Textile drying equipment for textiles

A technology for drying equipment and textiles, which is applied in drying, drying machines, lighting and heating equipment, etc., and can solve the problems of easy-to-contaminate textiles, unhygienic drying process, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

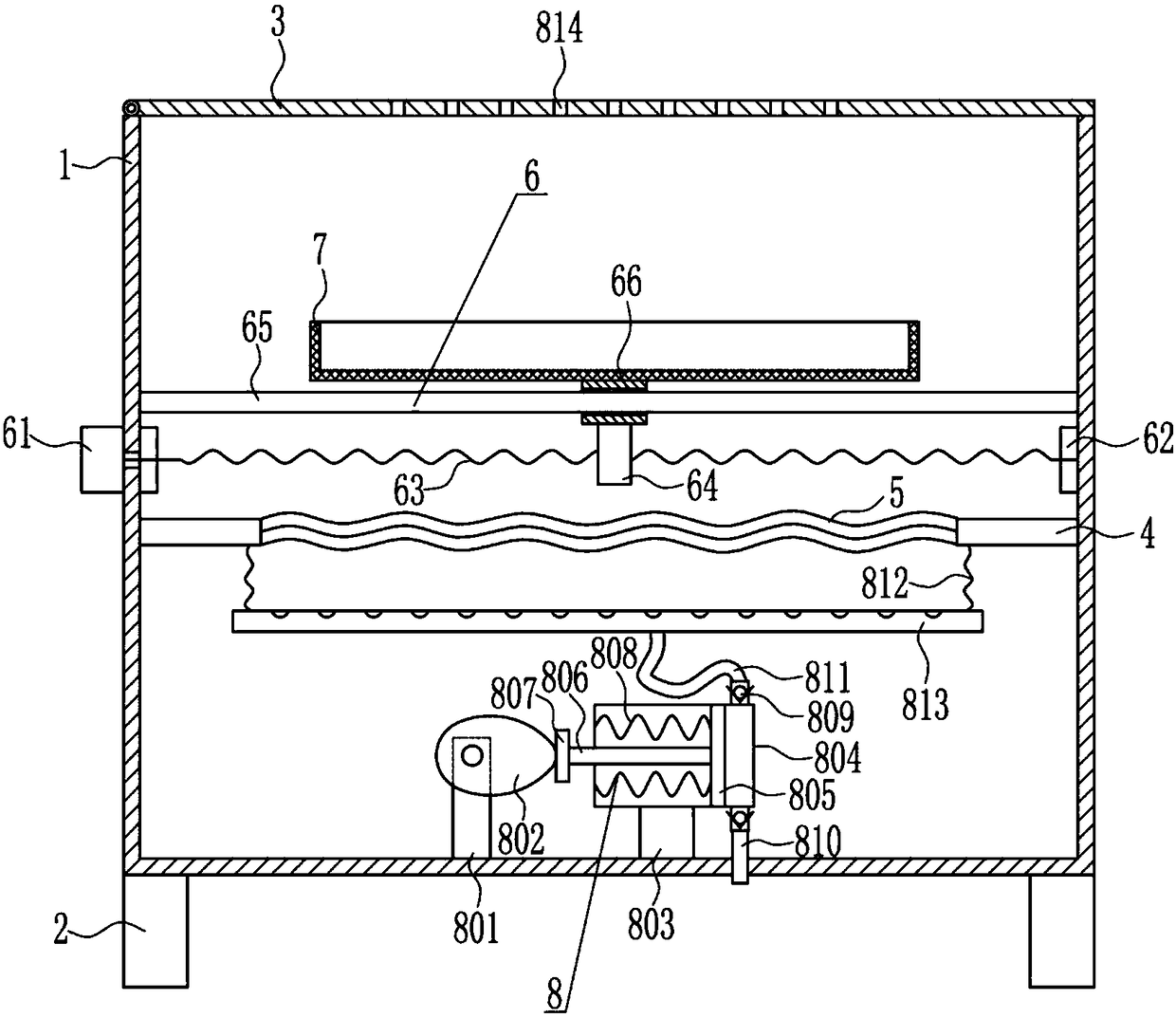

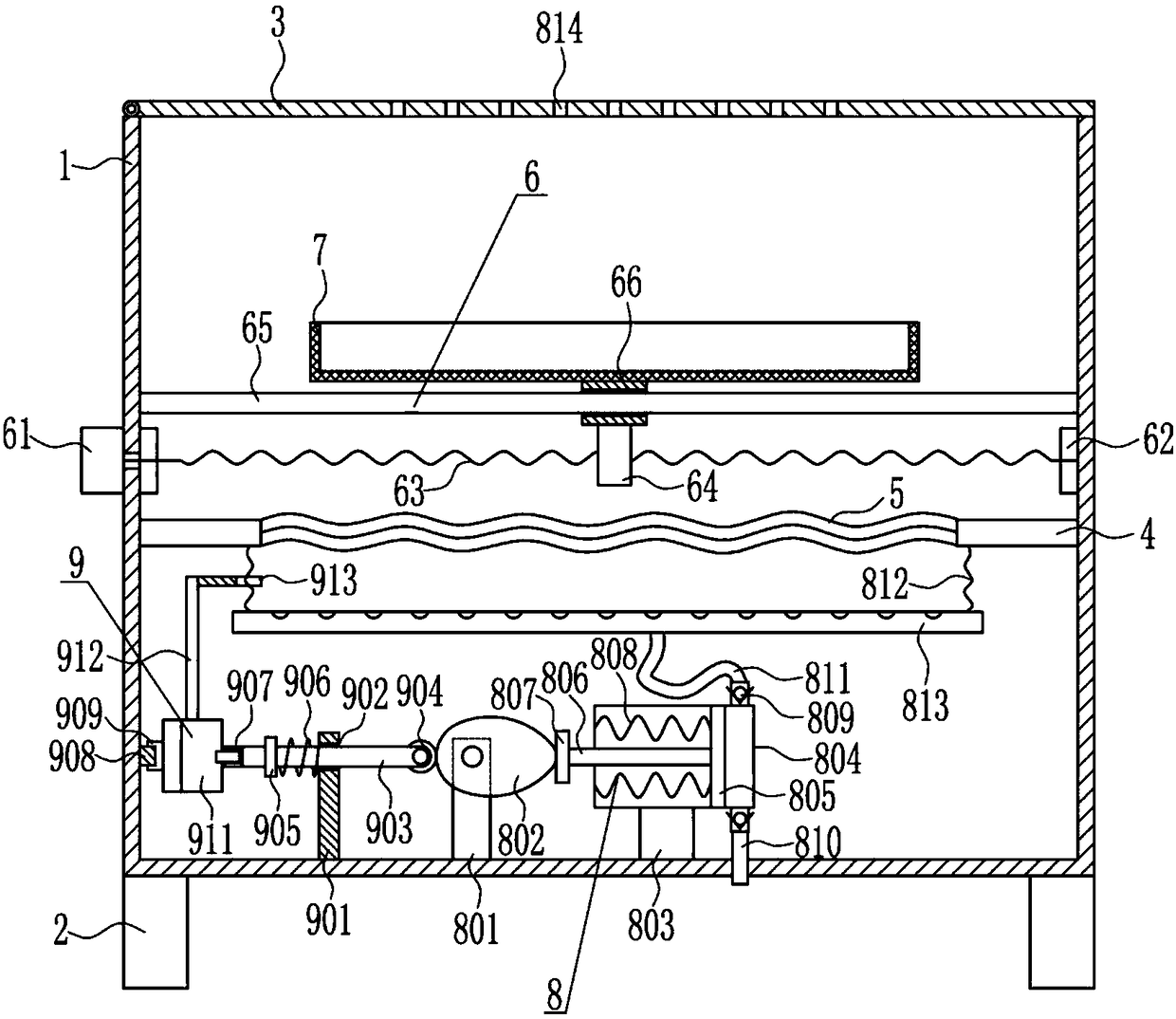

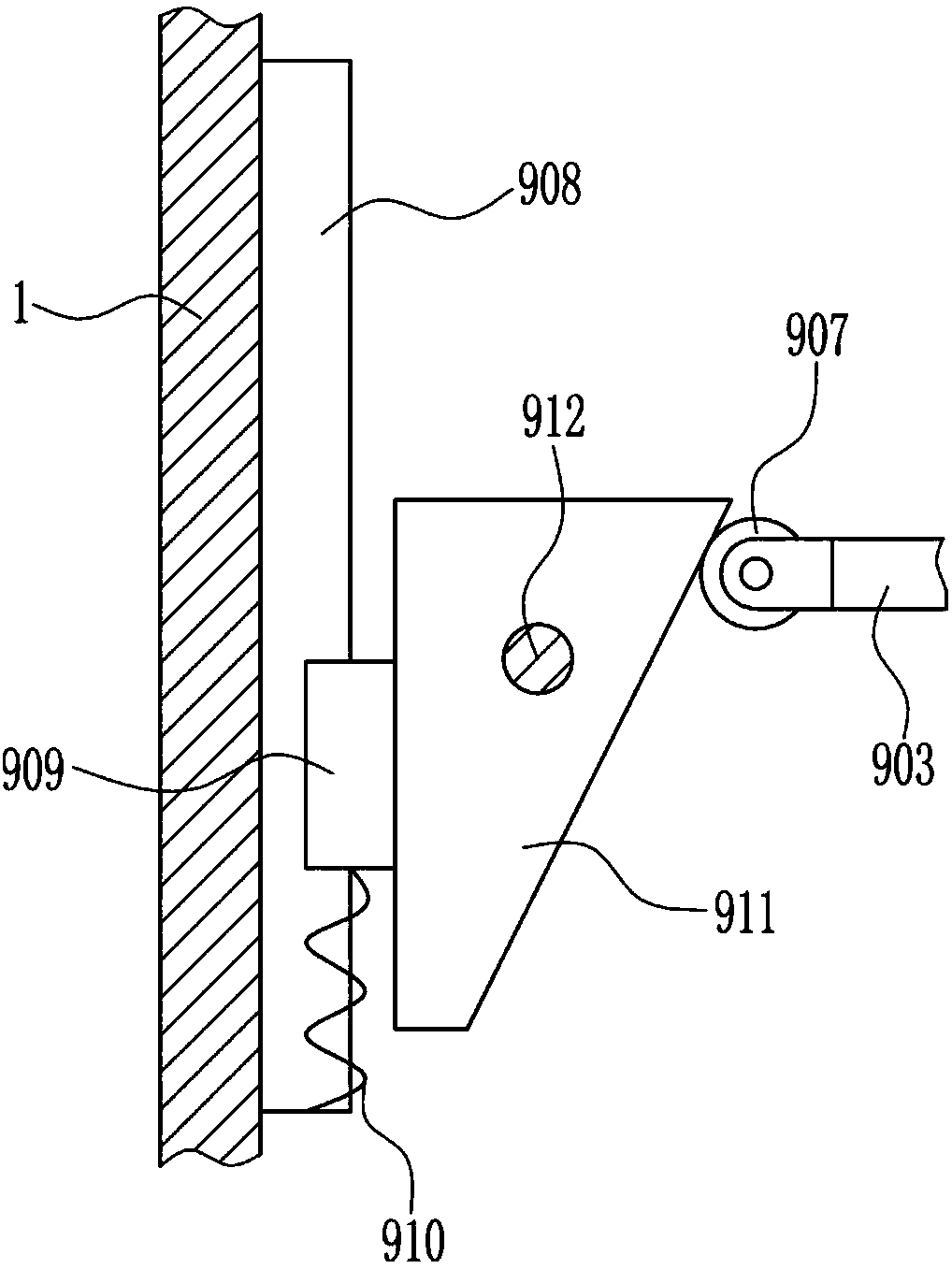

[0030] A textile drying equipment for textiles, such as Figure 1-5 As shown, it includes a box body 1, legs 2, box cover 3, horizontal plate 4, heating wire 5, left and right moving device 6, screen frame 7 and air blowing device 8, and four corners of the bottom of the box body 1 are equipped with support Leg 2, the top left side of the box body 1 is connected with a box cover 3 in a rotating manner, the middle part of the left and right sides of the box body 1 is connected with a horizontal plate 4, and a plurality of heating wires 5 are evenly spaced between the two horizontal plates 4, the box The upper part of the body 1 is provided with a left and right moving device 6, a screen frame 7 is arranged on the left and right moving device 6, and an air blowing device 8 is arranged in the middle of the inner bottom of the box body 1.

Embodiment 2

[0032] A textile drying equipment for textiles, such as Figure 1-5 As shown, it includes a box body 1, legs 2, box cover 3, horizontal plate 4, heating wire 5, left and right moving device 6, screen frame 7 and air blowing device 8, and four corners of the bottom of the box body 1 are equipped with support Leg 2, the top left side of the box body 1 is connected with a box cover 3 in a rotating manner, the middle part of the left and right sides of the box body 1 is connected with a horizontal plate 4, and a plurality of heating wires 5 are evenly spaced between the two horizontal plates 4, the box The upper part of the body 1 is provided with a left and right moving device 6, a screen frame 7 is arranged on the left and right moving device 6, and an air blowing device 8 is arranged in the middle of the inner bottom of the box body 1.

[0033] Left and right moving device 6 comprises motor 61, bearing seat 62, screw mandrel 63, nut 64, slide bar 65 and sliding sleeve 66, and c...

Embodiment 3

[0035] A textile drying equipment for textiles, such as Figure 1-5 As shown, it includes a box body 1, legs 2, box cover 3, horizontal plate 4, heating wire 5, left and right moving device 6, screen frame 7 and air blowing device 8, and four corners of the bottom of the box body 1 are equipped with support Leg 2, the top left side of the box body 1 is connected with a box cover 3 in a rotating manner, the middle part of the left and right sides of the box body 1 is connected with a horizontal plate 4, and a plurality of heating wires 5 are evenly spaced between the two horizontal plates 4, the box The upper part of the body 1 is provided with a left and right moving device 6, a screen frame 7 is arranged on the left and right moving device 6, and an air blowing device 8 is arranged in the middle of the inner bottom of the box body 1.

[0036] Left and right moving device 6 comprises motor 61, bearing seat 62, screw mandrel 63, nut 64, slide bar 65 and sliding sleeve 66, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com