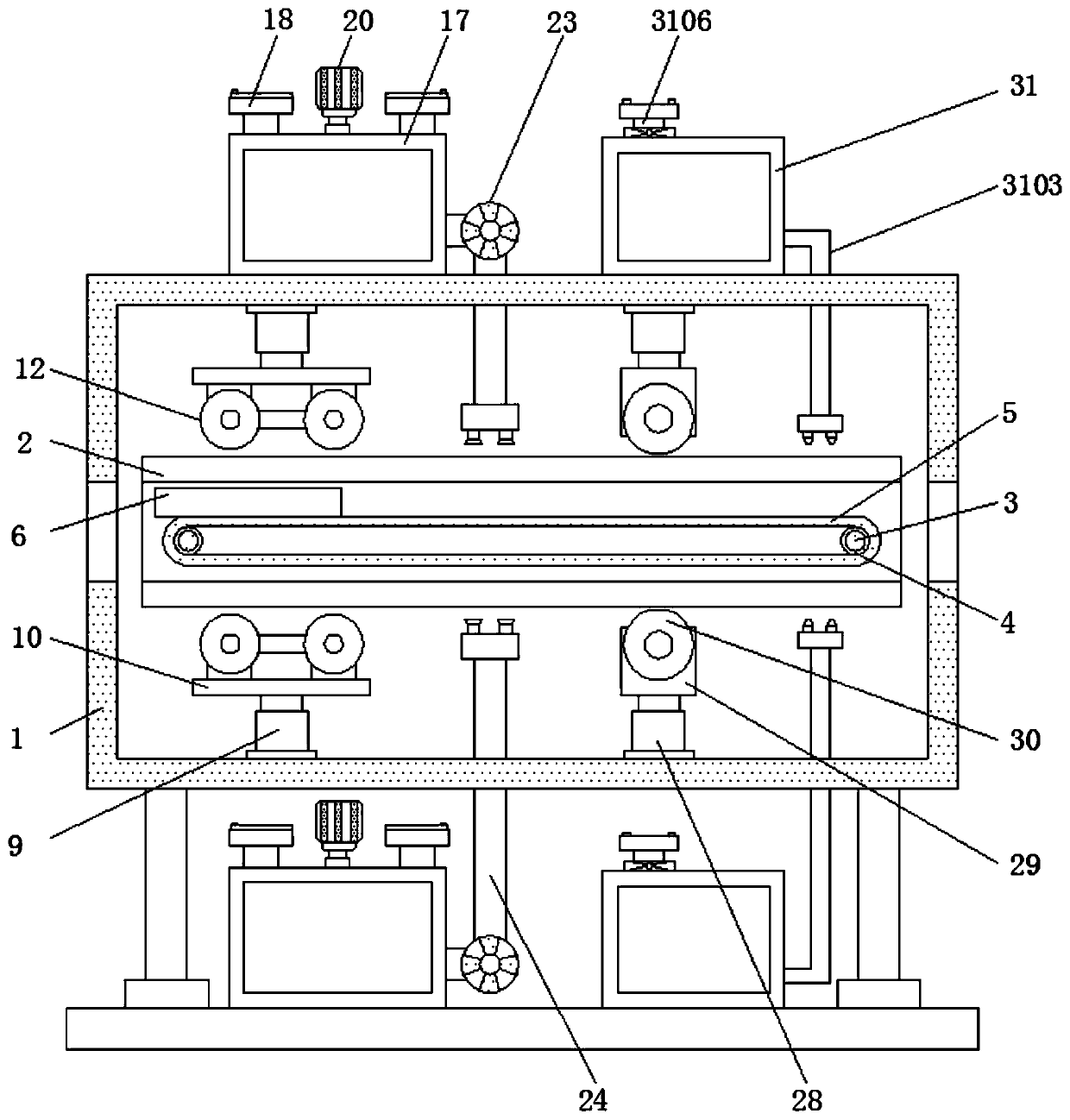

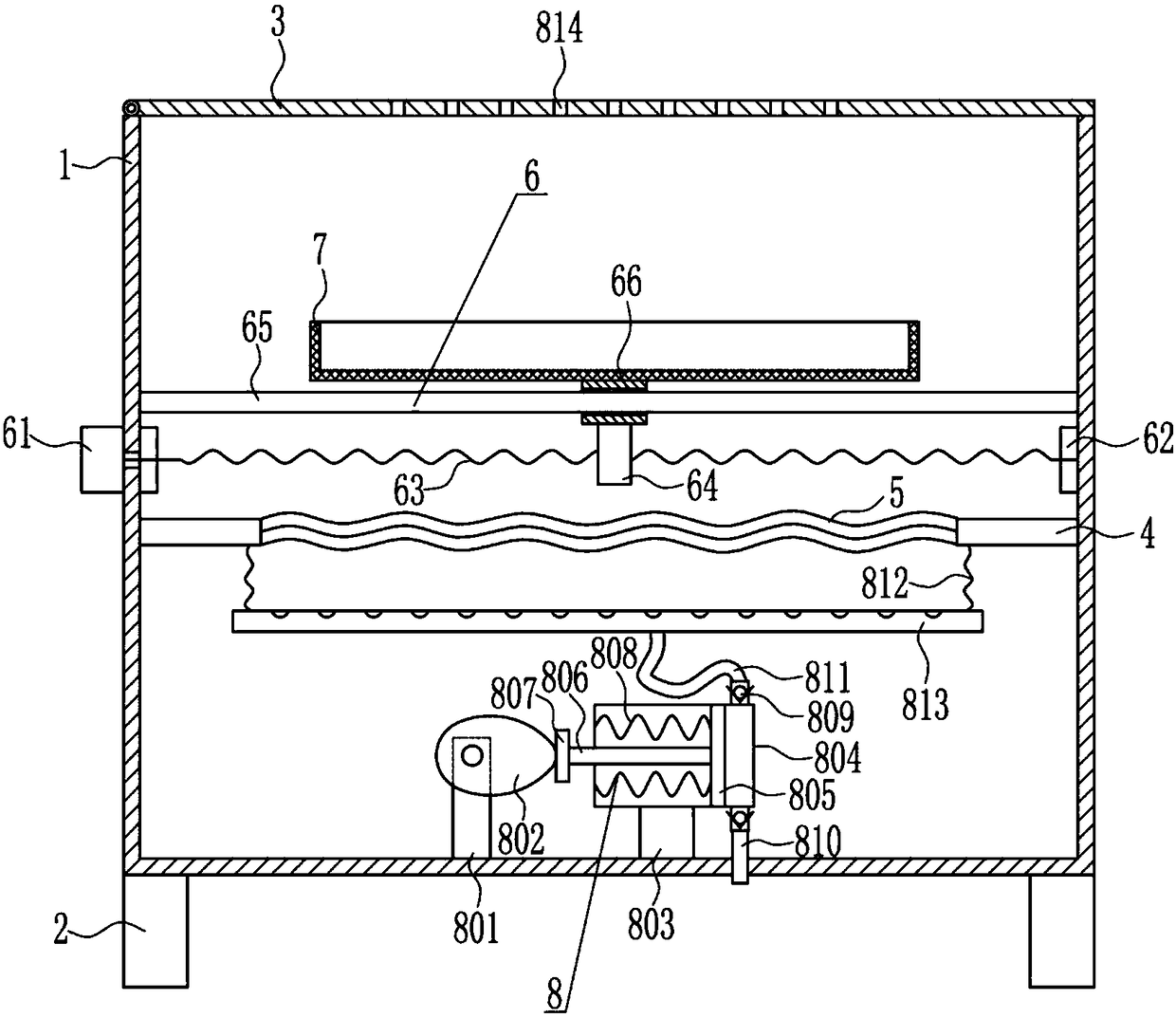

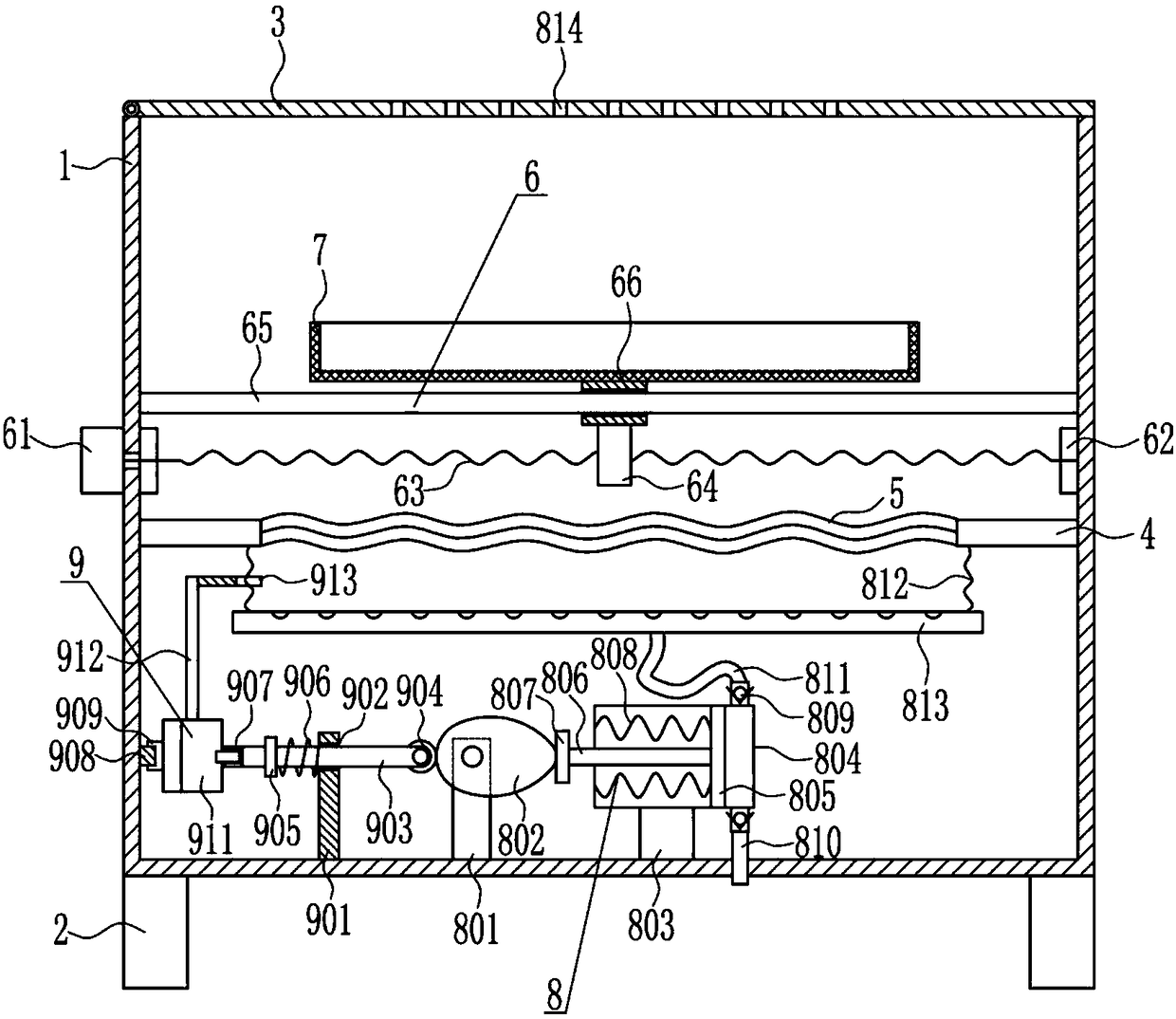

Textile drying equipment for textiles

InactiveCN108518946ASpeed up the flowEvenly heatedDrying gas arrangementsDrying solid materialsForeign matterEngineering

The invention relates to drying equipment, in particular to textile drying equipment for textiles. The invention aims to solve the technical problem that the textile drying equipment for the textileswhich is high in drying efficiency, and is hygienic and pollution-free is provided. The textile drying equipment for the textiles provided by the invention comprises a box body and the like, wherein support legs are mounted at four bottom corners of the box body; the top left side of the box body is rotatably connected with a box cover; the middle parts of the inner left side and the inner right side of the box body are connected with horizontal plates; a plurality of electric heating wires are uniformly arranged between the two horizontal plates at intervals; a left-right movement device is arranged on the inner upper part of the box body; a net frame is arranged on the left-right movement device; and an air blowing device is arranged in the middle of the inner bottom part of the box body. According to the textile drying equipment for the textiles disclosed by the invention, through heating of the electric heating wires, air flow in the box body is driven by the left-right movement device and the air blowing device to flow, so that heat is driven to flow, the textiles are uniformly and fully heated, and dust and foreign matter in the air are adsorbed and filtered by an adsorbent,and thus, the effects of high drying efficiency, hygiene and no pollution are achieved.

Owner:于慧艳

Novel petroleum exploitation auxiliary device

The invention relates to a novel petroleum exploitation auxiliary device. The novel petroleum exploitation auxiliary device comprises a bracket, a cylinder body and a cylinder cover, wherein the bottom end of the left side of the cylinder body is provided with a petroleum inlet, and the top end of the right side of the cylinder body is provided with a petroleum outlet; a first motor and a speed reducer are arranged on the cylinder cover; the output shaft end of the speed reducer is connected with a rotating shaft; a bearing is arranged at the bottom end in the cylinder body, and the bottom end of the rotating shaft is fixedly connected with an inner ring of the bearing; a spiral blade is arranged on the rotating shaft, and blade holes are formed in the spiral blade; an annular heating cavity is arranged on the vertical outer side wall of the cylinder body, and an electric heater is arranged in the annular heating cavity; the top of the left side and the bottom of the right side, of the annular heating cavity, are separately provided with a liquid inlet and a liquid outlet, and a second motor is arranged at the top of the right side of the annular heating cavity; a plurality of mixing blades are arranged at the left end of an output shaft of the second motor; and the vertical outer side wall of the annular heating cavity is sequentially coated with a heat preservation layer, a thermal insulating layer and a wear-resistant layer. By adopting the structure, the novel petroleum exploitation auxiliary device can fully and uniformly heat petroleum and also effectively ensures the normal delivery of petroleum.

Owner:CHENGDU KECHUANG JIASI TECH

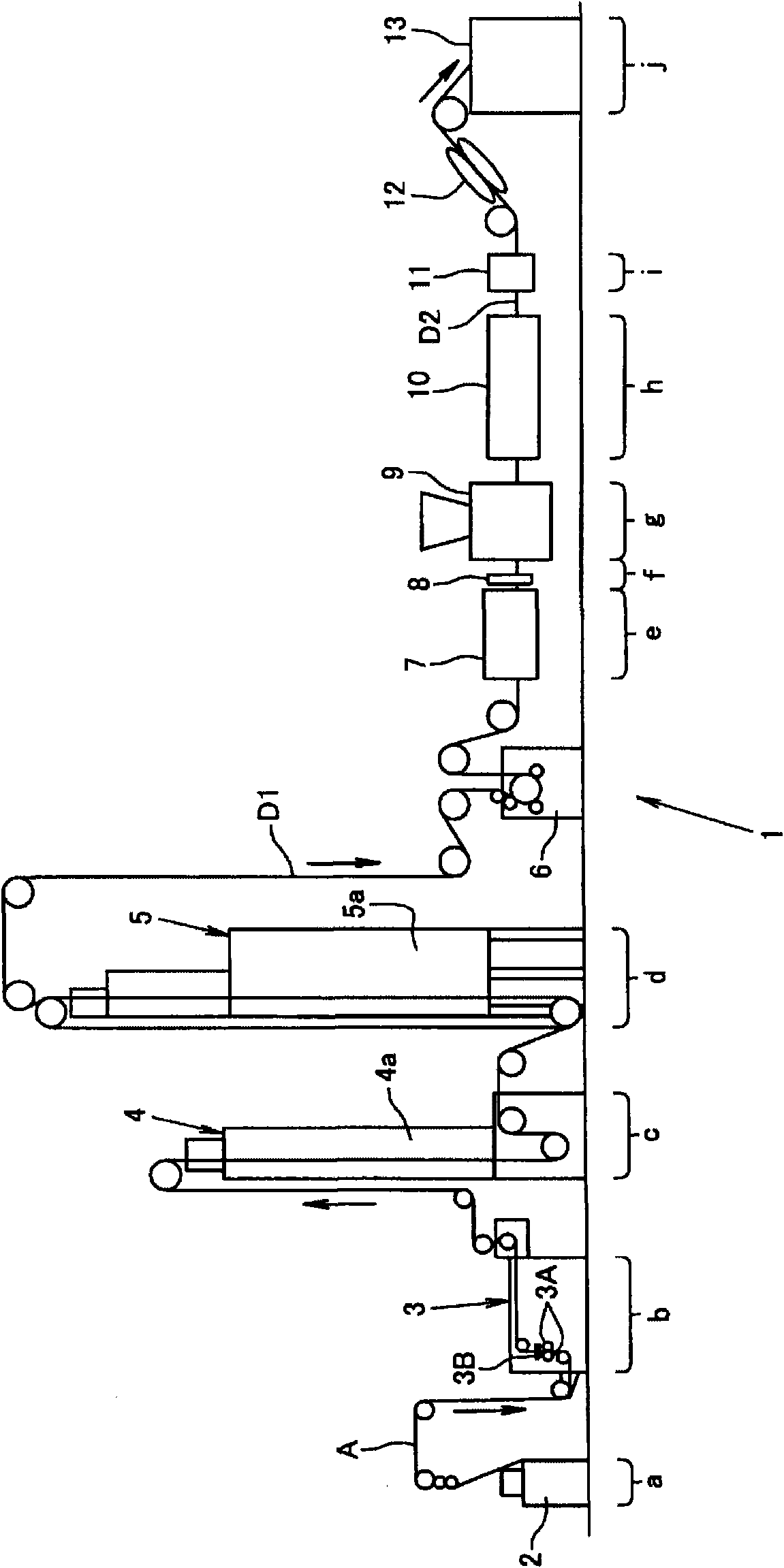

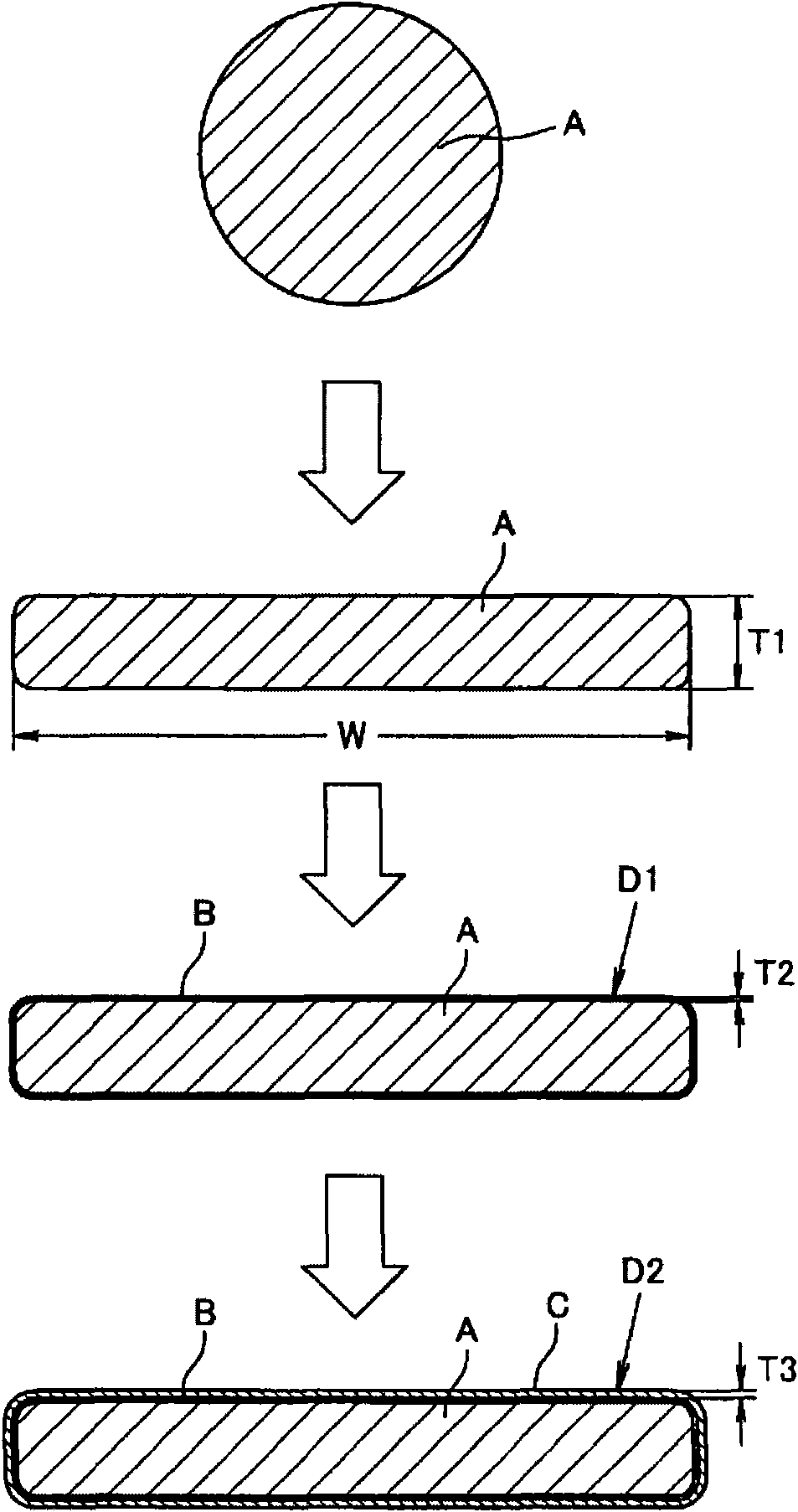

Method and apparatus for producing insulated wire

ActiveCN101558459AIncrease temperatureImprove adhesionInsulatorsInsulating conductors/cablesElectrical conductorEngineering

To provide insulated wire producing method and apparatus for producing a high quality corona-resistant insulated wire inexpensively. In the method for producing an insulated wire (D2), a primary coated wire (D1) wherein a primary coating layer (B) is applied to a conductor (A) is preheated at a temperature sufficient for enhancing adhesion of resin to the primary coating layer (B). Subsequently, resin such as polyphenylene sulfide resin is extruded onto the primary coating layer (B) of the preheated primary coated wire (D1), thus producing an insulated wire (D2) coated with a secondary coating layer (C) composed of PPS resin.

Owner:ESSEX FURUKAWA MAGNET WIRE JAPAN CO LTD

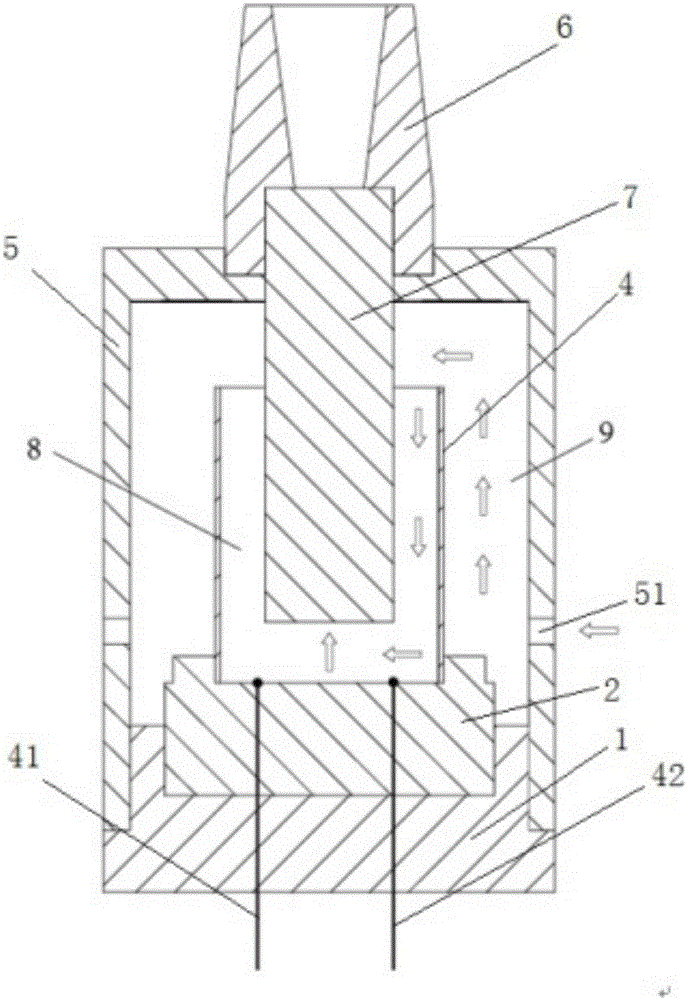

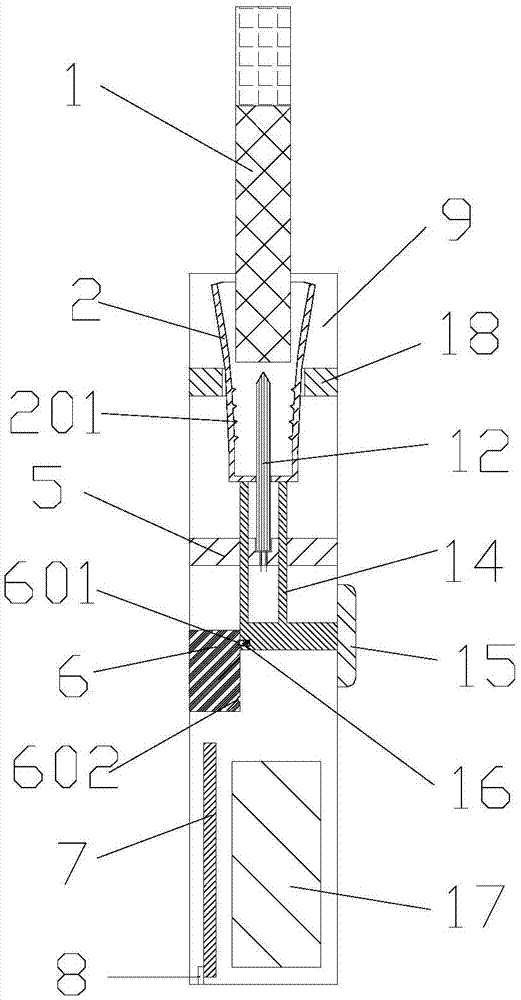

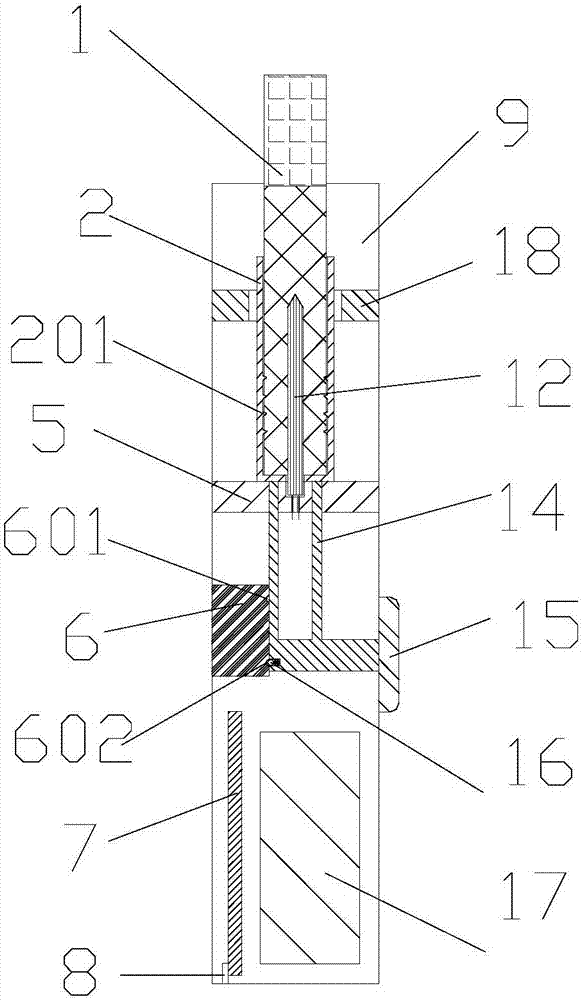

Cigarette heating device

PendingCN107568803AFully heatedImprove experienceTobacco devicesBiomedical engineeringHeating element

The invention discloses a cigarette heating device which mainly comprises wall needles (201) and a heating element (12), wherein the wall needles (201) are attached onto a cigarette cup (2). The wallneedles (201) and the heating element (12) can simultaneously heat the inside and the outside of a cigarette (1), a push rod (14) is driven by sliding a sliding key (15), the cigarette cup (2) can vertically move along a cigarette cup clamp ring (18), so that the size of the opening diameter of the cigarette cup (2) is controlled, and insertion and extraction of smoking products are easily achieved.

Owner:CHINA TOBACCO YUNNAN IND

Exhaust gas treatment method and incinerator used for steel plate color-coating line

The invention discloses an exhaust gas treatment method and an incinerator used for a steel plate color-coating line. The method comprises the step of: completely burning the exhaust gas which is directly discharged or discharged after traditional secondary burning under the conditions that the temperature is higher than 650 DEG C, the residence time is more than 1 second, and the flow rate is larger than 5 m / s. The incinerator comprises a furnace shell, an exhaust gas channel arranged in the furnace shell, a burner, a porous absorptive heat accumulator and a heat exchanger; a pre-heating chamber, a main burning chamber and a secondary burning chamber are arranged on the exhaust gas channel in sequence; the pre-heating chamber is arranged at the front part of the exhaust gas channel; the main burning chamber and the secondary burning chamber are arranged in the middle of the exhaust gas channel in sequence; the burner is arranged at an inlet of the main burning chamber; the porous absorptive heat accumulator is arranged above the secondary burning chamber; and the heat exchanger is arranged at the rear part of the exhaust gas channel. The invention can further reduce pollution emission, leads the organic solvent and part of incompletely burned exhaust gas to be fully burned, generates non-polluting carbon dioxide and water, and then implements heat exchange with fresh air by the heat exchanger and finally discharge the product.

Owner:福建凯景新型科技材料有限公司

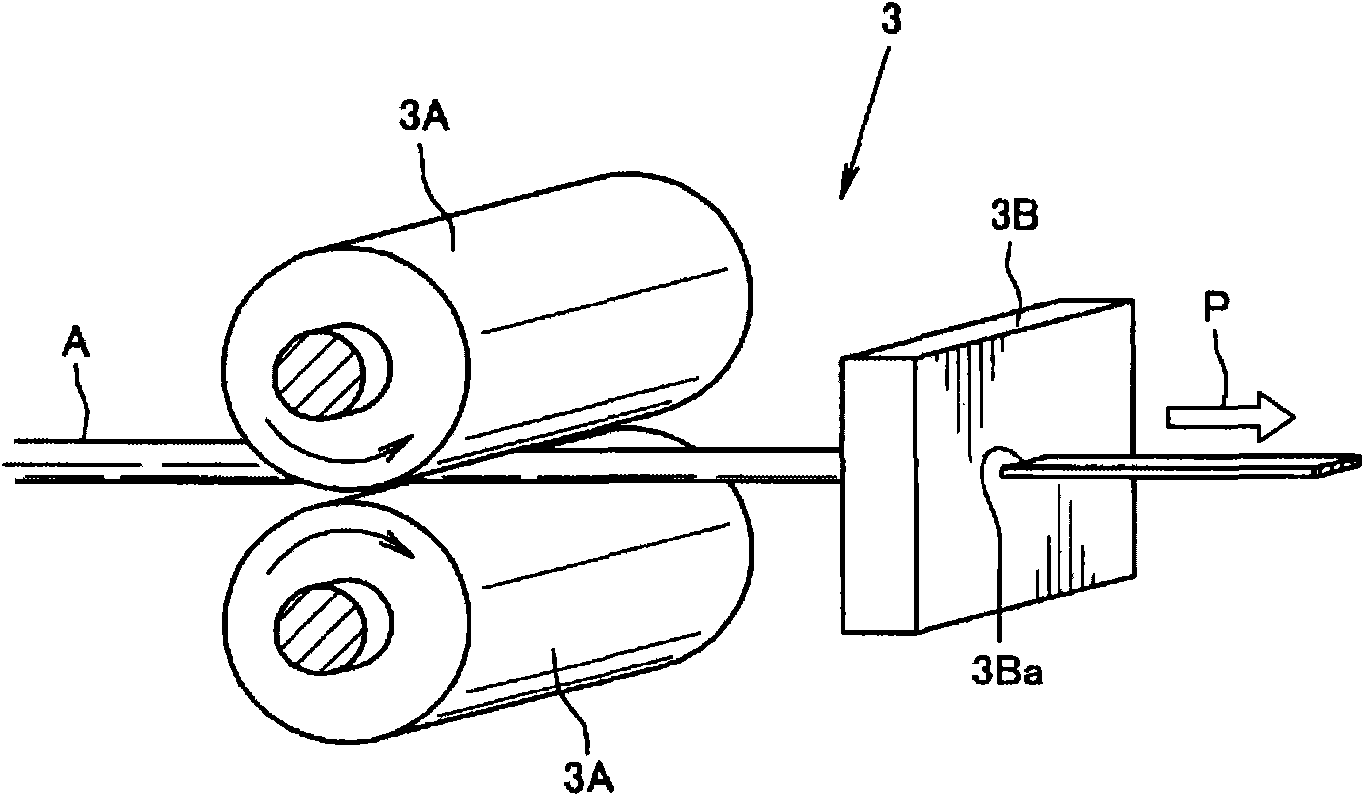

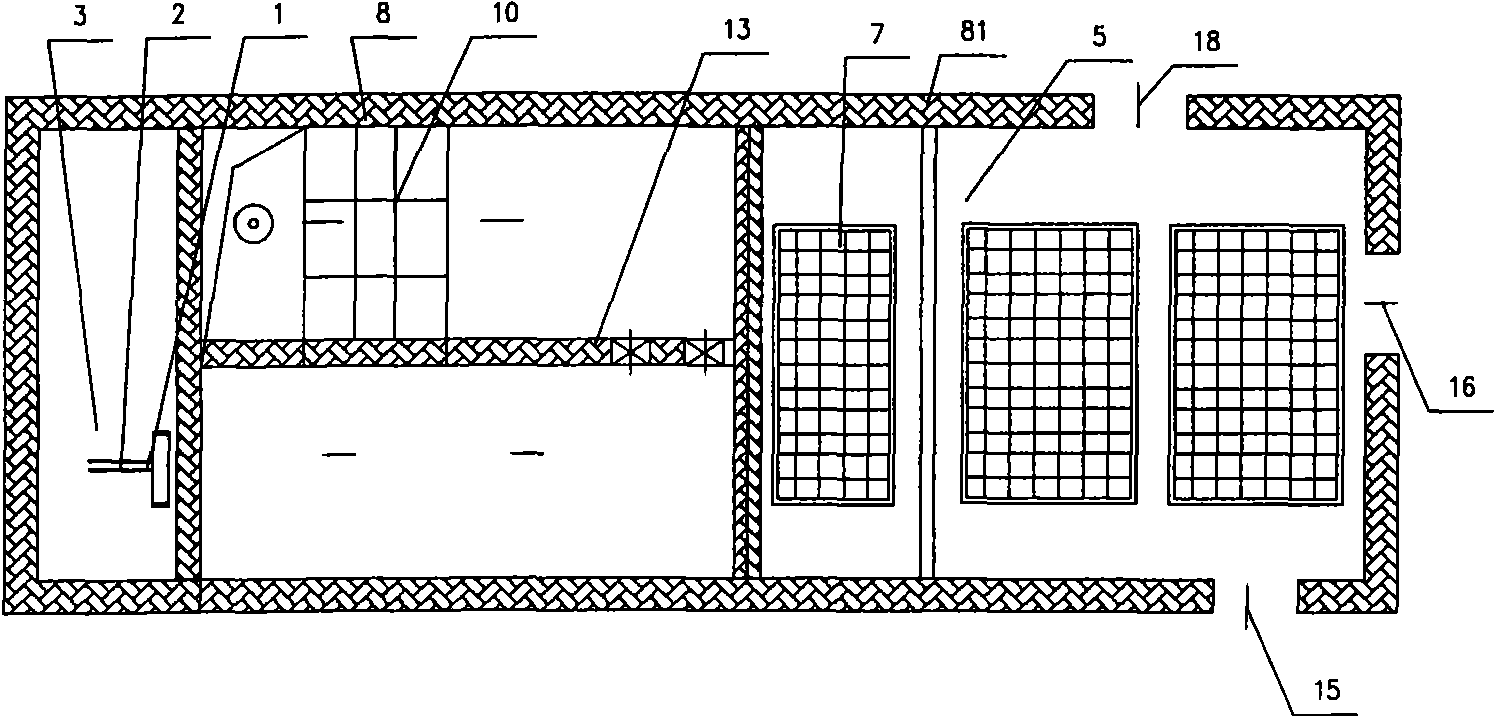

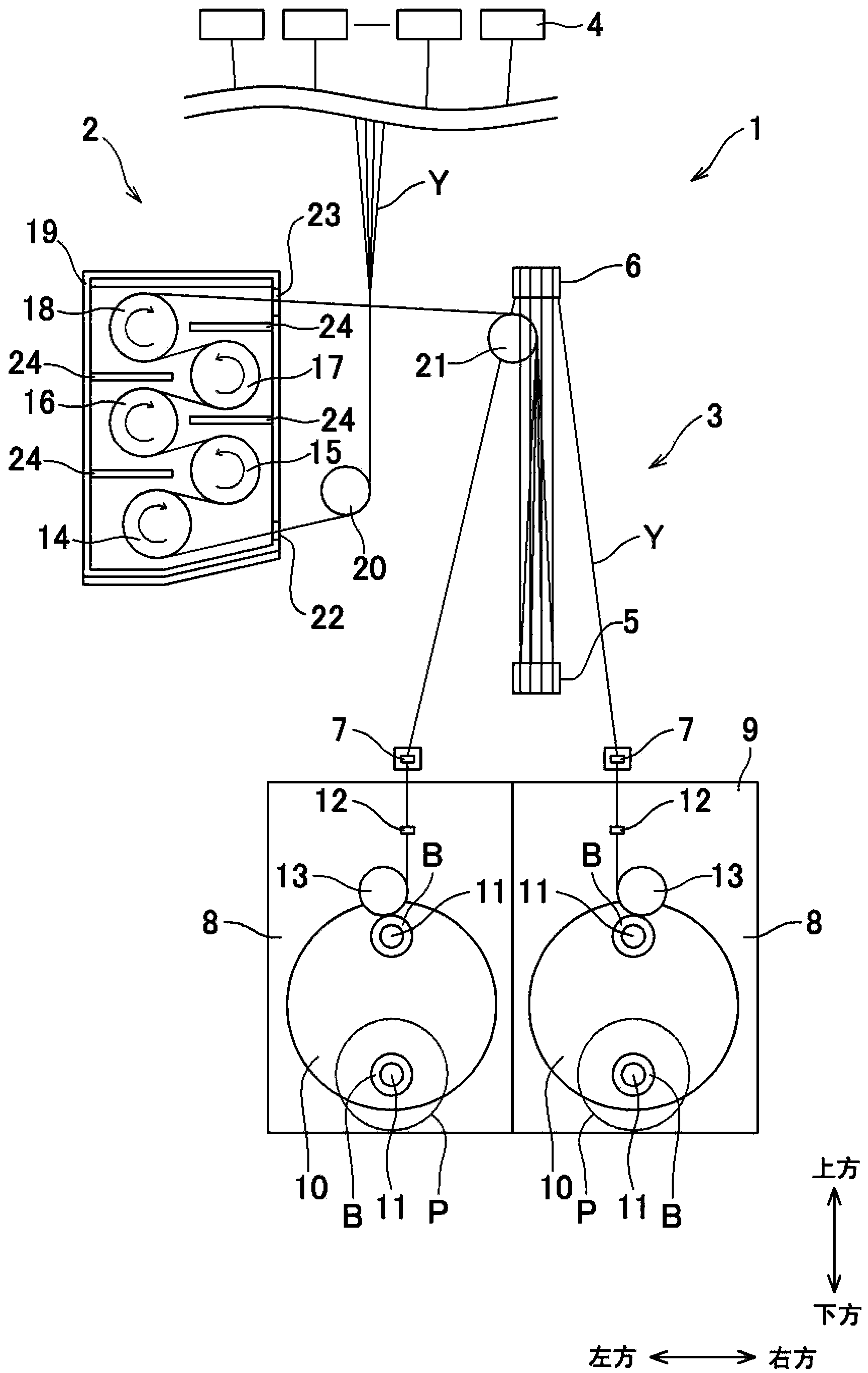

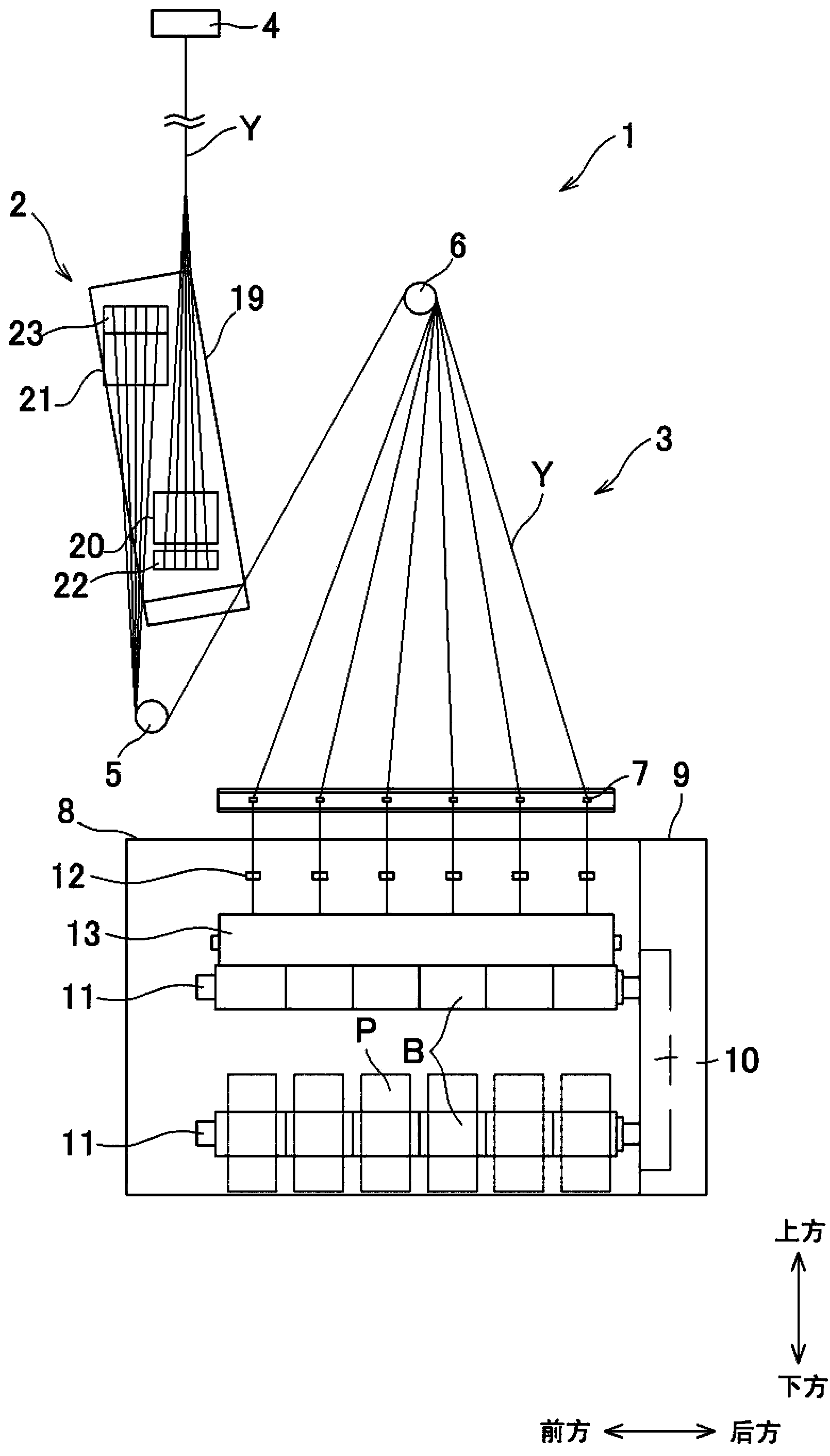

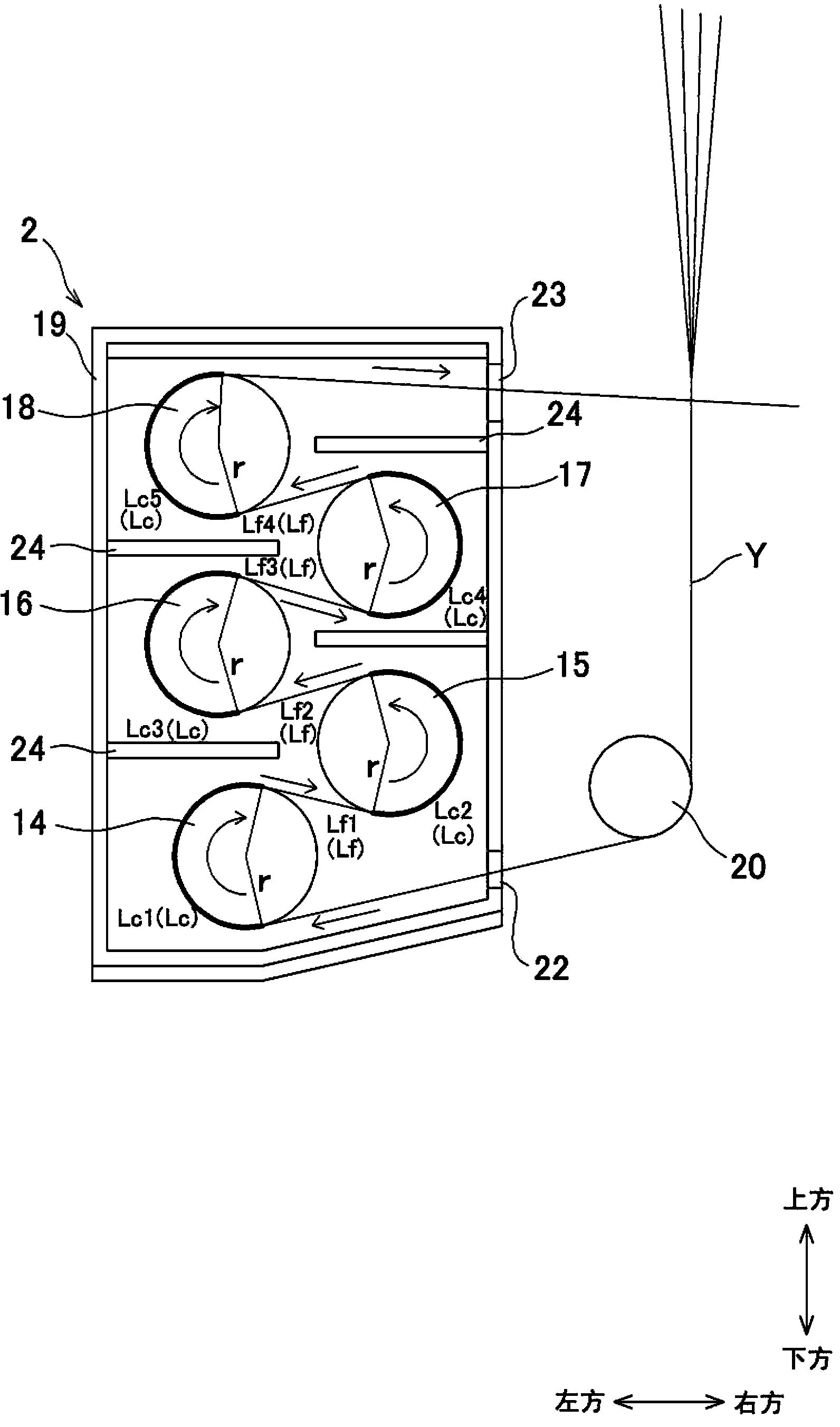

Spun yarn drawing apparatus

ActiveCN103510233APrevent slidingLight in massArtificial filament heat treatmentNon-woven fabricsYarn

A spun yarn drawing apparatus is disclosed, which is capable of inhibiting swinging of a yarn which is located between two rollers and does not contact with the rollers. The spun yarn drawing apparatus (2) includes godet rollers (14 to 18). The rotating directions of the adjacent two godet rollers in the advancing direction of the yarn (Y) are opposite. Each of the multiple godet rollers (14 to 18) is wound and hung with the yarn (Y) along the rotating direction at a winding angle of 360 degrees or lower. Among the multiple godet rollers (14 to 18), a non-contact length (Lf) of the yarn between the adjacent two godet rollers in the advancing direction of the yarn (Y) is shorther than a contact length (Lc) of the yarn (Y) with respect to each of the adjacent two godet rollers in the advancing direction of the yarn (Y).

Owner:TMT MACHINERY INC

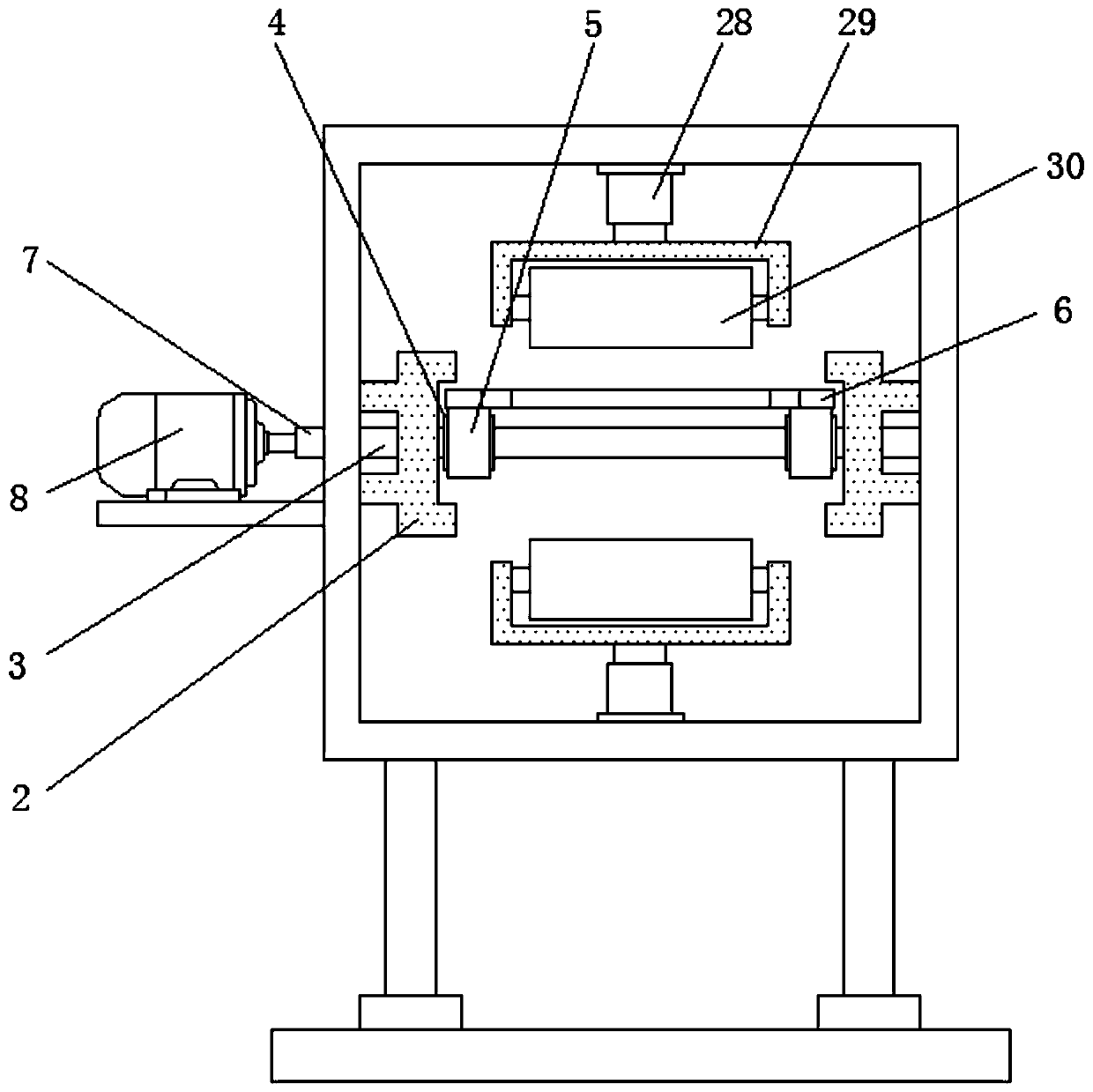

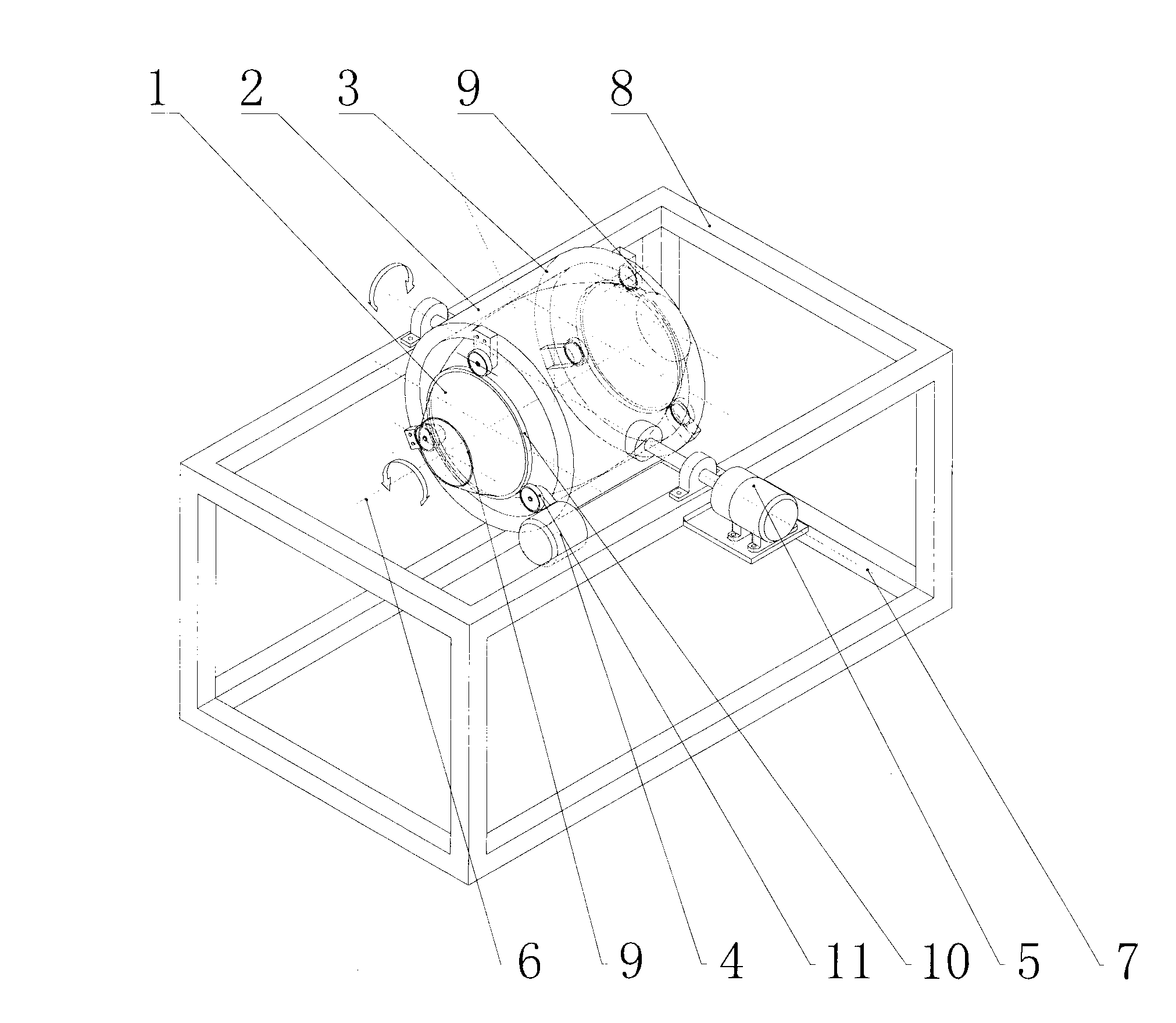

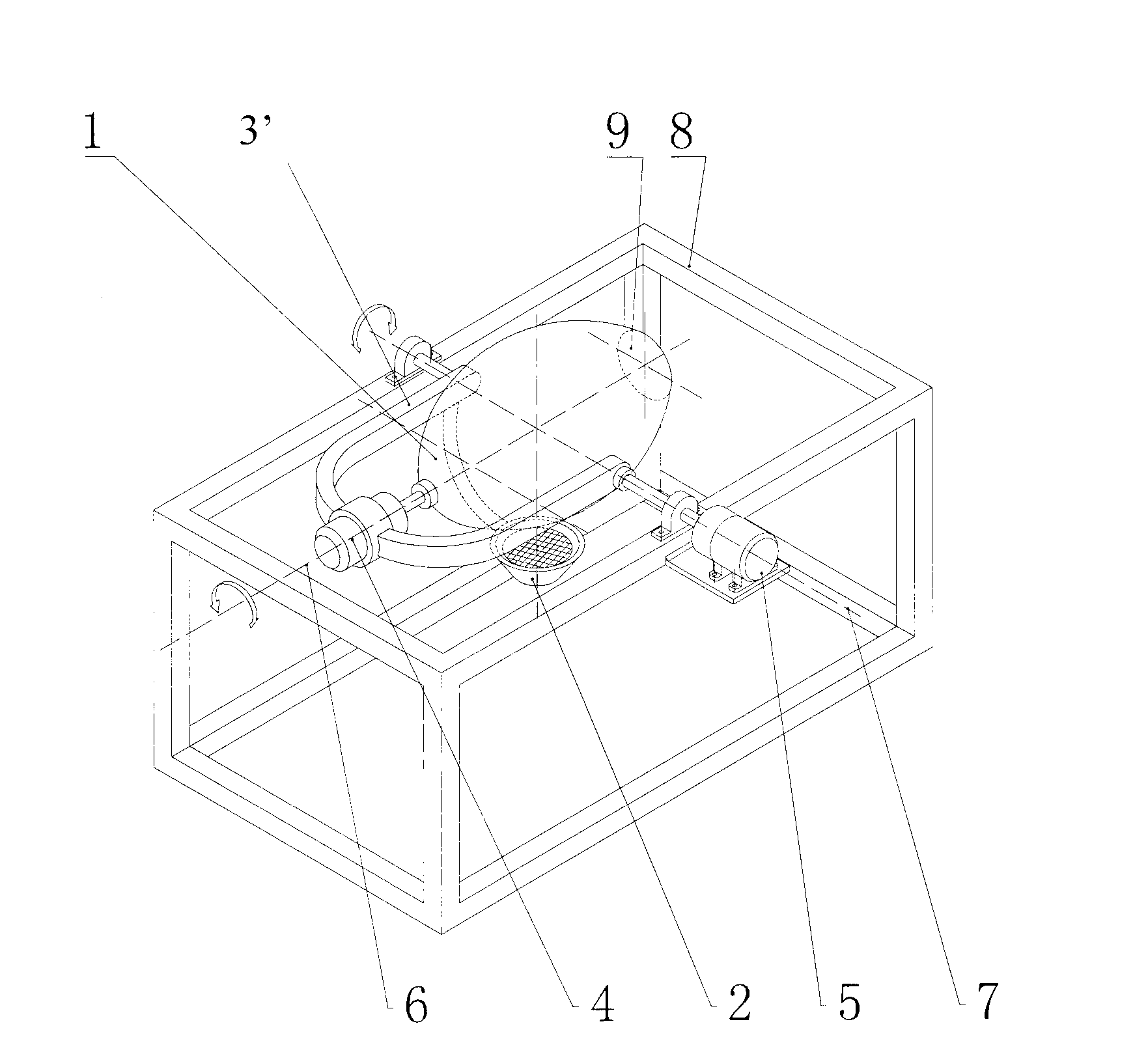

Rotary heating device and automatic cooking method thereof

ActiveCN102973159AVarious cooking functionsImprove cooking efficiencyWarming devicesProcess engineeringCooking methods

The invention provides a rotary heating device and an automatic cooking method of the rotary heating device. The rotary heating device comprises a container, a heating unit, a supporting mechanism and a machine frame, wherein the container is provided with at least one opening, the heating unit is used for heating the container, the supporting mechanism is used for limiting the container to rotate around a first rotary shaft relative to the supporting mechanism, and the machine frame is used for limiting a combination formed by the container and the supporting mechanism to move according to a predetermined trajectory relative to the machine frame. The rotary heating device is applicable for solid materials, liquid materials, adhesive materials and mixtures of the solid materials, the liquid materials and the adhesive materials. The effect that the materials are heated thoroughly and uniformly is guaranteed, and multiple functions such as scrapping, rolling, breaking up, cutting, overturning, fluid conveying and automatic cleaning can further be accomplished at the same time, cooking functions of automatic cooking are enriched, cooking efficiency is also improved, and meanwhile, the rotary heating device has high technical scalability at the same time.

Owner:SHENZHEN HANSC INTELLIGENT TECH CO LTD

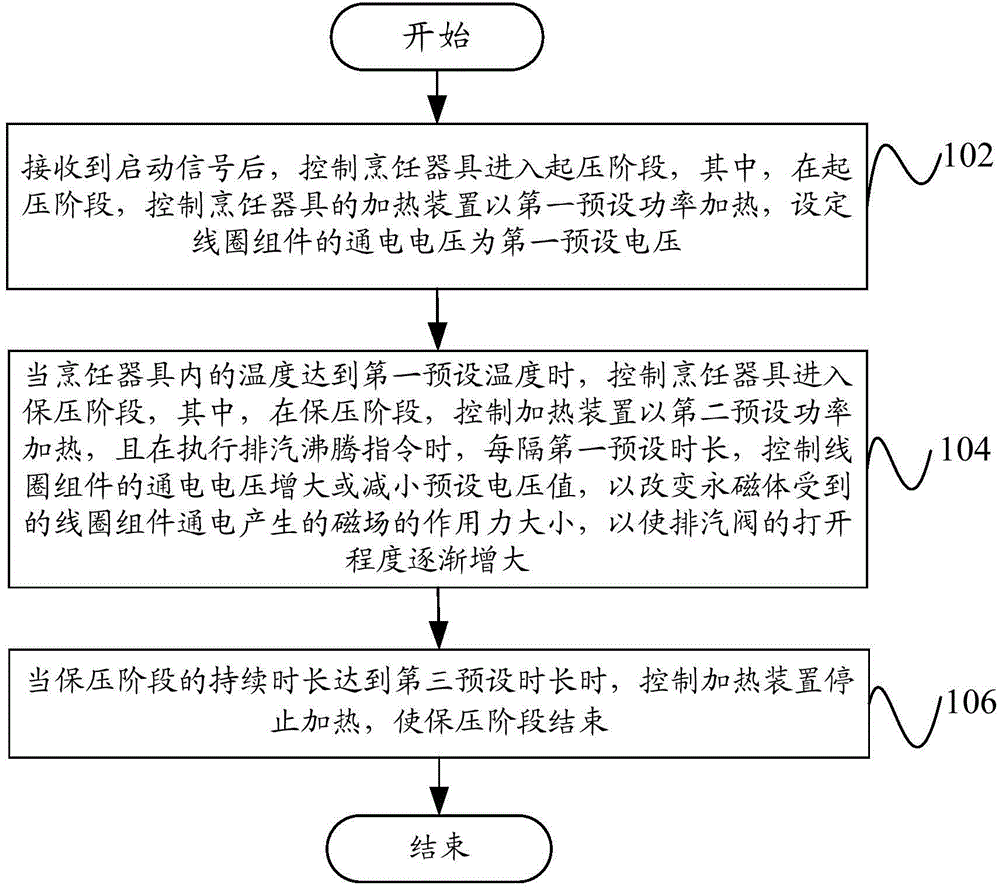

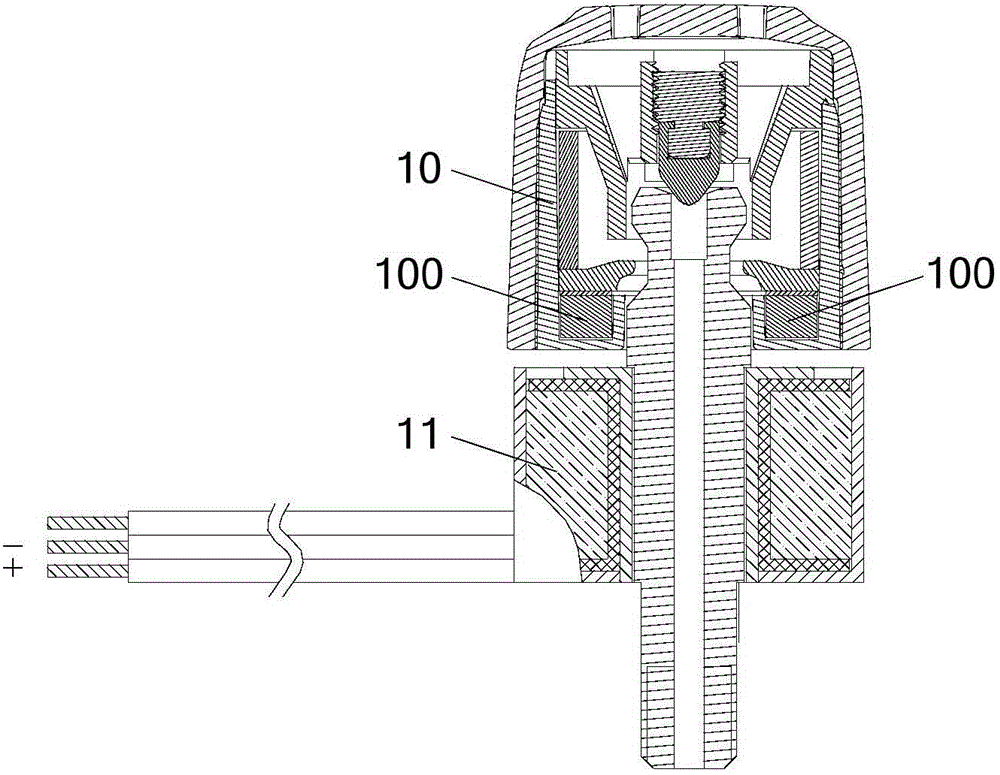

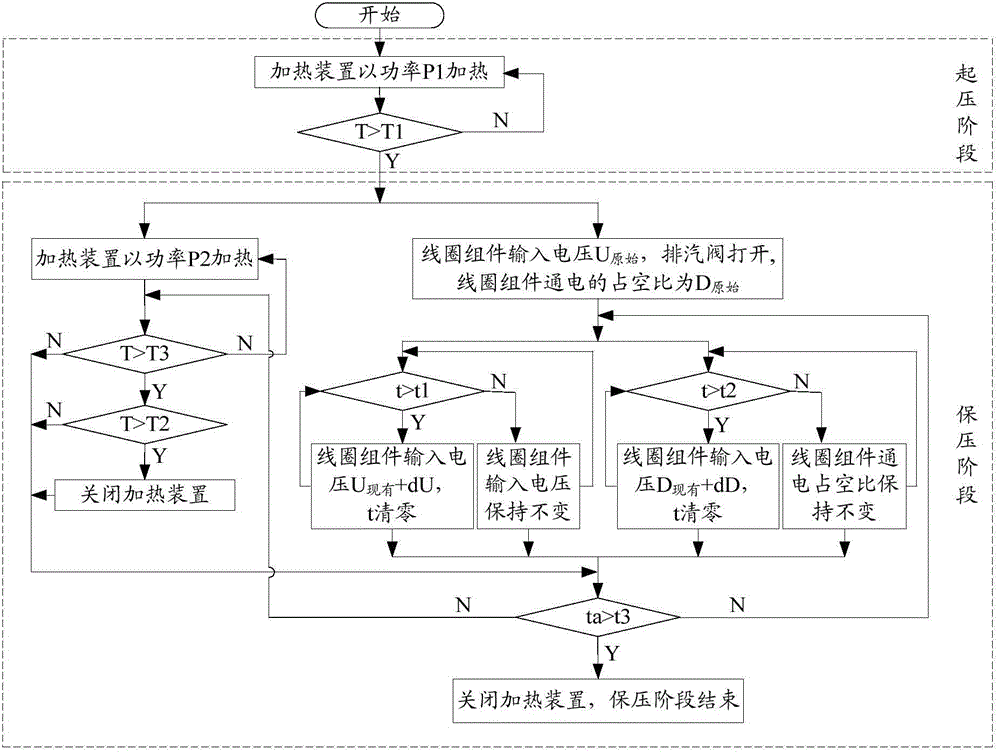

Control method, control device and cooking appliance

ActiveCN106136874AEffectively control the degree of openingRealize the boiling and tumbling effectPressure-cookersPressure riseExhaust valve

The invention provides a control method, a control device and a cooking appliance. The control method comprises the following steps: after a start signal is received, the cooking appliance is controlled to enter a pressure rising stage, a heating device of the cooking appliance is controlled for heating with first preset power, and the power-on voltage of a coil assembly is set as first preset voltage; when the temperature in the cooking appliance reaches a first preset temperature, the cooking appliance enters a pressure maintaining stage, the heating device is controlled for heating with second preset power, and third preset duration is lasted; moreover, when an exhaust and boiling order is executed, the power-on voltage of the coil assembly is controlled to increase or decrease a preset voltage value at an interval of first preset duration, so that the opening degree of an exhaust steam valve is gradually enlarged. The control method provided by the invention dynamically adjusts the magnitude of the power-on voltage of the coil assembly when the cooking appliance enters the pressure maintaining stage, so as to control the opening degree of the exhaust steam valve, effectively improve the intensity of food boiling and rolling, and improve the food cooking taste.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com